Meiwa RTX-75D, RTX-80D, RTX-60D, RTX-55D User Manual

OPERATION / MAINTENANCE

AND PARTS MANUAL

RTX-55D(U) /RTX-60D(U)

RTX-75D(U) /RTX-80D(U)

TAMPING RAMMER

( NEW ZEALAND MODEL )

Read this instruction manual before operating this equipment

DEC. 01, 2011

SECTION 1 -

SAFETY PRECAUTIONS AND GUIDELINES

Contents .......................................................................................................................................................................... Page

OVERVIEW ......................................................................................................................................................................... 1

PRE-START INSPECTION................................................................................................................................................. 1

OPERATING ....................................................................................................................................................................... 1

MAINTENANCE ................................................................................................................................................................. 2

OERATING PROCEDURES ..............................................................................................................................………….. 2

OVERVIEW

BEFORE YOU OPERATE, MAINTAIN OR IN ANY OTHER WAY, OPERATE THIS MACHINE:

READ and STUDY this manual. KNOW how to safely use the unit’s controls and what you must do for safe maintenance.

The machine has been built in accordance with state-of-the-art standards and the recognized safety rules. Nevertheless,

its use may constitute a risk to life and limb of the user or of third parties, or cause damage to the machine and to other

material property.

ALWAYS wear or use the proper safety items required for your personal protection.

For reasons of security, long hair must be tied back or otherwise secured, garments must be close fitting and no jewelry –

such as rings or watches - may be worn. Injury may result from being caught up in the machinery or from rings catching

on moving parts.

If you have ANY QUESTIONS about the safe use or maintenance of this unit, ASK YOUR SUPERVISOR OR CONTACT

ANY DISTRIBUTOR. NEVER GUESS - ALWAYS CHECK.

Never make any modifications, additions or conversions which might affect safety without the supplier’s approval. This

also applies to the installation and adjustment of safety devices and valves as well as to welding work on load-bearing

elements. Observe all fire-warning and fire-fighting procedures.

PRE-START INSPECTION

INSPECT your machine. Have any malfunctioning, broken or missing parts corrected or replaced before use.

Check the machine at least once per working shift for obvious damage and defects. Report any changes (incl. changes in

the machine’s working behavior) to the competent organization/person immediately. If necessary, stop the machine

immediately and lock it.

Take the necessary precautions to ensure that the machine is used only when in a safe and reliable state.

Operate the machine only if all protective and safety oriented devices, such as removable safety devices, emergency

shut-off equipment, sound-proofing elements and exhausts, are in place and fully functional.

The electrical equipment of machines is to be inspected and checked at regular intervals. Defects such as loose

connections or scorched cables must be rectified immediately.

VERIFY that all the instruction and safety labels are in place and readable. These are as important as any other

equipment on the compactor.

NEVER fill the fuel tank, with the engine running, while near an open flame, or while smoking. ALWAYS wipe up any

spilled fuel immediately.

1-1

SECTION 1 -

SAFETY PRECAUTIONS AND GUIDELINES

CHECK for WARNING tags placed on the machine. DO NOT operate the equipment until repairs have been made and

the WARNING tags have been removed by authorized personnel.

KNOW the location of the Emergency Shut-Down Control if the machine is so equipped.

OPERATING

In the event of safety-relevant modifications or changes in the behavior of the machine during operation, stop the

machine immediately and report the malfunction to the competent authority/person.

Always wear the prescribed ear protectors.

Always make sure that no person or obstruction is in your line of travel. Watch your step to avoid tripping.

USE extreme caution and be observant when working in close quarters or congested areas.

Before beginning work, familiarize yourself with the surroundings and circumstances of the site, such as obstacles in the

working and traveling area, the soil bearing capacity and any barriers separating the construction site from public

roads.

When traveling on public roads, ways and places always observe the valid traffic regulations and, if necessary, make

sure beforehand that the machine is in a condition compatible with these regulations

Always keep at a distance from the edges of building pits and slopes.

DO NOT run the engine in a closed building for an extended length of time. EXHAUST FUMES CAN KILL.

DO NOT operate the compactor on non-compactable material, such as concrete or hardened asphalt.

MAINTENANCE

Observe the adjusting, maintenance and inspection activities and intervals set out in the operating instructions,

including information on the replacement of parts and equipment. These activities must be executed by skilled

personnel only.

Ensure that the maintenance area is adequately secured.

After cleaning, examine all fuel, lubricant, and hydraulic fluid lines for leaks, loose connections, chafe marks and

damage.

Any defects found must be rectified without delay.

Always tighten any screwed connections that have been loosened during maintenance and repair.

1-2

SECTION 1 -

SAFETY PRECAUTIONS AND GUIDELINES

Any safety devices removed for set-up, maintenance or repair purposes must be refitted and checked immediately upon

completion of the maintenance and repair work.

Ensure that all consumables and replaced parts are disposed of safely and with minimum environmental impact.

AVOID, whenever possible, servicing, cleaning or examining the unit with the engine running.

NEVER fill the fuel tank, with the engine running, while near an open flame, or while smoking. ALWAYS wipe up any

spilled fuel immediately.

ALWAYS disconnect the spark plug before performing any work on the unit.

DO NOT alter the engine governor settings from those indicated in the engine manual.

ALWAYS replace damaged or lost decals. Refer to the Parts Manual for the proper location and part number of all

decals.

Carry out welding, flame-cutting and grinding work on the machine only if this has been expressly authorized, as there

may be a risk of explosion and fire.

Before carrying out welding, flame-cutting and grinding operations, clean the machine and its surroundings from dust

and other inflammable substances and make sure that the premises are adequately ventilated (risk of explosion).

1-3

SECTION 2 - INTRODUCTION

EXCELLENT CHOICE! MEIWA Tamping Rammer you have chosen will give you many hours of maintenance free

operation resulting in a faster return of your investment.

Safe operation depends on reliable equipment and the use of proper operating procedures. Performing the checks and

services described in this manual will help keep your machine in good condition. These recommended operation

procedures will help you to avoid unsafe practices.

Safety notes have been included throughout this manual to help you avoid injury and prevent damage to the equipment.

These notes are not intended to cover all eventualities; it is impossible to anticipate and evaluate all possible methods of

operation. Therefore, you are the only person who can guarantee safe operation and maintenance. It is important that

any procedure not specifically recommended in this manual be thoroughly evaluated from the standpoint of safety before

it is implemented.

Continuing improvement and advancement of product design may cause changes to your machine which may not be

included in this publication. Each publication is reviewed and revised, as required, to update and include these changes

in later editions. MEIWA reserves the right to modify or make changes within a specific model group without notice and

without incurring any liability to retrofit units previously shipped from the factory. Contact your MEIWA Distributor for

non-routine maintenance information that is not covered in this publication.

2-1

SECTION 3 - SYMBOL IDENTIFICATION AND METRIC CONVERSION

Contents Page

INTERNATIONAL MACHINE SYMBOLS ________________________ ______________________________________1

INTERNATIONAL HIGHWAY SYMBOLS ____________ __________________________________________________2

METRIC CONVERSIONS _____________________________________ _____________________ ________________ 4

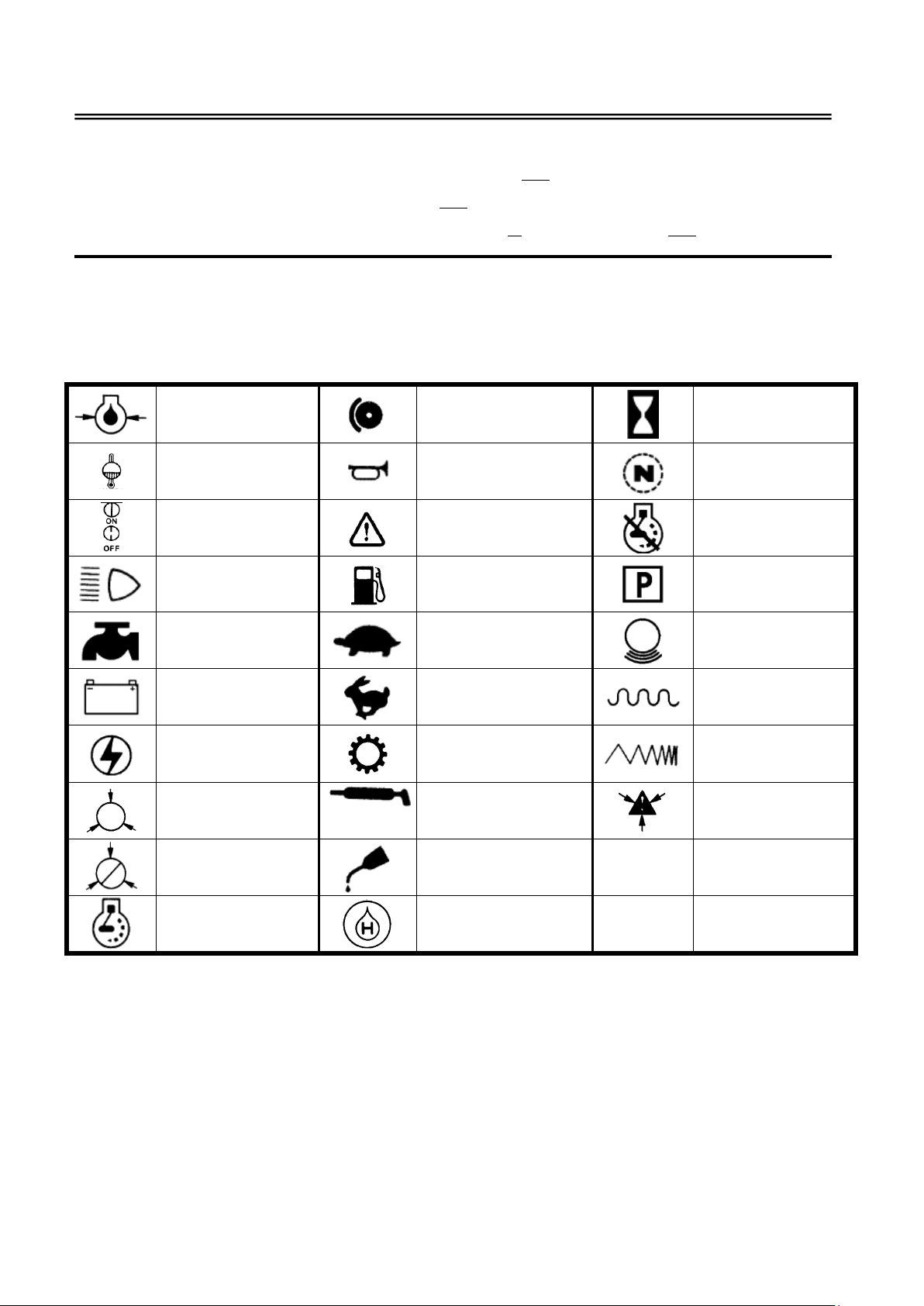

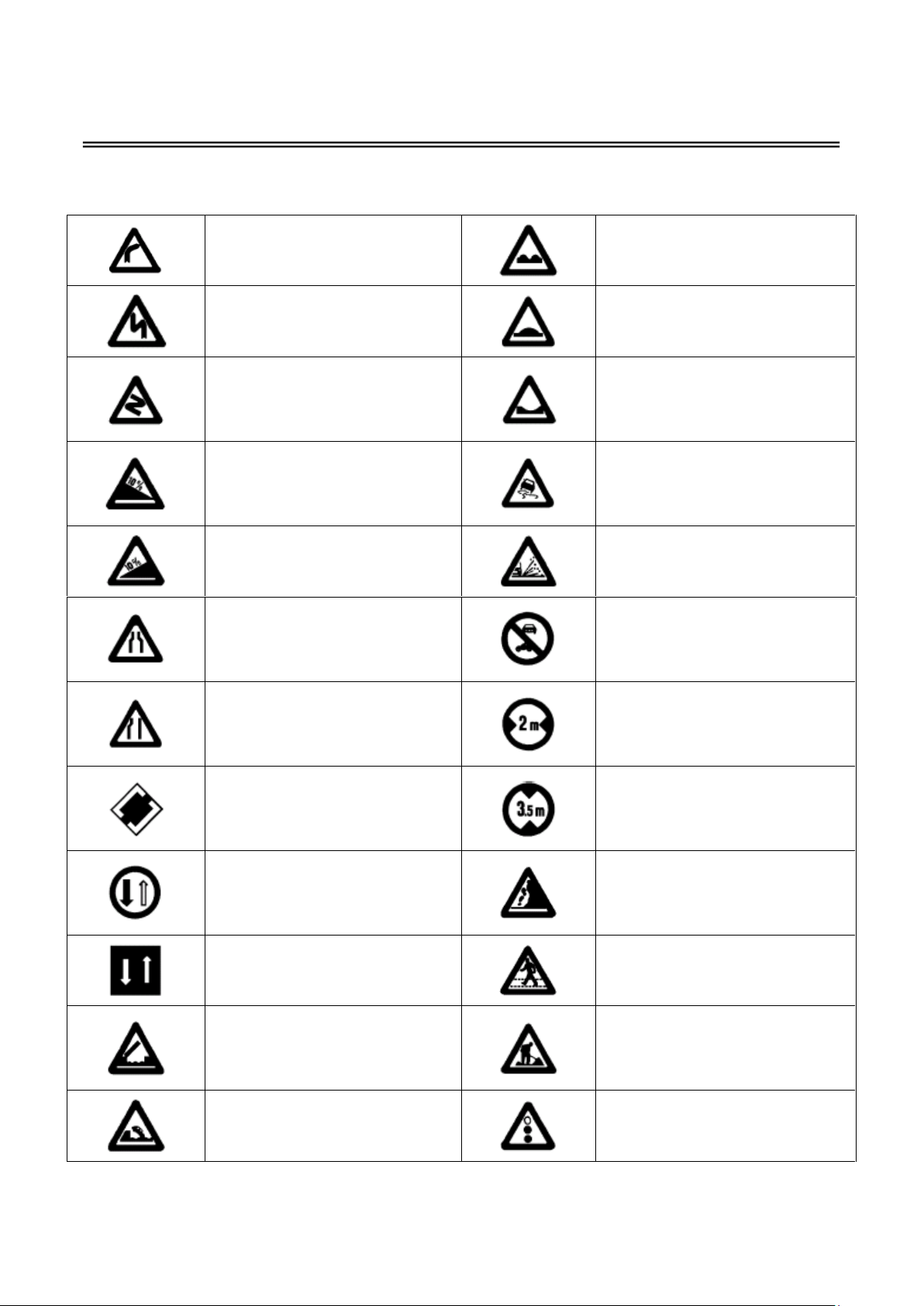

INTERNATIONAL MACHINE SYMBOLS

The following explains the meaning of international symbols that may appear on your machine

OIL PRESSURE BRAKE HOURS

WATER

HORN NEUTRAL

TEMPERATURE

ON / OFF CAUTION LOW ENGINE

RPM.

LIGHTS FUEL BRAKE-PARK

WATER SLOW VIBRATION

BATTERY FAST AMPLITUDE

AMMETE OR

TRANSMISSION FREQUENCY

VOLTMETER

AIR PRESSURE GREASE CAUTION-

PRESSURIZED

LOW AIR

OIL

PRESSURE

ENGINE RPM HYDRAULIC OIL

3-1

SECTION 3 - SYMBOL IDENTIFICATION AND METRIC CONVERSION

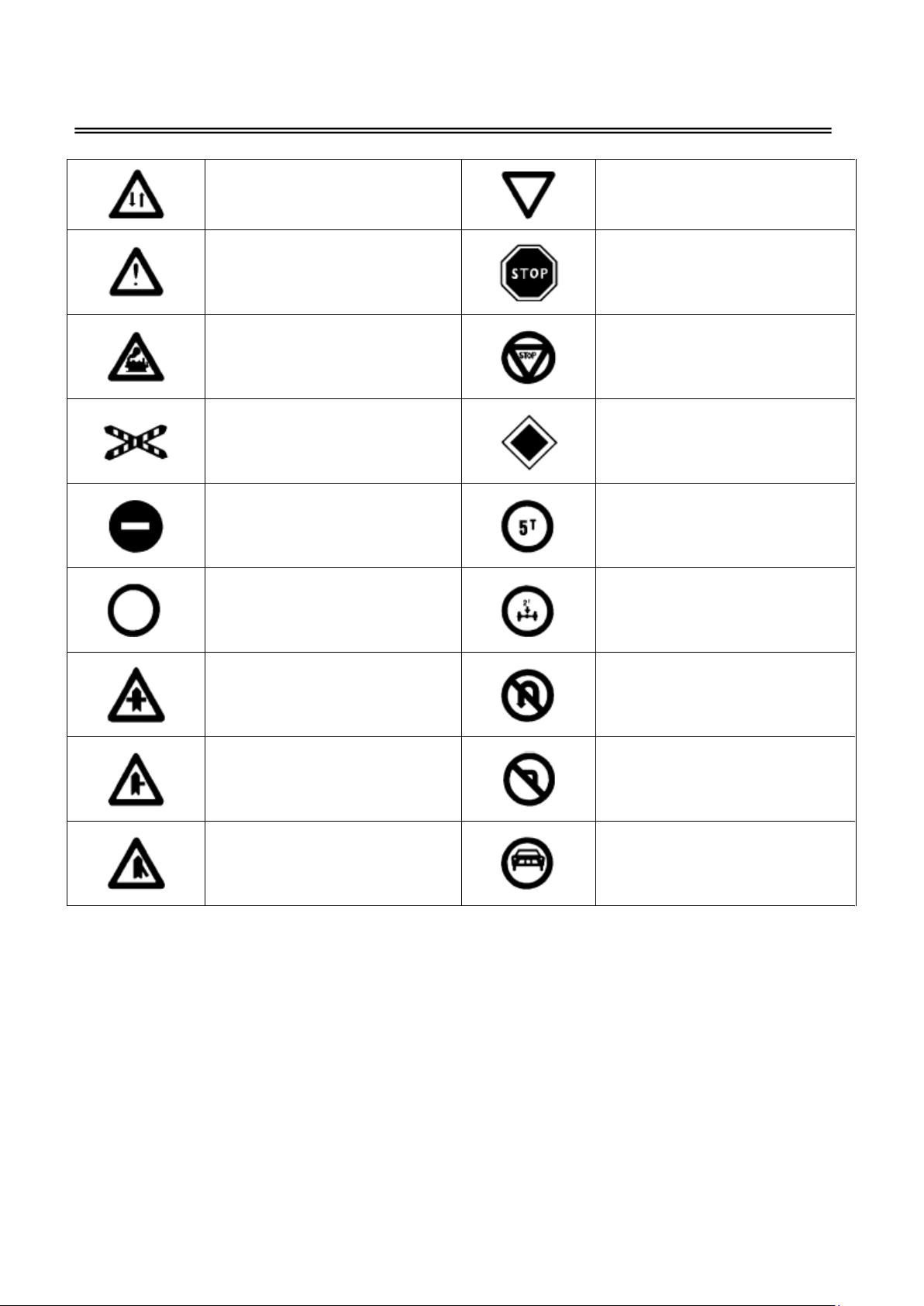

INTERNATIONAL HIGHWAY SYMBOLS

The following symbols may also appear in a yellow square instead of a red triangle.

Road bends Uneven road

Dangerous bend Ridge

Double bend Dip

Dangerous descent Slippery road

Steep ascent Loose gravel

No entry for power driven

Carriageway narrows

vehicles

No entry for vehicles exceeding

Carriageway narrows

length

No entry for vehicles exceeding

“end of priority” sign

length

Oncoming traffic has priority Falling rocks

Priority over oncoming traffic Pedestrian crossing

Swing bridge Road work

Road leads onto quay or river

Light signals

bank

3-2

SECTION 3 - SYMBOL IDENTIFICATION AND METRIC CONVERSION

Two-way traffic “give way” sign

Other dangers Stop sign (new)

Level crossing Stop sign (old)

Level crossing “priority road” sign

No entry

Closed to all vehicles in both

directions

Intersection, user must give

way

Intersection, user must give

way

Intersection, user must give

way

No entry for vehicles exceeding

weight

No entry for vehicles axle

weight exceeding

No u-turn

No turn direction shown

No entry for power driven

vehicles

3-3

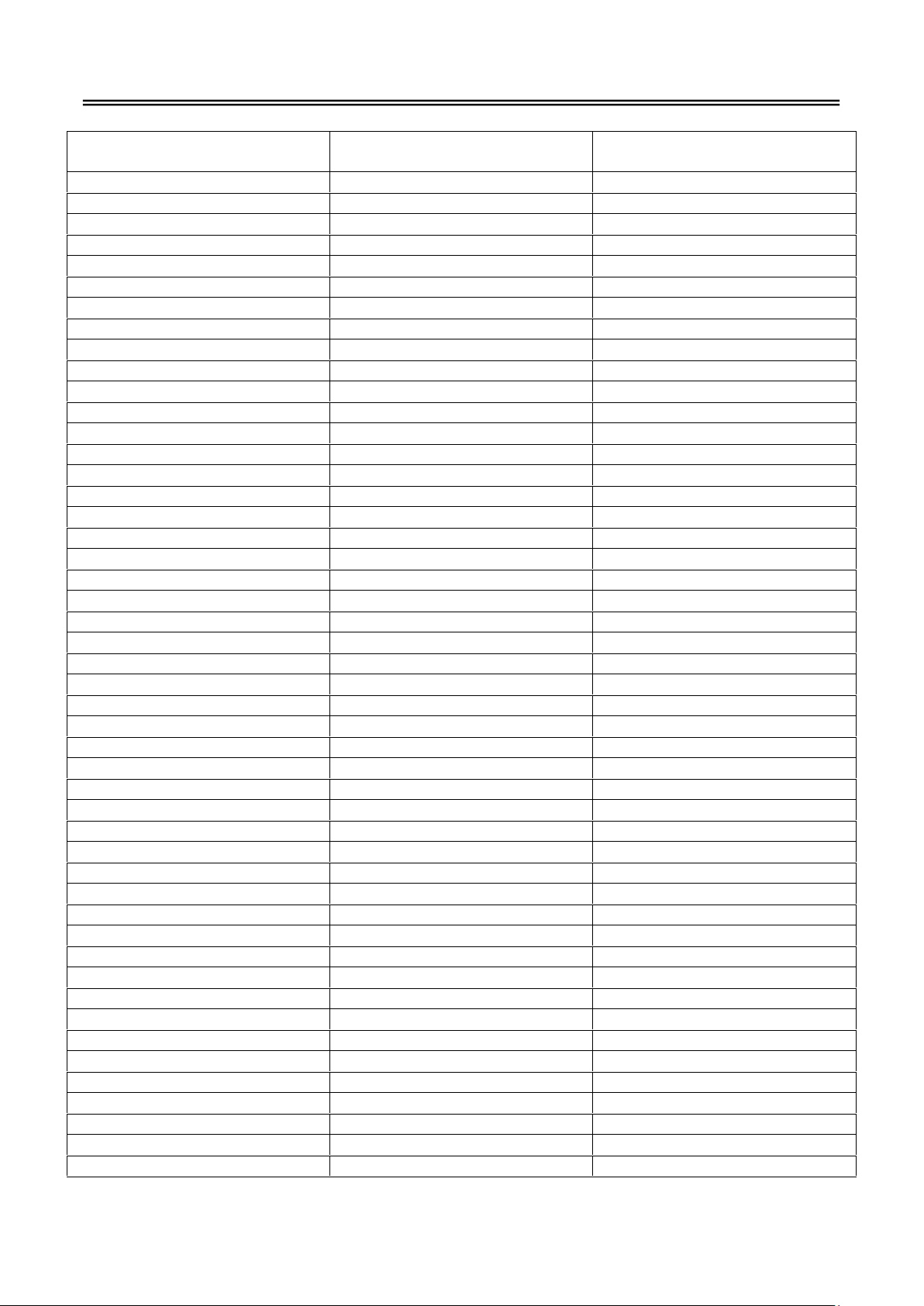

SECTION 3 - SYMBOL IDENTIFICATION AND METRIC CONVERSION

TO CONVERT

OMREGNET FRA

Bar Pound/sq.in 14.50

Bar Kilopascals 100.

Centigrade Fahrenheit (C° x 9/5) + 32

Centimeters Inches 0.3937

Centimeters Millimeters 10.0

Circumference Radians 6.283

Cubic centimeters cu.inches 0.06102

Degrees (angle) Radians 0.01745

Degrees/sec. Revolutions/min 0.1667

Feet Meters 0.3048

Feet/min Meters/min. 0.3048

Foot-pounds Kg-meters 0.1383

Gallons Liters 3.785

Hertz Vibrations/min. 60.

Horsepower Kilowatts 0.7457

Inches Centimeters 2.540

Inches Millimeters 25.40

Kilograms Pounds .250

Kilogram meters -Pounds 7.233

Kilopascal Pounds/sq.in 0.1450

Kilopascal Bars 0.01

Kilowatts Horsepower 1.341

Liters Gallons (U.S. liq) 0.2642

Liters Pints (U.S. liq) 2.113

Liters Quarts (U.S. liq) 1.057

Meters Feet 3.281

Meters Inches 39.37

Meters/min Feet/sec 0.05468

Miles/hr kms/hr 1.609

Millimeters Inches 0.03937

Newtons Pounds 4.448

Newton-meter Pound-feet 0.737

Pounds Kilograms 0.4536

Pounds Newtons 0.225

Pound feet Newton-meter 1.356

Pounds/ft. kgs/meter 1.488

Pounds/sq in Bars 0.06895

Pounds/sq in Kilopascals 6.895

Quarts (liq) Liters 0.9463

Radians Degrees 57.30

Radians/sec Revolutions/min 9.549

Revolutions/min Degrees/sec 6.0

Revolutions/min Radians/sec 0.1047

Temperature (°C) + 17.78 Temperature (°F) 1.8

Temperature (°F) - 32 Temperature (°C) 5/9

Tons (short) Tons (metric) 0.9078

Vibrations/min Hertz 0.0167

INTO

TIL

MULTIPLY BY

MULTIPLICERES MED

3-4

SECTION 4 - OPERATING INSTRUCTIONS

Contents Page

SAFETY CHECKS - PRE-STARTING __________________________________________________________________1

INSPECTION PRIOR TO OPERATION ________________________________________________________________2

OPERATION ________________________________________________________________________________________2

STORAGE ___________________________________________________________________________________________6

Improper maintenance can be hazardous.

Read and understand SECTION 1 - SAFETY PRECAUTIONS AND GUIDELINES before you perform any maintenance,

service or repairs.

SAFETY CHECKS - PRE-STARTING

Before starting each day, in addition to the 10 hour daily routine maintenance, check or inspect the following items to

ensure trouble free performance.

1. Check fluid lines, hoses, fittings, filler openings, drain plugs, pressure cap, muffler, safety shrouds and the area

underneath.

2. The unit for signs of leakage or damage. Fix any leaks and correct any damage before operating.

3. Inspect the entire unit for damaged or missing parts and repair or replace them as needed.

4. Check the fuel level. If necessary, fill the fuel tank with the proper fuel.

5. Check all fastening hardware to ensure it is adequately tightened and that none is missing or broken.

6. Do not operate faulty equipment.

7. Be observant of people and obstructions within the work area.

Please read “INSTRUCTIONS FOR USE” for ROBIN engine and this instruction manual for correct use and care.

4-1

SECTION 4 - OPERATING INSTRUCTIONS

Please check if the unit is correctly maintained in good operating condition.

INSPECTION PRIOR TO OPERATION

CHECK ENGINE OIL

Before checking or refilling engine oil, be sure the compactor is located on a stable level surface.

Do not thread the gauge into oil filler to check oil level. If the oil level is below the lower level line on the dipstick, refill

with the proper oil to the upper level (to the neck of oil filler). See section 9.

CHECK ENGINE FUEL

Do not refuel while smoking, near an open flame or other potential hazards.

CLEANING AIR CLEANER

Check Air Cleaner to be sure it is clean and not contaminated. If it needs cleaning perform the following steps:

Remove the outer urethane foam and inner element. Wash the element in fuel. Saturate it in a mixture of 3 parts

kerosene or diesel fuel and 1 part engine oil. Shake off excessive oil and reinstall. Wash the air cleaner case using

kerosene. After cleaning it up, apply engine oil on the inner part of the case.

If the air cleaner element is seriously contaminated, engine start up failure, poor output or engine malfunction may

result.

CHECK EACH PART FOR LOSE OR BROKEN BOLTS AND NUTS

Tighten loose bolts and nuts, if any. Check each part for fuel or oil leak. Replace broken or damaged parts, if any, with

new ones.

LUBRICATION OF MAIN BODY

Check the Main Body oil level with the oil gauge before each operation. Change oil after the first 50 hours and every 200

hours. See Section 11.

OPERATION

STARTING

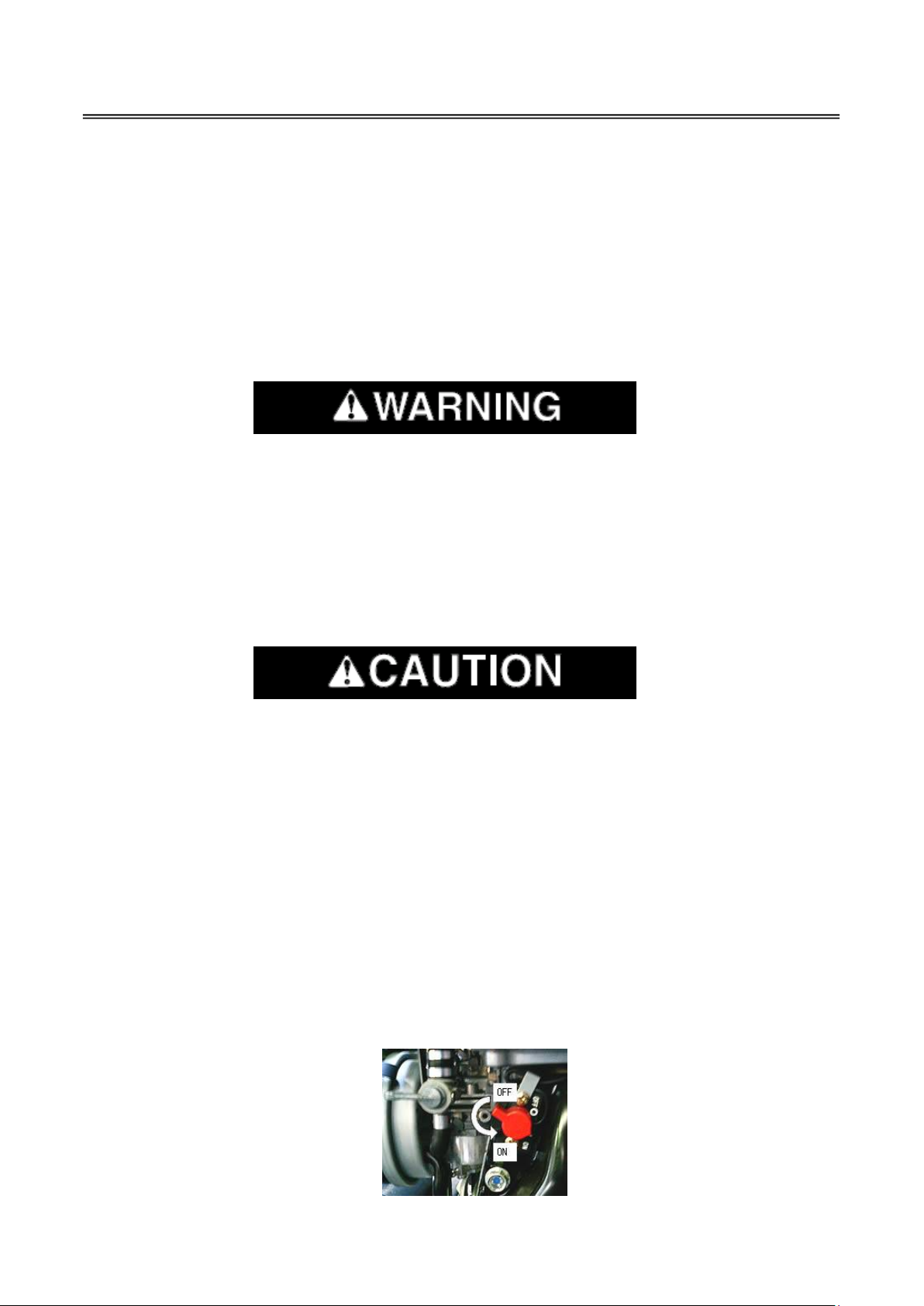

1. Turn the STOP SWITCH (Figure 4-1) clockwise to the position “I” (ON).

Figure 4-1

4-2

Loading...

Loading...