Meiko AZP80 User Manual

AZP 80

Meiko's AZP 80 is an advanced, high-capacity

waste pulper that reduces food and mixed waste

volume by up to 85%.

Normal kitchen waste, with its high water content,

is a recognized carrier for disease and odors. The

AZP 80 solves these problems by reducing food

waste to a dry, relatively odorless pulp, using a

vertical, side-mounted tungsten carbide grinding

mechanism and a vertical dewatering press. A

flushing mechanism keeps the unit operating at

maximum efficiency during peak loads.

Reducing waste volume also reduces labor

costs,as well as costs associated with waste

transportation, disposal and pest control.

As with all products synonymous with the name

“Meiko,” engineering excellence, manufacturing

quality and performance come to the forefront in

the AZP 80.

WASTE

PULPER

Standard Features:

• Processes food and mixed kitchen waste, including

styrofoam, paper, and cardboard

• Waste is reduced to a dry pulp, with a volume

reduction of 70-85%. Water and liquid waste is filtered

and drained

• Includes a vertical, side-mounted grinding mechanism

and a vertical dewatering press in one unit

• Waste can be loaded using a continuous flushing

trough, or manually

• Safety features prevent metal objects such as knives

and forks from entering the grinding mechanism

• Door safety switches protect the operator. The unit is

shut down automatically if the grinder or dewatering

press access doors are opened during operation

• Convenient, reliable electromechanical controls

• Powerful 8.8 hp grinding motor is mounted horizontally

for easy serviceability

• Grinding disk incorporates tungsten carbide cutters

• Vertical dewatering press chamber incorporates selfflushing system to ease cleanup

• Flush-paneled, stainless steel exterior

• Automatic water level control

• Built-in connection points for odor neutralizing pumps

AZP 80 • Updated 07-09 Meiko • 1349 Heil Quaker Blvd. • La Vergne, TN 37086 • (800) 55-MEIKO • FAX (615) 399-6620 • www.meiko.us

Options:

• Available in left-to-right or right-to-left configurations

• Available with or without external water trough and

water recirculation connections

• Choice of waste chute locations: front, rear or inline

• Choice of water circulation pumps to accomodate a

variety of flushing trough systems

• Separate control panel at remote location

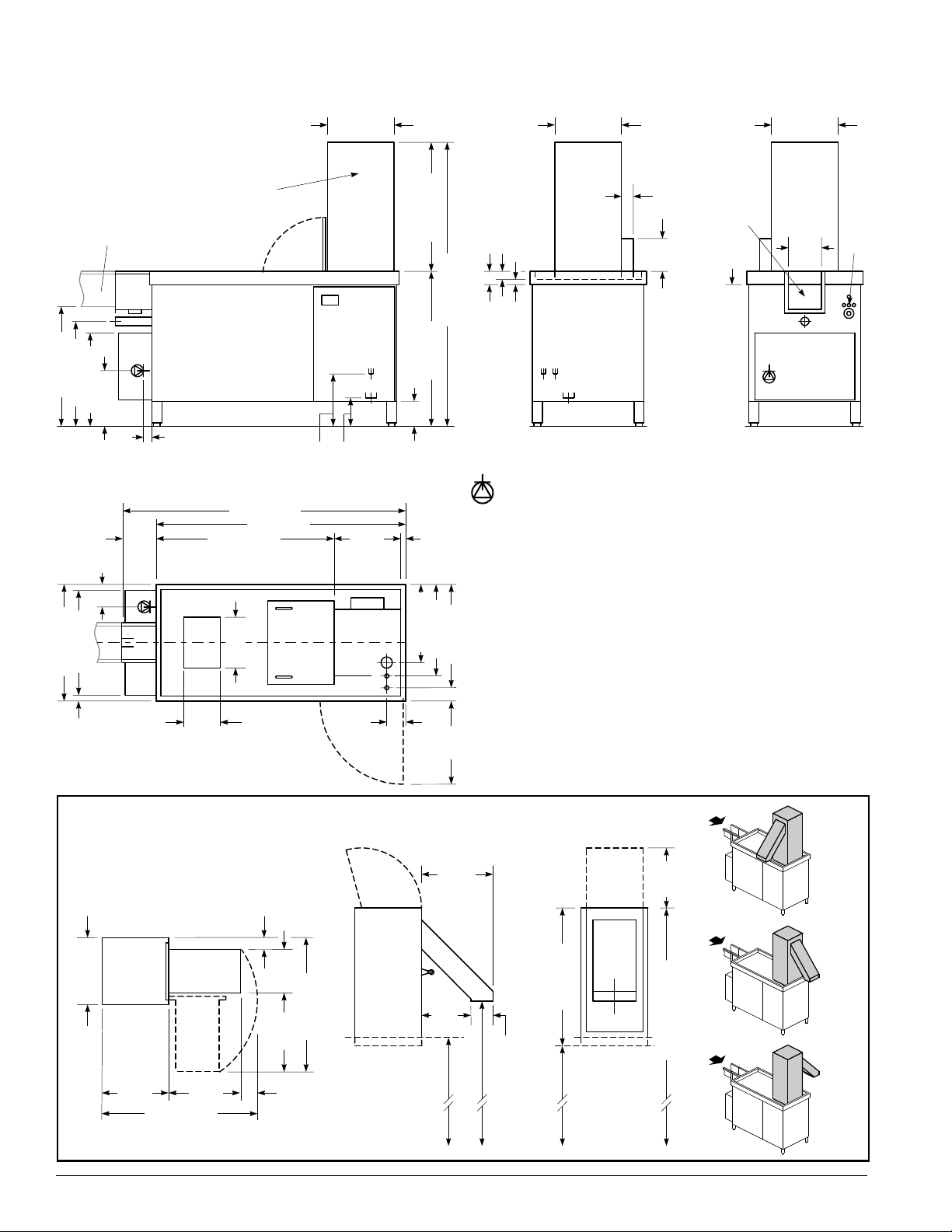

D

H

C

1' 6-1/2" (470mm)

1' 9-5/8" (550mm)

2' 3/8" (620mm)

4-1/2"

(115mm)

2' 3-1/2" (700mm)

4' 11" (1500mm)

7-7/8"

(200mm)

5' 6-7/8" (1700mm)

5-7/8"

(150mm)

3' 5/8" (930mm)

5' 7-1/8" (1705mm)

2' 6-1/2" (775mm)

1' 10-1/8" (560mm)

1' 11-3/4" (605mm)

3' 6-1/8" (1070mm) 1' 3-3/4"

(400mm)

1' (304mm)

8-5/8"

(220mm)

1' 3-3/4" (400mm)

1-1/8"

(30mm)

1' 3-3/4" (400mm)

1-1/8" (30mm)

2" (50mm)

3-1/8" (80mm)

7-1/8"

(180mm)

2-3/4"

(70mm)

1' 3-3/4" (400mm)

R

5-5/8"

(143mm)

7-7/8"

(200mm)

Control

panel

Trough

(see inset

drawing)

5' 7-1/8" (1705mm) A.F.F.

1' 2-1/8"

(360mm)

1' 4-7/8"

(430mm)

5-1/4"

(133mm)

11-3/4"

(297mm)

Base of tower

2' 10-3/4" (880m) A.F.F.

2' 8-1/2" (825mm)

3' 9" (1145mm) A.F.F.

Top of machine lip

3' 5/8" (930mm) A.F.F.

1' 3-3/4" (400mm)

1' 3-3/4"

(400mm)

1' 4-3/8"

(415mm)

2-3/4"

(70mm)

10-1/4"

(260mm)

1' 6-1/2"

(470mm)

2' 7-1/2" (800mm)

2' 11-7/8" (909mm)

3-3/4"

(94mm)

HH

Water supply connections

Hot water (110-140°F/43-60°C)

3/4" NPT male connection. 36-72

PSI (2.5-5.0 bars). Consumption

31.7 US gals. (120 l)/hr.

Trough

(supplied

by others)

1' 7-3/4"

(500mm)

Plan view

Left side viewRight side viewFront view

Dewatering press tower

AZP 80 Left-to-Right

Units with recirculating trough

5-3/8"

(137mm)

2' 3/4" (630mm)

1-3/8"

(35mm)

RR

Recirculating trough

connection

2" (51mm) O.D. connection via

clamp (provided). Route piping to

beginning of water trough. Piping

must incorporate 2" ball valve for

regulation of trough water supply.

Chute can be specified to

discharge to the front, inline

or rear at time of order. Door

can be hinged on either side

(left hinge is shown).

Plan view

Chute can be

specified to discharge

to the front, inline or

rear at time of order.

See detail drawings

for dimensions.

All dimensions from floor

are +/- 1/2" (12mm)

due to adjustable feet.

All

dimensions

from floor are

+/- 1/2"

(12mm) due

to adjustable

feet.

2' 3-1/2" (700mm)

2" (51mm)

1' 7/8" (327mm)

D

H,C

6-3.4"

(171mm)

1' 1/2"

(318mm)

CDH

R

R

Cold water (50°F/10°C)

3/4" NPT male connection. 36-72

PSI (2.5-5.0 bars). Initial fill 21.1

US gals. (80l). Consumption 39.6

US gals. (150 l)/hour

CC

Front

chute

Inline

chute

Rear

chute

DD

Electrical supply connection

4-wire (L1, L2, L3, GND)

connection without neutral.

Supply routed from below the

machine (strain relief provided).

Individual circuit breaker/

disconnect with lockout/tagout

strongly recommended.

Drain connection

2" NPT female vertical drain

outlet (HDPE piping).

Recommended placement

directly above 3" (75mm) floor

drain. Grease trap/separator

required (provided by others).

AZP 80 • Updated 07-09 Meiko • 1349 Heil Quaker Blvd. • La Vergne, TN 37086 • (800) 55-MEIKO • FAX (615) 399-6620 • www.meiko.us

Recirculating Trough Connection

Downslope

required

(1-1/4" per 10'

suggested

minimum)

(trough to be supplied by others)

3/4"

(20mm)

All dimensions

from floor

are +/- 1/2"

(12mm) due to

adjustable feet.

Front

view

"Step" down to attached stub

trough forms cutlery catch box

(magnet is supplied)

Magnet

2' 3-1/2" (700mm)

Left-to-Right

operation shown.

Right-to-Left

is a mirror image.

2" clamp

provided for

recirculating

water pipe

connection

1' 11-3/4" (605mm)

3/4"

(20mm)

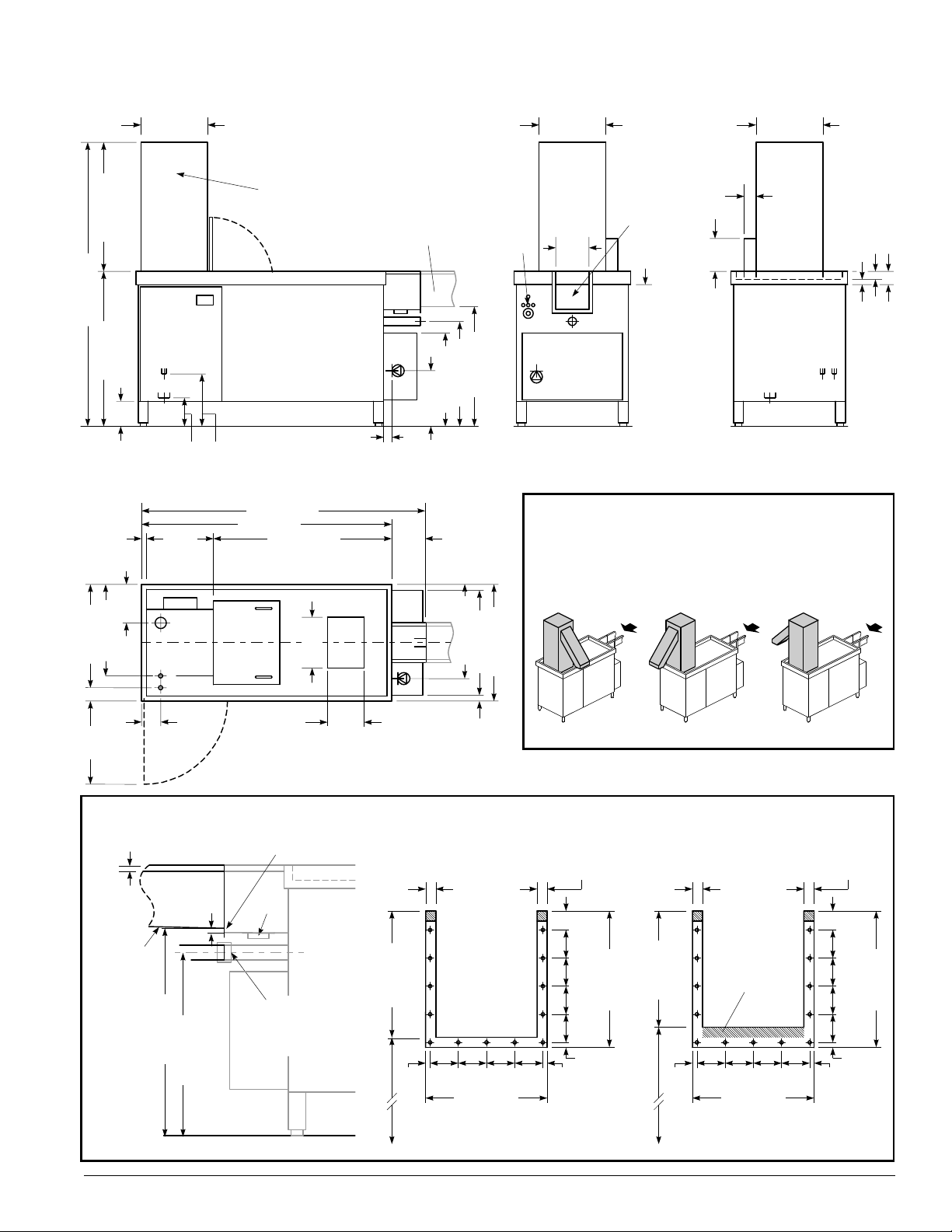

AZP 80 Right-to-Left

Units with recirculating trough

Front

chute

Inline

chute

Rear

chute

D

H

C

9"

(230mm)

1' 9-5/8" (550mm)

2' 3/8" (620mm)

4-1/2"

(115mm)

2' 3-1/2" (700mm)

4' 11" (1500mm)

7-7/8"

(200mm)

5' 6-7/8" (1700mm)

5-7/8"

(150mm)

3' 5/8" (930mm)

5' 7-1/8" (1705mm)

2' 6-1/2" (775mm)

1' 10-1/8" (560mm)

1' 11-3/4" (605mm)

3' 6-1/8" (1070mm)1' 3-3/4"

(400mm)

1' (304mm)

8-5/8"

(220mm)

1' 3-3/4" (400mm)

1-1/8"

(30mm)

1' 3-3/4" (400mm)

1-1/8" (30mm)

2" (50mm)

3-1/8" (80mm)

7-1/8"

(180mm)

2-3/4"

(70mm)

R

R

1' 3-3/4" (400mm)

R

5-5/8"

(143mm)

7-7/8"

(200mm)

Control

panel

Trough

(see inset

drawing)

Trough

(supplied

by others)

1' 7-3/4"

(500mm)

Plan view

Left side viewRight side viewFront view

2' 3/4" (630mm)

1-3/8"

(35mm)

Chute can be

specified to discharge

to the front, inline or

rear at time of order.

See detail drawings

for dimensions.

All dimensions from floor

are +/- 1/2" (12mm)

due to adjustable feet.

2' 3-1/2" (700mm)

2" (51mm)

1' 7/8" (327mm)

D

H,C

6-3.4"

(171mm)

1' 1/2"

(318mm)

C

D

H

1' 10-1/8" (563mm)

R

2-3/16"

(56mm)

3/8" (10mm)

9-7/16" (244mm)

10-5/8" (270mm)

2-3/16"

(56mm)

2-3/16"

(56mm)

2-3/16"

(56mm)

1-1/2" (37mm)

2-3/16"

(56mm)

2-3/16"

(56mm)

2-3/16"

(56mm)

2-3/16"

(56mm)

3/8"

(10mm)

9-13/16" (250mm)

trough depth

2' 2-3/4" (680mm) A.F.F.

3/8"

(10mm)

13/16"

(20mm)

7-7/8" (200mm)

13/16" (20mm)

squared edge

2-3/16"

(56mm)

3/8" (10mm)

9-7/16" (244mm)

10-5/8" (270mm)

2-3/16"

(56mm)

2-3/16"

(56mm)

2-3/16"

(56mm)

1-1/2" (37mm)

2-3/16"

(56mm)

2-3/16"

(56mm)

2-3/16"

(56mm)

2-3/16"

(56mm)

3/8"

(10mm)

9-1/16" (230mm)

trough depth

2' 3-1/2" (700mm) A.F.F.

3/8"

(10mm)

13/16"

(20mm)

7-7/8" (200mm)

13/16" (20mm)

squared edge

Customer-supplied

trough flange includes

20mm additional

material to form wall

of cutlery catch box

Detail view: AZP 80 flange

(supplied with machine)

Detail view: trough flange

(to be supplied by others)

Dewatering press tower

For tower dimensions, refer to the facing page.

AZP 80 • Updated 07-09 Meiko • 1349 Heil Quaker Blvd. • La Vergne, TN 37086 • (800) 55-MEIKO • FAX (615) 399-6620 • www.meiko.us

Loading...

Loading...