Page 1

Installation, Operation, and

Maintenance manual for

the EMT 10T, 10/4, and 10/4T

embroidery peripherals

• Single- and four-head tubular

embroidery peripherals

•

Part Number 11817, Revision A

Page 2

1575 West 124th Avenue

Denver, Colorado 80234

United States of America

E-mail: editor@melco.com

© Copyright 1998 by Melco Embroidery Systems

ALL RIGHTS RESERVED No part of this publication may be reproduced, stored in a retrieval system,

or transmitted in any form or by any means (electronic, mechanical, photocopying, recording, or

otherwise) without prior written approval of Melco Embroidery Systems. Melco reserves the right

to revise this publication and to make changes in it at any time without obligation of Melco to

notify any person or organization of such revisions or changes.

All precautions have been taken to avoid errors or misrepresentations of facts, equipment, or

products. However, Melco does not assume any liability to any party for loss or damage caused by

errors or omissions.

All trademarks and trade names contained within this publication are the property of their respective owners.

Printed in the United States of America

Revision A, November 1998

Page 3

Table of Contents

General

EMT 10T Specifications iv

EMT 10/4 and 10/4T Specifications v

Explanation of Symbols vi

1. Installation

Unpacking 1-1

Moving the Peripheral 1-4

Cart Assembly (EMT 10T only) 1-6

Installing the Tabletop (EMT 10/4 and 10/4T only) 1-8

Connecting cables 1-10

First Powerup 1-13

Support Brackets (EMT 10/4 and 10/4T only) 1-15

2. Operation

Hazards of Operation 2-2

Threading 2-4

Tensions 2-5

Keypad 2-6

The Menus 2-8

Main Operator Menu 2-8

Disk Directory Menu 2-8

Design Menu 2-8

Color Menu 2-8

Run Design Menu 2-8

Function Menu 2-9

Options Menu 2-10

Frame Menu 2-12

Reset Menu 2-12

Service/Maintenance Menu 2-12

Head Timing Menu 2-13

4 Hr Lubrication Menu 2-14

8 Hr Lubrication Menu 2-14

40 Hr Lubrication Menu 2-14

80 Hr Lubrication Menu 2-14

480 Hr Lubrication Menu 2-14

2100 Hr Lubrication Menu 2-14

Table of Contents

i

Page 4

Configuration Menu 2-15

Move Function Menu 2-17

Define Custom Hoop 2-18

Test Mode 2-18

Diagnostics Menu 2-19

Disk Drive 2-19

Loading a Design 2-21

Hooping 2-22

Quick Start 2-23

Set Home 2-23

Select Hoop 2-23

Select Orientation 2-23

Center Hoop 2-23

Attach Hoop 2-24

Select a Design 2-26

Color Menu 2-26

Run Menu 2-26

Trace the Design 2-26

Start Embroidering 2-27

Embroidery Speed 2-27

Idle Display 2-27

3. Accessories

Standard Cap Frame 3-1

Wide-Angle Cap Frame 3-6

Sash Frame 3-15

Spider Hoops 3-16

Lamps 3-18

Bobbin Winder 3-19

4. Operator Maintenance

Installing a Needle 4-1

Cleaning 4-2

Lubrication 4-3

Time to oil hook 4-3

8 Hr Maintenance 4-4

40 Hr Lubrication Menu 4-5

80 Hr Maintenance 4-5

480 Hr Maintenance 4-8

2100 Hr Maintenance 4-10

Replacement Parts 4-12

Table of Contents

ii

Page 5

5. Troubleshooting Guide

Thread Breakage 5-1

Skipped Stitches 5-2

Needle Breaks 5-2

Loose Stitches 5-3

6. Error Messages

7. Glossary of Embroidery Terms

Index

Quick Reference Guides

Table of Contents

iii

Page 6

iv

Single-Head Embroidery Peripheral

EMT 10T Specifications

Maximum embroidery speed

1000 stitches per minute

Number of heads

1

Needles per head

10

Dimensions

114cm W x 92cm H x 89cm D

45" W x 36" H x 35" D

Weight

97.7kg

215 lbs

Shipping weight

136.4kg

300 lbs

Power consumption

100 W

Noise level and test conditions

Equivalent continuous A weighted sound pressure level at 1 meter from the floor is 78db.

The peak C weighted instantaneous sound

pressure level is 77db.

The noise level was measured sewing a test

design at 800 spm.

Recommended power conditioning equipment

LC 1800 Line stabilizer (available from Accessory Resource Corporation)

Embroidering field size

28 x 50cm (11 x 19.7") with the Sash Frame

26 x 41cm (10.25 x 16.15") with a tubular frame

Options

Cap frame option

Wide-angle cap frame option

Sash frame option

Bobbin winder option

Cart option

Compatibility

EDS III and Wilcom

Intended use

The EMT 10T is designed to embroider on textile products which are placed easily in a Melco

embroidery hoop. The machine should not be

used on thick leather, wood, plastic, or other

dense material.

The EMT 10T is designed to embroider using

tubular and flat hoops, cap frames, and the

sash frame.

Page 7

v

Multi-Head Embroidery Peripheral

EMT 10/4 and 10/4T Specifications

Maximum embroidery speed

1000 stitches per minute

Number of Heads

4

Number of needles

10 per sewing head

Dimensions

244cm W x 152cm H x 88cm D

96" W x 60" H x 34.5" D

Weight

332kg

730 lbs

Shipping weight

355kg

780 lbs

Power consumption

400 W

Noise level and test conditions

Equivalent continuous A weighted sound pressure level at 1 meter from the floor is 84db.

The peak C weighted instantaneous sound

pressure level is 84db.

The noise level was measured sewing a test

design at 850 spm.

Recommended power conditioning equipment

LC 1800 Line stabilizer (available from Accessory Resource Corporation)

Embroidering field size

28 x 40.6cm (11.02 x 16.0") with the Sash Frame

26 x 41cm (10.25 x 16.15") with a tubular frame

Options

Cap frame option

Wide-angle cap frame option

Sash frame option

Compatibility

EDS III and Wilcom

Intended use

The EMT 10/4 and 10/4T are designed to

embroider on textile products which are placed

easily in a Melco embroidery hoop. The

machine should not be used on thick leather,

wood, plastic, or other dense material.

The EMT 10/4 and 10/4T are designed to

embroider using tubular and flat hoops, cap

frames, and the sash frame.

Page 8

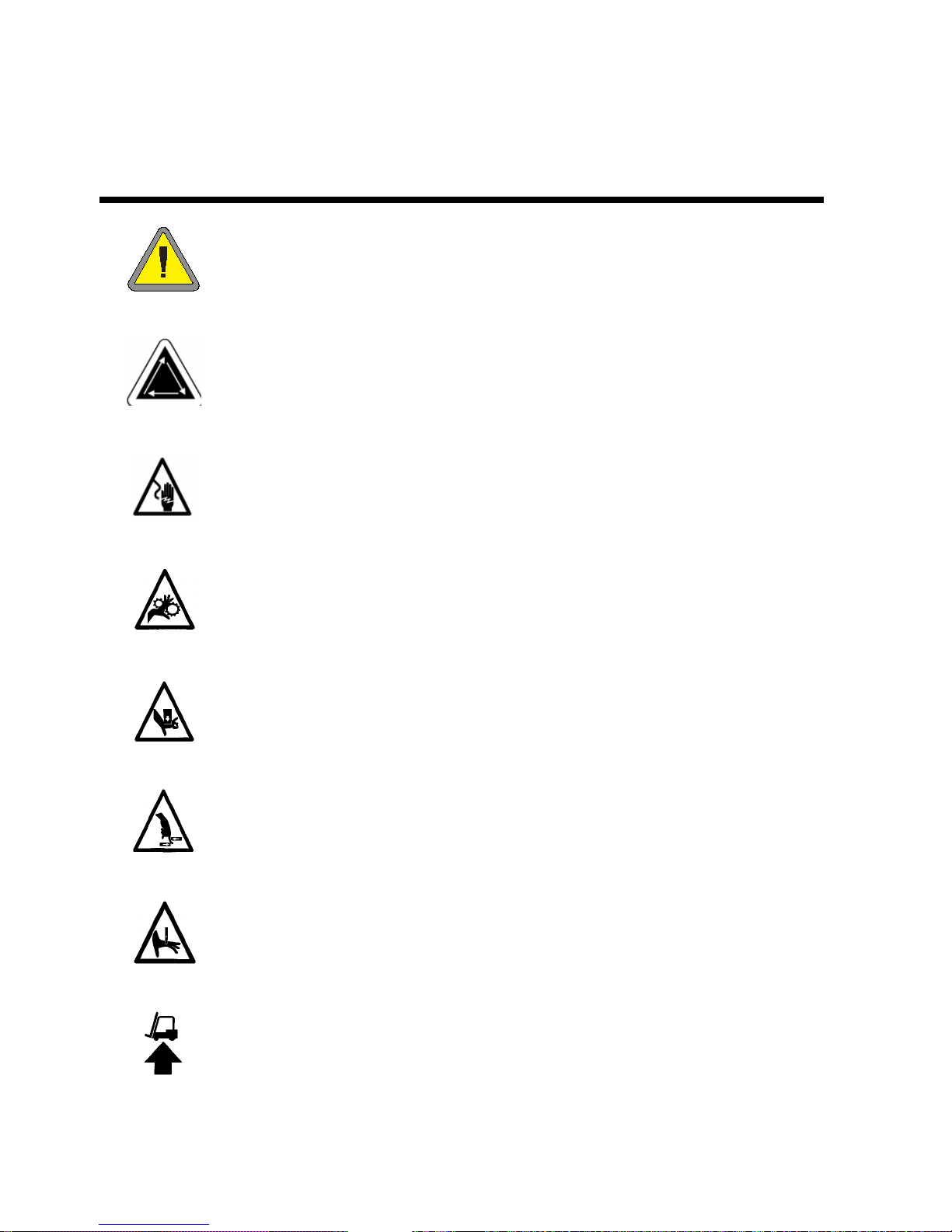

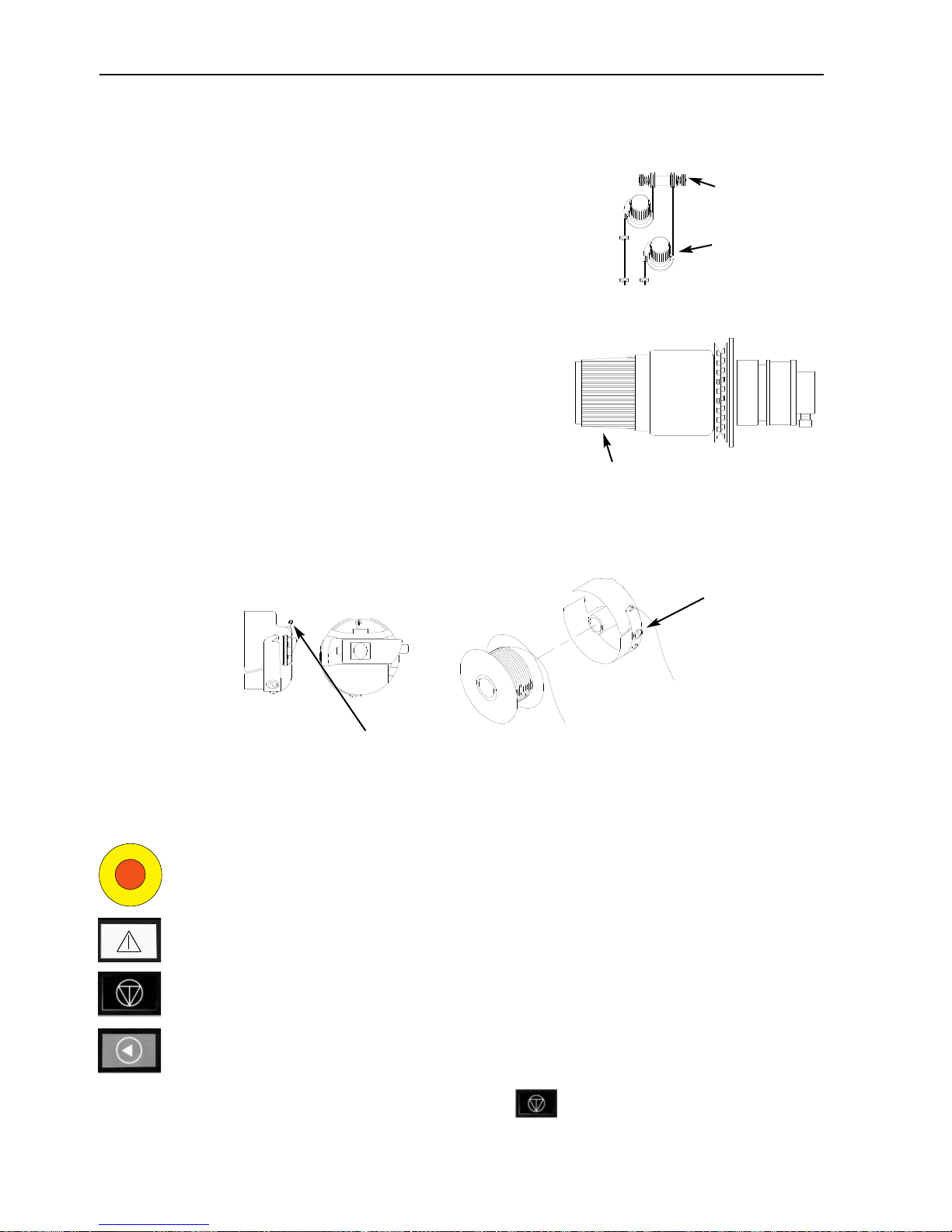

Explanation of Symbols

Caution!

Indicates a machine component will move. Keep clear!

Shock hazard. No user replaceable parts behind this label. Do not open!

Pinch point, Keep clear!

Pinch point, Keep clear!

Pinch points, Keep clear!

Needle pinch point, Keep clear!

Use a forklift.

vi

Page 9

Unpacking 1-1

11817 Rev. A 1. Installation

1.Installation

Read the entire manual before operating the machine. Save all packing material; if you ever need

to move the peripheral, use the original packing material.

Unpacking

EMT 10T

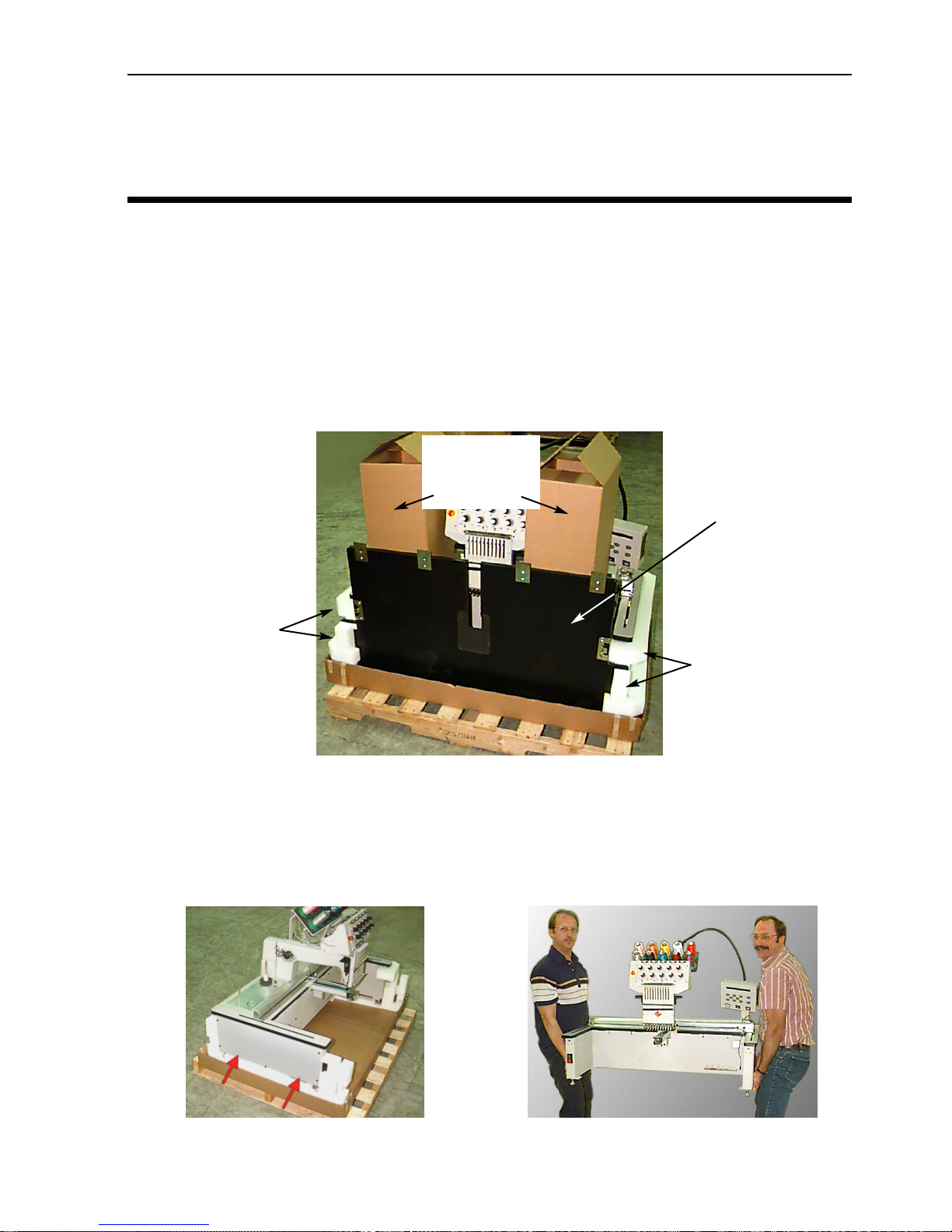

Remove the packing straps holding the box together using a knife. Lift off the top of the box, and

then remove the sides of the carton. Remove the plastic bag enclosing the equipment. When the

plastic is off, refer to Figure 1-1 for further instructions.

Prepare the designated area for the peripheral. If you have purchased the cart option, you must

clear a temporary location for the machine (until you have assembled the cart). If you purchased

the foot option, install the 4 feet before removing the machine from the box. Two people are

required to lift the EMT 10T. Refer to Figure 1-2 to locate the hand-holds, and lift as shown in Figure 1-3.

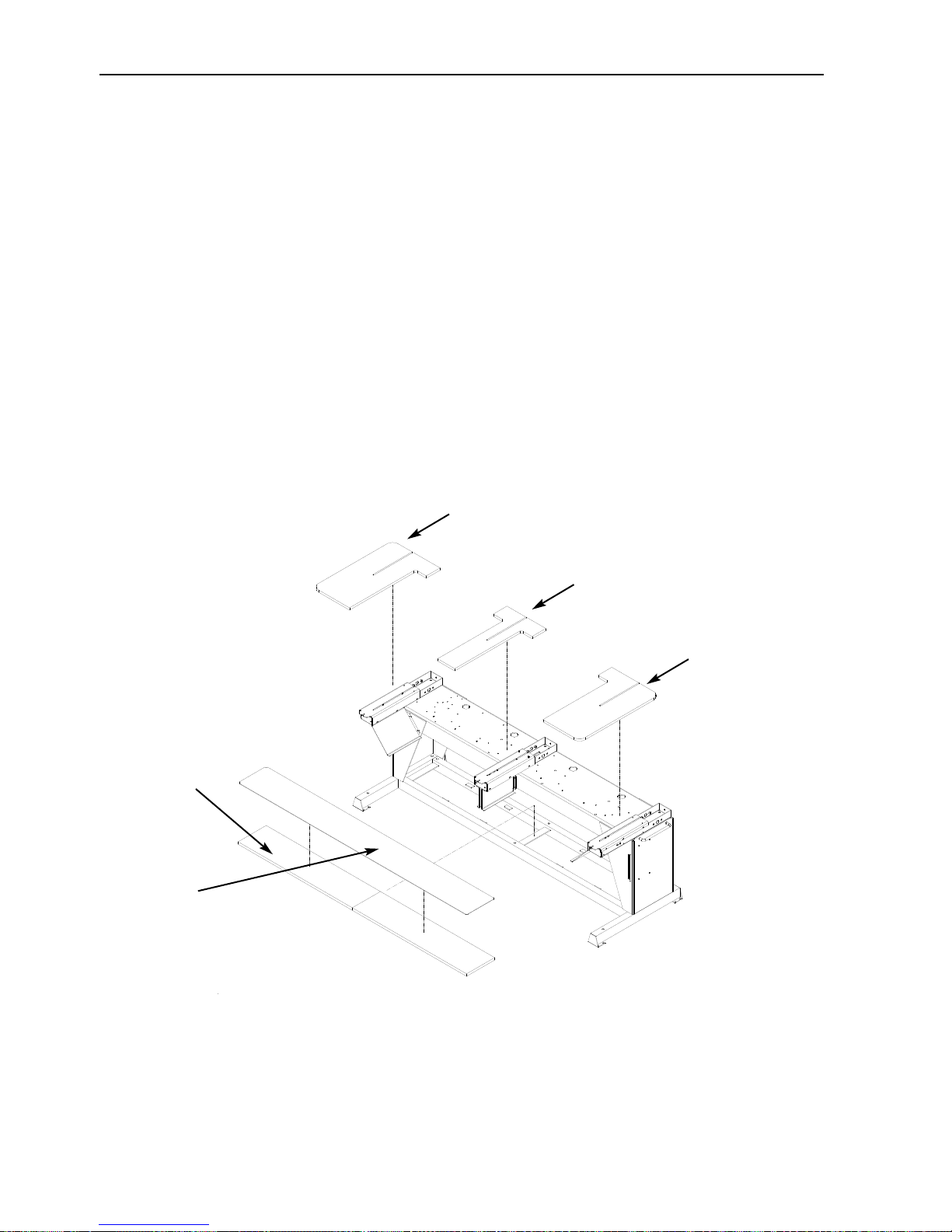

Figure 1-1

Remove these

boxes (one contains the opera-

tor kit)

Remove the

tabletop

Remove these

foam braces

Remove these

foam braces

Figure 1-2 Figure 1-3

Page 10

1-2 Unpacking

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

EMT 10/4 and 10/4T

There are two versions of the EMT 10/4 and 10/4T machines, and each are shipped in a different

way. Domestic models are shipped with a “coffin-style” crate surrounding the heads. International

models are shipped in a full crate and are packed on a palette within the crate. Determine which

style you have, and refer to the pertinent section.

Domestic models

Two people are required to unpack the EMT 10/4 or 10/4T. Be careful when unpacking your new

peripheral. On one end of the “coffin-style” crate is a wooden cover that protects the power

switches during shipment (refer to Figure 1-

4). 2 bolts secure this cover to the crate.

remove both bolts, and remove the cover.

Along the back of the crate are 2 “L” shaped

brackets; these brackets hold the crate to the

frame, protecting the heads. Remove the

bolts holding the bracket to the crate, then

remove the bolts holding the bracket to the

frame. When the bolts have been removed,

remove the bracket.

The crate weighs 115lbs (52.3kg) and is very

awkward, so use caution. With one person

standing at each end of the crate, carefully

lift the crate until it is clear of the heads.

Remove the crate. Store all packing materials

and hardware in a safe place. Reuse the

packing materials if you ever relocate the

peripheral.

Figure 1-4

Bolts

Wood-

en cover

Page 11

Unpacking 1-3

11817 Rev. A 1. Installation

International models

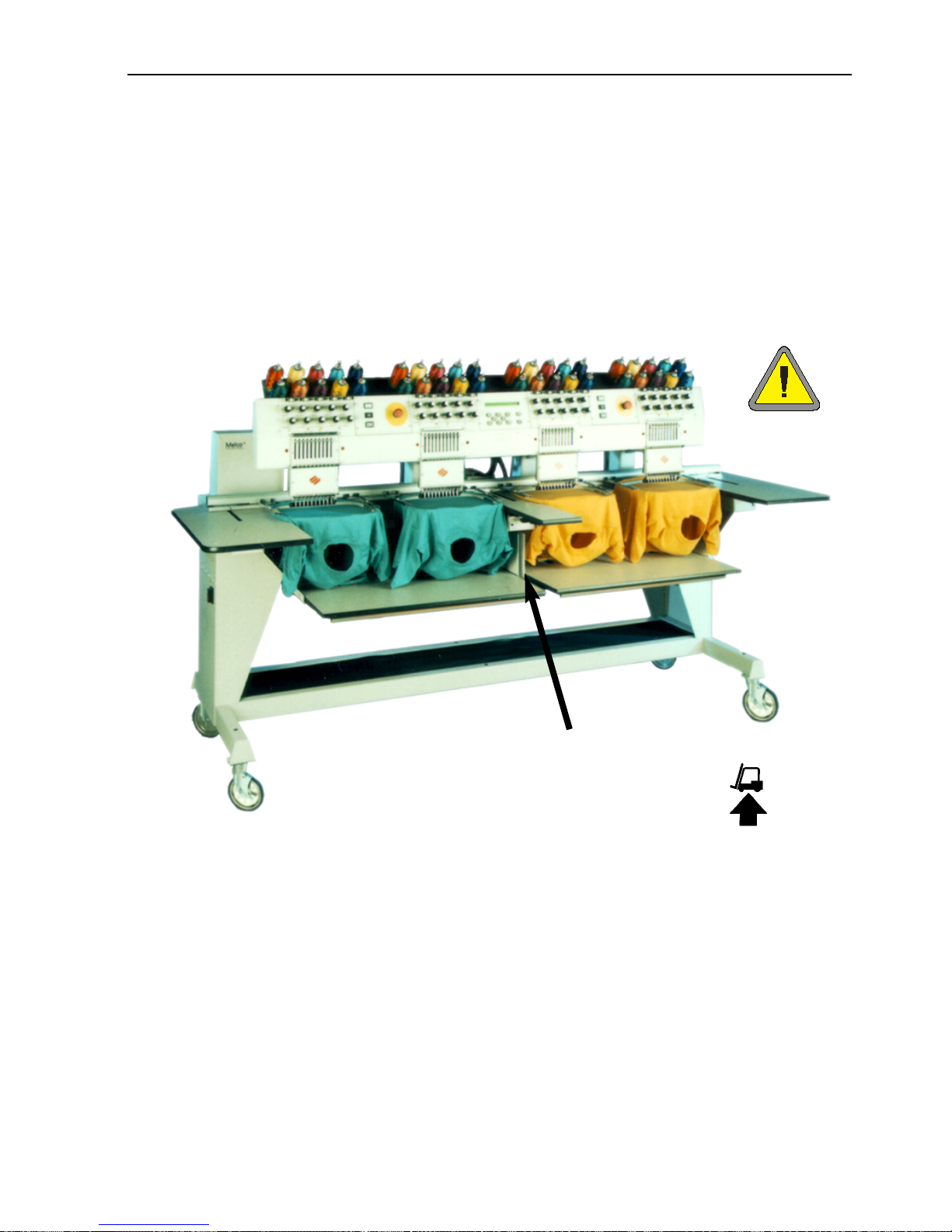

Two people and a forklift are required to unpack the EMT 10/4 or 10/4T. Be careful when unpacking your new peripheral. On one end of the crate is a “window” of wood. This end is the door.

Open the door by removing the nails from around the perimeter. Next, remove the nails from

around the bottom perimeter of the box. Slide the crate off the pallet. Use a forklift to lift the

peripheral off the pallet. Place the forks in the locations shown below.

Figure 1-5

Do not make contact with

the motors located here!

Page 12

1-4 Moving

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Moving the Peripheral

Make sure you leave enough room around your peripheral

to have easy access to all sides.

EMT 10T

Use two people to lift the machine; use the hand-holds

shown in Figure 1-6.

If the machine is on a cart, disengage the brakes on the

indicated wheels before attempting to move the machine.

Engage the brakes when the machine is in the desired

location. Observe the precautions below. You cannot remove the machine from the cart without

first removing the 4 bolts securing the machine to the cart.

Figure 1-7

Push carefully in the

directions shown or

the cart may tip.

Figure 1-6

Brakes

Page 13

Moving 1-5

11817 Rev. A 1. Installation

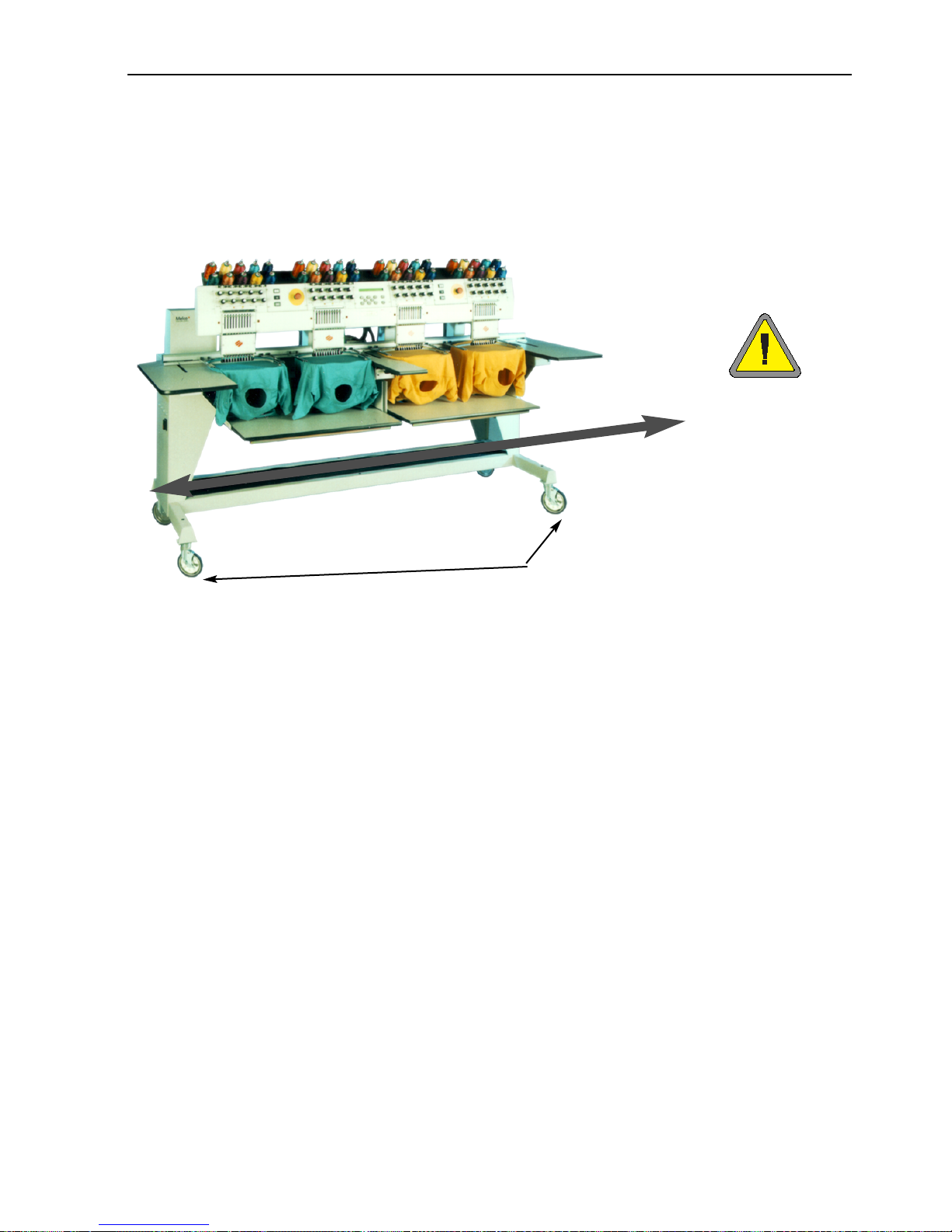

EMT 10/4 and 10/4T

Move the machine as indicated below. Disengage the brakes on the indicated wheels before

attempting to move the machine. Engage the brakes when the machine is in the desired location.

Figure 1-8

Push only in the direction of

the arrows when moving

the machine more than a

short distance.

Brakes

Page 14

1-6 Assembly

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

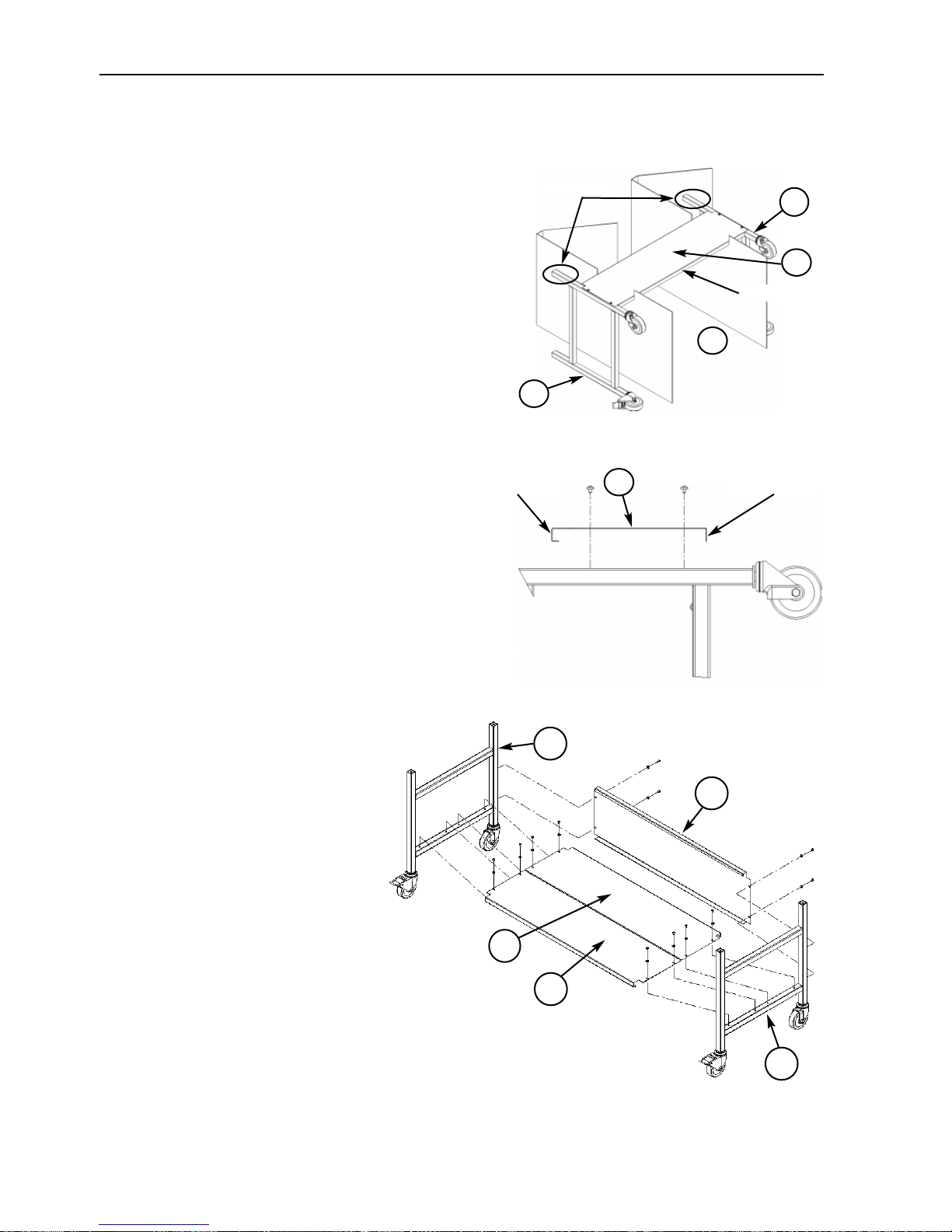

Cart Assembly (EMT 10T Only)

If you purchased the optional cart with the EMT

10T, you must assemble the cart and mount the

peripheral on the cart. The following section

describes how to assemble the cart and attach the

EMT 10T. To dismantle, reverse these steps.

The cart has 5 pieces. They attach as shown in Figure 1-11. Use the enclosed hardware to build the

cart. Pieces 1, 4, and 5 are identical to each other.

Pieces 2 and 3 are also identical to each other.

Referring to Figure 1-9 and 1-10, lay piece 1 on top

of the existing cardboard packaging with the

straight flange pointing down. Attach piece 2 with

wheels on the same end as the straight flange on

piece 1 (see Figure 1-10). The wheels with the

brakes on them should be on the ground as shown

in Figure 1-9. Insert the necessary screws (M5

phillips head screw with a flat washer between the

screw and the cart piece) securing them tightly.

Attach piece 3 the same way. While standing in

area indicated in Figure 1-9, grasp and carefully lift

cart off of cardboard and place all four wheels onto

floor.

Referring to Figure 1-11, place pieces

4 and 5 resting on top of the cross

bars of pieces 2 and 3 and piece 4

resting on the straight flange of piece

1. The straight flange of pieces 4 and

5 will be placed together in the mid-

dle of the cart assembly. Insert the

necessary screws (M5 phillips head

screw with a flat washer between the

screw and the cart piece) securing

them tightly.

Figure 1-11

1

2

4

3

5

Figure 1-9

1

2

3

x

Stand here

Grasp here

Figure 1-10

Straight flange

1

Bent flange

Straight Flange

Page 15

Assembly 1-7

11817 Rev. A 1. Installation

Mounting the EMT 10T on the cart

1. Remove the main tabletop.

2. Remove the side covers; there are 5 screws holding each

side cover in place (see Figure 1-12). Use the #2 Phillips

head driver included in the operator kit to remove the

screws.

Caution! The side panels are heavy; if

dropped, damage may occur.

3. Lift the EMT 10T (2 people are required) and carefully place the machine on the “pillars” of

the cart. The 4 holes where the feet attach should be aligned with the 4 holes on the cart’s

pillars. If the holes do not match up then slightly loosen all of the cart screws for flexibility.

4. Secure the machine to the cart using the M6 socket-head cap screws, a flat washer, and a

lock washer (provided with the cart). Refer to Figure 1-13.

Install the flat washer, then the lock washer, then the bolt.

5. Make sure the cart is standing straight, tighten all screws.

6. Replace the side covers.

7. Replace the tabletop (if desired).

Installing the feet

If you have purchased the Foot option with your EMT 10T, refer to these steps to install the feet.

1. Remove the main tabletop.

2. Remove the side covers; there are 5 screws holding each side cover in place (see Figure 1-12).

Use the #2 Phillips head driver included in the operator kit to remove the screws.

Caution! The side panels are heavy; if dropped, damage may occur.

3. Working on one side at a time, raise the machine and support it securely. The machine should

be lifted approximately 4" (10cm).

4. Install the 4 “feet” on the peripheral (see Figure 1-14). Turn

the indicated flat section of the stem with an adjustable

wrench to install or remove the foot on to the peripheral.

5. Place the machine on the surface where you intend to use it,

and level the machine. Adjust the appropriate feet by turning

the stem up or down and sequre with the lock nut against

the peripheral.

Figure 1-12

Screws

Figure 1-14

Turn at

the flats

to adjust

Figure 1-13

lock nut

Page 16

1-8 Tabletop

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

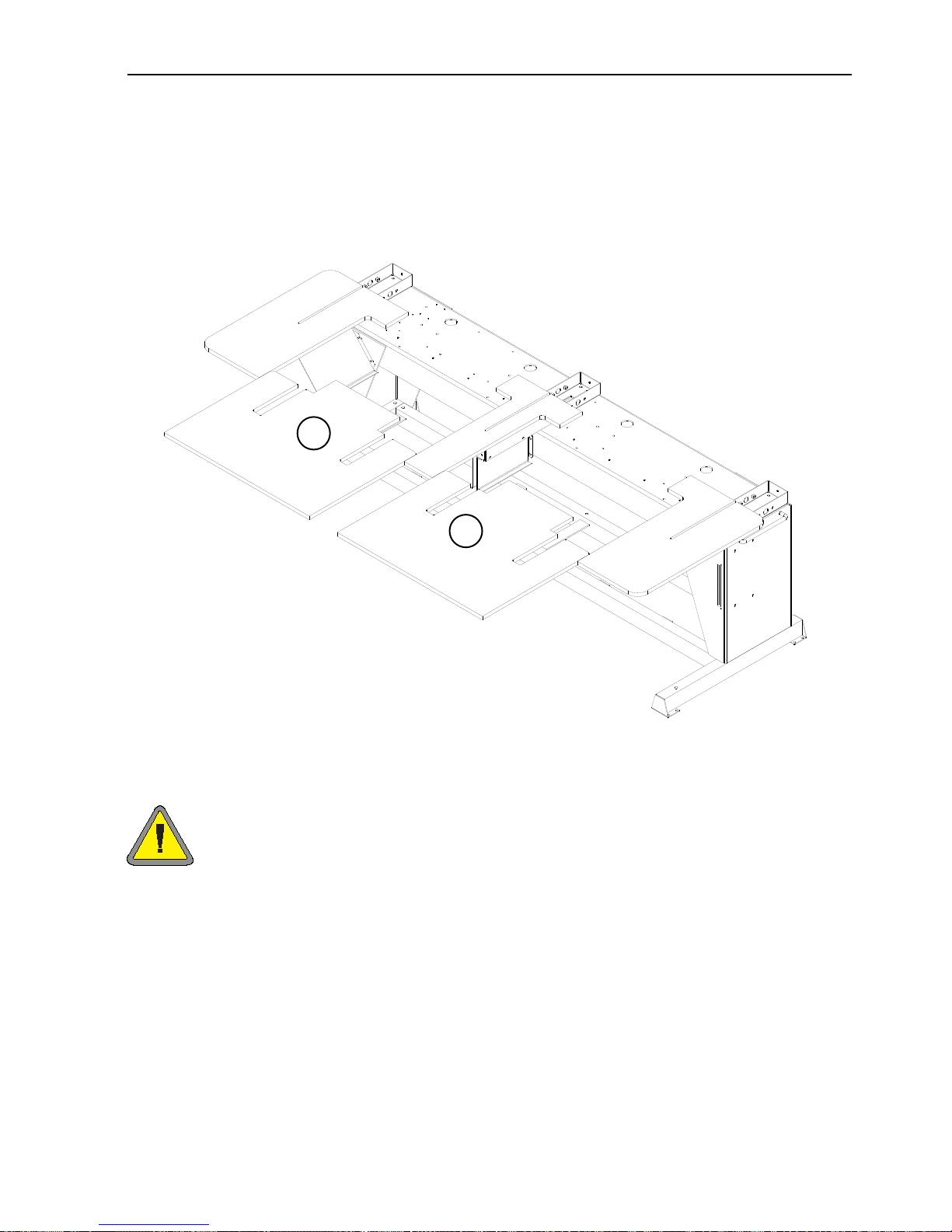

Installing the tabletop (EMT 10/4 Only)

You only need to install the tabletop on the EMT 10/4 if you are going to embroider flat goods or

use the sash frame. To install the tabletop, refer to the instructions below.

The tabletop is shipped in five parts (see Figure 1-15). The two ends and the center section slide

into place in the positions shown in Figure 1-15. The remaining two sections slide into place as

shown in Figure 1-16. This design makes it easy to remove the tabletop to embroider tubular

goods, to embroider with a cap frame, or to perform routine maintenance.

1. Using four thumb screws for each section, slide the right, left, and center sections into the

metal channels on the table. The screws are inserted from the underside of each piece.

2. There is a 2-section shelf and a covering mat that comes with the table top assembly (see Figure 1-15). Place the shelf pieces on top of the brackets located in the base of the machine and

lay the mat on top of the shelf pieces.

Figure 1-15

2-piece shelf

Rubber

mat

Left section

Center section

Right section

Page 17

3. Slide the last two pieces into place (see Figure 1-16). They fit on the table support tabs on the

end and center sections.

4. Tighten the thumb screws under the table to secure the pieces.

Special note on the tabletops

You MUST remove all 5 tabletop inserts before embroidering tubular goods or caps

on the EMT 10/4 or 10/4T. Failure to do so may result in damage to the equipment or

bodily injury. You may use parts A and B of the tabletop (in Figure 1-16) in the LOWERED POSITION to support heavy garments during tubular embroidery only.

Tabletop 1-9

11817 Rev. A 1. Installation

Figure 1-16

A

B

Page 18

1-10 Connecting cables

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Connecting cables

Power requirements

Melco suggests using a dedicated line with a line conditioner (available from Accessory Resource

Corporation). Do not use any power cable that appears to be damaged. If your power cable

appears to be damaged, order a new power cable from your Melco representative.

EMT 10T

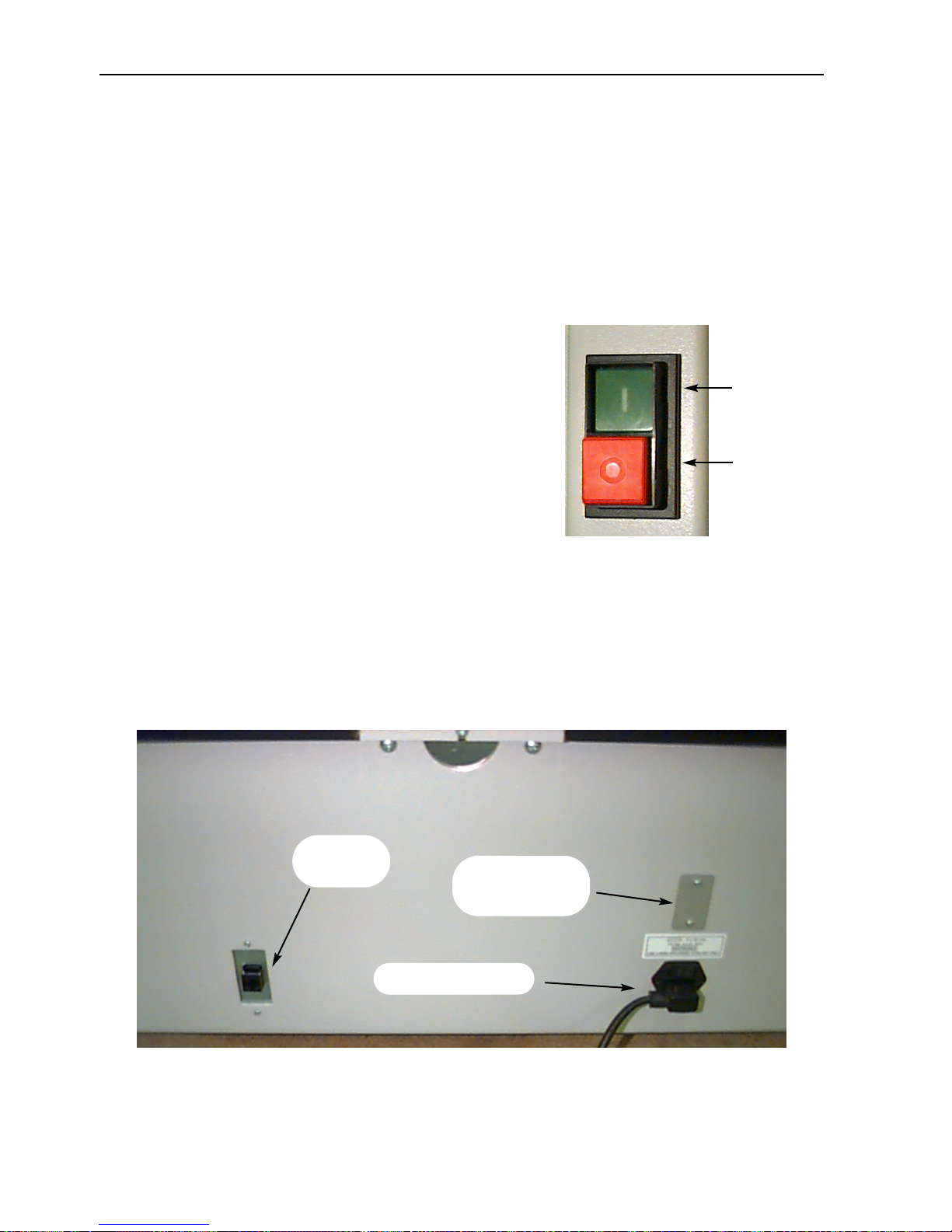

1. Figure 1-17 shows the power in the ON position. Turn

the power OFF before connecting ANY cables.

2. If your peripheral is equipped with a voltage selector

switch, set it to the correct position for your area.

3. Plug the power cable to the rear of the unit as shown in

Figure 1-18.

4. Plug the other end of the cable into the line conditioner.

5. Connect the line conditioner to the power source.

Note: The fuses have been installed for the voltage in your area; if you use a voltage other than

the factory preset, make sure you replace the factory fuses with appropriately rated fuses.

Refer to Chapter 4 for more information about fuses.

Figure 1-18

Net-

work cable

Voltage

selector switch (if

applicable)

Rear of peripheral

Power cable plug

Figure 1-17

ON

(green)

OFF

(red)

Page 19

Connecting cables 1-11

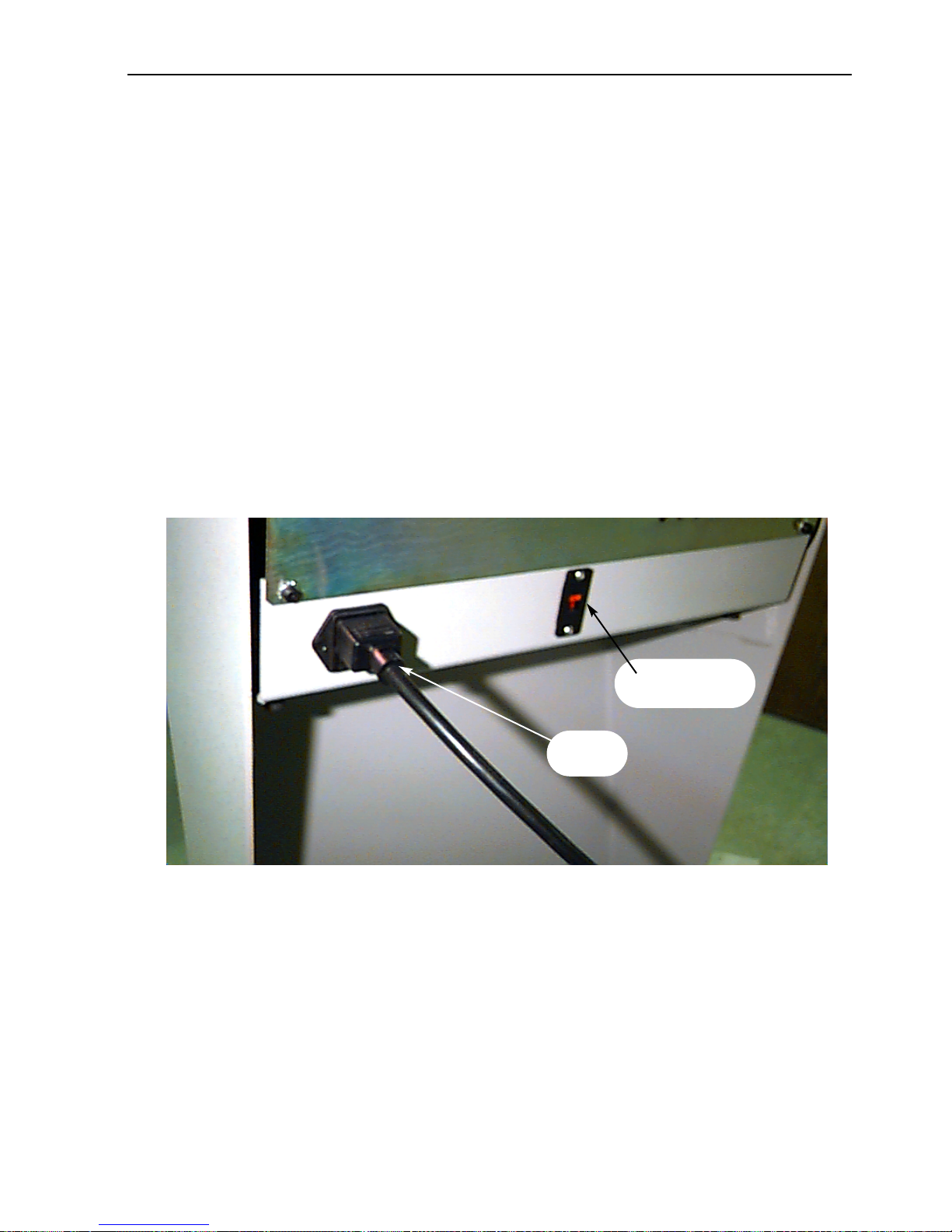

EMT 10/4

1. Figure 1-17 shows the power in the ON position. Turn the power OFF before connecting ANY

cables.

2. If your peripheral is equipped with a voltage selector switch, set it to the correct position

(115VAC or 220VAC) for your area.

3. Plug the power cable to the leg of the unit as shown in Figure 1-19.

4. Plug the other end of the cable into the line conditioner.

5. Connect the line conditioner to the power source.

Note: The fuses have been installed for the voltage in your area; if you use a voltage other than

the factory preset, make sure you replace the factory fuses with appropriately rated fuses.

Refer to Chapter 4 for more information about fuses.

11817 Rev. A 1. Installation

Figure 1-19

Voltage

selector switch

Power

cable

Page 20

1-12 Connecting cables

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Attaching the peripheral to a network

The EMT product line is compatible with Ethernet network technology. With Ether net, peripherals

connect to a wiring hub, and the hub connects to an EDS III or Wilcom computer. The hub is a

small electronic device that contains a number of cable jacks and diagnostic lights. The peripherals, EDS III computers, and Wilcom computers can plug into any port on the hub. You can connect

as many peripherals or computers as your hub can hold. If you have more peripherals or computers than your hub has ports, you can daisy-chain 2 (or more) hubs together.

Refer to Figure 1-20 for a sample Ethernet network.

*Note: You may have as many licensed EDS III systems operating on an Ethernet network as you

choose. Each computer running EDS III on the network must have a licensed EDS System

(including the dongle) installed to operate properly.

Figure 1-20

Ethernet hub

EMT 10/12

EDS III

Computer

*

EDS III

Laptop

Each cable may be up to 100 meters (327 feet) long. Hubs may be daisy-chained

for more capacity or distance.

*

EMT Products

Page 21

First powerup 1-13

First powerup

Diagnostic tests

Every time the peripheral powers up, it goes through a series of diagnostic tests. A series of messages will flash on the display. These diagnostic tests verify the proper function of the peripheral’s

CPU and the network card (if present). After the tests, the BIOS revision level will be displayed; if

you are running an Ethernet network and no EDS or Wilcom computer is on-line, the display may

read: Insert Boot Disk.

If any of the diagnostics fail, the CPU will halt and the machine will not boot. This indicates a

problem with the CPU. Contact your Melco Service Representative.

Configuring the peripheral

The first time the machine is turned on, it must be configured with a peripheral program and unit

name. This information is stored in memory and retrieved during each power up. If the peripher-

al is not configured correctly, it will not operate properly and may be damaged.

The unit name is a unique address for each machine. The machine uses the unique EtherNet

address as a default. You may change this to any 16 (or less) character name. Use a unique name

for each machine if you have more than one machine on your network.

To configure the peripheral:

1. Turn ON the power.

2. Ignore any message flashing on the LCD.

3. Press and hold at the same time within 12 seconds after you turn

on the power.

4. Continue to hold the keys until the machine beeps, then release.

5. The LCD should display the model name; press or to scroll to the correct

model name for your machine.

6. Press and the peripheral program is set.

7. Press or to change the characters in the name and press or

to move to the next or previous character.

8. Press to set the unit name.

The machine should now be properly configured.

11817 Rev. A 1. Installation

▼▲▼▲▼

▲

▲

▲

▼

▲

Page 22

1-14 First powerup

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Language selection

All Melco products use English as the default language. If you wish to change the display to a different language, follow these steps to select the machine language:

Note: The machine must be configured before you can change the display language.

1. Press to enter Language Selection

2. Press or to scroll through the available language selections.

3. When the desired language is selected, press to return to the Main Menu.

Note: You can only change the language after the machine has downloaded the RSA files.

▲

▼

▼

▲

▲

▲

▼

▲

▼

▼

▲

▲

Page 23

Support brackets 1-15

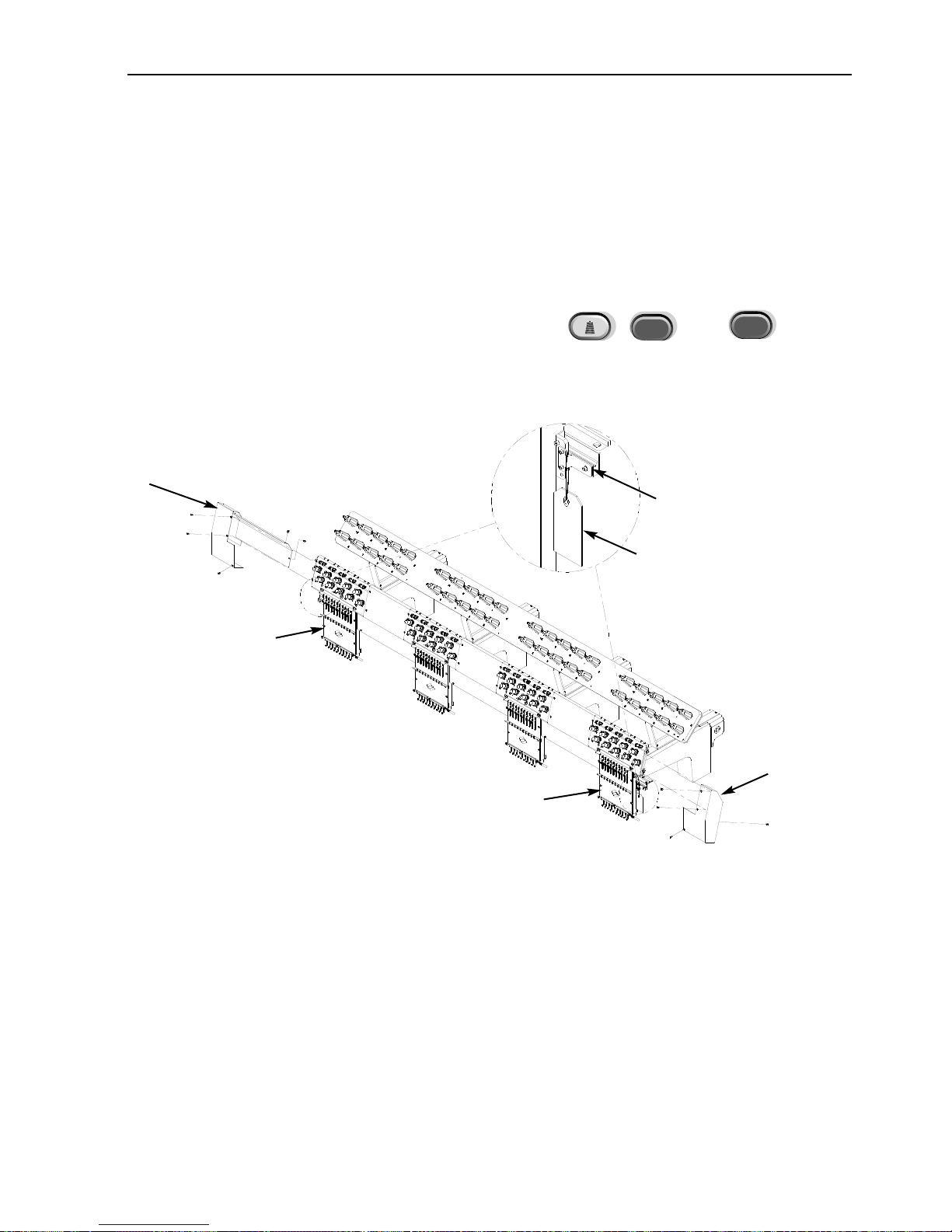

Support brackets (EMT 10/4 or 10/4T only)

Two supports brackets, one on the right needle case (sewing head 1) and one on the left needle

case (sewing head 4) hold the needle case during shipping; these brackets must be removed prior

to operation. Follow the steps below:

1. Remove the two supports (a caution tag is attached to each). Refer to Figure 1-21.

2. Manually move the needle case to needle 5 or 6 using or .

3. Install the left and right end covers, as shown in Figure 1-21. The screws for the covers are

installed on the machine.

11817 Rev. A 1. Installation

▼

▲

▼

▲

Figure 1-21

Left end

cover

Caution tag

Support bracket

Sewing

head #4

Sewing

head #1

Right end

cover

Page 24

1-16 Support brackets

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Page 25

Operation 2-1

11817 Rev. A 2. Operation

2.Operation

This chapter outlines machine operation; in addition, operators must attend a Melco approved

training course prior to operating the machine.

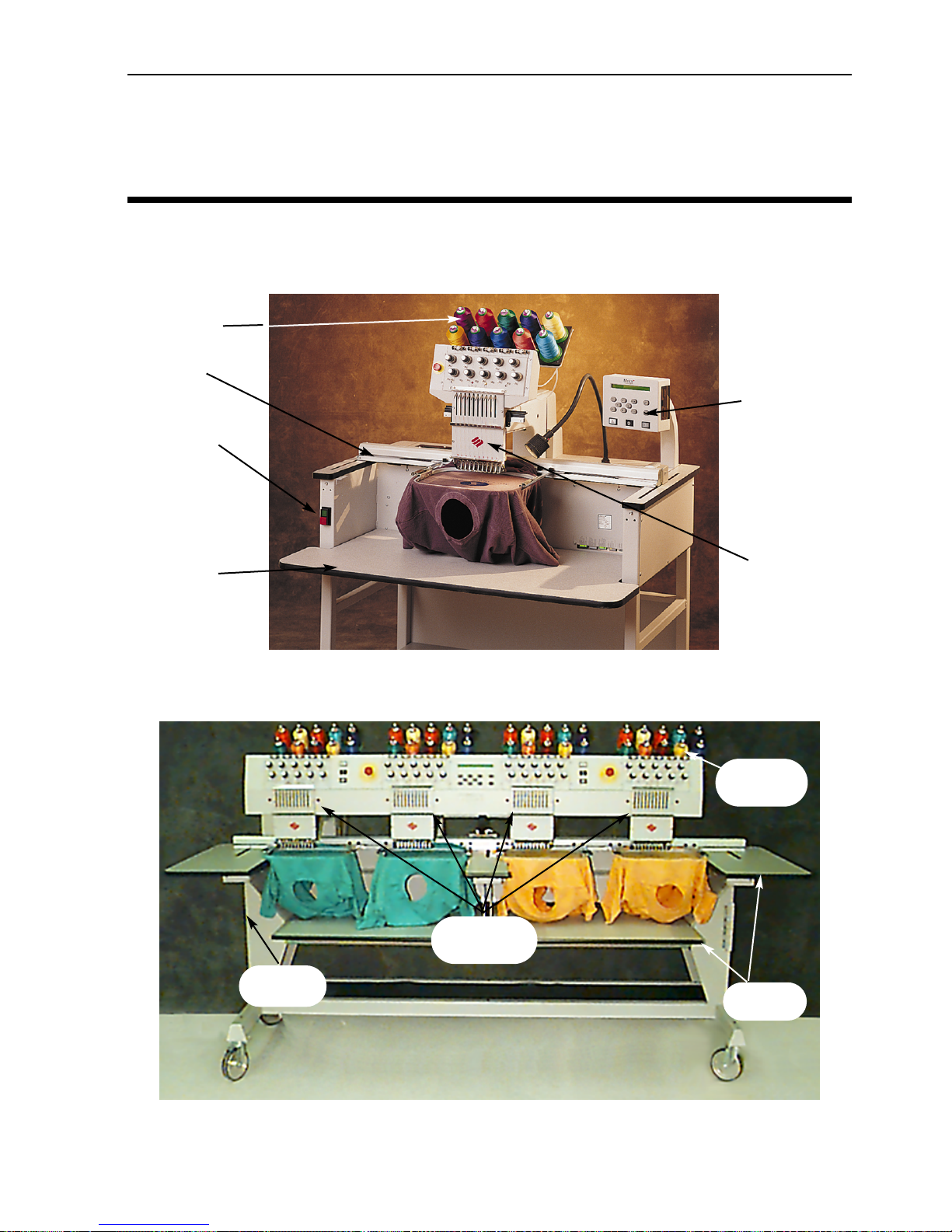

Figure 2-2

Thread

tree

Power

switch

Needle

cases

Table-

Figure 2-1

Power switch

Table

Thread tree

Needle case

Keypad

X-carriage

Page 26

2-2 Operation

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

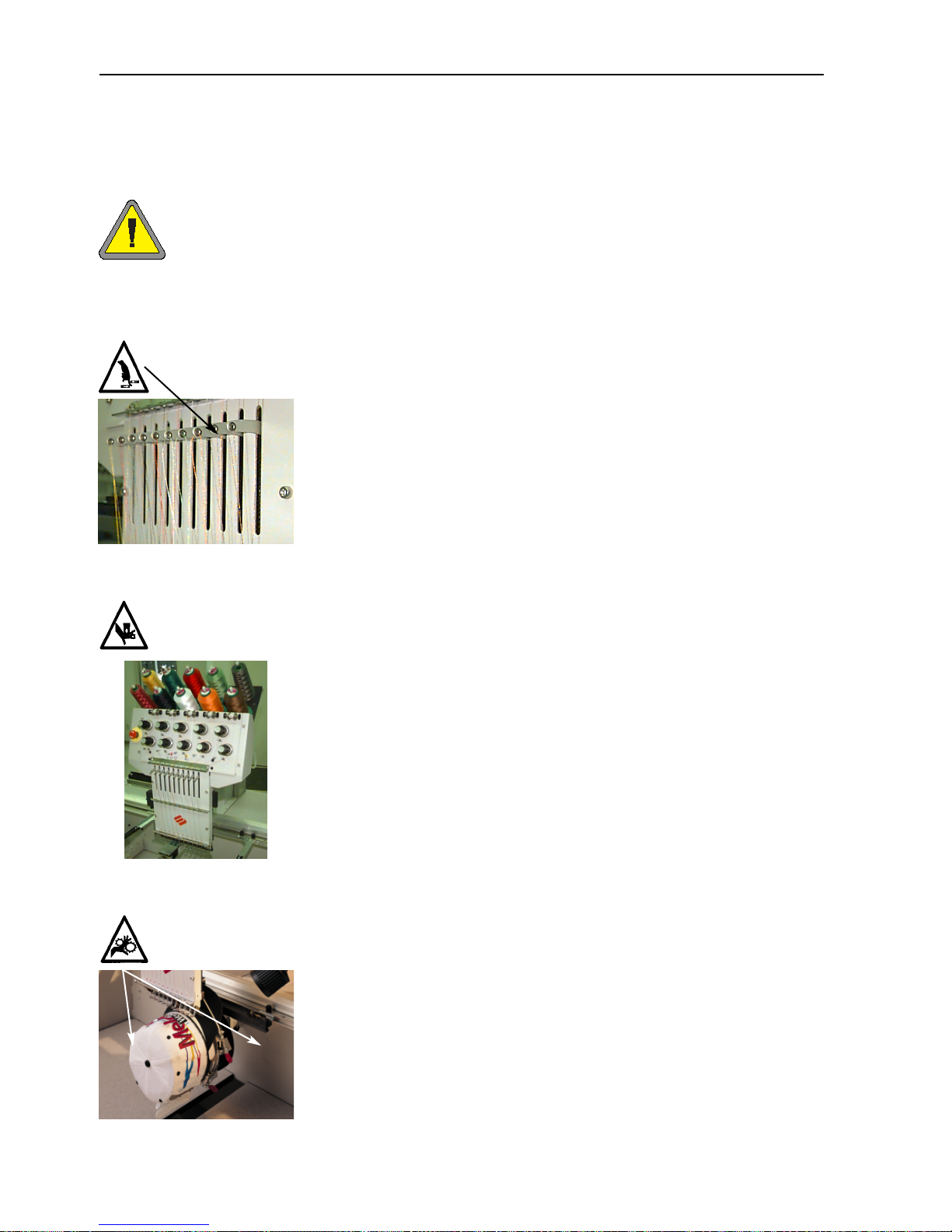

Hazards of operation

Caution! Below are risk areas or danger points encountered during operation. Always wear eye protection while operating the

machine to prevent injury in the event of a needle break. Do not

wear loose or baggy clothing when operating the machine.

Take-up Lever Oscillation

Do not touch the take-up levers during operation

Needle Case Movements

Do not place hands or other objects on or around the needle case during operation.

Cap Frame Pinch Points

Do not touch the cap frame, driver, or driver bar during operation.

Page 27

Operation 2-3

11817 Rev. A 2. Operation

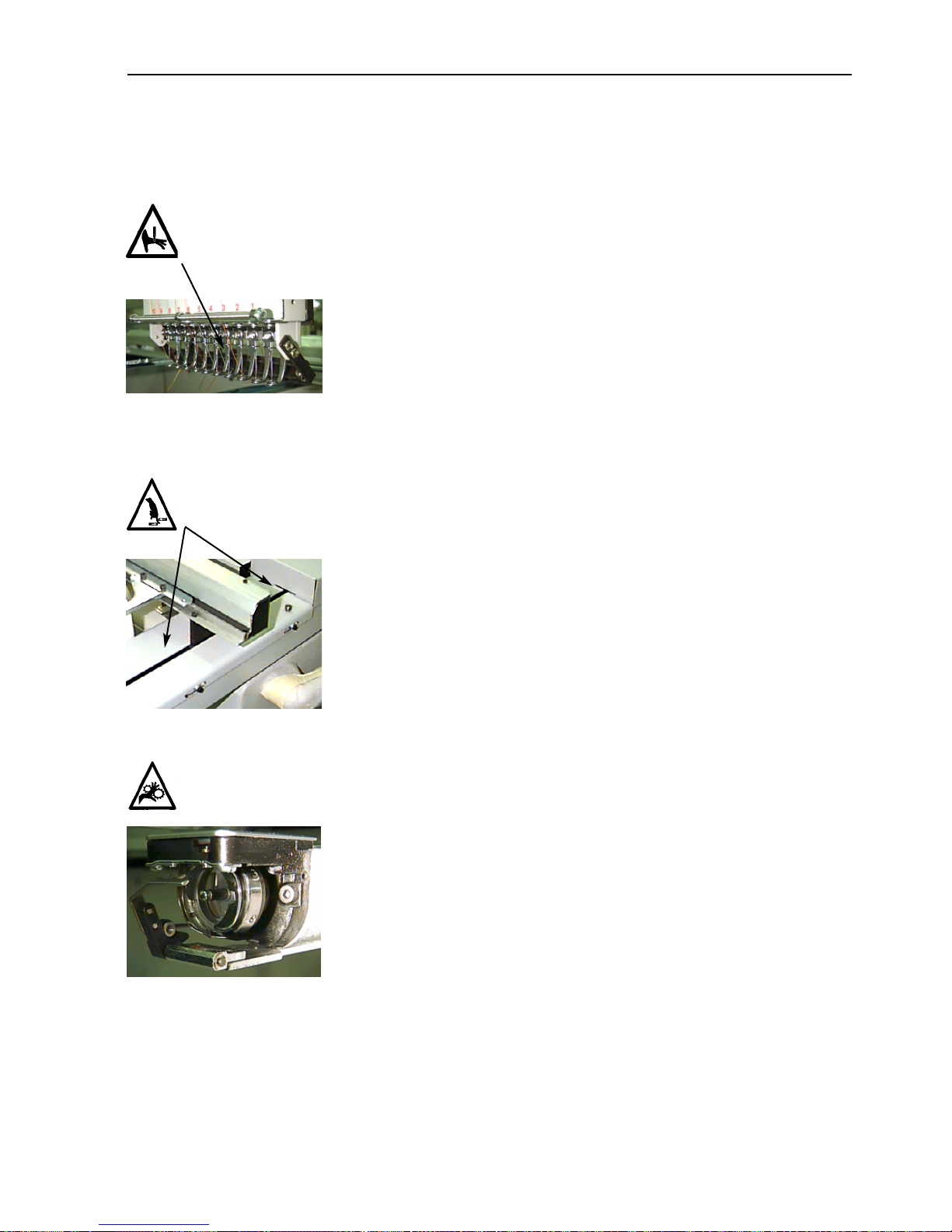

Exposed Needles During Operation

Do not place body parts or other foreign objects under the needles

during operation.

Pinch Points

Do not rest hands or other objects on the table top during operation.

Do not reach behind the x-carriage during operation with or without

table top in place.

Rotary Hook Rotation

Do not attempt to change bobbin thread during operation. Do not

place hands or other objects in the rotary hook area during operation.

Do not operate the machine without the hook guards in place.

Page 28

2-4 Operation

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

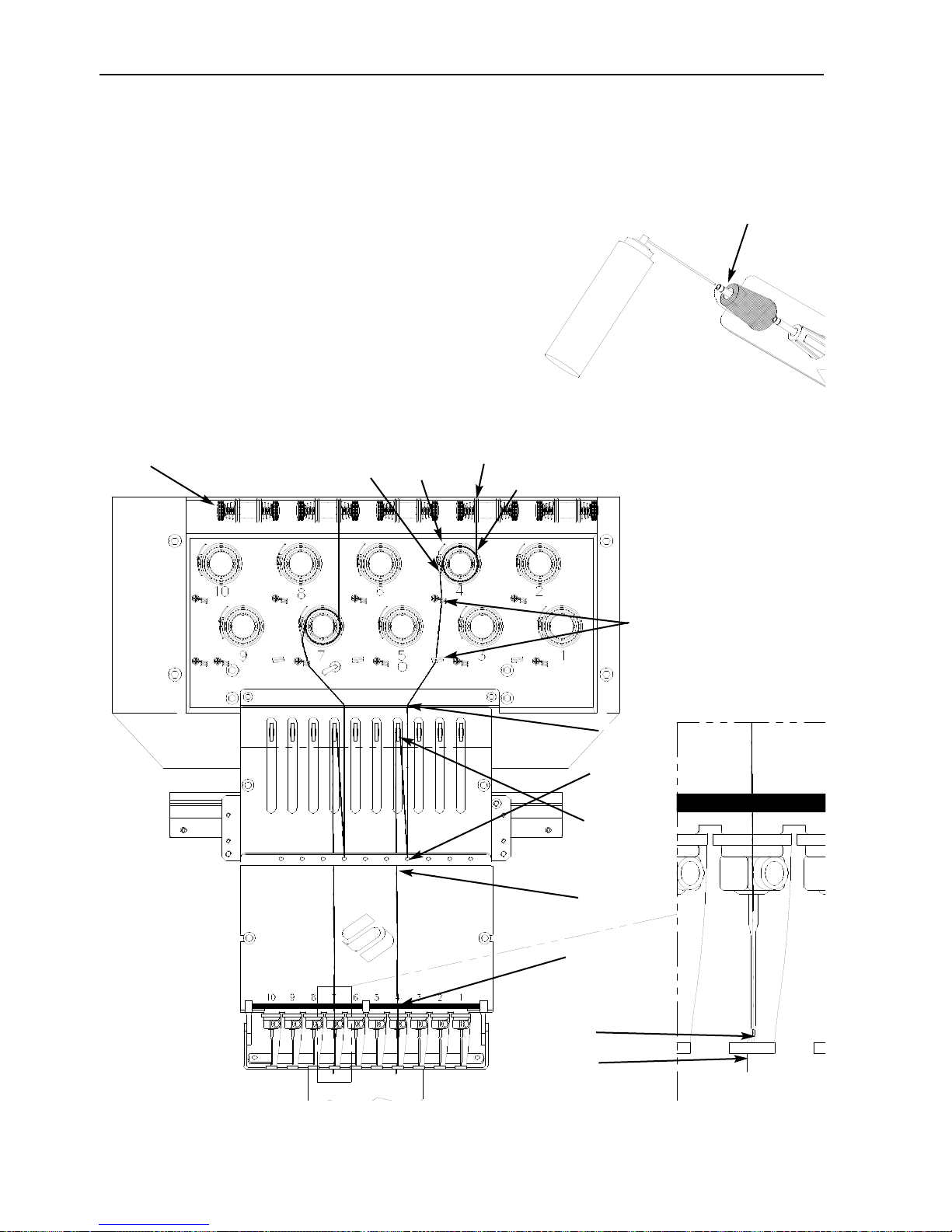

Threading

Push the metal thread tubes up from behind the head, and

remove the magnetic strips from the front of the heads.

Place a cone of thread onto the stand and push the first

few inches of thread into the supply tube. Use a can of

compressed air to blow the thread through the supply tube.

If you do not have compressed air, use the clear monofilament (approximately 24" or 70cm long) provided in the

operator’s kit. There is a small hole behind the pretensioners; Push the monofilament into this hole and up

through the supply tube, then “hook” the thread on the

cut and pull the thread through the tube.

Figure 2-3

Figure 2-4

THE THREAD PATH

Numbers here represent

numbered steps from

the following page.

1

2

3

4

5

6

7

8

9

10

11

12

Pretensioner

The thread tube should extend

approximately 0.5" above the

thread cone

Page 29

Operation 2-5

11817 Rev. A 2. Operation

1. Pull the thread from the guide hole down between the pretensioner disks.

2. Route the thread down through the pretensioner, between the two metal wheels.

3. Pull the thread down to the main tensioner and wrap the thread around the disk clockwise 1

1

/2

times.

4. Route the thread through the tension take-up spring. When you tug on the thread, the take-

up spring should move and break contact with the thread break sensor post.

5. Route the thread down through the thread guide post(s). Threads using the top tensioners

have two posts, threads using the bottom tensioners have one post.

6. The upper thread guide is just above the the take-up levers. Route the thread through it.

7. The middle thread guide is just below the take-up levers. Route the thread though the hole

facing outward, from back to front.

8. Bring the thread through the take-up lever eye, from right to left.

9. Route the thread straight down to the middle thread guide, through the hole facing down-

ward.

10. Drop the thread through the lower guide, just above the presser foot.

11. Run the thread through the eye of the needle, from front to back.

12. Pass the thread through the center of the presser foot.

13. Pull on the thread until you feel tensioner pressure.

14. Set the tension to equal 80-120 grams required to pull the thread at the needle end.

15. Fasten the thread to the retainer spring and trim the end to about an inch in length.

Tensions

Embroidery tensions are controlled on both the upper and bobbin thread. To set the tension, sew

a column (satin stitch), or embroider a capital letter “I”. You should have bobbin thread across

approximately 1/3 of the total column width on the back. If you do not, refer to the following table

to adjust tensions.

Note: Do not attempt to judge tension by looking at the back of a fill stitch.

Problem

Solution

Bobbin thread showing on top of garment

Top tension too tight and/or bobbin tension

too loose

More than 1/3 of column showing bobbin

thread on back of garment

Bobbin tension too loose and/or top tension

too tight

Less than 1/3 of column showing bobbin

thread on back of garment

Bobbin tension too tight and/or top tension

too loose

Design puckering

Top and/or bobbin tension too tight

Top thread in design loose (looping)

Top tension too loose

Page 30

2-6 Tensions

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Top tensions

Pretensioners

The purpose of the pretensioner is to hold the thread taut for the main

tensioner. The thread should pull easily through the pretensioners.

Main tensioners

Sets the upper tension. Tighten tension by turning the

knob clockwise. Loosen by turning counterclockwise.

Bottom tensions

Leave 2-3 inches (5-7.5cm) of thread hanging free.

Insert the bobbin and case with the pigtail facing up.

Set the tension at approximately 7-14 ounces (20-40

grams) required to pull thread from the bobbin.

Keypad

Figure 2-6

Rotate to adjust tension

Figure 2-5

Figure 2-7

Side

Front

Bobbin

Bobbin case

Pigtail

Set screw

Note the thread

direction

Starts embroidering (sometimes referred to as the start button). It is also used to execute selected functions in the Function menu.

Stops machine motion. Press twice to enable manual jogs of the rack when you are in

the middle of a design.

Used to “frame forward” or “frame backward” in idle or in the FRAME menu. Holding

the key will cause the machine to frame one stitch at a time; release the key to stop

framing. Holding the key for 10 seconds starts the auto-frame function; once the autoframe function has started, you must press to stop framing.

Emergency Stop (Bright yellow with a red center); stops all sewing motion immediately.

To reset, pull or twist slightly and the button snaps back into place.

Pretensioner

Main tensioner

Make sure you

insert the

thread through

the pigtail.

Page 31

Keypad 2-7

11817 Rev. A 2. Operation

Hotkeys

Moves from one menu to the next. After the last menu displays, it wraps back to the

first menu.

Never used alone. It is held down while pressing an additional key, allowing the other

key to take on an alternate function.

▲

Makes a selection. It is similar to clicking the OK button in Windows or pressing the

[ENTER] key on your keyboard.

Toggles the hoop carriage speed fast or slow when manually jogging the rack.

▼

Moves the needle position to the right in the embroidery field (hoop moves left). It is

also used to select values for sub-menu options and for manual color changes.

▲

Moves the needle position to the left in the embroidery field (hoop moves right). It is

also used to select values for sub-menu options and for manual color changes.

▲

Moves the needle position back in the embroidery field. It also scrolls up a menu list. It

is also used to change sub-menu values.

▼

Moves the needle position forward in the embroidery field. It also scrolls down a menu

list. It is also used to change sub-menu values.

▼

▲

A color change enable switch; hold down and use the left and right arrow keys to

manually

▲

▼

▼

▲

A rack enable switch; hold down and use the arrow keys to manually jog the rack.

When pressed simultaneously, displays the previous menu.

When pressed simultaneously, exits any sub-menu and displays one of the idle

menus, even when the machine is embroidering.

▲

Toggles between the Main menu and the Service/maintenance menu.

Increases sewing speed by 50 spm (while machine is in operation).

▲

Decreases sewing speed by 50 spm (while machine is in operation).

▼

Toggles to Language Selection from current menu.

▲

▼

▼

▲

Page 32

2-8 The Menus

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

The Menus

The menu structure is divided into two top-level menus, the Main Operator menu and the Service/Maintenance menu. To toggle between these top-level menus press . To enter

any submenu under one of the two top-level menus, press . Following is a list of all the

menus available in each and what commands are available. If your machine is not equipped with

trimmers, you may not see all the menus and commands listed here.

Main Operator Menu

The Main operator menu is the menu the machine defaults to when powered up. All functions

required for embroidering are found in this menu. Eight submenus are in the Main operator menu.

Press to toggle between the Main menu and the Service/Maintenance menu.

Disk Directory Menu

Lists designs on the floppy disk in the EMT Disk Drive. Use or to scroll through

design names. Press to load the design into machine memory.

Design Menu

Lists designs stored in machine memory. Use or to scroll through the design

names. Press to select a design to be sewn. Up to 16 designs (or up to 500K) may be

queued.

Color Menu

Used to setup the color/needle sequence. The following characters are allowed:

1-10 needle number

0 pause at this color change only (does

not move to next color)

– skip this color change

P pause after all color changes

A stop for applique

Run Design Menu

Confirms the selected design and color sequence is ready to be embroidered. Press to

load the design into the job queue (up to 16 designs may be queued—or up to 500K). Press

(the machine will emit several beeps) to start embroidering the design.

▲

▼

▲

▲

▼

▲

▲

Needle position

▲

COLOR

1 : 1 2 3 4 5 6 7 8 9

10 0 - P A

Page 33

The Menus 2-9

Function Menu

All the commands in this menu result in machine motion and multiple beeps. The commands are described below. Press or to view selections.

Go to hoop center?

Forces an X/Y move to the center of the selected hoop. Only allowed if you are not in the middle

of a design. Press to perform function.

Trace design outline?

Traces the outline of the queued design. Press to perform function. Refer to the Trace

part of the Quick Start section for more information.

Trim immediate?

Forces a trim. Press to perform function.

Set home?

Causes the X and Y axis motors to move to home, then return to their starting positions. This

position is defined as home. Press to perform function. Unless an error condition

occurs, this function is performed automatically every time the machine is powered up.

Power Fail rescue?

Power Fail rescue allows you to resume embroidering a design after the machine has a power loss.

A power loss might occur if an error requires turning the power switch OFF and then back ON for

recovery or if a power failure occurs. Follow these steps to regain your position in the design and

continue embroidering.

1. If large garments are installed, remove them from all heads while the power is OFF; if you are

booting from the disk drive, insert the Boot Disk..

2. Turn the power ON. Wait for the machine to download and power up.

3. Scroll through the menus until the display reads FUNCTION MENU.

4. Press . The display reads GOTO HOOP CENTER?.

5. Press or until the display reads GO TO HEADUP.

6. Press ; if you are loading a design from the disk drive, remove the Boot Disk and insert

the Design Disk now.

7. Press or until the display reads POWER FAIL RESCUE.

8. Press . The beam and carriage assemblies will move to find home, then

return to the next to last stitch embroidered before the power failure. This may take

a minute or so if it is a large design.

9. Press to return to the top level menu.

10. Reinstall any large garments that you removed in step 1.

11. Press . The peripheral will resume embroidering.

11817 Rev. A 2. Operation

▲

▼

▲

▲

▲

▲

▼

▼

Page 34

2-10 The Menus

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Return to origin?

Returns to the start position of a design that has been partially embroidered. Press to perform function.

Return to last stitching position?

Returns to the last stitched position before continuing if manual jog X/Y was used to view the

design. You may use this function if you have manually moved the x or y axis in the middle of a

design. this function will return you to the last position a stitch was sewn.

1. When the machine is stopped (but still in the middle of a design), press along with

any arrow key to move the hoop.

2. Scroll to the Function Menu and press .

3. Press or until the display reads Return to last stitching position?

4. Press ; the machine will return to the llast stitched position in the design.

5. Press to return to the top-level menu.

6. Press to resume embroidering.

Go to stitch?

Allows you to move to a specified stitch number within a design. For example, you may use this

function to move to a certain position in a design that may not have sewn well.

1. From the Function Menu, press or until the display reads: Go to Stitch?,

then press .

2. Use the arrow keys to enter the desired

stitch number (see illustration).

3. Press ; the machine moves to

that stitch.

4. If you were in the middle of a design when you performed this function, press

to return to the top-level menu, and press to resume embroidering.

Go to color change?

Allows you to move to a specified color change number within a design. For example, you may

use this function to move to a certain color in a design that may not have sewn well.

1. From the Function Menu, press

or until the display

reads: Go to Color Change?, then

press .

2. Use the arrow keys to enter the desired

color change number (see illustration).

Press or to change a character

Press or to change the cursor

position

▲

▼

▲

▼

Press or to change a character

Press or to change the cursor

position

▲

▼

▲

▼

▲

▼

▼

▲

▲

▲

▲

▼

▲

▲

▼

▲

▲

▲

▼

▲

ENTER STITCH NUMBER

0 0 0 0 0

ENTER COLOR CHANGE NUMBER

0 0 0

Page 35

The Menus 2-11

11817 Rev. A 2. Operation

3. Press ; the machine moves to that color change.

4. If you were in the middle of a design when you performed this function, press

to return to the top-level menu, and press to resume embroidering.

Go to headup?

Forces a move to the headup position, ready to sew. Press to perform function.

Options Menu

Used to set all machine options. Press or to view the selections. Use or

to select submenu options. All options are stored in machine memory until changed manually or

until a hard reset is performed.

Select hoop:

Lists all defined hoops. The hoops will appear in the units you select during configuration (i.e.,

English or Metric). Remember when selecting your hoop to select the correct type and size. The

list of defined hoops follows:

• 11.8" X 17.3" (30 X 44cm) Tube

• 11.8" X 14.2" (30 X 36cm) Tube

• 8.3" (21cm) Tube

• 7.1" (18cm) Tube

• 5.9" (15cm) Tube

• 4.7" (12cm) Tube

• 8.3" (21cm) Round (this is a wood frame)

• 7.1" (18cm) Spider

• 5.9" (15cm) Spider

• 4.7" (12cm) Spider

• 3.5" (9cm) Spider

• 2.8" (7cm) Spider

• Sock hoop

• 2.8" X 5.6" (7 X 14.2cm) Large cap frame

• 2.5" X 5.6" (6.3 X 14.2cm) Small cap frame

• 2.8" X 14.3" (7 X 36.2cm) Wide-angle cap frame

• Sash Frame

▲

▼

▲

▼

▲

Page 36

2-12 The Menus

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Orientation option:

Select from eight different design orientations

represented by the letter F (illustrated at right).

Used to turn a design within a hoop (e.g., for

caps, you would change the orientation).

Trim jump count:

Forces a trim function when consecutive jump stitches or needle ups equal or exceed the number

entered here. The range is 0-20, with 0 disabling the option. The default value is 8. If you enter a

trim value of 1 or 2, the peripheral will trim between letters of an alphabet.

Turbo mode:

When disabled, the machine uses a reduced speed-to-stitch table, resulting in higher embroidery

quality, but slower embroidery speed. Enabled is the default. The maximum embroidery speed is

fastest when Turbo mode is enabled.

Center design:

Allows the design to be centered with respect to the start point. Enabled is the default.

Disk design format:

Selects the format of a floppy disk when loading designs from a disk. Options are DOS, TAJIMA,

BARUDAN FMC, BARUDAN FDR, ZSK, and NO FORMAT. You must choose the format in order to

load a design. The NO FORMAT option will remove the Directory menu from the menu tree. This

saves keystrokes if you never load designs from the disk drive. Select a format other than NO

FORMAT to make the Directory menu re-appear.

Frame Menu

Selects the frame forward or frame backward function. Change by pressing or .

Reset Menu

Clear design

Clears the current design from the queue (does not delete the design from memory). Press

to perform function.

Note: If you started to perform a Move Command, but decided not to move, you must perform

a Clear Design command to continue.

Hard reset

Resets all operator selectable options to the default values, clears the current design from the

queue. Press to perform function.

Service/Maintenance Menu

Contains all service and maintenance functions. Eleven submenus are in the Service/maintenance menu.

Press to toggle between the Service/Maintenance menu and the Main menu.

▲

▲

▲

▼

Page 37

The Menus 2-13

11817 Rev. A 2. Operation

Head Timing Menu

Use the keystroke guide below to move to each position. Refer to the Hook timing section

of Chapter 4 for more information. The Z position (in degrees) will be displayed after each

function.

Go to headup

Forces the z axis to make one plus rotation and stop with needle in up position.

One revolution

Forces z axis to move to headup position with needle in down position.

Needle depth

Must be done after One revolution command to insure the z axis is at its proper position.

Hook timing

Must be done after Needle depth command to insure the z axis is in its proper position.

Top dead center

Must be done after Needle depth command to insure the z axis is in its proper position. Used to

set upper dead stop position.

1 degree forward

Forces z axis to move forward one degree.

10 degrees forward

Forces z axis to move forward ten degrees.

1 degree back

Forces z axis to move back one degrees.

10 degrees back

Forces z axis to move backwards ten degrees.

Z position

Releases the z axis to allow manual rotation with current z position display in degrees. Press

twice to exit Z position and lock Z axis.

▲

▼

▲

▼

▲

▼

▲

▼

▼

▲

▲

▲

Page 38

2-14 The Menus

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

4 Hr Lubrication Menu

Go to this menu when the message time to oil hook appears. This menu forces the machine to

move the hook to its proper position for oiling. Refer to the Lubrication section of Chapter 4 for

the proper place to apply lubricant.

8 Hr Lubrication Menu

Go to this menu when the message 8hr maintenance due appears. This menu forces the

machine to move to the proper positions for oiling. Refer to the Lubrication section of Chapter 4

for the proper place to apply lubricant.

40 Hr Lubrication Menu

Go to this menu when the message 40hr maintenance due appears. This menu forces the

machine to move to the proper position for oiling. Refer to the Lubrication section of Chapter 4

for the proper place to apply lubricant.

80 Hr Lubrication Menu

Go to this menu when the message 80hr maintenance due appears. This menu forces the

machine to move to the proper positions for oiling. Refer to the Lubrication section of Chapter 4

for the proper place to apply lubricant.

480 Hr Lubrication Menu

Go to this menu when the message 480hr maintenance due appears. This menu forces the

machine to move to the proper positions for oiling. Refer to the Lubrication section of Chapter 4

for the proper place to apply lubricant.

2100 Hr Lubrication Menu

Go to this menu when the message 2100hr maintenance due appears. This menu forces the

machine to move to the proper positions for oiling. Refer to the Lubrication section of Chapter 4

for the proper place to apply lubricant.

Page 39

The Menus 2-15

11817 Rev. A 2. Operation

Configuration Menu

This menu allows you to configure certain options. Normally these options are only configured

once, but you may set them as often as you wish. If a hard reset is performed, all these values will

return to their default values. If your periphal is not equipped with trimmers, some of these

menus may not appear. The options follow:

Thread trimmer:

Disables or enables the trimmers. Enabled is the default. Press or to

change.

Trimmer tail length:

Allows a short or long tail length after a trim. Short is the default. Press or

to change.

Trim on stitch length:

The stitch length defined here forces a trim when the next stitch is equal to or greater than the

selected length. The allowable range is 0-127. 0 disables the option. 127 is the default. Press

or to change.

Bobbin detect:

Turns ON or OFF the Under Thread Control

(UTC). ON is the default. On the EMT 10T,

press or to change.

On the EMT 10/4 or 10/4T, refer to the

illustration to the right to turn it on or off

on individual heads. A 0 means the bobbin

detect is turned on for that head, a means it is turned off.

Bobbin detect count:

Allows for selection of consecutive bobbin breaks before machine stops. The allowable range is 0-

50. 0 disables the option. 8 is the default. Press or to change.

Lock stitch:

Forces a lock stitch to be inserted at the beginning of every design and on every restart after a

trim. Enabled is the default. Press or to change.

Accumulate needle ups:

Accumulates consecutive needle ups and converts them into one motion. Enabled is the default.

Press or to change.

Return to design origin at EOD (end of design):

Forces an X/Y motion back to the position at the start of the design if the end point is not the

same. Enabled is the default. Press or to change.

▼▲▼▲▼▲▼▲▼▲▼▲▼▲▼

▲

Press or to change a character

Press or to

change the cursor position

▲

▼

▲

▼

Page 40

2-16 The Menus

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Start rack motion offset:

Allows a delayed start time of the X/Y rack motion in 5 degree increments depending on different

types of material used. Range is 0-20. 0 is normal movement, and the default. This delayed start

time may produce better embroidery results on delicate fabrics by allowing the needle to come

out of the fabric completely before rack motion occurs. Does not affect sewing speed, instead the

rack moves more quickly. Press or to change.

Unit of measure:

Allows selection of all operator prompts to be in IN (English) or CM (Metric). English is the default.

Press or to change.

Hoop limits:

Turns ON or OFF hoop limits. Default is ON. If you turn the hoop limits OFF, the machine will NOT

beep when it encounters a rack limit during a trace. You are at risk to hit the hoop when Hoop

Limits are turned OFF. Press or to change.

Design filter:

Filters a design when it is downloaded to the machine. Filtering removes all stitches equal to or

less than the selected short stitch length. Jump

stitches and needle ups are changed to normal

stitches if their sum is less than 12.7mm. If their

sum is longer than 12.7mm, they will be divided

into equal jump stitches less than 12.7mm. Refer

to the example illustration to the right. 3 jump

stitches (20 points each) are converted into 1

normal movement. Enabled is the default. Press or to change.

Design filter stitch length:

Determines what short stitch length to use for filtering up to 0.9mm. The allowable range is 0-9

points. It accumulates stitches that are shorter than this value and adds them to the next stitch.

The default is 4 points. Press or to change.

▼▲▼▲▼▲▼▲▼

▲

Page 41

The Menus 2-17

11817 Rev. A 2. Operation

Language selection:

Allows for different languages. Several languages are available.

Inching count:

Selects number of inching stitches (the slow stitches at the beginning of a design and on restart after

a trim or color change) sewn before the machine begins to speed up. These stitches allow the top

thread to catch and hold the bobbin thread. The allowable range is 0-9. Default is 3.

Max Jump Stitch Speed

Selects the maximum speed that jump stitches can be sewn. The range is 400-900 spm; default is

700 spm.

Move Function Menu

Move function

X+00.00 in Y+00.00 in

Forces an X/Y move to a selected distance

from the present position. Press

or to toggle between the X and Y

axis. Press to perform the move.

This is useful to select a position in a hoop that is not the hoop center.

The X and Y coordinates you enter are relative to your current position, NOT to the center of the

hoop.

▲

▼

Press or to change a character

Press or to change the cursor

position

▲

▼

▲

▼

MOVE X/Y X:+00.00IN Y:+00.00IN

Page 42

2-18 The Menus

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Define custom hoop

Note: Before you attempt to define a new custom hoop, center the 11.8" X 17.3" (30 X

44cm) Tube hoop.

Defines custom hoop sizes based on type of hoop, X/Y dimensions, and hoop center. Press

to start the process. You will be prompted to enter a hoop name (available names are Custom

Hoop 1-8). Use or to change the hoop name. Press to go on.

You will be prompted to choose the type of hoop (available choices are rectangle, cap, oval, and

circle). Press or to select the hoop type. Press to continue.

You will be prompted to choose the X and Y

dimensions (or diameter); refer to the illustration to the right. Press to go

on.

Next you must define your custom hoop’s

center. To do this, measure from the center

of the needle plate to the center of the

hoop in the Y direction. Enter this value to

define the new hoop’s center. Press

to go on.

You will be prompted to save the hoop; press for Yes or for No. Then press

to save the hoop. Your custom hoop will appear in the hoop list in the Options Menu. You

can overwrite a custom hoop, but once you have saved a custom hoop, it will remain in memory

until you reconfigure the peripheral.

Test Mode

Places the machine in test mode, where thread breaks are ignored and the queued design continues to run until is pressed. Must be disabled to return to normal embroidery. This is primarily a service function.

Press or to change a character

Press or to

change the cursor position

▲

▼

▲

▼

▲▲▲

▲

▼

▲

▼

▲▲▲

▲

▼

Y/X LENGTH Y:00.00IN X:00.00IN

Page 43

The Menus 2-19

11817 Rev. A 2. Operation

Diagnostics Menu

The following service diagnostic test are available to run or view:

RSA rev level

Displays the current revision level of the RSA files and the selected machine type.

BIOS rev level

Displays the current revision level of the ROM BIOS.

Motion Controller rev level

Displays the current revision level of the DSP chip set.

FPGA rev level

Displays the FPGA (Field Programmable Gate Array) rev level.

+5 Volt Current

Displays the current supplied by the +5V power supply.

Sew timers

Displays the total accumulated CPU time, and total sew time. The CPU time accumulates when

the machine is turned on, and the sew time accumulates when the machine is embroidering.

Bobbin Control Test

Allows manual testing of the UTC assembly. A beep will sound every time the bobbin sensor is

tripped. Press to start the test; press to stop the test.

Grabber Test

Allows manual testing of the grabber assembly. Press to extend the grabber, and

to retract the grabber.

▲

▼▲▼

Page 44

2-20 Disk Drive

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Disk Drive

The EMT Disk Drive is a read only disk system allowing the user to embroider EXPANDED designs

in the following formats: DOS 1.44MB, DOS 720K,Tajima, Barudan FMC, Barudan FDR, and ZSK.

The drive does NOT support condensed format designs. The disk drive replaces the need for the

EDS System Controller, thus converting a peripheral into a single embroidery device.

Installing .RSA Files

If the peripheral is part of an EDS or Wilcom System and the network will boot the peripheral, you

must install the .RSA files into the EDS III computer. To install the .RSA files, start Microsoft®Windows®, put the RSA disk into the disk drive, and follow these steps:

1. Click on Start→→Run from the Windows 95 taskbar (or File→→Run from the Windows 3.x Pro-

gram Manager) to display the Run dialog box.

2. Type a:\setup.exe and click Open (or OK if you are using Windows 3.x).

3. Follow the on-screen instructions to install the RSA files.

The operating program or .RSA file for each of the embroidery peripherals that supports the disk

drive will automatically load into the computer.

Note: If you upgrade your RSA files, all parameters are automatically set to their default values.

Configuring The EMT Disk Drive Controlled Unit

If you are operating from an EDS or Wilcom network as well as using the disk drive, install the

correct .RSA files as previously indicated and follow the rules of the network when assigning Unit

names to peripheral devices. Specifically, after setting the Peripheral Program, the Unit name must

be set differently for each peripheral attached to a single EDS System Controller.

If no network is attached to the EMT Disk Drive controlled embroidery peripheral, the Unit name

may be set to any name with 1-16 characters.

Operation

Booting The Peripheral

You may boot one of two ways. If the embroidery peripheral is properly configured and attached

to an EDS or Wilcom System containing the .RSA files, the peripheral will boot from the network

when the peripheral is powered up.

If the peripheral is not connected to an EDS or Wilcom System, or if the system is not turned on

and operating in EDS or Wilcom, the peripheral will boot from the disk drive. A boot disk must be

in the disk drive. If a boot disk is not located in the disk drive, the message: INSERT BOOT DISK

will show on the display. Insert the boot disk and press . After the machine boots

correctly, it will display the model name.

▲

Page 45

Loading a Design 2-21

11817 Rev. A 2. Operation

Loading a Design

Through the Network

After the embroidery peripheral is booted, you may load designs into the embroidery peripheral

buffer. If you are loading designs through the network, please refer to the EDS III Basic manual for

a detailed explanation of sending designs from the computer to the peripheral.

Through the Disk Drive

Once the embroidery peripheral is booted, you may load designs.

Directory Menu

1. Press to display the Directory Menu. If the design format setting in the Options

Menu is correct, proceed to the next step. If the format is not correct, see the “Selecting the

Format” section below before you proceed.

2. Place the diskette with the design to be loaded in the disk drive, then press .

The name of the first design in the directory will show on the peripheral display.

3. To load the design showing on the display, press . If the design name showing on the

display is not the design you wish to load, press or until the desired

design name is showing on the display, then press .

When is pressed, the disk drive light comes on as the design is loaded into the

embroidery peripheral design buffer. While the design is being loaded, the display shows the

name of the design and that it is loading. When loading is complete, the display will show

DESIGN MENU.

Selecting The Format

Options are DOS, TAJIMA, BARUDAN FMC, BARUDAN FDR, ZSK, and NO FORMAT. You must

choose the format in order to load a design. The NO FORMAT option will remove the Directory

menu from the menu tree. This saves keystrokes if you never load designs from the disk drive.

Select a format other than NO FORMAT to make the Directory menu re-appear.

Format Selection

If you need to change the format selection, go into the Options Menu, then press or

to display Floppy disk format. Follow these steps to select a new format:

1. The currently selected format will show on the display. To change the selected format, press

or until the correct format is displayed.

2. When the desired format is displayed, press .

▲

▲

▼

▲

▲

▲

▲

▼

▲

▼

Page 46

2-22 Hooping

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Hooping

Proper hooping is essential for quality embroidery. The garment or fabric must be taut and flat,

and the weave or knit must be aligned. Follow these basic hooping guidelines to ensure proper

hooping:

• Always hoop on a flat surface

• Use the correct backing

• Use the smallest hoop possible that will accommodate the design within the rack limits (see

the Trace menu for more information).

• Smooth the garment as much as possible before

hooping, including any lining or backing

• Always check the back of the garment after

hooping to make sure there are no wrinkles or

parts which will be inadvertently sewn.

• Do not over-tighten or over-stretch the material

in the hoop

• Be sure the inner hoop does not extend past the outer hoop on the bottom; both rings of

the hoop should be evenly aligned

• Practice

To hoop with a tubular or flat hoop, place the outer hoop on a clean, flat surface. Place the backing down, then the fabric, and then place the inner hoop inside the outer hoop with the mounting brackets facing UP (see Figure 2-8).

Figure 2-8

Mounting brackets

facing UP

(tubular hoop shown here)

Page 47

Quick Start 2-23

11817 Rev. A 2. Operation

Quick Start

The following section outlines the required steps to embroider a design.

Set home

This is normally done on power-up; if the machine detects an error during its test sequence on

power-up, you must correct the error condition (e.g., if the machine is not at HEADUP, you must

GO TO HEADUP), then Set Home.

Press until the display reads FUNCTION MENU, then press . Press

or until the display reads SET HOME. Press .

Select hoop

In the Options Menu, press or until the display reads SELECT HOOP.

Press or to scroll to the proper hoop option. Press to continue.

Select orientation

In the Options Menu, Press or until the display reads Orientation Option. Press

or to scroll through the orientation options. When the desired orientation is dis-

played, press to continue.

Center hoop

In the Function Menu, press or until the display reads GO TO HOOP

CENTER?. Press to center the hoop.

▲

▲

▼

▼

▲

▲▼▲

▼

▲

▼

▲

▼

Page 48

2-24 Quick Start

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Attach hoop

Tubular hoops attach to the peripheral via the inner frame (see Figure 2-8). This allows the material to hang down around the frame without being sewn together during embroidery. Flat hoops

attach to the peripheral via the outer frame.

Tubular hoops

Refer to the following steps to attach the tubular hoop to the peripheral:

1. Lower the sewing table by lifting the front of the table and pulling it towards you. Place the

table top on the lower table supports (Figure 2-9) and push the table top towards the rear of

the machine. The table top will snap into place.

2. Attach the tubular frame support arms to the proper holes on the X-carriage for the selected hoop.

Use two thumb screws for each support arm (see

Figure 2-10). Make sure the clips (on the ends

where the tubular frame will attach) face UP.

3. Insert the hoop frames by sliding the side brackets

underneath the spring clips on the support arms.

Make sure the slotted bracket (see Figure 2-11) is to

the right (as you are facing the machine). Slide the

hoop towards the rear of the machine until it snaps

into place.

Special note for the EMT 10/4 and 10/4T

You MUST remove all 5 tabletop inserts before embroidering tubular goods on the EMT 10/4 or

10/4T. Failure to do so may result in damage to the equipment or bodily injury. Refer to Chapter 1

for more information.

Figure 2-12

Upper-table

support

Figure 2-13

Figure 2-14

Flat hoop

mounting brack-

et (behind nee-

dle case)

Push the hoop to the right (as you

are facing the machine) then insert

the left side of the hoop

Page 49

Quick Start 2-25

Flat hoops

You can purchase an optional kit to embroider using flat hoops. Flat hoops attach to the peripheral via the outer frame and attach to the peripheral differently than tubular hoops.

Refer to the following steps to attach the flat hoop to

the peripheral:

1. Raise the sewing table by lifting the front of the

table and pulling it towards you. Place the table top

on the upper table supports (Figure 2-12) and push

the table top towards the rear of the machine. The

table top will snap into place.

2. Remove the tubular frame support arms from the

front of the X-carriage. Remove the two thumb

screws holding each support arm (refer to Figure

2-10).

3. Attach the flat hoop adapter bracket to the x-car-

riage using the thumb screws. Make sure the slotted end of the adapter is facing to the right.

4. Along the x-carriage (behind the needle case) are

the mounting locations for the flat hoops. The

mounting brackets on the peripheral are springloaded, so insert the right side (as you are facing

the machine) of the hoop’s bracket first, then push

slightly to the right (to move the spring-loaded

bracket). Insert the left side of the hoop’s bracket

next. Refer to Figures 2-13 and 2-14.

11817 Rev. A 2. Operation

Figure 2-11

Inner frame attaches

to peripheral

Figure 2-9

Lower table

support

Figure 2-10

Thumb screws

Slotted bracket

Page 50

2-26 Quick Start

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Select a design

To select a design after it has been sent to the peripheral, press until the display scrolls to

DESIGN MENU. Press and the first design is displayed. Use to scroll forward or

to scroll backward through the designs in the buffer. Scroll through the menu until you

reach the design you want. The LCD displays the name of the design, the stitch count, the number of colors in the design, and the current orientation that is selected. Press to select

the design; the LCD displays the next menu.

Color Menu

To set the color sequence press until the display shows COLOR MENU, then press

. Press to move to the next

number and to move back. Press

or to change the needle

position. Press to select the

color sequence; the LCD displays the next

menu.

Press to insert a color sequence and to delete a color

sequence.

Available color choices:

• 1-10 = needle number

• 0 = pause for this color change only

• – = skip this color change

• P = pause at this color change and all color changes thereafter.

• A = stop for applique

Run Menu

Press to queue the design; the LCD displays the next idle menu.

Trace the Design

Note: Do NOT pull the needle or presser foot down to trace.

Press until the display reads: FUNCTION MENU, then press . Press

or until the display shows Trace design outline?, then press . The

LCD will display Calculating design outline. When the outline is calculated, it will display Trace Design name and show you the needle number. Press to initiate

the trace function and the pantograph will begin to move. The hoop moves along the outline of

the design without embroidering. The machine beeps and displays Rack Limit if a rack limit is

encountered. The beep means the needle will strike the hoop if sewn. To correct this, recenter the hoop, select and use a larger hoop, or manually jog the hoop into position. Perform

another trace after you have corrected the problem.

▲

▲

▼

▲

▲

▲

▼

▲▼▲

▲

▼

▲

Needle position

▲

▲

▲

▼

COLOR

1 : 1 2 3 4 5 6 7 8 9

10 0 - P A

Page 51

Quick Start 2-27

Start Embroidering

After the tracing function is finished, press to return to the idle menu

again. Press and the machine will move to the beginning of the design. Press

again and the peripheral will embroider the design selected (you may have

to press an additional time if the design began with a Needle Ups command). The embroidery will stop when the job is complete and the display reads: END OF

DESIGN. To stop the embroidery process before the design is complete, press

on the keypad. To continue after a stop or thread break repair, press again.

Embroidery Speed

While the design is being embroidered you may change the speed of the machine by pressing

or .

Idle Display

While the machine is operating, you may press at any time to see the Idle

display. There are two screens available in the Idle display; press to toggle between

them.

The first display (Figure2-15) shows the

design name, the current sewing speed, the

current orientation, and the current needle

number.

The second display (Figure 2-16) shows the

stitch count, the selected sewing speed, the

needle number, and the percent complete.

11817 Rev. A 2. Operation

▲

▼

▲

Figure 2-15

Figure 2-16

▲

▲

Page 52

2-28 Quick Start

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

Page 53

Standard Cap Frames 3-1

11817 Rev. A 3. Accessories

3.Accessories

Standard Cap Frames

Because a cap is not flat, it cannot be hooped in a flat hoop. To solve this problem, a special

device called a cap frame has been created to hoop caps. There are two sizes of cap frames:

7.0cm X 14.2cm (Large) and 6.3cm X 14.2cm (Small).

There are three parts to a cap frame:

• The cap hoop

• The cap frame driver

• The cap frame gauge

Installing the Standard Cap Frame Driver

Follow these steps and consult Figures 3-1 and 3-2 to attach the cap frame.

1. Lower the tabletop to gain

access to the cap frame

mounting brackets under the

head.

Special note for the EMT 10/4

and 10/4T

You MUST remove all 5 tabletop

inserts before embroidering caps

on the EMT 10/4 or 10/4T. Failure to do so may result in damage to the equipment or bodily

injury. Refer to Chapter 1 for

more information. Also, correlate

the number on the driver with

the number on the head to

ensure sew quality.

2. Select the Large or Small cap frame hoop size from the Options Menu.

3. Under the cylinder arm, locate these cap frame mounting brackets:

• The dove-tail bracket under the needle area

• The bracket with a round hole at the rear of the head.

4. Loosen the thumb screw on the rear mounting bracket.

Figure 3-1

Dove-tail mounting bracket

Rear mounting

bracket

Thumb screw

Page 54

3-2 Standard Cap Frames

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

5. Loosen the thumb screw on

the dove tail bracket on cap

frame driver.

6. Pull the cap frame shaft

towards you, and attach the

hoop bracket to the carriage.

It attaches like a flat hoop.

7. Guide the cap frame shaft into

the hole in the rear mounting

bracket. At the same time,

insert the dove-tail bracket

into the dove-tail mount.

8. Push the cap frame shaft into the bracket hole until the silver ring on the shaft touches the

rear mounting bracket.

9. Tighten the thumb screw on the rear bracket.

10. Tighten the thumb screw on the dove-tail bracket.

11. Repeat this procedure for each head on a four-head peripheral.

12. Press to go to the Function menu then press ; select Go to Hoop Cen-

ter? and press to center the hoop.

First time adjustment

The first time you install the standard cap frame driver(s), you must adjust them to your peripheral

to ensure sew quality. Follow these steps to adjust the driver(s).

1. Install the drive(s) onto the head(s), if you have not.

2. Loosen the four button-head screws across the top

of the drive bracket (see Figure 3-3).

3. Move the beam numerous times to the left and right

extremes (x direction) to align the guide bar in the

ring drive slot.

4. Once the guide bar is aligned, move the beam so

that one of the screws is aligned with the needle

plate. Tighten this screw slightly.

5. Repeat step 4 for the remaining three screws.

6. Move the beam to the left and right extremes one

time. Repeat step 4 again, but this time, tighten the screws fully.

Figure 3-2

Side view

Front view

Thumb

screw

Dove-tail

bracket

Figure 3-3

▲

Page 55

Standard Cap Frames 3-3

11817 Rev. A 3. Accessories

Using the Cap Hoop Gauge

Because the cap hoop is curved, it is difficult to control on a flat surface. The cap hoop gauge

clamps to a table edge to resolve this problem. Once the gauge is clamped, snap the cap hoop

into it to hoop the cap. Hoop the cap according to the instructions on the next page.

Hooping a Cap

To hoop a cap, follow these steps and see Figure 3-4

1. With the latch on the left side,

open the cap frame and rest the

cover on the arm of the gauge.

2. Remove any cardboard or packing

material from the cap.

3. If the cap has a sweat band, pull it

to the outside. If the cap has a

braided cord, move it to the inside

of the cap.

4. If you are using backing, place it

inside the cap.

5. Slide the cap on the hoop frame so

that:

• The brim of the cap is away

from you

• The front of the cap is up

• The sweat band is under the square retainer at the center of the frame

• The sides of the cap are inside the outer arms of the cap frame

6. Push the cap onto the cap frame until the embroidery field is centered. Since caps come in different styles and sizes, you will have to determine how far forward the cap should be.

7. Hook the wire of the hoop latch over the catch, but do not fasten it.

8. Pull the cap as straight, fold free, and taut as possible.

9. Use your right hand to grasp the cap securely from underneath while fastening the frame

latch with your left hand.

10. Pull the elastic cord of the frame over the brim of the cap to secure it.

11. Snap the hoop out of the frame gauge.

Figure 3-4

Brim holder

Page 56

3-4 Standard Cap Frames

Operation Manual for the EMT 10T, 10/4, and 10/4T Melco Embroidery Systems

12. Install the cap frame on the cap frame driver by aligning the frame and the driver, then snapping the frame slots under the roller clamps on the driver.

13. Repeat this procedure for each head on a four-head peripheral.

Raised needle plates

Raised needle plates improve embroidery quality on caps. When cap frames are attached, the

curve of the frame leaves extra space between the cap and the needle plate. To eliminate the

space and ensure high-quality embroidery, a qualified operator or maintenance person should

install raised needle plates as described below. See Figure 3-5.

Note: When using a raised needle plate, use spacers to raise the presser foot.

1. Remove the two screws attaching the standard needle plate and replace the standard plate

with the raised plate. Use the same screws to attach the raised needle plate. The needle

should be centered in the hole in the raised needle plate.

2. Remove the lower cover on the front of the needle case. It is not necessary to remove any

thread.

3. Using a small flat-bladed screwdriver,

push the standard spacer up to the top

of the presser foot assembly (see Figure

3-5).

4. Shim spacers come in two thicknesses:

0.020" and 0.040". Each shim spacer

has five holes, which will cover half of

the needles in each sewing head. The

raised needle plates are 0.090" higher

than a standard needle plate, so you

should add two 0.040" spacers to both

sides of each sewing head (needles 1-

10).

Figure 3-5

Add the extra spacers

beneath the standard shims.

Lower cover

Page 57

Standard Cap Frames 3-5

11817 Rev. A 3. Accessories