Meiko B-M74V6N1010P8 User Manual

HOT WATER SANITIZING

MULTIPLE-TANK

FLIGHT TYPE

B-M74 SERIES

W AREWASHERS

The clean solution

Special Features:

• Industry-leading low water, energy and chemical

consumption

At less than 60 gallons (227 liters) per hour, M-iQ is one of

the most efficient dishwashers in the world. Advanced

technologies further reduce energy and detergent use.

• M-iQ Filter Technology

Each tank features a multiple stage filtration process that

first collects food soil, then flushes it out of the tank

completely in high-pressure cycles. This improves

performance, eases cleanup and reduces detergent

consumption by up to 50%.

• M-iQ Airflow Management

M-iQ features an advanced, fully integrated airflow system

that retains and redirects hot air within the machine. This

improves heating efficiency and reduces exhaust

emissions.

• M-iQ Tank Management

Each tank is equipped with an M-Filter system. Water levels

are monitored and controlled intelligently and

automatically. M-iQ automatically diverts water within the

machine to maintain optimum level control and soil

distribution.

• M-iQ Washing Dynamics

M-iQ employs a higher-pressure wash for improved soil

removal and reduced water consumption. Water flow has

been modeled using computational fluid dynamics. Water,

energy and chemical consumption are all dramatically

reduced.

• M-iQ Energy Management

M-iQ incorporates a 3-stage energy control system, as

well as a variable-output booster heater, for optimal energy

balance. The system dynamically adjusts to changes in

heating distribution for minimal energy consumption.

• M-iQ Control System

M-iQ features a CC Touch glass touch screen with a high

resolution color display. Screen information is customized

based on the machine’s operating mode for fast, intuitive

operation. Kitchen management, dishroom staff and

service personnel can quickly call up customized

information, or save data to the controller’s built-in memory.

• M-iQ Intuitive Cleaning

M-iQ features an automatic cleaning mode. Assisted by

the soil removal capabilities of the M-Filter, this

dramatically reduces cleanup time. Areas that require

regular manual cleaning are marked in

effort by the staff.

This dishwasher is compliant with the Reduction of Lead in Drinking

Water Act (201 1) amendment to the Safe Drinking W ater Act (SDW A).

Page 1 • M-iQ Flight - B-M74 Series • Updated 7-14 • MEIKO • 1349 Heil Quaker Blvd. • LaVergne, TN 37086 • (800) 55-MEIKO • www.meiko.us • sales@meiko.us

blue for less wasted

Standard Features:

• ENERGY STAR Qualified

• Wash chamber with 3 HP (2.2 kW) pump motor

• Power rinse chamber with 1 HP (0.75 kW) pump motor

• Pumped final rinse with 3/4 HP (0.55 kW) pump motor

• Integral heated blower dryer with 2/3 HP (0.5 kW) motor

• Choice of prewash sections:

• B-M74 V6 N** P8: 1’ 11-5/8” (600mm) prewash with

1 HP (0.75 kW) pump, conveyor speed 6.0’ (1.8m)/min.,

56.2 gals. (212.7 liters)/hr.

• B-M74 V8 N** P8: 2’ 7-1/2” (800mm) prewash with

3 HP (2.2 kW) pump, conveyor speed 6.5’ (2.0m)/min.,

56.8 gals. (215.0 liters)/hr.

• Conveyor width 29-1/2” (750mm); passing height 15-3/4”

(400mm); accommodates standard 18 x 26” sheet pans

• 304-series stainless steel construction

• Fully automatic operation. Prewash, wash, power rinse and

final rinse are activated only when ware is present

• Front-sloping tanks for complete drainage and easier cleaning. Automatic self-cleaning and drain feature is accessed

from control panel to eliminate manual drain levers

• Double-wall insulated construction on front, top and back

improves operator safety, conserves heating energy, and

reduces noise and heat loss into the dishroom. Insulation

is fully waterproofed to eliminate heavy doors and

unsanitary waterlogging

• Standard lifting doors are full-width for each chamber,

including the blower drying zone, for improved access

• Pumps are vertically-mounted to be self-draining and easily

removed for servicing. Pumps include safety alert feature

to inform the operator of a leaking pump seal

Optional Features:

• Hinged doors

• Drain water tempering

• Flanged, bolt-down feet

• Single-point electrical connection (electrically-heated

machines only; standard on steam-heated machines)

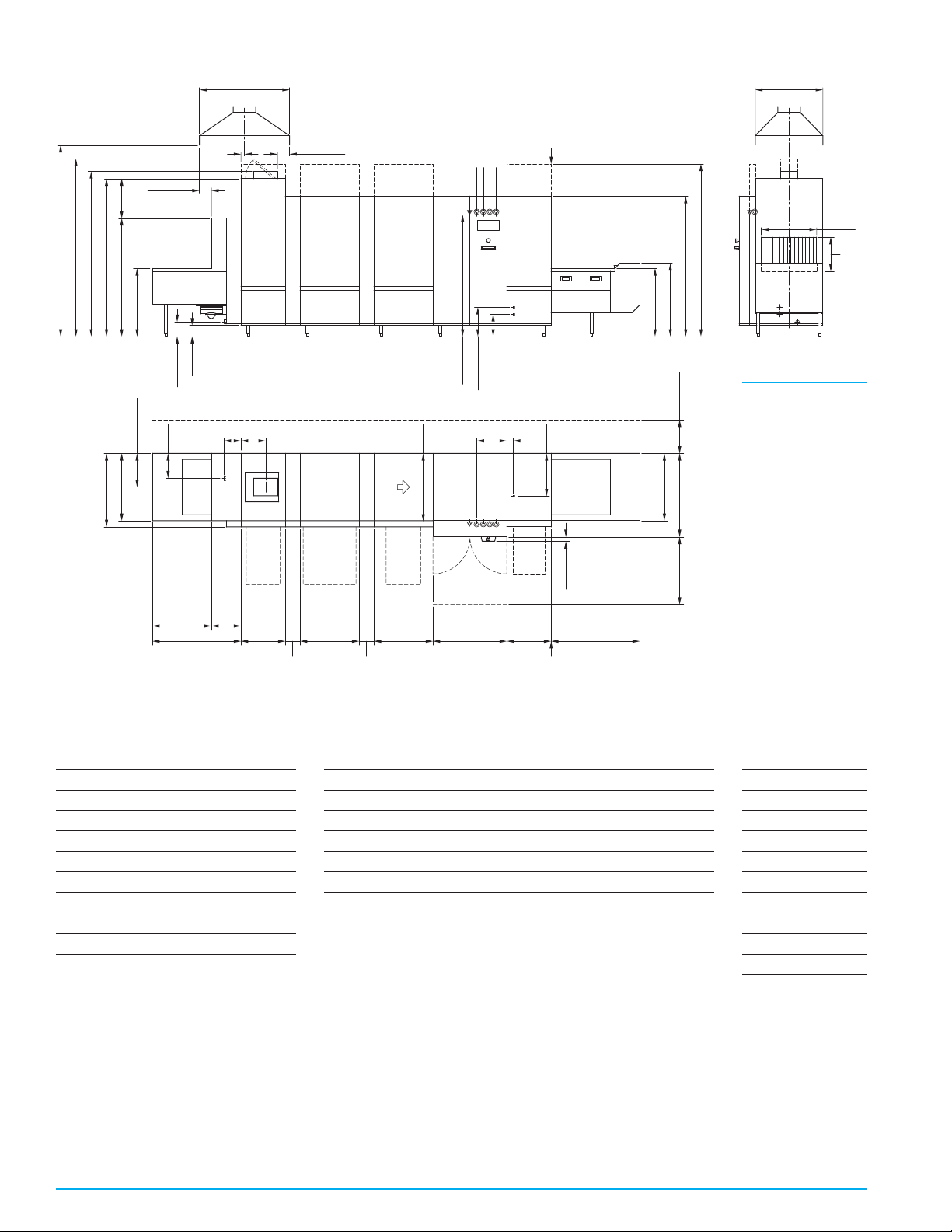

M-iQ Flight - B-M74 Series - Electric heat, left to right

(535mm)

7' 4" (2235mm)

7' (2135mm)

5' 3" (1600mm)

2' 11-7/8" (910mm)

3' 3-1/8" (995mm)

1' 9-1/8"

8' 6" (2590mm) recommended

7' 10-5/8" (2405mm)

6-3/8" (162mm)

3' 1/4" (920mm)

1' 5-7/8" (455mm)

(340mm)

Clear loading

()L

Load section ( )L

1-7/8"

(47mm)

7-5/8" (195mm)

6" (152mm)

1' 1-3/8"

9"

(230mm)

A

4' (1220mm) Recommended extraction area or

C

L

D

D

V

V6: 1' 11-5/8"

1' 3-3/4"

(400mm)

V8: 2' 7-1/2"

V

1' 1-1/8"

(335mm)

Prewash

(600mm)

(800mm)

Contact-plus zone 1

vent hood sizing and placement

(by others)

6-3/8" (162mm)

Wash

2' 7-1/2"

(800mm)

A

Contact-plus zone 2

()N

2' 7-1/2" (800mm)

()N

B

Power rinse and

final rinse

(920mm)

3' 1/4"

(493mm)

3' 3-3/8" (1000mm)

Additional blower dryers (if so equipped)

follow the standard blower dryer.

Each is 1' 11-5/8" (600mm) long

3214

1' 3-1/2" (395mm)

5' 5" (1650mm)

11-3/4" (300mm)

1' 7-3/8"

3214

Control panel

Additional blower dryers (if so equipped)

follow the standard blower dryer.

Each is 1' 11-5/8" (600mm) long

C

W

3-3/8"

(85mm)

W,C

Blower dryer

1' 11-5/8"

(600mm)

1' 10-7/8"

(580mm)

2-3/8" (60mm)

Unload section ( )U

3' 1/4" (920mm)

C

L

6' 2-3/4" (1900mm)

3' 3" (990mm)

service access

recommended

1' 6" (457mm)

2' 11-7/8" (910mm)

3' 8-1/2" (1130mm)

access recommended

3' (914mm) service

Vent hood

by others

7' 7-7/8" (2335mm)

3' (915mm)

1,2,3,4

C

W

Blower dryers

NOTE: All M-iQ flight type

warewashers feature at

least one heated blower

dryer section. One blower

dryer provides good results

for plates, cutlery and

glassware in most cases.

For melamine ware or

plastics (trays, insulated

items, etc.) a second blower

dryer is available, adding

1’ 1 1-5/8” (600mm) to overall

machine length.

For some special ware

types, additional blower

dryer zone(s) beyond the

second may provide

improved drying results.

Consult MEIKO for

assistance.

C

L

V

Horizontal

clearance

2' 5-1/2"

(750mm)

Vertical

clearance

1' 6-1/4"

(465mm)

D

Load sections (L) Clear loading (LA)

3’ 3-3/8” (1000mm) 1’ 11-5/8” (600mm)

3’ 11-1/4” (1200mm) 2’ 7-1/2” (800mm)

4’ 7-1/8” (1400mm) 3’ 3-3/8” (1000mm)

5’ 3” (1600mm) 3’ 11-1/4” (1200mm)

5’ 10-7/8” (1800mm) 4’ 7-1/8” (1400mm)

6’ 6-3/4” (2000mm) 5’ 3” (1600mm)

7’ 2-5/8” (2200mm) 5’ 10-7/8” (1800mm)

7’ 10-1/2” (2400mm) 6’ 6-3/4” (2000mm)

8’ 6-3/8” (2600mm) 7’ 2-5/8” (2200mm)

9’ 2-1/4” (2800mm) 7’ 10-1/2” (2400mm)

9’ 10-1/8” (3000mm) 8’ 6-3/8” (2600mm)

NOTE: Load sections with a lowered loading height of

2’ 7-1/2” (800mm) are available for specific applications,

such as when the loading area is underneath a table

or tray conveyor. Consult MEIKO for details.

Recommended load sections:

• Single worker loading items while standing at the

end of the machine - L = 3’ 11-1/4” (1200mm)

• Two workers loading items, each standing on one

side of the machine - L = 4’ 7-1/8” (1400mm)

• Large items placed flat on the belt (totes, containers,

etc.) - LA = 2’ (600mm) longer than the item

• Operations with special delivery systems and/or

multiple workers loading items may require

extended load sections. Consult MEIKO for

assistance.

Contact-plus 1 (NA) Contact-plus 2 (NB) Model number code

None 7-7/8” (200mm) B-M74 V? N02 P8

7-7/8” (200mm) 7-7/8” (200mm) B-M74 V? N22 P8

11-7/8” (300mm) 11-7/8” (300mm) B-M74 V? N33 P8

1’ 3-3/4” (400mm) 1’ 3-3/4” (400mm) B-M74 V? N44 P8

1’ 7-5/8” (500mm) 1’ 7-5/8” (500mm) B-M74 V? N55 P8

1’ 11-5/8” (600mm) 1’ 11-5/8” (600mm) B-M74 V? N66 P8

2’ 7-1/2” (800mm) 2’ 7-1/2” (800mm) B-M74 V? N88 P8

3’ 3-3/8” (1000mm) 3’ 3-3/8” (1000mm) B-M74 V? N1010 P8

NOTE: As ware proceeds through the machine and closer to the final rinse, the

water contacting the ware becomes warmer and cleaner. Large items and flat

items (particularly sheet pans, trays, totes, etc.) can carry over cooler, soiled

water forward in the machine. The contact-plus zone provides a landing area for

this water, allowing it to return to the previous tank. This reduces detergent

consumption and tank heating energy use.

Wider contact-plus zones also provide a surface that may be used to front-mount

detergent or rinse aid systems.

Recommended contact-plus zone configurations:

• For machines washing plates/glasswares - N02

• For machines washing a typical ware mix - cafeteria trays and some sheet

pans in addition to plates and glasswares - N22

• For machines washing a high proportion of sheet pans - N33

• For machines washing large containers - N44 or larger, depending on the size

of the container

• For machines with front-mounted detergent and rinse aid dispensers - N33 or

larger, depending on the size of the dispensing systems

Unload sections (U)

2’ 7-1/2” (800mm)

3’ 3-3/8” (1000mm)

3’ 11-1/4” (1200mm)

4’ 7-1/8” (1400mm)

5’ 3” (1600mm)

5’ 10-7/8” (1800mm)

6’ 6-3/4” (2000mm)

7’ 2-5/8” (2200mm)

7’ 10-1/2” (2400mm)

8’ 6-3/8” (2600mm)

9’ 2-1/4” (2800mm)

9’ 10-1/8” (3000mm)

Recommended unload

sections:

• Typical ware mix, limited

space available - U =

3’ 11-1/4” (1200mm)

• Typical ware mix, more

space available - U =

4’ 7-1/8” (1400mm) or

longer for improved drying

• Large items placed flat

on the belt (totes,

containers, etc.) - U = at

least 1’ (300mm) longer

than twice the length of

the item

Page 2 • M-iQ Flight - B-M74 Series • Updated 7-14 • MEIKO • 1349 Heil Quaker Blvd. • LaVergne, TN 37086 • (800) 55-MEIKO • www.meiko.us • sales@meiko.us

/

(

)

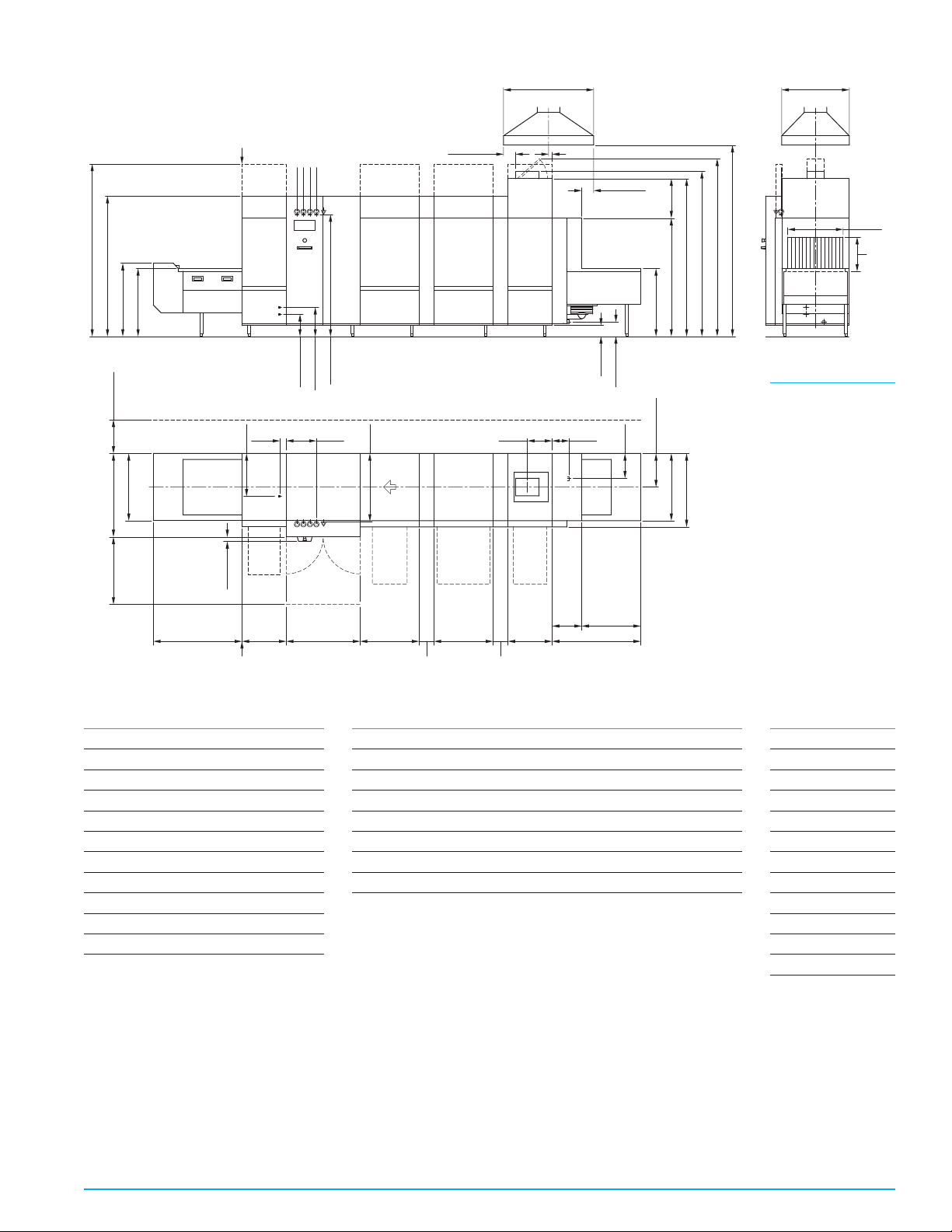

M-iQ Flight - B-M74 Series - Electric heat, right to left

2335mm

8"

7' 7-7

6' 2-3/4" (1900mm)

1' 6" (457mm)

recommended

service access

3' 8-1/2" (1130mm)

3' (914mm) service

access recommended

3' 3" (990mm)

3' 1/4" (920mm)

C

2' 11-7/8" (910mm)

Additional blower dryers (if so equipped)

follow the standard blower dryer.

Each is 1' 11-5/8" (600mm) long

L

Unload section ( )U

Additional blower dryers (if so equipped)

follow the standard blower dryer.

Each is 1' 11-5/8" (600mm) long

(580mm)

1' 10-7/8"

2-3/8" (60mm)

Blower dryer

1' 11-5/8"

(600mm)

3-3/8"

(85mm)

C

W

W,C

3 2 1 4

5' 5" (1650mm)

11-3/4" (300mm)

1' 3-1/2" (395mm)

1' 7-3/8"

(493mm)

3 2 1 4

Control panel

3' 3-3/8" (1000mm)

3' 1/4"

(920mm)

Power rinse and

final rinse

2' 7-1/2" (800mm)

Recommended extraction area or

vent hood sizing and placement

(by others)

6-3/8" (162mm)

Wash

2' 7-1/2"

(800mm)

Contact-plus zone 2

()N

Contact-plus zone 1

B

1' 1-1/8"

(335mm)

()N

A

4' (1220mm)

V

Prewash

V6: 1' 11-5/8"

(600mm)

V8: 2' 7-1/2"

(800mm)

V

C

L

1-7/8"

(47mm)

D

1' 3-3/4"

(400mm)

6-3/8" (162mm)

6" (152mm)

9"

(230mm)

D

Clear loading

Load section ( )L

7-5/8" (195mm)

1' 1-3/8"

(340mm)

()L

A

1' 9-1/8"

(535mm)

7' (2135mm)

5' 3" (1600mm)

3' 1/4" (920mm)

1' 5-7/8" (455mm)

2' 11-7/8" (910mm)

3' 3-1/8" (995mm)

7' 10-5/8" (2405mm)

7' 4" (2235mm)

8' 6" (2590mm) recommended

1,2,3,4

3' (915mm)

C

L

V

C

W

D

Vent hood

by others

Blower dryers

NOTE: All M-iQ flight type

warewashers feature at

least one heated blower

dryer section. One blower

dryer provides good results

for plates, cutlery and

glassware in most cases.

For melamine ware or

plastics (trays, insulated

items, etc.) a second blower

dryer is available, adding

1’ 1 1-5/8” (600mm) to overall

machine length.

For some special ware

types, additional blower

dryer zone(s) beyond the

second may provide

improved drying results.

Consult MEIKO for

assistance.

Horizontal

clearance

2' 5-1/2"

(750mm)

clearance

1' 6-1/4"

(465mm)

Vertical

Load sections (L) Clear loading (LA)

3’ 3-3/8” (1000mm) 1’ 11-5/8” (600mm)

3’ 11-1/4” (1200mm) 2’ 7-1/2” (800mm)

4’ 7-1/8” (1400mm) 3’ 3-3/8” (1000mm)

5’ 3” (1600mm) 3’ 11-1/4” (1200mm)

5’ 10-7/8” (1800mm) 4’ 7-1/8” (1400mm)

6’ 6-3/4” (2000mm) 5’ 3” (1600mm)

7’ 2-5/8” (2200mm) 5’ 10-7/8” (1800mm)

7’ 10-1/2” (2400mm) 6’ 6-3/4” (2000mm)

8’ 6-3/8” (2600mm) 7’ 2-5/8” (2200mm)

9’ 2-1/4” (2800mm) 7’ 10-1/2” (2400mm)

9’ 10-1/8” (3000mm) 8’ 6-3/8” (2600mm)

NOTE: Load sections with a lowered loading height of

2’ 7-1/2” (800mm) are available for specific applications,

such as when the loading area is underneath a table

or tray conveyor. Consult MEIKO for details.

Recommended load sections:

• Single worker loading items while standing at the

end of the machine - L = 3’ 11-1/4” (1200mm)

• Two workers loading items, each standing on one

side of the machine - L = 4’ 7-1/8” (1400mm)

• Large items placed flat on the belt (totes, containers,

etc.) - LA = 2’ (600mm) longer than the item

• Operations with special delivery systems and/or

multiple workers loading items may require

extended load sections. Consult MEIKO for

assistance.

Contact-plus 1 (NA) Contact-plus 2 (NB) Model number code

None 7-7/8” (200mm) B-M74 V? N02 P8

7-7/8” (200mm) 7-7/8” (200mm) B-M74 V? N22 P8

11-7/8” (300mm) 11-7/8” (300mm) B-M74 V? N33 P8

1’ 3-3/4” (400mm) 1’ 3-3/4” (400mm) B-M74 V? N44 P8

1’ 7-5/8” (500mm) 1’ 7-5/8” (500mm) B-M74 V? N55 P8

1’ 11-5/8” (600mm) 1’ 11-5/8” (600mm) B-M74 V? N66 P8

2’ 7-1/2” (800mm) 2’ 7-1/2” (800mm) B-M74 V? N88 P8

3’ 3-3/8” (1000mm) 3’ 3-3/8” (1000mm) B-M74 V? N1010 P8

NOTE: As ware proceeds through the machine and closer to the final rinse, the

water contacting the ware becomes warmer and cleaner. Large items and flat

items (particularly sheet pans, trays, totes, etc.) can carry over cooler, soiled

water forward in the machine. The contact-plus zone provides a landing area for

this water, allowing it to return to the previous tank. This reduces detergent

consumption and tank heating energy use.

Wider contact-plus zones also provide a surface that may be used to front-mount

detergent or rinse aid systems.

Recommended contact-plus zone configurations:

• For machines washing plates/glasswares - N02

• For machines washing a typical ware mix - cafeteria trays and some sheet

pans in addition to plates and glasswares - N22

• For machines washing a high proportion of sheet pans - N33

• For machines washing large containers - N44 or larger, depending on the size

of the container

• For machines with front-mounted detergent and rinse aid dispensers - N33 or

larger, depending on the size of the dispensing systems

Unload sections (U)

2’ 7-1/2” (800mm)

3’ 3-3/8” (1000mm)

3’ 11-1/4” (1200mm)

4’ 7-1/8” (1400mm)

5’ 3” (1600mm)

5’ 10-7/8” (1800mm)

6’ 6-3/4” (2000mm)

7’ 2-5/8” (2200mm)

7’ 10-1/2” (2400mm)

8’ 6-3/8” (2600mm)

9’ 2-1/4” (2800mm)

9’ 10-1/8” (3000mm)

Recommended unload

sections:

• Typical ware mix, limited

space available - U =

3’ 11-1/4” (1200mm)

• Typical ware mix, more

space available - U =

4’ 7-1/8” (1400mm) or

longer for improved drying

• Large items placed flat

on the belt (totes,

containers, etc.) - U = at

least 1’ (300mm) longer

than twice the length of

the item

Page 3 • M-iQ Flight - B-M74 Series • Updated 7-14 • MEIKO • 1349 Heil Quaker Blvd. • LaVergne, TN 37086 • (800) 55-MEIKO • www.meiko.us • sales@meiko.us

Loading...

Loading...