Page 1

EMT16 & Melco OS V11

EMT16 & Melco OS V11 Classroom Notes & Quick Reference Guide

EMT16 & Melco OS V11 Classroom Notes & Quick Reference Guide

w w w . m e l c o u n i v e r s i t y . c o m

w w w . m e l c o u n i v e r s i t y . c o m

w w w . m e l c o u n i v e r s i t y . c o m

Page 2

Contents

Page 3

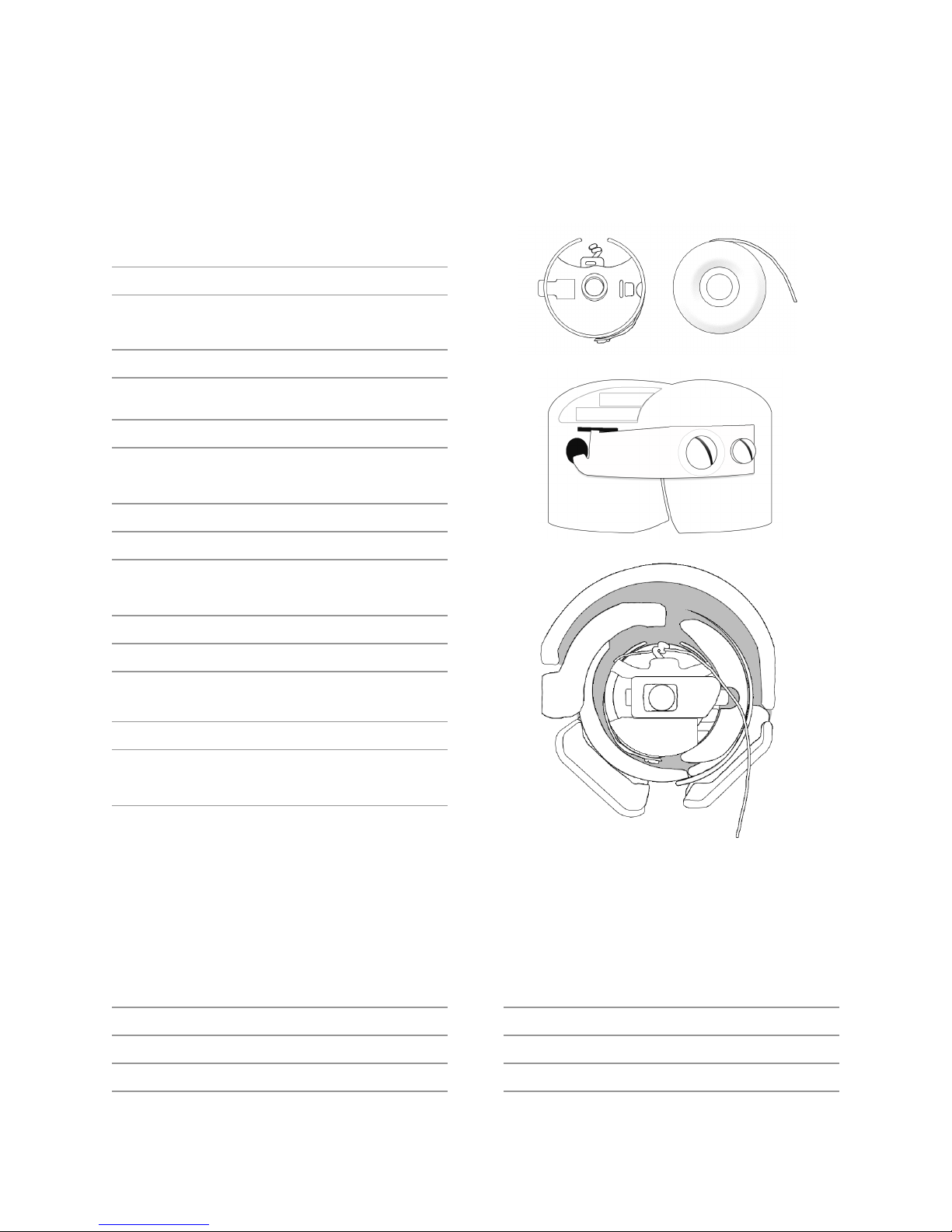

Bobbins

Needle Types

4

Choosing A Needle

5

Changing Needles

6

Backings & Toppings

7

Backing & Topping Information

8

EMT16 Keypad

9

Loading Sequence

10

Adjusting Presser Foot

11

Hooping & Troubleshooting

12

Machine Maintenance

13

Applique & Color Sequence Commands

14

Embroidery File Formats

15

Cap Sewing Basics

16

Puff Foam Embroidery

17

Puff Foam Embroidery continued

18

Moving through a design & EMT16 Laser Alignment

19

EMT16_MOS_v11_EMT16_Handout.pub 2 Rev: 080515

Page 3

We recommend continuous filament polyester bobbin thread.

Cleaning the bobbin case

Types of bobbins

Threading up the bobbin case

Testing the bobbin tension

Bobbin

Adjusting the bobbin tension

Reinserting the bobbin case

Bobbin tail

Thread

Threading the EMT16 Types of Thread

EMT16_MOS_v11_EMT16_Handout.pub 3 Rev: 080515

Page 4

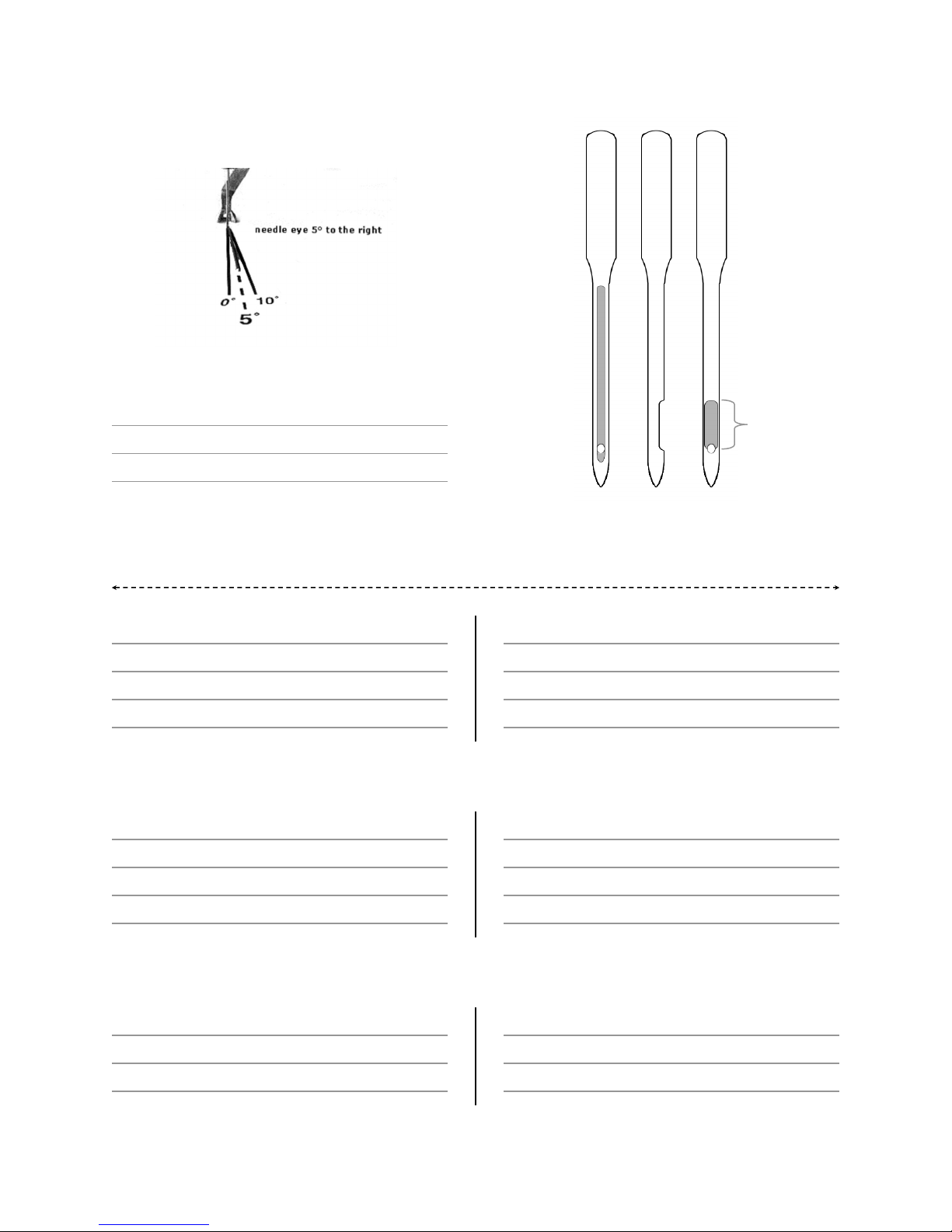

Needles

FRONT

SIDE

BACK

Needle Orientation

Needle Sizes

65/9 75/11 100/16

Smaller Larger

Scarf

Sharp Ball

Standard Titanium

EMT16_MOS_v11_EMT16_Handout.pub 4 Rev: 080515

Needle Points

Needle Coatings

Page 5

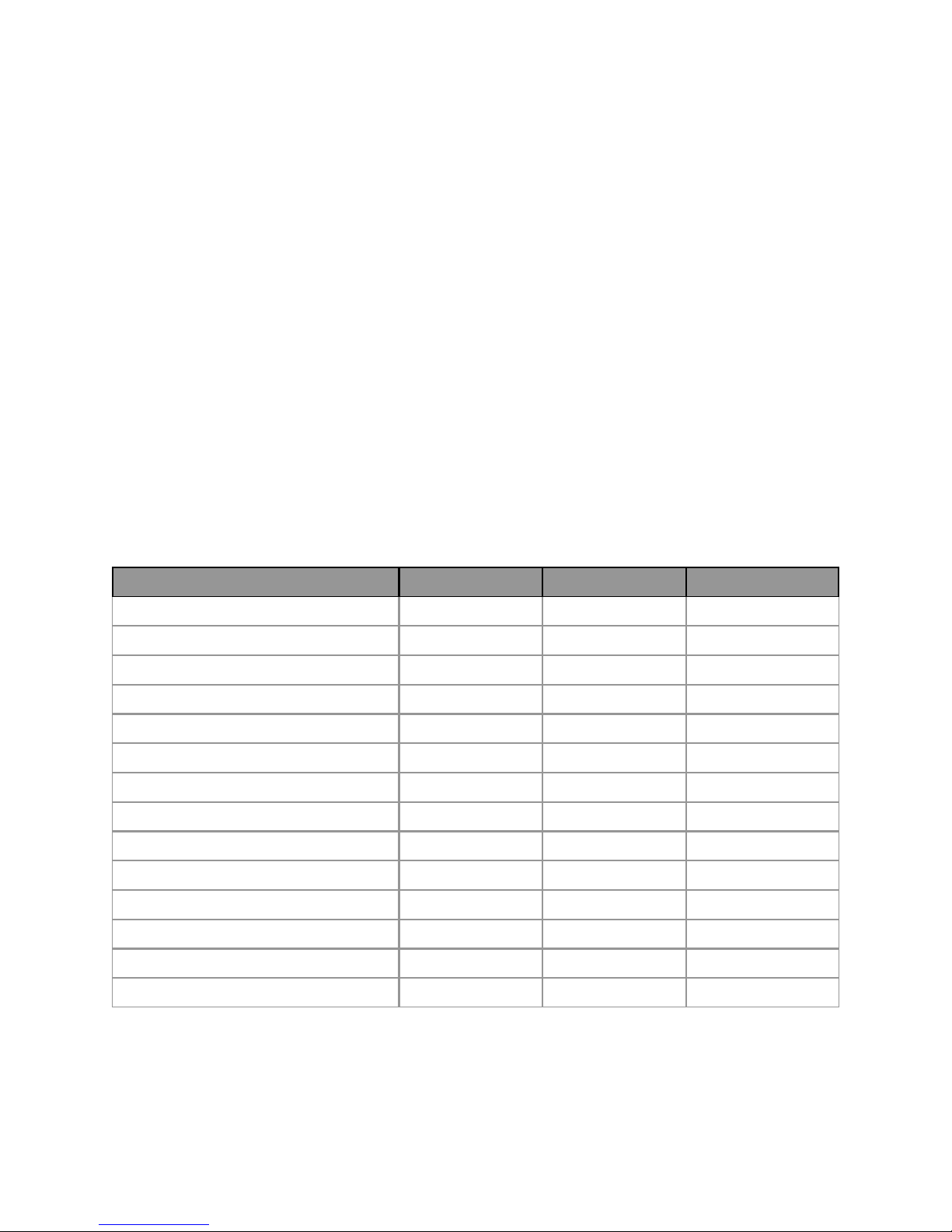

Choosing a Needle

Choosing the appropriate needle for the job being run is extremely important to the success of

the embroidery. Different fabrics and threads will determine what needle should be used.

General Guidelines

Ball Point needles are commonly used on knits. The idea behind this is for the slightly round-

ed tip of the needle to move the threads of the material out of the way. Common knit garments include T-shirts and sweatshirts.

Sharp point needles are sharper than ball points and are generally used on tightly woven

goods. Some good examples of tighter weaves would include canvas, denim, and twill.

Combination points (SES or RG types) are a good choice for most fabrics and keep needle

changes to a minimum. This saves on labor costs.

Titanium coated needles create less friction and heat when moving through a material. They

are a good choice for sewing on coated fabrics or embroidering with adhesive backings.

Smaller needles can clean up the appearance of small lettering and fine details.

Larger needles create larger holes which can help prevent thread breaks due to friction

when sewing an abrasive materials like a cotton duck jacket.

Fabric Type Needle Size Needle Type Coating

Coated Fabrics 80/12 Sharp Titanium optional

Corduroy 80/12 Sharp

Cotton Sheeting 70/10 - 80/12 Sharp

Denim 80/12 Sharp

Dress Shirt (Woven) 70/10 - 80/12 Sharp

Golf Shirt 70/10 - 80/12 Ball Point

Leather 70/10 - 80/12 Ball or Sharp Titanium optional

Lycra or Spandex 70/10 - 80/12 Ball Point

Nylon Windbreaker 70/10 - 80/12 Ball Point

Satin Jacket 70/10 - 80/12 Ball Point

Sweater (knit) 70/10 - 80/12 Ball Point

Terry Cloth 75/11 - 80/12 Ball or Sharp

Delicate Satins or Sheers 65/9 - 70/10 Ball Point

Twill Caps 75/11 - 80/12 Sharp

Note: These values are guidelines only, and you may need to adjust your needle usage according to the needs of the individual application.

EMT16_MOS_v11_EMT16_Handout.pub 5 Rev: 080515

Page 6

Changing a Needle

When installing new needles, always use industrial grade needles recommended by Melco for use in

the EMT16.

How to Change a Needle

1. Make sure the safety grabber blade is in the back position before changing a needle. If it is not,

press the Adjustment and Center keys on the EMT16 keypad to move the grabber back.

2. Each needle has a needle clamp set screw that holds it in place.

3. Using a small flat-blade screwdriver, turn the needle clamp set screw counterclockwise about ½

turn, until the needle can slide down and out of the needle bar. Do not loosen too much or remove the set screw. Loosen the screw just enough for the needle to be removed.

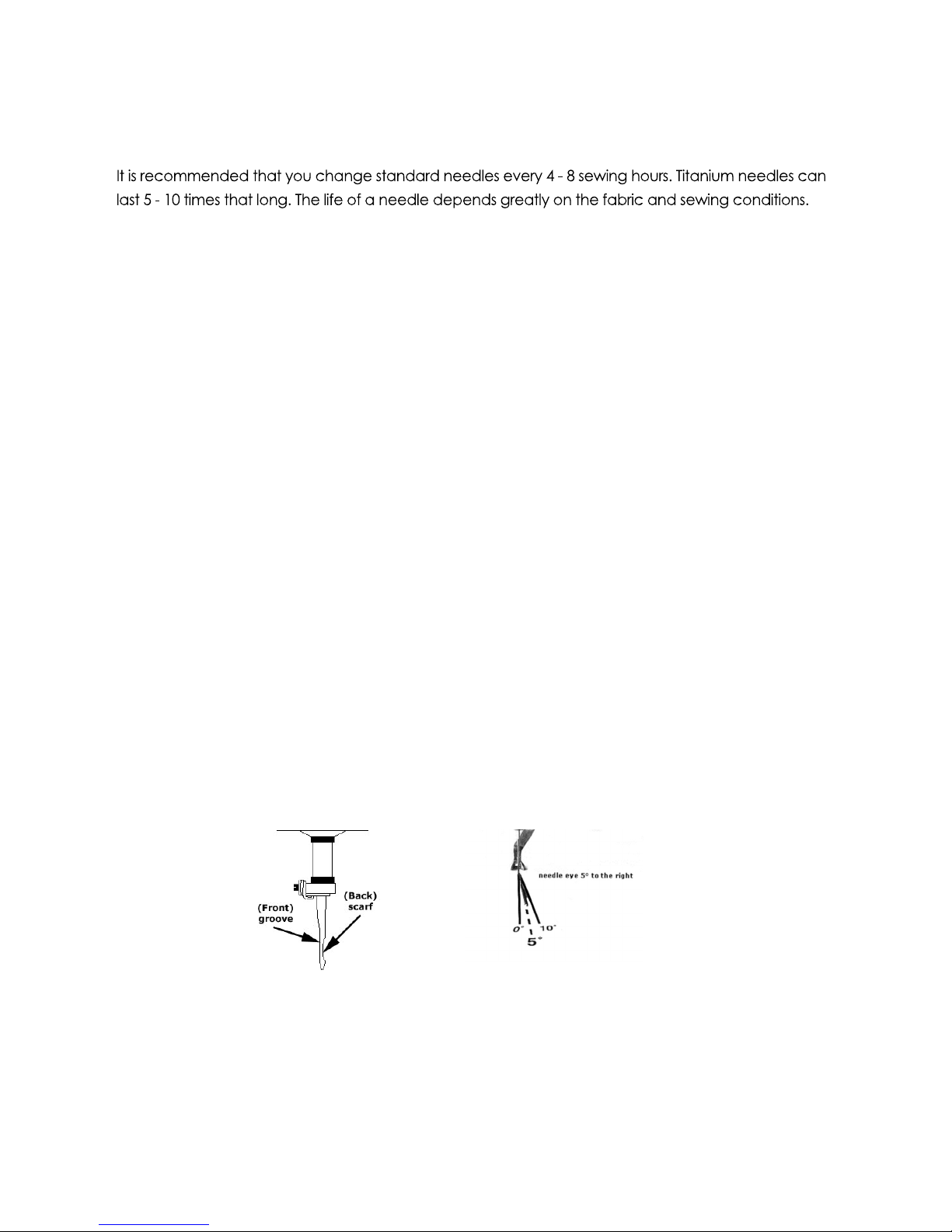

4. Embroidery needles have a front and a back side. The needle must be installed correctly or

the sewing quality may suffer. If you install the needle incorrectly, you my also get thread

breaks. The front of the needle has a long groove (thread guide), while the back has and

indented notch (scarf).

5. With the thread guide facing forward and the scarf facing back, slide the needle up and

into the needle clamp as far as it will go. The eye of the needle should be turned 5°to the

right. (There is an acceptable range of 0° - 20° to the right)

6. A needle orientation magnet may be used to help determine the angle of the needle eye.

This cylindrical magnet can be temporarily attached to the front of the needle just above

the eye. The end of the magnet will rest on the thread guide and stick out from the needle.

This will better indicate the angle of the eye. For reference, one minute is 6 degrees on a

clock face.

7. Re-tighten the needle clamp set screw to hold the needle in place.

The needle breaks or is bent.

The thread will consistently fray - this usually means there is a bur on the needle causing it to

fray a part of the thread.

The needle is dull.

Sewing conditions change, such as a change in fabric.

EMT16_MOS_v11_EMT16_Handout.pub 6 Rev: 080515

Reasons to Change a Needle

Page 7

Backings and Toppings

Standard Backings

Cut Away Tear Away

Specialty Backings

Water Soluble Toppings and Backings

EMT16_MOS_v11_EMT16_Handout.pub 7 Rev: 080515

Other Toppings and Backings

Page 8

More Backing and Topping Information

Appropriate backing is essential for embroidering most fabrics. Without backing, fabrics can slip

even when they are hooped tightly. Using the proper backing is directly linked to the production of consistently high quality embroidery. It is important to understand that many different

embroiderers with identical criteria may choose completely different backing and topping formulas and still achieve successful embroidery results. Experimentation and experience are essential in creating consistently high quality embroidery. New products are constantly being developed and introduced. Find the combinations that work best for you.

Tear Away Backing

Tear away backing is a non-woven material that tears easily in any direction and can be easily

removed after embroidery. Tear away is extremely simple and fast to use, but the uses are limited because it offers little support to unstable fabrics. Some examples of fabrics suitable for

tear away are cotton sheeting, woven dress shirts, denim, terry cloth, hats, and some satins. Be

aware that tear away can be a bit scratchy, and use on fabrics that will be worn against skin

may want to be avoided.

Cut Away Backing

Cut Away backing is a woven or non-woven material that must be cut form the fabric after the

embroidery is complete. This type of backing is used to support the embroidery on the fabric

during and after the embroidery process. It also prevents the fabric from stretching during embroidery. Cut Away backings are generally used for unstable goods like knits. Examples of a knit

would be a t-shirt, golf shirt, sweater, or a sweatshirt.

Specialty Backings

Specialty backings such as poly mesh and nylon mesh are also options. While they may not be

as stable as traditional cut aways, they are much less visible through lighter weight garments.

They also tend to be softer than other backings.

Water soluble backing is also available for jobs that require that no backing be left after the completion of the embroidery. Be aware that this would require a fairly stable garment as the backing will

be dissolved completely and offer no support once the garment has been laundered.

Toppings

Toppings are used to keep your stitches from falling into the nap of a lofty material like terry

cloth or polar fleece. It can also be used to clean up small lettering and the overall appearance of your embroidery. Most toppings are water-soluble and can be easily removed after

the embroidery is complete.

EMT16_MOS_v11_EMT16_Handout.pub 8 Rev: 080515

Page 9

EMT16 Keypad

Step Back Step Forward

Center the Hoop on the machine

+

Trim Immediate

+

Move the hoop on the machine

+

Open/Close the Grabber

+

Trace the Design Within Selected Hoop

E-Stop

Move Needle Case

+

+

Change Sewing Speed

+

Hold to Turn on Laser

EMT16_MOS_v11_EMT16_Handout.pub 9 Rev: 080515

Page 10

Procedure to Run the EMT16

1. Load Design Screen

Color Sequence Screen

3. Hoop Selection Screen

4. Garment Selection Screen

5. Set the Sewing Speed

6. Move & Rotate Screen (if need-

ed)

7. Center hoop (if needed)

8. Adjust Presser Foot Height

Must have a garment loaded

9. Trace Design

10.Check Pinch Rollers

11.GO

EMT16_MOS_v11_EMT16_Handout.pub 10 Rev: 080515

Page 11

Adjusting the Presser Foot

The machine has an adjustable presser foot that can be set from 0.5mm to

3.5mm above the needle plate. The presser foot height should be changed

when the thickness of the material you are sewing changes dramatically. To

adjust the presser foot height, the software must be open, and your machine

must be on and communicating with it. A hoop with the fabric you

will be using should be installed.

1. Adjusting the presser foot is easiest with the needle case moved

to needle 16. It is not necessary, but it makes the adjustment gear

easier to see. If the machine is not on needle #16, the gear can still

be accessed. Do not attempt to move the needle case during the

following steps.

2. In the software, press the settings button.

3. Make sure that only the material is under the needle, for the next

step will command the machine to lower the needle.

4. Press the Lower Presser Foot button.

5. Locate the presser foot eccentric (gear) behind the needle case.

6. Turn the gear with your fingers to adjust the presser foot height up

or down as needed.

7. Set the presser foot height over an unsewn section of the fabric.

Set the presser foot so that it is just touching the material.

8. Once adjusted, press the raise presser foot button in the software.

EMT16_MOS_v11_EMT16_Handout.pub 11 Rev: 080515

Page 12

Hooping

Round hoops give the most even tension of all the hoop shapes.

Wooden hoops will have registration marks on them. These help main-

tain the shape and hold of the hoop.

Many wooden hoops are double-high, meaning their sides are twice

as tall as normal hoops. They help grip slick or bulky goods because of

the larger surface area and slight tooth the wood provides.

Choose the smallest hoop that the design will fit in without going over

the hoop limitations (the dotted line in EMT16 Melco OS).

Adjust the hoop tension before hooping the final garment. If you ad-

just the tension of the hoop while the garment is in it, you will increase

your chances of “hoop burn” and create ripples in the garment.

Sew out Troubleshooting

After you complete your first sew out of a design, it is a good idea to examine the quality of the

piece and how well it sewed. Reassess the hooping, backing, and machine settings. A few adjustments now can save you from frustrations later on.

Symptom Possible Solutions

Thread breaks Slow down the EMT16. Make sure the piece is hooped properly. Adjust

presser foot. Check bobbin tension. Check needle orientation. Oil the

rotary hook.

Bobbin pulled to top Check bobbin tension. Slow down the EMT16. Adjust presser foot.

Registration loss Check hooping tension. Slow down the EMT16.

Fabric is puckering Avoid stretching or pulling the fabric too much when hooping it.

EMT16_MOS_v11_EMT16_Handout.pub 12 Rev: 080515

Page 13

Maintenance

EMT16_MOS_v11_EMT16_Handout.pub 13 Rev: 080515

Page 14

Appliqué Command

Color Sequence Commands

Sequence for Sewing Appliqué

1. Locator Stitch

Color 1

Pause Puff Micro Chenille Recursive

2. Place Appliqué

Appliqué Command

3. Tack-down Stitch 4. Cover Stitch

Color 2

EMT16_MOS_v11_EMT16_Handout.pub 14 Rev: 080515

Page 15

Embroidery File Formats

Wire Frame (Outline) Files

.cnd - older Melco condensed format

.ofm - DesignShop and native format

cnd & ofm

Elements are outlined shapes that con-

tain element properties like density,

stitch length, and stitch direction.

Shapes can be edited.

cnd files saved from DSV9 save as a

manual stitch

ofm only

Contains lettering properties. You can

change spelling, font, size, or any other

property of the lettering.

Notes are available.

Color information is available.

Scaling a Wire Frame File

You can usually scale a wire frame file up

or down in size about 25%.

Stitch Files

.exp - Melco expanded stitch file

.dst - Tajima stitch file

Stitch files do not contain properties. They are

just plotted out needle penetrations. The colors that show up will be the default colors.

If you open an ofm and see expanded data

in the project view, it is plotted stitch information. You can save stitch files as ofms to

keep notes and color information, but they

will still be expanded data.

Scaling a Stitch File

Stitch files can usually be scaled 10% up or

down in size, but with the assistance of the

Expanded Stitch Processor, you can push

that to about 25%.

Expanded Stitch Processor

Converts stitch files to wireframe in order to

maintain densities when scaled. This may

change the fill patterns in some designs.

EMT16_MOS_v11_EMT16_Handout.pub 15 Rev: 080515

Page 16

Sewing Caps

1. Load the Design

2. Set the Color Sequence

3. Select the Hoop

(Driver color / Cap Frame)

4. Set the Sewing Speed

5. Select Hat as the Garment Type

6. Set the Design Orientation

Flip upside-down for caps.

7. Center Cap (Center Hoop won’t work)

Careful - you may not be able to use the

laser to do this. Line up with the needle.

X

Y

Measurements for Caps

X = Distance from bill to start of real curve

Y = Center point for design

X - 1” = safe zone

X - ½” = actual sew field

8. Trace Design

9. Adjust Presser Foot

10. Check that Pinch Rollers are

down

Sew Order for Cap Designs

11. GO!

EMT16_MOS_v11_EMT16_Handout.pub 16 Rev: 080515

1. Bottom Up

2. Center Out

3. Finish as you go

Page 17

3-D Foam Digitizing and Embroidering Help

General tips:

1. The type of garment or finished product you’re working with should be evaluated for design

with 3-D foam. Stay away from unstable fabrics such as pique. The more stable the fabric,

the better. Examples are denim shirts, sweatshirts, jackets and caps. This process would also be nice for bags, aprons and other stable surfaces.

2. The portion of the design that will be puffed must be the last section to sew. You will be laying down a piece of 3-D foam, so all flat sections of the embroidery must be sewn first.

3. The needle penetrations perforate the foam and allow for the excess to be pulled away

upon completion of the sewing.

4. In addition to being the last section to sew, the segment of the design that will take on the

raised appearance must be hefty enough to allow the foam to work its magic. Only satin

stitches will give the raised puff look. A satin stitch width of between 3mm and 11mm

should be used.

5. Alphabet text can be used as a starting point for puff letters, but they must be modified to

work with Foam due to the “open ends” of traditional alphabet letter stitching.

Digitizing Tips:

1. Set your walk stitch and edge walk underlay stitch lengths to 20 – 25 pts. (2 – 2.5 mm). It is

important to use a shorter stitch length for the edge walk stitching. This helps to cut the

foam aiding in the excess removal process.

2. Digitize the satin cover stitching using a very heavy density, about 1.5 to 1.7 pts. A heavier

than normal cover stitching is used to insure that none of the foam peeks through the foam.

Also, overlapping the satin stitches in areas where any two sections of the stitches meet at

perpendicular or parallel angles will help ensure that the foam does not push through the

top of these seams.

3. Close any open satin stitch ends with a capping or pinching method. This is important because needle penetrations are required around the entire perimeter of the foam satin top

stitching in order to get the excess foam to separate. Sample pictures of both of these

open end treatment methods are shown at the end of this document.

4. Increase the “Use Fill for stitch lines greater than” parameter in the Top Stitching properties

tab to 300 pts. This will disable the “Auto fill” wide satin stitches feature of DesignShop. We

don’t want this active for puff.

Use 5 tie-in and 5 tie-off stitches to make sure that the thread is securely locked down.

Embroidering tips:

1. Leave the presser foot at the usual setting for the non-puff colors in the design, but raise it

all of the way to its highest setting for the puff colors. This will better define the raised edges

of the puff embroidery.

2. Insert the Hold command in the color sequence just before the puff color. This will stop the machine so you can

set the foam piece on top of the garment. Applique

pause also works, but there is really not a need to have

the hoop feed out since the foam is cut oversized and

doesn’t have to be placed accurately.

3. Drag the puff icon on top of the puff color in the color

sequence in MOS. This will give you the sewing properties required.

EMT16_MOS_v11_EMT16_Handout.pub 17 Rev: 080515

Page 18

1. Don’t tear off the foam until after the puff color is finished. If you get foam “crumbs”

peeking through the embroidery, you can make them shrink away by using a heat gun.

2. Slow the machine to 900 SPM, or so for the puff color.

3. A larger needle, such and an 80/12, helps to make larger perforations so the foam tears

off more easily.

4. Thread and foam colors should match. Fewer stitches can be used to cover the foam

without it showing through. Foam comes in about 15 different colors, so match as closely

as possible.

5. The foam is washable but avoid over-drying in a hot dryer. Do not dry clean garments

that have puff embroidery. Doing so will dissolve the foam.

6. The foam is usually available in several thicknesses 2, 3, 4, 5, and 6 mm.

Capping method for closing open satin stitch ends

Pinching method for closing open satin stitch ends

EMT16_MOS_v11_EMT16_Handout.pub 18 Rev: 080515

Page 19

Moving Through a Design

EMT16 Laser Alignment

EMT16 has a laser alignment feature. This feature allows you to line up an embroidery design to

a mark, such as a stripe, on the garment. To do this, you use the hoop and the arrow keys to

move the laser to your first reference point, like the top of stripe on the left side. Press the laser

and an arrow key to confirm this point. Move the laser with the hoop and arrow keys to your

second reference point. Press the laser and an arrow key to confirm this point. Now, press the

laser and the center key. The design will align to the line created by your two reference points.

The placement of the design along the line will depend on the arrow keys used to input the reference points. The three variations follow.

1. Laser + Left

2. Laser + Right

+

+

1. Laser + Left

2. Laser + Left

+

+

1. Laser + Right

2. Laser + Left

+

+

+

EMT16_MOS_v11_EMT16_Handout.pub 19 Rev: 080515

+

+

Loading...

Loading...