Meiko B-US232 User Manual

B-US 231/232/233

SERIES

HOT WATER

SANITIZING

FLIGHT-TYPE

WAREWASHERS

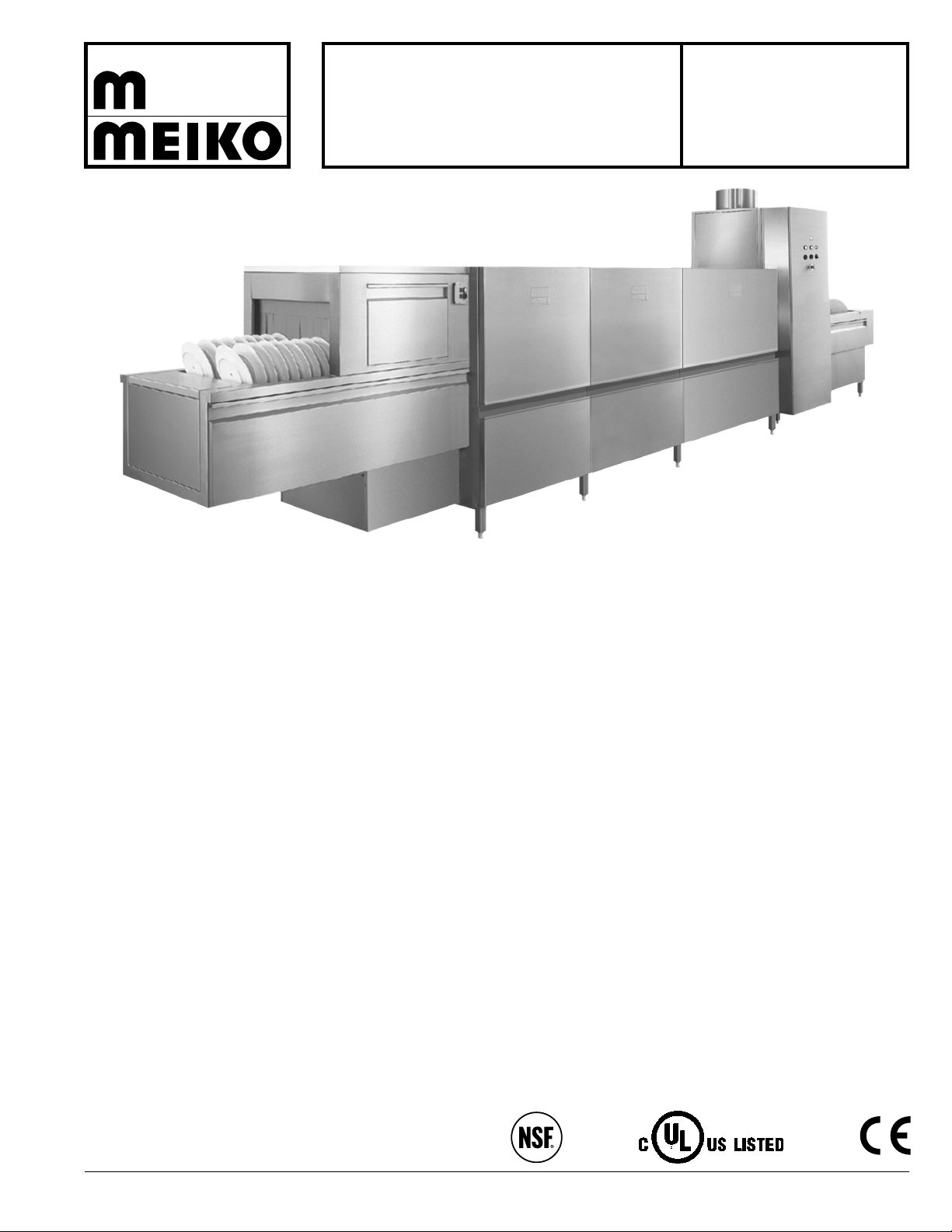

Meiko's flight-type conveyors are the ideal choice for high-volume applications. They feature dramatically improved water savings

and Meiko’s exclusive Chemical Savings System (CSS) that reduces detergent consumption from 30-50 percent. As with all products

synonymous with the name “Meiko,” engineering excellence, manufacturing quality and performance come to the forefront in the

B-US 23 Series flight machines.

• Model B-US 231 includes: wash section, pumped auxiliary rinse zone, pumped fresh water final rinse.

• Model B-US 231 PW includes: prewash section, wash section, pumped auxiliary rinse zone, pumped fresh water final rinse.

• Model B-US 231 LPW includes: large prewash section, wash section, pumped auxiliary rinse zone, pumped fresh water final rinse.

• Model B-US 232 LPW includes: large prewash section, wash section, recirculating rinse section, pumped auxiliary rinse zone,

pumped fresh water final rinse.

• Model B-US 233 LPW includes: large prewash section, two wash sections, recirculating rinse section, pumped auxiliary rinse

zone, pumped fresh water final rinse.

Exclusive Features:

• Optional Waste Air Heat Recovery System utilizes heat

generated by the machine to heat the incoming fresh water.

This utilizes “free” energy and allows the machine to use an

incoming water supply with temperatures as low as 50°F.

• Insulated double-wall construction on doors, front, top

and back

• Pumped auxiliary rinse supplements the pumped fresh

water final rinse

• Standard Chemical Savings System (CSS) Basic reduces

detergent consumption by 30% (based on Meiko’s low water

consumption)

• Optional CSS Top reduces detergent consumption by 50%

Options:

• Waste Air Heat Recovery System

• Single blower dryer (steam or electric)

• Dual blower dryer (steam or electric)

• CSS Top

• Load and unload ends in various lengths

• Steam or electric tank/booster heat

• Factory-installed external fan controller

B-US 23 Series • Updated 11-04 Meiko • 917 Airpark Center Drive • Nashville, TN 37217 • (800) 55-MEIKO • FAX (615) 399-6620 • www.meiko.us

Standard Features:

• Low NSF-rated water consumption

• High capacity

• Built-in booster heater (steam or electric)

• Central control panel with simple electro-mechanical controls

• Operator-activated start/stop controls at both ends of machine

• Two-speed conveyor

• Stainless steel wash pump assemblies with verticallymounted, self-draining pumps and powerful 3 hp motors

• V-shaped wash tanks for faster draining and easier cleaning

• Block-manifold wash arms for fast removal and easier cleaning

• Tethered or “captivated” wash arm end caps

• Slotted, concave, non-clogging wash arm nozzles

• Large, balanced front access doors stay open without latching

• Contacts for external fan control and external transport control

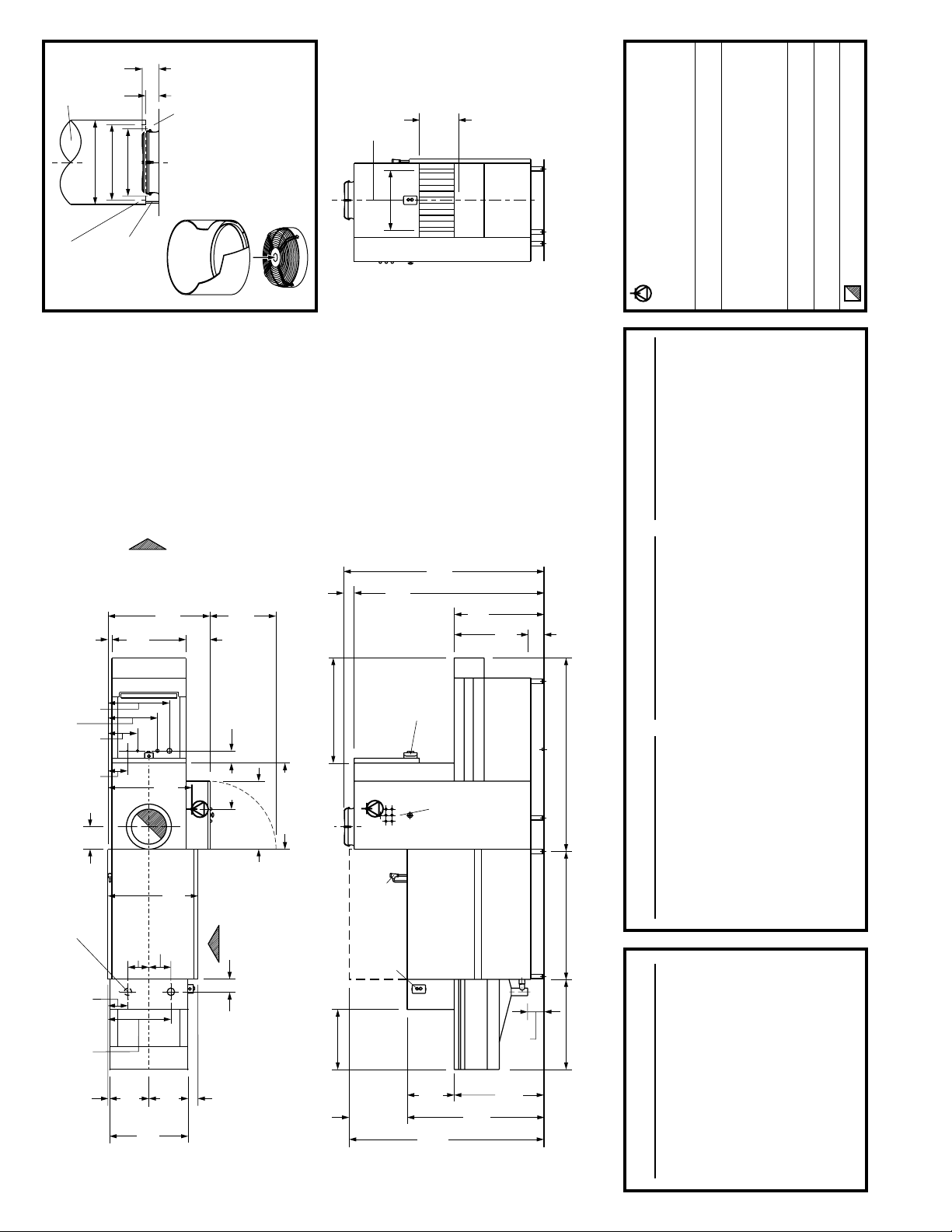

2' 2-3/4" (680mm)

3' 7-1/4" (1100mm)

2' 3-1/2"

(700mm)

Vent shroud

Left-to-Right machine shown.

Right-to-Left

machine is a

mirror

image.

All

dimensions from floor are

+/-

1/2" due to adjustable feet.

(supplied by

customer)

Condensation

trough

3-7/8"

(100mm)

3-1/8"

(80mm)

1' 7-5/8" (500mm) dia.

1' 5-3/4" (450mm) dia.

Condensation

can be drained

into machine

1' 3-3/4"

(400mm) dia.

(drain supplied

by customer)

Gap permits

room air to

SUPPLIED BY

CUSTOMER:

enter vent

Vent shroud to be

shroud

constructed with 1"

(25mm) trough to

VENT

collect condensation,

which can be

drained into machine

DETAIL

SUPPLIED WITH

MACHINE:

VIEW

Exhaust vent

1' 11-3/8"

Left-to-Right machine shown.

(600mm)

Right-to-Left machine is a

horizontal

clearance

mirror image.

All dimensions from floor are

+/- 1/2" due to adjustable feet.

passing height

1' 3-3/4" (400mm)

Electrical connection

Units with steam heat: Single terminal block at the location shown.

UTILITY CONNECTIONS

ELEVATION VIEW (RIGHT)

DUAL BLOWER DRYER

Unl (U1) Clear unload (U2)oad section

Units with electric heat: 4 (four) individual terminal blocks, approx.

2-1/2" (64mm) apart, centered on the location shown.

6' 7/8" (1850mm)-long drying tunnel:

Leads must be appropriate for electrical supply. Maximum wire

gauge #2 AWG.All connection points to be drilled during installation.

9' 10-1/8" (3000mm) 3' 9-1/4" (1150mm)

10' 9-7/8" (3300mm) † 4' 11" (1500mm) †

13' 1-1/2" (4000mm) 6' 2-3/4" (1900mm)

Drain

3" (76mm) IPS drain. 4" indirect floor drain recommended.

Water connection(s)

D

7' 6-1/2" (2300mm)-long drying tunnel:

16' 7/8" (4900mm) 12' 5-5/8" (3800mm)

10' 9-7/8" (3300mm) † 3' 3-3/8" (1000mm) †

Used only for initial fill

3/4" NPT. on units that equipped with

optional waste air heat recovery system. Used as single water

connection on all other units.

H

8' 10-3/8" (2700mm)-long drying tunnel:

13' 1-1/2" (4000mm) 5' 6-7/8" (1700mm)

16' 7/8" (4900mm) 8' 6-3/8" (2600mm)

Used only for final rinse

1/2" NPT. on units equipped with optional

waste air heat recovery system. Not present on other units.

C

13' 1-1/2" (4000mm) † 4' 3-1/8" (1300mm) †

16' 7/8" (4900mm) 7' 2-5/8" (2200mm)

Steam connection

Units with steam tank/booster heat only. 1-1/2" NPT.SCondensate return connection

10' 2" (3100mm)-long drying tunnel:

13' 1-1/2" (4000mm) † 2' 11-3/8" (900mm) †

16' 7/8" (4900mm) 5' 10-7/8" (1800mm)

Units with steam tank/booster heat only. 1" NPT.CRVent connection

See exhaust vent detail view.

1' 6-7/8"

(480mm)

for indirect floor drain

Recommended location

1-5/8"

1' 11-1/4"

11-7/8"

8-5/8"

8-7/8"

7-7/8"

2' 3/4"

(40mm)

(590mm)

(300mm)

(220mm)

(225mm)

(200mm)

(630mm)

C

2' 5-1/8"

H

8-1/4"

Direction

belt travel

of conveyor

(740mm)

CR

8-5/8"

(210mm)

3' 4-1/8"

(1020mm)

S

2' 9-1/8"

(840mm)

2' 11-3/8"

(220mm)

D

9-1/2"

(900mm)

(240mm)

PLAN

2' 2-3/4"

3-7/8"

(100mm)

2' 3-1/2"

(700mm)

VIEW

Front

4-7/8"

(125mm)

(680mm)

2' 2-3/4" (680mm)

3' 7-1/4" (1100mm)

3-7/8"

(100mm)

U2

clear unload area

(FRONT)

ELEVATION VIEW

L2

clear load area

breaker

Fill vacuum

Start/stop

6' 2-3/4"

(1900mm)

controls

6' 6-3/4"

controls

Start/stop

Control

(2000mm)

panel

2' 11-3/8"

(900mm)

2' 6-1/8"

Aux. rinse

pump 0.75 hp

(765mm)

Final rinse

pump 0.75 hp

3.0 hp

Wash pump

6-1/2"

(165mm)

5-3/8"

(135mm)

U1

unload section length

4' 3-1/8" (1300mm)

L1

load section length

SINGLE BLOWER DRYER

Unl (U1) Clear unload (U2)oad section

3' 7-1/4" (1100mm)-long drying tunnel:

6' 2-3/4" (1900mm) 2' 7-1/2" (800mm)

7' 6-1/2" (2300mm) † 3' 11-1/4" (1200mm) †

Unl (U1) Clear unload (U2)oad section

6' 2-3/4" (1900mm) † 3' 5-3/8" (1050mm) †

8' 6-3/8" (2600mm) 4' 11" (1500mm)

7' 6-1/2" (2300mm) 4' 9-1/8" (1450mm)

8' 6-3/8" (2600mm) 5' 8-7/8" (1750mm)

9' 10-1/8" (3000mm) 7' 5/8" (2150mm)

UNLOAD SECTIONS

STANDARD

9' 10-1/8" (3000mm) 6' 2-3/4" (1900mm)

10' 9-7/8" (3300mm) 7' 2-5/8" (2200mm)

13' 1-1/2" (4000mm) 9' 6-1/8" (2900mm)

16' 7/8" (4900mm) 12' 5-5/8" (3800mm)

10' 9-7/8" (3300mm) 8' 1/2" (2450mm)

13' 1-1/2" (4000mm) 10' 4" (3150mm)

16' 7/8" (4900mm) 14' 9-1/8" (4500mm)

4' 11" (1500mm)-long drying tunnel:

7' 6-1/2" (2300mm) 2' 7-1/2" (800mm)

8' 6-3/8" (2600mm) † 3' 7-1/4" (1100mm) †

9' 10-1/8" (3000mm) 4' 11" (1500mm)

10' 9-7/8" (3300mm) 5' 10-7/8" (1800mm)

13' 1-1/2" (4000mm) 8' 2-1/2" (2500mm)

16' 7/8" (4900mm) 11' 1-7/8" (3400mm)

6' 2-3/4" (1900mm)-long drying tunnel:

9' 10-1/8" (3000mm) † 3' 7-1/4" (1100mm) †

10' 9-7/8" (3300mm) 4' 7-1/8" (1400mm)

13' 1-1/2" (4000mm) 6' 10-5/8" (2100mm)

16' 7/8" (4900mm) 9' 10-1/8" (3000mm)

Consult Meiko for special ware

considerations.

† Recommended standard element.

3/4"

(20mm)

B-US 231

1' 3-3/8"

(390mm)

2' 6-3/4"

1' 3-3/8"

(780mm)

(390mm)

3-7/8"

(100mm)

(562mm)

1' 10-1/8"

door

opening

2' 6-1/2"

6' 4-3/4"

(775mm)

(1950mm)

4' 6-5/8"

(1388mm)

2' 11-3/8"

(900mm)

LOAD SECTIONS

STANDARD

Load section length (L1) Clear load area (L2)

2' 11-3/8" (900mm) † 1' 11-5/8" (600mm) †

3' 7-1/4" (1100mm) 2' 7-1/2" (800mm)

4' 7-1/8" (1400mm) 3' 7-1/4" (1100mm)

7' 10-1/2" (2400mm) 6' 10-5/8" (2100mm)

7' 10-1/2" (2400mm)* 6' 10-5/8" (2100mm)*

Meiko for special ware considerations.

* With optional 2' 6-3/8" (770mm) loading height

† Recommended standard element. Consult

B-US 231 Technical Specifications

Operating Capacities (NSF Rated)

Dishes per hour (maximum) ...........................................7,920

Consumption ..................................... 100 U.S. gals. (379

Conveyor Specifications

Conveyor belt speed:

Minimum ........................................................ 4’ (1.2m)/min.

Maximum ....................................................... 6’ (1.8m)/min.

Horizontal clearance ................................. 1’ 11-3/8” (600mm)

Vertical clearance .......................................1’ 3-3/4” (400mm)

Conveyor belt minimum peg spacing .............. 2-1/8” (55mm)

Water Specifications

Minimum water temperatures:

Wash tank....................................................... 160°F (72°C)

Auxiliary rinse ................................................. 165°F (77°C)

Final rinse ....................................................... 180°F (82°C)

Water requirements:

Recommended fill temp ..................... 110-140°F (43-60°C)

Minimum incoming water temperature:

For 40°F/22°C minimum rise ...................... 140°F (60°C)

For 70°F/39°C minimum rise ...................... 110°F (43°C)

For 130°F/72°C minimum rise * ................... 50°F (10°C)

* Requires waste air heat recovery option.

Initial fill ................................................. 45 U.S. gals. (250l)

Consumption at 100% cap. ........... 100 U.S. gals. (379

l)/hr.

l)/hr.

Venting Specifications

Venting requirements (standard) ................ 471 CFM (800m3/h)

Venting requirements (with blower dryer) . 706 CFM (1200m

Room air to cool exhaust (recommended) ...... 120 CFM (202m

Waste air temp. (approx.) .................................. 122°F (50°C)

Waste air temp. (with optional waste

air heat recovery option, approx.) ....................... 95°F (35°C)

Minimum incoming water line size:

Initial fill line (units with waste heat

recovery option) or single water

connection (all other units) ....................................... 3/4” NPT

Final rinse line (units with waste heat

recovery option only) ................................................ 1/2” NPT

Minimum final rinse flow rate .................... 1.8 U.S. gals.(6.8l)/min.

Recommended max. water hardness ............ 4 grains/U.S. gal.

Drain ................................................ 3” IPS drain pipe; indirect

connection to 4” (102mm)

floor drain recommended

Tank capacities:

Wash tank ................................................ 31 U.S. gals. (117l)

Auxiliary rinse tank ..................................... 16 U.S. gals. (60

3

/h)

3

/h)

l)

Machine Electrical Specifications

Total Machine Current Draw: 208 V/60 Hz/3 Ph 230 V/60 Hz/3 Ph 460 V/60 Hz/3 Ph

Electric tank heat, 40°F/22°C rise booster 149.0 A 134.6 A 66.1 A

Electric tank heat, 70°F/39°C rise booster 174.0 A 157.1 A 77.1 A

Electric tank heat, opt. waste air heat recovery (130°F/72°C rise) 174.0 A 157.1 A 77.1 A

Steam tank heat/steam booster 15.0 A 14.6 A 7.1 A

Single blower dryer (electric) Add 26.5 A Add 23.3 A Add 12.3 A

Single blower dryer (steam) Add 1.6 A Add 1.4 A Add 0.9 A

Dual blower dryer (electric) Add 28.0 A Add 24.6 A Add 13.1 A

Dual blower dryer (steam) Add 3.1 A Add 2.7 A Add 1.7 A

Component Electrical Specifications

Motors:

Wash pump motor ........................... 3 hp

Auxiliary rinse pump motor......... 0.75 hp

Final rinse pump motor .............. 0.75 hp

Conveyor motor / min spd ......... 0.17 hp

Conveyor motor / max speed ..... 0.25 hp

Vent motor .................................. 0.21 hp

Steam Specifications (steam-heated units only)

Steam line connection ........................................... 1-1/2” NPT

Condensate return connection .................................... 1” NPT

Recommended steam pressure ..............15-30 psi (1-2 bars)

Blower dryer motors (1x for single blower

dryer, 2x for dual blower dryers):

• Electric or steam heat,

208 V or 240 V .......................... 0.5 hp

• Electric or steam heat,

460 V ......................................... 0.6 hp

Consumption

Incoming water temp. 110°F/43°C........... 216 lbs./hr. (57 kW)

Incoming water temp. 140°F/60°C ..........182 lbs./hr. (48 kW)

Incoming water temp. 50°F/10°C (with

optional waste air heat recovery sys.) ..... 216 lbs./hr. (57 kW)

Optional steam blower dryer ................ Add 34 lbs./hr. (9 kW)

Electric Heating Elements (electricallyheated units only):

Wash tank.................................... 27 kW

Auxiliary rinse tank ......................... 9 kW

Booster heater / 40°F rise ........... 12 kW

Booster heater / 70°F rise ........... 21 kW

Booster heater / Waste heat

recovery option, 130°F rise ......... 21 kW

Blower dryer heater (single

or dual blower dryers ) ............. 1 x 9 kW

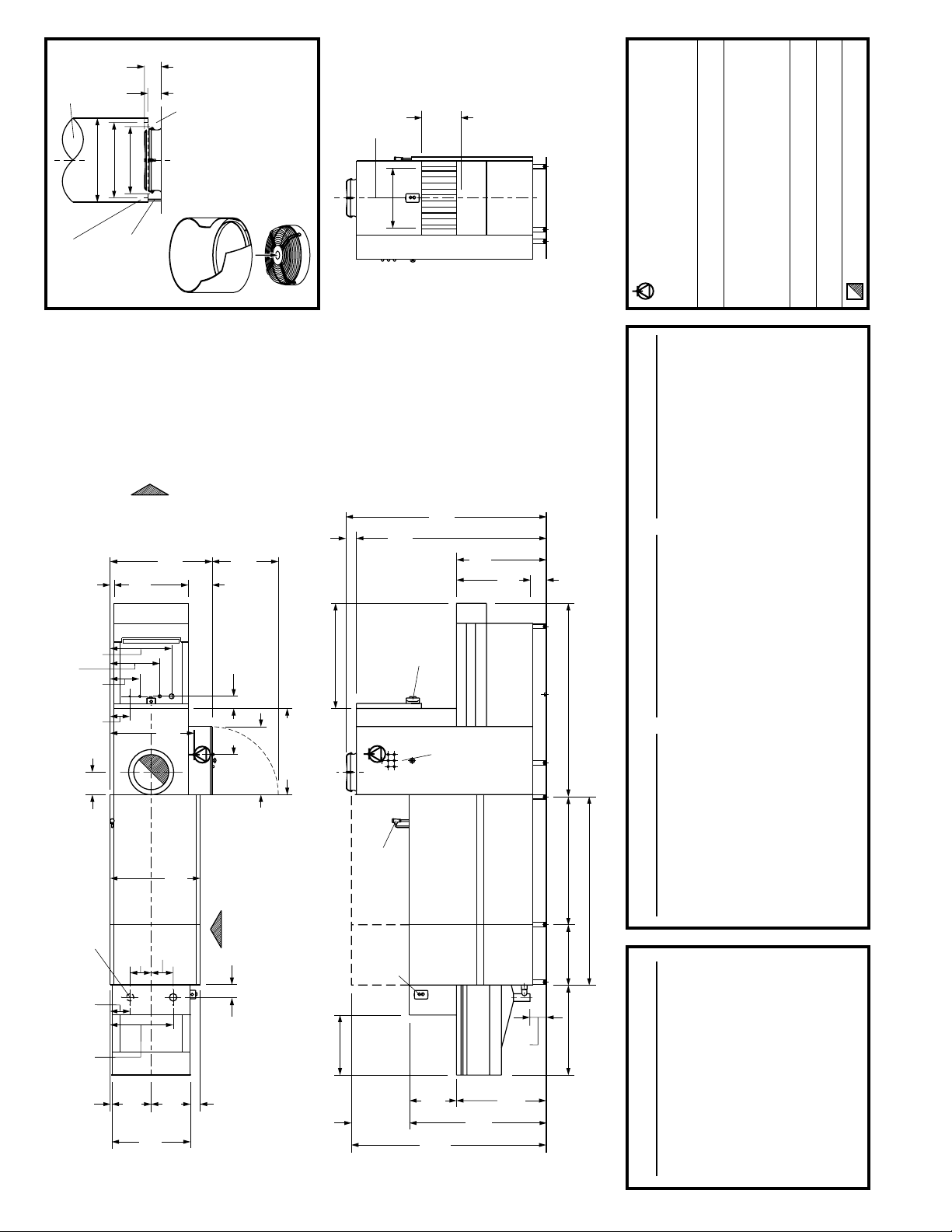

2' 2-3/4" (680mm)

3' 7-1/4" (1100mm)

2' 3-1/2"

(700mm)

Vent shroud

Left-to-Right machine shown.

Right-to-Left

machine is a

mirror

image.

All

dimensions from floor are

+/-

1/2" due to adjustable feet.

(supplied by

customer)

Condensation

trough

1-5/8"

3-7/8"

3-1/8"

1' 7-5/8" (500mm) dia.

1' 5-3/4" (450mm) dia.

Condensation

can be drained

into machine

(40mm)

(100mm)

(80mm)

1' 3-3/4"

(400mm) dia.

(drain supplied

by customer)

2' 5-1/8"

Direction

belt travel

of conveyor

(740mm)

3' 4-1/8"

(1020mm)

Gap permits

room air to

SUPPLIED BY

CUSTOMER:

9-1/2"

enter vent

shroud

Vent shroud to be

constructed with 1"

(240mm)

(25mm) trough to

collect condensation,

which can be

2' 2-3/4"

VENT

DETAIL

drained into machine

SUPPLIED WITH

(680mm)

VIEW

MACHINE:

Exhaust vent

3-7/8"

1' 11-3/8"

Left-to-Right machine shown.

(100mm)

(600mm)

horizontal

Right-to-Left machine is a

mirror image.

clearance

All dimensions from floor are

6' 2-3/4"

(1900mm)

+/- 1/2" due to adjustable feet.

passing height

1' 3-3/4" (400mm)

6' 6-3/4"

(2000mm)

2' 11-3/8"

(900mm)

2' 6-1/8"

(765mm)

ELEVATION VIEW (RIGHT)

5-3/8"

(135mm)

Used only for initial fill

Drain

3" (76mm) IPS drain. 4" indirect floor drain recommended.

Water connection(s)

Electrical connection

Units with steam heat: Single terminal block at the location shown.

Units with electric heat: 4 (four) individual terminal blocks, approx.

2-1/2" (64mm) apart, centered on the location shown.

Leads must be appropriate for electrical supply. Maximum wire

UTILITY CONNECTIONS

gauge #2 AWG.All connection points to be drilled during installation.

3/4" NPT. on units that equipped with

D

DUAL BLOWER DRYER

Unl (U1) Clear unload (U2)oad section

6' 7/8" (1850mm)-long drying tunnel:

9' 10-1/8" (3000mm) † 3' 9-1/4" (1150mm) †

10' 9-7/8" (3300mm) 4' 11" (1500mm)

7' 6-1/2" (2300mm)-long drying tunnel:

13' 1-1/2" (4000mm) 6' 2-3/4" (1900mm)

16' 7/8" (4900mm) 12' 5-5/8" (3800mm)

10' 9-7/8" (3300mm) † 3' 3-3/8" (1000mm) †

13' 1-1/2" (4000mm) 5' 6-7/8" (1700mm)

Used only for final rinse

optional waste air heat recovery system. Used as single water

connection on all other units.

1/2" NPT. on units equipped with optional

H

8' 10-3/8" (2700mm)-long drying tunnel:

16' 7/8" (4900mm) 8' 6-3/8" (2600mm)

waste air heat recovery system. Not present on other units.

C

13' 1-1/2" (4000mm) † 4' 3-1/8" (1300mm) †

16' 7/8" (4900mm) 7' 2-5/8" (2200mm)

Steam connection

Units with steam tank/booster heat only. 1-1/2" NPT.SCondensate return connection

10' 2" (3100mm)-long drying tunnel:

13' 1-1/2" (4000mm) † 2' 11-3/8" (900mm) †

16' 7/8" (4900mm) 5' 10-7/8" (1800mm)

Units with steam tank/booster heat only. 1" NPT.CRVent connection

See exhaust vent detail view.

1' 6-7/8"

1' 11-1/4"

(480mm)

11-7/8"

8-5/8"

8-7/8"

for indirect floor drain

Recommended location

7-7/8"

(200mm)

2' 3/4"

(630mm)

(590mm)

(300mm)

(220mm)

(225mm)

C

H

8-1/4"

CR

8-5/8"

(210mm)

S

2' 9-1/8"

(840mm)

2' 11-3/8"

(220mm)

D

(900mm)

3-7/8"

(100mm)

2' 3-1/2"

(700mm)

VIEW

PLAN

Front

4-7/8"

(125mm)

2' 2-3/4" (680mm)

3' 7-1/4" (1100mm)

U2

clear unload area

(FRONT)

ELEVATION VIEW

L2

clear load area

breaker

Fill vacuum

Start/stop

controls

controls

Start/stop

Control

panel

Aux. rinse

U1

unload section length

Final rinse

pump 0.75 hp

pump 0.75 hp

4' 3-1/8" (1300mm)

3.0 hp

Wash pump

1.0 hp

Prewash pump

1' 11-5/8"

6' 2-3/4" (1900mm)

(600mm)

SINGLE BLOWER DRYER

Unl (U1) Clear unload (U2)oad section

3' 7-1/4" (1100mm)-long drying tunnel:

7' 6-1/2" (2300mm) 3' 11-1/4" (1200mm)

8' 6-3/8" (2600mm) † 4' 11" (1500mm) †

6' 2-3/4" (1900mm) 3' 5-3/8" (1050mm)

7' 6-1/2" (2300mm) † 4' 9-1/8" (1450mm) †

8' 6-3/8" (2600mm) 5' 8-7/8" (1750mm)

9' 10-1/8" (3000mm) 6' 2-3/4" (1900mm)

9' 10-1/8" (3000mm) 7' 5/8" (2150mm)

UNLOAD SECTIONS

STANDARD

Unl (U1) Clear unload (U2)oad section

10' 9-7/8" (3300mm) 7' 2-5/8" (2200mm)

13' 1-1/2" (4000mm) 9' 6-1/8" (2900mm)

16' 7/8" (4900mm) 12' 5-5/8" (3800mm)

10' 9-7/8" (3300mm) 8' 1/2" (2450mm)

13' 1-1/2" (4000mm) 10' 4" (3150mm)

16' 7/8" (4900mm) 14' 9-1/8" (4500mm)

4' 11" (1500mm)-long drying tunnel:

7' 6-1/2" (2300mm) 2' 7-1/2" (800mm)

8' 6-3/8" (2600mm) † 3' 7-1/4" (1100mm) †

9' 10-1/8" (3000mm) 4' 11" (1500mm)

10' 9-7/8" (3300mm) 5' 10-7/8" (1800mm)

13' 1-1/2" (4000mm) 8' 2-1/2" (2500mm)

16' 7/8" (4900mm) 11' 1-7/8" (3400mm)

6' 2-3/4" (1900mm)-long drying tunnel:

9' 10-1/8" (3000mm) † 3' 7-1/4" (1100mm) †

10' 9-7/8" (3300mm) 4' 7-1/8" (1400mm)

13' 1-1/2" (4000mm) 6' 10-5/8" (2100mm)

16' 7/8" (4900mm) 9' 10-1/8" (3000mm)

Consult Meiko for special ware

considerations.

† Recommended standard element.

L1

6-1/2"

(165mm)

load section length

3/4"

(20mm)

B-US 231 PW

1' 3-3/8"

(390mm)

2' 6-3/4"

1' 3-3/8"

(780mm)

(390mm)

3-7/8"

(100mm)

(562mm)

1' 10-1/8"

door

opening

2' 6-1/2"

6' 4-3/4"

(775mm)

(1950mm)

4' 6-5/8"

(1388mm)

2' 11-3/8"

(900mm)

LOAD SECTIONS

STANDARD CSS BASIC

Load section length (L1) Clear load area (L2)

2' 11-3/8" (900mm) † 1' 11-5/8" (600mm) †

3' 7-1/4" (1100mm) 2' 7-1/2" (800mm)

4' 7-1/8" (1400mm) 3' 7-1/4" (1100mm)

7' 10-1/2" (2400mm) 6' 10-5/8" (2100mm)

7' 10-1/2" (2400mm)* 6' 10-5/8" (2100mm)*

Meiko for special ware considerations.

* With optional 2' 6-3/8" (770mm) loading height

† Recommended standard element. Consult

B-US 231 PW Technical Specifications

Operating Capacities (NSF Rated)

Dishes per hour (maximum) ...........................................7,920

Consumption ..................................... 100 U.S. gals. (379

Conveyor Specifications

Conveyor belt speed:

Minimum ........................................................ 4’ (1.2m)/min.

Maximum ....................................................... 6’ (1.8m)/min.

Horizontal clearance ................................. 1’ 11-3/8” (600mm)

Vertical clearance .......................................1’ 3-3/4” (400mm)

Conveyor belt minimum peg spacing .............. 2-1/8” (55mm)

Water Specifications

Minimum water temperatures:

Prewash tank .................................................. 110°F (43°C)

Wash tank....................................................... 160°F (72°C)

Auxiliary rinse ................................................. 165°F (77°C)

Final rinse ....................................................... 180°F (82°C)

Water requirements:

Recommended fill temp ..................... 110-140°F (43-60°C)

Minimum incoming water temperature:

For 40°F/22°C minimum rise ...................... 140°F (60°C)

For 70°F/39°C minimum rise ...................... 110°F (43°C)

For 130°F/72°C minimum rise * ................... 50°F (10°C)

* Requires waste air heat recovery option.

Initial fill ................................................. 66 U.S. gals. (250l)

Consumption at 100% cap. ........... 100 U.S. gals. (379

l)/hr.

l)/hr.

Venting Specifications

Venting requirements (standard) ................ 471 CFM (800m3/h)

Venting requirements (with blower dryer) . 706 CFM (1200m

Room air to cool exhaust (recommended) ...... 120 CFM (202m

Waste air temp. (approx.) .................................. 122°F (50°C)

Waste air temp. (with optional waste

air heat recovery option, approx.) ....................... 95°F (35°C)

Minimum incoming water line size:

Initial fill line (units with waste heat

recovery option) or single water

connection (all other units) ....................................... 3/4” NPT

Final rinse line (units with waste heat

recovery option only) ................................................ 1/2” NPT

Minimum final rinse flow rate .................... 1.8 U.S. gals.(6.8l)/min.

Recommended max. water hardness ............ 4 grains/U.S. gal.

Drain ................................................ 3” IPS drain pipe; indirect

connection to 4” (102mm)

floor drain recommended

Tank capacities:

Prewash tank ............................................. 19 U.S. gals. (72l)

Wash tank ................................................ 31 U.S. gals. (117l)

Auxiliary rinse tank ..................................... 16 U.S. gals. (60

3

/h)

3

/h)

l)

Machine Electrical Specifications

Total Machine Current Draw: 208 V/60 Hz/3 Ph 230 V/60 Hz/3 Ph 460 V/60 Hz/3 Ph

Electric tank heat, 40°F/22°C rise booster 151.8 A 137.5 A 67.5 A

Electric tank heat, 70°F/39°C rise booster 176.8 A 160.0 A 78.5 A

Electric tank heat, opt. waste air heat recovery (130°F/72°C rise) 176.8 A 160.0 A 78.5 A

Steam tank heat/steam booster 17.8 A 17.5 A 8.5 A

Single blower dryer (electric) Add 26.5 A Add 23.3 A Add 12.3 A

Single blower dryer (steam) Add 1.6 A Add 1.4 A Add 0.9 A

Dual blower dryer (electric) Add 28.0 A Add 24.6 A Add 13.1 A

Dual blower dryer (steam) Add 3.1 A Add 2.7 A Add 1.7 A

Component Electrical Specifications

Motors:

Prewash pump motor ................. 0.75 hp

Wash pump motor ........................... 3 hp

Auxiliary rinse pump motor......... 0.75 hp

Final rinse pump motor .............. 0.75 hp

Conveyor motor / min spd ......... 0.17 hp

Conveyor motor / max speed ..... 0.25 hp

Vent motor .................................. 0.21 hp

Steam Specifications (steam-heated units only)

Steam line connection ........................................... 1-1/2” NPT

Condensate return connection .................................... 1” NPT

Recommended steam pressure ..............15-30 psi (1-2 bars)

Blower dryer motors (1x for single blower

dryer, 2x for dual blower dryers):

• Electric or steam heat,

208 V or 240 V .......................... 0.5 hp

• Electric or steam heat,

460 V ......................................... 0.6 hp

Consumption

Incoming water temp. 110°F/43°C........... 216 lbs./hr. (57 kW)

Incoming water temp. 140°F/60°C ..........182 lbs./hr. (48 kW)

Incoming water temp. 50°F/10°C (with

optional waste air heat recovery sys.) ..... 216 lbs./hr. (57 kW)

Optional steam blower dryer ................ Add 34 lbs./hr. (9 kW)

Electric Heating Elements (electricallyheated units only):

Wash tank.................................... 27 kW

Auxiliary rinse tank ......................... 9 kW

Booster heater / 40°F rise ........... 12 kW

Booster heater / 70°F rise ........... 21 kW

Booster heater / Waste heat

recovery option, 130°F rise ......... 21 kW

Blower dryer heater (single

or dual blower dryers ) ............. 1 x 9 kW

Loading...

Loading...