Meiko AZP80 Installation Manual

MODEL AZP 80

Waste Pulper (USA Version)

OWNER’S INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

Meiko • 917 Airpark Center Drive • Nashville, TN 37217 • Phone: (615) 399-6600 • (800) 55-MEIKO • Fax: (615) 399-6620

Rev. 05/06

TABLE OF CONTENTS

1. INTRODUCTION ................................. 3

1.1 Overview of Equipment ............................. 3

1.2 General Safety Information ........................ 4

2. TRANSPORT AND SHIPPING ............. 4

3. INSTALLATION .................................... 4

3.1 Overview of Installation ............................. 4

3.2 Requirements Before Installation .............. 5

3.3 Uncrating, Positioning and Leveling ............. 5

3.4 Connecting a Feeding Trough ................... 6

3.5 Accessing the Utility Connections ............. 7

3.6 Main Electrical Supply Connection ............ 8

3.7 Remote Control Box Installation ................ 8

3.8 Water Supply Connections ........................ 9

3.9 Drain Connection ..................................... 10

3.10 Installing a Deodorizing System .............. 11

3.11 Final Assembly ........................................ 11

4. OPERATION ....................................... 12

4.1 Location and Description of Controls....... 12

4.2 Startup ..................................................... 13

4.3 Loading .................................................... 14

4.4 Idle Periods ............................................. 14

4.5 Clearing Jams ......................................... 15

4.6 Shutdown ................................................ 15

5. CLEANING.......................................... 16

5.1 Daily or As Required ................................ 16

5.2 Weekly or As Required ............................ 17

5.3 Exterior Cleaning ..................................... 18

5.4 Deliming .................................................. 18

6. TROUBLESHOOTING ........................ 19

AN ELECTRICAL WIRING DIAGRAM IS LOCATED INSIDE THE CONTROL BOX OF THIS

MACHINE.

MEIKO WASTE PULPERS HAVE BEEN DESIGNED EXCLUSIVELY FOR PULPING/

DEWATERING OF FOOD WASTE AND MIXED KITCHEN WASTE IN A COMMERCIAL OR

INSTITUTIONAL SETTING ACCORDING TO THE GUIDELINES IN THIS MANUAL AND MAY NOT BE

USED FOR ANY OTHER PURPOSE WITHOUT THE WRITTEN PERMISSION OF MEIKO.

MEIKO ACCEPTS NO RESPONSIBILITY FOR DAMAGE TO THE APPLIANCE,

SURROUNDING EQUIPMENT OR ENVIRONMENT THAT IS CAUSED BY INAPPROPRIATE

INSTALLATION OR OPERATION, OR FROM ANY SERVICE THAT IS UNDERTAKEN BY

NON-AUTHORIZED PERSONNEL, OR FROM THE USE OF ANY PARTS EXCEPT THOSE

THAT ARE APPROVED BY THE MANUFACTURER. ANY SUCH INSTALLATION, USE OR

SERVICE WILL IMMEDIATELY VOID THE MANUFACTURER’S WARRANTY.

ANY MODIFICATIONS TO THE APPLIANCE THAT ARE PERFORMED WITHOUT THE

WRITTEN PERMISSION OF MEIKO WILL IMMEDIATELY VOID THE MANUFACTURER’S

WARRANTY.

Meiko reserves the right to change any specifications without notice at any time.

Page 2

Meiko • 917 Airpark Center Drive • Nashville, TN 37217

Phone: (615) 399-6600 • (800) 55-MEIKO • Fax: (615) 399-6620

www.meiko.us

SECTION 1 - INTRODUCTION

1INTRODUCTION

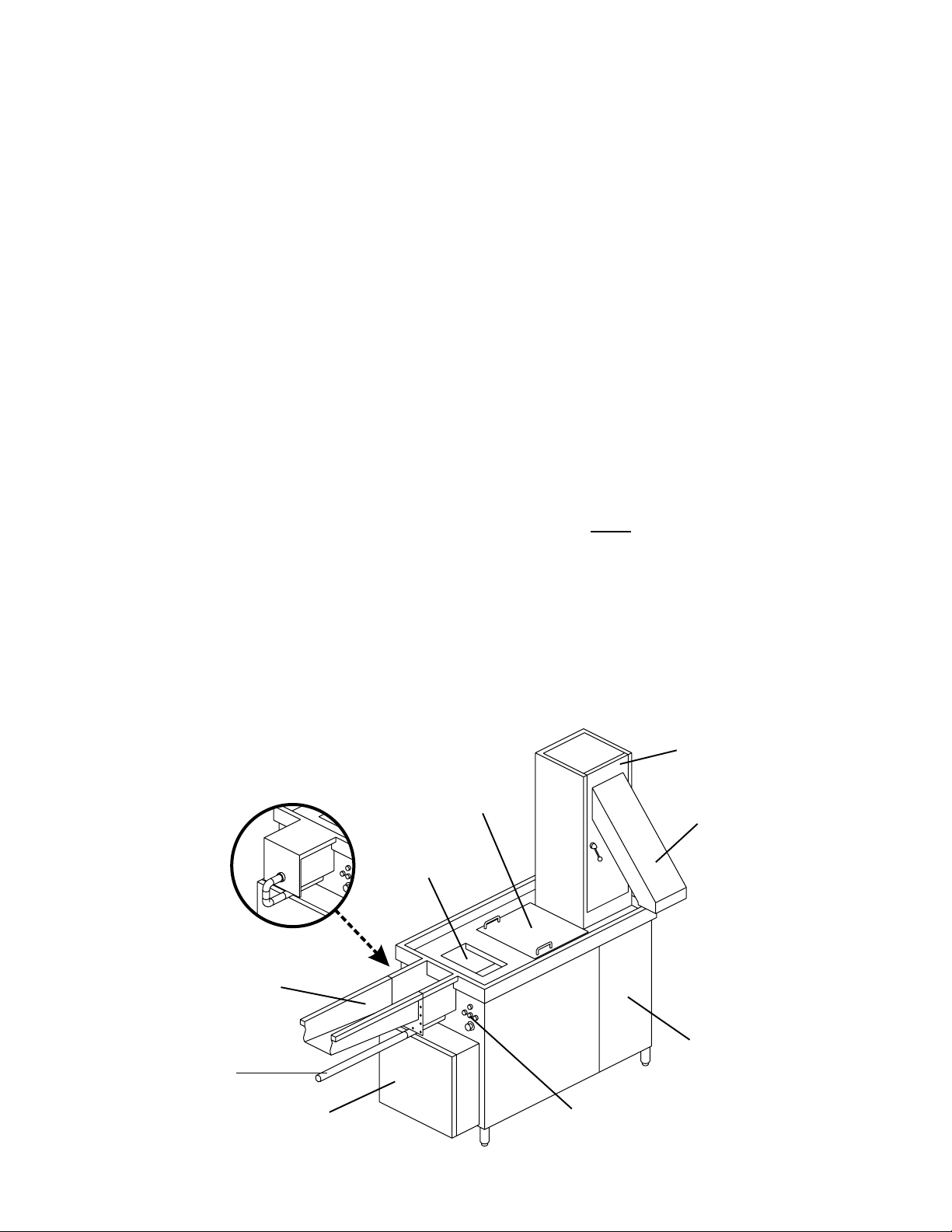

1.1 Overview of Equipment

The Meiko AZP 80 is a commercial waste

pulper intended for processing food waste

and mixed kitchen waste. The appliance

consists of a grinder and a water separator in

a close-coupled formation inside a common

housing.

Waste is fed into the machine using either a

manual feeding opening, or by an optional

water trough. Waste is moved through the

machine by the flow of water controlled by

an internal recirculating pump that minimizes

the need for additional water. For units

equipped with a feeding trough, the machine’s

internal recirculating pump also provides a

water supply for the trough system.

Waste is drawn into the grinding wheel by

water flow. The grinder consists of a powerful

8.8 hp/6.6 kW motor, grinding disk, filter ring

and knife. Cutting teeth are made from

tungsten carbide for superior performance

and longer life. After the waste is ground into

a pulped mass, sieve openings in the grinder

wall allow it to be drawn through and guided

to the water separator.

The separator consists of a perforated

cylinder and a screw. As the screw rotates

inside the cylinder, the ground waste is

pressed against the perforations, which

removes water from the waste, compacts it,

and lifts it. Separated water escapes through

the perforations in the cylinder, drains downward,

and is returned to the grinding tank. The solid,

nearly-dry pulp is routed out of the top of the

machine by a waste chute, which can be

emptied into a normal, lined garbage can for

easy disposal. A volume reduction of up to

85% is possible using the AZP 80 with normal

kitchen waste. A 70% reduction is typical.

For efficient and SAFE operation, be sure to

follow the installation and operating

instructions provided in this manual. In

particular, all safety symbols and notices on

the equipment and in the supplied documentation must be followed.

IMPORTANT

Meiko waste pulpers have been designed

exclusively for the pulping/dewatering of food

and mixed kitchen waste in a commercial or

institutional setting according to the

guidelines in this Manual and must not be

used for any other purpose.

Figure 1-1: AZP 80 overview

Machines

without

feeding

trough

Feeding trough (if

so equipped -

supplied by others)

Recirculating

water line (if

equipped with

feeding trough)

Electrical

compartment

Manual

feeding

opening

Grinding

compartment

Water

separator

(inside tower)

Waste

chute

Machinery

compartment

Control

panel

Page 3

SECTION 1 - INTRODUCTION

1.2 General Safety Information

The following symbols and headings are used

throughout this manual to indicate possible

hazards to persons or to the equipment. The

symbols and headings are shown in order of

importance. The descriptive text following these

headings is italicized for easy recognition.

WARNING! Possible hazard to per-

sons, such as from electrical shock, crushing, or

hot surfaces.

CAUTION Possible hazard to the

dishwasher or to other

equipment.

IMPORTANT Vital information or tips for

the installer or operator.

NOTE Information or tips for the

installer or operator.

3INSTALLATION

3.1 Overview of Installation

The owner should contract with qualified

personnel to move the appliance to the

installation location, unpack it, and prepare

it for final utility connections. In most cases,

local codes prevent the final utility connections from being made by any party other

than a licensed electrician and/or plumber.

IMPORTANT

It is the responsibility of the owner to ensure

that all aspects of the installation comply with

all applicable local and national codes.

IMPORTANT

The appliance’s warranty is not valid until a

Meiko Authorized Service Agent performs a

Startup and Demonstration on the appliance.

This Demonstration should be scheduled after

the installation.

2TRANSPORT AND SHIPPING

IMPORTANT

• Observe any notices on the crating material that pertain to shipping.

• Use care when transporting the equipment.

• As you unpack the equipment, check that

all components shown on the shipping

invoice are present and intact. Be sure to

check for shipping damage. If shipping

damage is present, file a freight claim

immediately and inform Meiko of the

damage, identifying all affected parts.

WARNING!

In NO EVENT should a damaged appliance be installed or operated!

Installation of the waste pulper involves the

following steps:

• Verifying that the utility connections are

present, are appropriate for the appliance,

and comply with all applicable local and

national codes.

• Unwrapping the appliance (leaving the

shipping skid in place for easier movement) and checking for shipping damage.

• Moving the appliance to the installation

location, removing the skid, and leveling

the feet.

• Attaching a feeding trough (if so equipped).

• Connecting the electrical supply.

• Connecting the water supplies.

• Connecting the drain line, and routing it

to an appropriately-sized floor drain.

• Installing a deodorizing system (if so

equipped), following the manufacturer’s

instructions.

Page 4

• Contacting your Meiko Authorized Service

Agent to perform a Startup and Demonstration on the appliance. This step also

validates the appliance’s warranty.

SECTION 3 - INSTALLATION

3.2 Requirements Before Installation

Before the installer can uncrate and move the

appliance to the installation location, the following conditions MUST be met:

• INSTALLATION AREA REQUIREMENTS

- The area MUST be frost-free. Freezing temperatures (32°F/0°C or lower)

inhibit proper operation and can damage internal components.

- The area MUST have a firm floor surface. It is possible to compensate for

uneven flooring by adjusting the feet.

• UTILTITY CONNECTION REQUIREMENTS

- Connections must be present and

ready for hookup to the appliance. All

utility supplies must comply with the

electrical information labels, on the

data plate, and with all applicable local and national codes.

- Electrical leads and the water supply

lines (supplied by the customer) must

be present. The water supplies must

be of the pressure and temperature

specified on the data plate.

- For units equipped with an optional

trough feeding system, the trough

should be present, and must match the

requirements of the machine as per all

specification sheets and supplied

drawings.

- For units using a deodorizing system,

an appropriate dispenser or container

should be installed and ready for connection to the appliance.

• GENERAL REQUIREMENTS

Authorized personnel should be available

to perform the actual utility connections.

3.3 Uncrating, Positioning and Leveling

1. Remove all shipping and packaging material from the appliance, including supports and wrappings. Leave the shipping

skid in place at this time to allow for easier

movement to the installation location.

2. Check for shipping damage as described

in Section 2, Transport and Shipping.

If damage is present, call Meiko Customer

Service at 1-800-868-3840, providing full

details on the customer, serial number and

extent of damage present. Meiko will file

a freight claim based on this information.

3. Move the appliance to the installation area

and remove the skid. Meiko recommends

using a pallet truck to lift the entire pallet

and avoid damage to the machine. Use

caution to avoid damaging the appliance

or any of its components.

CAUTION

If the pallet is removed, the frame of the

machine can be damaged by improper

lifting. Always use wooden members to

properly distribute the machine’s weight

and avoid damage. Note that motors or

other components may extend below the

frame; use caution to avoid damaging

these components.

CAUTION

Do not attempt to slide the machine on its

feet. This may damage the feet or bend

the legs of the machine. Move the

machine to the installation location by

lifting it, using a palette truck with wooden

members to distribute the weight.

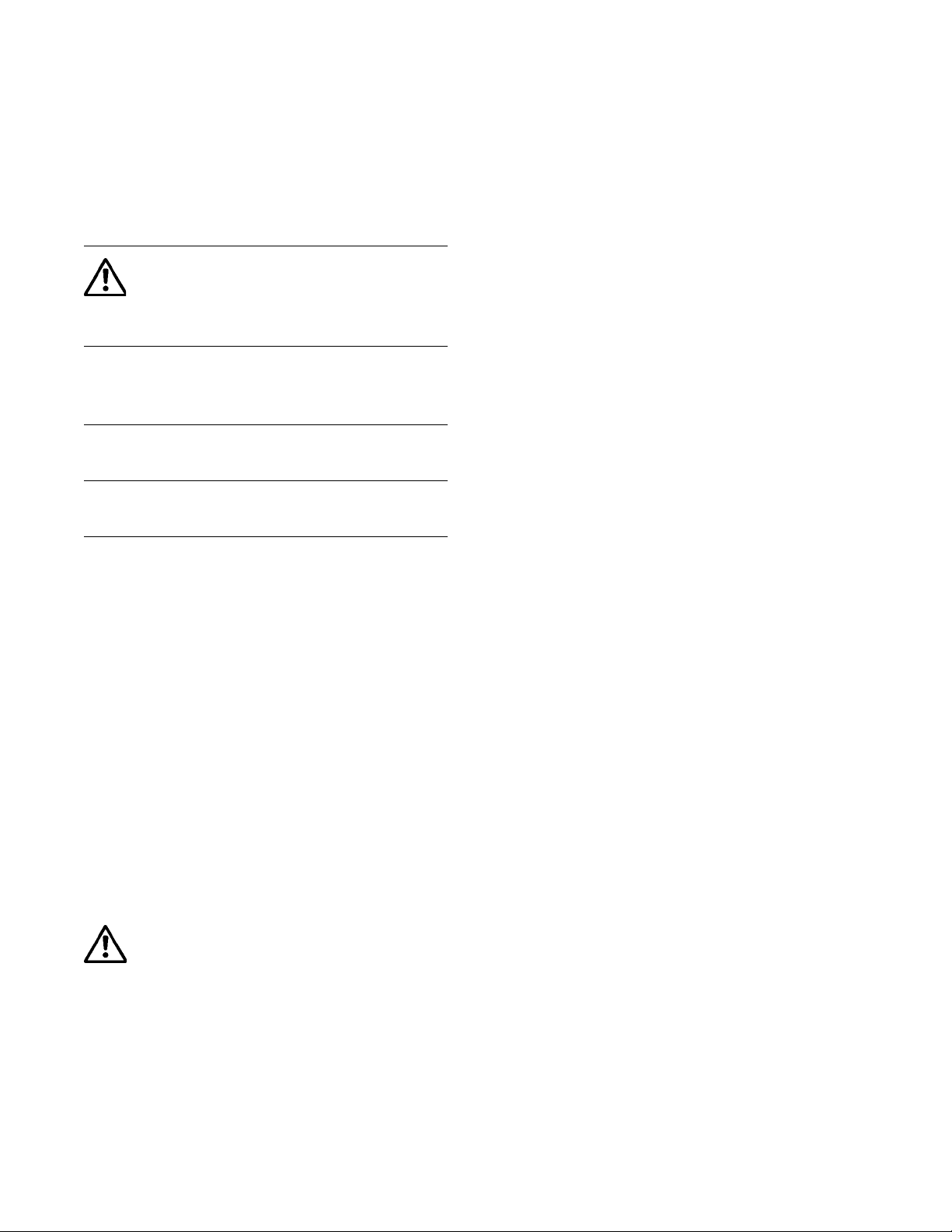

5. Using a spirit level, check that the

appliance is level in both directions (frontto-back AND side-to-side). If necessary,

level the appliance by accessing the bolts

above each foot and adjusting them using

a 17mm wrench. It is necessary to lift the

machine to remove the pressure from the

foot before adjustment. Refer to Figure 3-1.

CAUTION

The waste pulper MUST be level for

proper operation.

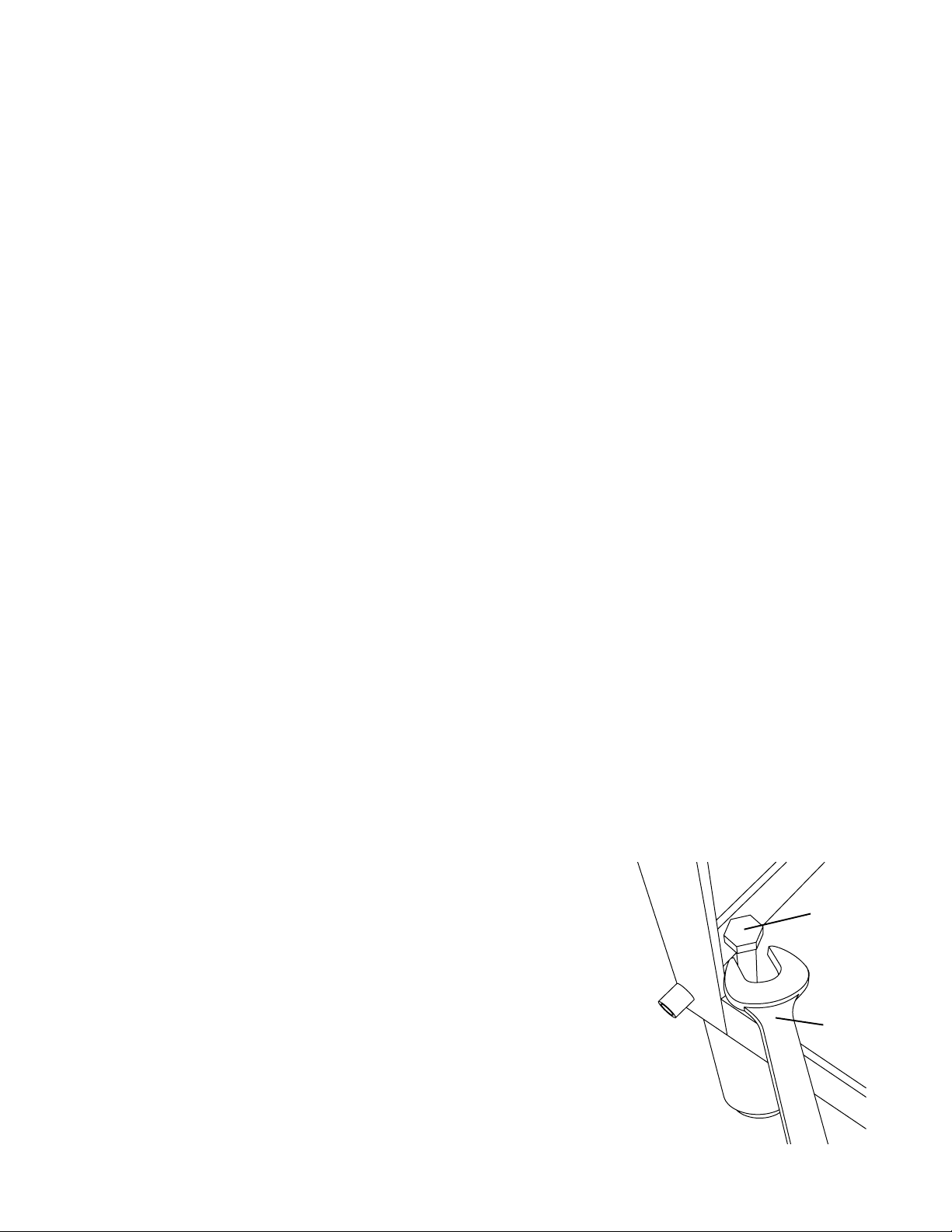

Figure 3-1:

Adjustment

bolt

Foot

adjustment

17mm

Open access doors or

remove side panels to

access adjustment bolts

Lift machine to remove

pressure before

adjusting foot

17mm

wrench

Page 5

SECTION 3 - INSTALLATION

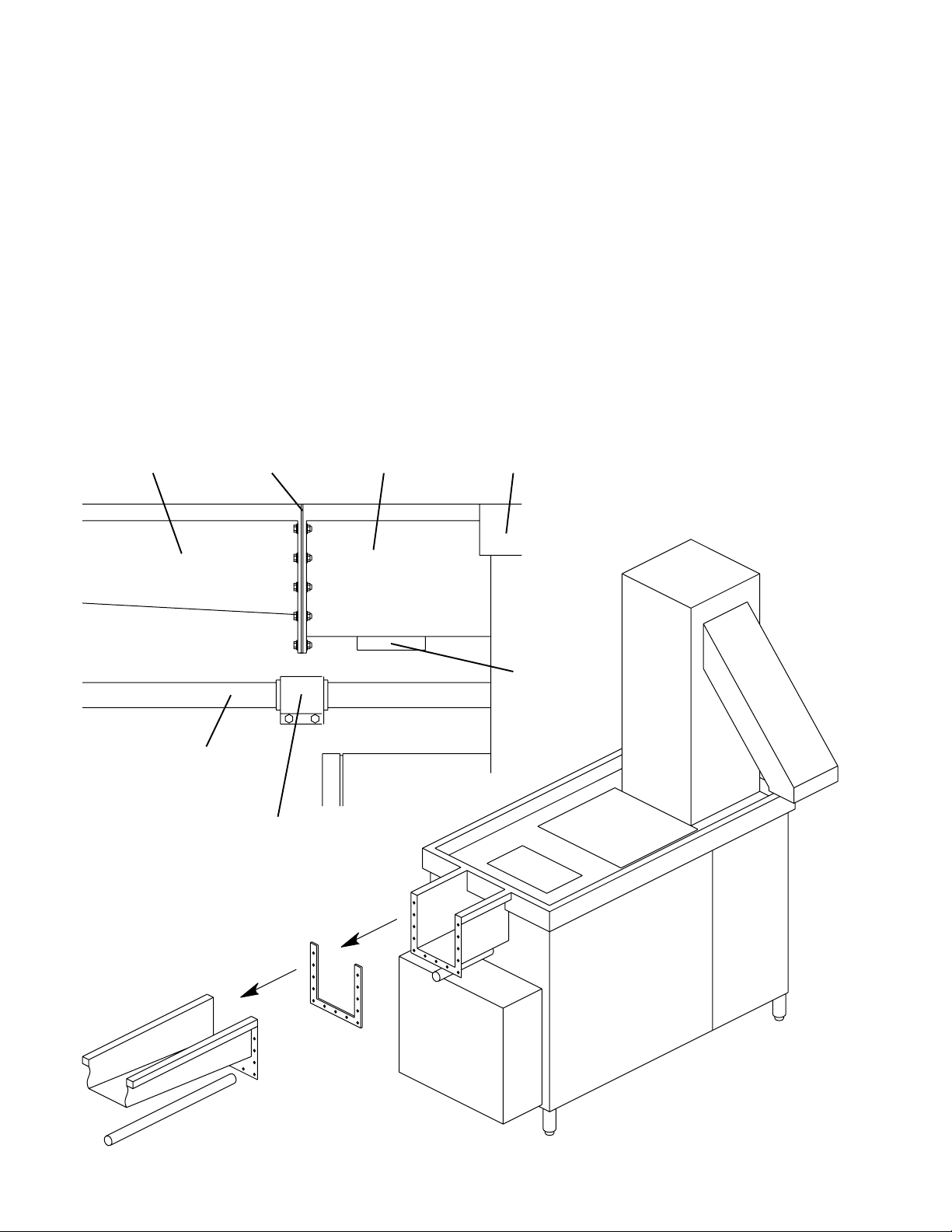

3.4 Connecting a Feeding Trough (if so

equipped)

Waste pulpers intended for use with a feeding

trough are equipped with a short trough

section at the load end of the machine. This

section incorporates a cutlery catch box,

magnet, and a mating plate. The end of the

trough (supplied by others), when constructed

to drawings supplied by Meiko, will

incorporate a matching plate to allow for

connection to the pulper.

Figure 3-2: Trough connection

Customer-

supplied

trough

Gasket

(supplied with

AZP 80)

Short trough

section (supplied

with AZP 80)

1. Attach the trough using qty. 13 hex bolts,

flat washers, lockwashers and hex nuts

as shown in Figure 3-2. Be sure to install

the supplied gasket between the mating

surfaces. Seal the connection with silicone

sealant to prevent water leakage.

2. Attach the recirculating water line to the

machine’s 2” OD pipe connection using

the supplied clamp and rubber boot.

AZP 80

Customer-supplied

recirculating water

line (2” OD)

Clamp fits over

rubber boot

Magnet

Page 6

Loading...

Loading...