Page 1

TRANSISTORIZED INVERTER

FR-S500

INSTRUCTION MANUAL (Detailed)

SIMPLE INVERTER

FR-S520E-0.1K to 3.7K (-C)

FR-S540E-0.4K to 3.7K

FR-S520SE-0.1K to 1.5K

FR-S510WE-0.1K to 0.75K

WIRING

FUNCTIONS

PROTECTIVE

FUNCTIONS

SPECIFICA TIONS

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Page 2

Thank you for choosing this Mitsubishi Transistorized inverter.

WARNING

CAUTION

CAUTION

This instruction manual (detailed) provides instructions for advanced use of the FRS500 series inverters.

Incorrect handling might cause an unexpected fault. Before using the inverter, always

read this instruction manual and the instruction manual (basic) [IB-0600151E] packed

with the product carefully to use the equipment to its optimum.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the inverter until you have read

through this instruction manual (basic) and appended documents carefully and can

use the equipment correctly. Do not use the inverter until you have a full knowledge

of the equipment, safety information and instructions.

In this instruction manual (detailed), the safety instruction levels are classified into

"WARNING" and "CAUTION".

Assumes that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

Assumes that incorrect handling may cause hazardous

conditions, resulting in medium or slight injury, or may cause

physical damage only.

Note that even the level may lead to a serious consequence

according to conditions. Please follow the instructions of bo th levels because they are

important to personnel safety.

1. Electric Shock Prevention

WARNING

While power is on or when the inverter is running, do not open the front cover. You

may get an electric shock.

Do not run the inverter with the front cover or wiring cover removed. Otherwise,

you may access the exposed high-voltage terminals or the charging part of the

circuitry and get an electric shock. Also, the inverter's ability to withstand

earthquakes will deteriorate.

Even if power is off, do not remove the front cover except for wiring or periodic

inspection. You may access the charged inverter circuits and get an electric shock.

Before starting wiring or inspection, check to make sure that the 3-digit LED inverter

monitor is off, wait for at least 10 minutes after the pow er s upply ha s b een switched

off, and check to make sure that there are no residual voltage using a tester or the

like.

This inverter must be earthed (grounded). Earthing (grounding) must conform to

the requirements of national and local s afety regulations and el ectrical codes. (JIS,

NEC section 250, IEC 536 class 1 and other applicable standards)

Any person who is involved in the wiring or inspection of this equipment should be

fully competent to do the work.

Always install the inverter before wiring. Otherwise, you may get an electric shock

or be injured.

Perform setting dial and key operations with dry hands to prevent an electric

shock.

Do not subject the cables to scratches, excessive stress, heavy loads or pinching.

Otherwise, you may get an electric shock.

Do not change the cooling fan while power is on. It is dangerous to change the

cooling fan while power is on.

When you have removed the front cover, do not touch the connector above the 3-

digit monitor LED display. Otherwise, you get an electrick shock.

A-1

Page 3

2. Fire Prevention

*Temperatures applicable for a short time, e.g. in transit.

Environment

Ambient

Temperature

-10°C to +50°C (non-freezing)

(-10°C to +40°C for totally enclosed structure feature)

Ambient humidity 90%RH maximum (non-condensing)

Storage

temperature

-20°C to +65°C *

Atmosphere

Indoors (free from corrosive gas, flammable gas, oil mist,

dust and dirt)

Altitude/

vibration

Max.1000m above sea level 5.9m/s

2

or less

(conforming to JIS C 60068-2-6)

CAUTION

Mount the inverter and bra ke res is to r on an i ncom bus t ibl e surf ac e. In st a lli ng th e i nve rter

and brake resistor directly on or near a combusti ble surface could lead to a fire.

If the inverter has become faulty, switch off the inverter power . A contin uous flow of

large current could cause a fire.

When using a brake resistor, make up a sequence that will turn off power when an

alarm signal is output. Otherwise, the brake resistor may excessively overheat due

to damage of the brake transistor and such, causing a fire.

Do not connect a resistor directly to the DC terminals P, N. This could cause a fire.

3. Injury Prevention

CAUTION

Apply only the voltage specified in the instruction manual to each terminal to

prevent damage, etc.

Always connect to the correct terminal to prevent damage, etc.

Always make sure that polarity is correct to prevent damage, etc.

While power is on or for some time after power-off, do not touch the inverter as it is

hot and you may get burnt.

4. Additional Instructions

Also note the following points to prevent an accidental failure, injury, electric shock,

etc.

(1) Transportation and installation

CAUTION

When carrying products, use correct lifting gear to prevent injury.

Do not stack the inverter boxes higher than the number recommended.

Ensure that installation position and material can withstand the weight of the

inverter. Install according to the information in the instruction manual.

Do not install or operate if the inverter is damaged or has parts missing.

When carrying the inverter, do not hold it by the front cover or setting dial; it may

fall off or fail.

Do not stand or rest heavy objects on the inverter.

Check the inverter mounting orientation is correct.

Prevent other conductive bodies as screws and metal fragments or other

flammable substance as oil from entering the inverter.

As the inverter is a precision ins trument, do not d rop or subject it to impact .

Use the inverter under the following environmental conditions: This could cause

the inverter damage.

A-2

Page 4

(2) Wiring

CAUTION

Do not fit capacitive equipment such as power factor correction capacitor, radio

noise filter (option FR-BIF(-H)) or surge suppressor to the output of the inverter.

The connection orientation of the output cables U, V, W to the motor will affect the

direction of rotation of the motor.

(3) Trial run

CAUTION

Check all parameters, and ensure that the machine will not be damaged by a

sudden start-up.

When the load GD

output current may v ary whe n the outp ut fre quency is i n the 20H z to 30 Hz ra nge.

If this is a problem, set the Pr.72 "PWM frequency selection" to 6kHz or higher.

(When setting the PWM to a higher frequency, check for noise or leakage current

problem and take countermeasures against it.)

(4) Operation

2

is small (at the motor GD or smaller) for 400V from 1.5K to 3.7K, the

WARNING

When you have chosen the retry function, stay away from the equipment as it will

restart suddenly after an alarm stop.

The [STOP] key is valid only when the appropriate function setting has been made.

Prepare an emergency stop switch separately.

Make sure that the start signal is off before resetting the inverter alarm. A failure to

do so may restart the motor suddenly.

The load used should be a three-phase induction motor only. Connection of any

other electrical equipment to the inverter output may damage the equipment.

Do not modify the equipment.

Do not perform parts removal which is not instructed in this manual. Doing so may

lead to fault or damage of the inverter.

A-3

Page 5

CAUTION

The electronic thermal relay function does not guarantee protection of the motor

from overheating.

Do not use a magnetic contactor on the inverter input for frequent starting/stopping

of the inverter.

Use a noise filter to reduce the effect of electromagnetic interference. Otherwise

nearby electronic equipment may be affected.

Take measures to suppress harmonics. Otherwise power supply harmonics from

the inverter may heat/damage the power capacitor and generator.

When a 400V class motor is inverter-driven, please use an insulation-enhanced

motor or measures taken to suppre ss s urge vo ltages. Surge voltages at tributable to

the wiring constants may occur at the motor terminals, deteriorating the insulation of

the motor.

When parameter clear or all clear is performed, reset the required parameters

before starting operations. Each parameter returns to the factory setting.

The inverter can be easily set for high-speed operation. Before changing its

setting, fully examine the performances of the motor and machine.

In addition to the inverter's holding function, install a holding device to ensure safety.

Before running an inverter which had been stored for a long period, always

perform inspection and test operation.

(5) Emergency stop

CAUTION

Provide a safety backup such as an emergency brake which will prevent the

machine and equipment from hazardous conditions if the inverter fails.

When the breaker on the inverter primary side trips, check for the wiring fault (short

circuit), damage to internal parts of the inverter, etc. Identify the cause of the trip,

then remove the cause and power on the breaker.

When any protective function is activated, take the appropriate corrective action,

then reset the inverter, and resume operation.

(6) Maintenance, inspection and parts replacement

CAUTION

Do not carry out a megger (insulation resistance) test on the control circuit of the

inverter.

(7) Disposing of the inverter

CAUTION

Treat as industrial waste.

(8) General instructions

Many of the diagrams an d dra wi ng s in th i s inst ruc ti o n ma nua l (detailed) show the inverter

without a cover, or p artiall y open. N ever ope rate the inverter in this m anner. Always replace

the cover and fo llow t his ins tructi on man ual (detailed) when operating the inv erter.

A-4

Page 6

CONTENTS

1. WIRING 1

1.1 Standard connection diagram and terminal specifications ..2

1.1.1 Standard connection diagram .......................................................................2

1.1.2 Explanation of main circuit terminals.............................................................3

1.2 Main circuit termina ls ............ ................ ............... ....................6

1.2.1 Terminal block layout ....................................................................................6

1.2.2 Cables, wiring length, and crimping terminals...............................................8

1.2.3 Wiring instructions.........................................................................................9

1.2.4 Selection of peripheral devices...................................................................10

1.2.5 Leakage current and installation of earth (ground) leakage circuit breaker 12

1.2.6 Power-off and magnetic contactor (MC)......................................................16

1.2.7 Regarding the installation of the power factor improving reactor................17

1.2.8 Regarding noise and the installation of a noise filter...................................18

1.2.9 Earthing (Grounding) precautions...............................................................19

1.2.10 Power supply harmonics.............................................................................20

1.2.11 Harmonic suppression guideline.................................................................21

1.2.12 Inverter-driven 400V class motor................................................................24

1.3 How to use the control circuit terminals...............................25

1.3.1 Terminal block layout ..................................................................................25

1.3.2 Wiring instructions.......................................................................................25

1.3.3 Changing the control logic............................... ...... ...... ..... ...........................26

CONTENTS

1.4 Input terminals.........................................................................28

1.4.1 Run (start) and stop (STF, STR, STOP) .....................................................28

1.4.2 Connection of frequency setting potentiometer and

output frequency meter (10, 2, 5, 4, AU).....................................................31

1.4.3 External frequency selection (REX, RH, RM, RL).......................................32

1.4.4 Indicator connection and adjustment (FM)..................................................34

1.4.5 Control circuit common terminals (SD, 5, SE).............................................36

1.4.6 Signal inputs by contactless switches.........................................................36

1.5 How to use the input signals

(assigned terminals RL, RM, RH, STR)..................................37

1.5.1 Multi-speed setting (RL, RM, RH, REX signals):

Pr. 60 to Pr. 63 setting "0, 1, 2, 8"

Remote setting (RL, RM, RH signals):

Pr. 60 to Pr. 63 setting "0, 1, 2"...................................................................37

1.5.2 Second function selection (RT signal): Pr. 60 to Pr. 63 setting "3".............37

I

Page 7

1.5.3 Current input selection "AU signal": Pr. 60 to Pr. 63 setting "4".................. 37

1.5.4 Start self-holding selection (STOP signal): Pr. 60 to Pr. 63 setting "5"....... 38

1.5.5 Output shut-off (MRS signal): Pr. 60 to Pr. 63 setting "6"........................... 38

1.5.6 External thermal relay input: Pr. 60 to Pr. 63 setting "7".............................39

1.5.7 Jog operation (JOG signal): Pr. 60 to Pr. 63 setting "9"..............................39

1.5.8 Reset signal: Pr. 60 to Pr. 63 setting "10"................................................... 40

1.5.9 PID control valid terminal: Pr. 60 to Pr. 63 setting "14"...............................41

1.5.10 PU operation/external operation switchover: Pr. 60 to Pr. 63 setting "16".. 41

1.6 Connection to the Stand-Alone Option.................................42

1.6.1 Connection of the dedicated external brake resistor (option) (FR-S520E-0.4K

to 3.7K only)................................................................................................ 42

1.6.2 Connection of the brake unit (BU type)....................................................... 43

1.6.3 Connection of the high power factor converter (FR-HC)............................. 44

1.6.4 Connection of the power regeneration common converter (FR-CV)........... 45

1.7 Handling of the RS-485 connector ................................ ........46

1.7.1 Connection of the parameter unit (FR-PU04).............................................46

1.7.2 Wiring of RS-485 communication ............................................................... 47

1.8 Design information .................................................................50

2. FUNCTIONS 51

2.1 Function (Parameter) list................. .......................................52

2.2 List of parameters classified by purpose of use..................65

2.3 Expl a n a ti on o f fu n c ti o n s (p a ra m e t e rs ) .. ............................. ..67

2.3.1 Torque boost (Pr. 0 , Pr. 46 )...................................................................... 67

2.3.2 Maximum and minimum frequency (Pr. 1 , Pr. 2 )...................................... 68

2.3.3 Base frequency, base frequency voltage (Pr.3 , Pr.19 , Pr.47 )..................69

2.3.4 Multi-speed operation (Pr. 4, Pr. 5, Pr. 6, Pr. 24 to Pr. 27, Pr. 80 to Pr. 87)70

2.3.5 Acceleration/deceleration time (Pr. 7 , Pr. 8 , Pr. 20 , Pr. 44 , Pr. 45 ) ....... 71

2.3.6 Selection and protection of a motor (Pr. 9 , Pr. 71 , H7 )............................ 73

2.3.7 DC injection brake (Pr. 10 , Pr. 11 , Pr. 12 )............................................... 75

2.3.8 Starting frequency (Pr. 13 )......................................................................... 76

2.3.9 Load pattern selection (Pr. 14 )...................................................................77

2.3.10 Jog operation (Pr.15 , Pr.16 )......................................................................78

2.3.11 RUN key rotation direction selection (Pr.17 )..............................................78

2.3.12 Stall prevention function and current limit function (Pr. 21 ) .......................79

2.3.13 Stall prevention (Pr. 22 , Pr. 23 , Pr. 28 ).................................................... 81

2.3.14 Acceleration/deceleration pattern (Pr. 29 ).................................................83

II

Page 8

2.3.15 Extended function display selec tio n (Pr. 30 )..............................................84

2.3.16 Frequency jump (Pr. 31 to Pr. 36 ).............................................................84

2.3.17 Speed display (Pr. 37 )................................................................................85

2.3.18 Biases and gains of the frequency setting voltage (current)

(Pr. 38 , Pr. 39 , C2 to C7 ).........................................................................86

2.3.19 Start-time earth (ground) fault detection selection (Pr. 40 ) ........................90

2.4 Output terminal function parameters....................................90

2.4.1 Up-to-frequency (Pr. 41 ).............................................................................90

2.4.2 Output frequency detection (Pr. 42 , Pr. 43 )...............................................91

2.5 Curren t d et e c ti o n fun c t io n p ar a me t e rs........... .. ............... .....92

2.5.1 Output current detection functions (Pr. 48 , Pr. 49 )....................................92

2.5.2 Zero current detection (Pr. 50 , Pr. 51 ).......................................................93

2.6 Display fu n c ti o n pa r a me te r s ................. ............... ............... ...94

2.6.1 Monitor display (Pr. 52 , Pr. 54 )..................................................................94

2.6.2 Setting dial function selection (Pr. 53 )........................................................95

2.6.3 Monitoring reference (Pr. 55 , Pr. 56 ).........................................................96

2.7 Restart operation parameters ................................................96

2.7.1 Restart setting (Pr. 57 , Pr. 58 , H6 )...........................................................96

2.8 Additio n a l fu n c tion parameters ... ............... ................ .. .........9 9

2.8.1 Remote setting function selection (Pr. 59 ).................................................99

2.9 Termin a l fu n c ti o n se le c t io n pa r a me ters .............................102

2.9.1 Input terminal function selection (Pr. 60 , Pr. 61 , Pr. 62 , Pr. 63 )............102

2.9.2 Output terminal function selection (Pr. 64 , Pr. 65 ) ..................................104

2.10 Operation selection function parameters ...........................105

2.10.1 Retry function (Pr. 66 , Pr. 67 , Pr. 68 , Pr. 69 )........................................105

2.10.2 PWM carrier frequency and long wiring mode (Pr. 70 , Pr. 72 )................107

2.10.3 Voltage input selection (Pr. 73 )................................................................108

2.10.4 Input filter time constant (Pr. 74 )..............................................................109

2.10.5 Reset selection/PU stop selection (Pr. 75 )...............................................109

2.10.6 Cooling fan operation selection (Pr. 76 )...................................................111

2.10.7 Parameter write disable selection (Pr. 77 )...............................................112

2.10.8 Reverse rotation prevention selection (Pr. 78 ).........................................113

2.10.9 Operation mode selection (Pr. 79 ) ...........................................................113

2.10.10PID control (Pr. 88 to Pr. 94 )...................................................................117

CONTENTS

2.11 Auxiliary pa ra meters.................. ................ ........................... 1 2 4

2.11.1 Slip compensation (Pr. 95 , Pr. 96 , Pr. 97 )..............................................124

2.11.2 Automatic torque boost selection (Pr. 98 )................................................125

III

Page 9

2.11.3 Motor primary resistance (Pr. 99 ) ............................................................ 126

2.12 Maintenance parameters......................................................126

2.12.1 Maintenance output function (H1, H2 )..................................................... 126

2.12.2 Current average value monitor signal (H3, H4, H5)..................................127

2.13 Brake parameters (FR-S520E-0.4K to 3.7K only)...............130

2.13.1 Regenerative braking operation (b1 , b2 )................................................130

2.14 Calibration parameters.........................................................131

2.14.1 Meter (frequency meter) calibration (C1 )................................................. 131

2.15 Clear param e te r s... .. ................ ............... ................ ...............134

2.15.1 Parameter clear (CLr )..............................................................................134

2.15.2 Alarm history clear (ECL )......................................................................... 134

2.16 Communicatio n p a ra me t e rs ... ............... .. ................ .............135

2.16.1 Communication settings (n1 to n7 , n11 )................................................137

2.16.2 Operation and speed command source (n8 , n9 ) ....................................152

2.16.3 Link startup mode selection (n10 )............................................................ 153

2.16.4 E2PROM write selection (n12 )................................................................. 155

2.17 Parameter un it (FR-PU04) sett in g.................. ............... ... ....156

2.17.1 PU display language selection (n13 ) .......................................................156

2.17.2 PU buzzer control (n14 )........................................................................... 156

2.17.3 PU contrast adjustment (n15 ).................................................................. 157

2.17.4 PU main display screen data selection (n16 )...........................................157

2.17.5 Disconnected PU detection /PU setti ng lock sel ec tio n (n17 )....................158

3. PROTECTIVE FUNCTIONS 159

3.1 Errors (A l a rms).. ............... ............... ................ ............... .......160

3.1.1 Error (alarm) definitions............................................................................ 161

3.1.2 To know the operating status at the occurrence of alarm

(only when FR-PU04 is used)................................................................... 169

3.1.3 Correspondence between digital and actual characters........................... 169

3.1.4 Resetting the inverter................................................................................ 169

3.2 Troubleshooting....................................................................170

3.2.1 Motor remains stopped............................................................................. 170

3.2.2 Motor rotates in opposite direction............................................................ 171

3.2.3 Speed greatly differs from the setting.......................................................171

3.2.4 Acceleration/deceleration is not smooth................................................... 171

3.2.5 Motor current is large................................................................................171

IV

Page 10

3.2.6 Speed does not increase...........................................................................171

3.2.7 Speed varies during operation ..................................................................171

3.2.8 Operation mode is not changed properly..................................................172

3.2.9 Operation panel display is not operating...................................................172

3.2.10 Parameter write cannot be performed.......................................................172

3.2.11 Motor produces annoying sound...............................................................172

4. SPECIFICATIONS 173

4.1 Specifi c a tion list. .. ................ ............... ................ ............... ...174

4.1.1 Ratings......................................................................................................174

4.1.2 Common specifications.............................................................................178

4.2 Outline drawings ...................................................................180

APPENDIX 183

APPENDIX 1 Parameter Instruction Code List .............................184

CONTENTS

V

Page 11

1. WIRING

This chapter explains the basic "wiring" for use of this product. Always

read the instructions before use.

For description of "installation", refer to the instruction manual (basic).

1.1 Standard connection diagram and terminal

specifications .....................................................

1.2 Main c ir c u it te r m i n a ls .......... ............... ............... 6

1.3 How to use the control circuit terminals.......... 25

1.4 Input terminals.................................................... 28

1.5 How to use the input signals (assigned

terminals RL, RM, RH, STR) ..............................

1.6 Connection to the Stand-Alone Option............ 42

1.7 Handling of the RS-485 connector...................... 46

1.8 Design information............................................. 50

<Abbreviations>

•PU

Operation panel and parameter unit (FR-PU04)

•Inverter

Mitsubishi transistorized inverter FR-S500 series

•FR-S500

Mitsubishi transistorized inverter FR-S500 series

•Pr.

Parameter number

2

37

Chapter 1

Chapter 2

Chapter 3

Chapter 4

1

Page 12

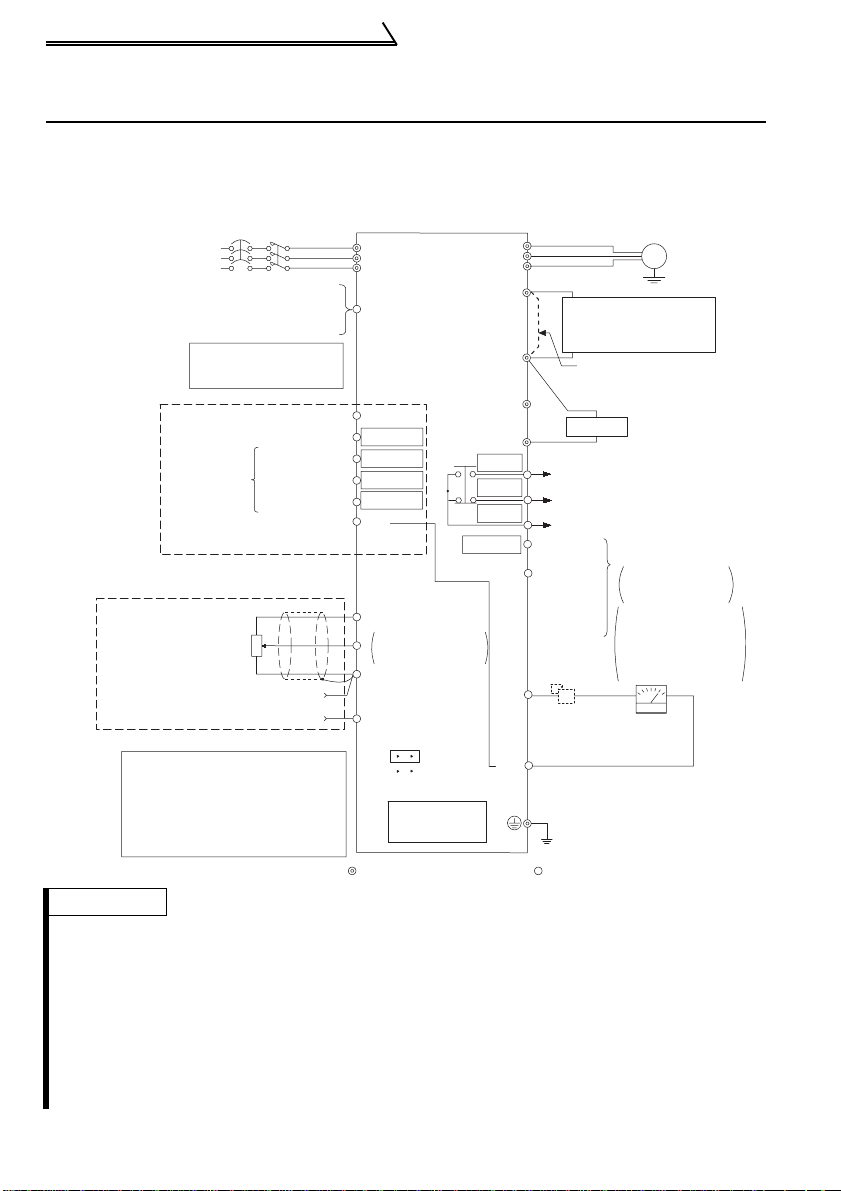

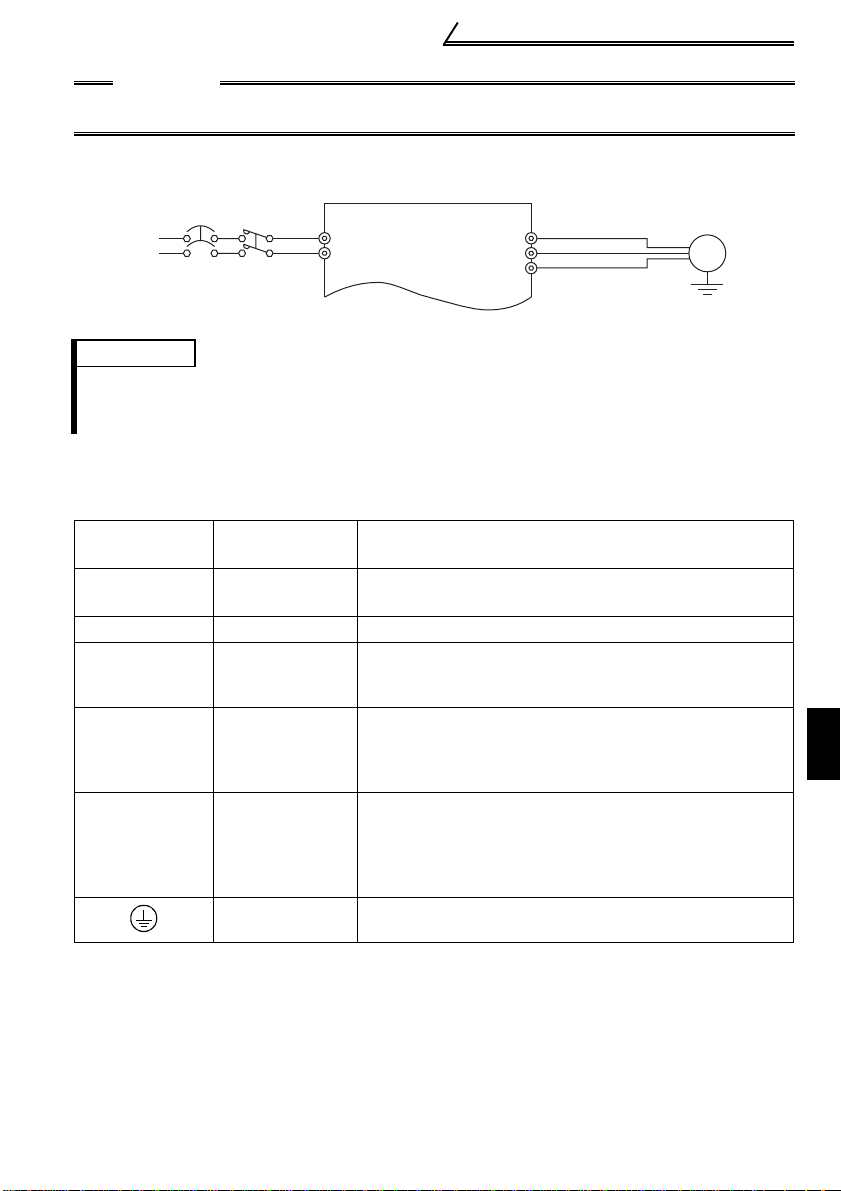

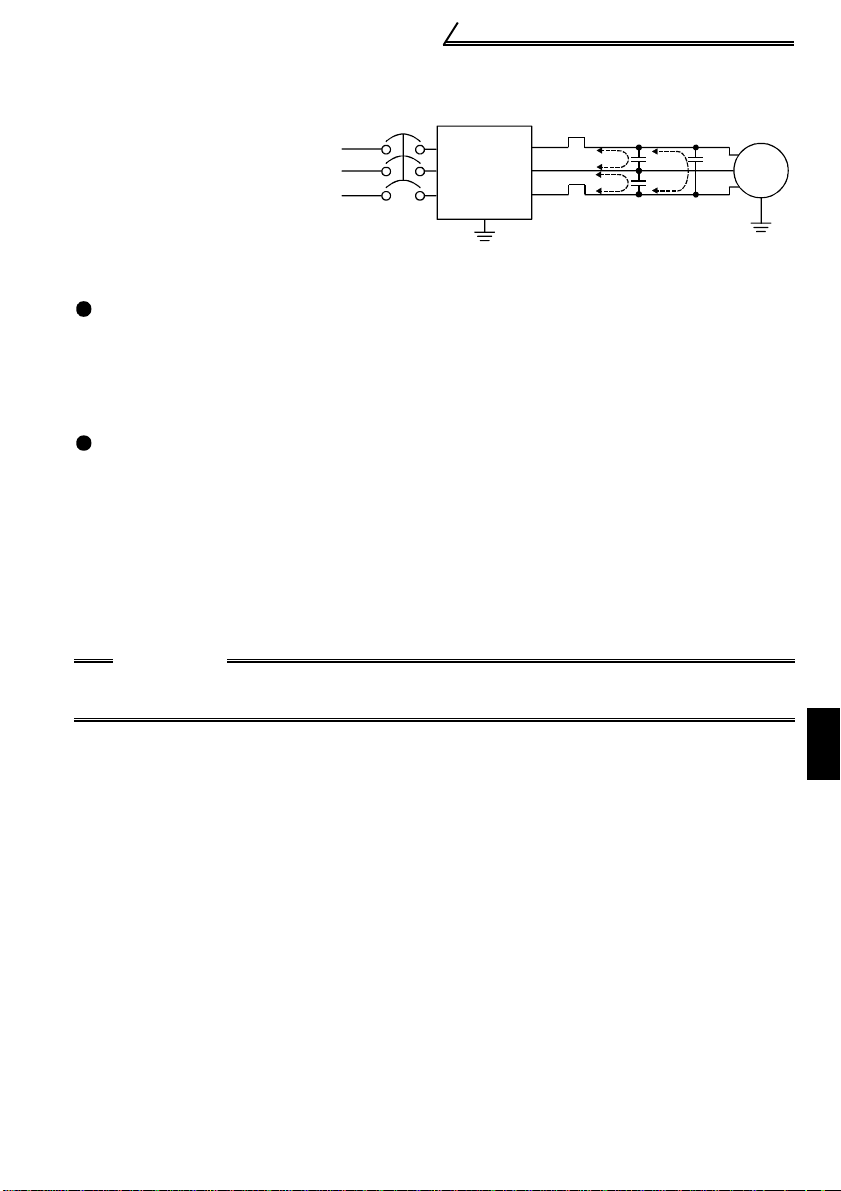

Standard connection diagram and terminal specifications

Inverter

Motor

IM

U

V

W

RUN

SE

Running

Alarm output

Operation status

output

Open

collector

Open collector

outputs

A

B

C

Frequency setting

potentiometer

1/2W1kΩ

Frequency setting signals (Analog)

10

2

2

3

1

4 to 20mADC(+)

4

0 to 5VDC

0 to 10VDC

5

Current input(-)

(+5V)

(Common)

(4 to 20mADC)

Selected

output

common

Low speed

RL

NFB MC

Power factor improving

DC reactor

(FR-BEL: Option)

Jumper:

Remove this

jumper when FR-BEL

is connected.

P1

SINK

SOURCE

Multi-speed

selection

Take care not to short

terminals PC-SD.

RS-485

Connector

Three-phase AC

power supply

Control circuit terminalMain circuit terminal

When using the current input as

the frequency setting signal, set

"4" in any of Pr. 60 to Pr. 63 (input

terminal function selection), assign

AU (current input selection) to any

of terminals RH, RM, RL and STR

and turn on the AU signal.

Control input

signals

(No voltage

input allowed)

STF

STR

RM

Forward rotation start

Reverse rotation start

Middle speed

High speed

RH

*3

FM

SD

(+)

Calibration

resistor

(-)

Earth (Ground)

R

Brake resister

Earth

(Ground)

External transistor common

24VDC power supply

Contact input common (source)

SD

PC

Contact input common

Indicator

1mA full-scale

Analog meter

(Digital indicator)

*6

*4

*6

*6

*6

*7

*7

*7

*7

*1

*2

*5

PR

R/L1

S/L2

T/L3

P/+

N/-

1.1 Standard connection diagram and terminal specifications

1.1.1 Standard connection diagram

Three-phase 200V power input

Three-phase 400V power input

REMARKS

*1. The N/- terminal is not provided for the FR-S520E-0.1K to 0.75K.

*2. The PR terminal is provided for the FR-S520E-0.4K to 3.7K.

*3. Not needed when the setting dial is used for calibration.

Used when calibration must be made near the frequency meter for such a reason as a remote frequency meter.

However, the frequency meter needle may not deflect to full-scale if the calibration resistor is connected.

In this case, use this resistor and setting dial together.

*4. You can switch the position of sink and so urce logic. Refer to page 26.

*5. When the setting potentiometer is used frequently, use a 2W1kΩ potentiometer.

*6. The terminal functions change with input terminal function selection (Pr . 60 to Pr . 63). (Refe r to page 102.)

(RES, RL, RM, R H, R T, AU, STOP, MRS, OH, REX, JO G, X14, X16, (STR) si gna l s elec tion )

*7. The terminal function changes according to the setting of output terminal function selection (Pr. 64, Pr. 65).

(Refer to page 104.) (RUN, SU, OL, FU, R Y, Y12, Y13, FDN, FUP, RL, Y93, Y95, LF, ABC signal selectio n)

2

Page 13

Standard connection diagram and terminal specifications

1

WIRING

CAUTION

To prevent a mal function d ue to nois e, keep the signa l cable s mor e than 10 cm away

from the power cables.

Single-phase 200V power input

Single-phase 100V power input

Power

supply

MC

R/L1

S/L

U

2

V

W

Motor

IM

Earth (Ground)

NFB

REMARKS

•To ensure safety, connect the power input to the inverter via a magnetic contactor and earth leakage

circuit breaker or no-fuse breaker, and use the magnetic contactor to switch power on-off.

•The output is three-phase 200V.

1.1.2 Explanation of main circuit terminals

(1) Main circu it

Terminal

Symbol

R/L1, S/L2,

T/L3 (*1)

U, V, W Inverter output

P/+, PR (*2)

P/+, N/−

P/+, P1

*1. When using single-phase power in put , te rm inals are R/L1 and S/L2.

*2. The PR terminal is provided for the FR-S520E-0.4K to 3.7K.

Terminal Name Description

AC power input

Brake resistor

connection

Brake unit

connection

Power factor

improving DC

reactor

connection

Earth (ground)

Connect to the com m erc i al pow er supply.

Connect a three-ph ase squirrel-cage motor.

Connect the optional brake resistor (MRS/MYS typ e, FR ABR) (The brake resi st or can be connected to the FRS520E-0.4K to 3.7K only.)

Connect the brake un it (BU), power regeneration

common converter (FR-CV) or high power factor

converter (FR-HC) . (The N/- terminal is not provided for

the FR-S520E-0.1K to 0.75 K. )

Remove the jumper across terminals P - P1 and connect

the option al power factor i m proving DC reac t or (FRBEL(-H)).

(The single-phase 10 0V power input model cannot be

connected.)

For earthing (groun di ng) th e i nve rt er chassis. Must be

earthed (grounded).

3

Page 14

Standard connection diagram and terminal specifications

(2) Control circuit

Symbol Terminal Name Definition

Turn on the STF signal to

start forward rota t i on and

turn it off to stop.

Turn on the STR signal to

start rev erse rotat i on and

turn it off to stop.

Turn on the RH, RM and RL signals in

appropriate combinations to select

multiple speeds.

The priorities of the spee d com m ands

are in order of jog, multi-speed setting

(RH, RM, RL, REX) and AU.

Common to the contact input terminals (STF, STR, RH, RM,

RL) and terminal FM. (*6)

When connecting the transistor output (open collector output),

such as a programmable controller (PLC), connect the positive

external power supply for transistor output to this terminal to

prevent a malfunction caused by undesirable currents.

This terminal can be used as a 24VDC, 0.1A power output

across terminals PC-SD.

When source logic has been selected, this terminal serves

as a contact input common.

5VDC, Permissible l oa d current 10mA.

Inputting 0 to 5VDC (or 0 to 10V) provides the maximum output

frequency at 5 V (10 V) and makes input and ou tput p ropor tion al.

Switch between 5V and 10V using Pr. 73 "0-5V , 0-10V selection".

Input resistance 10kΩ. Maximum permissible input voltage 20V

Input 4 to 20mADC. It is factory set at 0Hz for 4mA and at

60Hz for 20mA.

Maximum permiss ib le in put current 30mA. Input resistanc e

approximately 250Ω.

Turn ON signal AU for current inpu t .

Turning the AU signal on makes voltage input invalid. Use any of

Pr. 60 to Pr. 63 (input terminal function selection) to set the AU

signal.

Frequency setting signal (terminal 2, 4) common terminal.

(*6)

Input signals

STF

STR

RH

Contact input

RM

RL

SD

(*1)

PC

(*1)

10

Frequency setting

5

Forward rotation

start

Reverse rotation

start

Multi-speed

selection

Contact input

common (sink)

External

transistor

common, 24VDC

power supply,

contact input

common (source)

Frequency setting

power supply

Frequency setting

2

(voltage signal)

Frequency setting

4

(current signal)

Frequency setting

input common

When the STF and STR

signals are turned on

simultaneously, the stop

command is given.

The terminal

functions change

with input terminal

function selection

(Pr. 64, Pr.65).

(*3)

4

Page 15

Standard connection diagram and terminal specifications

1

WIRING

Symbol Terminal Name Definition

Changeover contact output indicates

A

BCAlarm output

Inverter

RUN

running

Open collector

Open collect or

SE

Output signals

common

FM For meter

Indicator

that the inverter protective function has

activate d and the output stopped.

230VAC 0.3A, 30VDC 0.3A. Alarm:

discontinuity across B-C (continuity

across A-C), Normal: continuity across

B-C (discontinuity ac ro ss A- C ) .(*5)

Switched low when the inverter output

frequency is equal to or higher than the

starting frequency (f actory set to 0.5Hz

variable). Switched high during stop or

DC injection brake ope ra tion. (*2)

Permissible load 24VDC 0. 1A (a

voltage drop is 3.4V maximum when

the signal is on)

Common terminal fo r inv er te r r unn in g t er m in al RU N .

The output signal across terminals FM-SD is factory set to about

1mA at 60Hz and is proportional to the corresponding output

frequency. Since output voltage is pulse shape, a digital meter

can be connected.

Frequency permissi ble load current 1mA

Pulse specification 1440 pulses/s at 60Hz

The function of the

terminals changes

according to the

output terminal

function selection

(Pr. 64, Pr.65).

(*4)

(*6)

Using the parameter unit connection cable (FR-CB201 to

205), the parameter unit (F R-PU04) can be connected.

Communication op er at io n can be performed using RS- 485.

For details of RS-485 comm unication, refer to page 47.

——

RS-485

connector

Communication

*1. Do not co nnect terminals SD and PC eac h ot her or to the earth (ground).

For sink logic (factory setting), terminal SD acts as the com m on terminal of contact in pu t.

For source log ic, terminal PC acts as the commo n terminal of contact input. (Re fer to

page 26 for switching meth od.)

*2. Low ind icates that the open collector outpu t transistor is on (conducts). High in dicates

that the transistor is off (does not conduct).

*3. RL, RM, RH, RT, AU, STOP, MRS, OH, REX, JOG, RES, X14, X16, (STR) signal

selection (Refer to page 10 2. )

*4. RUN, SU, OL, FU, RY, Y12, Y 13, FDN, FUP, RL , Y93, Y95, LF, ABC signal selec tion

(Refer to page 104.)

*5. To be compliant with the European Directive (Low Voltage Directive), the operating

capacity of relay outputs (A, B, C) s hould be 30VDC 0.3A.

*6. Terminals SD, SE and 5 are isolated from each other. Do not earth (gro und) .

5

Page 16

Main circuit terminals

r

P1

Motor

Jumper

U V W

IM

Power supply

R/L1 S/L2

P/+

PR

T/L3

1.2 Main circuit terminals

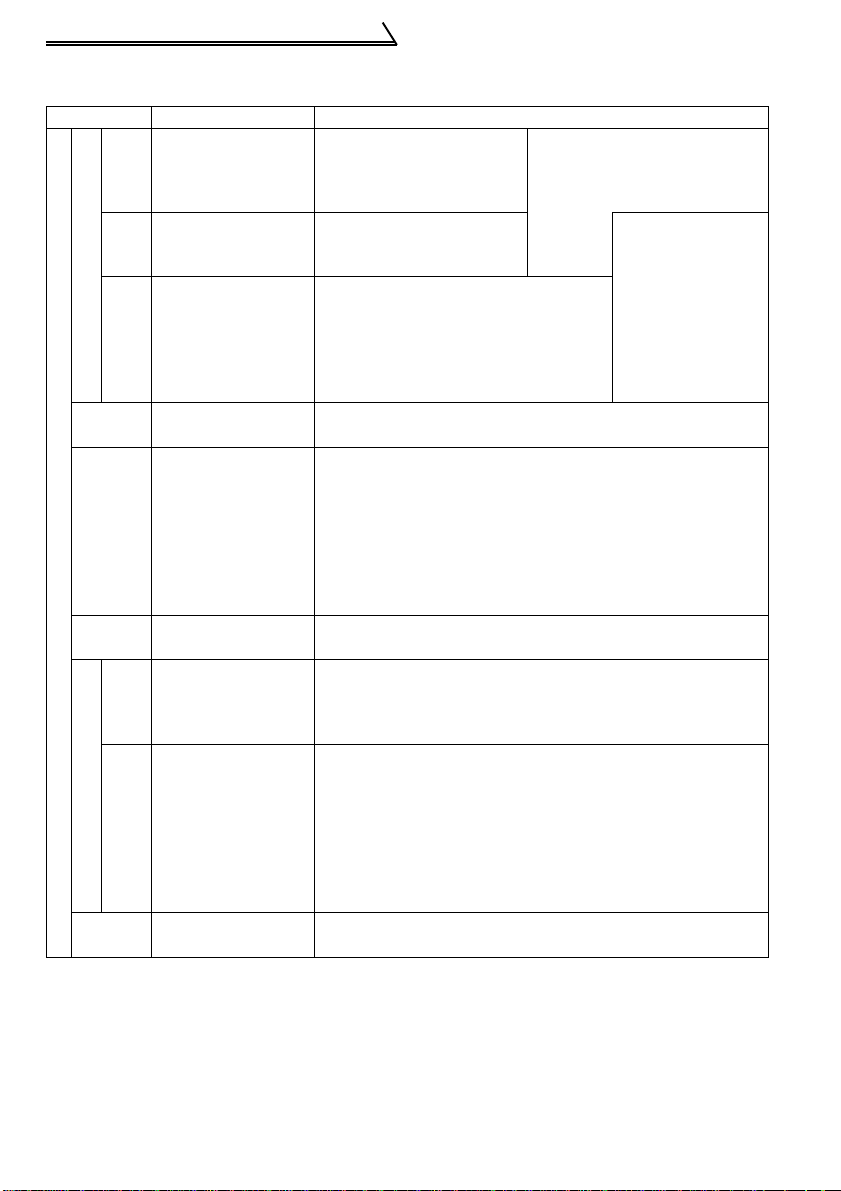

1.2.1 Terminal block layout

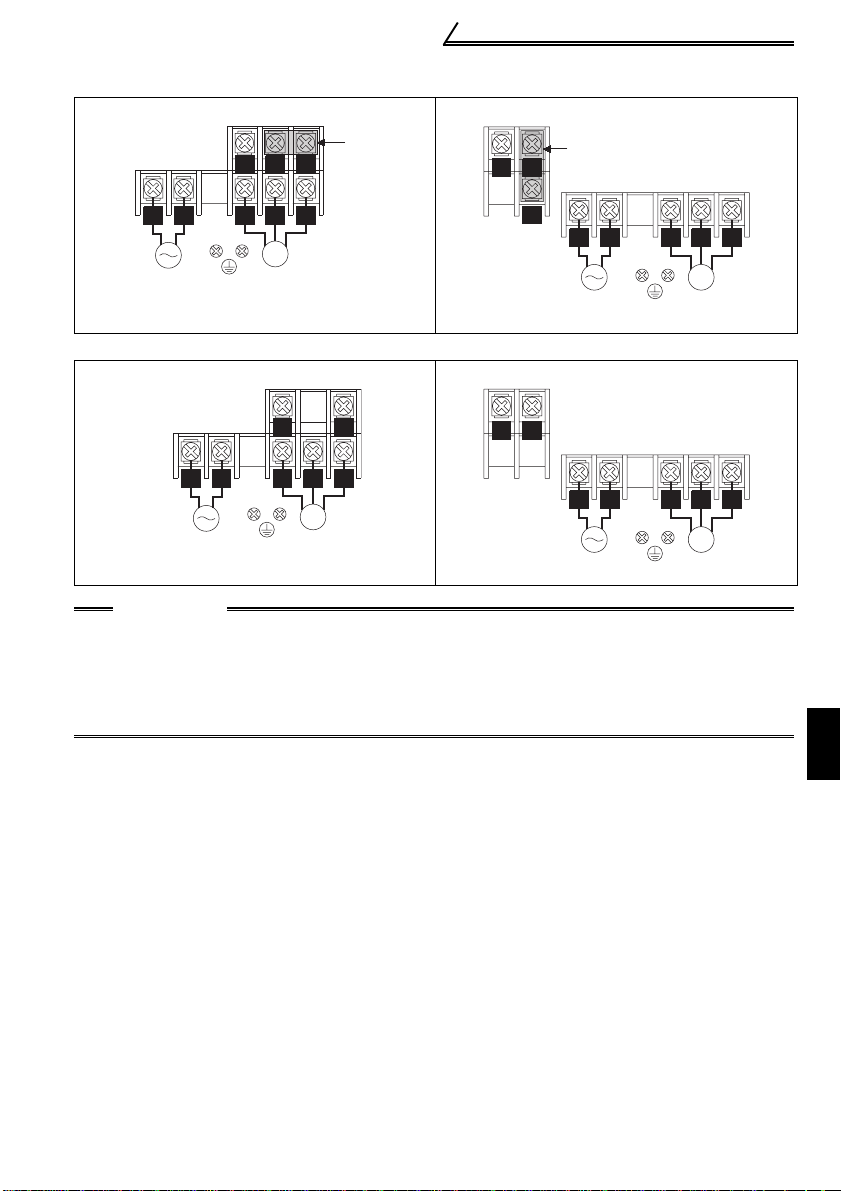

1)Three-phase 200V power input

• FR-S520E-0.1K, 0.2K (-C) • FR-S520E-1.5K, 2.2K, 3.7K (-C)

Jumpe

P/+

P1

R/L1 S/L2 T/L3

Power supply

U V W

IM

Motor

• FR-S520E-0.4K, 0.75K (-C)

2)Three-phase 400V power input

• FR-S540E-0.4K, 0.75K, 1.5K, 2.2K, 3.7K (-C)

N/-

PR

P/+

P1

Jumper

R/L1 S/L2 T/L3

Power supply

U V W

IM

Motor

N/-

Jumper

P/+

P1

R/L1 S/L2 T/L3

Power supply

U V W

IM

Motor

6

Page 17

1

WIRING

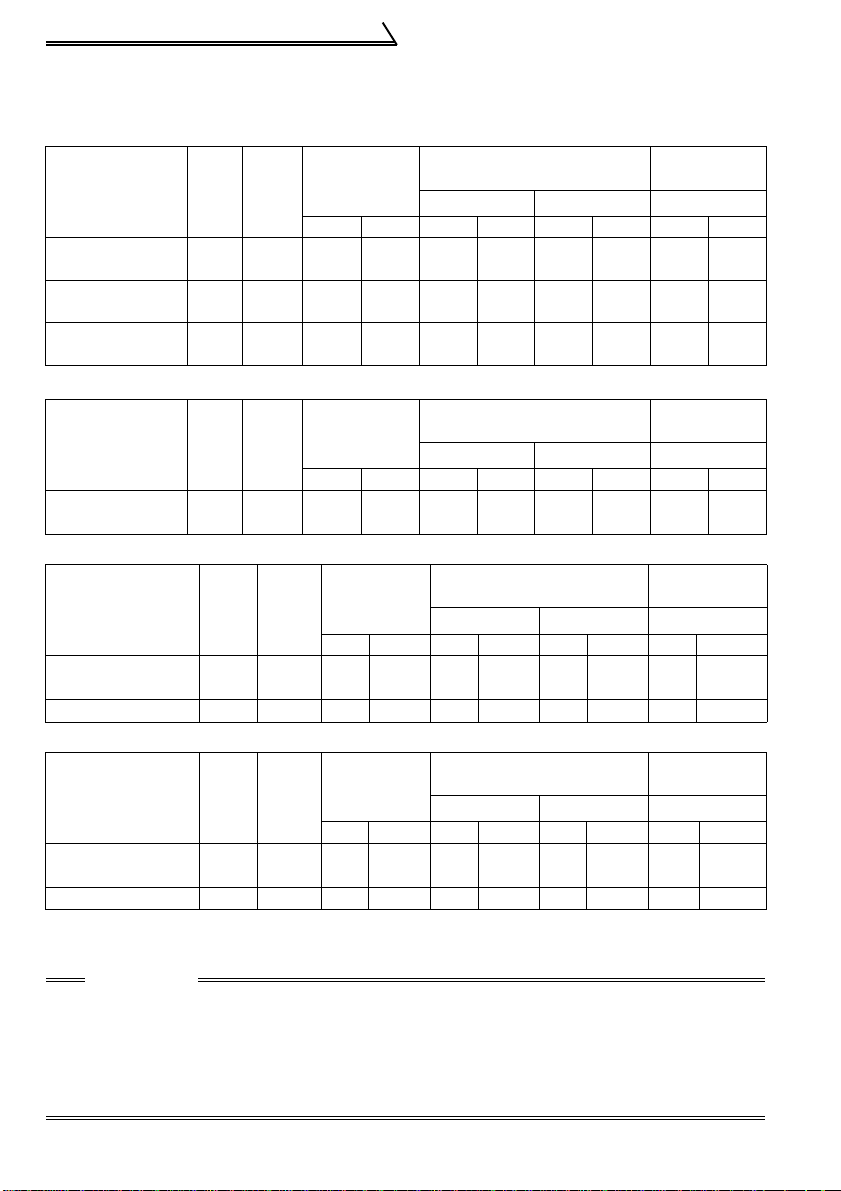

3)Single-phase 200V power input

r

• FR-S520SE-0.1K, 0.2K, 0.4K, 0.75K • FR-S520SE-1.5K

N/-

P1

P/+

N/-

Jumpe

Jumper

P/+

Main circuit terminals

R/L1 S/L2

Power supply

U V W

IM

Motor

P1

R/L1 S/L2

Power supply

U V W

IM

Motor

4)Single-phase 100V power input

• FR-S510WE-0.1K, 0.2K, 0.4K • FR-S510WE-0.75K

R/L1 S/L2

Power supply

P/+N/-

U V W

IM

Motor

N/-

P/+

R/L1 S/L2

Power supply

U V W

IM

Motor

CAUTION

•Make sure the power cables are connected to the R/L1, S/L2, T/L3 of the inverter.

Never connect the power cable to the U, V, W of the inverter. (Phase need not be

matched)

•Connect the motor to U, V, W. At this time, turning on the forward rotation switch

(signal) rotates the motor in the counterclockwise direction when viewed from the

motor shaft.

7

Page 18

Main circuit terminals

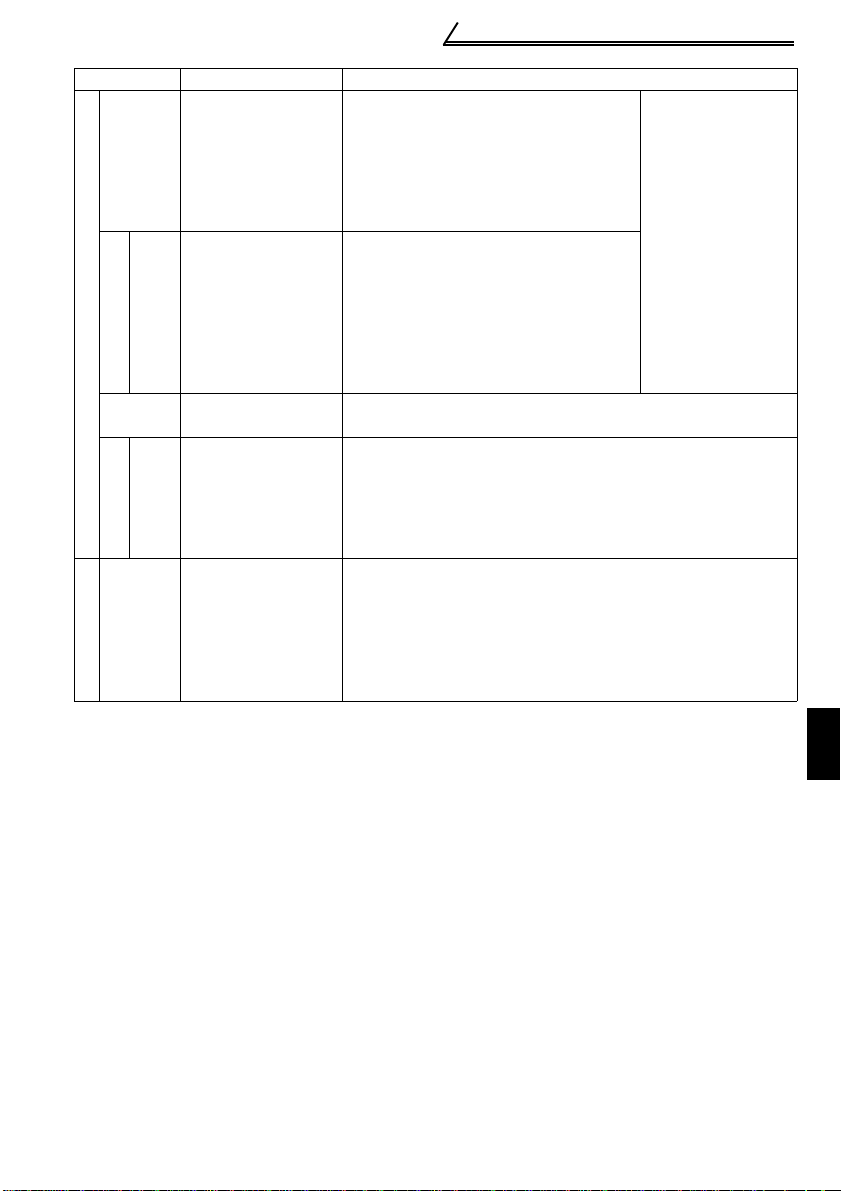

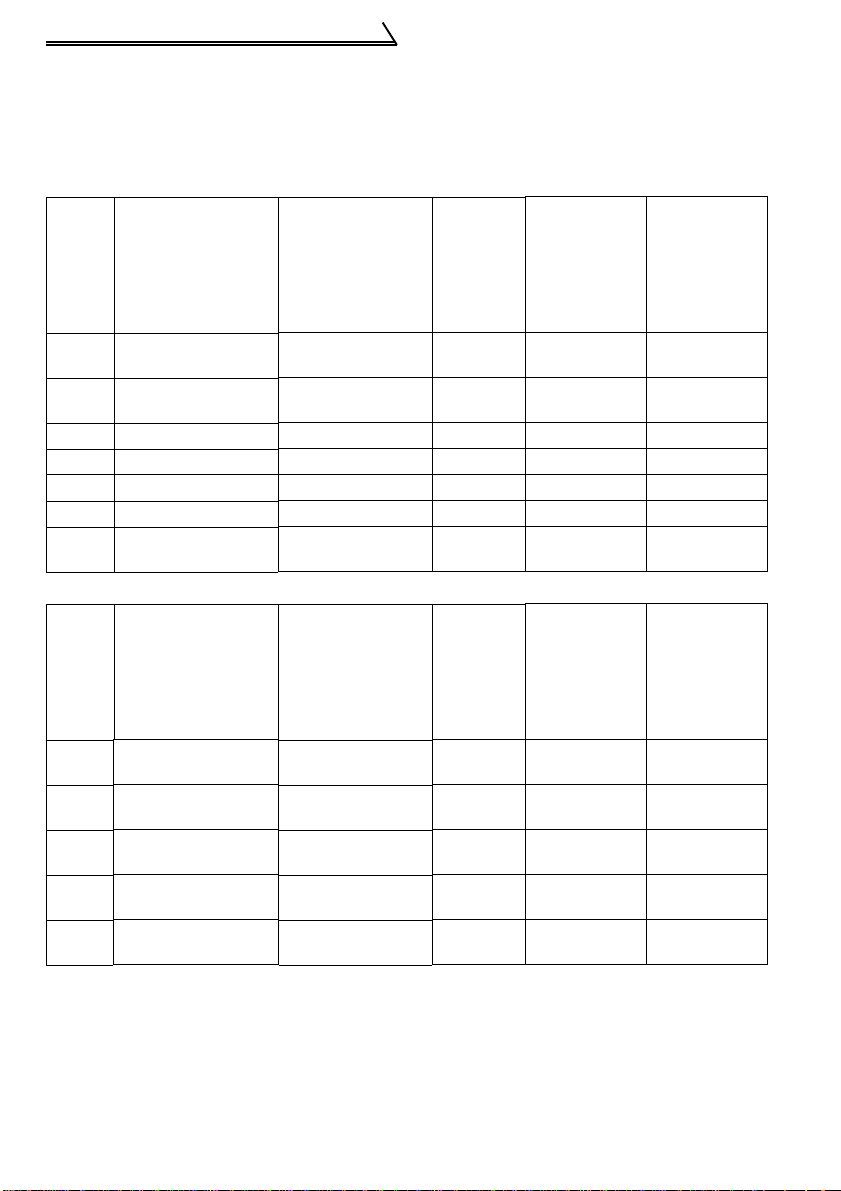

1.2.2 Cables, wiring length, and crimping terminals

The following table indicates a selection example for the wiring length of 20m.

1) Three-phase 200V power input

U, V, W

PVC Insulation

Cable

2

mm

R, S, T

U, V, W

PVC Insulation

Cable

2

mm

PVC Insulation

Cable

2

mm

PVC Insulation

Cable

2

mm

Ter-

Applied Inverter

FR-S520E-0.1K

to 0.75K (-C)

FR-S520E-

1.5K, 2.2K (-C)

FR-S520E-3.7K

(-C)

Tight-

minal

ening

Screw

Torque

size

N

M3.5 1.2 2-3.5 2-3.5 2 2 14 14 2.5 2.5

M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

M4 1.5 5.5-4 5.5-4 3.5 3.5 12 12 4 2.5

⋅

m

R, S, T U, V, W

Crimping

Terminal

R, S, T

mm

Cable

2

U, V, W

AWG

R, S, T

2) Three-phase 400V power input

Ter-

Applied Inverter

FR-S540E-0.4K

to 3.7K

Tight-

minal

ening

Screw

Torque

size

N

M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

Crimping

Terminal

⋅

m

R, S, T U, V, W R, S, T U, V, W R, S, T U, V, W R, S, T U, V, W

mm

2

Cable

AWG

3) Single-phase 200V power input

Applied Inverter

FR-S520SE-0.1K

to 0.75K

FR-S520SE-

1.5K

Termi-

Screw

Tight-

nal

ening

Torque

size

M3.5 1.2 2-3.5 2-3.5 2 2 14 14 2.5 2.5

N

M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

⋅

m

Crimping

Terminal

U, V, W U, V, W U, V, W U, V, W

mm

2

Cable

AWG

4) Single-phase 100V power input

Applied Inverter

FR-S510WE-

0.1K

to 0.4K

FR-S510WE-0.75K

Termi-

Screw

Tight-

nal

ening

Torque

size

M3.5 1.2 2-3.5 2-3.5 2 2 14 14 2.5 2.5

N

M4 1.5 5.5-4 2-4 3.5 2 12 14 4 2.5

Crimping

Terminal

⋅

m

R, S U, V, W R, S U, V, W R, S U, V, W R, S U, V, W

mm

2

Cable

AWG

Wiring length

100m maximum. (50m maximum for the FR-S540E-0.4K.)

CAUTION

•When the wiring length of the 0.1K and 0.2K of the three-phase 200V, singlephase 200V, and single-phase 100V class and 0.4K and 0.75K of the threephase 400V class is 30m or more, set the carrier frequency to 1kHz.

•When automatic torque boost is selected in Pr. 98 "automatic torque boost

selection (motor capacity)", the wiring length should be 30m maximum. (Refer

to page 125.)

8

Page 19

Main circuit terminals

1

WIRING

1.2.3 Wiri ng instructions

1) Use insulation-sleeved crimping terminals for the power supply and motor cables.

2) Application of power to the output terminals (U, V, W) of the inverter will damage the

inverter. Never perform such wiring.

3) After wiring, wire offcuts must not be left in the inverter.

Wire offcuts can cause an alarm, failure or malfunction. Always keep the inverter

clean.

When drilling a control box etc., take care not to let wire offcuts enter the inverter.

4) Use cables of the recommended size to make a voltage drop 2% maximum.

If the wiring distance is long between the inverter and motor, a main circuit cable

voltage drop will cause the motor torque to decrease especially at the output of a

low frequency.

5) For long distance wiring, the high response current limit function may be reduced or

the devices connected to the secondary side may malfunction or become faulty

under the influence of a charging current due to the stray capacity of wiring.

Therefore, note the maximum overall wiring length.

6) Electromagnetic wave interference

The input/output (main circuit) of the inverter includes high frequency components,

which may interfere with the communication devices (such as AM radios) used near

the inverter. In this case, install a FR-BIF(-H) optional radio noise filter (for use on

the input side only) or FR-BSF01 or FR-BLF line noise filter to minimize

interference.

7) Do not install a power capacitor, surge suppressor or radio noise filter (FR-BIF(-H)

option) on the output side of the inverter.

This will cause the inverter to trip or the capacitor and surge suppressor to be

damaged. If any of the above devices are connected, remove them. (When using

the FR-BIF(-H) radio noise filter with a single-phase power supply, connect it to the

input side of the inverter after isolating the T phase securely.)

8) Before starting wiring or other work after the inverter is operated, wait for at least 10

minutes after the power supply has been switched off, and check that there are no

residual voltage using a tester or the like. The capacitor is charged with high

voltage for some time after power off and it is dangerous.

9

Page 20

Main circuit terminals

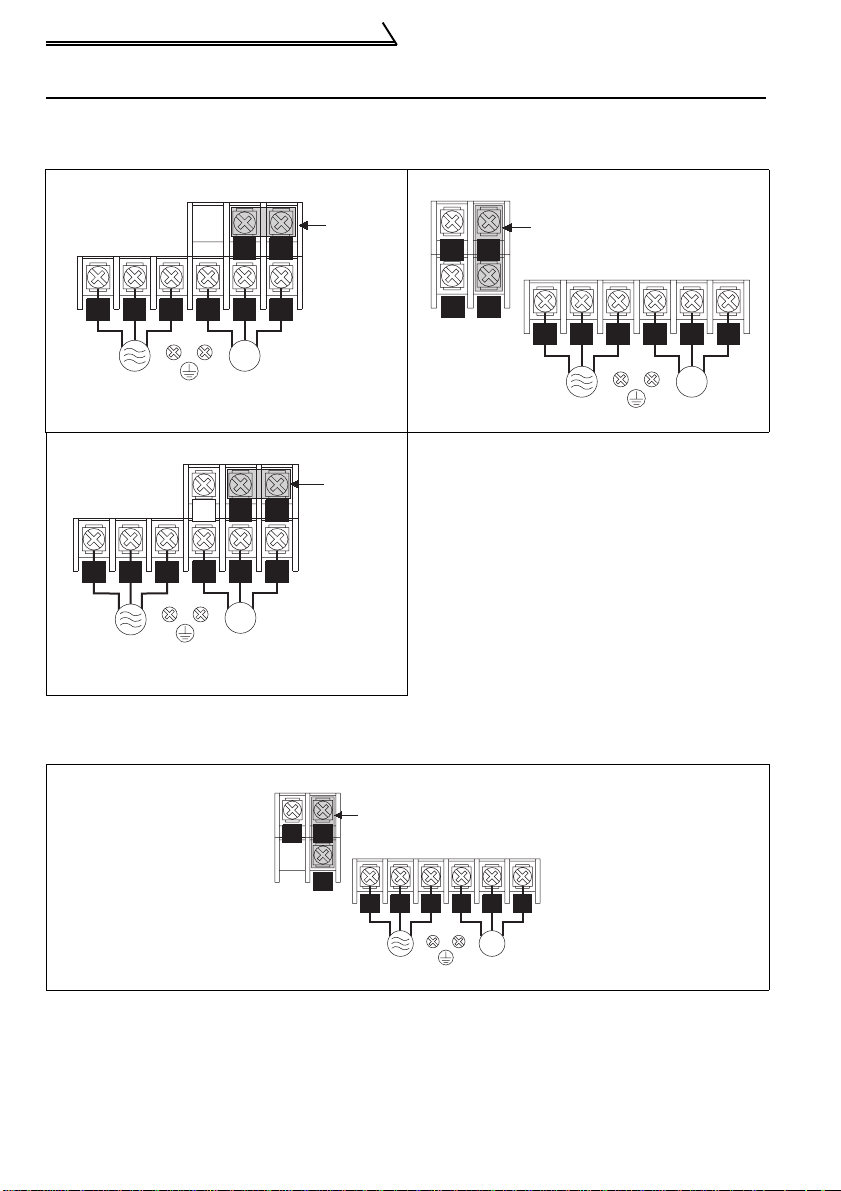

1.2.4 Selection of peripheral devices

Check the capacity of the motor applicable to the inverter you purchased. Appropriate

peripheral devices must be selected according to the capacity.

Refer to the following list and prepare appropriate peripheral devices:

1) Three-phase 200V power input

No-fuse Breaker

Motor

Output

(kW)

Applied Inverter

Type

(NFB *1, 4) or

Earth Leakage

Circuit Breaker

(ELB) (Refer to

page 12) (*2, 4)

0.1 FR-S520E-0.1K(-C) 30AF/5A S-N10

0.2 FR-S520E-0.2K(-C)

0.4 FR-S520E-0.4K(-C)

0.75 FR-S520E-0.75K(-C)

30AF/5A S-N10

30AF/5A S-N10 FR-BAL-0.4K FR-BEL-0.4K

30AF/10A S-N10 FR-BAL-0.75K FR-BEL-0.75K

1.5 FR-S520E-1.5K(-C) 30AF/15A S-N10 FR- BAL- 1.5K FR-BEL-1.5K

2.2 FR-S520E-2.2K(-C)

3.7 FR-S520E-3.7K(-C)

30AF/20A S-N10 FR- BAL- 2.2K FR-BEL-2.2K

30AF/30A

2) Three-phase 400V power input

No-fuse Breaker

Motor

Output

(kW)

Applied Inverter

Type

(NFB *1, 4) or

Earth Leakage

Circuit Breaker

(ELB) (Refer to

page 12) (*2, 4)

0.4

0.75

1.5

2.2

3.7

FR-S540E-0.4K

FR-S540E-0.75K

FR-S540E-1.5K

FR-S540E-2.2K

FR-S540E-3.7K

30AF/5A S-N10

30AF/5A S-N10

30AF/10A S-N10

30AF/15A S-N10

30AF/20A

Magnetic

Contactor

(MC)

(Refer to

page 16 )

S-N20,

S-N21

Magnetic

Contactor

(MC)

(Refer to

page 16)

S-N20,

S-N21

Power Factor

Improving AC

Reactor

(Refer to page

17)

FR-BAL-0.4K

(*3)

FR-BAL-0.4K

(*3)

FR-BAL-3.7K FR-BEL-3.7K

Power Factor

Improving AC

Reactor

(Refer to page

17)

FR-BAL-

H0.4K

FR-BAL-

H0.75K

FR-BAL-

H1.5K

FR-BAL-

H2.2K

FR-BAL-

H3.7K

Power Factor

Improving DC

Reactor

(Refer to page

17)

FR-BEL-0.4K

(*3)

FR-BEL-0.4K

(*3)

Power Factor

Improving DC

Reactor

(Refer to page

17)

FR-BEL-

H0.4K

FR-BEL-

H0.75K

FR-BEL-

H1.5K

FR-BEL-

H2.2K

FR-BEL-

H3.7K

10

Page 21

1

WIRING

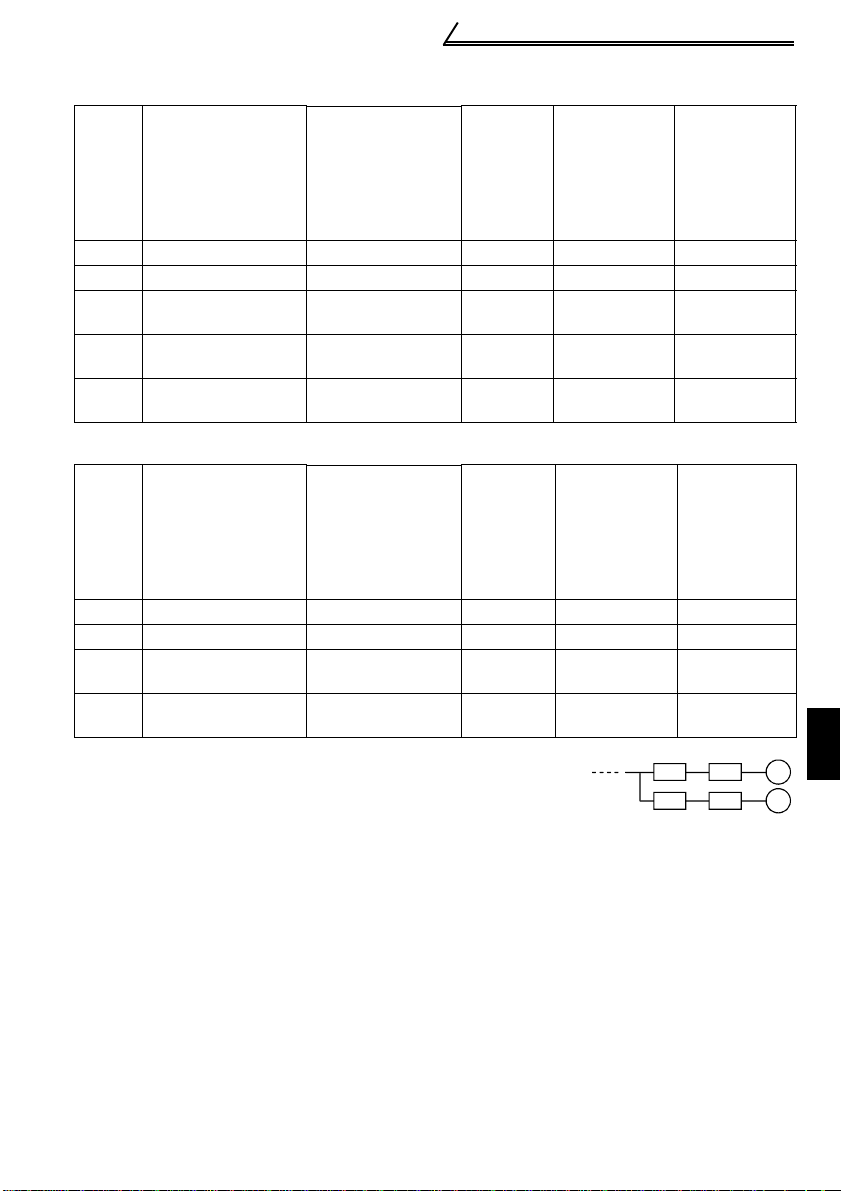

3) Single-phase 200V power input

No-fuse Breaker

Motor

Output

(kW ))

Applied Inverter

Type

(NFB *1, 4) or

Earth Leakage

Circuit Breaker

(ELB) (Refer to

page 12) (*2, 4)

0.1

FR-S520SE-0.1K 30AF/5A S-N10 FR-BAL-0.4K FR-BEL-0.4K

0.2

FR-S520SE-0.2K

0.4

FR-S520SE-0.4K

0.75

FR-S520SE-0.75K

1.5

FR-S520SE-1.5K

30AF/10A S-N10 FR- BAL- 0.4 K FR-BEL-0.4K

30AF/10A

30AF/15A

30AF/20A

4) Single-phase 100V power input

No-fuse Breaker

Motor

Output

(kW )

Applied Inverter

Type

(NFB *1, 4) or

Earth Leakage

Circuit Breaker

(ELB) (Refer to

page 12) (*2, 4)

0.1

FR-S510WE -0.1K

0.2

FR-S510WE -0.2K

0.4

FR-S510WE -0.4K

0.75

FR-S510WE-0.75K

30AF/10A S-N10 FR-BAL-0.75K

30AF/15A S-N10 FR-BAL-1.5K

30AF/20A

30AF/30A

Magnetic

Contactor

(MC)

(Refer to

page 16)

S-N20,

S-N21

S-N20,

S-N21

S-N20,

S-N21

Magnetic

Contactor

(MC)

(Refer to

page 16)

S-N20,

S-N21

S-N20,

S-N21

Main circuit terminals

Power Factor

Improving AC

Reactor

(Refer to page

17) (*3)

FR-BAL-0.75K FR-BEL-0.75K

FR-BAL-1.5K FR-BEL-1.5K

FR-BAL-2.2K FR-BEL-2.2K

Power Factor

Improving AC

Reactor

(Refer to page

17) (*3)

FR-BAL-2.2K

FR-BAL-3.7K

Power Factor

Improving DC

Reactor

(Refer to page

17) (*3)

Power Factor

Improving DC

Reactor

(Refer to page

17) (*5)

*1. •Select the NFB according to the inverter power

supply capacity.

•Install one NFB per inverter.

NFB

NFB INV

INV

IM

IM

*2. For installations in the United States or Canada, the circuit breaker must be inverse

time or instantaneous trip type.

*3. The power factor may be slightly lower.

*4. When the breaker on the inverter primary side trips, check for the wiring fault (short

circuit), damage to internal parts of the inverter, etc. Identify the cause of the trip,

then remove the cause and power on the breaker.

*5. The sing le-pha se 100V po wer in put model do es not al low the power fact or improv ing

DC reactor to be fitted.

11

Page 22

Main circuit terminals

1.2.5 Leakage current and installation of earth (ground) leakage circuit breaker

Due to static capacitances existing in the inverter I/O wiring and motor, leakage

currents flow through them. Since their values depend on the static capacitances,

carrier frequency, etc., take the following countermeasures.

(1) To-earth (ground) leakage currents

Leakage currents may flow not only into the inverter's own line but also into the

other line through the earth (ground) cable, etc.

These leakage currents may operate earth (ground) leakage circuit breakers and

earth (ground) leakage relays unnecessarily.

Countermeasures

• If the carrier frequency setting is high, decrease the carrier frequency (Pr. 72) of the

inverter.

Note that motor noise increases. Selection of Soft-PWM control (Pr. 70) will make it

unoffending. (Factory setting)

• By using earth leakage circuit breakers designed for harmonic and surge

suppression in the inverter's own line and other line, operation can be performed

with the carrier frequency kept high (with low noise).

12

Page 23

Main circuit terminals

1

WIRING

(2) Line-to-line leakage currents

Harmonics of

leakage currents

flowing in static

capacities between

Power

supply

the inverter output

cables may operate

the external thermal

relay unnecessarily.

Countermeasures

• Use the electronic thermal relay function of the inverter.

• Decrease the carrier frequency. Note that motor noise increases. Selection of

Soft-PWM (Pr. 70) makes it unoffending.

To ensure that the motor is protected against line-to-line leakage currents, it is

recommended to use a temperature sensor to directly detect motor temperature.

Installation and selection of no-fuse breaker

Install a no-fuse breaker (NFB) on the power receiving side to protect the wiring of

the inverter primary side. Select the NFB according to the power supply side power

factor (which depends on the power supply voltage, output frequency and load).

Especially for a completely electromagnetic NFB, one of a slightly large capacity

must be selected since its operation characteristic varies with harmonic currents.

(Check it in the data of the corresponding breaker.) As an earth (ground) leakage

breaker, use the Mitsubishi earth (ground) leakage breaker designed for harmonics

and surge suppression. (Refer to page 8 for the recommended models.)

NFB

Inverter

Line-to-Line Leakage Current Path

Thermal relay

Line static

capacitances

Motor

IM

CAUTION

•Select the NFB according to the inverter power supply capacity.

•Install one NFB per inverter.

13

Page 24

Main circuit terminals

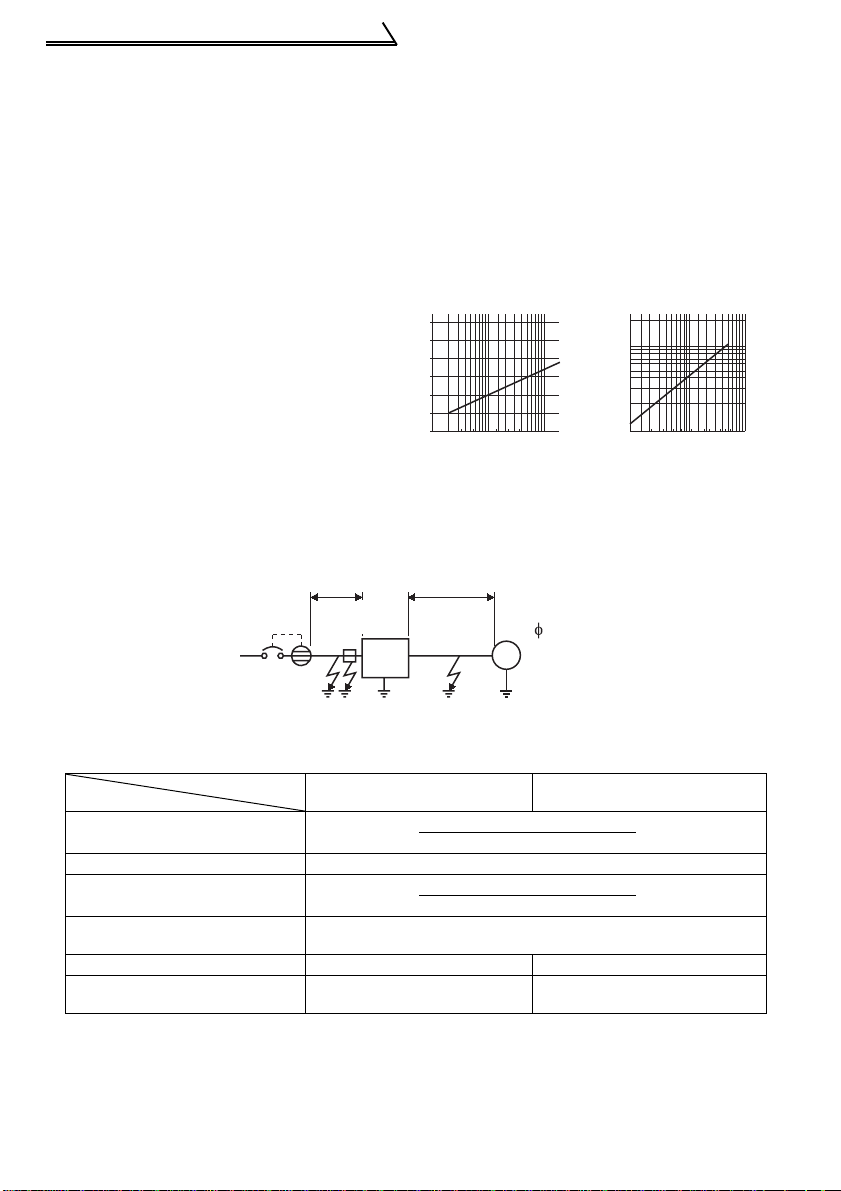

Motor capacity (kW)

Example of leakage

current per 1km in cable

path during commercial

power supply operation

when the CV cable is

routed in metal conduit

Leakage current (mA)

Leakage current (mA)

Cable size (mm)

2

Leakage current

example of three-phase

induction motor

during commercial

power supply

operation

(200V 60Hz)

(200V 60Hz)

0

20

40

60

80

100

120

2 3.5 8 142238 80

5.5 3060100

150

1.5 3 .7

2.2

7.5 15 2 21137

30

55

45

5.5 18.5

2.0

1.0

0.7

0.5

0.3

0.2

0.1

NV

Ig1 Ign Ig2 Igm

2mm ×5m

2mm ×70m

IM

3

200V

1.5kW

Inverter

Noise

filter

22

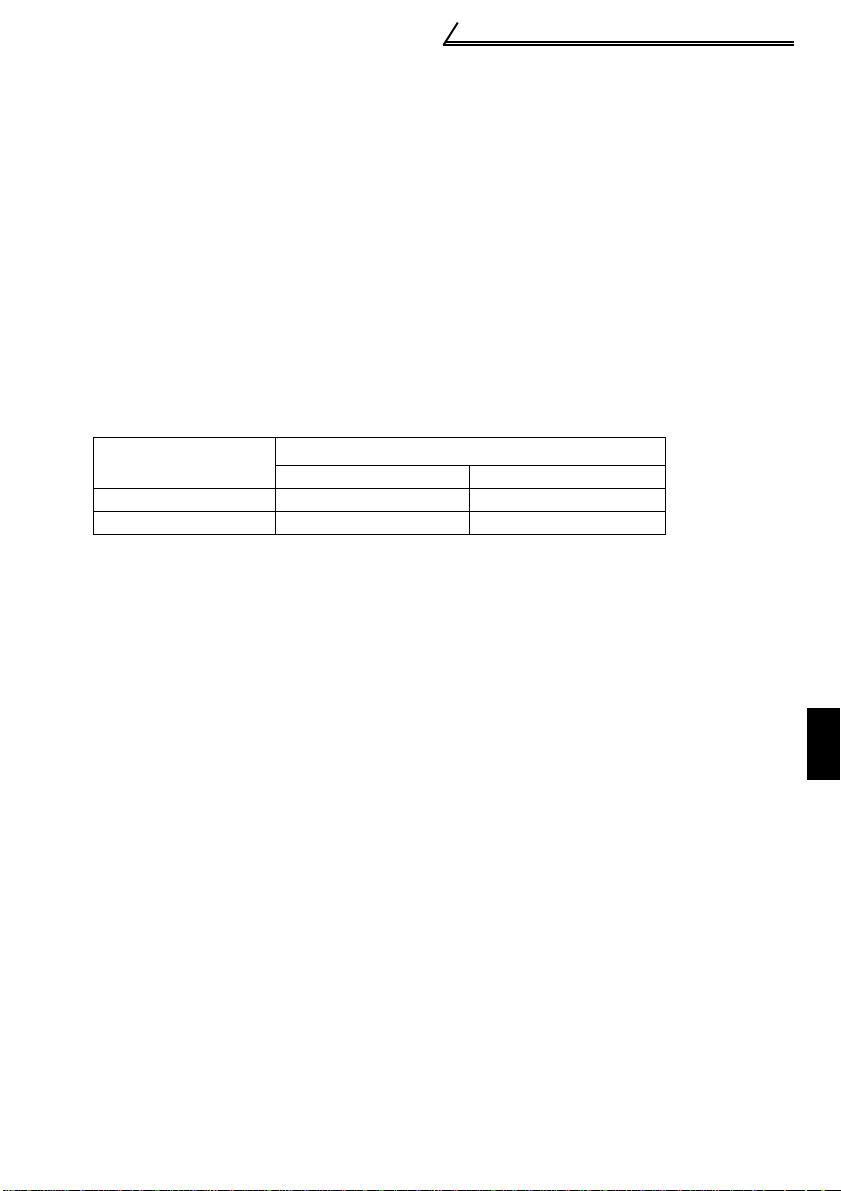

(3) Selecting the rated sensiti vity current f or the earth leakage ci rcuit

breaker

When using the earth leakage circuit breaker with the inverter circuit, select its rated

sensitivity current as follows, independently of the PWM carrier frequency:

• Breaker for harmonic and surge

Rated sensitivity current:

I

∆n ≥ 10 × (lg1+Ign+lg2+lgm)

• Standard breaker

Rated sensitivity current:

I

∆n ≥ 10 × {lg1+lgn+3 × (lg2+lgm)}

lg1, lg2 : Leakage currents of cable

path dur ing commercial

lgn* : Leakage current of noise

lgm : Leakage current of motor

* Note the l eakage current value of the

<Example>

power supply operation

filter on inverter input side

during commercial power

supply operation

noise filter installed on the inverter

input side.

Breaker for harmonic and

surge

Leakage current (Ig1) (mA)

20 ×

5m

1000m

Leakage current (Ign) (mA) 0 (without noise filter)

Leakage current (Ig2) (mA)

Motor leakage

current ( Igm) (mA)

Total leakage current (mA ) 1.66 4.78

Rated sensitivity cu rr ent

(mA) (≥ Ig

× 10)

20 ×

30 100

14

70m

1000m

0.16

Standard breaker

= 0.10

= 1.40

Page 25

Main circuit terminals

1

WIRING

CAUTION

•The earth (ground) leakage circuit breaker should be installed to the primary

(power supply) side of the inverter.

•In the connection neutral point earthed (grounded) system, th e sensitivity

current becomes worse for earth (ground) faults on the inverter secondary

side. Earthing (grounding) must confor m to the requirements of national and

local safety regulations and electrical codes. (JIS, NEC section 250, IEC 536

class 1 and other applicable standards)

•When the breaker is installed on the secondary side of the inverter, it may be

unnecessarily operated by harmonics if the effective value is less than the

rating. In this case, do not install the breaker since the eddy current and

hysteresis loss increase and the temperature rises.

•General products indicate the following models: BV-C1, BC-V, NVB, NV-L, NVG2N, NV-G3NA, NV-2F, earth (ground) leakage relay (except NV-ZHA), NV with

AA neutral wire open-phase protection

The other models are designed for h armonic and surge suppression: NV-C/

NV-S/MN series, NV30-FA, NV50-FA, BV-C2, earth (ground) leakage alarm

breaker (NF-Z), NV-ZHA, NV-H

15

Page 26

Main circuit terminals

r

1.2.6 Power-off and magnetic contactor (MC)

(1) Inverter input side magnetic contactor (MC)

On the inverter's input side, it is recommended to provide an MC for the following

purposes. (Refer to page 10 for selection)

1)To release the inverter from the power supply when the inverter protective function

is activated or the drive becomes faulty (e.g. emergency stop operation)

When cycle operation or heavy-duty operation is performed with an optional brake

resistor connected, overheat and burnout of the electrical-discharge resistor can be

prevented if a regenerative brake transistor is damaged due to insufficient heat

capacity of the electrical-discharge resistor and excess regenerative brake duty.

2)To prevent any accident due to an automatic restart at restoration of power after an

inverter stop made by a power failure

3)To rest the inverter for an extended period of time

The control power supply for inverter is always running and consumes a little power.

When stopping the inverter for an extended period of time, powering off the inverter

will save power slightly.

4) To separate the inverter from the power supply to ensure safe maintenance and

inspection work

The inverter's input side MC is used for the above purpose, select class JEM1038AC3 for the inverter input side current when making an emergency stop during

normal operation.

REMARKS

The MC may be switched on/off to start/stop th e inverter. However, since repeated inrush

currents at power on will shorten the life of the converter circuit (switching life is about 100,000

times), freque nt starts and stops must be avoi ded. Turn on/off the inverter start controlling

terminals (STF, STR) to run/stop the inverter.

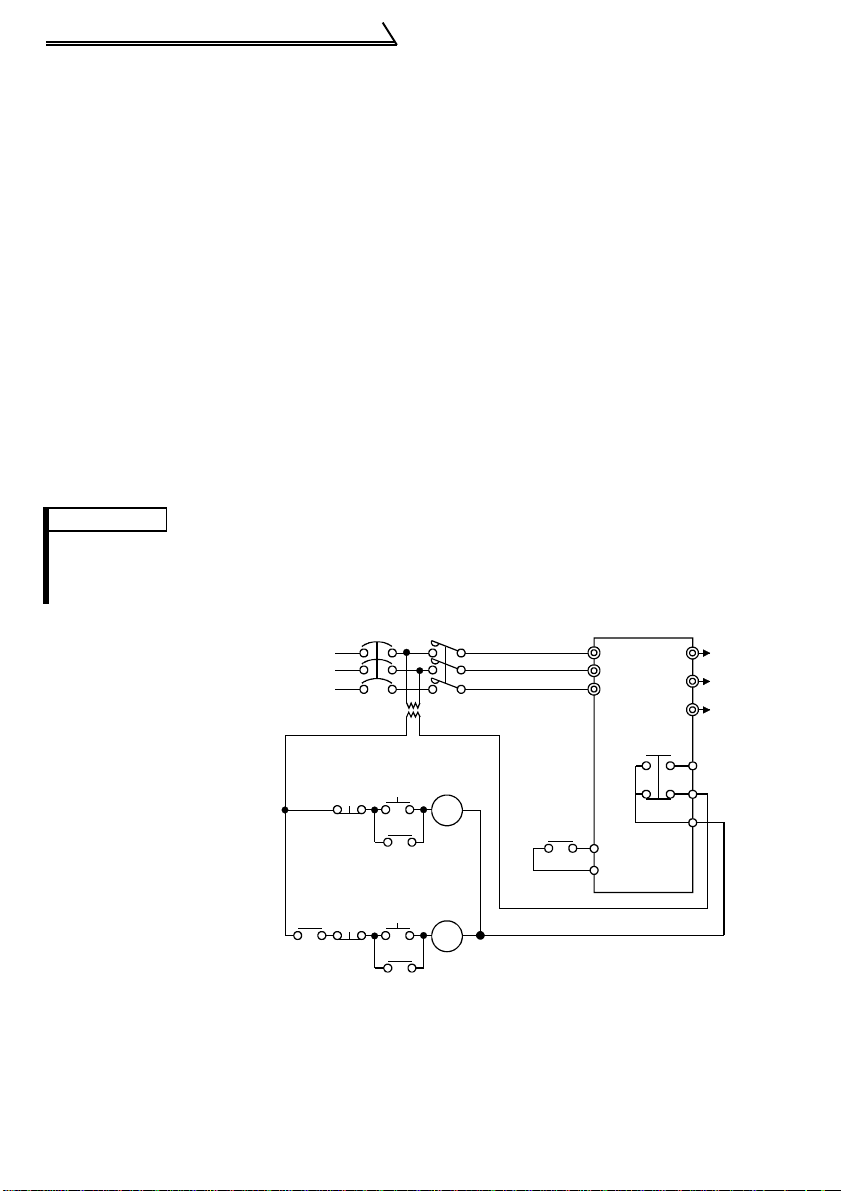

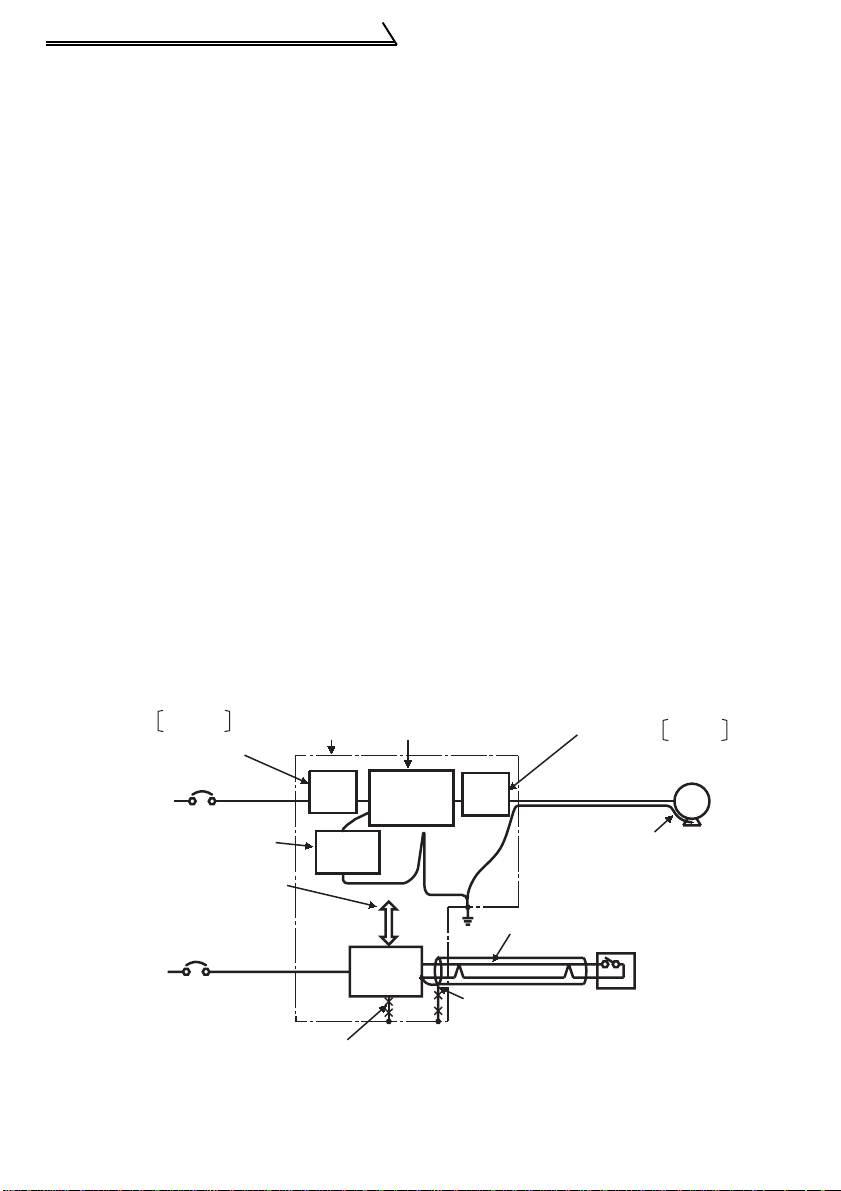

As shown on the right,

always use the start signal

(ON or OFF across

terminals STF or STR-SD)

Power

supply

to make a start or stop.

(Refer to page 28)

*1. When the power supply

is 400V class, install a

step-down transformer.

MC

(2) Handling of output side magnetic contactor

In principle, do not provide a magnetic contactor between the inverter and motor and

switch it from off to on during operation. If it is switched on during inverter operation, a

large inrush current may flow, stopping the inverter due to overcurrent shut-off. When

an MC is provided for switching to the commercial power supply, for example, switch it

on/off after the inverter and motor have stopped.

NFB

Operation ready

OFF

Start/Stop

Operation

OFF

ON

MC

RA

MC

T (*1)

MC

RA

RA

Inverter Start/Stop Circuit Example

R/L1

S/L2

T/L3

Inverter

STF(STR)

SD

W

U

To

V

moto

A

B

C

16

Page 27

Main circuit terminals

1

WIRING

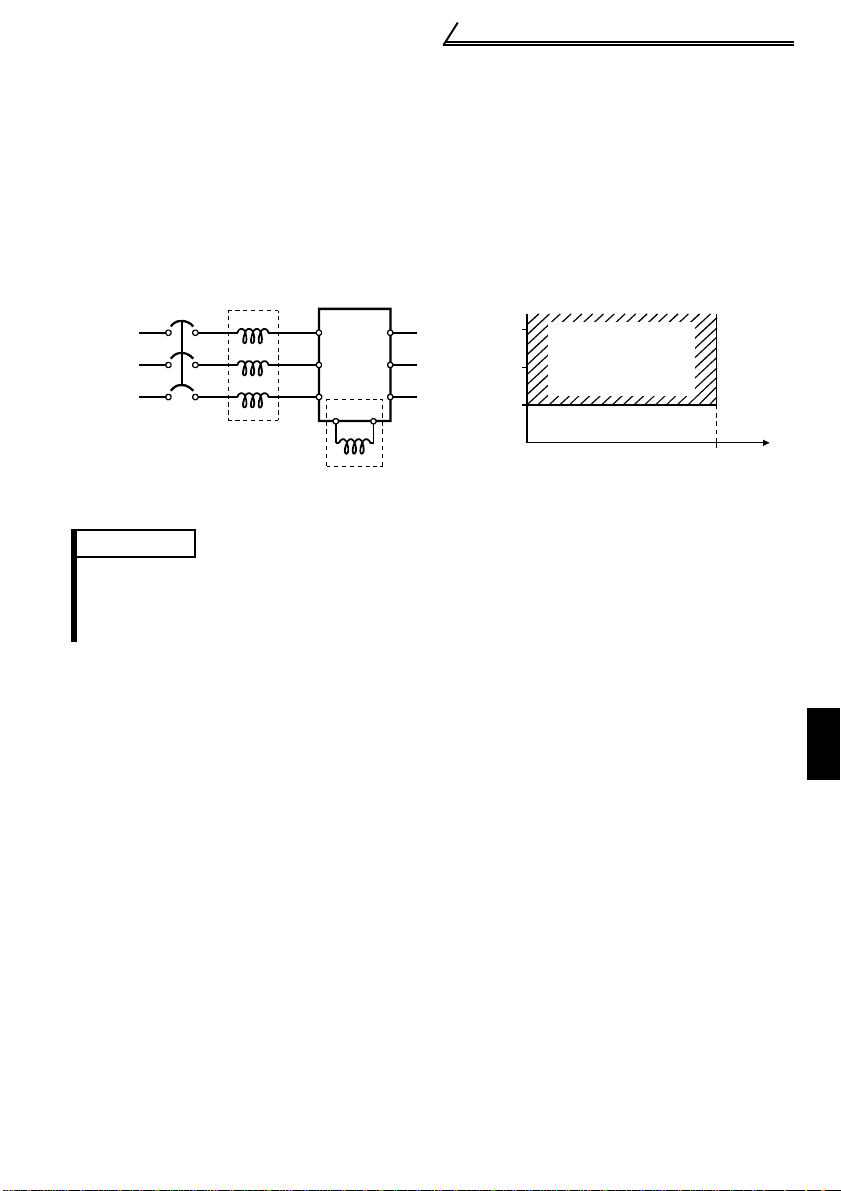

1.2.7 Regarding the installation of the power factor improving reactor

When the inverter is installed near a large-capacity power transformer (500kVA or

more with the wiring length of 10m or less) or the power capacitor is to be switched, an

excessive peak current will flow in the power supply input circuit, damaging the

converter circuit. In such a case, always install the power factor improving reactor (FRBEL(-H) or FR-BAL(-H)).

Power

supply

FR-BAL(-H)

NFB

R

S

TZ

Inverter

X

R

Y

S

T

P

FR-BEL(-H)(*)

P1

W

U

V

1500

1000

500

Power supply equipment

capacity (kVA)

Power factor

improving reactor

installation range

010

Wiring length (m)

REMARKS

*When connecting the FR-BEL(-H), remove the jumper ac ross terminals P- P1.

The wiring lengt h between t he FR-BEL(- H) and the i nverter should be 5m maxim um and as

short as possible.

Use the cables which are equal in size to those of the main circuit. (Refer to page 8)

17

Page 28

Main circuit terminals

1.2.8 Regarding noise and the installation of a noise filter

Some noise enters the inverter causing it to malfunction and others are generated by

the inverter causing the malfunction of peripheral devices. Though the inverter is

designed to be insusceptible to noise, it handles low-level signals, so it requires the

following general countermeasures to be taken.

(1) General countermeasures

• Do not run the power cables (I/O cables) and signal cables of the inverter in parallel

with each other and do not bundle them.

• Use twisted shield cables for the detector connecting and control signal cables and

connect the sheathes of the shield cables to terminal SD.

• Earth (Ground) the inverter, motor, etc. at one point.

• Capacitances exist between the inverter's I/O wiring, other cables, earth (ground)

and motor, through which leakage currents flow to cause the earth leakage circuit

breaker, earth (ground) leakage relay and external thermal relay to operate

unnecessarily. To prevent this, take appropriate measures, e.g. set the carrier

frequency in Pr. 72 to a low value, use an earth (ground) leakage circuit breaker

designed for suppression of harmonics and surges, and use the electronic thermal

relay function built in the inverter.

• The input and output of the inverter main circuit include high-degree harmonics,

which may disturb communication devices (AM radios) and sensors used near the

inverter. In this case, install a FR-BIF(-H) optional radio noise filter (for use on the

input side only) or FR-BSF01 line noise filter to minimize interference.

<Noise reduction examples>

Install filter

on inverter's input side.

Inverter

power supply

Separate inverter and power

line by more than 30cm and

at least 10cm from sensor

circuit.

Control

power supply

FR-BSF01

Install filter FR-BIF

on inverter's input side.

Do not earth (ground)

control box directly.

Do not earth (ground)

control cable.

Control

box

FRBSF01

FR-BIF

Reduce carrier

frequency.

Inverter

Power

supply

for sensor

18

Install filter

on inverter's output side.

FRBSF01

Use 4-core cable for motor

power cable and use one

cable as earth (ground) cable.

Use twisted pair shielded cable.

Do not earth (ground) shield but connect

it to signal common cable.

Sensor

FR-BSF01

IM

Motor

Page 29

Main circuit terminals

1

WIRING

1.2.9 Earthing (Grounding) precautions

Leakage currents flow in the inverter. To prevent an electric shock, the inverter and

motor must be earthed (grounded). Earthing (grounding) must conform to the

requirements of national and local safety regulations and electrical codes.

(JIS, NEC section 250, IEC 536 class 1 and other applicable standards)

Use the dedicated earth (ground) terminal to earth (ground) the inverter. (Do not use

the screw in the casing, chassis, etc.)

Use a tinned* crimping terminal to connect the earth (ground) cable. When

tightening the screw, be careful not to damage the threads.

*Plating should not include zinc.

Use the thickest possible earth (ground) cable. Use the cable whose size is equal to

or greater than that indicated in the following table, and minimize the cable length.

The earthing (grounding) point should be as near as possible to the inverter.

Motor Capacity

2.2kW or less 2 (2.5) 2 (2.5)

3.7kW 3.5 (4) 2 (4)

Earth (Ground) Cable Size (Unit: mm

200V class, 100V class 400V class

2

)

For use as a product compliant with the Low Voltage Directive, use PVC cable

whose size is indicated within parentheses.

Earth (Ground) the motor on the inverter side using one wire of the 4-core cable.

19

Page 30

Main circuit terminals

Inverter

NFB

Do not provide power factor

improving capacit or.

Motor

IM

FR-BEL(-H)

FR-BAL(-H)

FR-BAL

FR-BEL

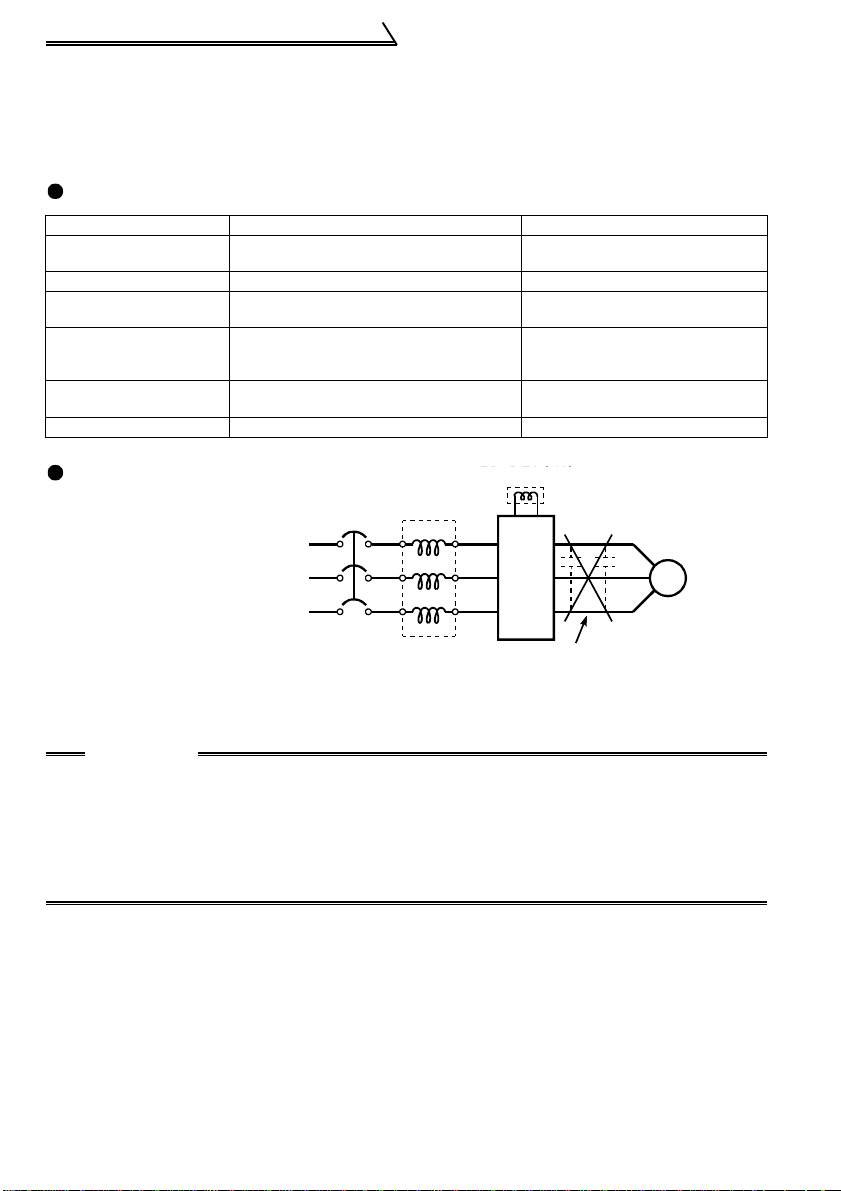

1.2.10 Power supply harmonics

The inverter may generate power supply harmonics from its converter circuit to affect

the power generator, power capacitor etc. Power supply harmonics are different from

noise and leakage currents in source, frequency band and transmission path. T ake the

following countermeasure suppression techniques.

The following table indicates differences between harmonics and noise:

Item Harmonics Noise

Frequency

Environment To-electric channel, power impedance To-space, distance, wiring path

Quantitative

understanding

Generated amount Nea rly proportional t o load capacity

Affected equipment

immunity

Suppression example Provide reactor. Increase distance.

Suppression technique

Harmonic currents produced

on the power supply side by

the inverter change with such

conditions as whether there

are wiring impedances and a

power factor improving reactor

(FR-BEL(-H) or FR-BAL(-H))

and the magnitudes of output

frequency and output current

on the load side.

For the output frequency and output current, we understand that they should be

calculated in the conditions under the rated load at the maximum operating frequency.

CAUTION

The power factor improving capacitor and surge suppressor on the inverter

output side may be overheated or dama ged by the har moni c co mponents of the

inverter output. Also, since a n exces sive c urr ent flows in the inverter to activa te

overcurrent protection, do not provide a capacitor and surge suppressor on the

inverter output side when the motor is driven by the inverter. To improve the

power factor, insert a power factor improving reactor on the inverter's primary

side or DC circuit. For full information, refer to page 17.

Normally 40th to 50th degrees or less

(up to 3kHz or less)

Theoretical calculation possible

Specified in standard per equipment

High frequency (several 10kHz

to 1GHz order)

Random occurrence,

quantitative grasping difficult

Change with current variation

ratio (larger as switching speed

increases)

Different depending on maker's

equipment specifications

20

Page 31

Main circuit terminals

1

WIRING

Not more than

reference capacity

New installation/addition/

renewal of equipment

Calculation of equivalent

capacity sum

Sum of equivalent

capacities

Over reference

capacity

Calculat io n of outgoing

harmonic current

Is outgoing harmonic

current equal to or lower

than maximum valu e?

Not more than

maximum value

Harmonic suppression

technique is not required.

Over maximum value

Harmonic suppression

technique is required.

1.2.11 Harmonic suppression guideline

Harmonic currents flow from the inverter to a power receiving point via a power

transformer. The harmonic suppression guideline was established to protect other

consumers from these outgoing harmonics.

The transistorized inverter has been excluded from the target products covered by

"harmonic suppression guideline for household appliances and general-purpose

products" in January 2004. In addition, all models of transistorized inverter used by

specific consumers are covered by "harmonic suppression guideline for consumers

who receive high voltage or special high voltage" (hereinafter referred to as "guideline

for specific consumers").

"Guideline f or spec ific c ons umers"

This guideline sets forth the maximum values of harmonic currents outgoing from a

high-voltage or spec i all y high-v ol ta ge con sume r who wi ll ins t all , add or rene w harm onic

generating equipment. If any of the maximum values is exceeded, this guideline

requires that c onsume r to t ak e cert ai n supp ressi on me asures .

T able 1 Maximum Values of Outgoing H armonic Curr ent s per 1 kW Contract Power

Received Power Voltage 5th 7th 11th 13th 17th 19th 23rd

6.6 kV 3.5 2.5 1.6 1.3 1.0 0.9 0.76 0.70

22 kV 1.8 1.3 0.82 0.69 0.53 0. 47 0.39 0.36

33 kV 1.2 0.86 0.55 0.46 0.35 0.32 0.26 0.24

(1) Application of the guideline for specific consumers

Over

23rd

21

Page 32

Main circuit terminals

Table 2 Conversion Factors for FR-S500 Series

Circuit Type Conversion Factor (Ki)

Without reactor K31 = 3.4

Three-phase bridge

(Capacitor-smoothed)

Single-phase bridge

(capacitor smoothed)

* K42=0.35 is a value when the reactor value is 20%. Since a 20% reactor is large and

considered to b e not prac tical , K42=1. 67 is wr itte n as c onversi on fa ctor f or a 5% react or in

the technica l data JEM-TR2 01 of the Japan Electric Machin e Industry Associati on and th is

value is recommended for calculation for the actual practice.

With reactor (AC side) K32 = 1.8

With reactor (DC side) K33 = 1.8

With reactors (AC, DC sides) K34 = 1.4

Without reactor K41 = 2.3

With reactor (AC side) K42 = 0.35 *

Table 3 Equivalent Capacity Limits

Received Power Voltage Reference Capacity

6.6kV 50 kVA

22/33 kV 300 kVA

66kV or more 2000 kVA

Table 4 Harmonic Contents (Values of the fundamental current is 100%)

Reactor 5th 7th 11th 13th 17th 19th 23rd 25th

Not used 65 41 8.5 7.7 4.3 3.1 2.6 1.8

Three-phase

bridge

(capacitor

smoothed)

Single-phase

bridge

(capacitor

smoothed)

* The harm onic contents for "single-phase bridge/with reactor" in the table 4 are values when

the reactor val ue is 20%. Since a 20% reactor is lar ge and cons idered to be not pract ical,

harmonic con tents when a 5% reactor is used is writte n in the technical data JEM-TR201 of

the Japan Electric Machine Industry Association and this value is recommended for

calculation for the actual practice.

Used (AC side) 38 14.5 7.4 3.4 3.2 1.9 1.7 1.3

Used (DC side ) or

with filter pack

Used (AC, DC

sides)

Without reactor 50 24 5.1 4.0 1.5 1.4

With reactor (AC

side) *

30 13 8.4 5.0 4.7 3.2 3.0 2.2

28 9.1 7.2 4.1 3.2 2.4 1.6 1.4

6.0 3.9 1.6 1.2 0.6 0.1

1) Calculation of equivalent capacity (P0) of harmonic generating equipment

The "equivalent capacity" is the capacity of a 6-pulse converter converted from the

capacity of consumer's harmonic generating equipment and is calculated with the

following equation. If the sum of equivalent capacities is higher than the limit in

Table 3, harmonics must be calculated with the following procedure:

P0=Σ (Ki × Pi) [kVA]

Ki: Conversion factor (refer to Table 2)

Pi: Input rated capacity of harmonic

generating equipment* [kVA]

i: Number indicating the conversion

circuit type

*Input rated capacity: Determined by

the capacity of the applied motor and

found in Table 5. It should be noted

that the rated capacity used here is

used to calculate a generated

harmonic amount and is different

from the power supply capacity

required for actual inverter drive.

22

Page 33

Main circuit terminals

1

WIRING

2) Calculation of outgoing harmonic current

Outgoing harmonic current = fundamental wave current (value converterd from

received power voltage) × operation ratio × harmonic

content

• Operation ratio: Operation ratio = actual load factor × operation time ratio during

30 minutes

• Harmonic content: Found in Table 4.

Table 5 Rated Capacities and Outgoing Harmonic Currents for Inverter Drive

Applied

Motor

(kW)

0.4 1.61 0.81 49 0.57 14.7 6.37 4.12 2.45 2.30 1.57 1.47 1.08

0.75 2.74 1.37 83 0.97 24.9 10.76 6.97 4.15 3.90 2.66 2.49 1.83

1.5 5.50 2.75 167 1.95 50.10 21.71 14.03 8.35 7.85 5.34 5.01 3.67

2.2 7.93 3.96 240 2.81 72.00 31.20 20.16 12.00 11.28 7.68 7.20 5.28

3.7 13.0 6.50 394 4.61 118.2 51.2 33.10 19.70 18.52 12.61 1 1.82 8.67

Rated

Current [A]

200V 400V 5th 7th 11th 13th 17th 19th 23rd 25th

6.6kV

Equivalent of

fundamental

wave input

current (mA)

Input

rated

capacity

(kVA)

Outgoing Harmonic Current Converted from

6.6kV (mA)

(without reactor, 100% operation ratio)

3) Harmonic suppression technique requirement

If the outgoing harmonic current is higher than; maximum value per 1kW (contract

power) × contract power, a harmonic suppression technique is required.

4) Harmonic suppression techniques

No. Item Description

Reactor inst a llation

1

(ACL, DCL)

Installation of power

2

factor improving

capacitor

Transformer multiphase operation

3

Passive

4

(AC filter)

Active filter This filter detects the current of a circui t generating a harm o nic

5

Install a reactor (ACL) in the AC side of the inverter or a reactor

(DCL) in its DC side or bo th to suppress outgoing harmonic

currents.

When used with a series reactor, the power factor i m proving

capacitor has an effect of absorbing harmonic currents.

Use two transformers with a phase angle difference of 30

∆, ∆-∆ combination to provide an effect corresponding to 12 pulses,

reducing low-degree harmonic currents.

A capacitor and a reactor are used together to reduce impedances

at specific freq u en cies, producing a great effect of abs o rb i n g

harmonic currents.

current and gen erates a ha rmonic cu rrent equ ivalent to a diff erence

between that current and a fundamental wave current to suppress

a harmonic current at a detection poi n t, providing a great effect of

absorbing harmonic currents.

23

° as in -

Page 34

Main circuit terminals

1.2.12 Inverter-driven 400V class motor

In the PWM type inverter, a surge voltage attributable to wiring constants is generated

at the motor terminals. Especially for a 400V class motor, the surge voltage may

deteriorate the insulation. When the 400V class motor is driven by the inverter,

consider the following measures:

•Measures

It is recommended to take either of the following measures:

(1) Rectifying the motor insulation

For the 400V class motor, use an insulation-enhanced motor. Specifically

1) Specify the "400V class inverter-driven, insulation-enhanced motor".

2) For the dedicated motor such as the constant-torque motor and low-vibration

motor, use the "inverter-driven, dedicated motor".

CAUTION

When the wiring length between the motor and inverter is 40m or more, take

the above countermeasure and also set the long wiring mode in Pr. 70 "SoftPWM setting". (Refer to page 107 for Pr. 70.)

(2) Suppressing the surge voltage on the inverter side

On the secondary side of the inverter, connect the optional surge voltage

suppression filter (FR-ASF-H).

24

Page 35

How to use the control circuit terminals

1

WIRING

1.3 How to use the control circuit terminals

1.3.1 Terminal block layout

In the control circuit of the inverter, the terminals are arranged as shown below:

Terminal arrangement

of control circuit

10 2 5 4

RUN

PC SE

A BC

Terminal screw

size: M3

Tightening torque: 0.5N m to 0.6N m

SD SD STF

Wire size: 0.3mm

STR

Terminal screw size: M2

Tightening torque: 0.22N m to 0.25N m

RM RH

RL FM

2

to 0.75mm

2

1.3.2 Wiri ng instructions

1) Terminals SD, SE and 5 are common to the I/O signals isolated from each other. Do

not earth them.

Avoid connecting the terminal SD and 5 and the terminal SE and 5.

2) Use shielded or twisted cables for connection to the control circuit terminals and run

them away from the main and power circuits (including the 200V relay sequence

circuit).

3) The input signals to the control circuit are micro currents. When contacts are

required, use two or more parallel micro signal contacts or a twin contact to prevent

a contact fault.

*Information on bar terminals

Introduced products (as of Oct., 2003): Phoenix Contact Co.,Ltd.

Bar Terminal Model

T erminal Screw Size

(With Insulation