HOT WATER

SANITIZING

FV 250.2

POT AND PAN

WASHER

Meiko’s FV 250.2 introduces state of the art warewashing technology with standard features

and benefits currently unavailable in pot-and-pan washers. Upper and lower oscillating

wash arms and two powerful 3 hp wash pumps guarantee outstanding ware coverage as

well as enhanced performance. And with the ability to hold 22 standard 18x26” sheet

pans every cycle, the FV 250.2 has the capacity to meet the most demanding needs.

The FV 250.2 offers three variable programmed time cycles for various soil loads.

Meiko’s exclusive “Mike 2” programmable controller simplifies operation and service

diagnostics. Other unique features include our “Active Plus” wash tank soil removal

system, “Soft Start” fine china and glassware protection system, “Aqua-Stop” water

leakage protection system, and the “Auto Safe” temperature control system. Together

with the unit’s internal booster heater and power rinse pump, “Auto Safe” provides

constant, guaranteed temperature and pressure for the wash and final rinse cycles.

As with all products synonymous with the name “Meiko,” engineering excellence,

manufacturing quality and performance come to the forefront in the FV 250.2.

Special Features:

• Mike 2 Programmable Controller - advanced micro-

computer technology for service diagnostics and end-user

dishmachine settings

• Active Plus - Double filtration of wash water removes food

soil, improving washing efficiency and saving detergent while

easing cleaning chores

• Auto Safe - Guarantees minimum required wash and rinse

temperatures regardless of incoming water temperature

• Soft Start Wash Pump - Protects dishes and glasses from

chipping or breaking

• Aqua-Stop - Automatically turns off incoming water supply

should leakage occur

• Built-in Booster Heater with Power Rinse Pump - Guarantees

constant pressure and temperature during final rinse

• Oscillating wash arms for complete ware coverage

• Double-wall construction keeps heat inside the machine,

reducing energy consumption and heat loss into the

dishroom environment

Standard Features:

• High capacity. Includes wheeled, stainless steel ware basket

(50-1/2”W x 26”D x 34”H). One stainless steel sheet pan

rack is also provided (holds 11 pans). One additional rack

can be added for a capacity of 22 pans per cycle.

• Variable programmed time cycles - 4, 6 and 8 minutes

• Utilizes only 2.55 gallons of rinse water per rack

• Fully automatic - automatic fill, automatic start, and

automatic reset

• Pumped drain for both floor and wall drain applications

• Self cleaning cycle - automatic cleaning of the wash chamber

following machine shutdown

• Stainless steel non-clogging wash and rinse arms

• Sloping wash tank directs food soil into large, easilyremoved pan strainer

• Front mounted controls with digital cycle and temperature

displays

• Two 3 hp wash pumps

• All 304 and 316L stainless steel construction for advanced

corrosion resistance

• Type A air gap system eliminates need for vacuum breaker

FV 250.2 • Updated 7-06 Meiko • 917 Airpark Center Drive • Nashville, TN 37217 • (800) 55-MEIKO • FAX (615) 399-6620 • www.meiko.us

Technical Specifications:

Optimum Capacity:

Cycles per hour .................................................... 15

Optimum Cycle Tme (seconds):

Wash cycle ......................................................... 204

Dwell/drain time ................................................... 26

Rinse cycle ........................................................... 10

Total cycle .......................................................... 240

Water requirements:

Gallons per cycle .............................................. 2.55

Gallons per hour ............................................. 38.25

Flow pressure ....................................... 8.7-72.5 psi

Incoming water line ............. 3/4” male garden hose

Drain line ................................3/4” OD flexible hose

Required Operating Temperatures:

Incoming water (maximum) ........................... 140°F

Wash (minimum) ............................................ 150°F

Rinse (minimum) ............................................ 180°F

Tank Capacities:

Wash tank .......................................... 26.42 gallons

Booster heater ..................................... 4.76 gallons

Electrical Requirements:

Wash tank heat ............................................. 12 kW

Booster heater .............................................. 18 kW

Wash pump ................................................ 2 x 3 HP

Approximate Total Load:

• 208-230/60/3 ...... 86.8 A @ 208V, 94.0A @ 230V

• 460/60/3 ....................................... 46.6A @ 460V

Dimensions:

Overall ...................76-1/8”H x 58-5/8”W x 35-1/4”D

Wall clearance .............................................. 0” min.

Ware clearances (inside basket): 50-1/2” x 26” x 34”H

Machine/Shipping Details:

Machine Weight .......................................... 618 lbs.

Shipping Weight .......................................... 680 lbs.

Shipping dimensions ............... 79”H x 63”W x 44”D

Wall clearance .............................................. 0” min.

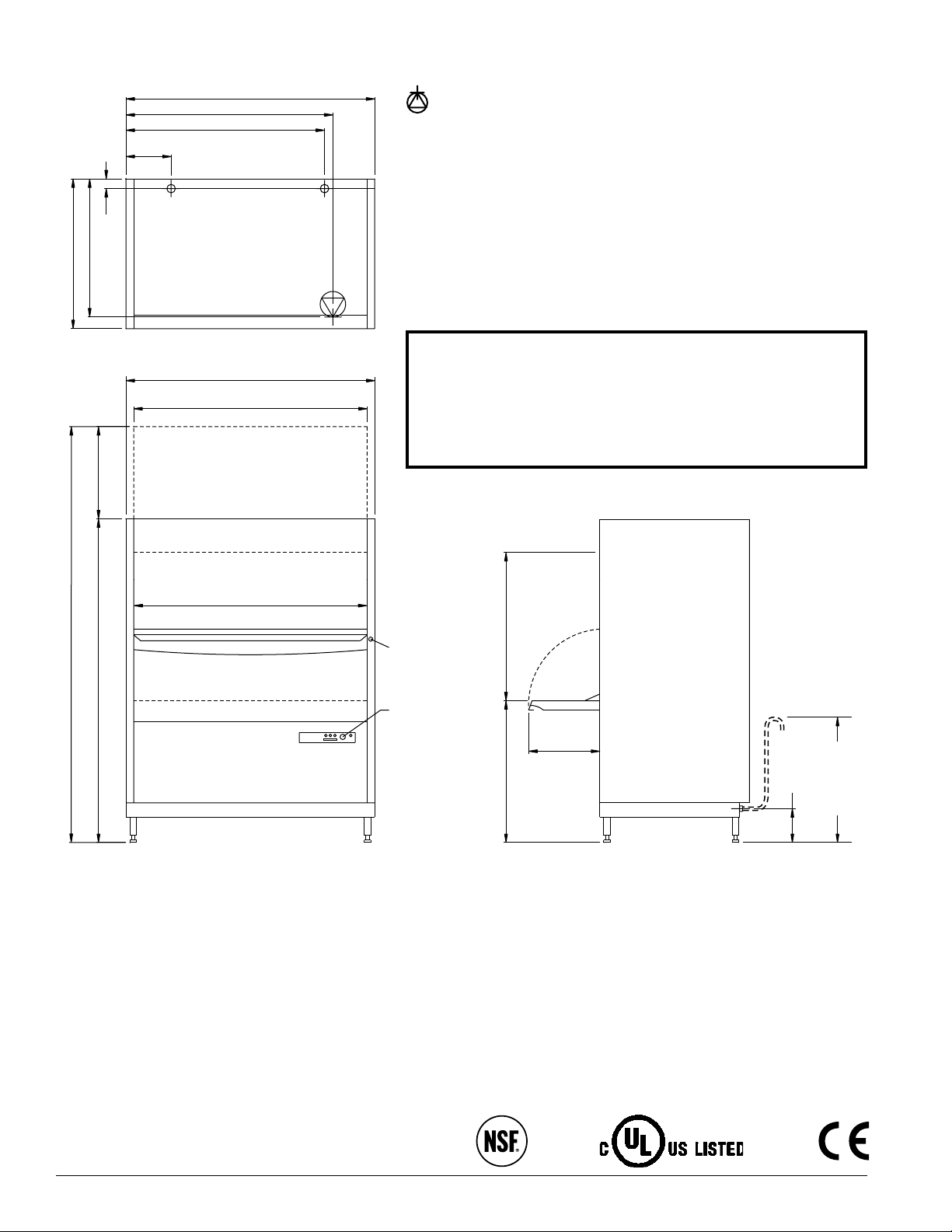

Dimensions

10 5/8"

[270mm]

2 1/4" [58mm]

32 1/2" [825mm]

35 1/4" [895mm]

48 7/8" [1240mm]

46 7/8" [1190mm]

D

58 5/8" [1490mm]

H

- Electrical supply connection

Strain relief is provided at lower rear of machine. Terminal block is located

at front of machine and is accessed by removing lower front panel. Adequate

slack in the wiring connection should be provided to allow the machine to

be removed for servicing.

H - Fresh water connection

Requires hookup to 3/4” male garden hose fitting. Supplied hose extends

4’7” from machine connection.

D - Drain hose connection

Requires indirect connection to 1-1/2” drain pipe (wall or floor). Supplied

drain hose extends 4”7” from machine connection.

21 7/8" [555mm]

98" [2490mm]

door clearance

76 1/8" [1935mm]

Top View

58 5/8" [1490mm]

54-5/8" [1387mm]

door clearance

52-1/2" [1334mm] horizontal clearance

Inside rack: 50-3/4" [1289mm]

“Auto Safe” Feature

The FV250.2 guarantees that the minimum NSF temperature

requirements of 150°F during the wash and 180°F during the final rinse

are achieved regardless of the incoming water temperature, even if the

dishmachine is installed to a cold water line. Exact rack capacity is

dependent upon the incoming water temperature and on the electrical

supply voltage.

Secondary

cycle start switch

Control

panel

Inside rack: 34" [864mm]

35" [890mm] vertical clearance

33 3/8" [847mm]

16 3/4" [425mm]

door clearance

8" [202mm]

If drain hose

is positioned

as a water trap,

top of loop

may be no

higher than

27" from floor

Front View Side View

Note: All specifications are subject to change without notice

based on Meiko’s dedicated product improvement program.

Specification

FV 250.2 Item Number _____________

Unit will be a Meiko FV 250.2 hot water sanitizing pot and

pan washer.

Unit will be : _____ 208-230 V / 60Hz / 3 Ph

_____ 460 V / 60 Hz / 3 Ph

Unit will have front mounted microcomputer controls, a 240

second total time cycle, and utilize 2.55 gallons fresh rinse

water per cycle. Unit will utilize a fresh water pumped rinse

for constant pressure and temperature every cycle. Unit will

have oscillating wash arms to ensure complete coverage of

ware as well as to enhance performance. Unit will have

FV 250.2 • Updated 7-06 Meiko • 917 Airpark Center Drive • Nashville, TN 37217 • (800) 55-MEIKO • FAX (615) 399-6620 • www.meiko.us

integral wash tank soil removal system to maintain clean wash

water and have built-in temperature safeguards to guarantee

washing and rinsing at minimum required temperatures

regardless of incoming water temperatures. Wash pumps will

be equipped with a smooth start feature to eliminate chipped

and broken dishware. Unit will also incorporate features to

stop operation and shut off water flow to the machine should

leakage occur. Unit will have variable time cycles for heavier

than normal soil loads.

Loading...

Loading...