Page 1

INVERTER

FR-D700

Safety stop function instruction manual

CONTENTS

1. General description ............................................................................. 1

2. Installation and wiring ......................................................................... 2

3. Example of safety system configuration ........................................... 5

4. Test and checking failure .................................................................... 8

Page 2

Compliance with the EU Machinery Directive – Functional Safety

DANGER

Any misuse of safety function could lead to personal injury or death, property damage, or economic loss.

To ensure that the system complies fully with requirement of safety, make a system-level risk assessment.

Mitsubishi Electric Co. cannot assume responsibility for any system to comply with safety directive.

ATTENTION

The information of this manual is merely a guide for proper installation.

Mitsubishi Electric Co. cannot assume responsibility for the compliance or the noncompliance to any code,

national, local or otherwise for the proper installation of this equipment.

A hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

DANGER

To avoid an electric shock hazard, verify that the voltage on the bus capacitors has discharged before

performing any work on the drive. Measure the DC bus voltage at the P(+) and N(-) terminals or test points

(refer to your drive’s User Manual for locations and discharging time). The voltage must be zero.

DANGER

The safety stop function do not isolate electrically between drive and motor. To avoid an electric shock

hazard, disconnect/isolate power to the drive and verify to ensure that the voltage is zero before

performing any work on the motor (refer to your drive’s User Manual for discharging time).

ATTENTION

If you are using a FR-D740-EC or FR-D740-CHT with serial number shown below, safety function does not

work according to safety standard. In such case please contact your sales person.

<Europe model : suffixed with ‘-EC’>

D740-012 to 080–EC : Axxxxx, Bxxxxx, Cxxxxx, Dxxxxx, Exxxx and Fxxxxx

D740-120 to 160–EC : Axxxxx, Bxxxxx, Cxxxxx and Dxxxxx

<China model : suffixed with ‘–CHT’>

D740-0.4K to 3.7K–CHT : Axxxxx, Bxxxxx, Cxxxxx, Dxxxxx,Exxxx and Fxxxxx

D740-5.5K to 7.5K–CHT : Axxxxx, Bxxxxx, Cxxxxx and Dxxxxx

Page 3

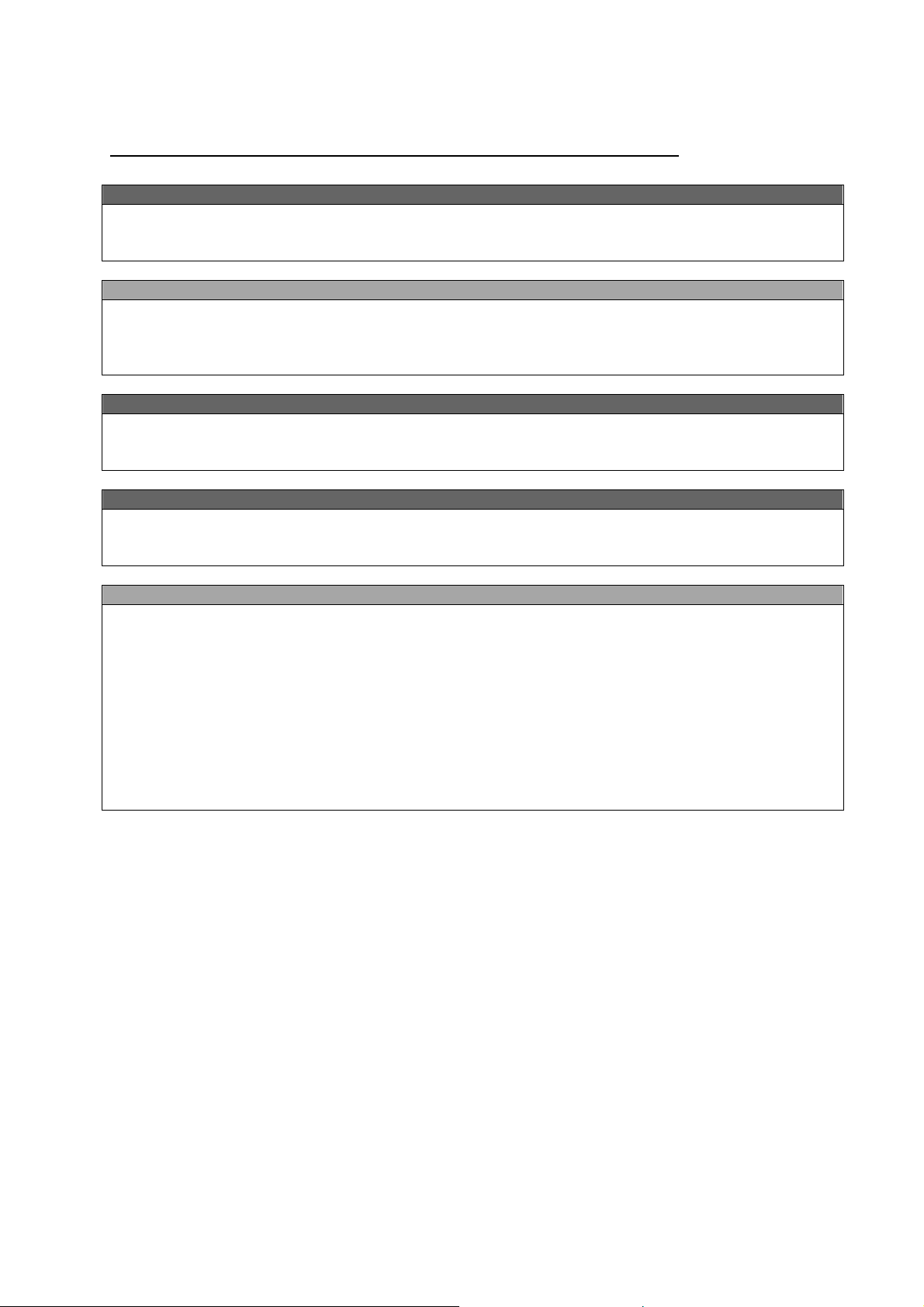

1. General description

Features

Mitsubishi FR-D700 safety stop function prevents a drive from supplying rotational energy to motors.

Dual safety channels ‘S1’ and ‘S2’ cut off the gate-drive power for IGBT to turn off.

S2

FR-D700

S1

SC

CPU

Gate

Driver

Gate

Driver

Fig.1 FR-D700 safety stop function diagram

DANGER

The safety stop function doesn’t isolate electrically between drive and motor. To avoid an electric shock

hazard, disconnect power to the drive and verify that the voltage is zero before performing any work on the

motor (refer to your drive’s User Manual for discharging time).

Directives

Mitsubishi FR-D700 safety stop function meets the following directives and categories.

EN954-1 Category 3

IEC60204-1 Stop category 0

DANGER

The misuse of safety function leads to personal injury or death, property damage, or economic loss.

To ensure that the system complies fully with requirement of safety, make a system-level risk assessment.

Mitsubishi Electric Co. cannot assume responsibility for any system to comply with safety directive.

Input power

IGBTs

M

1

Page 4

2. Installation and wiring

ATTENTION

The following information is merely a guide for proper installation.

Mitsubishi Electric Co. cannot assume responsibility for the compliance or the noncompliance to any code,

national, local or otherwise for the proper installation of this equipment.

A hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

ATTENTION

Ensure the safety relay unit and the D700 unit is mounted closely in enclosure meeting IP54 and all

interconnection wiring is short and protected against open and short circuit faults.

Refer EN/ISO13849-2.

Installation

Mitsubishi FR-D700 safety stop function should be used under following condition and environment.

Table.1 The condition and environment for using safety stop function

Item Condition

Operation -10Cto+50C (non-freezing) Temperature

range

Ambient humidity 90%RH maximum (non-condensing)

Vibration 5.9m/s2 or less

Altitude maximum 1000m above sea level

Atmosphere Indoors (without corrosive gas, flammable gas, dust and dirt etc.)

Over voltage category II or less

Pollution degree II or less

Mounting wall mounting / vertical orientation

In order to meet safety stop, an approved safety relay unit to EN954-1 safety category 3 or better shall be used in

conjunction with D700 as shown in example1,2.

In addition, all other components with in the safety stop loop shall be ‘safety approved’ types.

To avoid an electric shock hazard, insert the magnetic contactor (MC) between power source and drive.

Open the contact of MC and keep away from drive for discharging time (refer to your drive’s User Manual

for information) before performing any work on the drive.

And verify that the voltage on the bus capacitors has discharged before Measure the DC bus voltage at the

P(+) and N(-) terminals or test points (refer to your drive’s User Manual for locations). The voltage must be

zero.

To avoid systematic faults, a test even for faulty demands of the safety function has to be performed in order to check

the correct function of the monitor signal. This test shall be carried out at system installation, any software changes,

parameterization changes, and/or at least once per year.

Refer to ‘4. Test and checking failure’.

Storage -20Cto+65C

ATTENTION

DANGER

ATTENTION

2

Page 5

Wiring

The safety related terminals are described in Table.2 and Table.3

Table.2 The safety related terminals

Terminal

Symbol

S1

S2

SO

SC

RUN

SE

A,C

SD

For input of safety stop channel1.

S1-SC is

Open: In safety stop mode.

Short: Non safety stop mode.

For input of safety stop channel2.

S2-SC is

Open: In safety stop mode.

Short: Non safety stop mode.

As output for safety stop condition.

SO terminal type is ‘Open collector output’.

SO-SC is

OFF(Open) :Drive enabled

ON(Close) :Drive shutoff, no fault

Important: SO terminal should be used for monitoring safety stop

condition only. SO terminal cannot be used for safety function.

Common terminal for S1,S2,SOsignals.

*SC is connected terminal SD internally.

As output for failure detection and alarm. RUN terminal type is ‘Open

collector output’.

RUN-SE is

OFF(Open): Detect failure or Alarm.

ON(Close): No failure detected.

Attention: To use RUN terminal for monitor output of failure

detection, The parameter No.190 should be set 199

(Alarm output).

Note: This terminal can be used for alarm or to prevent restart only,

no other safety function.

Common terminal for safety RUN signal.

As output for failure detection. A,C terminal type is ‘Relay output’.

A-C is

OFF(Open): Detect failure or Alarm.

ON(Close): No failure detected.

Attention: To use A,C terminal for monitor output of failure

detection, The parameter No.192 should be set 199

(Alarm output).

Note: This terminal can be used for alarm or to prevent restart only,

no other safety function.

Signal ground

Description Rating

Input resistance:4.7kOhm

Current : 4 to 6 mA

(In case of shorted to SC)

Voltage : 21 to 26 V

(In case of open from SC)

Load: 24VDC/0.1A max.

Voltage drop: 3.4V max.

(In case of ‘ON’ state)

Load: 24VDC/0.1A max.

Voltage drop: 3.4V max.

(In case of ‘ON’ state)

Load: 30VDC/0.3A max.

Table.3 Truth table of Safety related signals

Input power S1-SC S2-SC Failure SO-SC RUN-SE or A-C Drive state

OFF - - - OFF(Open) OFF(Open) Drive shutoff (Safe state)

No failure OFF(Open) ON(Close) Drive enable

Detected OFF(Open) OFF(Open) Drive shutoff (Safe state)

No failure ON(Close) ON(Close) Drive shutoff (Safe state)

Detected OFF(Open) OFF(Open) Drive shutoff (Safe state)

ON

Short Short

Open Open

Short Open Detected OFF(Open) OFF(Open) Drive shutoff (Safe state)

Open Short Detected OFF(Open) OFF(Open) Drive shutoff (Safe state)

3

Page 6

Wire and ferrule specification

Table.4 wire and ferrule specification

Wire size (mm2) Ferrule with insulation collar * Crimping tool *

0.3 / 0.5 AI 0,5-10WH

0.75 AI 0,75-10GY

1 AI 1-10RD

CRIMPFOX ZA3

1.25 / 1.5 AI1,5-10BK

0.75 (combined 2 wire) AI TWIN 2 X 0,75-10GY

*Ferrules and tools are distributed by Phoenix Contact.

Jumper cable

The jumper cable between S1,S2 and SC terminal has been installed in the factory as shown in Fig.2.

Before connecting safety input wire to S1,S2 and SC terminal, remove this jumper cable.

AMAM

Fig.2. Short wire

4

Page 7

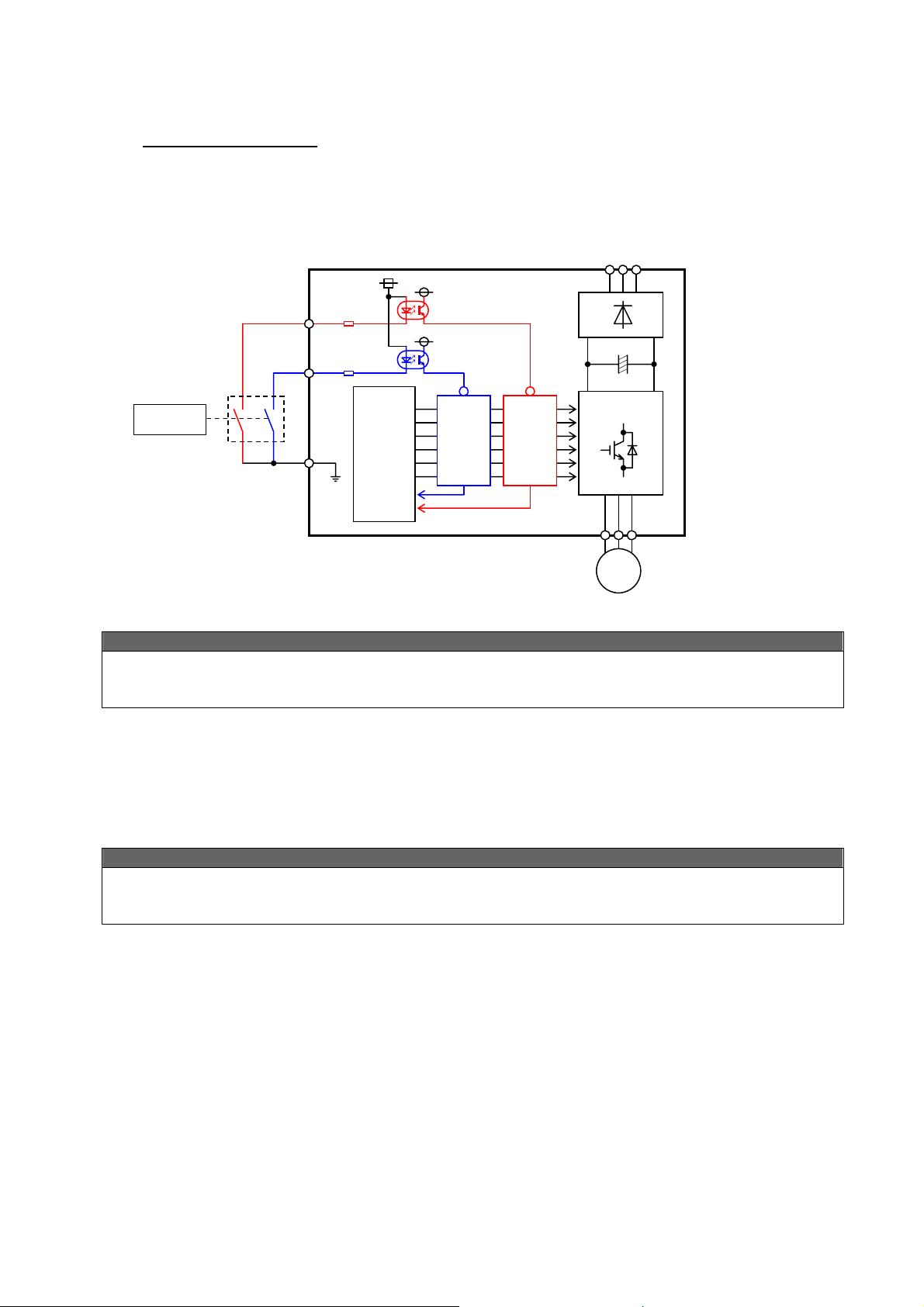

3. Example of safety system configuration

Example 1

EM

START

STOP

STF

+24V

COM0 COM1

X0 X1

XS0 XS1 Z10 Z00 Z20

DC24V

Safety

Logic

Circuit

K1

K2

24G

MITSUBISHI MELSEC Safety relay unit

QS90SR2SN-Q

Z11 Z01 Z21

Fig.3 Safety system example 1 – STOP asynchronous with EM and fault detection through A-C output.

For safety stop, configure the wiring as shown in Fig.3 above.

Note: the above wiring is configured to prevent restart in case of a fault.

The parameter No.192 must be set to ‘199’. This setting makes the A-C output to open in case of failure.

After the power-up, to reset the safety stop mode, press the START switch, and also press the STF switch,

then start the motor rotation.

In the above configuration, after reset of EM switch, drive will be in safe-state until START switch is

pressed.

To prevent restart in case of recovering from input power loss of drive, 3-wired connection for STF/STOP

control is recommended.

In case of 2-wire connection and using latching type switch to short between STF and SD/PC for starting,

ensure the compliance with safety requirement for the restarting when the drive recover from input power

loss.

A

B

C

STF

STOP

PC

S1

S2

SC

RY

SOURCE

ATTENTION

CPU

Gate

Driver

FR-D700

Gate

Driver

RST

IGBTs

UVW

IM

5

Page 8

EM

START

STOP

STF

STF

STOP

PC

S

RT

A

B

C

RY

SOURCE

CPU

Gate

Driver

Gate

Driver

IGBTs

DC24V

+24V

COM0 COM1

X0 X1

Safety

Logic

Circuit

24G

MITSUBISHI MELSEC Safety relay unit

QS90SR2SN-Q

XS0 XS1 Z10 Z00 Z20

K1

K2

STOP

Z11 Z01 Z21

STF

*

*

STF

STOP

PC

S1

S2

SC

FR-D700

A

B

C

RY

SOURCE

CPU

Gate

Driver

Gate

Driver

U V W

IM

RTS

IGBTs

*

S1

*

S2

SC

FR-D700

U V W

IM

* When connecting multiple inverters, use a diode on the each safety input terminal to prevent a malfunction due to

undesirable current.

Fig.4 Example of multiple inverters connected to a safety relay unit

The number of inverters connected to a safety relay unit should be decided under considerations of output

terminal rating of a safety relay unit.

6

Page 9

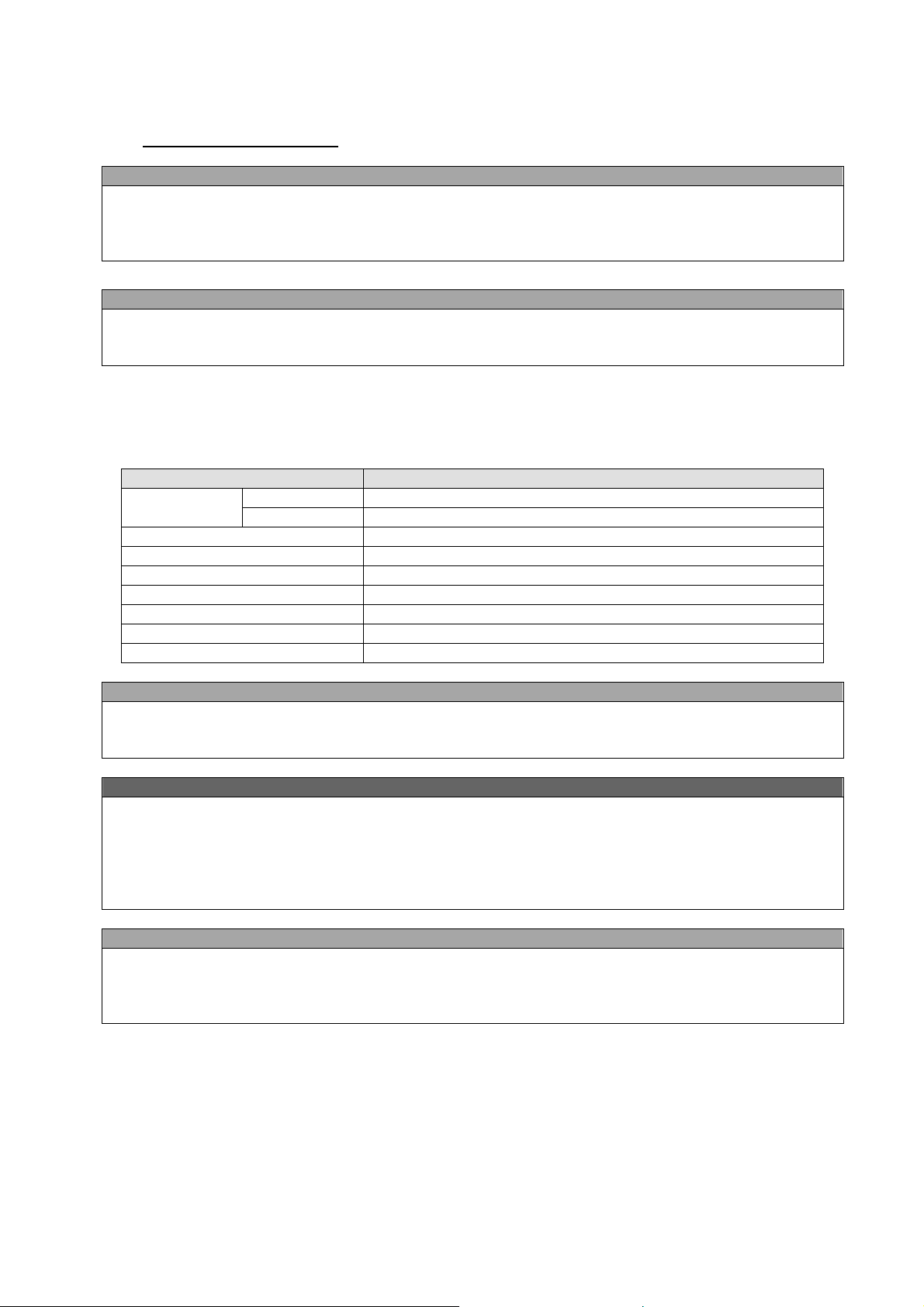

Example 2

RUN

DC24V

START

EM

+24V

COM0 COM1

X0 X1

Safety

Logic

Circuit

24G

MITSUBISHI MELSEC Safety relay unit

QS90SR2SN-Q

STF

STOP

XS0 XS1 Z10 Z00 Z20

K1

K2

Z11 Z01 Z21

SE

STF

STOP

S1

S2

SC

SD

SINK

CPU

Gate

Driver

FR-D700

Gate

Driver

Fig.5 Safety system example 2 – STOP synchronous with EM and fault detection through RUN output.

For safety stop, configure the wiring as shown in Fig.4 above.

Note: the above wiring is configured to prevent restart in case of a fault.

XS0 should be connected to RUN terminal and XS1 should be connected to SE, because polarity of XS0 is

positive, XS1 is negative.

The parameter No.190 must be set to ‘199’. This setting makes the RUN output to turn off in case of

failure.

After the power-up, to reset the safety stop mode, press the START switch, and also press the STF switch,

then start the motor rotation.

In the above Fig.4, wired example2, in the event of reset of ‘safe-condition’ the motor rotation will not occur

until STF is pressed.

(for normal ‘non-safety’ STF/STOP function, please refer to your drive’s User Manual)

ATTENTION

To prevent restart in case of recovering from input power loss of drive, 3-wired connection for STF/STOP

control is recommended.

In case of 2-wire connection and using latching type switch to short between STF and SD/PC for starting,

ensure the compliance with safety requirement for the restarting when the drive recover from input power

loss.

RST

IGBTs

UVW

IM

7

Page 10

4. Test and checking failure

ATTENTION

To avoid systematic faults, a test even for faulty demands of the safety function has to be performed in order to check

the correct function of the monitor signal. This test shall be carried out at system installation, any software changes,

parameterization changes, and/or at least once per year.

I/O status and failure

FR-D700 safety related I/O status obeys the following truth table.

Table.5 Truth table of Safety related signals

Input power S1-SC S2-SC Failure SO-SC RUN-SE or A-C Drive state

OFF - - - OFF(Open) OFF(Open) Drive shutoff (Safe state)

No failure OFF(Open) ON(Close) Drive enable

Detected OFF(Open) OFF(Open) Drive shutoff (Safe state)

No failure ON(Close) ON(Close) Drive shutoff (Safe state)

Detected OFF(Open) OFF(Open) Drive shutoff (Safe state)

ON

Short Short

Open Open

Short Open Detected OFF(Open) OFF(Open) Drive shutoff (Safe state)

Open Short Detected OFF(Open) OFF(Open) Drive shutoff (Safe state)

In case of diagnostic or functionality test, check the I/O state whether it is same or not as Table.5.

Diagnostic

If the failure detected, FR-D700 output alarm signal and indicate ‘E.SAF’ at the display.

In case of FR-D700 output the alarm, please take following action.

(1) Check the S1-SC and S2-SC input signal logic is the same. If these are different logic, collect the input

signal and reset the FR-D700.

(2) Disconnect the wire from S1, S2, SC terminal, then reset or power-off and on, If the ‘SA’ letter is

flashed up at display, there is failure in system except FR-D700. But, still ‘E.SAF’ is displayed and

alarm output, there is malfunction on FR-D700.

Self diagnostic test

FR-D700 does the self-diagnostic test on the power-ON.

If FR-D700 output alarm at power-ON, please take the action described in ‘Diagnostic’ at above.

Test procedure for functionality

As depicted ‘ATTENTION’ in above, the test for the functionality is important.

Please do the test following procedure.

(1) Please make each state of S1-SC and S2-SC depicted at Table.5.

(2) If there is any different state from Table.5, FR-D700 has some malfunction.

(3) If there is no different state from Table.5, check the systematic performance, such as, press the

Emergency switch, press the start/restart button at the failure detected (RUN-SE opened), and so on.

(4) Finally clear the error record of the FR-D700 (see the user manual how to clear the error record).

8

BCN-A211508-000-D

Page 11

REVISIONS

Print Date Manual Number Revision

Aug. 2009 BCN-A211508-000-C First edition

Dec. 2009 BCN-A211508-000-D

Change

Example of Safety stop connection

Loading...

Loading...