Page 1

Mitsubishi Electric Air Conditioning Network System

Integrated centralized control software TG-2000A(Ver. 2)

Operation Manual (Site adjustment)

1. Safety Precautions................................1

2. System Requirements............................2

3. System Configuration.............................5

4. Flow of Site Adjustment..........................6

5. Installation .........................................9

6. Part Names and Functions..................... 13

7. Initial Startup and Shutdown................... 20

8. System Setting Procedure..................... 22

8.1 System Setting Screen................... 22

8.2 System Setting Procedure............... 22

8.3 User Set-up................................ 23

8.4 Site Name Set-up .........................25

8.5 G-50A Connection Set-up............... 27

8.6 System Configuration Set-up............ 28

8.7 Monitoring screen Set-up................ 34

8.8 Watt Hour Meter Set-up.................. 40

8.9 Energy monitoring Set-up ................42

8.10 Time Set-up............................... 50

8.11 Password Change........................ 52

9. Charge Data Correction and Remedy ........ 53

9.1 Result of Air - conditioning

Charge Calculation....................... 53

9.2 Maintenance of Charge Data............ 55

9.3 Operation Amount Data Monitoring..... 60

9.4 Charge Parameter Output............... 61

9.5 Charging Remedy ........................ 62

10. Error code list.................................... 74

11. Setting Check List ............................. 78

Appendix 1 Installing Windows XP

Professional ........................ 91

Appendix 2: Auto Log-in Confirmation Method. 93

Appendix 3: Correction to Charge Calcution

in the Event of G- 50A

Replacement due to Fault.......... 94

Please read this manual before using the unit.

Please keep this manual for future use. WT03901X01

Contents

2002-Sep. (Ver. 2. 00)

Page 2

Contents

1. Safety Precautions..............................................1

2. System Requirements ..........................................2

2.1 Requirements (system recommendations)............2

2.2 Compatible units..........................................2

2.3 Restrictions................................................3

2.4 Other devices .............................................4

3. System Configuration ...........................................5

3.1 System Configuration Example.........................5

3.2 Hardware Connection Diagram.........................5

4. Flow of Site Adjustment........................................6

4.1 Flow of Site Adjustment ..................................6

4.2 Tools for Site Adjustment................................6

4.3 Step 1: Test operation from central controller

G-50A ............................................7

4.4 Step 2: Initial setting of integrated centralized

control software TG-2000A.....................7

4.5 Step 3: Test operation from integrated centralized

control software TG-2000A.....................8

5. Installation.......................................................9

5.1 Pre-installation Steps ....................................9

5.2 TG-2000A Setup.........................................9

5.2.1 Setup...............................................9

5.2.2 Running TG-2000A Setup (New setup) ......10

5.3 TG-2000A Uninstall.................................... 12

6. Part Names and Functions................................... 13

6.1 Window E lements...................................... 13

6.2 Basic Mouse Operation................................ 14

6.3 Accessing Functions and Moving between

Windows................................................. 14

7. Initial Startup and Shutdown .................................20

7.1 Before startup........................................... 20

7.2 Startup................................................... 20

7.3 Shutdown ................................................21

8. System Setting Procedure ................................... 22

8.1 System Setting Screen................................ 22

8.2 System Setting Procedure............................. 22

8.3 User Set-up ............................................. 23

8.3.1 General Operation.............................. 23

8.3.2 Connection Setting............................. 24

8.3.3 Reliability Function............................. 24

8.3.4 Energy Monitoring Related.................... 25

8.4 Site Name Set-up...................................... 25

8.5 G-50A Connection Set-up............................. 27

8.5.1 Setting Procedure and Restrictions........... 27

8.5.2 Number of G-50A (Step1)..................... 27

8.5.3 G-50A IP Address Set-up (Step 2) ............27

8.6 System Configuration Set-up ..........................28

8.6.1 Setting Procedure and Restrictions........... 28

8.6.2 G-50A Data Collecting (Step 1)............... 29

8.6.3. Unit Composition Set-up (Step 2)............. 29

8.6.4. Set-up of Refrigerant System (Step3) .... 31

8.6.5 Set-up of Group (Step4)....................... 32

8.6.6 Interlocked setting(Step 5)..................... 33

8.7 Monitoring Screen Set-up............................. 34

8.7.1 Configuration Procedure and Restrictions ... 34

8.7.2 Set-up of Model Name (Step1)................ 34

8.7.3 Set- up of the Number of Floors,

and Floor Name (Step2) ....................... 35

8.7.4 Creation of a Plane View (Step 3) ............. 36

8.7.5 Set-up of Floor Name and G-50A(Step 4)... 36

8.7.6 Set-up of IIon arrange and Name (Step 5)... 37

8..7.7 Set-up of Block (Step 6 ).....................................38

8.8 Watt Hour Meter Set-up ................................40

8.8.1 Setting Procedures and Restrictions ......... 40

8.8.2 Watt Hour Meter Setting (Step 1) ............ 40

8.8.3 Set- up for the Name and the Maximium

Integrated Value of WHM (Step 2)............ 41

8.9 Energy Monitoring Set-up............................. 42

8.9.1 Setting Procedures and Restrictions ......... 42

8.9.2 Division Mode (Step 1)......................... 43

8.9.3 Relation between Outdoor Units and

Watt Hour Meter (Step 2) .................... 43

8.9.4 Electrical Specification of Outdoor Units

(Step 3) ........................................ 44

8.9.5 Relation between Indoor Units and

Watt Hour Meter (Step 4) .................... 45

8.9.6 Electrical Specification of Indoor Units

(Step 5) ........................................ 46

8.9.7 Charge Block (Step 6).......................... 46

8.9.8 Currency Unit Set (Step 7)..................... 48

8.9.9 Charge Set (Step 8) ........................... 48

8.9.10 Standard Charge Set........................... 49

8.10 Time Set-up............................................. 50

8.11 Password Change...................................... 52

9. Charge Data Correction and Remedy...................... 53

9.1 Result of Air-conditioning Charge Calculation....... 53

9.2 Maintenance of Charge Data ..........................55

9.2.1 Preparing for Charging Data Maintenance... 55

9.2.2 Maintenance Methods and Restrictions...... 55

9.2.3 Unit Data Maintenance......................... 56

9.2.4 Watt Hour Meter Data Maintenance.......... 59

9.2.5 Verfy Test Operation of Watt Hour Meter.... 60

9.3 Operation Amount Data Monitoring .................. 60

9.4 Charge Parameter Output............................. 61

9.5 Charging Remedy...................................... 62

9.5.1 Preparing to Perform Charging Remedy..... 63

9.5.2 Remedial Apportioning Setting Screen....... 64

9.5.3 Remedy when personal computer HDD

fails (no backup) ............................... 66

9.5.4 Remedy when personal computer HDD

fails (backup).................................... 67

9.5.5 Apportioning method when computer

crashes........................................... 69

9.5.6 Remedy when watt hour meter fails

(monitoring impossible) ....................... 70

9.5.7 Remedy for system information setting error72

10. Error Code List................................................ 74

11. Setting Check List ........................................... 78

11.1 Setting Check List ..................................... 78

11.2 Test Run Check ....................................... 79

11.3 Charging Test Run Check ............................ 82

11.3.1 Charging (No WHM connection)

Test Run Check.................................82

11.3.2 Proportionally Diveded Power Charge

(RS-485 WHM connection) Test Run Check86

Appendix 1: Installing Windows XP Professional ........... 91

Appendix 2: Auto Log-in Confirmation Method............... 93

Appendix 3: Correction to Charge Calcution in the Event

of G-50AReplacement due to Fault............. 94

Page 3

In this manual, Microsoft® Windows® 2000 Professional is called Windows 2000 and Microsoft® Windows®

XP Professional is called Windows XP. In this manual, Microsoft® Excel 2000/XP is called Excel.

Trademarks

MS, Microsoft, Microsoft logo, and Windows are registered trademarks and trade names of Microsoft

Corporation.

Each company may use as registered trademarks and trade names the product names used in this

manual.

– Term description –

• “Man-machine”: Indicates a personal computer with integrated centralzed control software TG-2000A.

(M an-machine interface abbreviation)

• “G-50A ” : Indicates a central controller G-50A.

On the screen of integrated centralized control software TG-2000A, G-50A is displayed

as "G-50."

- About screen -

• This instruction manual may use the development version screen in some case.

Page 4

1. Safety Precautions

contract between the customer and Mitsubishi Electric Corporation. By using this

or

if notified by the distributor of the possibility of a certain type of damage.

Please observe the safety precautions detailed in the installation manuals and operation

The customer must not do any wiring or

Have the dealer or a specialist do any wiring or

work. Do not do it yourself. Doing the

result in improper installation

Do not relocate the unit yourself.

Relocating the unit yourself may result in

ic

To relocate the unit, consult the

Do not make any improvements or repairs

electric shock or fire. For repairs, consult

the company from which the unit was purchased.

Read the installation manuals and operat-

for the computer, peripherals

Improper operation could result in fire or damage

to the computer or peripherals.

Stop operation immediately if an error

appears on the computer and the

Immediately contact the company from

which the unit was purchased.

Read the installation manual and operation

Improper operation could result in fire or damage

WARNING

Do not use the product for any other

This product is for use with the Mitsubishi

Building Air Conditioning Control

function.

Keep children away from the unit.

let children near the unit

Do not use with other applications.

Use the PC that uses this product with this

Using it with other applications

CAUTION

• Please read the Safety Precautions section very carefully before using the unit.

• The safety cautions pro vided here are very important for your safety. Please observe them at all times.

• The degree of danger involved with incorrect operation of the unit are indicated in this manual using

the following symbols.

WARNING Incorrect operation could result in death or severe injury.

CAUTION Incorrect operation could result in injury or damage to property.

• After reading this information, please keep this manual together with the operation manual (Management)

in a location where the operator can see it. Also, when changing operators give both of these manuals to

the new operator.

Note :

manuals of the other machines such as computers, peripherals, and air conditioners.

electrical work.

electrical

work yourself may

which may cause electric

for any reason.

Making improper improvements or repairs may

cause

message

unit stops or is not operating properly.

Failing to do so may result in fire or damage to

the unit.

purpose.

Electric

System. Do not use it with any other air conditioning control system or for any other application. Doing s o may cause the unit to mal-

product only.

may cause faulty operation.

Warning to all users (User Agreement)

This document is a

application, you agree to the following conditions and are considered a user.

• Mitsubishi Electric and associated suppliers are not responsible for any collateral, secondary,

special damages, even

Mitsubishi Electric is not responsible for any rights claimed by a third party.

incorrect installation which may cause electr

shock or fire.

company from which the unit was purchased.

ion manuals

and other machines.

manual for the air conditioner controller.

to the air conditioner controller.

Inspections and maintenance can be

dangerous. Do not

during these times.

1

Page 5

(A separate watt hour meter is

Billing is done with

ating/

(A separate watt hour meter is

Billing is done with

(A separate watt hour meter is

Billing is done with

(A separate watt hour meter is

Billing is done with

2. System Requirements

2.1 Requirements (system recommendations)

We recommend the following software and hardware when using this application (TG-2000A).

Item Requirement Recommended

PC PC/AT interchangeable machine Operation check completed, using IBM,

COMPAQ, and DELL

CPU Pentium III 350 MHz or faster :

within 1000 indoor units

Pentium III 1GHz or faster :

1001 indoor units or over

Memory 128 MB or more 256 MB or more

HDD 6 GB or more (2GB or more of C drive free

space necessary)

Storage device FDD, CD-ROM drive Devices other than those shown at the left may

Resolution 1024 × 768 or higher, 65536 colors or more

Serial port 1 port or more Required when using RS-485 communication WHM

LAN Internal LAN (10/100 Mbps) *1

OS Windows XP Professional

Windows 2000 Professional

Service Pack 2 and above

Other Computer must be dedicated for this use

(TG-2000A).

Pentium 4 1.8GHz or faster

4 GB or more of C drive free space necessary

also be installed.

English version only

* Personal computer must support each OS.

*1 Purchase the option, or use the equipment recommended for the personal computer when

purchasing the personal computer.

2.2 Compatible Units

The TG -2000A has two main functions: air conditioner controller and cost accounting. However, not all

functions are available with all air conditioners.

Table: Compatible units and function list

(¡: supported, : Certain restrictions apply, ×: Not supported)

Function

Model

Y series ¡ ¡ *1

Super Y series ¡ ¡ *1

R2 series ¡ ¡ *1

WR2 series ¡ ¡ *1

WY series ¡ ¡ *1

Multi S series ¡ ¡ *1

Free plan Indoor unit

Free plan LOSSNAY

LOSSNAY with he

humidifying

“A” control type ¡

“K” control type ¡

*1 : Can be calculated for each charging block.

May not be available with some older models.

Control/

Maintenance

¡ ¡ *1

¡ ×

¡ ×

(Adapter required)

(Converter required)

Charging (Billing)

without WHM

×

×

Charging (Billing) with WHM

required.

watt-hour units)

required.

watt-hour units)

required.

watt-hour units)

required.

watt-hour units)

2

Page 6

2.3 Restrictions

The following restrictions apply to the TG -2000A application.

(1) System configuration limits

Number of units Notes

G-50A Max. 40 units G-50A Ver. 2.10 or higher

Indoor unit Max. 50 units/G -50A Max. 2000 units (including all IC, KIC, AIC, LC, and FU)

[Symbol]IC: Indoor unit, LC: LOSSNAY, FU: OA processing unit, A IC: “A” controller,

KIC: “K” controller

(2) Group setting restrictions

Item Restrictions Note

Remote controls 2 per group * Other remote controls besides M-NET

Number of indoor units

connected to a group

Number of SC and RC

connected to a group

Groups per floor Max. 50 groups per floor Up to 50A groups can be displayed on

*1 The ME remote controller and MA remote controller cannot be used together for the same group.

*2 Set the same function unit for the group.

[Symbol]SC: System controller, RC: Remote controller

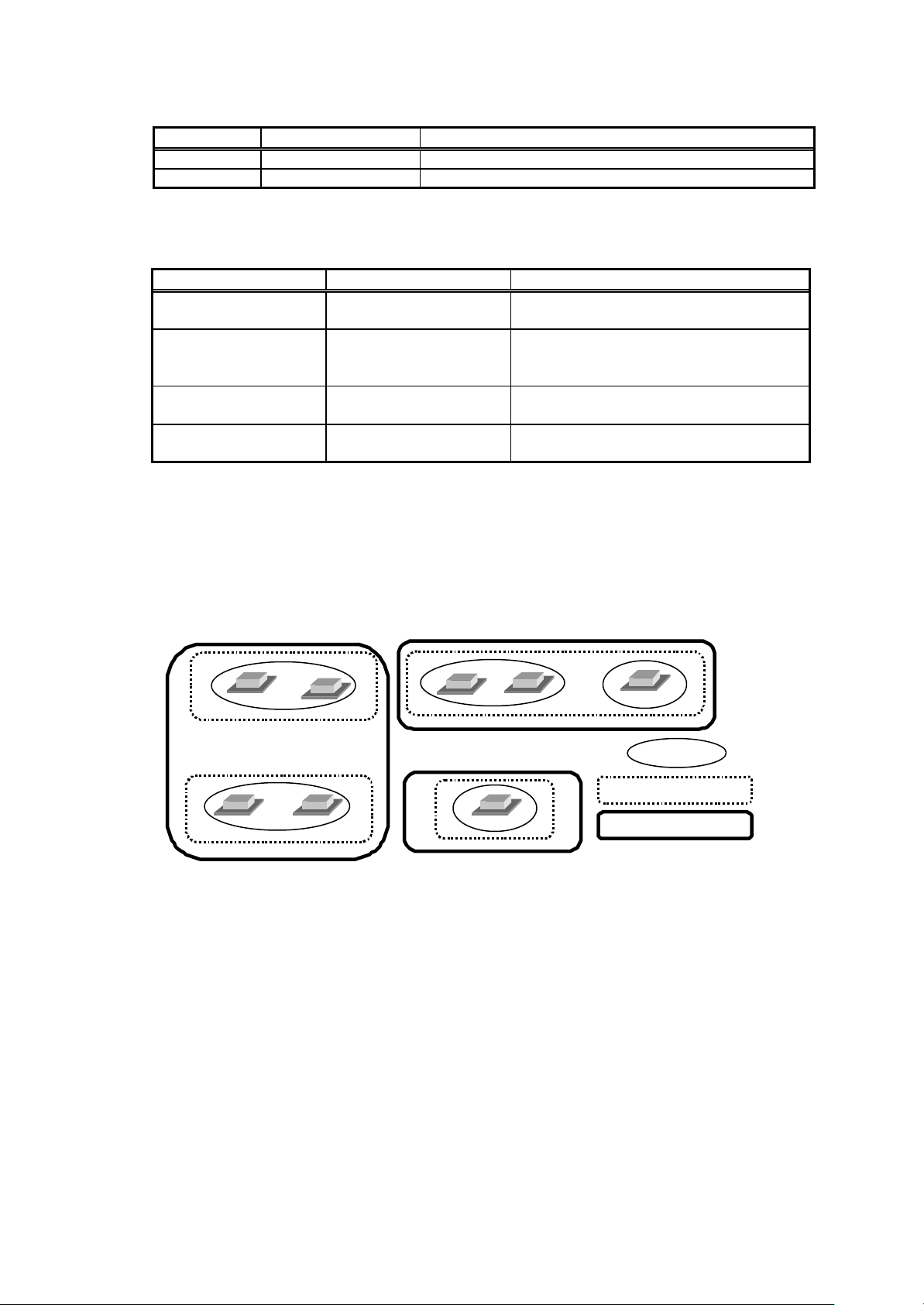

(3) Block setting

• The block comes in two types, operation block and charge block.

• The operation block is an aggregate of groups, and it is possible to set a different model group

for the same operation block.

• The charge block consists of an aggregate of operation blocks.

(4) Notes on using K control models

When using a K transmission converter (model name: PAC -SC25KA, PAC-SC25KAA(-E)) to manage K

control models, take note of the following. See the documentation provided with the K transmission

converter for more detail.

• The address of the K transmission converter will be the smallest address of the K control model +

200.

• Set the K control model addresses so that they are larger than the M transmission model

addresses.

• When setting a group containing K control models, make the group number the same as the

smallest unit address in the group.

(5) Notes on using A control mode

• Use the A/M NET Adapter (model name: PAC-SF48MA(-E)). Set the group to “Group with only

A control”.

(6) Countermeasure when an error occurs

• Note that each control or function may not operate properly when rebooting (*1) or when a fault

occurs in the centralized Controller G-50A. Since each error is displayed when it occurs, it is

recommended to solve the faults quickly.

*1 Indicates that the system is restarting.

1 to 16 * IC, AIC, KIC, or LC cannot be used

4 per group * The number of G-50A is not included

type will not work

within the same group. It is not pos-

sible for group settings to span G-50A

one floor of the whole building window.

Group

Block for operation

Block for charging

3

Page 7

(7) Notes on charge system

485 output of

Necessary when measuring the

F or

att hour meter 2,

Installation is recommended to

billing (Charge data) and other

use

• If there is a group that is not set in the charge block, the electric power amount for that group will

not be included in the air-conditioning charge. If there are groups which require charging to be

divided, set those groups as operation blocks or charge blocks to accomplish this.

• The air conditioning charge can be calculated by block units or by power meter units. Note that

even when OA processing unit, LOSSNAY, A control unit or K control unit are included in the

block setting, they are not included in the air conditioning charge of the block unit.

• The function for Charge calculation (Without WHM connection) is only applicable to the indoor

unit. It does not apply to OA processing unit, LOSSNAY, A control unit, and K control unit, etc.

• Some older M-NET control indoor units are not compatible with the charge function.

• When the system is changed or the air conditioner is extended, which may require address

changes, the charge calculation may be affected in some cases.

Executing such changes or extensions are recommended after gaining approval from the

building owner(s).

(8) Charging (Billing) restrictions

The air conditioning cost calculation method use by this integrated software TG -2000A is the

Mitsubishi proprietary general electric power apportioning method. Thus, it is not calculated

using watt hour meters installed at the power supply to each unit. Additionally, it cannot be

employed in applications demanding calculations based on watt hour meters installed at each

unit. Thus when using this unit, we recommend a separate contract be established between the

building owner and the tenant that specifies “air conditioning fees will be collected based on

proport ional usage (including special considerations for downtime).”

(9) Function description

• The function/specifications may partially change and improvements may be made without any

notice.

2.4 Other Devices

Other devices specified or recommended for use with the TG-2000A are listed below.

Name Manufacturer Model Notes

Printer (None specified) (None specified) Supports a page printer only

Watt hour meter 1 Northern Design

RS -232C/

RS -485

converter

UPS

(Uninteruptable

power supply)

1 POWER RAIL 323 +

(Electronics) Ltd.

2 Elcomponent

Limited

3 CIRCUTOR

4 elcontrol energy

(None specified) (None specified)

(None specified) (None specified)

OPTION Module

2 AEM31D/485

3 CVM-BC-ITF-RS485-

C2

4 ED39din 485

(Must run under the OS used

(Windows 2000/XP Professional).)

Only supports RS the specified model and

manufacturer

electric power.

Ex) B&B Electronics Model

485DRJ

Black Box Model IC520A IC108A

* Regarding w

the converter from the manufacturer may also emit light.

prevent destruction or loss of

data. (Any type suitable for

with personal computers)

4

Page 8

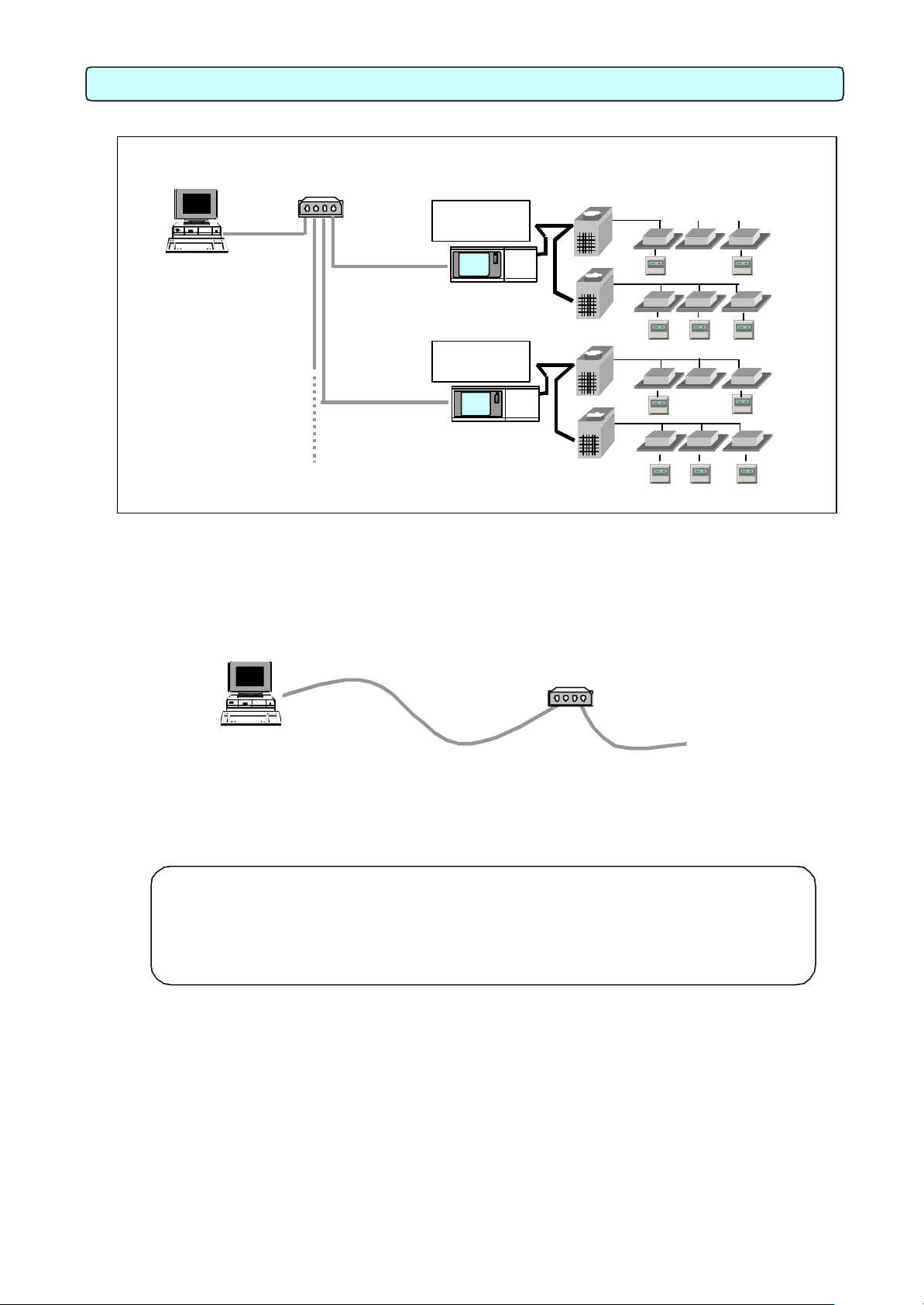

3. System Configuration

controller

G-50A

G-50A

Integrated software

3.1 System Configuration Example

[Image drawing]

HUB

LAN

Integrated software

TG-2000

3.2 Hardware Connection Diagram

(1) LAN connection

Connect the LAN cable to the personal computer. For the location of the LAN connector for the

personal computer, refer to the Instruction Manual of the personal computer.

LAN

TG-2000

Note:

• Be sure to use the hub.

• Execute the LAN cascade connection as shown below.

For 10BASE-T, the cascade connection is executable up to a maximum of 4 sta ges.

For 100BASE-T, the cascade connection is executable up to a maximum of 2 stages.

Power

supply unit

Power

supply u

10BASE-T

straight cable

Outdoor unit

Indoor unit

Remote

HUB

To G-50A

5

Page 9

ners and controllers

PC connections and settings

-

machine system can correctly operate air conditioner units of all

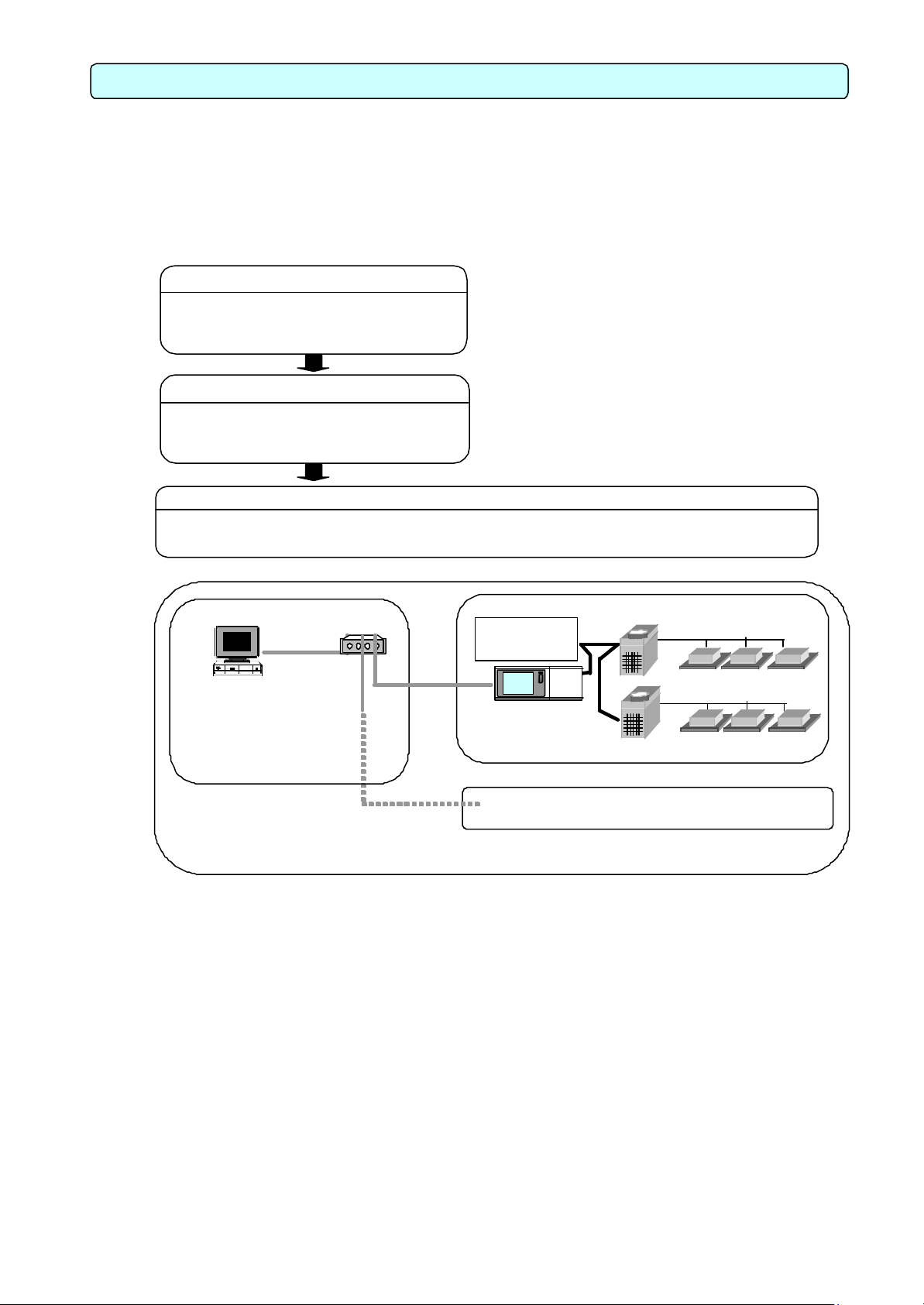

4. Flow of Site Adjustment

For the test operation method of the air

50A,

that only the air conditioner test

operation has been completed before

Power

G- 50A

4.1 Flow of Site Adjustment

When the task of site adjustment is subdivided into smaller tasks as shown in the figure below, the

tasks can be broadly grouped into three steps. The benefit of following these three steps when

carrying out the tasks of site adjustment is that if troubles do arise, it will be clear which step caused

the problem. This makes it easier to solve problems and this results in a more efficient execution of

site adjustment tasks.

Carry out site adjustment, by following the step by step instructions shown below.

Check that the air conditio

are correctly configured and that the air conditioner works.

Step 2

Connect and set up the software and hard

ware on the PC with TG -2000A installed.

Check that it is ready for operation.

Check that the TG -2000A manthe managed systems by issuing TG -2000A commands.

Step 1 G-50A test run

Integrated centralized

control software

TG-2000A

Step 2

S tep 3

4.2 Tools for Site Adjustment

You will need the following equipment and reference material in order to easily carry out site adjustment.

<Measurement instruments>

• Tester : to check the wiring and the voltage

<Reference material>

• All necessary drawings of the air conditioning control system

• TG-2000A Instruction Manual (Site Adjustment (this manual), Management)

• Operation Manual for each air conditioner unit and controller

<Ot her material>

• Floppy disk : used when copying data

• CD-R : used to store generated data and copy it to the site PC.

• Initial setting tool: Personal computer in which this tool is installed

• LAN cable : PAC-YG00FA LAN cable

• Screwdriver kit

• Other usual maintenance tools

*

conditioner and centralized controller Grefer to the relevant installation manuals.

l Check

starting Step 1.

* See Chapter 4 in this booklet for details.

Step 3 TG-2000A system test run

HUB

supply unit

LAN

S tep 1

Step 1

6

Page 10

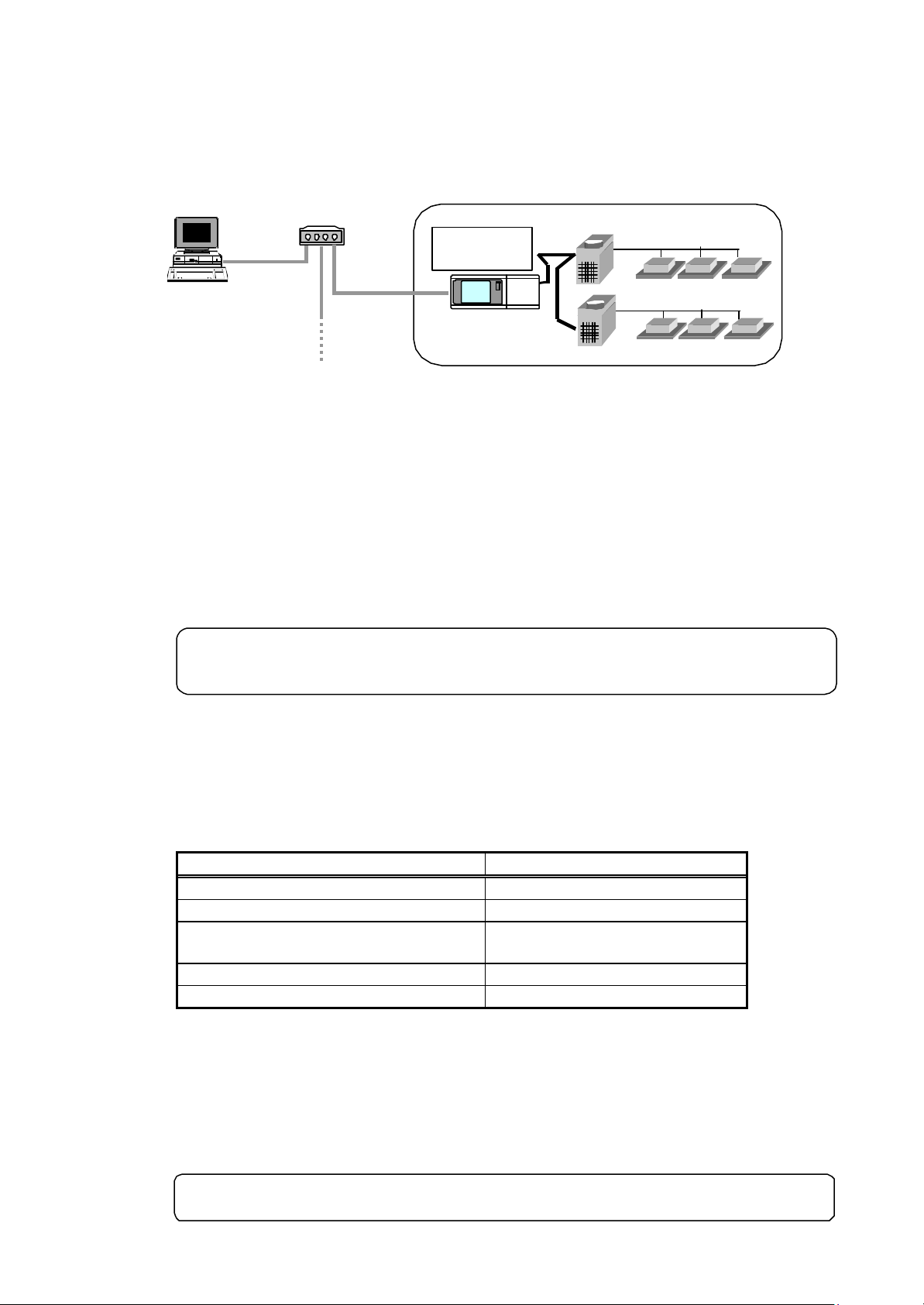

4.3 Step 1: Test operation from centralized controller G-50A

Perform only the test operation of the air-conditioning system of the central controller G-50A.

(1) Preliminary check

Check that the test operation of the air conditioner has been completed.

Check that the central controller G-50A is set to Group and Interlock.

(The initial setting is executable using the initial setting tool or the G-50A.)

Integrated centralized

control software

TG-2000A

(2) Test operation from central controller G-50A

After supplying power to the central controller G-50A and all air conditioners, perform the test

operation from the central controller G-50A, and check the operation state of each unit.

* For the test operation method, refer to the installation manual for the air conditioner or the

central controller G-50A.

HUB

Power

supply unit

G-50A

S tep 1

4.4 Step 2: Initial setting of integrated centralized control software TG-2000A

(1) Set -up of integrated centralized control software TG -2000A

Make preparations to allow the personal computer to be operative in order to install the integrated

centralized control software TG-2000A. After performing the set-up preparations, set up the

integrated centralized control software TG -2000A.

(2) Check the G-50A IP address and personal computer (which uses the integrated centralized control

Note:

• For the set -up procedure, refer to Chapter 5.

• For safety, check the installation state/connection before turning the power ON.

software)

Check the G-50A IP address. Check the IP address used for the integrated centralized control

software at the same time. Normally, set the sub-net to "255.255.255.0".

For a LAN dedicated to the G-50A system, it is recommended to set the IP address

within the following range.

Models IP address range

G-50A main unit [192.168.1.1] to [192.168.1.40]

Personal computer for browser [192.168.1.101]to [192.168.1.149]

Personal computer

for integrated centralzed control software

PLC [192.168.1.151]to [192.168.1.200]

Personal computer of initial setting tool [192.168.1.201]

* To connect to the existing LAN, set the IP address and sub-net mask set by the LAN manager.

(3) LAN connection confirmation

Check that the LAN cable is connected to the G-50A, personal computer (using integrated

software), and hub, and that power is supplied to the hub.

(4) Initial setting of integrated centralized control software

Start the integrated centralized control software TG -2000A to execute the initial setting.

Note:

• For the initial setting method of the integrated software, refer to Chapters 6 to 8.

[192.168.1.150]

7

Page 11

4.5 Step 3: Test operation from integrated centralized control software TG-2000A

2000A to

execute the test operation/confirmation. (The test operation function is not included in the

Perform the test operation from the integrated centralized control software TG-2000A to check the

operation state and monitor display of the air conditioner.

For the operation procedure, refer to the Instruction Manual (Management).

Note:

• For confirmation in the test operation, use the checklist shown in Chapter 11.

• Perform the normal operation from the integrated centralized control software TGstart/stop function.)

8

Page 12

If not the correct version,

Check that there is at least 128 MB of

Check that there is at least 2GB of free

the C drive. (OS already set

Install the printer driver and check that

For details, refer to the

In the Windows Control Panel, select

Time” and set the date, time

For details, refer to the

At the “display” in the Windows Control

the screen size to 1024 × 768

color to 65536 colors

For details, refer to the

cedure, see Appendix 2

t the network settings have

performed (even if the adapter is

For details, refer to the

5. Installation

2000A will not be started automatically after starting (rebooting) the personal computer

2000A is set

5.1 Pre-installation Steps

Preparing for installation

Before installing the TG -2000A application, do the following checks and preparatory steps.

Steps

1 Check the OS Check the OS Service Pack version.

2 Check the memory

3 Check the HDD free

4 Printer settings

5 Set the date and time

6 Screen size and color

7 Automatic login

8 Network settings Check tha

*1 Check when using the printer.

*2 Auto log-in sets the automatic start-up without entering the log-in name or password at the OS

start -up.

Note:

• The TG when the TG -2000A is set to Auto reboot, unless the Auto log-in is set. When the TGto Auto re-boot, be sure to set the Auto log-in.

5.2 TG-2000A Setup

5.2.1 Setup

The following shows the TG-2000A setup disk (CD-ROM) folder configuration and files. However, it

only describes the files to be run.

CD-ROM drive \Setup\Step1\MSDEInst.bat

\ Step2\DbSetup.bat

\ Step3\SetupTG.exe

[Reference] CD-ROM directory structure

readme.txt : Directory structure and setup precautions of this CD-ROM

\ Setup : Set -up folder

\Tool : Air-conditioning charge calculation support tool (chargecalc.xls)

\ Manual : Operation Manual

Action Details How to

space

settings

settings

*

• Windows XP Professional

• Windows 2000 Professional: SP2

and above

RAM (256MB or more is

recommended.)

space on

up)

printing is possible.

“Date and

and region

Panel, set

or larger and the

(High Color (16-bit)) or more.

Check that the Auto log-in is set. *2 * For the setting check pro-

been

not connected).

9

refer to the attached

documentation, “Installing

• Windows 2000/XP” and

upgrade the OS.

* If necessary, add more

RAM.

* Refer to the Windows

instruction manual for

more details.

*

attached instruction

manual.

*

Windows users manual.

*

Windows users manual.

Auto Log-in Check Proce dure.

*

Windows users manual.

Page 13

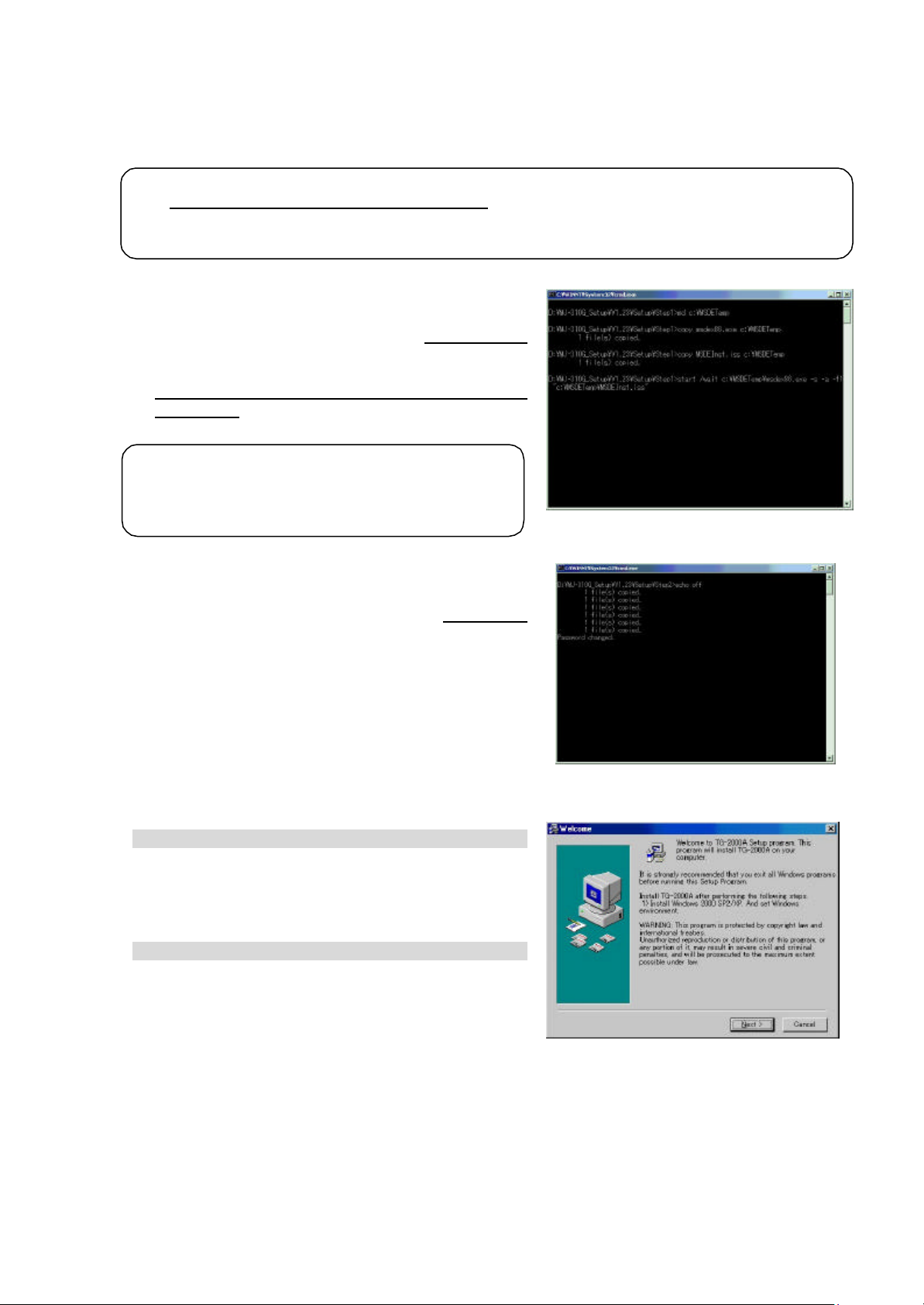

5.2.2 Running TG-2000A Setup (New setup)

Restart the personal computer after completing the

up. Otherwise, Step 2 which follows may

The TG -2000A setup is performed in three stages:

Step 1) MSDE setup

Step 2) Database setup

Step 3) TG-2000A setup

Note:

• Perform the 3 setup steps sequentially. Otherwise, the TG-2000A will not operate properly.

• Be sure to log -in to Windows, using the Auto log-in name and password before executing the set-up.

(It is necessary to execute the log-in with a log-in name having administrator rights.)

Step 1) MSDE setup

Run the “MSDEInst.bat” file in the “\Setup\Step1” folder.

A DOS window will ope n and the close 2 or 3 minutes

later when the process has finished.

When the installation is completed, restart the

computer.

Note:

•

MSDE setnot be able to be set up properly.

Step 2) Database setup

Run the “DbSetup.bat” file in the “\Setup\Step2” folder.

A DOS window will open and the close 10 se cond s

later when the process has finished.

Step 3) TG-2000A setup

Run the setup program for TG-2000A. Perform the

setup in accordance with the instructions on the

screen.

(1) Starting the setup program

1) Starting SetupTG.exe

Use Windows Start -Run to execute Run SetupTG.exe

in the “\Setup\Step3” folder in the root directory of the

Setup CD.

The setup start confirmation window appears. Read

and check the cautions which appear on the screen.

2) Check the displayed items and click the [Next] button.

If there is no problem with the cautions, click the [Next]

button to continue on to the next screen.

* Click the [Cancel] button to stop the setup.

10

Page 14

(2) Read the license agreement

Be sure to restart the personal computer after

1) Read the license agreement and click the [Next] button.

The license agreement screens will be displayed one at

a time. Carefully read all of the agreement and check

that you agree with each item before selecting “It

agrees” and clicking [Next] to continue.

* If you cannot agree with the license agreement,

click the [Cancel] button and stop the installation of

TG-2000A.

(3) Check the installation folder

1) Check the location where the program is to be installed

and click the [Next] button.

Check the location where the program is to be installed.

If the location needs to be changed, set the new

location by clicking the [Browse] button.

After checking the installation location, click the [Next]

button.

* Click the [Cancel] button to stop the installation.

(4) Installation start confirmation

1) Confirm that you want to start the installation and

select the [ Next] button.

If the [ Next] button is clicked the installation will start.

* Click the [Cancel] button to stop the installation.

(5) TG-2000A setup completion

1) Select [ Finish] button

Click [Finish] button on installation screen.

After the installation is completed, restart the computer.

When the installation is completed, the program is

registered in the start menu and automatically run from

the nex t time the computer is started.

Store the CD is a safe place.

Note:

•

installing TG -2000A.

11

Page 15

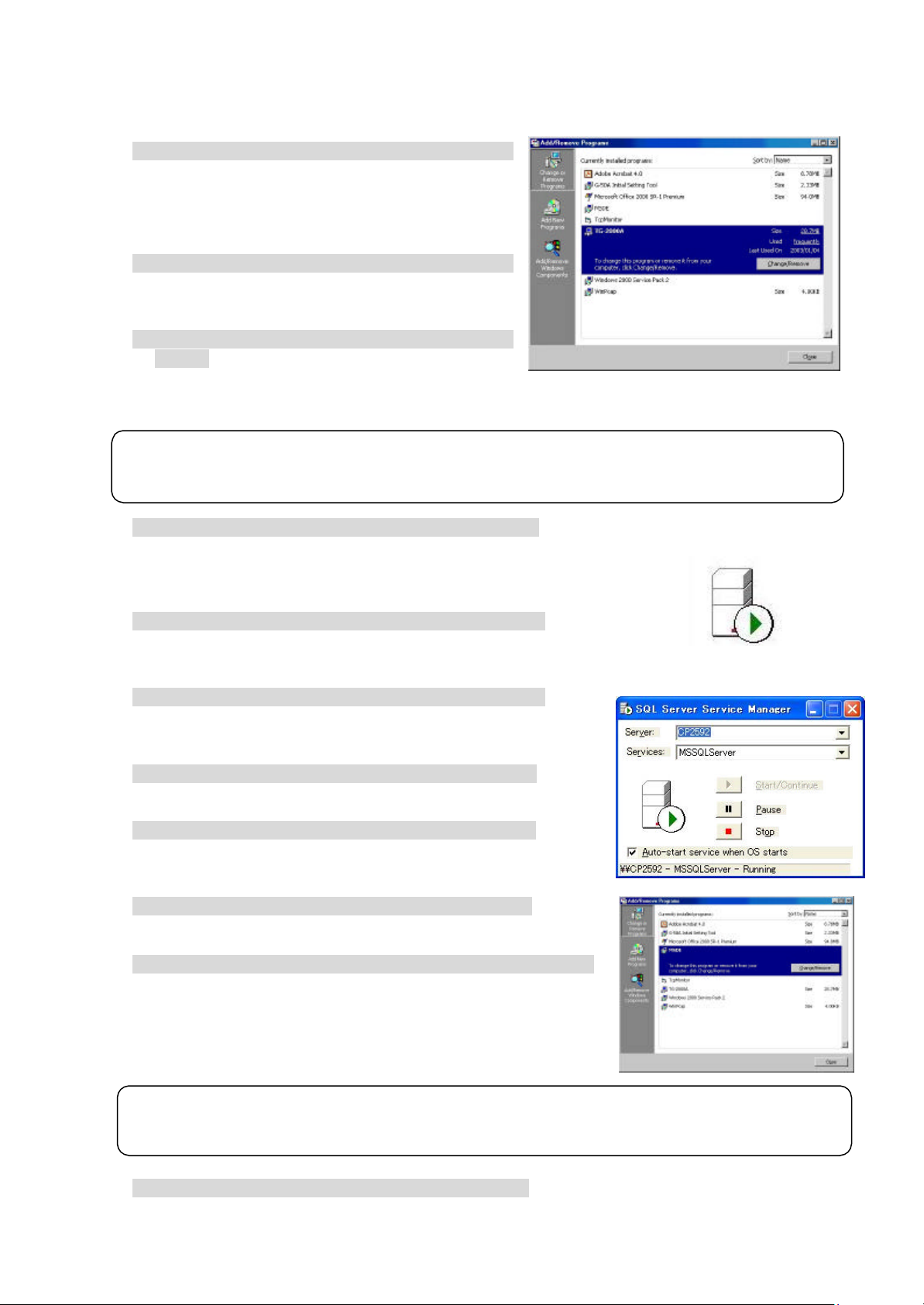

5.3 TG-2000A Uninstall

This section describes how to uninstall an installed “MSDE” and “TG -2000A” program.

(1) TG-2000A uninstall

1) Check to see if TG -2000A has ended

Check to see if the TG-2000A program has ended. If

it has not ended, end it.

* For a description of the ending method, see

Chapter 7.

2) Start “Add/Remove Programs”.

Start by clicking Control Panel’s Add/Remove Programs.

3) Select “TG-2000A”, and click [Change/Remove]

button.

Select “Integrated centralized control software

TG-2000A” from the displayed programs, and click the [Change/Remove] button. Uninstallation of

the TG -2000A program begins.

Note:

• We recommend that you do not delete all the shared files.

• This uninstall cannot delete some folders and files. (Ex: C: \TG-2000)

4) “Add/Remove Programs” ending

When program uninstallation ends, Add/Remove Programs ends.

(2) MSDE uninstall

1) Start the SQL Server Service Manager

Start the “SQL Server Service Manager” by right-clicking the MSDE

icon on the taskbar.

2) Stop all service

To stop all service, make your selection at the Service field and

click the [Stop] button.

3) End the SQL Server Service Manager

The “SQL Server Service Manager” window closes.

4) Close the MSDE icon

Right-click the MSDE icon on the taskbar and select [Exit]. The

MSDE icon is removed from the taskbar.

5) Start “Add/Remove Programs”.

Start by clicking on the Control Panel’s Add/Remove Programs.

6) Choose “MSDE”, and click the [Change/Remove] button.

Select “MSDE“ from the displayed programs, and click the

[ Change/Remove] button.

Uninstallation of the MSDE program begins.

Note:

• This uninstall cannot delete some folders and files. (Ex: C: \Mssql7)

• When MSDE is used, uninstall is unnecessary.

7) “Add/Remove Programs” ending

When program uninstallation ends, “Add/Remove Programs” ends.

MSDE icon

12

Page 16

6. Part Names and Functions

functions that may be

-

-

Maintenance group:

Shows the title of the

for the

function, site name, and

Exits the Initial window

Shows time, warnings,

Equipment state

Displays the system

equipment as error or

Display the title of

Message bar:

Display comments

next,

6.1 Window Elements

The window displayed when the power is turned on and no system settings have been made is called

the Initial window. The Initial window has the following parts.

(The Initial window can be accessed from the menu bar with a password. For details, see section 6.3.)

Title bar:

window

Menu bar:

Shows a list of

selected

System setting

group:

Sets the group infor

mation, monitor dis play, charge calcula

tion system, etc.

display:

normal.

Click the buttons to display the window associated with that feature. An example is shown below.

Title bar:

the window.

User setting group:

Sets valid/invalid

password.

Function to correct the

charge calculation, etc.

Exit button:

and moves to the Management window

Message bar:

and other comments

Initial window

Function display operation setting

section:

Used to display/set the setting contents.

about function display and operation

Displays the operation contents of the [Next], [Back], [Cancel], and [OK] buttons on each setting screen.

Buttons Operation contents

[OK]

Advances to the setting screen with the confirmation contents on the preparation

screen determined not to have any problems.

Validates the contents set on this display screen to advance to the next setting screen.

[Next] Advances to the next setting screen.

[Back] Invalidates the contents set on this display screen to return to the last screen.

[Cancel] Invalidates the contents set on this display screen to shift to the initial screen.

System Configuration Options Control Window

13

Next, Back, Cancel,

and OK buttons:

Choose to end, return,

or cancel the setting of function display and operation

settings

Page 17

6.2 Basic Mouse Operation

First, use of the mouse as a pointing device will be explained. If a device other than a mouse is being

used, consult with the manual for that device.

The following is a list of terms used in describing mouse operations.

Click : This refers to pressing and releasing the button one time.

To use this function, click the button

Double Click: This refers to pressing and releasing the button twice in quick succession.

Drag : This refers to moving the mouse pointer on top of an object on the screen, pressing

and holding down the button to select the object, then, while holding the button down,

moving the mouse pointer, and the object, to a different location.

Keyboard : Primarily used when entering password, characters, or numerics.

6.3 Accessing Functions and M oving between Windows

The functions of the TG -2000A can be divided into two general categories.

1) Functions that monitor air conditioner operation status and control functions……Initial window

2) Operation and system initialization and charge data maintenance functions (functions used to

accomplish functions in 1) above)……Control window(Management screen)

This section deals mostly with functions in category 2).

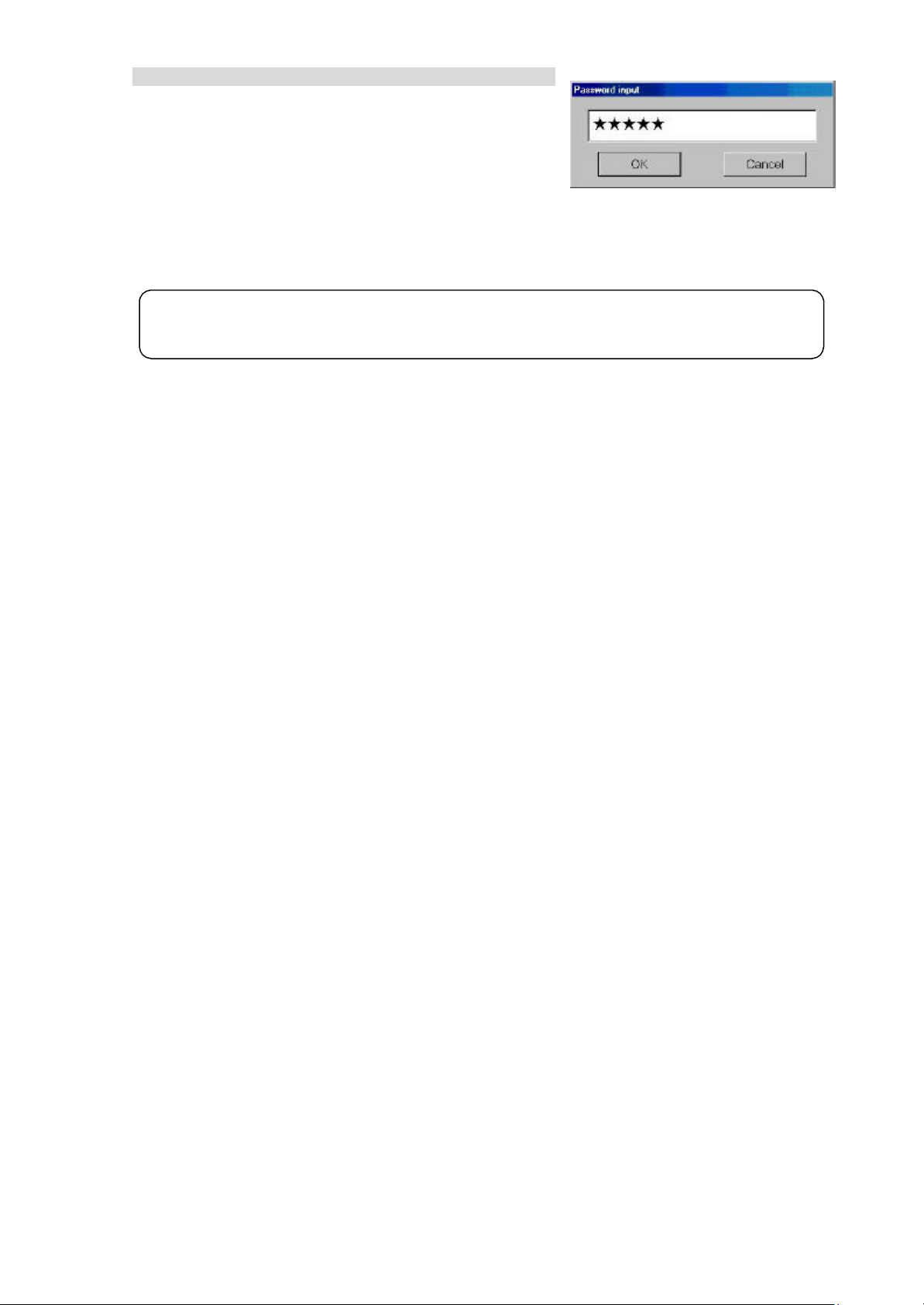

(1) Shift from the initial window to the control window

The following shows the procedure to shift from the initial window to the control window. Shift the

screen to the control window after completing the initial setting shown in Chapter 8.

[Procedure]

1) Select [Finish] button.

Click the [Finish] button located on the lower right on

the initial screen. With the above step, the

confirmation screen (asking whether or not to trans mit the setting contents to the G-50A) is displayed.

2) Select [OK] button.

Click the [OK] button to transmit the initial setting

contents to the G-50A.

The start-up display screen is displayed after the

screen has been shifted to the control window. The

system information set or changed is transmitted to

each G-50A to enter upon the start -up processing.

It takes approximately 10 to 20 minutes to start-up.

* Note that the setting contents will not be trans-

mitted to the G-50A when the [Cancel] button is

clicked. If it is used when only the maintenance

group function is operated, it is possible to shorten

the time required until the control window

resumes.

(2) Shift from the control window to the initial

window

The control window shifts to the initial window when

the initial setting contents are changed or when the

charge calculation maintenance is performed.

[Procedure]

1) Select [Configuration] and then [System set] in the

menu bar.

Click the [Configuration] in the menu bar on the

control window to select the [System set]. The

password confirmation screen is displayed.

Display screen of Shift to setting screen

Screen of confirmation for

transmitting set contents

Start-up display screen

14

Page 18

2) Enter the password

Manage the password to prevent unauthorized personnel from accessing the system. The

Enter the word “*****” in the password verification box, then

click the [OK] button. Doing so returns you to the initial

window.

There are two kinds of passwords.

Initialization password: All the items in the initial

window can be used. The

initial password is “SYSTEM”.

Maintenance password: The initial window maintenance group and personal password can be

changed. The initial password is “Maintenance”.

Maintenance Tip

•

password can be changed.

Password input screen

15

Page 19

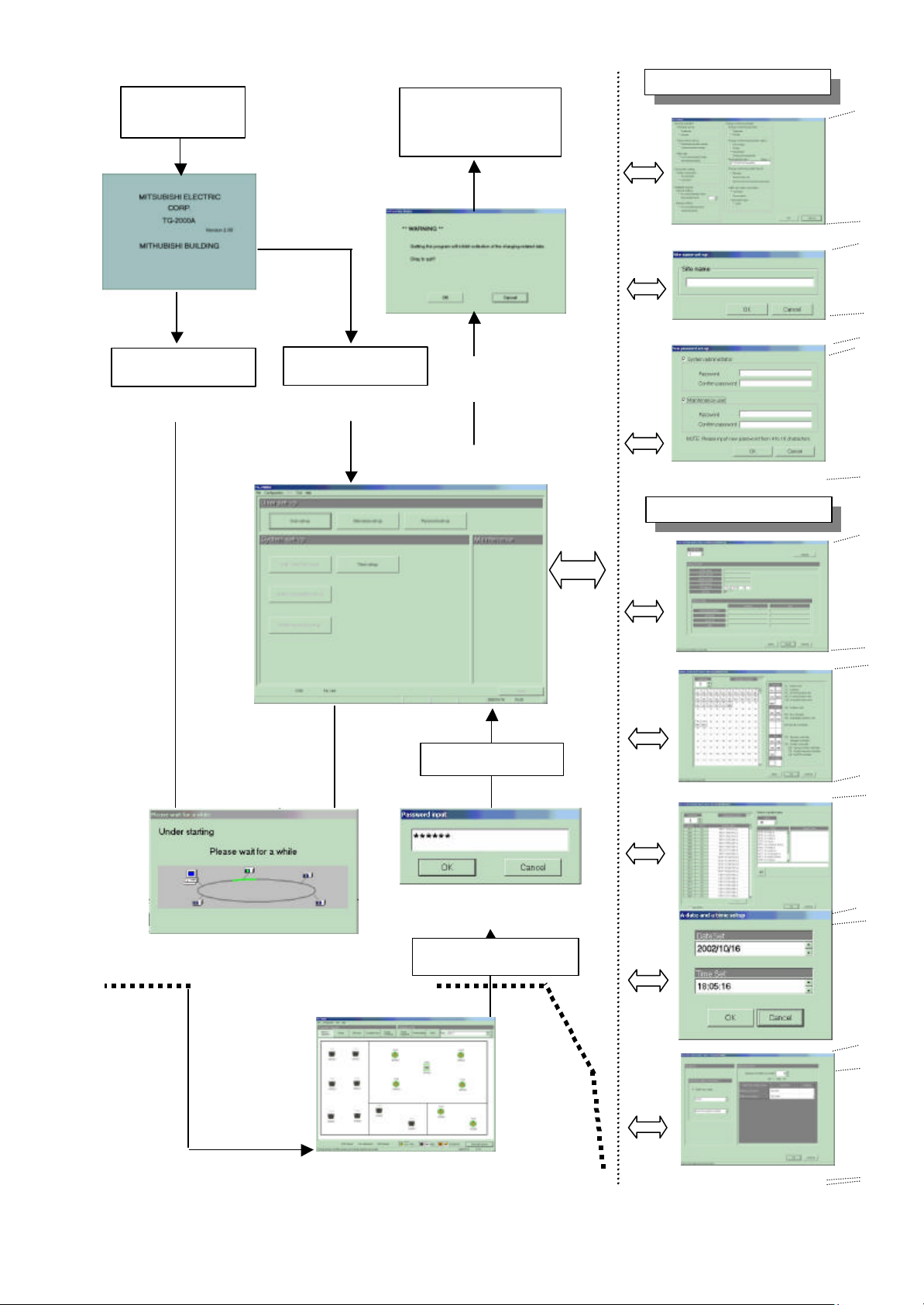

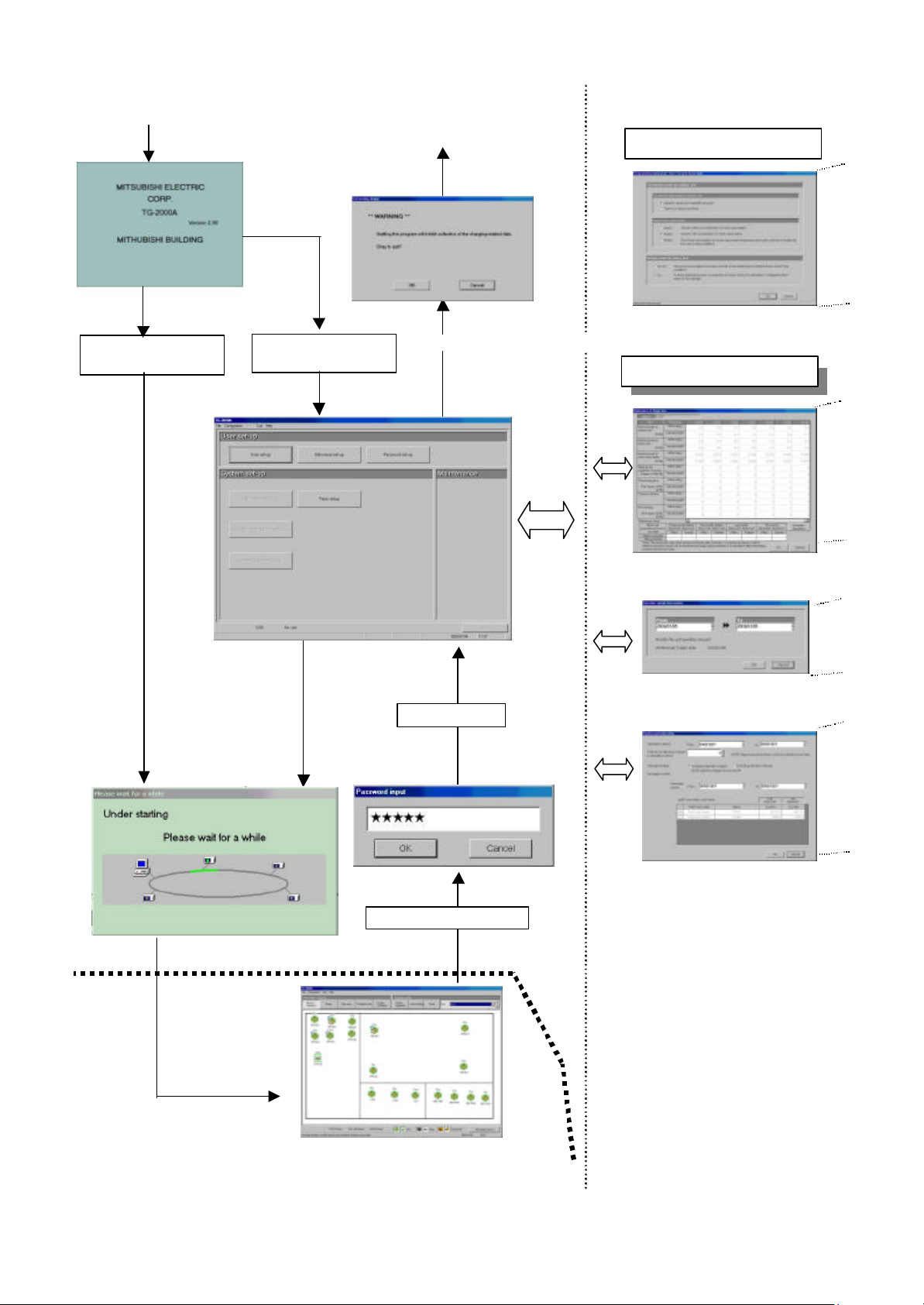

<TG -2000A screen order 1>

turn

]

]

Power On + Start

TG-2000A

System data

No system data

[User setup group]

Exit TG -2000A, shut

down the OS, and

the power off

Select [ File]-[End

button

[System setup group]

Select [ Exit

button

* Range described in this manual

Control window(Management screen)

(see separate management manual)

Password input

Return to Initial window

16

Page 20

Wizard name Primary settings contained in the activated window

User Set -up Set TG -2000A functions

Wizard name Primary settings contained in the activated window

Site Name Set -up Set the product name (site name)

Wizard name Primary settings contained in the activated window

Password change Changes the password to the two types of Initial window

Wizard name Primary settings contained in the activated window

Preparation for the G-50A

connection setting

Number of G-50A units setting Sets the number of G-50A units.

G-50A IP address setting Sets the IP address for each G-50A.

Wizard name Primary settings contained in the activated window

Preparation for System

configurations setup

Collecting G-50A data Collects the setting information for the G-50A during the initial

Unit configurations setup Sets the unit configurations in G-50A.

System structure of refrigerant

system

Function of each group Set indoor unit and ventilation groups.

Ventilation unit grouping Set ventilators and indoor unit groupings .

Wizard name Primary settings contained in the activated window

Preparation for Monitoring screen

set -up

Set -up of model name Sets the model name of unit

Set -up of the number of floors, and

floor name

Creation of a plane view Create a floor plane to be used in the floor window of the Management

Set -up of floor name and G-50A Set floor and G-50A assignment

Set -up of icon arrange and name Layout icons on the floor plane, and set names

S et-up of block

Wizard name Primary settings contained in the activated window

Time set -up Sets the current time.

Wizard name Primary settings contained in the activated window

Preparation for WHM set -up Check the WHM setting order and notes display .

Watt hour meter setting Sets the watt hour meter connection port and watt hour meter

Set -up for the name and the

maximum count value of WHM

Checks the step/caution display for the G-50A connection

setting.

It is possible to display the optional functions of the G-50A.

Verifies the order of system configuration settings and displays

warnings

setting.

Set refrigerant connections .

Verifies the order of monitoring screen settings and displays

warnings

Sets the number of floors and floor name.

screen(control window)

Set groups in blocks

address.

Sets the WHM name, installation location, and maximum

integrated value.

17

Page 21

<TG -2000A screen order 2>

No system data

System data

Exit TG -2000A, shut down the OS, and turn the power off

Select [File] - [End] button

Select [Exit] button

* Range described in this manual

[Maintenance setup group]

Control windows(Management screen)

(see separate management manual)

Power On + Start TG -2000A

Password input

Return to Initial window

[System setup group]

18

Page 22

Wizard name Primary settings contained in the activated window

Preparation for Energy monitoring

set -up

Model name Sets the unit model No.

Number of floors, and floor name Set floor number and names.

Floor plane drawing Create a floor plane to be used in the floor window of the

Relation between floor and G-50A Sets the number of G-50A terminals.

Group icon placing and naming Layout icons on the floor plane, and set names.

Operation block setting Set groups in blocks.

Wizard name Primary settings contained in the activated window

Maintenance of charge data

(Present value monitor)

Maintenance of charge data

(Meter maintenance)

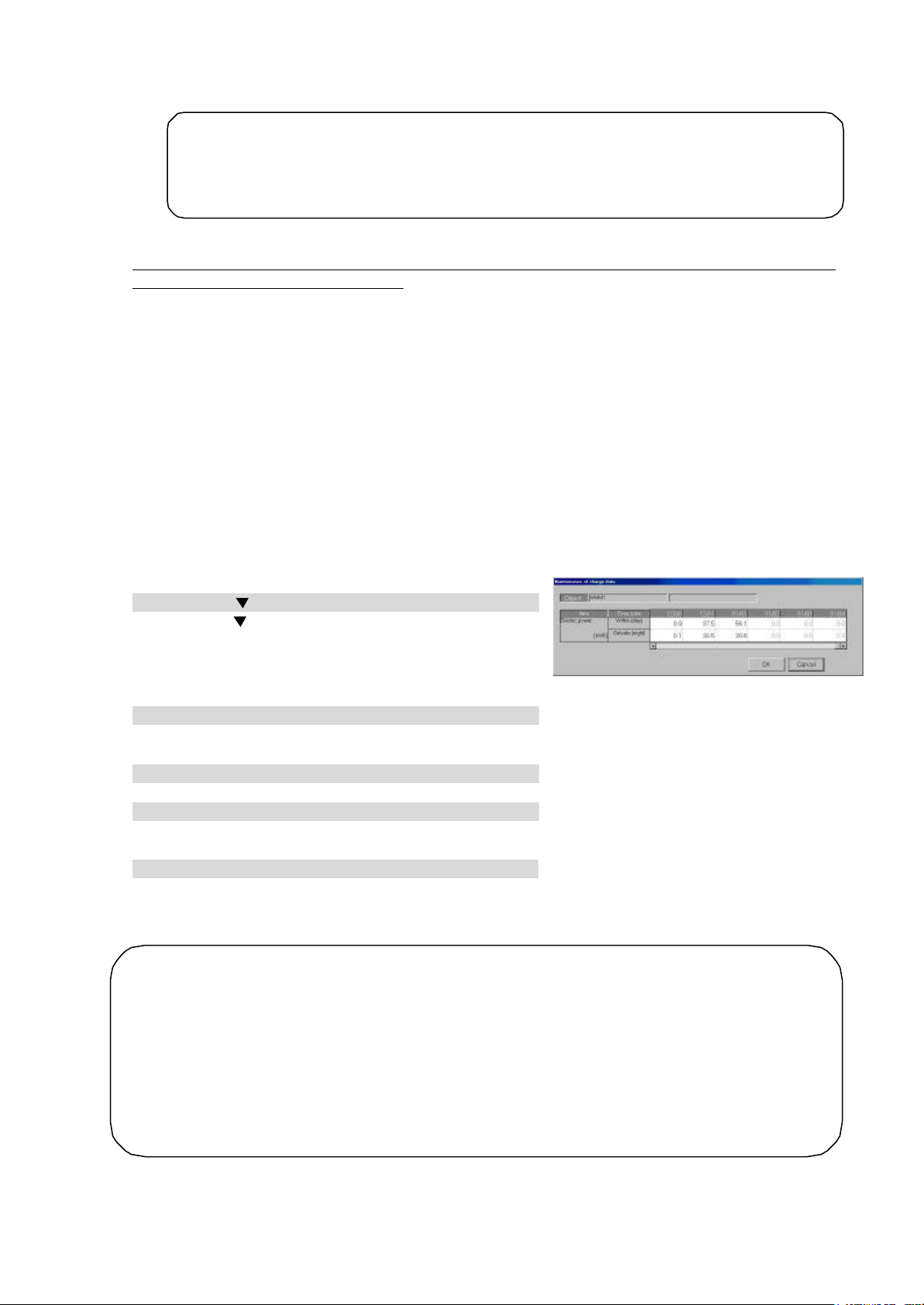

Maintenance of charge data (Unit) Data for the last 62 days from indoor units and outdoor units can

Wizard name Primary settings contained in the activated window

Operation amount data monitoring Operation data stored in G-50A can be monitored and saved.

Wizard name Primary settings contained in the activated window

Remedial apportioning setting Remedial apportioning can be tentatively performed when

Verifies the order of billing settings and displays warnings .

Management window.

Dat a for the last 62 days from the watt hour meter, indoor units,

and outdoor units can be viewed and edited.

(Also, current values for watt hour meters can be monitored.)

Watt hour meter data from the last 62 days can be viewed and

edited.

be viewed and edited.

charging trouble occurs.

19

Page 23

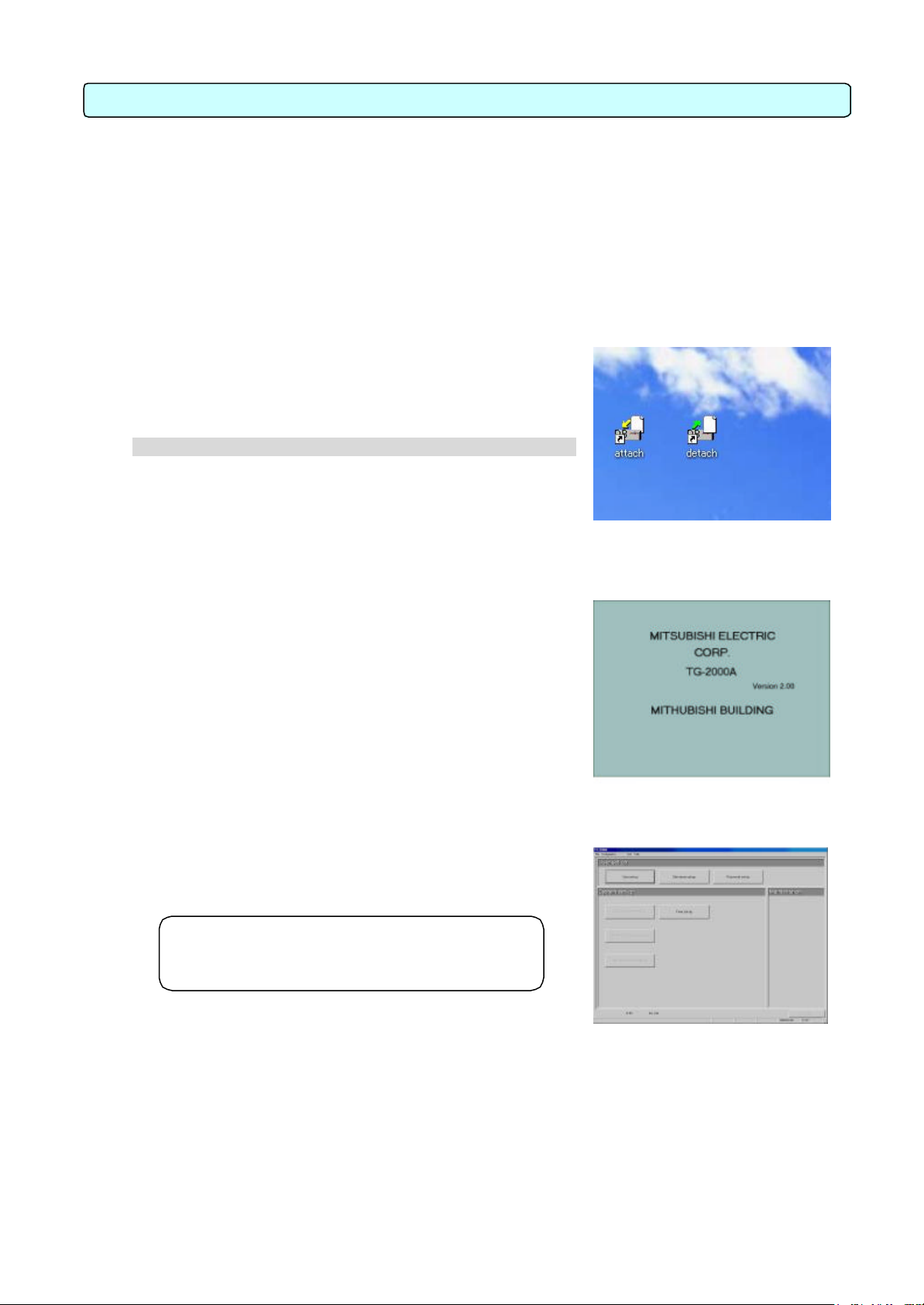

7. Initial Startup and Shutdown

For safety reasons, make a thorough check of

Desktop screen

7.1 Before Startup

Please confirm the following items before starting the TG-2000A application.

(1) A test run of the air conditioning system has been completed.

(2) Check that the personal computer, hub, G-50A, power supply unit, and air conditioner power are

turned on.

(3) All PC hardware and cables have been connected and the proper software installed.

(4) “Date and time” setting are correct.

7.2 Startup

Start the integrated centralized control software TG-2000A

application.

Follow these steps to startup the TG -2000A application.

[Procedure]

1) Restart Windows

When Windows OS restarts, the user automatically logs on

and the TG-2000A program starts. When the startup process

begins, the setup screen is displayed.

* When Windows OS restarts, the integrated software

TG-2000A application starts automatically.

After the startup screen is displayed, the behavior of the

application depends on the existence of System Settings

data.

Case 1: Without System Settings data: (the first startup)

The initial screen is displayed. Start with Chapter 8

“Changing System Settings”

Case 2: With system setting data

After the system has been set up once, turning on the

power brings up the Management window, and the startup

process begins immediately.

The startup process takes some time (approx. 10 to 20 minutes).

To change the initial settings, go to the initial window.

See the procedure in chapter 6.3 “Accessing functions

and moving between windows”.

Maintenance Tip

•

all equipment and connections.

Startup screen

Initial window

20

Page 24

2000A application before

turning off the PC. Failing to do so could result in

2000A application is

When the charge

the operation

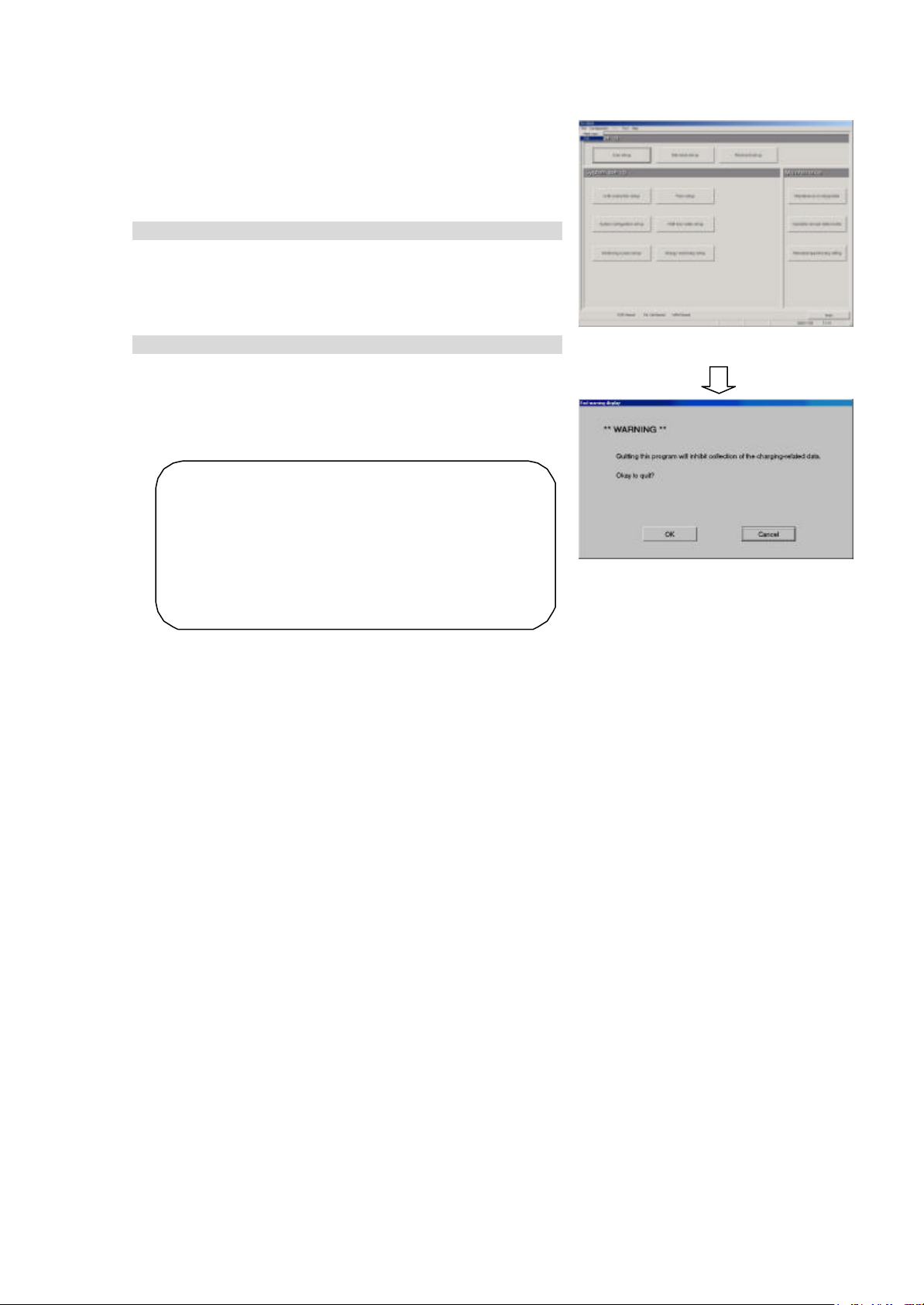

7.3 Shutdown

TG-2000A Shutdown

Follow these steps to shutdown TG -2000A.

[Procedure]

1) Select the E nd option in the File menu in the Menu Bar

Always end the application before turning off the power.

Shutdown is done from the initial window.

Select the File menu in the Menu Bar and select the End

option.

* To switch to the Initial window, refer to chapter 6.3.

2) Select [ OK] button.

The shutdown confirmation dialog box appears asking to

confirm this action.

After verifying the content of the dialog box, click the [OK]

button to exit the application.

* Click the [Cancel] button to return to the Initial window.

Maintenance Tip

• Always exit the TG damage.

• Note that when the TG exited, the functions used stop.

calculation function is used, set

mode to 24-hour continuous operation.

Shutting down the OS

Shut down the OS (Windows 2000/XP) after verifying that the TG -2000A application has been exited.

Turn off the PC after shutting down the OS.

* Please see the OS or PC owner’s manual for procedures on shutting down the OS and turning

off the PC.

End the application

Shutdown verification

21

Page 25

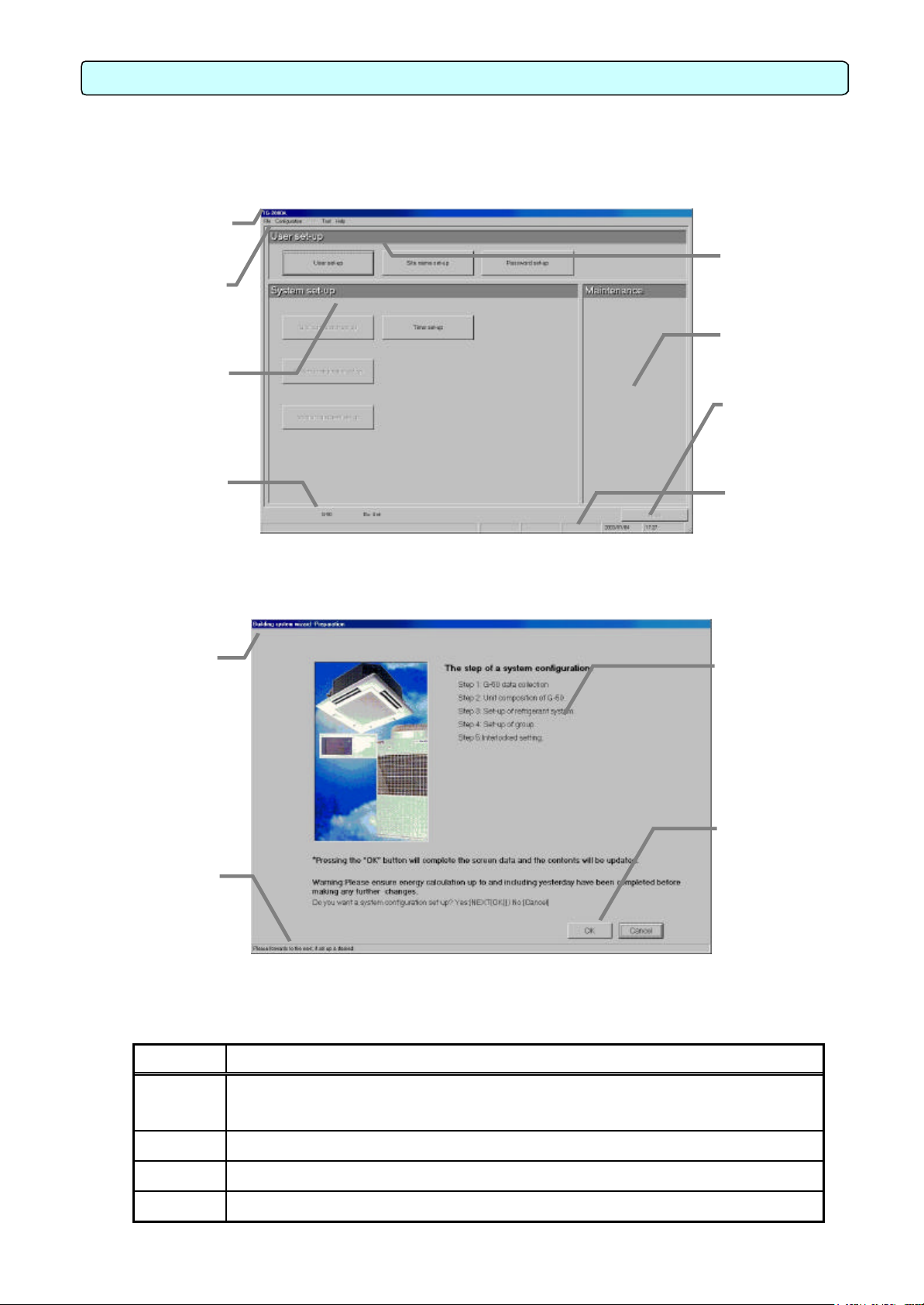

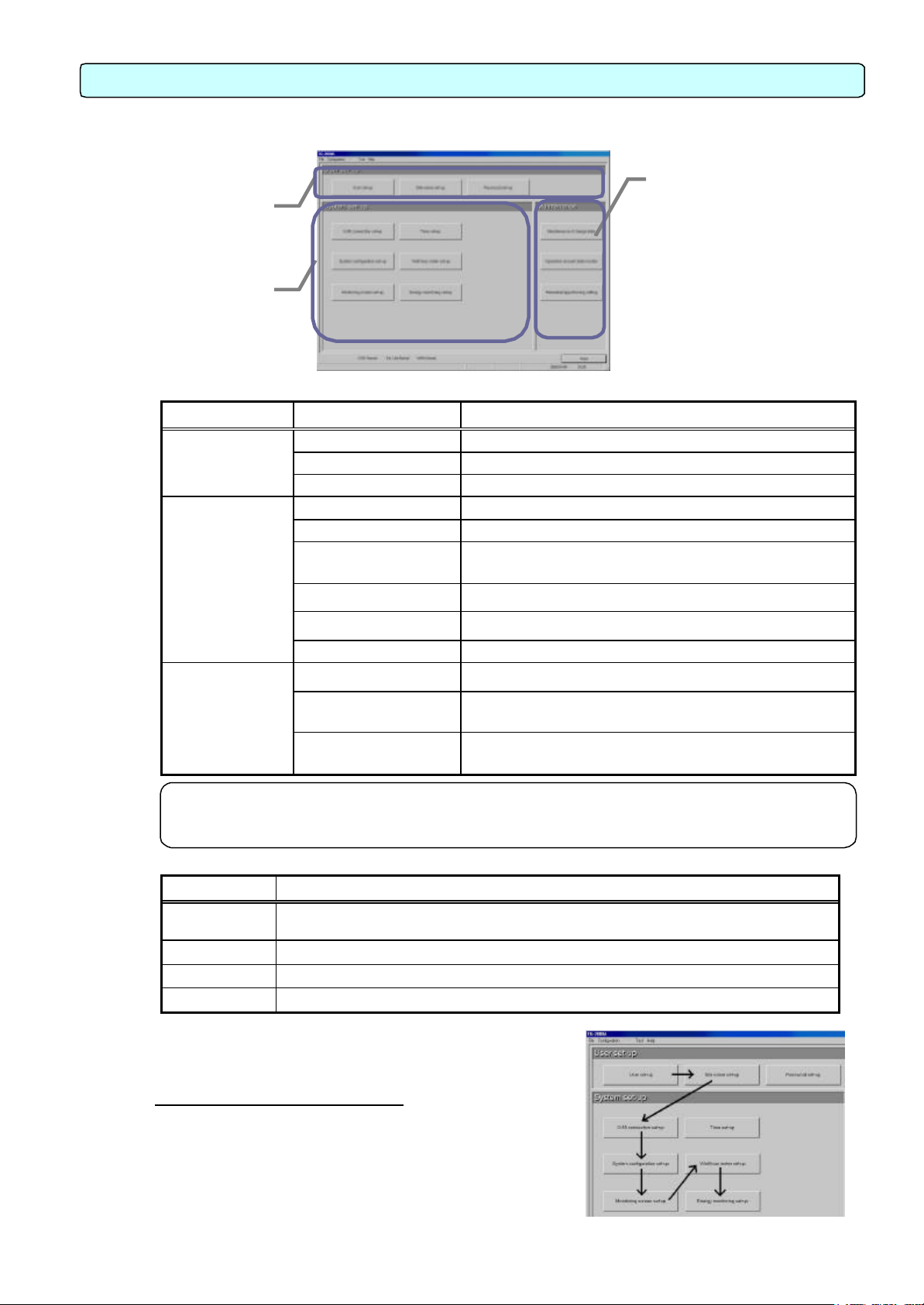

8. System Setting Procedure

8.1 System Setting Screen

The following is an explanation of the items found in the System Settings window.

User Set-up

group

System Set-up

group

Initial window

Function group Function Operation details

User set- up Allow or disallow certain functions

[User Set- up group]

[System Set-up group]

Site name set- up Set the building name

Password set- up The password can be changed

G- 50A connection set-up Sets the number of G-50A units connected and the IP address.

System configuration set-up Sets the system configuration, group, interlocking unit, etc.

Monitoring screen set-up Executes the model name setting, plane drawing creation, group icon

arrangement, etc.

Watt hour meter set- up Set the watt hour meter serial port and watt hour meter address

Maintenance group

Energy monitoring set-up Set the system billing function

Time set- up Set the current time

Maintenance of charge data Proportional billing information can be revised.

[Maintenance group]

Note:

• See Chapter 9 for the maintenance group items.

• The set items that are displayed depend on the functions of the TG -2000A purchased.

Operation amount data

monitor

Remedial apportioning

setting

Operation amount data stored in G-50A can be monitored and saved.

Remedial apportioning can be tentatively performed when charging

trouble occurs.

Displays the operation contents of the select buttons on each setting screen.

Buttons Operation contents

[OK]

[Next] Advances to the next setting screen.

[Back] Invalidates the contents set on this display screen to return to the last screen.

[Cancel] Invalidates the contents set on this display screen to shift to the initial screen.

Validates the contents set on this display screen to advance to the next setting screen.

(Advances to the next setting screen if it is the preparation screen.)

8.2 System Setting Procedure

The following is an explanation of the System Settings

performed at the Initial window.

When no System Settings exist

User set -up Site name set -up G-50A connection set -up

System configuration set -upMonitoring screen set-up

Watt hour meter set-up Energy monitoring set-up

(Password set-up Time set -up)

22

Page 26

* Even if the G-50A is not actually connected, it is possible to set it in advance as long as

If the settings are done out of order, some items will not be available and others will have to be

Check the time for each

When filter sign automatic display is deactivated, the filter status is not reflected automatically even

ter status is

, it only possible

information such as system configuration, etc. is available.

Note:

•

set again.

• Time set -up and Site name set-up are only performed when necessary.

G-50A with “Time set -up”, and set the time when necessary.

When System Settings exist

Make any changes to the settings.

Note:

• Changing certain settings affects the status of other settings.

• User set -up in particular affect other settings and functions.

• Changing the settings on the left affects the settings on the right.

System configuration set -up > Monitoring screen set -up, Energy monitoring set-up

Monitoring screen set -up > Energy monitoring set -up

Watt hour meter set -up > Energy monitoring set-up

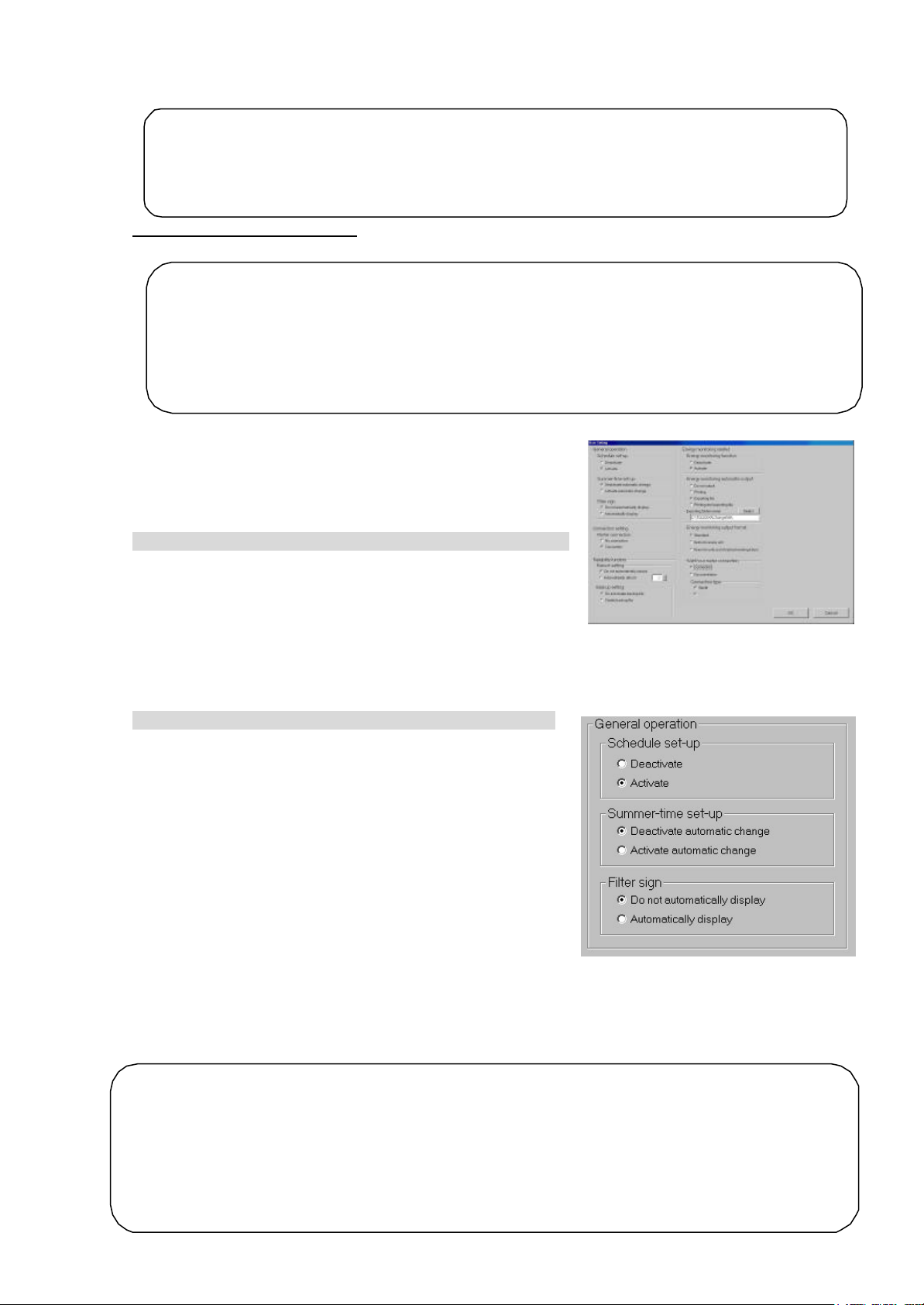

8.3 User Set-up

Use these settings to allow or disallow TG-2000A general

operations, printer, charge (billing), and external I/O functions.

Activating TG-2000A Functions

[Procedure]

1) Click the User set -up button

From the Initial window, click the User set-up button in the

User set -up group. The User set -up window appears.

8.3.1 General Operation

Set the schedule and summer time and turn on and off the

filter sign automatic display function.

Setting general operation options

[Procedure]

1) Click the option button.

Set the Schedule Set-up, Summer Time Set-up and Filter

sign automatic display setting. To do this, click the option

button of the setting.

User set -up window

Schedule Set-up

Off (Deactivate) : Turns the scheduling function off.

On (Activate) : Turns the scheduling function on.

(Default)

Summer Time Set-up

Off (Deactivate) : Do not automatically adjust the

G-50A for summer time.

On (Activate) : Automatically adjust the G-50A for

summer time. (Automatic updates

take place at 04: 15 AM) (Default)

Filter sign

Off (Deactivate) : Do not automaticaly display.

On (Activate) : Automaticaly display . (Default)

Note:

•

when the filter sign window is selected. When the View filter button is clicked, the fil

reflected.

• To use the Schedule S et-up, it is necessary to register the license number of the annual/weekly

schedule separately with the G-50A. When the license is not registered with the G-50A

to use the week ly schedule function of the G-50A. In this case, the schedule setting made from the

integrated centralized control software TG -2000A is invalidated, resulting in operation failure.

23

General operation set-up

Page 27

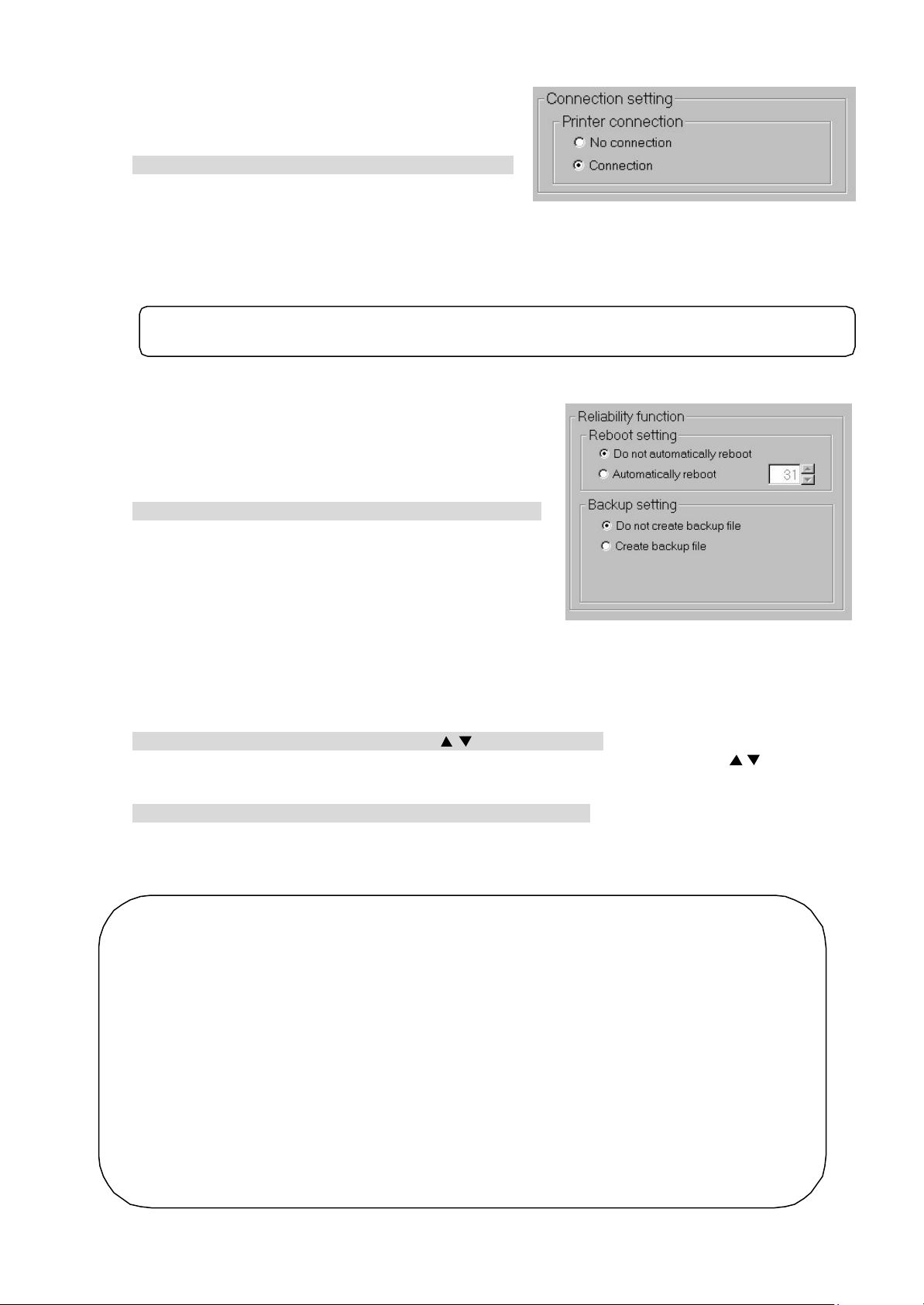

8.3.2 Connection Setting

2000A application and Windows 2000/XP OS on a regular basis

continuously without restarting, system errors may

The automatic restart function serves to insure that the system restart is done on a regular basis.

automatic restart, the system must be restarted manually. Since

it is recommended to periodically restart the

31st

The system configuration, history, and charge data databases are backed up. The trend and

Connection settings

Turn on and off the printer.

Setting connector options

[Procedure]

1) Click the option buttons

Use the option button to select the printer an d WHM

connection.

Available printer options are ON or OFF.

Printer connection

Off (No connection): Turns the printing function off. (Default)

On (Connection) : Turns the printing function on.

Note:

• Data cannot be printed if this option is OFF.

8.3.3 Reliability Function

Turn on and off the automatic reboot function as backup

and the database backup function.

Setting automatic reboot and database backup function

[Procedure]

1) Click the option button

Use the option button to select the Automatic Reboot

function and Database Backup function.

Automatic reboot setting

Off (Deactivate) : Does not automatically reboot.

(Default)

On (Activate) : Automatically reboots.

Backup setting

Off (Deactivate) : Do not back up the database. (Default)

On (Activate) : Back up the database.

2) Select the reboot interval using the “/ ” buttons .

When automatic reboot was set to On, select the automatic reboot day using the “/” buttons.

The setting range is the 7th thru 31st day after booting. The initial value is the 31st day.

3) Set the output folder.

When database backup was set to On, set the database folder to be backed up using the Browse

button. The initial value is “C: \TG2000\databackup”.

* Set the folder to be backed up to an HDD drive different from the C: drive.

Maintenance Tip

• Manually restart the TG-

(once a week). (Perform the restarting operation during the period from 08:00 to 21:45.)

Note:

• When Windows 2000/XP OS is used

accumulate. Thus it is necessary to restart both TG -2000A and the OS.

•

If there is an error during the

there is a possibility of the error not being detected,

system manually.

• When automatic reboot is set to [ON], Windows reboots automatically at 06:35 on the 7th to

day after booting. (The number of days depends on the set value.)

•

display characters databases are not backed up.

Reliability Function Settings

24

Page 28

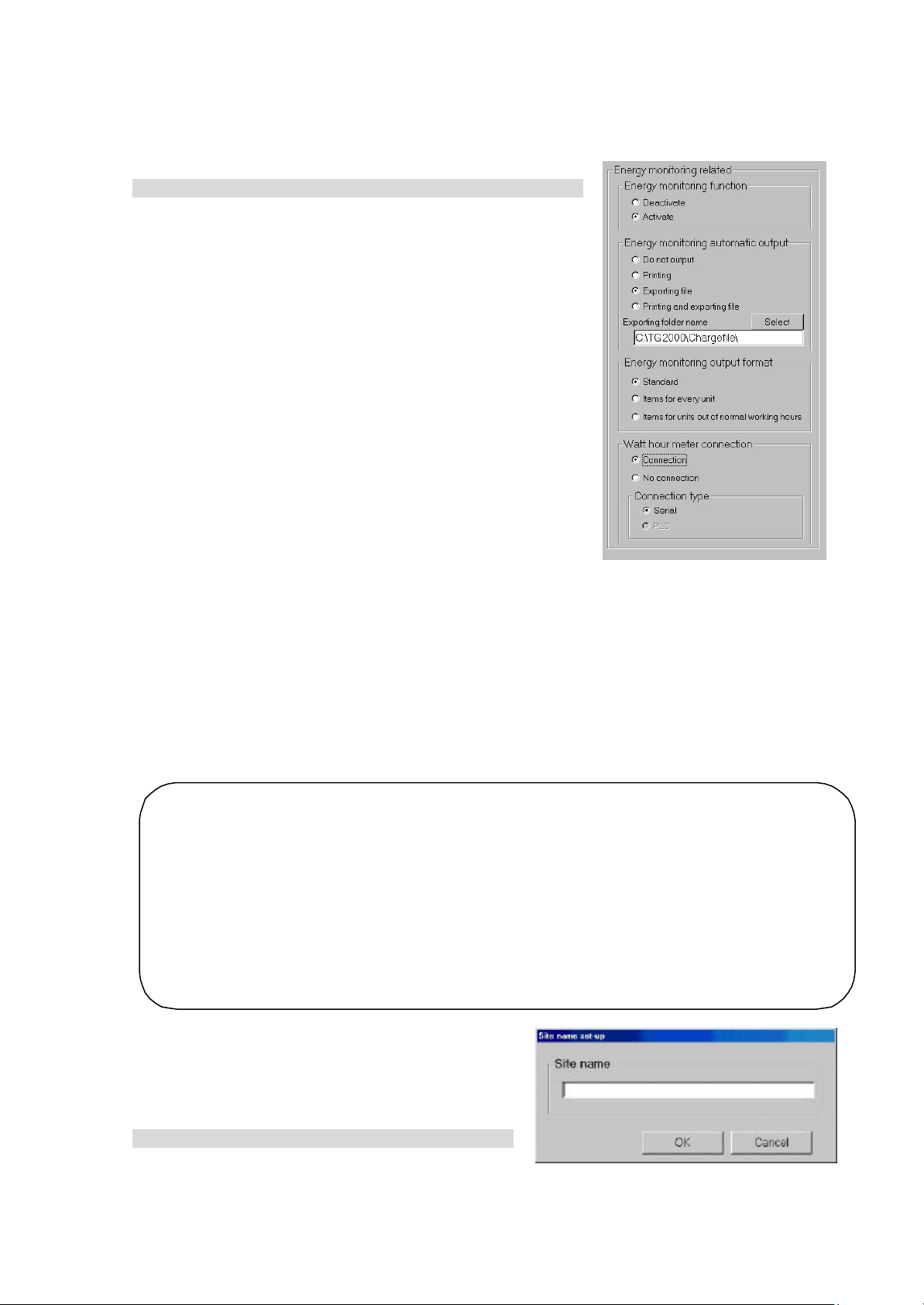

8.3.4 Energy Monitoring Related

auto

In

of

. If the license is not registered with

, the charge calculation function will not operate properly. It is necessary to register

the " Charge calculation function" license with all G-50A units controlled by the TG-2000A.

Follow these steps to energy monitoring functions On or Off , automatically print air conditioning

charges, and set printing options.

Energy monitoring functions On or Off

[Procedure]

1) Click the option button

Use the option button to select Energy Monitoring function,

Automatic Air Conditioning Charges Print, or Air Conditioning

Charge Output Processing function setup.

Energy monitoring function

Off (Deactivate) : Deactivates Energy monitoring related

(Default)

On (Activate) : Activates Energy monitoring related

Energy monitoring automatic output

Off (Deactivate) : Do not automatically print air conditioning

charges. (Default)

Printing : Print Energy monitoring auto- matic

printing information auto- matically.

Exporting file : Automatically output air conditioning

charge result as a file.

Printing and : Automatically print and automatically

output air conditioning charges as

exporting file a file.

* For file output, set the output destination. The initial output

destination is “C: \TG2000\Chargefile”.

Energy monitoring output format

Standard : Output by standard item. (Default)

Unit details : Output detailed air conditioning charges for each unit also.

Regular/Off details : Output detailed air conditioning charges for regular hours and off hours also.

W att hour meter connection

Non-connection : Charge calculation function without WHM connected (default)

Connection : Charge calculation function with WHM connected

It is possible to select Serial connection.

* Note that it is not possible for this version to select the PLC connection.

Note:

• When the printer is not connected, it is unable to set the printing for the "Energy monitoring

output".

• When this TG -2000A is not provided with the "Charge function", this screen is not displayed.

order to use the charge function, please contact a Mitsubishi official sales office or supplier.

• The charge function can be set only for either WHM or No WHM.

• The filename is “(Month) (Year) *.csv”. (*: B=Block units, W=WHM units)

• When using the " Charge calculation function", it is necessary to register the license number

the " Charge calculation function" separately with the G-50A

the G-50A

8.4 Site Name Set-up

Set the site name which this integrated centralized

control software TG - 2000A is installed.

Set the site name.

[Procedure]

1) Click the [Site name set -up] button.

Click the [Site name set-up] button in the User

Set -up Group in the Initial window.

Site Name Set -up

25

Page 29

2) Enter the site name.

up

Enter the name of the site on the site name set -up screen from keyboard.

3) Click the [ OK] button.

When finished entering the site name, click the [OK] button.

* Click the [Cancel] button, the site name is left unchanged.

Note:

• Site names may contain a maximum of 20 characters. The site name is reflected upon the start screen and version confirmation screen display.

26

Page 30

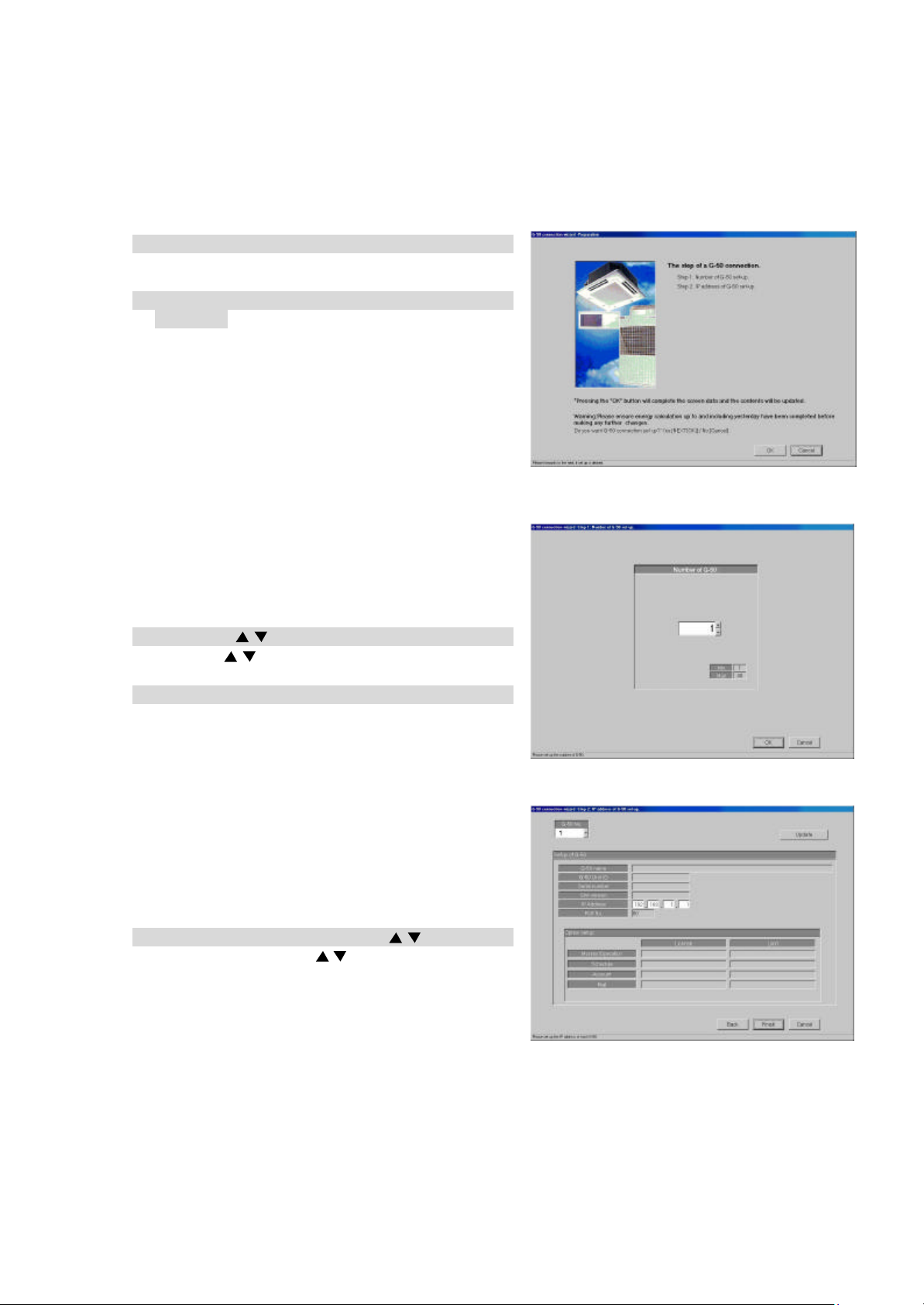

8.5 G-50 Connection Set-up

Number of G-50A set-up

Set the integrated centralized control software TG-2000A, number of G-50A units connected, and the

IP address. It is possible for this setting to monitor and display the option functions state of the G-50A.

8.5.1 Setting Procedure and Restrictions

Confirm the precautions and procedure before setting the G-50A connection.

Perform the check before setting the G-50A connection.

[Procedure]

1) Select the [G-50 connection set -up] button.

Click the [G-50 connection set -up] button located in

the system setting group on the initial window.

2) Select the [ON] button after confirming the display

contents.

Check the contents of the alarm displayed. When

there are not any problems found, click the [OK]

button to advance to the setting.

* When the [Cancel] button is clicked, this setting is

terminated to return to the initial screen.

Set the G-50A connection in accordance with the

following procedure.

Step 1: Number of G-50 set -up

Step 2: IP address of G-50 set -up

8.5.2 Number of G-50A set-up (Step 1)

Set the number of G-50 connected to the system.

Set-up the number of G-50A

[Procedure]

1) Click the “/ “ buttons.

Use the “

Number of connectable G-50A units: 1 to 40 units

2) Click [ OK] button.

When finished making settings , click the [OK] button.

* When the [Cancel] button is clicked, this setting is

terminated to return to the initial window.

/

“ buttons to set the number of G-50A.

8.5.3 IP address of G-50A set-up (Step 2)

Set the data of the G-50A IP address connected to

the data of the integrated centralized control

software.

Register the G-50A IP address.

[Procedure]

1) Select the G-50 No. with the “/ “ buttons.

In this case, use the “/ “ buttons to select the

G-50A No. for which the IP address information is

registered.

G-50 connection Set -up

27

IP address of G-50A set-up

Page 31

2) Set the IP address.

main unit or initial setting tool.

, and to confirm whether the license

Required when the monitor operation is executed, using this

is

Preparation screen

Input the IP address for the number of G-50A units to be connected.

Set the IP address for the number of G-50A units connected.

3) After completing the setting, press the [OK] button.

After fully completing the IP address set -up for the G-50A units, set the [OK] button, by which the

G-50A connection setting is completed.

* When the [Cancel] button is clicked, this setting is terminated to return to the initial screen.

Note:

• It is necessary to set the IP address for the G-50A using the G-50A

Monitor the optional functions being used.

[Procedure]

1) Select the G-50 No.

Select the G-50A No. desired to monitor the optional function used with the “/ “ buttons.

2) Select the [Update] button.

When the [Update] button located on the IP address screen of the G-50A is clicked, the result is

displayed.

Note:

• It is possible to monitor the optional function of the G-50A

desired to be used for the integrated software TG -2000A is registered (exists).

Web monitor :

(Monitor/Operation)

Annual/weekly schedule: Required when the schedule setting is used.

(Schedule)

Charge : Required when the Charge calculation (charging function)

(Charge calculation)

Sending error mail : Required when the error mail addressing is used.

(Mail) (It is prepared for service maintenance.)

TG-2000A and the Web.

used. (It is also required when the operation time is used.)

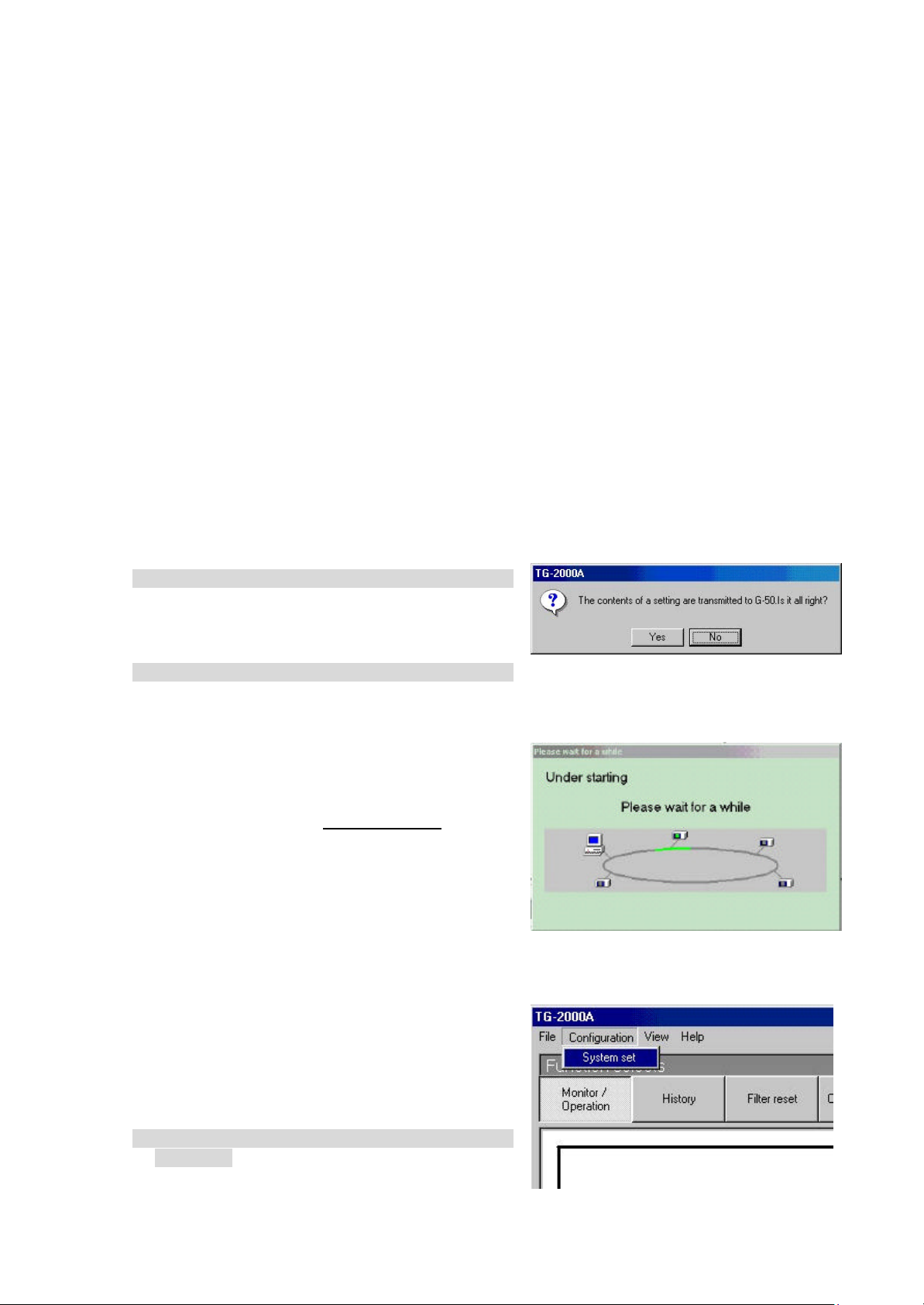

8.6 System Configuration Set-up

Set the information of the air-conditioning system to be monitored using this integrated software

TG-2000A. It is possible for this setting to monitor the system information possessed by the G-50A.

8.6.1 Setting Procedure and Restrictions

Confirm the precautions and procedure before setting the system configuration.

Perform the confirmation before setting the

system configuration.

[Procedure]

1) Select the [System configuration set-up] button.

Click the [System configuration set-up] button

located in the system setting group on the initial

window.

2) Select the [OK] button after confirming the

display contents.

Check the contents of the alarm displayed.

When there are not any problems found, click

the [OK] button to advance to the setting.

* When the [Cancel] button is clicked, this setting

is terminated to return to the initial screen.

Execute the S ystem configuration set -up in accordance with the following procedure.

Step 1: G-50 data collection

Step 2: Unit composition of G-50

Step 3: Set -up of refrigerant system

Step 4: Set -up of group

Step 5: Interlocked set ting

28

Page 32

8.6.2 G-50A data collection (Step 1)

data collecting function may cause the system information possessed

execute the initial

e

It is possible to collect the system information (group information, interlocking ventilation unit

setting information, etc.) set for the G-50A with the integrated centralzed control software

TG-2000A during the initial setting.

Caution:

• Note that using the G-50A

in the TG -2000A to be completely cleared. When the information is collected,

setting again as it is written over the G-50A information.

• It can only collect the information when all the G-50A units are connected.

• It is recommended to execute this function after the test operation of the air conditioner and th

G-50A have been completed normally.

Collect the information from the G-50A during the

initial setting.

[Procedure]

1) Select the [Collecting of information from G-50]

button.

To collect the system information from the G-50A

during the initial setting, click the [Collecting of

information from G-50] button.

After completing the information collecting, the operation advances automatically to the next step. Wait a

moment, as it takes time for information collecting.

* When the [Cancel] button is clicked, this setting is

terminated to return to the initial screen.

Skip the collecting information from the G-50A.

[Procedure]

1) Select the [Next] button.

If it is not necessary to collect the informat ion, click the [Next] button.

8.6.3 Unit composition set-up (Step 2)

It is possible to confirm and change the configuration of the unit in each G-50A .

G-50A Data collection screen

G-50A Selection:

Select the G-50 No.

Unit configuration table:

Displays the system

configuration unit of

the G-50 concerned.

Unit configuration address setting

Confirm the unit configuration.

[Procedure]

1) Select the G-50 No. with the “/“ buttons.

In this case, use the “/ “ buttons to select the G-50A No. desired to confirm the unit

configuration.

2) Select the [OK] button after checking the unit configuration of each G-50A .

If it is not necessary to change the unit configuration of each G-50 A when it is checked, click the [OK] button.

*When the [Cancel] button is clicked, this setting is terminated to return to the initial window .

Selected unit icon:

Displays the icons (symbols)

such as the indoor unit, outdoor

unit, remote controller, system

remote controller, etc. and their

names.

29

Page 33

Change the unit configuration.

m controller actually connected. When the

icon is changed, it is possible to display the unit in which the error occurred with the type easily

the

[Procedure]

1) Select the G-50 No. with the “

In this case, use the “/ “ buttons to select the G-50A No. desired to change the unit

configuration.

2) Delete/add the unit icon.

Unit icon deletion: Click the unit icon to be deleted.

Unit icon addition:Click the unit icon to be added from the selected unit icon column to set it to

the selected state.

(The symbol of the selected unit is displayed by the pointer.)

When the address column to be added is clicked, the unit icon is displayed.

Table: Icon symbol and unit name

Icon Name Address range

IC Indoor unit

LC LOSSNAY

FU OA processing unit

KIC “K” Control Units

AIC “A” Control Units

OC Outdoor unit

BC BC controller (master)

BS BC controller (slave)

OS Subsidiary outdoor unit

RC ME remote controller (compact remote controller) /

LOSSNAY remote controller

SC System controller (Including GR, SR, and AN)

GR Group remote controller

SR System remote controller

A N On/Off controller

KA K -transmission converter (201 to 250)

TR Central controller (MJ-103) (201 to 250)

G-50 Central controller G-50 (0, 201 to 250)

?? Unconfirmed unit (1 to 250)

3) Select the [OK] button.

After fully completing the unit icon change, click the [OK] button.

Note:

• When the system information is collected from the G-50A, all the SR, GR, and AN display "SC".

It is possible to change the icon to that of the syste

discriminated.

• Delete the "??" icon displayed, and set the original icon. Note that it is unable to advance to

next step if the "??" icon exists.

/

“ buttons.

1 to 50

51 to 100

101 to 200

201 to 250

30

Page 34

8.6.4 Set-up of refrigerant system (Step 3)

It cannot change the actual refrigerant system even if the addition or deletion is executed on the

refrigerant system information is used for the charge calculation function. When the charge

calculation function is used, be sure to execute the setting and confirmation. This refrigerant

up state. In

Refrigerant

(IC, FU) for

It is possible to confirm and change the information of the refrigerant system within each G-50A.

G-50A Selection:

Select the G-50 No.

system information:

Displays the refrigerant system information for the multibuilding.

Confirm the refrigerant system information.

[Procedure]

1) Click the “/” button to select the G-50 No.

Click the “

2) Select the [OK] button after confirming the refrigerant system information.

If it is not necessary to change or correct the refrigerant system information for each G-50A when it

is checked, click the [OK] button.

* When the [Cancel] button is clicked, this setting is terminated to return to the initial window.

Change the refrigerant system information.

[Procedure]

1) Select the G-50 No. with the “/” buttons.

In this case, use the “/” buttons to select the G-50A No. desired to change the refrigerant

system information.

2) Delete/add the unit icon.

Unit icon deletion: Click the unit icon to be deleted.

Unit icon addition: Click the unit icon to be added, from the unconnected indoor unit icon and

3) Select the [OK] button.

After fully completing the refrigerant system information changes, click the [OK] button.

Note:

•

refrigerant system setting change screen.

• This

system information is used for error occurrence display.

• It cannot collect all the refrigerant system information depending on the G-50A startthis case, execute the addition or change on this refrigerant system setting screen.

The information possessed by the integrated software is compared with the G-50A refrigerant

information when the integrated cenralized control software TG-2000A starts to display the

coincidence or error message of caution in the event of nonreception when this refrigerant system

setting change screen is selected.

/

” button to select the G-50A No. for which the unit Model name is to be set.

unconnected sub-unit columns to set it to the selected state.

(The symbol of the selected unit is displayed by the pointer.)

When the OC column to be added is clicked, the unit icon is displayed.

31

Unconnected indoor

unit:

Displays the indoor unit and OA

processing unit

which the refrigerant system

connection is not displayed.

Unconnected outdoor

sub-unit:

Displays the OS and BC for

which the refrigerant system

connection is not displayed.

Page 35

8.6.5 Set-up of group (Step 4)

When the group setting change screen is changed, it is possible to reflect the changed contents

NET type), K control unit, A control unit, and LOSSNAY for the

number of groups and the number of indoor units connectable to the GR, SR, and AN

Group

Unconnected remote

Group No.:

It is possible to confirm and change the group information of the indoor unit and ventilation unit

within each G-50A .

G-50A selection:

Select the G-50 No.

Displays the group

No.

information:

Displays the group

configuration of the

indoor unit or ventilation unit.

Confirm the group information.

[Procedure]

1) Click the “/” button to select G-50 No.