Meistergram M100-J, M80-J User Manual

M'100-J and M'80-J MONOGRAM MACHINES

-~

AND PARTS BOOK

Main

Office

3517

West

Greensboro,

(919)

ORDERS

L~H~~LD

and

Plant

Wendover

854-6200

NC

27

Ave.

407

FOR PARTS OR

BEDIRECT~~-~?

New York Showroom

14

New

(212)

East

York,

INQUIRIES

THE

GREENSBORO

38th

St.

NY

10016

685-0888

FOR

monogram and embroidery systems

©

MEISTERGRAM,

1975

SERVICE

~~~~CE

Los

INC.

Angeles Showroom

3505

Cadillac

Ave.

Building

Costa

(714)

Mesa,

241-8033

#A

CA

92626

TABLE

OF

CONTENTS

Section I

M'100-J

M'100-J and M'80-J

Threading

Bobbin

Thread

Bobbin

Stitch

Presser

Motor

Cleaning

Timing

M'1

Section II (see

Instructions

different

ing

Machine

Machine

Winder

Types,

Tension

00-J

Hoop

Upper

Lower

Template

Pantograph

problems.

Take-up

Case

Width

Foot

and

Clutch

and

the

Hook

Pantograph

Arm

Pantograph

Pantograph

types

Complete

Assembly

Adjusting

Threading

Control

Assembly

Oiling

and

Assembly

Holder

Instruction . ..

front

as

to

of

material

............................................................................... .

Machine

and

Spring

and

Assembly

Machine

Needle

Parts:

Assembly

Assembly

Assembly

page

monogramming

Head

................................................................. .

Needles

and

Upper

............................................................................... .

and

Adjustment

and

.................................................................................... .

. . . . . . . . . . . . . . . . . . . . . . . .

of

and

................................................................... .

Adjustment

Thread

Adjustment

Adjustment

............................................. .

Head

................................ .

............................ .

. .....

... . ..

. ..... .....

..

...

..

.....

this

section

and

garments,

..................................................... .

Tension,

..................................................... .

............................................................. .

..... . ................ .

..

........ ....... ....

...

....... ..... .... .............

..

... . ...

.....

.. . ..

for

basic

cause

...

. . ....

....

..

..

........

. . . . . . . . . . . . . . . .

contents}

operation

and

correction

....

..

...

...

.....

....

....

... . ...

..

. . . . .

of

equipment,

.. . ..

Page No.

..

. . ....... .... ..... 13

...

.....

...

...

. ....

..

. . . .

...

. .

..

...

..

. .

..

. . . . . . . . . . . 14

working

of

common

operat-

1

2

3

4

5

6

7

8

9

10

11

12

13

13

with

Section Ill (see

Detailed

machine

with

parts

head.

M'

80-J

Supply Cabinet

and Panels

front

listing

page

for

of

internal

this

section

components

for

contents}

of

the

M'80-J and M'100-J

monogram

M'

100-J

with Panels

eJ

I ,

~~~~~

(:

~

y I

~'

('fA~~~~~

INSTRUCTION MANUAL

~~~'1/A~

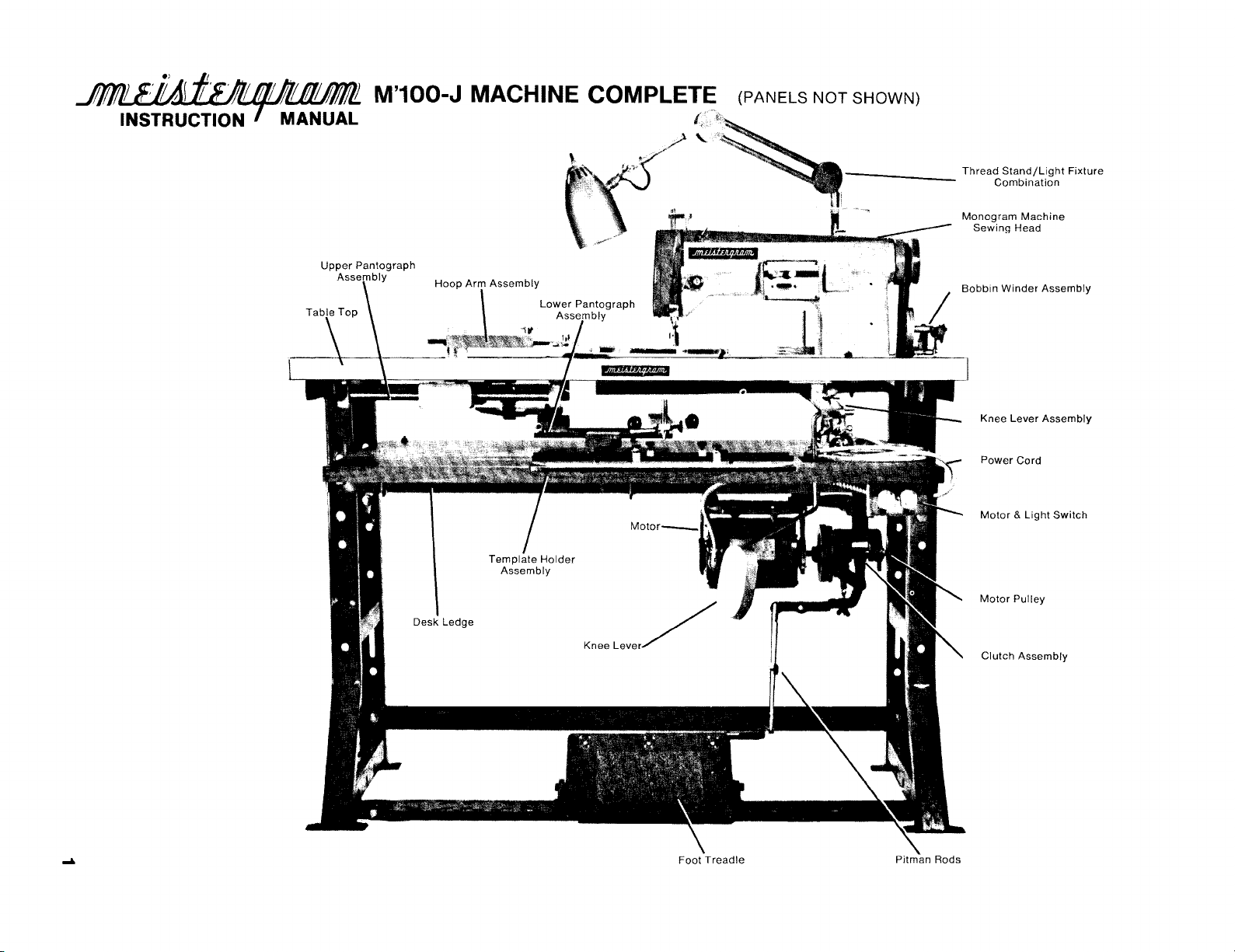

M'100-J MACHINE COMPLETE (PANELS

NOT

SHOWN)

Desk

Ledge

Knee

levee/

l

Thread

Stand/Light

Combination

Monogram

Sewing

Bobbin

Winder

Knee

Power

Motor & Light

Motor

Clutch

Machine

Head

Assembly

Lever

Assembly

Cord

Pulley

Assembly

Fixture

Switch

"""'

Foot

Treadle

Pitman

Rods

~

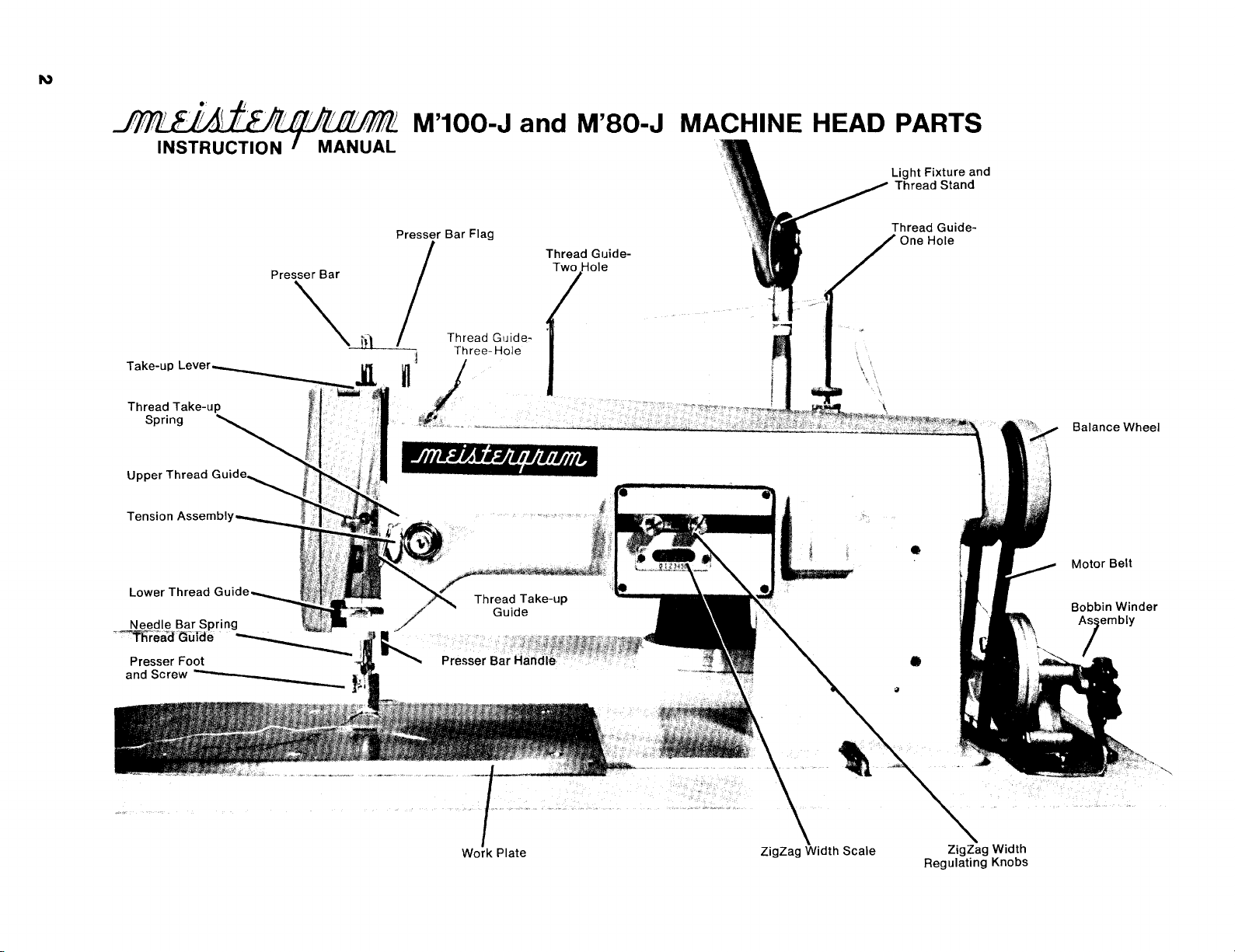

M'100-J and M'80-J MACHINE HEAD PARTS

Light

Fixture

Thread

Stand

Presser Bar Flag

Thread

Guide-

Two

Hole

and

Thread Take-u

Spring

Tension

Assembly

Pres\

fi) .

Thread

Guide~

Three-Hole

Thread Take-up

Guide

lw

•

Balance Wheel

Motor

Belt

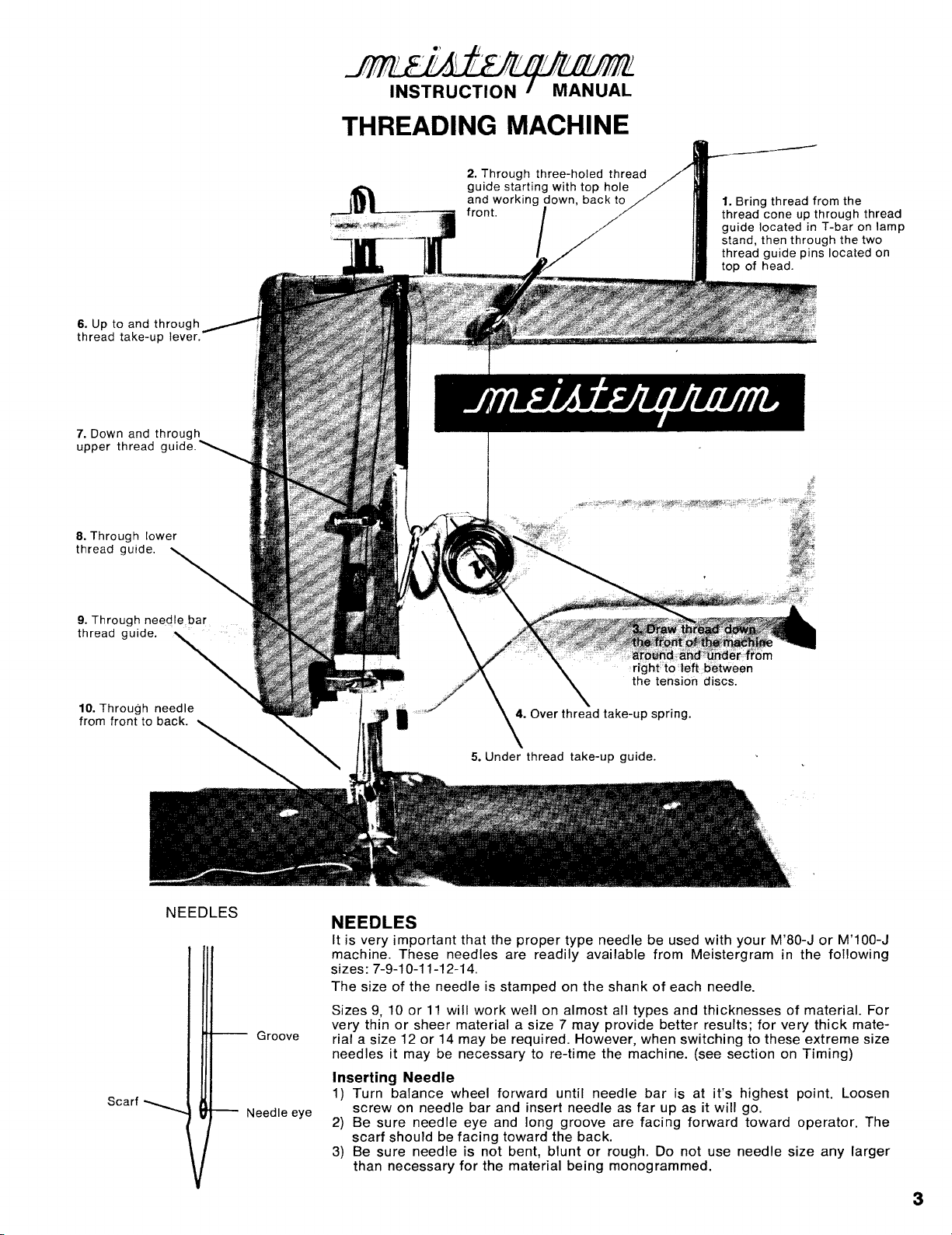

THREADING MACHINE

2.

Through

guide

and

front.

starting

working

three-holed

with

top

down,

back

thread

hole

to

1.

Bring

thread cone up

guide

stand, then

thread

top

thread from the

located

through

guide

of

head.

through

in

pins located on

T-bar

the two

thread

on

lamp

6. Up to and

thread take-up lever.

7.

Down and

upper

Through

10.

from

through

through

thread guide.

needle

front

to back.

NEEDLES

NEEDLES

It is very

important

that the

proper

machine. These needles are readily available from Meistergram in the

sizes: 7-9-10-11-12-14.

of

the needle is stamped on the shank

9,

10

or

11

will

work

or

sheer material a size 7 may provide better results;

or

it

14 may be required. However, when

may be necessary to re-time the machine. (see section on

well on almost all types and thicknesses

Groove

The size

Sizes

very thin

rial a size 12

needles

Inserting Needle

1)

Scarf

Needle eye

Turn balance wheel forward until needle

screw

2)

Be sure needle eye and long groove are

scarf

3)

should be

Be sure needle

than necessary

on needle

bar

and insert needle as

facing

toward the back.

is

not

bent,

for

the material being monogrammed.

blunt

type needle be used with

of

each needle.

switching

bar

is at

far

up

as

facing

or

rough. Do not use needle size any

forward toward operator. The

your

to these

it's

highest point. Loosen

it

will go.

M'80-J

for

of

very

or

M'100-J

following

material. For

thick

extreme

mate-

size

Timing)

larger

3

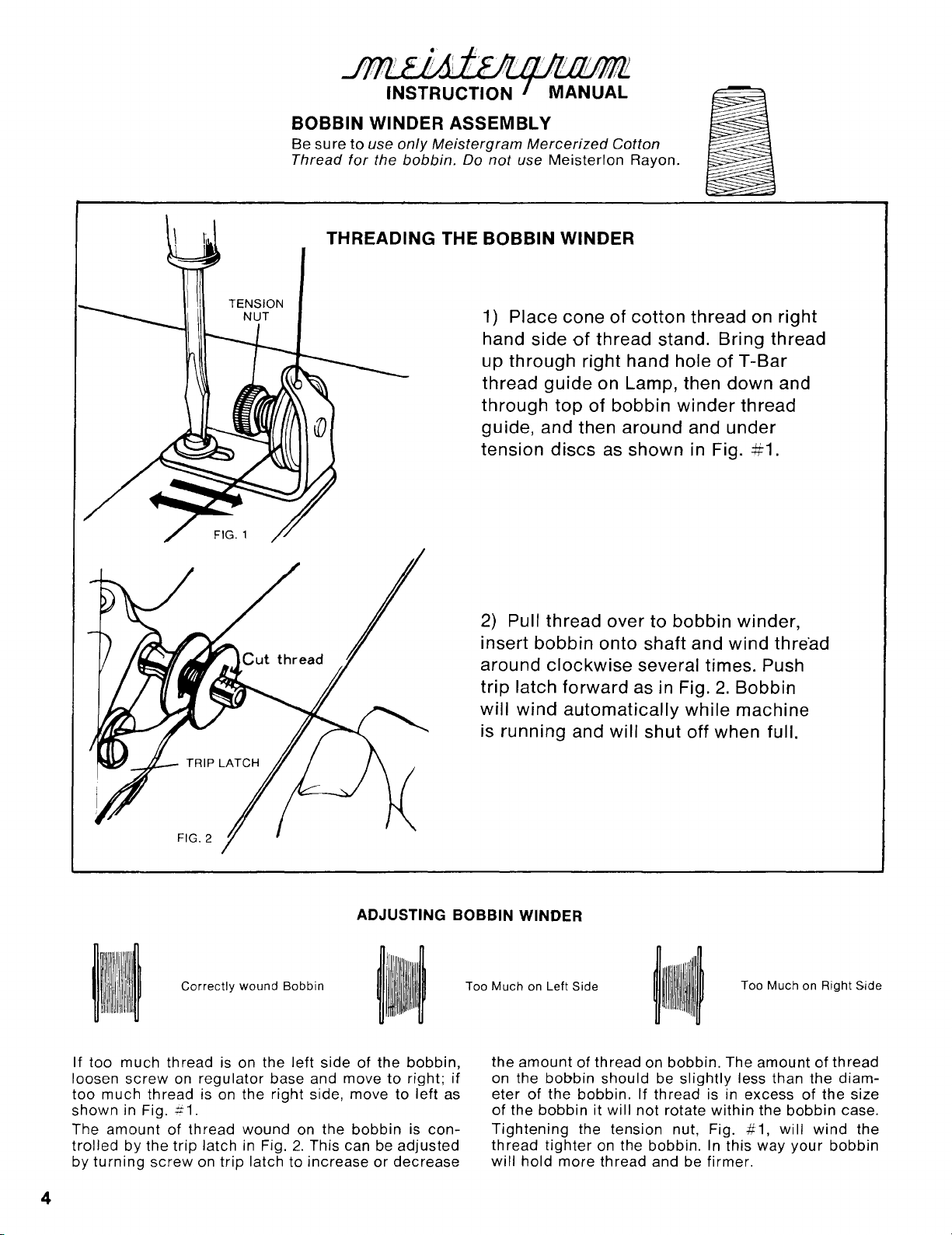

BOBBIN WINDER ASSEMBLY

Be

sure

to

use

only

Thread

for

the

Meistergram

bobbin.

Do

not

use

Mercerized

Meisterlon

THREADING THE BOBBIN WINDER

1)

Place

hand side

through

up

thread

through

guide

top

guide, and then

tension

discs

Cotton

Rayon.

cone

of

cotton

of

thread stand. Bring thread

right hand hole

on Lamp, then

of

bobbin

around

as

shown

thread on

ofT-Bar

down

winder

and

under

in Fig.

thread

#1.

right

and

Correctly

I~

II~

If

too

loosen

too

much

shown

The

amount

trolled

by

turning

much

thread

screw

in Fig. #

by

on

thread

of

the

trip

screw

1.

thread

wound

is on

regulator

is on

the

wound

latch

in Fig.

on

trip

latch

ADJUSTING BOBBIN WINDER

Bobbin

the

left

side

of

base and move

right

side, move

on the

2.

to

bobbin

This can be

increase

the

bobbin,

to

right;

to

is

adjusted

or

decrease

left

con-

2)

Pull thread

insert

around

trip

latch

will

wind

is running and

Too

Much

the

amount

on the

if

as

eter

of

the

Tightening

thread

will

hold

bobbin

onto

clockwise

forward

automatically

on Left

Side

of

thread

bobbin

of

the

bobbin.

bobbin

tighter

it

the

on the bobbin. In

more

thread

over

to

bobbin

shaft and

several times. Push

as in Fig.

2.

while

will

shut

off when full.

!111~''''11~

I

on

bobbin.

should

will

be

If

thread

not

tension

and be firmer.

slightly

is in

rotate

nut, Fig.

within

winder,

wind

thre'ad

Bobbin

machine

Too

Much

The

amount

less than

excess

the

#1,

will

this

way

on

Right

of

the

of

the

bobbin

wind

your

Side

thread

diam-

size

case.

the

bobbin

4

e.·

I

~

I ( I ' ( '

~·~

I I

~·~

;.

~

~'!J~

INSTRUCTION MANUAL

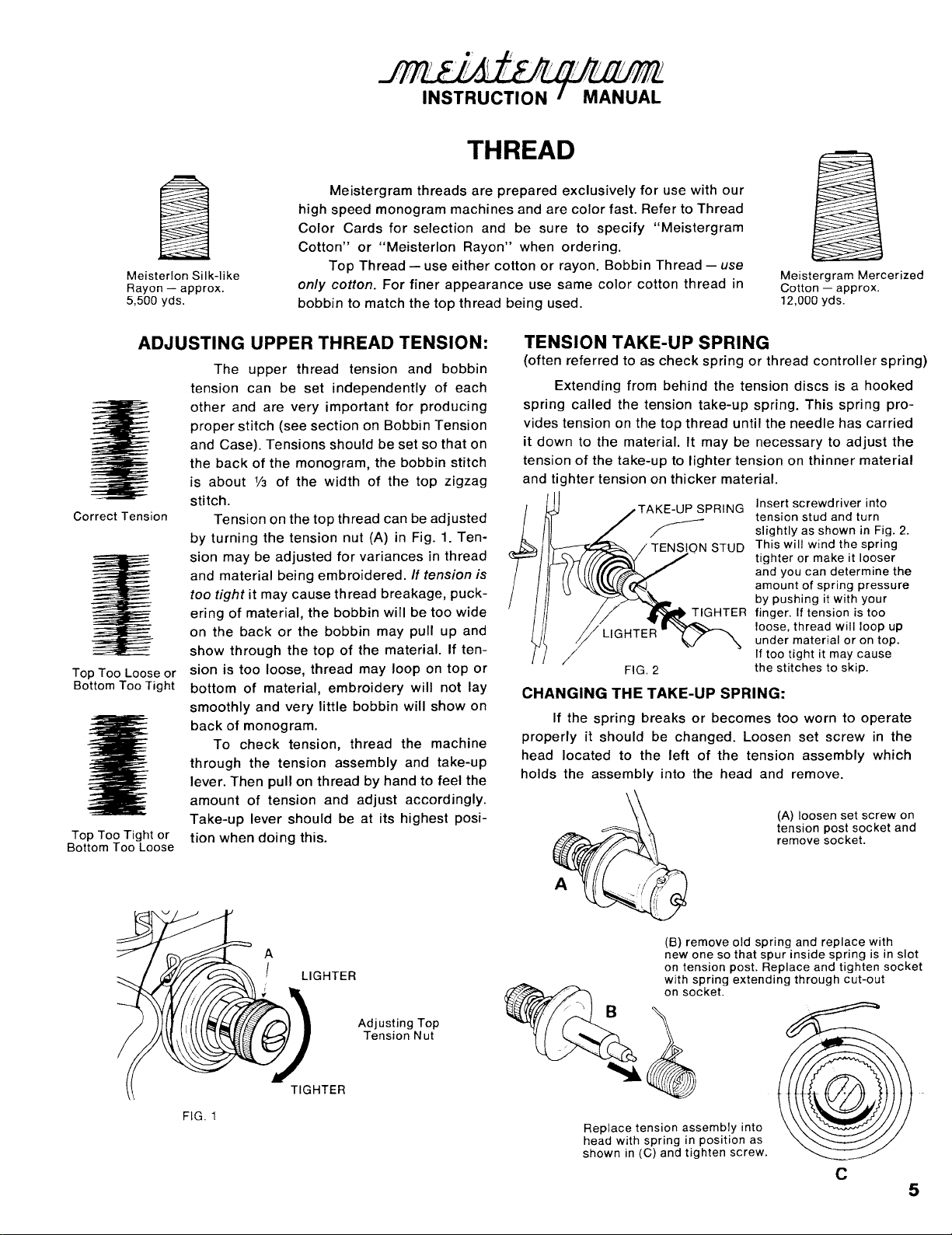

THREAD

~

Correct

Top

Too

Bottom

Top Too

Bottom

Meistergram threads are prepared

high speed monogram machines and are

Color

Cards

for

selection and be sure

Meisterlon

Rayon - approx.

5,500 yds.

Silk-like

Cotton"

only

bobbin

or

Top

Thread-

cotton.

to

"Meisterlon

use

For

finer appearance use same

match the

ADJUSTING UPPER THREAD TENSION:

The

upper

tension can be set

other

and are very

proper

stitch (see section on Bobbin Tension

and Case). Tensions should be set so that on

the

back

is about

stitch.

Tension Tension on the

by turning the tension nut (A) in Fig. 1. Tension may be adjusted

and material being embroidered.

too

tight

it

ering

of

material, the bobbin will be

on the

back

show through the

Loose

or

sion is too loose, thread may

Too

Tight

bottom

of

smoothly

back

of

monogram.

To

check

through the tension assembly and take-up

lever. Then pull on thread

amount

of

Take-up lever should be at its highest posi-

Tight

or

Too

Loose

tion when

thread tension and bobbin

independently

important

of

the monogram, the bobbin stitch

1fJ

of

the width

top

thread can be adjusted

for

for

producing

of

the

top

variances in thread

If tension is

may cause thread breakage,

or

the bobbin may pull

top

of

the material. If ten-

loop

on

material,

embroidery

will

and very little bobbin will show on

tension, thread the machine

by

hand to feel the

tension and

doing

this.

adjust

accordingly.

Rayon" when ordering.

either

cotton

or

top

thread being used.

TENSION TAKE-UP SPRING

(often referred to as

of

each

spring

vides tension on the

it

down

tension

zigzag

puck-

too

up

top

not

wide

and

or

lay

and

CHANGING THE TAKE-UP SPRING:

properly

head located

holds

exclusively

color

to

rayon. Bobbin

Extending from behind the tension

for

fast. Refer

specify

color

"Meistergram

cotton thread in

use with

to

Thread

Thread-

check

our

use

spring

Meistergram

Cotton - approx.

12,000 yds.

or

thread

discs

controller

called the tension take-up spring. This spring

top

thread until the needle has carried

to

the material. It may be necessary to

of

the take-up to

tighter

tension on

If the spring breaks

it

should be changed. Loosen set

to

the

lighter

thicker

or

left

of

tension on

thinner

material.

Insert

screwdriver

tension stud and turn

slightly

This

tighter

and you can

amount

by pushing it with

finger. If tension is too

loose, thread

under

If too

the

becomes

as shown in Fig. 2.

will

wind

or

make it

determine

of

spring pressure

material

tight

it may cause

stitches

too

to

worn

screw

the tension assembly

the assembly into the head and remove.

(A) loosen set

tension post

remove socket.

Mercerized

spring)

is a hooked

pro-

adjust

the

material

into

the

spring

looser

the

your

will

loop

up

or

on top.

skip.

to

operate

in the

which

screw

socket

on

and

Adjusting

Tension

FIG. 1

Top

Nut

one

so

spring

position

old

that

extending

as

screw.

(B) remove

new

on tension post. Replace and tighten

with

on socket.

Replace tension assembly into

head with spring in

in

shown

(C) and

tighten

spring

spur

and

replace

inside

through

spring

cut-out

c

with

is in

socket

slot

5

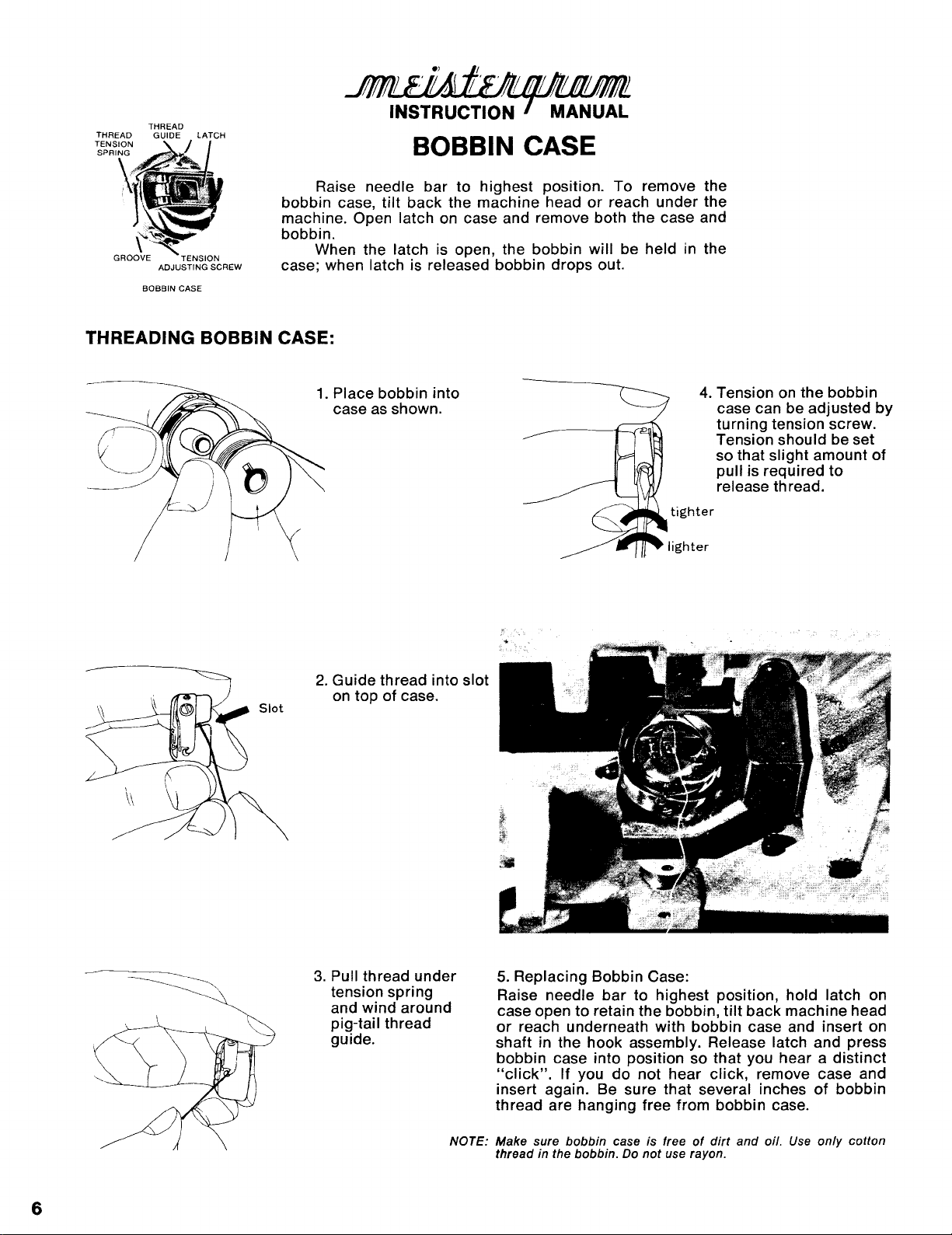

THREAD

TENSION

SPRING

THREAD

GUIDE LATCH

Raise needle bar to highest position. To remove the

bobbin case,

machine.

bobbin.

TENSION

ADJUSTING SCREW

BOBBIN CASE

When the

case; when

THREADING BOBBIN CASE:

1.

~....,.WIIioool~·

fA

V

~

V

fA.V

~ V 'Ill/A~

INSTRUCTION MANUAL

BOBBIN CASE

tilt

back the machine head

Open latch on case and remove both the case and

latch is open, the bobbin will be held in the

latch is released bobbin drops out.

Place bobbin into

as

case

shown.

or

reach under the

4.

Tension on the bobbin

case can be adjusted

turning tension screw.

Tension

so that

pull is required

should be set

slight amount

to

release thread.

by

of

2.

Guide thread into slot

on top

3.

Pull thread under

of

case.

tension spring

and wind around

pig-tail thread

guide.

5.

Replacing Bobbin Case:

Raise

case open

or

shaft in the hook

needle

bar

to highest position, hold latch on

to

retain the bobbin,

tilt

back machine head

reach underneath with bobbin case and insert on

assembly. Release latch and press

bobbin case into position so that you hear a

"click".

insert again. Be sure that

If you do

not

hear click, remove case and

several inches

of

thread are hanging free from bobbin case.

distinct

bobbin

NOTE: Make sure

thread in the bobbin. Do

6

bobbin

case is free

not

use rayon.

of

dirt

and

oil.

Use

only

cotton

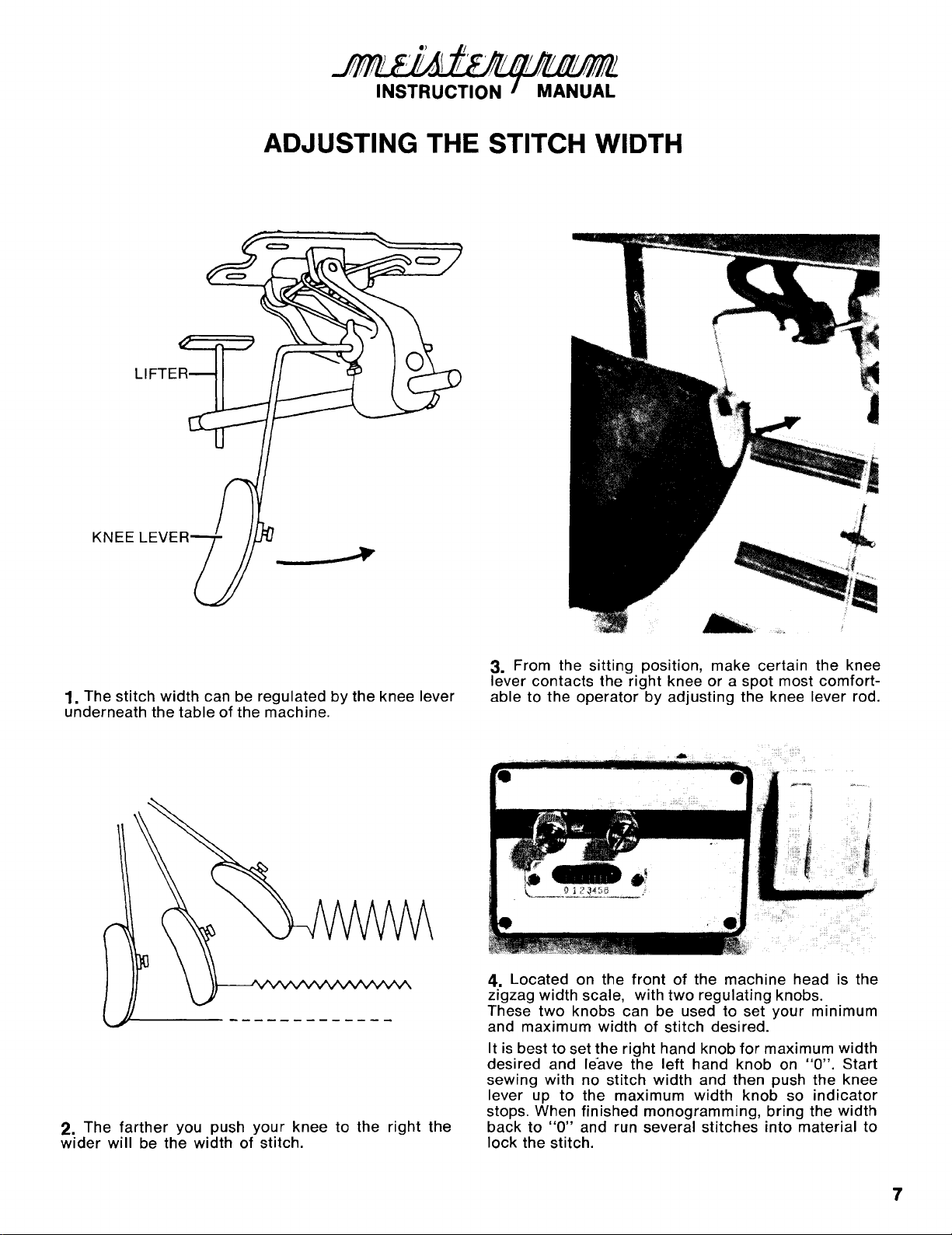

ADJUSTING THE STITCH WIDTH

1. The stitch width can be regulated

underneath the table

2. The

wider

farther

will

be the width of stitch.

of

you push

the machine.

your

knee to the right the

by

the knee lever

3. From the sitting position, make certain the knee

lever contacts the right knee

able to the

operator

by

4. Located on the front

zigzag width

These

and maximum width of stitch desired.

It is best to set the

desired and

sewing with no stitch width and then push the knee

lever up

stops. When finished monogramming, bring the width

back

to

lock

the stitch.

scale, with

two

knobs can be used to set your minimum

right

hand knob

leave the left hand knob on

to

the maximum width knob so

"0"

and run several stitches

or a spot

adjusting the knee lever rod.

of

the machine head is the

two

regulating knobs.

most

comfort-

for

maximum width

"0".

indicator

into

material to

Start

7

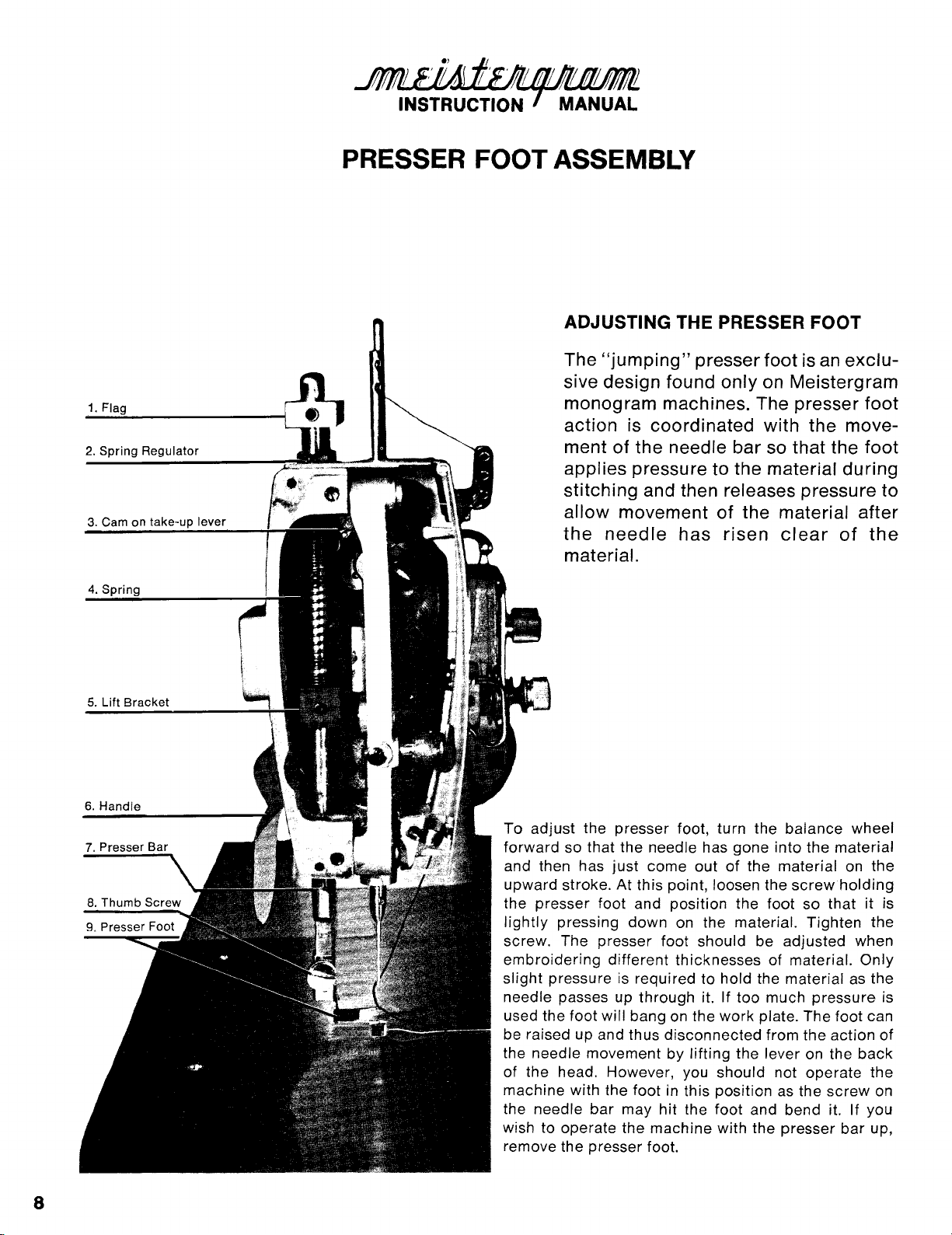

1.

Fl

2.

Spring Regulator

3.

Cam on take-up lever

4.S

PRESSER FOOT ASSEMBLY

ADJUSTING THE PRESSER FOOT

The

"jumping"

sive design found

monogram machines. The presser

action is

ment

applies pressure to the material

stitching

allow

the

material.

coordinated with

of

the needle

and then releases pressure

movement

needle

has

presser

only

bar

of

the material

risen

foot

is

an

exclu-

on Meistergram

foot

the move-

so that the

foot

during

to

after

clear

of

the

5.

Lift

6.

Handle

Bracket

To

adjust

forward

and then has

upward

the presser foot and

lightly

screw. The

embroidering

slight

needle passes up

used the

be raised up and thus

the needle

of

the head. However, you

machine

the

needle

wish to operate the

remove the presser foot.

the presser foot,

so

that

the needle has gone

just

stroke.

pressing

pressure is

At

down

presser

different

foot

will bang on the

movement

with the

bar

may

come

this point, loosen the

foot

required

through

disconnected

by

foot

in this position as the

hit

machine

turn

the

balance

into

out

of

the

material

screw

position

on the material.

thicknesses

the foot and bend it. If you

the foot so

should

to

it. If

lifting

be

of material.

hold

the material as

too

much

work

plate. The foot can

from the

the lever on the

should

with the presser

adjusted

not

wheel

the

material

on the

holding

that

Tighten

pressure

action

operate

screw

bar

it

is

the

when

Only

the

is

of

back

the

on

up,

8

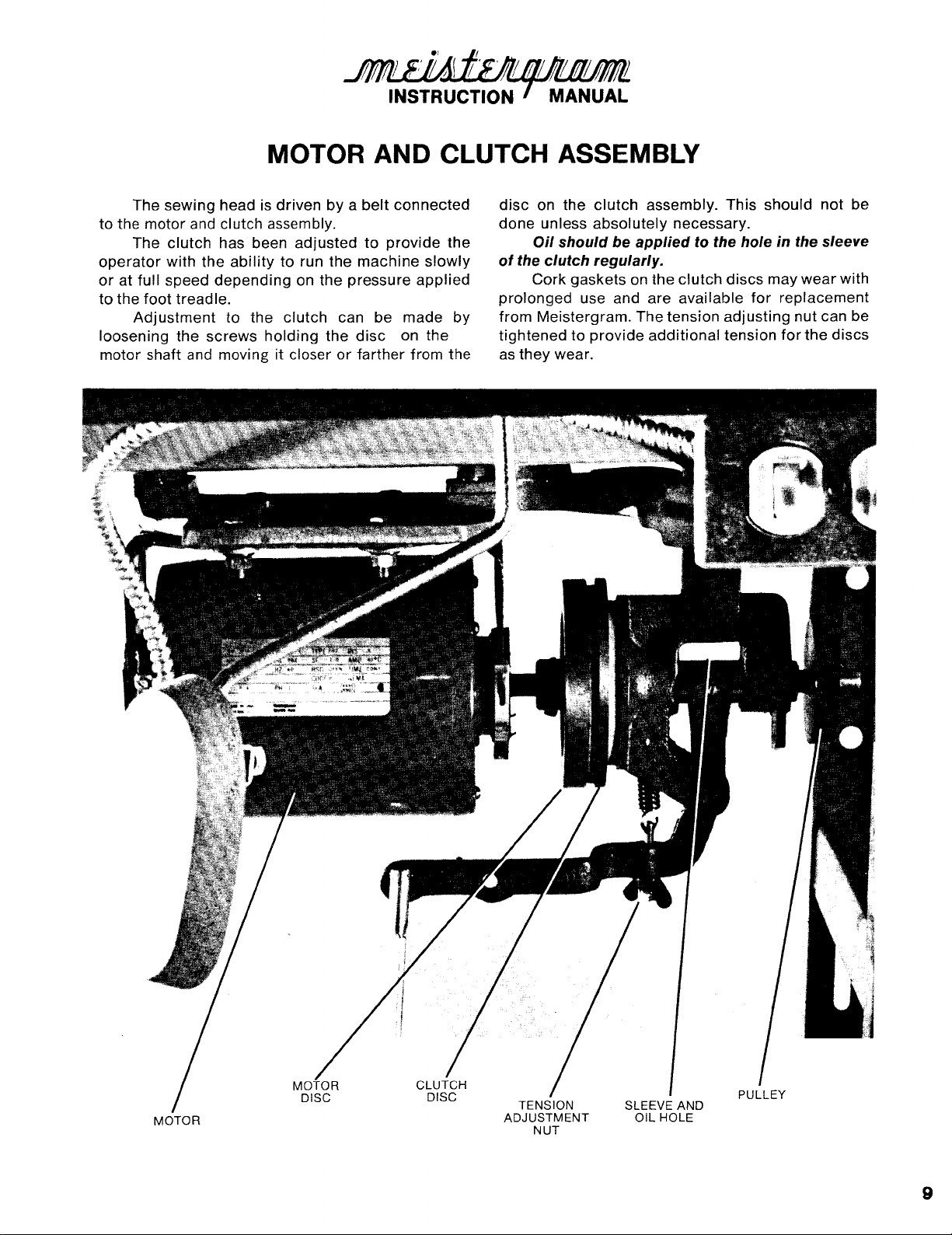

MOTOR AND CLUTCH ASSEMBLY

The

sewing

to the motor and clutch assembly.

The

clutch

operator

or

at full speed

to

the foot treadle.

loosening the

motor shaft and moving

with the

Adjustment

head is driven

has been

ability

depending

to

screws

to

the

holding

it

clutch

adjusted

run the

on the pressure

the

closer

by a belt

can be made

or

connected

to

provide

machine

disc

on the

farther

from the

the

slowly

applied

by

disc

on the

done

unless

Oil should be applied

of the clutch regularly.

Cork

prolonged

from Meistergram. The tension

tightened

as

they

clutch

absolutely

gaskets on the

use and are available

to

provide

wear.

assembly. This

necessary.

clutch

additional

to

should

the hole in the sleeve

discs

may

for

adjusting

tension

not

be

wear

with

replacement

nut can be

for

the discs

MOTOR

SLEEVE AND

OIL HOLE

9

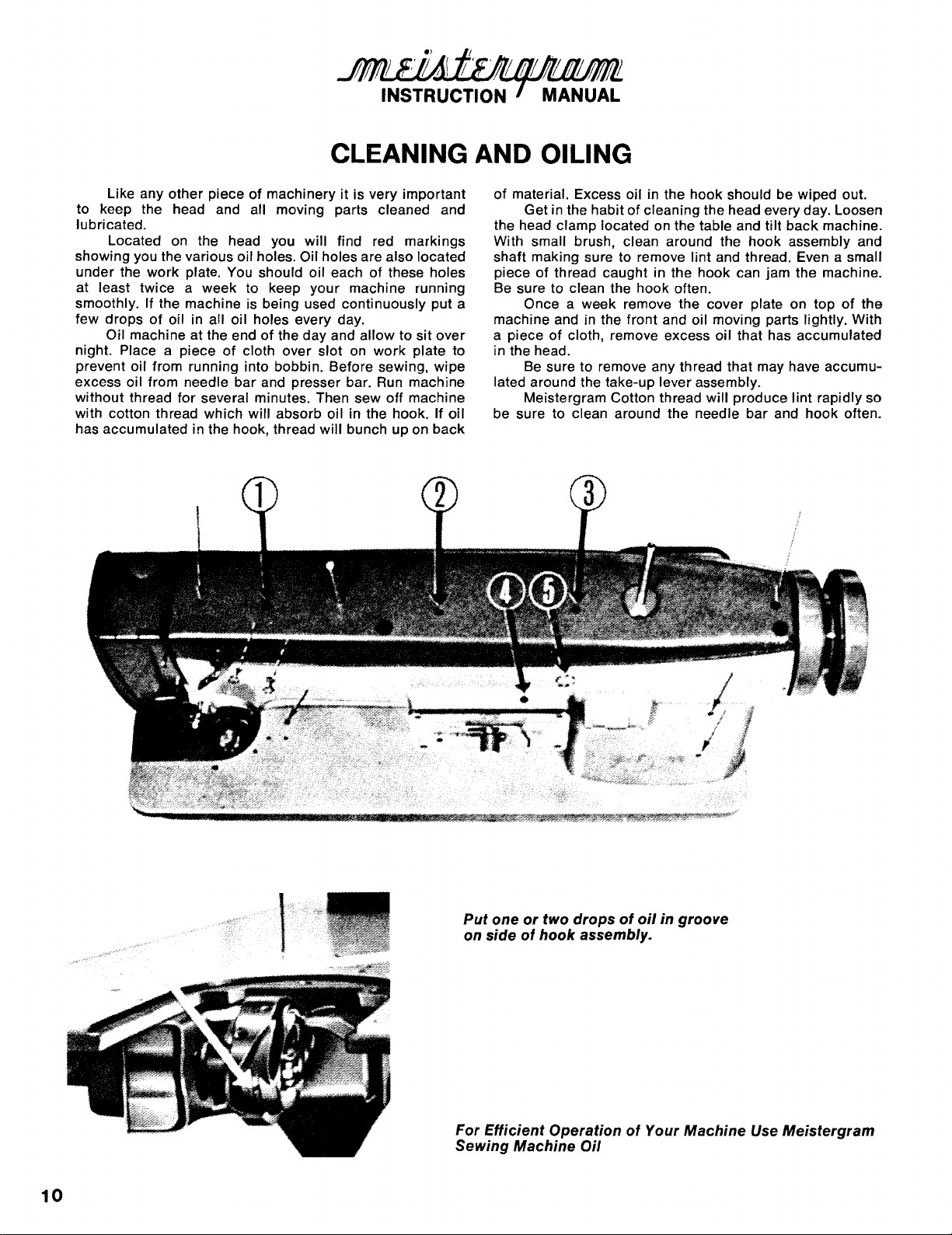

CLEANING AND OILING

Like any other piece

to keep the head and all moving parts cleaned and

lubricated.

Located on the head you will find red markings

showing you the various

under the

at least twice a week to keep

smoothly. If the machine is being used continuously put a

few drops

night. Place a piece

prevent

excess oil from needle bar and presser bar. Run machine

without thread

with cotton thread which will absorb oil in the hook. If oil

has accumulated in the hook, thread will bunch up on back

work

plate. You should oil each of these holes

of

oil in all oil holes every day.

Oil machine at the end

oil from running into bobbin. Before sewing, wipe

for

several minutes. Then sew off machine

of

machinery

oil holes. Oil holes are also located

of

of

the day and allow

cloth over slot on

it

is very important

your

machine running

work

to

sit

plate to

over

of

material. Excess oil in the hook should be wiped out.

Get in the habit

the head clamp located on the table and tilt

small brush, clean around the hook assembly and

With

shaft making sure to remove lint and thread. Even a small

piece

of

thread caught in the hook can jam the machine.

Be sure to

machine and in the front and oil moving parts lightly. With

a piece

in the head.

lated around the take-up lever assembly.

be sure to clean around the needle bar and

clean the hook often.

Once a week remove the cover plate on top

of

cloth, remove excess oil that has accumulated

Be sure to remove any thread that may have accumuMeistergram Cotton thread will produce lint rapidly so

of

cleaning the head every day. Loosen

back

machine.

hook

of

the

often.

Put one or two drops of oil in groove

on side of hook assembly.

For Efficient Operation of

Sewing Machine

10

Oil

Your Machine Use Meistergram

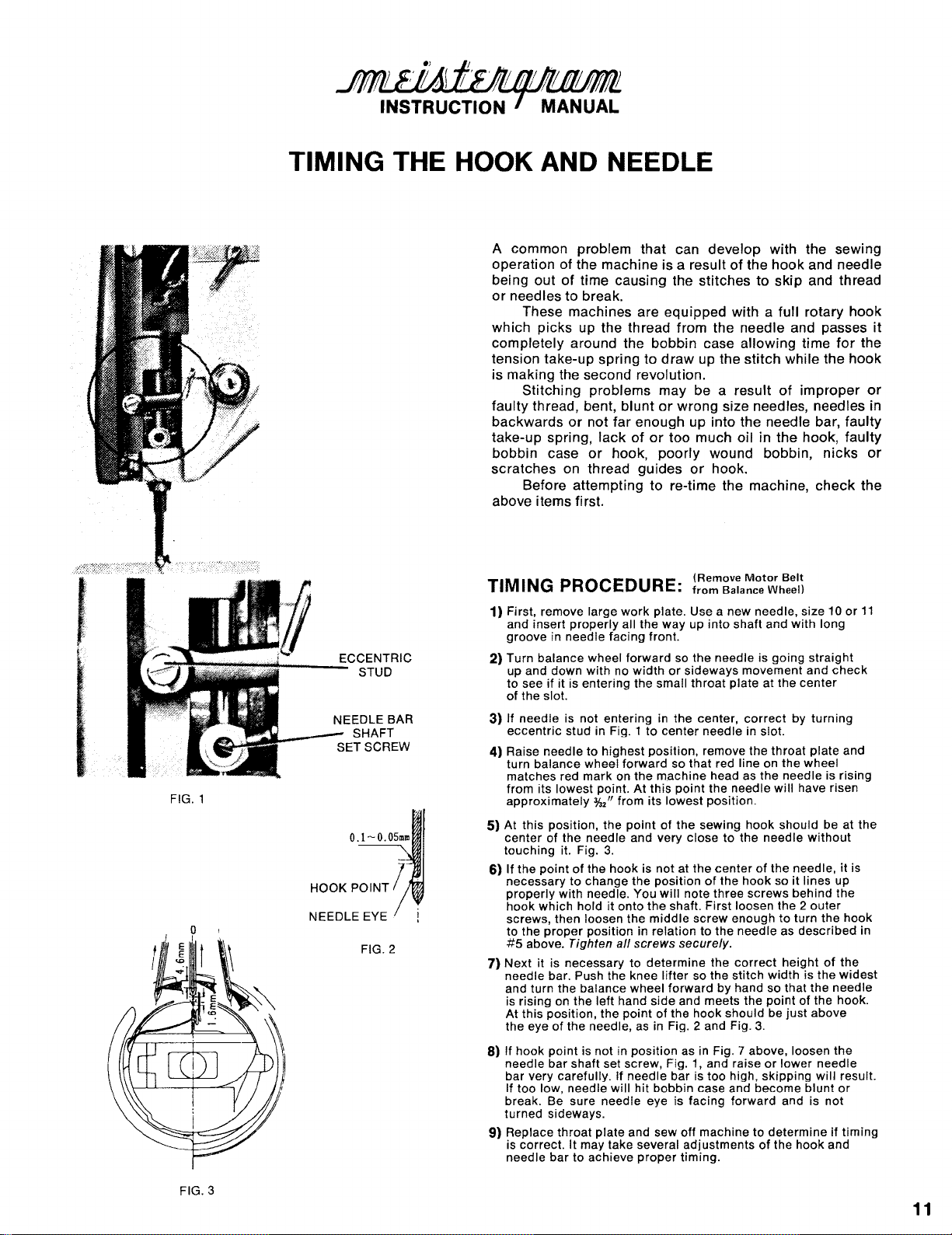

TIMING THE HOOK AND NEEDLE

A common problem that can develop with the sewing

operation of the machine is a

being out

or

needles to break.

of

time causing the stitches to skip and thread

These machines are equipped with a

which picks up the thread from the needle and passes

completely around the bobbin case allowing time

tension take-up spring to draw up the stitch while the hook

is making the second

revolution.

Stitching problems may be a result

faulty thread, bent, blunt

backwards

or

not far enough up into the needle bar, faulty

take-up spring, lack of

bobbin case

or

hook, poorly wound bobbin, nicks

scratches on thread guides

Before attempting to re-time the machine, check the

above items first.

result

or

wrong size needles, needles in

or

too much oil in the hook, faulty

or

of

the hook and needle

full rotary hook

of

improper

hook.

for

it

the

or

or

f

FIG. 1

NEEDLE BAR

SHAFT

SET SCREW

O.l-0.05mm

------..

HOOK POINT 1

NEEDLE EYE

FIG. 2

(Remove

M

Tl lNG PRQC UR :

1)

First, remove large

and insert

groove in needle facing front.

2)

Turn balance wheel forward so the needle is going

up and down with no

to see if it is entering the small

of

the slot.

3)

If needle is not entering in the center,

eccentric

4)

Raise needle

turn

matches red mark on the machine head as the needle is rising

from its

approximately%/'

5)

At this position, the

center of the needle and very close

touching it. Fig.

6)

If the

necessary

properly

hook

screws, then loosen the

to the

#5

7)

Next it is necessary

needle bar. Push the knee

and turn the balance wheel

is rising on the left hand side and meets the point of the hook.

At this position, the point

the eye

8)

If hook

needle bar shaft set screw, Fig.

bar very carefully.

If

too low, needle will hit bobbin case and become

break. Be sure needle eye is facing forward and is

turned sideways.

9)

Replace throat plate and sew off machine

is correct.

needle

stud in Fig. 1

balance wheel forward so that red line on the wheel

lowest point. At this

point

with needle. You

which hold it onto the shaft. First loosen the 2

proper

above. Tighten

of

the needle,

point

bar

ED

properly

to

highest position, remove the throat plate and

from its lowest position.

3.

of

the hook is

to

change the position

position in relation

all

is

not

in position as in Fig. 7 above, loosen the

If

It may take several adjustments

to

achieve

E

from

work

plate. Use a new needle, size 10

all the way up into shaft and

width

or

sideways movement and

throat

to

center

point

point

of

the sewing

not

at the

will

note three screws behind the

middle

screw

screws securely.

to

determine the

lifter

so the

forward

of

the hook should be just

as

in Fig. 2 and Fig.

needle bar is too high, skipping

proper

1,

timing.

Motor

Balance

plate at the center

needle in slot.

the needle will have risen

to

center

of

the

enough

to

the needle as

correct

stitch

by hand so that the needle

and raise

Belt

Wheel)

with

straight

correct

hook

the needle

hook

by turning

should be at

without

of

the needle, it is

so it lines up

outer

to

turn the

described

height

width

is the

3.

to

of

abov~

or

lower needle

blunt

determine if timing

the hook and

long

of

will

or

check

hook

the

widest

result.

or

not

11

the

in

FIG. 3

11

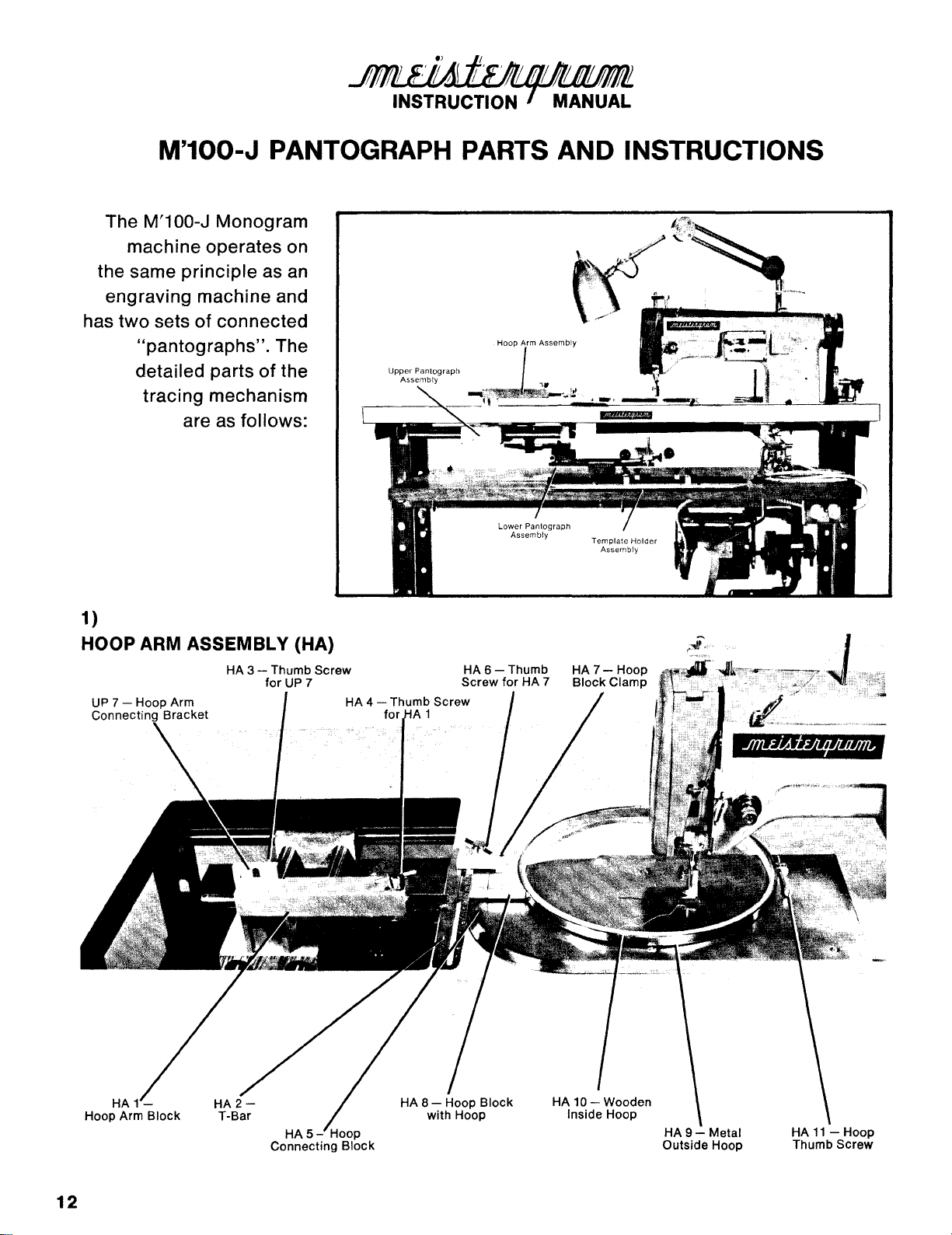

M'100-J PANTOGRAPH PARTS AND INSTRUCTIONS

The

M'1

00-J Monogram

machine operates on

the same

engraving machine and

two

has

principle

sets

of

connected

"pantographs".

detailed parts

tracing mechanism

are as

follows:

as an

The

of

the

Hoop

Arm

Assembly

1)

HOOP ARM ASSEMBLY {HA)

HA 3-Thumb Screw

for UP 7

12

HA

11-

Thumb

Hoop

Screw

Loading...

Loading...