Page 1

WWW.MEGGER.COM

User’s Manual

SVERKER900

Relay and Substation Test System

Art No. ZP-CR02E Doc. CR0333LE V12a 2016

Page 2

Page 3

SVERKER900

Relay and Substation Test System

NOTICE OF COPYRIGHT & PROPRIETARY RIGHTS

© 2013-2016, Megger Sweden AB. All rights reserved.

The contents of this manual are the property of Megger Sweden AB. No part of this work may be reproduced or transmitted in any form or

by any means, except as permitted in written license agreement with Megger Sweden AB. Megger Sweden AB has made every reasonable

attempt to ensure the completeness and accuracy of this document. However, the information contained in this manual is subject to change

without notice, and does not represent a commitment on the part of Megger Sweden AB. Any attached hardware schematics and technical

descriptions, or software listings that disclose source code, are for informational purposes only. Reproduction in whole or in part to create

working hardware or software for other than Megger Sweden AB products is strictly prohibited, except as permitted by written license

agreement with Megger Sweden AB.

TRADEMARK NOTICES

Megger® and Programma® are trademarks registered in the U.S. and other countries. All other brand and product names mentioned in this

document are trademarks or registered trademarks of their respective companies.

Megger Sweden AB is certified according to ISO 9001 and 14001.

User’s Manual

Postal address:

Megger Sweden AB

Box 724

SE-182 17 DANDERYD

SWEDEN

T +46 8 510 195 00

F +46 8 510 195 95

seinfo@megger.com

www.megger.com

Visiting address:

Megger Sweden AB

Rinkebyvägen 19

SE-182 36 DANDERYD

SWEDEN

CR0333LE ZP-CR02E SVERKER900

3

Page 4

4 SVERKER900 ZP-CR02E CR0333LE

Contents

1 Safety

............................................................. 6

1.1 General ............................................................... 6

Symbols on the instrument ................................. 6

1.2 Safety instructions ............................................... 6

2 Introduction

............................................................. 8

2.1 General ............................................................... 8

2.1 Unpack system .................................................... 9

2.2 Service and support ............................................ 9

Training ..............................................................9

Contact information ........................................... 9

3 Instrument description

........................................................... 10

3.1 Panel ................................................................ 10

3.2 The lid .............................................................. 10

3.3 Binary Inputs ..................................................... 11

3.4 Binary Output ................................................... 11

3.5 Current generators: I1, I2, I3 ............................. 12

3.6 Voltage generators: U1, U2, U3 and U4 ............ 13

Voltage generator U4 as auxiliary supply ...........13

3.7 Extra timer ........................................................ 14

Start and Stop conditions ................................ 14

3.8 A-meter / V-meter .............................................. 15

Voltage ........................................................... 15

Current ........................................................... 15

Ammeter and Voltmeter windows ..................15

Other entities .................................................... 16

3.9 USB port ........................................................... 16

USB 2.0 Interface ............................................. 16

Firmware upgrade via SVERKER900 USB port ... 16

USB software upgrade .................................... 16

3.10 Ethernet port .................................................. 17

3.11 Low current generation (Optional) .................. 17

4 Operating SVERKER 900

........................................................... 18

4.1 Local interface .................................................. 18

Display buttons ................................................. 18

Momentary buttons ........................................ 18

Switch buttons ............................................... 18

Start SVERKER 900 ........................................... 18

4.2 Home menu ...................................................... 19

Home menu buttons ....................................... 19

System configuration ........................................ 19

Generator configuration ................................... 20

4.3 Main instrument ............................................... 21

Main instrument buttons ................................ 21

Non-generating mode ...................................... 21

Generating mode ........................................... 21

Numerical keypad ............................................. 22

Equals ............................................................. 22

Setting frequency to DC ................................. 22

Balance ........................................................... 22

Finding the pick-up and drop-off value using

the hold function .............................................. 23

Binary Inputs ..................................................... 23

BI window buttons ......................................... 23

Make BI settings ............................................. 24

Trig condition.................................................. 24

Event recording............................................... 24

Debounce filter ............................................... 25

Special settings available for BI1 ...................... 25

4.4 Prefault->Fault instrument ................................ 26

Prefault->Fault view .......................................... 26

Navigation ...................................................... 26

Prefault -> Fault instrument buttons ................. 26

Prefault view ................................................... 27

Fault view ......................................................... 27

Automatic Prefault->Fault button ......................27

The phase angle graph ................................... 27

4.5 Ramping instrument ......................................... 28

Ramping view ................................................... 28

Navigation ...................................................... 28

Ramping instrument buttons .......................... 28

Start a ramp test ............................................... 28

Speed and Stop ramping set views .................. 28

The phase angle graph ................................... 28

4.6 Sequencer instrument ....................................... 29

Navigation ...................................................... 29

Sequencer instrument buttons ........................ 29

Page 5

CR0333LE ZP-CR02E SVERKER900

5

4.7 CT magnetization instrument ............................ 32

CT magnetization instrument buttons ............ 33

Set-up .............................................................. 33

Manual test ...................................................... 33

Manual/auto test .............................................. 34

Auto test .......................................................... 34

Demagnetization .............................................. 35

4.8 Impedance instrument ...................................... 35

Navigation ...................................................... 35

Impedance instrument buttons ....................... 35

Prefault view ..................................................... 36

Fault + Manual pickup search view ...................36

Prefault – Fault view..........................................37

Manual binary search view ................................ 38

The impedance plane graph .............................. 39

4.9 Test file management ........................................ 40

Buttons in Test file management ..................... 40

Save a test ........................................................ 40

Quick save ........................................................ 41

View and reuse test files ...................................41

Storage file ..................................................... 41

Reference file .................................................. 41

Transfer files to PC ............................................ 41

Copy test files from USB stick to SVERKER 900..42

4.10 Calibration ...................................................... 42

Calibration procedure .......................................42

Automatic calibration ..................................... 42

Manual calibration ............................................ 43

Calibration report .............................................43

5 Troubleshooting

........................................................... 44

5.1 Problems ........................................................... 44

Outputs .......................................................... 44

BINARY INPUTS ............................................... 44

Harmonics ...................................................... 44

Voltmeter / Ammeter ...................................... 44

File handling ................................................... 44

EXTRA TIMER .................................................. 44

5.2 Error messages .................................................. 45

5.3 Warning messages ............................................ 45

5.4 Alarms .............................................................. 46

Distortion alarm ................................................ 46

Other generator alarms ..................................... 46

A-meter / V-meter alarm ...................................47

6 Specifications

........................................................... 48

Index ....................................................... 52

Page 6

6 SVERKER900 ZP-CR02E CR0333LE

1 SAFETY

1

Safety

1.1 General

Important

Read and comply with the following instructions.

Always comply with local safety regulations.

Symbols on the instrument

Caution, refer to accompanying documents.

Protective conductor terminal.

WEEE, Waste Electrical and Electronic

Equipment. Please utilize your local

WEEE collection facilities in the disposition of this product and otherwise

observe all applicable requirements.

1.2 Safety instructions

Warning

1]

High voltage/current on output terminals.

2] The instrument is equipped with a power

cord with integral safety ground pin. The

equipment must be connected to a grounded

mains outlet.

The instrument case must also be grounded

by the separate protective ground wire with

connection to the protective earth terminal

on the rear panel. This is to eliminate difference in earth potential between the instrument and the device to be tested. Check the

continuity of the protective ground wire

before each use.

3] Do not attempt to service the instrument

yourself. Opening or removing covers may

expose you to dangerous voltage. If you attempt to service the instrument yourself the

warranty is no longer valid.

4] Do not use any accessories that are not in-

tended for use together with the instrument.

5] Do not use the instrument for any purpose

other than indicated by the manufacturer.

6] If the equipment is used in a manner not

specified by the manufacturer, the protection

provided by the equipment may be impaired.

7] Disconnect the instrument from the mains

before cleaning. Use a damp cloth for cleaning. Do not use liquid cleaners or aerosol

cleaners.

Important

1] Always turn the equipment off before con-

necting.

2] Always use manufacturer approved and sup-

plied cable sets.

3] Always connect protective earth (ground).

4] Slots and openings in the instrument are

provided for ventilation. They ensure reli-

Page 7

CR0333LE ZP-CR02E SVERKER900

7

1 SAFETY

able operations, keeping it from overheating. These openings must not be blocked nor

covered during operation.

5] The instrument may not be positioned so

that the mains switch is blocked.

6] The mains connector may not be used as

disconnecting device.

7] The plug to the mains inlet is to be used as

disconnector.

8] Never leave the instrument unattended while

it is turned on and in the high-current mode.

9] Use only approved mains detachable cable

set with the instrument. Main supply cables

shall be rated for the maximum current for

the equipment and the cable shall meet the

requirements of IEC60799 (Cord sets and interconnection cord sets). Mains supply cables

certified or approved by a recognized testing authority are regarded as meeting this

requirement.

10] Unplug the instrument from the mains sup-

ply when it is left unattended or not in use.

11] Do not expose the instrument to rain or

moisture.

12] Refer all servicing to Megger authorized

personnel.

13] If you need to return the instrument, please

use either the original crate or one of equivalent strength

Page 8

8 SVERKER900 ZP-CR02E CR0333LE

2 INTRODUCTION

2

Introduction

2.1 General

The SVERKER900 is an instrument designed for

testing of electrical equipment e.g. protective relay

systems in substations and industrial plants.

SVERKER 900 comes in three models.

Model Test instruments

Basic Main instrument

Prefault-Fault instrument

Standard Main instrument

Prefault-Fault instrument

Ramping instrument

Sequencer instrument

CT magnetization instrument

Expert Main instrument

Prefault-Fault instrument

Ramping instrument

Sequencer instrument

CT magnetization instrument

Impedance instrument

The rugged hardware design is built for field use over

a wide temperature range.

SVERKER 900 is a three-phase test equipment. It can

generate voltage and current from its four voltage

generators and three current generators respectively,

receive binary inputs and a binary output that is a

make/brake contact.

SVERKER 900 can measure external voltages and currents as well, and properties like level, phase, power

factor and frequency of each. The voltage and current

generator outputs can be activated in many combinations. It also includes an external timer with various

start and stop conditions.

All setting for the instrument are made using the

touch screen. The main instrument includes the

"ON+TIME" and "OFF + TIME" functionality.

Another instrument is the prefault fault sequence with

binary input used for trip signals.

The Ramping instrument is used to ramp voltage, current, angle and frequency. One or several parameters

can be ramped at the same time..

The Sequencer instrument has 16 states that can be

individually configured for parameter value, timing

and BI/BO. Equipment for multi task purpose can be

automatically tested here, e.g. different protections

and parameter limit values.

The CT magnetization instrument is used for manual

or automatic "knee point" control on current transformers.

The Impedance instrument is used for testing in so

called impedance plane, where the conversion from

the impedance into voltage and current is done automatically .

Page 9

CR0333LE ZP-CR02E SVERKER900

9

2 INTRODUCTION

2.1 Unpack system

Unpack the unit and check for evidence of any shipping damage. If there is any visual damage, immediately notify the freight carrier to make a damage

claim, and notify Megger of the damage.

2.2 Service and support

For technical assistance please contact your local

representative or direct your request to Megger in

Sweden.

When sending the instrument, please use either the

original crate or one of equivalent strength.

Add the return authorization number to the address

label of the shipping container for proper identification and quicker handling.

Note Ship the equipment without nonessential

items such as test leads, etc. These items are

not needed by the factory to perform service.

Training

For information about training courses contact your

local distributor or the Megger Sweden office.

Contact information

Internet: www.megger.com

E-mail: support-sweden@megger.com

Tel: +46 8 510 195 00

Fax: +46 8 510 195 95

Page 10

10 SVERKER900 ZP-CR02E CR0333LE

3 INSTRUMENT DESCRIPTION

1

10

8

15

5

2

4

11

14

6

7

9

13

12

3

3

Instrument description

3.1 Panel

1. Binary inputs

2. Binary output

3. F2 fuse

4. Current generators I1, I2, I3

5. Voltage generators U1, U2, U3

6. Voltage generator U4 or AUX supply

7. Control knob

8. Touch screen

9. Power ON/OFF switch

10. Mains inlet socket

11. Protective earth terminal

12. Ethernet port

13. USB port

14. Extra timer

15. Ammeter & voltmeter

3.2 The lid

Inside the lid are:

▪

Jumpers

▪ CTM-box for use with the CT magnetization instrument

▪ Pen to use for the touch screen

Page 11

CR0333LE ZP-CR02E SVERKER900

11

3 INSTRUMENT DESCRIPTION

3.3 Binary Inputs

The SVERKER 900 have 4 binary inputs, independent programmable gate circuits that permit simple

selection of the desired mode for voltage or contact

monitoring operation. Binary input 1 has a selectable

threshold voltage.

The binary inputs are used to monitor relay trip contacts for performing pickup and dropout tests as well

as for performing timing functions.

The binary inputs are specifically designed to measure

high speed operation of electromechanical, solid-state

and microprocessor-based protection relays. All binary

inputs are default set to monitor mode, contact /voltage change of state.

To change a binary input state from contact sensing to

voltage applied / removed, touch the "BI" button.

At each binary input there is an input state indicator

lamp that shows the state of the input. It indicates

either a closed circuit (for contact mode) or the presence of a voltage (for voltage mode). These indicators

permit (for example) to check the circuits involved

before starting a sequence.

Dry contacts

Open

Timer stops and a continuity indicator goes out at the opening of

normally closed contacts.

Dry contacts

Close

Timer stops and a continuity indicator glows at the closing of the

normally open contacts.

Application or

removal of AC

or DC voltage

Timer stops. The continuity indicator will glow (application) or darkens (removal) upon the application

or removal of either an AC or DC

voltage. A higher threshold voltage

helps to eliminate false triggers

due to a noisy source. Lower

thresholds allow starting and stopping of timer from TTL voltage

signals.

Binary input 1 has a settable

threshold value for pickup & dropout and minimum settable threshold voltage is 5 V

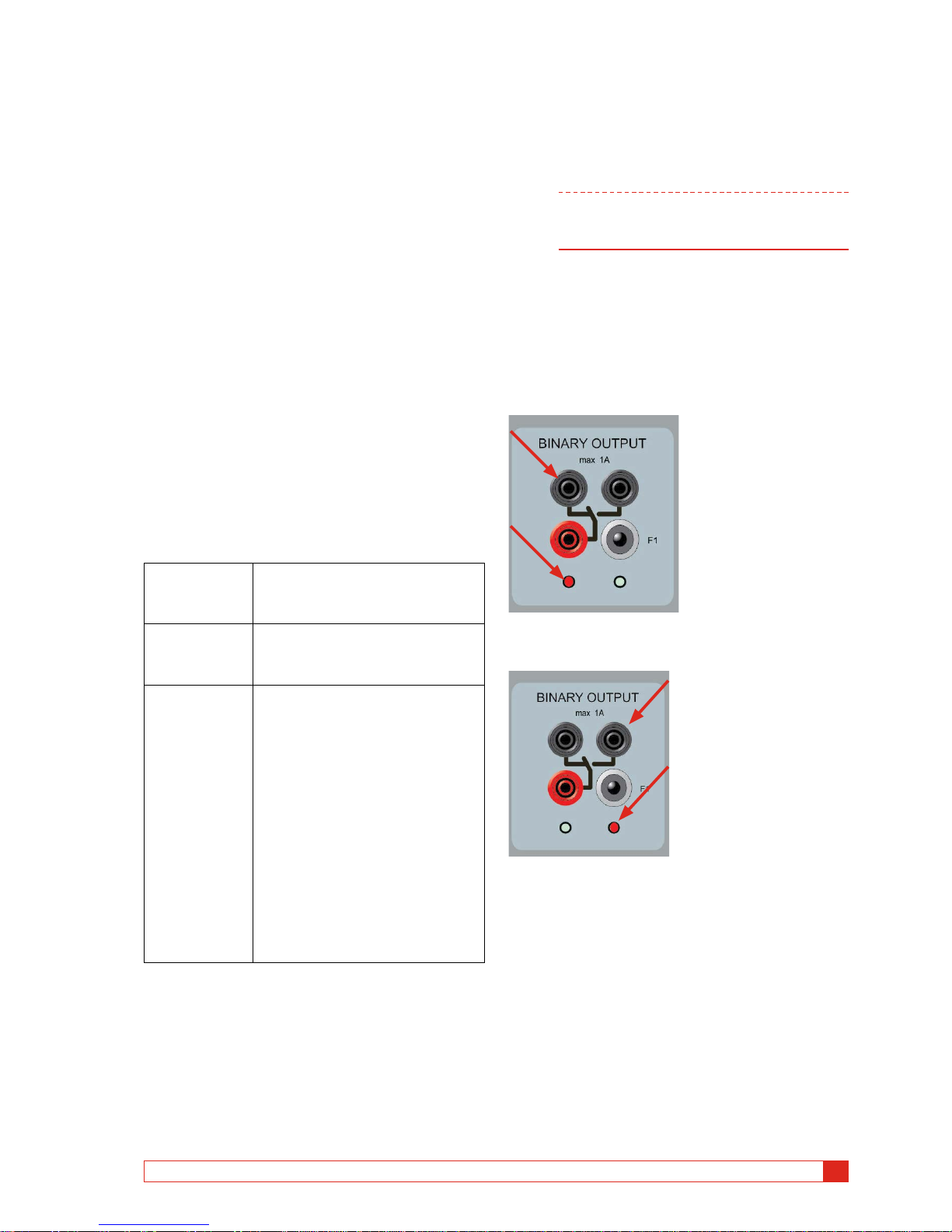

3.4 Binary Output

The binary output is a make/break contact that is

actuated when the SVERKER 900 is set to ON-generating or OFF-generating mode.

Note In the"Sequence instrument" the make/break

contact position can be set for each state

individually.

The binary output is used to simulate normally

open / normally closed contacts for testing breaker

failure schemes, or similar power system operations. In

addition it may also be used to switch AC/DC voltages

and currents.

For maximum switching capacity see the specification

section.

BO position when SVERKER 900 is OFF (not generating).

Left terminal is on.

BO position when SVERKER 900 is ON (generating)

Right terminal is on..

Page 12

12 SVERKER900 ZP-CR02E CR0333LE

3 INSTRUMENT DESCRIPTION

3.5 Current generators: I1,

I2, I3

The current generators can be used separately, in parallel or in series. Constant power output in many cases

eliminates the need to connect the current channels in

parallel or series to test high burden relays.

▪

All outputs are isolated or floating and provide variable

frequency.

▪ The current generators delivers maximum compliance

voltage to the load constantly during the test, and range

changing is done automatically, on-the-fly, under load.

The per channel output current and power ratings are

specified in AC rms values. Specified duty cycles are

based upon ambient temperature of 20°C.

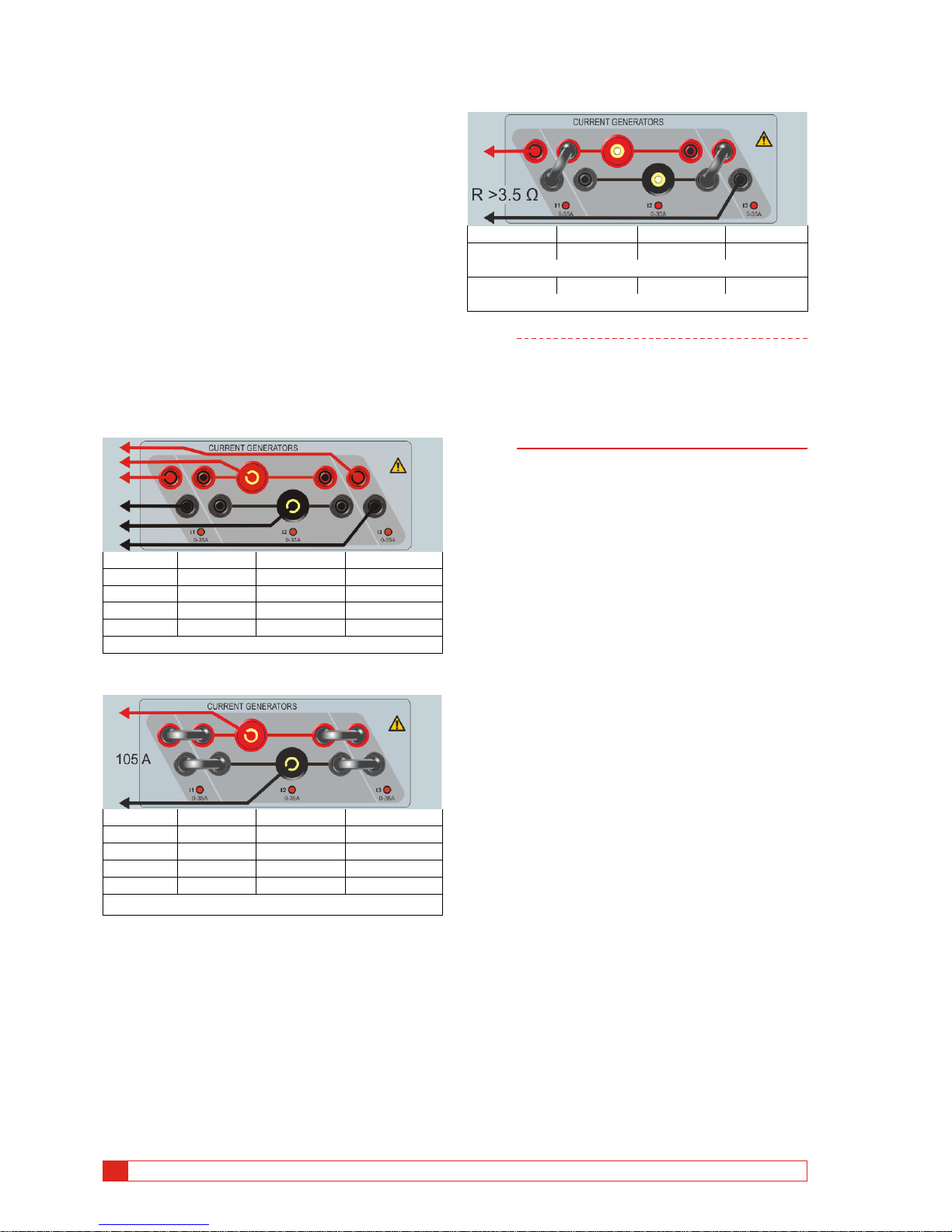

Current generators separately: I1, I2, I3

Current Power (max) Voltage (max) Duty cycle

5 A 250 VA 50 V Continuous

10 A 250 VA 25 V Continuous

20 A 200 VA 10 V Continuous

35 A 100 VA 2.8 V 10 s ON / 20 s OFF*

*Thermo protected

Current generators in parallel: I1 // I2 // I3

Current Power (max) Voltage (max) Duty cycle

15 A 750 VA 50 V Continuous

45 A 750 VA 16.5 V Continuous

60 A 600 VA 10 V Continuous

105 A 300 VA 2.8 V 10 s ON / 20 s OFF*

*Thermo protected

Current gene rators in series: I1 – I2 – I3

Current (max) Power (max) Volta ge (max) Duty cycle

18 A 625 VA 14 0 V Continuous

With external inductive load. Frequency: max 200 Hz

15 A 625 VA 140 V Continuous

With minimum 3.5 Ω external resistive load. Frequency: max 200 Hz.

Note The current amplifiers outputs are protected

from open circuits and thermally protected

against prolonged overloads. In case of an

open circuit or a thermal overload, the amplifier will automatically turn off, and an error

message will be displayed.

Page 13

CR0333LE ZP-CR02E SVERKER900

13

3 INSTRUMENT DESCRIPTION

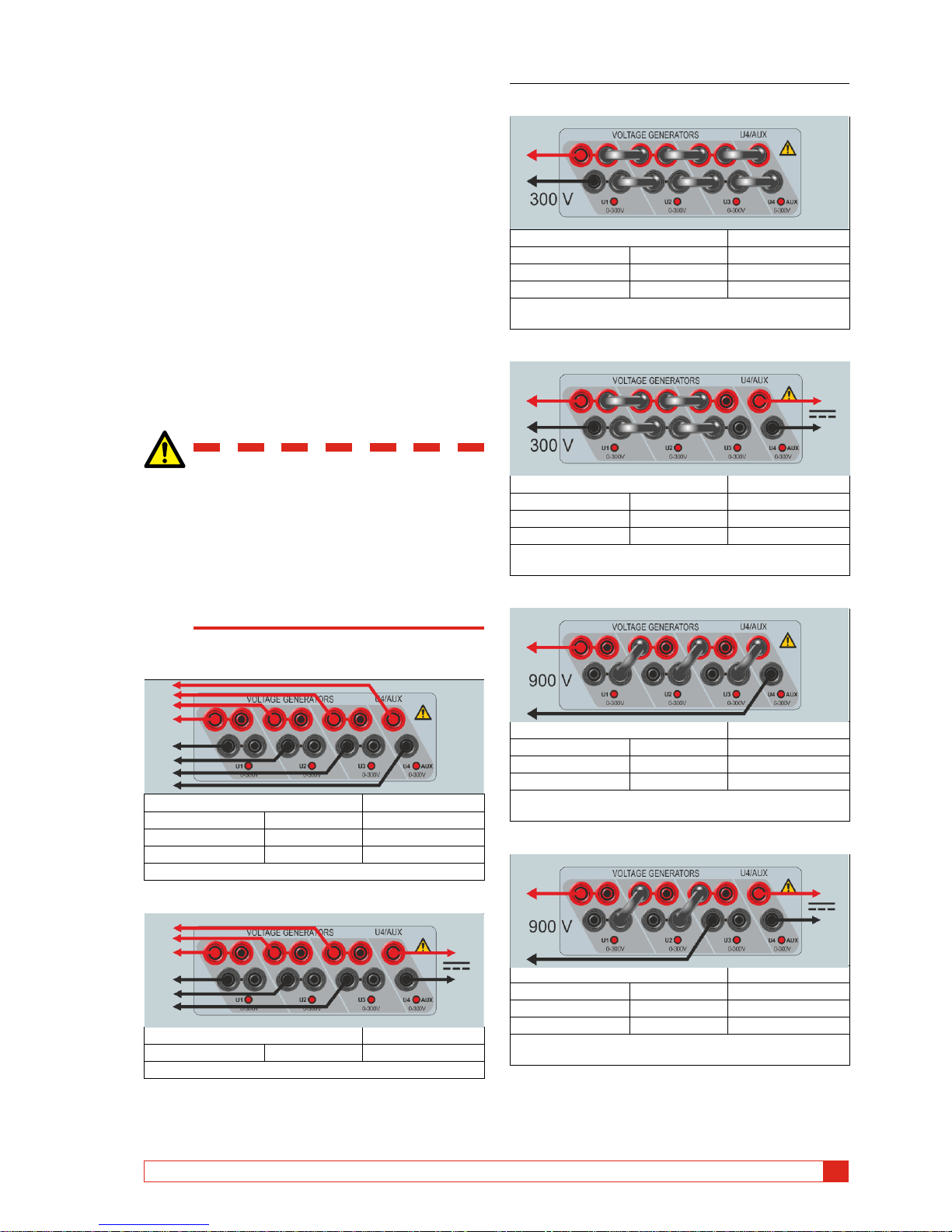

3.6 Voltage generators: U1,

U2, U3 and U4

The voltage generators can be used separately, in

parallel or in series.

▪

All outputs are independent from sudden changes in

mains voltage and frequency, and are regulated so

changes in load impedance do not affect the output.

▪ All outputs are isolated or floating.

▪ All outputs provide variable frequency.

Voltage generator U4 as auxiliary

supply

The primary application for U4 is to provide auxiliary

voltage for protective relays. U4 provides a variable

output from 0 to 300 V AC/DC.

Warning

Do not plug or insert any test lead into

the voltage outputs without first connecting the test leads to the load.

When voltage generators are connected

in series for output over 600 V the special

test leads (brown and purple) must be

used.

Voltage generators separately: U1, U2, U3, U4

Voltage range Power (max) Current (max)

300 V 125 VA 0.42 A

100 V 100 VA 1.0 A

67 V 100 VA 1.5 A

External load: min. 25 Ω

Voltage generators separately: U1, U2, U3 (U4 AUX)

Voltage range Power (max) Current (max)

300 V* 125 VA 0.42 A

* U4 DC

Voltage generators in parallel: U1 // U2 // U3 // U4

Voltage range Power (max) Current (max)

300 V 375 VA 1.2 A

100 V 300 VA 3.0 A

67 V 300 VA 4.5 A

External load: min. 7 Ω

Frequency: max. 200 Hz

Voltage generators in parallel: U1 // U2 // U3 (U4 DC)

Voltage range Power (max) Current (max)

300 V 312 VA 1.0 A

100 V 250 VA 2.5 A

67 V 250 VA 3.7 A

External load: min. 9 Ω

Frequency: max. 200 Hz

Voltage generato rs in series: U1 – U2 – U3 – U4

Voltage range Power (max) Current (max)

900 V 450 VA 0.5 A

400 V 360 VA 0.9 A

268 V 350 VA 1.3 A

External load: min. 100 Ω

Frequency: max. 200 Hz

Voltage generators in series: U1 – U2 – U3 (U4 AUX)

Voltage range Power (max) Current (max)

900 V 350 VA 0.4 A

300 V 280 VA 0.9 A

200 V 275 VA 1.4 A

External load: min. 75 Ω

Frequency: max 200 Hz

Page 14

14 SVERKER900 ZP-CR02E CR0333LE

3 INSTRUMENT DESCRIPTION

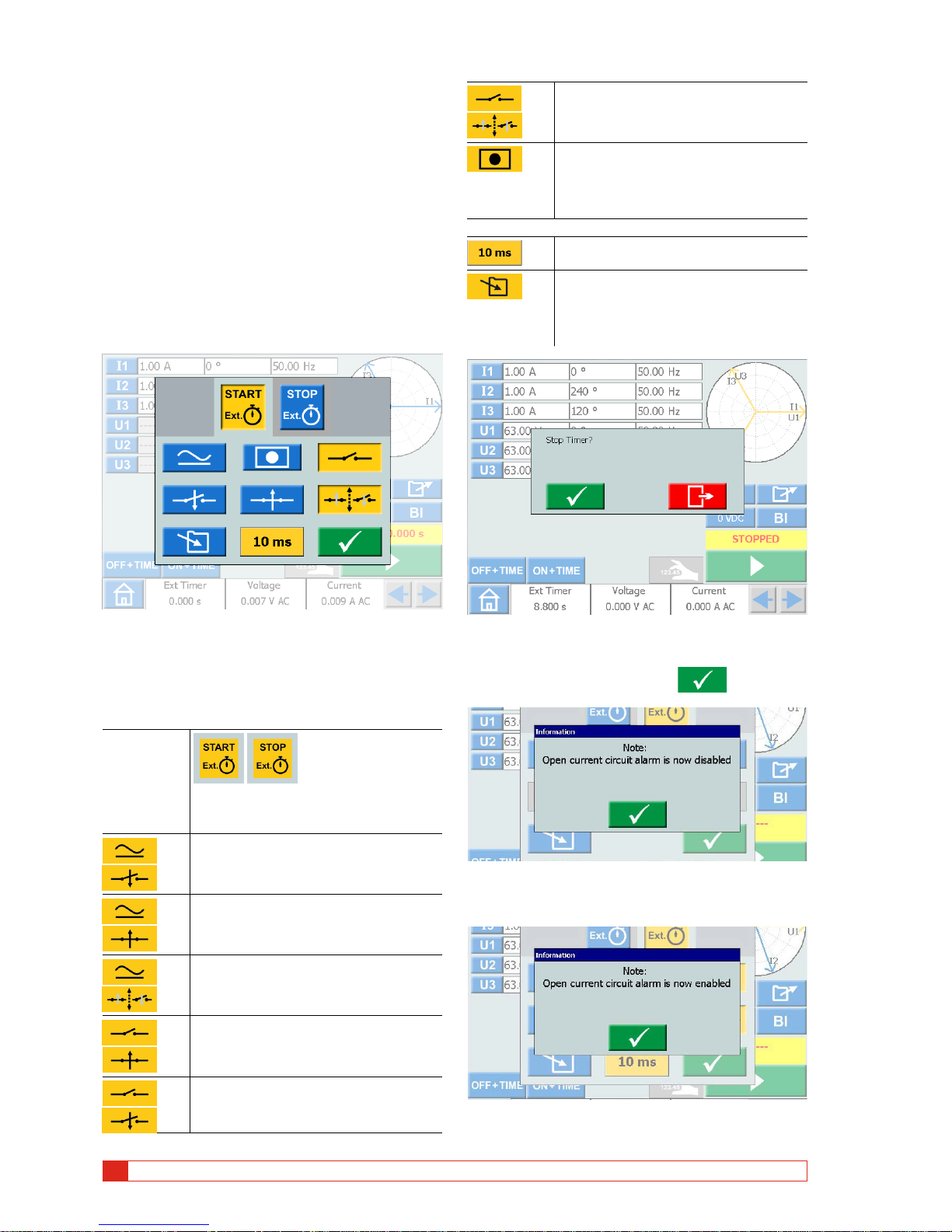

3.7 Extra timer

The SVERKER900 has two independent gate inputs

that permit simple selection of the desired mode for

timing operation.

To monitor operation of the contacts in the device

under test, a light is provided for each gate. The gate

circuit is isolated for voltage-sensing and can monitor

solid-state logic signals. Each light will illuminate once

contacts close or voltage is applied to the gate.

1] Press ”Ext Timer” at bottom of display, from

any of the instruments.

A new window opens.

2] Make settings for the START and STOP condi-

tions.

The conditions can be set different for START

and STOP.

Start and Stop conditions

Condition

The settings for starting and stopping

are done independently..

At application of either an AC or DC

voltage.

At removal of either an AC or DC voltage.

At application or removal of AC or DC

voltage.

At the opening of normally closed

contacts

At the closing of normally open contacts

At the opening or closing of contacts.

When a generator is turned on or off,

or that a trip signal stops the generating or that an open current circuit is

detected.

Other functions

Filter time can be set from 0 to 999 ms.

The timer value is stored

Note: The timer value can not be saved

separately only together with a test

made in any instrument.

If the "Ext.timer" has failed to stop, it can be manually stopped and reset.

1] Press "Ext Timer" and then

When internal start and stopp are selected the open

current circuit alarm is disabled.

When one of the internal start/stop settings is removed the open circuit alarm is enabled.

Page 15

CR0333LE ZP-CR02E SVERKER900

15

3 INSTRUMENT DESCRIPTION

3.8 A-meter / V-meter

SVERKER is equipped with an ammeter and voltmeter.

These instruments can also be used to display resistance, frequency, impedance, phase angle, power and

power factor. Moreover, these instruments can be

used to perform measurements in external circuits. In

both cases, the values appear on the display.

The ammeter input (marked “A”) measures 0 – 10 A

(ACrms or DC) in an external circuit.

The voltmeter input (marked “V”) shows the voltage

connected to the voltmeter on the panel. The voltmeter can be used to measure up to 900 V AC or DC. It

can be set in ranges or automatically mode.

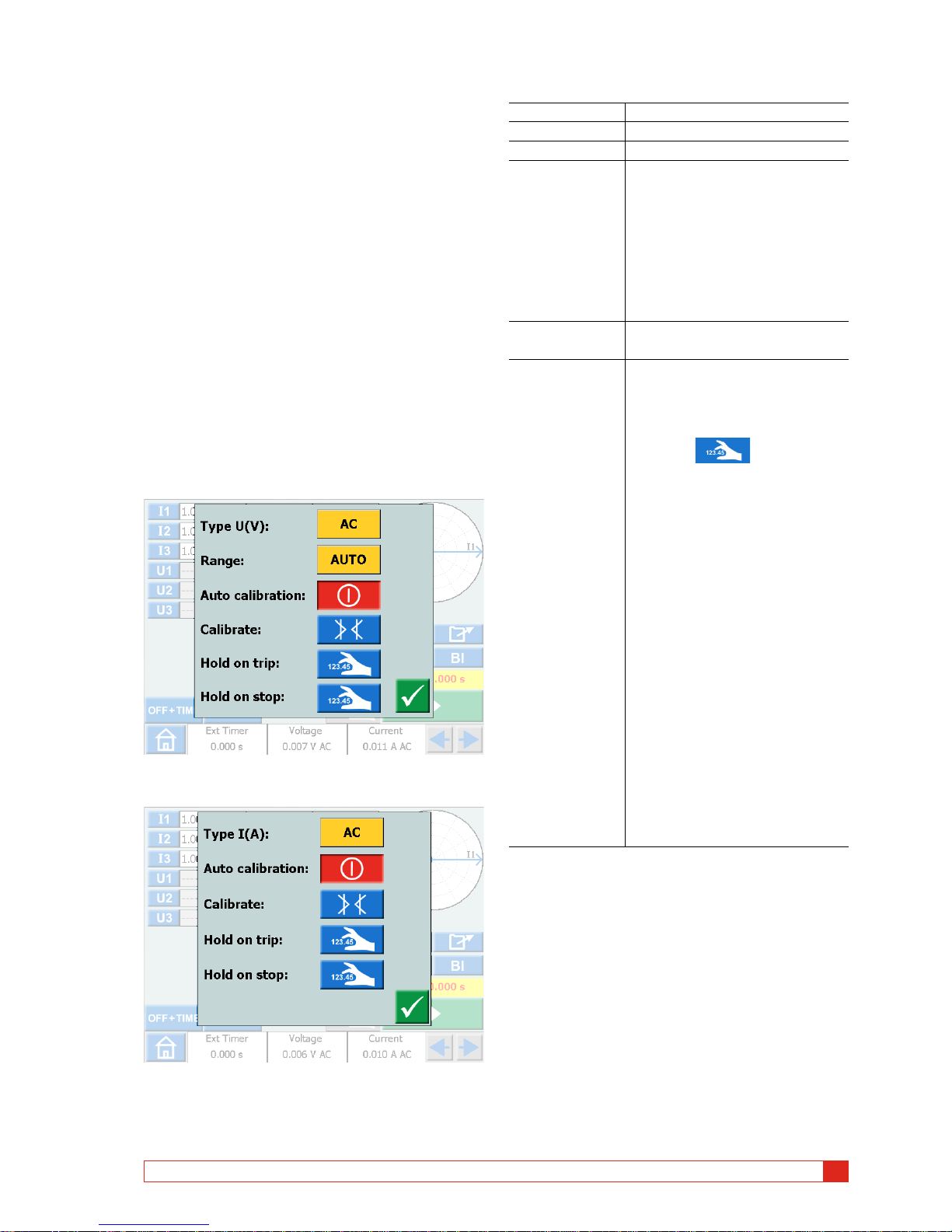

1] Press ”Voltage” or "Current" at bottom of

display, from any of the instruments.

You will see the respective new windows

below.

Voltage

Current

Ammeter and Voltmeter windows

Type U (V) Select AC or DC

Range Auto, 0-9 V, 9-90 V, 90-900 V

Type I (A) Select AC or DC

Auto calibration The auto calibration can be set to

on or off individually (Ammeter/

Voltmeter).

If auto calibration is set to “ON”

it will recalibrate the offset each

10 minutes period and also do an

offset calibration within 5 minutes

if the temperature is changed.

Calibrate The AC and DC offset will be

calibrated.

Hold on trip The value measured on the volt

and / or ammeter is frozen when a

trip signal has been detected. The

"ON+TIME" has to be activated.

1] Press to activate

the HOLD function in the

volt and/or current menu.

The Voltage and / or Current field

turns blue and at trip it turns yellow.

The voltage and current values can

be stored to a test file.

A] In the Main menu, the volt-

age and current values for

pick-up or drop-off, can also

be locked.

B] In the Ramp instrument this

will be valid for a whole

ramp sequence.

C] In the Prefault/fault in-

strument this will be

valid for fault state and

prefault+fault state

Page 16

16 SVERKER900 ZP-CR02E CR0333LE

3 INSTRUMENT DESCRIPTION

Hold on stop Values from the volt and /or amme-

ter are held after stop of generating.

1] Press to activate

the HOLD function in the

volt and/or current menu.

The Voltage and / or Current field

turns blue and at stop it turns yellow.

The volt and current values can be

stored to a test file.

A] In the Main menu, the volt-

age and current values for

pick-up or drop-off, can also

be locked.

B] In the Ramp instrument this

will be valid for the start

ramp value and for the

whole ramp sequence.

C] In the Prefault/fault instru-

ment this will be valid for

prefault state, fault state

and prefault+fault state

Note If O.L. (Over Load) appears, the cycle being

measured may have been so fast that there

was not time for automatic range changing,

or that the range was overridden.

If over 900 V or 10 A, it gets +OL.

Other entities

1] By pressing the buttons you can view

the Frequency (Hz), Power (VA and W) , Impedance (R and Z) and phase angle values.

3.9 USB port

USB 2.0 Interface

The USB port is used to:

▪

Update the firmware in the SVERKER900

▪ Update the software

▪ Connect a mouse or keyboard

▪ Download test files from the SVERKER900 Local for

transfer data, e.g. to a PC for storage or printing.

▪ Copy test files from USB to SVERKER 900

Firmware upgrade via

SVERKER900 USB port

1] Contact Megger Sweden AB technical sup-

port to get a USB memory stick with upgraded files.

USB software upgrade

1] Before startup, insert USB memory stick, with

new software, to the USB port.

SVERKER 900 scans the available files in the

USB memory. If a bootable image can be

found and the image signature is newer than

the currently installed image, you are asked

to upgrade SVERKER 900.

After loading new software you must reboot.

2] Press and hold (5 s) the button to reboot.

Page 17

CR0333LE ZP-CR02E SVERKER900

17

3 INSTRUMENT DESCRIPTION

3.10 Ethernet port

Note The Ethernet port is used for service of the

instrument only.

3.11 Low current

generation (Optional)

An optional accessory (CR-91010) is the Low Current

Adapter. The adapter consists of two boxes LCA1

and LCA2. It is used to test e.g. sensitive earth fault

protection, capacitor unbalance protection and three

phase reverse power protection.

The LCA1 and LCA2 are to be connected to the current generator outputs, see figure below, for generation of low currents, 0 – 50 mA. The built in ammeter,

in SVERKER 900, is connected to measure the current

injected into the test object.

The ratio between the input and output currents is

somewhat depending on the load, e.g. a 0.5 Ω load

and 1 A current generation gives an output of 9 mA.

Max current input is 5 A.

Page 18

18 SVERKER900 ZP-CR02E CR0333LE

4 OPERATING SVERKER 900

4

Operating SVERKER 900

4.1 Local interface

The SVERKER900 local interface is the manual control

and user interface for the unit. All manual entries will

be made through the SVERKER900 local interface.

Display buttons

The buttons are of two types, momentary and switch.

Momentary buttons

▪ A momentary button keep the colour when it is pressed.

▪ When it is gray, the button is disabled.

Examples:

Switch buttons

1. When a switch button is pressed the background

colour change from blue to yellow and foreground

change from white to black. – the function is active.

2. A button with gray background is disabled.

• If the foreground is black the function is active,

but you cannot use the button to make changes.

• If the foreground is white the function is disabled.

Examples:

On/Off button

Run/Stop button

Start SVERKER 900

1] Plug the unit line cord into an appropriate

power source and press the button .

During the power up sequence the test system automatically run a self-test to insure everything is operating properly. When this is done the Main instrument

screen is presented. This is the default screen and

depending on how the channels are configured the

SVERKER900 will display and provide the appropriate

number.

From the Main instrument you can perform the general tests with SVERKER, see section "4.3 Main instrument" on page 21

Note The basic description of how to use the

SVERKER is in section "Main instrument". It

also applies to several of the other instruments.

The other instruments are available from the Home

menu.

1] Press for the Home menu

Page 19

CR0333LE ZP-CR02E SVERKER900

19

4 OPERATING SVERKER 900

4.2 Home menu

In Home menu you can:

▪ Select type of test instrument

▪ Select system configuration

▪ Activate already saved test files or download on external

memory (USB)

▪ Select Voltage / Current and External Timer configuration.

This can also be done in all the test menus.

Home menu buttons

Symbol Description

Main instrument

The Main instrument screen is the default screen

for SVERKER 900, and is presented when started.

Prefault -> Fault instrument

Ramping instrument

Sequencer instrument

CT-Magnetization instrument

Impedance instrument

Test file management

System configuration

Configuration of Voltage / Current generators

Browse left/right

System configuration

1] Press for the Home menu

2] Press

▪ Advanced mode

When advanced mode is ON the following functions are

enabled in certain instruments: Harmonics and Event

recording.

▪ Change State On 0-crossing

Setting of how to change state in the Sequencer

instrument.

When “Change State On 0-crossing” is

OFF it

means that the curve form (amplitude, phase, frequency)

is changed immediately if amplitude or phase or

frequency is changed between the different states.

When “Change State On 0-crossing” is

ON it

means that the state is not finished until the curve form of

phase I1 reaches the zero crossing (If I1 is not included in

the test I2 is the master). Then the state is completed.

▪ Hide warning messages

When this setting is OFF

all the warning messages

will be displyed.

When this setting is ON

the warning messages listed

in Troubleshooting section of this User's manual will be

hidden.

▪ IEC / IEEE30 / IEEE45

• IEC – voltage channels will be depicted “U”

Time values will be referenced in seconds and

milliseconds.

• IEEE30 / IEEE45 – voltage channels will be depicted “V”

Time values will be referenced to cycle times.

• The CT instrument can be set for the standards IEC,

IEEE30 or IEEE45.

▪ 50 Hz / 60 Hz / 16 2/3 Hz

Select frequency

The trip times will be based on the selected frequency.

▪ The same is valid when trip results are set to cycles when

IEEE30 or IEEE45 standard is set

Page 20

20 SVERKER900 ZP-CR02E CR0333LE

4 OPERATING SVERKER 900

▪ Versions

About SVERKER 900: year manufactured etc.

▪ Date and time setting

▪ TouchCal

Follow instructions for calibration of touch screen.

If no keyboard is used, press middle of screen when new

calibration is done.

▪ Labels for test files

Setting of four fields for report handling.

Note: The language setting for the volt and ammeter is

shifted when instrument is restarted.

▪ Field calibration

For detailed information and instructions see section

"4.10 Calibration" on page 42.

▪ Language

Czech, English, French, German, Spanish, Swedish

▪ Ext.KeyBoard

Select language for an external keyboard.

▪ License file

To add additional instruments to the SVERKER 900, press

the “License file” button. Insert the USB stick with the

license file and follow instructions on the display.

Generator configuration

1] Press for the Home menu

2] Press

The generators can be configured in three different

connections: individual, serial or parallell. Voltage generators can be used as 3AC+1AUX (AC/DC) or 4AC.

Use the supplied jumpers to make the connections.

See page 12 and page 13.

Generators individual

Generators in serial

Generators in parallel

Use as a fourth generator or as an

auxiliary power source

Select AC or DC

Voltage generator in individual connection 3 AC + AUX DC

Voltage generator in individual connection 3 AC + AUX AC

Voltage generator in individual connection 4 AC

Page 21

CR0333LE ZP-CR02E SVERKER900

21

4 OPERATING SVERKER 900

4.3 Main instrument

The Main instrument screen is the default screen for

SVERKER 900, and is presented when started.

SVERKER 900 will be opened with the settings from

last time it was run.

In the example above all current and voltage generators are

set to work separately. See sections "Current generators

separately" page 12 and "Voltage generators separately

"page 13. for configuration.

Main instrument buttons

Symbol Description

Voltage and current generators

▪ Parameter table rows turns into green for

active generators.

▪ Press parameter to make settings.

OF F +TIME: Current source is turned off. When

a valid trip indication occurs, the yellow Trip time

field shows the trip time and the binary input that

detected the trip signal

ON +T I ME: Current source is activated until the

object being tested has operated. When a valid

trip indication occurs, the yellow Trip time field

shows the trip time and the binary input that

detected the trip signal.

HOLD: Captures voltage or current value at trip

signal.

SAV E Tes t

OPEN Test

0 VDC

U4 - DC/AC: Setting the voltage for the U4

generator

When used as AUX supply in voltage configuration

Measuring: Sets the instrument into measurement mode. To stop measurement mode, press

the button again.

Measurement mode is not settable if Advanced

mode is selected in the system configuration

menu.

BI: Configuration of the binary inputs

Equals values for current, voltage and frequency

Balances the phase angle values

Run

Stop

Returns to Home menu

Non-generating mode

This is the default state for the Main instrument. All

generator outputs are inactive, not generating output.

1] In non-generating mode, you can choose to

activate one or more generators and configure the voltage, current, phase and frequency parameters, for each.

2] Select a parameter to configure, the on-

screen numerical keypad will show up.

Generating mode

Selected generators will be activated.

1] Press

You can manually increase or decrease a selected parameter using the control knob and

observe the output.

2] Press the to set the instrument

to measurement mode. The generator table

change colour and the measured amplitude

values vill be presented.

Note “Off+time”, “On+time” or the pick-up/

drop-off functionality cannot be used.

Page 22

22 SVERKER900 ZP-CR02E CR0333LE

4 OPERATING SVERKER 900

3] To stop measurement mode press

.

Note Any combination of parameters can be se-

lected to be manually operated when generating is on. Press on the desired parameters to

change and turn the control knob.

Press

to stop the output

OFF+TIME

1]

Press

2] Press

3] Press to stop the output. The but-

ton changes to and the timer starts

counting.

4] When a trip has been identified on any of

the binary inputs the sequence is ended,

clock stops and result is displayed.

Picture shows trip on binary input 2 after 3.044 s.

ON+TIME

1]

Press

2] Press

3] When a trip has been identified on any of

the binary inputs the sequence is ended,

clock stops and result is displayed.

Note The configured off delay time period is to be

added before turning off generation.

Numerical keypad

The keypad view always shows up when you select a

configurable parameter on screen but only when the

generators are inactive.

1] Use the on-screen numerical keypad for con-

figuration of test parameters.

2] Use the button to confirm the en-

tered value or the button to abort

and exit.

Equals

When you select to configure the voltage level, current level or the frequency parameter, you will find the

button

1] Enter desired value and press

All three VGs or CGs will be configured with

the same value.

Setting frequency to DC

A]

Press "0" and then twice the to set DC

output on the selected channel.

B] Press "0" and then press twice on the button

to set DC output on all channels.

Balance

When you select to configure the phase angle parameter for a selected generator, you will find the button

1] Enter desired value and press button.

The phase angle between the VGs or CGs will

be balanced by 120 degrees.

Page 23

CR0333LE ZP-CR02E SVERKER900

23

4 OPERATING SVERKER 900

Example:

You configure the UL2 angle to 240 degrees and press

the BALANCE button.

UL1 = 0 deg (= 240 + 120)

UL2 = 240 deg

UL3 = 120 deg (= 240 - 120)

Finding the pick-up and drop-off

value using the hold function

1] Press

2] Press

3] Select parameter(s) by pressing the field(s).

The field(s) turns yellow.

4] Turn the control knob clockwise to increase

parameter(s), value(s).

When a trip signal is detected on a binary

input, the amplitude value is saved and a

pick-up value is obtained.

5] Press again.

6] Turn the control knob anticlockwise to de-

crease parameter(s), value(s).

When a trip signal is detected on a binary

input, the amplitude value is saved and a

drop-off value is obtained.

7] Press to stop the output.

The result is shown on display, the pick-up

and drop-off value and the ratio between

the values.

Note You can return to the result window by press-

ing the yellow or red field above the

button.

When a test is saved the field is red.

When the “condensed” view is selected, only the

generators used are shown. The check box "Condensed" is in bottom of the result window.

Note You can return to the result window by

pressing the yellow field above the

button.

Binary Inputs

The binary inputs are polarity sensitive when used in

voltage DC mode. The continuity indicator will light

if in right polarity and the contact condition is met.

When the BI is set to voltage sense and a DC or AC

signal is applied on the BI contact. A constant light is

seen.

For binary input BI1 the trigger level can be defined

(both from low to high and high to low level change)

when voltage mode are selected. For BI2-BI4 the levels

are fixed.

BI window buttons

Symbol Description

Binary input

BI1. The trigger level can be defined (both from

low to high and high to low level change) when

voltage mode are selected.

BI2 – BI 4. The trigger levels are fixed.

Red dot. Indicates that input is active.

≥1 Indicates that the input is logic connected to

another input with OR function (only in advanced

mode).

& Indicates that the input is logic connected to another input with AND function (only in advanced

mode).

indicates that the input is recording all the

events. (only in advanced mode)

Voltage mode. Detects if voltage is applied or

not.

Contact mode. Detects if circuit is closed or not.

Page 24

24 SVERKER900 ZP-CR02E CR0333LE

4 OPERATING SVERKER 900

Make. Trig when a voltage is applied to the start

input or when a contact is closed.

Break. Trig when a voltage applied to the start

input vanishes or when a contact is opened.

Make / Break . Trig when the state of the input

changes.

BI OFF. Turns off the selected binary input

BI ON. Turns on the selected binar y input

Confirm. Settings are confirmed and window

closes

Make BI settings

The procedure for BI-setting are the same in all menus

except sequence instrument.

1] In Main instrument press

The window shown below appears. Here you can se

how the binary inputs are configured.

2] Press a BI button e.g.

The button turns yellow and settings can be

done.

The small red indicator tells that the BI is active.

The BI setting window is shown. Below is an example

for settings of the binary inputs.

3] Press buttons for desired conditions for each

BI, e.g. Contact or Voltage mode, Make or

Break, or Make/Break.

4] Press to turn off a BI.

The button is greyed out and the red indicator is turned off.

Trig condition

The trig condition for the binary inputs is normally

"OR" logic but you can set two or more of the binary

inputs to a logic “AND” when SVERKER 900 is set to

”Advanced mode” (see "System configuration" on

page 19).

1] Press on BI number button to toggle be-

tween trig logic conditions.

Event recording

If SVERKER 900 is set to ”Advanced mode”, all events

on individual active binary inputs will be recorded during the test period.

Each BI can be set to only event record mode if it shall

not be included in trig condition.

1] Press on BI number button to toggle be-

tween different modes.

2] Recorded events will be displayed on the

screen and can be also saved as test results in

the report.

Page 25

CR0333LE ZP-CR02E SVERKER900

25

4 OPERATING SVERKER 900

Note Event recording is available only in certain

instruments.

Debounce filter

1] Press the "10 ms" button to set the debounce

time.

Set debounce

time

Set pickup

and hysteresis

voltage level

The debounce time for DC voltage can be set from 0

to 999 ms.

For AC voltage the debounce time has to be set to

maximum 5 ms.

Note When set to zero, it actually means 2 – 3 ms. A

debounce time of 0 ms is not a realistic value.

The debounce time means that as soon as a signal

(voltage or contact sense) is detected on the binary

input, SVERKER awaits the set debounce time. If the

signal is active during the whole debounce time the

signal is acknowledged as a valid signal, a “true” trip

signal is confirmed.

Special settings available for BI1

Adjustable threshold voltage

When voltage sense is chosen for BI1, the adjustable

pickup and dropout threshold values can be set

between 5 to 240 V and 0 to 235 V.

1] Press the "10.0 V" button, see picture above,

to set the threshold pickup and hysteresis

value.

Set pickup

value

Set hysteresis

value

Hysteresis voltage

The hysteresis voltage is the difference between the

pickup and dropout threshold voltages. If the pickup

threshold voltage e.g. is set to 48 V and the hysteresis

voltage is set to 5 V, the dropout voltage is 43 V.

1] Press the "10" buttons (see picture above) to

set the hysteresis voltage.

Harmonics

To use the harmonics function SVERKER 900 has to be

set to ”Advanced mode”

1] Press for the Home menu.

2] Press

3] Press button Advanced mode (OFF). It

will change to Advanced mode (ON).

Each individual generator can now be set to

generate a harmonic waveform.

Note When the harmonics is enabled the parameter

table has an orange outline.

Page 26

26 SVERKER900 ZP-CR02E CR0333LE

4 OPERATING SVERKER 900

4] Press on e.g. I1. The harmonics instrument is

shown.

In this example you can see that a fault current at

fundamental frequency with a superimposed third

harmonic of 25% will be injected on generator I1.

Highest possible "Component" to set is 10.

5] Press the button to impose the same

harmonics on the voltage or current channels.

6] Press to turn off a generator.

4.4 Prefault->Fault

instrument

The Prefault->Fault instrument is selected from the

Home menu using the button

Using the Prefault->Fault instrument you configure

two different states for the device, Prefault and Fault.

You can configure and activate both stages individually and make SVERKER 900 execute the test and

automatically change from Prefault to Fault state.

The Prefault state configuration is a valid condition

for the test object, meaning it does not trigger during

operation.

The Fault state is an invalid condition and it will trig

the test object.

Measurement mode, see main instrument, can only

be set in prefault mode.

Prefault->Fault view

Navigation

The Prefault->Fault screen scenario includes two views

to configure the conditions for Prefault and Fault

parameters, respectively. For test mode the third view

"Prefault->Fault" is selected.

Prefault -> Fault instrument buttons

Symbol Description

Prefault

Fault + Time

Prefault-Fault

Page 27

CR0333LE ZP-CR02E SVERKER900

27

4 OPERATING SVERKER 900

Prefault view

1] Press the Prefault button to enter prefault

view.

2] Select generators to be active and configure

the voltage, current, phase and frequency

parameters for each.

3] Set the time duration for how long to gener-

ate the Prefault state before SVERKER 900 is

automatically entering Fault state.

4] Press the button if you want to acti-

vate the selected generators.

Note The time duration condition is not valid,

during this operation, and the generators can

only be turned off by pushing the

button.

Fault view

1] Press the FAULT+TIME button from the

Prefault view, for the FAULT view screen.

Here you can configure the parameters for

the Fault state.

1] Select generators to be active and configure

the voltage, current, phase and frequency

parameters for each.

2] Configure the two timing parameters; the

max time duration, for how long the Fault

state will be generated and the off delay

duration, which is the time period after the

test object has triggered and until the output

generation will be switched off.

Automatic Prefault->Fault button

The third view "Prefault->Fault is selected for the test

mode. No values can be changed.

1] Press the button to generate the

Prefault condition for the set time duration

and then change to Fault state.

The device will generate the Fault state until any of

the following conditions are met:

A] Maximum configured time duration has time-

out

B] Test object trips

C] You press the button

Note The configured off delay time period is added

if condition B is met, before turning off generation.

The phase angle graph

On both screen views, Prefault and Fault, a phase

diagram is displayed which illustrates I and U phase

relationship for both states.

1] Press the graph to make it full screen.

2] Tap on full screen to minimize.

Page 28

28 SVERKER900 ZP-CR02E CR0333LE

4 OPERATING SVERKER 900

4.5 Ramping instrument

The Ramp instrument is selected from the Home

menu using the button

The Ramping test is very similar to the Prefault->Fault

scenario. The difference is that you can configure a

ramping condition, between the Prefault and the Fault

state. This includes the step-changes in voltage, current, phase and/or frequency, as well as the ramping

time duration.

Measurement mode, see main instrument, can only

be set in “Set ramp start” mode.

Ramping view

Navigation

Ramping includes four views; Start, Speed, Stop and

Test mode view. You can navigate back and forth

between these four views, by pressing the respective

buttons.

Ramping instrument buttons

Symbol Description

Set ramp start

Set ramp speed

Set ramp stop

Test mode (initiate a ramp test)

No values can be changed

1] Select the generators to be active and config-

ure the voltage, current, phase and frequency parameters for each.

2] Press to set the preferred start values

in the parameter table. The prefault time can

also be set here.

3] Press to set ramp speed.

Note For the phase angle, the direction is indicated

by setting “-“ or not in the keypad menu.

4] Press to set stop values.

5] To initiate a ramp sequence, press

Start a ramp test

1] In the views "Set ramp start" and "Test

mode" you can start generating by pressing

In "Set ramp start" generating can only be

stopped by pressing

For "Test mode view" the output generating is turned

off if any of the following conditions are met.

A] Pressing the

button

B] The ramping state has reached any end

condition

C] The test object trips

If test object trips, the measured trip time is displayed

on screen.

Speed and Stop ramping set views

The Speed and Stop ramping views are only a configuration views, no output generation can be activated

from these screens. Here you configure the ramping

conditions. This includes the ramping step-changes

for the voltage level, current level, phase angle and

frequency.

Note You have to configure the ramping param-

eters before activating the test.

If the settings for ramping have been sat

wrong, e.g. start and stop settings are in

conflict it is not possible to start a ramp test.

The phase angle graph

The phasor diagram in ramping instrument shows the

I and U phase relationship both for prefault state as

well as the end condition state after ramping.

1] Press the graph to make it full screen.

2] Tap on full screen to minimize.

Page 29

CR0333LE ZP-CR02E SVERKER900

29

4 OPERATING SVERKER 900

4.6 Sequencer instrument

The sequencer instrument is used to test several

conditions in a system, e.g. the automatic recloser.

The sequencer instrument is selected from the Home menu

using the button

Navigation

There are 16 programmable states in the sequence instrument. In each state you can set values for voltage,

current, phase angles, frequency.

The following configurations/changes can be made in

each state.

Sequencer instrument buttons

Symbol Description

Copy or delete state

Go to first / last state

Go forward / backward between states

Activates or deactivates BI for each

state individually

Set the time for selected state.

Set the end of sequence

Make voltage/contact sensing configuration for the binary input

Stop condition for selected state

Set contact condition for the binary

inputs for each state individually

Set position for binary outputs for each

state individually

Edit

Copy selected state

Insert selected state

Page 30

30 SVERKER900 ZP-CR02E CR0333LE

4 OPERATING SVERKER 900

Insert and replace state

Delete state

1] Press to copy/paste, delete/

replace or rename a state.

2] Press to make a copy of the selected

state.

3] Go to the state were you want to insert the

state.

4] Press “ STATE ….. (16) “.

In the picture below, state 4 has been selected. As seen underlined text “State #2 is

copied”.

• Press to insert the state. State #2 will be

inserted as #4 and all higher states will be moved

upwards.

If for example 10 states are used (State 10 is

marked as “END SEQ”) the inserted state will be

added and there will be at total of 11 states.

If there are 16 states (maximum number) the last

state will be lost.

• Press

to insert state #2. State #4 will be

deleted.

• Press

to delete the state.

5] Press to edit the state name, for

example "Prefault 1(16)".

6] Press to set the time (milliseconds).

7] Press button to configure, voltage/

contact sensing, Hysteresis and Debounce.

Note When this is changed in any "state" it will

automatically be valid for all states.

8] Select binary inputs and make the settings.

Voltage or contact sense.

Hysteresis voltage (BI 1 only), see page 25

Debounce filter, see page 25

Page 31

CR0333LE ZP-CR02E SVERKER900

31

4 OPERATING SVERKER 900

9] Press button to activate the

and

10] Press

11] Select binary inputs and make the settings.

Note For setting BI, see explanation in BI menu,

page 23.

12] Press to set a stop condition for the

selected state.

The sequence is terminated when a trip signal is detected in that particular state

13] Press to set the current state to be

the last state in the sequence. It also stops to

step further up to a higher numbered state.

14] Press to set the binary output posi-

tion for each state, see "3.4 Binary Output"

on page 11.

15] Start a sequence by pressing

As soon as the condition for a state has been fulfilled the sequencer goes to next state, irrespective of set time (max time for each state).

The results are shown in new window when any of

the following occurred:

▪

After stop on a trip signal

▪ The sequence is terminated with the stop button

▪ All the states have passed.

When the “condensed” view is selected, only the

generators used are shown.

The check box "Condensed" is in bottom of the result

window.

Note You can return to the result window by press-

ing the yellow or red field above the

button.

When a test is saved the field is red.

Page 32

32 SVERKER900 ZP-CR02E CR0333LE

4 OPERATING SVERKER 900

Note The BO relay has a switching time at opening

or closing of relay contact that is not compensated for. The switching time is normally

around 3 to 4 ms. When doing a sequence

the BO relay will be switched directly after the

change of sequence state. Meaning that the

switching relay time extends this transition

between the states with this 3 to 4 ms.

4.7 CT magnetization

instrument

In the lid is an accessory placed that is to be used for

the CT magnetization instrument.

The CT magnetization instrument is used to determine

the knee point voltage of a current transformer.

In CT-mode SVERKER 900 can generate up to 900 V

by connecting the four voltage generators in series

and 300 V by connecting the four voltage in parallel.

The magnetization can be made manual or automatic

or as a combination, to start in manual mode and

then switch to auto for the demagnetization part. This

method is good to use for the first test on a CT.

CTM-box to be used in serial with volt/ampere meter and CT.

Page 33

CR0333LE ZP-CR02E SVERKER900

33

4 OPERATING SVERKER 900

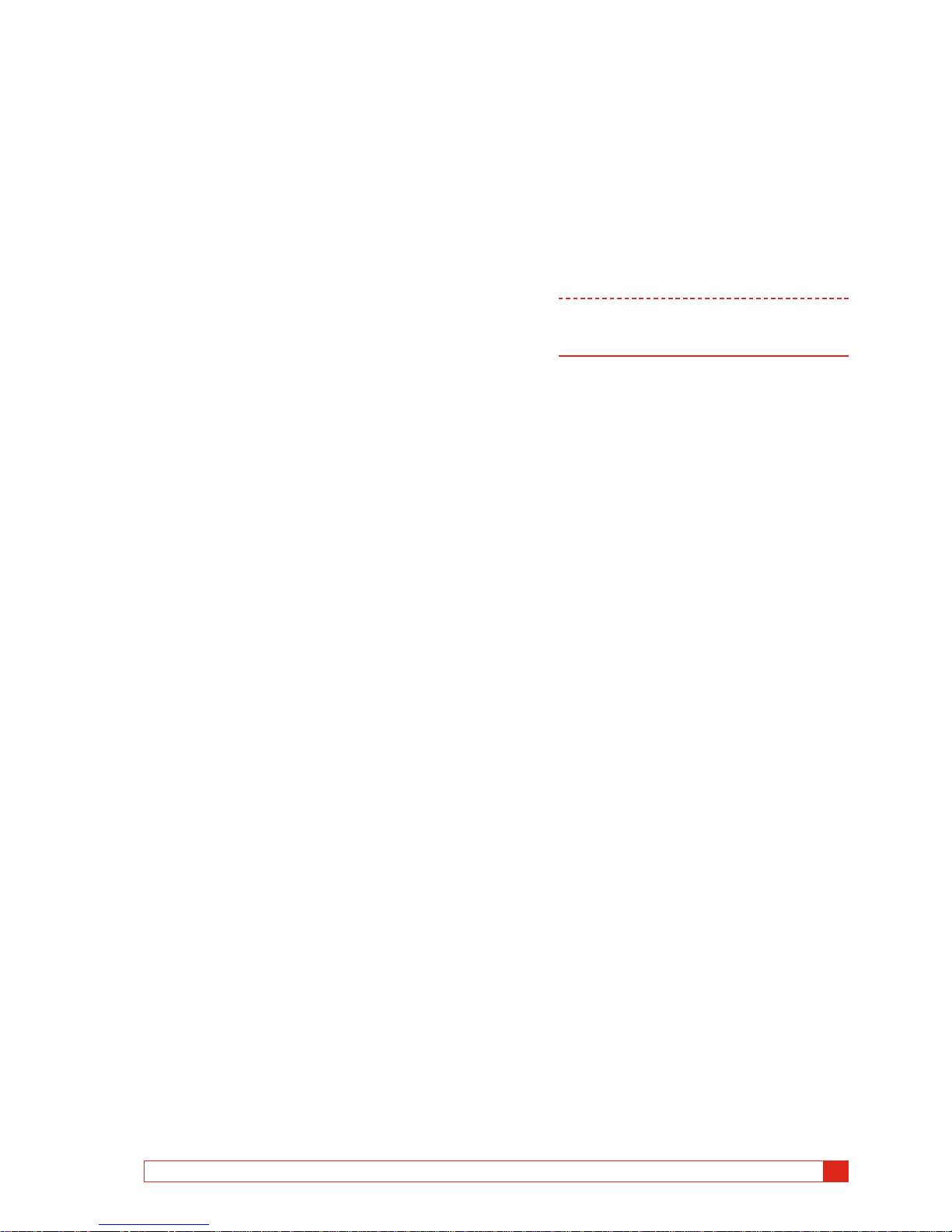

0

0,2

0,4

0,6

0,8

1

1,2

1,4

1,6

0

50

100

150

200

250

300

350

400

450

500

0 100 200 300 400 500 600 700 800 900 1000

A

VA

V

Voltage generators - Series

VA--4

I--4

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

0

50

100

150

200

250

300

350

400

0 50 100 150 200 250 300 350

A

VA

V

Voltage generators - Parallel

VA//4

I//4

CT magnetization instrument buttons

Symbol Description

Set maximum voltage

Possible in all test modes

Set maximum current

Possible in all test modes

Manual mode for the test

Automatic mode for the test

Set-up

1] From the Home menu you press to con-

figure the voltage generators.

Two configurations are possible to use, 4

generators in parallel (300 V) or serial (900 V)

mode, depending on desired output voltage

and power. See adjacent diagrams for guidance.

2] From the Home menu you press

Select IEC or IEEE(45° or 30°) standard.

3] From the Home menu you press the CT in-

strument button

When the CT instrument is opened, a picture

shows how to connect the voltage output to

the CT.

4] Press to confirm the connection.

The screen will show as below.

Note If the screen will show as below you must

correct your configuration, see step 1 above.

Manual test

1] The default mode is manual mode

If not, press the button.

Page 34

34 SVERKER900 ZP-CR02E CR0333LE

4 OPERATING SVERKER 900

2] You can set limits for maximal voltage and

current if needed. Press the buttons

or and make the settings.

3] Start test by pressing and then slowly

turn the control knob clockwise until knee

point is reached.

Note If the control knob is not turned a knob sym-

bol will pop-up in upper left corner to indicate

that turning should be done.

Note The magnetization can be stopped manually

by turning the control knob back to zero.

4] When the arrow on the control knob symbol

changes direction, from clockwise to anticlockwise, you should start the demagnetization by turning the control knob anticlockwise.

5] Press the control knob repeatedly to plot the

graph during the demagnetization.

The graph is plotted and the knee point with

plotting values presented.

6] Press the diagram to get full screen.

Press again to return.

7] The test is completed and ready to save.

Manual/auto test

1] Start in the same way as for the manual test

2] When the arrow on the control knob symbol

changes direction, from clockwise to anticlockwise, press

3] The demagnetization and plotting will be

made automatically.

4] The test is completed and ready to save.

Auto test

1] Press the button to position

2] Press to start a test.

3] Magnetization starts and when the prede-

fined relationship between voltage and current for the knee-point has been reached the

demagnetization will start.

Page 35

CR0333LE ZP-CR02E SVERKER900

35

4 OPERATING SVERKER 900

The graph is plotted automatically and the

knee point and plotted values are presented.

4] The test is completed and ready to save.

Demagnetization

If the demagnetization is interrupted by e.g. pressing

the button a warning message will be displayed.

Important

Make a couple of magnetization and demagnetization sequences manually before

you continue with the test.

4.8 Impedance instrument

The Impedance instrument is selected from the Home

menu using the button

Using the Impedance instrument you configure

sequence(s) with different states including Fault

state(s) with support for impedance entry mode.

Prefault and Fault state can be configured and activated individually or you can also make SVERKER 900 to

execute the test and automatically/manually change

from Prefault to Fault state.

Navigation

The Prefault->Fault sequence includes two views to

configure the conditions for Prefault and Fault parameters, respectively. For test mode Prefault->Fault and/

or Manual binary search views are selected.

Impedance instrument buttons

Symbol Description

Prefault

Fault + Manual pickup search

Prefault-Fault

Manual binary search

CT direction

Configuration

Advanced configuration

Cartesian diagram

Polar diagram

Reset to factory settings

Important

Following generator configurations are

valid for Impedance instrument. Please

verify your generator configuration before start testing in this instrument.

Page 36

36 SVERKER900 ZP-CR02E CR0333LE

4 OPERATING SVERKER 900

Prefault view

1] Press the button to enter prefault

view.

2] Select number of phases and generators to

be active throughout the test and configure

the prefault voltage, current, phase and

frequency parameters using the knob or

keypad.

Tip!

Voltage, phase and frequency parameters

can be set individually for U4 generator if

it is configured as an AC generator and it

can be used as a reference voltage source

throughout the entire test.

3]

Select CTdirection to be also used throughout the test by pressing the or

button.

4] You can set limits for maximum voltage and

current if needed by configuring Umax and

Imax parameters, respectively. These settings

will be applied to all test modes within this

instrument.

5] Press to activate the selected genera-

tors.

Note The generators can only be turned off by

pressing the button and no timer is

applied in prefault view.

Fault + Manual pickup search view

1] Press the button to enter Fault view.

2] Select the fault type by pushing the

button.

3] Set the fault impedance by configuring R

and X or Z and Φ parameters.

Tip!

Press the

on keypad while setting

the Z parameter to move your test point

by 180 degrees.

Note Fault voltage and current phasors are by

default calculated using 1A constant current method. Moreover for one phase fault

the phasor calculations are by default done

in so called ohm/loop domain. In order to

change these default settings and/or testing

in primary domain press

button and

configure relevant parameters.

Page 37

CR0333LE ZP-CR02E SVERKER900

37

4 OPERATING SVERKER 900

4] Press to select binary inputs and

make the settings.

Note For setting BI, see "Make BI settings" on page

24.

5] Press the button to activate the gen-

erators with calculated fault phasors shown

in this view.

6] During generation the R,X,Z and Φ param-

eters can be selected and changed one at a

time by turning the knob as shown in following picture in order to manually search for

pickups in the impedance plane.

As soon as the configured binary input is activated

the trig is registered. You can continue changing the

above parameters to further evaluate the behaviour of

your test object.

Following figure illustrates a possible scenario for

searching a pickup value.

Note The registered trig will not be saved as test

results.

The generators can only be turned off by

pressing the button and no timer is

applied in fault view.

Prefault – Fault view

1] Press the button to enter Prefault –>

Fault view.

2] Press the button to generate pre-

fault-> fault sequence with your previous

configured settings done in Prefault and

Fault views, respectively or follow the following steps to configure and test a new test

point.

3] Press the button to select the fault

type.

4] Set the fault impedance by configuring R

and X or Z and Φ parameters

Note Fault voltage and current phasors are by

default calculated using 1A constant current

method. Moreover for one phase fault the

phasor calculations are by default done in so

called ohm/loop domain. In order to change

these default settings and/or testing in pri-

mary domain press

button and configure

relevant parameters.

Tip!

Factory default settings can be restored

by pressing the

button following

with pressing the

button

5]

Press the button to generate prefault-> fault sequence.

The device will generate the Prefault state following by Fault state until any of the following

conditions are met:

•

Default Prefault time + Maximum Fault time duration

(1+5 sec) has timeout.

• Test object trips.

• You press the button.

Page 38

38 SVERKER900 ZP-CR02E CR0333LE

4 OPERATING SVERKER 900

The default Prefault and Fault durations can be

changed by pressing the

button and configuring

the relevant settings. Moreover, Off Delay and/or Post

Fault state(s) can be added to the sequence.

Following figures illustrate two possible scenarios

when all the states are configured.

6] The result will be displayed and added to the

result table for relevant fault type

7] Continue testing the next test point by re-

peating step 3 to 6 or move to step 8

8] You can save and/or delete the registered

results in the table by pressing the

and/or the button, respectively.

Note Pressing the

button will save all

your results disregarding which fault type is

selected. However, by pressing the

button only the results for previewed fault

type will be deleted. In order to delete all

available results disregarding which fault type

is selected and to start a new test press the

button.

Manual binary search view

1] Press the button to enter this view.

2] Select the fault type by pushing the

button.

3] Press the button to generate prefault

state.

Important

No Prefault timer is applied in this view

and the generators can only be turned off

by pressing the

button if no more

action is done.

4] Set the fault impedance by selecting and

configuring R and X or Z and Φ parameters

using the knob.

5] Press the knob to apply your settings and

generate the Fault state.

Note Fault voltage and current phasors are by

default calculated using 1A constant current

method. Moreover for one phase fault the

phasor calculations are by default done in so

called ohm/loop domain. In order to change

these default settings and/or testing in pri-

mary domain press

button and configure

relevant parameters.

Page 39

CR0333LE ZP-CR02E SVERKER900

39

4 OPERATING SVERKER 900

The device will generate the Fault state until any of

the following conditions are met:

•

Default (5 s) or the previously configured Maximum

Fault time duration has timeout

• Test object trips

6] The result will be displayed and added to the

result table for relevant fault type.

7] The device will generate again Prefault state

directly after fault state

8] You can press the button to stop the

generators or continue testing the next test

point by repeating step 4 to 7.

Following figure illustrates possible scenario for evaluating the behavior of a test object in different imped-

ance zones.

The Maximum Fault duration can be changed by

pressing the

button and configuring the relevant

setting. No Off Delay and/or Post Fault state(s) can be

added to the sequence in this test mode. To generate

a complete sequence Prefault/Fault view to be used.

9] You can save and/or delete the registered

results in the table by pressing the

and/or the button, respectively.

Note Pressing the button will save all

your results disregarding which fault type is

selected. However, by pressing the

button only the results for previewed fault

type will be deleted. In order to delete all

available results disregarding which fault type

is selected and to start a new test press the

button.

The impedance plane graph

On Prefault-Fault view and Manual binary search view

the impedance plane graph always illustrates your present configured test point together with your previous

test results, if any. Registered trips will be marked by X

and no trips with O.

1] Tap on the graph to make it full screen.

2] Toggle between Polar and Cartesian graph

by pressing or

3] Tap on full screen to minimize.

Page 40

40 SVERKER900 ZP-CR02E CR0333LE

4 OPERATING SVERKER 900

4.9 Test file management

From all instruments you can save any test results or

test configuration in SVERKER 900 persistent storage

or to an external USB memory.

When you save a test the first time you will have to

select where to save the test.

When a second test is to be saved, it will by default be

saved in the previous used test file.

Tip!

In the active windows you can turn the

Control knob to browse lists and press the

knob to select an item.

Buttons in Test file management

Symbol Description

Save test

Open test

Quick save

View

Edit

Save to USB

Open USB

Open test file library

Create new file

Delete test file

Save a test

1] Press to save a test.

If no test file are selected the window below

will be shown: "SELECT TEST FILE FOR STORAGE".

2] Select file by pressing on desired row in table

and press

To save in a new file, see point 5 below.

3] Type in the name of the test and add com-

ments.

If you want to select another file to save the

test, press

4] Press to save.

5] To create a new file, press

Page 41

CR0333LE ZP-CR02E SVERKER900

41

4 OPERATING SVERKER 900

6] Enter the label names.

7] Press to confirm.

Quick save

Note By using this option you can save additional

tests in the same file. The first test in the file

cannot be in quick save mode.

1] Press and press the check box

"Quick save mode".

2] Press

3] After each following test press to

save.

The test are not named but placed in the

same file as the first test.

4] To leave Quick save mode, press

and press, to uncheck, the check box "Quick

save mode.

View and reuse test files

1] Press

From the “STORAGE FILE” and “REFERENCE FILE” all

the test files can be selected and opened. Selected

test will be opened in the instrument that is running.

Note Only tests made for the instrument that is

running can be opened.

Storage file

1] In the "STORAGE FILE"window, press

"SELECT TEST FILE FOR STORAGE" is opened.

2] In "STORAGE FILE" window, press the upper

button to edit the "Test File Header".

3] In "STORAGE FILE" window, press the lower

button to edit test name and com-

ments.

Reference file

In the “REFERENCE FILE” window you can view and

open a test for reuse.

1] In the “REFERENCE FILE” window, press

"SELECT REFERENCE TEST FILE" window is

opened.

2] Select the test file you want to reuse for your