Page 1

AVTMTTR330

Rev 3

March 2010

Instruction Manual

for

Three-Phase TTR®

Transformer Turn Ratio Test Set

TTR330 Series

Catalog Nos. TTR330, TTR330-47

HIGH-VOLTAGE EQUIPMENT

Read this entire manual before operating.

M

Valley Forge Corporate Center

2621 Van Buren Avenue

Norristown, PA 19403-2329

U.S.A.

610-676-8500

www.megger.com

Page 2

Page 3

Three-Phase TTR®

Transformer Turn Ratio Test Set

TTR330 Series

Page 4

Copyright© 2010 by Megger. All rights reserved.

The information presented in this manual is believed to be adequate for the intended use of the product.

If the product or its individual instruments are used for purposes other than those specified herein,

confirmation of their validity and suitability must be obtained from Megger. Refer to the warranty

information below. Specifications are subject to change without notice.

WARRANTY

Products supplied by Megger are warranted against defects in material and workmanship for a period of

one year following shipment. Our liability is specifically limited to replacing or repairing, at our option,

defective equipment. Equipment returned to the factory for repair must be shipped prepaid and insured.

Contact your Megger representative for instructions and a return authorization (RA) number. Please

indicate all pertinent information, including problem symptoms. Also specify the serial number and the

catalog number of the unit. This warranty does not include batteries, lamps or other expendable items,

where the original manufacturer’s warranty shall apply. We make no other warranty. The warranty is

void in the event of abuse (failure to follow recommended operating procedures) or failure by the

customer to perform specific maintenance as indicated in this manual.

M

Valley Forge Corporate Center

2621 Van Buren Ave

Norristown, PA 19403-2329

610-676-8500 (Telephone)

610-676-8610 (Fax)

www.megger.com

Page 5

Table of Contents

1. Getting to know the TTR330 ............................................................................................................................ 1

Product Overview ................................................................................................................................................ 1

User Interface Panel ............................................................................................................................................. 4

Communications ports ........................................................................................................................................ 5

HOME Action Icons ........................................................................................................................................... 5

Utility Icons ........................................................................................................................................................... 6

2. Safety ..................................................................................................................................................................... 7

Safety is the responsibility of the user ............................................................................................................... 7

Input Power precautions ..................................................................................................................................... 8

3. PREPARING FOR TEST ................................................................................................................................ 9

Site Preparation ..................................................................................................................................................... 9

Making Circuit Connections ............................................................................................................................... 9

4. Connecting to the Transformer ...................................................................................................................... 11

Single-Phase, Two-Winding Transformers .................................................................................................... 11

Three-Phase, Two-Winding Transformers .................................................................................................... 14

Three-Phase, Three-Winding Transformers ................................................................................................. 15

Current Transformers (CTs) ............................................................................................................................ 16

BCTs Mounted on Three-Phase Transformers ............................................................................................ 19

T-Type Transformers ....................................................................................................................................... 22

5. Operation ........................................................................................................................................................... 23

Power up ............................................................................................................................................................. 23

Navigating the screen ........................................................................................................................................ 23

HOME Screen Action Icons ........................................................................................................................... 23

Remote Control Operation for LTC Testing ................................................................................................ 27

Error Messages .................................................................................................................................................. 27

Upon completion of TEST – Powering down ............................................................................................. 28

6. Service ................................................................................................................................................................ 31

Maintenance ....................................................................................................................................................... 31

Fuse Replacement ............................................................................................................................................. 31

Calibration .......................................................................................................................................................... 31

TTR330 – Self check ........................................................................................................................................ 35

Troubleshooting ................................................................................................................................................ 37

Repairs ................................................................................................................................................................. 38

7. Replacement Parts List and Optional Accessories ...................................................................................... 39

8. Specifications ..................................................................................................................................................... 41

Electrical ............................................................................................................................................................. 41

Environmental Conditions............................................................................................................................... 43

Physical Data

...................................................................................................................................................... 43

Addendum A TTR 300 Series PowerDB Lite User Manual ........................................................................... 43

AVTMTTR330 Rev 3 March 2010

i

Page 6

List of Figures

Figure 1-1 Top Panel Controls ....................................................................................................................... 3

Figure 1-2. User Interface Panel ...................................................................................................................... 4

Figure 1-3. Communications ports ................................................................................................................. 5

Figure 1-4. HOME Action Icons .................................................................................................................... 5

Figure 1-5. Utility Icons .................................................................................................................................... 6

Figure 4-1. Setup for Testing Single-Phase Transformer .......................................................................... 12

Figure 4-2. Setup for Testing Single-Phase Autotransformer ................................................................... 12

Figure 4-3. Setup for Testing Single-Phase, Type A (Straight Design) Step Voltage Regulator .......... 13

Figure 4-4. Setup for Testing Single-Phase, Type B (Inverted Design) Step Voltage Regulator ......... 14

Figure 4-5. Setup for Testing Unmounted Current Transformer ............................................................ 17

Figure 4-6. Setup for Testing Taps on Multiple Tap CT ........................................................................... 18

Figure 4-7. Setup for Testing BCT Mounted on Single-Phase Two-Winding Transformer ................ 19

Figure 4-8. Setup for Testing BCT Mounted on Delta Winding on a Three-Phase Power

Transformer ................................................................................................................................. 20

Figure 4-9. Setup for Testing BCT Mounted on Wye Winding of a Three-Phase Transformer ......... 21

Figure 5-1 New Test Form screen ............................................................................................................... 24

Figure 5-2 Three Phase QUICK test Screen .............................................................................................. 25

Figure 5-3 File Manager -Recall Test ........................................................................................................... 25

Figure 5-4. File Manager –SAVE Test screen ............................................................................................. 26

Figure 5-5 Global Settings – Preferences screen ....................................................................................... 26

List of Tables

Table 4-1. Test Lead Markings for Single-Phase Transformers ................................................................... 13

Table 4-2. Test Lead Markings for Three-Phase Transformers ................................................................... 15

Table 4-3. T-type Transformer Winding Phase Relationship....................................................................... 22

Table 6-1. Troubleshooting Guide ................................................................................................................... 37

Table 7-1. Replacement Parts List .................................................................................................................... 39

ii

AVTMTTR330 Rev 3 March 2010

Page 7

Upon Receipt of Product

Prior to operation, check for loosened hardware or damage incurred during

transit. If these conditions are found, a safety hazard is likely, DO NOT attempt

to operate equipment. Please contact Megger as soon as possible.

TTR330 Transformer Turn Ratio test set

AVTMTTR330 Rev 3 March 2010

iii

Page 8

M

iv

AVTMTTR330 Rev 3 March 2010

Page 9

1

Getting to know the TTR330

Product Overview

The Three-Phase TTR Test Set is fully automatic, self-checking, menu-driven

unit. The test set measures the turn ratio, phase shift, and excitation current of

power, distribution, and instrument transformers. A “-47” suffix added to the

catalog number denotes a 230-V input power supply, rather than the standard

120-V supply. The test set is a portable instrument housed in a sturdy plastic case

with removable lid and carrying strap. The inside lining of case is metal shielded.

A canvas carrying bag is supplied to hold all accessories.

The test set can be used to test single-phase and three-phase transformers, both

with and without taps in accordance with the requirements of the IEEE

C57.12.90 – 1997 standards. For three-phase measurements, the test set is

connected to all three phases of the transformer to be tested. The TTR lead

selection circuitry permits automatic measurement of all phases without changing

connections. This feature eliminates the need to refer to hook-up charts when

testing three-phase transformers. Turn ratio, phase shift and excitation current

readings are displayed on a large LCD. Transformer excitation current as well as

phase shift angle helps to detect transformer shorted turns or an unequal number

of turns connected in parallel. Operating condition (error) messages identify

incorrect test connections, abnormal operating condition, or winding problems.

Test results can be saved either to internal memory, to an external USB storage

device, or can be uploaded to a personal computer (PC) via an Ethernet port.

Features include:

Fully automatic operation

Self-checking at power-up

User-friendly, menu-driven operation

Test turn ratio, phase shift (in both degree and centiradian), and excitation

Easy measuring of regular windings, tertiary windings, and CTs

Storage capacity to handle over 1000 test files (depending on size)

AVTMTTR330 Rev 3 March 2010

current

1

Page 10

M

Checking reverse polarity at start of each test

Via Ethernet port, an external PC or laptop can be connected to operate the

TTR (in remote control mode) or to transfer test results and to provide full

transformer test report

Quick test mode provides the fastest testing of a transformer

Three excitation test voltages: 80 V, 40 V, and 8 V

Testing to ANSI, IEC, and Australian standards

Leads marked to ANSI, IEC, and Australian standards

Multi-lingual support

Large, easy-to-read, full VGA color display

Meets the requirements of both the European EMC and Low Voltage

Directives

It is recommended that the user becomes familiar with the TTR330 before ever

connecting to a transformer.

2

AVTMTTR330 Rev 3 March 2010

Page 11

Top Panel Controls

Getting to Know the TTR330

Figure 1-1 Top Panel Controls

1. Power input receptacle, ON/OFF switch, and fuse holder. ON/OFF power

switch and input power receptacle provides power to the test set.

2. Emergency OFF switch. This red push button interrupts testing. When

pressed, the switch is locked in off position. To reset the switch, twist the

button in the direction indicated by the arrows.

3. Voltage ON light. Red indicator lamp indicates when lit that test voltage is

being supplied to the Unit Under Test (UUT).

4. Remote Trigger receptacle. Plug receptacle for connecting Remote Trigger

cable for testing transformers with Load-Tap-Changers.

5. H – Cable receptacle. Plug receptacle for connecting test leads to the high-

voltage (H) winding of a transformer

6. X – Cable receptacle. Plug receptacle for connecting test leads to the low-

voltage (X) winding of a transformer.

7. Ground lug. Wing-nut terminal allows connection of test set to Station Earth

AVTMTTR330 Rev 3 March 2010

ground.

3

Page 12

M

User Interface Panel

Test Button:

Navigation Keys:

Home Key:

Zone Key:

Keypad:

Initiates and Terminates Testing

Use Arrow keys to highlight a desired Selection. Use

Enter button (in center) to Activate the Selection.

Toggles HOME Action Icons

Allows User to select Active area of the screen.

Key board for entering notes and data.

Power Suspend:

Help Function:

Information Key:

Page Up/Down Keys:

Prepares the Instrument for Shutdown. A message will

indicate when Input Power can be safely removed (not

used on some models).

Provides on screen Help to assist operator.

Provides on screen information to assist operator.

Pages up or down as appropriate for the displayed

screen.

Figure 1-2. User Interface Panel

4

AVTMTTR330 Rev 3 March 2010

Page 13

Communications ports

Figure 1-3. Communications ports

Getting to Know the TTR330

Ethernet port

USB Storage/Print

HOME Action Icons

Select to create NEW test.

Select to RECALL test.

Select to SAVE Test.

Select to ZOOM-IN.

Select to ZOOM-OUT.

Print Icon. Prints the Selected Test Form. Printer driver is factory installed. Please

contact Megger for specific printer model availability.

AVTMTTR330 Rev 3 March 2010

Select to enter PREFERENCES screen.

Figure 1-4. HOME Action Icons

5

Page 14

M

Utility Icons

Cancel Icon. Select to Cancel without Saving.

Delete Icon. Deletes the Selected File or Report.

Print Icon. Prints the Selected Report. Printer must be standard USB

supporting HP PCL protocol.

USB Out Icon. Select to Transfer Files or Reports from external USB

Memory Stick to the TTR.

USB In Icon. Select to Transfer Files or Reports from the TTR to the external

USB Memory Stick.

Back Icon. Select to return back to the previous screen.

Figure 1-5. Utility Icons

6

AVTMTTR330 Rev 3 March 2010

Page 15

2

Safety

Safety is the responsibility of the user

Only qualified and trained operators should operate the TTR330 system.

Operator must read and understand this entire Instruction Manual prior to

operating the equipment. Operator must follow the instructions of this

Instruction Manual and attend the equipment while the equipment is in use. In

the event of equipment malfunction, the unit should immediately be deenergized and returned to Megger for repair. The Safety precautions herein are

not intended to replace your Company’s Safety Procedures. Refer to IEEE 510 -

1983, IEEE Recommended Practices for Safety in High-Voltage and High-Power Testing,

for additional information.

General Safety Precautions

The TTR330 and the Unit Under Test (UUT) should both be considered as

sources of instantaneously lethal levels of electrical energy. Observe the

following safety precautions:

Observe all safety warnings on the equipment. They identify areas of

immediate hazard that could result in injury or death.

Use this equipment only for the purposes described in this manual. Strictly

observe the Warning and Caution information provided in this manual

Treat all terminals of high-voltage power equipment systems as potential

electric shock hazards. Use all practical safety precautions to prevent contact

with energized parts of the equipment and related circuits.

Use suitable barriers, barricades, or warnings to keep persons not directly

involved with the work away from test activities.

Never connect the test equipment to energized equipment.

Do not use in an explosive atmosphere.

Use the grounding and connection procedures recommended in this manual.

AVTMTTR330 Rev 3 March 2010

Always disconnect test leads from power equipment before attempting to

disconnect them at the test set. The ground connection must be the first

7

Page 16

M

Input Power precautions

made and the last removed. Any interruption of the grounding connection

can create an electrical shock hazard.

Personnel using heart pacemakers should obtain expert advice on the

possible risks before operating this equipment or being close to the

equipment during operation.

This instrument operates from a single-phase, sine wave, power source. It has a

three-wire power cord and requires a two-pole, three-terminal (live, neutral, and

ground) type input source. The voltage to ground from the live pole of the

power source must be within the following rated operating voltage:

For Cat. No TTR330 120 V ±10%, single phase sine, 50/60 ±2 Hz

For Cat. No. TTR330-47 230 V ±10%, single phase sine, 50/60 ±2 Hz

The neutral pole must be at ground potential. Before making connection to the

power source, determine that the instrument rating matches the voltage of the

power source. The power input plug must be inserted only into a mating

receptacle with a ground contact. Do not bypass the grounding connection. Any

interruption of the grounding connection can create an electric shock hazard.

Determine that the receptacle is properly wired before inserting the plug.

For test sets energized with 230 V input (TTR330-47), the neutral terminal of the

input supply cord (white or blue lead) must be connected to the neutral pole of

the line power source. The ground terminal of the input supply cord (green or

yellow/green lead) must be connected to the protective ground (earth) terminal

of the line power source. The black or brown cord lead is the live (hot) lead.

The control circuits of the instrument are protected by two mains circuit fuses.

These fuses are located in the ON/OFF switch module and are replaceable by

the operator. To avoid electric shock and fire hazard, use only the fuse specified

in Sections 6 and 8, that is identical in respect to type, voltage rating, and current

rating. Refer to the Fuse Replacement procedure in the Section 6.

WARNING

Before replacing the fuses, disconnect the

F

power input plug from the live power source.

8

AVTMTTR330 Rev 3 March 2010

Page 17

3

PREPARING FOR TEST

Site Preparation

Choose a location that meets the following conditions:

The location is as dry as possible.

There is no flammable material stored in the vicinity.

The test area is adequately ventilated.

Be sure all equipment is de-energized and all terminals of the UUT are

accessible. Erect suitable safety barriers to protect the operator from traffic

hazards and to prevent intrusion by unauthorized personnel. User provided

Warning lights are recommended.

Verify that the Local station ground is intact and has impedance continuity to

earth.

Making Circuit Connections

Connections should be made in the order as listed below.

1. Ground. Use the Megger supplied Safety Ground Cable 15 ft (4.6 m) to

connect the TTR330 Wing Nut Ground Terminal directly to Local Station

Earth ground. Ensure the Transformer chassis also has impedance continuity

to Local Station Earth ground potential.

2. Input Power Source Ground. Input Power Source Ground Terminal

should be less than 100 milliohms of impedance to Local Station Earth

Ground.

3. Connect the Input Power Cord. Before making this connection, Ensure

the Input Power Source meets the requirements as listed in Section 2 and

Specifications Section 8. Also make sure that the ON/OFF switch (Figure 11, No. 1) is in the OFF position. Connect the input power cable to the

TTR330 first, then to the power source. At this time, leave the ON/OFF

switch in the OFF position.

AVTMTTR330 Rev 3 March 2010

9

Page 18

M

4. Connect the Ethernet cable (optional). If the user chooses to operate the

TTR330 in a remote-control mode, using PowerDB PC software, then

connect the Ethernet cable between the TTR330 and the PC at this time.

5. Connect the Load-Tap-Changer cable (optional). If the user chooses to

operate the “Test button” of the TTR330 from a remote distance then,

connect the LTC cable at this time.

6. Connect the H and X leads (to the TTR330 end only at this time). With

the clamps disconnected from the UUT, connect the Bayonet Plug on the

Cable labeled “H” to the TTR panel connector also labeled “H”. Repeat this

process for the “X” labeled cable. Ensure each connector is securely fastened

using a clockwise rotation.

7. Connect the H and X clamps. With the ON/OFF Switch in the OFF

position, connect the H and X clamps in accordance with Section 4 as

appropriate for the specific transformer type and test to be conducted.

10

AVTMTTR330 Rev 3 March 2010

Page 19

4

Connecting to the Transformer

The setup and connection instructions included in Section 4 pertaining to ratio,

polarity, and phase relation, assume that the transformer under test, connections,

and terminal markings comply with the requirements of ANSI C57.12.70-1990

American National Standards Terminal Markings and Connections for

Distribution and Power Transformers. The H test leads of the test set are the

exciting (high voltage) leads (8 V, 40 V, or 80 V). The X test leads are the low

voltage leads.

When testing high-voltage transformers, caution must be used at all times and all

safety precautions followed. Read, understand, and employ all safety precautions

and circuit connections described in Sections 2 and 3.

WARNING

Ensure that the transformer to be tested is completely

de-energized. Check every winding. Ensure that all

F

F

F

terminals of the transformer are disconnected from line

or load at the transformer. Connections to ground may

be left in place.

WARNING

For all testing as described herein, care shall be taken

to ensure any and all unused clamps shall be isolated

from each other, from ground, and from personnel.

WARNING

Except for CTs as described herein, never interchange

connections between the high- and low-voltage

transformer terminals. Failure to observe proper

connections will result in a safety hazard and may

result in damage to the test set or transformer.

Single-Phase, Two-Winding Transformers

Perform the following setup procedure for single-phase, two-winding

transformers:

1. With the ON/OFF Switch in the OFF position, make the circuit

AVTMTTR330 Rev 3 March 2010

connections as described in Section 3.

11

Page 20

M

2. Connect the H and X test cables to the respective H and X receptacles of the

TTR330. Make sure that the connectors are securely fastened (using

clockwise rotation) to the receptacles.

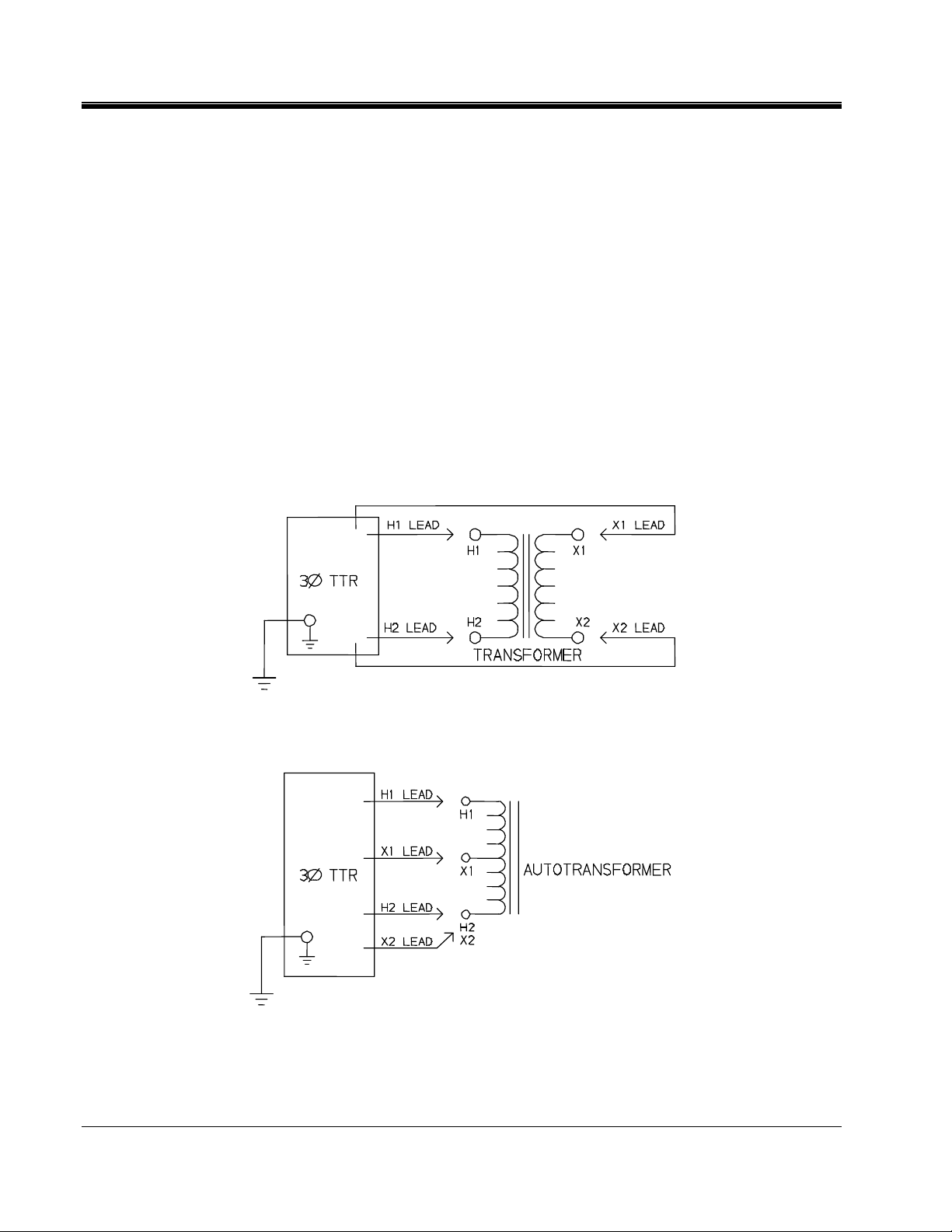

3. Connect the heavy-duty clamps marked H1 and H2 of the test lead to the

corresponding (high-voltage winding) terminals of the transformer under

test. Figures 4-1 and 4-2 show test setups for single-phase transformers.

Figures 4-3 and 4-4 show test setups for regulators.

4. Connect the heavy-duty clamps marked X1 and X2 of the test lead to the

corresponding (low-voltage winding) terminals of the transformer under test.

Figures 4-1 and 4-2 show test setups for single-phase transformers. Figures

4-3 and 4-4 show test setups for regulators.

5. On/OFF Switch. It is only after all of the above connections are safely made

and all safety precautions of sections 2 and 3 are satisfied, should the

On/OFF switch be turned to the ON position.

Figure 4-1. Setup for Testing Single-Phase Transformer

Figure 4-2. Setup for Testing Single-Phase Autotransformer

To test windings other than H1 – H2 and X1 – X2, ensure that the heavy-duty

clamp marked H1 is connected to the lower numbered terminal and H2 to the

12

AVTMTTR330 Rev 3 March 2010

Page 21

Connecting to the Transformer

higher numbered terminal of the high-voltage winding. Similarly, X1 and X2

should be connected to the low-voltage winding.

Test lead markings for the ANSI, CEI/IEC, and Australian standards are as

shown in Table 4-1.

Table 4-1. Test Lead Markings for Single-Phase Transformers

Test Lead Marking Transformer Heavy-Duty

Clamp

ANSI CEI/IEC Australian Terminal Voltage Boot Color Color Band

H1 1 U A2 High Red Red

H2 1 V A1 High Red Yellow

X1 2 U a2 Low Black Red

X2 2 V a1 Low Black Yellow

Test Lead

Figure 4-3. Setup for Testing Single-Phase, Type A (Straight Design) Step Voltage Regulator

AVTMTTR330 Rev 3 March 2010

13

Page 22

M

Figure 4-4. Setup for Testing Single-Phase, Type B (Inverted Design) Step Voltage Regulator

Three-Phase, Two-Winding Transformers

Perform the following setup procedure for three-phase, two-winding

transformers:

1. With the ON/OFF Switch in the OFF position, make the circuit

connections as described in Section 3.

2. Connect the H and X test cables to the respective H and X receptacles of the

TTR330. Make sure that the connectors are securely fastened (using

clockwise rotation) to the receptacles.

3. Connect the heavy-duty clamps marked H0, H1, H2, and H3 of the test lead

to the corresponding (high-voltage winding) terminals of the transformer

under test. Refer to Table 4-2 for test lead markings. With delta connected

windings, H0 is not used. With wye connected windings, a neutral

connection for H0 is normally available.

4. Connect the heavy-duty clamps marked X0, X1, X2, and X3 of the test lead

to the corresponding (low-voltage winding) terminals of the transformer

under test. Refer to Table 4-2 for test lead markings. With delta connected

windings, X0 is not used. With wye connected windings, a neutral connection

for X0 is normally available.

14

AVTMTTR330 Rev 3 March 2010

Page 23

Connecting to the Transformer

5. On/OFF Switch. It is only after all of the above connections are safely

made and all safety precautions of sections 2 and 3 are satisfied, should the

On/OFF switch be turned to the ON position.

Table 4-2. Test Lead Markings for Three-Phase Transformers

Test Lead Marking Transformer Heavy-Duty

Clamp

ANSI

H0 1N N Neutral Red White

H1 1U A2/A4 High Red Red

H2 1V B2/B4 High Red Yellow

H3 1W C2/C4 High Red Blue

X0 2N N Neutral Black White

X1 2U a1/a2/a

X2 2V b1/b2/b

X3 2W c1/c2/c

CEI/IEC Australian Terminal Voltage Boot Color Color Band

4

4

4

Low Black Red

Low Black Yellow

Low Black Blue

Test Lead

Note: According to Australian standard, wye and delta transformer winding

connections have a numerical suffix of 1 and 2. The zigzag transformers

have a numerical suffix of 4.

Three-Phase, Three-Winding Transformers

This type of transformers has primary, secondary, and tertiary windings. Primary

and secondary windings are tested as a regular three-phase, two-winding

transformer. To test tertiary winding, perform the following setup procedure:

1. With the ON/OFF Switch in the OFF position, make the circuit

2. Connect the H and X test cables to the respective H and X receptacles of the

3. Connect the heavy-duty clamps marked H0, H1, H2, and H3 of the test lead

4. Connect the heavy-duty clamps marked X0, X1, X2 , and X3 of the test lead

AVTMTTR330 Rev 3 March 2010

connections as described in Section 3.

TTR330. Make sure that the connectors are securely fastened (using

clockwise rotation) to the receptacles.

to the corresponding terminals of the transformer under test. Refer to Table

4-2 for test lead markings. With delta connected windings, H0 is not used.

With wye connected windings, a neutral connection for H0 is normally

available

to the corresponding tertiary (low-voltage winding) terminals (Y0, Y1, Y2,

15

Page 24

M

Current Transformers (CTs)

and Y3) of the transformer under test. Refer to Table 4-2 for test lead

markings. With delta connected windings, X0 is not used. With wye

connected windings, a neutral connection for X0 is normally available.

5. On/OFF Switch. It is only after all of the above connections are safely made

and all safety precautions of sections 2 and 3 are satisfied, should the

On/OFF switch be turned to the ON position.

Connections to CTs are made backwards compared to power or potential

transformers. The H terminals on the test set must be connected to the X

terminals on the CT; and the X terminals on the test set must be connected to

the H terminals on the CT.

NOTE: Dots on the housing of the transformer are commonly used to identify

terminals of the same polarity.

WARNING

Failure to observe proper connections will result in a

safety hazard and may result in damage to the test set

F

G

Most of the CTs are tested at 8 V ac excitation voltage.

NOTE: Most of the current transformers are tested at 8 V ac excitation voltage.

or CT. Failure to observe voltage rating of low-current

X winding may result in damage to the CT.

CAUTION

Never use AUTO mode of operation when testing the

current transformers with the rated voltage below80 V

ac.

Some current transformers with turn ratio of 100:5 and less get

saturated at 8V ac. They require lower excitation voltage for testing and

therefore can not be tested with the Cat.No TTR330. For this case, use

the TTR100 or TTR25.

Unmounted CTs

1. With the ON/OFF Switch in the OFF position, make the circuit

connections as described in Section 3.

2. Connect the H and X test cables to the respective H and X receptacles of the

TTR330. Make sure that the connectors are securely fastened (using

clockwise rotation) to the receptacles.

16

AVTMTTR330 Rev 3 March 2010

Page 25

Connecting to the Transformer

3. As shown in Figure 4-5, connect the heavy-duty clamps marked H1 and H2

of the test lead to the respective X1 and X2 terminals of the CT. Note that

the H and X leads are connected in reverse as compared to the Single and

Three phase Transformer testing described in the previous sections.

4. As shown in Figure 4-5, connect the heavy-duty clamps marked X1 and X2

of the test lead to the respective H1 and H2 terminals of the CT. Ensure

correct polarity. Note that the H and X leads are connected in reverse as

compared to the Single and Three phase Transformer testing described in the

previous sections.

Figure 4-5. Setup for Testing Unmounted Current Transformer

AVTMTTR330 Rev 3 March 2010

17

Page 26

M

Figure 4-6 shows the setup for testing the taps on a multiple-tap CT.

Figure 4-6. Setup for Testing Taps on Multiple Tap CT

Bushing Current Transformer (BCT) Mounted on Single-Phase,

Two-Winding Transformer

A turn-ratio test can be performed on a BCT after it has been mounted on a

circuit breaker or power transformer entrance bushing. The test can be

performed without removal of the BCT from the equipment. Proceed as follows:

1. With the ON/OFF Switch in the OFF position, make the circuit

connections as described in Section 3.

2. Connect the H and X test cables to the respective H and X receptacles of the

TTR330. Make sure that the connectors are securely fastened (using

clockwise rotation) to the receptacles.

3. Using user supplied shorting jumper leads, short-circuit the winding on the

opposite voltage side of the power transformer core.

4. Connect the heavy-duty clamps marked H1 and H2 of the test leads to the

respective X1 and X2 terminals of the BCT as shown in figure 4-7.

5. Connect the heavy-duty clamp marked X1 to the power transformer terminal

on which the BCT is mounted and the X2 heavy-duty clamp to the terminal

on the opposite side of the power transformer winding (H2 side of BCT).

Check to make sure that the BCT is mounted with proper polarity with

18

AVTMTTR330 Rev 3 March 2010

Page 27

Connecting to the Transformer

respect to power transformer entrance bushing and that connection polarities

are correct.

Figure 4-7. Setup for Testing BCT Mounted on Single-Phase Two-Winding Transformer

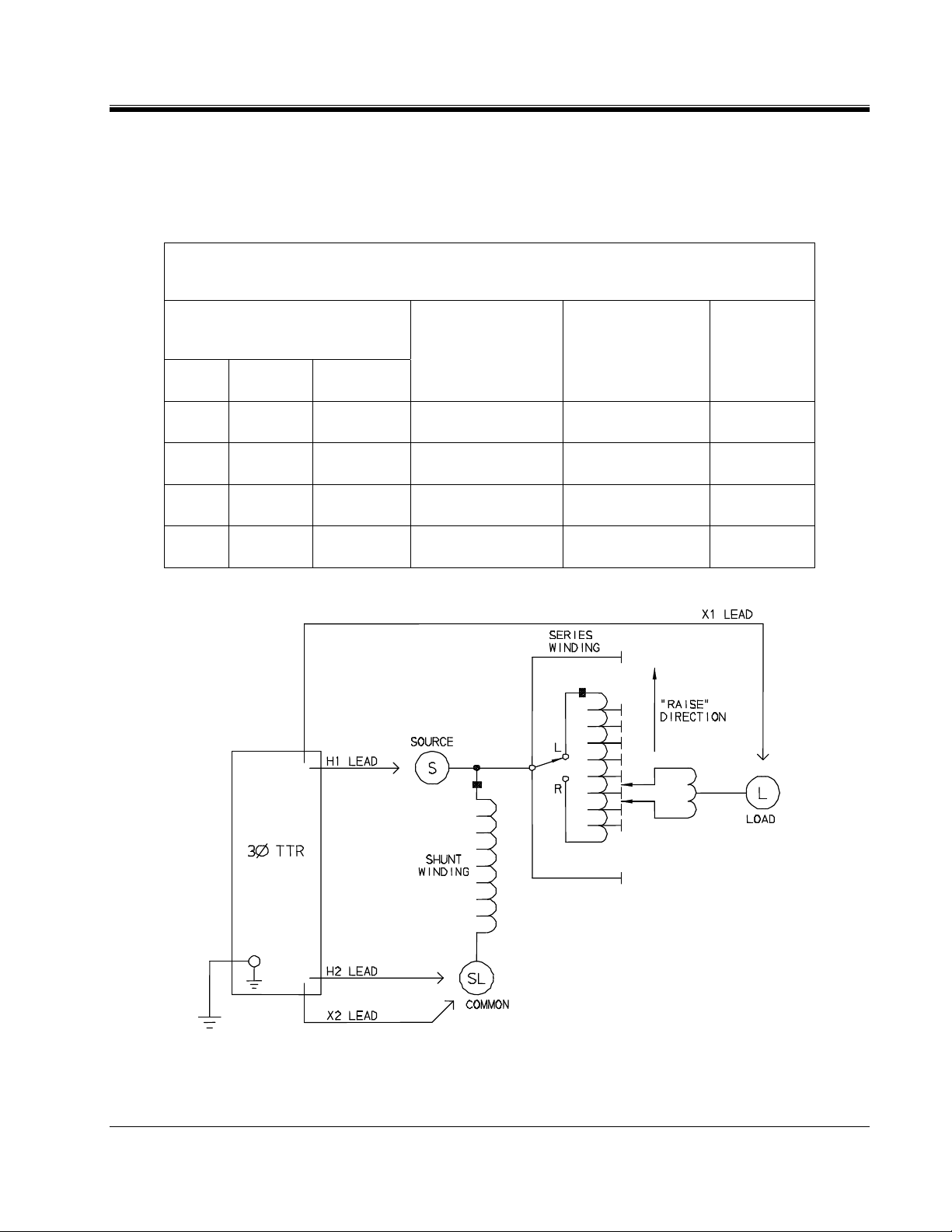

BCTs Mounted on Three-Phase Transformers

A turn-ratio test can be performed on all three BCTs using a single setup. Figure

4-8 shows how (to make the proper connections) when the BCTs are mounted

on a typical delta winding and Figure 4-9 shows how when mounted on a typical

wye winding.

1. With the ON/OFF Switch in the OFF position, make the circuit

connections as described in Section 3.

2. Connect the H and X test cables to the respective H and X receptacles of the

TTR330. Make sure that the connectors are securely fastened (using

clockwise rotation) to the receptacles.

3. Short-circuit all windings on the opposite voltage side of the power

transformer core using jumper leads.

4. Check to make sure that all BCTs are mounted with proper polarity with

respect to the power transformer entrance bushing. Ensure that all

connection polarities are correct. Make connections as shown in Figure 4-8

AVTMTTR330 Rev 3 March 2010

19

Page 28

M

for delta winding configurations and figure 4-9 for wye winding

configurations.

Figure 4-8. Setup for Testing BCT Mounted on Delta Winding

on a Three-Phase Power Transformer

20

AVTMTTR330 Rev 3 March 2010

Page 29

Connecting to the Transformer

Figure 4-9. Setup for Testing BCT Mounted on Wye Winding of a Three-Phase Transformer

AVTMTTR330 Rev 3 March 2010

21

Page 30

M

T-Type Transformers

T-type transformers represent a special type of thee-phase transformer. This

transformer may be tested as a single phase transformer. In this case, the jumpers

indicated in Table 4-3 should be applied to the appropriate terminals of the Ttype transformers. The TTR measured turn ratio should be compared to the

calculated turn ratio indicated in Table 4-3.

Table 4-3. T-type Transformer Winding Phase Relationship

Winding Connection Winding Tested

IEC

Vector

Group

T-T

0

T-T

30

lag

High-Voltage

Winding (H)

Low-Voltage

Winding (X)

External

jumpers

-

H

-H

1

2

X1 -X2

H

-H

2

3

X

-X2

1

Phase

tested

A

B

A

B

High-

Voltage

Winding

H

1

H

1

H

1

H

2

- H

– H3

– H

– H3

2

3

Low-

Voltage

Winding

- X

X

1

X

– X3

1

X

- X

1

X1 – X

2

2

3

T-T

30

lead

H

-H

2

X1 –X3

3

A

B

H

– H

1

H2 – H3

X

3

– X

1

3

X2 – X1

Calculated

Turn Ratio

V

H

V

X

V

H

V

X

V

3

H

•

V

2

X

2

V

H

•

V

3

X

3

V

H

•

2

V

X

2

V

H

•

V

3

X

Remarks

22

AVTMTTR330 Rev 3 March 2010

Page 31

5

Operation

Power up

Proceed only after reading and fully reading and understanding Sections 2, 3, and

4, with particular attention on the safety related precautions.

Once all safety precautions are taken, and all circuit connections are made, then

the user may safely turn the ON/OFF switch to the ON position and operate

the test instrument as described herein.

For Emergency shutdown, Push red EMERGENCY OFF

F

On power up, a beep sounds, the test set performs a self-test check, and all

hardware and software variables are initialized.

button or toggle On/OFF switch to OFF.

Navigating the screen

Use Arrows keys to highlight desired action

Use ENTER key (in center) to select highlighted action

HOME Screen Action Icons

Select HOME key to display Action Icons.

EMERGENCY SHUTDOWN

AVTMTTR330 Rev 3 March 2010

23

Page 32

M

Action Icons:

Select NEW TEST to open new form.

Figure 5-1. New Test Form screen

Quick test: This setup provides a quick path for single phase transformer

testing. It requires minimum transformer nameplate information to be entered

before testing. The test results displayed do not include either the calculated ratio

(per nameplate) or ratio deviation values.

Full test: This setup requires entering main transformer nameplate

information. The FULL test is used for obtaining full test information of a

transformer. This setup may be saved and recalled later for future testing of the

same or similar type transformers.

24

AVTMTTR330 Rev 3 March 2010

Page 33

3-Phase QUICK test, example

Operation

Use Navigation keys

Arrows/ENTER)

to select winding

configuration,

then Press TEST

Figure 5-2. Three Phase QUICK test Screen

Select Recall to open test from memory (either internal or USB memory).

AVTMTTR330 Rev 3 March 2010

Use Zone Key to move

cursor to various zones

on display

Figure 5-3. File Manager -Recall Test

25

Page 34

M

Select SAVE to save test to memory.

Figure 5-4. File Manager –SAVE Test screen

Select PREFERENCES to set global parameters.

Figure 5-5. Global Settings – Preferences screen

26

AVTMTTR330 Rev 3 March 2010

Page 35

Owner: User specified field

SN: Serial Number of Test Instrument

Language: Indicates displayed language

Save File Prefix: All Saved files will begin with this prefix

Units: Units of Measure setting

Type: Transformer type convention

Test voltage: Default test signal voltage level

Show Diagram Number: Allows Transformer type diagram number to be

shown on test form

Default form: Indicates default form, upon power-up

Remote Control Operation for LTC Testing

Use the remote control mode of the TTR for load tap changer (LTC) testing.

The remote control mode provides two-way-communication between the

operator and the TTR, allowing you to stay close to an LTC, change taps, and

initiate the test routine.

Operation

Connect the hand-held control unit, Megger p/n 30915-220, to the Remote

Trigger Receptacle port of the TTR. The remote control unit pushbutton lamp

will illuminate.

Now an operator may come to the remote location, and set (for example), the

LTC to the desired position, and would then depress the remote control unit

pushbutton for a short time, then release it. The pushbutton lamp extinguishes

until the TTR is ready for the next test. When the current testing is complete, the

test results are automatically saved, the test ID is advanced to the next number,

the pushbutton lamp lights, and the TTR test set is ready for the next remote test

Error Messages

When an error message appears in the transformer test result screen indicating an

abnormal operating condition, verify the condition by taking a repeat

measurement before attempting to take any corrective action.

Open connections, wrong connections, open windings, shorted windings, high

resistance windings, other abnormal transformer problems, or a combination of

these may cause a large deviation from normal turn ratio or indicate an unusual

message. The unusual operating conditions may be caused by an abnormal

leakage reactance or capacitive coupling within the transformer windings. If

abnormal operating conditions occur during transformer testing, error messages

may appear (such as below) and may be accompanied by three short beeps.

AVTMTTR330 Rev 3 March 2010

27

Page 36

M

CHECK CONNECTIONS

PHASE A (or B, or C) EXCITATION CURRENT TOO HIGH

TURNS RATIO TOO LOW, <0.8

PHASE A (or B, or C) TURNS RATIO TOO HIGH

This message indicates that the transformer is not connected to the test set. The

message may be caused by poor connection of one of the test leads, as well.

This message indicates that excitation current exceeds 500 mA. Excitation

current can be reduced by using lower test voltages (40 V or 8 V).

This message shows that a transformer under test turn ratio is less than 0.8. The

TTR is not designed to test a transformer turn ratio under 0.8.

This message shows that a transformer under test turn ratio is higher than 10,000

(if 80 V or 40 V is used) or is higher than 4,000 (if 8 V is used). The message may

be caused by poor connection of one of the test leads, as well.

CHECK PHASE A (or B, or C) CONNECTIONS, REVERSED

This message is caused by incorrect connection of the H and X leads. The H and

X leads have either been reversed or the test transformer connections or

markings do not comply with the requirements of ANSI, IEC, or the Australian

standard. The message may be caused by wrong diagram number specified, as

well.

CHECK PHASE A (or B, or C) POLARITY

This message shows that the H or X test leads are incorrectly connected or the

test transformer connections or markings do not comply with the requirements

of ANSI, IEC, or the Australian standard.

Upon completion of TEST – Powering down

1. Upon completion of testing, press the (Power Suspend) button on the

TTR330 to prepare the unit for shutdown. Then, once directed by the onscreen instruction, Switch the ON/OFF Switch to OFF.

2. Using an adequately grounded Safety Ground Stick, ground all exposed high

voltage connections. Then, while wearing the appropriately rated rubber

gloves, connect Safety Ground Jumpers from all exposed high voltage cable

terminals to Local Station Earth Ground. It is a good idea to leave the

jumpers in place for at least as long as the specimen was at test voltage.

28

AVTMTTR330 Rev 3 March 2010

Page 37

Operation

3. Remove the Test Instrument clamps from the Transformer, leaving the

Safety Ground Jumper in place to drain any stored charge.

4. Disconnect the Power Cord from the Input Power Source.

5. Lastly, disconnect the safety ground cable.

AVTMTTR330 Rev 3 March 2010

29

Page 38

M

M

30

AVTMTTR330 Rev 3 March 2010

Page 39

6

Service

Maintenance

Maintenance should be performed only by qualified persons familiar with the

hazards involved with high-voltage test equipment. Read and understand

Sections 2, 3, 4, and 5 before performing any service.

The TTR330 requires only periodic inspection. Periodically, inspect all hardware

items, including the cable assemblies, to ensure all is in good condition.

The TTR330 may be cleaned periodically. In so doing, do not allow water to

penetrate panel holes. An all-purpose, household spray cleaner can be used to

clean the panel. Polish with a soft, dry cloth, taking care not to scratch the

display screen cover. Clean the cables and mating panel receptacles with

isopropyl or denatured alcohol applied with a clean cloth.

Fuse Replacement

The TTR330 is protected by two mains fuses. Fuse replacement is indicated if

the electronic circuits do not function. Refer fuse replacement to qualified

personnel only. To avoid electric shock and fire hazard, use only the fuses

specified on Instrument panel. Note that 2 spare fuses are included with each

TTR.

F

To replace fuse(s), proceed as follows:

1. Remove power cord.

2. Pry door open at socket.

3. Lift and swing door into socket.

4. Lift fuse holder out of housing.

5. Install one (1) AG fuse or two (2) metric fuses*.

WARNING

Before replacing the fuses, disconnect the power input

plug from the live power source.

AVTMTTR330 Rev 3 March 2010

31

Page 40

M

6. Replace fuse holder into housing.

7. Swing and snap door back in place.

*Install fuses on one side only, do not install both AG and metric fuses at the

same time

32

AVTMTTR330 Rev 3 March 2010

Page 41

Voltage Selection

To change selected voltage: open cover, using small blade screwdriver or similar

tool; set aside cover/fuse block assembly; pull voltage selector card straight out

of housing, using indicator pin; orient selector card so that desired voltage is

readable at the bottom; orient indicator pin to point up when desired voltage is

readable at bottom (note that when indicator pin is fixed, successive voltages are

selected by rotating the card 90° clockwise); insert voltage selector card into

housing, printed side of card facing forward toward IEC connector and edge containing the

desired voltage first; replace cover, and verify that indicator pin shows the desired

voltage.

Voltage Selector Card Orientation

Service

1. Insert a pocket screwdriver at point “X” as shown. Gently lift UP until the

2. Once lifted, the door will pivot on its hinges and expose the fuse holder.

AVTMTTR330 Rev 3 March 2010

entire door lifts up approximately 1/4" (minimum).

33

Page 42

M

3. When the fuse holder is installed in the single fuse position, apply the

screwdriver as shown and gently pry up. Use screwdriver as shown, do not

use fingers.

When the fuse holder is installed in the dual fuse position, it should normally

release as soon as the door is open.

Calibration

A complete performance and calibration check should be made at least once

every year. This will ensure that the TTR test set is functioning and calibrated

properly over the entire measurement range. The 3-phase TTR calibration is

performed on each new or repaired unit before sending it to a customer. There is

a special 3-phase TTR final calibration procedure which requires a NISTtraceable test equipment to be used. As a result of such calibration procedure,

each TTR test set may be NIST certified.

To check the 3-phase TTR calibration at a customer site or in the field, the

Megger Calibration Standard Cat. No. 550055 or equivalent standard should be

used. To perform a quick simplified calibration check, the TTR Check Box Cat.

No. 550555 may be used. (Please note the one-digit difference in the catalog

numbers). The TTR Check Box has eleven switchable turns ratio settings which

cover the turns ratio range from 1:1 to 2000:1.

34

AVTMTTR330 Rev 3 March 2010

Page 43

TTR330 – Self check

A customer may want to make sure that the test set is functioning properly

before testing a transformer. Traditionally, for the transformer turns ratio testers,

a customer performed this test by connecting H1-X1 and H2-X2 test leads. The

1:1 turns ratio was expected to be measured. Additionally, the displayed test

results were interpreted as a test set calibration check.

The 3-phase TTR test set is designed and optimized for the transformer turns

ratio testing. It uses a mixed analog-digital technique to provide the high accurate

readings of the tested transformer turns ratio. The test set measurement

approach is based on high impedance input and output transformer voltage

monitoring circuits. The high impedance of the monitoring circuits is optimized

for the accurate transformer turns ratio testing.

When performing a 3-phase TTR functional test, the H and X test leads

interconnect the input and output monitoring circuits without a transformer

being connected. Such connection cause an impedance mismatch and, as a result

of the mismatch, the displayed turns ratio reading is not exactly 1:1 as it may be

expected. A customer should be aware that a functional test is not a real

transformer turns ratio test. Due to the intrinsic and inevitable impedance

mismatching, the 3-phase TTR functional test readings may be from 0.9980 to

1.0020. The TTR functional test readings do not represent its calibration. It

simply shows that the TTR test set circuitry functions properly. To check the 3phase TTR calibration, a customer should use the Calibration Standards

mentioned in Calibration heading above.

Service

To perform a 3-phase TTR functional test proceed as follows:

1. Turn TTR test set power off.

2. Connect H1 lead to X1 lead, H2 lead to X2 lead, H3 lead to X3 lead, and H0

3. Turn TTR test set power on.

4. After self-test is complete and a QUICK TEST.

5. Enter transformer type DIAG 07 YNyn0.

F

AVTMTTR330 Rev 3 March 2010

lead to X0 lead. Make sure the leads are properly connected and that H/X

pairs are not electrically in contact with each other.

WARNING

Do not continue functional test if the diagram type

DIAG 07 YNyn0 transformer type is not listed.

Keep the leads, which are energized, clear of ground,

and personnel and each of the other lead-pair sets.

35

Page 44

M

6. Start TEST.

7. The readings for phases A, B, and C should be:

RATIO: 1.0000 ±0.0020

PHASE(min): 0 ±5

Iexc (mA): 0.0 to 0.5

8. If needed, (as identified on the Preference screen), perform the test

according to steps 1 through 7 for all the excitation voltages of 8V, 40 V,

and/or 80V. The readings should be the same as shown in Step 7.

36

AVTMTTR330 Rev 3 March 2010

Page 45

Service

Troubleshooting

The Troubleshooting Guide, Table 6-1, is arranged to help you evaluate the

reasons for TTR test set malfunction. The table lists possible test set

malfunctions which may be encountered during operation and lists possible

causes. Electronic circuit repairs should not be attempted in the field. Refer to

Repairs heading below. Refer to Section 7 for a list of spare parts.

Table 6-1. Troubleshooting Guide

MALFUNCTION POSSIBLE CAUSE

Display stays blank after POWER switch is

turned on.

No service power

Defective line cord

Defective fuse(s)

Defective display or electronics

Error message:

ANALOG OFFSET VOLTAGE

HIGH

and/or

ANALOG GAIN OUT OF

TOLERANCE appears after self-test is

complete.

Red TEST VOLTAGE ON lamp does not

light on start of testing.

One of the following messages appear on the

test result screen.

CHECK CONNECTIONS

PHASE A (or B, or C) EXCITATION

CURRENT TOO HIGH;

TURNS RATIO TOO LOW, <0.8; or

PHASE A (or B, or C) TURNS RATIO

TOO HIGH;

CHECK PHASE A (or B, or C)

CONNECTIONS, REVERSED;

CHECK PHASE A (or B, or C)

POLARITY

RATIO and/or Iexc (mA) readings erratic.

Out of tolerance condition(s) in

measurement circuit

Defective lamp

EMERGENCY TEST OFF switch

is not released

Problem in measuring circuit

Abnormal operating condition

Incorrect setting of

TRANSFORMER TYPE in the

quick test setup or the full test setup

1 menus

Incorrect connection of leads

Defective test leads

Incorrect marking of a transformer

Problem in test specimen

Problem in measuring circuit.

Defective test leads (open circuit,

poor connection)

Severe abnormal transient in service

power

Problem in test specimen (poor

connection)

Problem in measuring circuit

AVTMTTR330 Rev 3 March 2010

37

Page 46

M

Repairs

Any service or repair of this equipment should be performed only by qualified

persons who are aware of electrical hazards and the necessary precautions

required to prevent injury.

Megger offers a complete Repair and Calibration Service and recommends that

its customers take advantage of this service for routine maintenance or in the

event of any equipment malfunction.

In the event Service is required, contact your Megger representative for a product

Return Authorization (RA) number and shipping instructions.

Ship the product prepaid and insured and marked for the attention of the

Megger Repair Department. Please indicate all pertinent information, including

catalog number, serial number, and problem symptoms.

38

AVTMTTR330 Rev 3 March 2010

Page 47

7

Replacement Parts List and Optional Accessories

Table 7-1. Replacement Parts List

Item Cat. No.

Three-phase Transformer Turns Ratio Test Set

120 V ac ±10%, single phase, 50 ±2 Hz or 60 ±2 Hz, 100 VA

230 V ac ±10%, single phase, 50 ±2 Hz or 60 ±2 Hz, 100 VA

Fuse Kit

For TTR330 35026-5

For TTR330-47 35026-2

Included Accessories

Canvas carrying bag for test leads 30915-211

Power supply cord, 8 ft (2.5 m) 17032-4

Ground lead, 15 ft (4.6 m) 4702-7

Test Leads

For 3-phase connections, shielded, clamp-end terminated

H winding, 10 ft (3.1 m)

TTR330

TTR330-47

30915-509

X winding, 10 ft (3.1 m)

Extensions, shielded

H winding, 33 ft (10 m)

X winding, 33 ft (10 m)

Hand-held switch assembly for LTC remote control testing 30915-220

PowerDB Lite Software

Ethernet cable for connecting to a PC 36798

Bushing clamps (6 pcs) MC7144

Transformer Vector Voltage Diagrams

ANSI Standards

IEC Standards

AS (Australian) Standards

AVTMTTR330 Rev 3 March 2010

30915-508

30915-501

30915-500

35298

35299

35300

39

Page 48

M

Table 7-1. Replacement Parts List cont’d

Item Cat. No.

Optional Accessories

Calibration Standard (for Operation Check)

Inverter with 3 ft (0.91 m) cigarette adapter cord:

12 V dc to 120 V ac, 60 Hz

12 V dc to 120 V ac, 50 Hz

12 V dc to 230 V ac, 60 Hz

12 V dc to 230 V ac, 50 Hz

Test Leads

For 1-phase connections, shielded, clamp-end terminated

H winding, 10 ft (3.1 m)

X winding, 10 ft (3.1 m)

For 3-phase connections, shielded, clamp-end terminated

H winding, 20 ft (6.2 m)

550555

35271-1

35271-3

35271-2

35271-4

30915-528

30915-529

30915-530

X winding, 20 ft (6.2m)

Transit case for instrument leads and accessories

30915-531

37009

40

AVTMTTR330 Rev 3 March 2010

Page 49

8

Specifications

Electrical

Input Power

Cat. No. TTR330: 120 V ac ±10%, single phase, sine, 50 ±2 Hz or 60 ±2

Hz, 100 VA, IEC 1010-1 installation category II

Cat. No. TTR330-47: 230 V ac ±10%, single phase, sine, 50 ±2 Hz or 60 ±2

Protective Devices

Fuses (2)*:

Cat. No. TTR330: Type T, 250 V, 2.0 A (IEC 127 designation)

Cat. No. TTR330-47: Type T, 250 V, 1.6 A (IEC 127 designation)

High voltage and low voltage measurement circuit shorting relays

Heavy duty varistors, transient voltage suppressors, and gas surge voltage

protectors

* Two spare fuses are included with each TTR as spare parts

Hz, 100 VA, IEC 1010-1 installation category II

Output Test Voltage and Current

3 test voltages: 80 V rms, 40 V rms, 8 V rms.

Current: up to 500 mA

AVTMTTR330 Rev 3 March 2010

41

Page 50

M

Test Frequency

Loading of Test Transformer

Measuring Ranges

Same as line frequency.

Less than 0.2 VA

Accuracy

Turn ratio:

80 V ac: 0.8 to 45,000, 5 digit resolution

40 V ac: 0.8 to 25,000, 5 digit resolution

8V ac: 0.8 to 8,000, 5 digit resolution

Excitation Current: 0 to 500 mA, 3 digit resolution

Phase Angle

Deviation:

± 90 degrees, 1 decimal point for the minutes display, 2

decimal point for the degree display, 2 decimal points

for the centiradian display

Turn ratio:

80 V ac:

±0.1% (0.8 to 2000)

±0.15% (2001 to 4000)

±0.25% (4001 to 10000)

±0.3% (10001 to 45000)

40 V ac:

±0.1% (0.8 to 2000)

±0.15% (2001 to 4000)

±0.3% (4001 to 10000)

±0.35% (10001 to 25000)

8 V ac:

±0.1% (0.8 to 2000)

±0.25% (2001 to 4000)

±0.35% (4001 to 8000)

Excitation Current (rms): ±(2% of reading + 1 digit)

Phase Angle Deviation: ±3 minutes

42

AVTMTTR330 Rev 3 March 2010

Page 51

Measurement Method

In accordance with ANSI/IEEE C57.12.90

Transformer Winding Phase Relationship

ANSI C57.12.70-1990

CEI/IEC 76-1:1993 and Publication 616:1978

AS-2374, Part 4-1997 (Australian Standard)

Measuring Time

Up to one minute depending on mode of operation and type of transformer

Display

Specifications

8.4 inch, full VGA color display

Memory Storage

Internal and USB memory device: Over 1000 test results (depending on size)

Interface

Ethernet

USB (as host), qty=2

Environmental Conditions

Operating temperature range:

Storage temperature range:

Relative humidity:

23 to 122 F (-5 to 50 C)

-58 to 140 F (-50 to 60 C)

0 to 90% noncondensing (operating)

0 to 95% noncondensing (storage)

Physical Data

Dimensions: 21.5 x 13.5 x 8.5 in. (44.5 x 26.5 x 17.5 cm) (L x W x H)

Weight (test set): 25 lbs. (11.5 kg)

Case: Ruggedized plastic case with removable lid and carrying

AVTMTTR330 Rev 3 March 2010

strap

43

Page 52

M

M

44

AVTMTTR330 Rev 3 March 2010

Page 53

Addendum A

TTR 300 Series PowerDB Lite User Manual

Introduction

PowerDB Lite is a free, but limited capability, version of the PowerDB software

tool that is designed specifically to control and/or extract data from Megger

instruments. The primary difference between PowerDB Lite and PowerDB is

that PowerDB is designed to work with all manufacturers’ equipment and has

field and office synchronization capabilities. PowerDB Lite will present your test

data into a professional looking data form that can be sent to a printer or .pdf file

distiller such as PDF995.

PowerDB Lite allows you to use a sub-set of the standard PowerDB forms that

are appropriate for specific Megger instruments. PowerDB Lite detects the

instrument and enables the appropriate form(s). Data can be entered on-screen

or captured directly while using the test instrument. Completed data forms can

be saved as files to your computer.

Minimum Recommended System

Operating System: Windows 2000 or later

RAM: 64 MB RAM minimum, 512+ MB RAM recommended

Processor: 300 MHz Pentium Class processor minimum, 1 GHZ or better

recommended

For information about the features of the full version of PowerDB please visit

our website at www.powerdb.com. Get acquainted with the following features by

scheduling a live demonstration at info@powerdb.com.

Synchronize all of your test records into a single corporate database

Reduce test time

Improve data integrity

Standardize test procedures

Easily use historical trending for evaluation of test results

AVTMTTR330 Rev 3 March 2010

45

Page 54

M

Eliminate the need to install and maintain a software application per

instrument

Eliminate all hand written test sheets

Create your own test forms

Use or modify one of our 200 built-in test forms

One step procedure to generate test reports with table of contents and

deficiency summaries

Allow all of your field test data to be integrated with cmms systems such as

maximo or sap

Imports >from many other industry standard software applications

Control and import data from many non-Megger instruments

AVTMTTR300 Rev B Sept 2008

46

Page 55

TTR Series PowerDB Lite User Manual

Software Installation

To install PowerDB Lite, load the PowerDB Lite CD into your CD-ROM drive

and follow the on-screen instructions.

1. Accept the terms of the License agreement.

2. Choose the destination location for the PowerDB Lite files.

AVTMTTR330 Rev 3 March 2010

47

Page 56

M

3. Select Default Settings.

4. InstallShield Wizard will complete the installation of PowerDB Lite. Click

Finish to close the installation program.

AVTMTTR300 Rev B Sept 2008

48

Page 57

TTR Series PowerDB Lite User Manual

Using PowerDB Lite

1. Home

1. Select your Instrument from the Instrument Setup screen.

a. You can always view the Instrument Setup screen from the Tools

menu or F3.

b. Select the appropriate row in the Description column.

Then click the “...” button in the Setup column.

AVTMTTR330 Rev 3 March 2010

c. The TTR 300/310 only uses serial communicate, do not check ‘Use

Ethernet’ if you are using a TTR 300 or TTR 310. Select the

appropriate communication settings on the Serial Device

Configuration screen. Use the Refresh button to find any ports that

may have not been connected at the startup of PowerDB Lite. If you

are using a USB serial port and do not know the port assigned to it

perform the following:

1. Remove the USB serial adapter.

2. Press Refresh.

3. Click on the port drop down and record the options.

4. Plug the adapter back in.

5. Press refresh.

6. Select the port that was not in the original list.

49

Page 58

M

Verify that the baud rate is set to 9600, Parity is set to none, Byte Size is set to 8,

and Stop Bits is set to 1.

d. Only check ‘Use Ethernet’ if connected to the TTR330. If you leave

the IP address blank, PowerDB Lite will discover the unit. If you

have problems with the discovery, enter the IP address which is

displayed on the instrument’s Preferences screen.

e. Then Click OK on the Instrument Setup Screen to finish.

2. Open a New Form

a. Select the File>New menu item, or type CTRL+N, or press the New

toolbar button.

b. The forms associated with the detected instrument will be shown in

the Select a Form screen.

c. Choose a form by double-clicking or by navigating with the arrow

keys and pressing the OK key.

d. See Specific Form Help Instructions for further instruction on test

steps. You can view the Form Help by pressing the F1 key once the

form is loaded.

AVTMTTR300 Rev B Sept 2008

50

Page 59

TTR Series PowerDB Lite User Manual

3. Enter Test Data

a. Header and nameplate information can be manually typed into a

b. Click the Initialize Instrument button to initialize the test set.

c. Form fields with automation will now be colored cyan. Right-clicking

form.

these fields will start the test.

AVTMTTR330 Rev 3 March 2010

51

Page 60

M

d. To change the settings of the TTR place the mouse on the form and

right-click. Then select “TTR Settings”.

e. This dialog box allows you to change the TTR settings. The settings

that can be changed are as follows:

1. Show Diagram Number

When enabled, this will display a numeric field below the

winding configuration diagram on the form. The diagram can

then be changed by entering a number in this field.

2. Standard

This enables you to choose between the ANSI, Australian, or

IEC Standard.

3. Test Voltage

This enables you to choose the test voltage at which the test

is run. Auto allows the instrument to choose an acceptable

test voltage for testing. You may choose between Auto, 8, 40,

or 80.

4. Running an Automated Test

a. Select the Initialize Instrument button.

b. Automated fields should now turn cyan colored.

c. Right-click on the cyan colored fields.

d. Follow the on screen instructions specific to the test.

AVTMTTR300 Rev B Sept 2008

52

Page 61

TTR Series PowerDB Lite User Manual

5. Comments and Deficiencies

When imported into the full version of PowerDB, the comments and

deficiencies on each form are used to generate summary reports. These summary

reports repeat the notations and lists the page number where reported. This

allows the user to scroll to a particular page to view a reported anomaly. For

more information on features of PowerDB visit us at our website at

www.PowerDB.com.

6. Save the Data

a. Select the File>Save menu item, or press CTRL+S, or press the Save

toolbar button.

b. The Save As screen will allow you to specify a location and file name

for your PowerDB Lite XML file.

AVTMTTR330 Rev 3 March 2010

53

Page 62

M

7. Opening an Existing File

a. Select the File> Open menu item.

b. Browse to the file you would like to open.

c. Press the Open dialog button.

d. If the file contains multiple test dates, select the date that you would

like to open for editing or select New to append a new set of results

to the file. To remove a set of results, click on the selected file and

press the delete button.

AVTMTTR300 Rev B Sept 2008

54

Page 63

TTR Series PowerDB Lite User Manual

8. Loading Data Files

When testing with the TTR 320 or TTR 330 you may load files saved on the

instrument’s USB drive. Refer to Step 7 for instructions on selecting and opening

files.

9. Setting the Logos

a. Select the Tools>Options menu item.

b. The Logos section specifies paths to the left and right logos files to

use.

c. To change the left logo press the “…” button by the left logo path.

d. The Open screen allows you to browse to a file location, select a

.JPG or .BMP file, and press the Open button.

e. Repeat steps (c) and (d) for the right logo path.

f. Note that a logo will not be shown if the logo file path is blank or the

file does not exist.

g. Note after specifying the logo files the image will not be shown until

the next time a form is opened (File>Open, or the File>New menu

items).

h. Note that the logos will look the best if the resolution of the file is

pixels wide by 240 pixels high. DPI is not important.

AVTMTTR330 Rev 3 March 2010

55

Page 64

M

10. How to change Languages

a. Select the Tools>Options menu item.

b. Select the appropriate language in the dropdown menu.

11. How to change units of measurement

a. Select the Tools> Options menu item.

b. Select the units in the drop down Default Units under Measurements.

.

AVTMTTR300 Rev B Sept 2008

56

Page 65

TTR Series PowerDB Lite User Manual

12. Additional Notes

a. Additional forms can be filled out by repeating steps 2, 3 and 6.

b. Forms can be printed with the File>Print menu item, or type

CTRL+P, or press the Print toolbar button.

c. A help guide may be found in the Help>PowerDB Lite Help menu

item.

Frequently Asked Questions (FAQ’s)

1. Can I change the forms?

No. You must have the full version of PowerDB to change forms.

2. Can I synchronize forms to a database?

No. You must have the full version of PowerDB for database support and to

synchronize multiple field databases to a single master database.

3. Can I import PowerDB Lite files into PowerDB?

Yes. You can use the File>Import menu item in PowerDB to import files from

PowerDB Lite.

AVTMTTR330 Rev 3 March 2010

57

Page 66

M

Specific Form Help Instructions

Operating Instructions for the Multiple Quick Test Form

a. Type in the asset ID and then press the Enter key.

b. Use the left and right arrow keys to select the high-side winding

configuration.

c. Press the Enter or Tab key.

d. Use the left and right arrow keys to select the low-side winding

configuration.

e. Press the Enter or Tab key.

f. Select the test voltage from the dropdown menu, then press Enter or

Tab.

g. Type in the high side tap number and press the Enter key.

h. Type in the high side voltage and press the Enter key.

i. Type in the low side tap number and press the Enter key.

j. Type in the low side voltage and press the TEST key (F2) or right

click on the blue highlighted fields.

k. Hit the Enter key and repeat for each tap you would like to test.

AVTMTTR300 Rev B Sept 2008

58

Page 67

TTR Series PowerDB Lite User Manual

Operating Instructions for the Simple 3PH TTR Form

This form can be used for testing a two or three winding transformer with

multiple taps on one or more of the windings.

If you are testing a three winding transformer please check the “Has Tertiary”

checkbox.

Next select the winding configuration by using the left and right arrow keys.

Press the Enter or Tab key to move to the next field.

The default total number of tests is defined as follows:

1. Test for each secondary (or tertiary) tap tested with the primary nominal tap.

2. Test for each primary tap with the nominal secondary (or tertiary) tap.

If you do not wish to test all of the secondary or tertiary taps you can reduce the

“# tests” field for each category of tests (primary, secondary, tertiary).

Once the total number of taps and the # tests field are entered the form will

display the correct number of rows to perform testing.

Once the voltage is entered for the first and last tap values (from the

transformer’s nameplate tap voltage table), the ratios for all taps will

automatically be calculated and populated. Please note that the calculated values

can be over written.

Right click on each of the blue highlighted fields in each table to run the tests.

AVTMTTR330 Rev 3 March 2010

59

Page 68

M

AVTMTTR300 Rev B Sept 2008

60

Page 69

TTR Series PowerDB Lite User Manual

Operating Instructions for the 3PH TTR with TAP Changer Form

The procedure for this form is the same as the Simple TTR form. The only

difference is that it allows the user to enter additional nameplate information.

AVTMTTR330 Rev 3 March 2010

61

Page 70

M

M

AVTMTTR300 Rev B Sept 2008

62

Loading...

Loading...