Page 1

0 PN: 81127

Rev 4, 6/2017

User Manual

STVI

Smart Touch View Interface

SPI225

Smart Primary Injection Test System

Page 2

1 PN: 81127

Rev 4, 6/2017

Revision History

Revision

ECN #

Date

1

32660

11/26/2014

2

32893

9/27/2015

3

32994

2/19/2016

4

33376

6/26/2017

Page 3

2 PN: 81127

Rev 4, 6/2017

License Notice

This manual, as well as the hardware and software described in it, is furnished under license and may be

used or copied only in accordance with the terms of such license. The content of this manual is furnished

for informational use only, is subject to change without notice. Megger assumes no responsibility or

liability for any errors or inaccuracies that may appear in this manual.

The information and data in this User Manual are proprietary. The equipment described herein may be

protected by U.S. patents. Megger specifically reserves all rights to such proprietary information as well

as rights under any patent, none of which is waived by the submission of this user manual.

Except as permitted by such license, no part of this publication may be reproduced, stored in a retrieval

system, or transmitted, in any form or by any means, electronic, mechanical, recording, or otherwise,

without the prior written permission of Megger.

Megger, the Megger logo are trademarks of Megger. All other trademarks are the property of their

respective owners.

Notice to U.S. government end users. The hardware, software and documentation are “commercial

items”, as that term is defined at 48 C.F.R. §2.101, consisting of “commercial computer software” and

“commercial computer software documentation,” as such terms are used in 48 C.F.R. §12.212 or 48

C.F.R. §227.7202, as applicable. Consistent with 48 C.F.R. §12.212 or 48 C.F.R. §§227.7202-1 through

227.7202-4, as applicable, the commercial computer software and commercial computer software

documentation are being licensed to U.S. government end users (1) only as commercial items and (2)

with only those rights as are granted to all other end users pursuant to the terms and conditions set forth

in the Megger standard commercial agreement for this software and hardware. Unpublished rights

reserved under the copyright laws of the United States. The recipient, if a Government agency,

acknowledges that this manual and the equipment described were procured with "Limited Rights" to

technical data as described in ASPR 9-203 (b).

The STVI includes an RTOS-resident computer program. This program belongs to Megger and contains

trade secret ideas and information of Megger.

WEEE

Waste Electrical and Electronic Equipment - The crossed out wheeled waste bin placed on

Megger products is a reminder not to dispose of the product at the end of its life with general

waste. Please utilize your local WEEE collection facilities, or observe all applicable local

requirements.

Megger is registered in the UK as a Producer of Electrical and Electronic Equipment. The Registration No

is WEE/DJ2235XR.

Written and designed at Megger, 4271 Bronze Way, Dallas, Texas 75237.

__________________________

Printed in the USA.

2017 Megger, all rights reserved.

Page 4

3 PN: 81127

Rev 4, 6/2017

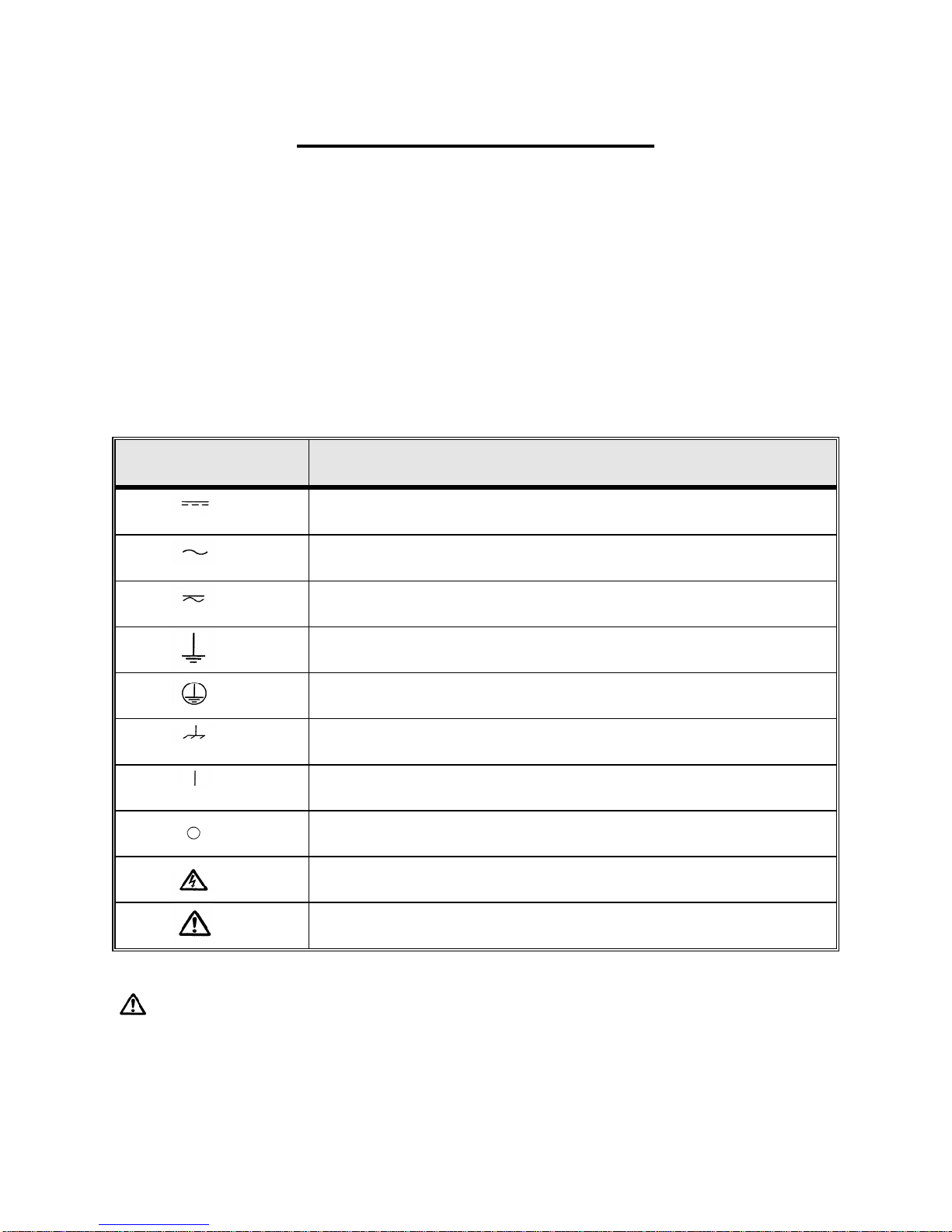

SAFETY PRECAUTIONS

WARNING:

VOLTAGES GENERATED BY THIS INSTRUMENT CAN BE

HAZARDOUS

This instrument has been designed for operator safety; however, no design can completely protect

against incorrect use. Electrical circuits are dangerous and can be lethal when lack of caution and

poor safety practices are used. There are several standard safety precautions that should be

taken by the operator. Where applicable, IEC safety markings have been placed on the

instrument to notify the operator to refer to the user manual for instructions on correct use or

safety related topics. Refer to the following table of symbols and definitions.

Symbol

Description

Direct Current

Alternating Current

Both direct and alternating current

Earth (ground) Terminal. There is a common chassis ground terminal

located on the front panel (see Front panel under Description of Controls).

Protective Conductor Terminal

Frame or Chassis Terminal

On (Supply)

Off (Supply)

Caution, risk of electric shock

Caution (refer to accompanying documents)

WARNING: Under no circumstances should the operator or technician attempt to open or

service any Megger instrument while connected to a power source. Lethal voltages are present

and may cause serious injury or death!

Page 5

4 PN: 81127

Rev 4, 6/2017

SAFETY PRECAUTIONS (Continued)

The following are specific safety related items associated with the test system.

Read and understand all safety precautions and operation instructions before attempting

to use this unit.

The purpose of this equipment is limited to use as described in this instruction manual.

Should a situation arise that is not covered in the general or specific safety precaution

please contact Megger regional representative or Megger, Dallas, Texas.

Safety is the responsibility of the user. Misuse of this equipment can be extremely

dangerous.

Always start with the power OFF, before connecting the power cord. Make

sure outputs are off before attempting to make test connections.

Never connect the test set to energized equipment.

Always use properly insulated test leads. The optional test leads are rated for

the continuous output ratings of the test system, and should be properly used

and cared for. DO NOT use cracked or broken test leads.

Always turn the test system off before disconnecting the power cord.

DO NOT attempt to use the unit without a safety ground connected.

DO NOT attempt to use the unit if the power cord ground prong is broken or

missing.

DO NOT use the test set in an explosive or flammable atmosphere.

DO NOT use the test set in a wet environment.

The instrument must only be used by suitably trained and competent persons.

Observe all safety warnings marked on the equipment.

Safety related or other important topics, like the statement below, will be

notated with the adjoined symbol. Read the topic carefully as it may relate

either to the safe operation of the test system or the safety of the operator.

The Model SPI is not designed for use on energized circuits. For the safety of the

operator and protection of the instrument, do not connect it to circuits that are

energized. This includes circuits that could become energized during the

course of a test procedure utilizing this instrument.

Page 6

5 PN: 81127

Rev 4, 6/2017

Table of Contents

Section Page

STVI .............................................................................................................................................................. 0

Smart Touch View Interface ....................................................................................................................... 0

SPI225 ........................................................................................................................................................... 0

Smart Primary Injection Test System ....................................................................................................... 0

Revision History .......................................................................................................................................... 1

Safety Precautions ...................................................................................................................................... 3

1.0 STVI Introduction ............................................................................................................................. 8

1.1 Smart Touch View Interface ............................................................................................................... 8

1.2 Terminology ...................................................................................................................................... 9

1.2.1 Glossary of Terms for Circuit Breaker Testing ............................................................................... 9

1.2.2.1 Pickup (Tap / Sensitivity Rating) ................................................................................................. 9

1.2.2.2 Time Delay .................................................................................................................................. 9

1.2.2.2.1 Long-Time Delay ......................................................................................................................... 9

1.2.2.2.2 Short-Time Delay ........................................................................................................................ 9

1.2.2.3 Instantaneous.............................................................................................................................. 9

1.2.2.4 Test Multiple .............................................................................................................................. 10

1.2.2.5 Frame Size ................................................................................................................................ 10

1.2.2.6 Continuous Current Rating ....................................................................................................... 10

1.2.2.7 Expected Trip Time ................................................................................................................... 10

1.2.2.8 Interrupting Rating .................................................................................................................... 10

1.3 Power Over Ethernet Input Power ................................................................................................ 10

2.0 SETUP ............................................................................................................................................. 10

2.1 Unpack System ................................................................................................................................ 10

2.1.1 Initial Start Up ............................................................................................................................... 10

2.2 Communication Ports .................................................................................................................... 10

2.2.1 Ethernet Port ................................................................................................................................. 11

2.2.2 USB 2.0 Interface ......................................................................................................................... 11

2.3 Smart Touch View Interface .......................................................................................................... 12

2.3.1 Configuration ................................................................................................................................ 14

2.3.1.1 Max Time .................................................................................................................................. 15

2.3.1.2 Max Current .............................................................................................................................. 15

2.3.1.3 Tap Verification Current ............................................................................................................ 15

2.3.1.4 Timer Stop Cfg .......................................................................................................................... 15

2.3.1.4.1 Current Actuate Mode ............................................................................................................... 16

2.3.1.4.2 Normally Closed Contact Opening............................................................................................ 16

2.3.1.4.3 Normally Open Contact Closing ................................................................................................ 16

2.3.1.4.4 Voltage Applied ......................................................................................................................... 16

2.3.1.4.5 Voltage Removed...................................................................................................................... 16

2.3.1.4.6 Post Deb (Debounce) ............................................................................................................... 16

2.3.1.4.7 Post Volt Thres. (Voltage Threshold) ........................................................................................ 16

2.3.1.5 Help Button ............................................................................................................................... 17

2.3.1.6 Default Settings Options ........................................................................................................... 17

2.3.1.6.1 Save as Default ......................................................................................................................... 17

2.3.1.6.2 Restore Default ......................................................................................................................... 17

2.3.1.6.3 Restore Factory......................................................................................................................... 17

2.3.1.7 Versions (Information Screen) .................................................................................................. 17

2.3.1.8 Update Firmware....................................................................................................................... 17

2.3.1.9 Current Status ........................................................................................................................... 17

2.3.1.10 Time Unit ................................................................................................................................... 17

2.3.1.11 Bluetooth Pwd ........................................................................................................................... 18

2.3.1.12 Line Freq ................................................................................................................................... 18

Page 7

6 PN: 81127

Rev 4, 6/2017

2.3.1.13 Ld (Load) Connection ............................................................................................................... 18

2.3.1.14 Color Options ............................................................................................................................ 18

2.3.1.15 Pickup Ramp Rate .................................................................................................................... 18

2.3.1.16 Pulse On Duration ..................................................................................................................... 18

2.3.1.17 Pulse Off Duration ..................................................................................................................... 18

2.3.1.18 Ethernet (DHCP) IP Address .................................................................................................... 18

2.3.1.19 Set Date and Time .................................................................................................................... 19

2.3.1.20 Number Format ......................................................................................................................... 19

2.3.1.21 Adjust Screen Brightness .......................................................................................................... 19

2.3.1.22 Logging ..................................................................................................................................... 19

2.3.1.23 Screen Exit ................................................................................................................................ 19

2.4 Setting Output Currents ................................................................................................................ 20

2.4.1 Numeric Keypad Entry .................................................................................................................. 20

2.4.2 Manual Ramping ........................................................................................................................... 20

2.4.3 Control Knob ................................................................................................................................. 21

2.4.4 Virtual Alphanumeric Keypad ....................................................................................................... 21

2.5 STVI - File Management ................................................................................................................. 22

3.0 STVI – Basic Operating Descriptions ........................................................................................... 24

3.1 STVI / PC Manual Test Screen ...................................................................................................... 24

3.1.1 Home button ................................................................................................................................. 24

3.1.2 Configuration button ..................................................................................................................... 24

3.1.3 Add To Report button ................................................................................................................... 25

3.1.4 Clear Results button ..................................................................................................................... 25

3.1.5 Nameplate Data button ................................................................................................................. 25

3.1.6 System Reset button .................................................................................................................... 25

3.1.7 System Reset button .................................................................................................................... 25

3.1.8 System Reset button .................................................................................................................... 25

3.1.9 System Reset button .................................................................................................................... 25

3.1.10 Requested Current (A) Amplitude Button ..................................................................................... 25

3.1.11 Mode button .................................................................................................................................. 25

3.1.11.1 Momentary Mode ...................................................................................................................... 26

3.1.11.2 Continuous Mode ...................................................................................................................... 26

3.1.12 Mode button .................................................................................................................................. 26

3.1.13 Play button .................................................................................................................................... 26

3.1.14 Timer Display Window .............................................................................................................. 28

3.1.15 Output Current Amplitude Window ........................................................................................... 28

3.2 Selection of SPI225 Output Terminals ......................................................................................... 28

3.2.1 Selection of Output Leads ............................................................................................................ 28

3.3 SPI225 Output Current and Overload Capability ........................................................................ 30

3.3.1 Parallel Operation ......................................................................................................................... 31

3.3.1.1 Two SPI Units in Parallel .......................................................................................................... 31

3.3.1.2 Three or Four SPI Units in Parallel ........................................................................................... 32

3.3.2 Series Operation ........................................................................................................................... 33

3.4 Manual Test ..................................................................................................................................... 35

3.4.1 Timing Test ................................................................................................................................... 35

3.4.2 Testing Instantaneous Pickup ...................................................................................................... 37

3.5 Advanced Pickup and Timing Test ............................................................................................... 39

3.5.1 Advanced Timing Test Setup ....................................................................................................... 39

3.5.1.1 Breaker Manufacturer and Curve Selection .............................................................................. 40

3.5.2 Advanced Pickup and Timing Test Screen .................................................................................. 41

3.5.2.1 PC or STVI to SPI connection button ....................................................................................... 41

3.5.2.2 Configuration button .................................................................................................................. 41

3.5.2.3 View Report button ................................................................................................................... 41

3.5.2.4 Clear Results button ................................................................................................................. 42

3.5.2.5 Nameplate Data button ............................................................................................................. 42

3.5.2.6 Home button .............................................................................................................................. 42

Page 8

7 PN: 81127

Rev 4, 6/2017

3.5.2.7 System Reset button ................................................................................................................. 42

3.5.2.8 File Folder button ...................................................................................................................... 42

3.5.2.9 Long Time Delay Test Selection button .................................................................................... 42

3.5.2.10 Short Time Delay Test Selection button ................................................................................... 42

3.5.2.11 Instantaneous Test Selection button ........................................................................................ 42

3.5.2.12 Ground Trip Test Selection button ............................................................................................ 42

3.5.2.13 Time Curve Test Display ........................................................................................................... 42

3.5.2.14 Select Breaker Curve button ..................................................................................................... 43

3.5.2.15 Frame Size, Sensitivity Rating, Band and Pickup windows ...................................................... 43

3.5.2.16 Pickup and Timing Test Selection windows .............................................................................. 43

3.5.2.16.1 Automated Pickup Tests ....................................................................................................... 43

3.5.2.16.2 Automated Timing Tests ....................................................................................................... 43

3.5.2.17 Help button ................................................................................................................................ 43

3.5.3 Advanced Automated (Manufacturer Specific) Timing Test ......................................................... 44

3.5.4 Advanced Manual (Generic) Timing Test ..................................................................................... 46

4.0 Warranty Statement ....................................................................................................................... 48

5.0 Service Data .................................................................................................................................... 48

5.1 Preventive Maintenance ................................................................................................................ 48

5.1.1 Examine the Unit .......................................................................................................................... 48

5.1.2 Upgrading STVI Software ............................................................................................................. 48

5.2 Updating SPI225 Firmware ............................................................................................................ 49

5.3 Service and Repair Instructions ................................................................................................... 50

5.3.1 Basic Troubleshooting .................................................................................................................. 50

5.3.1.1 Power Input ............................................................................................................................... 50

5.3.1.2 Ethernet Cable .......................................................................................................................... 51

6.0 Preparation for Reshipment .......................................................................................................... 51

Page 9

8 PN: 81127

Rev 4, 6/2017

1.0 STVI Introduction

The STVI is a user friendly interface to control the Megger SPI test equipment. This manual contains the

information that you will need in order to set up and use your STVI with the SPI Device. How the unit

operates, some of the different types of testing you can do, and how to save and view your test results

with the Smart Touch View Interface software is described. It also covers running the STVI software

using the PowerDB software on your PC.

1.1 Smart Touch View Interface

Figure 1 - Smart Touch View Interface

1. TFT LCD Color Display – this 8.5 inch touch panel display provides high resolution, and features

Wide Viewing Angle Technology with high luminance for reading in direct sunlight.

2. Control Knob – this knob will adjust values once the box location of the value to be changed is

selected.

Figure 2 - STVI Rear-View

3. Built-in Foldout Stand – the STVI may be operated as a handheld controller, or foldout the

built-in stand and use a desktop controller.

4. STVI Ethernet Port – this Ethernet port is a 10/100BaseTX PoE (Power over Ethernet) port, and

is the SPI connection port.

Page 10

9 PN: 81127

Rev 4, 6/2017

5. USB Interface – the USB port is used to update the firmware in the SPI as well as update the

software in the STVI using a USB memory stick. It may also be used to download test results

from the STVI for download into another PC with Power DB software for storage or printing. For

control of the SPI, an Ethernet cable is provided. The STVI gets its power over the Ethernet

cable. Even though the STVI has a built-in virtual keyboard, the user can use a USB keyboard

with the STVI, as well as a mouse (including Logitech wireless mouse). The keyboard and/or

mouse are not provided with the accessories.

1.2 Terminology

The acronyms, terms, and definitions used throughout this manual are described below:

1.2.1 Glossary of Terms for Circuit Breaker Testing

The STVI display screens prompt the user to select, or set, various values. The values vary depending

on the protective device under test. Many of the terms used are similar in nature and mean virtually the

same thing regardless of the type of breaker. For example, the term Time Dial is commonly used to

define the time dial setting on the device under test. Unfortunately, some of the terms described here

may apply to different types of devices under test in different ways, and thus may not cover every

possible device made. However, it is hoped that this glossary will help the user to understand every

setting value on every device under test.

1.2.2.1 Pickup (Tap / Sensitivity Rating)

A numerical value associated with a tap or sensitivity rating setting on the device under test. It is used to

define a setting value, pick up value, or minimum operating point, of the device under test.

1.2.2.2 Time Delay

It is a numerical value of time, normally associated with the minimum operating time of the device under

test. Low Voltage Power Circuit Breakers are available with three types of tripping characteristics: LongTime, Short-Time, and Instantaneous.

1.2.2.2.1 Long-Time Delay

The long time delay characteristic is normally associated with direct acting low voltage power circuit

breakers providing overload protection with typical time delays of approximately 10 - 60 seconds at 300%

of pickup.

1.2.2.2.2 Short-Time Delay

The short time delay characteristic is normally associated with direct acting low voltage power circuit

breakers providing protection for short circuit or fault conditions. It is used whenever a small delay is

necessary for coordination or selectivity with other protective devices. Typical delays of this type

characteristic are approximately 6-30 cycles.

1.2.2.3 Instantaneous

A numerical value associated with a tap setting of the instantaneous element of the device under test. It

is used to define a pick up value, or minimum operating point, of the instantaneous element of the device

under test. The instantaneous trip characteristic is used for short circuit or fault protection and has no

intentional time delay.

Page 11

10 PN: 81127

Rev 4, 6/2017

1.2.2.4 Test Multiple

A numerical value normally associated with timing tests. Multiples are normally expressed in terms of

whole numbers like 2, 3, 4, etc., times the Pickup or Tap value of the device under test. Fractions of test

multiples may also be entered and the appropriate test values and theoretical trip times will be calculated

automatically.

1.2.2.5 Frame Size

The frame rating is the maximum continuous current rating in amperes of all parts except the overcurrent

device. All current-carrying parts, contacts, and pivot points are designed to carry current up to the frame

size rating without exceeding heating limits.

1.2.2.6 Continuous Current Rating

The continuous current rating is a current value equal to or less than the frame rating. This value of

current is printed or stamped on the overcurrent device. It is possible to have a 600-ampere frame rating,

with a continuous current rating of only 100 amperes (due to the size of the overcurrent trip device).

1.2.2.7 Expected Trip Time

A numerical value representing the expected operating time of the device under test.

1.2.2.8 Interrupting Rating

A numerical value associated with the highest current at rated voltage that the device can interrupt

without external damage.

1.3 Power Over Ethernet Input Power

The STVI gets Power Over Ethernet (PoE) of 48 Volts DC at 0.5 A from the SPI STVI port.

2.0 SETUP

2.1 Unpack System

Unpack the unit and check for evidence of any shipping damage. If there is any visual damage,

immediately notify the freight carrier to make a damage claim, and notify Megger of the damage.

2.1.1 Initial Start Up

1. With the Ethernet cable supplied with the unit, connect the STVI Ethernet Port on the SPI unit to

the Ethernet port on the top of the Smart Touch View Interface (STVI).

2. Before connecting power to the unit, make sure the SPI POWER ON/OFF Switch is in the OFF

position (0). Plug the unit line cord into an appropriate power source and turn the POWER

ON/OFF Switch to ON (1). As the SPI unit goes through its power up sequence, in about a

minute the STVI power up screen will appear, then the manual start up screen will appear.

2.2 Communication Ports

There are two types of communication ports on the STVI, one Ethernet, and two USB ports. On the SPI

unit there is a USB port and three Ethernet ports.

Page 12

11 PN: 81127

Rev 4, 6/2017

2.2.1 Ethernet Port

There is one Ethernet port on the STVI for connecting to the SPI unit. Connect the STVI to the SPI unit

using the port labeled STVI (as shown in Figure 3).

Figure 3 - STVI port on the SPI

2.2.2 USB 2.0 Interface

There are two USB 2.0 Interface ports on the STVI unit (see Figure 2). These ports are used for

upgrading firmware in the unit, or upgrading the STVI software using a USB Memory Stick. They may

also be used in conjunction with a USB mouse for ease of manual control, even a USB wireless mouse

may be used with the STVI.

The Ethernet Port labeled “IN” is a 10/100BaseTX port, and is the primary PC connection port. This port

supports MDI/MDI-X auto crossover configuration, which means both standard and “crossover” Ethernet

cables may be used. Note that only one of the Ethernet ports may be used at a time (the intended use is

for control by the STVI or the PC).

Page 13

12 PN: 81127

Rev 4, 6/2017

2.3 Smart Touch View Interface

The STVI is the manual control and user interface for the unit. All manual entries will be made through

the STVI unless the unit is connected to a personal computer. During the power up sequence the test

system automatically does a self-test to insure everything is operating properly. Once the system has

completed it’s self-checks the Introduction Screen will appear as shown in Figure 4. If the software

detects a SPI it will be automatically connected and the main SPI Startup Screen (Figure 8) will be

displayed.

Figure 4 - Introduction Screen

When using the PC version of the STVI software, the Instrument Selection Screen will be displayed.

Note that the software is used to communicate with numerous instruments. The SPI icon should be

located under the heading of Breaker Test Sets. Click on the SPI button in the Instrument Selection

Screen to connect to a SPI.

Figure 5 - Instrument Selection Screen

Page 14

13 PN: 81127

Rev 4, 6/2017

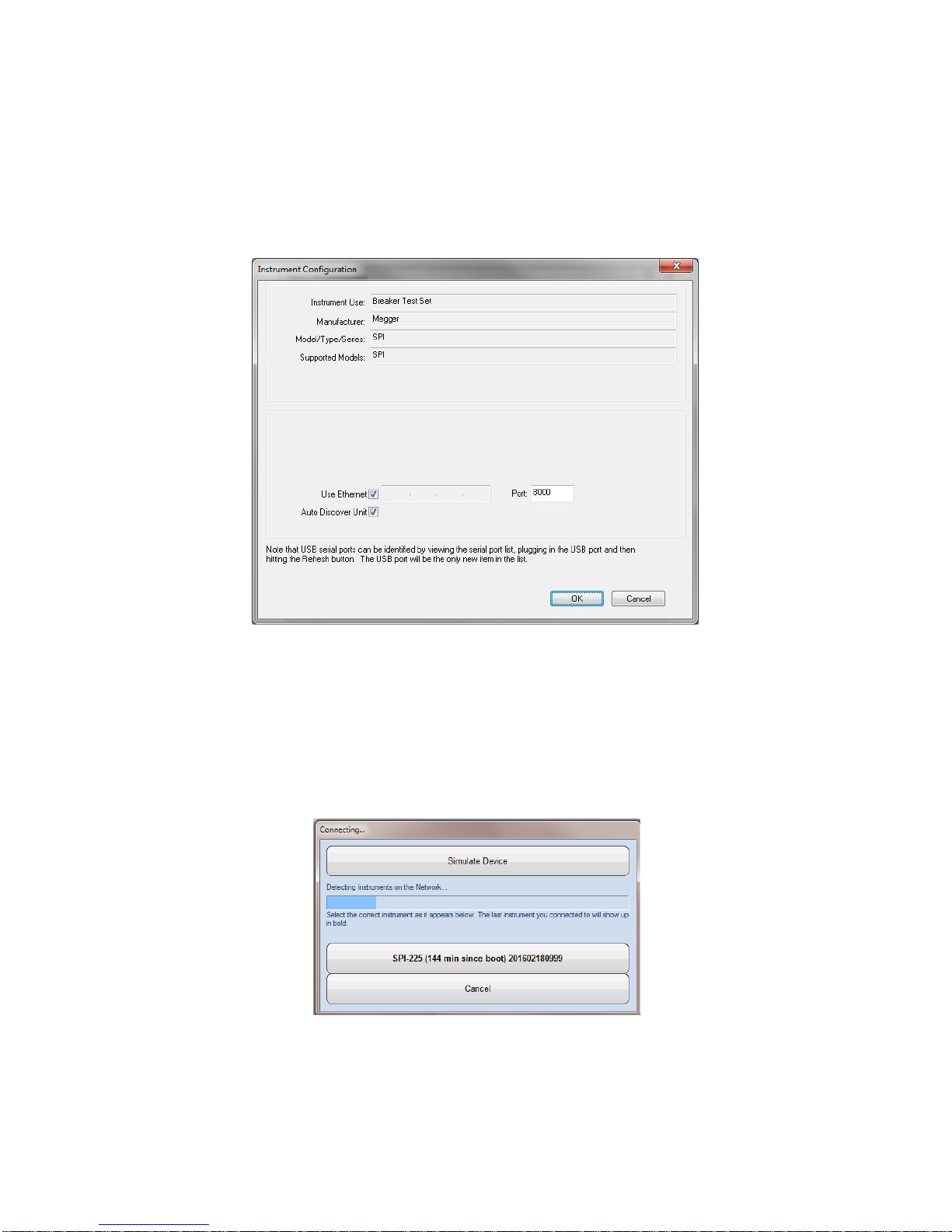

The PC version will then display the Instrument Configuration screen as shown in Figure 6. Click the OK

button and the software will attempt to auto detect an instrument and connect. If no instrument is

detected due to firewall, VPN settings or an incorrect IP address the user will need to take appropriate

corrective action. In this case the firewall can be turned off or you can enter the IP address directly using

the Instrument Configuration screen. The user can un-check the Auto Discover Unit box and enter the IP

address directly in the field provided. The Auto Config IP address of the SPI unit can be found on the

nameplate of the test set.

Figure 6 - Instrument Configuration Screen

If the unit is on a network with a DHCP server, the user must use the Auto Discovery mode. Note that the

SPI Port selection field should be set to port 8000.

If the software detects a unit, the user will be shown a connection dialog similar to Figure 7. The user can

then select the desired SPI unit for connection.

Figure 7 – Connection Dialog

Page 15

14 PN: 81127

Rev 4, 6/2017

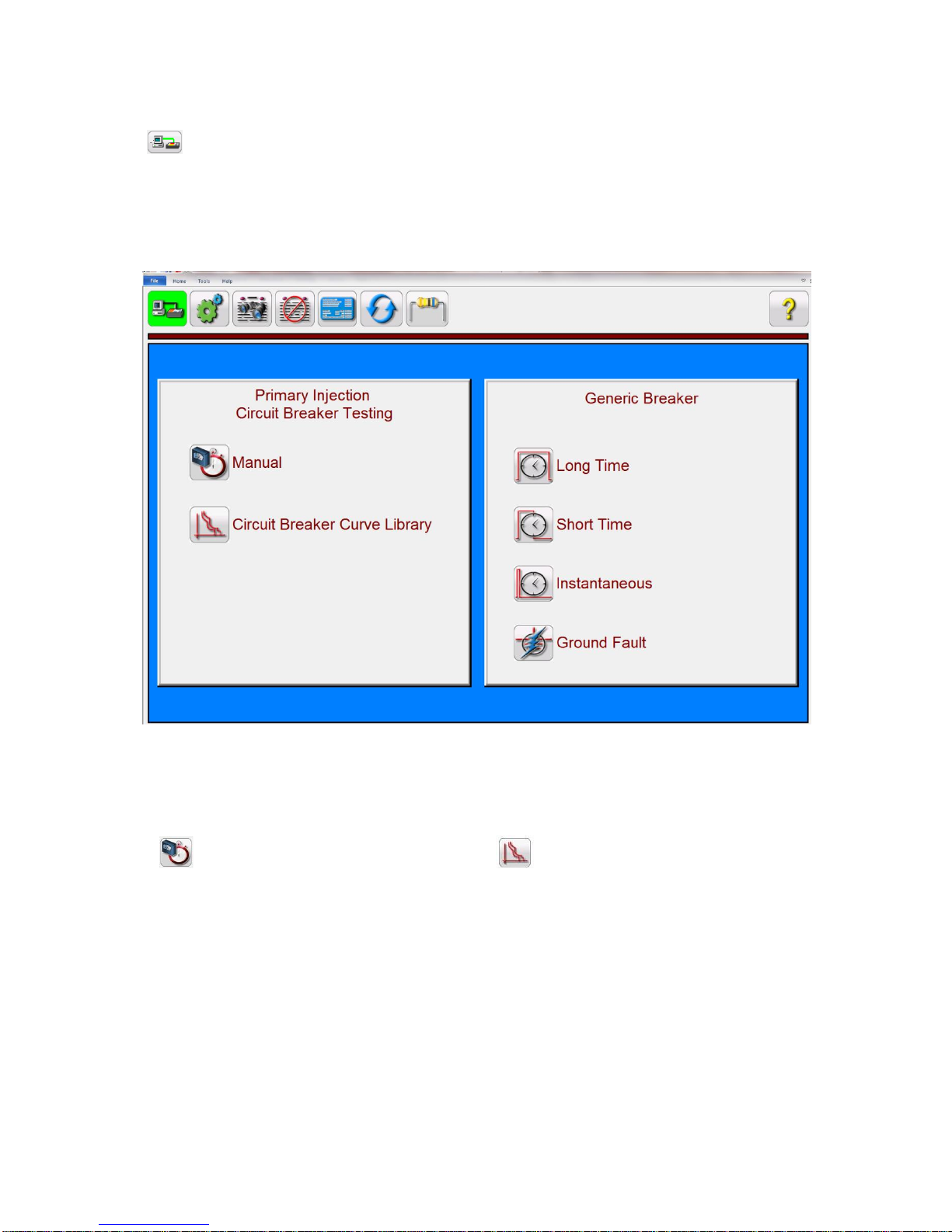

The PC version of the software will then display the main SPI Startup Screen. Note that the connection

icon in the upper left corner will have a green background indicating that the SPI unit is connected

and the IP address was automatically set through the Ethernet port. The auto-detect process does not

require the user to enter an IP address. Once the software detects and connects to a unit, the connection

icon background will turn green and the SPI Startup Screen will appear (as shown in Figure 8).

Figure 8 - SPI Startup Screen

The SPI Startup screen provides access to the Manual test screen by pressing the Manual test

button , or the Circuit Breaker Curve Library button . The Circuit Breaker Curve Library screen

provides automated timing tests of circuit breakers and overload devices using either Generic or

Manufacturer Specific time curves. The software has ANSI and IEC standard time curve algorithms builtin for molded case breakers. In addition, it includes time curves and time curve algorithms for different

specific molded case and air frame circuit breakers selectable by Manufacturer, Breaker Type, Curve

Family, Curve Model, Curve Trip Unit and Curve Name as applicable.

If this is the first time you have started up the SPI software it is recommended that you go to the

Configuration Screen first to setup the hardware, maximum durations, test currents, pulse times, and the

timer configuration.

2.3.1 Configuration

Page 16

15 PN: 81127

Rev 4, 6/2017

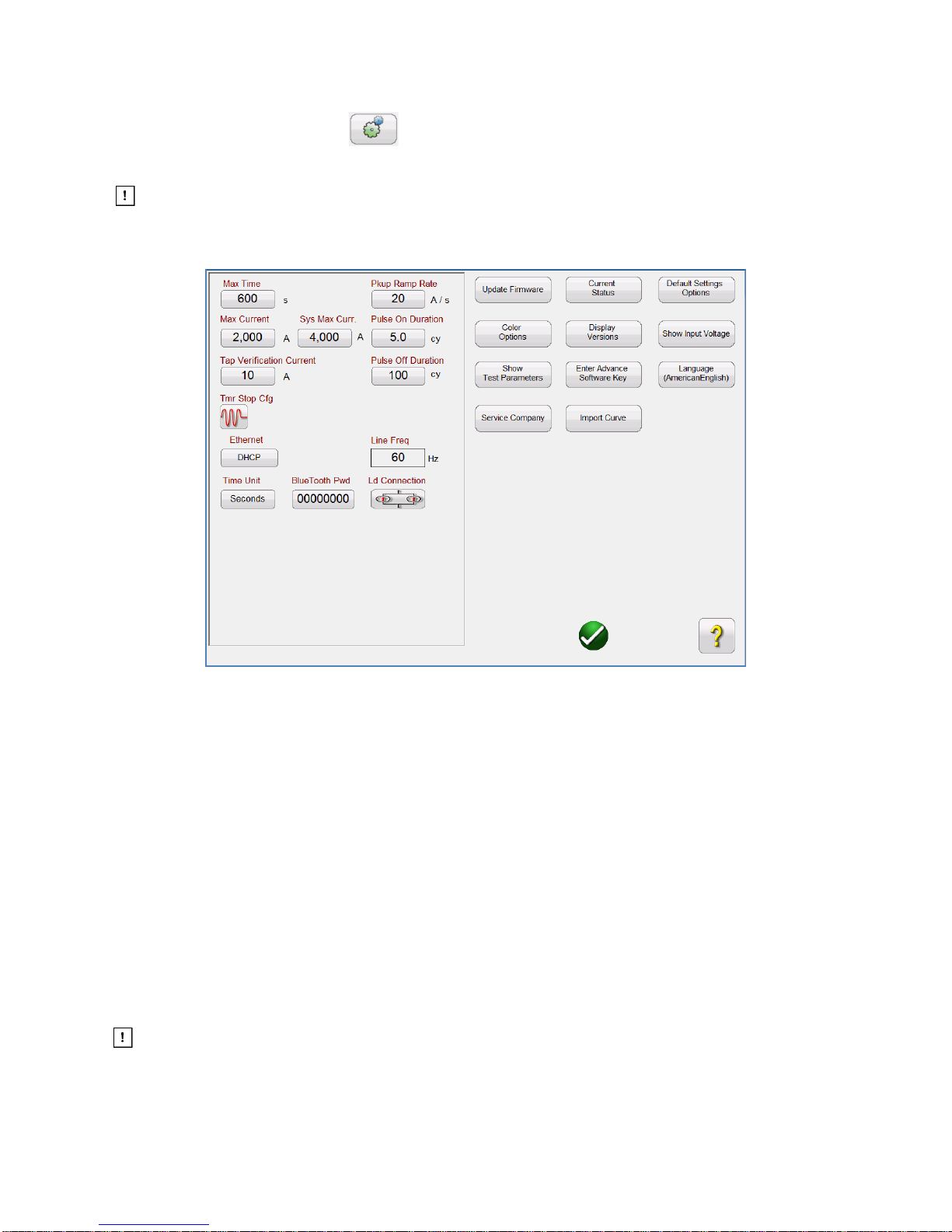

Pressing the Configuration button will allow the user to configure both the SPI hardware and SPI

software. Pressing this button will display the Configuration screen (see Figure 9).

Note: The following button descriptions vary depending on hardware configuration and the

version of the SPI software. The STVI version of the software includes extra buttons as indicated

with an * in the descriptions below.

Figure 9 – SPI Configuration Screen

2.3.1.1 Max Time

The user can set the Maximum Time in seconds that the SPI will stay ON during a test. The default value

is 600 seconds.

2.3.1.2 Max Current

The user can set the Maximum Current that the SPI will output on the selected Output Tap. The default

value is 2000 Amps.

2.3.1.3 Tap Verification Current

This is a time saving feature used to automatically determine the Output Tap selected by the user. The

user simply connects to the desired output tap, and then to the device under test. Prior to applying a test

current the unit will pulse the Tap Verification Current into the load. Based upon the current value read

back by the measuring circuit, and knowing the ratio of the output taps, the software will automatically

reconfigure for the selected output tap. The default is 10 Amps.

Make sure that the Tap Verification Current value is below any instantaneous setting or

ground trip device setting of the device under test.

2.3.1.4 Timer Stop Cfg

Page 17

16 PN: 81127

Rev 4, 6/2017

Controls the modes to stop the Timer and turn the output off. Pressing the button will present to the user

with three selections: Current Actuate, Dry Contacts Normally Open/Closed, and Voltage

Applied/Removed, see the following descriptions.

2.3.1.4.1 Current Actuate Mode

Current Actuate Mode: Timer will initiate only when the output circuit is completed, and a threshold

current of approximately 10% of the selected test current is exceeded. Timer will continue to run until

output circuit opens and the current drops below threshold level or output is de-energized by the user.

2.3.1.4.2 Normally Closed Contact Opening

With the BINARY INPUT terminals connected to normally closed external contacts, output circuit will

remain energized and timer will continue to run until contacts open.

2.3.1.4.3 Normally Open Contact Closing

With the BINARY INPUT terminals connected to normally open external contacts, output circuit will

remain energized and timer will continue to run until contacts close.

2.3.1.4.4 Voltage Applied

With the BINARY INPUT terminals connected to an external monitoring circuit, output circuit will

remain energized and timer will continue to run until an AC or DC Voltage is applied.

2.3.1.4.5 Voltage Removed

With the BINARY INPUT terminals connected to an external monitoring circuit, output circuit will

remain energized and timer will continue to run until an AC or DC Voltage is removed.

2.3.1.4.6 Post Deb (Debounce time)

This setting is associated with the BINARY INPUT Terminals, and Normally Open Contacts closing.

The Debounce time is set in milliseconds. The trip contacts must stay closed for the duration of the

Debounce time setting for the time test to be true. If the contacts open in less than the set Debounce

time the timer will continue to run. Once the input condition is true then the time test will conclude.

The trip time displayed will be the total test time less the debounce time.

2.3.1.4.7 Post Volt Thres. (Voltage Threshold)

This setting is associated with the BINARY INPUT Terminals and Voltage Applied test applications.

To serve a wide range of test applications the BINARY INPUT has a programmable voltage

threshold. For typical test applications the binary input has a defaulted threshold of 5 volts. A higher

threshold voltage helps to eliminate false triggers due to a noisy source. Lower thresholds allow

stopping of timer from TTL voltage signals. The allowable voltage applied is 1 to 300 Volts AC or DC,

programmable in 1 Volt increments.

Page 18

17 PN: 81127

Rev 4, 6/2017

2.3.1.5 Help Button

Press this button to access the built-in manual or for help associated with the Configuration Screen.

2.3.1.6 Default Settings Options

Press this button to get access to the settings options of Save as Default, Restore Default, and Restore

Factory default settings (see Figure 10).

Figure 10 - Default Settings Options

2.3.1.6.1 Save as Default

Press this button and all of the changes made to the Configuration Screen and most of the

default values for all screens are now saved as the power up defaults.

2.3.1.6.2 Restore Default

Pressing this button provides the ability to restore the original system power up defaults.

2.3.1.6.3 Restore Factory

Pressing this button provides the ability to restore the original system factory power up defaults.

2.3.1.7 Display Versions (Information Screen)

Pressing this button will display model, serial number, software and firmware versions, and build dates.

This information is useful when calling Megger for service or technical support related issues.

2.3.1.8 Update Firmware

This button is used to update the SPI firmware.

2.3.1.9 Current Status

Displays the SPI current status screen. This information is mainly for use by Megger support staff.

2.3.1.10 Time Unit

Page 19

18 PN: 81127

Rev 4, 6/2017

Set the time unit display to seconds or cycles.

2.3.1.11 Bluetooth Pwd

This button allows the user to set the SPI Bluetooth password.

2.3.1.12 Line Freq

This button displays the current Line Frequency.

2.3.1.13 Ld (Load) Connection

This button appears when the user selects one or more Slave units. This button provides for either

Parallel or Series connections of multiple SPI units. Press or click on the Ld

Connection button to toggle between Series or Parallel. In the parallel mode the SPI software will

automatically divide the requested test current by the number of units and output equally the same test

current from each unit in parallel so that the currents add across the load to equal the requested current

value. If two units are in series, it will set the requested test current from each unit so that the compliance

voltage from each unit will add together to push the current through the load.

2.3.1.14 Color Options

Press this button to adjust the colors of the vectors, backgrounds, lettering, etc.

2.3.1.15 Pickup Ramp Rate

Press this button to set the Current Ramp Rate in Amps/Sec to be used in the Pickup Test in the

Advanced Screen.

2.3.1.16 Pulse On Duration

Press this button to set the Pulse ON time in Cycles. Used when operating the test set in the Momentary

mode in the manual test screen, or when performing Instantaneous Pickup tests in the Automatic Mode.

2.3.1.17 Pulse Off Duration

Press this button to set the Pulse OFF time used in pulse ramping.

2.3.1.18 Ethernet (DHCP) IP Address

The STVI will auto-detect the SPI unit (the DHCP mode does not require the user to input an IP address).

If the unit is on a network with a DHCP server, the user must use the Auto Discovery mode. Using the

STVI, pressing the DHCP button will produce the Static IP Address Dialog box.

Figure 11 - Static IP Address Dialog Box

If using the PC version it too can auto-discover the SPI unit connected to the PC. On the PC version, the

PC might not auto detect due to firewall, VPN settings or anti-virus software. In this case the firewall can

be turned off, or you can enter the IP address directly using the PowerDB Instrument Configuration

Page 20

19 PN: 81127

Rev 4, 6/2017

screen by clicking the SPI icon on the Instrument Selection screen (Figure 12). Un-checking the Auto

Discover Unit box will enable the IP address entry box (shown highlighted in red in Figure 12).

The AutoConfig IP address of the SPI225 unit can be found on the nameplate of the unit.

Figure 12 - PowerDB Instrument Configuration Screen

2.3.1.19 Set Date and Time*

Press this button to set the Date and Time in the STVI. This information is critical for saving tests and test

results using the internal file manager. The PC version uses the PC time and date.

2.3.1.20 Number Format*

Press this button to set the decimal point number format either as a period or as a comma.

2.3.1.21 Adjust Screen Brightness*

The brightness is adjustable on the STVI. The display will always be visible since hardware limits the

brightness from becoming too bright or too dark to be seen. Press this button and use the Control Knob

to increase or decrease the brightness. For the PC version use the PC screen controls to adjust the

display.

2.3.1.22 Logging*

Select this button to set up the logging with the STVI. The log will store a record of the commands sent to

the SPI unit from the STVI (used when troubleshooting).

2.3.1.23 Screen Exit

Page 21

20 PN: 81127

Rev 4, 6/2017

To exit the screen and return to the previous screen press the green check button (you will see this

same button on other screens).

2.4 Setting Output Currents

Pressing the Requested Current button on the STVI hand held controller will display the following pop-up

numeric keypad to enter the required test current. If using the PC version, click in the Requested Current

window and use the PC keyboard numeric keys to enter the desired output current value.

2.4.1 Numeric Keypad Entry

The STVI numeric keypad entry provides an interface to the user when entering values using the STVI

touch screen. Touching a data entry window (Requested Current or Increment) on the STVI will activate

the Numeric Keypad. If using the PC version of the software, click in the window using the mouse. Use

the numeric keys to type in the value you want and press the button (press the Enter key on the PC).

Pressing the clear all will clear the value you just entered. Pressing the clear last digit button

will clear the least significant digit of the value in the display window.

Figure 13 - STVI Numeric Keypad

The button will enter the value and take you back to the test screen. Pressing Cancel will return

the user to the previous screen that is in use.

2.4.2 Manual Ramping

The output current can be ramped manually using either the Control Knob on the STVI or the up/down

arrow keys/mouse wheel on the PC version. The amplitude of each step is set using the Increment

Selection Screen (Figure 14) accessed by pressing the Increment button.

Page 22

21 PN: 81127

Rev 4, 6/2017

Figure 14 - Increment Selection Screen

Increment – Select the desired increment. The value selected will be shown on the Increment button.

The output current will increment in 1, 5, 10, 15, or 20 Amp increments. The Auto button is associated

with the control knob on the STVI, see Control Knob for more information.

In the Momentary Mode (see section 3.1.11.1) the output current will come on after pressing the blue Play

button, and will only stay on for the Pulse On Duration Time setting in the Configuration Screen (see

2.3.1.15). When rotating the Control Knob, or the up/down cursor arrows on the PC keyboard, the output

current will pulse on for the Duration Time with each increment, thus allowing an instantaneous pickup

test (Duration Time needs to be set longer than the expected instantaneous pickup time).

In the Continuous Mode (see section 3.1.11.2) the output can be ramped using the control knob or the

up/down cursor arrows on the PC keyboard, and the output current will stay on until the device trips or

until the user presses either the Simulate Contact button or the Red X button that appear

at the top of the test screen.

2.4.3 Control Knob

The control knob will change the value of the output current based upon the increment value setting, after

the blue Play button is pressed. Clockwise rotation increases and counterclockwise decreases. In the

Auto Increment Mode the control knob uses a speed control algorithm to provide fine adjustment, with a

slow rotation (one click equals the lowest increment level), and a larger step adjustment with a faster

rotation. The Control Knob can also be used to scroll up and down when viewing the test results in the

Add Results and View Results screens, or when viewing the Help screen.

2.4.4 Virtual Alphanumeric Keyboard

The virtual alphanumeric keyboard allows the entry of ASCII text into the appropriate STVI windows. This

keypad is used to enter information in the Nameplate Data screen or file names in the file management

screen.

Page 23

22 PN: 81127

Rev 4, 6/2017

Figure 15 - STVI Virtual Alphanumeric Keyboard

2.5 STVI - File Management

The file management display is used by the STVI hand held controller to access files stored in the STVI’s

internal memory. This display will allow test files to be loaded, make/change directories, rename

files/directories and delete files/directories that were created by the user. To access the File

Management system, touch the File Folder icon at the top of the test screen. This icon only appears

on the STVI (not on PC version). It provides the user the ability to save tests or open saved tests. If using

the PC version users will have the PowerDB file system to save test (job) files (see PowerDB Help).

Pressing the File Folder icon presents the user with the following tool bar (Figure 16). It defaults to the

Save Current Form icon highlighted.

Figure 16 - STVI File Folder Tool Bar

Note: Pressing the Power ON/OFF button will power down the STVI but is not required for a safe

shutdown.

Pressing on the highlighted folder will provide the user with the following file explorer screen.

Figure 17 - STVI File Folder Explorer

Page 24

23 PN: 81127

Rev 4, 6/2017

Press in the File Name field and the user will be provided with the virtual keyboard to enter a file name.

The file can then be saved to the internal memory or saved to a USB memory stick. This same window is

also used to open saved files. To save results directly to a USB memory stick check the Save to USB

box. To transfer test results from the STVI to a USB memory stick use the up down blue colored buttons

to selected the desired test result to be transferred and then press on the USB button. To retrieve a

test file from a USB memory stick press on the USB button to retrieve the selected file from the list of

files that appear in the right hand window. To delete a file use the up/down arrows to highlight the file and

then press the trash can icon. The left pointing blue arrow is the exit button to go back to the

test screen. To open an existing test file from the File Folder tool bar, press the Open File Folder icon

. The user will be presented with the File Folder Explorer. Use the up/down blue arrows buttons to

highlight the desired file to be opened, and then press the Open File Folder button in the lower left corner.

The user will be presented with a menu bar to open a New Test or to open the file selected showing the

date and time of the saved file. Pressing the date/time button will open the saved test. To view the saved

results press the More button in the upper right display next to the vector screen, then press the

View Report button.

Page 25

24 PN: 81127

Rev 4, 6/2017

3.0 STVI – Basic Operating Descriptions

This section describes basic operating procedures for using the STVI with the SPI for such applications

as basic pickup, basic timing test, paralleling current outputs from multiple SPI units.

3.1 STVI / PC Manual Test Screen

Pressing the Manual test button will present the user with the Manual Test screen.

Figure 18 - Manual Test Screen

Note: the Current and Time windows do not appear until the test is started by pushing the blue play

button.

3.1.1 Home button

The HOME button is used in several screens. Pressing the Home button takes the user back to the Start

Up Screen.

3.1.2 Configuration Button

Press the button to go to the STVI Configuration Screen. See Section 2.3.1 Configuration for more

information of the Configuration Screen.

Page 26

25 PN: 81127

Rev 4, 6/2017

3.1.3 Add To Report Button

Press this button to either View Report or Add to the Report. It also allows the user to enter limits,

comments or deficiencies. Reports can be saved to the STVI internal memory and transferred to

PowerDB via a USB memory stick. Previous tests results can be loaded and the ‘Retest’ option can be

used to repeat the test using the same parameters as the previous test.

3.1.4 Clear Results Button

Press or click on the Clear Results button to Clear Active (last test) or Clear All test results that have been

added to the report.

3.1.5 Nameplate Data Button

Press this button to go to the Nameplate Data entry screen. Here the user can input all the related data

associated with the device under test. This information will appear in the Test Result Header.

3.1.6 System Reset Button

The SPI unit is self protected against internal overcurrent in the amplifier, and thermal overloads. In the

event that the unit should alarm off due to one of these situations the system must be reset before testing

can continue. Press the System Reset button to reset the error sensing circuitry.

3.1.7 Insulation/Contact Resistance Button

Allows the user to enter insulation and contact resistance data for the device under test. This data is not

determined by the SPI test set.

3.1.8 File Folder

It provides the user the ability to save tests and test results, or open saved tests or test results (see

section 2.5). If using the PC version users will have the PowerDB file system to save test (job) files (see

PowerDB Help).

3.1.9 Help Button

Press this button to access the online manual or for help associated with the Configuration Screen.

3.1.10 Requested Current (A) Amplitude Button

Pressing or clicking this button will provide the user with the virtual numeric keypad (STVI), or use the

keyboard (PC version) to enter the desired test current.

3.1.11 11 Mode Button

Pressing or clicking on the Mode button will toggle between Continuous and Momentary Modes.

Page 27

26 PN: 81127

Rev 4, 6/2017

3.1.11.1 Momentary Mode

In the Momentary Mode the output current will come on after pressing the Blue Play button, and will only

stay on for the Pulse On Duration Time setting in the Configuration Screen, see 2.3.1.14. When rotating

the Control Knob, or the up/down cursor arrows on the PC keyboard, the output current will pulse on for

the Duration Time with each increment, thus allowing an instantaneous pickup test (Duration Time needs

to be set longer than the expected instantaneous pickup time).

3.1.11.2 Continuous Mode

In the Continuous Mode the output will stay on until the device trips, or until the user presses either the

Simulate Contact button or the Red X button that appear at the top of the test screen.

The output can be ramped using the control knob or the up/down cursor arrows on the PC keyboard.

3.1.12 12 Increment Window

Pressing or clicking this window will provide the user with the Increment selection screen to enter the

desired increment current level to be used when doing pickup tests (either manually or in the automatic

modes). See 2.4.2 for more information.

3.1.13 13 Play button

Pressing or clicking the blue play button will start the test. If in the Momentary Mode the following

parameters screen will be displayed for the user to enter the test values and setup the timer stop

configuration.

Figure 19 - Momentary Mode Pulse Test Parameters Screen

The Output Current previously set in the test screen will be displayed. The Max Time and Max Current

settings from the Configuration screen are displayed. Touch or click in the appropriate window to change

the defaulted values. Stop Post Configuration allows the user to set the desired mode to stop the timer

and turn the outputs off, see section 2.3.1.3. Press the Increment button to display the Increment values

selection window. Select the size of the desired increment Ramp Rate in Amps / Pulse. Press the green

Page 28

27 PN: 81127

Rev 4, 6/2017

check button to return to the test screen and start the test. Note that if there are two or more units

connected in parallel (see the Parallel | Series button in the test parameters screen) the Pretest current

will be equally divided between the multiple units. If in series the Pretest current will be equal to the

Pretest Current value setting.

Make sure that the Pretest Current value is below any instantaneous setting, or ground trip device

setting of the device under test.

In the manual test screen, in the Momentary Mode, each time the Control Knob (or the PC cursor arrows)

are moved the output will turn on for the Pulse On Time value entered, and will increment the value

entered in the Ramp Inc window (up or down). The test is automatically stopped when the Timer Stop

condition is true. To manually stop the test or turn the output off, press or click on the red button, or

press the Simulate Contact button.

If the Continuous Mode is selected the following parameters screen will be displayed (Figure 20).

Figure 20 - Continuous Mode Test Parameters Screen

In the Continuous Mode it will apply the test current set in the Requested Current Window, start the timer

running, and watch for the device under test to operate. If the device has not operated by the Max Time

setting, the test set will turn off indicating Maximum Time was reached. To manually increase / decrease

the output current press the Increment button and set the increment value. Once the test has started,

each time the PC up/down arrow keys are pressed, or the control knob on the STVI is rotated, the output

will increment up or down by the entered value. To manually stop the test or turn the output off, press or

click on the red button, or press the Simulate Contact button.

Page 29

28 PN: 81127

Rev 4, 6/2017

3.1.14 14 Timer Display Window

Displays operating time of the device under test. The Time window does not appear until the test is

started by pushing the blue play button.

3.1.15 15 Output Current Amplitude Window

Displays the test current being applied to the device under test. . The Current window does not appear

until the test is started by pushing the blue play button. Pressing or clicking on the eraser in the Current

window will clear the recorded test current and time like a reset button.

3.2 Selection of SPI225 Output Terminals

The Megger Model SPI225 primary injection test set has multiple output terminals to provide a wide range

of current-voltage capabilities. There are three output terminals to choose from: 25 Amp at 70 V, 125 Amp

at 14 V, and 500 Amp at 3.5 V. The terminal with the lowest current rating provides an output with the

highest voltage for testing devices of low current requirements but with higher impedance characteristics.

The highest current rated output terminal provides high current availability for testing devices of high current

requirements of relatively low impedance. Should the current required for the device to be tested exceed

the ability of the lowest tap or the impedance of the device to be tested require more voltage to "push" the

current than is available from the highest current tap, the medium range current tap can be utilized to

provide the current or voltage necessary to perform the desired test.

Should the test current requirement exceed the maximum output capability of the unit, multiple SPI units

can be operated in parallel to multiply the maximum output current, see section 3.3.1. If the load has

significant impedance two or more units (output tap dependent) may be operated in series to multiply the

maximum output voltage “pushing” the test current, see section 3.3.2.

Note that the SPI units are high current test sets and a good supply voltage is required for proper operations.

When possible, avoid the use of any type of power strips and small gauge extension cords. When extension

cords must be used, use only properly rated cords with sufficient current capability. Additionally, when

maximum current capability is required, remember that the SPI can be powered from a 240 AC supply.

This can help to obtain maximum current output from the test set.

3.2.1 Selection of Output Leads

The Megger SPI unit is equipped with output connecting bars and a 125 A output tap for attachment of the

provided high current test leads or other leads suitable for the test application.

The SPI unit comes with appropriate test leads and attachments rated for the output of the unit. There are

two sets of leads provided with the SPI unit. One set are heavy-duty high current leads (AWG 4/0 cables

with lead adapter) that connect to the 500 Amp output tap (Figure 21).

Page 30

29 PN: 81127

Rev 4, 6/2017

Figure 21 - High Current Test Lead

There is also a dedicated test lead (AWG #6 cable assembly with lead adapter) that connects to the 125

Amp output tap. It has a special twist lock connector that plugs into the 125 Amp output tap and works in

Figure 22 - 125 Amp Twist Lock Connector

conjunction with the 500 Amp (black) return cable. Both leads include unique screw connections to allow

different test connector adapters to be screwed into the end of the test lead. There are three round test

probes that vary in size from 0.3 to 0.125 inches in diameter that will fit most small molded case circuit

breakers. In addition, there are two different sized clamps that screw into the end of the test lead adapter

that allows the user to connect directly to the de-energized bus where the circuit breaker cannot be

removed (Figure 23).

Page 31

30 PN: 81127

Rev 4, 6/2017

Figure 23 - Test Lead Adapter with Screw-in Accessories

Due to the voltage drop from the inductive reactance of the test circuit, a significant loss of current will result

for each inch of test lead. Therefore, when choosing test leads (other than the leads provided) the length

and size of leads chosen will determine the maximum available test current. It is worthwhile to sacrifice

cross section of test leads for the sake of reducing length. Every inch of lead that can be eliminated provides

worthwhile increase in available test current. Heating is not a significant problem in testing, even though

the leads may become hot. Paralleling of sufficient cables provides higher test currents. Each cable can

be fitted with a compression lug on each end, and then bolted to the output terminals of the test set and the

device under test.

The two cables between the test set and the device under test can be twisted together or bundled with tape

or cord to maintain close proximity, which helps to minimize inductive reactance.

3.3 SPI225 Output Current and Overload Capability

The current rating of the output terminals may be exceeded for short durations provided the voltage rating

is sufficient to "push" the desired current through the device under test and the connecting test leads. The

overload capacity, represented by multiples of rated current, versus TIME ON and TIME OFF are given

below.

%Rated Maximum Minimum

Current Time ON1 Time OFF

100 (1x) 30 minutes 30 minutes

200 (2x) 3 minutes 8 minutes

300 (3x) 30 seconds 4 minutes

400 (4x) 7 seconds 2 minutes

1

Time On will vary depending on the ambient temperature. The SPI is protected against thermal

overload.

Page 32

31 PN: 81127

Rev 4, 6/2017

Where more current is required than one unit can provide, multiple units may be operated in parallel, see

section 3.3.1 for parallel operation. Where more compliance voltage is required due to load impedance

two units may be operated in series, see section 3.3.2.

3.3.1 Parallel Operation

Each SPI current output tap is capable of providing a full rated output; see the appropriate output terminal

ratings. For example - the SPI225 using the 500 Amp output tap can provide a maximum of 500 Amps

for 30 minutes on followed by 30 minutes off, and up to 2000 Amps for 7 seconds on followed by 2

minutes off. If more than 2000 amps is required, two or more units may be connected in parallel to

provide 1000 Amperes each for 30 minutes (with 2 each SPI225 units in parallel), or up to 8,000 amperes

for 7 seconds (4 each SPI225 units in parallel).

NOTES:

1. Parallel or series operation of SPI’s can only be performed using the 500 amp tap.

2. Each unit should be supplied power via separate circuits with a common phase angle (do NOT

use 180 degrees out of phase circuits or 120 degrees out of phase circuits from a 3-phase

source).

3. The output leads from paralleled SPI’s should run from each SPI directly to the input terminals of

the device under test (this provides for maximum current capability).

4. It is suggested that the output cables from each of the SPI’s outputs be twisted to help minimize

the inductive reactance and obtain maximum current (this is especially helpful with longer cables).

Note: When operating multiple SPI units in parallel or series they should not share the same power

circuit. Each unit should be powered from independent circuits of the same phase angle with appropriate

current ratings. Do NOT use out of phase circuits to power parallel/series connected SPI units.

3.3.1.1 Two SPI Units in Parallel

To assist in multiple unit operations the SPI units may be stacked on top of each other. Use the following

guidelines to parallel the 500 Amp current channels of two units:

1. Stack the Master SPI unit on top of the Slave SPI unit. Connect an Ethernet cable from the

Master Unit Ethernet port labeled OUT to the Slave unit Ethernet port labeled IN.

2. Connect the high current test cables to the 500 Amp Output Terminals of each SPI unit and then

directly to the device under test (paralleling the cables directly at the DUT input terminals). Using

cables from both SPI units to the device under test helps to provide the maximum current

capacity. It is not recommended to parallel the two SPI units directly at the output tap terminals

and use one set of leads to the device under test.

3. Connect the STVI (or PC) to the Master unit STVI port (or the IN port for the pc). When the

Select Number of Slave Units menu appears press or click on 1.

4. Power up the SPI units within 1 to 2 seconds of each other. The boot-up process will detect that

there are multiple SPI units in a Master/slave configuration.

5. When the Select a Tap window appears, select the 500 Amp tap. The test screen will now

appear.

6. Observe the Connection icon in the upper left hand corner of the screen. You will note the

number 1 appears in the Connections icon indicating that you now have control of the Master and

1 slave unit.

7. The STVI software, knowing there are two SPI units, will automatically divide the current equally

between the two current output terminals. When setting an output, simply enter the value of the

desired output current. For example, for an output of 2000 Amperes, enter 2000, and with 2 SPI

500 Amp output terminals in parallel each unit will be providing 1000 Amperes.

8. See Simple Manual Timing Test for step by step operation.

Page 33

32 PN: 81127

Rev 4, 6/2017

3.3.1.2 Three or Four SPI Units in Parallel

To parallel the current channels of three or four units, perform the following:

1. Stack the Master unit on top of the Slave units. Interconnect the two slave units together using

the top Slave unit Ethernet port labeled OUT, and connect to the bottom Slave unit Ethernet port

labeled IN (repeat if stacking 4 units). Connect the Master Unit Ethernet port labeled OUT to the

top Slave unit Ethernet port labeled IN.

2. To parallel three or four SPI units together on the 500 Amp output terminals you will need to use

multiple high current cables to connect the output terminals directly to the device under test. It is

recommended that separate test leads be run from each SPI unit directly to the device under test.

Figure 24 - Three SPI Units in Parallel

3. Connect the current outputs to the device under test using properly rated output test leads. If

using test leads other than those supplied by Megger insure that the cable has sufficient size to

carry the test current.

4. Power up all the SPI units within 1 to 2 seconds of each other. The boot-up process will detect

that there are multiple SPI units in a Master/slave configuration.

5. With the STVI (or PC) connected to the Master unit STVI port (or the IN port for a pc), when the

Select Number of Slave Unit menu appears press or click on the number of slave units in use.

6. When the Select a Tap window appears, press or click on 500 Amp tap. The test screen will now

appear.

7. Observe the Connection icon in the upper left hand corner of the screen. You will note that the

number of slave units appears in the Connections icon indicating that you now have control of the

Master and slave units.

8. The software will automatically divide the requested current equally between the connected SPI

units. When setting an output, simply enter the value of the desired output current. For example,

with a three unit stack for an output of 3000 Amperes, enter 3000, and with 3 SPI 500 Amp output

terminals in parallel each unit will be providing 1000 Amperes.

9. See Simple Manual Timing Test for step by step operation

Page 34

33 PN: 81127

Rev 4, 6/2017

3.3.2 Series Operation

Up to four SPI units (500 Amp tap) may be connected in series in order to increase the available

compliance voltage for high impedance test applications. The series connection should be used only

when the parallel connection does not have sufficient voltage to "push" the desired test current through

the test leads and the device under test. To series the current channels of two units, perform the

following:

1. Stack the Master SPI unit on top of the Slave SPI unit. Connect an Ethernet cable from the

Master Unit Ethernet port labeled OUT to the Slave unit Ethernet port labeled IN.

2. Use the short high-current cable to interconnect the COMMON of the top unit to the 500 A output

terminal of the lower unit together. Connect current output to the device under test as shown in

the following figure (Figure 25) using properly rated output test leads. If using test leads other

than those supplied by Megger insure that the wire has sufficient size to carry the test current.

3. Connect the STVI (or PC) to the Master unit STVI port (or the IN port for the pc). When the Select

Number of Slave Units menu appears press or click on 1.

4. Power up the SPI units within 1 to 2 seconds of each other. The boot-up process will detect that

there are multiple SPI units in a Master/slave configuration.

5. When the Select a Tap window appears, select the 500 Amp tap. The test screen will now

appear.

6. Observe the Connection icon in the upper left hand corner of the screen. You will note the

number 1 appears in the Connections icon indicating that you now have control of the Master and

1 slave unit.

7. For series operation, the user will need to access the Configuration Screen and use the

Ld Connection icon to select the Series operation icon (see section 2.3.1.12).

8. The STVI software, knowing there are two SPI units in series, will automatically supply the

requested current to both units. Simply enter the value of the desired output current.

9. See Simple Manual Timing Test for step by step operation.

Use the short high current lead to connect the COMMON of the top unit to the 500 A output terminal of

the lower unit together (see Figure 25). Connect the current output of the top (Master) unit to the device

under test and the return to the COMMON of the bottom (slave) unit using properly rated output test

leads. If using test leads other than those supplied by Megger insure that the cable is of a sufficient size

to carry the test current.

NOTES:

1. Up to four SPI units may be connected in series. Do not attempt to series connect more than four

SPI units.

2. Each unit should be supplied power via separate circuits with a common phase angle (do NOT

use 180 degrees out of phase circuits or 120 degrees out of phase circuits from a 3-phase

source).

3. Only the 500 Amp tap can be used for SPI units in a series connection.

Page 35

34 PN: 81127

Rev 4, 6/2017

Figure 25 - Series Connection of Two SPI Units

Page 36

35 PN: 81127

Rev 4, 6/2017

3.4 Manual Test

The manual test section is designed for general purpose high current test applications or primary current

tests such as motor overload relays, etc. It may also be used to test single pole molded case circuit

breakers by configuring the Timer Stop for Current Actuation, see section 2.3.1.4 (Timer Stop Cfg) for

more information.

Figure 26 - SPI Start Up Screen

3.4.1 Timing Test

1. Press the Manual Test button.

2. Select the appropriate output terminal (see section 3.2, Selection of Output Terminal) and connect

one end of a high-current lead to one side of the thermal element or current coil in the overload

relay or breaker. Connect the other test lead to the COMMON terminal of test set.

3. To monitor dry contacts, connect a pair of light leads (timer leads) from Normally Closed Contacts

or Normally Open Contacts of overload relay to the binding posts of the BINARY INPUT terminals

of the test set.

4. Enter the desired test current value in the Requested Current field (section 3.1 item 9) using the

numeric keypad or PC numeric keys.

5. Set the Mode to Continuous (section 3.1 item 10).

6. Press the Blue Play button, and the Continuous Test Parameters screen will be displayed.

7. In the Continuous Parameters screen, you can leave the Max Time and Max Current settings, or

change them to new values, see section 3.1 for more information. Select the desired Time Unit

(Seconds or Cycles). Set the Tap Verification Current to an appropriate value (see section