Page 1

Operation Manual for

the Advantage 18

embroidery peripheral

Part Number 110265-01, Revision A

• 18 Colors

• One Needle

• Automatic Color Change

• Automatic Rethreading

• Under Thread Control

A Saurer Group Company

Page 2

1575 West 124th Avenue

Denver, Colorado 80234

United States of America

E-mail via Internet: publications@melco.com

Copyright © Melco Embroidery Systems, 1995.

ALL RIGHTS RESERVED No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means (electronic, mechanical, photocopying, recording, or

otherwise) without prior written approval of Melco Embroidery Systems. Melco reserves the right to

revise this publication and to make changes in it at any time without obligation of Melco to notify any

person or organization of such revisions or changes.

All precautions have been taken to avoid errors or misrepresentations of facts, equipment, or

products. However, Melco Embroidery Systems does not assume any liability to any party for loss or

damage caused by errors or omissions.

Printed in the United States of America

FIRST DRAFT: November 2, 1995

Page 3

Table of Contents

Advantage 18

Operation Manual

1. Introduction and Installation

Physical Arrangement 1 - 1

The Controller 1 - 2

The Embroidery Head 1 - 2

The Thread Tree 1 - 2

The Keyboard 1 - 2

The Pantograph 1 - 2

Installation 1 - 3

Power Requirements 1 - 3

Static Electricity 1 - 3

Inspecting Your Embroidery Peripheral 1 - 3

Unpacking the Advantage 18 1 - 3

Tables And Cabinets 1 - 3

Embroidery Peripheral 1 - 3

The Air Compressor 1 - 6

Canned Compressed Air 1 - 6

Configuring The Advantage 18 1 - 6

What to Configure 1 - 6

The Peripheral Program 1 - 7

The Unit Number 1 - 7

The Language 1 - 7

How to Configure 1 - 7

Start-Up Messages 1 - 8

2. Operating the Advantage 18

How Threads Are Spliced 2 - 1

Threading the Advantage 18 2 - 1

Threading to the Selector Carriage 2 - 1

Inserting the Thread into the Splicing Cell 2 - 3

Rethreading After a Failure 2 - 3

Thread Types and Needles 2 - 5

Thread Types 2 - 5

Needles 2 - 5

Tensions 2 - 5

The Upper Tension 2 - 5

Bobbin Tension 2 - 5

Installing a Needle 2 - 6

Hooping 2 - 7

Hooping Flat Goods 2 - 7

Loading The Hoop 2 - 8

Cap Frames 2 - 9

Installing the Cap Frame Drive 2 - 9

Cap Hooping 2 - 11

Using a Raised Needle Plate 2 - 11

i

Page 4

Table of Contents

Operation Manual

Advantage 18

Keyboard Operation 2 - 12

3. The Setup Menus

An Overview of the Advantage 18 Menus 3 - 1

Design Menu 3 - 2

Color Menu 3 - 3

Tension Menu 3 - 5

Orientation Menu 3 - 6

Run Design Menu 3 - 7

The Idle Menus 3 - 7

Introduction 2 - 12

The Keys and Their Functions 2 - 12

Key Combinations 2 - 13

Sending a Design 2 - 14

Receiving a Design 2 - 14

Selecting a Design 3 - 2

Deleting a Design 3 - 2

An Example 3 - 4

Change Now 3 - 4

Select the Thread Position 3 - 6

Select the Tension Setting 3 - 6

Setting Orientation 3 - 6

4. The Customizing Menus

Frame Menu 4 - 1

The Frame Idle Display 4 - 2

Return To Origin 4 - 2

Trace Menu 4 - 3

Home Menu 4 - 4

Set Home 4 - 4

Hoop Limits 4 - 4

Power Fail Rescue 4 - 5

Move Menu 4 - 6

When to Use The Move Menu 4 - 6

Trim Menu 4 - 8

Setting the Options 4 - 8

Trim Immediate 4 - 8

Jump Count 4 - 8

Bobbin Menu 4 - 9

The Splicing Menu 4 - 9

Change Thread 4 - 10

Insert Thread 4 - 10

Valve 1 Off 4 - 11

Up Trim Mtr On 4 - 11

Trim Thread 4 - 12

Draw Motor 4 - 12

Low Pressure On 4 - 13

ii

Page 5

Table of Contents

Advantage 18

Operation Manual

High Pressure On 4 - 13

Reset Menu 4 - 14

System Reset 4 - 14

Hard Reset 4 - 14

5. Operator Maintenance

Cleaning the Advantage 18 5 - 1

Cleaning Your Machine’s Exterior Surfaces 5 - 1

Cleaning the Rotary Hook Area 5 - 1

Lubricating the Advantage 18 5 - 2

Lubricating The Embroidery Head 5 - 2

Rotary Hook 5 - 2

Needle Bar 5 - 3

Needle Bar Driver 5 - 4

Upper Connecting Rod 5 - 4

Lower Connecting Rod 5 - 5

Lubricating The Beam 5 - 6

Lubricating the Pulley Assembly 5 - 7

Lubricating the X-Carriage Rollers 5 - 9

Lubricating the Y-Rails 5 - 10

Lubricating the Lower Trimmers 5 - 11

The Rear Trimmer Parts 5 - 12

The Front Trimmer Parts 5 - 12

Embroidery Head Timing 5 - 13

Machine Out Of Timing 5 - 13

Making A Stitch 5 - 14

Setting Timing 5 - 15

Needle Depth Check/Adjustment 5 - 15

Hook Timing 5 - 17

Checking Hook Timing 5 - 18

Adjusting Hook Timing 5 - 19

Cleaning the Color Change Area 5 - 21

Color Change Cover Removal 5 - 21

The Manifold 5 - 22

Upper Trimmers 5 - 23

Pretensioner 5 - 24

Addendums

A. Glossary of Embroidery Terms

B. Error Messages

C. Hoop Sizes

D. The Quick Reference Guide

INDEX

iii

Page 6

Table of Contents

Operation Manual

Advantage 18

iv

Page 7

1 - 1

110265-01, Rev. A 1. Introduction and Installation

1. Introduction and Installation

The Advantage 18 is an 18 color embroidery peripheral using an innovative, air driven, color

change process that automatically rethreads its single needle. You may embroider a design with up

to 18 colors without pausing to change spools or manually rethread the needle. In addition to

embroidering on flat goods, the Advantage 18 embroiders on caps using the optional cap frame

attachment.

WARNING! For operator safety, Never allow untrained

personnel operate the Advantage 18.

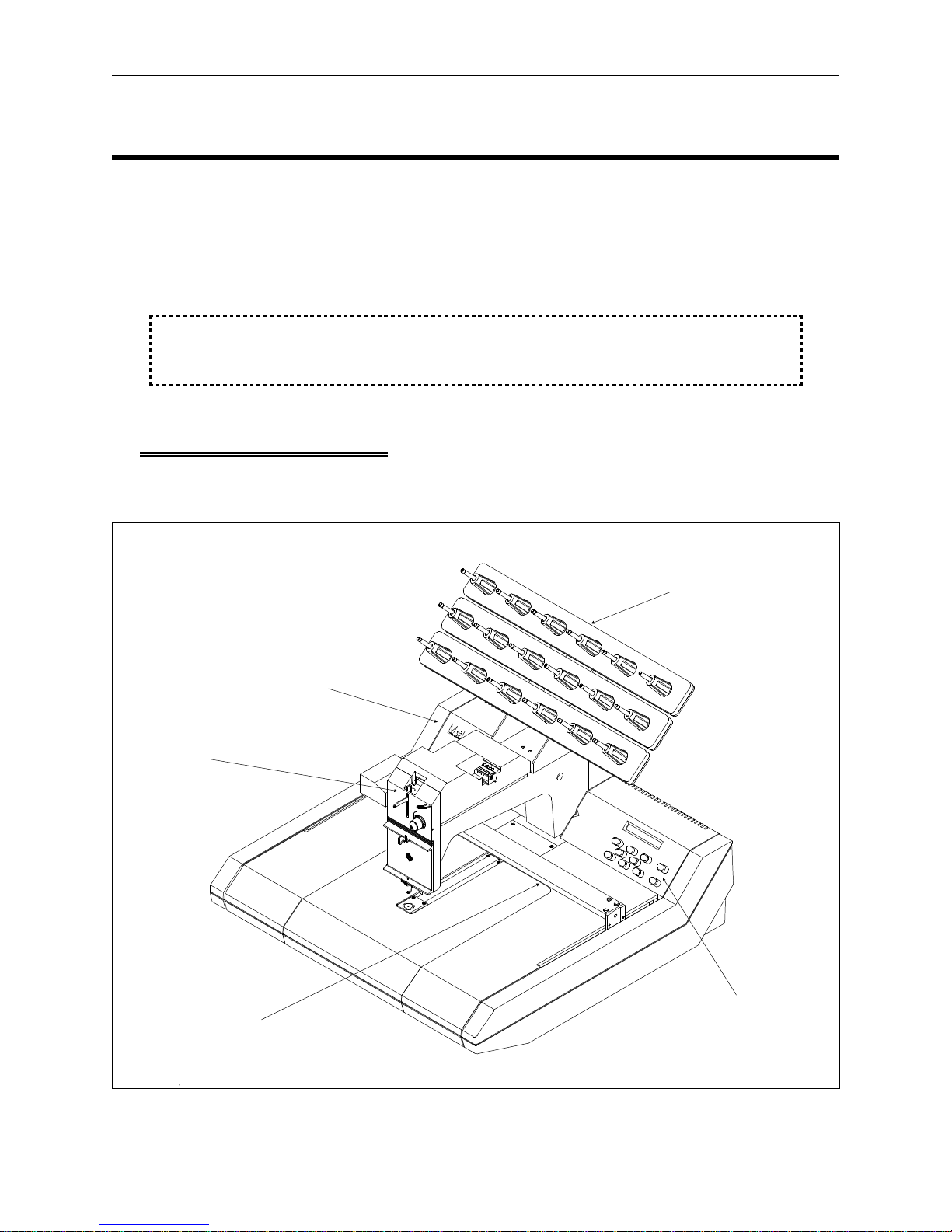

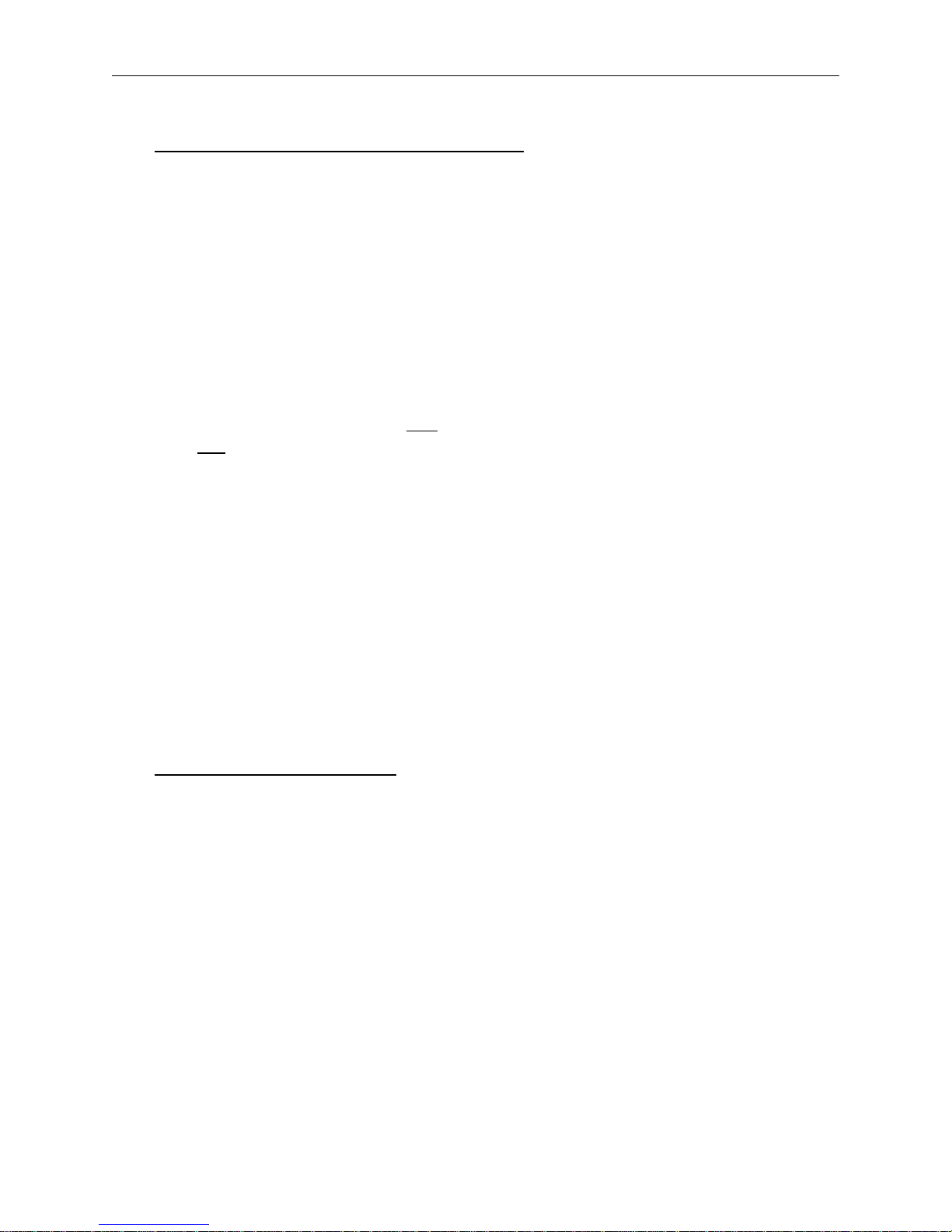

Physical Arrangement

The Advantage 18 has five sections: the controller, the embroidery head, the thread tree, the

keyboard, and the pantograph (see Figure 1-1).

Embroidery

Head

Pantograph

Thread Tree

Controller

Keyboard

Figure 1-1

Page 8

1 - 2 Physical Arrangement

Advantage 18 Operation Manual Melco Embroidery Systems

The Controller

The controller contains the printed circuit boards (PCB’s) and electronics that control much of the

machine’s operation.

The Embroidery Head

The embroidery head consists of the parts that move the needle, advance the thread, and produce

stitches.

The Thread Tree

The thread tree holds up to 18 spools of thread and mounts on the embroidery head. Its

connecting plastic tubes feed the individual threads from the spools to the thread select carriage.

The Keyboard

Commands are given to the peripheral through the keyboard. The Liquid Crystal Display (LCD)

displays informative messages. The main power supply and the motor that moves the pantograph

forward and backward are located under the keyboard cover.

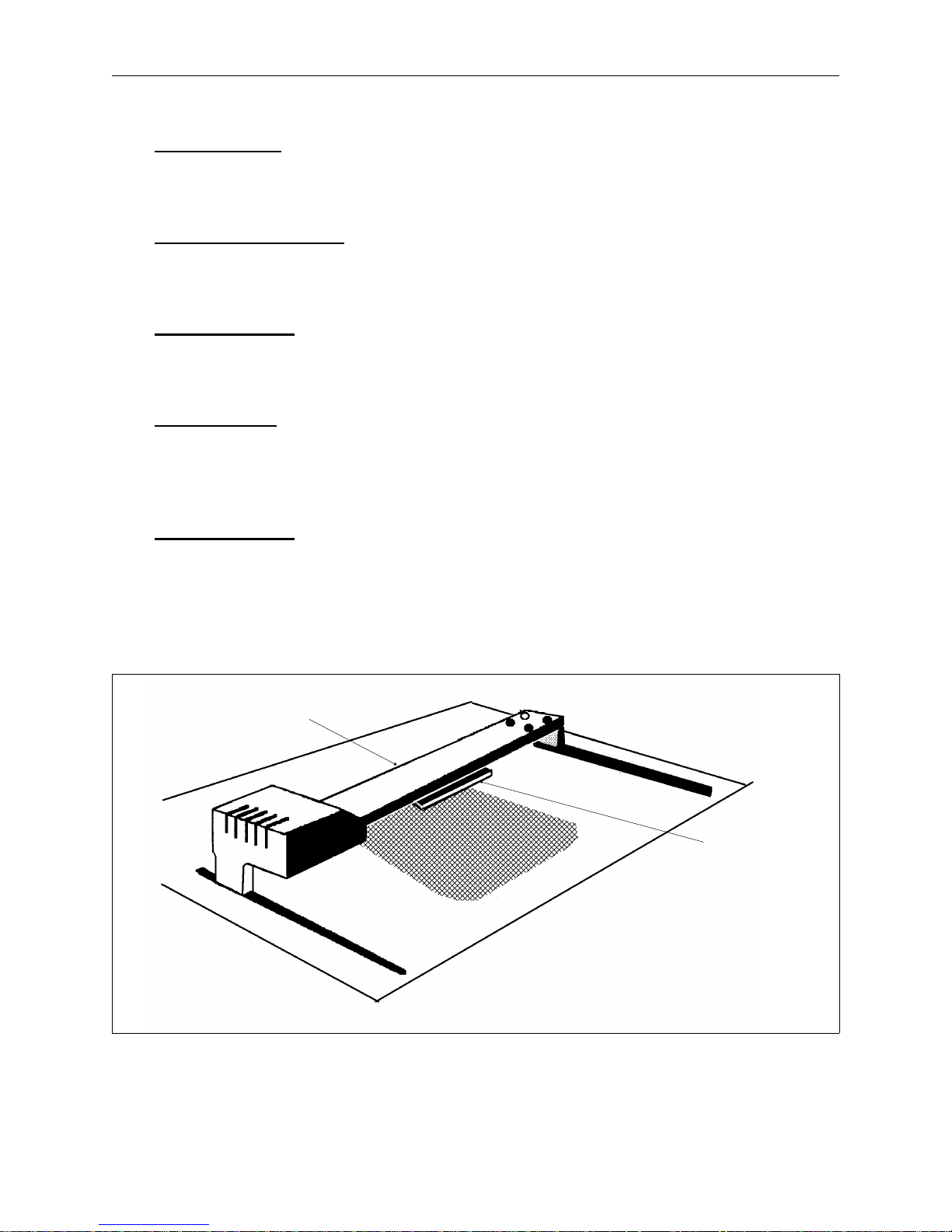

The Pantograph

The pantograph (see Figure 1-2) moves the hoop right or left (the X axis) and forward or backward

(the Y axis). The beam is the arm of the pantograph that moves forward or backward. Inside the

beam is the X-carriage that moves left or right. The hooped garment attaches to the X-carriage. As

the X-carriage moves the hoop left or right, the beam moves the X-carriage forward or backward.

This movement controls the placement of the stitching.

Beam

X-Carriage

and Hoop

Attachment

Figure 1-2

Page 9

Unpacking the Advantage 18 1 - 3

110265-01, Rev. A 1. Introduction and Installation

Installation

This section explains how to get your Advantage 18 unpacked, powered up, and connected to your

computer. Directions for installing software are in the software operation manuals.

If you are using the Advantage 18’s optional disk drive, skip the directions for connecting the

Advantage 18 to a computer. All instructions for the optional disk drive are in its operation manual.

Power Requirements

Electricity can have power spikes or surges that may affect your computer or embroidery

peripheral’s operation. Melco suggests a dedicated power for your system with a line conditioner.

Inspecting Your Embroidery Peripheral

Inspect all cartons for physical damage. If any damage is found, contact the shipper.

Unpacking the Advantage 18

When cutting open the boxes be careful not to damage any of the equipment. Continue to inspect

the parts for any physical damage not apparent from the condition of the cartons. Again, contact

the shipper to report any damage.

Tables And Cabinets

Unpack and place the work station furniture before unpacking the embroidery equipment.

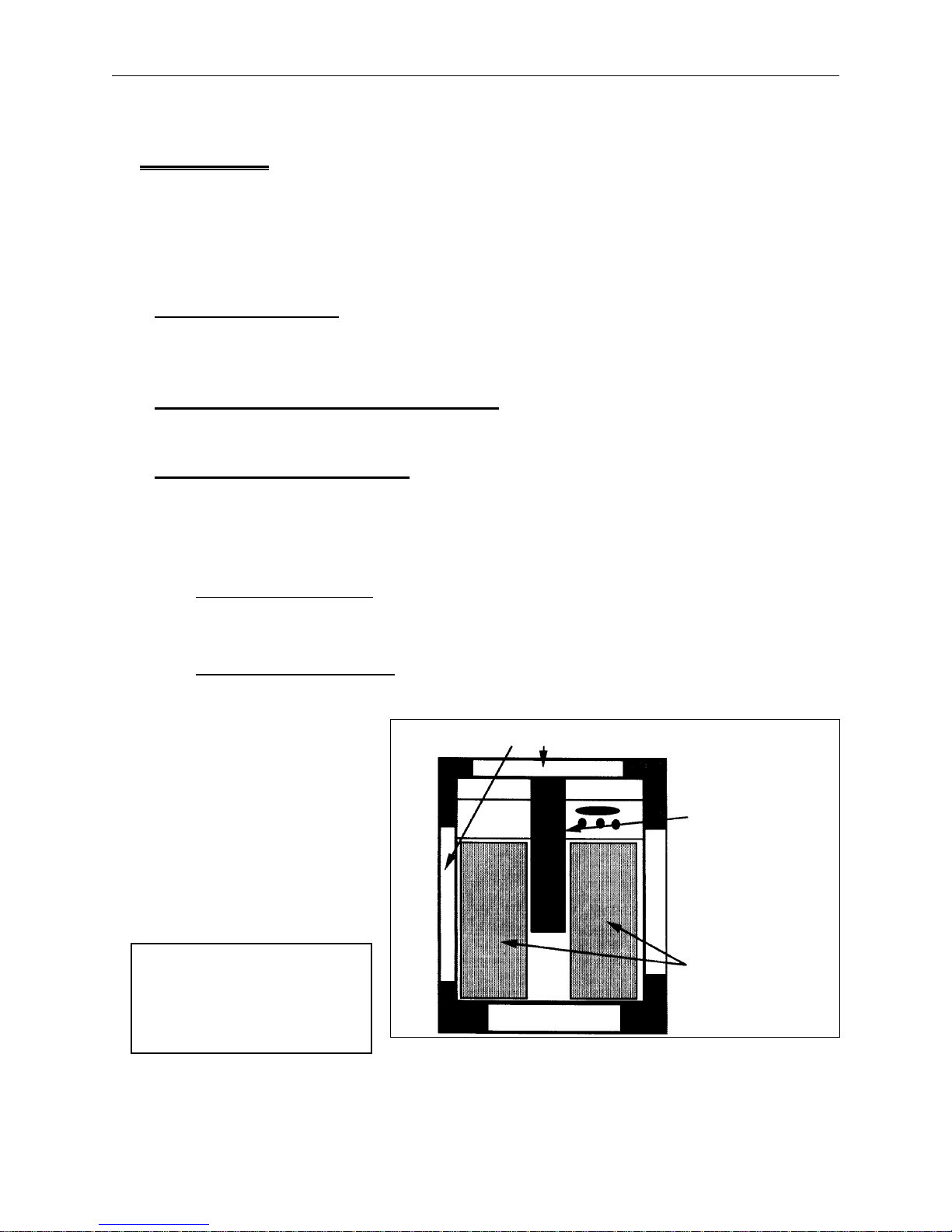

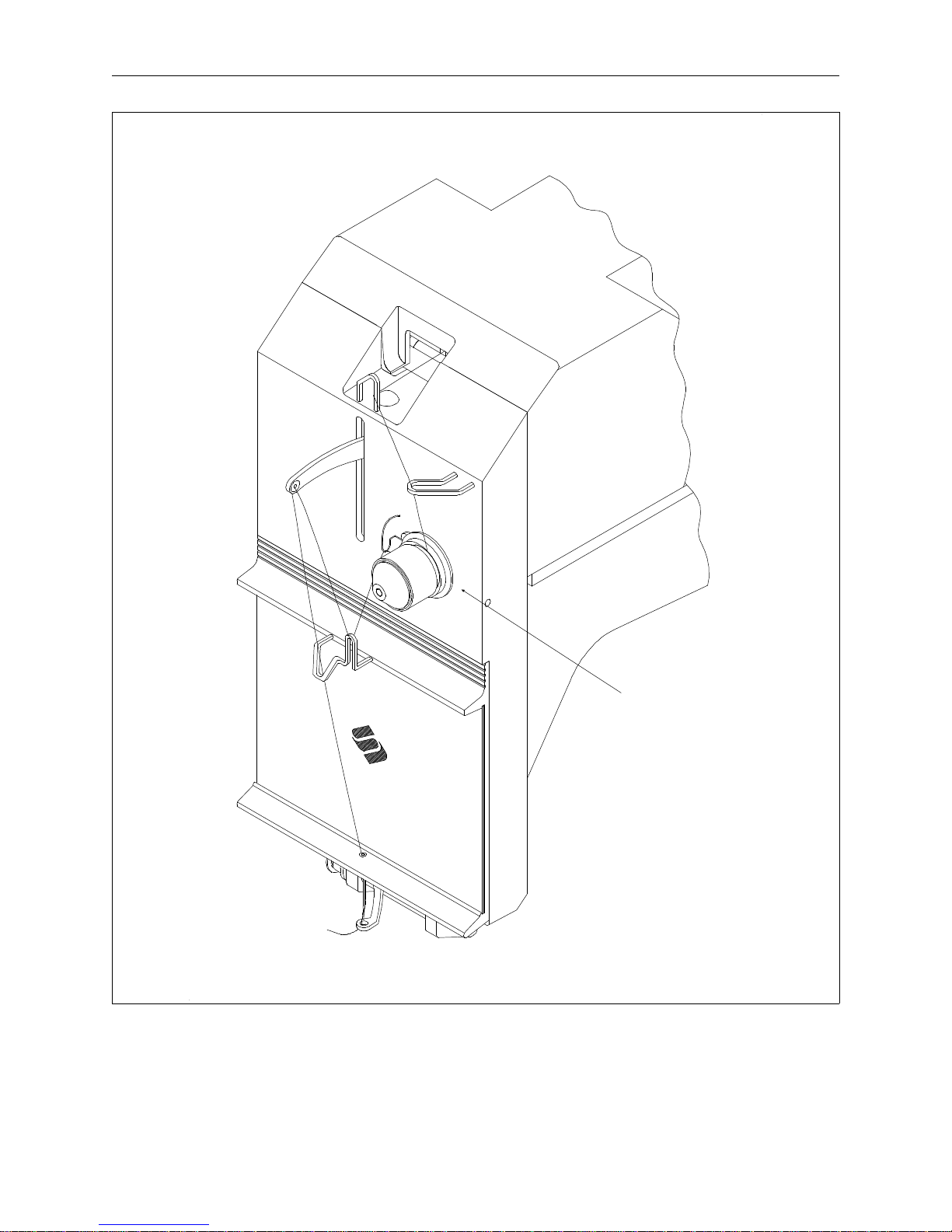

Embroidery Peripheral

1. Carefully cut and remove the binding straps from the cardboard shipping carton containing the

embroidery peripheral.

Foam Cushions

2. Lift the top cover off the outside

carton.

3. Remove the outside carton from

Embroidery

Head

the bottom cover.

4. Remove any packing boxes and

protective pads from around the

embroidery head (see Figure 1-3).

CAUTION: Use two

Packing Boxes

people to remove and

place the embroidery

peripheral.

Figure 1-3

Page 10

1 - 4 Installation

Advantage 18 Operation Manual Melco Embroidery Systems

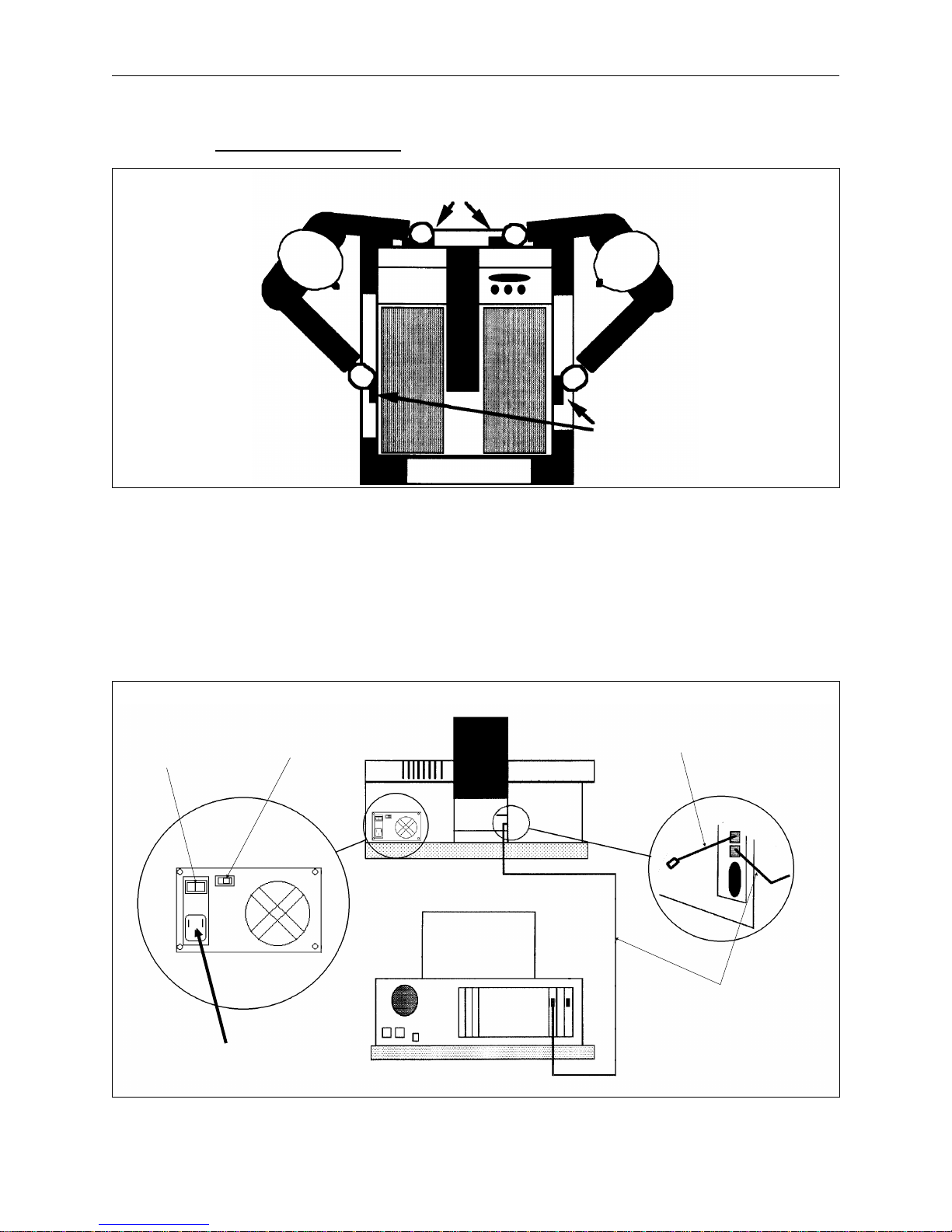

5. Grasp the underside of the machine at the four locations indicated in Figure 1-4.

Lift Here

Lift Here

Figure 1-5

6. Keep the embroidery peripheral level. The unit and foam packaging should come out of the

carton with relative ease.

7. Place the embroidery peripheral onto its dedicated work station.

8. Set the 115V/220V selector switch to the proper setting for your power supply. The switch is

just to the right of the ON/OFF switch (see Figure 1-5).

Machine

ON/OFF

Switch

Voltage

Selector

Switch

Rear of Peripheral

Terminator

Cable

Attach Power

Cable here

Network

Cable

Rear of Computer

Figure 1-4

Page 11

Canned Compressed Air 1 - 5

110265-01, Rev. A 1. Introduction and Installation

9. Attach the power cable to the rear of the unit as shown in Figure 1-5.

10. Still referring to Figure 1-5, install the network cable between the computer and the Advantage

18. If you only have one peripheral device attached to the computer, install the terminator

cable to the machine as the figure shows. If more than one peripheral device is attached to the

computer, install the terminator cable on the last peripheral in the series.

11. Install the power cords of the computer, the monitor, and the embroidery peripheral to the

power source.

The Air Compressor

You must provide an air compressor for attaching the Advantage 18. The air compressor must meet

the following requirements:

• Air pressure of 100 to 120 psi (pounds per square inch)

• Air flow of 2 scfm (standard cubic feet per minute) at 90 psi for each Advantage 18

• A regulator with a minimum range of 70 to 100 psi

• A 5 micron particle filter

• A 0.5 micron oil-coalescing filter

The Advantage 18 comes with a 6 foot long air supply line with a standard quick-disconnect fitting.

To install the tubing on the Advantage 18:

1. Route the free end of the tubing through the open base of the thread tree.

2. Insert the end of the tubing into the air supply fitting with a red ring around it. It is located just

in front of the thread tree, at the back of the color change assembly.

3. Push the tubing into the fitting as far as it will go.

Canned Compressed Air

Use a can of compressed air that is free from contaminants to insert threads through the thread

guide tubes.

Configuring The Advantage 18

When turning on the Advantage 18 for the first time it must be configured to operate properly.

After configuration is completed, each time the Advantage 18 is turned on it checks its memory for

the needed data. The peripheral requires reconfiguration when a new PCB is installed.

Page 12

1 - 6 Configuring The Advantage 18

Advantage 18 Operation Manual Melco Embroidery Systems

What to Configure

The three items of information set during configuration are:

• Peripheral Program

• Unit Number

• Language

The Peripheral Program

The CPU used in the Advantage 18 is also used in other Melco peripherals. The peripheral program

is set to match the CPU to the peripheral it is controlling. On new units the peripheral program is

set at the factory. However, if you replace the CPU board, you must reset the peripheral program.

the Advantage 18 is configured with the incorrect peripheral program, it will not operate properly,

and may be damaged.

The Unit Number

A network address or unit number for each peripheral attached to an EDS system must also be set

at the peripheral. The number may be between 1 and 16 when using EDS II software or between 1

and 64 when using other Melco software. Each peripheral must have a unique unit number.

If

Before sending designs to the Advantage 18, enable the unit number on the computer. See your

software operation manual for instructions.

The Language

Set the language displayed by the LCD to either English or Spanish.

How to Configure

Access the configuration mode by

following these steps:

1. Before you turn on the Advantage 18,

Keyboard

locate the keyboard in the upper right

area of the peripheral as shown in

Figure 1-6.

2. Locate the power switch at the rear of

the unit. It is a rocker switch above

the power cord as shown in Figure

1-5.

3. Press and hold [ALT], [

⇑], and [⇓] while

turning the power ON.

Figure 1-6

Page 13

How to Configure 1 - 7

110265-01, Rev. A 1. Introduction and Installation

4. Continue to press these keys until the unit ‘‘beeps’’ and the display shows a message that says

ADV-18 (or some other peripheral identification code). Release the three keys.

5. If the LCD displays anything other than ADV-18, press [

⇑] or [⇓] until it displays: ADV-18.

6. Press [ENTER] to set the peripheral program.

7. Press [

⇑] or [⇓] and the LCD will display: UNIT NUMBER 01. Keep pressing the arrow key until the

number you want displays. You cannot have two peripherals with the same unit number

attached to the same computer.

8. Press [ENTER] to set the unit number.

9. The last item you select is the display language. Press [

⇑] or [⇓] to display English or Spanish and

press [ENTER] to select that language.

Start-Up Messages

Once configured, a series of messages will display during power up. Usually the messages are

simply informational, but sometimes they will require a keyboard entry from the operator. The

messages displayed will depend on the combination of the computer and peripheral operating

modes.

When there is a completed link to the computer the series of messages are:

DSKBIOS Version# Bytes of free memory

DNLOAD REQUESTED

POWER UP. . .

ADV-18 Version#

If a link to the computer is not make because it is not on or it is busy, the following messages will

flash alternately until the Advantage 18 can link:

DSKBIOS version # bytes of free memory

UNIT #

If the Advantage 18 finds a problem in its self-check, it will display the appropriate error message

and wait for a response.

Appendix B contains a complete listing of the error messages.

Page 14

1 - 8 Start-Up Messages

Advantage 18 Operation Manual Melco Embroidery Systems

Page 15

Threading to the Selector Carriage 2 - 1

110265-01, Rev. A 2. Operating the Advantage 18

2. Operating the Advantage 18

How Threads Are Spliced

During a color change, both the current and new threads enter into the thread splicing cell. Inside

the splicing cell a short, forceful burst of air fluffs out the fibers of both threads causing them to

intertwine, making a secure slice between them. The old thread is then pulled through the needle,

followed by the splice and the new thread. The new thread is trimmed after passing through the

needle, and the old thread and splice are directed into a holding bin for later disposal. This

patented process allows the Advantage 18 to perform color changes and rethreading automatically

while using a single needle and tensioner.

Threading the Advantage 18

Although the Advantage 18 will automatically rethread when it performs a color change, you may

need to perform manual threading when the following occurs:

• Initial set-up

• Using short-fiber threads that do not splice well

• A thread break

• Mechanical failures

Follow these directions to thread the machine:

Threading to the Selector Carriage

1. Put a spool of thread on position number 1 of the thread tree.

2. Insert an inch or two of thread into the center of the thread guide tube.

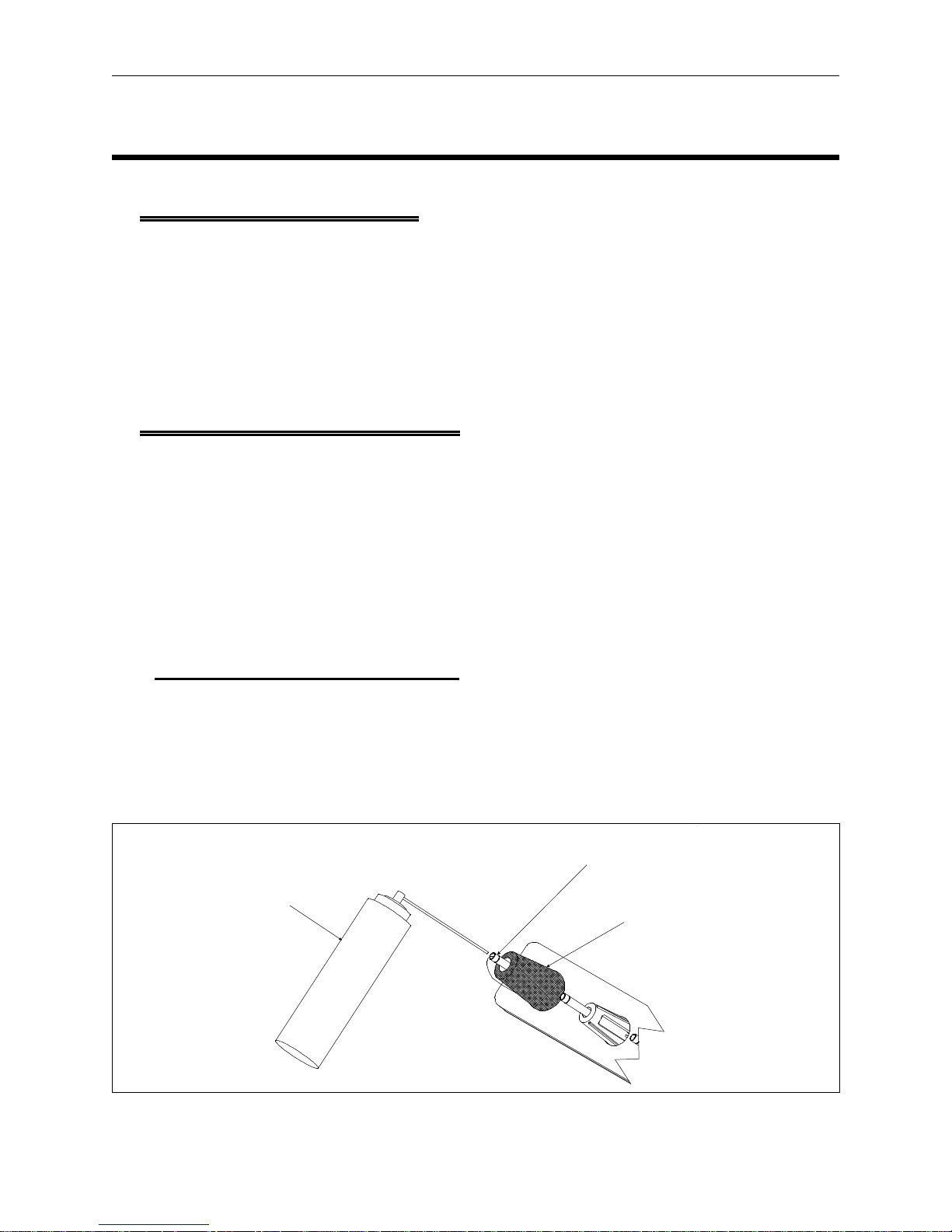

3. Use a can of compressed air to direct a short burst of air into the tube as shown in Figure 2-1.

The compressed air will force the thread through the tubing to the thread selector carriage.

Thread Guide Tube

Compressed Air

Thread Spool

Figure 2-1

Page 16

2 - 2 Threading the Advantage 18

Advantage 18 Operation Manual Melco Embroidery Systems

4. Lift the pretensioner magnet. Position the thread in the groove, over the idler roller, and through

the guide hole as shown in Figures 2-2 and 2-3.

Pretensioner Magnet

(lifted for thread placement)

Groove

Guide Hole

Idler Roller

Figure 2-2

5. Repeat steps 1 through 4 for all the thread positions.

6. Replace the pretensioner.

7. Trim the ends of the thread to 1/8 inch in front of the carriage (see Figure 2-3).

Thread tubes

from the

thread tree

Threads trimmed

to 1/8 inch.

Pretensioner Magnet

(in operating position)

Figure 2-3

Page 17

Rethreading After a Failure 2 - 3

110265-01, Rev. A 2. Operating the Advantage 18

Inserting the Thread into the Splicing Cell

1. Move the selector carriage to the desired thread position by pressing [ALT][

space to the left or [ALT][

⇒] to move one space to the right.

⇐] to move one

2. Press [ALT][ENTER] to display one of three idle menus. Press [ENTER] to toggle through these

menus until reaching one that displays: THD: 1* TENSION: 27. The number with the asterisk

beside it is the current thread position of the selector carriage. A complete description of the

Idle menus is in the next chapter.

3. Press [ALT][

⇑] to move the selector carriage to thread position 18 or press [ALT][⇓] to move the

selector carriage to thread position 1.

4. To move the selector carriage to the previously selected thread and insert it through the splicing

cell, press the [FAST/SLOW] key. The

it is the

first key pressed after moving the selector carriage with one of the [ALT][arrow key]

only time [FAST/SLOW] will perform this function is when

combinations.

NOTE: By allowing the selector carriage to move off the selected thread position and then travel

back to it before performing an insert, the tails of the neighboring threads become

positioned to avoid interference. Using [ALT][

⇑] or [ALT][⇓] stores the previous thread

position so the selector carriage knows where to return. Press [FAST/SLOW] immediately

after accessing [ALT]

[⇐] or [ALT][⇒] to perform an insert at that position.

OR

Access the insert thread option in the Splicing Menu. This is discussed in the Splicing Menu section

later in this chapter.

5. Finish threading the machine using Figure 2-4 as a guide.

Rethreading After a Failure

If a thread fails to insert through the splicing cell, perform these recovery steps before trying the

insert again.

1. Press [ALT][

⇑] or [ALT][⇓] to move the selector carriage all the way to the left or right depending

on which gives you the best access to the thread position.

2. If the tail of the thread is free, trim it back to 1/8 inch.

OR

If the tail of the thread has become tangled under the color change cover, be sure to clear the

entire thread path. You may have to remove the color change cover to do this.

3. Trim the thread to 1/8 inch.

4. Press [FAST/SLOW]. The selector carriage will move back to the previous thread and perform an

insert.

Page 18

2 - 4 Threading the Advantage 18

Advantage 18 Operation Manual Melco Embroidery Systems

The Advantage 18 Thread Path

Figure 2-4

NOTE: The thread is passed

between the disks of the

tensioner only once.

Page 19

Bobbin Tension 2 - 5

110265-01, Rev. A 2. Operating the Advantage 18

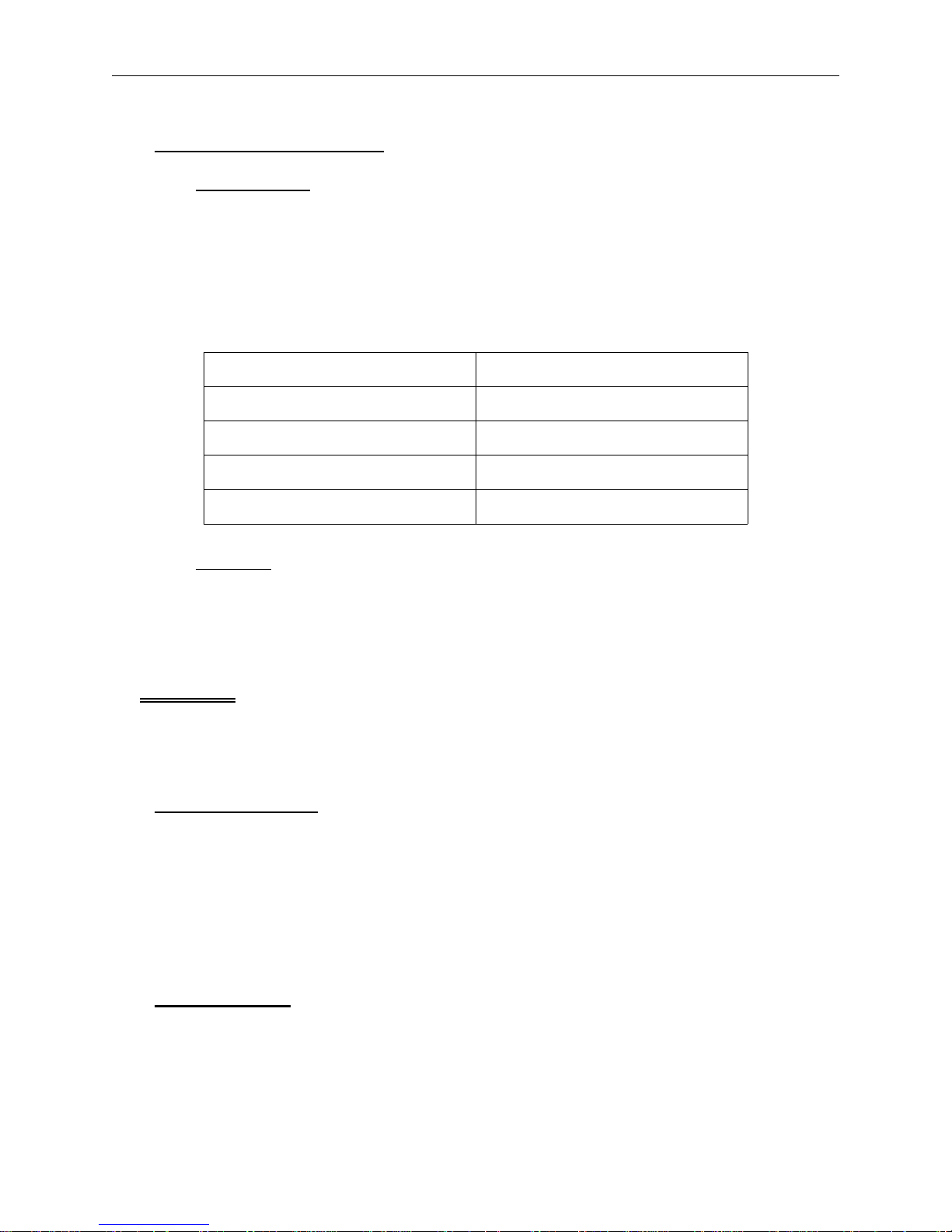

Thread Types and Needles

Thread Types

The Advantage 18 can perform automatic color changes between a variety of thread types.

However, the longer the thread fibers, the better the splice. Because synthetic threads have longer

fibers than natural threads such as cotton, a synthetic to synthetic splice is the most consistent. The

following table lists general guidelines for the splicing quality of different thread types. Of course,

the two threads in a splice can be different types of thread. Even if a thread does not splice well,

you may embroider with it on the Advantage 18 by threading it manually.

Synthetic Best for splicing

Blends of Synthetic and Natural Better than all natural

Natural May need manual rethreading

Monofilaments Must be manually threaded

Metalics Must be manually threaded

Needles

During an Advantage 18 color change, the actual splice of the two threads passes through the eye

of the needle. For the splice to easily pass through the eye, use a standard 80/12 size needle or

larger.

Tensions

Excellent embroidery quality is achieved when both the upper thread and bobbin thread tensions

are set properly. Experience and practice allows customized tension settings based on factors such

as: threads, material, backing, needle type, stitch size, and hooping.

The Upper Tension

There is one upper tensioner on the Advantage 18 used by all 18 thread positions. Because

different types and weights of threads require different tensions, the Advantage 18 tensioner is

designed to store the tension setting for each thread position in memory.

When a tension is reset, the new setting replaces the old one in memory for that thread position.

Keeping the same types and weights of threads in the same thread positions will reduce the

number of tension adjustments.

Bobbin Tension

The same factors affecting upper tensions affect bobbin tension. The bobbin tension is adjusted

manually, however, by rotating a set screw on the bobbin case (see Figure 2-5).

Page 20

2 - 6 Installing a Needle

Advantage 18 Operation Manual Melco Embroidery Systems

Bobbin Case

Spring

Set

Screw

Slit

Thread

Side View End View

Bobbin Case

Bobbin

Spool

Pigtail

Note the direction that the thread is wound on the

bobbin spool for insertion into the bobbin case.

Figure 2-5

1 Put the bobbin spool into the bobbin case as illustrated in Figure 2-5. When looking at the open

end of the bobbin case, the thread should rotate clockwise off the bobbin spool when you pull

on the thread.

2. Pass the thread through the slit in the bobbin case and under the spring.

3. Using a small, flat-blade screw driver, turn the set screw until you feel a slight resistance when

the thread is pulled from the bobbin. Set the tension so that when you hold the bobbin case

suspended by its thread:

• No thread feeds out when you are not moving it

• About an inch of thread feeds out when you jiggle it slightly

4. With the bobbin tension adjusted, pass the bobbin thread through the bobbin case pig tail.

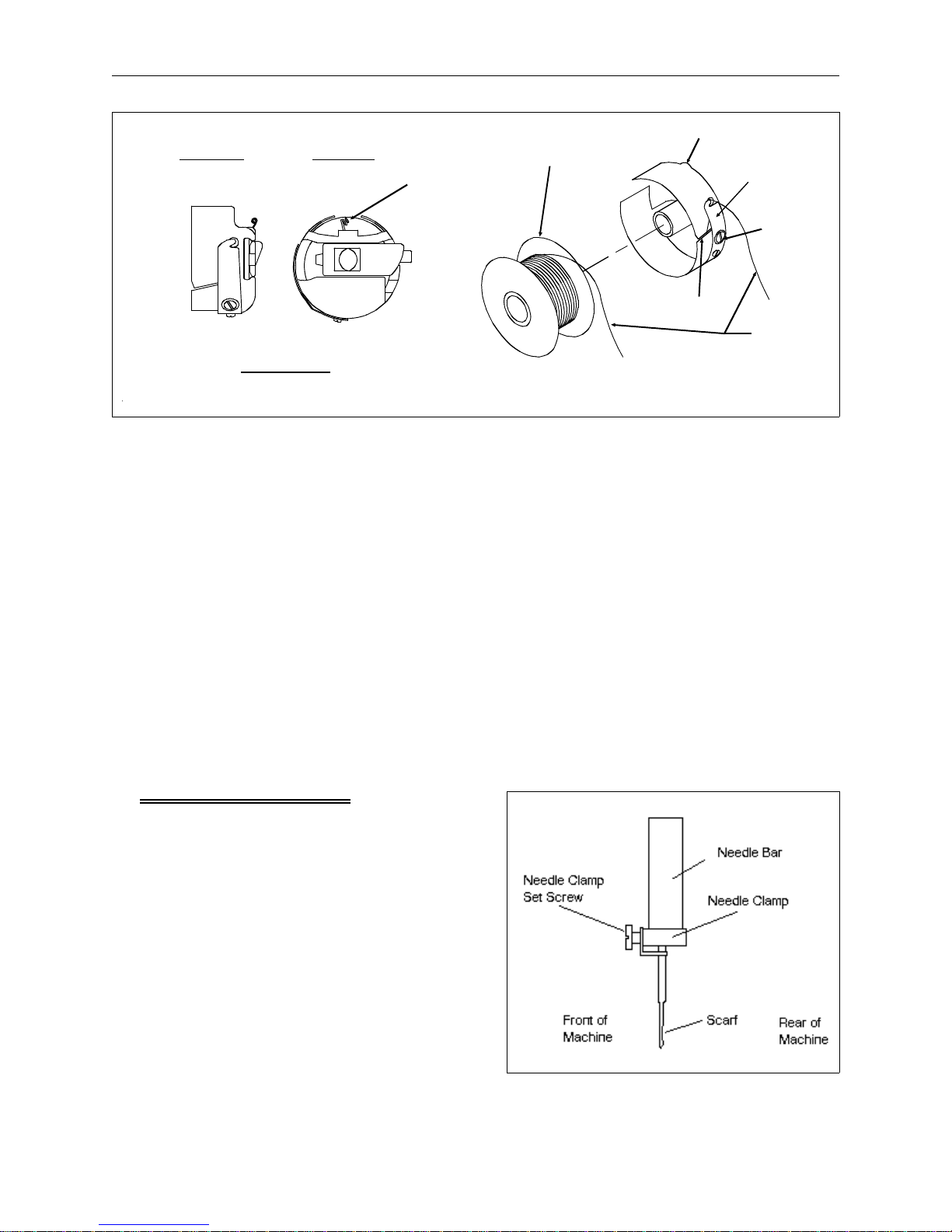

Installing a Needle

The needle clamp set screw holds the needle in place

as shown in Figure 2-6. Using the small, flat-blade

screw driver from the operator’s tool kit:

1. Turn the set screw counterclockwise until the

needle can slide down and out of the needle bar.

2. With the scarf of the new needle toward the rear

of the embroidery head, slide the needle into the

needle bar as far as it will go and tighten the set

screw.

Figure 2-6

Page 21

Hooping Flat Goods 2 - 7

110265-01, Rev. A 2. Operating the Advantage 18

Hooping

A properly hooped garment is one without any folds caught in the hoop and is as taut as possible

without permanently stretching the fabric, especially knits, jerseys, and other loosely woven fabrics.

Hooping Flat Goods

Follow these steps for hooping material in a circular or oval hoop on the table top insert.

1. Select a hoop that allows the complete design to fit with a comfortable margin of blank fabric

around the inside edge. Later you will learn how to use the Trace menu to make sure you have

the right size hoop.

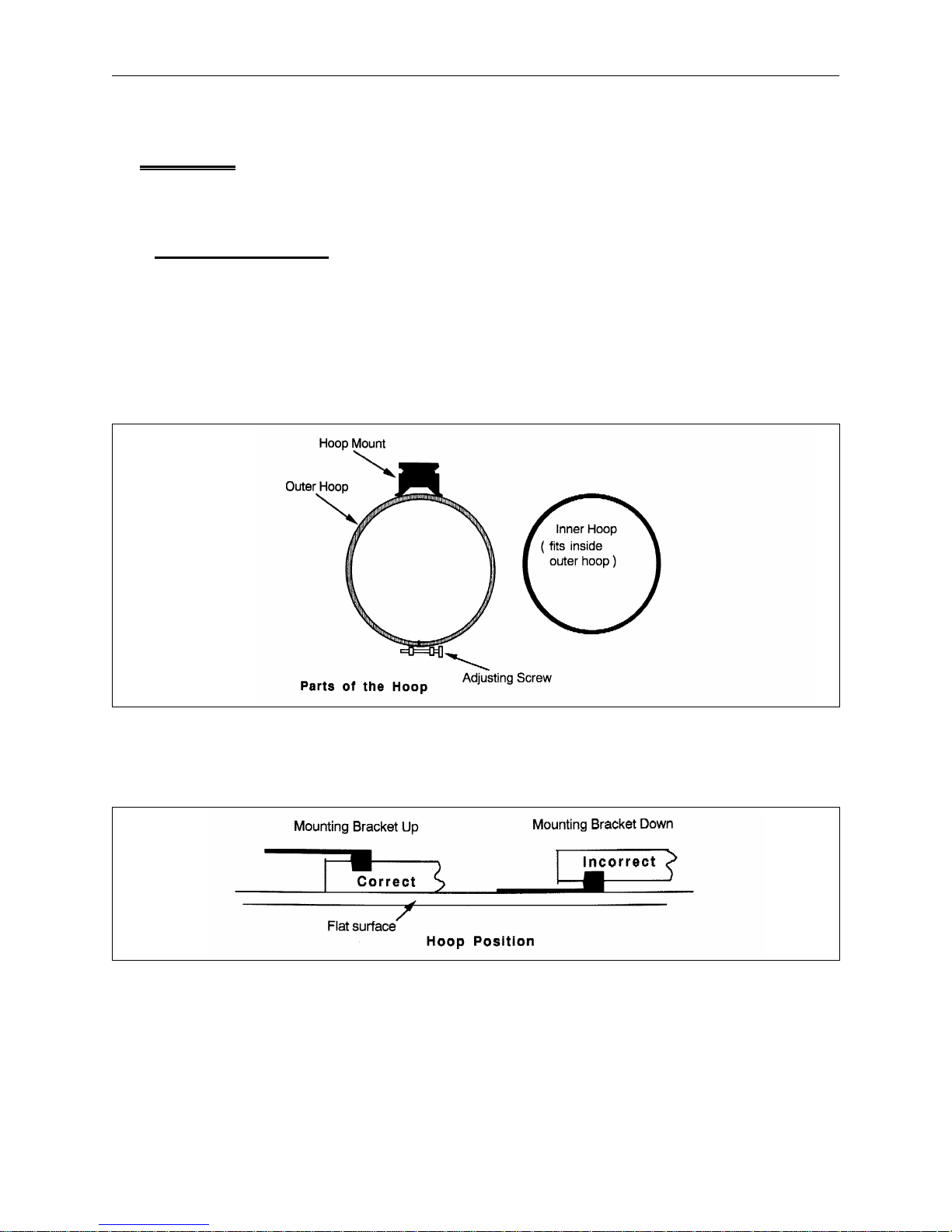

2. Loosen the adjusting screw on the outer hoop by turning it counterclockwise (see Figure 2-7).

Figure 2-7

3. Place the outer hoop on a clean, flat surface with the mounting bracket on the side that is up

and away from the flat surface (see Figure 2-8).

Figure 2-8

4. On top of the outer hoop, place enough backing material to cover it.

5. Place your material on top of the backing.

Page 22

2 - 8 Hooping

Advantage 18 Operation Manual Melco Embroidery Systems

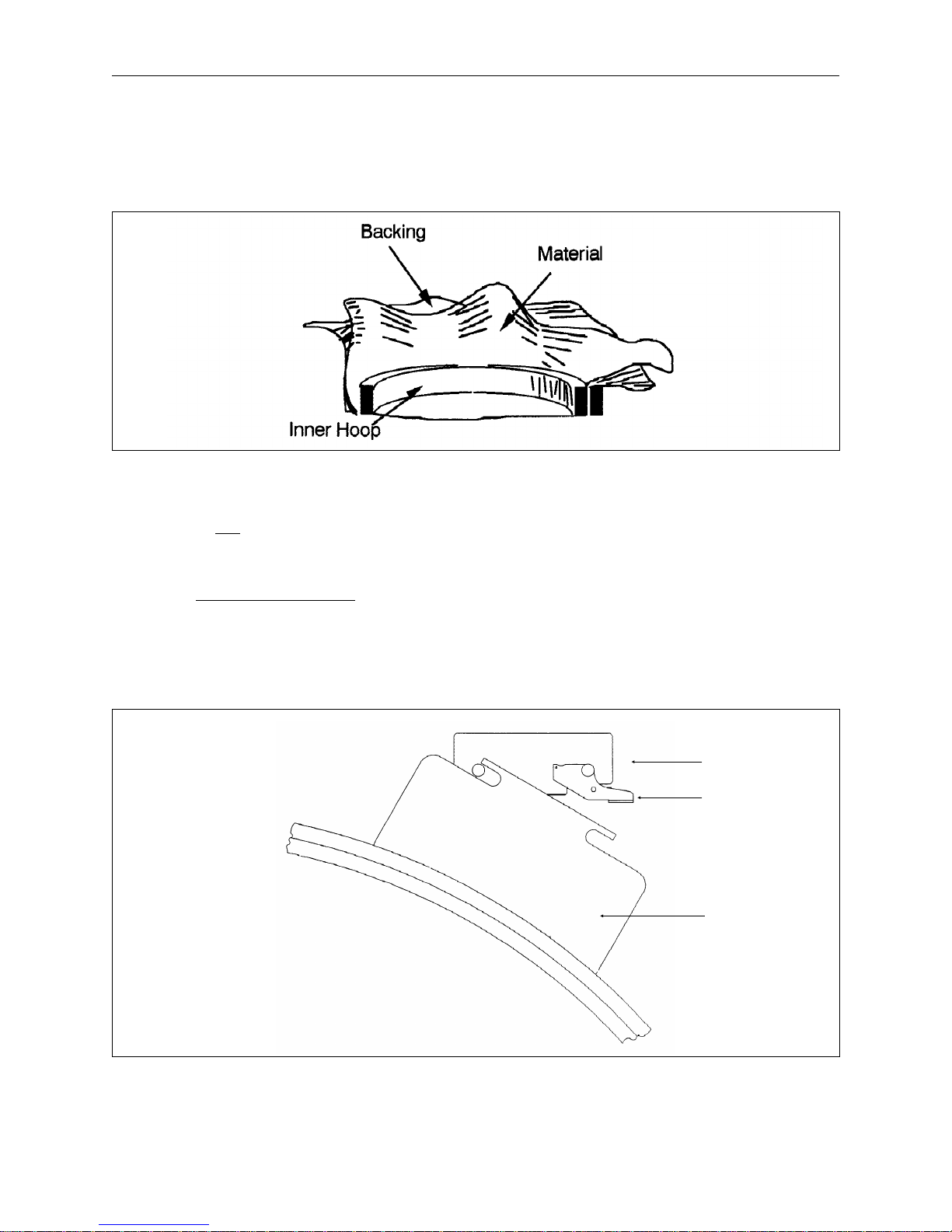

6. Press the inner hoop into the outer hoop with the fabric and backing between them as shown in

Figure 2-9. Pull the outside edges of the material inward, toward the center of the hoop. This

tightens the material inside the hoop without popping the hoop apart.

Figure 2-9

7. When the material is hooped properly, tighten the outer hoop adjusting screw. Tightening this

screw will

permanent imprint in your material.

not tighten the fabric, it simply secures it. Tightening it too much can leave a

Loading The Hoop

To attach the hoop to the carriage:

1. Place the left notch of the hoop mounting bracket against the carriage stub as shown in Figure

2-10.

X-Carriage

Thumb Lever

Hoop Mounting

Bracket

Figure 2-10

Page 23

Cap Frames 2 - 9

110265-01, Rev. A 2. Operating the Advantage 18

2. Press the thumb lever towards the rear of the carriage.

3. Push the hoop bracket up to the lever stub and release the lever, snapping the lever stub into

the right carriage notch.

Cap Frames

Because a cap is not flat it cannot be hooped in a flat hoop. To solve this problem, a special device

called a cap frame is used. The cap frame option consists of two parts: 1) The cap frame that holds

the cap and attaches to the cap frame drive; and 2) The cap frame drive that secures to the X

carriage and the front of the machine.

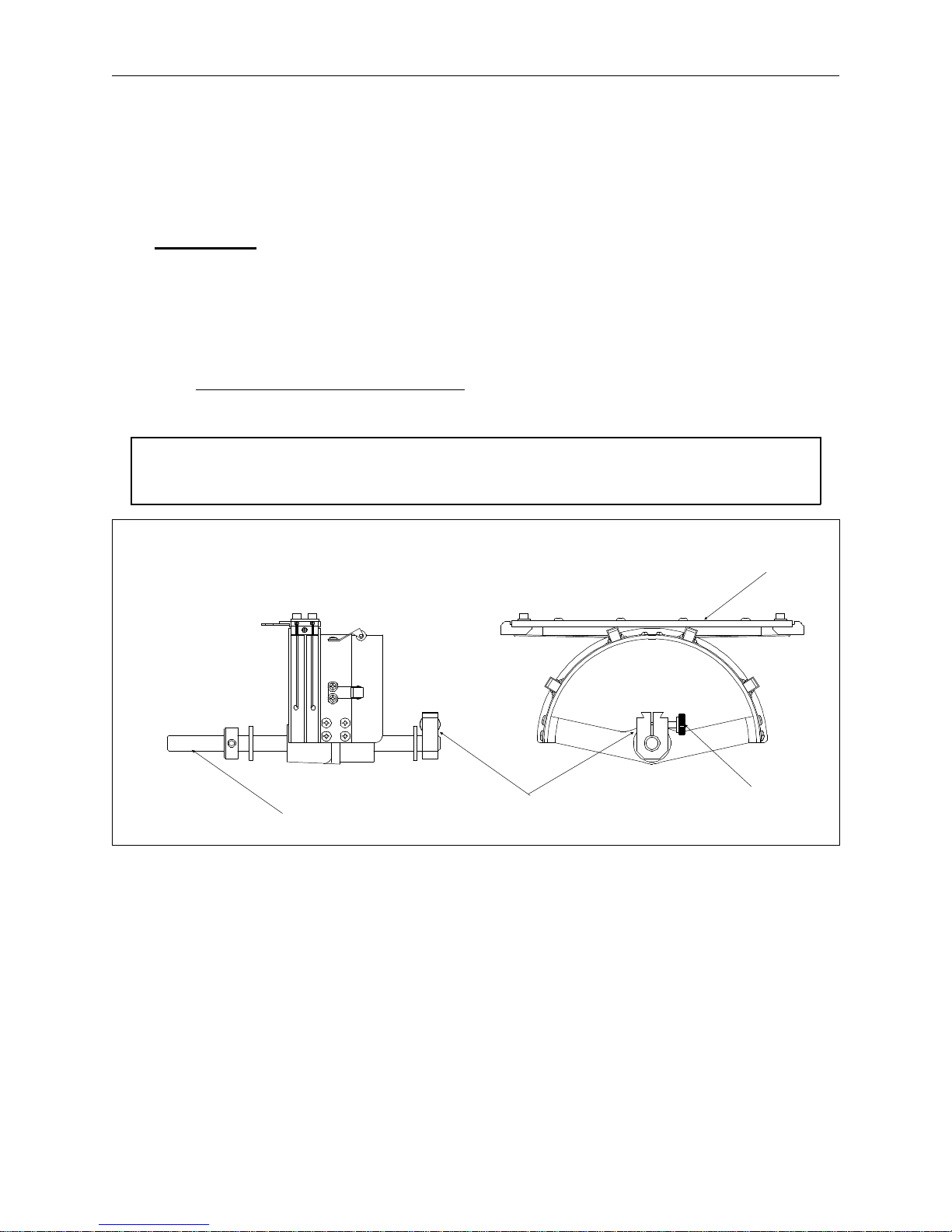

Installing the Cap Frame Drive

Attach the cap frame drive by following these steps and referring to Figure 2-11.

CAUTION! To avoid possible cap frame drive or other machine damage, Set

Home before installing the cap frame drive.

Cap Frame Drive

SIDE VIEW

Cap Frame Drive Shaft

Dove-Tail Bracket

Figure 2-11

FRONT VIEW

Thumb Screw

Hoop

Bracket

1. Remove the table top insert from the embroidery area. This allows access to the cap frame

mounting brackets under the bed of the embroidery head.

2. Center the pantograph in both X and Y directions using the arrow keys.

Page 24

2 - 10 Hooping

Advantage 18 Operation Manual Melco Embroidery Systems

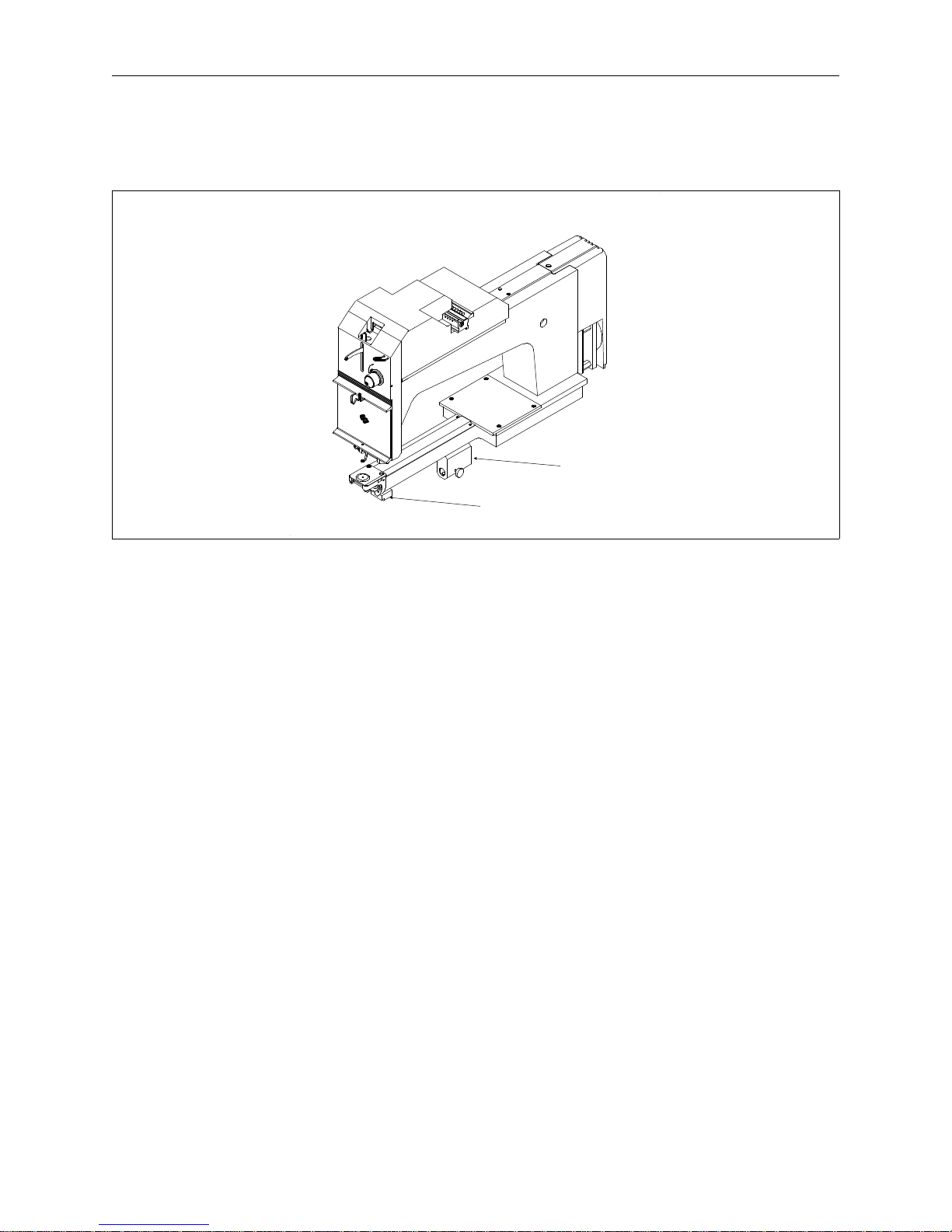

3. Under the cylinder arm, locate the dove-tail mount under the needle area and a bracket with a

round hole at the rear of the embroidery head (see Figure 2-12).

Rear Mounting Bracket

Dove-Tail Mount

Figure 2-12

4. Loosen the thumb screw on the rear bracket.

5. Loosen the thumb screw on the cap frame drive dove tail bracket.

6. The cap frame drive has a hoop bracket on top of it. Pulling the cap frame drive shaft towards

you, attach the hoop bracket to the X carriage. It attaches just like a regular hoop.

7. Guide the cap frame drive shaft into the hole in the rear mounting bracket. At the same time,

insert the cap frame drive dove-tail bracket into the dove-tail mount.

8. Push the cap frame drive shaft into the bracket hole as far as it will go.

9. Tighten the thumb screw on the rear bracket.

10. Tighten the thumb screw on the dove-tail bracket.

Page 25

Cap Frames 2 - 11

110265-01, Rev. A 2. Operating the Advantage 18

Cap Hooping

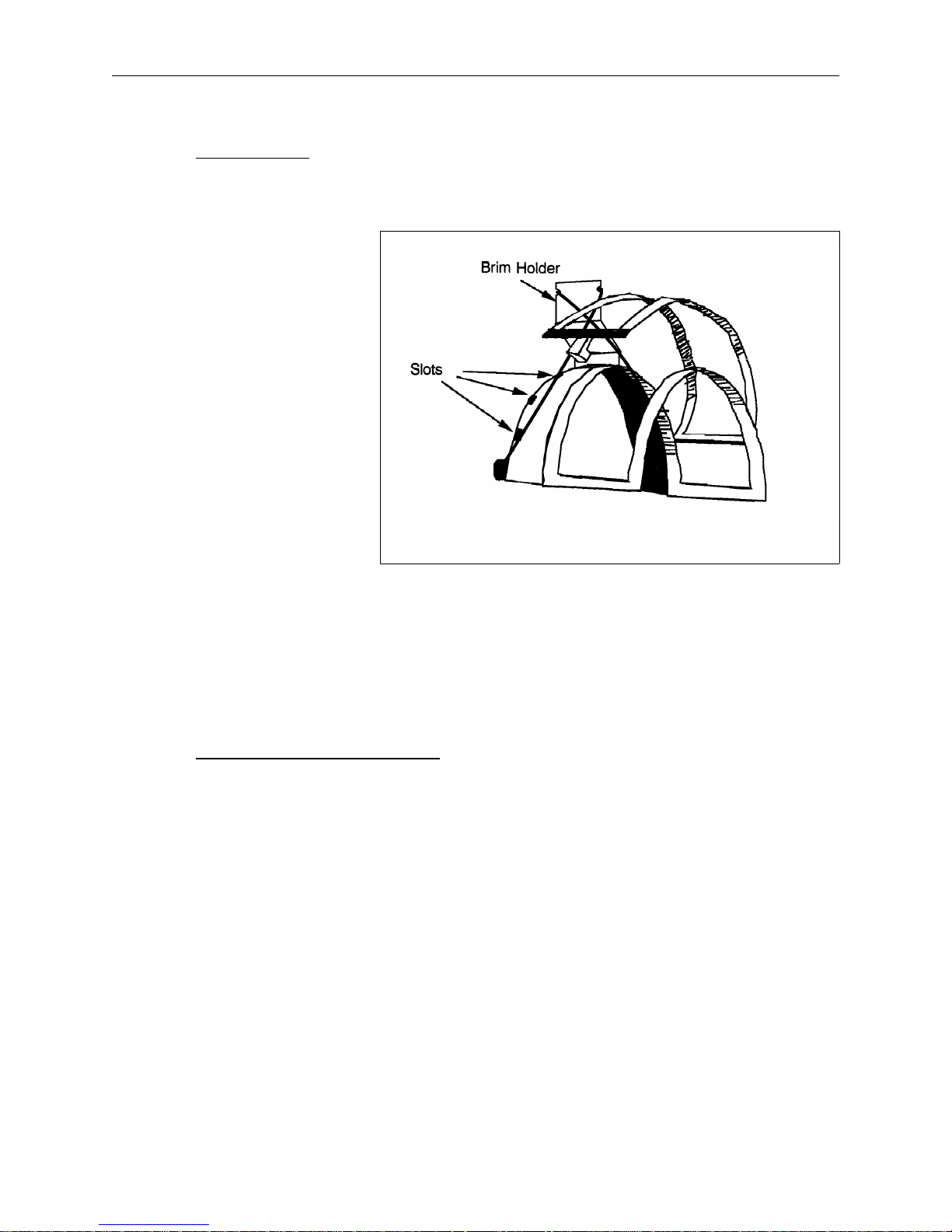

The following steps and Figure 2-13 explain how to put a cap in the cap frame.

1. Open the cap frame cover. The

latch should be on the left side

of the cap frame.

2. If you are using backing, place it

inside the cap.

3. Slide the top of your cap around

the body of the cap frame.

Keep the sides of the cap inside

the outer edges of the cap

frame. Push the cap completely

onto the cap frame.

4. Close the cap frame cover while

keeping the cap as straight,

fold-free, and taut as possible.

5. Secure the cap’s brim within the

brim holder mechanism.

Cap Frame

Figure 2-13

6. Install the cap frame onto the cap frame drive by:

• Aligning the cap frame and cap frame drive.

• Snapping the cap frame slots under the roller clamps on the cap frame drive.

Using a Raised Needle Plate

When the cap frame is attached, the curve of the frame leaves extra space between the needle

plate and the cap. This sometimes creates poor embroidery quality. Cap embroidery may be

improved by installing the raised needle plate option to reduce this extra space.

When embroidering with the raised needle plate, place extra spacers around the needle bar in the

needle case. The spacers raise the presser foot to compensate for the height of the raised needle

plate.

When returning to flat goods, install the normal needle plate and remove the extra spacers from

around the needle bars.

The raised needle plate option comes with its own installation procedures. Refer to those

procedures for proper installation and use.

Page 26

2 - 12 Keyboard Operation

Advantage 18 Operation Manual Melco Embroidery Systems

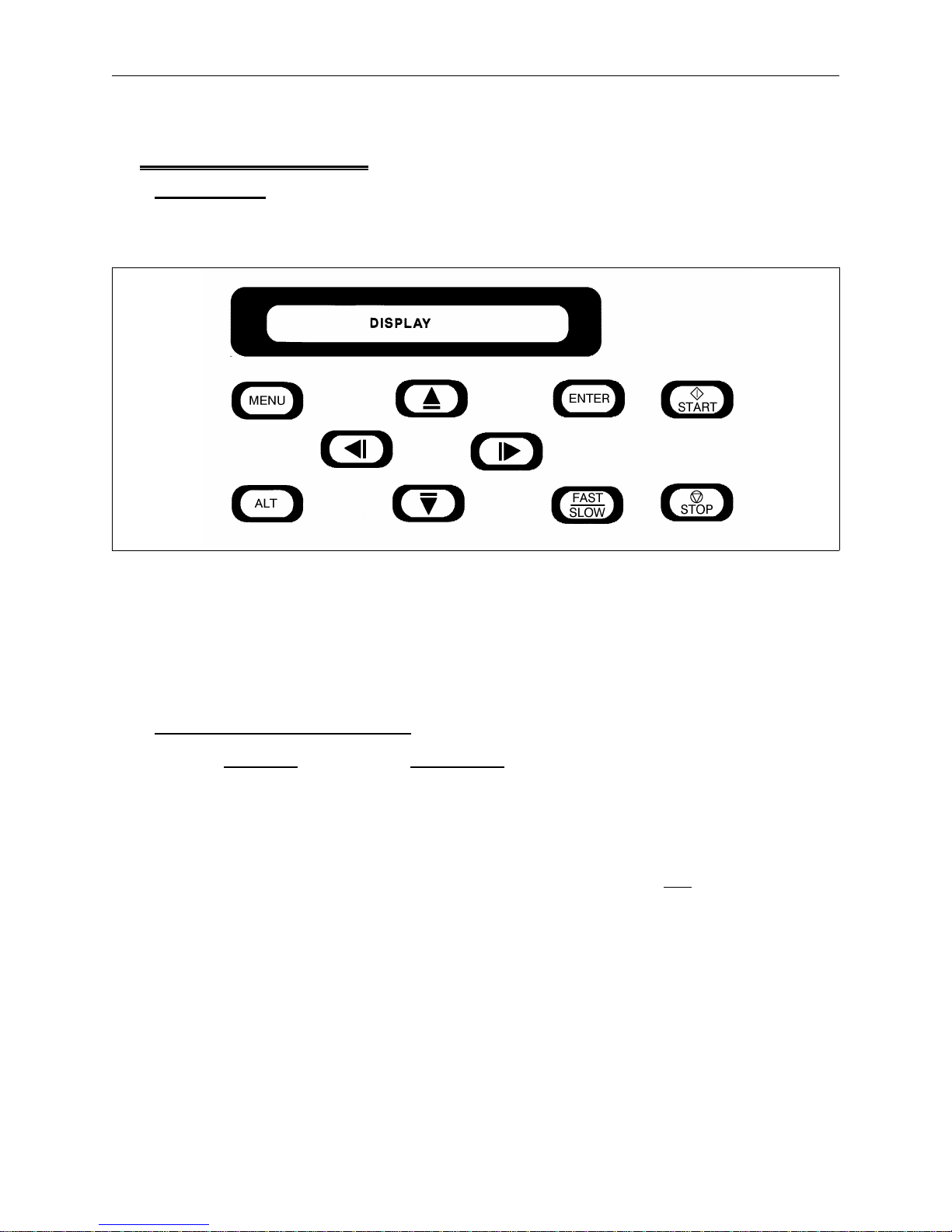

Keyboard Operation

Introduction

After receiving a design, the Advantage 18 uses its own program to start and direct the embroidery

process. The Advantage 18 operation is controlled through the keyboard illustrated in Figure 2-14.

Figure 2-14

The keyboard has ten keys and a display window called a Liquid Crystal Display (LCD). The LCD

displays menu options and messages. The keys allow you to move between menus, enter

commands, and select various other settings. Following is a description of the keys and their

functions in the main menus and the idle menus.

The Keys and Their Functions

Key Name Key Function

[MENU] Moves from one menu to the next. After the last menu

displays, it wraps back to the first menu.

[ALT] Never used alone. Held down while pressing another key,

allows the other key to take on an

ALTernate function.

See Key Combinations.

[ENTER] Makes a selection similar to clicking on the OK button in

Windows or pressing the [ENTER] key on your computer

keyboard. Also scrolls through the idle menus.

[FAST/SLOW] Toggles the hoop carriage speed fast or slow. Also inserts

a thread through the splicing cell when used immediately

after an [ALT][ARROW] key combination.

Page 27

The Keys and Their Functions 2 - 13

110265-01, Rev. A 2. Operating the Advantage 18

[⇒] or [RIGHT ARROW] Moves the needle position to the right in the embroidery

field (hoop moves left). Also used to select values for sub

menu options.

[

⇐] or [LEFT ARROW] Moves the needle position to the left in the embroidery

field (hoop moves to the right). Also used to select values

for sub menu options.

[

⇑] or [UP ARROW] Moves the needle position back in the embroidery field

and scrolls up a menu list. Also used to change sub menu

values.

[

⇓] or [DOWN ARROW] Moves the needle position down in the embroidery field

and scrolls down a menu list. Also used to change sub

menu values.

START Starts embroidering. Also starts the TRACING function.

STOP Stops any job. Also used to "frame forward" or

"frame backward" in idle or in the FRAME menu.

Key Combinations

Keys Combination Functions

[ALT][MENU] Displays the

previous menu.

[ALT][ENTER] Exits sub menu and displays one of three idle menus even

while the machine is embroidering.

[ALT][

⇐] Moves the selector carriage one thread position to the left

when the machine is in idle. Decreases upper thread

tension while the machine is embroidering.

[ALT][

⇒] Moves the selector carriage one thread position to the right

when the machine is in idle. Increases the upper thread

tension while the machine is embroidering.

[ALT][

⇑] Increases the maximum embroidery speed in increments

of 50 spm (stitches per minute) when the machine is

embroidering. The maximum is 900 spm for flat goods

embroidery and 800 spm for the cap frame. Also moves

the selector carriage to thread position 18 when the

machine is in idle.

[ALT][

⇓] Decreases the embroidery speed in increments of 50 spm

when the machine is embroidering. The minimum is 400

spm. Also moves the selector carriage to thread position 1

when the machine is idle.

Page 28

2 - 14 Keyboard Operation

Advantage 18 Operation Manual Melco Embroidery Systems

Sending a Design

The Advantage 18 operates with either EDS II or EDS III software. In your EDS system prepare and

save an EXP design. The following steps are individualized instructions for EDS II and EDS III users.

Complete

For EDS II:

1. Press F10: Peripherals in the main menu.

2. From the peripherals menu, press: F2: Send Design.

3. Type the file name of the design, a space, and the Advantage 18 unit number.

4. Press the Enter key.

For example, to send the design "SHIP" to peripheral #1, type:

only the instructions that apply to your system.

SHIP 1

For EDS III:

1. Click on Peripherals in the application or layout window and a drop-down menu displays.

2. Click on Transfer and a dialog box displays.

3. Select the appropriate information.

4. Click on OK.

More information is available in the EDS II and EDS III operation manuals. Consult the sections

concerning sending designs from the computer to the peripheral.

Receiving a Design

Now access the design in the Advantage 18’s design buffer. Remember the SHIP design is just an

example. Your file name and statistics may differ.

1. At the Advantage 18 keyboard, press [MENU] until the display reads:

DESIGN MENU

2. Press [ENTER]. The display now reads:

SHIP 1380

SHIP is the design name. 1380 is the size of the design in bytes.

3. If you had more than one design in the buffer, pressing [

⇑] or [⇓] scrolls through the list.

Page 29

3 - 1

110265-01, Rev. A 3. The Setup Menus

3. The Setup Menus

Find all the Advantage 18 menus listed below with a brief description of their functions. Detailed

explanations of the Design, Color, Tension, Orientation and Run menus follow the brief overview.

These are "The Setup Menus" used for every design. Except for the Head Timing menu, the

remaining menus are discussed in Chapter 4, "The Customization Menus." Discussion of the Head

Timing menu is in Chapter 5, "Maintenance."

An Overview of the Advantage 18 Menus

DESIGN MENU

Lists all the designs in the Advantage 18 design buffer, in the order sent. Select a design for

embroidery or to delete a design from the buffer.

COLOR MENU

Sets the color sequence.

TENSION MENU

Sets and remembers the upper tension for each thread position.

ORIENTATION MENU

Positions a design in one of eight combinations for placement in the embroidery field.

RUN DESIGN

Inserts the selected design and color sequence into the run buffer. Also allows the design to

embroider after you Set Home.

FRAME MENU

Sets the direction, either forward or backward, to move through a design to correct embroidery

errors. Allows precise corrections.

TRACE MENU

Traces the outline of a design to verify a design fits in the selected hoop.

HOME MENU

Sets the"HOME POSITION," selects hoop sizes, and provides power fail rescue functions.

MOVE MENU

Moves the needle within the embroidery field.

HEAD TIMING MENU

Enables the operator to set, correct, or adjust the Needle Depth and Hook Timing.

TRIM MENU

Sets the Trimmer Option.

Page 30

3 - 2 Design Menu

Advantage 18 Operation Manual Melco Embroidery Systems

SPLICING MENU

Primarily used for troubleshooting. Provides an option to insert the thread through the splicing cell

or change a thread selection temporarily.

RESET MENU

Clears stitch counts and run buffer without turning off the machine. You do

not delete a job from

this menu. Used to perform a "hard reset" which restores any altered parameters to their default

settings.

Design Menu

When a design is sent from the computer to the Advantage 18, it is stored in the design buffer.

The Design Menu displays the buffer contents and allows you to select a design to embroider or

delete. To access the Design Menu, the Advantage 18 must be powered up but not embroidering

or making a color change.

Selecting a Design

To select a design, follow these steps:

1. Press [MENU] until the LCD displays: DESIGN MENU.

2. Press [ENTER] to display the first design.

3. Scroll through the designs with the [

⇑] key or [⇓] key until you reach the design you want.

4. Press [ENTER] to select the design. The LCD displays the next menu.

Deleting a Design

If you are not using the AutoDelete option on your computer, the design remains in the buffer. To

delete a design from the buffer, follow these steps:

1. Press [MENU] until the LCD displays: DESIGN MENU.

2. Press [ENTER].

3. Use [

4. Press [ALT][

5. Press [

⇑] or [⇓] to scroll to the design you want to delete.

⇓] and the LCD displays: KILL design name?

⇑] for YES, or [⇓] for NO.

6. Press [ENTER] to complete the deletion.

Page 31

Deleting a Design 3 - 3

110265-01, Rev. A 3. The Setup Menus

Color Menu

Scroll through the top level menus, or press [ENTER] from the Design Menu to reach the Color

Menu.

The Advantage 18 can embroider up to 99 colors in a single design. The number of colors used and

the order in which they embroider is called the color sequence. Use the Color Menu to set the color

sequence.

1. Press [MENU] until the LCD displays: COLOR MENU.

2. Press [ENTER] and the display reads

:

COLOR 1:1 (18)

Color Sequence

Thread Position

The color sequence number indicates the current position in the color change order. The 1 in this

position means that it is the first color used in the design, before any color change commands. A

six in this position would mean that this is the sixth color used in the design, and there have been

five color change commands. Acceptable numbers in this position are 1 through 99.

3. Press [

⇒] to move forward or [⇐] to move backward toward the desired color sequence

number. Press and hold to scroll.

The

thread position number refers to the cone number on the thread tree. Acceptable numbers in

this position are 1 through 18, and the special characters:

-- Embroiders using the previous color selection.

Total Color Selections

0 Stops the machine at this color change. Press [Start] to resume embroidering.

P Pauses the machine at each subsequent color change. Press [Start] each time to resume

embroidering.

4. Press [

The

⇑] to increase or [⇓] to decrease the thread position number. Press and hold to scroll.

total color selections number refers to the number of positions in the color sequence. The

number (18) means there are eighteen thread positions individually programmed in the Color Menu.

Acceptable numbers in total color selections are 1 through 99. When the Advantage 18 comes

from the factory, the default number is (18). As you insert or delete color sequences, the total color

selections number increases or decreases respectively.

Page 32

3 - 4 Color Menu

Advantage 18 Operation Manual Melco Embroidery Systems

5. To add to the end of the color sequence, press and hold [⇒] until you reach color sequence 19.

Notice that the total color selections value is still 18.

6. Press [

7. To insert a new color sequence before the current color sequence location, press [ALT][

⇑] or [⇓] to create another color sequence. The total color selections value is now 19.

⇑]. The

total color selections number will increase by one.

8. Press [ALT][

⇓] to delete the current color sequence number. The total color selections number

will decrease by one.

9. When finished setting the Color Menu, press [ENTER] or [MENU].

A hard reset or reconfiguration reset all Color Menu values to their default settings. The default

total color selections is 18.

An Example

Following is an example to demonstrate how to set the Color Menu using two methods:

If you have a design with three flowers, each to be embroidered in green (cone 6), blue (cone 12),

and yellow (cone 5), you could set each individual color selection as shown in the left column. This

results in a total color selections value of 9. In the example on the right, however, only three

selections are made. The total color selections become (3), forcing the color sequence to wrap after

every third color change command. The embroidery result will be identical.

COLOR 1: 6 (9) COLOR 1: 6 (3)

COLOR 2:12 (9) OR COLOR 2:12 (3)

COLOR 3: 5 (9) COLOR 3: 5 (3)

COLOR 4: 6 (9)

COLOR 5:12 (9)

COLOR 6: 5 (9)

COLOR 7: 6 (9)

COLOR 8:12 (9)

COLOR 9: 5 (9)

Change Now

This option allows you to change the color sequence of the job currently embroidering or the next

job in the run buffer. To use this option:

1. Scroll to the Color Menu (you can do this while the machine is embroidering).

Page 33

Change Now 3 - 5

110265-01, Rev. A 3. The Setup Menus

2. Press [ENTER] and the current color sequence displays.

3. Reset the color sequence using the normal Color Menu commands: Press [

through the color sequence; press [

4. When you finish resetting the color sequence, press [ALT][

5. Press [

⇑] for YES or [⇓] for NO.

⇑] or [⇓] to change the thread selection.

⇒]. The LCD displays: CHANGE NOW?

⇒] or [⇐] to move

6. Press [ENTER]. If you responded YES the new color sequence takes effect at the next color change

in the current design. If you responded NO, the new color sequence takes effect in the next

design in the run buffer.

7. Press [START] to resume embroidering.

Tension Menu

Scroll through the top level menus, or press [ENTER] from the Color Menu to reach the Tension

Menu.

As the Advantage 18 moves from one thread to another, each individual tension setting becomes

recorded in memory. Each tension setting remains recorded until you change the setting, perform a

hard reset, or reconfigure the peripheral. At that time all the tensions return to the default setting

of 30.

1. Press [MENU] until the LCD displays: TENSION MENU.

2. Press [ENTER] and the display reads:

THD: 1* TENS: 30

Thread Number

The

thread number refers to the selector carriage (and thread tree) positions 1 through 18.

An asterisk next to the thread number (the

position. If the tension is changed while the asterisk is present, the tensioner is moved and the new

setting is saved.

The

selection indicator signals where you are working. When changing the thread number, the

colon next to THD is underlined. When you are changing the tension setting, the colon next to

TENS is underlined.

Active Thread

Indicator

Selection

Indicator

Tension Setting

active thread indicator) signifies the current thread

The

tension setting has a range of 1 to 75. The default is 30.

Page 34

3 - 6 Orientation Menu

Advantage 18 Operation Manual Melco Embroidery Systems

Select the Thread Position

3. Press [

⇑] to increase the thread position by 1 or [⇓] to decrease the thread position by 1. Press

and hold to scroll.

Select the Tension Setting

4. Press [

⇒] to increase the tension by 1 or [⇐] to decrease the tension by 1. Press and hold to

scroll.

5. Press [ENTER] when finished.

Orientation Menu

Scroll through the top level menus, or press [ENTER] from the Tension Menu to reach the

Orientation Menu.

The Orientation Menu allows you to embroider a design in any of the positions shown in Figure

3-1. Because of the way a cap mounts into the cap hoop, you may want to embroider it like the

third example.

1 2 3 4 5 6 7 8

Figure 3-1

Setting Orientation

1. Press [MENU] until the LCD displays: ORIENTATION MENU.

2. Press [ENTER] and the display will show an F in the current orientation.

3. Press [

4. When you reach the desired orientation, press [ENTER].

⇑] or [⇓] to scan through the eight orientation choices.

Page 35

Setting Orientation 3 - 7

110265-01, Rev. A 3. The Setup Menus

Run Design Menu

Scroll through the top level menus, or press [ENTER] from the Orientation Menu to reach the Run

Design Menu.

1. Press [ENTER]. If this is the first job since turning on the machine, Set Home before continuing. If

you do not, the LCD will display the error message: HOME NOT SET

2. Press [START]. The machine starts embroidering. It stops embroidering when the job is complete

and the LCD displays: END OF DESIGN.

The Idle Menus

The Idle menus display information about the currently selected design. You can access the idle

menus while a design is embroidering or when you are in another menu.

1a. Press [ENTER] when a design is embroidering.

OR

1b. Press [ALT][ENTER] when you are in any other menu or sub menu. The diagram below shows

the first idle menu.

SHIP1 550 F

File Name

2. Press [ENTER] and the second Idle menu displays as shown in the following diagram:

Actual embroidery

Speed

Design Orientation

15000 900*

Stitch Count

Maximum embroidery

Speed

Page 36

3 - 8 The Idle Menus

Advantage 18 Operation Manual Melco Embroidery Systems

3. Press [ENTER] and the third Idle menu displays as shown below. If you press [ENTER] again, you

will scroll back to the first Idle menu.

THD: 1* TENS: 27

Thread Number

Active Thread

Indicator

Tension Setting

Page 37

4 - 1

110265-01, Rev. A 4. The Customizing Menus

4. The Customizing Menus

Although you may not use these menus every time you embroider, they may be valuable in specific

situations.

Frame Menu

Framing is when the machine moves through a design stitch-by-stitch without embroidering. It is

useful for correcting small embroidery errors.

As the machine moves through the design, it tracks the location and thread color. If a color change

is necessary, the Advantage 18 will do it when [START] is pressed, and before it starts embroidering.

NOTE: If you are going to embroider with a new color or make a lengthy move, perform a Trim

Immediate before you start framing. This eliminates a tail of thread across the

embroidery field. The Trim Immediate option is in the Trim menu.

Framing can be performed anytime a design is loaded and the machine is stopped. To Frame, press

and hold the [STOP] key until the beam moves. You may frame either forward or backward. Set the

forward and backward direction in the Frame menu as described in these steps:

1. Scroll through the top level menus to reach the Frame Menu.

2. Press [MENU] until the LCD displays: FRAME MENU.

3. Press [ENTER] and the LCD displays: FRAME BACK.

4. Press [

5. After selecting the direction, press [ENTER].

6a. Press [STOP] until the beam moves forward or backward one stitch then release [STOP].

6b. Press and hold [STOP] until the beam moves several stitches and release [STOP].

6c. Press and hold [STOP] for about five seconds, then release it. The beam will continue moving

⇒]. The LCD now displays: FRAME FORWARD.

OR

OR

until you press [STOP] a second time.

Framing occurs in the set direction

design is loaded, the Frame Menu defaults to frame back.

as long as you are embroidering that design. Every time a new

Page 38

4 - 2 Trace Menu

Advantage 18 Operation Manual Melco Embroidery Systems

The Frame Idle Display

If an Idle Menu is displayed when you begin framing, it is replaced by a special Frame Idle message.

To display an Idle menu, press [ALT][ENTER]. This message gives the stitch count and thread color as

you frame through the design. For example:

322 THD:12

indicates the framing function has reached stitch 322 which should embroider with the color in

thread position 12. As you frame past a color change command, the machine will beep. Press

[ENTER] to leave this display.

Return To Origin

Return to Origin returns the beam and carriage all the way to the starting point, or origin, of the

currently loaded design.

1. If the machine is embroidering, press [STOP].

2. Press [MENU] until the LCD displays: FRAME MENU.

3. Press [ENTER] and the LCD displays: FRAME BACK or FRAME FORWARD.

4. Press [

⇓] and the LCD displays: RETURN TO ORIGIN.

5. Press [ENTER].

6. Press [START] and the beam and carriage moves back through the design and stops at the origin.

When the machine stops, the LCD displays: FRAME FORWARD.

7. Press [ENTER] to resume embroidering at the start of the design.

Trace Menu

Scroll through the top level menus, or press [ENTER] from the Frame Menu to reach the Trace Menu.

The Trace Menu allows you to verify the design fits within the hoop by tracing the outline of the

design. If the design does not fit, switch to a more appropriately sized hoop and retrace the design.

1. Install the hooped garment or cap.

2. Press [MENU] until the LCD displays: TRACE MENU.

3. Press [ENTER] and the LCD displays: CENTERING OFF.

4. Press [

⇒] to turn the centering function ON. Press [⇐] to turn it OFF. When centering is ON, the

beam and carriage stop at the calculated center of the traced design. When centering is OFF,

the needle stops at the outside edge of the design outline, or at its starting point.

5. Press [

⇑] and the LCD displays: TRACE OUTLINE.

Page 39

Set Home 4 - 3

110265-01, Rev. A 4. The Customizing Menus

6. Press [ENTER] to calculate the design’s center. The LCD may read: CALCULATING for a few

seconds before it displays: TRACE filename. The beam and carriage assemblies do not move.

7. Press [START]. The beam and carriage assemblies move to indicate the outline of the design,

then stop at the center of the design.

8. If a rack limit is encountered, change to a more appropriately sized hoop. Be aware that using

an excessively large hoop may yield quality problems.

9. When ready, press [START] to retrace the design. Repeat as necessary.

10. Press [ENTER] to return to the Idle Menus.

11. Press [START] to begin embroidering.

Home Menu

Scroll through the top level menus, or press [ENTER] from the Trace Menu to reach the Home Menu.

The Home Menu allows you to Set Home, select hoop sizes, and recover from a power loss. The

Advantage 18 will not embroider until you set home after each time you turn on power.

The set home process moves the beam and carriage assemblies to the upper left corner of the

embroidery area, and then returns to the starting position. This home position remains the

reference point for all machine calculations until the machine is turned off.

CAUTION! The beam and carriage move rapidly during the set home

process. To prevent damage to equipment or material, do not set home if:

*The cap frame driver is installed.

*A large or heavy garment is hooped and attached to the carriage.

*The needle bar is not is the up position.

Set Home

1. Use the direction keys to position the needle at the design starting point.

2. Press [MENU] until the LCD displays: HOME MENU.

3. Press [ENTER] and the LCD displays: SET HOME.

4. Press [ENTER] again to activate Set Home.

NOTE: If set home has already been performed since the machine was turned on, pressing the

[ENTER] key in Step 4 produces the error message: MACHINE RUNNING.

If this happens:

Press [MENU] until the LCD displays: MOVE MENU.

Press [ALT][MENU] and the LCD displays: HOME MENU.

Press [ENTER] and the LCD displays: SET HOME.

Page 40

4 - 4 Home Menu

Advantage 18 Operation Manual Melco Embroidery Systems

Hoop Limits

1. Press [

2. Press

3. Press [ENTER].

4. Press [

5. When the desired size displays, press [ENTER]. The LCD displays: HOOP LIMITS ON and the beam

Power fail rescue allows you to resume embroidering a design after the machine suffers a loss of

power. Follow these steps to regain your position in the design and continue embroidering:

1. While the power is OFF, remove any large garment or the cap frame option, if installed.

2. Turn the power ON. Wait for the machine to power up and download.

3. Scroll through the menus until the LCD displays: HEAD TIMING MENU.

4. Press [ENTER] and the LCD displays: HEAD TIMING ON.

⇑] and the LCD displays: HOOP LIMITS ON or OFF. The [⇐] key turns them OFF, the [⇒]

key turns them ON. Leave them on for normal embroidery.

[⇑] and the LCD displays: SELECT HOOP.

⇑] or [⇓] to scroll through the hoop options. See Appendix C for the hoop size options.

will move to the center of the embroidery field.

Power Fail Rescue

5. Press [ALT][

⇑] until the LCD displays: GO TO HEADUP.

Warning! When you press [ENTER] to activate Go To Headup,

the Z Motor will rotate 1-2 revolutions and the needle will

move. Keep clear of the needle and needle plate!

6. Press [ENTER].

7. Scroll through the main menus until the LCD displays: DESIGN MENU.

8. Press [ENTER]. Make sure your design is in the design buffer. If it is not, reload it.

Clear the thread path. To do this, you must be in a main menu so you can use [ALT][

to move the selector carriage. The next steps instruct you how to do this:

9. Press [MENU] to scroll to any main menu.

10. Press [ALT][

11. Trim the thread to 1/8 inch past the end of the selector carriage. Remove the trimmed thread

completely from the thread path and splicing cell.

⇐] or [ALT][⇒] to move the selector carriage until you can access the current thread.

⇐] or [ALT][⇒]

Page 41

Power Fail Rescue 4 - 5

110265-01, Rev. A 4. The Customizing Menus

Now you are ready to activate the power fail rescue function as directed in the following steps:

12. Scroll through the menus until the LCD displays: HOME MENU.

13. Press [ENTER].

14. Press [

⇑] until the LCD displays: POWER FAIL RESCUE.

15. Press [ENTER]. The beam and carriage assemblies move home, then return to the next to last

stitch embroidered before the power failure. The selector then moves to the color it was on

before the power fail and performs an insert thread.

16. Finish threading the machine.

17. Reinstall the hoop or cap frame if necessary.

18. Press [START]. The Advantage 18 will continue embroidering the design.

Move Menu

Scroll through the top level menus, or press [ENTER] from the Home Menu to reach the Move

Menu.

The Move Menu allows you to perform controlled movement of the embroidery position within the

embroidery field.

1. Press [MENU] until the LCD displays: MOVE MENU.

2. Press [ENTER] and the LCD displays: MOVE X +00.00 IN. The value displayed after the prompt is

either the last number entered or the default value (+00.00).

3. Pressing [

⇑] increases the value by 0.01 inches, pressing [⇓] decreases the value by 0.01 inches. If

you press and hold either of the keys, the values continue to increase or decrease.

4. Press [ENTER] and the LCD displays: MOVE Y +00.00 IN.

5. Press [

⇒] for a positive value (+), or [⇐] for a negative value (-). The following statements

describe the general embroidery position in relation to the centerlines of the X and Y axes.

• X Positive = Right of center.

• X Negative = Left of center.

• Y Positive = Rear of center.

• Y Negative = Front of center.

NOTE: Pressing [ALT][

⇓] from any setting resets both X and Y values to +00.00 IN.

X

+X, +Y-X, +Y

+X, -Y-X, -Y

Front of Machine

Y

Page 42

4 - 6 Move Menu

Advantage 18 Operation Manual Melco Embroidery Systems

When to Use The Move Menu

The Move Menu allows precise placement of a design by repositioning the embroidery area under

the needle.

In Figure 4-1, the machine has already embroidered a three-letter monogram on the forward, left

side of the embroidery field.

Figure 4-1

The dashed lines show the center of the embroidery field. The box with three small plus signs (+) in

the rear, right shows the next position of the design.

1. After the first design finishes embroidering, the LCD displays: END OF DESIGN.

2. Press [MENU] to scroll to the Move Menu. The LCD displays: MOVE MENU.

3. Press [ENTER] and the LCD displays: MOVE X +00.00 IN.

4. If necessary, press [

5. Press and hold the [

⇒] to make the value positive.

⇑] key and the value increases rapidly. Stop at +2.00. The display now reads:

MOVE X +02.00 IN.

NOTE: Keep in mind that the X movement of the carriage is in reference to the needle position.

That means, for the needle position to move to the right in the embroidery field, the

carriage must move to the left.

6. Press [ENTER] and the LCD displays: MOVE Y +00.00 IN.

7. If necessary, press [

⇒] to make the value positive.

8. Press and hold [

⇑] until the value reaches +2.50. The display now reads: MOVE Y +02.50 IN.

Page 43

Setting the Options 4 - 7

110265-01, Rev. A 4. The Customizing Menus

This Y Move positions the needle to the rear of the embroidery field. If the value was negative, the

Y Move would position the needle to the front of the embroidery field.

9. Press [ENTER].

10. Press [START]. The machine moves in both the X and Y axes to reposition the hoop.

After the Move Menu repositions the hoop, use the Trace Menu to verify the design fits in the

embroidery field, then press [ENTER] and then [START] to begin embroidering.

NOTE: If the LCD displays: MACHINE RUNNING, either a job is in progress and must be canceled

(see Reset Menu); or a move has been entered but not executed using the [START] key.

Trim Menu

When designs are created, trim commands may be included as part of the design. When the

Advantage 18 reads these commands, a trim occurs automatically. The trimmer function performs

when it encounters:

• A color change

• A set of commands called a trim dataset

• The start and the end of the design

• The number of consecutive jump stitches set in the jump count option

• A trim immediate selection, if the machine is not embroidering

• A change thread selection, if the machine is not embroidering

Setting the Options

Scroll through the top level menus, or press [ENTER] from the Head Timing Menu to reach the Trim

Menu.

Use the Trim Menu only when the machine is idle. If you try to enter the Trim Menu while the

machine is embroidering, you will receive the error message: MACHINE RUNNING.

1. Press [MENU] until the LCD displays: TRIM MENU.

2. Press [ENTER].

Trim Immediate

3. Press [

⇓] and the LCD displays: TRIM IMMEDIATE. Press [ENTER] to activate the trimmer. Trim

Immediate can only be activated when the embroidery head is stopped.

Jump Count

4. Press [

⇓] again and the LCD displays: JUMP COUNT. This option allows you to select the number

of consecutive jump stitches that will force an automatic trim. The machine trims before the

jump stitches occur. The default jump count is 8.

Page 44

4 - 8 The Splicing Menu

Advantage 18 Operation Manual Melco Embroidery Systems

Acceptable values are 0 through 15, but a value of 0 disables the function. Pressing [⇒] will

increase the count by one, pressing [

⇐] will decrease the count by one.

5. Press [MENU] to exit the Trim Menu.

Bobbin Menu

This feature is not available with the Advantage 18 and must remain OFF at all times. If the Bobbin

Control is ON, follow these steps to turn it OFF:

1. Press [MENU] until the LCD displays: BOBBIN MENU.

2. Press [ENTER].

3. Press [

4. Press [

⇑] until the LCD displays:BOBBIN CTRL ON.

⇒] to turn the feature OFF.

5. Press [ENTER] to leave the menu.

The Splicing Menu

Scroll through the top level menus, or press [ENTER] from the Trim Menu to reach the Splicing

Menu.

The Splicing Menu provides:

• The ability to change the current thread color

• An alternative way to insert thread through the splicing chamber

• A way to toggle on or off certain functions

• A tool for troubleshooting that can activate valves, motors, and trimmers

The Splicing Menu options are:

• Change Thread

• Insert Thread

• Valve ON/OFF

• Upper Trim Motor ON/OFF

• Trim Thread

• Draw Motor

• Low Pressure ON/OFF

• High Pressure ON/OFF

Page 45

Change Thread 4 - 9

110265-01, Rev. A 4. The Customizing Menus

Change Thread

If you want to change the thread that is currently embroidering, use the Change Thread option. For

instance, you might want to embroider with two colors in a design with no color change

commands. The Change Thread option performs a color change, then embroiders with the new

color until it reaches a color change command or the end of the design. Using the change thread

option does not alter the color sequence, nor is it used again if the color sequence wraps.

Follow these steps to use the Change Thread option:

1. If the machine is embroidering, press [STOP].

2. Press [MENU] until the LCD displays: SPLICING MENU.

3. Press [ENTER] and the LCD displays: CHANGE THD: 0.

4. Press [

⇐] or [⇒] to decrease or increase the thread position value. Press and hold to scroll

through the values. Release the key when the desired thread position is displayed.

CAUTION! The following step includes making trims and stitches. Keep the

embroidery area clear.

5. Press [ENTER] to execute a color change.

NOTE: Press [ENTER] when the Change Thread value is in the range of 1 to 18 to execute

a color change to that thread position. No color change takes place if:

* The value is set to 0.

* There is an asterisk next to the value as in: CHANGE THD: 5*. The asterisk means the

carriage selector is at that thread position.

6. Press [ALT][ENTER] to return to the Idle Menu.

7. Press [START] to resume embroidering with the new color.

If you are in a design and use the [FAST\SLOW] key to insert the thread after the Change Thread

option performs, the selector moves to the Change Thread selection. If you are not in a design, the

selector carriage moves to the previous thread position.

Page 46

4 - 10 The Splicing Menu

Advantage 18 Operation Manual Melco Embroidery Systems

Insert Thread

Use this option to insert a thread into the splicing cell. It performs the same function as [ALT][

[ALT][

⇒], or [FAST/SLOW] discussed in the Threading the Advantage 18 section of this manual.

⇐],

To use the Splicing Menu follow these steps:

1. Press [MENU] until the LCD displays: SPLICING MENU.

2. Press [ENTER].

3. Press [

⇑] and the LCD displays: INSERT THREAD.

4. Secure the thread under the pretensioner, in the groove, and through the thread guide hole.

Trim to 1/8 inch.

5. Move the selector carriage to that thread position.

6. Press either [

⇐] or [⇒] to insert the thread through the splicing cell.

7. Complete the manual threading process.

Valve 1 Off

This option can turn each of the six air pressure valves ON and OFF. The default is OFF. These valves

normally function automatically during a thread splice or insert. If you are troubleshooting one of

these processes, test the valves individually. If they are working properly, you will hear a hiss of

compressed air or a mechanical action such as a moving clamp as each is turned ON. If there is no

reaction when turning ON a valve, call your Melco service representative. To activate this option:

1. Press [MENU] until the LCD displays: SPLICING MENU

2. Press [ENTER].

3. Press [

4. Press [

5. Press [

6. Press [

⇑] until the display reads: VALVE 1 OFF

⇒] to turn value 1 ON and listen for a moving clamp.

⇐] to turn valve 1 OFF.

⇑] to move to another valve and repeat steps 3 and 4, each time listening for a

compressed air hiss or a mechanical action.

7. Press [ENTER] to leave this option.

Page 47

Trim Thread 4 - 11

110265-01, Rev. A 4. The Customizing Menus

Up Trim Mtr On

This display is to verify that the upper trim motor is functioning. When you toggle it ON, the motor

runs for about 15 seconds, producing an audible buzzing sound. It does not perform a trim. If you

do not hear the motor start, call your Melco service representative.

CAUTION! Do not allow the motor to run continuously or the drive

electronics may overheat.

1. Press [MENU] until the LCD displays: SPLICING MENU.

2. Press [ENTER] until the LCD displays: UP TRIM MTR OFF.

3. Press [

4. Press [

⇒] to turn the motor ON, and listen for the motor.

⇐] to turn the motor OFF.

5. Press [ENTER].

Trim Thread

This option performs an upper trim when the machine is completely threaded and you press either

the [

⇐] or [⇒] key.

1. Press [MENU] until the LCD displays: SPLICING MENU.

2. Press [ENTER].

3. Press [

4. Press either [

5. Press either [

⇑] until the display reads: TRIM THREAD.

⇐] or [⇒] and the machine displays: TOP TRIM PAUSE.

⇐] or [⇒] again, to perform a trim.

The upper trimmer has separate left and right cutting edges. You may get a successful trim when

moving

left from thread to thread, but not when moving right, or vice versa.

When you press [

⇐] or [⇒] to perform the trim, you are also selecting the left or right cutting edge

of the trimmer. To troubleshoot an upper trimmer problem, rethread the machine and trim at the

same thread using the other arrow key.

6. Remove the trimmed pieces from the splicing cell and the rest of the machine, and rethread the

machine.

You may move the selector carriage and repeat this process, but you must clear away all trimmed

threads and rethread the machine each time.

If the trimmer is not performing correctly, call your Melco service representative.

Page 48

4 - 12 The Splicing Menu

Advantage 18 Operation Manual Melco Embroidery Systems

Draw Motor

The draw motor moves the thread through the splicing cell and along the thread path. This option

allows you to check that the draw motor is working properly. If it is not, call your Melco service

representative.

With a thread through the splicing cell:

1. Press [MENU] until the LCD displays: SPLICING MENU.

2. Press [ENTER].

3. Press [

4. Press [

5. Press [

⇑] until the LCD displays: DRAW MOTOR.

⇒] and the thread should move forward.

⇐] and the thread should move backward.

Low Pressure On

The Advantage 18 has a sensor that detects when the compressed air pressure falls below 75 psi.

When this happens the LCD displays: PRESSURE LOW!

This message will only display before a function that requires compressed air. The purpose of the

sensor is to tell you the air pressure may be too low to make a good thread splice. You must

respond to this message before the Advantage 18 will resume embroidering.

If PRESSURE LOW! is displayed, check your air compressor regulator and make any necessary

adjustment. When the air pressure returns to the 75 psi to 95 psi range, the message remains until

[START] is pressed.

If you check your air pressure regulator and find the pressure is between 75 psi and 95 psi, you

may have a broken sensor. Call your Melco service representative to order a new pressure sensor.

Meanwhile, this option allows you to turn the sensor OFF and continue embroidering.

1. Scroll to the SPLICING MENU.

2. Press [ENTER].

3. Press [

4. Press [

⇑] until the LCD displays: LOW PRESSURE ON.

⇐] to disable the sensor. The LCD displays: LOW PRESSURE OFF.

NOTE: When you want to enable the sensor, press [

LOW PRESSURE ON.

5. Press [ENTER] to leave this option.

The sensor will stay OFF until you reconfigure or perform a hard reset.

⇒] and the display will once again read:

Page 49

System Reset 4 - 13

110265-01, Rev. A 4. The Customizing Menus

High Pressure On

High compressed air pressure can also cause problems with splicing. If the compressed air is

detected above 95 psi, the LCD displays: PRESSURE HIGH!

You must respond to this message before the Advantage 18 will embroider again. Check the

regulator on your air compressor and make any necessary adjustment. When the air pressure

returns to the 75 psi to 95 psi range, the message will remain until you press [START] to resume

embroidering.

If the air compressor regulator is between 75 psi and 95 psi, and you get this message, you may

have a broken sensor. Call your Melco service representative to order a new pressure sensor.

Meanwhile, this option allows you to turn the sensor OFF and continue embroidering.

1. Scroll to the SPLICING MENU.

2. Press [ENTER].

3. Press [

4. Press [

⇑] until the LCD displays: HI PRESSURE ON.

⇐] to disable the sensor. The LCD displays: HI PRESSURE OFF. Press [⇒] to enable the

sensor.

5. Press [ENTER] to leave this option.

The sensor will stay off until you reconfigure or perform a hard reset.

Reset Menu

The Reset Menu allows you to delete the current job in the run buffer, or to reset to the default

values.

System Reset

Performing a "System Reset" clears the run buffer, but it does not clear the design buffer. Scroll

through the top level menus, or press [ENTER] from the Splicing Design Menu to reach the Reset

Menu.

1. Press [MENU] until the LCD displays: RESET MENU.

2. Press [ENTER] and the LCD displays: SYSTEM RESET.

3. Press [ENTER] again and the LCD displays: **RESET**.

Page 50

4 - 14 Reset Menu

Advantage 18 Operation Manual Melco Embroidery Systems

Hard Reset

A Hard Reset resets all operator entered values to their default settings and clears the run buffer.

After a hard reset you must set home before you can embroider again.

1. Use the [MENU] key to scroll to the Reset Menu. Press [ENTER] to display the SYSTEM RESET

message.

2. Press [

⇑] or [⇓] and the LCD displays: HARD RESET.

3. Press [ENTER] and the LCD displays: **RESET**.

4. Press [ENTER] again and the LCD displays: MEMORY CLEARED.

The Advantage 18’s stitch count is cleared from memory and the operator supplied parameters are

restored to default values in the Move, Trace, Home, Color, Tension, Orientation, and Splice menus.

Page 51

5 - 1

110265-01, Rev. A 5. Operator Maintenance

5. Operator Maintenance

To keep the Advantage 18 running at peak efficiency, maintenance procedures must be performed

on a routine basis. This chapter covers operator maintenance and service.

Warning! Avoid personal injury by turning the machine OFF

and unplugging it before removing covers.

Cleaning Exterior Surfaces

Clean outer plastic surfaces with a soft, clean cloth, a mild detergent and water. Wring out the

cloth before wiping the surfaces. Do not get water or any other fluids inside the machine or on any

of the working mechanical surfaces.

NOTE: In the event of an accidental spill, mop up the excess fluid with a clean dry cloth and

allow the machine to dry completely before turning on the power. If the fluid gets

inside the plastic covers, remove the covers to access the interior. Contact your Melco

representative for recommendations.

Cleaning the Rotary Hook Area

1. Turn the machine power OFF.

2. Remove the 2 screws holding the needle plate and lift it off the cylinder arm. Set the needle

plate aside.

3. Clean the area with the brush supplied in the operator’s kit.

Cleaning the Color Change Area

As you embroider with your Advantage 18, the area under the color change cover will accumulate

lint and bits of thread. Clean this area two or three times a week, and anytime you are having a

color change or thread splicing problem.

Page 52

5 - 2 Cleaning the Color Change Area

Advantage 18 Operation Manual Melco Embroidery Systems

Color Change Cover Removal

Refer to Figure 5-1 in removing the color change cover.

Thread

Select

Carriage

Aim compressed

air into this

opening for

cleaning

cover

screws

Color

Change

Cover

1. Slide the thread select carriage to the left of the head to remove it from the manifold assembly.

2. Remove the two socket head screws from the color change cover.

3. Lift the rear of the cover about 3 to 3 1/2 inches as indicated in circle inset in Figure 5-1. Lift the

cover straight up to remove it.

Figure 5 - 1

Page 53

The Manifold 5 - 3

110265-01, Rev. A 5. Operator Maintenance

The Manifold

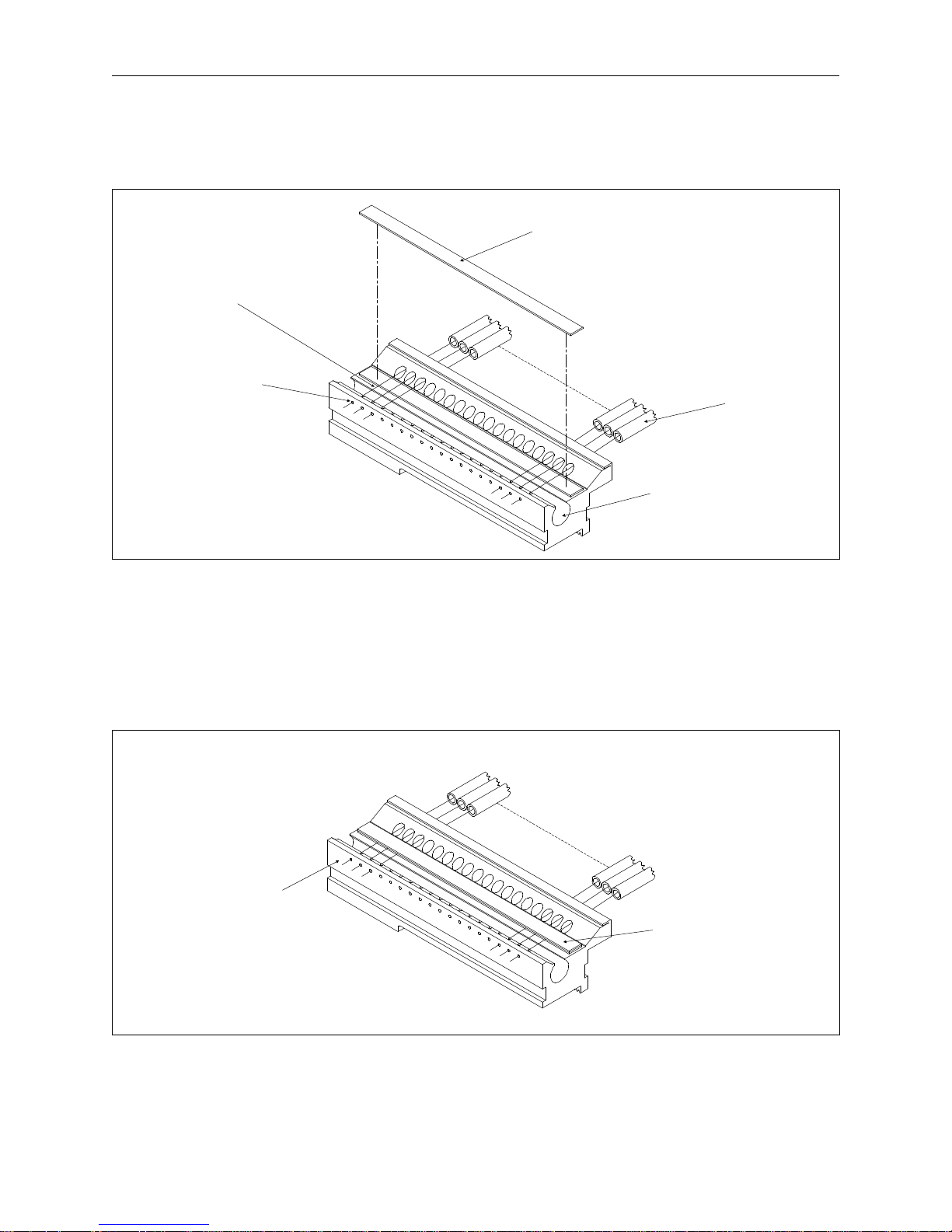

The manifold is the under the color change cover. See Figures 5-2 and 5-3.

The manifold shown with the

color change cover removed.

Figure 5-2

A close-up view of the manifold.

Keep this area free of lint or debris.

Figure 5-3

The manifold holds valves and rollers, the splicing cell, and various other small parts. They may not

work at their peak efficiency if the area becomes contaminated with lint. Use a can of compressed

air to blow away any lint or thread. You can do this without removing the color change cover. Aim

the air into the opening in the needle case above the first thread guide as shown in Figure 5-1.