Page 1

AVTMST16-EN

User Manual

Portable Fault Locating System

SMART THUMP ST16

Rev 1

May 2016

Read this entire manual before operating.

M

Valley Forge Corporate Center

2621 Van Buren Avenue

Norristown, PA 19403-2329

U.S.A.

610-676-8500

www.megger.com

Page 2

M

Page 3

Portable Fault Locating System

SMART THUMP ST16

User Manual

Page 4

M

Copyright© 2016 by Megger. All rights reserved.

No part of this handbook may be copied by photographic or other means unless Megger have beforehand declared their consent in writing. The content of this handbook is subject to change without

notice. Megger cannot be made liable for technical or printing errors or shortcomings of this handbook.

Megger also disclaims all responsibility for damage resulting directly or indirectly from the delivery,

supply, or use of this matter.

The information presented in this manual is believed to be adequate for the intended use of the product.

If the product or its individual instruments are used for purposes other than those specified herein,

confirmation of their validity and suitability must be obtained from Megger. Refer to the warranty

information below. Specifications are subject to change without notice.

WARRANTY

Products supplied by Megger are warranted against defects in material and workmanship for a period of

one year following shipment. Our liability is specifically limited to replacing or repairing, at our option,

defective equipment. Equipment returned for repair must be shipped prepaid and insured. Contact your

local MEGGER representative for instructions and a return authorization (RA) number. Please indicate

all pertinent information, including problem symptoms. Also specify the serial number and the catalog

number of the unit. This warranty does not include batteries, lamps or other expendable items, where

the original manufacturer’s warranty shall apply. We make no other warranty. The warranty is void in the

event of abuse (failure to follow recommended operating procedures) or failure by the customer to

perform specific maintenance as indicated in this manual.

Page 5

Local Megger Offices

Australia Canada France

Megger Pty Limited

Unit 1, 11-21 Underwood Road

Homebush

NSW 2140

T: +61 (0)2 9397 5900

F:+61 (0)2 9397 5911

Germany India Kingdom of Bahrain

SebaKMT

Dr. Herbert Iann Str. 6

96148 Baunach / Germany

T: +49 9544 680

F: +49 9544 2171

Kingdom of Saudi Arabia South Africa Sweden

PO Box 1168

Khobar 31952

T: +966 3889 4407

F: +966 3889 4077

mesales@megger.com

Switzerland United Kingdom (Dover)

Megger Schweiz AG

Ob. Haselweg 630

5727 Oberkulm

Aargau

T: +41 62 768 20 30

F: +41 62 768 20 33

United States

(Dallas)

4271 Bronze Way,

Dallas, Texas 75237-1019 USA

T: 1-800-723-2861

F: 1-214-331-7399

110 Milner Avenue Unit 1

Scarborough Ontario

M1S 3R2 Canada

T: 1 416 298 6770

F: 416 298 0848

Megger (India) Pvt Limited

501 Crystal Paradise Mall

Off. Veera Desai Road

Andheri (W)

Mumbai 400053

T: +91 22 26740468

F: +91 22 26740465

PO Box 22300

Glen Ashley 4022

Durban

South Africa

T: +27 (031) 5646578

F:+27 (031) 5637990

Megger Limited

Archcliffe Road

Dover CT17 9EN

T: 01304 502101

F: 01304 207342

United States

(Valley Forge)

Valley Forge Corporate Centre

2621 Van Buren Avenue

Norristown, PA 19403 USA

T: 610 676 8500

F: 610-676-8610

23 rue Eugène Henaff

ZA du Buisson de la Couldre

78190 TRAPPES

T: 01 30 16 08 90

F: 01 34 61 23 77

P.O. Box 15777

Office 81, Building 298

Road 3306, Block 333

Manama

Kingdom of Bahrain.

T: +973 177 40 620

F: + 973 177 20 975

mesales@megger.com

Megger Sweden AB

Eldarvägen 4

Box 2970

SE-187 29 TÄBY

SWEDEN

T: +46 8 510 195 00

F: +46 8 510 195 95

United States

(College Station)

4064 State Highway 6 South

College Station, TX 77845 USA

T: 979-690-7925

F: 979-690-0276

Page 6

M

M

Page 7

Table of Contents

1 SAFETY ................................................................................................................................................................ 1

Precautions ............................................................................................................................................................ 1

Warning and Caution Notices ............................................................................................................................ 1

Working with the Product ................................................................................................................................... 2

Operating Personnel ............................................................................................................................................ 2

Repair and Maintenance ...................................................................................................................................... 2

General Cautions and Warnings ........................................................................................................................ 2

Intended Application ....................................................................................................................................... 2

What to Do if Equipment Malfunctions ...................................................................................................... 3

2 TECHNICAL DESCRIPTION ........................................................................................................................ 5

System Description .............................................................................................................................................. 5

Functional Description ................................................................................................................................... 5

Product Models ................................................................................................................................................ 5

Features ............................................................................................................................................................. 6

Scope of Delivery ............................................................................................................................................. 6

Available Accessories ...................................................................................................................................... 7

Technical Data ...................................................................................................................................................... 7

Control Elements, Indicators and Connectors ................................................................................................ 9

Power Supply ..................................................................................................................................................... 11

Battery Operation ......................................................................................................................................... 11

AC Line Operation ....................................................................................................................................... 12

3 SETTING UP THE SYSTEM ....................................................................................................................... 13

Connection Diagram ......................................................................................................................................... 14

Connection Sequence ....................................................................................................................................... 14

4 OPERATING INSTRUCTIONS .................................................................................................................. 15

Power on the System ........................................................................................................................................ 15

Basics of Operation ........................................................................................................................................... 15

Operation with Rotary Knob ...................................................................................................................... 15

High Voltage Control ................................................................................................................................... 16

Safety Circuit ...................................................................................................................................................... 16

Introduction ................................................................................................................................................... 16

Conditions of the Safety Circuit ................................................................................................................. 17

User Modes ........................................................................................................................................................ 17

System Settings (only accessible in Expert Mode) ................................................................................... 18

AVTMST16 Rev 1 May 2016

i

Page 8

M

5 HOW TO PERFORM A TEST ...................................................................................................................... 21

Detecting and Locating a Cable Fault in a Shielded Medium Voltage Power Cable ............................... 21

Locating a Faulty Cable Section (Sectionalizing) ...................................................................................... 21

Locating a Cable Fault (shielded MV power cable) ......................................................................................... 25

How to Pre-Locate the Fault ....................................................................................................................... 26

How to Pinpoint the Fault (shielded MV power cable) ................................................................................. 31

Detecting a Sheath Fault OR a Ground Fault in an Unshielded, Low Voltage Cable (both must be

directly buried) .................................................................................................................................................... 32

How to Pinpoint a Sheath Fault OR a Ground Fault in an Unshielded Low Voltage Cable (both must

be directly buried) ............................................................................................................................................... 34

6 CUSTOMIZE TDR FEATURES (applicable to TDR and ARM Mode) ................................................ 37

Introduction ........................................................................................................................................................ 37

Customized TDR Features ............................................................................................................................... 38

Completing the Operation ................................................................................................................................ 41

7 ADVANCED SYSTEM SETTINGS ............................................................................................................ 43

How to Edit the Cable List ............................................................................................................................... 43

Introduction ................................................................................................................................................... 43

XML Structure of a Cable List File ............................................................................................................. 43

How to Edit the Cable List .......................................................................................................................... 44

How to Setup Customer-Specific TDR Features .......................................................................................... 45

How to Use EasyPROT Software to Plot DC HIPOT/Sheath Test Data ............................................... 47

8 CARE and MAINTENANCE ........................................................................................................................ 49

Maintenance ........................................................................................................................................................ 49

Storage ................................................................................................................................................................. 49

APPENDIX 1 - Overview of TDR Features .................................................................................................... 51

AVTMST16 Rev 1 May 2016

ii

Page 9

Receiving Instructions

1. Check the equipment received against the packing list to ensure that all materials are

present. Notify Megger of any shortage. Email your local Service Representative or

send to VFCustomerSupport@Megger.com.

2. Examine the equipment for damage received in transit. If damage is discovered, file a

claim with the carrier at once and notify Megger, giving a detailed description of the

damage.

3. Prior to operation, check for loosened hardware or damage incurred during transit.

If these conditions are found, a safety hazard is likely, DO NOT attempt to operate

equipment.

Please contact Megger as soon as possible.

Please check your delivery against:

a) your order

b) our advice note

c) the item delivered, and

d) the parts list

any shortages must be reported immediately.

Consultation with Megger

The present system manual has been designed as an operating guide and for

reference. It is meant to answer your questions and solve your problems in as

fast and easy a way as possible. Please start with referring to this manual should

any trouble occur.

In doing so, make use of the table of contents and read the relevant paragraph

with great attention. Furthermore, check all terminals and connections of the

instruments involved.

Should any question remain unanswered, please contact:

VFCustomerSupport@Megger.com

or

phone: +1.610.676.8500 (USA)

AVTMST16 Rev 1 May 2016

iii

Page 10

M

M

AVTMST16 Rev 1 May 2016

iv

Page 11

1

SAFETY

Precautions

This manual contains basic instructions on commissioning and operating the

SMART THUMP system. For this reason, it is important to ensure that the

manual is available at all times to authorised and trained personnel. Any

personnel who will be using the devices should read the manual thoroughly. The

manufacturer will not be held liable for any injury or damage to personnel or

property through failure to observe the safety precautions contained in this

handbook.

Locally applying regulations have to be observed.

Warning and Caution Notices

Warning and caution notices are used throughout this manual where applicable.

These notices appear in the format shown below and are defined as follows:

Warning, as used in this manual, is defined as a condition or

F

G

NOTE: The notes contain important information and useful tips for using the

practice which could result in personal injury or loss of life.

Caution, as used in this manual, is defined as a condition or

practice which could result in damage to or destruction of the

equipment or apparatus under test.

system. Failure to observe them can render the measuring results useless.

WARNING!

CAUTION

AVTMST16 Rev 1 May 2016

1

Page 12

M

Working with the Product

Operating Personnel

It is important to observe the general electrical regulations of the country in

which the device will be installed and operated, as well as the current national

accident prevention regulations and internal company rules (work, operating and

safety regulations).

After working with the equipment, make sure to de-energise, protect against reenergising, discharge, earth and short-circuit the instrument and installations that

have been worked on.

Use genuine accessories to ensure system safety and reliable operation. The use

of other parts is not permitted and invalidates the warranty.

This system and its peripheral equipment may only be operated by trained or

instructed personnel. Anyone else must be kept away.

The system may only be installed by a trained or authorized electrician. In

Germany DIN VDE 0104 (EN 50191), DIN VDE 0105 (EN 50110) and the

German accident prevention regulations (UVV) define an electrician as someone

whose knowledge, experience and familiarity with the applicable regulations

enables him to recognize potential hazards.

Repair and Maintenance

Repairs and service must only be done by Megger or authorized service

departments of Megger. Megger recommends having the equipment serviced and

checked once per year at a Megger service location.

Megger also offers direct on-site support. Please contact our service office for

more information

General Cautions and Warnings

Intended Application

Safe operation is only warranted if using the equipment for its intended

purpose. Using the equipment for other purposes may result in bodily harm or

death of the operator and damage the equipment itself and that of the involved

test site.

AVTMST16 Rev 1 May 2016

The limits described under technical data may not be exceeded. Operating

Megger products in environments, which feature high humidity in combination

with condensation, may lead to flash-over, creapage, danger and damage. The

2

Page 13

instruments should only be operated under tempered conditions. It is not

allowed to operate Megger products in direct contact with humidity, water or

near aggressive chemicals nor explosive gases and fumes.

What to Do if Equipment Malfunctions

The equipment may only be used when working properly. If irregularities or

malfunctions appear which cannot be solved consulting this manual, the

equipment must immediately be put out of operation and marked as not

functional. In this case inform the person in charge who should inform the

Megger service to resolve the problem. The instrument may only be operated

when the malfunction is resolved.

SAFETY

Five Safety Rules

The five safety rules must always be followed when working with HV (High

Voltage):

De-energize

Protect against re-energizing

Confirm absence of voltage

Ground and short-circuit

Cover close by energized components

Using cardiac pacemaker

Fire fighting in electrical installations

Physical processes during operation of high voltage may endanger persons

wearing a cardiac pacemaker when near these high voltage facilities

According to regulations, Carbon Dioxide (CO

as extinguishing agent for fighting fire in electrical installations.

Carbon Dioxide is electrically non conductive and does not leave residues.

It is safe to be used in energized facilities as long as the minimum

distances are maintained. A Carbon Dioxide fire extinguisher must be

always available within electrical installations.

If, contrary to the regulations, any other extinguishing agent is used for fire

fighting, this may lead to damage at the electrical installation. Megger

disclaims any liability for consequential damage. Furthermore, when using

a powder extinguisher near high-voltage installations, there is a danger that

the operator of the fire extinguisher will get an electrical shock from an ARC

FLASH (voltage arc-over created by the powder dust cloud).

It is essential to observe the safety instruction on the extinguishing agent.

Applicable is DIN VDE 0132 in Germany

) is required to be used

2

AVTMST16 Rev 1 May 2016

3

Page 14

M

F

WARNING - Dangers when working with HV

Special attention and safety awareness is needed when ope rating HV equipment

and especially non-stationary equipment. The regulations VDE 0104 about setting

up and operation of electric test equipment, i.e. the corresponding EN 50191 as

well as country-specific regulations and standards must be observed.

The system generates a dangerous voltage of up to 16 kV during operation. This

is supplied via a HV cable to the test object.

The system may not be operated without supervision.

Safety installations may not be by-passed nor deactivated.

All metallic parts in close proximity of the test equipment must be grounded in

order to avoid the build-up of hazardous electric surface charges.

AVTMST16 Rev 1 May 2016

4

Page 15

2

TECHNICAL DESCRIPTION

System Description

Functional Description

The SMART THUMP is a compact, battery or AC operated fault location system

typically to be used for fault locating of solid dielectric low voltage and medium

voltage cables.

It is ideally suited for use in URD systems and also feeder cables. The main

advantages of the SMART-THUMP are its solid HV performance, simple

operation, automated fault locating process, operation in rainy conditions, weight

and economics.

Beside proven prelocation technique (inductive ARM, current decoupling (ICE)),

the SMART THUMP provides sectionalizing capability (trouble shooting in

URD loop systems, North America), acoustic pinpointing with the integrated

1500 J surge generator as well as DC for breakdown detection, insulation

resistance estimation and sheath testing and sheath locating (sheath locating

requires optional receiver ESG-NT).

Product Models

Typically, the SMART THUMP is mounted on a hand truck and equipped with a

lead-acid battery/inverter system.

The hand truck mounted version is also available as an AC unit only (without

battery/inverter system, but with an AC isolation transformer).

The SMART-THUMP can be also permanently installed in a vehicle and is

powered by the power circuit of the vehicle (via inverter), a generator system or

optionally by an external battery with internal inverter.

When installed into a vehicle, the SMART-THUMP also offers an optional

remotely operated configuration, with a separation of up to 8 ft between the

control and HV units.

AVTMST16 Rev 1 May 2016

This manual covers all models of the SMART THUMP. If necessary, any

differences are noted in the text.

5

Page 16

M

Features

The SMART THUMP system combines the following features and functions as

a single device:

Quick Steps and Expert Mode (full feature mode), Automatic detection and

localization of transformers

Automatic fault prelocation and localization with regard to the 2 closest

transformers (optional Sectionalizing software)

Automatic cable end and fault detection and localization

DC test up to 16 kV with automatic breakdown detection and insulation

resistance measurement

Pinpointing of high resistance faults in surge mode

Sheath test with automatic breakdown detection

(Sheath) fault pinpointing (requires optional receiver ESG-NT)

Integrated safety circuit for user’s safety (F-OHM safe grounding)

Optional external remotely operated safety device to shut off HV

Operation from internal battery / inverter or from an external AC or DC

source

Sturdy and weatherproof enclosure for outdoor use

Scope of Delivery

The scope of delivery of the SMART THUMP system comprises the following

components:

HV output cable hard wired

Safety Grounding cable

AC Power cord

Owner’s manual

AVTMST16 Rev 1 May 2016

6

Page 17

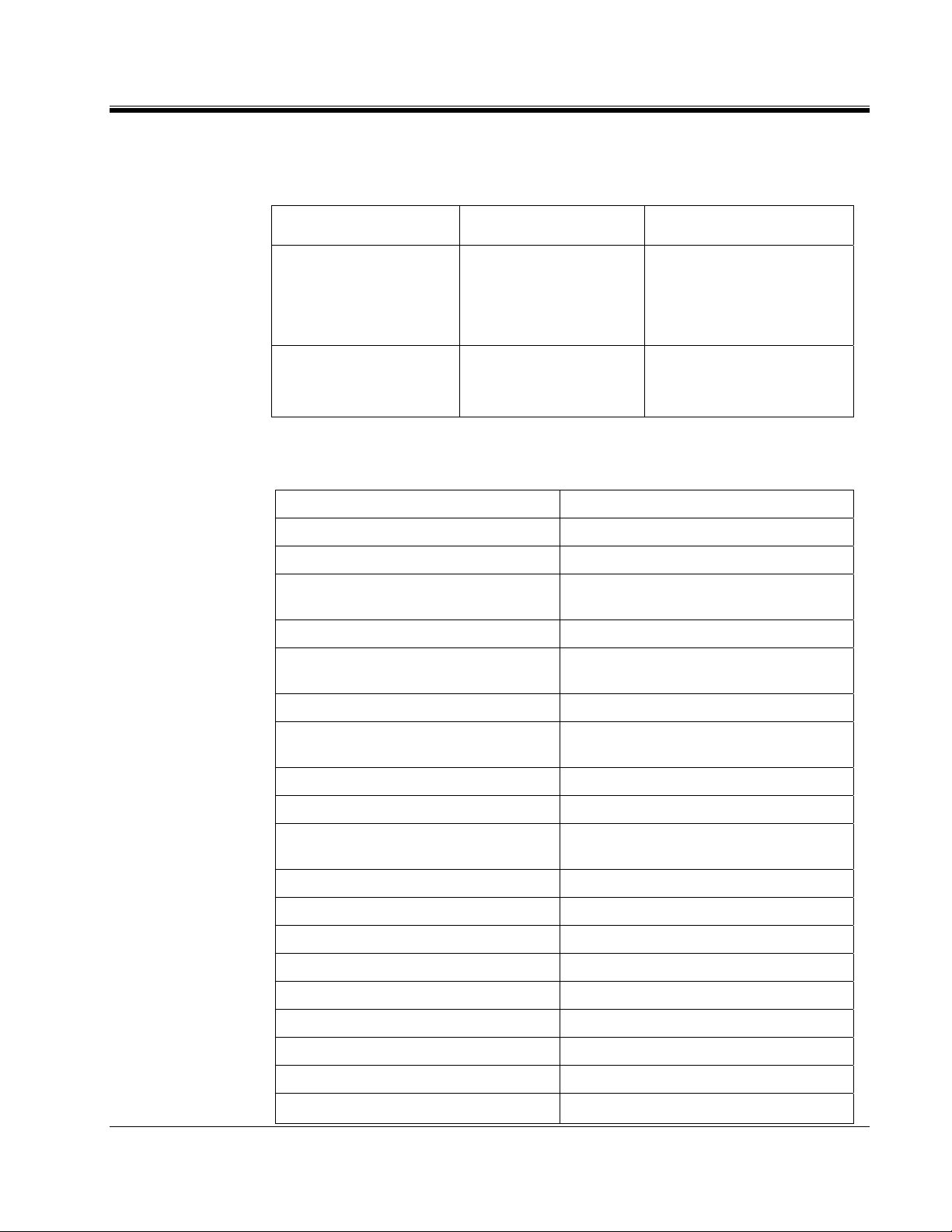

Available Accessories

The following accessories can be ordered from Megger, if required:

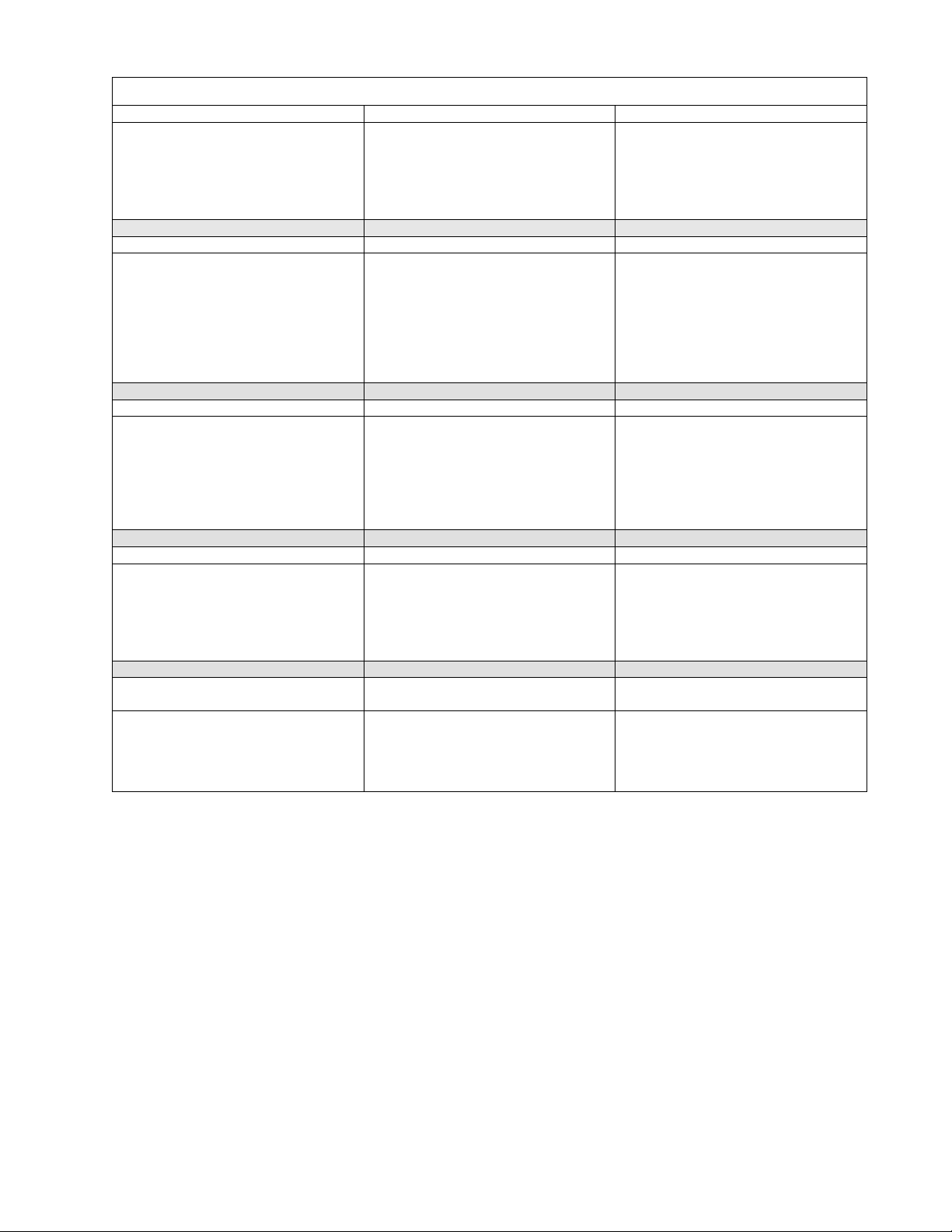

Accessories Description Item number

TECHNICAL DESCRIPTION

Elbow adaptor with 14 mm

female MC connector

(NAFTA market)

External safety device Safety device with signal

Technical Data

Parameter Value

DC Test voltage

Surge voltage

Source current

Insulation measurement

Surge energy

Power supply

Used to connect HV output

cable

lamps, key switch and

EMERGENCY OFF switch

0 to 16 kV

0 to 8 / to16 kV,

0 to 60 mA (up to 8 kV)

0 to 30 mA (8 … 16 kV)

20 kΩ … 10 MΩ

1500 J at the maximum surge voltage of

the respective surge levels (8 kV / 16 kV)

110 V to 230 V ±15%, 50 / 60 Hz

865000100100000 (15 kV)

865000200100000 (25 kV)

865000300100000 (35 kV)

893024147 and 890024896

AVTMST16 Rev 1 May 2016

Battery

Operating time battery

Power consumption

Display

Memory

Interfaces

Measuring range (extended range) 8000 m , 25,000 ft, (32km, 100000ft)

Measuring resolution

Max. sampling rate

Update rate

Dynamic range

Output impedance

Operating temperature

7

Internal lead-acid gel type battery (12 V /

74 Ah

>90 min (pinpointing)

700 W

640 x 480 pixel Transflective / high Brite

TFT direct sunlight readable

>1000 traces

USB port

0,8 m (2,5 ft) at 80 m/µs (250 ft/µs)

100 MHz

5 samples / second

64 db

64 Ω

20 °C to +50 °C

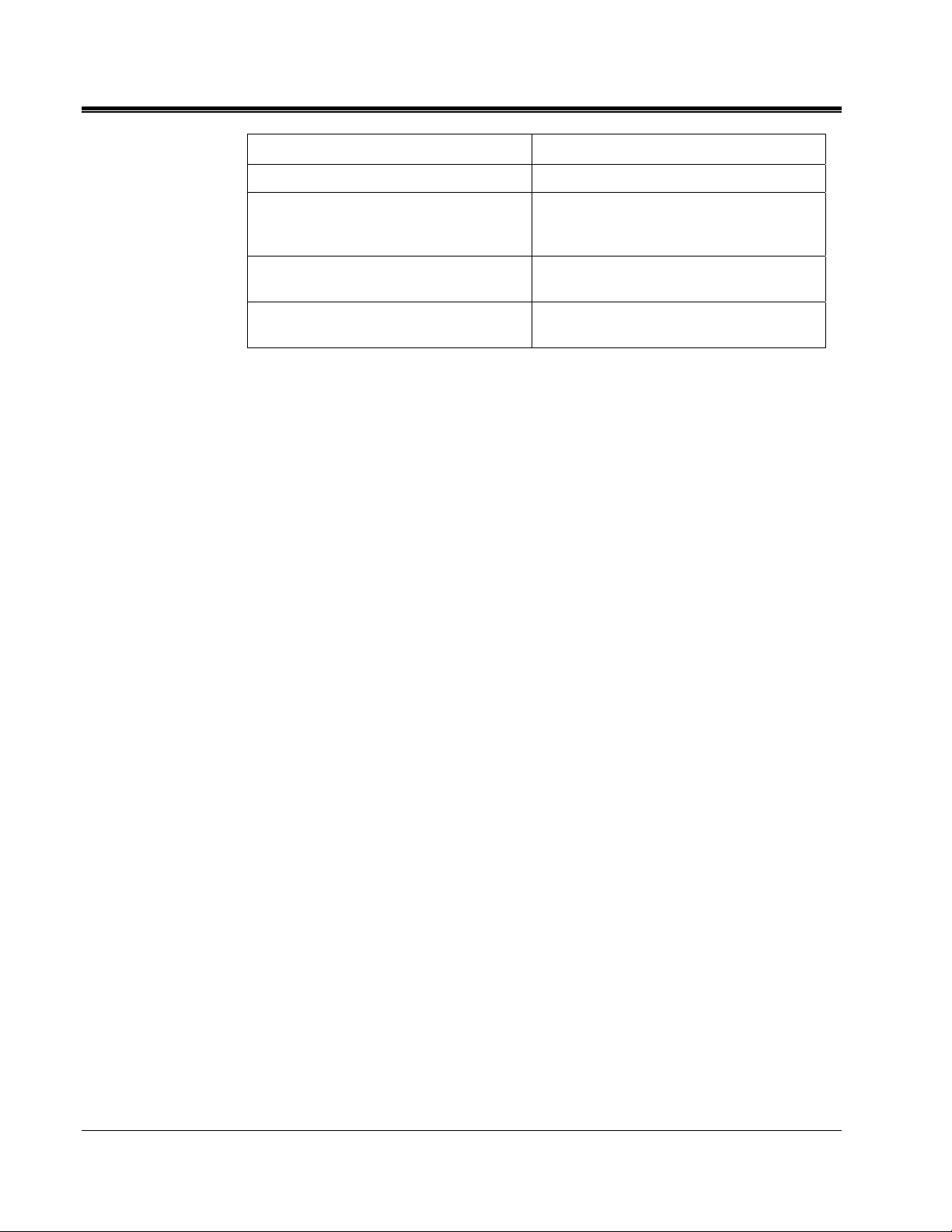

Page 18

M

Storage temperature

25 °C to +70 °C

Dimensions (W x H x D)

Weight

Protection class

(in accordance with IEC 61140)

Protection rating

(in accordance with IEC 60529)

690 x 1165 x 600 mm

145 kg, hand truck mounted incl. battery/

inverter and 50ft (17m) each of HV and

Safety Ground cable

I

IP53

AVTMST16 Rev 1 May 2016

8

Page 19

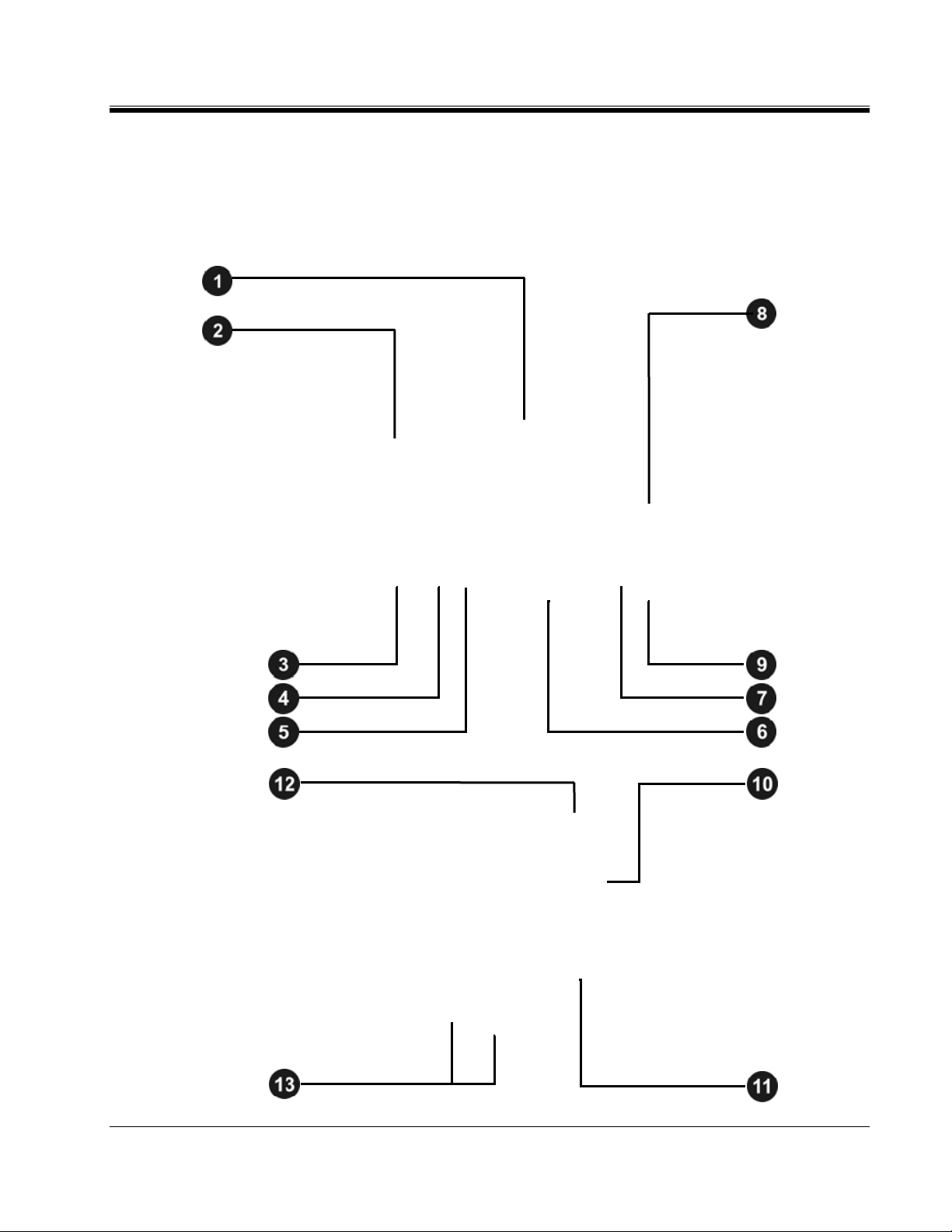

TECHNICAL DESCRIPTION

Control Elements, Indicators and Connectors

The SMART THUMP has the following control elements, indictors and

connectors:

AVTMST16 Rev 1 May 2016

9

Page 20

M

Element Description

Display

Emergency stop button

HV “interlock” key switch

“HV ON” button

“HV OFF” button

Rotary control knob

“ON / OFF” button

USB port

Charging status LED (yellow: charging | green: charging completed)

AC power connector

Safety ground connection

Jack for connecting external safety device (See page 7 'Available

Accessories').

Terminals for external 12 V DC power supply

AVTMST16 Rev 1 May 2016

10

Page 21

Power Supply

Battery Operation

Introduction

The SMART THUMP can be equipped with an internal battery. In this case

there is no requirement for an AC line supply to operate the unit in the field. For

a good trade-off between weight and operation time, the battery is sized for up

to more than 400 capacitor discharges at 90% of full voltage which equals

approximately 1 hour of thumping (pinpointing).

Battery Status and Automatic Shutoff

As long as more than 50% of the battery capacity is available, no battery icon is

shown on the screen. As soon as the battery is discharged by more than 50%, the

battery icon

bar graph).

in the upper right corner of the screen starts flashing (

TECHNICAL DESCRIPTION

not

an active

LOCATE

Battery capacity >50% Battery capacity <50%

To protect the battery from a deep discharge, the unit turns automatically off, if

the battery is discharged too low for safe operation.

Low Battery!

Shutdown unit

Note: To find out whether the battery charge is sufficient for further use of the

unit in the field, just turn the unit on and check if the battery symbol is

visible on the main screen. If the symbol is visible you should strongly

consider recharging the battery before using the unit or plan to operate off

AC line power.

LOCATE

AVTMST16 Rev 1 May 2016

11

Page 22

M

Backup Battery

Charging

If the internal battery is becoming drained while fault locating, any 12 V battery

providing more than 50 A (e.g. a car battery) can be connected to the

12 V terminals in order to extend the operation time or the unit must be

connected to an AC source (see below AC Line Operation).

The battery automatically is being charged as soon as the SMART THUMP has

been connected to 120/230 AC line power. Charging time on a fully drained

battery is about 10 to 12 hours. The progress of the charging process is indicated

by the battery charging status LED . During charging, the LED lights yellow.

It turns to green, when the battery is full and charging is finished.

NOTE: Always charge the battery immediately after use. Lead-acid batteries

must always be kept in a charged condition. The battery life is longer

with an almost fully charged battery rather than fully discharged one.

Store the unit always at a full charge by keeping the charger connected

while the unit is not in use (trickle charge).

AC Line Operation

As soon as the AC power cord is connected to the receptacle of the SMART

THUMP and the AC line,

charged at the same time.

the system is operating on AC power and being

AVTMST16 Rev 1 May 2016

12

Page 23

3

SETTING UP THE SYSTEM

WARNING - Safety instructions for setting up

The guidelines to maintain occupational safety when operating a

F

non-stationary test system often differ between network operators

and it is not uncommon to use National regulations (like, i.e. the

German BGI 5191) to be used as well.

Operator must inform him/her self about the guidelines applicable

in the area of operation beforehand, and comply with specific work

rules for non-stationary test systems.

Always follow the safety instructions (see Section 1 SAFETY) - in

particular the five safety rules

be tested.

- before connecting to the cable to

Before connecting the system to the cable to be tested, be sure

that the cable has been tested for voltage, discharged / isolated

and grounded tested in compliance with all OSHA & company

safety procedures.

Select a setup location which is sufficient for the weight and size of

the system and insure that it stands securely. Always locate the

system off to the side of the cable path, never on top of the cable

path.

When setting up the testing system, ensure that it does not impair

the function of any other systems or components. If other systems

and components have to be modified in order to set up and

operate the test system, be sure to reverse these actions when the

work is finished. Always take the special requirements of these

systems and components into account and only carry out work on

them after consulting and obtaining approval from whoever is in

charge of them.

Install protective equipment (such as railings, chains or bars)

around the test site to block access to the danger zone and

prevent the risk of touching live parts.

Always operate the SMART THUMP system in a vertical position.

Grounding and HV contacts both require a vertical orientation to

ensure proper functioning as well as a “Fail Safe Position” in case

of an AC or DC power failure or if the unit is shut off.

AVTMST16 Rev 1 May 2016

After receiving clearance, make sure that NO dangerous voltages

can reach unprotected places or technical equipment.

As a matter of principle, all de-energized cables that are part of the

test circuit shall be connected together and shorted to ground

13

Page 24

M

Connection Diagram

110 V … 230 V

50 / 60 Hz

Connection Sequence

Step Description

The following figure shows the simplified connection diagram.

±15%,

Connect the unit in the following order:

Connect the safety ground lead

transformer ground rod. Do not drive a separate ground rod!).

Connect the HV return lead

specific cable to be tested. The resistance between the HV return (operational

ground) and the safety ground should be less than 5 Ω (check with ohmmeter, if

questionable), if not the F-OHM safety feature will be activated, disabling the HV

ON function or activating the HV OFF function.

to a reliable ground (e.g. station-ground,

to the cable shield or the concentric neutral of the

NOTE: The closer and better the HV return is connected to the

shield / concentric of the cable to be tested, the better the

TDR trace readings will be.

Connect the HV lead

adapter or vice-grip. (See 'Available Accessories' in Section 2).

Connect the supplied power cord

and connect the other end to a power outlet.

to the phase conductor to be tested (optional elbow

to the connector on the back of the unit

NOTE: If no power connection can be established, the unit can be

operated from the internal battery, provided it is equipped

with this feature and is properly charged. The unit also

provides 2 battery terminals that are accessible from the

out-side, which can be connected to an external battery

Only after all necessary connections have been made, the ground connection

to the cable under test can be lifted.

AVTMST16 Rev 1 May 2016

14

Page 25

4

OPERATING INSTRUCTIONS

Power on the System

Once the “ON / OFF” button is pressed, the system starts up. After startup, the system is in the 'Ready for operation' state and the main menu is

displayed:

SMART-THUMP

16-1500

Test

In this state, the high voltage source is still switched off and the high voltage

output is grounded via a discharge resistor.

Basics of Operation

Operation with Rotary Knob

Navigation within the menus is done using the rotary knob as follows:

Turning

Clicking

Selecting

Confirming (“ENTER” function)

AVTMST16 Rev 1 May 2016

15

Page 26

M

The currently selected menu item is identified by a red circle.

not selected selected

With the aid of the rotary knob, the individual menus can be accessed and values

can be entered. If a selected menu item requires a value to be adjusted, the

following dialog is displayed:

The value for the parameter can then be adapted by turning the rotary knob and

clicking it again to confirm.

High Voltage Control

Before the start of the test, the user is prompted to enable high voltage. To do

so, the green illuminated “HV ON” button (green) must be pushed. This

lifts the discharge resistor and enables the generation of high voltage. The red

illuminated “HV OFF” button signals that the HV output is now energized

(hot) and the green button goes dark.

The activation of high voltage requires that all conditions of the safety circuit are

met. See page 16 in Section Safety Circuit.

The high voltage can be switched off at any time during the course of the test by

pushing the “HV OFF” button . The test is then immediately aborted and the

system is placed in the 'Ready for operation' state. The high voltage power supply

is turned off and the entire test circuit including the SMART-THUMP is

discharged and grounded, which is indicated by the illumination of the light in

the green push button.

Safety Circuit

Introduction

AVTMST16 Rev 1 May 2016

Once high voltage is turned on, the system's safety circuit continuously checks all

safety-relevant parameters and switching operations of the system. Should the

safety circuit detect a violation of the monitored thresholds / conditions while in

high voltage mode, the system automatically switches the high voltage power

16

Page 27

supply off and discharges and grounds the HV output. A message will be

displayed on the LCD display which

operation can be re-activated again.

Conditions of the Safety Circuit

The following conditions must be met in order to perform tests under high

voltage:

The HV key switch must be in the

The emergency off button must be unlocked (up).

The F-Ohm safety circuit must have a loop resistance below 6.5 Ω

(if resistance is higher, warning on LCD will be provided.

Note: If the HV application is disabled because of one or more of these

conditions are not being met, they must be eliminated and the message

must be acknowledged before HV ON can be enabled.

Operating Instructions

must be acknowledged

position.

before HV

User Modes

The E-TRAY system platform offers two operational modes, to the operator,

which are fully customer configurable:

QUICK STEPS mode:

This mode is tailored for the “everyday jobs” where the basic settings may

need no or just minor adjustments This is typically configured with a limited

range of adjustment features and no access to the system settings.

EXPERT MODE:

This password-protected mode is recommended for experienced users. It

offers the full range of adjustment features and access to the system settings,

incl. the default settings.

For detailed information on how to switch modes, please refer to the next page

AVTMST16 Rev 1 May 2016

17

Page 28

M

System Settings (only accessible in Expert Mode)

In order to change the system settings, EXPERT settings from the main

menu must be accessed.

These settings are only available, if the system is operated in Expert Mode. If

this is not the case, the rotary knob must pushed down and held down

shortly on any of the main menu icons until the system displays the prompt for

the password, which is required to activate the Expert Mode. The default

password is “0000” (can be changed – see below).

After activation of the EXPERT MODE

, you are automatically forwarded to

the system settings:

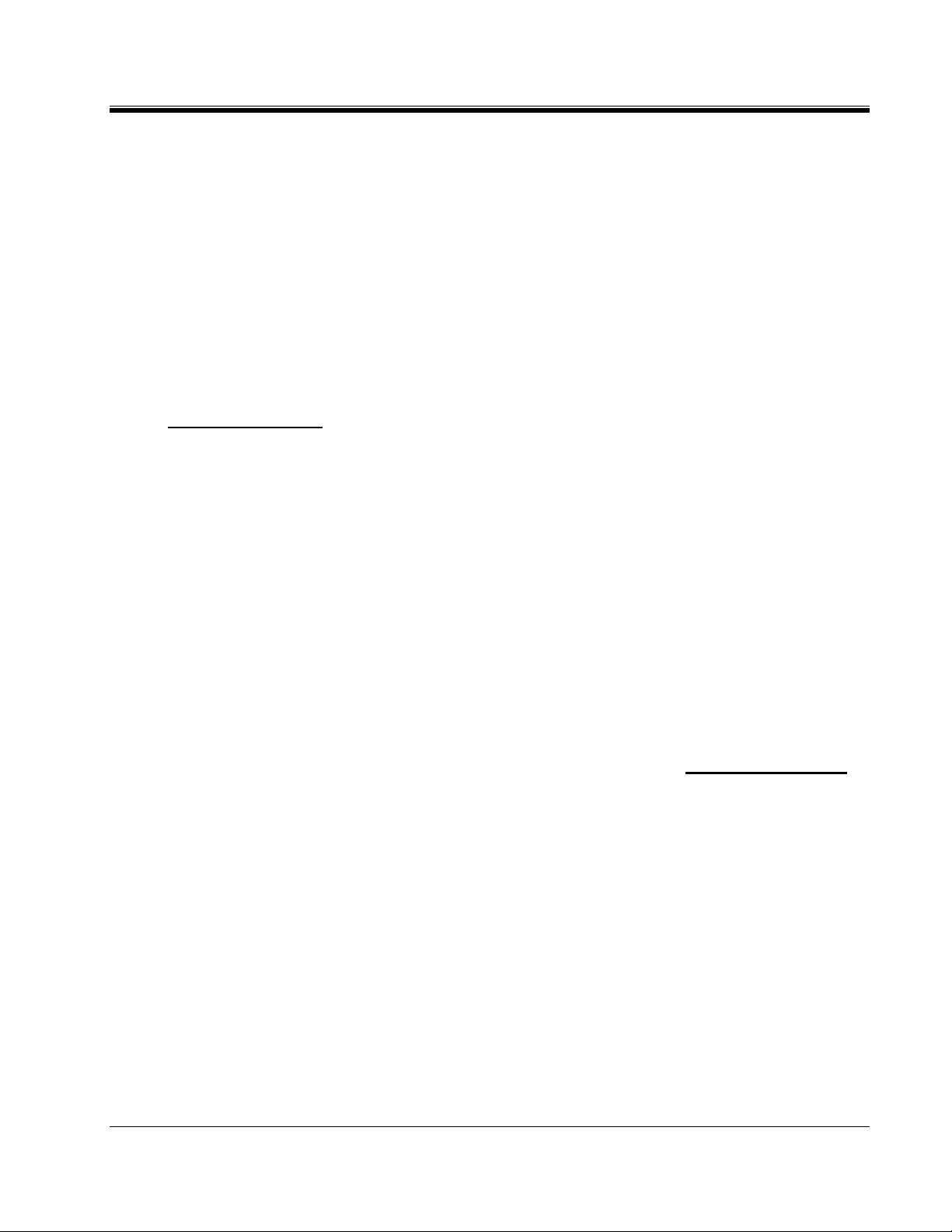

Menu item Description

Leave EXPERT

MODE

Date / Time

Language

Default Settings

>> Measurement

unit

>> V/2 or NVP Only available, if Length is set to Meter or Feet

By leaving the expert settings through this menu item the new settings are saved

and the system is switched to QUICK STEPS mode

The

persons from changing the system and default settings.

Date and time settings

Language settings

Length

Rate Only available, if Length is set to Meter or Feet

Propagation velocity of the cable under test can be expressed as

percentage of speed of light (NVP), e.g. 0.53 corresponds to 53% of speed of light

V/2 (half of the actual velocity of propagation) in m/μs

is no longer be displayed in the main menu which prevents unauthorized

Unit of the x-axis (Meter, Feet or Time).

If set to Time, the actual runtime of the pulse is displayed and no

conversion to length of cable is performed.

Rate refers to how the propagation velocity of the TDR pulse is

specified. This can be done either relative to the speed of light (% of

NVP) or in absolute units in μs (μsec = microseconds = 10

.

-6

sec).

>> Trigger delay

time

AVTMST16 Rev 1 May 2016

Delay time between the time of flash-over at the fault and the time to trigger and

capture the TDR trace. The delay time allows the flash-over to build up well before

a measurement is done (ideally when the arc reaches it highest current).

If Delay time too short: Flash-over is not fully developed and may cause poor or

no reflections of the TDR pulse.

If Delay time too long: Flash-over is extinguished already when TDR pulse

arrives and reflection measurement is too late. Thus, the fault trace looks identical

to reference trace.

The default value for the ST16 is 700 µms.

18

Page 29

Menu item Description

Operating Instructions

>> Automatic HV

release

Voltage

selection

Sheath Test

Limit

Continuous

Testing

The way a HV test is started, automatic or manual.

Automatic means that after initializing HV by pushing the HV ON button, HV will

build up in the test mode or will charge the capacitor and

has been reached (typically preferred in North America).

Manual means that in both situations the HV has to be manually “released”, once

the preset level has been reached (typically preferred in Europe).

When set to Manual the unit will always default to 2kV as a starting level in all HV

modes. The operator must then select the actual HV level in any operating mode

and operation menu (Quick-Steps and Expert mode).

When set to Automatic, the unit, when in Quick Steps mode only, will always

fire a shot in ARC reflection at the full voltage (max. energy) and when in thump

mode will go to maximum voltage (operator can down adjust). If a

HIPOT/Breakdown test was performed before hand, then the unit will match the

thump voltage to the breakdown voltage during the HIPOT test plus 4kV, i.e.

breakdown 4kV, thump voltage will be set to 8kV.

Units, which have the Sheath Test Option enabled, have a default test voltage that

can be adjusted between 2 and 5kV.

1. When disabled, only DC HIPOT / breakdown tests can be performed.

2. When enabled, DC HIPOT /Proof tests can be performed for up to 30 minutes

and the data can be exported via USB stick and loaded on the EasyPROT

software.

fire as soon as voltage

3. Must be enabled to perform Sheath Tests.

>> Set-up Start

Marker

Cable List

Procedure to adjust the start marker position to the end of the actual length of the

HV output cable (typically on SMART-THUMP at the end of the 50ft (17m) HV output cable).

The procedure is fully automatic and the operator is prompted when necessary!

First a measurement is taken with the ends of the connection cable open. Then the

gain setting is adjusted if needed and confirmed and a copy of the trace is frozen.

A second trace is recorded with the ends of the connection cable shorted to each

other, which should show a significant change. The marker is automatically placed

on the position where both traces start to split.

If required, the marker can be manually adjusted. This setting of the start marker

will be stored as the default, if operator acknowledges the prompt, and should

only be changed if the length of the connection cable is changed.

By means of the cable list the appropriate propagation velocity can be quickly

adjusted / selected by identifying the type of cable to be tested

Cable list can be exported and imported which allows for example to edit an

exported list (XML file) according to the preferences of the customer (see page

43) and then share it among all units of a customer

This submenu offers the following options:

Set default

Menu item to select the default cable list out of all available cable

lists. Only the cable types of the default cable list can be accessed

during measurement.

AVTMST16 Rev 1 May 2016

19

Page 30

M

Menu item Description

User mode

Backlight settings

Time Out Settings

Stored Traces

System information

Change password

Import from

USB

Export to

USB

Remove

cable list

Menu item to select the User Mode which is the default after start-up.

If set to Last, the unit starts up in last active mode, recommended is to set to

QUICK STEPS.

Backlight timeout and contrast settings

Minutes of inactivity after which the system is automatically shut down.

Menu item to export or delete all traces which have been stored in the internal

memory.

Exporting traces requires a USB flash drive plugged into the USB port . The

traces are written into the EtrayTraces folder which is automatically created.

The data can be viewed in any regular web browser by opening the index.html file

which is also located in the EtrayTaces folder.

Displays the detailed hardware and software configuration of the unit.

Menu item to change the password required to enable the EXPERT MODE.

Imports a cable list from an inserted USB drive. The cable list must

be located in the CableLists folder.

Exports the selected cable list to the CableLists folder on the USB

drive.

Removes the selected cable list from internal memory.

Customize TDR

features

Return

Menu item to configure the options which are available during measurement, See

page 45.

By leaving the EXPERT MODE through this menu item, the new settings are

saved.

AVTMST16 Rev 1 May 2016

20

Page 31

5

HOW TO PERFORM A TEST

Detecting and Locating a Cable Fault in a Shielded Medium

Voltage Power Cable

Locating a Faulty Cable Section (Sectionalizing)

Introduction

The sectionalizing technique is used to trouble shoot a distribution loop circuit in

order to identify the faulted section, so it can be quickly switched out, and the

rest of the circuit can be re-energized to provide service to all customers.

For this purpose, a LV reflection image is taken and scanned for impedance

changes which are related to the cable end and transformers. A second reflection

image of the TDR pulse is taken while an electrical arc is ignited by a sudden

discharge of the charged capacitor at the fault location. This reflection is

negative.

With both traces lying on top of each other, the fault location (position where

the two traces diverge from each other) is identified and the transformers

reflections provide the landmarks to identify the faulted cable segment. It will be

switched out by pulling the elbows to the left and right side of the fault. Service

to all customers is provided by closing the normally open point within the

distribution loop.

2 Alternatives

AVTMST16 Rev 1 May 2016

The procedure called “Sectionalizing” in the configuration set up will work flow

perform the following steps:

Pattern 1

low voltage TDR trace to identify cable end (blue trace)

low voltage trace to identify all transformers in the faulted (half) loop (blue

trace)

high voltage trace to identify fault (negative reflection in red trace)

21

Page 32

M

How to Determine the Faulty Section

Step Description

The procedure called "COMED" in the configuration set up will perform the

following steps:

Pattern 2

low voltage trace to identify cable end (blue trace)

high voltage trace to identify fault (negative reflection in red trace)

low voltage trace to identify all transformers leading up to the fault plus one

additional transformer past the fault (blue trace) if there is a transformer past

the fault

Proceed as follows to perform sectionalizing according to Pattern 1:

1

Select the menu item from the main menu or from the submenu (depends on the

system configuration).

Result: A LV pulse is fed into the cable. The reflection image is processed by the

transformer identification software. After a few seconds, the reference trace which shows

the distance to the cable end and, in addition, the approximate distance to each

transformer is presented in the display.

This reference trace is also called “live” trace as it is permanently refreshed.

Compare the indicated transformers with the actual plans of the cable system.

2

If necessary adjust the transformer search sensitivity and / or the propagation velocity in

the options. See page Error! Bookmark not defined..

AVTMST16 Rev 1 May 2016

NOTE: Sectionalizing is a transformer prediction algorithm based of

impedance changes. If all transformers in a loop cause similar

signatures the prediction works very well. If there are impedance

changes for some other reasons (most likely joints) the software cannot

tell them apart in every case. Please always check the distances to

identify missing or "phantom" transformers.

22

Page 33

Step Description

3

Select to start the fault location.

4

Adjust the surge voltage and select to confirm the val ue (not required in automatic

mode).

5

Press the green illuminated “HV ON” button .

6

Select to charge the surge capacitor (only if measurement start option is set to

manual. See page 18).

Result: The capacitor is charged up to the selected voltage.

7

Select to discharge capacitor (only if measurement start option is set to manual (not

required in automatic mode). See page 18.

How to Perform a Test

Result: A capacitor discharge (shot) is initiated.

If a voltage breakdown takes place, the red fault trace is shown in the display. The red

fault marker is automatically set to the position where both traces diverge from each other.

The fault is referenced to the 2 closest transformers, which identify the cable section

containing the fault.

NOTE: If no trigger is received and, thus, no fault trace is shown, you may

try to repeat the procedure with a higher surge voltage (if possible) by

selecting the menu item.

If necessary, adjust the display settings, TDR settings and marker position through the

8

menu in order to uniquely identify the affected section. See page 38).

AVTMST16 Rev 1 May 2016

23

Page 34

M

How to Verify Whether it is Actually a Bad Section

Step Description

1

Select the menu item from the main menu or from the submenu (depends on the

system configuration).

2

Adjust the test voltage and select to confirm the value.

3

Press the green illuminated “HV ON” button .

4

Select to start the test (only if measurement start option is set to manual. See

“System Settings” on page 17).

The HIPOT test within the context of Sectionalizing is done to confirm, that the

section of cable identified as bad during the Sectionalizing procedure can be

verified to be actually bad. Proceed as follows to perform a HIPOT test after the

identified cable section has been isolated at the 2 closest transformers:

Result: The selected voltage is applied to the cable.

During the rise of the voltage the maximum current of the HVPS will be displayed till the

cable has been fully charged, at which time the current will drop down to the actual

leakage current level. The insulation resistance is displayed. This scenario is observed if

the cable has no insulation breakdown, otherwise the high voltage will be shut off when

the flashover/breakdown occurs.

Depending on whether or not a breakdown takes place during the test, one of the

following results is presented in the display:

Breakdown

at…kV

No Flashover

Cable not

chargeable

Low

resistance

at …kV

A voltage breakdown took place at the indicted test voltage.

The cable has successfully withstood the applied DC test voltage. If

possible, repeat ( ) the test with higher voltage (do not exceed the

maximum permissible voltage).

The cable could not be charged by the test voltage. This is typically due to

a short (fault) in the cable.

The HV source cannot charge the cable beyond the indicated voltage value

due to the very high leakage current level.

5

Select to return to the main menu.

AVTMST16 Rev 1 May 2016

24

Page 35

How to Perform a Test

Locating a Cable Fault (shielded MV power cable)

How to Test the Dielectric Strength of the Cable

A HIPOT/breakdown test is used to test the dielectric strength of a cable and, if

the test fails, to determine the breakdown voltage. For this purpose, a test

voltage of up to 16 kV is applied to the cable under test.

Proceed as follows to perform a HIPOT test:

Step Description

1

Select the menu item from the main menu or from the submenu (depends on the

system configuration).

2

Adjust the test voltage and select to confirm the value.

3

Press the green illuminated “HV ON" button .

4

Select to start the test (only if Measurement Start option is set to Manual. See section

“System Settings” on page 17).

Result: The selected voltage is applied to the cable.

During the rise of the voltage the maximum current of the HVPS will be displayed till the

cable has been fully charged, at which time the current will drop down to the actual leakage

current level. The insulation resistance is displayed. This scenario is observed if the cable

has no insulation breakdown, otherwise the high voltage will be shut off when the flashover

/ breakdown occurs.

Depending on whether a breakdown takes place during the test, one of the following

results is presented in the display:

Breakdown

at…kV

No Flash-over

Cable not

chargeable

Low

resistance at

…kV

A voltage breakdown took place at the indicted test voltage.

The cable has successfully withstood the applied DC test voltage. If

required, repeat ( ) the test with higher voltage (do not exceed the

maximum permissible voltage).

The cable could not be charged while the test voltage was applied. This

may be due to a short on the cable.

The HV source cannot charge the cable beyond the indicated voltage

value due to a very high leakage current level.

5

Select to proceed with fault pre-location or to return to the main menu.

AVTMST16 Rev 1 May 2016

25

Page 36

M

How to Pre-Locate the Fault

Arc Reflection Method (ARM)

Step Description

1

Select the menu item from the main menu or from the submenu (depends on

the system configuration).

For pre-location of high resistance fault the SMART THUMP applies the widely

approved and well-known ARM (Arc Reflection Method).

Locating the fault becomes possible by comparing a reflection image taken with a

LV pulse (reference trace) to a reflection image taken while the arc, ignited by

sudden discharge of the charged capacitor, was present g at the fault location

(fault trace). With this method, the two measured traces diverge at the position,

where the arc caused a negative reflection of the TDR pulse, indicating the fault

location.

Proceed as follows to pre-locate the cable fault:

Result: A LV pulse is fed into the cable. The reflection image with the determined

distance to the cable end is presented in the display.

This reference trace is also called “live” trace as it is permanently refreshed (blue color,

a black color trace indicates a “frozen” or “saved” LV trace).

Note: The software provides its best estimate for the cable end. If the trace beyond the flag

“open at 950 ft” does not show any significant upwards or downwards reflection,

then click to confirm. If there is a substantial reflection beyond this point, turn the

rotary to the , click and adjust the end marker manually to where the end of

the cable is visible, then click to save and confirm.

Either the suggested or the manually adjusted cable end must

be confirmed, otherwise unit will not display any distances.

AVTMST16 Rev 1 May 2016

26

Page 37

Step Description

In case the software cannot determine the end of the cable, a message will be

displayed stating “CABLE END NOT CLEARLY VISIBLE” and offering to proceed by

“IGNORE” this fact.

Do NOT acknowledge the IGNORE message, but turn to the icon asking to

perform a manual adjustment of the End Marker by activating the END MARKER icon in

the feature menu. After adjustment to identify the cable end manually, click again and

acknowledge the manually identified cable end.

How to Perform a Test

2

Select to start the fault pre-location.

3

If required, the surge voltage can be adjusted through the menu item. Otherwise,

the maximum surge voltage is automatically used, if default AUTOMATIC VOLTAGE

CONTROL.

4

Press the green illuminated “HV ON” button .

5

Select to charge the capacitor (only if Measurement Start option is set to Manual.

See page 18).

Result: The surge capacitor is charged up to 16 kV.

AVTMST16 Rev 1 May 2016

27

Page 38

M

Step Description

6

Select to discharge the capacitor (only if Measurement Start option is set to

Manual. See page 18.

Result: A capacitor discharge (shot) is initiated.

If a breakdown / flashover takes place, the red fault trace typically has a strong negative

reflection. The red fault marker is automatically set to the position where both traces

diverge from each other.

NOTE: If no trigger is received, no fault trace (red) is shown. Repeat the

If necessary, adjust the display settings, TDR settings and marker position through the

7

menu in order to identify the fault distance as precisely as possible. See page 38.

8

Select to proceed with pinpointing or to return to the main menu.

procedure with a higher surge voltage (if possible) by selecting the

menu item.

If the blue trace (TDR trace) and the red trace are either 100%

matching or following each other very closely, the trigger has been

activated, however no breakdown/flashover was detected - increase

( ) voltage or possibly good cable.

AVTMST16 Rev 1 May 2016

28

Page 39

Current Decoupling (ICE)

As an alternative way for pre-location of high resistance faults, the SMART

THUMP provides the current decoupling method (ICE, Surge Pulse).

The capacitive discharge of the surge capacitor via the surge switch triggers and

ignites the fault and causes it to a flash over. This flashover results in a travelling

wave current on the HV return, which is inductively de-coupled and shown on

the Reflectometer as a transient. Subsequently, an attenuated transient wave

travels back and forth between fault and surge generator (standing wave)

By decoupling the current signal from the HV return, an oscillation is obtained

where the period length corresponds directly to the fault distance.

Note: Fault distance includes length of HV output cable: deduct this length to

get the distance to the fault going forward from the connection point, e.g.

transformer, switchgear etc.

Proceed as follows to pre-locate the cable fault:

How to Perform a Test

Step Description

1

Select the menu item from the main menu or from the submenu (depends on

the system configuration).

2

Adjust the surge voltage and select to confirm the value.

3

Press the green illuminated “HV ON” button .

4

Select to charge the capacitor (only if Automatic High Voltage Release is disabled).

See page 20.

Result: The capacitor is charged up to 16 kV.

5

Select to discharge the capacitor (only if Automatic High Voltage Release is

disabled). See page 20.

Result: A sudden capacitor discharge (shot) is initiated.

If a voltage breakdown takes place, a red oscillating curve is shown in the display.

AVTMST16 Rev 1 May 2016

NOTE: If no trigger is received and, thus, no fault trace is shown, you may

try to repeat the procedure with a higher surge voltage (if possible) by

selecting the menu item.

29

Page 40

M

Step Description

If necessary, adjust the display settings, TDR settings and marker position through the

6

menu in order to identify the fault distance as precisely as possible. See page 38.

7

Go into the simple options menu in order to measure out the distance. Use the cursor

to select one peak first. Drop a marker at the cursor position and move the cursor

to the next peak. The distance between the cursor and the marker is given on the screen.

8

Select to return to the main menu.

AVTMST16 Rev 1 May 2016

30

Page 41

How to Perform a Test

How to Pinpoint the Fault (shielded MV power cable)

The thumping mode can be used to pinpoint a fault between two phase

conductors or between a phase conductor and the neutral conductor or on

unshielded cables between the phase conductor and earth ground..

The SMART THUMP serves as surge pulse generator to continuously feed high

voltage pulses into the defective cable, producing voltage flash-overs (arcing) at

the fault position. The fault can either be pinpointed using a magnetic / acoustic

coincidence detector for best results or a simple acoustic detector with distinct

and well understood limitations. The criterion for pinpointing with a simple

acoustic detector is the greatest loudness of the flash-over noise at the fault

location, or, in the case of a magnetic / acoustic coincidence measurement, the

smallest propagation time difference between speed of light and speed of sound,

where it is not the loudest sound, but the first after receiving the magnetic signal.

The latter one is more accurate and can be used in all high resistance fault

situations (e.g. Megger Digiphone Plus) and even for locating faults in

conduit.

Proceed as follows to pinpoint the fault:

Step Description

1

2

3

4

Select the menu item from the main menu or from the submenu (depends on the

system configuration).

Adjust the surge voltage and select to confirm the value.

Press the green illuminated “HV ON” button .

Select to start the thumping mode (only if Measurement Start option is set to Manual.

See page 18.

Result: The capacitor is charged up and a discharge takes place after 5 se conds or, if the

charging takes longer, right after the selected surge voltage has been reached.

This process is then repeated until thumping is manually stopped.

If required, you can adjust the surge voltage by selecting the menu item.

5

6

AVTMST16 Rev 1 May 2016

Pinpoint the fault within the pre-located area with a surge wave receiver like the Megger

Digiphone Plus.

For detailed instructions, please refer to the user manual of the surge wave receiver.

Select to stop thumping.

31

Page 42

M

Detecting a Sheath Fault OR a Ground Fault in an

Unshielded, Low Voltage Cable (both must be directly

buried)

NOTE: The methods described to detect and pinpoint sheath faults in shielded

cables or ground faults in unshielded cables assumes that in both

situations the cables are direct buried; cables in conduit, especially PVC

conduit, will not respond to this method.

IMPORTANT

In contrast to the connection diagram on page 14 the HV Output lead has to be

connected to the cable shield (concentric neutral)

disconnected from the common bonding point on both ends

which in turn has to be

of the specific

cable to be tested. Consequently, the HV return lead has to be connected directly

to the system ground or a separately driven ground rod.

Fault locating on

unshielded, direct buried low voltage cables

must be

carried out in the sheath fault locating mode in order to ensure that the

maximum voltage is limited to 5kV; in this case the HV out put cable is

connected to the center conductor and the HV return to a driven ground rod.

The insulation of any high or medium voltage shielded power cable is protected

from water ingress by a jacket made from XLPE or PVC. The Sheath test

checks if the integrity of the jacket has been compromised, typically during

installation.

With a sheath test the dielectric strength of the cable jacket can be tested by

applying a DC voltage of up to 5 kV between the cable shield (concentric

neutral) and ground. Any leakage indicates a fault in the jacket.

Proceed as follows to perform a sheath test:

Step Description

1

Select the menu item from the submenu.

2

Confirm the following two notices with .

AVTMST16 Rev 1 May 2016

32

Page 43

Step Description

3

Adjust the test voltage and select to confirm the value.

4

Press the green illuminated “HV ON” button .

5

Select to start the test (only if Measurement Start option is set to Manual. See

“System Settings on page 17).

Result: The selected voltage is applied to the cable shield.

During the rise of the voltage the maximum current of the HVPS will be displayed till

the cable has been fully charged, at which time the current will drop down to the actual

leakage current level. The insulation resistance is displayed. This scenario is

observed if the cable has no insulation breakdown, otherwise the high voltage will be

shut off when the flashover / breakdown occurs.

Depending on whether a breakdown takes place during the test, one of the following

results is presented in the display:

How to Perform a Test

6

Breakdown

at … kV

No Flashover

Cable not

chargeable

Low

resistance

at … kV

Select to proceed with sheath fault pinpointing or to return to the main menu.

A voltage breakdown took place at the indicted test voltage.

The cable jacket has successfully withstood the applied DC test voltage.

You can repeat the test using the menu item.

The cable shield could not be charged with the test voltage. This may be

due to a short on the circuit (fault in the jacket).

The HV source failed to charge the cable shield beyond the indicated

voltage value due to the very high leakage current level.

AVTMST16 Rev 1 May 2016

33

Page 44

M

How to Pinpoint a Sheath Fault OR a Ground Fault in an

Unshielded Low Voltage Cable (both must be directly

buried)

Step Description

Following a failed sheath test (see page Error! Bookmark not defined.) fault

location of the sheath fault in

direct buried cables

based on the step voltage

method (earth gradient method) can be performed with the SMART THUMP

serving as HV pulse generator (limited to a voltage of 5 kV, see below) An

additional receiver is required to read the strength and polarity of the earth

gradient voltage (e.g. Megger ESG-NT) in order to pinpoint the sheath fault.

When approaching the fault position, the step voltage increases quickly and

decreases to a zero reading directly over the fault and then will swing to a strong

voltage of the opposite polarity.

Proceed as follows to pinpoint the sheath fault:

1

Select the menu item from the submenu.

2

Confirm the following two notices with .

3

Adjust the surge voltage and select to confirm the value.

Press the green illuminated “HV ON” button .

4

5

Select to start the sheath fault pinpointing mode. The Voltage Selection, Automatic

should be disabled (see page 18) allowing you to select a voltage between 2 and 10 kV.

If the Voltage Selection , Automatic is enabled, the maximum voltage is limited to 4 kV,

AVTMST16 Rev 1 May 2016

34

Page 45

Step Description

Result: The capacitor is charged up and a discharge takes place after 5 se conds

injecting a pulsed voltage signal into the cable.

This process is then repeated until the process is manually stopped.

If required, you can adjust the pulse voltage by selecting the menu item.

Pinpoint the sheath fault with an earth fault locator like the Megger ESG-NT.

6

For detailed instructions, please refer to the user manual of the earth fault locator.

7

Select to stop pulsing.

How to Perform a Test

AVTMST16 Rev 1 May 2016

35

Page 46

M

M

AVTMST16 Rev 1 May 2016

36

Page 47

6

CUSTOMIZE TDR FEATURES (applicable to TDR and

ARM Mode)

Introduction

As soon as a trace has been recorded and is shown on the display, the operator

can access the TDR Features in order to adjust the display and TDR settings in

order to optimize the trace.

Depending on the system configuration, the TDR Features may be divided into

simple options

options, easily available as icons, are placed along the bottom of the screen.

Extended options are available from a scroll down sub menu.

( menu item) and

extended options

( menu item). Simple

NOTE: The selection of available features depends on the system configuration

and the active user mode. All TDR features are configurable by the

customer to best fit his requirements in both Quick Steps mode and

Expert Mode.

In general, the majority of features listed will be made available when

working in

STEPS MODE

offered.

For detailed information on how to adjust the selection of available

features to the customer's needs (for both modes) see page 45).

EXPERT MODE

typically only a selection of the most basic features is

(see page 45); while in

QUICK

AVTMST16 Rev 1 May 2016

37

Page 48

M

Customized TDR Features

Menu item Description

The following table lists and describes all TDR features included in the system:

Adjust Gain

Change visible

range

Change value of

Cable Velocity

Adjusts the gain setting. By doing so, the amplification of the received signal

and, thus, the amplitude of the Y-axis can be adjusted.

With an adjustment of the gain setting, the fault trace, if present, is erased and

a new “live” trace is immediately recorded.

NOTE: The unit adjusts the gain automatically; however the

operator can set his own gain. Too much or too little gain

makes the interpretation of the trace impossible!

Changes the displayed range. By doing so, the trace can be zoomed in and

out.

Allows manual adjustment of the velocity of propagation. While changing the

velocity, the distance values (X-axis scaling) are immediately refreshed and

adapted.

This menu option is only effective, if the Rate parameter is set to Meter or

Feet. See page 18.

You may either manually adjust the value or automatically adopt the value by

identifying /selecting a cable from the cable list. See page 19.

Set / Move Cursor

Adjust the End

Marker

AVTMST16 Rev 1 May 2016

Changes the cursor position. By doing so, the distance value for any point on

the trace (typically to the fault) can be obtained.

You can also use the cursor to scroll along the X-axis in zoomed view.

At first, a coarse adjustment is made and confirmed by pressing the rotary

knob once - subsequently, the position can be fine-tuned.

Allows the manual adjustment of the blue end marker.

At first, a coarse adjustment is made and confirmed by pressing the rotary

knob once - subsequently, the position can be fine-tuned.

38

Page 49

Menu item Description

How to Perform a Test

Put Trace on Hold

Set Marker at

Current Cursor

Position

Save Current

Trace

Export, Recall or

Delete Stored

Traces

Makes an exact copy (blue trace) of the “live” trace.

NOTE: This function is very helpful when making a phase

comparison on a 3 phase circuit. It is also very helpful

when just using the TDR function on low voltage cables

with 2 or 3 phases and by comparing them. Typically

this will show the location of the fault in one of the

phases provided the fault is either an “OPEN” or a

“SHORT” or shows enough of an impedance change

compared to the impedance of the cable.

Places an additional marker (green) at the cursor position (red). As only one

additional marker can be placed, the very last marker is erased every

time the marker is placed on a new position.

Saves the current screen view to the internal memory.

Enables you to export, recall and delete stored data from internal memory.

By selecting All traces you can delete or export all traces which are currently

stored in the internal memory.

AVTMST16 Rev 1 May 2016

In case you want to select a specific trace, you need to select the recording

date first. You are then allowed to scroll through preview pictures of all traces

stored on this day.

After you selected the desired trace(s), you can choose from the following

options:

Export

Remove

Copies the selected trace(s) to the EtrayTraces folder on the

USB flash drive which has been plugged into the USB slot .

The data can be viewed in any regular web browser by opening

the index.html file which is also located in the EtrayTaces

folder.

Removes the selected trace(s) from internal memory.

39

Page 50

M

Menu item Description

Adjust Trigger

Delay Time

Adjust Pulse

Width

Recall

Allows manual adjustment of the trigger delay time (see page 18). It

synchronizes the HV pulse with the LV TDR pulse to a reflection measurement

at the highest or closest to highest current of the arc occurring at the fault

location.

With an adjustment of the trigger delay time, the fault trace, if present, is

erased and a new “live” trace is immediately recorded. Typical value for the

ST16 is 700μs.

Allows manual adjustment of the pulse width.

Pulse width is automatically selected as a function of cable length Narrow

pulses lead to short ranges but at very high resolution. Wide pulses which

provide lower resolution have to be used when measuring on long cables.

With an adjustment of the pulse width, the fault trace, if present, is erased and

a new “live” trace is immediately recorded.

Displays the selected trace on the screen. The screen view can

then be adjusted using any function which does not require the

trace to be updated.

By selecting , the loaded trace is closed and the last

recorded trace is displayed again.

Change

transformer

sensitivity

Find Transformers

in Actually Trace

Disable live

trace/

Enable live

trace

Only applicable in combination with the sectionalizing software. Allows manual

adjustment of the transformer search sensitivity. Decreasing or increasing the

sensitivity has an effect on the number of transformers identified by the

software, but will not change the position of the transformers relative to

each other and the 2 cable ends.

Note: The sectionalizing method is typically only used in

North American URD loop type circuits!

Allows manual start of the transformer search.

Disables / enables continuous “live” trace recording.

For most operators it is beneficial to “disable live trace”, which means the

trace is always live and any adjustment becomes immediately visible.

AVTMST16 Rev 1 May 2016

40

Page 51

Completing the Operation

After the fault location procedure has been finished switch off the system by

pressing the “ON / OFF” button .

The test object is to be grounded and shorted. Afterwards, the unit can be

disconnected from the test object in accordance with the safety instructions

below:

Follow the five safety rules described on page 3.

How to Perform a Test

WARNING

F

Even if proper disconnection and discharging has taken