Meiko U 400, U 500, U 500S Instructions Manual

Professional warewashing technology

Operating instructions

UPster U 400 / U 500 / U 500S

Glass and dishwashing machine

Translation of the "Original operating instructions"

9735077 / Valid from: 2015-09 / Update: 2017-04-06

EN

Operating Instructions UPster U 400 / U 500 / U 500S

Contents

1 Introduction and general instructions 4

1.1 Storage 5

1.2 Name and address of manufacturer 5

1.3 Authorisations for Service Partners' Service technicians 5

1.4 Designation of machine type 5

2 Explanation of the safety symbols used 6

3 Intended use 6

4 EC Declaration of Conformity 7

5 General safety instructions 8

5.1 Operator’s duty of care 8

5.2 Basic safety measures 9

6 Delivery, transport, installation and assembly 11

6.1 Delivery 11

6.2 Transport, installation and assembly 11

6.3 Operating conditions 12

6.4 Requirements for the electrical connection 12

6.5 Requirements for the fresh water connection 13

6.6 Requirements for the waste water connection 13

6.7 Emergency-off 13

6.8 Chemicals for the operating the machine 14

6.9 Instructions for disposal of packing material 14

7 Settings for initial commissioning by the service engineer 14

7.1 Commissioning 14

8 Washing using the washing machine 14

8.1 Operating panel 15

8.2 Preparation for washing and rinsing 16

8.3 Manual dosing of detergent 16

8.4 Automatic dosing 16

8.5 Operation during washing and rinsing cycle 16

9 Shutting down the machine 17

10 Maintenance and care 18

10.1 Care, general 18

10.2 Refill detergent 18

10.3 Refilling with rinse aid 18

10.4 Cleaning 19

10.5 Care of stainless steel surfaces 19

10.6 De-scaling 20

11 Appliance with built-in water softening device EW10 (only U 500S) 20

11.1 General 20

11.2 Adjustment of water hardness 20

11.3 Capacity of the built-in water softening device 20

11.4 Regeneration 21

12 Basic information about the warewashing machine 21

12.1 General description of the warewashing machine 22

12.2 Noise emission 23

12.3 Electrical and hydraulic equipment data 23

12.4 Dimensions, technical data, installation instructions 23

13 Non-ionising radiation 23

14 Help yourself in case of faults 24

15 Staff training 25

16 Authorised user of this documentation 25

9735077 Design and construction subject to change without prior notice

Page 2 of 44

Operating Instructions UPster U 400 / U 500 / U 500S

17 Settings / modifications / on-site adaptation 26

17.1 Using the keyboard for programming 26

17.2 Code input 26

17.3 Service level 27

17.4 Parameter list 32

17.5 Assignment list View inputs / control outputs 35

17.6 Rinse programmes parameter update: 01.06.2012 36

18 Operating errors 37

18.1 Information reporting and troubleshooting 37

18.2 Error messages and troubleshooting 38

19 Maintenance, servicing 39

19.1 Basic safety measures during normal operation 40

19.2 Dosing equipment 40

19.3 Maintenance plan 40

20 Environmentally acceptable measures, Disposal of the installation 42

21 Documentation 42

9735077 Design and construction subject to change without prior notice

Page 3 of 44

Operating Instructions UPster U 400 / U 500 / U 500S

1 Introduction and general instructions

Dear Customer,

We are delighted about the confidence you have shown in our products.

It is very important to us that you should obtain a great deal of pleasure and usefulness

from MEIKO products and that they should make your work easier.

If you follow the instructions in this document carefully, your washing machine will always

give you total satisfaction and will have a long service life.

After assembly at our factory, this machine was put through a thorough inspection. This

helps us make sure, and gives you the guarantee that you always receive a mature product.

We would therefore ask you to read these operating instructions carefully before

using the installation. Any further related operating instructions for accessories and

incorporated third-party products must be strictly observed!

These operating instructions are designed to familiarise the owner/operator of this system

with its installation, modes of operation, use, safety instructions and servicing.

This information will help you to get to know the installation fully and to use it properly. It

will also enable you to avoid repairs and the concomitant loss of productive work.

In the event of any damage caused by non-observance of these operating instructions, any

guarantee claims are invalid. We accept no liability for any additional damage caused as a

result.

MEIKO operates a policy of continuous development on all its appliances.

As a result of this, please understand that we thus reserve the right to make changes to

the scope of supply concerning the design, equipment and technical features at any time.

No claims may therefore be based on the details, the images or the descriptions contained

in these operating instructions.

Should you require any further information, or in case any particular problems not dealt

with in great detail in the operating instructions should arise, you may contact the relevant

MEIKO branch to obtain the information you require.

Further, we draw your attention to the fact that the content of these instructions does not

form part of a former or existing agreement, promise or legal relationship and does not

modify such a point.

All MEIKO’s obligations arise from the relevant purchase contract which also contains the

entire and only valid guarantee provisions.

The operating instructions must exist in the local language for each EU country. If this is

not the case, the washing machine must not be commissioned.

The original operating instructions in German and all operating instructions in all languages

for EU countries can be downloaded from the following address: https://partnernet.meiko.de

You receive all this technical documentation free of charge.Any additional copies required

are available for a nominal fee.

These contractual guarantee rules shall be neither extended nor restricted as a result of

any explanations given in the instructions.

MEIKO wishes you much pleasure and success!

9735077 Design and construction subject to change without prior notice

Page 4 of 44

Operating Instructions UPster U 400 / U 500 / U 500S

1.1 Storage

Always store the operating instructions close to the system!

The operating instructions must always be kept within easy reach!

1.2 Name and address of manufacturer

In case of further questions, technical problems, etc. contact directly:

MEIKO Maschinenbau GmbH & Co. KG

Englerstr. 3

D - 77652 OFFENBURG

Phone + 49 (0)781 / 203-0

http://www.meiko.de

info@meiko.de

or:

Name and address of the MEIKO branch, manufacturer’s agent or dealer.

(Enter company’s stamp or address)

1.3 Authorisations for Service Partners' Service technicians

MEIKO exclusively authorises authorised Service Partners for commissioning, inductions,

repairs, maintenance, assembly and installation of the corresponding product groups within

MEIKO devices.

1.4 Designation of machine type

Please provide the following information on any query and/or when ordering spare parts:

Model:

SN:

This information can be found on the type plate.

9735077 Design and construction subject to change without prior notice

Page 5 of 44

Operating Instructions UPster U 400 / U 500 / U 500S

CAUTION!

This symbol warns that there is danger to human life and health.

DANGER!

This symbol warns that there is danger to the installation, to material or to the environment.

This symbol denotes information that helps you to understand the

installation’s operation.

Warning against dangerous electric voltage!

Warning against hand injuries!

No splashing water: prohibits the use of a pressure cleaner.

Danger of explosion: indicates a potential explosion hazard.

Non-potable water: The water is not for drinking. Health can be

endangered by drinking.

Danger of burning: indicates possible hazard due to hot surfaces or media.

DANGER!

The glass and dishwashing machine has exclusively been designed for the washing of

dishes, cutlery and glasses.

The warewashing machine must only be deployed and operated only for its intended

use. Other uses are prohibited.

The items to be washed must be suitable for washing in warewashing machines.

This warewashing machine is intended solely for use in a commercial environment.

2 Explanation of the safety symbols used

The following safety symbols will appear throughout these operating instructions. These

symbols are designed to draw the reader's attention to the text next to the safety instructions.

3 Intended use

9735077 Design and construction subject to change without prior notice

Page 6 of 44

Operating Instructions UPster U 400 / U 500 / U 500S

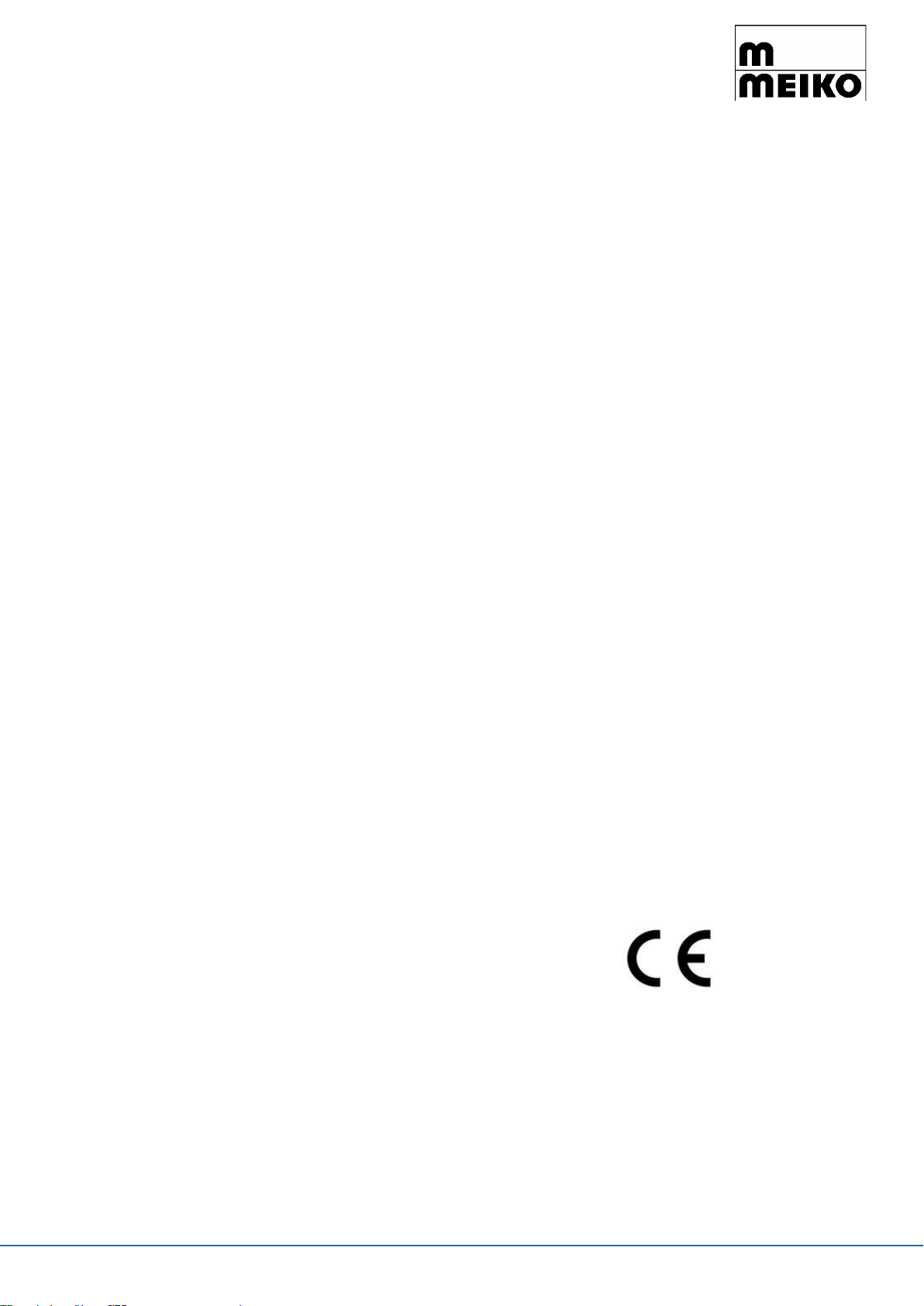

Muster / Example / Exemple / Esempio / Ejemplo / Voorbeeld

EG-Konformitätserklärung

EC Declaration of Conformity / Déclaration de conformité CE / Dichiarazione di conformità CE / Declaración de conformidad CE / CE-conformiteitsverklaring

Firma / Company / Société / Ditta / Empresa / Fabrikant

Adresse / Address / Adresse / Indirizzo / Dirección / Adres

MEIKO Maschinenbau GmbH & Co. KG

Englerstraße 3

77652 Offenburg

Germany

Kontakt

Contact / Contact / Contatto / Contacto / Contact

Internet: www.meiko.de

E-mail: info@meiko.de

Telefon: +49(0)781/203-0

Auftrag Nr.

Order no. / No. de commande / No. d’ordine / No. de pedido / Opdracht nr.

Spülmaschine Typ

Dishwasher model / Lave-vaiselle modèle / Lavastoviglie modello / Lavavajillas modelo / Vaatwasmachine model

UPster U 400

UPster U 500

UPster U 500S

Konformitätserklärung

Declaration of Conformity / Déclaration de conformité / Dichiarazione di conformità / Declaración de conformidad / Conformitetsverklaring

Hiermit bescheinigen wir in alleiniger Verantwortung die Konformität des Erzeugnisses mit den grundlegenden Anforderungen der folgenden EG-Richtlinien, harmonisierten Normen, nationalen Normen.

We hereby declare at our sole responsibility that the product conforms to the essential requirements of the following EC Directives, harmonized standards, national standards.

Par la présente nous certifions sous notre seule responsabilité la conformité du produit avec les exigences fondamentales des directives CE,

normes harmonisées et normes nationales suivantes.

Con la presente dichiariamo sotto la nostra responsabilità la conformità del prodotto con i regolamenti basilari delle seguenti direttive CE,

normative armonizzate e normative nazionali.

Por la presente declaramos bajo nuestra sola responsabilidad que nuestros productos están en conformidad con las exigencias básicas de las siguientes

directivas de la CE, normas homologadas y normas nacionales.

Hiermee verklaren wij onder geheel eigen verantwoordelijkheid de conformiteit van het product met de fundamentele en gestelde eisen volgens

EG-richtlijnen, geharmoniseerde normen en nationale normen.

EG-Richtlinie / EC Directive / Directive CE / Regolamento CE / Directiva CE / EG-richtlijn

2006/42/EG / 2014/30/EU

Dokumentationsbevollmächtigter

Viktor Maier

Responsible for documentation / Responsable de la documentation / Responsabile della documentazione/ Responsable de la documentación / Voor deze documentatie verantwoordelijk

MEIKO Maschinenbau GmbH & Co. KG

Englerstr. 3 - 77652 Offenburg - Germany

MEIKO Maschinenbau GmbH & Co. KG

ppa.

(per procura)

Dr. Thomas Peukert

Leiter Entwicklung und Konstruktion

Head of Development-Design / Responsable Développement-Construction / Direttore SviluppoCostruzione / Jefe de la sección de desarrollo y diseño / Chef Ontwikkeling-Constructie

4 EC Declaration of Conformity

9735077 Design and construction subject to change without prior notice

Page 7 of 44

Operating Instructions UPster U 400 / U 500 / U 500S

CAUTION!

This warewashing machine has been constructed and designed based on a risk assessment and careful selection of the applicable harmonised standards, as well as additional

technical specifications. It is therefore state of the art and guaranteed to provide maximum

safety.

Safety can only be guaranteed during operation if all necessary measures are taken. The

operator of the installation has an obligation of care to ensure that these measures are

planned for, and also to check that they are correctly implemented.

CAUTION!

The operator must ensure in particular that ...

... the washing machine is only used in accordance with the regulations

in case of other use or operation, damage or risks may arise for which we accept no lia-

bility (cf. chapter "Intended use").

… in order to guarantee functionality and safety, use only original parts supplied by the

manufacturer when needed.

Any potential claims by the user shall be rendered void if the system was altered using

parts other than original spare parts.

CAUTION!

... only appropriately qualified and authorised employees may use, maintain, and repair

the machine.

CAUTION!

… staff is regularly trained in all questions relating to occupational safety and environ-

mental protection and, in particular, that staff is familiar with the Operating Instructions

as well as with the safety instructions they provide.

CAUTION!

... the washing machine is only operated in a perfect, operationally efficient condition

and, in particular, that the safety systems and switch elements are checked on a regular

basis for their operational efficiency.

CAUTION!

... machines accessible only from behind may be operated only with rear panel cladding.

CAUTION!

... the required personal protective equipment is made available to and used by maintenance and repair personnel.

CAUTION!

... a functional test on all safety systems of the machine / installation is carried out during every regular maintenance.

CAUTION!

... the operating instructions are always in a legible state, complete, and available at the

machine's location of use.

CAUTION!

... any necessary regular checks on supply parts are carried out. More detailed information, if required, can be found in the relevant operating instructions.

5 General safety instructions

5.1 Operator’s duty of care

Measures to ensure the safe machine operation:

9735077 Design and construction subject to change without prior notice

Page 8 of 44

Operating Instructions UPster U 400 / U 500 / U 500S

CAUTION!

After installation, commissioning and handing over of the washing machine to the customer/operator, no modifications may be made (e.g., electrical system or location).

Modifications to the warewashing machine, and in particular technical modifications carried out without the manufacturer’s written authorization, or any modifications carried

out by unauthorized persons, will lead to the complete loss of any guarantee claims and

will invalidate any liability for the product.

CAUTION!

... equipment for optimising energy consumption must not be used to reduce essential

operating temperatures, as set out in DIN 10511, 10512 and 10522. If you, the client,

install equipment for optimising energy consumption, any possible reduction in the quality of the wash and hygiene is your responsibility.

CAUTION!

Danger can arise from the improper use of the machine or if it is used for purposes for

which it was not intended.

Parts carrying electric current as well as moving or rotating parts can cause·dangers to

the user’s life and limb and material damage.

CAUTION!

The warewashing machine may only be operated by adequately qualified staff who have

been trained by the operating company and who have been trained about the hazard

and safety instructions.

Qualified staff, as defined by the Operating Instructions, are persons:

over 14 years of age

who have read and who observe the safety instructions,

who have read and who observe the operating instructions (or the part applicable to

the work to be carried out).

The machine operates with hot water. The machine operates with hot water (Temperature of wash water = 58-60 °C, by Cleaning and disinfection machine must be 74 °C).

Avoid all contact with the rinse water Danger of scalding! The washed items as well as

the components in contact with the wash water have the same temperature. Please observe appropriate protective measures.

Observe all the instructions posted on the machine.

Warning !

When electrical equipment is in operation, it is inevitable that some parts of this equipment are live with dangerous current.

Before opening the machine or electrical equipment, it is essential to de-energise the

entire washing machine via the connected mains disconnecting device and secure it

from switching back on using appropriate measures.

Work and troubleshooting on electrical parts of the machine must be performed by specialists only. Observe accident prevention regulations.

The operator must not restart the machine until all cover panels have been put back in

place.

The warewashing machine may not be sprayed with a water hose or high-pressure

cleaner.

CAUTION!

The warewashing machine may only be operated under the supervision of trained personnel.

The water in the wash-up area is non-potable and must not be used for food preparation!

CAUTION!

Do not use the washing machine if you are unsure about system operation.

5.2 Basic safety measures

9735077 Design and construction subject to change without prior notice

Page 9 of 44

Operating Instructions UPster U 400 / U 500 / U 500S

CAUTION!

The appliance must not be used to transfer waste water from other sources into the drain.

CAUTION!

Steel scrub pads are not to be used for the pre-scouring nor for cleaning the items to be

washed.

Do not wash any metal items in the warewashing machine which are not made of stainless steel.

The operator must reliably prevent metal parts (especially iron, tinplate, copper) entering the machine.

The appliance must not be used to transfer waste water from other sources into the

drain (Warning: risk of corrosion and blockage).

Only use suitable products for cleaning the stainless steel surfaces. They must not attack

the material, form any deposits, or cause any discolouration.

CAUTION!

The door must be closed!

Open the door very carefully during the programme cycle, as otherwise wash water could

splash out.

The tank heating element may still be hot after the tank has been emptied. As a result,

there is a risk of burns or scalding when cleaning the machine manually!

CAUTION!

Only use detergents and rinse aids suitable for commercial dishwashing machines.

Please contact the manufacturers of these products für information.

Detergent and rinse aid may contain hazardous substances.

Observe the manufacturers' hazard warnings on the original containers and safety data

sheets.

CAUTION!

On completing operation, switch off the warewashing machine completely using the local

circuit breaker.

The accompanying Operating Instructions must be observed for accessory devices, e.g.

water treatment installations.

CAUTION!

WE DO NOT ACCEPT ANY LIABILITY FOR

DAMAGE OR INJURY ARISING FROM FAILURE

TO OBSERVE AND ABIDE BY THESE SAFETY

INSTRUCTIONS!!!!

CAUTION!

Any repair work and troubleshooting on the machine's electrical equipment must be carried out by a qualified electrician!

Check the electrical equipment regularly! Tighten any loose connections! Replace any

damaged leads/cables immediately!

5.2.1 Working on the electrical equipment

9735077 Design and construction subject to change without prior notice

Page 10 of 44

Operating Instructions UPster U 400 / U 500 / U 500S

In the event of any transport damage please inform MEIKO immediately in writing, and

also send a photo of the damaged parts to MEIKO.

CAUTION!

Damaged appliances must not be commissioned.

CAUTION!

Transport works must only be performed only by qualified persons observing the

safety instructions.

Observe transport instructions on the packing.

Handle with care.

Unpack the machine.

CAUTION!

Small quantities of steam may escape through the machine's door. For this reason,

furniture and equipment situated near the door must be protected.

On request, an engineer from your local MEIKO representative is available to install

the machine. An engineer from your local MEIKO Service Centre can install the appliance at the correct point and connect the tables - upon request.

6 Delivery, transport, installation and assembly

6.1 Delivery

Check that the delivery is complete immediately after receiving it by comparing it to

MEIKO’s contract confirmation and/or the delivery note.

If necessary, complain about any missing parts immediately to the shipping company and

notify MEIKO.

Check the entire scope of delivery for any damage that may have occurred during shipping.

6.2 Transport, installation and assembly

In order to avoid damage or life-threatening injuries during shipping of the installation, the

following points must be observed:

For safe transport, the machine parts are supported by a special square-timber frame.

The warewashing machine must only be transported on the supplied wooden frame. The

packing is specifically designed to allow the appliances to be moved safely and securely

using a pallet truck.

The enclosed dimensional drawing states the connected load and consumption specifications of the warewashing machine.

Dishwashing machine installation steps:

The complete unit must be levelled in both directions using a water level.

Compensate for an uneven floor by adjusting the feet.

Table joints must be sealed with detergent-resistant sealing compound (e.g. sili-

cone).

9735077 Design and construction subject to change without prior notice

Page 11 of 44

Operating Instructions UPster U 400 / U 500 / U 500S

The machine is only frost-resistant in the state it is delivered or when provided with

special features (option: frost drainage).

If the machine is installed in an area where the surrounding temperatures are below 0°

C, water freezing inside the machine damage the internal water circuit components

(pump, solenoid valve, boiler, etc.).

Work on the electrical part of the machines may only be undertaken by specialist personnel.

The customer must guarantee the following points relating to the connection:

CAUTION!

Current applicable standards and requirements of local utility companies are to be adhered to with regard to protective measures and connection of the potential compensation system.

The products are intended for permanent connection to the on-site power supply and

have been tested for the market accordingly. Any other form of electrical connection is

to be established by a licensed electrician.

Do not connect any additional consumers to the fuse protecting the machine.

The wiring diagram is behind the warewashing machine's front panel. The enclosed

wiring diagram must remain in the appliance.

6.3 Operating conditions

It is assumed that the planning of the system, as well as installation, setting in operation

and maintenance works are executed by sufficiently instructed staff and that these works

are checked by responsible specialists. The details on the machine's type plate must

match those of the standard drawing and the local connection conditions.

Conditions to be provided by the customer:

Frost free storage and installation area

Electrical connection in accordance with the dimensional drawing

Fresh water connection in accordance with the dimensional drawing

Waste water connection in accordance with the dimensional drawing

Anti-slip floor coverings should be provided around the dish-washing appliance.

6.3.1 Requirements to the installation area

Ensure that the storage and installation area is permanently frost free.

6.4 Requirements for the electrical connection

The correct voltage and type of current must be available

Safeguard the power supply cable according to regulations and provide it with a

power disconnection device in the fixed electrical installation.

The appliance must be connected to a potential equalisation system!

If an unearthed neutral (N) is used with alternating current, the power disconnection

device must have 4-poles (with alternating current 2-poles).

For connection to three-phase current a 5-pole terminal strip (L1, L2, L3, N, PE)

must be used.

Electricity supply without neutral conductor (N): when connecting to three-phase

current, use a 4-pole clamping strip (L1, L2, L3, PE).

Conductor colours: live conductor L1 = black/1, L2 = brown/2, L3 = grey/3, neutral

conductor N = blue/4, ground wire conductor PE = green-yellow.

Re-tighten all terminal fixing screws before the setting in operation.

9735077 Design and construction subject to change without prior notice

Page 12 of 44

Operating Instructions UPster U 400 / U 500 / U 500S

CAUTION!

The minimum flow pressure of the clean water supply upstream of the solenoid

valve must be 2.5 bar.

The minimum flow pressure of the clean water supply upstream of the solenoid

valve must be 2.5 bar with the booster pump option.

The maximum pressure must not exceed 5 bar.

Note to the customer

Warewashing machines, bedpan washers and systems are provided for the permanent

connection to the electrical power supply and the connection to the on-site potential

equalisation system and are accordingly equipped with a connection option.

The operator can decide at his/her own discretion and under his/her own responsibility to

alternatively implement personal protection in collaboration with a licensed electrician

company using:

Fault current protection switch sensitive to universal current with max. 30mA EN

62423

or

Automatic switching off of the supply when the protective earth conductor for the

consistency is lost (EN 60204-1 Chap. 8.2.8.c)

6.5 Requirements for the fresh water connection

Each appliance carries the DVGW test symbol and does not require an extra safety

valve in the water feed.

The fresh water connection must be effected as per EN 1717 or local regulations.

If the minimum flow pressure is not reached, increase the flow pressure with a

booster pump; if the maximum pressure is exceeded, limit it with a pressure reducer.

Suitable protective measures must be taken to ensure that no iron particles can enter

the appliance via the mains water supply. Similarly, precautions must be taken to

prevent the entry of other metal particles, for example copper turnings. Corresponding instructions are contained in the installation drawing. Appropriate

measures must be taken.

A dirt trap must be fitted into the fresh water supply to protect the solenoid valve.

Special requirements for Australia

Installation in accordance with AS/NZS 3500

6.6 Requirements for the waste water connection

Build an odour trap into the waste water connection if this is not already built-in

(further information about this is in the Installation drawing / Technical Sheet).

The drain hose must be connected to the waste water pipe in the building.

A grease trap may be needed, depending on the warewashing machine application.

6.7 Emergency-off

Switch the machine off completely via the on-site power disconnection device.

9735077 Design and construction subject to change without prior notice

Page 13 of 44

Operating Instructions UPster U 400 / U 500 / U 500S

CAUTION!

Only alkali detergents and acid rinse agents suitable for use in commercial warewashing machine may be used. Relevant information is provided by the manufacturers of these products.

MEIKO recommends brand cleaning products from leading manufacturers. - clean-

ing and hygiene products are an excellent choice. Using unsuitable products can considerably reduce the service life of the dosing units. Observe the manufacturers' dosing instructions.

Detergents and rinse aids can present a health hazard if they are not correctly used.

Observe the manufacturers' indication on the original containers and safety data

sheets.

"Items for rinsing are tribologically influenced in particular by chemicals and increased temperatures during the process, as well as mechanical stresses caused by

handling and transporting."

If a descaling agent is used, please strictly observe the manufacturer’s handling and

safety instructions. After having used such an agent, the product must be completely

removed from the machine, as even small residues are sufficient to destroy plastic

parts and packing materials.

CAUTION!

The warewashing machine may only be commissioned by suitably qualified per-

sons observing the safety instructions.

Before the first start, check if all tools and foreign parts are removed out of the

machine.

Check any escaped fluids have been removed.

Activate all the safety systems and door switches before commissioning

Check that all screw connections are tight.

Please also read the chapter “General safety instructions".

Commissioning and training will be handled and provided by MEIKO-trained

service engineers. The operator must not use the installation before completing

training.

The appliance must not be used without a thorough knowledge of the Operating Instructions. Incorrect operation may result in personal injury or material damage.

6.8 Chemicals for the operating the machine

Chemical product settings

The correct settings for the quantity of detergent and rinse aid depend on the product

used. The relevant chemical product supplier can install the correct setting.

6.9 Instructions for disposal of packing material

The four-sided wooden frame consists of untreated, raw wood.

Special country-specific import regulations may also stipulate the use of wood which

has been treated against pests.

The plastic sheeting (PE sheeting) can be recycled.

The cardboard packaging material used to protect the edges can also be recycled.

The steel strap from the packaging can be recycled as steel scrap.

The plastic tensioning strap (PP) can be recycled.

7 Settings for initial commissioning by the service engi-

neer

7.1 Commissioning

To avoid damages or dangerous injuries during the setting in operation of the washing

machine, please observe the following points:

Perform any required initial checks on supplied parts. More detailed information, if required,

can be found in the relevant operating instructions.

9735077 Design and construction subject to change without prior notice

8 Washing using the washing machine

Page 14 of 44

Operating Instructions UPster U 400 / U 500 / U 500S

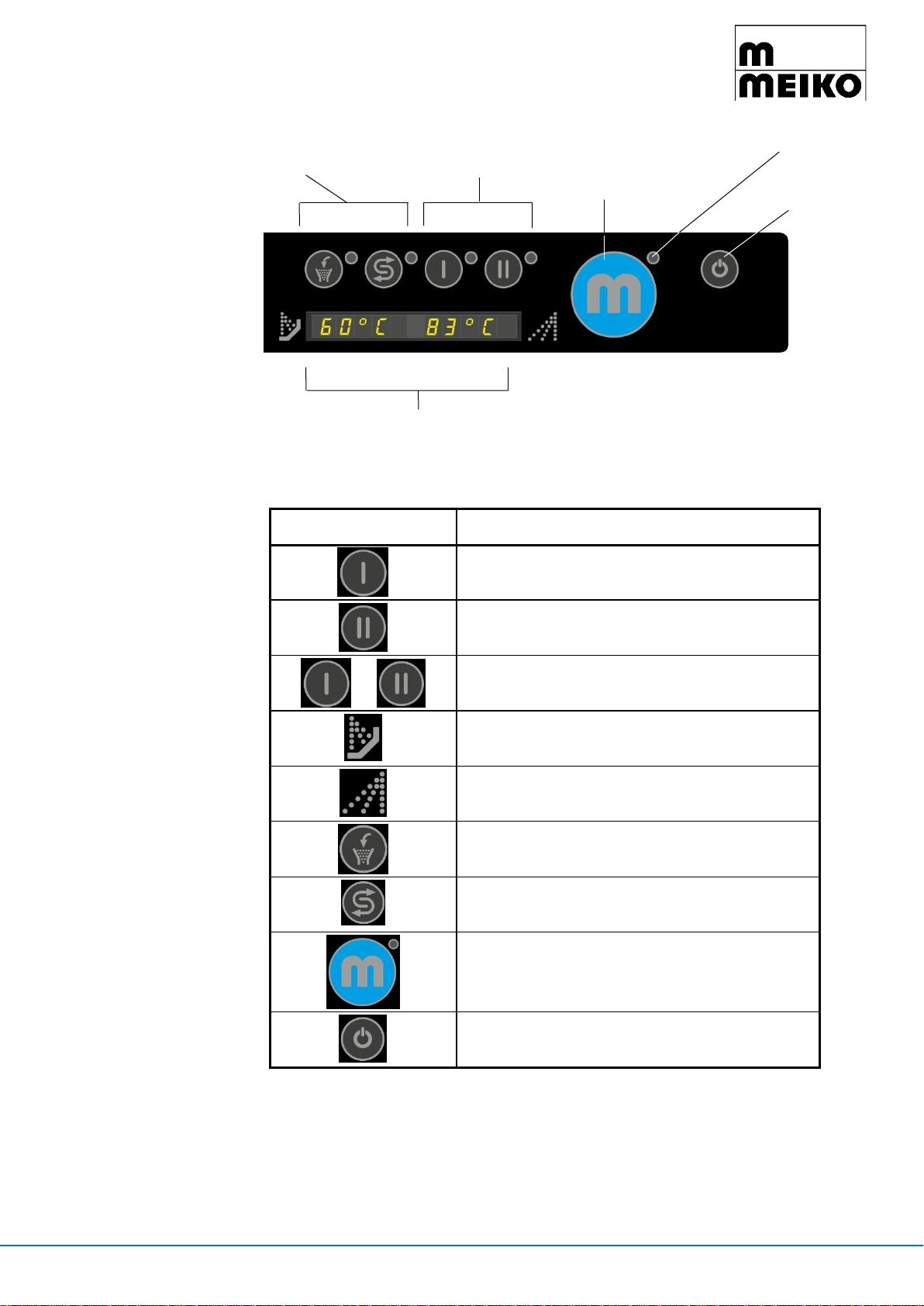

Key/display

Meaning

Short program – Wash programme I

Normal program – Wash program II

+

Intensive program – Wash program III

Wash temperature

Final rinse temperature

Refill regeneration salt (option)

Regeneration (option)

Programme Start

Drain tank

Self-cleaning programme

Switch on/off appliance /

Cycle interruption

Program is running

Program selection buttons /

appliance is switched on

Program start key

On/Off button

Temperature display tank/boiler,

Fault display - information display - code display

Option:

Incorporated softener

8.1 Operating panel

Figure 1; Operating panel

Table 1; Program key function / items to be washed

9735077 Design and construction subject to change without prior notice

Page 15 of 44

Loading...

Loading...