Page 1

Test and Diagnosis System

TDS40 / TDS60

(Stand-alone test operation)

Operating Manual

Issue: 01 (01/2014) - EN

Item-Nr.: 83549

Page 2

Page 3

1-3

Consultation with Megger

The present system manual has been designed as an operating guide and for reference.

It is meant to answer your questions and solve your problems in as fast and easy a way

as possible. Please start with referring to this manual should any trouble occur.

In doing so, make use of the table of contents and read the relevant paragraph with great

attention. Furthermore, check all terminals and connections of the instruments involved.

Should any question remain unanswered or should you need the help of an authorized

service station, please contact:

Megger Limited

Seba Dynatronic

Mess- und Ortungstechnik GmbH

Archcliffe Road

Kent CT17 9EN

T: +44 (0) 1304 502100

F: +44 (0)1 304 207342

E: uksales@megger.com

Dr.-Herbert-Iann-Str. 6

D - 96148 Baunach

T: +49 / 9544 / 68 – 0

F: +49 / 9544 / 22 73

E: sales@sebakmt.com

Hagenuk KMT

Kabelmesstechnik GmbH

Megger USA

Röderaue 41

D - 01471 Radeburg / Dresden

T: +49 / 35208 / 84 – 0

F: +49 / 35208 / 84 249

E: sales@sebakmt.com

4271 Bronze Way

Dallas, Texas 75237-1019 USA

T: 1-800-723-2861

F: 1-214-331-7399

E: DEanfrage@megger.com

Megger

All rights reserved. No part of this handbook may be copied by photographic or other means unless Megger have before-hand

declared their consent in writing. The content of this handbook is subject to change without notice. Megger cannot be made liable for

technical or printing errors or shortcomings of this handbook. Megger also disclaims all responsibility for damage resulting directly or

indirectly from the delivery, supply, or use of this matter.

Page 4

1-4

TERMS OF WARRANTY

Megger accept responsibility for a claim under warranty brought forward by a customer

for a product sold by Megger under the terms stated below.

Megger warrant that at the time of delivery Megger products are free from manufacturing

or material defects which might considerably reduce their value or usability. This warranty

does not apply to faults in the software supplied. During the period of warranty, Megger

agree to repair faulty parts or replace them with new parts or parts as new (with the same

usability and life as new parts) according to their choice.

This warranty does not cover wear parts, lamps, fuses, batteries and accumulators.

Megger reject all further claims under warranty, in particular those from consequential

damage. Each component and product replaced in accordance with this warranty

becomes the property of Megger.

All warranty claims versus Megger are hereby limited to a period of 12 months from the

date of delivery. Each component supplied by Megger within the context of warranty will

also be covered by this warranty for the remaining period of time but for 90 days at least.

Each measure to remedy a claim under warranty shall exclusively be carried out by

Megger or an authorized service station.

This warranty does not apply to any fault or damage caused by exposing a product to

conditions not in accordance with this specification, by storing, transporting, or using it

improperly, or having it serviced or installed by a workshop not authorized by Megger. All

responsibility is disclaimed for damage due to wear, will of God, or connection to foreign

components.

For damage resulting from a violation of their duty to repair or re-supply items, Megger

can be made liable only in case of severe negligence or intention. Any liability for slight

negligence is disclaimed.

Since some states do not allow the exclusion or limitation of an implied warranty or of

consequential damage, the limitations of liability described above perhaps may not apply

to you.

Page 5

1-5

INHALTSVERZEICHNIS

1. GENERAL INTRODUCTION ................................................. 1-9

1.1 General Instructions ............................................................................ 1-10

1.2 General Safety Instructions and Warnings ........................................ 1-11

2. TECHNICAL DESCRIPTION ............................................... 2-13

2.1 Description of the Functions .............................................................. 2-13

2.2 Model Options ...................................................................................... 2-13

2.3 Technical Specifications ..................................................................... 2-14

2.4 Scope of Delivery and Options ........................................................... 2-15

2.5 Description of the Test Procedure with VLF-Voltage ....................... 2-16

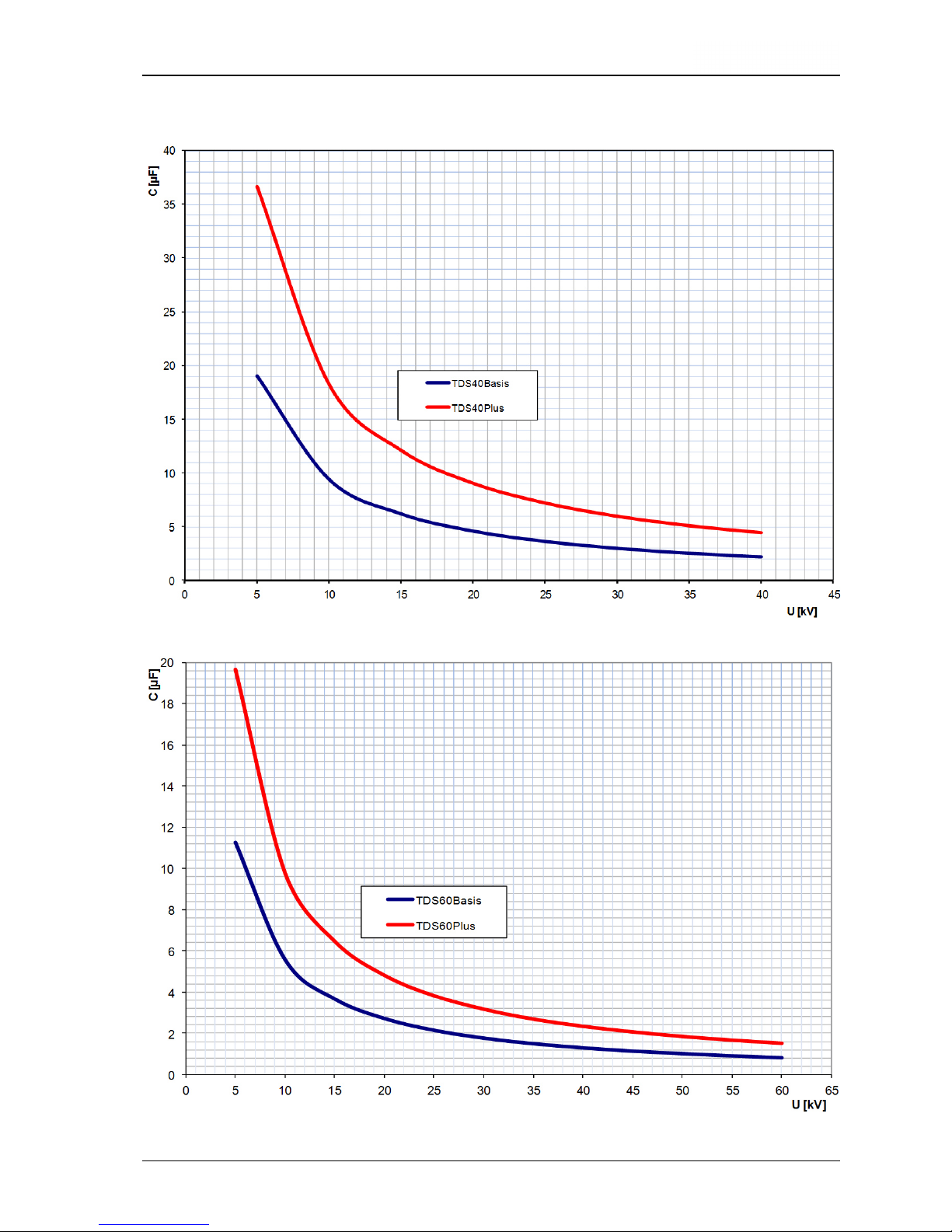

2.6 Testable Cable Capacitance in VLF Mode ......................................... 2-19

2.7 Cable Capacitance that Can be Diagnosed in DAC Mode ................ 2-20

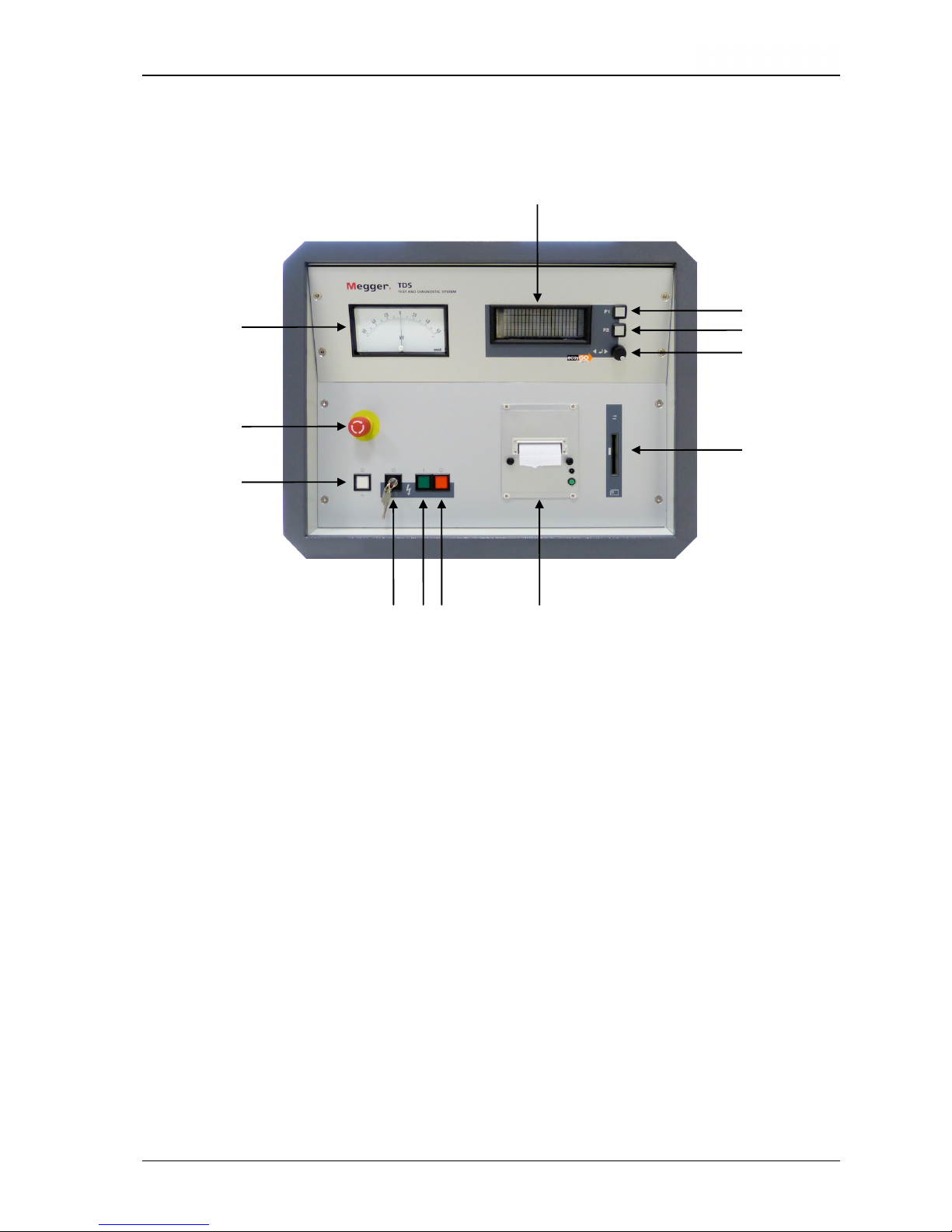

2.8 Description of Components ................................................................ 2-21

2.8.1 Operating Module .................................................................................. 2-21

2.8.2 Display of the Operating Module ............................................................ 2-22

2.8.3 Connections ........................................................................................... 2-23

2.8.4 Protection Covers of the Module ............................................................ 2-24

2.8.5 Transportation Protection Bottom from the Operating Module ............... 2-25

3. SETTING UP OPERATION .................................................. 3-27

3.1 Safety Precautions ............................................................................... 3-27

3.2 Electrical Connection for Stand-alone Test Operation ..................... 3-29

3.2.1 General Rules for Making Connections ................................................. 3-29

3.2.2 Procedure .............................................................................................. 3-30

3.2.3 Connection of the External Safety Device (Optional) ............................. 3-31

4. Operating in Stand-alone Test Mode ................................ 4-33

4.1 VLF- / DC-Test ...................................................................................... 4-33

4.2 Sheath Fault Location ......................................................................... 4-35

4.3 Starting the Test / Location ................................................................. 4-36

5. Additional Functions .......................................................... 5-39

5.1 Adjustment of Language ..................................................................... 5-39

5.2 Viewing the System Information ......................................................... 5-39

Page 6

1-6

5.3 Viewing / Setting the System Parameters .......................................... 5-40

5.4 Entering / Changing the Administrator Password............................. 5-41

5.5 Returning to the Start Menu ................................................................ 5-42

6. Optional Features ............................................................... 6-43

6.1 Detection of Breakdown and Short Circuit ........................................ 6-43

6.2 Measurement of Leakage Current....................................................... 6-43

6.3 Internal Protocol Printout .................................................................... 6-44

6.4 Cable Tests using a SystemCard ........................................................ 6-47

6.4.1 SystemCard and „WinkisVLF“ ................................................................ 6-47

6.4.2 Parametrising the SystemCard .............................................................. 6-48

6.4.3 Logging to SystemCard .......................................................................... 6-49

6.4.4 Operating the Test and Diagnosis System with a SystemCard .............. 6-50

6.5 Function User Setup / User Level ....................................................... 6-52

6.6 Re-Setting the System Settings / Deleting the Print Templates ....... 6-53

6.7 Adjustment of the System Time .......................................................... 6-54

7. Repair and Fault Diagnostics............................................. 7-55

7.1 Replacing Fuses ................................................................................... 7-55

7.2 Exchanging the Paper Roll or Ink Ribbon of the Printer ................... 7-56

7.3 Replacing the Battery of the System Clock ....................................... 7-57

7.4 Connecting Cables, HV Couplings ..................................................... 7-58

7.5 Operational and Error Messages ........................................................ 7-58

7.5.1 Classification of Messages ..................................................................... 7-58

7.5.2 Operational Messages about State of System ....................................... 7-59

7.5.3 Operational Messages about Switching Conditions ............................... 7-62

7.5.4 Error Messages and Warnings ............................................................... 7-64

Page 7

1-7

Abbildungsverzeichnis

Fig. 1: Time frame of polarity reversal (type Plus) ............................................ 2-16

Fig. 2: Shape of 0.1 Hz cosine-rectangular VLF voltage (type Plus) ................. 2-17

Fig. 3 Operating module - Front View .............................................................. 2-21

Fig. 4: Display of the Operating module (View of the standard operating mode)2-22

Fig. 5: Connections (in the example of the TDS60) .......................................... 2-23

Fig. 6: Protection cover of the Operating module .............................................. 2-24

Fig. 7: Shorting device / Protection cover of the HV module ............................. 2-24

Fig. 8: Transportation protection bottom from the Operating module ................ 2-25

Fig. 9: Connection scheme ............................................................................... 3-30

Fig. 10: Connection of the external safety device ............................................... 3-31

Fig. 11: Start menu ............................................................................................. 4-33

Fig. 12: Selection of the operation mode ............................................................ 4-33

Fig. 13: Selection of the test voltage ................................................................... 4-34

Fig. 14: Selection of the test time ........................................................................ 4-34

Fig. 15: Selection of the pulse rate ..................................................................... 4-35

Fig. 16: Switching on high voltage ...................................................................... 4-36

Fig. 17: Display of the logged measurement values ........................................... 4-36

Fig. 18: Display of instantaneous data ................................................................ 4-37

Fig. 19: Display of the set voltage value ............................................................. 4-37

Fig. 20: Start menu after the test has been finished ........................................... 4-38

Fig. 21: User Setup: Language ........................................................................... 5-39

Fig. 22: Setup: System information ..................................................................... 5-39

Fig. 23: Setup: Parameters ................................................................................. 5-40

Fig. 24: Setup: Enter password ........................................................................... 5-41

Fig. 25: Setup: Entered password ok .................................................................. 5-41

Fig. 26: Setup: Enter new password ................................................................... 5-42

Fig. 27: Setup: New password stored ................................................................. 5-42

Fig. 28: Setup: Return to start menu ................................................................... 5-42

Fig. 29: Breakdown detection ............................................................................. 6-43

Fig. 30: Setup: Protocol printout off .................................................................... 6-44

Fig. 31: Setup: Protocol Printout Standard.......................................................... 6-44

Fig. 32: Setup: Protocol off ................................................................................. 6-49

Fig. 33: Setup: Protocol extended ....................................................................... 6-49

Fig. 34: Start menu with system card inserted .................................................... 6-50

Fig. 35: Start menu after new system settings have been stored ....................... 6-51

Fig. 36: Setup: User profile ................................................................................. 6-52

Fig. 37: Setup: Memory....................................................................................... 6-53

Fig. 38: Setup: Date / Time ................................................................................. 6-54

Page 8

1-8

Fig. 39: Setup Date / Time: Adjusting the day of the week .................................. 6-54

Fig. 40: Setup Date / Time: Adjusting the minutes .............................................. 6-54

Fig. 41: Setup Date / Time: Saving by F1 ........................................................... 6-54

Fig. 42: Unscrewing the printer front cover ......................................................... 7-56

Fig. 43: Removing the front cover ....................................................................... 7-56

Fig. 44: Removing the ribbon cartridge ............................................................... 7-56

Fig. 45: Inserting the ribbon cartridge ................................................................. 7-56

Fig. 46: Inserting the paper roll into the printer.................................................... 7-57

Fig. 47: Paper feed button .................................................................................. 7-57

Page 9

1-9

1. GENERAL INTRODUCTION

The test and diagnosis system TDS40/60 shall be used for the stated field of application

in cable diagnosis and cable testing only. Any other application is strictly forbidden!

Megger cannot be made liable for any damage to persons or matter caused by using the

system for some other application.

This is why we advise you to absolutely abide by the safety precautions given in chapter1

whenever you use the TDS40/60.

Each person involved in the assembly, operation, maintenance, and repair of the

TDS40/60 is required to have read this handbook carefully.

Only trained and/or instructed staff are permitted to deal with the TDS40/60 and its

periphery. Other persons have to stay away.

This handbook must be available to the supervising, operating, and maintenance staff for

reference.

Never use foreign components on the TDS40/60 and its periphery, otherwise the safety

of the system is jeopardised.

The user is obliged to immediately report any occurring change in the system to the

supervisor in charge.

The operator is obliged to immediately shut down the system should any fault occur that

might pose a threat to the staff. The system is permitted to be switched on again only

after the fault has been eliminated.

The TDS40/60 and all its supplementary equipment has to be connected and operated

according to instructions. All relevant standards (DIN, VDE) shall be met. Any repair or

maintenance operation may be carried out only after all circuits have been shut down

(are in a dead state) and only by an electrical expert. A person is regarded an electrical

expert if due to his or her practical training, knowledge, and experience as well as

knowledge of the relevant standards he or she is able to assess the operation to be

carried out and detect every possible risk.

Attention!

The test and diagnosis system TDS40/60 is an upright device and has to be only

transported and operated in upright position.

Page 10

1-10

1.1 General Instructions

Safety precautions

This manual contains basic instructions for the commissioning and operation of the

device / system. For this reason, it is important to ensure that the manual is always

available to the authorised and trained operator. He needs to read the manual

thoroughly. The manufacturer is not liable for damage to material or humans due to nonobservance of the instructions and safety advices provided by this manual.

Locally applying regulations have to be observed!

Labelling of safety instructions

The following symbols may be present on the packaging material, on the instrument and

in the manual:

Symbol Description

WARNING

Indicates a potential danger of an electric shock that may result in fatal

or serious injury.

CAUTION

Caution (refer to accompanying manual for instructions)!

Indicates a potential danger that may lead to slight or moderate injury.

The notes contain important information and useful tips for using the

system. Failure to observe them can render the measurement results

useless.

Working with products from Megger

It is important to observe the generally applicable electrical regulations of the country in

which the device will be installed and operated, as well as the current national accident

prevention regulations and internal company directives (work, operating and safety

regulations).

After working on the system, it must be voltage-free and secured against reconnection as

well as having been discharged, earthed and short-circuited.

Use genuine accessories to ensure system safety and reliable operation. The use of

other parts is not permitted and invalidates the warranty.

Page 11

1-11

Operating Staff

This system and its peripheral equipment may only be operated by trained or instructed

personnel. Anyone else must be kept away.

The system may only be installed and operated by an authorised electrician. DIN VDE

0104 (EN 50191), DIN VDE 0105 (EN 50110) and the German accident prevention

regulations (UVV) define an electrician as someone whose knowledge, experience and

familiarity with the applicable regulations enables him to recognise potential hazards.

Declaration of Conformity (CE)

The product meets the following security requirements of the European Council

Directives:

• EMC Directive (2004/108/EG)

• Low Voltage Directive (2006/95/EG)

1.2 General Safety Instructions and Warnings

Intended application

The operating safety is only guaranteed if the delivered system is used as intended.

Incorrect use may result in danger to the operator, to the system and the connected

equipment.

The limits described under Technical Data may not be exceeded.

Behaviour at malfunction of normal operation

The equipment may only be used when working properly. When irregularities or

malfunctions appear that cannot be solved consulting this manual, the equipment must

immediately be put out of operation and marked as not functional. In this case inform the

person in charge who should inform the Megger-service to resolve the problem. The

instrument may only be operated when the malfunction is resolved.

Five safety rules

The five safetey rules must always be followed when working with HV (High Voltage):

1. De-energise

2. Protect against re-energising

3. Confirm absence of voltage

4. Earth and short-circuit

5. Cover up or bar-off neighbouring energised parts

Page 12

1-12

Using cardiac pacemaker

Physical processes during operation of high voltage may endanger persons

wearing a cardiac pacemaker when near these high voltage facilities.

Firefighting in electrical installations

• According to regulations, carbon dioxide (CO2) is required to be

used

as extinguishing agent for fighting fire in electrical installations.

•

Carbon dioxide is electrically non conductive and does not leave

residues. It is safe to be used in energized facilities as long as the

minimum distances are maintained. A CO2 fire

extinguisher must be

always available within electrical installations.

•

If, contrary to the regulations, any other extinguishing agent is used

for fire fighting, this may lead to damage at the electrical installation.

Megger disclaims any liability for cons

equential damage.

Furthermore, when using a powder extinguisher near high-

voltage

installations, there is a danger that the operator of the fire

extinguisher will get an electrical shock from a voltage arc-

over (due

to the powder dust created).

• It is essen

tial to observe the safety instruction on the extinguishing

agent.

• Applicable is DIN VDE 0132.

WARNING

Dangers when working with high voltage

Working on high voltage systems and equipment – especially in nonstationary operation – requires particular care and safety-

conscious action

on the part of test personnel. VDE regulations 0104 on setting up and

operating electrical test systems, as well as EN 50191 and national

standards and regulations must be strictly adhered to.

• The test system generates a da

ngerous test voltage of up to 40

resp. 60 kV

PEAK

.

• The test system may not be operated without supervision.

• Never fail to use safety equipment or put it out of operation.

•

Operation requires minimum two people whereas the second person

must be able to activate the emergency switch in case of danger.

•

To prevent dangerous charge accumulation, earth all metal parts in

the vicinity of the high voltage equipment.

Page 13

2-13

2. TECHNICAL DESCRIPTION

2.1 Description of the Functions

The test and diagnosis system TDS40/60 enables the standard-compliant testing of

medium voltage cables and other equipment with a 0.1 Hz cosine rectangular test

voltage of up to 40 kV

PEAK

or 60 kV

PEAK

.

With the help of such a cable test, operation-endangering faults as well as insulation

faults (e.g. water tree damages in PE/XLPE cables or local damages in PILC cables) can

be safely brought to failure. Due to the integrated breakdown detection, this test process

takes place without damage to the fault-free cable insulation.

In combination with the partial discharge measurement system PDS 60, the TDS40/60

forms a fully adequate diagnosis system (TDS NT) which is suitable for the partial

discharge diagnosis on medium voltage cables according to the standards. In this stage

of expansion the system is operated by remote control and can be operated in the VLF or

DAC (damped AC) mode.

This manual solely describes the operation of the test and diagnosis system

TDS40/60 in the stand-alone test operation. For info

rmation regarding the

connection of the partial discharge measurement system PDS

60 and the remote

operation of the system please read the manual of the PDS 60.

2.2 Model Options

The model options of the test and diagnosis system differ in the following attributes:

TDS40Basis

40 kV test voltage; only negative voltage source

TDS40Plus

40 kV test voltage; negative and positive voltage source (higher test

performance as a result)

TDS60Basis

60 kV test voltage; only negative voltage source

TDS60Plus

60 kV test voltage; negative and positive voltage source (higher test

performance as a result)

Page 14

2-14

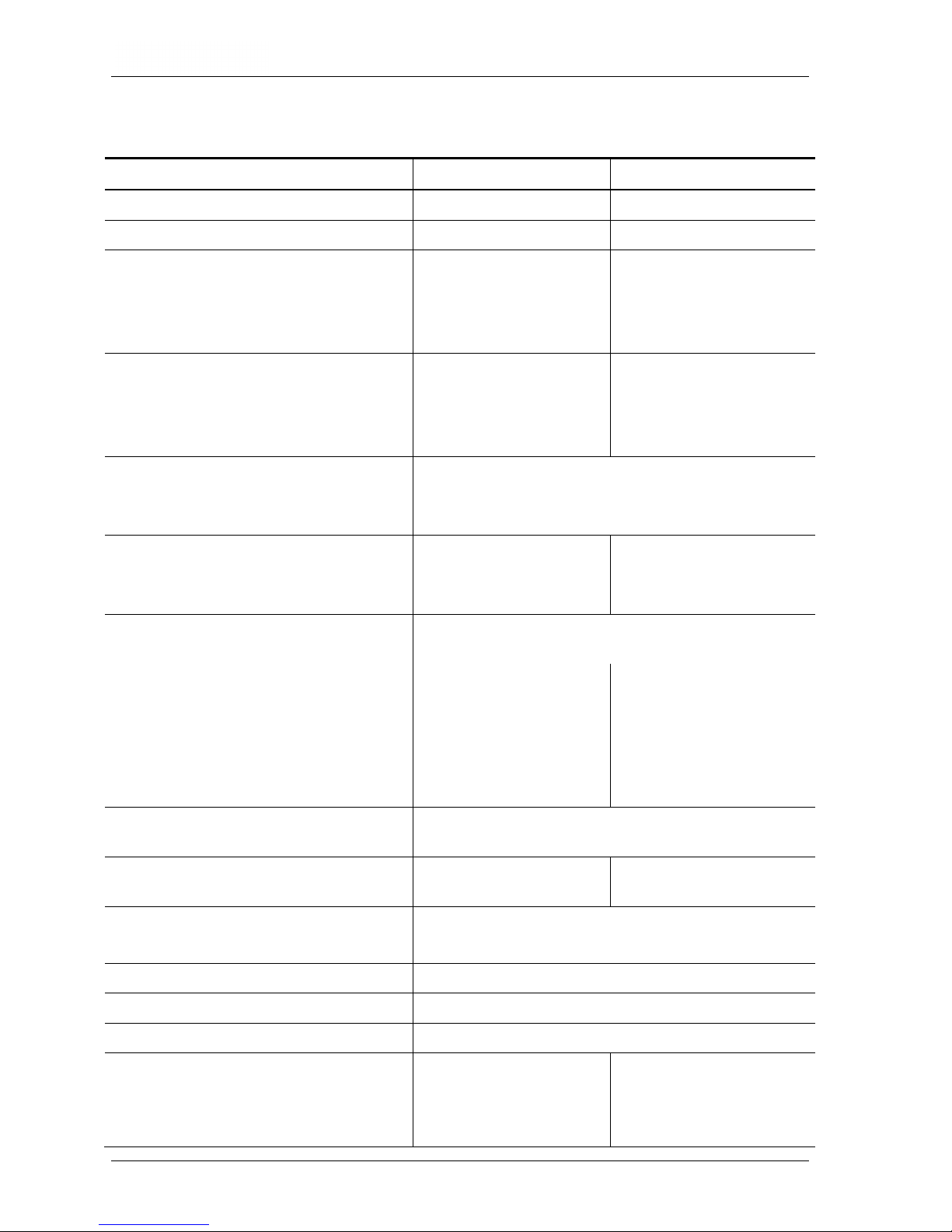

2.3 Technical Specifications

Parameter TDS40 TDS60

Output voltage DC 3 … 40 kV 3 … 60 kV

Output current source 7 mA 5 mA

Leakage current measurement

(optional)

Range of indication

Resolution of indication

0 - 7 mA

10 µA

0 - 5 mA

10 µA

VLF-test

Output voltage

Frequency

Voltage form

3 … 40 kV

PEAK

0.1 Hz

cosine rectangular

3 … 60 kV

PEAK

0.1 Hz

cosine rectangular

Sheath fault location

Voltage

Pulse rate

3 … 10 kV

4 s (1:3), 4 s (1:5), 6 s (1:5), 6 s (1:9)

DAC-operation

Output voltage

Frequency

3 … 40 kV

PEAK

58 … 410 Hz

3 … 60 kV

PEAK

58 … 475 Hz

Testable cable capacitance in the

VLF-operation

(also see section 2.6)

for full operating temperature range 2.2 µF (Basis)

4.4 µF (Plus)

0.8 µF (Basis)

1.6 µF (Plus)

At normal temperatures (≤20 °C) and

with restrictions regarding the

accuracy of the leakage current

measurement values

2.4 µF (Basis)

4.7 µF (Plus)

1.0 µF (Basis)

2.0 µF (Plus)

Cable capacitance to be tested in

the DAC-mode

(see section 2.7)

Discharge device integrated, 4,7 µF in 5 s integrated, 2,0 µF in 2 s

Power supply

230 V ±10 %, 50 ... 60 Hz or optionally

120 V ±10 %, 60 Hz

Power consumption max. 500 VA

Operating temperature range -25 °C ... +55 °C

Storage temperature range -40 °C ... +70 °C

Operating humidity 30 °C, 93% rel.

humidity

30 °C, 93% rel. humidity

up to 50 kV

30 °C, 70% rel. humidity

from 50 to 60 kV

Page 15

2-15

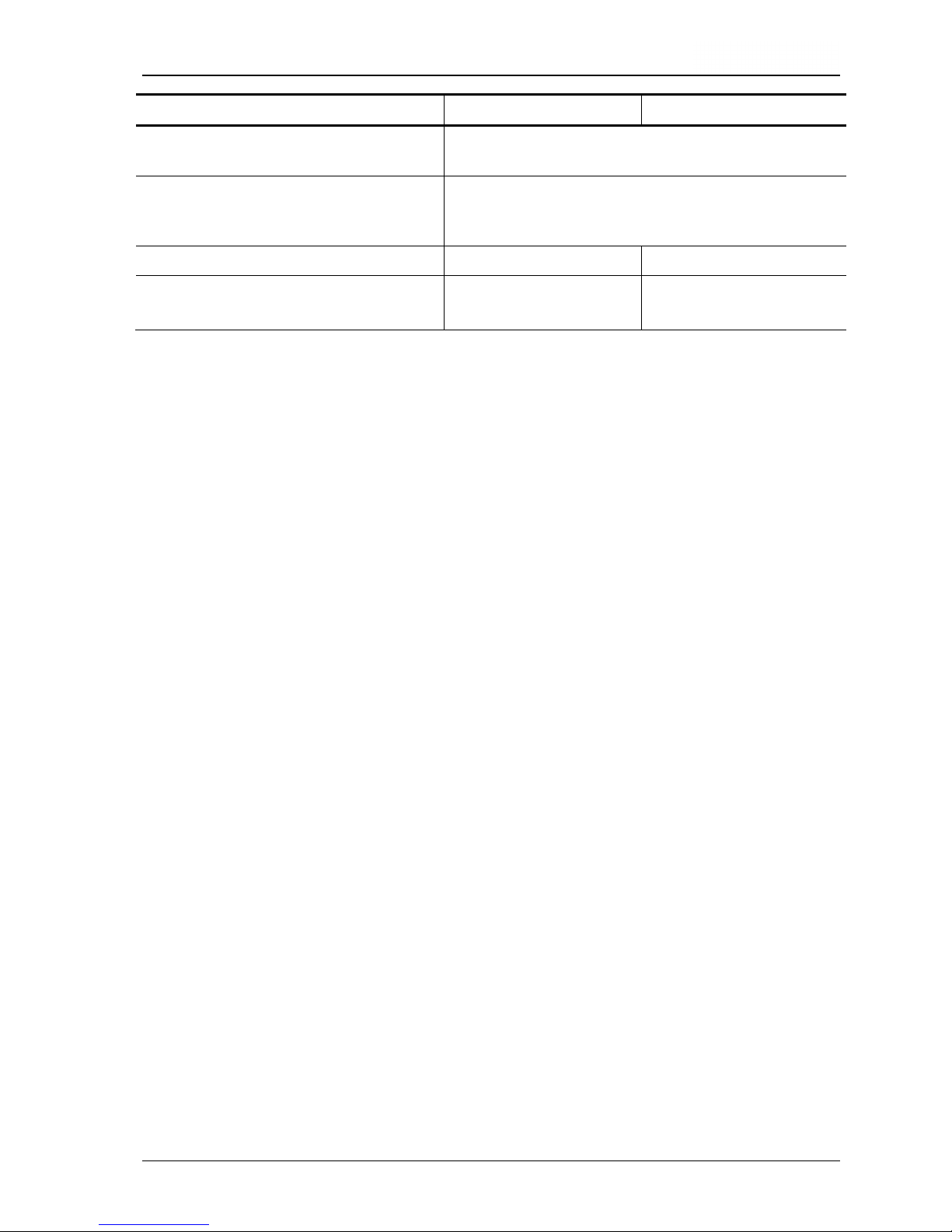

Parameter TDS40 TDS60

Protection class (in accordance with

IEC 61140 (DIN VDE 0140-1))

I

Ingress protection rating (in

accordance with IEC 60529 (DIN

VDE 0470 1))

IP21

Dimensions (W x H x D) 56 x 113 x 41.5 cm 62.5 x 118 x 62 cm

Weights (depending on the model) 55 kg + 48.5 kg (Basis)

55 kg + 55.5 kg (Plus)

85 kg + 48.5 kg (Basis)

85 kg + 55.5 kg (Plus)

2.4 Scope of Delivery and Options

Equipment Power cord 2.5 m

Earth cable 5 m

HV connection cable 5 m

HV connection clamp (red) with MC plug

Operational earth connection adapter

Manual

Equipment case

Optional features Detection of breakdown

Leakage current measurement

Logging

Protocol printout

Optional equipment External safety device (128309600)

Page 16

2-16

2.5 Description of the Test Procedure with VLF-Voltage

Because of the space charges formed in the dielectric of the cable, DC test methods

prove to be dangerous when applied to PE and VPE cables and should therefore never

be used on such types of cables.

Nowadays we can take it for granted that the 0.1 Hz VLF method for testing cables with

plastics insulation outclasses any other test method using DC voltage or powerfrequency AC voltage as used so far.

A 0.1 Hz VLF test system must meet the following demands:

• The repetition rate has to be so low, that the power that is set free in any

existing PD-channel (PD = partial discharge) is small enough not to cause

further erosion and so increase gas pressure.

• The inversion of polarity, on the one hand, must be slow enough to

exclude any transients caused by travelling waves. On the other hand, it

must be fast enough that any space charge at the tip of a PD-channel from

where it grows in the direction of the opposite electrode is preserved.

A system that meets these requirements has to supply a 0.1 Hz oscillation, with the quick

polarity reversal taking place within a frequency close to the power frequency.

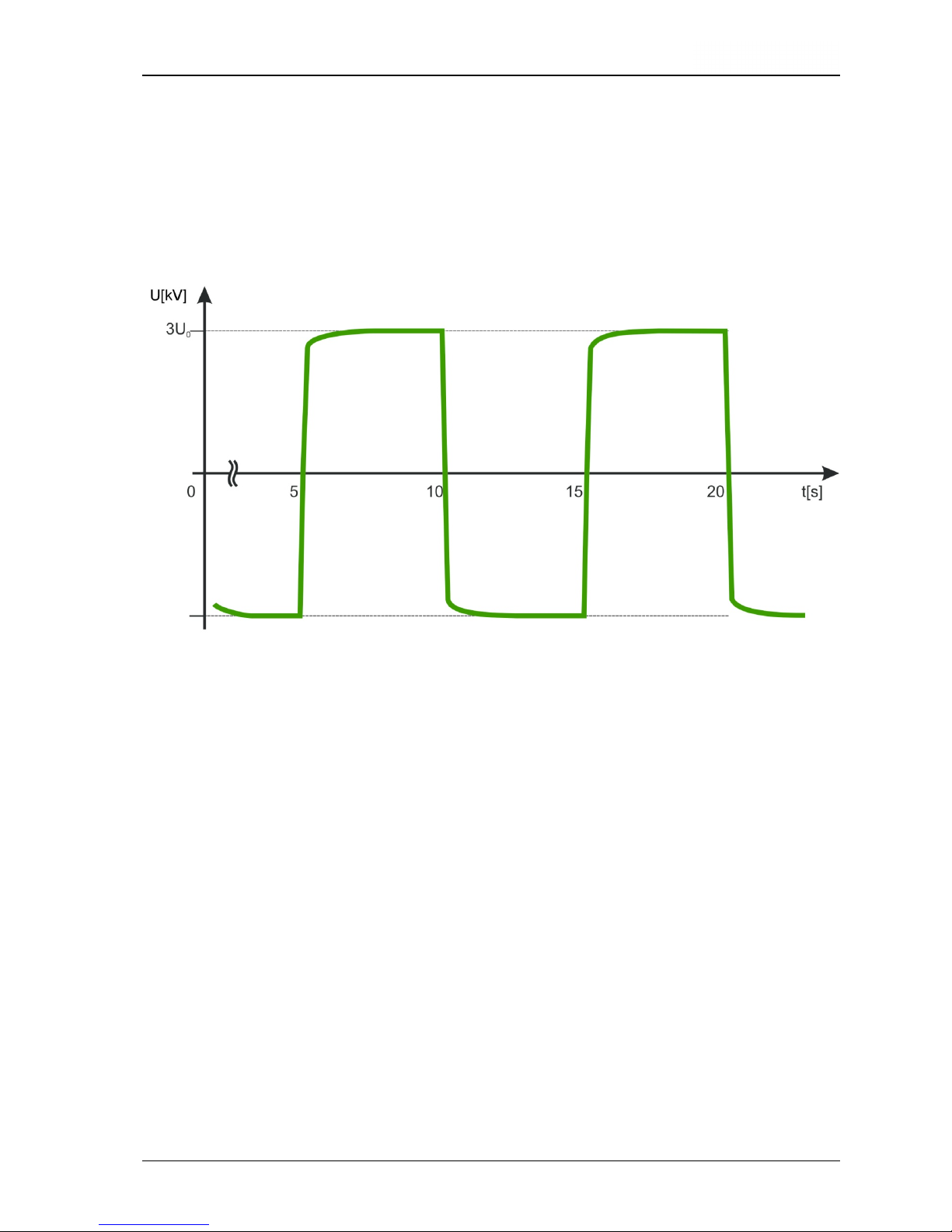

Fig. 1: Time frame of polarity reversal (type Plus)

Load-dependend frequency during polarity inversion:

TDS40Basis

40 ≤ f < 410 Hz

TDS40Plus

30 ≤ f < 410 Hz

TDS60Basis

55 ≤ f < 475 Hz

TDS60Plus

40 ≤ f < 475 Hz

VLF CR 0.1 Hz

polarity reversal

Oscillation with

30 … 475 Hz

(see below)

Page 17

2-17

Another vital characteristic to be considered when designing this system was to ensure

simple on-site testing by

- small dimensions,

- light weight and

- low power consumption.

Every cycle starts with a charging phase in which the test object as well as the back-up

capacitor switched in parallel are charged from a DC source until the desired test voltage

is reached.

Fig. 2: Shape of 0.1 Hz cosine-rectangular VLF voltage (type Plus)

After a period of 5 seconds, the voltage source will be disconnected from the system

resp. discharged via a resistance.

Subsequently, the polarity reversal is initiated. The test voltage changes its polarity from

minus to plus.

Depending on the size of capacitance of the connected test object, time of the polarity

reversal is between 1 and 17 ms.

Due to the losses which occur during the polarity inversion, the positive voltage is always

decreased by these losses.

After a 5 seconds dwelling period at positive polarity (device option Basis) or equalisation

of the polarity reversal losses due to recharging by the positive DC voltage source

(device option Plus), the return to negative polarity takes place.

The negative voltage source is reconnected to the test object.

Page 18

2-18

The loss of voltage caused by twice changing the polarity (device option Basis) will now

be compensated for by recharging with the negative DC source. In contrast to this at the

device option Plus the losses of a polarity reversal are immediately compensated.

The back-up capacitor has the following tasks:

- It slows the ring-around event down to the ms range even for short cables,

- It compensates a part of the losses during the polarity reversal.

Page 19

2-19

2.6 Testable Cable Capacitance in VLF Mode

Page 20

2-20

2.7 Cable Capacitance that Can be Diagnosed in DAC Mode

TDS40

TDS60

Page 21

2-21

2.8 Description of Components

2.8.1 Operating Module

Fig. 3 Operating module - Front View

1 Key "Emergency Off"

2 Analogue indication instrument test voltage (kV)

3 Display

4 Menu key F1

5 Menu key F2

6 Knob / push-button

7 Intake slot for the System Card

8 Protocol printer

9 Key "HVOff" (red)

10 Key "HVOn" (green)

11 Key-operated switch "Interlock"

12 Key "Mains On" (white)

3

4

5

6

7

2

1

12

11 10 9 8

Page 22

2-22

2.8.2 Display of the Operating Module

Fig. 4: Display of the Operating module (View of the standard operating mode)

1 Representation of parameters with value and content resp.

2 Representation of residual time and/or measuring values

3 Representation of operator guidance / status display

Following signals are indicated in the line of operator guidance / status display (Fig. 4,

item 3):

• Operator guidance „Select mode OK?“ e. g.

• Status display „Running. HVOff?“ e. g.

• Switching condition „HV interlock“ e. g.

• Cause for shutdown „Breakdown in cable“ e. g.

• Warning „34: No printer data“ e. g.

• Failure message „19: Coil overload“ e. g.

1

2

3

VLF mode

10kV

5min

0.

0kV

0.00mA

Prepared . HVOn?

Page 23

2-23

2.8.3 Connections

Fig. 5: Connections (in the example of the TDS60)

1 Power supply socket with F1, F2

2 Terminal clip for earth connection of the Operating module

3 Terminal clip for earth connection HV module

4 RJ45 network socket for the connection with the notebook

(required for remote control)

5 Connector socket for connection line to PDS 60

6 Test voltage output

7 Terminal clip for signal ground

4

2

3

5

1

7

6

Page 24

2-24

2.8.4 Protection Covers of the Module

VLF

Test System

Fig. 6: Protection cover of the Operating module

!

Fig. 7: Shorting device / Protection cover of the HV module

Page 25

2-25

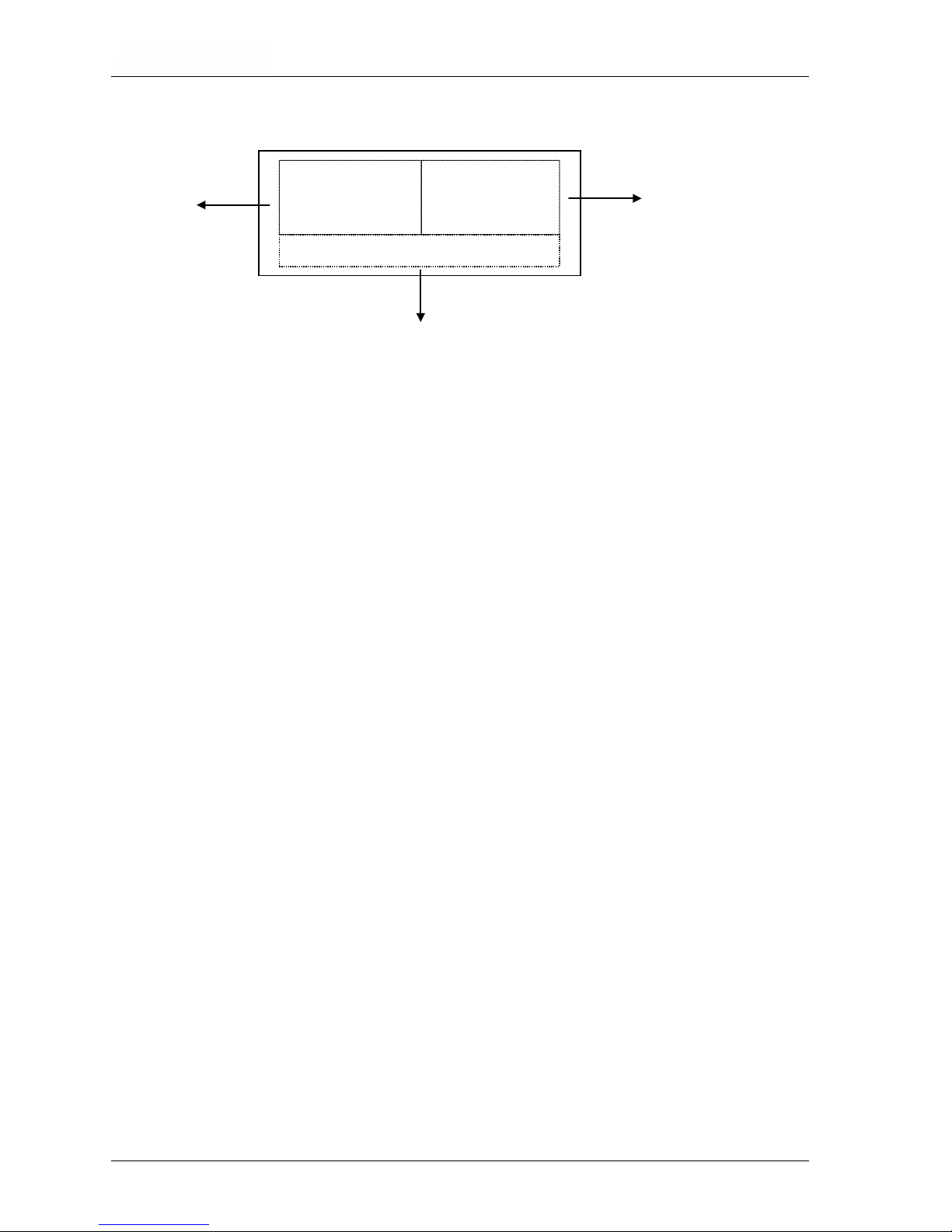

2.8.5 Transportation Protection Bottom from the Operating Module

Fig. 8: Transportation protection bottom from the Operating module

Pull out in order to remove

the transportation protection

bottom

Pull out in order to remove

the transportation protection

bottom

Push in in order to fix

the transportation

protection bottom

Push in in order to fix

the transportation

protection bottom

Page 26

Page 27

3-27

3. SETTING UP OPERATION

3.1 Safety Precautions

Before starting any operation, always observe the 5 rules of safety:

• Disconnect the test object

• Protect it against reclosure

• Check for absence of voltage

• Connect it to earth and short-circuit it

• Cover all neighbouring parts carrying voltage or seal them off by a barrier

In order to prevent any damage to persons and/or installations that might directly be

caused by the operation of the test and diagnosis system alone or in combination with

other systems or instruments, always observe the following safety precautions:

Make sure there are no unprotected systems or system components carrying voltage in

the immediate vicinity of the test and diagnosis system with which you or your system

may unintentionally get into contact. This applies in particular to all components under

high voltage or components the voltage of which is not known.

Protect these components by putting up insulating covers. If, for technical reasons, this

cannot be done, disconnect these components or have them disconnected for the

duration of your test at this site after having consulted the relevant supervisor and asked

for his/her permission. Make sure this measure is carried out properly.

Take a test measurement using an appropriate voltage meter. Beforehand, check the

proper operation of this meter, e.g. by taking a test measurement of a known voltage.

Position your system in a place suitable with regard to its dimensions and its weight.

Check whether the system stands in a stable position.

Make sure that the site where the HV module is situated is vented properly to avoid the

accumulation of ozone during lengthy periods of operation.

Make sure that no other system/system component is restricted in its operation by the

presence of your test and diagnosis system. If due to the installation and operation of

the test and diagnosis system some changes have to be made on another

system/system component, always make sure that the former condition is restored after

all operations have been concluded. Observe the special requirements of these

systems/system components without fail, and start any operation on them only after

having consulted the supervisor in charge and asked for his/her permission.

Page 28

3-28

This applies in particular to all changes made on an existing safety device.

The test and diagnosis system TDS40 generates during the test process a dangerous

test voltage up to 40 kV or the test and diagnosis system TDS60 a test voltage up to 60

kV resp. The test voltage is fed via the HV connecting cable in the test object.

Protect the test object against unintentional contact of persons to active parts by means

of protective devices (handrails, chains, bars, etc.) which guarantee that no one can get

into the zone of danger.

Disconnect the test object to ensure that no dangerous voltage can get to unprotected

places or unprotected technical equipment.

Whenever the test and diagnosis system is operated, a second person must be present

within viewing and hearing distance who can recognise possible hazards and press the

Emergency Off key.

Never leave the test and diagnosis system unattended while operating.

In order to avoid dangerous charging, connect all metal parts in the vicinity of the test

and diagnosis system to earth.

As a matter of principle, all unused cables not needed for the test have to be shorted

and connected to earth.

Attention! The test object has to be connected to earth and shorted after terminating

of the test.

You are not excused from this duty even if the complete discharge by the

internal discharging unit and the zero positioning of the residual voltage

(Fig. 3, item 2) have been performed.

In the case of an incomplete discharge of the test object the complete

discharging must be carried out with a suitable discharge rod.

Page 29

3-29

Attention! The HV module of the test and diagnosis system contains electrical

energy storage devices also. These devices are discharged in the same

way like the test object by the internal discharging unit of the test device.

To avoid the re-charging by space charges the HV module has to be

immediately equipped by means of the provided shorting device (Fig. 7)

after disconnection of the both components HV module and Operating

module. The shorting device has to be remained at the HV module even in

the case of transportation and storage and may not be removed until the

Operating module had been put on.

Attention! Before each use it has to be checked whether the following components of

the system are intact, dry and clean:

* HV-connector (device side) and end termination (test object side) of

the movable high-voltage connecting

* HV- output socket of the HV module

* HV connector between HV module and operating module

3.2 Electrical Connection for Stand-alone Test Operation

3.2.1 General Rules for Making Connections

Always keep in mind that you are required to comply with all relevant safety precautions

for high voltage and power systems when you bring the system into service!

In particular, make sure that the test object is connected to earth and shorted and the

cable testing apparatus is switched off when it is connected to the test object or

disconnected from it.

It is only for the duration of intrinsic testing that this short-circuit and earth connection

may be removed.

Please regard the discharge switch contained in the device only as a facility for

discharging the capacitors without risk. Do not use it for earthing and shorting according

to VDE 0104!

Page 30

3-30

3.2.2 Procedure

The descriptions in this section solely apply to the stand-alone operation. The

features regarding the electrical connection in order to diagnose partial

discharge are described in the manual of the discharge

measurement system

PDS 60.

Fig. 9: Connection scheme

The earth cable has be connected to the protective earth system of the

station at an appropriate point and then to be attached to the Terminal clips

of the operating module (see Fig. 5, item 2) and of the HV-module (see Fig.

5, item 3).

The HV connection cable with its HV connector has to be plugged into the

HV module (see Fig. 5, item 6) and to be fixed by turning the latch. The

terminal clip for signal ground has to be plugged into the appropriate

connection (see Fig. 5, item 7).

Afterwards the test cable is connected to the earthed test object.

Plug the mains cable supplied with the system into the power supply socket

(see Fig 5, item 1) and connect it to a mains outlet.

Page 31

3-31

3.2.3 Connection of the External Safety Device (Optional)

The optional external safety device can be connected in between the power outlet and

the power inlet in order to ensure norm-compliant signalling and Emergency Stop

according to DIN EN 50191 / VDE 0104.

Fig. 10: Connection of the external safety device

As soon as the system has been connected to a mains outlet, the red signal light lights

up and signals that high voltage could be generated.

By using the Emergency Stop button or key-operated switch, the power supply can be

interrupted abruptly or be locked. A system that is currently operating is completed

turned off and the discharge switch closed. High voltage cannot be generated, which is

indicated by the green lamp.

Page 32

Page 33

4-33

4. Operating in Stand-alone Test Mode

This manual solely describes the operating of the test and diagnosis system

TDS40/60 in the stand-alone mode.

For information on operating the system by

remote control

in order to diagnose partial discharge please read the manual of

the operating system TDS NT.

4.1 VLF- / DC-Test

For high voltage tests by using the test and diagnosis system to be carried out, all

electrical connections must have been established as described in sections before.

Now the test system can be put into operation. After activation of the "Mains On"

pushbutton (Fig. 3, item 12) the system can be operated using the knob / push-button (Fig.

3, item 6) and the display (Fig. 3, item 3).

The following start menu is represented on the display (Fig. 3, item 3) after start-up:

Fig. 11: Start menu

A singular pressure on the knob / push-button (Fig. 3, item 6) will enable the operation

mode to be selected:

Fig. 12: Selection of the operation mode

Now the user is able to choose the operation mode out of VLF, DC– and DC+ (only

available on systems with two voltage sources) by turning the knob / push-button (Fig. 3,

item 6). The selection has to be confirmed by a singular pressure on the knob / pushbutton (Fig. 3, item 6). Now it is possible to select the test voltage level:

*VLF mode

20kV

15min

Select Mode ? OK?

VLF mode

20kV

15min

F1:Print

F2:Setup

Ready . OK:Start

Page 34

4-34

Fig. 13: Selection of the test voltage

The test voltage level can be adjusted in steps of 1 kV up to the maximum test voltage of

the system by turning the knob / push-button (Fig. 3, item 6). The adjusted test voltage

level has to be confirmed by pressure on the knob / push-button (Fig. 3, item 6). Now it is

possible to adjust the test time:

Fig. 14: Selection of the test time

The test time can be adjusted in steps of 1 min from 5 min up to 45 min and in steps of 5

min from 45 min up to 90 min test duration at maximum by turning the knob / push-button

(Fig. 3, item 6). The adjusted test time has to be confirmed by pressure on the knob /

push-button (Fig. 3, item 6).

Use the information given in DIN VDE 0276 - 620 and 0276 - 621 as a guideline to start

from. These standards recommend a test level of 3 x Uo and a test duration of 30 or 60

minutes, respectively.

When you follow these guidelines, the test level is near the peak voltage of a 50 Hz test (2 x

U0 rms).

For sheath tests with DC voltage, the test voltage should not exceed 3 kV for PVC cables or

5 kV for PE cables respectively.

VLF mode

20kV

*15min

Set test time ? OK?

VLF mode

*2

0kV

15min

Set Voltage ? OK?

Page 35

4-35

4.2 Sheath Fault Location

Following a failed sheath test with DC voltage fault location based on the step voltage

method can be immediately performed at the cable under test with the test and diagnosis

system serving as voltage source.

The test current coming from the pulsed DC source is flowing into the ground at the point

of fault and results in a maximum step voltage at the fault. This peak is located with an

earth fault locator (e.g. ESG).

By turning the knob / push-button (Fig. 3, item 6) the SFL operation mode has to be

selected. Afterwards, the voltage level (max. 10 kV) and the pulse rate can be selected as

described in the section before.

By changing the pulse rate you can vary the cycle period too (between 4 or 6 seconds).

E.g. the setting 4s 1:3 enables 4 seconds cycles where 1 second of high voltage is

followed by a 3 seconds dropout.

Fig. 15: Selection of the pulse rate

SFL mode

10kV

*4s 1:3

Set pulsing . OK?

Page 36

4-36

4.3 Starting the Test / Location

After the system has carried out all necessary settings which takes a short period of time,

the high voltage can be enabled.

Fig. 16: Switching on high voltage

It depends on the following conditions whether or not HV can be switched on using the

respective pushbutton (Fig. 3, item 10):

- the key "Emergency Off" (Fig. 3; item 1) is not activated,

- the key-operated switch "Interlock" (Fig. 3; item 11) is activated,

- both the Operating and the HV module are assembled in proper form.

If these conditions have been fulfilled, the "HVOn" key (green) (Fig. 3, item 10) lights up for

about 10 s and can be activated during this time. Afterwards, the "HVOff" key (red) (Fig. 3,

item 9) lights up. Under maintaining of the predetermined charging parameters the test

voltage will be regulated to the adjusted test voltage level.

At the analogue indication instrument (Fig. 3, item 2) and on the display (Fig. 3, item 3) the

level and the polarity of the test voltage are represented. In addition, the leakage current of

the test object is indicated on the display (Fig. 3, item 3).

By default, the measurement values for the voltage and the leakage current are updated

every 5 seconds at a defined moment (in the VLF mode directly before the start of the

polarity reversal. These logged measured values are displayed in square brackets (e.g.

[10.1 kV]) and remain in the display until the next moment of the next measurement.

Fig. 17: Display of the logged measurement values

VLF mode

20kV

15min

11:42

[20.1kV]

[0.13mA]

Running . HVOff?

VLF mode

20kV

15min

0.0kV

0.00mA

Prepared . HVOn?

Page 37

4-37

By using the menu button F2 (Fig. 3, item 5) the user can switch at any time to the display

with the instantaneous data. The instantaneous data are displayed without square

brackets and updated every 100 ms.

Fig. 18: Display of instantaneous data

If the button F2 is pushed again, the display changes back to the logged measured values.

Beyond this, by clicking the menu button F1, the user can switch between the display of

the remaining time and the set voltage value (e.g. !10.0 kV!).

Fig. 19: Display of the set voltage value

VLF mode

20kV

15min

!20.0kV!

[20.1kV]

[0.13mA]

Running . HVOff?

VLF mode

20kV

15min

11:32

3.6kV

0.02mA

Running . HVOff?

Page 38

4-38

During normal operation, the voltage source is / can be switched off

- by pressing the "HVOff" key (red) (Fig. 3, item 9)

- automatically after the lapse of the test time

- automatically after a voltage breakdown in the cable under test or a short

circuit has been detected

In these cases the predefined discharging of the voltage source, back-up capacitor and

test object follows.

Fig. 20: Start menu after the test has been finished

In addition, the voltage source is / can be switched off

- by activating the “Emergency Off” switch (Fig. 3; item 1),

- by turning the HV interlock key switch (Fig. 3; item 11)

- after drop out of the operating voltage

- by removing a system card which has been inserted prior to the test (see

section 6.4)

- after detection of an internal failure (see section 7.5)

In these cases the predefined discharging of the voltage source, back-up capacitor and

test object follows too.

Attention ! The test object has to be connected to earth and shorted after termination of

the test.

You are not excused from this duty even if the complete discharge by the

internal discharging unit and the zero positioning of the residual voltage

(Fig. 3, item 2) have been performed.

In the case of an incomplete discharge of the test object the complete

discharging must be carried out by a suitable discharge rod.

After the test session has been finished, the test system has to be switched off.

Afterwards, it must be disconnected from the cable under test which has been grounded

and shorted before. Finally, the earth cable has to be disconnected.

VLF mode

20kV

15min

F1:Print

F2:Setup

Test time over

Page 39

5-39

5. Additional Functions

5.1 Adjustment of Language

By pressing the F2 key (Fig. 3, item 5) and turning the knob / push-button (Fig. 3, item 6)

the "User setup" menu can be accessed. Here the language on the display and in the

protocol printing of the test and diagnosis system can be adjusted. Any new setting will be

saved after pressing of the knob / push-button (Fig. 3, item 6).

Fig. 21: User Setup: Language

5.2 Viewing the System Information

By pressing the F2 key (Fig. 3, item 5) and turning the knob / push-button (Fig. 3, item 6)

the "System info" menu can be accessed. When accessing this menu, the software

versions of several system components and the system ID, you should have on-hand

when calling a service centre, are shown on the display. In some cases the system ID is

also required for the subsequent activation of optional system features. A short instruction

how to enable optional system features is handed out with the certificate you get when

buying one or more options.

Fig. 22: Setup: System information

*System info

ID:12345678

1.21-1 1.21-1 1.21

USER PROT CTRL

User-Setup

*Language: English

Level : Standard

Select user language?

Page 40

5-40

5.3 Viewing / Setting the System Parameters

Certain test parameters in the test and diagnosis system are permanently stored as

system parameters and secured against unauthorized changes. As a standard user you

can only view these parameters. In order to adjust these parameters you have to gain

administrator rights by entering the administrator password first (see section 5.4).

By pressing the F2 key (Fig. 3, item 5) and turning the knob / push-button (Fig. 3, item 6)

the "Parameters" menu can be accessed. Provided you own administrator rights (see

section 5.4), the following parameters can be adjusted:

Fig. 23: Setup: Parameters

• Adjustment of the maximum test voltage in kV: By this adjustment the maximum

output voltage of the system can be permanently restricted in the space of its standard

data. Any re-setting can be only carried out by the administrator. The standard

maximum voltage of the test system represents the default setting.

• Adjustment of the rate of the test voltage increase v in kV/s: By this means the rate

of increase of the test voltage during the charging phase can be adjusted. Any resetting can be only carried out by the administrator. The default setting is 1 kV/s.

• Adjustment Step in kV: By this means the increment at stepwise increasing of the test

voltage during the charging phase can be adjusted. Any re-setting can be only carried

out by the administrator. The default setting is 5 kV.

• Adjustment Pause (rest period) in s: Here the duration of the rest period at stepwise

increasing of the test voltage during the charging phase can be adjusted. Any re-setting

can be only carried out by the administrator. The default setting is 0 s.

Parameters <A>

*max.60kV

step 5kV

v= 1kV/s pause 0s

Set HV parameters ?

Page 41

5-41

5.4 Entering / Changing the Administrator Password

By pressing the F2 key “setup” (Fig. 3, item 5) and turning the knob / push-button (Fig. 3,

item 6) the "Password" menu can be accessed. When entering this menu, you have to

enter the administrator password in order to gain the administrator rights enabling you to

adjust the test parameters accessible via the “Parameters” menu (see section 5.3). The

factory-provided default password for any VLF test system is 2345.

The first two digits of the password (23) have to be entered under 1. and the last two digits

(45) have to be entered under 2. Any entered number sequence has to be confirmed by

pressing the knob / push-button (Fig. 3, item 6).

Fig. 24: Setup: Enter password

The access will be gained, if the correct password has been entered. The respective

system message has to be confirmed by pressing the knob / push-button (Fig. 3, item 6).

You are now authorised as an administrator which is indicated by the characteristic <A> in

the top right of the display.

Fig. 25: Setup: Entered password ok

*Password <A>

43:Access released

Password

*1.: 00

2.: 00

Enter password

Page 42

5-42

After the password has been entered and accepted, it can be changed.

In order to change the password, you have to access the “Passw. Set” menu right after

you gained administrator rights. The new password has to be entered the same way as the

current password has been entered (see previous page).

Fig. 26: Setup: Enter new password

Fig. 27: Setup: New password stored

5.5 Returning to the Start Menu

In order to return to the start menu you have to access either the “Return” or the “Escape"

menu item.

If you leave the setup via “Return” (fully to the left), you lose the administrator rights.

If you leave the setup via “Escape” (fully to the right), you keep the administrator rights.

Fig. 28: Setup: Return to start menu

*Return <A>

Your selection ?

*Passw. Set <A>

55:Password stored

Passw. set <A>

*1.: 00

2.: 00

Change password ?

Page 43

6-43

6. Optional Features

6.1 Detection of Breakdown and Short Circuit

Systems with the optional breakdown and short circuit detection offers the following

additional functions:

The test voltage will be immediately switched off in any case of a breakdown in the cable

under test. The status message "Cable break down" is indicated on the display.

The level of the break down voltage is indicated on the display. That value is represented

as storage voltage (i.e. in parentheses).

In case of a short circuit (test voltage < 5% of rated voltage), the test voltage will be

switched off. The status message "Cable cannot be charged" is indicated on the display.

Fig. 29: Breakdown detection

6.2 Measurement of Leakage Current

If a system is equipped with the optional Leakage Current measurement, the leakage

currents of the test object are indicated on the display during the test.

During charging period, the instantaneous measurement values are indicated on the

display. Afterwards, the VLF final values are indicated on the display. The final values (test

voltage and leakage current) are represented in brackets. Change-over to the

representation of the instantaneous measurement values (values without parentheses or

brackets) and back can be carried out by activating the F2 key.

If the test and diagnosis system has been additionally equipped with the logging option or

protocol printout option, these measurement values can be additionally filed and printed

out respectively.

VLF mode

20kV

15min

6:32

(20.1kV

)

(0.19mA)

Breakdown in cable

Page 44

6-44

6.3 Internal Protocol Printout

Systems, that are equipped with a protocol printer (Fig. 3, item 8), offer the opportunity to

print those data that have been logged during the cable test.

By pressing the F2 key (Fig. 3, item 5) and turning the knob / push-button (Fig. 3, item 6)

the "Protocol" menu can be accessed. Here you can change the settings of the printer by

adjusting the “Print” parameter. The value of the parameter can be changed by rotating the

knob / push-button (Fig. 3, item 6) and can be accepted / saved by pressing it.

Fig. 30: Setup: Protocol printout off

Fig. 31: Setup: Protocol Printout Standard

After a cable test has been finished, the protocol printout can be triggered from the start

menu (Fig. 9) by pressing the F1 key once or repeatedly.

Depending on the print settings (see above), the following information are included in the

printout:

• Printout "Standard":

- Header (extended by the header from the SystemCard (if specified))

- System type and version

- Mode of operation, test voltage, test time

- Date / Time of test start

- Result of the test

- Measured data (time, test voltage in kV, leakage current in mA) of the test

(affected by the “print time points” set on the SystemCard (if specified))

- Footer (extended by the footer from the SystemCard (if specified))

- Date / Time of the printout

Protocol

Prot.: Extended

*Print: Standard

Set print mode ?

Protocol

Prot.: Extended

*Print: Off

Set print mode ?

Page 45

6-45

• Printout „Extended“:

- All information listed under “Standard”

- Maximum test voltage, test voltage increase, step increment, rest period

of the ramp (ramp pause)

- Settings for logging and printing

- User profile, service / administrator mode (if applicable)

- Measured data (time, test voltage, current) of the charging period

• Printout „Detailed“:

- All information listed under “Extended”

- A bunch of measuring data logged right before the end of the test

For systems equipped with the logging option (see section 6.4), up to 4 header lines and 4

footer lines (e.g. the company name or a field for the signature of the operator) can be

specified.

These so called individual “print templates” can be imported into the system using a

SystemCard (see section 6.4.2). It depends on the settings of the SystemCard whether

these print templates are permanently stored in the test system configuration or are only

valid for the period of the cable test under way.

In order to test the layout of the individual header lines and footer lines you can initiate a

test printout even if no cable test has been performed before. For this purpose, you have

to change the print settings to “Text” or “System” first. Afterwards, you can initiate the test

printout from the start menu by pressing F1.

Depending on the print settings, the following information are included in the printout:

• Printout „Text“:

- Header (extended by the header from the SystemCard (if specified))

- System type and version

- Footer (extended by the footer from the SystemCard (if specified))

- Date / Time of the printout

• Printout „System“:

- All information listed under “Text”

- All information about the system configuration (options, software

versions)

- If necessary, all calibration data from the system

Page 46

6-46

Attention: When initiating a test printout ("Text" or “System”), any set of measuring data

that may have been logged during a previous cable test will be deleted.

Attention: Immediately change the print settings back to your normal protocol printout

mode after you performed a test printout.

Note: a SystemCard is used with the system (see section 6.4), make sure that when

parametrizing the SystemCard under “WinkisVFL”, the "Settings: Protocol printout"

parameter has been set to [set on device]. Otherwise, the print settings are automatically

adopted from the SystemCard and cannot be changed manually.

Page 47

6-47

6.4 Cable Tests using a SystemCard

6.4.1 SystemCard and „WinkisVLF“

If the test and diagnosis system has been equipped with the logging option, the measured

data can be saved to a so-called SystemCard which has the dimensions of a conventional

credit card.

The SystemCard can be used to store and transfer logged data (see section 6.4.3) and to

hand over predefined test parameters to the system (see section 6.4.2).

In order to format and, if required, parametrize a SystemCard and to analyze / archive the

logged measuring data, the software WinkisVLF has to be used. For detailed information

about the WinkisVLF software, please refer to its online help.

In general, a SystemCard can be used for the following purposes:

• A SystemCard can be prepared for storing measured data only (Protocol card). No

test parameters are handed over to the system. The card may also contain header

lines and footer lines for printouts (see section 6.3) which, however, are only valid for

the cable test under way.

• A SystemCard can be prepared for parametrizing the system (Parameter card). In

this case, the SystemCard changes the settings of the system as specified under

WinkisVLF before. The card may also contain header lines and footer lines for printouts

(see section 6.3). Both, the parameters handed over by the SystemCard are and the

print templates are not permanently stored on the system and only valid for the cable

test under way.

• A SystemCard can be prepared for both parametrizing the system and storing the

measured data. The parameters handed over by such a SystemCard are not

permanently stored on the system and only valid for the cable test under way. The card

may also contain header lines and footer lines for printouts as well as “print time points”

(see section 6.3).

• A SystemCard can be prepared for parametrizing the system in a way that the

parameters handed over by the SystemCard change the device settings

permanently. The card may also contain header lines and footer lines for printouts

(see section 6.3) which are also permanently stored on the system.

Attention: This type of card cannot be used for storing measured data.

Page 48

6-48

6.4.2 Parametrising the SystemCard

Using a SystemCard appropriately parametrized under WinkisVLF will enable you to make

volatile (only for the cable test under way) or permanent changes to your device settings.

Depending on how the card has been parametrized, either all or only certain test

parameters are affected.

That way, cable tests can be planned and prepared in the office using WinkisVLF. Later,

on site, you only have to plug the SystemCard into the system in order to change the

system settings the way it has been planned.

Furthermore, this will allow you to prepare volatile print templates (individual header lines

and footer lines for the ongoing cable test) or non-volatile print templates (as default

protocol template for permanent use) (see section 6.3).

By defining “print time points” using WinkisVLF you can also schedule the logging timeline.

These “print time points” are only valid for the cable test under way and cannot be stored

permanently.

For detailed information about the WinkisVLF software, please refer to its online help.

The parameters stored on a SystemCard are automatically adopted by the test and

diagnosis system right after the card has been plugged into the respective slot on the

control unit (see section 6.4.4).

Page 49

6-49

6.4.3 Logging to SystemCard

By activating the logging function, measuring data logged during a cable test can be

written to a SystemCard. These data may consist of system information, system / test

settings, information about the course of the cable test, the measured data (test voltage,

leakage current) and the test result.

Back in the office, the logged data can be transmitted from the card to a PC where it can

be analyzed and archived using the WinkisVLF software.

For detailed information about the WinkisVLF software, please refer to its online help

By pressing the F2 key (Fig. 3, item 5) and turning the knob / push-button (Fig. 3, item 6)

the menu "Protocol" can be accessed. Here the logging mode (“Prot.”) of the test and

diagnosis system can be adjusted by rotating the knob / push-button and saved by

pressing it.

Fig. 32: Setup: Protocol off

Fig. 33: Setup: Protocol extended

Protocol

*Prot.: Extended

Print: Standard

Set protocol mode ?

Protocol

*Prot.: Off

Print: Standard

Set protocol mode?

Page 50

6-50

Depending on the logging mode, the following data are saved to the SystemCard:

• Protocol „Off“:

If the protocol mode is set to “Off”, no measured data is written to the

SystemCard.

• Protocol „Standard“:

- System type and version

- Test settings relevant for analysis

- Date / time of test start

- Result of the test and remaining test time

- Measured data (time, test voltage in kV, leakage current in mA) of the test

• Protocol „Extended“:

- All information listed under “Standard”

- Measured data (time, test voltage, current) of the charging period

Hint: Setting the protocol mode to "Standard" or "Extended" requires a

SystemCard to be plugged in.

Hint: After a test run has been finished, the system card has to remain in the slot

until the system is completely discharged (status message appears).

Otherwise, data may be lost.

6.4.4 Operating the Test and Diagnosis System with a SystemCard

In order to use a SystemCard for parametrizing the test and diagnosis system or storing

the logged data, the card has to be plugged into the respective slot (Fig. 3; item 7) of the

control unit prior to the start of the cable test (while the start menu is visible).

If it is a valid card, the parameters and other relevant information are read out from the

card. The operator has to identify the card as “Proper Card ?“ while the test parameters

obtained from the card are shown on the display.

After the card has been acknowledged by pressing the knob / push-button, the system

performs some more checks of the system card (e.g. available logging memory on the

SystemCard) whereupon the start menu should look as follows (Fig. 34):

Fig. 34: Start menu with system card inserted

VLF mode

20kV

15min

F1:Print

F2:Setup

By card OK:Start

Page 51

6-51

From now on, only the test parameters which have been specified as [set on device] under

WinkisVLF can be manually changed. This does also apply for the parameters accessible

via the setup menu (F2 key).

If the card is removed from the slot, the settings are undone and the standard start menu

appears on the display.

A cable test can be started as described in section 4.1.

Attention! If the SystemCard is removed during an ongoing cable test, the test is

interrupted!

For the special case of a SystemCard intended to change the settings of the test system

permanently (see section 6.4.1), the settings (test parameter, print templates etc.) are

handed over and stored in the system right after the card has been identified as a “Proper

Card ?”. Afterwards, the start menu looks as follows and the card has to be removed from

the slot.

Fig. 35: Start menu after new system settings have been stored

VLF mode

25kV

30min

F1:Print

F2:Setup

Card data stored.

Page 52

6-52

6.5 Function User Setup / User Level

By pressing the F2 key (Fig. 3, item 5) and turning the knob / push-button (Fig. 3, item 6)

the menu "User Setup" can be accessed.

After administrator rights have been gained as described in section 5.4, the “User Setup”

menu can be used to change the user level. That function is of importance when logging to

SystemCard (see section 6.4.3) or parametrizing the system using a SystemCard (see

section 6.4.2).

Fig. 36: Setup: User profile

By setting the user level to “Single”, the system can only be operated with a parametrized

SystemCard. That way, the users operating the system on-site are not allowed to change

test parameters not specified as [set on device].

By setting the user level to “Standard”, the system can be operated with or without

SystemCard.

Attention! Only the user level “Standard" allows the system to be operated without

SystemCard.

User-Setup <A>

Lang.: English

*Level: Standard

User level ?

Page 53

6-53

6.6 Re-Setting the System Settings / Deleting the Print Templates

The user interface of the test and diagnosis system allows you to reset the non-volatile

system settings back to the default factory settings and to delete permanently stored print

templates.

After administrator rights have been gained as described in section 5.4, the “Memory”

menu can be accessed via the “Setup” menu. The functions of this menu can be activated

by pressing the F1 key or F2 key respectively. By pressing the knob / push-button the

menu can be left without triggering a function.

Fig. 37: Setup: Memory

„F1: Reload setup” resets all parameters and system settings to the default factory

settings. The administrator password is not affected (see section 5.4).

“F2: Delete Texts” resets all print templates (individual header lines and footer lines)

stored on the system (see section 6.3).

Hint: These functions are not accessible, if a System Card inserted.

Memory <A>

F1: Reload setup

F2: Delete texts

F1/F2? else OK

Page 54

6-54

6.7 Adjustment of the System Time

If the test and diagnosis system is equipped with at least one of the system options

“Logging” or “Protocol printout”, the system contains a battery-operated and crystalcontrolled clock (see section 7.3).

After activating of the Menu key F2 (Fig. 3, item 5) and by turning the knob / push-button

(Fig. 3, item 6) the menu "Date / Time" can be accessed. Here the date and the clock time

of the system timer (test and diagnosis system) can be adjusted. By turning the knob /

push-button, the value of the selected segment is changed. You can toggle through the

segments by pressing the knob / push-button.

After all segments have been set, the date and time can be stored by pressing the F1 key.

By pressing the knob / push-button again, the changes are discarded.

Fig. 38: Setup: Date / Time

Fig. 39: Setup Date / Time: Adjusting the day of the week

Fig. 40: Setup Date / Time: Adjusting the minutes

Fig. 41: Setup Date / Time: Saving by F1

Date/Time

Mo 19.06.08 10:27:13

*

F1= Set! else OK

Date/Time

Mo 19.06.08 10:27:13

*

Set date & time

Date/Time

Mo 19.06.08 10:27:13

*

Set date & time

Date/Time

Mo 19.06.08 10:27:13

F1= Set! else OK

Page 55

7-55

7. Repair and Fault Diagnostics

Repair and maintenance work has to be carried out by Megger or authorised service

partners using original spare parts only. Megger recommends having the system tested

and maintained at a Megger service centre once a year.

This test allows, amongst others, checking the gas pressure of the discharge switch and

the state of the HV switch.

Megger also offers its customers on-site service. Please contact your service centre as

needed.

7.1 Replacing Fuses

If the device cannot be switched on, even though it is connected to the mains power

supply, both fuses below the power supply socket must be checked. The fuse holder must

be pulled out to do so.

If the fuses are defective, they must be replaced with suitable microfuses (5 x 20 mm) of

the type T2.5A. Disconnet from the mains before changing a fuse.

If the fuses continue to trip, please get in touch with the Megger service department in

order to have the problem resolved.

Page 56

7-56

7.2 Exchanging the Paper Roll or Ink Ribbon of the Printer

The optional built-in printer is housed in a robust metal case with removable front cover.

To exchange the paper roll or the ink-ribbon cartridge, first remove the front cover from the

printer.

a ) Removing the front cover

Turn both knurled screws anti-clockwise (Fig. 42) until the front cover comes off the printer

(Fig. 43).

Fig. 42: Unscrewing the printer front cover

Fig. 43: Removing the front cover

b ) Exchanging the ribbon

In order to exchange the ribbon, press down the left edge of the ink ribbon cartridge

marked "Push" and "Eject" (Fig. 44). The cartridge will come off on the right-hand side and

can now be removed. Tighten the ribbon of the new cartridge by turning the small wheel

on the right-hand side, following the direction of the arrow. After that, guide the ribbon

cartridge over the paper. See to it that the paper is between the textile ribbon and the

plastic bridge (Fig. 45). Let the ink cartridge engage distinctly. If you encounter blurred or

unbalanced printing, improper engagement of the ink cartridge is very likely to be the

cause.

Fig. 44: Removing the ribbon cartridge Fig. 45: Inserting the ribbon cartridge

Page 57

7-57

c ) Exchanging the paper roll

The container can hold paper rolls with up to 50 mm diameter.

First follow step b and remove the ribbon cartridge. Remove the spindle from the core of

the empty roll and insert it into the core of the new paper roll.

If necessary, cut the front edge of the paper strip in a straight line. Hold the paper roll in

your hand and thread the front end of the paper from below into the slot of the printer unit

intended to this purpose (see Fig. 46) until you sense some resistance. To lead the paper

past the print head, press the paper feed button (Fig. 47) until approx 5 cm (2 inches) of

paper stand out of the printer unit.

Insert the new paper roll with the spindle into the paper container und tension the paper.

After that, again insert the ribbon cartridge into the printer unit, as described in step b.

Fig. 46: Inserting the paper roll into the printer Fig. 47: Paper feed button

d ) Attaching the front cover

Lead the paper from the rear through the front cover and again screw the front cover onto

the printer.

7.3 Replacing the Battery of the System Clock

If the test and diagnosis system is equipped with at least one of the system options

“Logging” or “Protocol printout”, the system contains a crystal-controlled clock. The built in

lithium cell is capable of powering the clock for several years.

If this battery needs to be changed, please contact the next service centre.

Page 58

7-58

7.4 Connecting Cables, HV Couplings

Maintenance and troubleshooting include regularly checking the connecting cables such

as earth cables, mains cables and test cables for being in good repair. In addition to that

we recommend that the HV couplings at the Operating module and HV module should be

checked with regard to mechanical integrity and cleanness.

Make absolutely sure that after use the HV plug of the test voltage cable is again covered

with the included protective sleeve.

7.5 Operational and Error Messages

7.5.1 Classification of Messages

Operational and error messages occurring during the operation of the test and diagnosis

system are classified as follows:

Symbol

Class

Response

What to do

U

Operational message

about state of system

refer to instruction

manual

C

Operational message

about switching

condition

confirm - continue

operation

F

Error of type "fatal"

HVOff

confirm - restart system

T

Error of type "trans"

HVOff

confirm - repetition

possible

N

Error of type "normal"

HVOff

confirm - repetition

possible

W

Warning

none

confirm - continue

operation

R

Messages in remote

control mode