Meiko FV40.2 Installation Manual

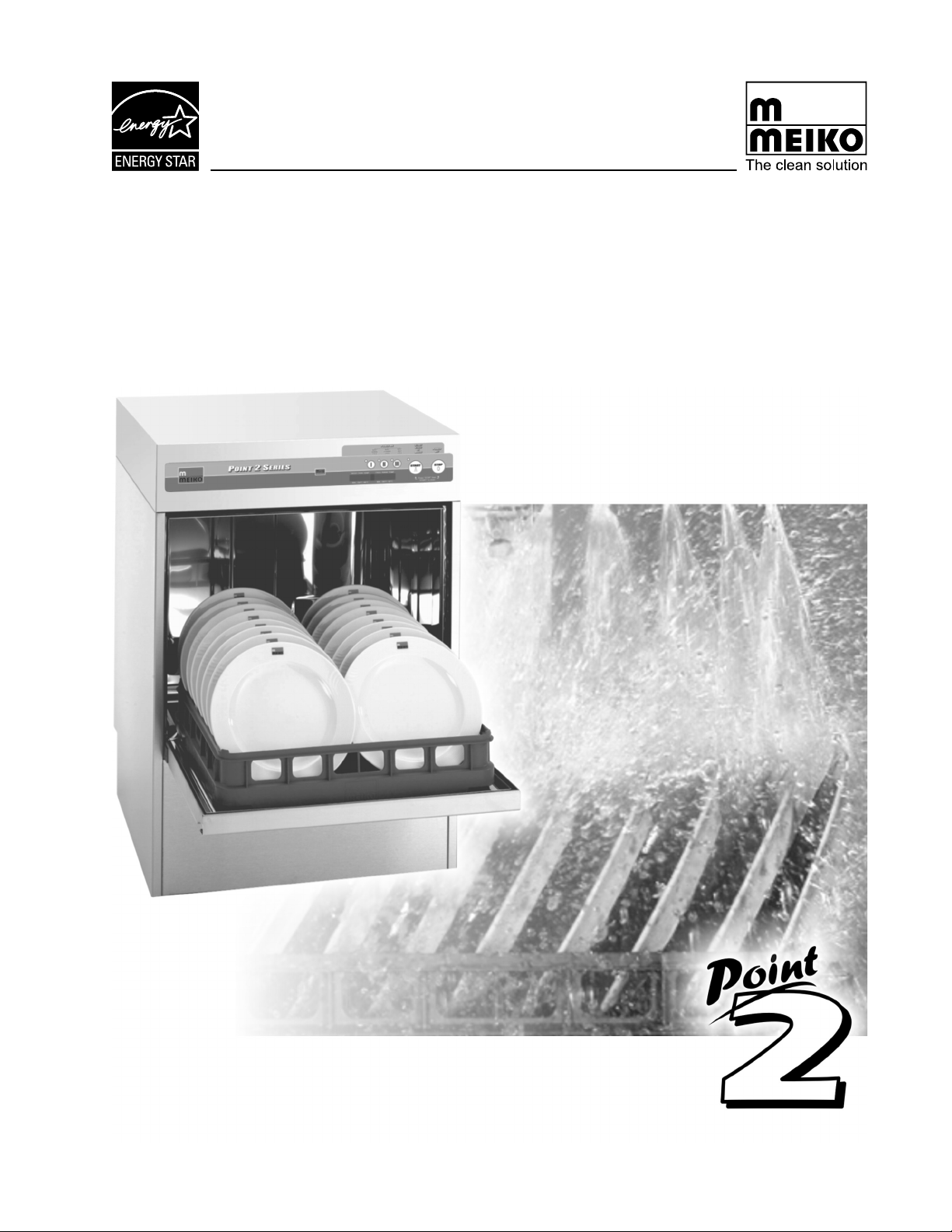

MODEL FV 40.2

Undercounter High Temperature Sanitizing Dishwasher

(USA Version)

OWNER’S INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

MEIKO • 1349 Heil Quaker Blvd. • La Vergne, TN 37086 • Phone: (615) 399-6600 • (800) 55-MEIKO • Fax: (615) 399-6620

Rev. 9/10

TABLE OF CONTENTS

1. INTRODUCTION ................................. 3

1.1 Overview of Equipment ............................. 3

1.2 General Safety Information........................ 3

2. TRANSPORT AND SHIPPING ............ 3

3. INSTALLATION .................................... 4

3.1 Overview of Installation ............................. 4

3.2 Requirements Before Installation............... 4

3.3 Uncrating, Positioning and Leveling ............. 5

3.4 Accessing the Utility Connections.............. 5

3.5 Main Electrical Supply Connection ............ 6

3.6 Dispensing System Overview.................... 6

3.7 Installing External Chemical Pumps .......... 7

3.8 Connecting Chemical Containers

or Dispensers ............................................ 8

3.9 Fresh Water Supply Connection................ 9

3.10 Drain Hose Positioning .............................. 9

3.11 Final Assembly ........................................ 10

3.12 Priming the Detergent and

Rinse Additive Lines ................................ 10

3.13 Checking for Correct Chemical

Concentration .......................................... 10

4. OPERATION ....................................... 11

4.1 Location and Description of Controls........11

4.2 Startup.....................................................12

4.3 Loading.................................................... 12

4.4 Operation................................................. 13

4.5 Between Cycles....................................... 13

4.6 Shutdown................................................. 13

5. CLEANING..........................................14

5.1 Daily Cleaning (or as required)................ 14

5.2 Weekly Cleaning (or as required) ............ 14

5.3 Exterior Cleaning (as required)................ 15

5.4 Deliming (as required) ............................. 15

6. TROUBLESHOOTING ........................ 16

AN ELECTRICAL WIRING DIAGRAM IS LOCATED INSIDE THE

LOWER-FRONT COMPARTMENT OF THIS MACHINE.

THE MEIKO MODEL FV 40.2 DISHWASHER HAS BEEN DESIGNED

EXCLUSIVELY FOR THE WASHING OF DISHES, GLASSWARE, CUTLERY

AND KITCHEN UTENSILS IN A COMMERCIAL OR INSTITUTIONAL SETTING

AND MUST NOT BE USED FOR ANY OTHER PURPOSE.

MEIKO ACCEPTS NO RESPONSIBILITY FOR DAMAGE TO THE APPLIANCE, SURROUNDING

EQUIPMENT OR ENVIRONMENT THAT IS CAUSED BY INAPPROPRIATE INSTALLATION OR

OPERATION, OR FROM ANY SERVICE THAT IS UNDERTAKEN BY NON-AUTHORIZED PERSONNEL,

OR FROM THE USE OF ANY PARTS EXCEPT THOSE THAT ARE APPROVED BY THE

MANUFACTURER. ANY SUCH INSTALLATION, USE OR SERVICE WILL IMMEDIATELY VOID THE

MANUFACTURER’S WARRANTY.

ANY MODIFICATIONS TO THE APPLIANCE THAT ARE PERFORMED WITHOUT THE WRITTEN

PERMISSION OF MEIKO WILL IMMEDIATELY VOID THE MANUFACTURER’S WARRANTY.

MEIKO reserves the right to change any specifications without notice at any time.

© 2010 MEIKO USA, Inc. All rights reserved.

MEIKO • 1349 Heil Quaker Blvd. • La Vergne, TN 37086

Phone: (615) 399-6600 • (800) 55-MEIKO • Fax: (615) 399-6620

www.meiko.us

Page 2

SECTION 1 - INTRODUCTION

1INTRODUCTION

1.1 Overview of Equipment

The MEIKO Model FV 40.2 is a commercial

dishwasher designed for cleaning dishes,

glassware, cutlery and kitchen utensils with a

minimum of employee intervention or

supervision.

A control keypad allows easy selection of

three different dishwashing cycles to

accommodate different levels of soiling. A

digital display permits easy monitoring of

operation.

Other features of the unit that affect operation

include:

Auto Safe - An internal booster heater is

regulated by the electronic control system to

ensure a proper sanitizing final rinse

temperature, regardless of the incoming water

temperature.

Soft Start - The wash water is pumped at a

reduced pressure for the first few seconds of

the wash cycle. This protects the ware from

being moved or damaged by a sudden burst

of pressure.

Pumped Rinse - An internal rinse pump

ensures that the final rinse pressure is

constant.

Pumped Drain - Accommodates wall or floor

drains.

Aqua Stop - The unit will automatically shut

down if a water leak is detected.

For efficient and SAFE operation, be sure to

follow the installation and operating

instructions provided in this manual. In

particular, all safety symbols and notices on

the equipment and in the supplied

documentation must be followed.

IMPORTANT

The Model FV 40.2 dishwasher has been

designed exclusively for the washing of

dishes, glassware, cutlery and kitchen utensils

in a commercial or institutional setting and

must not be used for any other purpose.

1.2 General Safety Information

The following symbols and headings are used

throughout this manual to indicate possible hazards to persons or to the equipment. The symbols and headings are shown in order of importance. The descriptive text following these headings is italicized for easy recognition.

WARNING! Possible hazard to per-

sons, such as from electrical shock, crushing, or

hot surfaces.

CAUTION Possible hazard to the

dishwasher or to other

equipment.

IMPORTANT Vital information or tips for

the installer or operator.

NOTE Information or tips for the

installer or operator.

2TRANSPORT AND SHIPPING

CAUTION

During shipping and installation, the

dishwasher may ONLY be positioned upright

or on its left side. Some water may remain in

the lines after pre-shipping testing. If the unit

is positioned in any manner EXCEPT upright

or on its left side, this water can affect the

operation of the water level sensor.

IMPORTANT

• Observe any notices on the crating

material that pertain to shipping.

• Use care when transporting the

equipment.

• As you unpack the equipment, check that

all components shown on the shipping

invoice are present and intact. Be sure to

check for shipping damage. If shipping

damage is present, call MEIKO Customer

Service at 1-800-868-3840, providing full

details on the customer, serial number and

extent of damage present. MEIKO will file

a freight claim based on this information.

WARNING!

In NO EVENT should a damaged

appliance be installed or operated!

Page 3

SECTION 3 - INSTALLATION

3INSTALLATION

3.1 Overview of Installation

The owner should contract with qualified

personnel to move the appliance to the

installation location, unpack it, and prepare it

for final utility connections. In most cases,

local codes prevent the final utility connections

from being made by any party other than a

licensed electrician and/or plumber.

IMPORTANT

It is the responsibility of the owner to ensure

that all aspects of the installation comply with

all applicable local and national codes.

IMPORTANT

The appliance’s warranty is not valid until a

MEIKO Authorized Service Agent performs a

Startup and Demonstration on the appliance.

This Demonstration should be scheduled after

installation.

Installation of the dishwasher involves the

following steps:

• Verifying that the utility connections are

present, are appropriate for the appliance,

and comply with all applicable local and

national codes.

• Unwrapping the appliance (leaving the

shipping skid in place for easier movement) and checking for shipping damage.

• Moving the appliance to the installation

location, removing the skid, and leveling

the feet.

• Connecting the electrical supply.

• Installing the chemical dispensing system.

For units equipped with the optional

dispensing system, this involves

connecting the warewasher’s detergent and

rinse additive tubes to appropriate dispensers.

For units without the optional system, the

dispensing system installer should follow

the manufacturer’s instructions AND the

instructions in Section 3 of this Manual.

• Connecting the fresh water supply.

• Positioning the drain hose.

Page 4

• Contacting your MEIKO Authorized Service

Agent to perform a Startup and

Demonstration on the appliance. This step

also validates the appliance’s warranty.

3.2 Requirements Before Installation

Before the installer can uncrate and move the

appliance to the installation location, the

following conditions MUST be met:

• INSTALLATION AREA REQUIREMENTS

- The area MUST be frost-free. Freezing

temperatures (32°F/0°C or lower)

inhibit proper operation and can

damage internal components.

- The area MUST have a firm floor

surface. It is possible to compensate for

uneven flooring by adjusting the feet.

- The area should be away from

appliances, furniture or surfaces that

can be damaged by steam. If this is

not possible, these items should be

protected from the small quantities of

steam that are released during normal

operation of the dishwasher.

• UTILTITY CONNECTION REQUIREMENTS

- Connections must be present and

ready for hookup to the appliance. All

utility supplies must comply with the

electrical information labels, with the

information on the data plate, and with

all applicable local and national codes.

- Electrical leads and the water supply

hose (supplied by the customer) must

be present.

- For units without the optional

dispensing system, external detergent

and rinse additive pumps (if used)

should be installed according to the

manufacturer’s instructions.

- For units with the optional dispensing

system, appropriate dispensers or

containers should be installed and

ready for connection to the appliance.

• GENERAL REQUIREMENTS

Authorized personnel should be available

to perform the actual utility connections.

SECTION 3 - INSTALLATION

3.3 Uncrating, Positioning and Leveling

CAUTION

During shipping and installation, the dishwasher

may ONLY be positioned upright or on its left side.

Some water may remain in the lines after preshipping testing. If the unit is positioned in any

manner EXCEPT upright or on its left side, this water

can affect the operation of the water level sensor.

1. Remove all shipping and packaging material

from the appliance, including supports and

wrappings. Leave the shipping skid in place at

this time to allow for easier movement to the

installation location.

2. Check for shipping damage as described in

Section 2, “Transport and Shipping.” If damage

is present, call MEIKO Customer Service at

1-800-868-3840, providing full details on the

customer, serial number and extent of damage

present. MEIKO will file a freight claim based on

this information.

3. Move the appliance to the installation area and

remove the skid. Use caution to avoid damaging

the appliance or any of its components.

4. Check that the plastic feet are attached to each

of the four adjustable leg bolts. If necessary,

attach them by pressing them firmly onto the

end of the bolts.

5. Using a spirit level, check that the appliance is

level in both directions (front-to-back AND sideto-side). If necessary, rotate the leg bolts to level

the appliance.

CAUTION

The dishwasher MUST be level for proper

operation.

3.4 Accessing the Utility

Connections

Slide panel down

to free retaining

clips on top edge,

then remove

In order to attach the utility connections,

the back panel of the dishwasher must

be removed. Follow the steps below.

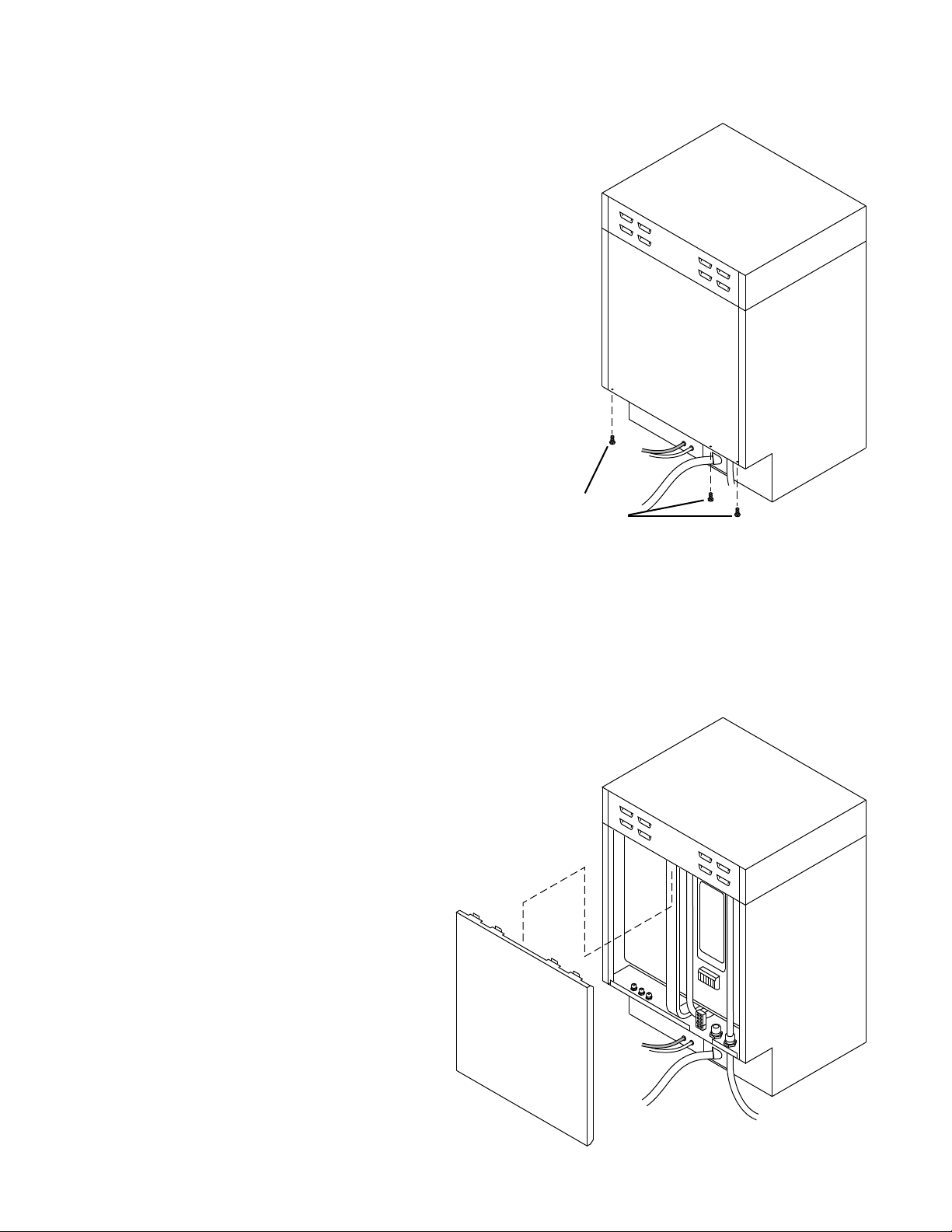

1. Remove AND RETAIN the three

retaining screws underneath the

bottom lip of the rear panel. See

Figure 3-1.

2. Carefully slide the rear panel down

to free the retaining clips along the

top edge. See Figure 3-2.

3. Remove the rear panel from the

dishwasher.

Figure 3-1

3 screws on

bottom edge

of rear panel

Figure 3-2

Page 5

SECTION 3 - INSTALLATION

3.5 Main Electrical Supply Connection

WARNING!

Check that the circuit breaker/fused

disconnect is in the OFF position and

that the unit is switched off before

making the electrical utility connections.

IMPORTANT

In some cases, local codes dictate that

electrical supply connections be made only

by a certified professional.

1. Check that the incoming power leads are

of sufficient rating for the appliance’s

current draw. Amperage and minimum

supply wire specifications are shown on

the serial plate and on the electrical

information label.

2. Check that the incoming power leads are

long enough to permit the unit to be

repositioned for servicing.

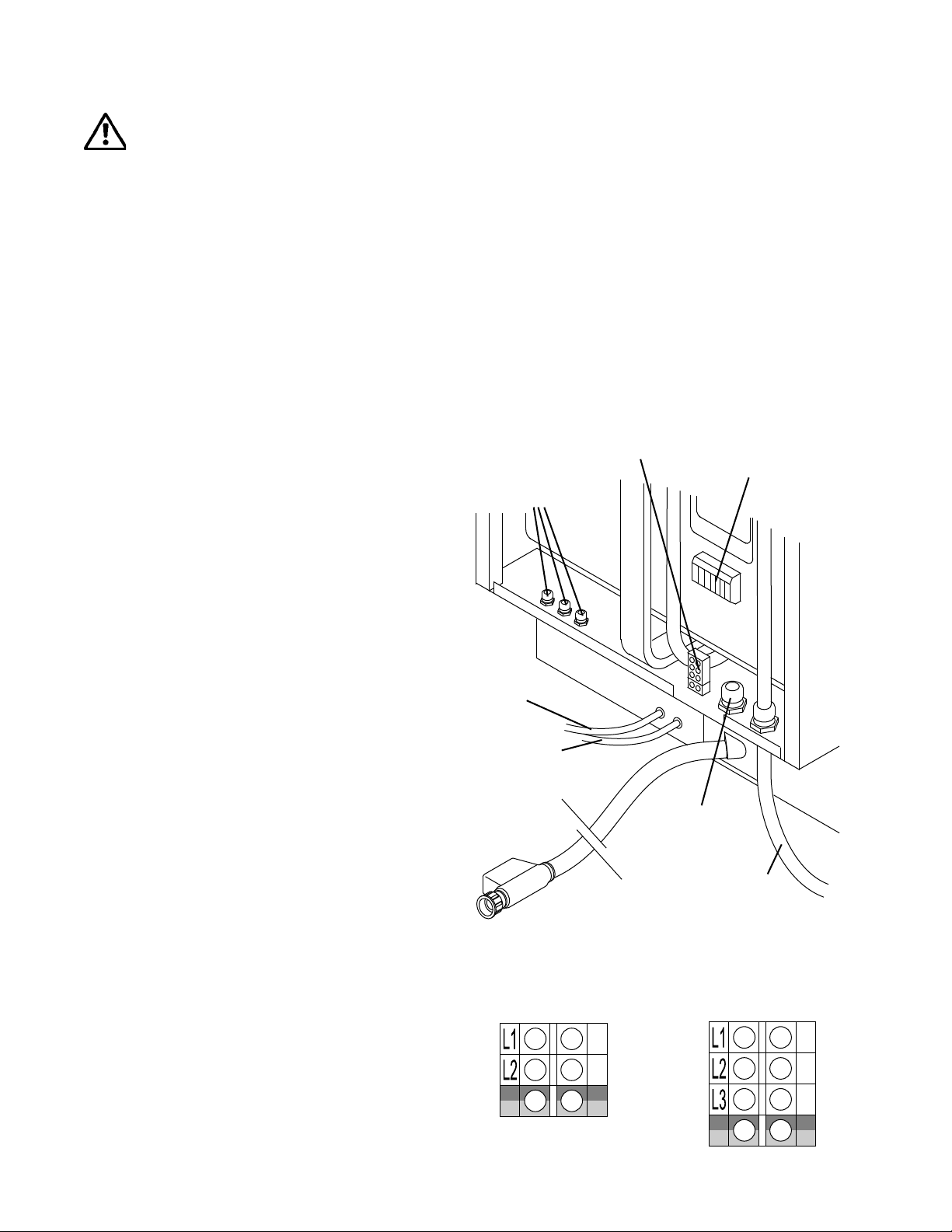

3. Locate the strain relief for the electrical

supply wiring at the lower rear of the

machine (Figure 3-3). Thread the incoming

supply leads through the strain relief and

to the main electrical supply terminal block.

tubes to be routed to external pumps, if they

are used.

CAUTION

If the unit will NOT use one or both of the

chemical supply tubes, cut the unused tube(s)

close to the point where it exits the machine’s

exterior panel and seal it using the supplied

plug and wire clamp. See Figure 3-5.

For units equipped with the optional internal

chemical dispensing system, skip ahead to

Section 3.8, “Connecting Chemical Containers

or Dispensers.”

Figure 3-3: Utility connections

Strain reliefs

for incoming

rinse additive

and detergent

dispenser

wiring (3)

Terminal block

for electrical

supply

Terminal block for

external rinse additive

and detergent dispenser

(if so equipped)

4. Refer to Figure 3-4 and to the electrical

wiring diagram. Connect the power supply

and ground leads as indicated.

5. Adjust the strain relief to fasten the wiring

in place. You should leave enough slack

in the wiring to prevent stress on the

terminal connections.

3.6 Dispensing system overview

The FV 40.2 is designed for use with liquid

detergent and liquid rinse additive. The unit

is not compatible with solid detergents

and/or rinse additives.

The tubes located at the lower rear of the

warewasher are pre-plumbed to supply liquid

detergent (clear tube) and liquid rinse additive

(blue tube). See Figure 3-3.

Some units are equipped with optional internal

liquid detergent and rinse additive dispensing

pumps, in which case containers can simply

be attached to the supply tubes. Units without

the optional internal pumps will require the

Page 6

Rinse

additive

(blue)

Detergent

(clear)

Fresh water

connection

Strain relief

for incoming

electrical

supply

Figure 3-4: Main electrical supply

• 208-230V/1 Phase:

L1 and L2 = “hot” (line)

yel/grn = ground

• 208-230V/3 Phase

L1, L2, L3 = “hot” (line)

yel/grn = ground

Drain

hose

Loading...

Loading...