Meiko B-US 281 LPW General Manual

HOT WATER

SANITIZING

B-US 281 LPW

FLIGHT-TYPE

WAREWASHERS

Meiko's flight-type conveyors are the ideal choice for highvolume applications. They feature dramatically improved

water savings and Meiko’s exclusive Chemical Savings

System (CSS) that reduces detergent consumption from

30-50 percent.

Other standard features include computer-positioned wash

and prewash arms that are pre-assembled into easilyremoved manifolds. Nozzles are slotted and concave to

minimize clogging, and feature captivated end caps which

can’t be lost during cleaning. A double-wall, insulated, flush

stainless steel exterior is present on all sides to conserve

energy and improve the working enviroment. Meiko’s

exclusive, optional Waste Air Heat Recovery System is

available on all models. This system eliminates the need for

the final hot water rinse to be supplied by an external water

heater, and dramatically improves energy efficiency.

As with all products synonymous with the name “Meiko,” engineering excellence, manufacturing quality and performance

come to the forefront in the B-US 281 LPW flight machine.

B-US 281 LPW

Model B-US 281 LPW includes: prewash section, wash section, pumped auxiliary rinse zone, pumped fresh water final

rinse.

Standard Features:

• Low NSF-rated water consumption

• High capacity

• Large opening (21-5/8” H x 28-1/2” W) accommodates

sheet pans and other large ware

• Pumped auxiliary rinse

• Pumped fresh water final rinse

• Built-in booster heater (steam or electric)

• Standard Chemical Savings System (CSS) Basic reduces

detergent consumption by up to 30%

• Flush stainless steel exterior panels with double-wall,

insulated construction

• Central control panel with simple electro-mechanical controls

• Start/stop controls at both ends of the machine

• Two-speed conveyor - adjustable during operation to

accommodate varying levels of soil

• Stainless steel prewash and wash pump assemblies with

vertically-mounted, self-draining pumps and powerful 3 hp

motors

• V-shaped prewash and wash tanks for faster draining and

easier cleaning

• Block-manifold wash arms for fast removal and cleaning

• Tethered or “captivated” wash arm end caps

• Slotted, concave, non-clogging wash arm nozzles

• Large, balanced front access doors stay open without latching

• Contacts for external fan control, detergent and rinse aid

dispensing systems

Options:

• Waste Air Heat Recovery System - utilizes heat generated

by the machine to heat the incoming fresh water. This

utilizes “free” energy, eliminates the need for an external

boiler or water heater, and allows the machine to use an

incoming water supply with temperatures as low as 50°F

• CSS Top - additional pre-flushing system prior to the

prewash, that includes cyclone separators to actively

remove food soil from the recirculated water in the machine.

The additional pre-flushing nozzles help to reduce the need

for thorough pre-scrapping of ware by the dishroom staff.

In addition, reducing the overall soil level of the wash water

improves washing performanceand reduces detergent

consumption by up to 50%

• Steam or electric tank/booster heat

• Single blower dryer (steam or electric)

• Dual blower dryer (steam or electric)

• Low-ceiling configuration (side vent and lower-opening front

access doors)

• Split, hinged front access doors

• Load and unload ends in various lengths

• Conveyor belts in varying configurations to accommodate

special ware

B-US 281 LPW • Updated 8-09 Meiko • 1349 Heil Quaker Blvd. • La Vergne, TN 37086 • (800) 55-MEIKO • FAX (615) 399-6620 • www.meiko.us

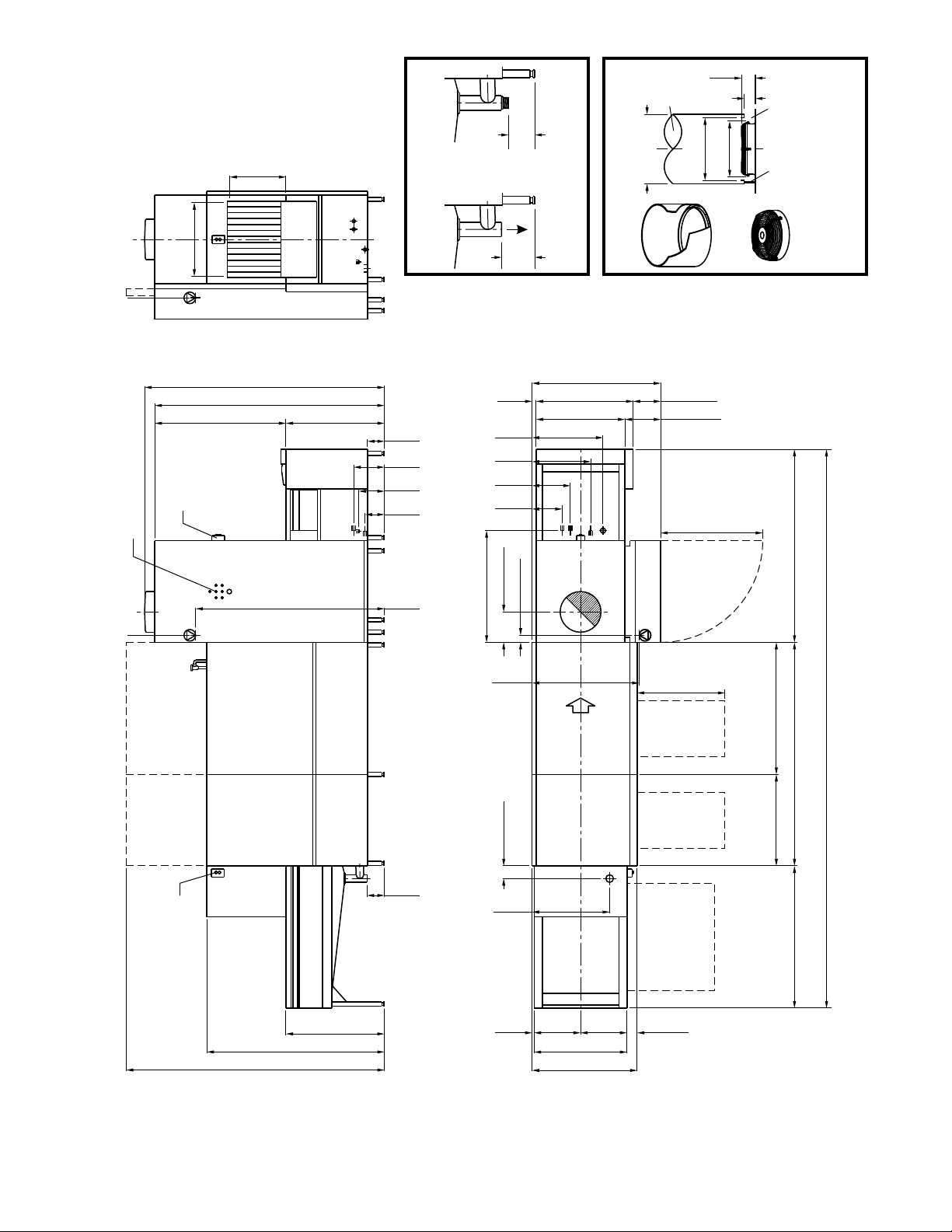

on-off

controls

control panel

on-off

controls

H,C

CR

D

HH

S

CRCR

C

D

6-1/2"

[165mm]

3' 2" [965mm]

7' 4-5/8" [2250mm]

7' 8-1/2" [2350mm]

3' 5-3/8"

[1050mm]

2' 5-7/8"

[760mm]

2' 11-3/8" [900mm]

7' 2-5/8" [2200mm]

4-7/8" [125mm]

2-3/4" [70mm]

11-3/4" [300mm]

3' 7-1/4" [1100mm]

1' 2-3/4"

[375mm]

1' 10-5/8"

[575mm]

2' 3-3/8"

[695mm]

1' 1-3/4" [350mm]

1-5/8"

[40mm]

10-5/8" [270mm]

3' 1-3/8" [950mm]

4' 1-5/8" [1260mm]

4' 3-1/8" [1300mm]

4' 2-5/8" [1285mm]

6-3/4"

[170mm]

7-1/2"

[190mm]

9-7/8"

[250mm]

11-3/4"

[300mm]

2' 10-1/4" [870mm]

11-5/8"

[295mm]

6' 7/8"

[1850mm]

D

2' 4-1/2" [724mm]

horizontal

clearance

3' 2" [965mm]

5' 8-1/2" [1740mm]

8' 3-5/8" [2530mm]

1' 5-7/8"

[455mm]

3/4"

[20mm]

3-7/8"

[100mm]

1' 5-7/8"

[455mm]

3' 4-1/2" [1030mm]

2' 11-7/8" [910mm]

S

H

C

CR

1' 9-5/8" [550mm]

vertical clearance

Load section length

(L1)

Unload section length

(U1)

B-US 281 LPW, Left-to-Right

2' 9-7/8" [860mm]

recommended for

scrap screen removal

Vent shroud

(supplied

by customer)

Machine

exhaust vent

Ø 20" or 500mm

Ø 18” or 450mm

Ø 16" or

400mm

Gap permits

room air to

enter vent

shroud

Condensation

can be drained

into machine

(drain supplied

by customer)

Vent shroud

(supplied by

customer)

3-1/8"

(80mm)

3-7/8"

(100mm)

Detail View: Vent

3' 3-3/8" [1000mm]

recommended for

service access

Detail View: Drain

D

D

6-3/4"

[170mm]

Directly

above floor

drain

2" NPT

adapter

(supplied)

or

5-1/2"

[140mm]

Standard machines:

Machines with blower dryer:

All machines:

824 CFM

1059 CFM

+120 CFM room air

SS

Overall machine length = Load section length (L1) + Unload section length (U1) + Wash section length (7' 2-5/8"/2200mm)

Choose a load and unload section from the choices below.

Plan View

Front Elevation

Right Side Elevation

Approx. flow rate 57 gpm (216 liters/min).

B-US 281 LPW • Updated 2-07 Page 2

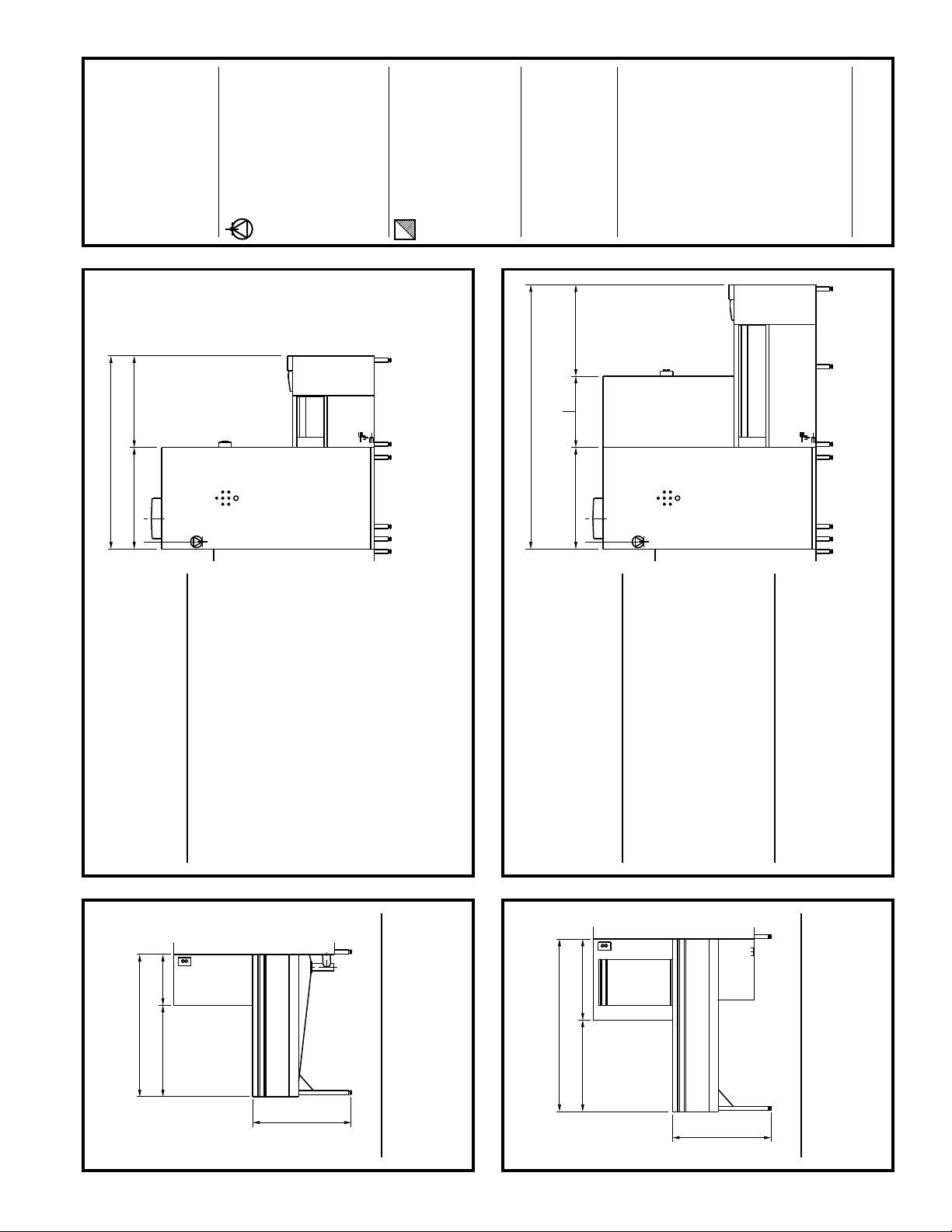

Load section length (L1) Clear load area (L2)

3' 7-1/4" (1100mm) 1' 11-5/8" (600mm)

4' 7-1/8" (1400mm) 2' 11-3/8" (900mm)

7' 10-1/2" (2400mm) 6' 2-3/4" (1900mm)

*7' 10-1/2" (2400mm) 6' 2-3/4" (1900mm)

* With optional 2' 6-3/8" (770mm) loading height

*

D

1' 7-5/8"

[500mm]

Load section length

(L1)

Clear load length

(L2)

Load Sections - CSS Basic

3' 2" [965mm]

Load section length (L1) Clear load area (L2)

4' 7-1/8" (1400mm) 1' 11-5/8" (600mm)

5' 6-7/8" (1700mm) 2' 11-3/8" (900mm)

*8' 10-3/8" (2700mm) 6' 2-3/4" (1900mm)

* With optional 2' 6-3/8" (770mm) loading height

*

Load Sections - CSS Top

D

2' 7-1/2" [800mm]

Load section length

(L1)

Clear load length

(L2)

3' 2" [965mm]

H,C

SS

CR

Unload section length (U1) Clear unload area (U2)

6' 2-3/4" (1900mm) 2' 11-3/8" (900mm)

8' 6-3/8" (2600mm) 5' 3" (1600mm)

9' 10-1/8" (3000mm) 6' 6-3/4" (2000mm)

10' 9-7/8" (3300mm) 7' 6-1/2" (2300mm)

11' 9-3/4" (3600mm) 8' 6-3/8" (2600mm)

13' 1-1/2" (4000mm) 9' 10-1/8" (3000mm)

16' 7/8" (4900mm) 12' 9-1/2" (3900mm)

Unload Sections - Standard

(no blower dryer)

3'3-3/8"[1000mm]

Unload section length

(U1)

Clear unload length

(U2)

Single blower dryer

Unload section length (U1) Clear unload area (U2)

8' 6-3/8" (2600mm) 2' 11-3/8" (900mm)

9' 10-1/8" (3000mm) 4' 3-1/8" (1300mm)

10' 9-7/8" (3300mm) 5' 3" (1600mm)

11' 9-3/4" (3600mm) 6' 2-3/4" (1900mm)

13' 1-1/2" (4000mm) 7' 6-1/2" (2300mm)

16-7/8" (4900mm) 10' 6" (3200mm)

Unload Sections -

with Blower Dryer

3' 3-3/8" [1000mm]

Unload section length

(U1)

Single blower dryer: 2' 3-1/2" [700mm]

Dual blower dryer: 5' 5" [1650mm]

Dual blower dryer

Unload section length (U1) Clear unload area (U2)

10' 9-7/8" (3300mm) 2' 1-5/8" (650mm)

11' 9-3/4" (3600mm) 3' 1-3/8" (950mm)

13' 1-1/2" (4000mm) 4' 5-1/8" (1350mm)

16-7/8" (4900mm) 7' 4-5/8" (2250mm)

H,C

SS

CR

Clear unload length

(U2)

D

Electrical connection

Machines with electric heat:

Machines with steam heat:

4 (four)

terminal blocks centered at location

shown.

1 (one)

terminal block at location shown.

Each terminal block is 4-wire with

ground (no neutral).

Opening(s) in the machine for the

supply lines are NOT provided and

should be executed on-site using

appropriate strain relief device(s).

Individual

disconnect with lockout/tagout strongly

recommended for each supply

(provided by customer).

Vent connection

Indirect connection to machine required

to avoid negative pressure inside

dishwasher. See

The connection must be corrosion-

resistant and frost-free. In particular,

provision must be made to prevent air

temperatures of 32°F/0°C or colder

from reaching the machine at any time.

A provision for draining moisture from

the waste air pipe is STRONGLY

RECOMMENDED.

Detail View: Vent.

Warm water connection

Used only for initial fill

Used for both initial fill and final rinse

on units with

Waste Air Heat Recovery System.

(single water connection) on all other

machines.

3/4" NPT, 110-140°F (43-60°C), 15-25

PSI

Cold water connection

Used only for final rinse on units

equipped with Waste Air Heat Recovery

System. Not present on other units.

1/2" NPT, 50°F (10°C), 15-25 PSI

C

H

Utilities

Steam connection

2" NPT, 15-30 PSI (1-2 bars).

For steam pressures below 15 PSI (1

bar), contact the factory. For pressures

above 30 PSI (2 bars), a regulator is

required (supplied by customer).

CONSTANT steam pressure is

REQUIRED. If supply pressure is

variable, use of a regulator is

REQUIRED (supplied by customer).

S

Condensate return connection

1-1/4" NPT. Condensate return line

MUST be pressure-free.

CR

Steam Utilities

(if so equipped)

Drain

2-15/16” (75mm) OD vertical, gravity-

fed drain outlet (HDPE piping). Optional

2" NPT male adapter supplied.

4” floor drain recommended. Additional

piping to drain (if so required) to be

supplied by customer.

Approx. flow rate 57 gpm (217 liters/min).

B-US 281 LPW • Updated 2-07 Page 3

Loading...

Loading...