Meister Cook DMW-22 Service Manual

DMW-22-TDL SERVICE MANUAL

For Systems Installed At:

Revision: 20150414

DMW-22-TDL SERVICE MANUAL

TABLE OF CONTENTS

1. INTRODUCTION…………………………………………………………………………………………………………….3

2. BASIC THEORY OF OPERATION……………………………………………………………………………………..3

3. OPERATING INSTRUCTIONS………………………………………………………………………………………….5

4. REVISION HISTORY……………………………………………………………………………………………………….9

5. DIAGNOSTIC METHODS………………………………………………………………………………………………..9

6. TROUBLESHOOTING……………………………………………………………………………………………………11

7. PARTS LIST………………………………………………………………………………………………………………….14

8. WIRING DIAGRAM……………………………………………………………………………………………………..14

Confidential and proprietary information of Meister Cook, LLC. Not to be reproduced or used in any manner other than

with the express written permission of Meister Cook, LLC.

2 | P a g e

DMW-22-TDL SERVICE MANUAL

1. INTRODUCTION

The purpose of this manual is to provide a guide for technical service of Meister Cook’s 2x2 Dry Moist

Warmer for Tim Hortons (model DMW-22-TDL). This manual will provide an overview of the

operation of the DMW-22-TDL, as well as a guide for troubleshooting fault symptoms.

Before getting started, it will be helpful to have the following tools and equipment:

Phillips screwdrivers - #00, #1, #2

Right-angle Phillips screwdriver - #2

Wrench and socket set

Needle nose pliers

Side-cut pliers or scissors

Plastic Cable Ties

Multimeter

Power monitor for 120VAC circuits (e.g. Kill-a-Watt, clamp-on current meter)

Heat gun

Degreasing cleaner (e.g. Goof-Off) and stainless steel cleaner

Cleaning rags – non-abrasive, lint-free

2. BASIC THEORY OF OPERATION

The DMW-22-TDL is designed to hold potentially-hazardous hot food products at safe temperatures

for an extended period of time, without degrading the quality of the food products.

The DMW-22-TDL has (2) independently-controlled heated holding chambers, each which can hold

(2) 1/3-size food pans. Underneath each chamber is a large, finned heater. Convection, provided by

a tangential blower, moves air across the heater and transfers that heat over top the food product in

the pans; the air recirculates, and continues to heat up. Also, heat from the heater is transferred to

the pan shelf, creating a hot plate.

Above each pan is a reversible moist/dry insert. In the “Dry” orientation, heated air passes directly

over the food product; this is recommended for food products that need to maintain a level of

crispiness. The dry orientation has a “third hand” feature that holds the pan in place when it is

partially removed. In the “Moist” orientation, heated air passes over the insert, effectively creating a

top hot plate; this is recommended for food products that need to maintain a level of moisture.

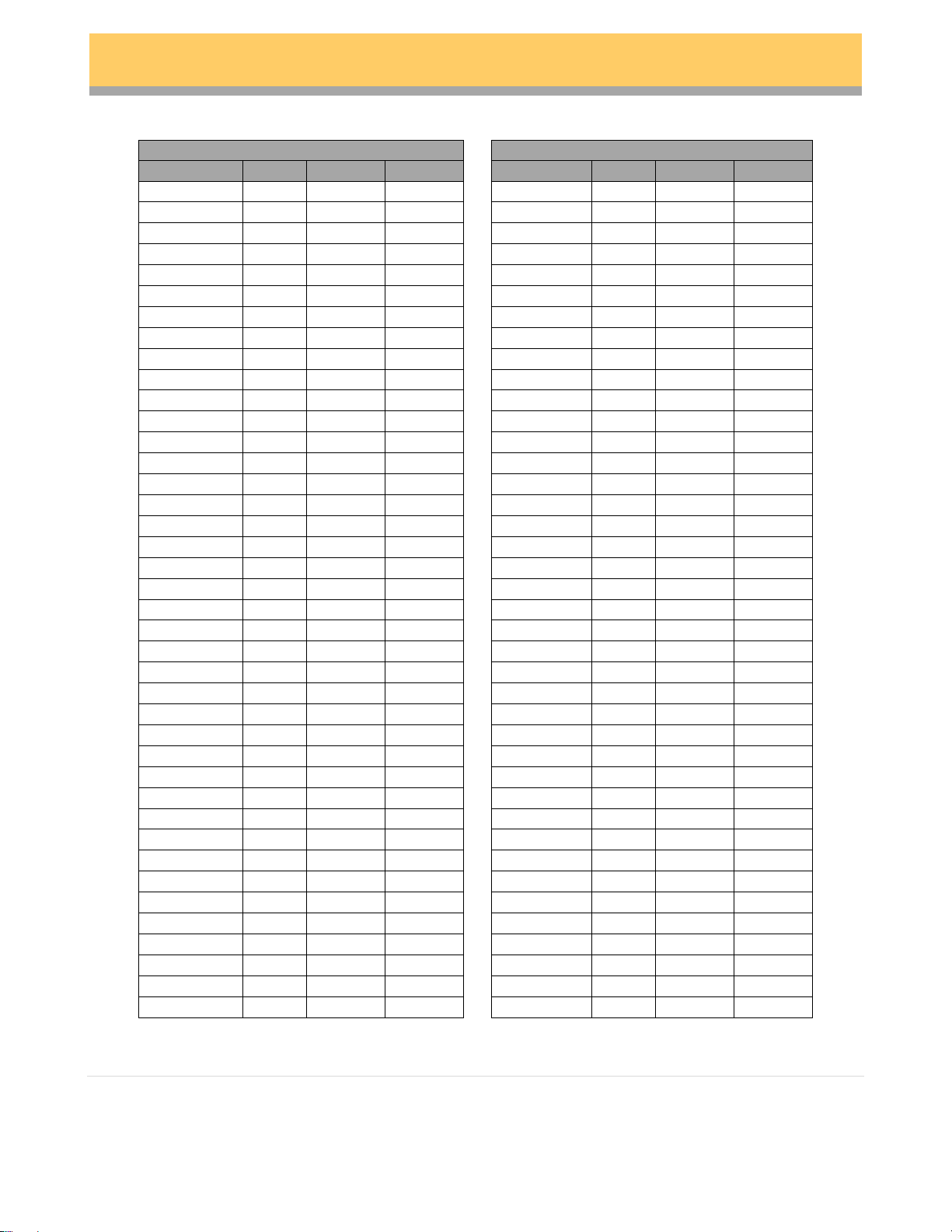

The DMW-22-TDL contains 40 factory default product presets, each of which can be modified and

saved by the operator. Each preset has a distinct 4-letter name, temperature setpoint (165F – 250F),

“Cook” alert time (up to 9hrs 59min) and a “Dump” product alert time (up to 9hrs 59min). See the

table below for factory defaults.

Confidential and proprietary information of Meister Cook, LLC. Not to be reproduced or used in any manner other than

with the express written permission of Meister Cook, LLC.

3 | P a g e

DMW-22-TDL SERVICE MANUAL

v1.26 Factory Default Product Presets

v1.46/v1.49 Factory Default Product Presets

Product

Temp

Dump

Cook

Product

Temp

Dump

Cook

VEG1

185

04:00

00:30 EGGS

185

04:00

00:30

EGGS

185

04:00

00:30 BACN

185

03:00

00:15

BACN

185

03:00

00:15 SAUS

185

04:00

00:30

SAUS

185

04:00

00:30 SCEG

185

02:00

00:30

HAM

185

04:00

00:30 HSBR

210

02:00

00:30

BEEF

185

04:00

01:00 HAM

185

02:00

00:30

CHIK

185

06:00

01:00 TURK

185

04:00

00:30

BCN2

185

04:00

01:00 CHKS

185

06:00

01:00

POTA

185

04:00

01:00 CCHK

210

02:00

00:30

CHC2

185

06:00

01:00 STK

185

06:00

01:00

LOAF

185

04:00

01:00 CHIP

210

08:00

00:15

BFF2

185

04:00

01:00 VEG1

185

04:00

01:00

MTBL

185

04:00

01:00 CHK2

185

06:00

01:00

FILL

185

04:00

01:00 BCN2

185

03:00

00:15

PSTA

185

04:00

01:00 CKS2

185

06:00

01:00

VEG2

185

04:00

01:00 VEG2

185

04:00

00:30

SCEG

185

02:00

00:30 PSTA

185

04:00

01:00

BCHK

200

02:00

00:30 PORK

185

06:00

01:00

CHIP

200

02:00

00:30 CCK2

210

02:00

00:30

HSBR

200

02:00

00:30 CBF

185

04:00

01:00

LEG1

185

04:00

00:30 OEUF

185

04:00

00:30

OEUF

185

04:00

00:30 BAC2

185

03:00

00:15

BAC2

185

03:00

00:15 SAU2

185

04:00

00:30

SAU2

185

04:00

00:30 OEBR

185

02:00

00:30

JAMB

185

04:00

00:30 GLPT

210

02:00

00:30

BOEU

185

04:00

01:00 JAMB

185

02:00

00:30

POUL

185

06:00

01:00 SAUD

185

04:00

00:30

BCND

185

04:00

01:00 POUL

185

06:00

01:00

PDT

185

04:00

01:00 PCRO

210

02:00

00:30

POUL

185

06:00

01:00 STK

185

06:00

01:00

PAIN

185

04:00

01:00 CROU

210

08:00

00:15

BFSA

185

04:00

01:00 LEG1

185

04:00

01:00

BOUL

185

04:00

01:00 POUL

185

06:00

01:00

VIAN

185

04:00

01:00 BAC2

185

03:00

00:15

PATE

185

04:00

01:00 POUL

185

06:00

01:00

LEG2

185

04:00

01:00 LEG1

185

04:00

00:30

OEBR

185

02:00

00:30 PATE

185

04:00

01:00

POPA

200

02:00

00:30 PORC

185

06:00

01:00

CROU

200

02:00

00:30 PCR2

210

02:00

00:30

GLPT

200

02:00

00:30 BFSA

185

04:00

01:00

Confidential and proprietary information of Meister Cook, LLC. Not to be reproduced or used in any manner other than

with the express written permission of Meister Cook, LLC.

4 | P a g e

DMW-22-TDL SERVICE MANUAL

v1.26 Defaults

v1.46/v1.49 Defaults

English

French

AM

EGGS

SCEG

AM

EGGS

SAUS

OEUF

SAU2

SAUS

BACN

HSBR

HSBR

GLPT

GLPT

PM

CHIK

CHIK

PM

CCHK

CCHK

PCRO

PCRO

BACN

VEG1

CHIP

CHIP

CROU

CROU

The UI has a menu of (4) product presets, (1) for each pan. These may be changed at any time. Each

row has (2) presets each. Based on which preset is selected, the highest temperature setpoint of the

two presets will determine that row’s temperature setpoint; this is why it is advised to either

program the same presets in the same row, or to program two different presets with equal

temperatures.

Also, the presets determine the countdown timers. If, in any of the 4 bins, the same preset is

selected, all timers will be based on a first-in, first-out basis; the first timer started for a given product

will flash the brightest.

There are (2) pages of menus presets, one for AM products and the other for PM products. See the

table below for factory defaults (note that v1.46 and later systems have both English and French

default menus):

Temperature feedback is provided by a thermocouple that is placed inside each intake funnel. As

part of a temperature-control circuit with the UI Board and TC Board, the temperature is measured

and compared against a programmed setpoint. As long as the measured temperature is below the

setpoint, the UI Board will signal the Power Supply to power the heater (via Triacs) at approximately

400W. As the measured temperature approaches the setpoint, the power draw on the heater is

gradually reduced. Once the measured temperature reaches the setpoint, the control circuit will

adjust the power to the heater to maintain a constant temperature; the average power draw beyond

this point is reduced. The warm-up process will take between 25-35 minutes, depending on the

setpoint.

3. OPERATING INSTRUCTIONS

Refer to the below diagram showing the UI button layout for the DMW:

Confidential and proprietary information of Meister Cook, LLC. Not to be reproduced or used in any manner other than

with the express written permission of Meister Cook, LLC.

5 | P a g e

Loading...

Loading...