Page 1

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 1 of 19

Safety Data Sheet

Copyright, 2012, Meguiar's, Inc. All rights reserved. Copying and/or downloading of this information for the purpose of

properly utilising Meguiar's, Inc. products is allowed provided that: (1) the information is copied in full with no changes

unless prior written agreement is obtained from Meguiar's, Inc., and (2) neither the copy nor the original is resold or otherwise

distributed with the intention of earning a profit thereon.

Document group:

28-5230-9

Version number:

1.02

Revision date:

26/04/2012

Supersedes date:

31/10/2011

Transportation version number: 1.00 (31/10/2011)

This Safety Data Sheet has been prepared in accordance with the REACH Regulation (EC) 1907/2006 and its modifications.

SECTION 1: Identification of the substance/mixture and of the

company/undertaking

1.1. Product identifier

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

1.2. Relevant identified uses of the substance or mixture and uses advised against

Identified uses

Mold release agent

1.3. Details of the supplier of the substance or mixture

Address:

Meguiars United Kingdon Limited, 3 Lamport Court, Heartlands, Daventry, Northants, NN11 8UF

Telephone:

+44 (0)870 241 6696

E Mail:

info@meguiars.co.uk

Website:

www.meguiars.co.uk

1.4. Emergency telephone number

+44 (0)870 241 6696

SECTION 2: Hazard identification

2.1. Classification of the substance or mixture

Dangerous substances(67/548/EEC)/preparations(1999/45/EC) directive

Indication of danger

Harmful.

Flammable

2.2. Label elements

Dangerous substances(67/548/EEC)/preparations(1999/45/EC) directive

Symbols

Xn Harmful.

Page 2

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 2 of 19

Contains:

Naphtha (petroleum), hydrotreated heavy

Risk phrases

R10 Flammable.

R65 Harmful: May cause lung damage if swallowed.

R67 Vapours may cause drowsiness and dizziness.

R66 Repeated exposure may cause skin dryness or cracking.

Safety phrases

S23A Do not breathe vapour.

S24 Avoid contact with skin.

S62 If swallowed, do not induce vomiting: Seek medical advice immediately and show this container or

label.

Notes on labelling

Nota P applied for CASRN 64742-48-9, 64742-82-1 and 8052-41-3.

2.3. Other hazards

None known.

SECTION 3: Composition/information on ingredients

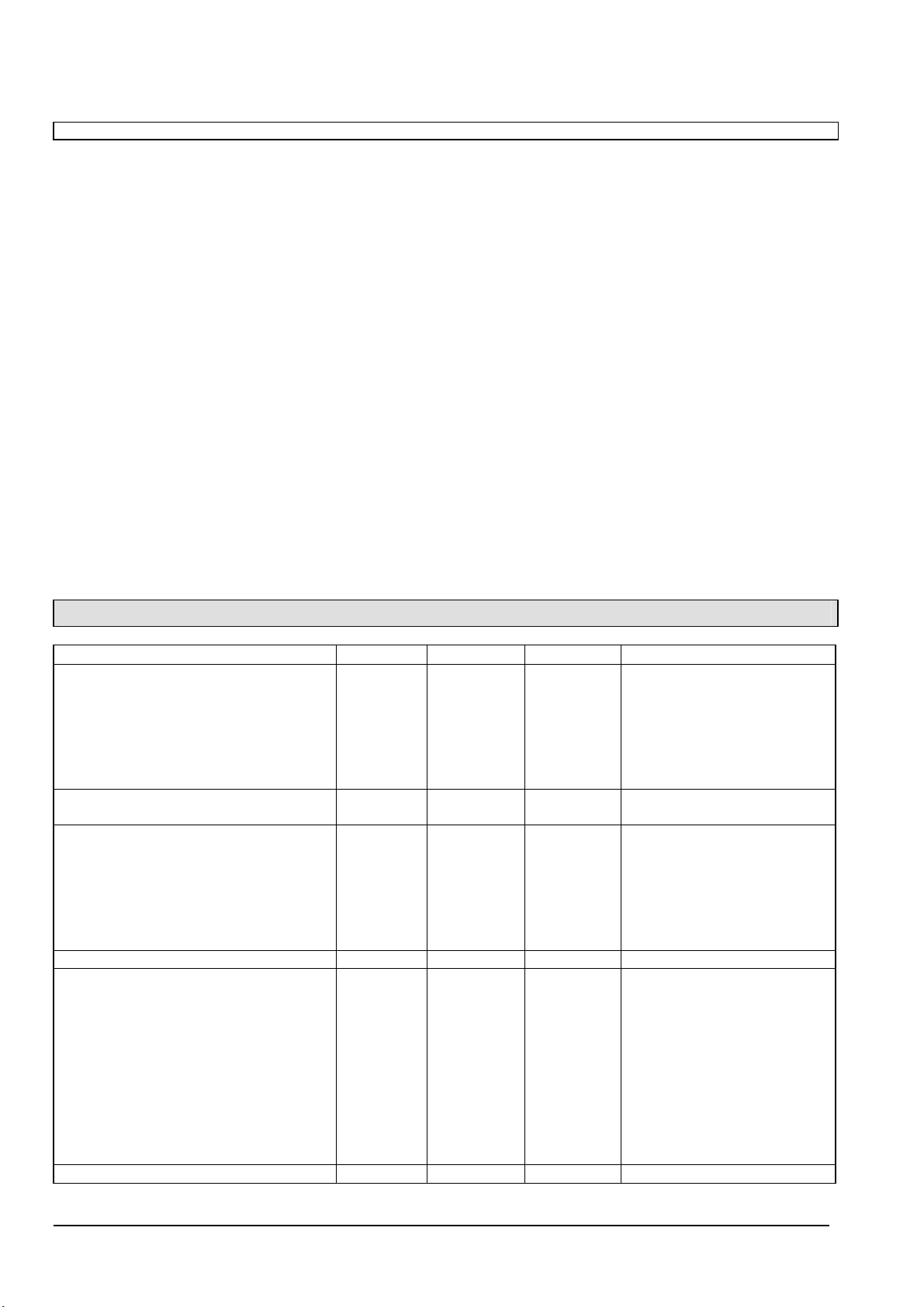

Ingredient CAS Nbr EU Inventory % by Wt Classification

Naphtha (petroleum), hydrotreated heavy 64742-48-9 EINECS 265-

150-3

85 - 95 Xn:R65 - Nota 4,P (EU)

R66; R67 (Self Classified)

Asp. Tox. 1, H304 - Nota P

(CLP)

STOT SE 3, H336; EUH066

(Self Classified)

Silicic acid, sodium salt, reaction products

with chlorotrimethylsilane and iso-Pr alc

68988-56-7 EINECS 273-

530-5

1 - 5

Stoddard Solvent 8052-41-3 EINECS 232-

489-3

1 - 5 Xn:R65 - Nota 4,P (EU)

R66; R67 (Self Classified)

Asp. Tox. 1, H304 - Nota P

(CLP)

STOT SE 3, H336; EUH066

(Self Classified)

Siloxanes and silicones, di-Me 63148-62-9 1 - 5

Naphtha (petroleum), hydrodesulphurised

heavy

64742-82-1 EINECS 265-

185-4

1 - 5 Xn:R65 - Nota 4,P (EU)

R10 (Vendor)

N:R51/53; R66; R67 (Self

Classified)

Asp. Tox. 1, H304 - Nota P

(CLP)

Flam. Liq. 3, H226 (Vendor)

STOT SE 3, H336; EUH066;

Aquatic Chronic 2, H411 (Self

Classified)

Ethylbenzene 100-41-4 EINECS 202- 0.1 - 1.0 F:R11; Xn:R20 (EU)

Page 3

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 3 of 19

849-4

Flam. Liq. 2, H225; Acute Tox.

4, H332 (CLP)

Toluene 108-88-3 EINECS 203-

625-9

<= 0.0045 Repr.Cat.3:R63; F:R11;

Xn:R48/20; Xn:R65; Xi:R38;

R67 - Nota 4 (EU)

Flam. Liq. 2, H225; Asp. Tox. 1,

H304; Skin Irrit. 2, H315; Repr.

2, H361d; STOT SE 3, H336;

STOT RE 1, H372 (CLP)

Please see section 16 for the full text of any R phrases and H statements referred to in this section

Please refer to section 15 for the any applicable Notas that have been applied to the above components

For information on ingredient occupational exposure limits or PBT or vPvB status, see sections 8 and 12 of this SDS

SECTION 4: First aid measures

4.1. Description of first aid measures

Eye contact

Flush with large amounts of water. Remove contact lenses if easy to do. Continue rinsing. If signs/symptoms persist, get

medical attention.

Skin contact

Immediately wash with soap and water. Remove contaminated clothing and wash before reuse. If signs/symptoms develop,

get medical attention.

Inhalation

Remove person to fresh air. If you feel unwell, get medical attention.

If swallowed

Do not induce vomiting. Get immediate medical attention.

4.2. Most important symptoms and effects, both acute and delayed

See Section 11.1 Information on toxicological effects

4.3. Indication of any immediate medical attention and special treatment required

Not applicable

SECTION 5: Fire-fighting measures

5.1. Extinguishing media

In case of fire: Use a fire fighting agent suitable for flammable liquids or gases such as dry chemical or carbon dioxide.

5.2. Special hazards arising from the substance or mixture

Closed containers exposed to heat from fire may build pressure and explode.

Hazardous Decomposition or By-Products

Substance Condition

Formaldehyde During combustion.

Carbon monoxide. During combustion.

Carbon dioxide. During combustion.

Irritant vapours or gases. During combustion.

Page 4

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 4 of 19

5.3. Advice for fire-fighters

Water may not effectively extinguish fire; however, it should be used to keep fire-exposed containers and surfaces cool and

prevent explosive rupture.

SECTION 6: Accidental release measures

6.1. Personal precautions, protective equipment and emergency procedures

Evacuate area. Keep away from heat/sparks/open flames/hot surfaces. - No smoking. Use only non-sparking tools. Ventilate

the area with fresh air. For large spill, or spills in confined spaces, provide mechanical ventilation to disperse or exhaust

vapours, in accordance with good industrial hygiene practice. Warning: A motor could be an ignition source and could cause

flammable gases or vapours in the spill area to burn or explode. Refer to other sections of this SDS for information regarding

physical and health hazards, respiratory protection, ventilation, and personal protective equipment.

6.2. Environmental precautions

Avoid release to the environment. For larger spills, cover drains and build dykes to prevent entry into sewer systems or

bodies of water.

6.3. Methods and material for containment and cleaning up

Contain spill. Cover spill area with a fire-extinguishing foam designed for use on solvents, such as alcohols and acetone, that

can dissolve in water. An AR-AFFF type foam is recommended. Working from around the edges of the spill inward, cover

with bentonite, vermiculite, or commercially available inorganic absorbent material. Mix in sufficient absorbent until it

appears dry. Remember, adding an absorbent material does not remove a toxic, corrosivity or flammability hazard. Collect

as much of the spilled material as possible using non-sparking tools. Place in a metal container approved for transportation

by appropriate authorities. Clean up residue with an appropriate solvent selected by a qualified and authorised person.

Ventilate the area with fresh air. Read and follow safety precautions on the solvent label and Safety Data Sheet. Seal the

container. Dispose of collected material as soon as possible.

6.4. Reference to other sections

Refer to Section 8 and Section 13 for more information

SECTION 7: Handling and storage

7.1. Precautions for safe handling

For industrial or professional use only. Do not use in a confined area or areas with little or no air movement. Do not handle

until all safety precautions have been read and understood. Keep away from heat/sparks/open flames/hot surfaces. - No

smoking. Ground/bond container and receiving equipment. Use only non-sparking tools. Take precautionary measures

against static discharge. Use explosion-proof electrical/ventilating/lighting/equipment. Avoid breathing

dust/fume/gas/mist/vapours/spray. Do not get in eyes, on skin, or on clothing. Do not eat, drink or smoke when using this

product. Wash thoroughly after handling. Avoid contact with oxidising agents (eg. chlorine, chromic acid etc.) Wear low

static or properly grounded shoes. Use personal protective equipment (eg. gloves, respirators…) as required. Vapours may

travel long distances along the ground or floor to an ignition source and flash back.

7.2. Conditions for safe storage including any incompatibilities

Store in a well-ventilated place. Keep cool. Keep container tightly closed. Store away from heat. Protect from sunlight.

Store away from acids. Store away from oxidising agents.

7.3. Specific end use(s)

See information in Section 7.1 and 7.2 for handling and storage recommendations. See Section 8 for exposure controls and

personal protection recommendations.

SECTION 8: Exposure controls/personal protection

8.1 Control parameters

Page 5

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 5 of 19

Occupational exposure limits

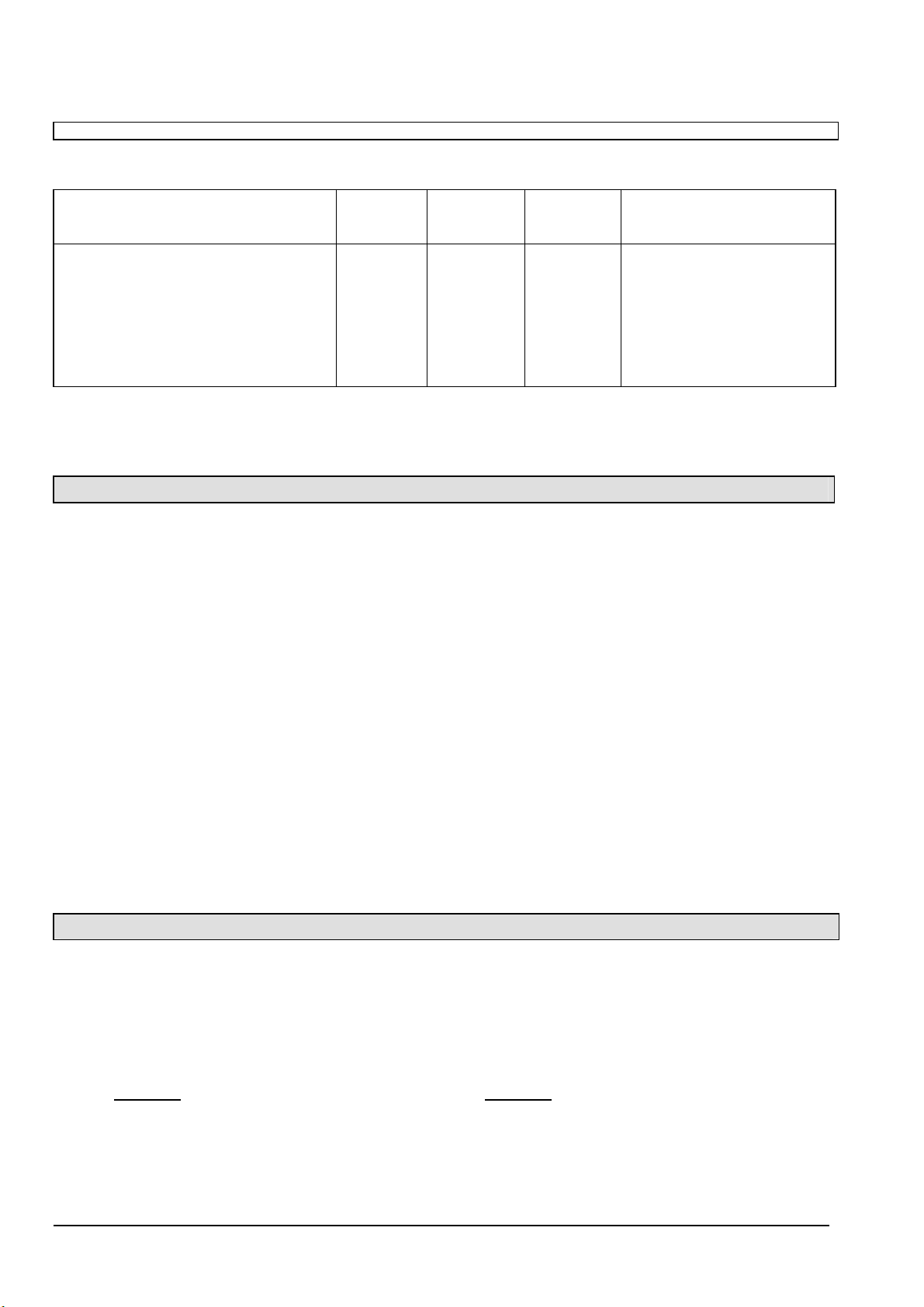

Ingredient CAS Nbr Agency Limit type Additional comments

Ethylbenzene 100-41-4 Health and

Safety Comm.

(UK)

TWA:441 mg/m3(100

ppm);STEL:552 mg/m3(125

ppm)

Skin Notation

Toluene 108-88-3 Health and

Safety Comm.

(UK)

TWA: 191 mg/m³ (50 ppm);

STEL: 384 mg/m³ (100 ppm)

Skin Notation

Naphtha (petroleum),

hydrotreated heavy

64742-48-9 Manufacturer

determined

TWA:100 ppm

Health and Safety Comm. (UK) : UK Health and Safety Commission

TWA: Time-Weighted-Average

STEL: Short Term Exposure Limit

ppm: parts per million

mg/m³: milligrams per cubic metre

CEIL: Ceiling

8.2. Exposure controls

8.2.1. Engineering controls

Use explosion-proof ventilation equipment. Use general dilution ventilation and/or local exhaust ventilation to control

airborne exposures to below relevant Exposure Limits and/or control dust/fume/gas/mist/vapours/spray. If ventilation is not

adequate, use respiratory protection equipment.

8.2.2. Personal protective equipment (PPE)

Eye/face protection

As a good industrial hygiene practice:

Wear eye/face protection.

The following eye protection(s) are recommended: Safety glasses with side shields.

Skin/hand protection

Wear protective gloves.

Gloves made from the following material(s) are recommended: Nitrile rubber.

Respiratory protection

In case of inadequate ventilation wear respiratory protection.

Select one of the following approved respirators based on airborne concentration of contaminants and in accordance with

regulations:

Half facepiece or full facepiece air-purifying respirator suitable for organic vapours

SECTION 9: Physical and chemical properties

9.1. Information on basic physical and chemical properties

Physical state

Liquid.

Appearance/Odour

Odourless; Clear liquid

pH

Not applicable.

Boiling point/boiling range

76.7 ºC

Melting point

Not applicable.

Flammability (solid, gas)

Flammable liquid: Category 3.

Explosive properties

Not classified

Page 6

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 6 of 19

Oxidising properties

Not classified

Flash point

40.6 ºC [Test Method:Pensky-Martens Closed Cup]

[Details:D93-90]

Autoignition temperature

No data available.

Flammable Limits(LEL)

No data available.

Flammable Limits(UEL)

No data available.

Vapour pressure

No data available.

Relative density

0.75 [Ref Std:WATER=1]

Water solubility

No data available.

Partition coefficient: n-octanol/water

No data available.

Evaporation rate

No data available.

Vapour density

No data available.

Viscosity

1.5 mm²/sec [@ 25 ºC ]

Viscosity

1.2 mm²/sec [@ 40 ºC ]

Density

0.75 g/cm3

9.2. Other information

Volatile organic compounds (VOC)

99.02 % weight

VOC less H2O & exempt solvents

742.64 g/l

SECTION 10: Stability and reactivity

10.1 Reactivity

This material may be reactive with certain agents under certain conditions - see the remaining headings in this section

10.2 Chemical stability

Stable.

10.3 Possibility of hazardous reactions

Hazardous polymerisation will not occur.

10.4 Conditions to avoid

Heat.

Sparks and/or flames.

10.5 Incompatible materials

Strong oxidising agents.

Strong acids.

Strong bases.

10.6 Hazardous decomposition products

Substance Condition

None known.

SECTION 11: Toxicological information

The information below may not be consistent with the material classification in Section 2 if specific ingredient

classifications are mandated by a competent authority. In addition, toxicological data on ingredients may not be

reflected in the material classification and/or the signs and symptoms of exposure, because an ingredient may be

present below the threshold for labelling, an ingredient may not be available for exposure, or the data may not be

Page 7

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 7 of 19

relevant to the material as a whole.

11.1 Information on Toxicological effects

Signs and Symptoms of Exposure

Based on test data and/or information on the components, this material may produce the following health effects:

Eye contact

Contact with the eyes during product use is not expected to result in significant irritation.

Skin contact

Mild Skin Irritation: Signs/symptoms may include localized redness, swelling, itching, and dryness.

Inhalation

Intentional concentration and inhalation may be harmful or fatal. Respiratory tract irritation: Signs/symptoms may include

cough, sneezing, nasal discharge, headache, hoarseness, and nose and throat pain. May cause target organ effects after

inhalation.

Ingestion

Gastrointestinal irritation: Signs/symptoms may include abdominal pain, stomach upset, nausea, vomiting and diarrhoea.

Chemical (aspiration) pneumonitis: Signs/symptoms may include coughing, gasping, choking, burning of the mouth,

difficulty breathing, bluish coloured skin (cyanosis), and may be fatal. May cause target organ effects after ingestion.

Target Organ Effects:

Central nervous system (CNS) depression: Signs/symptoms may include headache, dizziness, drowsiness, incoordination,

nausea, slowed reaction time, slurred speech, giddiness, and unconsciousness.

Carcinogenicity:

Contains a chemical or chemicals which can cause cancer.

Toxicological Data

Acute Toxicity

Name Route Species Value

Overall product Ingestion No test data available; calculated ATE

>5,000 mg/kg

Naphtha (petroleum), hydrotreated

heavy

Dermal Rabbit LD50 > 3,000 mg/kg

Naphtha (petroleum), hydrotreated

heavy

Inhalation-Vapor (4

hours)

Rat LC50 estimated to be 20 - 50 mg/l

Naphtha (petroleum), hydrotreated

heavy

Ingestion Rat LD50 > 5,000 mg/kg

Silicic acid, sodium salt, reaction

products with chlorotrimethylsilane

and iso-Pr alc

No data available

Stoddard Solvent Dermal Rabbit LD50 > 3,000 mg/kg

Stoddard Solvent Inhalation-Vapor (4

hours)

Rat LC50 estimated to be 20 - 50 mg/l

Stoddard Solvent Ingestion Rat LD50 > 5,000 mg/kg

Siloxanes and silicones, di-Me Dermal Rabbit LD50 > 19,400 mg/kg

Siloxanes and silicones, di-Me Ingestion Rat LD50 > 17,000 mg/kg

Naphtha (petroleum),

hydrodesulphurised heavy

Dermal Rabbit LD50 > 3,000 mg/kg

Naphtha (petroleum),

hydrodesulphurised heavy

Inhalation-Vapor (4

hours)

Rat LC50 estimated to be 20 - 50 mg/l

Naphtha (petroleum), Ingestion Rat LD50 > 5,000 mg/kg

Page 8

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 8 of 19

hydrodesulphurised heavy

Ethylbenzene Dermal Rabbit LD50 15,433 mg/kg

Ethylbenzene Inhalation-Vapor (4

hours)

Rat LC50 17 mg/l

Ethylbenzene Ingestion Rat LD50 4,769 mg/kg

Toluene Dermal Rat LD50 12,000 mg/kg

Toluene Inhalation-Vapor (4

hours)

Rat LC50 30 mg/l

Toluene Ingestion Rat LD50 2,600 mg/kg

ATE = acute toxicity estimate

Skin Corrosion/Irritation

Name Species Value

Naphtha (petroleum), hydrotreated heavy No data available

Silicic acid, sodium salt, reaction products with

chlorotrimethylsilane and iso-Pr alc

No data available

Stoddard Solvent Mild irritant

Siloxanes and silicones, di-Me Rabbit No significant irritation

Naphtha (petroleum), hydrodesulphurised heavy Mild irritant

Ethylbenzene Rabbit Mild irritant

Toluene Rabbit Irritant

Serious Eye Damage/Irritation

Name Species Value

Naphtha (petroleum), hydrotreated heavy No data available

Silicic acid, sodium salt, reaction products with

chlorotrimethylsilane and iso-Pr alc

No data available

Stoddard Solvent Mild irritant

Siloxanes and silicones, di-Me Rabbit No significant irritation

Naphtha (petroleum), hydrodesulphurised heavy Mild irritant

Ethylbenzene Rabbit Moderate irritant

Toluene Rabbit Moderate irritant

Skin Sensitisation

Name Species Value

Naphtha (petroleum), hydrotreated heavy Not sensitizing

Silicic acid, sodium salt, reaction products with

chlorotrimethylsilane and iso-Pr alc

No data available

Stoddard Solvent Not sensitizing

Siloxanes and silicones, di-Me No data available

Naphtha (petroleum), hydrodesulphurised heavy Not sensitizing

Ethylbenzene Human Not sensitizing

Toluene Guinea pig Not sensitizing

Respiratory Sensitisation

Name Species Value

Naphtha (petroleum), hydrotreated heavy No data available

Silicic acid, sodium salt, reaction products with

chlorotrimethylsilane and iso-Pr alc

No data available

Stoddard Solvent No data available

Siloxanes and silicones, di-Me No data available

Naphtha (petroleum), hydrodesulphurised heavy No data available

Ethylbenzene No data available

Toluene No data available

Germ Cell Mutagenicity

Name Route Value

Naphtha (petroleum), hydrotreated heavy Inhalation Not mutagenic

Naphtha (petroleum), hydrotreated heavy In Vitro Some positive data exist, but the data are not

Page 9

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 9 of 19

sufficient for classification

Silicic acid, sodium salt, reaction products with

chlorotrimethylsilane and iso-Pr alc

No data available

Stoddard Solvent Inhalation Not mutagenic

Stoddard Solvent In Vitro Some positive data exist, but the data are not

sufficient for classification

Siloxanes and silicones, di-Me No data available

Naphtha (petroleum), hydrodesulphurised heavy Inhalation Not mutagenic

Naphtha (petroleum), hydrodesulphurised heavy In Vitro Some positive data exist, but the data are not

sufficient for classification

Ethylbenzene In vivo Not mutagenic

Ethylbenzene In Vitro Some positive data exist, but the data are not

sufficient for classification

Toluene In Vitro Not mutagenic

Toluene In vivo Not mutagenic

Carcinogenicity

Name Route Species Value

Naphtha (petroleum), hydrotreated

heavy

Dermal Some positive data exist, but the data

are not sufficient for classification

Naphtha (petroleum), hydrotreated

heavy

Inhalation Some positive data exist, but the data

are not sufficient for classification

Silicic acid, sodium salt, reaction

products with chlorotrimethylsilane

and iso-Pr alc

No data available

Stoddard Solvent Dermal Some positive data exist, but the data

are not sufficient for classification

Stoddard Solvent Inhalation Some positive data exist, but the data

are not sufficient for classification

Siloxanes and silicones, di-Me No data available

Naphtha (petroleum),

hydrodesulphurised heavy

Dermal Some positive data exist, but the data

are not sufficient for classification

Naphtha (petroleum),

hydrodesulphurised heavy

Inhalation Some positive data exist, but the data

are not sufficient for classification

Ethylbenzene Inhalation Multiple animal

species

Carcinogenic.

Toluene Dermal Mouse Some positive data exist, but the data

are not sufficient for classification

Toluene Ingestion Rat Some positive data exist, but the data

are not sufficient for classification

Toluene Inhalation Mouse Some positive data exist, but the data

are not sufficient for classification

Reproductive Toxicity

Reproductive and/or Developmental Effects

Name Route Value Species Test result Exposure Duration

Naphtha (petroleum),

hydrotreated heavy

Inhalation Not toxic to

reproduction and/or

development

NOAEL

2.356 mg/l

Silicic acid, sodium

salt, reaction

products with

chlorotrimethylsilane

and iso-Pr alc

No data available

Stoddard Solvent Inhalation Not toxic to

reproduction and/or

development

NOAEL

2.356 mg/l

Siloxanes and

silicones, di-Me

No data available

Page 10

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 10 of 19

Naphtha (petroleum),

hydrodesulphurised

heavy

Inhalation Not toxic to

reproduction and/or

development

NOAEL

2.356 mg/l

Ethylbenzene Inhalation Some positive

developmental data

exist, but the data are

not sufficient for

classification

Rat NOAEL 4.3

mg/l

premating & during

gestation

Toluene Inhalation Some positive female

reproductive data

exist, but the data are

not sufficient for

classification

Human NOAEL Not

available

occupational

exposure

Toluene Inhalation Some positive male

reproductive data

exist, but the data are

not sufficient for

classification

Rat NOAEL 2.3

mg/l

1 generation

Toluene Ingestion Toxic to development Rat LOAEL 520

mg/kg/day

during gestation

Toluene Inhalation Toxic to development Human NOAEL Not

available

poisoning and/or

abuse

Target Organ(s)

Specific Target Organ Toxicity - single exposure

Name Route Target

Organ(s)

Value Species Test result Exposure

Duration

Naphtha

(petroleum),

hydrotreated

heavy

Inhalation nervous system Some positive

data exist, but the

data are not

sufficient for

classification

NOEL 6.5 mg/l

Naphtha

(petroleum),

hydrotreated

heavy

Inhalation respiratory

system

Some positive

data exist, but the

data are not

sufficient for

classification

NOEL 2.4 mg/l

Naphtha

(petroleum),

hydrotreated

heavy

Inhalation heart All data are

negative

NOAEL 2.5

mg/l

Naphtha

(petroleum),

hydrotreated

heavy

Inhalation liver | kidney

and/or bladder

All data are

negative

NOAEL 0.610

mg/l

Naphtha

(petroleum),

hydrotreated

heavy

Inhalation muscles All data are

negative

NOAEL 0.61

mg/l

Silicic acid,

sodium salt,

reaction

products with

chlorotrimeth

ylsilane and

iso-Pr alc

No data available

Stoddard

Solvent

Inhalation central nervous

system

depression

May cause

drowsiness or

dizziness

NOAEL N/A

Stoddard Inhalation respiratory Some positive Irritation

Page 11

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 11 of 19

Solvent irritation data exist, but the

data are not

sufficient for

classification

Positive

Stoddard

Solvent

Inhalation nervous system Some positive

data exist, but the

data are not

sufficient for

classification

NOEL 6.5 mg/l

Stoddard

Solvent

Inhalation respiratory

system

Some positive

data exist, but the

data are not

sufficient for

classification

NOEL 2.4 mg/l

Stoddard

Solvent

Inhalation heart All data are

negative

NOAEL 2.5

mg/l

Stoddard

Solvent

Inhalation liver | kidney

and/or bladder

All data are

negative

NOAEL 0.610

mg/l

Stoddard

Solvent

Inhalation muscles All data are

negative

NOAEL 0.61

mg/l

Siloxanes and

silicones, diMe

No data available

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation central nervous

system

depression

May cause

drowsiness or

dizziness

NOAEL N/A

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation respiratory

irritation

Some positive

data exist, but the

data are not

sufficient for

classification

Irritation

Positive

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation nervous system Some positive

data exist, but the

data are not

sufficient for

classification

NOEL 6.5 mg/l

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation respiratory

system

Some positive

data exist, but the

data are not

sufficient for

classification

NOEL 2.4 mg/l

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation heart All data are

negative

NOAEL 2.5

mg/l

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation liver | kidney

and/or bladder

All data are

negative

NOAEL 0.610

mg/l

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation muscles All data are

negative

NOAEL 0.61

mg/l

Ethylbenzene Inhalation central nervous

system

depression

May cause

drowsiness or

dizziness

Human NOAEL Not

available

Ethylbenzene Inhalation respiratory

irritation

Some positive

data exist, but the

data are not

sufficient for

Human and

animal

NOAEL Not

available

Page 12

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 12 of 19

classification

Toluene Inhalation central nervous

system

depression

May cause

drowsiness or

dizziness

Human NOAEL Not

available

Toluene Inhalation respiratory

irritation

Some positive

data exist, but the

data are not

sufficient for

classification

Human NOAEL Not

available

Toluene Inhalation immune system Some positive

data exist, but the

data are not

sufficient for

classification

Mouse NOAEL 0.004

mg/l

3 hours

Toluene Ingestion central nervous

system

depression

May cause

drowsiness or

dizziness

Human NOAEL Not

available

poisoning and/or

abuse

Specific Target Organ Toxicity - repeated exposure

Name Route Target

Organ(s)

Value Species Test result Exposure

Duration

Naphtha

(petroleum),

hydrotreated

heavy

Dermal nervous system Some positive

data exist, but the

data are not

sufficient for

classification

LOEL 691

mg/kg

Naphtha

(petroleum),

hydrotreated

heavy

Inhalation nervous system Some positive

data exist, but the

data are not

sufficient for

classification

LOEL 4.580

mg/l

Naphtha

(petroleum),

hydrotreated

heavy

Inhalation respiratory

system

Some positive

data exist, but the

data are not

sufficient for

classification

NOEL 0.619

mg/l

Naphtha

(petroleum),

hydrotreated

heavy

Inhalation endocrine

system | muscles

Some positive

data exist, but the

data are not

sufficient for

classification

LOEL 0.616

mg/l

Naphtha

(petroleum),

hydrotreated

heavy

Inhalation kidney and/or

bladder

Some positive

data exist, but the

data are not

sufficient for

classification

LOEL 0.57 mg/l

Naphtha

(petroleum),

hydrotreated

heavy

Inhalation bone, teeth,

nails, and/or

hair | blood |

liver

All data are

negative

NOAEL 5.62

mg/l

Naphtha

(petroleum),

hydrotreated

heavy

Inhalation heart All data are

negative

NOAEL 1.271

mg/l

Naphtha

(petroleum),

hydrotreated

heavy

Inhalation immune system All data are

negative

NOAEL 0.616

mg/l

Silicic acid,

sodium salt,

reaction

No data available

Page 13

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 13 of 19

products with

chlorotrimeth

ylsilane and

iso-Pr alc

Stoddard

Solvent

Dermal nervous system Some positive

data exist, but the

data are not

sufficient for

classification

LOEL 691

mg/kg

Stoddard

Solvent

Inhalation nervous system Some positive

data exist, but the

data are not

sufficient for

classification

LOEL 4.580

mg/l

Stoddard

Solvent

Inhalation respiratory

system

Some positive

data exist, but the

data are not

sufficient for

classification

NOEL 0.619

mg/l

Stoddard

Solvent

Inhalation endocrine

system | muscles

Some positive

data exist, but the

data are not

sufficient for

classification

LOEL 0.616

mg/l

Stoddard

Solvent

Inhalation kidney and/or

bladder

Some positive

data exist, but the

data are not

sufficient for

classification

LOEL 0.57 mg/l

Stoddard

Solvent

Inhalation bone, teeth,

nails, and/or

hair | blood |

liver

All data are

negative

NOAEL 5.62

mg/l

Stoddard

Solvent

Inhalation heart All data are

negative

NOAEL 1.271

mg/l

Stoddard

Solvent

Inhalation immune system All data are

negative

NOAEL 0.616

mg/l

Naphtha

(petroleum),

hydrodesulph

urised heavy

Dermal nervous system Some positive

data exist, but the

data are not

sufficient for

classification

LOEL 691

mg/kg

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation nervous system Some positive

data exist, but the

data are not

sufficient for

classification

LOEL 4.580

mg/l

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation respiratory

system

Some positive

data exist, but the

data are not

sufficient for

classification

NOEL 0.619

mg/l

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation endocrine

system | muscles

Some positive

data exist, but the

data are not

sufficient for

classification

LOEL 0.616

mg/l

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation kidney and/or

bladder

Some positive

data exist, but the

data are not

sufficient for

LOEL 0.57 mg/l

Page 14

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 14 of 19

classification

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation bone, teeth,

nails, and/or

hair | blood |

liver

All data are

negative

NOAEL 5.62

mg/l

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation heart All data are

negative

NOAEL 1.271

mg/l

Naphtha

(petroleum),

hydrodesulph

urised heavy

Inhalation immune system All data are

negative

NOAEL 0.616

mg/l

Ethylbenzene Inhalation kidney and/or

bladder

Some positive

data exist, but the

data are not

sufficient for

classification

Rat NOAEL 1.1

mg/l

2 years

Ethylbenzene Inhalation liver Some positive

data exist, but the

data are not

sufficient for

classification

Mouse NOAEL 1.1

mg/l

103 weeks

Ethylbenzene Inhalation hematopoietic

system

Some positive

data exist, but the

data are not

sufficient for

classification

Rat NOAEL 3.4

mg/l

28 days

Ethylbenzene Inhalation auditory system Some positive

data exist, but the

data are not

sufficient for

classification

Rat NOAEL 2.4

mg/l

5 days

Ethylbenzene Inhalation endocrine

system

Some positive

data exist, but the

data are not

sufficient for

classification

Mouse NOAEL 3.3

mg/l

103 weeks

Ethylbenzene Inhalation bone, teeth,

nails, and/or

hair | muscles

All data are

negative

Multiple

animal species

NOAEL 4.2

mg/l

90 days

Ethylbenzene Inhalation heart | immune

system |

respiratory

system

All data are

negative

Multiple

animal species

NOAEL 3.3

mg/l

2 years

Ethylbenzene Ingestion liver | kidney

and/or bladder

Some positive

data exist, but the

data are not

sufficient for

classification

Rat NOAEL 680

mg/kg/day

6 months

Toluene Inhalation auditory system

| nervous system

| eyes | olfactory

system

Causes damage to

organs through

prolonged or

repeated exposure

Human NOAEL Not

available

poisoning and/or

abuse

Toluene Inhalation respiratory

system

Some positive

data exist, but the

data are not

sufficient for

classification

Rat LOAEL 2.3

mg/l

15 months

Toluene Inhalation heart | liver |

kidney and/or

Some positive

data exist, but the

Rat NOAEL 11.3

mg/l

15 weeks

Page 15

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 15 of 19

bladder data are not

sufficient for

classification

Toluene Inhalation endocrine

system

Some positive

data exist, but the

data are not

sufficient for

classification

Rat NOAEL 1.1

mg/l

4 weeks

Toluene Inhalation immune system Some positive

data exist, but the

data are not

sufficient for

classification

Mouse NOAEL Not

available

20 days

Toluene Inhalation bone, teeth,

nails, and/or

hair

Some positive

data exist, but the

data are not

sufficient for

classification

Mouse NOAEL 1.1

mg/l

8 weeks

Toluene Inhalation hematopoietic

system |

vascular system

Some positive

data exist, but the

data are not

sufficient for

classification

Human NOAEL Not

available

occupational

exposure

Toluene Ingestion nervous system Some positive

data exist, but the

data are not

sufficient for

classification

Rat NOAEL 625

mg/kg/day

13 weeks

Toluene Ingestion heart Some positive

data exist, but the

data are not

sufficient for

classification

Rat NOAEL 2,500

mg/kg/day

13 weeks

Toluene Ingestion liver | kidney

and/or bladder

Some positive

data exist, but the

data are not

sufficient for

classification

Multiple

animal species

NOAEL 2,500

mg/kg/day

13 weeks

Toluene Ingestion hematopoietic

system

Some positive

data exist, but the

data are not

sufficient for

classification

Mouse NOAEL 600

mg/kg/day

14 days

Toluene Ingestion endocrine

system

Some positive

data exist, but the

data are not

sufficient for

classification

Mouse NOAEL 105

mg/kg/day

28 days

Toluene Ingestion immune system Some positive

data exist, but the

data are not

sufficient for

classification

Mouse NOAEL 105

mg/kg/day

4 weeks

Aspiration Hazard

Name Value

Naphtha (petroleum), hydrotreated heavy Not an aspiration hazard

Silicic acid, sodium salt, reaction products with chlorotrimethylsilane and

iso-Pr alc

Not an aspiration hazard

Stoddard Solvent Aspiration hazard

Siloxanes and silicones, di-Me Not an aspiration hazard

Page 16

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 16 of 19

Naphtha (petroleum), hydrodesulphurised heavy Aspiration hazard

Ethylbenzene Aspiration hazard

Toluene Aspiration hazard

Please contact the address or phone number listed on the first page of the SDS for additional toxicological information

on this material and/or its components.

SECTION 12: Ecological information

The information below may not be consistent with the material classification in Section 2 if specific ingredient classifications

are mandated by a competent authority. Additional information leading to material classification in Section 2 is available

upon request. In addition, environmental fate and effects data on ingredients may not be reflected in this section because an

ingredient is present below the threshold for labelling, an ingredient is not expected to be available for exposure, or the data

is considered not relevant to the material as a whole.

12.1. Toxicity

Acute aquatic hazard:

Not acutely toxic to aquatic life by GHS criteria.

Chronic aquatic hazard:

Not chronically toxic to aquatic life by GHS criteria.

No product test data available.

No component test data available.

12.2. Persistence and degradability

No test data available.

12.3 : Bioaccumulative potential

No test data available.

12.4. Mobility in soil

Please contact manufacturer for more details

12.5. Results of the PBT and vPvB assessment

No information available at this time, contact manufacturer for more details

12.6. Other adverse effects

No information available.

SECTION 13: Disposal considerations

13.1 Waste treatment methods

Dispose of contents/ container in accordance with the local/regional/national/international regulations

Dispose of waste product in a permitted industrial waste facility. As a disposal alternative, incinerate in a permitted waste

incineration facility. Empty drums/barrels/containers used for transporting and handling hazardous chemicals (chemical

substances/mixtures/preparations classified as hazardous as per applicable regulations) shall be considered,stored,treated &

disposed of as hazardous wastes unless otherwise defined by applicable waste regulations. Consult with the respective

regulating authorities to determine the available treatment and disposal facilities.

The coding of a waste stream is based on the application of the product by the consumer. Since this is out of the control of the

manufacturer, no waste code(s) for products after use will be provided. Please refer to the European Waste Code (EWC -

Page 17

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 17 of 19

2000/532/CE and amendments) to assign the correct waste code to your waste stream. Ensure national and/or regional

regulations are complied with and always use a licensed waste contractor

EU waste code (product as sold)

070104* Other organic solvents, washing liquids and mother liquors

SECTION 14: Transportation information

ADR: UN1268, PETROLEUM DISTILLATES, N.O.S., 3, III, +040C F1

IMDG: UN1268, PETROLEUM DISTILLATES, N.O.S., 3, III, EmS: F-E, S-E

IATA: UN1268, PETROLEUM DISTILLATES, N.O.S., 3, III

SECTION 15: Regulatory information

15.1. Safety, health and environmental regulations/legislation specific for the substance or mixture

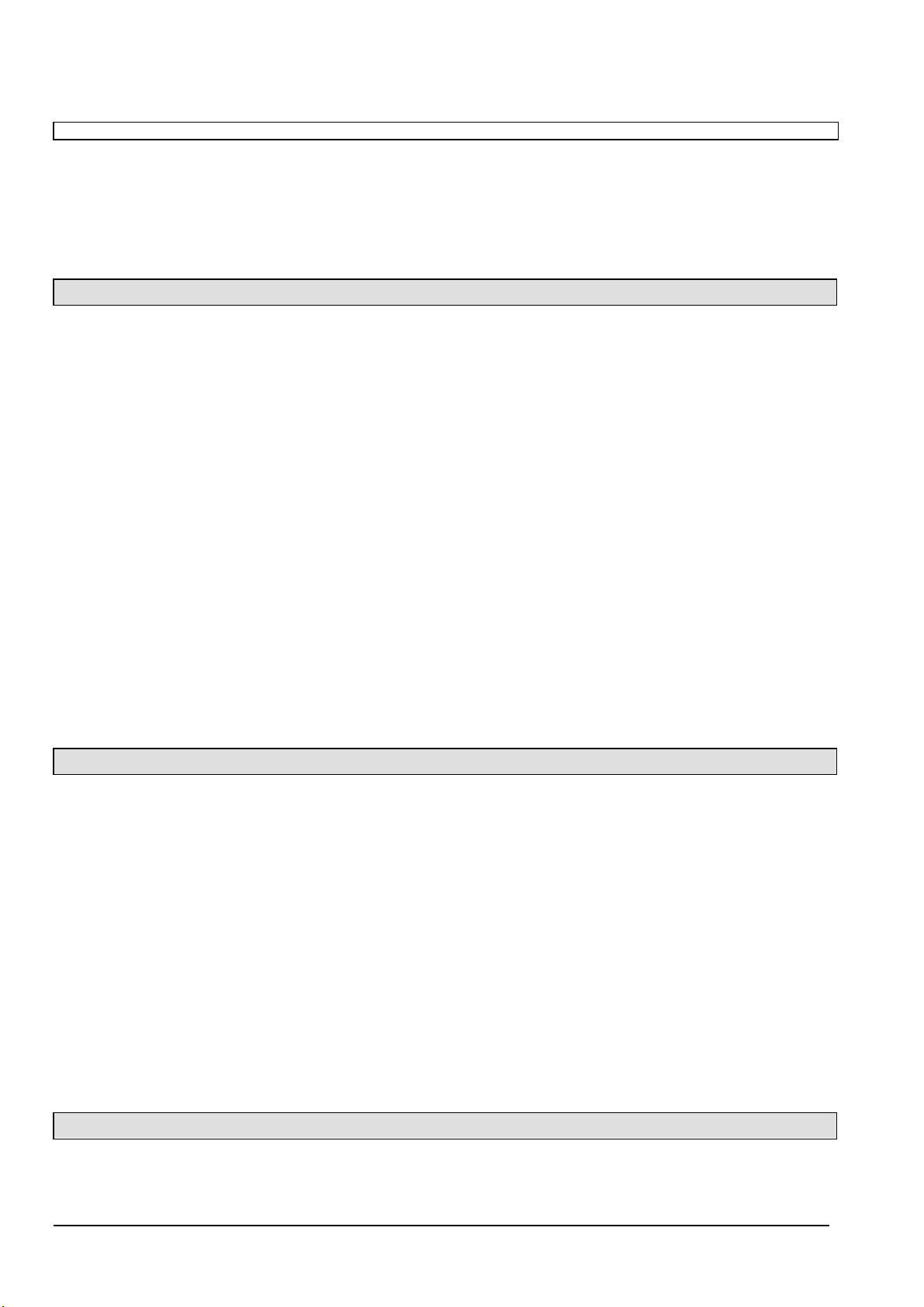

Carcinogenicity

Ingredient CAS Nbr Classification Regulation

Ethylbenzene 100-41-4 Grp. 2B: Possible human

carc.

International Agency

for Research on Cancer

Toluene 108-88-3 Gr. 3: Not classifiable International Agency

for Research on Cancer

Global inventory status

Contact manufacturer for more information The components of this product are in compliance with the chemical notification

requirements of TSCA.

15.2. Chemical Safety Assessment

Not applicable

SECTION 16: Other information

List of relevant H statements

EUH066 Repeated exposure may cause skin dryness or cracking.

H225 Highly flammable liquid and vapour.

H226 Flammable liquid and vapour.

H304 May be fatal if swallowed and enters airways.

H315 Causes skin irritation.

H332 Harmful if inhaled.

H336 May cause drowsiness or dizziness.

H361d Suspected of damaging the unborn child.

H372 Causes damage to organs through prolonged or repeated exposure.

H411 Toxic to aquatic life with long lasting effects.

List of relevant R-phrases

R10 Flammable.

R11 Highly flammable.

R20 Harmful by inhalation.

R38 Irritating to skin.

R48/20 Harmful: danger of serious damage to health by prolonged exposure through inhalation.

R51/53 Toxic to aquatic organisms. May cause long-term adverse effects in the aquatic environment.

R63 Possible risk of harm to the unborn child.

R65 Harmful: May cause lung damage if swallowed.

Page 18

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 18 of 19

R66 Repeated exposure may cause skin dryness or cracking.

R67 Vapours may cause drowsiness and dizziness.

Revision information:

Revision Changes:

Section 8: Respiratory protection - recommended respirators information was modified.

Section 3: Composition/ Information of ingredients table was modified.

Section 9: Flammability (solid, gas) information was modified.

Section 14: Transportation classification was modified.

Section 2: Label remarks was modified.

Copyright was modified.

Aspiration Hazard Table was modified.

Section 11: Acute Toxicity table was modified.

Carcinogenicity Table was modified.

Serious Eye Damage/Irritation Table was modified.

Germ Cell Mutagenicity Table was modified.

Skin Sensitisation Table was modified.

Respiratory Sensitisation Table was modified.

Reproductive Toxicity Table was modified.

Skin Corrosion/Irritation Table was modified.

Target Organs - Repeated Table was modified.

Target Organs - Single Table was modified.

Section 11: Health Effects - Skin information was modified.

Section 11: Health Effects - Inhalation information was modified.

Section 11: Health Effects - Ingestion information was modified.

Section 6: Accidental release personal information was modified.

Section 6: Accidental release environmental information was modified.

Section 6: Accidental release clean-up information was modified.

Section 7: Precautions safe handling information was modified.

Section 7: Conditions safe storage was modified.

Section 8: Appropriate Engineering controls information was modified.

Section 13: Standard Phrase Category Waste GHS was modified.

Section 4: First aid for skin contact information was modified.

Section 4: First aid for inhalation information was modified.

Section 4: First aid for ingestion (swallowing) information was modified.

Two-column table displaying the unique list of H Codes and statements (std phrases) for all components of the given

material. was modified.

Section 12: Acute aquatic hazard information was added.

Section 12: Chronic aquatic hazard heading was added.

Section 12: Acute aquatic hazard heading was added.

Section 12: Chronic aquatic hazard information was added.

Section 11: Carcinogenicity heading was added.

Section 11: Target Organ Effects heading was added.

Section 11: Health Effects - Other information was added.

Section 11: Cancer Hazards information was added.

Section 8: Personal Protection - Eye information was added.

Section 8: Personal Protection - Skin/hand information was added.

Section 8: Personal Protection - Respiratory Information was added.

Section 11: UN GHS Classification table heading was deleted.

DISCLAIMER: The information on this Safety Data Sheet is based on our experience and is correct to the best of our

knowledge at the date of publication, but we do not accept any liability for any loss, damage or injury resulting from its use

(except as required by law). The information may not be valid for any use not referred to in this Data Sheet or use of the

product in combination with other materials. For these reasons, it is important that customers carry out their own test to

satisfy themselves as to the suitability of the product for their own intended applications.

Page 19

MV83, Velocity Liquid Mold Sealer (XP4-57A): MV8301

__________________________________________________________________________________________

Page: 19 of 19

Meguiar's, Inc. United Kingdom MSDSs are available at www.meguiars.co.uk

Loading...

Loading...