Meiko K-200 User Manual

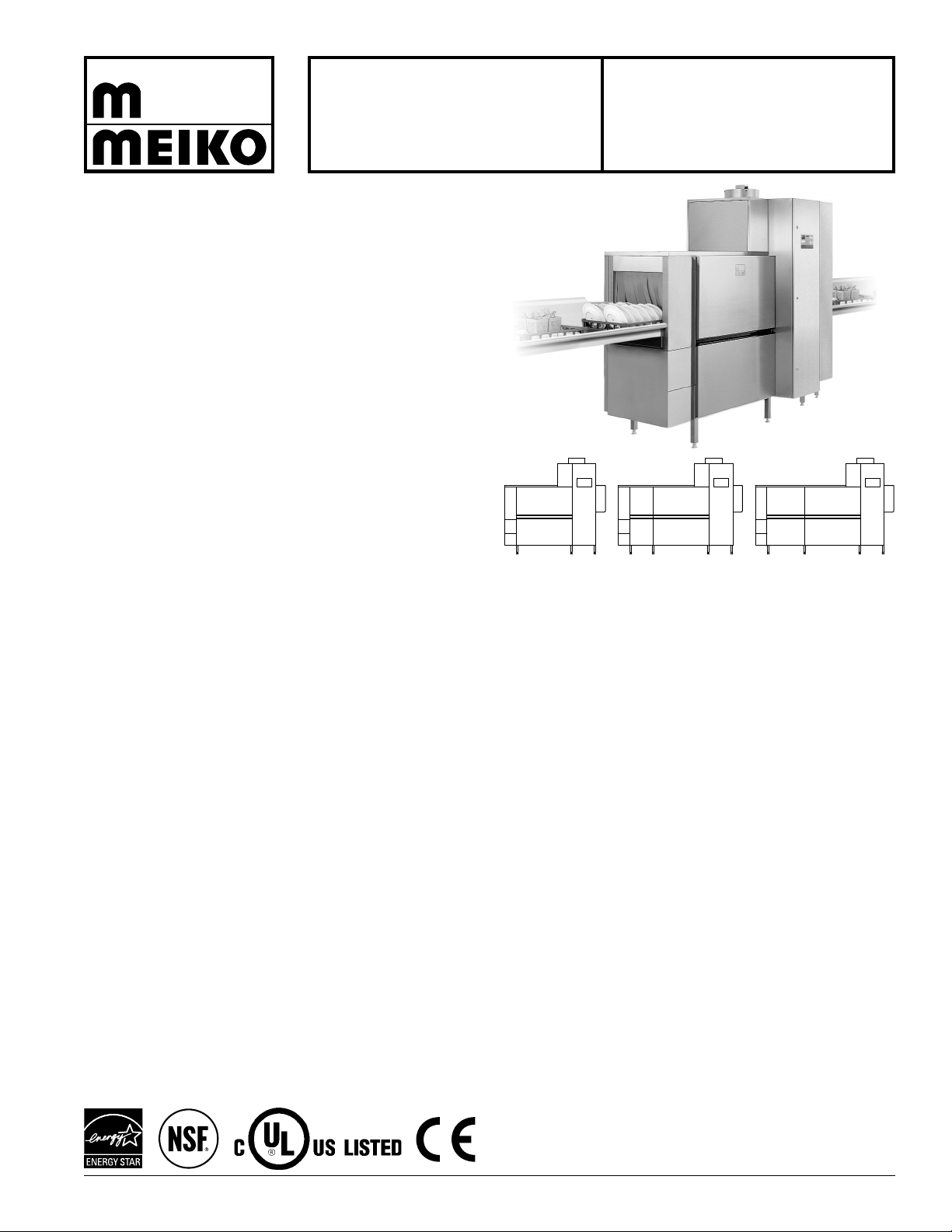

K-200 SERIES

Meiko's K-Tronic series rack conveyor warewashers

combine state-of-the-art advanced features with

economical and reliable operation. The K-Tronic series

features the lowest water consumption of any NSF-rated

rack conveyor warewasher, and makes use of an exclusive

pumped, heated auxiliary rinse zone to make use of the

rinse water a second time for pristine, consistent results.

Meiko’s exclusive Waste Air Heat Recovery System

reclaims the waste air generated by the machine as free

energy to pre-heat the incoming rinse water, saving energy.

Other standard features include computer-positioned wash

arms (and prewash arms, on models so equipped) that

are pre-assembled into easily-removed manifolds. Wash

nozzes are slotted and concave to minimize clogging, and

feature captivated end caps which can’t be lost during

cleaning. K-Tronic series machines also feature Meiko’s

Mike 3 electronic controller, and double-wall insulated

construction. As with all products synonymous with the

name “Meiko,” engineering excellence, manufacturing

quality and performance come to the forefront in the

K-Tronic series rack conveyors.

HOT WATER SANITIZING

SINGLE-TANK

RACK CONVEYOR

WAREWASHERS

K-200 K-200 PW K-200 LPW

• Model K-200 includes a 6’ 4-3/4” chamber with one pumped wash section (with 3 hp pump), pumped auxiliary rinse section

(with 3 hp pump) and pumped final rinse section (with 3/4 hp pump).

• Model K-200 PW adds a 19-5/8” prewash section (with 3/4 hp pump) to the base K-200 model (overall length 8’ 1/2”).

• Model K-200 LPW adds a 31-1/2” prewash section (with 3 hp pump) to the base K-200 model (overall length 9’ 1/4”).

Exclusive Features:

• The K-Tronic series features the lowest water

consumption in the industry. Model K-200 consumes 0.35

gallons per rack.

• Pumped auxiliary rinse zone supplements the final rinse

zone, providing pristine, consistent results.

• Waste air heat recovery system reclaims heat generated

by the machine and uses it as free energy to preheat the

incoming rinse water, reducing energy consumption and

allowing hot-water sanitizing from a cold water supply (50°F).

• Double-wall insulated construction retains heat inside

the machine, conserving energy and improving the working

environment.

• Improved drive system permits fast, smooth conveyor

travel. Rack rail-mounted pawl system does not obstruct

the wash pattern.

• Mike 3 electronic controller for fully automatic operation

and advanced service diagnostics. Wash and final rinse are

activated only when a rack is in place to conserve water

and detergent.

K-200 Series • Updated 12-07 Meiko • 917 Airpark Center Drive • Nashville, TN 37217 • (800) 55-MEIKO • FAX (615) 399-6620 • www.meiko.us

Standard Features:

• Computer-positioned wash arms in easily-removed

manifolds feature concave, slotted nozzles to minimize

clogging, and captivated end caps.

• Front-sloping wash tanks

• All 304-series stainless steel construction

• Large, easily-removed pan strainers. Models equipped with

a prewash include a separate prewash scrap basket.

• Powerful 3hp wash pump is vertically-mounted to be selfdraining and easily removed for servicing.

• Single-point drain connection

• Single-point ventilation connection

• Low-level heater protection

Options:

• Revolutionary blower drying system - uses only 3 kW for

heating. Available in two lengths: 23-5/8” (600mm) or 35-1/2”

(900mm)

• CSS Top Chemical Savings System

• Hinged front access doors

• Steam coil or electric tank heating

• Table limit switch

• External vent fan control

• Single-point electrical connection

• 90° loaders and power unloaders

K-200, K-200 PW, K-200 LPW, electric heating

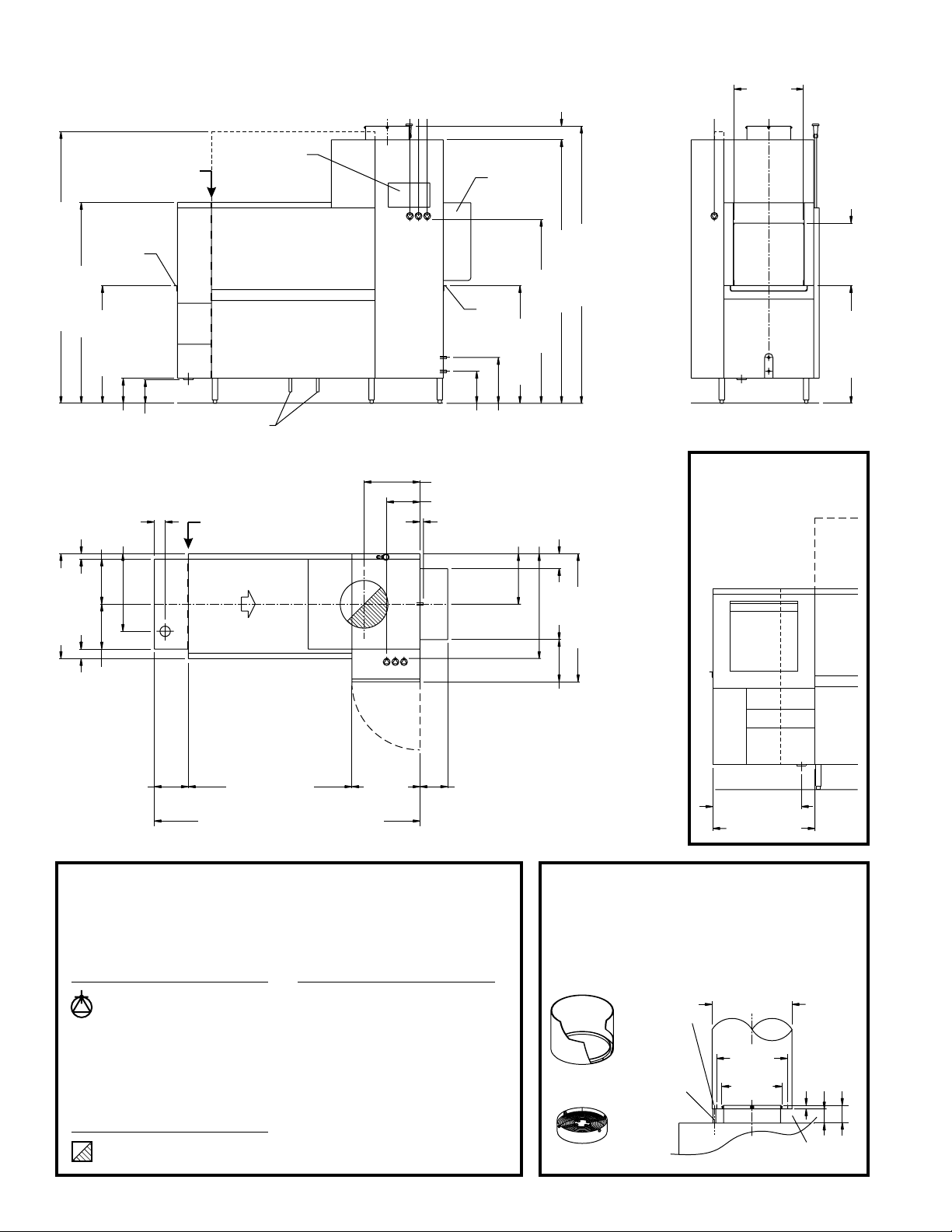

Machines without blower dryer, Left-to-Right

control

Prewash inserted here for

K-200 PW and K-200 LPW

P

panel

splash guard

[above table]

3 7/8"

[100mm]

Horizontal

clearance

1'-8 1/8"

[510mm]

Door open 6'-6 1/2" [1994mm]

4'-10" [1474mm]

1 5/8" [40mm]

2'-2" [660mm]

2'-6 3/8" [770mm]

table

support

2'-10" [864mm]

7 1/4"

[184mm]

1'-10 1/2" [570mm]

1'-1" [330mm]

lip

6 7/8"

[174mm]

3 1/8"

[80mm]

1-3

C

W

D

CSS TOP OPTION

(front view)

9-7/8" [250mm] load

section is replaced with

CSS Top section. Adds

Vertical

clearance

2'-10" [864mm]

1'-6" [458mm]

D

Prewash inserted here for

P

K-200 PW and K-200 LPW

drain

handle

123

C

W

1'-4 1/8" [410mm]

9 5/8" [244mm]

1" [25mm]

table

support

lip

9 1/4"

[235mm]

1'-1 1/4"

[335mm]

4'-5 1/8" [1350mm]

2'-10" [864mm]

2'-6 1/4" [770mm]

1'-2 5/8" [370mm]

6'-8 1/8" [2034mm]

6'-4 1/8" [1934mm]

4 3/8" [110mm]

1'-7 5/8" [500mm] to

overall machine length.

W

C

D

123

1'-8 1/2"

[521mm]

3'-1" [940mm]

1'-1" [330mm]

2 3/4" [70mm]

1'-0 1/4" [310mm]

9 7/8" [250mm]

3'-11 1/4" [1200mm]

K-200: Table-to-table 6'-4 3/4" [1950mm]

K-200 PW: Table-to-table 8' 1/2" [2450mm] ‡

K-200 LPW: Table-to-table 9' 1/4" [2750mm] ‡‡

1'-7 5/8"

[500mm]

UTILITY CONNECTIONS

Drain

D

2-15/16” (75mm) OD vertical, gravity-fed

drain outlet (HDPE piping). Optional 3" NPT

male adapter supplied. Recommend

placement directly above 4” floor drain.

Additional piping to drain (if so required) to

be supplied by customer.

Electrical connection

3 (three) individual terminal blocks at locations

shown. Each connection is 4-wire with

ground (no neutral).

with lockout/tagout strongly recommended

for each supply (provided by customer).

Incoming leads must be appropriately sized

for electrical supply. Opening(s) in the

machine for the supply lines are NOT

provided and should be executed on-site

using appropriate strain relief device(s).

Refer to Page 10 for supply details.

Vent connection

354 CFM (+120 CFM room air recommended)

K-200 Series • Updated 12-07 Page 2

Individual disconnect

Warm water connection (fill)

W

3/4" NPT female pipe connection

• Temperature 110-140°F (43-60°C)

• Pressure 15-25 PSI

• Initial fill - Refer to Page 10

• Hardness 4-6 grains/U.S. gal.

Cold water connection (rinse)

C

3/4" NPT female pipe connection

• Temperature 50°F (10°C)

• Pressure 15-25 PSI

• Consumption 84.7 U.S. gals./hour

• Hardness 4-6 grains/U.S. gal.

8" [203mm] splash

guard [above table]

K-200 PW: 1'-7 5/8" [500mm] prewash

‡

K-200 LPW: 2'-7 1/2" [800mm] prewash

‡‡

DETAIL VIEW: VENT

The vent shroud MUST NOT be connected directly to the machine, as this

prevents room air from being drawn into the shroud. All dimensions shown

are recommendations only. Actual exhaust connection must be adequate

for the exhaust air and comply with all applicable national and local codes.

The waste air connection must be corrosion-resistant and frost-free. In

particular, provision must be made to prevent air temperatures of 32°F/0°C

or colder from reaching the machine at any time. A provision for draining

moisture from the waste air pipe is STRONGLY RECOMMENDED.

Vent shroud

(supplied

by customer)

Machine

exhaust vent

Condensation

channel

Condensation

can be drained

into machine

(drain is

supplied by

customer)

2'-1 5/8" [650mm]

2'-5 1/2" [750mm]

Ø1'-6" [457mm]

Ø1'-4"

[406mm]

Ø1'-1 3/8"

[340mm]

D

3 1/8" [80mm]

3/4" [20mm]

Gap permits room

air to enter vent shroud

3 7/8" [100mm]

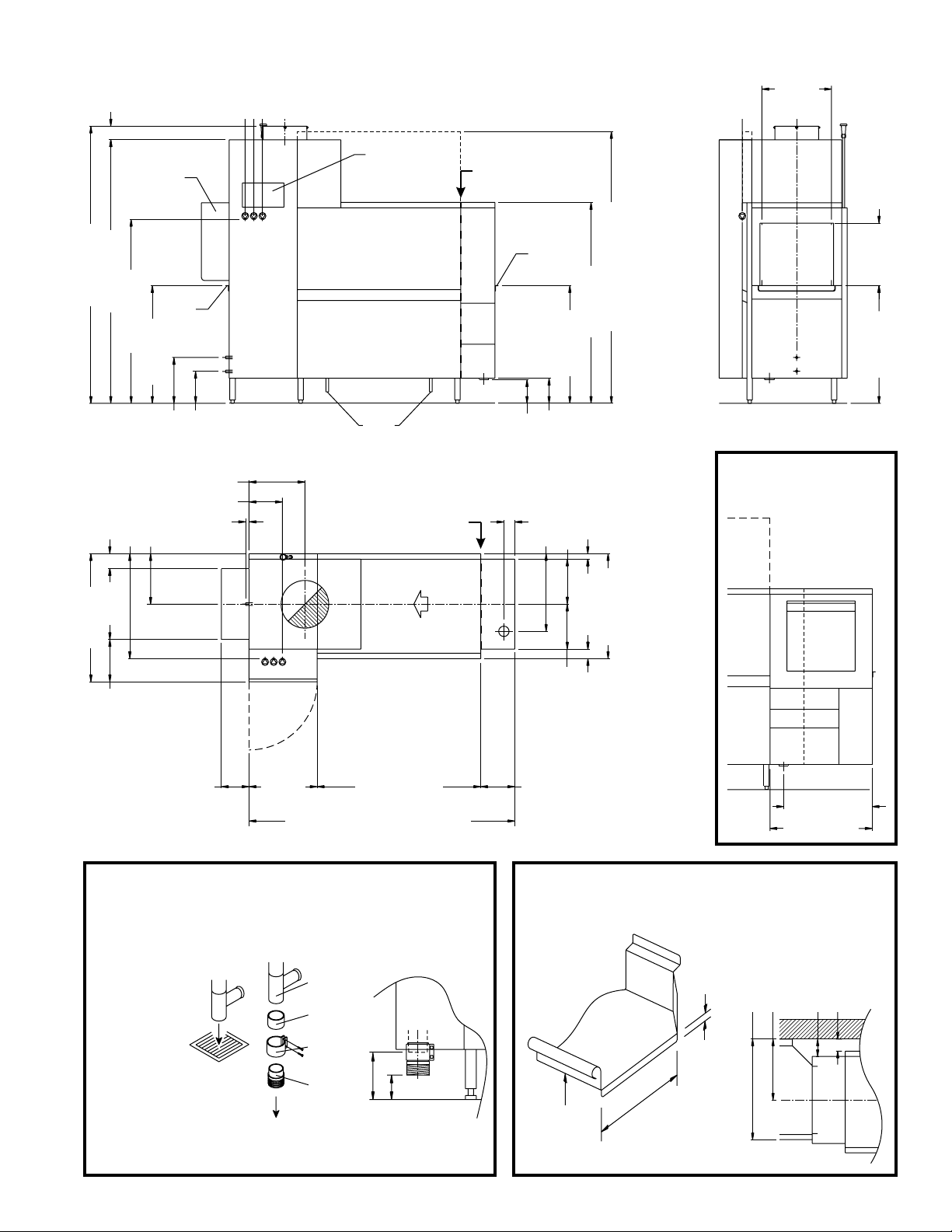

K-200, K-200 PW, K-200 LPW, electric heating

Machines without blower dryer, Right-to-Left

3 7/8"

[100mm]

control

splash guard

[above table]

panel

Prewash inserted here for

P

K-200 PW and K-200 LPW

Horizontal

clearance

1'-8 1/8"

[510mm]

6'-8 1/8" [2034mm]

6'-4 1/8" [1934mm]

4 3/8" [110mm]

1'-8 1/2"

3'-1" [940mm]

4'-5 1/8" [1350mm]

2'-6 1/4" [770mm]

[521mm]

table

support

lip

2'-10" [864mm]

9 1/4"

1'-1 1/4"

[335mm]

1'-4 1/8" [410mm]

9 5/8" [244mm]

1" [25mm]

1'-2 5/8" [372mm]

[235mm]

321

C

W

table

support

lip

4'-10" [1474mm]

2'-10" [864mm]

Door open 6'-6 1/2" [1994mm]

D

drain

handle

6 7/8"

[174mm]

7 1/4"

[184mm]

1-3

Vertical

clearance

1'-6" [458mm]

C

W

2'-10" [864mm]

D

CSS TOP OPTION

3 1/8"

Prewash inserted here for

K-200 PW and K-200 LPW

[80mm]

P

1'-10 1/2" [570mm]

1'-1" [330mm]

1 5/8" [40mm]

W

C

2'-2" [660mm]

D

321

2'-6 3/8" [770mm]

(front view)

9-7/8" [250mm] load

section is replaced with

CSS Top section. Adds

1'-7 5/8" [500mm] to

overall machine length.

1'-1" [330mm]

2 3/4" [70mm]

1'-0 1/4" [310mm]

2'-6" [762mm]

1'-6 1/8" [462mm]

D

2'-1 5/8" [650mm]

2'-5 1/2" [750mm]

5 1/8" [132mm]

3 5/8" [92mm]

8" [203mm] splash

guard [above table]

DETAIL VIEW: DRAIN

The machine is equipped with a 2-15/16" (75mm) OD vertical, gravity-fed drain. If possible, the

machine drain can simply be positioned directly above a 4" floor drain.

If a floor drain is not in the correct location, or if local codes require a trap, a 3" indirect drain

line may be attached using the supplied boot, clamp, and 3" NPT male adapter.

Choose a piping

material that:

• Complies with

any applicable

local and

national codes

• Is rated for use

with water

temperatures up

to 180°F/82°C

• Is rated for

3-12 pH to

accommodate

detergents and

rinse aid in the

drain water

K-200 Series • Updated 12-07 Page 3

Direct drain

(recommended

if possible)

1'-7 5/8"

[500mm]

K-200: Table-to-table 6'-4 3/4" [1950mm]

K-200 PW: Table-to-table 8' 1/2" [2450mm] ‡

K-200 LPW: Table-to-table 9' 1/4" [2750mm] ‡‡

Machine

drain

Boot

(supplied)

Clamp

(supplied)

3" NPT male

adapter,

HDPE

(supplied)

To 3" indirect

drain line

(supplied by

customer)

3'-11 1/4" [1200mm]

3 1/2" [90mm]

6 7/8" [174mm]

9 7/8" [250mm]

K-200 PW: 1'-7 5/8" [500mm] prewash

‡

K-200 LPW: 2'-7 1/2" [800mm] prewash

‡‡

DETAIL VIEW: TABLING

Wall clearances shown are for typical 30" D dishtable. Actual clearances will depend

upon table manufacturer and table dimensions.

Feeding and

discharge tables

to be supplied

by others

1"

[25mm]

max.

D

Table lip-in

height

2'-10"

[864mm]

A.F.F.

22" [559mm]

max.

20-1/2" [521mm]

recommended

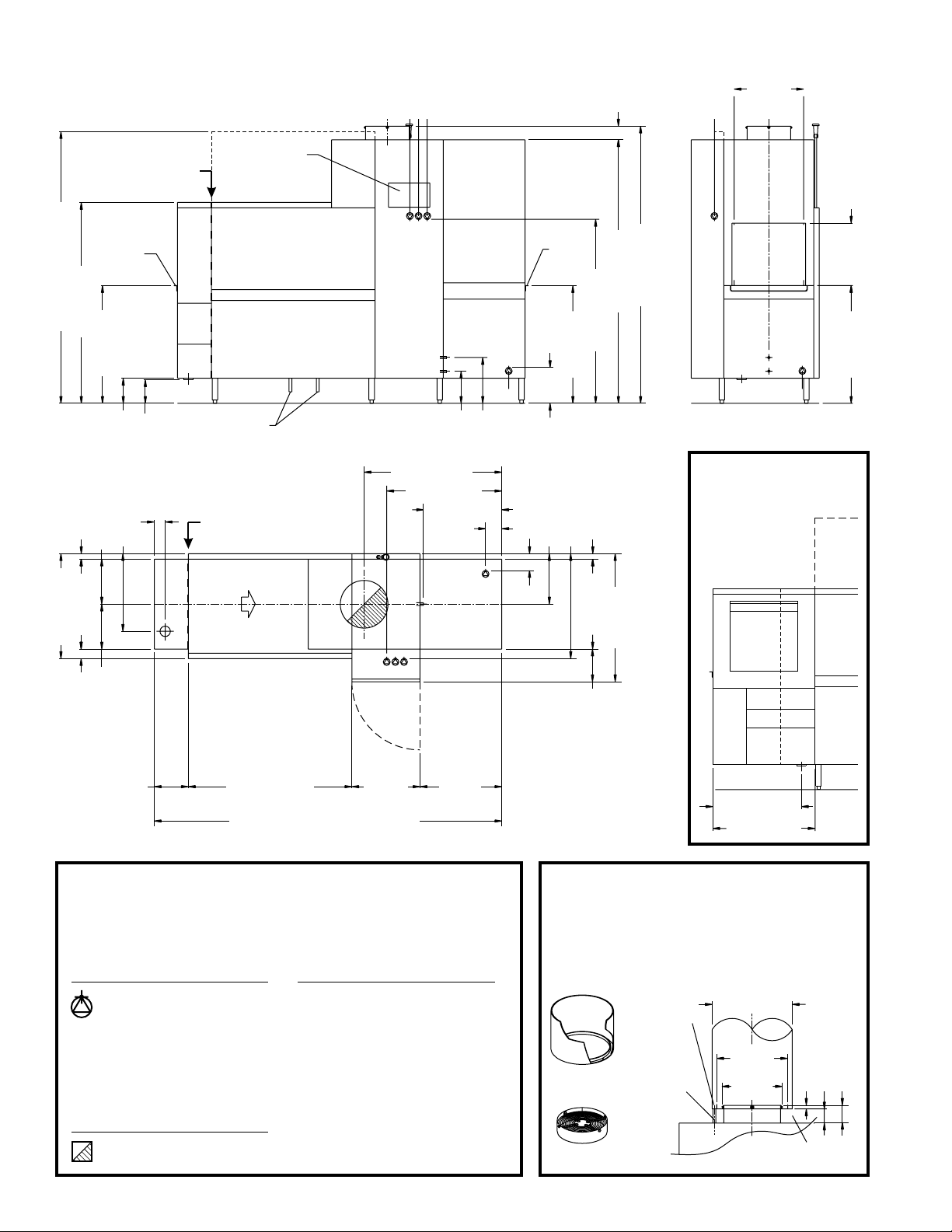

K-200, K-200 PW, K-200 LPW, electric heating

Machines with blower dryer, Left-to-Right

control

Prewash inserted here for

K-200 PW and K-200 LPW

P

panel

3 7/8"

[100mm]

Horizontal

clearance

1'-8 1/8"

[510mm]

Door open 6'-6 1/2" [1994mm]

4'-10" [1474mm]

1 5/8" [40mm]

2'-2" [660mm]

2'-6 3/8" [770mm]

table

support

2'-10" [864mm]

7 1/4"

[184mm]

1'-10 1/2" [570mm]

1'-1" [330mm]

lip

6 7/8"

[174mm]

3 1/8"

[80mm]

1-3

C

4

W

D

CSS TOP OPTION

(front view)

9-7/8" [250mm] load

section is replaced with

CSS Top section. Adds

Vertical

clearance

2'-10" [864mm]

1'-6" [458mm]

D

Prewash inserted here for

P

K-200 PW and K-200 LPW

drain

handle

123

C

W

9 1/4"

3'-3-3/4" [1010mm]

2'-9-1/4" [844mm]

1'-10-5/8" [575mm]

4 3/4"

[120mm]

1'-1 1/4"

[235mm]

4

[335mm]

table

support

lip

10 3/8"

4 7/8" [125mm]

1'-2 5/8" [370mm]

2'-10" [864mm]

[264mm]

2'-6 1/4" [770mm]

4'-5 1/8" [1350mm]

1 5/8" [40mm]

6'-8 1/8" [2034mm]

6'-4 1/8" [1934mm]

1'-7 5/8" [500mm] to

4

overall machine length.

W

C

2'-2" [660mm]

D

123

3'-1" [940mm]

1'-1" [330mm]

2 3/4" [70mm]

* 35-1/2" [900mm] blower dryer

section is also available.

Adds 11-3/4" [300mm] to

overall machine length.

K-200 PW: 1'-7 5/8"

‡

[500mm] prewash

K-200 LPW: 2'-7 1/2"

‡‡

[800mm] prewash

9 7/8" [250mm]

3'-11 1/4" [1200mm]

K-200: Table-to-table 8'-4 3/8" [2550mm]

K-200 PW: Table-to-table 10' 1/8" [3050mm] ‡

K-200 LPW: Table-to-table 10' 11-7/8" [3350mm] ‡‡

1'-7 5/8"

[500mm]

1'-11 5/8"

[600mm] *

UTILITY CONNECTIONS

Drain

D

2-15/16” (75mm) OD vertical, gravity-fed

drain outlet (HDPE piping). Optional 3" NPT

male adapter supplied. Recommend

placement directly above 4” floor drain.

Additional piping to drain (if so required) to

be supplied by customer.

Electrical connection

4 (four) individual terminal blocks at locations

shown. Each connection is 4-wire with

ground (no neutral).

with lockout/tagout strongly recommended

for each supply (provided by customer).

Incoming leads must be appropriately sized

for electrical supply. Opening(s) in the

machine for the supply lines are NOT

provided and should be executed on-site

using appropriate strain relief device(s).

Refer to Page 10 for supply details.

Vent connection

383 CFM (+120 CFM room air recommended)

K-200 Series • Updated 12-07 Page 4

Individual disconnect

Warm water connection (fill)

W

3/4" NPT female pipe connection

• Temperature 110-140°F (43-60°C)

• Pressure 15-25 PSI

• Initial fill - Refer to Page 10

• Hardness 4-6 grains/U.S. gal.

Cold water connection (rinse)

C

3/4" NPT female pipe connection

• Temperature 50°F (10°C)

• Pressure 15-25 PSI

• Consumption 84.7 U.S. gals./hour

• Hardness 4-6 grains/U.S. gal.

9 1/2"

[240mm]

D

2'-1 5/8" [650mm]

2'-5 1/2" [750mm]

DETAIL VIEW: VENT

The vent shroud MUST NOT be connected directly to the machine, as this

prevents room air from being drawn into the shroud. All dimensions shown

are recommendations only. Actual exhaust connection must be adequate

for the exhaust air and comply with all applicable national and local codes.

The waste air connection must be corrosion-resistant and frost-free. In

particular, provision must be made to prevent air temperatures of 32°F/0°C

or colder from reaching the machine at any time. A provision for draining

moisture from the waste air pipe is STRONGLY RECOMMENDED.

Ø1'-6" [457mm]

Ø1'-4"

[406mm]

Ø1'-1 3/8"

[340mm]

air to enter vent shroud

3 1/8" [80mm]

3/4" [20mm]

Gap permits room

Vent shroud

(supplied

by customer)

Machine

exhaust vent

Condensation

channel

Condensation

can be drained

into machine

(drain is

supplied by

customer)

3 7/8" [100mm]

Loading...

Loading...