Meiko CS70 Installation Manual

MODEL CS 70

Door-Type Low Temperature Chemical Sanitizing Dishwasher

OWNER’S INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

MEIKO • 1349 Heil Quaker Blvd. • La Vergne, TN 37086 • Phone: (615) 399-6600 • (800) 55-MEIKO • Fax: (615) 399-6620

Rev . 7/14

TABLE OF CONTENTS

1. INTRODUCTION ................................. 3

1.1 Overview of Equipment ............................. 3

1.2 General Safety Information........................ 3

2. TRANSPORT AND SHIPPING ............ 3

3. INSTALLATION.................................... 4

3.1 Overview of Installation ............................. 4

3.2 Requirements Before Installation .............. 4

3.3 Uncrating, Positioning and Leveling ............. 5

3.4 Accessing the Utility Connections ............. 5

3.5 Main Electrical Supply Connection............ 6

3.6 Dispensing System Overview.................... 7

3.7 Connecting Chemical Containers.............. 7

3.8 Fresh Water Supply Connection................ 8

3.9 Drain Connection....................................... 9

3.10 Tabling Attachment.................................. 10

3.11 Final Assembly ........................................ 12

3.12 Priming the Liquid Detergent, Rinse Aid

and Sanitizer Lines.................................. 12

3.13 Checking for Correct Chemical

Concentration.......................................... 13

4. PROGRAMMING ................................14

5. OPERATION.......................................15

5.1 Location and Description of Controls....... 15

5.2 Startup..................................................... 16

5.3 Loading....................................................16

5.4 Operation................................................. 17

5.5 Between Cycles....................................... 17

5.6 Shutdown ................................................ 17

6. CLEANING .........................................18

6.1 Daily Cleaning (or as required)................ 18

6.2 Weekly Cleaning (or as required)............ 18

6.3 Exterior Cleaning (as required)................ 19

6.4 Deliming (as required) ............................. 19

7. TROUBLESHOOTING........................20

8. PARTS LISTING .................................26

9. WIRING DIAGRAMS ..........................43

9.1 Ladder schematic, 115V/60Hz/1Ph ......... 43

AN ELECTRICAL WIRING DIAGRAM IS LOCATED INSIDE

THE COVER OF THE CONTROL BOX OF THIS MACHINE.

THE MEIKO MODEL CS 70 DISHWASHER HAS BEEN DESIGNED

EXCLUSIVELY FOR THE WASHING OF DISHES, GLASSWARE, CUTLERY

AND KITCHEN UTENSILS IN A COMMERCIAL OR INSTITUTIONAL SETTING

AND MUST NOT BE USED FOR ANY OTHER PURPOSE.

MEIKO ACCEPTS NO RESPONSIBILITY FOR DAMAGE TO THE APPLIANCE, SURROUNDING

EQUIPMENT OR ENVIRONMENT THAT IS CAUSED BY INAPPROPRIATE INSTALLA TION OR

OPERA TION, OR FROM ANY SERVICE THAT IS UNDERTAKEN BY NON-AUTHORIZED

PERSONNEL, OR FROM THE USE OF ANY PARTS EXCEPT THOSE THAT ARE APPROVED BY THE

MANUFACTURER. ANY SUCH INSTALLATION, USE OR SERVICE WILL IMMEDIATELY VOID THE

MANUFACTURER’S WARRANTY.

ANY MODIFICATIONS T O THE APPLIANCE THAT ARE PERFORMED WITHOUT THE WRITTEN

PERMISSION OF MEIKO WILL IMMEDIATELY VOID THE MANUFACTURER’S WARRANTY.

MEIKO reserves the right to change any specifications without notice at any time.

© 2014 MEIKO USA, Inc. All rights reserved.

MEIKO • 1349 Heil Quaker Blvd. • La Vergne, TN 37086

Phone: (615) 399-6600 • (800) 55-MEIKO • Fax: (615) 399-6620

www.meiko.us

Page 2

SECTION 1 - INTRODUCTION

1INTRODUCTION

1.1 Overview of Equipment

The MEIKO Model CS 70 kube is a

commercial dishwasher designed for cleaning

dishes, glassware, trays, cutlery and kitchen

utensils with a minimum of employee

intervention or supervision.

A control keyp ad allows easy selection of On/

Fill and Off/Drain cycles. A digital display

permits easy monitoring of operation.

Other features of the unit that affect operation

include:

CS 70 - advanced microprocessor technology

for maintenance and end user dishmachine

settings

Auto Prime - Timed priming function on all

chemical pumps

Temp Safe - User-selectable temperaturebased automatic drain/refill feature to ensure

desired wash and rinse temperatures

Delime Cycle - Automatically fills machine,

signals for delimer, delimes for five minutes,

then drains and rinses machine

Fully automatic operation - automatic fill,

automatic start, and automatic drain

Proof of delivery window - provides a visual

indication that chemicals are being dispensed

For efficient and SAFE operation, be sure to

follow the installation and operating

instructions provided in this manual. In

particular, all safety symbols and notices on

the equipment and in the supplied

documentation must be followed.

IMPORTANT

The Model CS 70 kube dishwasher has been

designed exclusively for the washing of

dishes, glassware, trays, cutlery and kitchen

utensils in a commercial or institutional setting

and must not be used for any other purpose.

1.2 General Safety Information

The following symbols and headings are used

throughout this manual to indicate possible

hazards to persons or to the equipment. The

symbols and headings are shown in order of

importance. The descriptive text following these

headings is italicized for easy recognition.

WARNING! Possible hazard to per-

sons, such as from electrical shock, crushing, or

hot surfaces.

CAUTION Possible hazard to the

dishwasher or to other

equipment.

IMPORTANT Vital information or tips for

the installer or operator.

NOTE Information or tips for the

installer or operator.

2TRANSPORT AND SHIPPING

IMPORTANT

• Observe any notices on the crating

material that pertain to shipping.

• Use care when transporting the equipment.

• Customers are required to inspect all

equipment upon receipt for freight

damage, concealed or otherwise. If a shipment is signed for without noting freight

damage, the receiving firm accepts all

responsibility, and MEIKO cannot collect

for a future discovery of freight damage.

If equipment arrives at the customer’s

site with crate and/or package damage,

the factory strongly suggests refusal

of the shipment due to damage claim.

Immediately contact MEIKO Customer

Service at 1-800-55-MEIKO (1-800-556-

3456), providing full details on the

customer, serial number and extent of

damage present.

WARNING!

In NO EVENT should a damaged

appliance be installed or operated!

Page 3

SECTION 3 - INSTALLATION

3INSTALLATION

3.1 Overview of Installation

The owner should contract with qualified

personnel to move the appliance to the

installation location, unpack it, and prepare it

for final utility connections. In most cases,

local codes prevent the final utility connections

from being made by any party other than a

licensed electrician and/or plumber.

IMPORTANT

It is the responsibility of the owner to ensure

that all aspects of the installation comply with

all applicable local and national codes.

IMPORTANT

The appliance’s warranty is not valid until a

MEIKO Authorized Service Agent performs a

Startup and Demonstration on the appliance.

This Demonstration should be scheduled after

installation.

Installation of the dishwasher involves the

following steps:

• Verifying that the utility connections are

present, are appropriate for the appliance,

and comply with all applicable local and

national codes.

• Unwrapping the appliance (leaving the

shipping skid in place for easier movement) and checking for shipping damage.

• Moving the appliance to the installation

location, removing the skid, and leveling

the feet.

• Connecting the electrical supply.

• Connecting the warewasher’s detergent,

rinse aid and sanitizer tubes to appropriate

dispensers.

• Connecting the fresh water supply.

3.2 Requirements Before Installation

Before the installer can uncrate and move the

appliance to the installation location, the

following conditions MUST be met:

• INST ALLATION AREA REQUIREMENTS

- The area MUST be frost-free. Freezing

temperatures (32°F/0°C or lower)

inhibit proper operation and can

damage internal components.

- The area MUST have a firm floor

surface. It is possible to compensate

for uneven flooring by adjusting the

feet.

- The area should be away from

appliances, furniture or surfaces that

can be damaged by water . If this is not

possible, these items should be

protected from the small quantities of

water that are splashed during normal

operation of the dishwasher.

• UTILTITY CONNECTION REQUIREMENTS

- Connections must be present and

ready for hookup to the appliance. All

utility supplies must comply with the

electrical information labels, with the

information on the data plate, and with

all applicable local and national codes.

- Electrical leads and the water supply

line (supplied by the customer) must

be present.

- Appropriate detergent, rinse aid and

sanitizer containers should be installed

and ready for connection to the

appliance.

• GENERAL REQUIREMENTS

Authorized personnel should be available

to perform the actual utility connections.

• Connecting the accumulator drain.

• Connecting the machine to tabling.

• Contacting your MEIKO Authorized

Service Agent to perform a Startup and

Demonstration on the appliance. This step

also validates the appliance’s warranty.

Page 4

SECTION 3 - INSTALLATION

3.3 Uncrating, Positioning and Leveling

1. Remove all shipping and packaging material

from the appliance, including supports and

wrappings. Leave the shipping skid in place at

this time to allow for easier movement to the

installation location.

2. Check for shipping damage as described in

Section 2, “Transport and Shipping.” If damage

is present, immediately contact MEIKO

Customer Service at 1-800-55-MEIKO (1-800-

556-3456), providing full details on the

customer, serial number and extent of damage

present.

3. Move the appliance to the installation area and

remove the skid. Use caution to avoid damaging

the appliance or any of its components.

4. Using a spirit level, check that the appliance is

level in both directions (front-to-back AND sideto-side). If necessary, level the appliance by

rotating the bottom section of each foot.

Figure 3-1

Remove 2

screws

CAUTION

The dishwasher MUST be level for proper

operation.

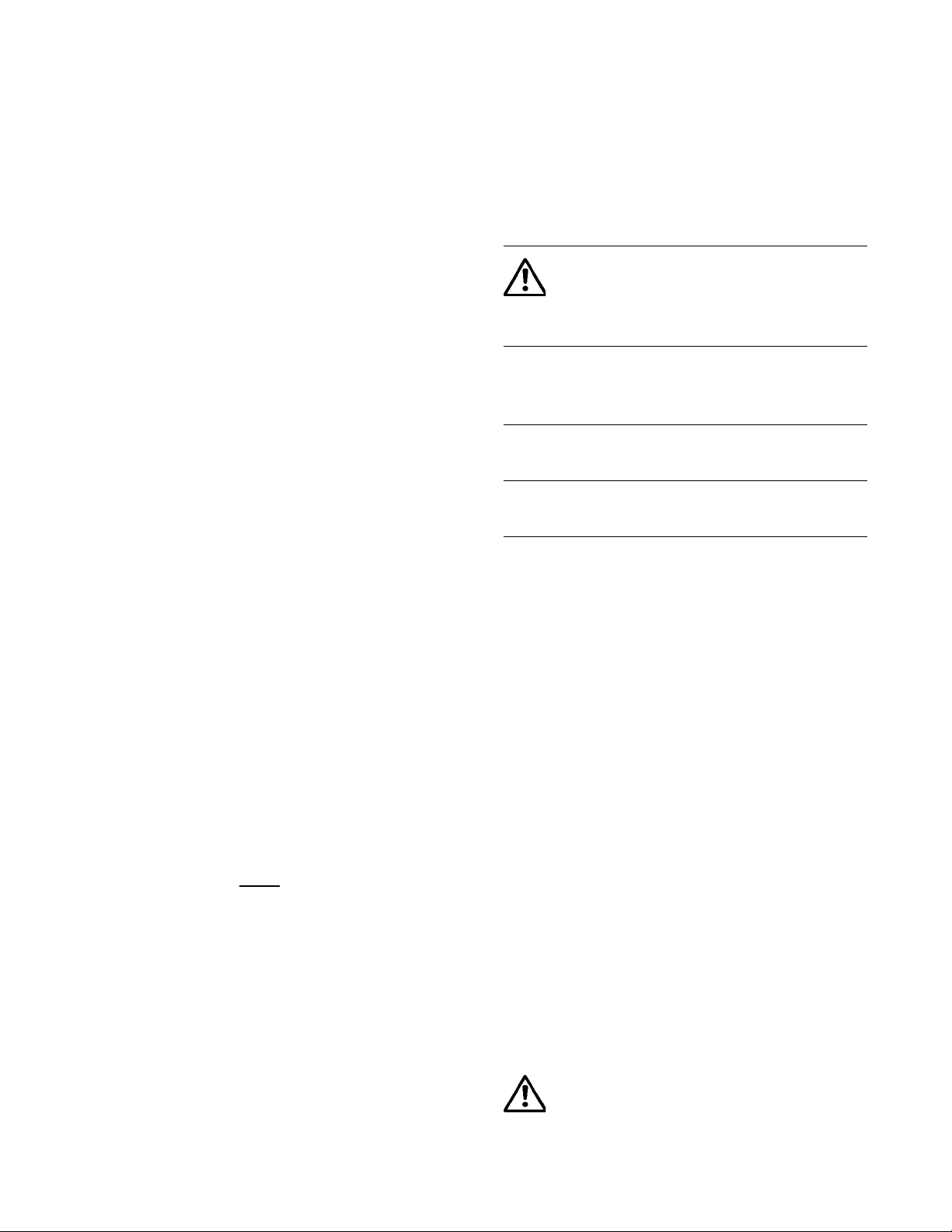

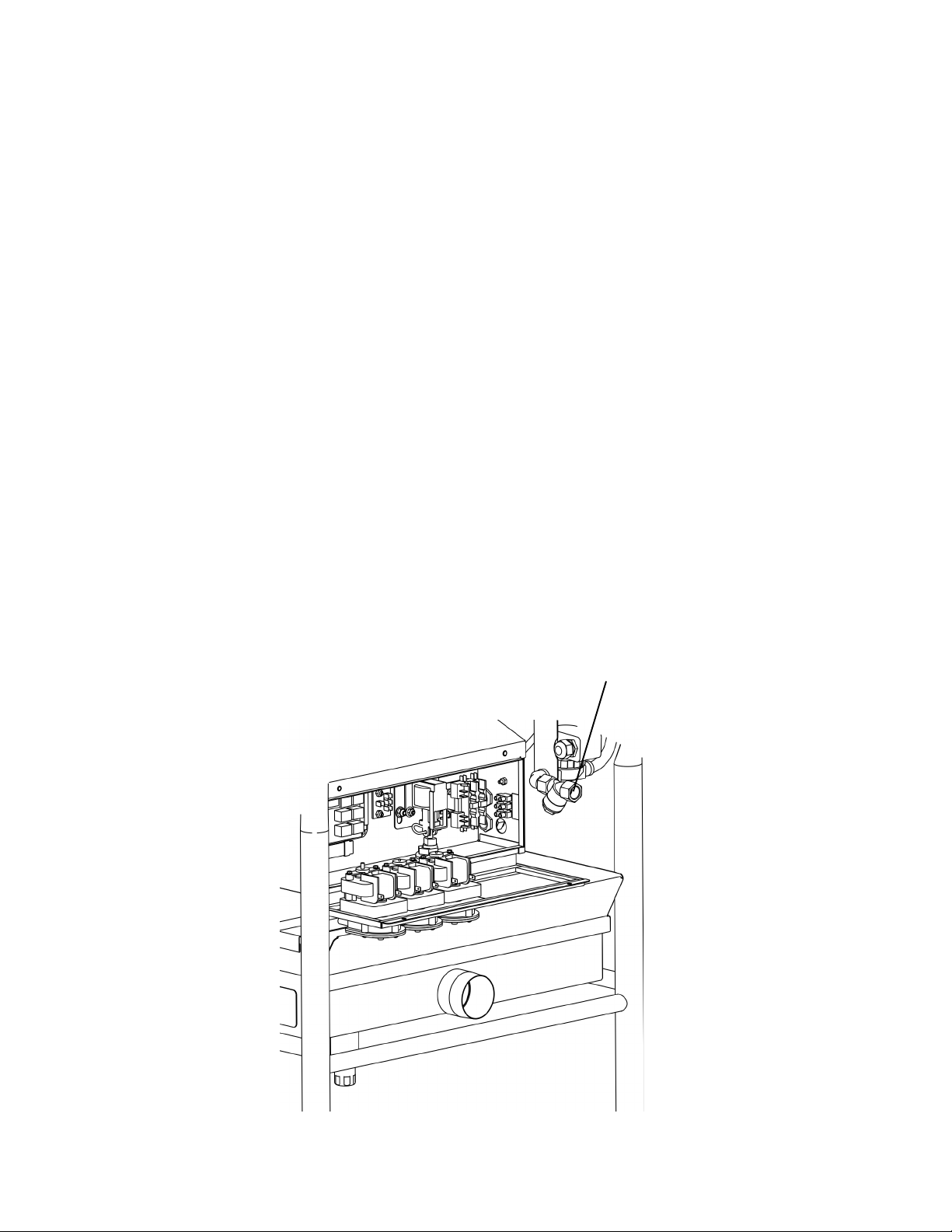

3.4 Accessing the Utility Connections

Water supply and drain connections are accessed

from the lower right side of the dishwasher. The

electrical supply enters through a strain relief at

the back of the control box. The terminal block is

located inside the control box.

To open the control box:

1. Remove AND RETAIN the two screws on the

top edge of the cover panel. See Figure 3-1.

2. Swing the cover panel down to access the

interior of the box. The main electrical supply

terminal block is located on the back wall of

the box.

Figure 3-2

Swing panel

down to access

interior of box

Main electrical

supply terminal

block

Page 5

SECTION 3 - INSTALLATION

3.5 Main Electrical Supply Connection

WARNING!

Check that the circuit breaker/fused

disconnect is in the OFF position and

that the unit is switched off before

making the electrical utility connections.

IMPORTANT

In some cases, local codes dictate that

electrical supply connections be made only

by a certified professional.

1. Check that the incoming power leads are

of sufficient rating for the appliance’s

current draw. Amperage and minimum

supply wire specifications are shown on

the serial plate and on the electrical

information label.

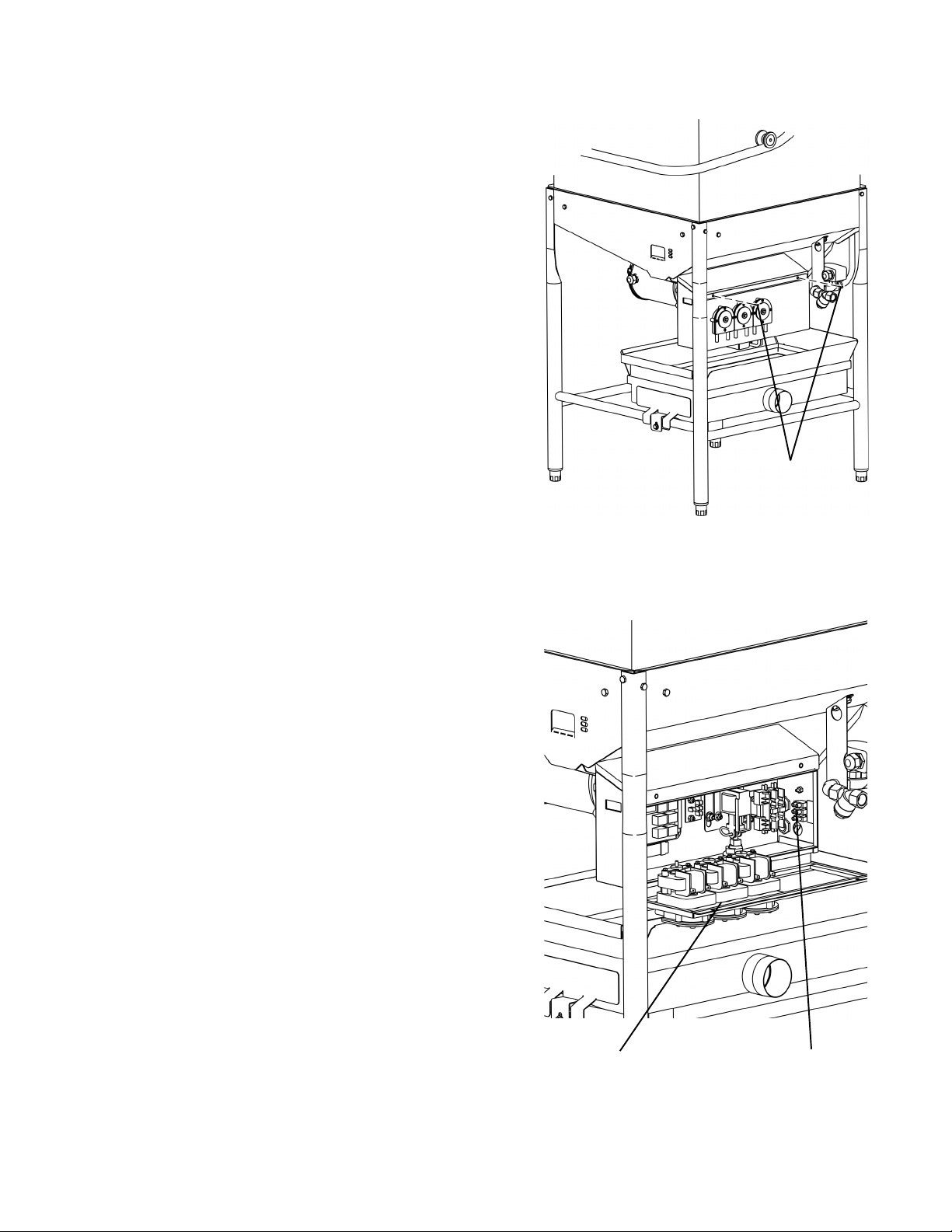

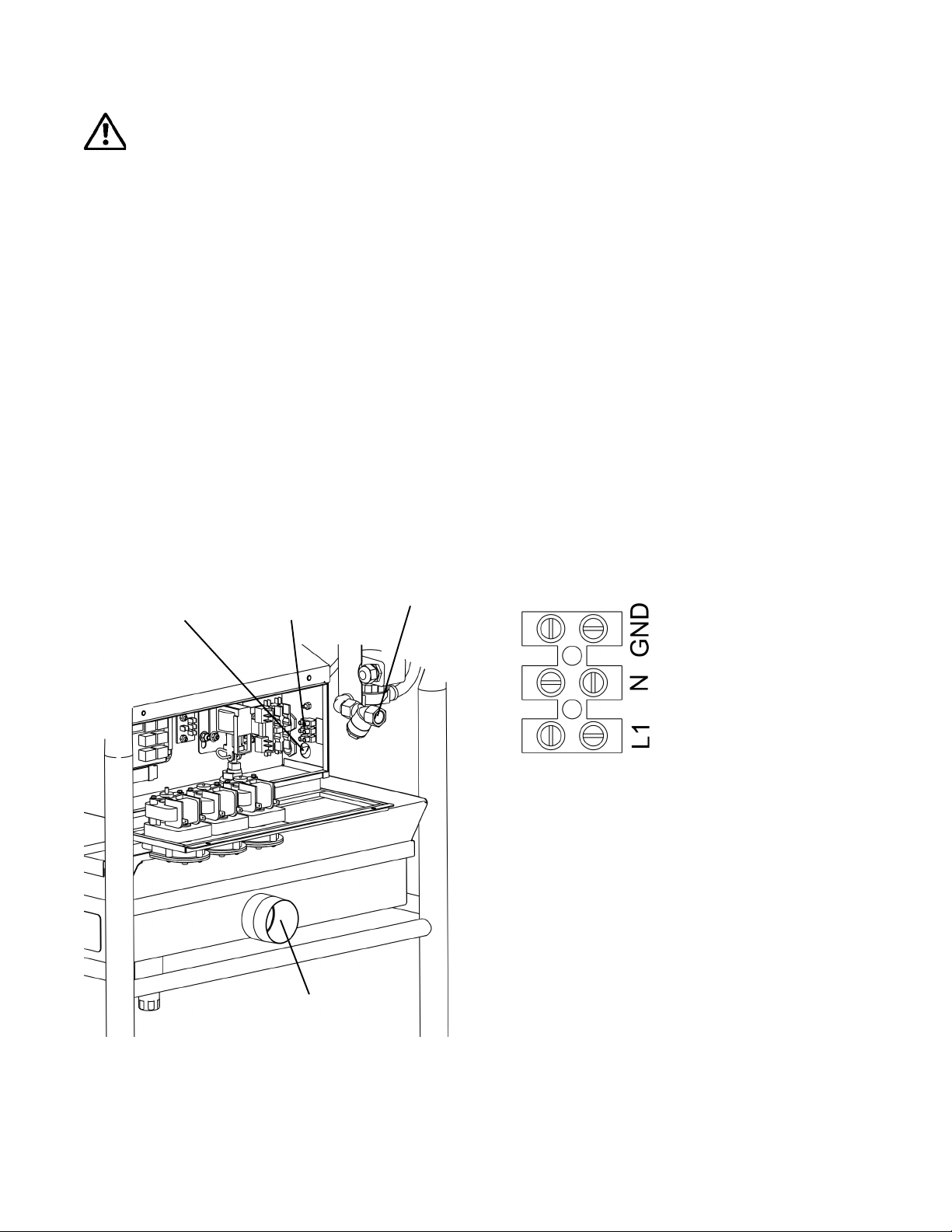

Figure 3-3: Utility connections

2. Check that the incoming power leads are

long enough to permit the unit to be

repositioned for servicing.

3. Locate the strain relief for the electrical

supply wiring at the lower rear of the

control box (Figure 3-3). Thread the

incoming supply leads through the strain

relief and to the main electrical supply

terminal block on the back wall of the box.

4. Refer to Figure 3-4 and the electrical wiring

diagram. Connect the power supply and

ground leads as indicated.

5. Adjust the strain relief to fasten the wiring

in place. You should leave enough slack

in the wiring to prevent stress on the

terminal connections.

Figure 3-4: Main electrical

supply connections

Electrical

supply

strain relief

Main electrical

supply terminal

block

Drain

Fresh water

connection

115V, 60 Hz, 1 Phase:

L1 = “hot” (line)

N = neutral

GND = ground

Page 6

ECTION 3 - INSTALLATION

S

3.6 Dispensing system overview

The CS 70 is equipped with liquid detergent,

rinse aid and sanitizer pumps. Each pump is

equipped with a supply tube that exits the rear

of the machine. A stiffener tube is also

provided for the ends of each tube. The end

of the tube with the stiffener should be

inserted and fastened into appropriate liquid

chemical containers (supplied by others).

During operation, chemicals are automatically

dispensed according to the timed settings for

each pump, which can be individually

configured as required. A proof of delivery

window provides a visual indication that

chemicals are being dispensed.

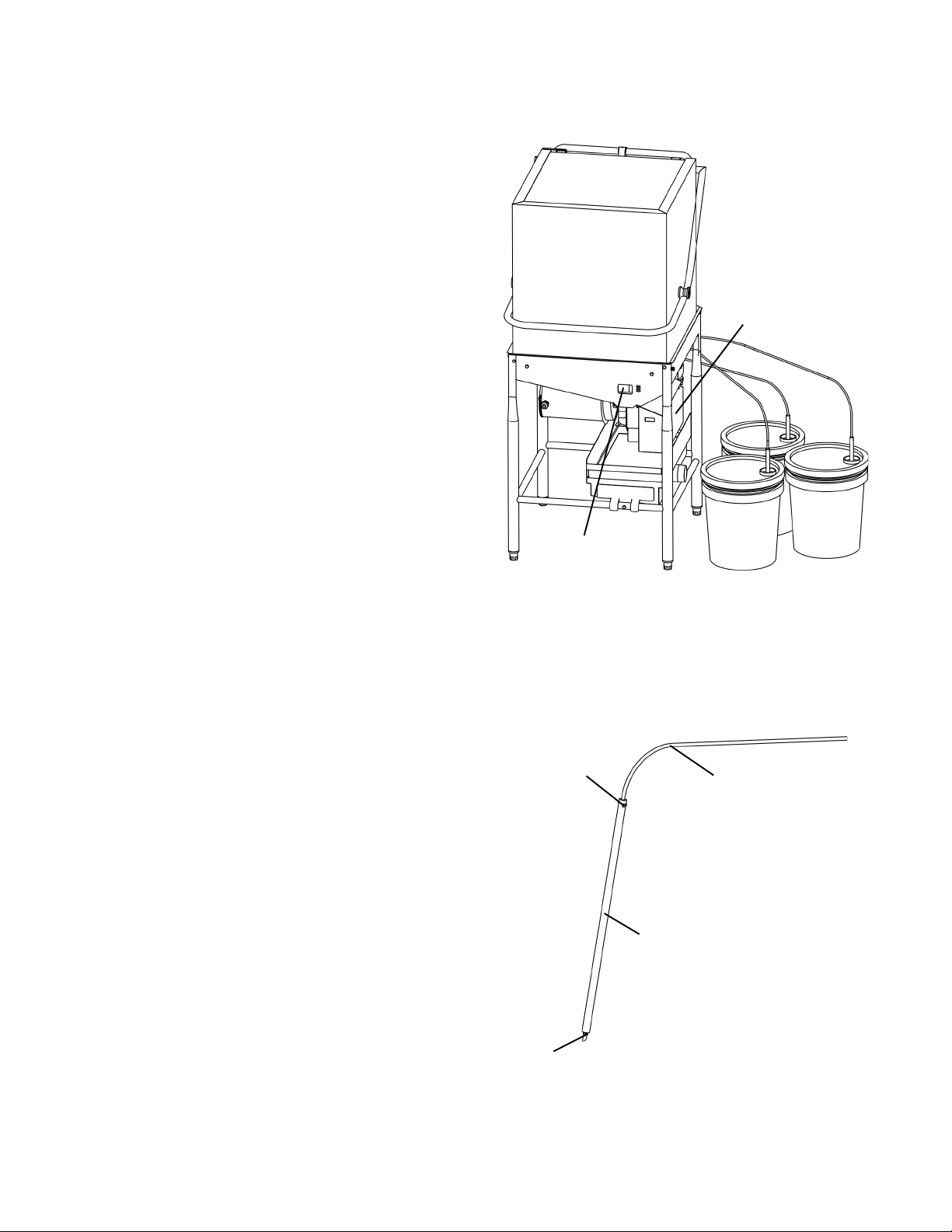

See Figure 3-5.

3.7 Connecting Chemical Containers

1. Check that all chemicals are compatible

with the unit. In particular, a commercial

(not a domestic) detergent MUST be used.

2 Check that the containers are correctly

installed or positioned according to the

manufacturer’s instructions.

3. Each chemical dispensing pump is

equipped with a supply tube that exits the

rear of the machine. A stiffener tube is also

provided for the end of each tube.

4. Assemble a stiffener tube onto the end of

each of the chemical tubes using two tie

wraps. See Figure 3-6.

5. Locate the RED liquid detergent tube,

marked DET. Insert the tube stiffener into

the liquid detergent container and fasten

it in place.

Figure 3-5: Dispensing

system components

Chemical

pumps are

inside

control box

Proof of

delivery

window

Chemical

containers

Figure 3-6: Assembling the

stiffener tubes

Tie

wrap

Flexible tube

(from rear of

machine)

6. Locate the BLUE liquid rinse aid tube

marked RIN. Insert the tube stiffener into

the liquid rinse aid container and fasten it

in place.

7. Locate the CLEAR or WHITE liquid

sanitizer tube marked SAN. Insert the tube

stiffener into the liquid sanitizer container

and fasten it in place.

Stiffener

tube

Tie

wrap

Page 7

SECTION 3 - INSTALLATION

3.8 Fresh Water Supply Connection

CAUTION

Before connecting the water supply, the line

MUST be flushed clean of all debris, including

(but not limited to) pipe sealant, metal

particles, solder, etc. This debris can damage

the appliance.

IMPORTANT

In some cases, local codes dictate that water

supply connections be made only by a

certified professional.

1. Check that iron or other metal particles

cannot contaminate the fresh water

supplied to the dishwasher.

2. Check that the incoming water pressure

is within the acceptable range for the

appliance (maximum 100 psi, 6.89 bars).

3. Check the incoming water temperature.

MEIKO recommends a water temperature

of 140°F/60°C for optimum operation.

4. Check the incoming water hardness.

MEIKO recommends a hardness of 4-6

grains per U.S. gallon.

5. Because the water inlet incorporates a “Y”

strainer, an additional “Y” strainer in the

water supply is unnecessary unless

required by local, national or international

codes.

6. Connect the customer-supplied water line

to the street elbow fitting on the fill

assembly . Use a sealing compound on the

threads to ensure that no leaks are present

in the connection. See Figure 3-7.

7. Check that the water line is long enough

to permit the unit to be repositioned for

servicing.

Figure 3-7: Fresh water connection

Fresh water

connection

Page 8

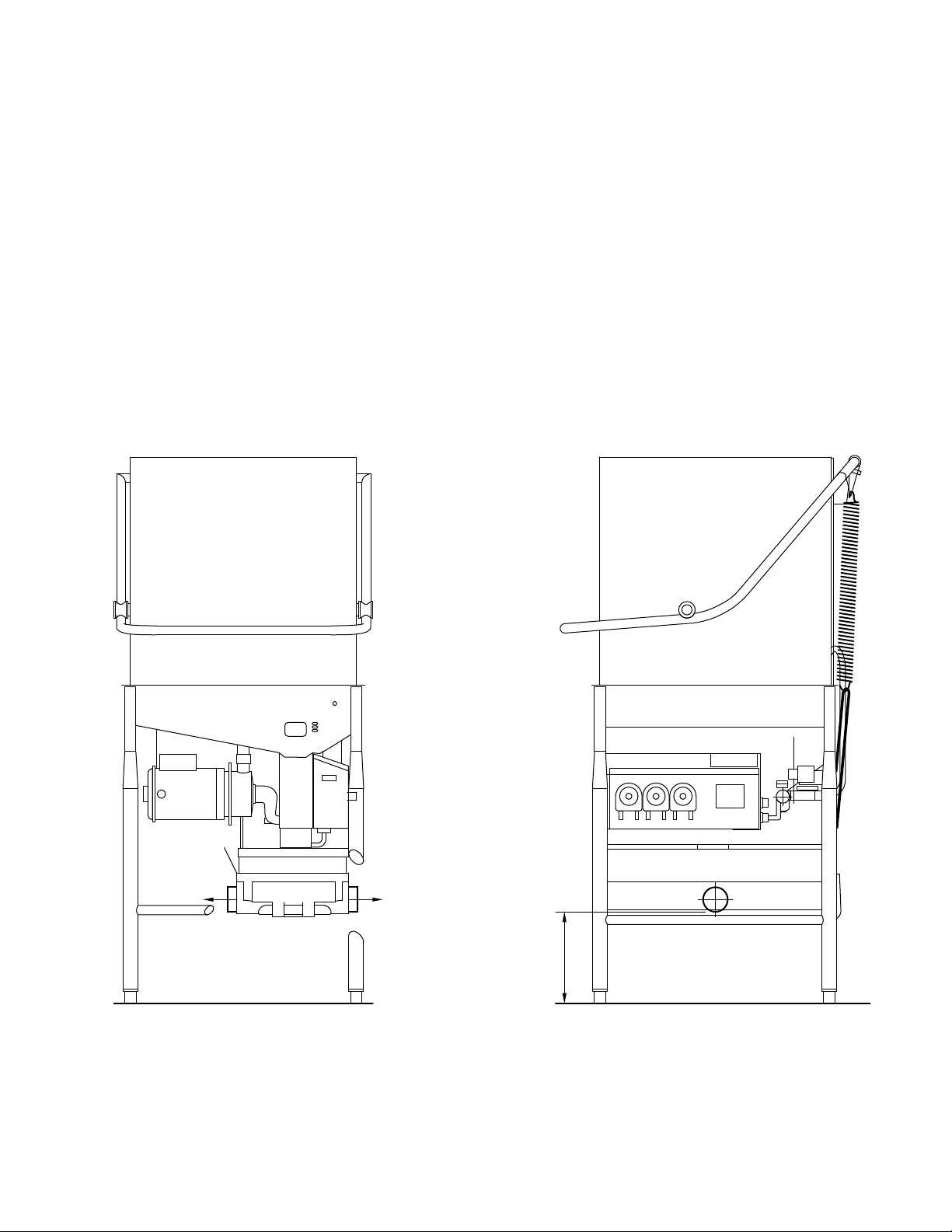

3.9 Drain Connection

ECTION 3 - INSTALLATION

S

1. Check that the floor drain is correctly sized

for the machine. A drain with a minimum

diameter of 2”/51mm is strongly

recommended.

2. Check the type of drain that will be used.

(wall or floor).

CAUTION

The CS 70 uses a gravity drain system.

No portion of the drain system may be

higher than 10-1/2” (267mm) A.F.F. to

ensure correct drain operation. See Figure

3-8.

Figure 3-8: Drain configuration and connection

3. Check the position of the machine drain

in reference to the intended facility drain.

If required, the drain pan can be removed

and reversed to change the position of the

drain. See Figure 3-8.

4. Route the drain line to the drain. In some

cases, a grease trap (supplied by others)

must be fitted into the waste water line. If

this trap is required for your installation,

check that it is present.

D

1

Drain faces

LEFT from

factory

If required,

remove and

reverse drain

pan so drain

faces RIGHT

D

2

No portion of

the drain

system may

be higher

than 10-1/2”

(267mm)

A.F.F.

10 1/2"

(267mm)

max. AFF

Page 9

SECTION 3 - INSTALLATION

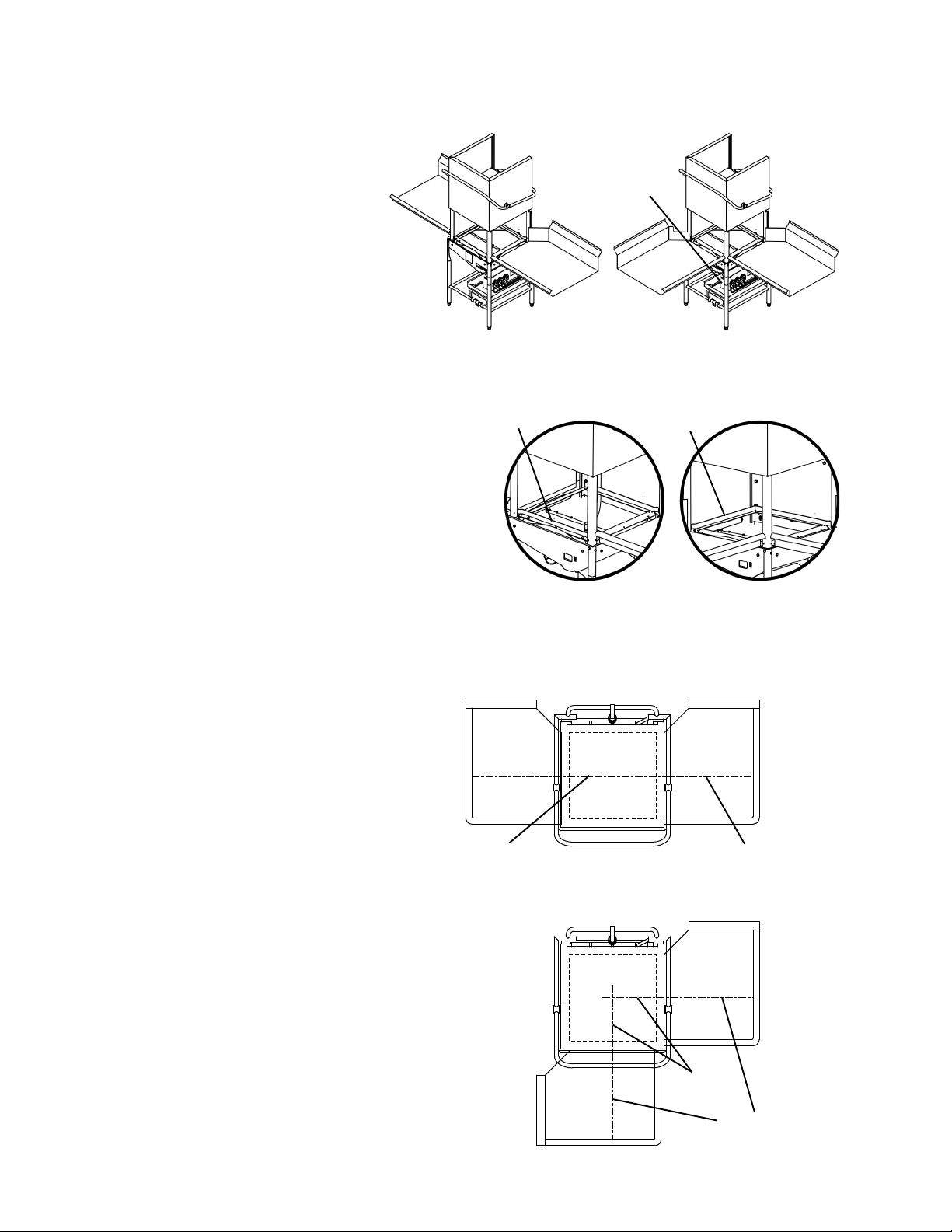

3.10 T abling Att achment

The CS 70 can be positioned in

either of two tabling configurations;

straight through, or in a corner

installation. See Figure 3-9.

1. IF the machine will be

positioned in a corner, perform

the following steps before

attaching the tables:

• Position the machine so that

the LEFT REAR corner of

the machine faces the

corner of the wall, as shown

in Figure 3-9. For corner

installations, this placement

is necessary to ensure that

the control panel can be

reached by the operator.

• Remove the FRONT rack

guide as shown in Figure 3-

9. The guide is held in place

by two screws. Replace the

guide on the LEFT SIDE

position in the 2 mounting

holes provided.

2. Position the machine and tables

as follows:

Figure 3-9: Straight-through and

corner tabling configurations

Control

panel

Straight-through

Before After

For a corner

installation ONLY,

move the rack rail

guide from the

FRONT position to

the LEFT SIDE

position.

Corner installation:

Left rear corner of machine

MUST face corner of wall to

ensure access to control panel.

Figure 3-10: Aligning the t able centerlines

with the dishmachine

• Check that the centerline of

the opening at the end of

each table is aligned with

the centerline of the rack

track of the machine. See

Figure 3-10.

• Check that the surface

height of each table

matches the height of the

rack track of the machine,

to ensure a smooth transition. The standard table surface height is 34” (864mm).

• Check that the machine is

level.

Page 10

Centerline of

rack track

Straight-through installation

Corner installation

Centerline

of rack track

Centerline of

table opening

Centerline of

table opening

FRONT OF

CS 70

SECTION 3 - INSTALLATION

The height of the machine, and of most

tables, can be adjusted by rotating the feet

at the end of the legs.

CAUTION

After adjusting the height of the machine,

always check that it is level to ensure

proper operation.

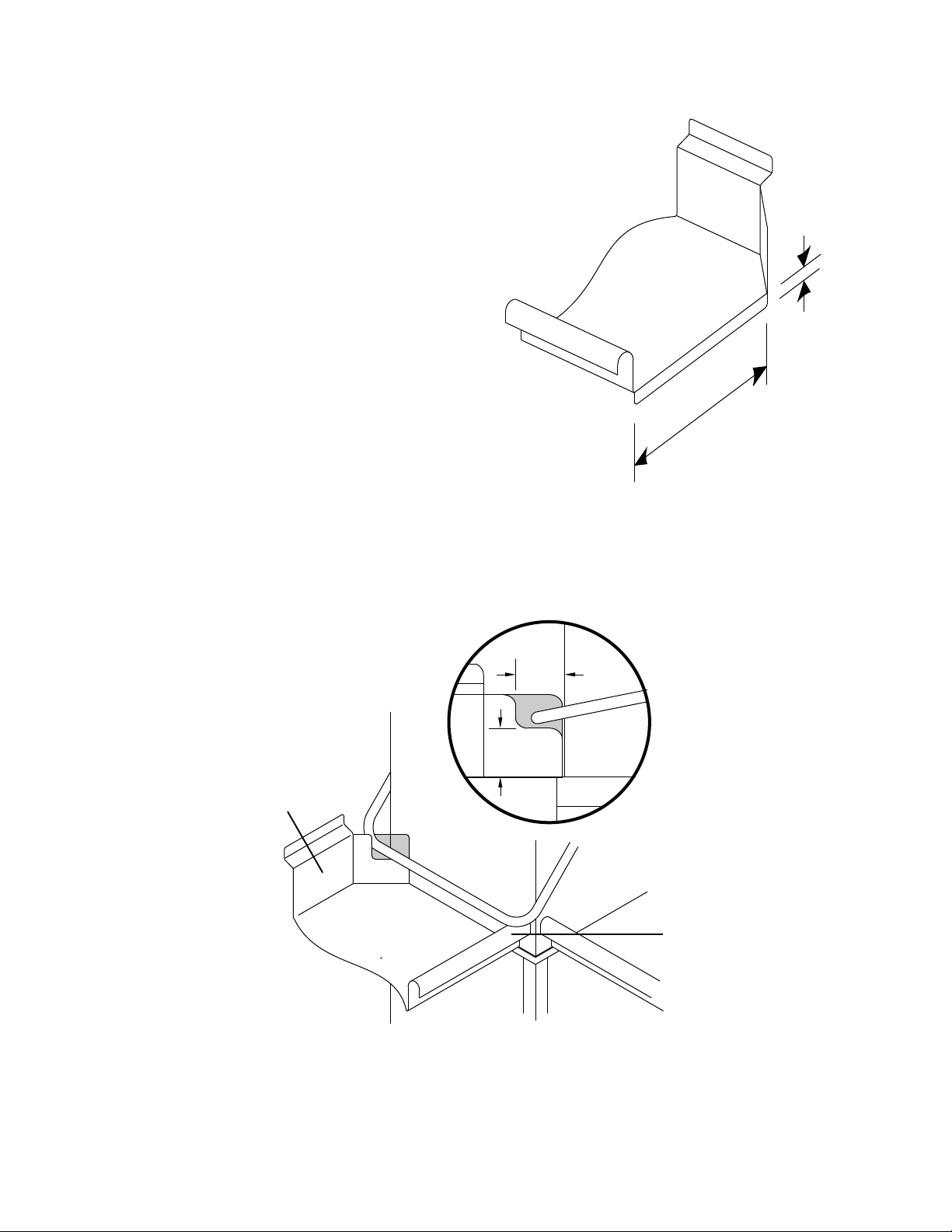

3. Position each table lip-in at the machine.

Be sure to seat the lip-in against the inner, vertical mounting surface. The lip-in

flange should be no more than 1” in height

as shown in Figure 3-11.

4. For corner installations, check that the

sides of the front table do not interfere with

the door handle when the door is closed.

If it is necessary to trim the table sides to

clear the handle, refer to Figure 3-12.

5. After the tables have been positioned

correctly, secure them to the machine

using silicone sealant.

Figure 3-11: Tabling attachment

Turndown

lip-in

flange

1” (25mm)

max.

20-1/4”

(515mm)

recommended

Figure 3-12: Door handle clearance for corner installations

(127mm), cut out as

shown to clear door

Backsplash

If backsplash is

higher than 5”

hande.

5" (127mm)

from front

of door

panel

5" (127mm)

max

Front-side cutout is

only necessary if

top of rolled edge is

more than 5”

(127mm) above

tabletop.

NOTE

An optional false panel is available to prevent splashing onto the walls or floor. The false

panel may be used with either straight-through or corner tabling configurations. Mounting

instructions are provided with the false panel. Contact MEIKO Customer Service at

1-800-55-MEIKO (1-800-556-3456) to order.

Page 11

ECTION 3 - INSTALLATION

S

3.11 Final Assembly

1. Check and tighten all electrical terminal

screws.

2. Replace the control box cover panel and

fasten in place with its two screws (Figure

3-1).

3. Switch the circuit breaker/fused

disconnect to the ON position. Be sure to

prime the chemical pumps and check for

correct chemical concentration before

operating the unit.

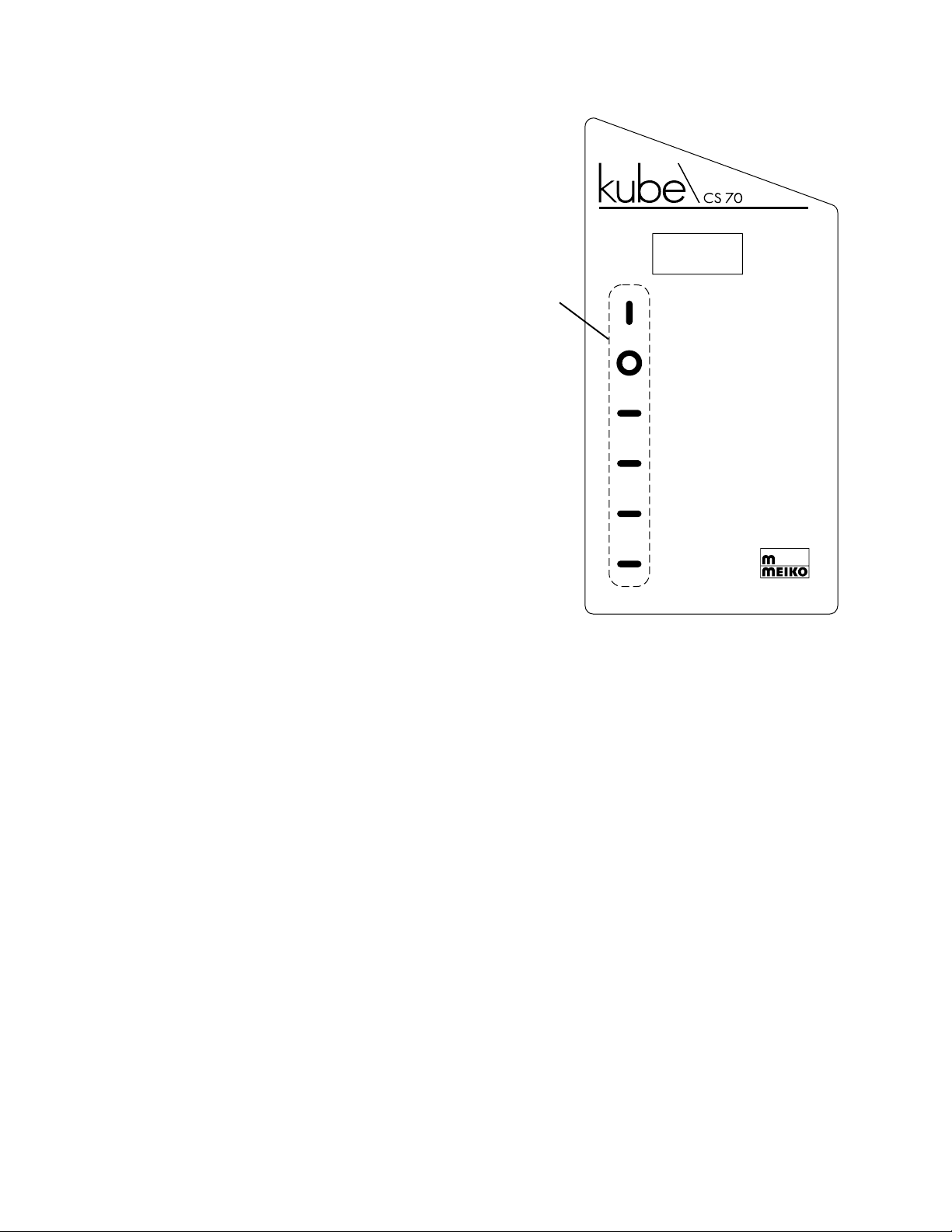

3.12 Priming the Liquid Detergent, Rinse

Aid and Sanitizer Lines

The chemical supply lines must be primed

before operating the unit. Keys are provided

on the control panel for this purpose. The

active area for each key is the symbol just to

the left of the text description. See Figure 3-

13.

1. Turn the machine on by pressing the ON/

FILL button.

Figure 3-13: kube\CS 70 control panel

MIN. 120° F / 49°C

Always press the

keys to the left of

the text (not the

text itself)

ON / FILL

EN MARCHE / REMPLIR

ENCENDIDO / LLENADO

OFF / DRAIN

ARRÊT / ÉVACUER

APAGADO / DRENAJE

DELIME

DÉTARTRER

DESCALCIFICAR

DETERGENT

DÉTERGENT

DETERGENTE

RINSE AID

AGENT DE RINÇAGE

ADITIVO DE ENJUAGUE

SANITIZER

DÉSINFECTANT

DESINFECTANTE

2. Prime the detergent pump. Press the

DETERGENT key twice, rapidly. The

pump will prime for 40 seconds and

automatically turn off.

3. Prime the rinse aid pump. Press the

RINSE AID key twice, rapidly. The pump

will prime for 5 minutes and automatically

turn off.

4. Prime the sanitizer pump. Press the

SANITIZER key twice, rapidly. The pump

will prime for 40 seconds and

automatically turn off.

5. If necessary, the pumps can be manually

primed for any length of time desired by

holding down the appropriate button.

Page 12

SECTION 3 - INSTALLATION

3.13 Checking for Correct Chemical

Concentration

The normal factory settings for chemical

injection are:

• Detergent - 0.256 oz. per gallon of wash

water (2.0 ml per liter).

• Rinse additive - 0.0256 oz. per gallon of

rinse water (0.2 ml per liter).

• Sanitizer - titrated using sodium

hypochlorite (NaClO) to 50 ppm minimum.

Other chemical sanitizing solutions

(iodine, etc.) may be used if permitted by

local, national and international codes.

• These settings are factory defaults, but all

settings used should always be checked

to ensure proper operation.

T o check if the normal settings are correct for

your chemicals, RUN THREE EMPTY

LOADS to completely cycle the water supply

and obtain accurate test results. This will only

take a few minutes. Then, run a sample load

with soiled ware and examine the results.

IMPORTANT

In all cases, any adjustments of the chemical

injection settings are to be performed either

by a chemical leasing company professional,

or by a MEIKO authorized service agent.

Changes by unauthorized personnel may void

your warranty.

If you need to contact your Authorized Service

Agency, please contact MEIKO Technical

Support at 1-800-868-3840.

• If the detergent setting is too low , the ware

will not be adequately cleaned.

• If the rinse aid setting is too low, spotting

or streaking may occur on the ware.

• The sanitizer setting should be confirmed

by the chemical leasing company

professional using an approved method

(typically test strips are used).

• If too much detergent or rinse aid is added,

the extra chemicals will be wasted. This

is often difficult to detect except by

determining how long your chemical

supplies last. If the chemicals are being

exhausted quickly , you may need to have

the chemical concentration adjusted.

• If it is necessary to adjust any of the

chemical injection settings, refer to

Section 4, Programming for instructions.

Page 13

SECTION 4 - PROGRAMMING

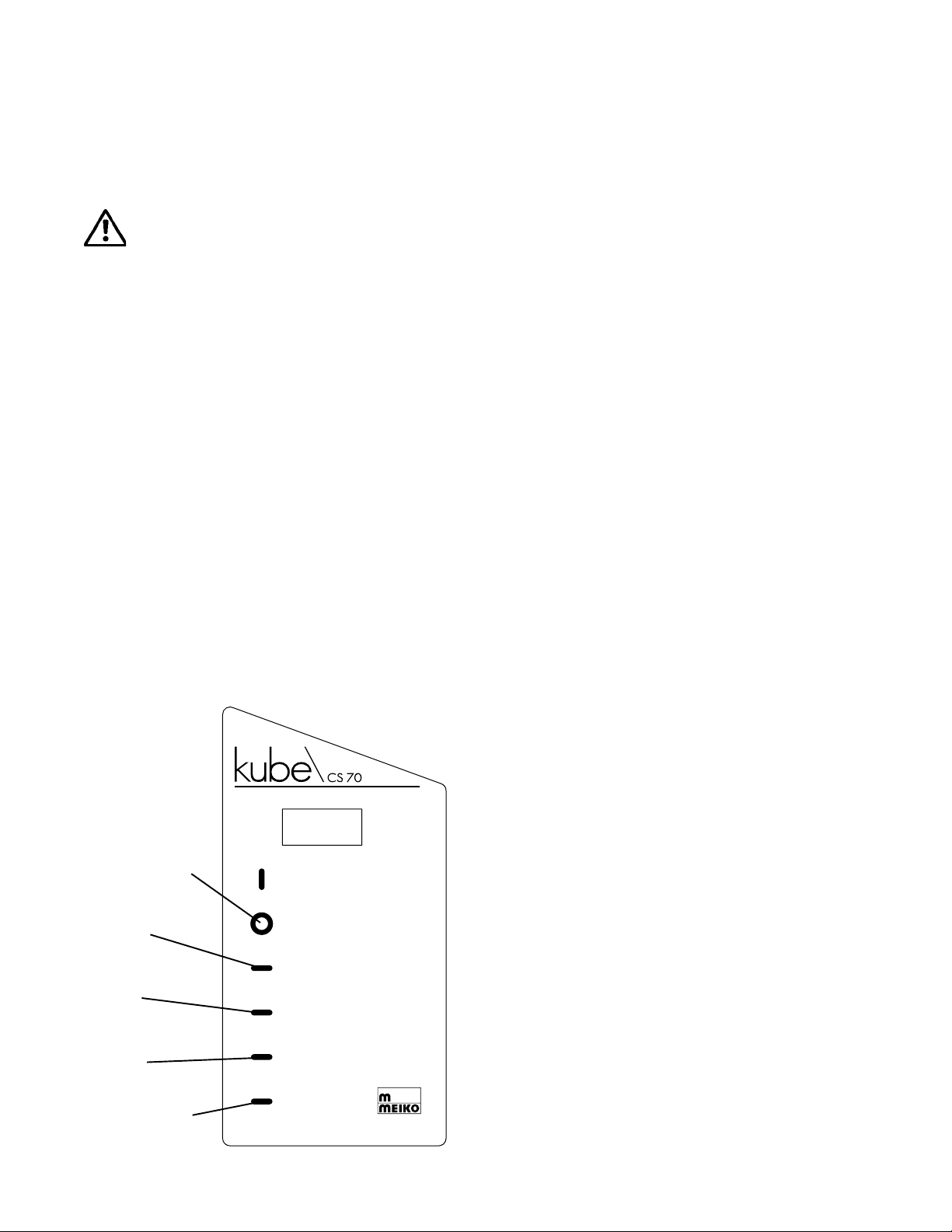

4PROGRAMMING

Before operating the machine, it may be

necessary to access the programming mode

of the CS 70 controller to select the desired

options and adjust the chemical concentration.

WARNING!

It is possible to select settings in

programming mode that may result in

ware that is not correctly washed or

rinsed. Always ensure that correct

settings are selected!

To access programming mode:

1. Check that the circuit breaker/fused

disconnect is in the ON position.

2. Check that the machine is turned OFF. If

necessary press the OFF/DRAIN key and

wait for the machine to drain.

3. Press and hold the SANITIZER button

until the machine enters programming

mode.

NOTE

If the machine is not turned off first,

pressing the SANITIZER button will simply

prime the sanitizer pump. It is not possible

to enter programming mode with the

machine already turned on.

Figure 4-1:

Control panel

in

programming

mode

Toggle to

previous

function

Toggle to

next

function

Toggle to

previous

value

Toggle to

next

value

Save

changes

and exit

Page 14

MIN. 120° F / 49°C

ON / FILL

EN MARCHE / REMPLIR

ENCENDIDO / LLENADO

OFF / DRAIN

ARRÊT / ÉVACUER

APAGADO / DRENAJE

DELIME

DÉTARTRER

DESCALCIFICAR

DETERGENT

DÉTERGENT

DETERGENTE

RINSE AID

AGENT DE RINÇAGE

ADITIVO DE ENJUAGUE

SANITIZER

DÉSINFECTANT

DESINFECTANTE

Once the machine is in programming mode:

• Press the OFF/DRAIN and DELIME keys

to scroll up and down through the functions.

• Press the DETERGENT and RINSE AID

keys to change the value/state shown.

• Press the SANITIZER key again to save

changes and exit programming mode. The

machine will then drain and turn off.

The programmable functions available are:

1. Fill Time

Length of fill in seconds. Selectable from 1-20.

2. Drain/Fill

Length of drain in seconds. Selectable

from 0.1-5.0.

3. Detergent

Run time for detergent pump (per cycle)

in seconds. Selectable from 0.1-20.0

(approx. flow rate is1.8 mL/sec).

4. Sanitizer

Run time for sanitizer pump (per cycle) in

seconds. Selectable from 0.1-10.0

(approx. flow rate is 1.8 mL/sec).

5. Rin. Aid

Run time for rinse aid pump (per cycle) in

seconds. Selectable from 0.1-10.0

(approx. flow rate is 0.25 mL/sec).

6. TDrain (temperature)

Selects the temperature for the (optional)

Temp Safe automatic drain/refill feature. If

enabled, the wash tank temperature is

checked whenever a cycle starts. If it is

below the temperature chosen here, the

machine will drain and refill before washing.

Selectable from 100-130 in degrees F.

Enabled or disabled by function 8, below .

NOTE

If the machine is configured to display

temperatures in degrees Celsius (C), the

technician must first translate the desired

temperature into degrees F to enter it here.

7. Temp C/F

Select to display temperatures in degrees

Fahrenheit (F) or Celsius (C).

8. TDrain (enable/disable)

Enables or disables the Temp Safe

automatic temperature-based drain/refill

feature, using the temperature selected

in function 6 above.

9. Cycle

Selects one of two approved total cycle

times for the machine. Choices are long

(90 sec - default) or short (72 sec).

Loading...

Loading...