Meiko B-US233LPW User Manual

HOT WATER SANITIZING

MULTIPLE-TANK

B-US 233 LPW

FLIGHT TYPE

W AREWASHER

The clean solution

Special Features:

• Narrow-belt configuration more easily fits into tighter

spaces, while accommodating common ware items such

as racked items, cafeteria trays, plates, and bowls

• Three full heated wash tanks provide outstanding washing

performance, reducing the need for re-washing items and

providing greater capacity for food soil

• Dual-rinse design allows separate rinse and sanitization

areas for lower overall water consumption

• Pumped final rinse fully isolates the machine from

fluctuations in building water supply pressure, providing

more consistent results

• Rugged electro-mechanical controls are front-mounted

for convenience, with additional start/stop controls at both

ends of the machine

• Two-speed conveyor - adjustable during operation to

accommodate varying levels of soil

• CSS Basic (Chemical Savings System) reduces detergent

consumption by up to 30% by diverting used rinse water

into the prewash section, reducing food debris

contamination in the wash tank

Standard Features:

• Prewash tank with 3 HP (2.2 kW) pump

• Two wash tanks, each with 3 HP (2.2 kW) pump

• Recirculating rinse tank1 with 3 HP (2.2 kW) pump

• Auxiliary rinse zone with 3/4 HP (0.55 kW) pump

• Final rinse zone with 3/4 HP (0.55 kW) pump

• Built-in booster heater (steam or electric)

• 304-series stainless steel construction

• Fully automatic operation

• Front-sloping, V-shaped wash tank design increases

visibility and accessibility for cleaning, and improves tank

draining

• Double-wall insulated construction on front, top and back

improves operator safety, conserves heating energy, and

reduces noise and heat loss into the dishroom. Insulation

is fully waterproofed to eliminate heavy doors and

unsanitary waterlogging

• Standard lifting doors are full-width for each chamber.

Doors are balanced and spring-loaded to stay open

without latching

• Pumps are vertically-mounted to be self-draining and

easily serviced

• Block-manifold wash arms for fast removal and cleaning.

Wash arms feature slotted, concave nozzles to resist

clogging, and tethered (“captivated”) end caps

• Contacts for external fan control, detergent and rinse aid

dispensing systems

• Single-point drain and single-point indirect ventilation

connections

Page 1 • B-US 233 LPW • Updated 7-14 • MEIKO • 1349 Heil Quaker Blvd. • LaVergne, TN 37086 • (800) 55-MEIKO • www.meiko.us • sales@meiko.us

Optional Features:

• Waste Air Heat Recovery System - utilizes heat generated

by the machine as free energy to preheat the incoming

final rinse water. This improves efficiency and permits the

final rinse to operate from a cold water supply.

• CSS Top (Chemical Savings System) - replaces standard

CSS Basic system with a dedicated pre-flushing system

located prior to the prewash. CSS Top receives cooled

water from the auxiliary rinse zone, and pumps it over the

ware to remove food soil prior to entering the prewash.

Water is then reclaimed and filtered through cyclone

separators for improved soil removal performance. An

automatic, continuous rinsing spray removes soil buildup

from inside the loading section. CSS Top reduces the

need for physical scrapping as well as reducing wash

water contamination, which in turn reduces detergent

consumption by up to 50%.

• Steam or electric tank/booster heat

• Single blower dryer

• Dual blower dryer

• Load and unload sections in various lengths

• Conveyor belts in varying configurations to accommodate

special ware

• Drain water tempering

• Flanged, bolt-down feet

• Water hammer arrestor

• Single-point electrical connection (electrically-heated

machines only; standard on steam-heated machines)

1 Model B-US 233 LPW is approved by NSF as a multiple-tank dishwasher. The

recirculating rinse tank is a complete third wash tank. Some manufacturers

and/or models may refer to this as a power rinse tank.

This dishwasher is compliant with the Reduction of Lead in Drinking

Water Act (201 1) amendment to the Safe Drinking W ater Act (SDW A).

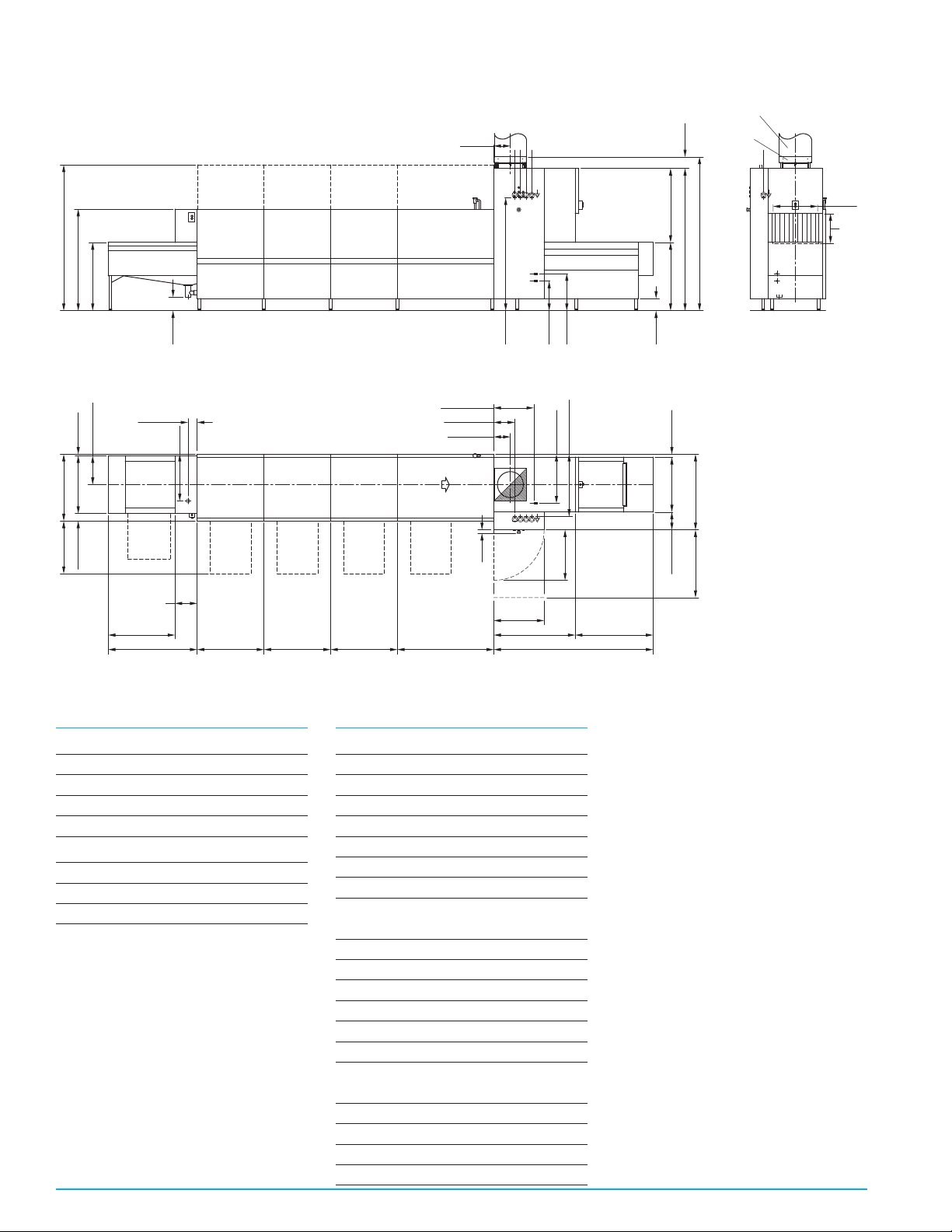

B-US 233 LPW, left to right - electric heat

1,2,3,4

8 7/8”

(225mm)

6'-5 1/2" (1968mm)

4'-5 7/8" (1370mm)

3'-0 1/4" (920mm)

D

17” (432mm)

Extraction via

outside dimension

square vent duct (by others).

Vent duct

C

L

by others

4321

W

C

See Vent Detail View (Page 6)

17” (432mm) inside

dimension collar

6 1/8”

(154mm)

3'-3 3/8" (1000mm)

6'-9 5/8" (2074mm)

6'-3 5/8" (1920mm)

3'-0 1/4" (920mm)

by MEIKO

1,2,3,4

C

L

Horizontal

clearance

1'-11 5/8"

(600mm)

Vertical

clearance

1'-3 3/4"

(400mm)

W

C

D

7 1/4"

(185mm)

4 7/8" (125mm)

3/4” (20mm)

1'-3 3/8” (390mm)

2'-6 3/4" (780mm)

2'-11 3/8" (900mm)

2'-4" (711mm)

3 7/8” (100mm)

CSS Basic (standard):

11 3/4" (300mm)

CSS Top (option):

2’-7 1/2” (800mm)

Clear loading ( )L

Load section ( )L

A

2’-0 3/4”

(630mm)

D

Prewash

2’-11 3/8” (900mm)

Wash 1

2’-11 3/8” (900mm)

Load sections (L) Clear loading (LA)

Standard CSS Basic:

2’-11 3/8” (900mm) 1’-11 5/8” (600mm)

3’-7 1/4” (1100mm) 2’-7 1/2” (800mm)

4’-7 1/8” (1400mm) 3’-7 1/4” (1100mm)

7’-10 1/2” (2400mm) 6’-10 5/8” (2100mm)

Optional CSS Top:

4’-7 1/8” (1400mm) 1’-11 5/8” (600mm)

5’-6 7/8” (1700mm) 2’-11 3/8” (900mm)

7’-10 1/2” (2400mm) 5’-3” (1600mm)

Recommended load sections:

• Single worker loading items while standing at the

end of the machine - LA = 1’-11 5/8” (600mm)

• Two workers loading items, each standing on

one side of the machine - LA = 3’ 7-1/4” (1100mm)

• Large items placed flat on the belt (totes, containers,

etc.) - LA = 2’ (600mm) longer than the item

• Operations with special delivery systems and/or

multiple workers loading items may require

extended load sections. Consult MEIKO for

assistance.

Notes on custom load sections:

Load sections with a lowered loading height are

available for specific applications, such as when the

loading area is underneath a table or tray conveyor.

Consult MEIKO for details.

5’

1’-3 3/4”

1’-7 5/8”

(400mm)

W,C

4321

Unload section ( )U

(500mm)

2'-9 1/8" (840mm)

2'-2" (660mm)

2'-2 3/4"

(680mm)

Wash 2

2’-11 3/8” (900mm)

1'-9 1/4" (540mm)

11 1/4" (285mm)

8 7/8" (225mm)

Recirculating rinse,

auxiliary rinse and

final rinse

4’-3 1/8” (1300mm)

2 3/8"

(60mm)

(1523mm)

Control panel

2’-2 3/4” (680mm)

Tunnel or blower dryer

Unload sections (U) Clear unloading (UA)

Standard - tunnel only [no blower dryer]:

6’-2 3/4” (1900mm) 3’-5 3/8” (1050mm)

7’-6 1/2” (2300mm) 4’-9 1/8” (1450mm)

8’-6 3/8” (2600mm) 5’-8 7/8” (1750mm)

9’-10 1/8” (3000mm) 7’-5/8” (2150mm)

10’-9 7/8” (3300mm) 8’-1/2” (2450mm)

13’-1 1/2” (4000mm) 10’-4” (3150mm)

16’-7/8” (4900mm) 14’-9 1/8” (4500mm)

Optional single blower dryer with 3’-7 1/4”

(1100mm)-long tunnel:

7’-6 1/2” (2300mm) 3’-11 1/4” (1200mm)

8’-6 3/8” (2600mm) 4’-11” (1500mm)

9’-10 1/8” (3000mm) 6’-2 3/4” (1900mm)

10’-9 7/8” (3300mm) 7’-2 5/8” (2200mm)

13’-1 1/2” (4000mm) 9’-6 1/8” (2900mm)

16’-7/8” (4900mm) 12’-5 5/8” (3800mm)

Optional dual blower dryer with 5’-7/8”

(1850mm)-long tunnel:

9’-10 1/8” (3000mm) 6’-2 3/4” (1900mm)

10’-9 7/8” (3300mm) 7’-2 5/8” (2200mm)

13’-1 1/2” (4000mm) 9’-6 1/8” (2900mm)

16’-7/8” (4900mm) 12’-5 5/8” (3800mm)

Clear unloading ( )U

6 1/2”

(165mm)

A

1 5/8" (40mm)

2'-5 1/8" (740mm)

3'-4 1/8" (1020mm)

9 1/2" (240mm)

3' (914mm) service

access recommended

All dimensions from

floor are +/- 1/2"

(13mm) due to

adjustable feet.

Recommended unload sections:

• Typical ware mix, limited space available - UA =

3’ 5-3/8” (1050mm)

• Typical ware mix, more space available - UA =

4’ 9-1/8” (1450mm) or longer for improved drying

• Large items placed flat on the belt (totes, containers,

etc.) - UA = at least 1’ (300mm) longer than twice

the length of the item

Notes on blower dryers:

A single blower dryer provides good results for plates,

cutlery and glassware in most cases.

A dual blower dryer is recommended for melamine

ware or plastics (trays, insulated items, etc.)

Extended-length blower drying tunnels are available

by special request, and may provide improved drying

results for some ware types. Consult MEIKO for

details.

Page 2 • B-US 233 LPW • Updated 7-14 • MEIKO • 1349 Heil Quaker Blvd. • LaVergne, TN 37086 • (800) 55-MEIKO • www.meiko.us • sales@meiko.us

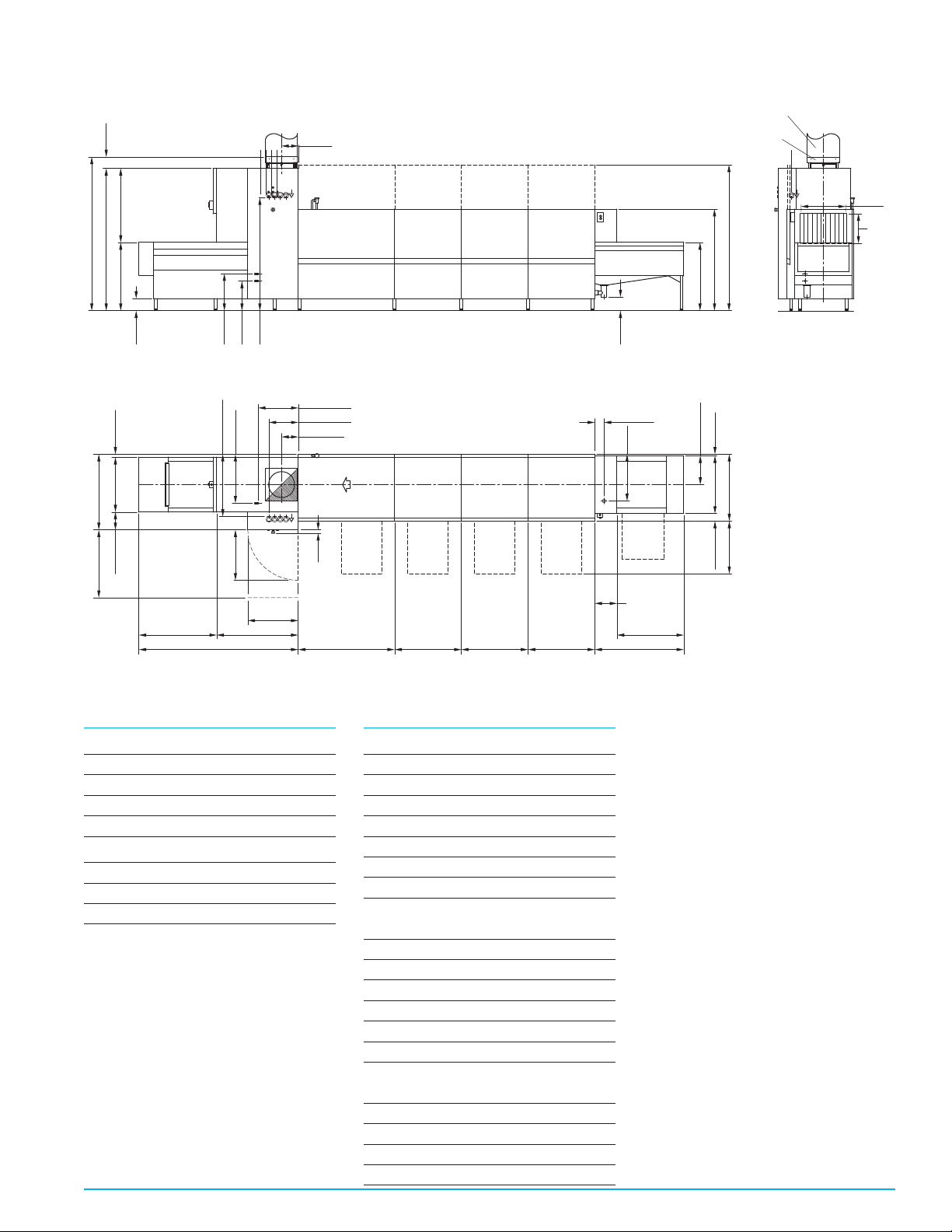

B-US 233 LPW, right to left - electric heat

/

(

)

1,2,3,4

6 1/8”

(154mm)

2074mm

3'-3 3/8" (1000mm)

8"

6'-9 5

6'-3 5/8" (1920mm)

3'-0 1/4" (920mm)

Vent duct

by others

C

L

8 7/8”

(225mm)

4321

W

C

17” (432mm)

Extraction via

outside dimension

square vent duct (by others).

See Vent Detail View (Page 6)

17” (432mm) inside

dimension collar

by MEIKO

6'-5 1/2" (1968mm)

4'-5 7/8" (1370mm)

D

3'-0 1/4" (920mm)

1,2,3,4

C

L

Horizontal

clearance

1'-11 5/8"

(600mm)

Vertical

clearance

1'-3 3/4"

(400mm)

W

C

D

6 1/2”

(165mm)

1 5/8" (40mm)

2'-5 1/8" (740mm)

3'-4 1/8" (1020mm)

9 1/2" (240mm)

3' (914mm) service

access recommended

Clear unloading ( )U

A

Unload section ( )U

Load sections (L) Clear loading (LA)

Standard CSS Basic:

2’-11 3/8” (900mm) 1’-11 5/8” (600mm)

3’-7 1/4” (1100mm) 2’-7 1/2” (800mm)

4’-7 1/8” (1400mm) 3’-7 1/4” (1100mm)

7’-10 1/2” (2400mm) 6’-10 5/8” (2100mm)

Optional CSS Top:

4’-7 1/8” (1400mm) 1’-11 5/8” (600mm)

5’-6 7/8” (1700mm) 2’-11 3/8” (900mm)

7’-10 1/2” (2400mm) 5’-3” (1600mm)

Recommended load sections:

• Single worker loading items while standing at the

end of the machine - LA = 1’-11 5/8” (600mm)

• Two workers loading items, each standing on

one side of the machine - LA = 3’ 7-1/4” (1100mm)

• Large items placed flat on the belt (totes, containers,

etc.) - LA = 2’ (600mm) longer than the item

• Operations with special delivery systems and/or

multiple workers loading items may require

extended load sections. Consult MEIKO for

assistance.

Notes on custom load sections:

Load sections with a lowered loading height are

available for specific applications, such as when the

loading area is underneath a table or tray conveyor.

Consult MEIKO for details.

5’

1’-3 3/4”

1’-7 5/8”

(400mm)

(500mm)

2'-9 1/8" (840mm)

2'-2" (660mm)

W,C

2'-2 3/4"

(680mm)

Control panel

2’-2 3/4” (680mm)

Tunnel or blower dryer

(1523mm)

1'-9 1/4" (540mm)

1’-3 1/2" (395mm)

8 7/8" (225mm)

4321

2 3/8"

(60mm)

Recirculating rinse,

auxiliary rinse and

final rinse

4’-3 1/8” (1300mm)

Wash 2

2’-11 3/8” (900mm)

Wash 1

2’-11 3/8” (900mm)

Prewash

2’-11 3/8” (900mm)

Unload sections (U) Clear unloading (UA)

Standard - tunnel only [no blower dryer]:

6’-2 3/4” (1900mm) 3’-5 3/8” (1050mm)

7’-6 1/2” (2300mm) 4’-9 1/8” (1450mm)

8’-6 3/8” (2600mm) 5’-8 7/8” (1750mm)

9’-10 1/8” (3000mm) 7’-5/8” (2150mm)

10’-9 7/8” (3300mm) 8’-1/2” (2450mm)

13’-1 1/2” (4000mm) 10’-4” (3150mm)

16’-7/8” (4900mm) 14’-9 1/8” (4500mm)

Optional single blower dryer with 3’-7 1/4”

(1100mm)-long tunnel:

7’-6 1/2” (2300mm) 3’-11 1/4” (1200mm)

8’-6 3/8” (2600mm) 4’-11” (1500mm)

9’-10 1/8” (3000mm) 6’-2 3/4” (1900mm)

10’-9 7/8” (3300mm) 7’-2 5/8” (2200mm)

13’-1 1/2” (4000mm) 9’-6 1/8” (2900mm)

16’-7/8” (4900mm) 12’-5 5/8” (3800mm)

Optional dual blower dryer with 5’-7/8”

(1850mm)-long tunnel:

9’-10 1/8” (3000mm) 6’-2 3/4” (1900mm)

10’-9 7/8” (3300mm) 7’-2 5/8” (2200mm)

13’-1 1/2” (4000mm) 9’-6 1/8” (2900mm)

16’-7/8” (4900mm) 12’-5 5/8” (3800mm)

7 1/4"

(185mm)

4 7/8" (125mm)

2’-0 3/4”

(630mm)

D

CSS Basic (standard):

11 3/4" (300mm)

CSS Top (option):

2’-7 1/2” (800mm)

Clear loading ( )L

Load section ( )L

3/4” (20mm)

1'-3 3/8” (390mm)

2'-6 3/4" (780mm)

3 7/8” (100mm)

A

2'-11 3/8" (900mm)

2'-4" (711mm)

All dimensions from

floor are +/- 1/2"

(13mm) due to

adjustable feet.

Recommended unload sections:

• Typical ware mix, limited space available - UA =

3’ 5-3/8” (1050mm)

• Typical ware mix, more space available - UA =

4’ 9-1/8” (1450mm) or longer for improved drying

• Large items placed flat on the belt (totes, containers,

etc.) - UA = at least 1’ (300mm) longer than twice

the length of the item

Notes on blower dryers:

A single blower dryer provides good results for plates,

cutlery and glassware in most cases.

A dual blower dryer is recommended for melamine

ware or plastics (trays, insulated items, etc.)

Extended-length blower drying tunnels are available

by special request, and may provide improved drying

results for some ware types. Consult MEIKO for

details.

Page 3 • B-US 233 LPW • Updated 7-14 • MEIKO • 1349 Heil Quaker Blvd. • LaVergne, TN 37086 • (800) 55-MEIKO • www.meiko.us • sales@meiko.us

Loading...

Loading...