Page 1

MIT

SUBIS

C

C

MR-J3-T

Ser vo Amplifier

Quick Start Manual

HI ELECTRI

Art. No.: xxxxxx

21122007

Version A

MR-J3-T Servo Amplifier

With Point Table Positioning

(Point-to-Point Positioning)

MITSUBISHI ELECTRI

INDUSTRIAL AUTOMATION

Page 2

Page 3

About This Manual

If you have any questions about programming or operating the equipment

described in this manual please don’t hesitate to contact your dealer or

one of our official distributors (see back cover).

You can find up-to-date information and answers to frequently-asked

questions on our website (www.mitsubishi-automation.com).

MITSUBISHI ELECTRIC EUROPE B.V. reserves the right to make

technical changes to the products or this manual at any time without prior

notice.

© December 2007

MITSUBISHI ELECTRIC EUROPE B.V.

Page 4

Page 5

MR-J3-T Servo Amplifier with Integrated Point Table Positioning

Version Changes / Additions / Corrections

A 10/2007 pdp First Edition

Quick Start Manual

Art. No.: xxxxxx

Page 6

Page 7

This Quick Start Manual for the servo amplifiers of the MR-J3-T series with point table positio

ning isdesignedtoenableyoutogetyoursysteminstalledand configured for use as quickly as

possible.Please notethat this guide only coversthe basic functionswith theinstructions neces

sary to use these functions. Complete descriptions of all the supported functions and all availa

ble extensions can be found in the instruction manuals.

Please also note that the servo amplifiers of the MR-J3-T series include the following additional

major functions that are not covered in this Quick Start Manual:

쎲 Communication via a serial port for controlling point table positioning

쎲 Positioning control in BCD format with the optional MR-DS60 digital switch

쎲 Amplifier c ontroller circuit settings and auto-tuning functions

Safety Instructions

Toensuresafeandproper installationoftheequipmentplease also observetheinstructionsand

safety precautions in the instruction manuals supplied for your hardware.

Notes in this Quick Start Manual:

-

-

-

NOTE Tips and useful information.

Additional documentation:

쎲 MR-J3-T Instruction Manual (SH(NA030061-A)

쎲 MR-J3-T Instruction Manual for CC-Link (SH(NA030058-B)

쎲 Instruction Manual for the CC-Link Master Module:

– QJ61BT11N

– A1SJ61BT11

– A1SJ61QBT11

– FX2N-16CCL-M

MR-J3-T i

Page 8

Contents

1 Introduction

1.1 Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2 Installing the Equipment

2.1 Installing the MR-J3-D01 Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

3 First Functional Test

3.1 Minimum Connections for the Functional Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.1.1 Connector pin assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.2 Functional Test Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3.3 Configuring Positioning Point Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3.4 Functional Test with MR Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3.4.1 Selecting point table position entries . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

4 Positioning with Digital Inputs

4.1 Additional Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.2 Turning off Automatic Input Signal Activation . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4.3 Home Position Return. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

4.3.1 Dogless Z-phase reference mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

4.3.2 Dog mode home position return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

4.4 Configuration for Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

4.4.1 Importing and exporting point tables. . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

4.5 Functional Test of Digital Input Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

5 Positioning via a CC-Link Network

5.1 Additional Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-31

5.2 CC-Link Communication Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-33

5.2.1 Settings on the servo amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-33

5.2.2 Configuration for communication with GX IEC Developer . . . . . . . . . .5-35

5.3 Testing the Servo Amplifier via CC-Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-37

A Appendix

A.1 Digital Signals − Quick Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-39

A.2 Standard Parameters − Quick Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-40

A.3 Alarms and Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-41

ii MITSUBISHI ELECTRIC

Page 9

Introduction Preparations

1 Introduction

The servo amplifiers of the MR-J3-T series are designed specifically for drive positioning appli

cations using point-to-point positioning without interpolation or trajectory control. The positions

tobeaccessedstored in atableandcanbe selected cyclically,individuallyor in any orderwith:

쎲 Digital signals

쎲 CC-Link communication

The MR Configurator setup software package enables the user to test the entered positioning

steps quickly and easily in test mode.

1. 1 Preparations

The following products and parts are needed for using the point table positioning features described in this manual:

쎲 A servo amplifier, for example MR-J3-10T

쎲 A servo motor compatible with the selected amplifier

Example: HF-KP13 motor for the MR-J3-10T servo amplifier

쎲 MRZJW3-SETUP221E Version C0 of the MR Configurator setup software package

쎲 MR-J3USBCBL3MUSBcableforconnectingyourPC/notebookwiththeservoamplifier

쎲 MR-PWS1CBL M-A1-L motor connection cable

-

쎲 MR-J3ENCBL M-A2-L rotary encoder cable

쎲 MR-J2CMP2 connector for CN6 I/O signal connector

쎲 Power supply cables conforming to the applicable installation regulations

쎲 Connection cables for the control terminals

Required for positioning control with digital signals:

쎲 MR-J3CN1 connector for communication connector CN10

쎲 Optional MR-J3-D01 expansion card

Useful but not absolutely necessary:

쎲 Simulation Box and terminal block with connection cable for testing:

FX Simulation Box (Art. No.3386)

MR-TB50 ter minal block for CN10 (MR-J3-D01)

MR-J2M-CN1TBL•M c able for connecting CN10 to MR-TB50

MR-J3-T 1-1

Page 10

Preparations Introduction

Required for positioning control via a CC-Link network:

Q-Rack with PLC and the CC-Link module QJ61BT11N

쎲

or

A–RackwithPLCandCC-LinkmoduleA1SJ61BT11,A1SJ61QBT11orFX2N-16CCL-M

CC-Link cable compatible with version V1.10 Standard

쎲

쎲 Cable for connecting the PC/notebook to the PLC CPU:

Q ser ies: SC-Q QC30R2

A and FX series: SC-09

쎲 The GX IEC Developer programming software package for configuration of the data com-

munications settings

NOTE This Quick Star t Manual describes theinstallation and setup of a typical servo system con-

sisting of an MR-J3-10T servoamplifier (single-phase, 230V / 100W) and an HF-KP13 servo motor. Note that the specifications of this sample system may differ from those of your

configuration–pleasecheckyourequipment’sinstr uction manualsfordetails ifnecessary.

1-2 MITSUBISHI ELECTRIC

Page 11

Installing the Equipment Installing the MR-J3-D01 Extension

2 Installing the Equipment

The procedure for the physical installation of the MR-J3-T series hardware is exactly the same

as for the MR-J3-A and MR-J3-B models. The dimensions of the MR-J3-T series amplifiers are

identical to those of the matching models of the MR-J3-A and MR-J3-B series.

NOTE Please consult the instruction manual for detailed installation instructions.

2. 1 Installing the MR-J3-D01 Extension

Procedure:

햲

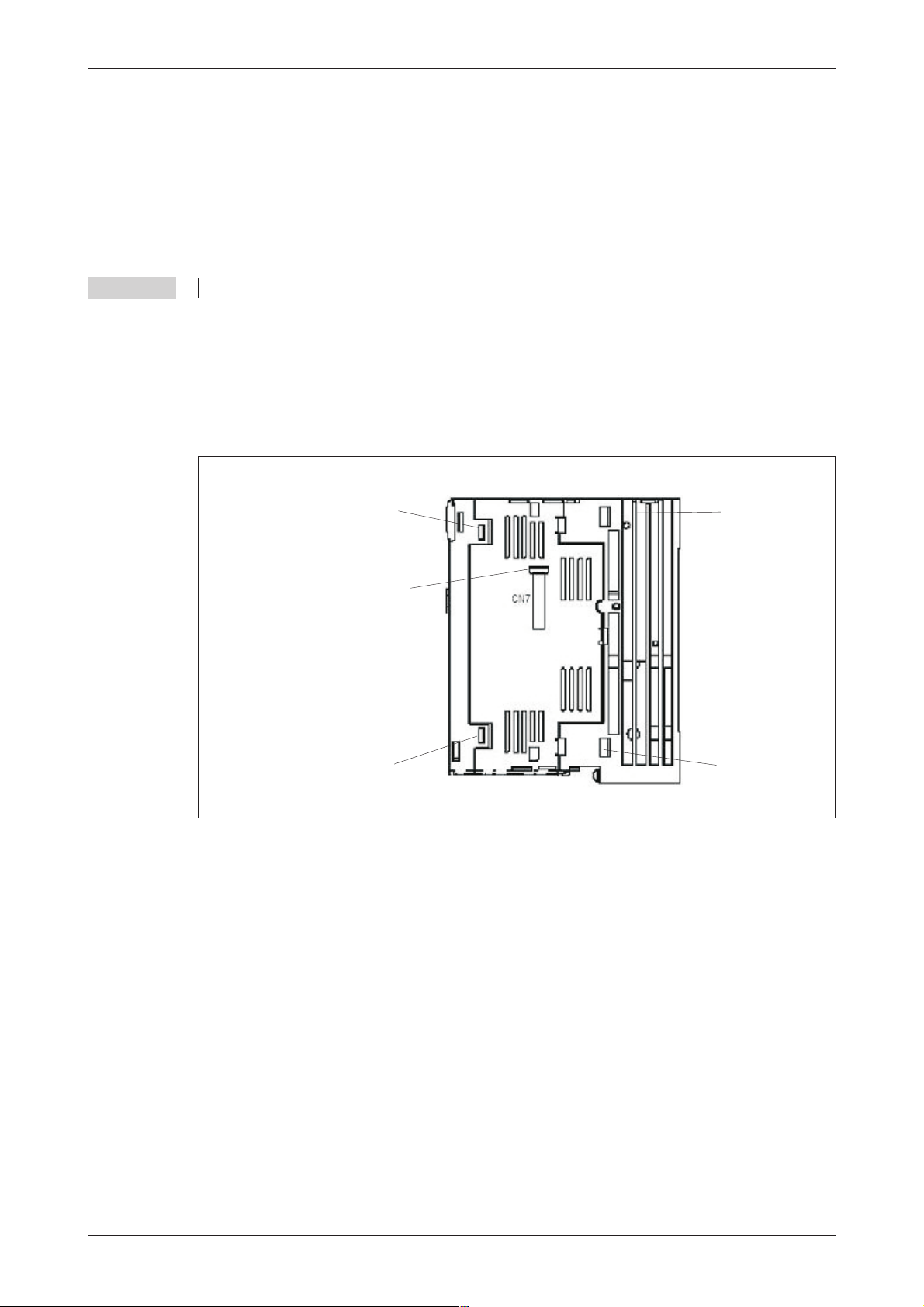

Remove the cover of the CN7 connector on the r ight side of the MR-J3-T housing.

Upper mounting

point 2

Cover forCN7

connector

Lower mounting

point 2

Upper mounting

point 1

Lower mounting

point 1

Fig. 2-1: Fixing points of the extension MR-J3-D01

햳

PositiontheMR-J3-D01 extension over theupper and lowermounting points 1 on the ser voamplifier,then press theextensionintoplace so thatthelugs click into positioninthe upperand lowermounting points 2.This also connects the extensionto theamplifier via connector CN7 on the amplifier.

햴

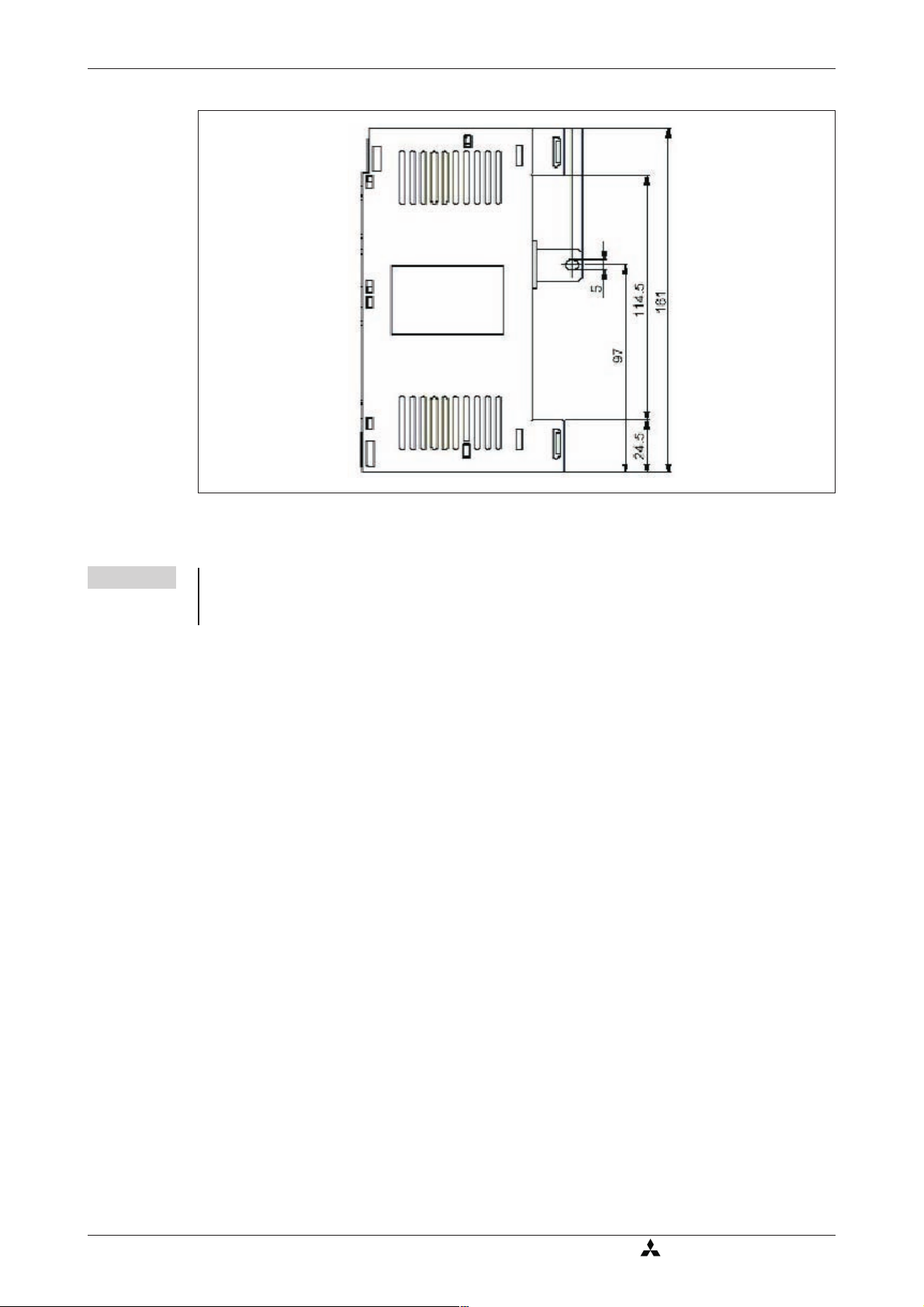

Fasten the extension securely to the servo amplifier with the M4 screw (included) as

showninFig.2-2.

MR-J3-T 2-3

Page 12

Installing the MR-J3-D01 Extension Installing the Equipment

Fig. 2-2: Fastening screw dimensions for extension MR-J3-D01

NOTE Touninstall the extensionperform the above steps in the reverseorder.To release the retai-

ning clips press the retaining tabs marked “Push” inwards and pull the extension out to the

side.

2-4 MITSUBISHI ELECTRIC

Page 13

First Functional Test MinimumConnections for the Functional Check

3 First Functional Test

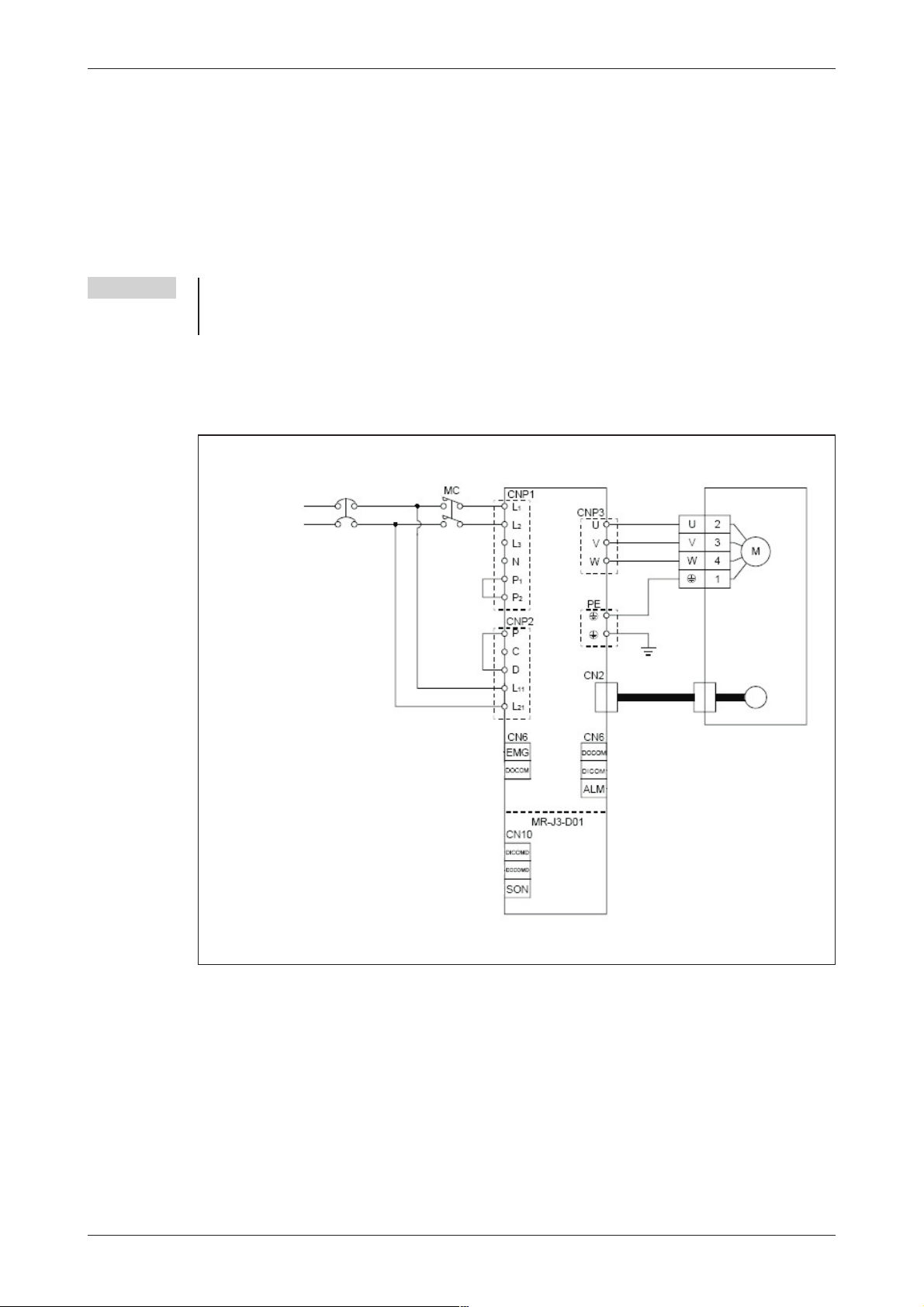

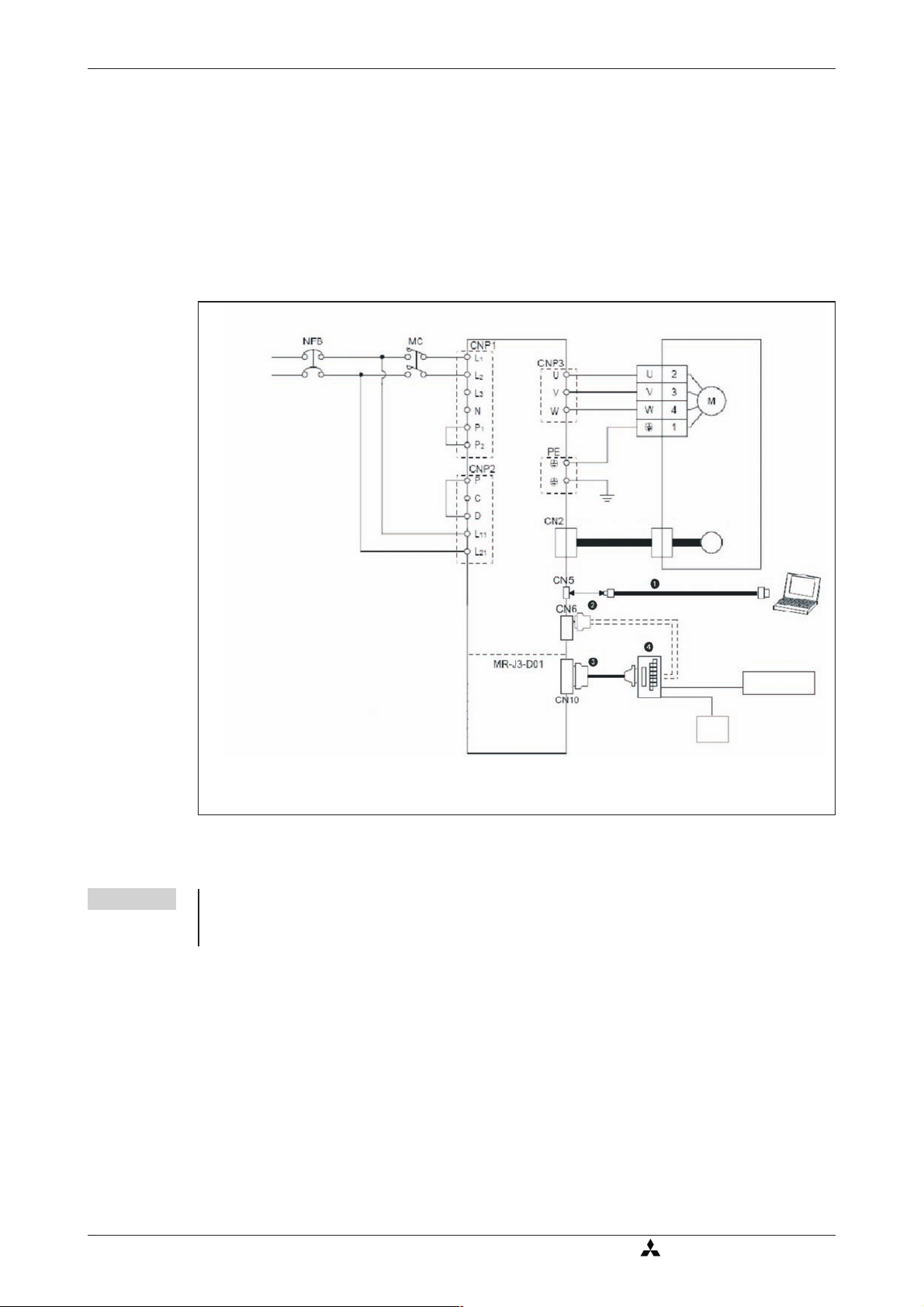

Thewiring diagram below (Fig. 3-1)shows theminimum connectionsthat youmust maketo test

an MR-J3-T series amplifier with the MR Configurator setup software. In test mode you can

check whether all the components are working properly.

NOTE You can also use the optional MR-PRU-03 HMI control terminal for performing initial tests

andsettingthe amplifier’sparameters.Forfur ther detailssee the MR-J3-Tseries instruction

manual.

3.1 Minimum Connections for the Functional Check

Servo motor

1-phase

200–230V AC

Motor

Fig. 3-1: Wir ing diagram for minimum configuration without control ter minals

MR-J3-T 3-5

Page 14

Minimum Connections for the Functional Check First Functional Test

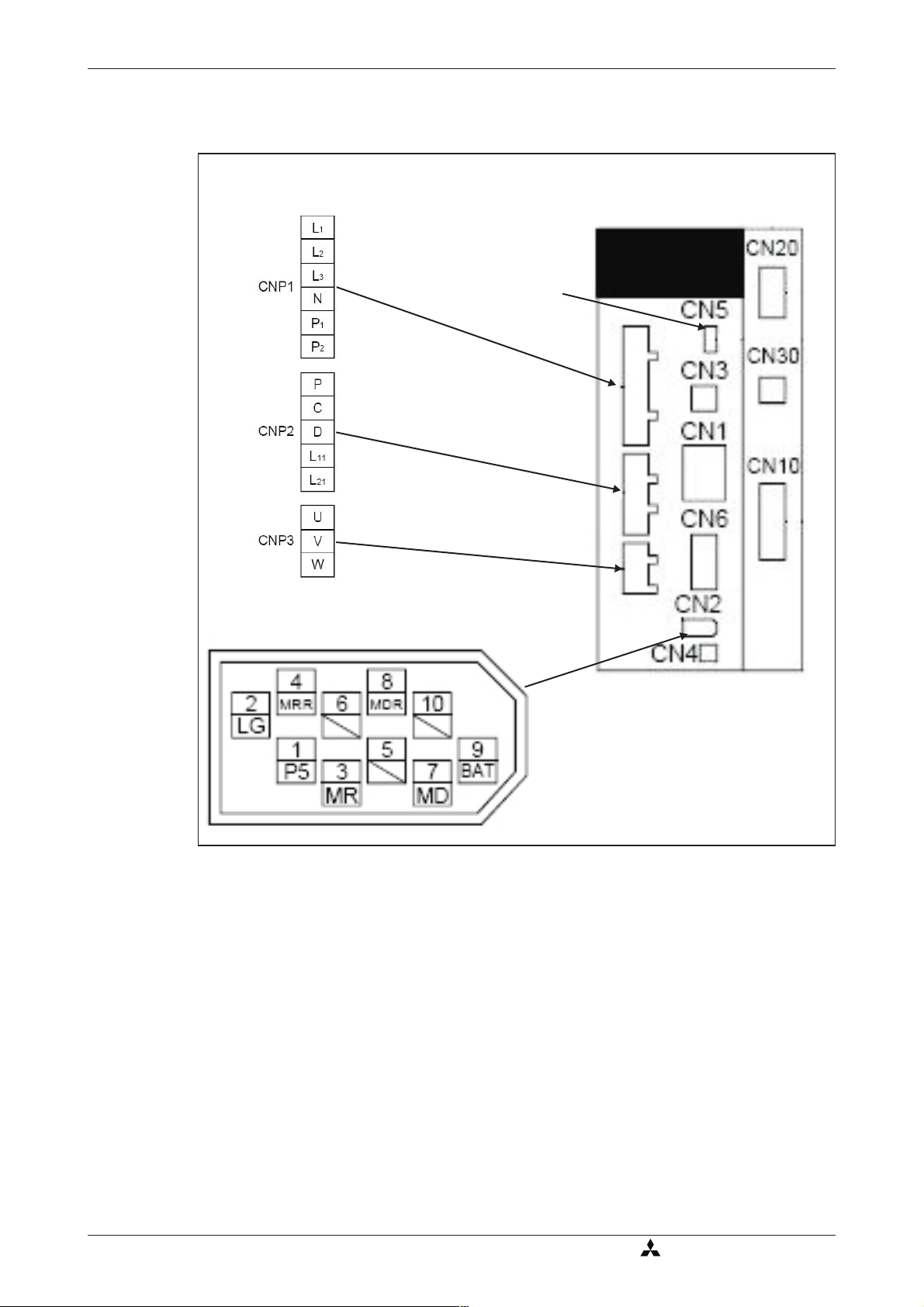

3.1.1 Connector pin assignments

Power terminals

Connector CN2

USB

port

Servo amplifier

MR-J3-첸T

I/O extension

MR-J3-D01

Fig. 3-2: Power and control connector pin assignments for minimum c onfiguration

3-6 MITSUBISHI ELECTRIC

Page 15

First Functional Test Functional Test Settings

3. 2 Functional Test Settings

The following input signals are required to activate the servo amplifier’s motor output:

EMG -> Force stop (safety signal)

쎲

쎲 SON -> Ser vo ON

쎲 LSP -> Forward rotation stroke end (limit switch)

쎲 LSN -> Reverse rotation stroke end (limit switch)

You can configure the servo amplifier to activate these signals automatically when the power is

switched on:

Procedure:

햲

Connect the PC / notebook to the servo amplifier’s USB port (CN5) with the

MR-J3USBCBL3M cable.

햳

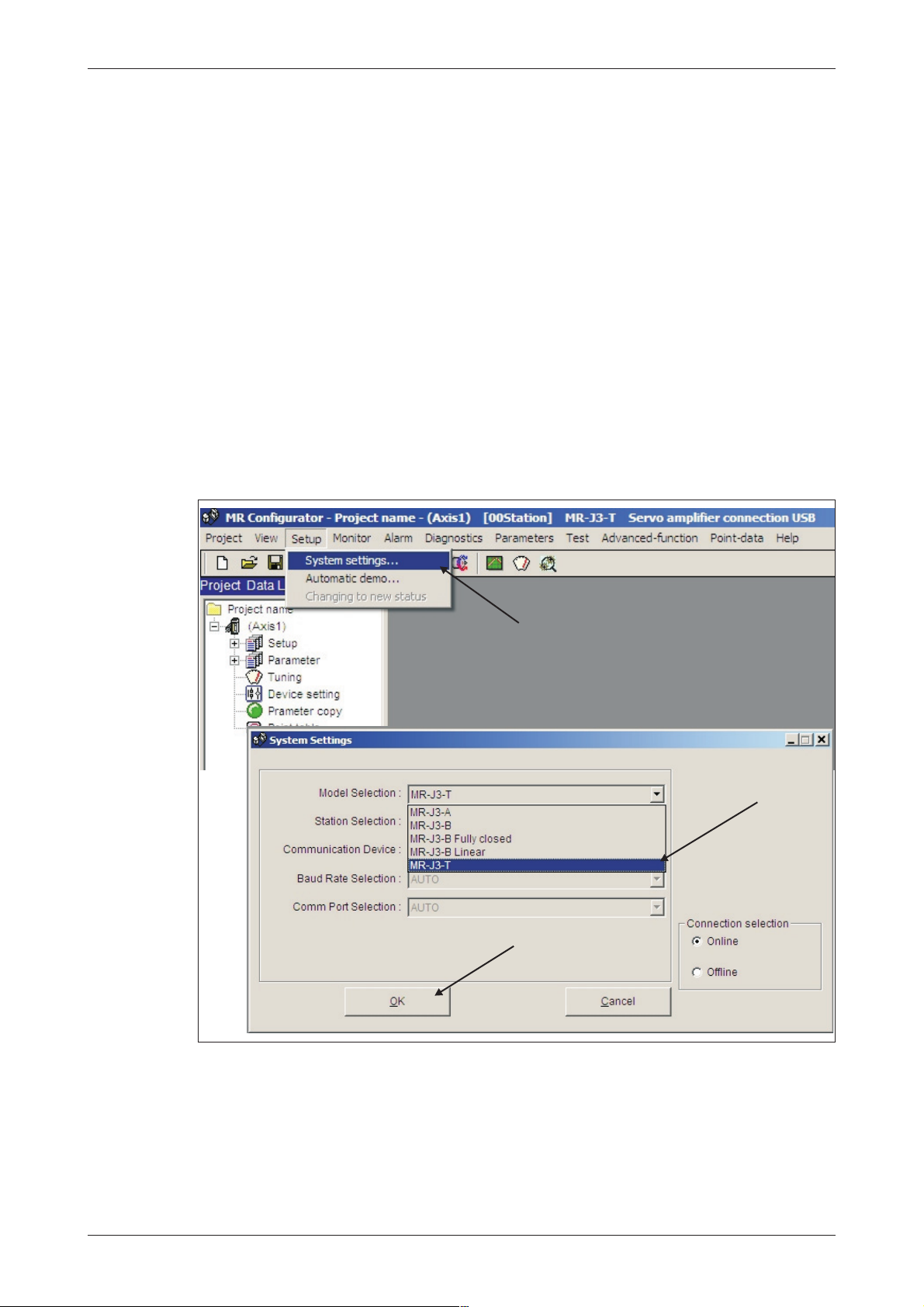

Start MR Configurator on the computer and make the following settings:

– Select the MR-J3-T series servo amplifier:

Fig. 3-3: Selecting the servo amplifier

MR-J3-T 3-7

Page 16

Functional Test Settings First Functional Test

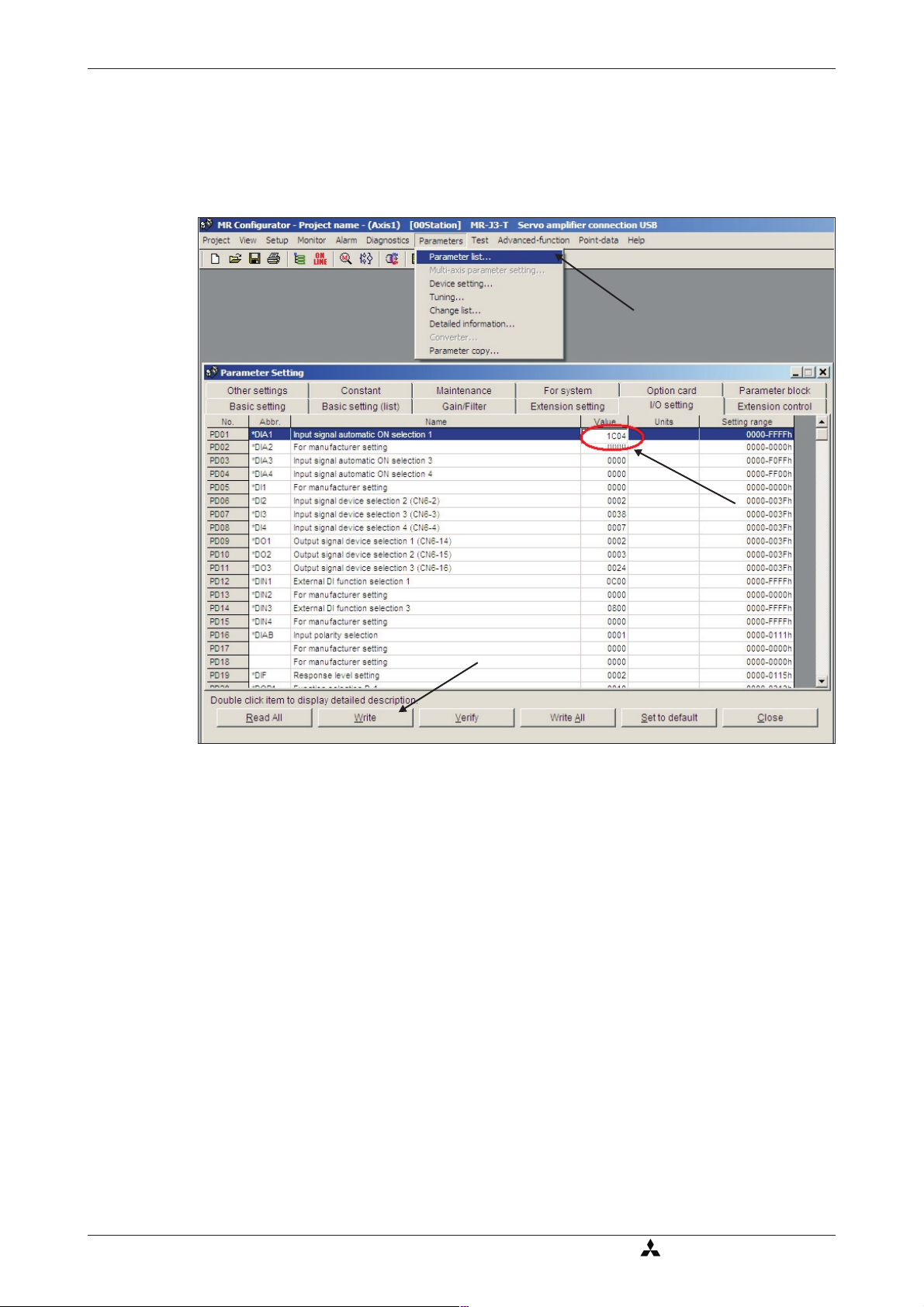

Set the parameter for the automatic activation of the EMG, SON and LSP/LSN input

–

signals:

Parameter PD01 “Input signal automatic ON selection 1” = 1C04

Fig. 3-4: Parameter settings for automatic input signal activation.

– Turn the servoamplifier off and then tur n it on again to initialise the newparameter set-

ting.

3-8 MITSUBISHI ELECTRIC

Page 17

First Functional Test Configuring Positioning Point Tables

3. 3 Configuring Positioning Point Tables

The position values, travel speeds and acceleration and deceleration times are stored in tables

known as “point tables”. We will now go through the steps required to configure and define a

point table.

Procedure:

햲

Select the

햳

Enterthevalues for the movements(position,speed,acceleration anddecelerationtimes)

in the

– Enter target position (a) in µm x 10

– Enter speed (b) in rpm.

– Enteracceleration/decelerationtimes(c) and (d)inms as requiredforthemotor’srated

speed.

Point Table

Point Table List

option from the

window, using one line for each movement:

Point-data

STM

menu.

(STM: e in diagram).

햴

Save the entries by clicking on the

a

Write All

button.

b c d

{

e

Fig. 3-5: Point table positioning entries in the point table list window

Make sure that the

ensure that selecting a position value in the table does not inadvertently activate any subsequent table entries.

NOTES Inthe factorydefault settings the absolutevalue commandsystem forthe targetpositions is

activatedwith parameter PA01 “*STY”.When this system is active all target position values

arereferred to the physical homeposition.Alter natively you can also select the incremental

value command system. The absolute position detection system for the home return function can be set with parameter PA03 “*ABS” (see chapter 4.3).

Loading the factory defaults will not overwrite your point table entries.

MR-J3-T 3-9

Aux. Func.

value in every line is left at the default factory setting (“0”) to

Page 18

Functional Test with MR Configurator First Functional Test

3. 4 Functional Test with MR Configurator

UsingMRConfigurator you canperform a basictestof the individualpositioningsteps andmake

adjustmentsfor your application. Note that setting parameter PA14 does not have any effect on

the rotation direction in jog mode when using MR Configurator. The rotation directions are

defined as follows, looking at the end of the drive shaft (i.e. towards the motor):

쎲 FORWARD -> anticlockwise

쎲 REVERSE -> clockwise

NOTES Homeposition return is not possible intest modewhen usingMR Configurator– usethe jog

function to move to the starting position.

You can set the rotation direction in “single-step feed mode” with parameter PA14.

3.4.1 Selecting point table position entries

Procedure:

햲

Select Single-step Feed in the

햳

To select a position enter its point table line number in the d ialog box displayed .

햴

Start the positioning operation .

Test

menu.

Fig. 3-6: Single-step Feed window for testing individual positioning steps

3-10 MITSUBISHI ELECTRIC

Page 19

Positioning with Digital Inputs Additional Connections

4 Positioning with Digital Inputs

Thischapterdescribes howpointtable positioning isusedin mostapplicationswith the MR-J3-T

series amplifiers and the MR-J3-D01 I/O extension.

NOTE Pleaserefertothe instructionmanual if youneedother functionsother than thosedescribed

here for your application.

4. 1 Additional Connections

Theinitial functional tests described in chapter 3.1 were performed with a minimumconnection

configuration. For the full range of standard functions you now need to make additional power

supplyand controlterminal connectionson theCN6 andCN10 terminal blocks, as shown below

in Figs. 4-1 and 4-2.

1-phase

200–230V AC

EMG. OFF

EMG. OFF

24V DC

24V DC ± 10 %

800 mA

OFF

Servo amplifier

ON

Encoder cable

24V DC

24V DC ±10%

150mA

Servo motor

Motor

Encoder

Alarm

Servo ON

Fig. 4-1: Single-phase power connections for the MR-J3-T amplifier

MR-J3-T 4-11

Page 20

Additional Connections Positioning with Digital Inputs

Connector CN6 Connector CN10 CN10 pin assignments

1 DI0

2 DI1

3 DI2

4 DI3

5 DI4

6 DI5

7 DI6

8 DI7

13 DICOM

14 DICOM

21 SON

22 ACD0

23 ACD1

24 ACD2

25 ACD3

26 RES

32 MD0

35 ST1

36 ST2

37 DOCOM

49 INP

Fig. 4-2: Pin assignments of connectors CN6 and CN10

4-12 MITSUBISHI ELECTRIC

Page 21

Positioning with Digital Inputs Additional Connections

24V DC ±10%

햲

150mA

EMG. OFF

Proximity dog

Forward stroke end

Reverse stroke end

24V DC ±10%

햲

800mA

Point

table

selection

SERVO ON

RESET

24V DC

max. 10m

max. 10m

MR-J3USBCBL3M

(Option)

24V DC

Alarm code

Automatic/Manuall

Forward rotation start

Reverse rotation start

햲

A 24V 1000mA power supply can be

used for all control terminals.

max.10 m

In position

max. 10m

Fig. 4-3: Connection of the control terminals with PNP logic (source logic)

NOTES You can find a brief descriptions of the signal functions in Appendix A.1.Please refer to the

instruction manual for a complete reference.

All digital signals described in this manual use source logic.

For safety reasons the EMG signal must be connected to pin 1 of connector CN6 if the

servo amplifier is not operated during the first functional test. The EMG signal is perma

nently assigned to pin 1 and the amplifier is deactivated when there is no EMG signal if it is

configured accordingly (see chapter 3.2).

-

MR-J3-T 4-13

Page 22

Turning off Automatic Input Signal Activation Positioning with Digital Inputs

4. 2 Turning off Automatic Input Signal Activation

Procedure:

햲

Reset parameter PD01 to a value of "0":

Fig. 4-4: Switching off automatic input signal activation

4-14 MITSUBISHI ELECTRIC

Page 23

Positioning with Digital Inputs Home Position Return

4. 3 Home Position Return

At the factory the MR-J3-T servo amplifiers are configured with the incremental system acti

vatedby default (i.e.the absoluteposition detectionsystem isswitched off).This meansthat the

currentposition is notstored when the amplifier's power supply is switched off, making it neces

sary to perform a return to home position every time the unit is powered up. You can configure

the home position return mode with Parameter PC02:

Parameter PC02

Home position return modes

0: Proximity dog mode

1: Count mode

2: Data setting mode

3: Stopper mode

4: Ignore home position

5: Dog mode, rear end reference

6: Count mode, front end reference

7: Dog cradle mode

8: Dog mode, last Z-phase reference

9: Dog mode, front end reference

A: Dogless Z-phase reference

-

-

The most commonly used modes are:

1. Dogless Z-phase reference mode (A)

2. Proximity dog mode (0)

Thesetwomodes aredescribed indetail below. DoglessZ-phase referencemode issuitable for

simple applications. Dog mode is frequently used for standard applications.

4.3.1 Dogless Z-phase reference mode

In this mode the Z-phase of the rotary encoder (zero position of the encoder) is used as the

machine'sphysical home position. However, it is quite rare to be able toconfigure a machine so

that its physical home position exactly matches the Z-phase of the encoder. It is thus almost

always necessary to enter an offset (shift) with parameter PC06.

After activation of the forward start command ST1 (or reverse ST2) the home position return is

initiatedby parameter PC04 (“homeposition return speed”). Whenthe Z-phase signalfrom the

encoder is registered the servo motor brakes to a halt. After this a precise return to home is performed at creep speed with parameter PC05.

The physical home position can be shifted in relation to the zero position of the encoder

(Z-phase) with the home position offset (shift) defined with parameter PC06. Parameter PC07

can be used to define a home position value other than zero.

When the home position return has been completed successfully the servo amplifier activates

the ZP signal.

MR-J3-T 4-15

Page 24

Home Position Return Positioning with Digital Inputs

Timing chart:

Auto/Manual mode (MD0)

Select point table no.(DI0)

Start command

Forward (ST1)ONOFF

Start command

Reverse (ST2)ONOFF

Servo motor speed setting

Z-phase of encoder

Home return complete (ZP)

ON

OFF

PC04 “Home pos.return speed”

PC06 “Home offset”

PC05 “Creep speed”

ON

OFF

ON

OFF

Fig. 4-5: Home position return sequence in dogless Z-phase reference mode

No. Code Function Description

햲

PA05

PC02

PC03

PC04 ZRF Home position re-

PC05 CRF Creep speed Speed for precise movement to home position in [rpm].

PC06 ZST Home position off-

PC07

*FTY Feed length multi-

햲

*ZTY Home position re-

햲

*ZDIR Home position re-

햲

*ZPS Home position re-

plication factor

turn mode

turn direction

turn speed

set (shift)

turn position value

Needed here to scale the home position value to the physical coordinate system.

Selects the home position return mode:

A: Dogless Z-phase reference mode

0: Incrementing counting of encoder pulses

1: Decrementing counting of encoder pulses

Sets home position return speed until first detection of the Z-phase

in [rpm].

Distance between the encoder zero point (Z-phase) and the physical home position in [µm].

The home position return stops when the Z-phase position is

reached.You can enter a non-zero coordinate for this position [in

STM

10

µm] with this parameter.

Table 4-1: Parameter reference table

햲

You must turn the power off and on again to activate this parameter.

4-16 MITSUBISHI ELECTRIC

Page 25

Positioning with Digital Inputs Home Position Return

Examples:

햲

TheZ-phaseof the encoderisdefined asthephysicalhomeposition ofthemachine.In this

example we are going to perform the home position return at 200 rpm in the direction in

which the encoder pulses are counted incrementally.

Parameter settings:

Parameter settings for example

Fig. 4-6: Relevant parameter settings for example 1

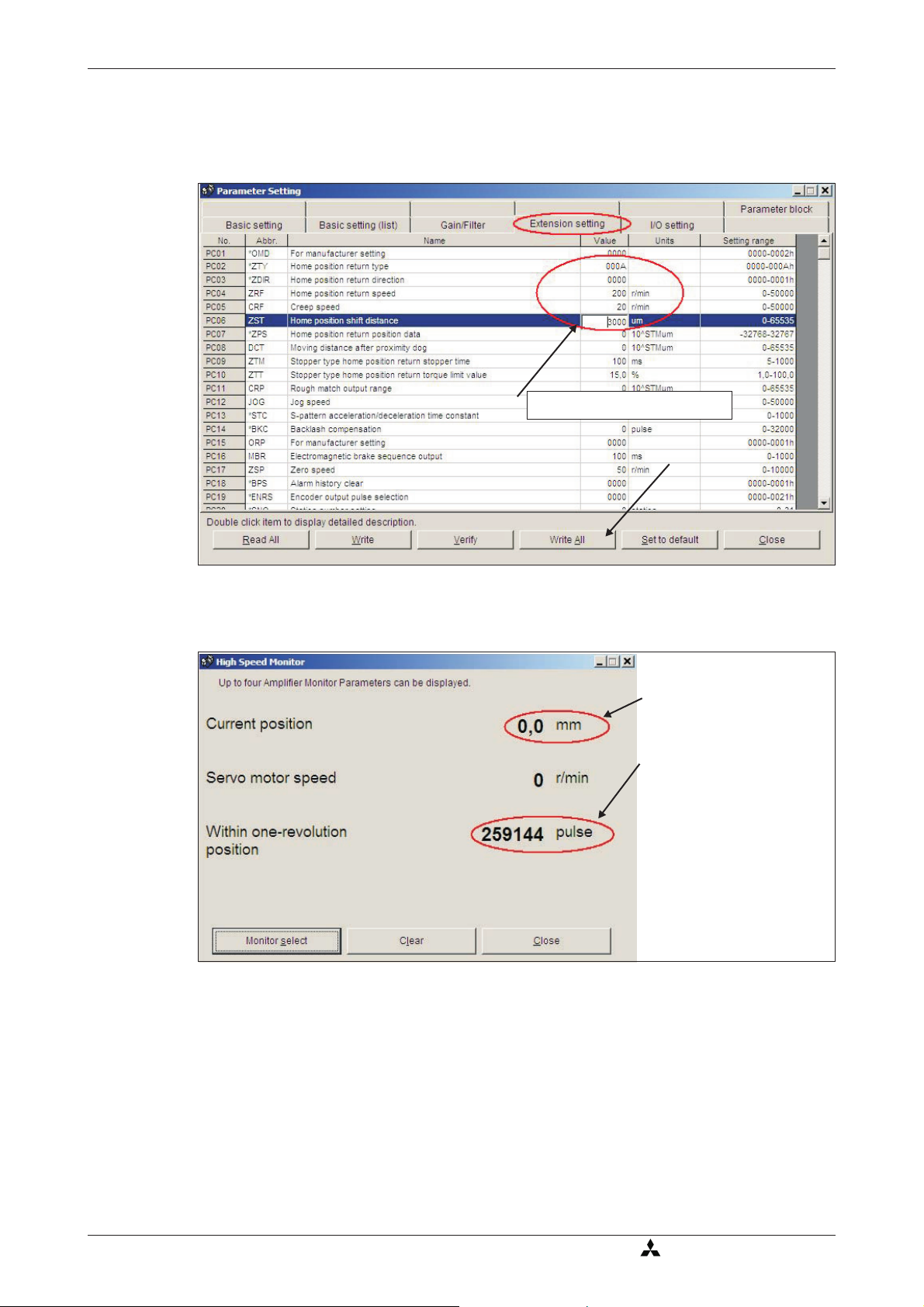

Fig. 4-7: Values shown when the home position return has

been completed correctly

MR-J3-T 4-17

Page 26

Home Position Return Positioning with Digital Inputs

햳

Perform ahomepositionreturnasinexample1butwithan offset betweenthephysicaland

encoder home positions, set with parameter PC06.

Parameter settings:

Parameter settings for example

Fig. 4-8: Relevant parameter settings for example 2. The offset is entered with param-

eter PC06.

Following completion of the home

position return:

The servo motor has travelled to

the specified home position. The

home position of the encoder has

been exceeded by the value of

PC06 = 3,000 µm. For the motor

connected this is equivalent to

259,144 encoder pulses.

Fig. 4-9: Values shown when the home position return has been completed correctly

4-18 MITSUBISHI ELECTRIC

Page 27

Positioning with Digital Inputs Home Position Return

4.3.2 Dog mode home position return

In this mode, instead of the encoder Z-phase(Fig. 4-6), the DOG signal is used to switch from

“homepositionreturn speed” PC04to“creep speed”PC05.You can useparameter PD16 “prox

imitydogdetection polarity” tospecify whether alogical “1” ora logical “0”should beidentifiedas

an active DOG signal.

As in 햲 above, the physical home position can be shifted in relation to the home (zero) position

ofthe encoder (Z-phase) withPC06 “homeposition offset(shift)”. Inaddition to this you can also

set a non-zero coordinate for the home position with PC07.

Conditions for the proximity dog signal:

Theproximity dog signal(DOG) mustfulfill the followingconditions toensure that theZ-phase of

the encoder is detected during the activation period of the DOG signal:

t

V

L

암60폷

1

L

암 2 폷욼S L2 = Length of the DOG signal in [mm]

2

d

2

L1 = Length of the DOG signal in [mm]

V = Home position retur n speed in [mm/min]

t

= Deceleration time in [s]

d

욼S = Distance for one rotation of the motor in [mm]

-

MR-J3-T 4-19

Page 28

Home Position Return Positioning with Digital Inputs

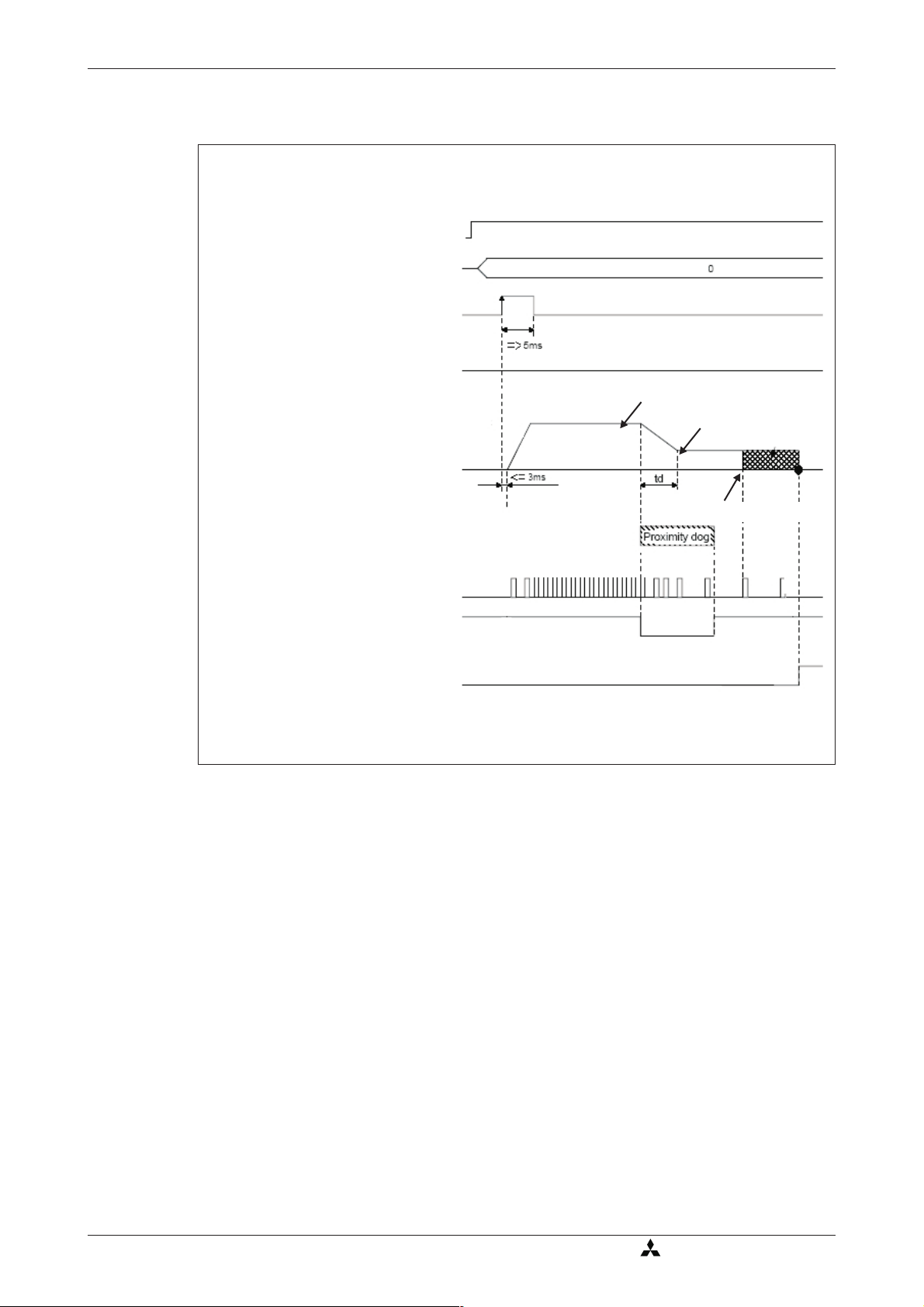

Timing chart:

Auto/Manual mode (MD0)

Select point table no.(DI0)

Start command

Forward (ST1)ONOFF

Start command

Reverse (ST2)ONOFF

Servo motor speed setting

Z-phase of encoder

DOG signal

Home return complete (ZP)

ON

OFF

PC04 “Home pos.return speed”

PC05 “Creep speed”

PC06 “Home offset”

ON

OFF

ON

OFF

ON

OFF

Fig. 4-10: Home position return in proximity dog mode

4-20 MITSUBISHI ELECTRIC

Page 29

Positioning with Digital Inputs Home Position Return

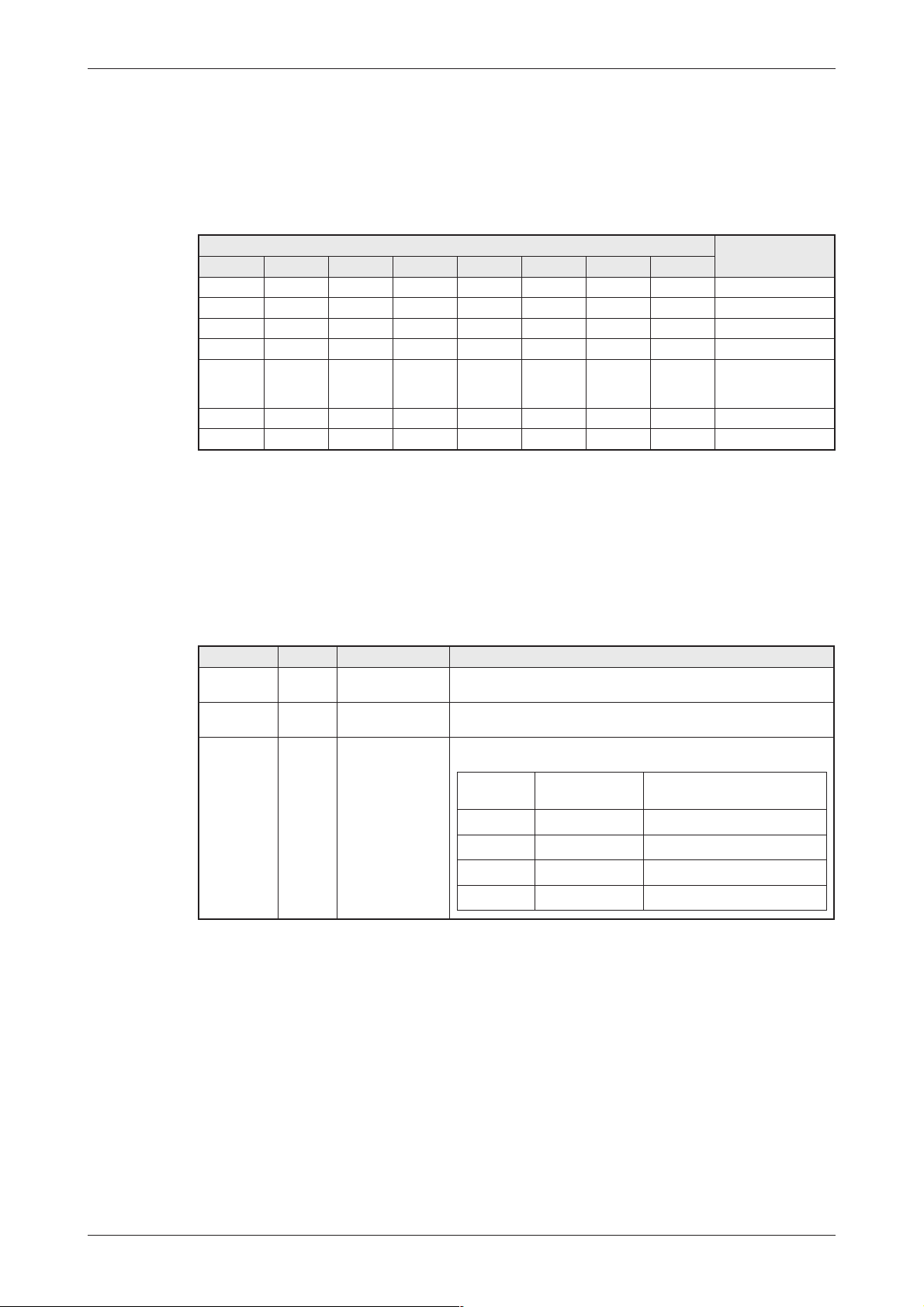

No. Code Function Description

햲

PA05

PC02

PC03

*FTY Feed length multi

햲

*ZTY Home position re

햲

*ZDIR Home position re-

plication factor

turn mode

turn direction

Needed here to scale the home position value to the physical coor

dinate system when a home position offset (shift) has been set.

Parameter value Multiplication factor STM

01

110

2 100

3 1000

-

Selects the home position return mode:

0: Proximity dog mode (DOG)

0: Incrementing counting of encoder pulses

1: Decrementing counting of encoder pulses

-

PC04 ZRF Home position re-

PC05 CRF Creep speed Speed for precise movement to home position in [rpm]

PC06 ZST Home position

햲

PC07

PD16

*ZPS Home position re-

햲

*DIAB Input signal

turn speed

offset (shift)

turn position value

polarity

Sets home position return speed until first detection of the Z-phase

in [rpm].

Distance between the encoder home position (Z-phase) and the

physical home position in [µm]. Does not change the zero point of

the physical coordinate system.

The home position return stops when the Z-phase position is

reached.You can enter a non-zero coordinate for this position [in

STM

10

µm] with this parameter.

Logical value for detection of the proximity dog signal (DOG):

0: Active DOG on logical "0"

1: Active DOG on logical "1"

Table 4-2: Parameter reference table

햲

You must turn the power off and on again to activate this parameter.

Example:

In the following example the physical home position is at the position of the Z-phase of the

encoder.However,we nowwantto assign anon-zero valueinthe physical coordinatesystem to

this position.

MR-J3-T 4-21

Page 30

Home Position Return Positioning with Digital Inputs

Parameter settings:

Parameter settings for example

Fig. 4-11: Relevant parameter settings for the example. The home position value is en-

teredwithPC07.

Following completion of the

home position return:

The servo motor has travelled to

the encoder home position

which is also the machine’s

physical home position.However, this position corresponds

to a value of 100mm in the machine’s coordinate system.

Fig. 4-12: Values shown when the home position return has been completed correctly

The position value is calculated as follows:

X = PA05 폷 PC07 in [mm]

STM

In the above example with PA05 = 1 and PC07 = 1000 [10

X = 1000 폷 10

1

µm

µm] this gives us:

4-22 MITSUBISHI ELECTRIC

Page 31

Positioning with Digital Inputs Configuration for Positioning

4. 4 Configuration for Positioning

Ifyouinstall theMR-J3-D01 I/Oexpansion youcan usepoint table positioning,which allowsyou

to select positions from a list of up to 256 table entries with a combination of eight digital inputs.

Table 4-3 shows how binary input signals are encoded to address the point table entries.

Digital Input Signals

DI7 DI6 DI5 DI4 DI3 DI2 DI1 DI0

00000001 1

00000010 2

00000011 3

00000100 4

·

·

·

11111110 254

11111111 255

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

Selected Point

Table Entry

·

·

·

Table 4-3: Selection of point table entries with digital input signals

In the factory default configuration the incremental system is activated, which means that the

absolute position detection system is turned off (PA03 “absolute position detection system”).In

this mode the current position is not stored when the power is turned off and you must thus perform a home position return every time the amplifier is powered on. The default configuration

also uses absolute target positions (PA01 “positioning control mode”).

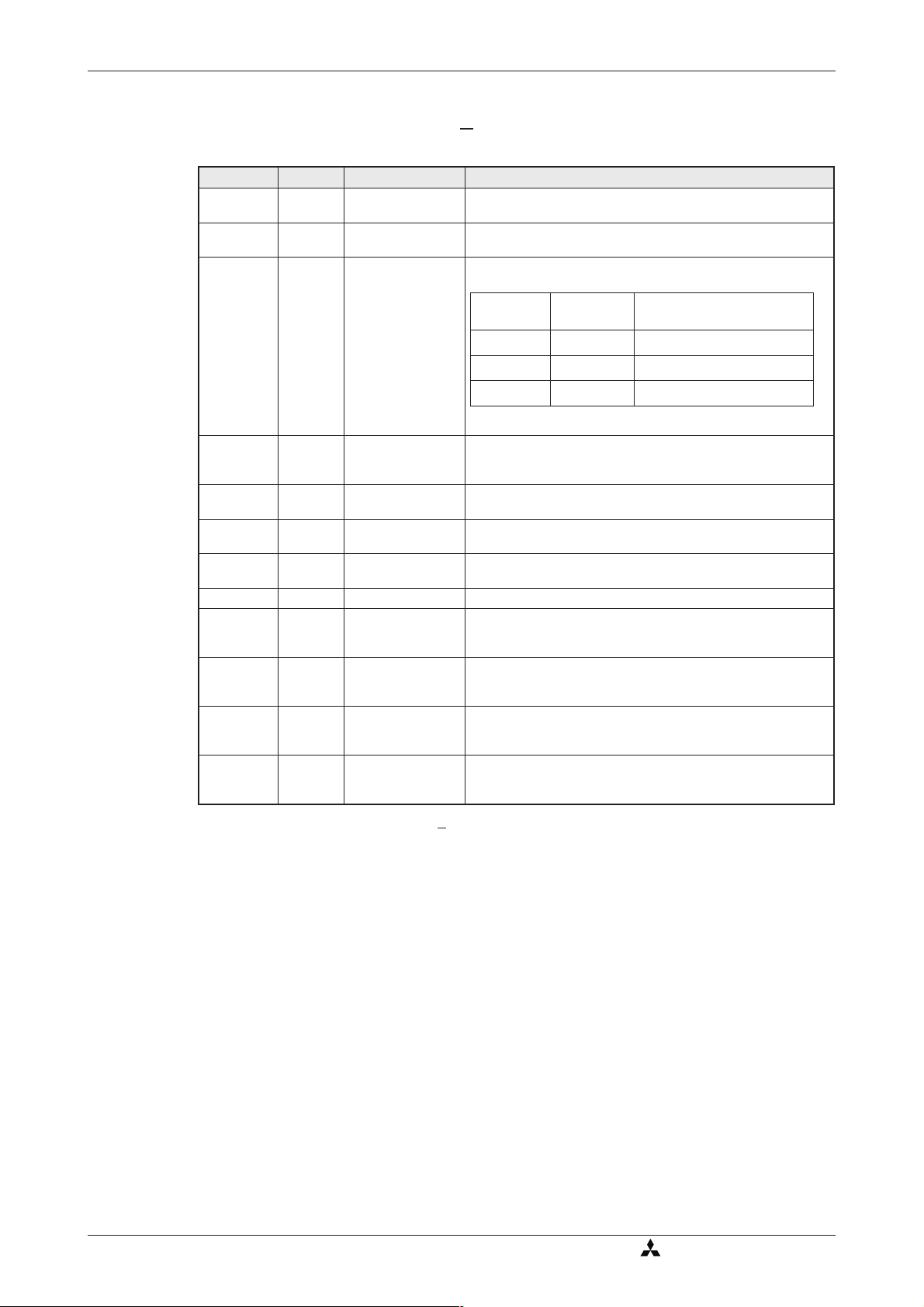

No. Code Function Description

햲

PA01

PA03

PA05

*STY Positioning control

햲

*ABS Absolute position

햲

*FTY Feed length multi-

mode

detection system

plication factor

0: Absolute target position values

1: Incremental target position values

0: Incremental system (absolute detection off)

1: Absolute position detection system on

Needed here to scale the home position value to the physical coordinate system when a home position offset (shift) has been set.

Parameter

value

01

110

2 100

3 1000

Multiplication

factor STM

Range of the target

position values

−999.999 .. +999.999

−9999.99 .. +9999.99

−99999.9 .. +99999.9

−999999 .. +999999

Table 4-4: Parameter reference

햲

To activate this parameter you must switch the amplifier power off and on again.

MR-J3-T 4-23

Page 32

Configuration for Positioning Positioning with Digital Inputs

The following example shows some typical configuration settings used for many common posi

tioning applications:

Procedure:

햲

Select the incremental system for positions with PA03 *ABS.

햳

Select absolute value command mode for target positions with PA01 *STY.

햴

Set a multiplication factor with PA05 *FTY = 1 => 10 times factor.

This gives us the following position system:

Min. absolute value

−9999.99

Range of possible position values

STM

in [10

µm]

0

Max. absolute value

+9999.99

Fig. 4-13: Effective range of the position values with the sample settings

-

Parameter settings for example

Fig. 4-14: Relevant parameters affecting the target position setpoint values

NOTE If target positions are entered using the incremental system it is not possible to change the

rotation direction via the point table.In this mode the rotation direction can only be changed

with the start commands (ST1/ST2).

4-24 MITSUBISHI ELECTRIC

Page 33

Positioning with Digital Inputs Configuration for Positioning

햵

The point table entries for the individual positioning steps are configured in the columns

numbered to in the point table list shown below.

Fig. 4-15: Example of a positioning application with 8 positioning steps

Tips for editing point table entries:

쎲 Thevalue in the

will automatically jump to the nextentry in the table and executethe nextpositioning commandaftercompletingapositioningstep,evenif thereisnochangeinthe input signals.

쎲 The

쎲 The button

쎲 The Verifyfunction checks whether the positioning table in MR Configurator matches the

DwellTime

of the positioning step for the current table line and continuing to the next table line.This

option should only be used when multiple positioning steps are performed automatically,

without changes in the input signals.

lected line.

table stored in the connected ser vo amplifier.If the tables don't match a message is displayed showing the line number where the difference was found:

Aux.Func.

columncan beused toinserta delaybetweenreaching the target position

Insert

inserts a new line above the selected table line.

columnshould normally alwaysbezero.Otherwise the system

Delete

Number of table line

where tables in amplifier

and MR-Configurator do

not match

deletes the se-

MR-J3-T 4-25

Page 34

Configuration for Positioning Positioning with Digital Inputs

AlwaysdeactivatestartcommandST1/ST2beforestarting a newpositioningsequence.

쎲

Then you can select a new table entr y with DI0 - DI7 and start the positioning sequence

with ST1/ST2.

Table entries are not reset when you restore the amplifier's factory default settings!

쎲

You do not need to tur n the amplifier off and on again after changing table entries.

쎲

NOTE Please see the instruction manual for full details on all these procedures.

4.4.1 Importing and exporting point tables

Therearetwo differentwaysto store thepointtable fromyourproject sothatyou caneditit again

later in external programs and MR Configurator:

쎲 Export the point table asa textfile with theextension .ptb.This creates a plain text filethat

can be edited with a normal text editor.

쎲 Export thepoint tableas afile withthe extension.csv. These files c ontain datathatcan be

edited by spreadsheet programs like Microsoft Excel.

Procedure:

햲

The Point Table List w indow must be open and active.

햳

How to export the point table to a file:

Fig. 4-16: Exporting the point table to a file for archival or editing

4-26 MITSUBISHI ELECTRIC

Page 35

Positioning with Digital Inputs Configuration for Positioning

햴

How to open/import a point table data file:

Fig. 4-17: Opening a point table file to import the data

Fig. 4-18: Point table position data imported from a .csv file

MR-J3-T 4-27

Page 36

Functional Test of Digital Input Positioning Positioning with Digital Inputs

4.5 Functional T est of Digital Input Positioning

Normallyyou need asimple controller toset the digitalinputs used toselect the pointtable posi

tionentries, forexample aPC, a mini PLC or an HMIcontrol terminal.This chapter explainshow

youcan performa thorough check ofthe functionality ofthe positioningcontrol functionswithout

needing to perform the additional work of programming and installing a controller.

Fig.4-19shows a testinstallationwithout anexternalcontroller. NotethattheFX SimulationBox

used in this setup can set a maximum of 14 digital inputs.

Servo motor

1-phase

200–230V AC

MR-J3USBCBL3M

Cable length: 3m

MR-J2CMP2

MR-J2M-CNT1TBL-M

Cable length: 0.5–1m

MR-TB50

Encoder cable

Motor

Encoder

PC

FX Simulation Box

-

24V DC

24V DC

power supply

Fig. 4-19: Test setup for simulating positioning with digital inputs

NOTE The test setup shown abovedoes not use any safetyfeatures forthe tests (EMG.OFF).You

should thus only use this setup in a controlled test environment where errors cannot cause

any danger for personnel or equipment!

4-28 MITSUBISHI ELECTRIC

Page 37

Positioning with Digital Inputs Functional Test of Digital Input Positioning

MR Configurator can monitor all the inputs and outputs of the MR-J3-T, including those on the

MR-J3-D01 I/O extension.

Procedure:

햲

Connect the PC/notebook to the USB port (CN5) of the ser vo amplifier using cable

MR-J3USBCBL3M.

햳

Start MR Configurator and make the following selections:

– Select the MR-J3-T series amplifier.

– Select the MR-J3-D01 expansion card (“option unit”).

Fig. 4-20: Settings in MR Configurator for checking the MR-J3-T with the MR-J3-D01

expansion card

Afterthisyoucan monitor thesignalsofthe expansion cardwith the option

in the

Monitor

Fig. 4-21: Selection of the “Option unit I/F display” terminal monitor option

menu.

OptionunitI/Fdisplay

MR-J3-T 4-29

Page 38

Functional Test of Digital Input Positioning Positioning with Digital Inputs

Fig. 4-22: The “Option unit I/F display” terminal monitor ing window

4-30 MITSUBISHI ELECTRIC

Page 39

Positioning via a CC-Link Network Additional Connections

5 Positioning via a CC-Link Network

As an alternative to using digital signals you can also control positioning with MR-J3-T servo

amplifiers via a CC-Link network connection.

NOTE Before proceeding ensure that the MR-J3-D01I/O expansion card is not installed. If it is in-

stalled CC-Link communications will be disabled.

5. 1 Additional Connections

In addition to the minimum configuration described in chapter 3.1 you also need to connect the

CC-Link cable and the cabling for connector CN6 for this mode.

1-phase

200–230V AC

EMG. OFF

EMG. OFF

24V DC

24V DC ±10%

800mA

OFF

Servo amplifier

ON

Encoder cable

24V DC

24V DC ±10%

150mA

Servo motor

Motor

Encoder

Alarm

CC-Link

module

Servo ON

CC-Link cable

V1.10 compatible

Fig. 5-1: Connections for operating the servo amplifier via a CC-Link network

MR-J3-T 5-31

Page 40

Additional Connections Positioningvia a CC-Link Network

Connections for the CC-Link network

CC-Link

Master module

(e.g.QJ61BT11N)

MR-J3-T

Fig. 5-2: Connections between the servo amplifier and the CC-Link master module

NOTE Youmust install a terminating resistor on terminals DB and DB on the physical first and last

stations in the CC-Link network.The required ohmage of the resistor depends on the cable

length, please check the version V1.10 specifications for details.

5-32 MITSUBISHI ELECTRIC

Page 41

Positioning via a CC-Link Network CC-Link Communication Settings

5. 2 CC-Link Communication Settings

5.2.1 Settings on the servo amplifier

Inthe instructions below we are assuming that you have an operating CC-Link network with the

following specifications:

쎲 Data rate 156Kbit/s

쎲 The master station is a QJ61BT11N module that is integrated in a System Q con-

troller platform with a Q02H-CPU.

Procedure:

햲

Set the number of reserved stations:

Factory default

setting

S1

1 reserved station

2 reserved stations

Fig. 5-3: Correct position of switch S1 for setting the number of reserved stations

햳

Set the station address (max. value 64):

x1

x10

higher values

lower values

address digits

Fig. 5-4: Set switches x1 and x10 to the correct station address

MR-J3-T 5-33

Page 42

CC-Link Communication Settings Positioningvia a CC-Link Network

햴

Set the data rate:

Mode Baud rate

Fig. 5-5: Mode switch setting for the network data rate

NOTE Theservoamplifiersettings required forpoint tablepositioningaredescribedinchapters 4.2

through4.4.Pleasecheckthatthesesettings havebeenmadecorrectly beforeproceeding.

5-34 MITSUBISHI ELECTRIC

Page 43

Positioning via a CC-Link Network CC-Link Communication Settings

5.2.2 Configuration for communication with GX IEC Developer

Generally,positioning control isperformed viaa CC-Linknetwork inapplications where anaddi

tional PLC system is used for automation tasks as well as the integrated controller in the ampli

fier. In this example we will thus only provide detailed descriptions of the settings required to

integrate the servo amplifier in your project.

Procedure:

How to open an existing project in GX IEC Developer:

햲

Select

햳

Select

햴

This opens the window

enter the settings shown in Fig. 5-6 .

Network

CC-Link

in the project directory tree in the left window.

in the

Network Parameter

Network parameters: Setting the CC-Link list

box.

where you can now

-

-

(a)

(b)

(c)

Fig. 5-6: Settings required in GX IEC Developer for CC-Link communication between

the controller and the servo amplifier

MR-J3-T 5-35

Page 44

CC-Link Communication Settings Positioningvia a CC-Link Network

Notes on the network settings:

(a)Inthe example onlyoneservoamplifier is connectedtotheCC-Link network.Thisvaluemust

be increased by the number of slave stations installed if applicable.

(b)These values specify which bits or data words are to be used to control the servo amplifier.

The settings shown in the example are for the following assignments:

PLC -> Servo Amplifier Servo Amplifier -> PLC

PLC I/Os Registers Signals PLC I/Os Registers Signals

Y100 RYn0 SON X100 RXn0 RD

Y101 RYn1 ST1 X101 RXn1 INP

Y102 RYn2 ST2 X103 RXn3 ZP

Y103 RYn3 DOG X11A RX(n+1)A ALM

Y104 RYn4 LSP

Y105 RYn5 LSN

Y106 RYn6 MD0

Y10A RYnA DI0

Y10B RYnB DI1

Y10C RYnC DI2

Y10D RYnD DI3

Y10E RYnE DI4

Y10F RYnF RES

NOTE:

Signals DI5, DI6 and DI7 are only available

when the amplifier is configured to occupy 2

stations in the network.

Table 5-1: Signal assignments

(c)Slave station type setting:

Fig. 5-7: This configuration also enables exchange of data words

햵

Connect the PC to the PLC and transfer the modified project to the controller.

NOTE If the CC-Link connection to the servo amplifier is established successfully the L.RUN, SD

und RD status LEDs on the servo amplifier will light up.

5-36 MITSUBISHI ELECTRIC

Page 45

Positioning via a CC-Link Network Testing the Servo Amplifier via CC-Link

5. 3 Testing the Servo Amplifier via CC-Link

Before proceeding it is a good idea use the monitoring function in GX IEX Developer to check

that the individual servo functions can be started correctly (e.g. return to home, positioning).

After this you can then test the correct operation of the servo system with the PLC program.

Procedure:

햲

Activate monitoring mode.

햳

Select

햴

Enter the individual remote I/Os to be set or monitored.

Entry Data Monitor

in the

Online

menu.

Fig. 5-8: The Entry Data Monitor window where you can set remote I/Os to test the

servo functions

MR-J3-T 5-37

Page 46

Appendix Digital Signals − Quick Reference

A Appendix

A.1

Digital Signals

Connector

Pins

CN6-1 EMG – Forced stop - emergency safety signal:

CN6-2 DOG RYn3 Proximity dog switch:

CN6-3 LSP RYn4 Forward rotation stroke end switch DI

CN6-4 LSN RYn5 Reverse rotation stroke end switch DI

CN6-14 RD RXn0 Servo amplifier ready DO

CN6-15 ALM RX(n+1)A Alarm, signals a servo error DO

CN6-16 ZP RXn3 Home position return completed successfully DO

CN10-1 DI0 RYnA Select point table entry, i.e. activate a line in the table for position-

CN10-2 DI1 RYnB DI

CN10-3 DI2 RYnC DI

CN10-4 DI3 RYnD DI

CN10-5 DI4 RYnE DI

CN10-6 DI5 RY(n+2)3 DI

CN10-7 DI6 RY(n+2)4 DI

CN10-8 DI7 RY(n+2)5 DI

CN10-13 DICOM – Connection for an external power supply for the digital control termiCN10-14

CN10-21 SON RYn0 SERVO ON:

CN10-22 ACD0 – Digital output signals for encoded error messages (see Appendix

CN10-23 ACD1 –

CN10-24 ACD2 –

CN10-25 ACD3 –

CN10-26 RES RY1A Reset for error messages DI

CN10-32 MD0 RYn6 Switch between automatic/manual mode:

CN10-35 ST1 RYn1 Start signal for forward rotation DI

CN10-36 ST2 RYn2 Start signal for reverse rotation DI

CN10-37 DOCO – Connection for an external power supply for the digital control termi

CN10-49 INP RXn1 IN Position: Target position reached signal. DO

Signal Codes

DI/DO CC-Link

Point table entry no.1

Point table entry no. 2

Point table entry no. 3

Point table entry no. 4

Point table entry no. 5

Point table entry no. 6

Point table entry no. 7

Point table entry no. 8

Quick R eference

Description

The signal is permanently assigned to this pin and must be activated for motor control.

This signal is used for some of the home position return modes.

(See chapter 4.3)

ing. Combinations of signals DI0 through DI7 (see Table 4-3) can

be used to selec up tot 256 positioning steps.

NOTE:

Signals DI5, DI6 and DI7 are only available when the amplifier occupies 2 stations in the network, thus making 64 bits available via

CC-Link.

nals. Negative connection for source interface logic (PNP).

Activating the SON signal powers on the base circuit and makes

the amplifier ready for operation.

A.3)

The MD0 signal must be off for opertion in jog mode. The signal

must be activated before starting a home position return or position

ing.

nals. Positive connection for source interface logic (PNP).

-

-

DI /

DO

DI

DI

DI

DI

DI

DO

DI

DI

Table A-1: Digital signals - quick reference

MR-J3-T A-39

Page 47

Standard Parameters − Quick Reference Appendix

A.2

Standard Parameters

No. Code Function Description

햲

PA01

PA03

PA05

PA14

PC02

PC03

PC04 ZRF Home position re-

PC05 CRF Creep speed Speed for precise movement to home position in [rpm]

PC06 ZST Home position

PC07

PD01

PD01

*STY Positioning control

햲

*ABS Absolute position

햲

*FTY Feed length multipli

햲

*POL Servo motor rotation

햲

*ZTY Home position re-

햲

*ZDIR Home position re-

햲

*ZPS Home position re-

햲

*DIA1 Automatic activation

햲

*DIAB Polarity of the input

mode

detection system

cation factor

direction

turn mode

turn direction

turn speed

offset (shift)

turn position value

of input signals

signal

Quick R eference

0: Absolute value command system for target positions

1: Incremental value command system for target positions

0: Incremental system (absolute position detection off)

1: Absolute position detection system on

-

Needed here to scale the home position value to the physical co

ordinate system when a home position offset (shift) has been set.

Parameter

value

01

110

2 100

Motor rotation direction (looking at shaft end facing motor):

0: Anticlockwise when ST1 signal is active

1: Clockwise when ST1 signal is active

Selects mode to be used for home position return:

0: Proximity dog mode

0: Incrementing counting of encoder pulses

1: Decrementing counting of encoder pulses

Sets home position return speed until first detection of the

Z-phase in [rpm].

Distance between the encoder home position (Z-phase) and the

physical home position in [µm]. Does not change the zero point of

the physical coordinate system.

The home position return stops when the Z-phase position is

reached.You can enter a non-zero coordinate for this position [in

STM

10

µm] with this parameter.

This parameter configures the amplifier to automatically set the

digital signals internally to a logical "1" when the power is

switched on.

Logical value for detection of the proximity dog signal (DOG):

0: Active DOG on logical "0"

1: Active DOG on logical "1"

Multiplication

factor STM

Range of the target

position values

−999.999 ... +999.999

−9999.99 ... +9999.99

−99999.9 ... +99999.9

-

Table A-2:

햲

To activate this parameter you must switch the amplifier power off and on again.

Standard parameters

quick reference

A-40 MITSUBISHI ELECTRIC

Page 48

Appendix AlarmsandWarningMessages

A.3 Alarms and Warning Messages

Display

A10

A12

A13

A15

A16

A17

A19

A1A

A20

A24

A25

A30

Alarme

A31

A32

A33

A35

A37

A45

A46

A47

A50

A51

Alarm Code

ACD3

ACD2

ACD1

(Bit 3)

(Bit 2)

(Bit 1)

ACD0

(Bit 0)

0010

0000

0000

0000

0110

0000

0000

0110

0110

1100

1110

0001

0101

0100

1001

1101

1000

0011

0011

0011

0011

0011

Error

Undervoltage

Memory error 1

Clock error

Memory error 2

(E²PROM)

Encoder error 1

(at power on)

Board error

Memory error 2

(Flash ROM)

Incorrect servo

motor

Encoder error 2

Main circuit error

Absolute position

lost/erased

Regenerative

braking overload

Overspeed

Overcurrent

Overvoltage

Input frequency

too high

Parameter error

Main circuit

overheat

Servo motor

overheat

Cooling fan error

Overload 1

Overload 2

Alarm Reset

Power

Supply

OFF

ON

MR-

Configurator/

HMI

Reset

(RES)

✔✔✔

✔ ——

✔ ——

✔ ——

✔ ——

✔ ——

✔ ——

✔ ——

✔ ——

✔✔✔

✔ ——

햲

✔

햲

✔

햲

✔

✔✔✔

✔ ——

✔✔✔

✔ ——

✔ ——

햲

✔

햲

✔

햲

✔

햲

✔

햲

✔

햲

✔

✔ ——

햲

✔

햲

✔

햲

✔

햲

✔

햲

✔

햲

✔

Table A-3: Error messages(1)

MR-J3-T A-41

Page 49

Alarms and Warning Messages Appendix

Display

A52

A61

A8A

Alarms

A8E

888

Alarm Code

ACD3

ACD2

ACD1

(Bit 3)

(Bit 2)

0101

0101

0000

0000

0 ———

(Bit 1)

ACD0

(Bit 0)

Error

Excessive discrep

ancy error

Operation alarm

Serial communica

tion timeout

Serial communica

tion error

Watchdog

Power

Supply

OFF

-

-

-

✔✔✔

✔✔✔

✔✔✔

✔✔✔

✔ ——

ON

Alarm Reset

MR-

Configurator/

HMI

Reset

(RES)

Table A-3: Error messages (2)

햲

Locateand correct the cause of the error and allow the servo amplifier,the servomotor and

the regenerative braking unit to cool down forat least 30 minutes before resetting the alarm

and restarting the system for normal operation.

햳

Switch on the RES signal.

햴

To reset the alarm click on the Alarm Reset button in the alar m display window in MR

Configurator.Youcan also reset the alar m by pressing theSTOP/RESET button on theHMI

control unit.

햵

0: OFF

1: ON

NOTE The output signal ALM is activated when an error or alarm signal is triggered.

Display Warning

A90 Home position return incomplete

A92 Battery cable disconnected

A96 Home position return error

A98 Software limit warning

A99 Stroke limit warning

A9A Option unit input data error

A9F Battery warning

AE0 Regenerative system overload warning

AE1 Overload warning 1

Warning messages

AE3 Absolute position counter error

AE6 Server emergency off warning

AE8 Cooling fan too slow

AE9 Main circuit off

AEC Overload warning 2

AED Output wattage exceeded

Table A-4:

Warning messages

NOTE Pleaseseetheinstruction manualformore detaileddescriptionsofthe alarmmessagesand

warnings.

A-42 MITSUBISHI ELECTRIC

Page 50

Index

Index

A

Alarm messages

List . . . . . . . . . . . . . . . . . . . .A - 41

Automatic input signal activation

Turning off. . . . . . . . . . . . . . . . . 4 - 14

C

CC-Link communications

Settings . . . . . . . . . . . . . . . . . . 5 - 33

Connections

Minimum connections . . . . . . . . . . . 3 - 5

Creep speed . . . . . . . . . . . . . . . . .4 - 15

D

Digital signals

Quick reference. . . . . . . . . . . . . . A - 39

DOG home position return . . . . . . . . . . 4 - 19

E

Expansion card MR-J3-D01

Installation . . . . . . . . . . . . . . . . .2 - 3

Settings . . . . . . . . . . . . . . . . . . 4 - 23

M

Minimum connections . . . . . . . . . . . . . 3 - 5

MR Configurator

functional check. . . . . . . . . . . . . . 3 - 10

P

Parameter

Quick reference . . . . . . . . . . . . . . 4 - 21

Pin assignments . . . . . . . . . . . . . . . . 3 - 6

Point table

configuring . . . . . . . . . . . . . . . . .3 - 9

Point table positioning . . . . . . . . . . . . 4 - 11

Preparations . . . . . . . . . . . . . . . . 1 - 1

Positioning

Settings . . . . . . . . . . . . . . . . . . 4 - 23

via a CC-Link network. . . . . . . . . . . 5 - 31

with digital inputs . . . . . . . . . . . . . 4 - 11

Positioning table

exporting . . . . . . . . . . . . . . . . . 4 - 26

importing . . . . . . . . . . . . . . . . . 4 - 26

Positioning table entries

selecting. . . . . . . . . . . . . . . . . . 3 - 10

F

Functional test . . . . . . . . . . . . . . . . . 3 - 5

CC-Link . . . . . . . . . . . . . . . . . . 5 - 37

Positioning with digital inputs . . . . . . . 4 - 28

Settings. . . . . . . . . . . . . . . . . . .3 - 7

G

GX IEC Developer

Data communications . . . . . . .5 - 35, 5 - 37

H

Home position return . . . . . . . . . . . . . 4 - 15

I

Installation

Hardware . . . . . . . . . . . . . . . . . . 2 - 3

S

Servo amplifier

selecting . . . . . . . . . . . . . . . . . .3 - 7

Signal assignments

Connectors CN6 and CN10. . . . . . . . 4 - 12

Standard parameters

Quick reference. . . . . . . . . . . . . . A - 40

W

Warning messages

Reference list . . . . . . . . . . . . . . . A - 42

Z

Z-phase reference

without DOG signal . . . . . . . . . . . . 4 - 15

MR-J3-T A-43

Page 51

Page 52

MITSUBISHI ELECTRIC

HEADQUARTERS

MITSUBISHI ELECTRIC EUROPE B.V.

German Branch

Gothaer Straße 8

Phone: +49 (0)2102 / 486-0

Fax: +49 (0)2102 / 486-1120

MITSUBISHI ELECTRIC EUROPE B.V.

French Branch

25, Boulevard des Bouvets

Phone: +33 (0)1 / 55 68 55 68

Fax: +33 (0)1 / 55 68 57 57

MITSUBISHI ELECTRIC EUROPE B.V.

Irish Branch

Westgate Business Park, Ballymount

Phone: +353 (0)1 4198800

Fax: +353 (0)1 4198890

MITSUBISHI ELECTRIC EUROPE B.V.

Italian Branch

Viale Colleoni 7

Phone: +39 039 / 60 53 1

Fax: +39 039 / 60 53 312

MITSUBISHI ELECTRIC CORPORATION

Office Tower “Z” 14 F

Tokyo 104-6212

Phone: +81 3 622 160 60

Fax: +81 3 622 160 75

MITSUBISHI ELECTRIC EUROPE B.V.

UK Branch

Travellers Lane

Phone: +44 (0)1707 / 27 61 00

Fax: +44 (0)1707 / 27 86 95

MITSUBISHI ELECTRIC EUROPE B.V.

Spanish Branch

Carretera de Rubí 76-80

Phone: +34 93 / 565 3131

Fax: +34 93 / 589 1579

500 Corporate Woods Parkway

Phone: +1 847 478 21 00

Fax: +1 847 478 22 83

EUROPEAN REPRESENTATIVES

GEVA

Wiener Straße 89

Phone: +43 (0)2252 / 85 55 20

Fax: +43 (0)2252 / 488 60

TEHNIKON

Oktyabrskaya 16/5, Off. 703-711

Phone: +375 (0)17 / 210 46 26

Fax: +375 (0)17 / 210 46 26

Koning & Hartman B.V.

Industrial Solutions

Woluwelaan 31

Phone: +32 (0)2 / 257 02 40

Fax: +32 (0)2 / 257 02 49

AKHNATON

4 Andrej Ljapchev Blvd. Pb 21

Phone: +359 (0)2 / 97 44 05 8

Fax: +359 (0)2 / 97 44 06 1

INEA CR d.o.o.

Losinjska 4 a

Phone: +385 (0)1 / 36 940 - 01/ -02/ -03

Fax: +385 (0)1 / 36 940 - 03

AutoCont Control Systems, s.r.o.

Jelinkova 59/3

Phone: +420 (0)59 / 5691 150

Fax: +420 (0)59 / 5691 199

AutoCont Control Systems, s.r.o.

Technologická 374/6

Phone: +420 595 691 150

Fax: +420 595 691 199

B:TECH, a.s.

Na Ostrove 84

Phone: +420 (0)569 / 408 841

Fax: +420 (0)569 / 408 889

B:TECH, a.s.

USAMITSUBISHI ELECTRIC AUTOMATION

Headoffice

U Borové 69

Phone: +420 569 777 777

Fax: +420 569 777 778

Beijer Electronics A/S

Lautruphoj 1-3

Phone: +45 (0)70 / 26 46 46

Fax: +45 (0)70 / 26 48 48

Beijer Electronics Eesti OÜ

Pärnu mnt.160i

Phone: +372 (0)6 / 51 81 40

Fax: +372 (0)6 / 51 81 49

Beijer Electronics OY

Jaakonkatu 2

Phone: +358 (0)207 / 463 500

Fax: +358 (0)207 / 463 501

UTECO A.B.E.E.

5, Mavrogenous Str.

Phone: +30 211 / 1206 900

Fax: +30 211 / 1206 999

MELTRADE Ltd.

Fertő utca 14.

Phone: +36 (0)1 / 431-9726

Fax: +36 (0)1 / 431-9727

EUROPEAN REPRESENTATIVES

Beijer Electronics SIA

Vestienas iela 2

Phone: +371 (0)784 / 2280

Fax: +371 (0)784 / 2281

Beijer Electronics UAB

Savanoriu Pr. 187

Phone: +370 (0)5 / 232 3101

Fax: +370 (0)5 / 232 2980

INTEHSIS srl

bld. Traian 23/1

Phone: +373 (0)22 / 66 4242

Fax: +373 (0)22 / 66 4280

Beijer Electronics AS

Postboks 487

Phone: +47 (0)32 / 24 30 00

Fax: +47 (0)32 / 84 85 77

Koning & Hartman B.V.

Haarlerbergweg 21-23

Phone: +31 (0)20 / 587 76 00

Fax: +31 (0)20 / 587 76 05

MPL Technology Sp. z o.o.

Ul. Krakowska 50

Phone: +48 (0)12 / 630 47 00

Fax: +48 (0)12 / 630 47 01

Sirius Trading & Services srl

Aleea Lacul Morii Nr. 3

Phone: +40 (0)21 / 430 40 06

Fax: +40 (0)21 / 430 40 02

CRAFT Consulting & Engineering d.o.o.

Toplicina str.4 lok 6

Phone: +381 (0)18 / 292-24-4/5 , 523 962

Fax: +381 (0)18 / 292-24-4/5 , 523 962

INEA SR d.o.o.

Karadjordjeva 12/260

Phone: +381 (0)26 / 617 163

Fax: +381 (0)26 / 617 163

CS MTrade Slovensko, s.r.o.

Vajanskeho 58

Phone: +421 (0)33 / 7742 760

Fax: +421 (0)33 / 7735 144

INEA d.o.o.

Stegne 11

Phone: +386 (0)1 / 513 8100

Fax: +386 (0)1 / 513 8170

Beijer Electronics Automation AB

Box 426

Phone: +46 (0)40 / 35 86 00

Fax: +46 (0)40 / 35 86 02

ECONOTEC AG

Hinterdorfstr. 12

Phone: +41 (0)44 / 838 48 11

Fax: +41 (0)44 / 838 48 12

GTS

Darulaceze Cad. No. 43 KAT. 2

Phone: +90 (0)212 / 320 1640

Fax: +90 (0)212 / 320 1649

CSC Automation Ltd.

15, M. Raskova St., Fl. 10, Office 1010

Phone: +380 (0)44 / 494 33 55

Fax: +380 (0)44 / 494-33-66

EURASIAN REPRESENTATIVES

Kazpromautomatics Ltd.

2, Scladskaya str.

Phone: +7 3212 / 50 11 50

Fax: +7 3212 / 50 11 50

AVTOMATIKA SEVER

Lva Tolstogo str. 7, off. 311

Phone: +7 812 / 718 3238

Fax: +7 812 / 718 3239

CONSYS

Promyshlennaya st. 42

Phone: +7 812 / 325 36 53

Fax: +7 812 / 325 36 53

Electrotechnical Systems Siberia

Derbenevskaya st. 11A, Office 69

Phone: +7 495 / 744 55 54

Fax: +7 495 / 744 55 54

STC DRIVE TECHNIQUE

Poslannikov per. 9, str 1

Phone: +7 495 / 790 72 10

Fax: +7 495 / 790 72 12

MIDDLE EAST

REPRESENTATIVE

Sherf Motion Techn. Ltd.

Rehov Hamerkava 19

Phone: +972 (0)3 / 559 54 62

Fax: +972 (0)3 / 556 01 82

AFRICAN REPRESENTATIVE

CBI Ltd.

Private Bag 2016

Phone: + 27 (0)11 / 928 2000

Fax: + 27 (0)11 / 392 2354

MITSUBISHI

ELECTRIC

FACTORY AUTOMATION

Mitsubishi Electric Europe B.V. /// FA - European Business Group /// Gothaer Straße 8 /// D-40880 Ratingen /// Germa ny

Tel.: +49(0)2102-4860 /// Fax: +49(0)2102-4861120 /// info@mitsubishi-automation.com /// www.mitsubishi-automation.com

Specifications subject to cha nge /// Art. no. XXXXXX-A /// 12.2007

Loading...

Loading...