Page 1

Consultation with Megger

1

SFC250

SmartFuse 250

USER GUIDE

Issue: 6 (04/2018) - EN

Article number: 85431

Page 2

Consultation with Megger

2

Page 3

Consultation with Megger

3

Consultation with Megger

The present system manual has been designed as an operating guide and for

reference. It is meant to answer your questions and solve your problems in as fast and

easy a way as possible. Please start with referring to this manual should any trouble

occur.

In doing so, make use of the table of contents and read the relevant paragraph with

great attention. Furthermore, check all terminals and connections of the instruments

involved.

Should any question remain unanswered or should you need the help of an authorized

service station, please contact:

Megger Limited Seba Dynatronic

Mess- und Ortungstechnik GmbH

Archcliffe Road

Kent CT17 9EN

T: +44 1304 502100

F: +44 1304 207342

E: uksales@megger.com

Dr.-Herbert-Iann-Str. 6

D - 96148 Baunach

T: +49 9544 68 – 0

F: +49 9544 22 73

E: team.dach@megger.com

Hagenuk KMT

Kabelmesstechnik GmbH

Megger USA

Röderaue 41

D - 01471 Radeburg / Dresden

T: +49 35208 84 – 0

F: +49 35208 84 249

E: team.dach@megger.com

Valley Forge Corporate Centre

2621 Van Buren Avenue

Norristown, PA 19403 USA

T: +1 610 676 8500

F: +1 610 676 8610

Megger

All rights reserved. No part of this handbook may be copied by photographic or other means unless Megger

have before-hand declared their consent in writing. The content of this handbook is subject to change without

notice. Megger cannot be made liable for technical or printing errors or shortcomings of this handbook.

Megger also disclaims all responsibility for damage resulting directly or indirectly from the delivery, supply, or

use of this matter.

Page 4

Terms of Warranty

4

Terms of Warranty

Megger accept responsibility for a claim under warranty brought forward by a customer

for a product sold by Megger under the terms stated below.

Megger warrant that at the time of delivery Megger products are free from manufacturing

or material defects which might considerably reduce their value or usability. This

warranty does not apply to faults in the software supplied. During the period of warranty,

Megger agree to repair faulty parts or replace them with new parts or parts as new (with

the same usability and life as new parts) according to their choice.

This warranty does not cover wear parts, lamps, fuses, batteries and accumulators.

Megger reject all further claims under warranty, in particular those from consequential

damage. Each component and product replaced in accordance with this warranty

becomes the property of Megger.

All warranty claims versus Megger are hereby limited to a period of 12 months from the

date of delivery. Each component supplied by Megger within the context of warranty will

also be covered by this warranty for the remaining period of time but for 90 days at

least.

Each measure to remedy a claim under warranty shall exclusively be carried out by

Megger or an authorized service station.

This warranty does not apply to any fault or damage caused by exposing a product to

conditions not in accordance with this specification, by storing, transporting, or using it

improperly, or having it serviced or installed by a workshop not authorized by Megger.

All responsibility is disclaimed for damage due to wear, will of God, or connection to

foreign components.

For damage resulting from a violation of their duty to repair or re-supply items, Megger

can be made liable only in case of severe negligence or intention. Any liability for slight

negligence is disclaimed.

Since some states do not allow the exclusion or limitation of an implied warranty or of

consequential damage, the limitations of liability described above perhaps may not

apply to you.

Page 5

Contents

5

Contents

Consultation with Megger ............................................................................................... 3

Terms of Warranty ........................................................................................................... 4

Contents ........................................................................................................................... 5

1 General Notes ................................................................................................... 7

2 Technical description ...................................................................................... 9

2.1 Abbreviations ...................................................................................................... 9

2.2 System description ........................................................................................... 10

2.3 Technical data .................................................................................................. 12

2.4 Connections, controls and display ................................................................... 14

2.4.1 Information plate ............................................................................................... 18

3 User interface ................................................................................................. 19

3.1 Access to the user interface ............................................................................. 19

3.1.1 Local operation ................................................................................................. 19

3.1.2 Access through a web browser ........................................................................ 20

3.2 Elements of the main screen ............................................................................ 20

4 Start-up ............................................................................................................ 24

4.1 Preliminary configuration in the office .............................................................. 24

4.2 Installation on site ............................................................................................. 27

4.3 Completing configuration, power up and commissioning ................................. 33

5 Controlling and monitoring in running operation ....................................... 34

5.1 Performing switching operations with the remote control ................................ 34

5.2 Monitoring, analysis and fault location ............................................................. 37

5.2.1 Event and measurement data evaluation ......................................................... 37

5.2.2 Fault location in pulse mode (optional „fault location“ function required) ......... 42

6 Configuration .................................................................................................. 45

6.1 Defining basic settings ..................................................................................... 45

6.2 Pairing and enabling the remote control .......................................................... 47

6.3 Modifying the notification and network settings ............................................... 49

6.3.1 Modifying the notification settings .................................................................... 49

6.3.2 Modifying LAN and WLAN settings .................................................................. 50

6.3.3 Ensuring Internet accessibility .......................................................................... 51

6.3.4 Specifying the outgoing mail server ................................................................. 54

6.4 Configuring trigger events for connected measurement equipment ................ 54

6.5 Updating the firmware ...................................................................................... 55

Page 6

Contents

6

7 Deinstallation .................................................................................................. 57

8 Maintenance and care .................................................................................... 58

9 Troubleshooting ............................................................................................. 63

Page 7

General Notes

7

1 General Notes

This manual contains basic instructions for the commissioning and operation of the

device / system. For this reason, it is important to ensure that the manual is always

available to the authorised and trained operator. He needs to read the manual

thoroughly. The manufacturer is not liable for damage to material or humans due to nonobservance of the instructions and safety advices provided by this manual.

Locally applying regulations have to be observed!

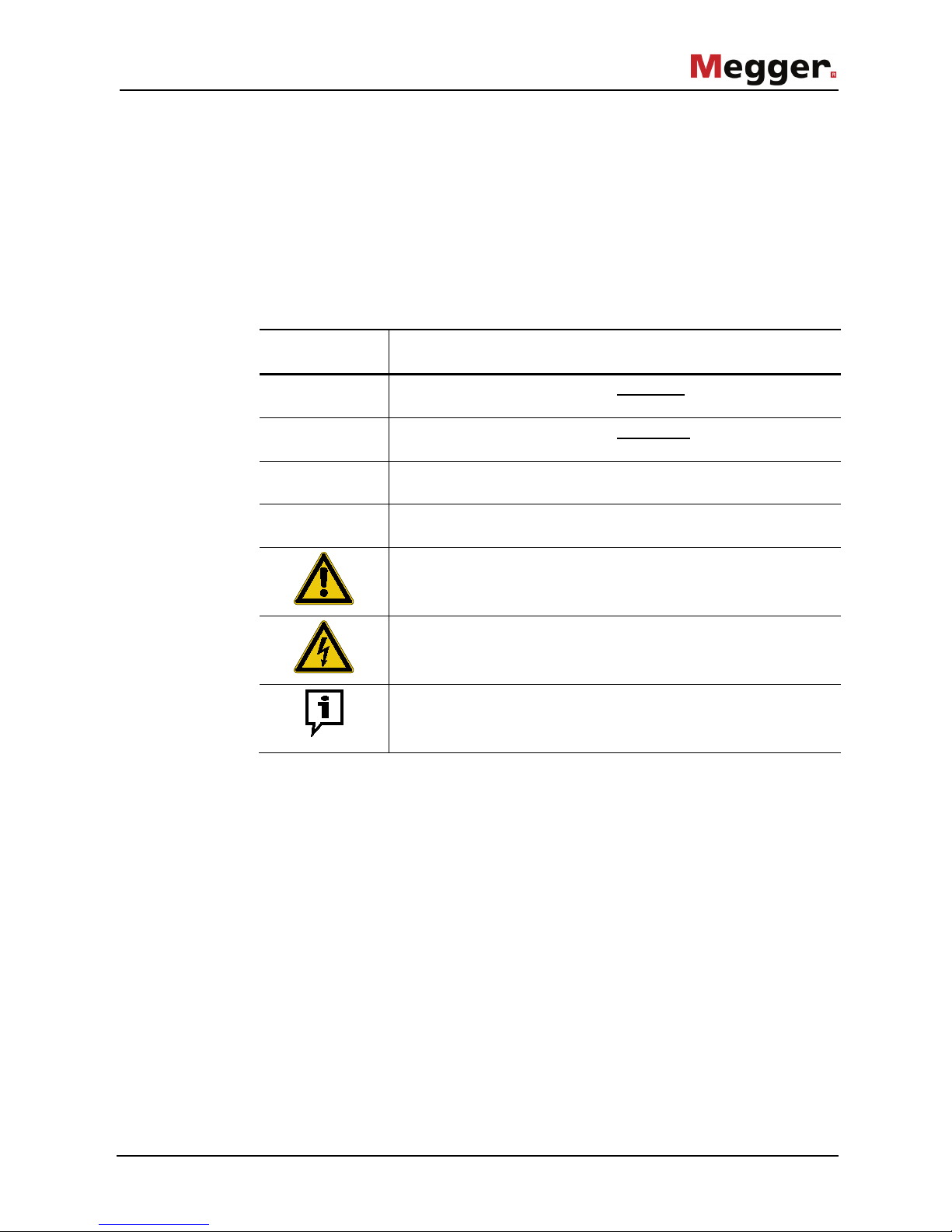

The following signal words and symbols are used in this manual and on the product

itself:

Signal word /

symbol

Description

DANGER Indicates a potential hazard which will result in death or serious

injury if not avoided.

WARNING Indicates a potential hazard which may result in death or serious

injury if not avoided.

CAUTION

Indicates a potential hazard which may result in moderate or minor

injury if not avoided.

NOTICE

Indicates a potential hazard which may result in material damage if

not avoided.

Serves to highlight warnings and safety instructions.

As a warning label on the product it is used to draw attention to

potential hazards which have to be avoided by reading the manual.

Serves to highlight warnings and safety instructions that explicitly

indicate the risk of an electric shock.

Serves to highlight important information and useful tips on the

operation of the device/system. Failure to observe may lead to

unusable measurement results.

It is important to observe the generally applicable electrical regulations of the country in

which the device will be installed and operated, as well as the current national accident

prevention regulations and internal company directives (work, operating and safety

regulations).

After working on the system, it must be voltage-free and secured against reconnection

as well as having been discharged, earthed and short-circuited.

Use genuine accessories to ensure system safety and reliable operation. The use of

other parts is not permitted and invalidates the warranty.

The system may only be installed and operated by an authorised electrician. DIN VDE

0104 (EN 50191), DIN VDE 0105 (EN 50110) and the German accident prevention

regulations (UVV) define an electrician as someone whose knowledge, experience and

familiarity with the applicable regulations enables him to recognise potential hazards.

Anyone else must be kept away!

Safety precautions

Labelling of safety

instructions

Working with products

from Megger

Operating staff

Page 8

General Notes

8

The product meets the following security requirements of the European Council

Directives:

• EMC Directive (2004/108/EC)

• Low Voltage Directive (2006/95/EC)

• RoHS Directive (2011/65/EU)

This product includes software components that are covered by the GNU Lesser

General Public License (LGPL). You are hereby granted the right to request the source

code of the following components licensed according to LGPL v.2.1, modify it and

distribute it:

• Libroxml 2.3.0

• GNU C Library 2.19

• Qt 5.4.0

The operating safety is only guaranteed if the delivered system is used as intended (see

page 10). Incorrect use may result in danger to the operator, to the system and the

connected equipment.

The thresholds listed in the technical data may not be exceeded under any

circumstances.

The equipment may only be used when working properly. When irregularities or

malfunctions appear that cannot be solved consulting this manual, the equipment must

immediately be put out of operation and marked as not functional. In this case inform the

person in charge who should inform the Megger service to resolve the problem. The

instrument may only be operated when the malfunction is resolved.

Declaration of

Conformity (CE)

Use of LGPL software

Intended application

Behaviour at

malfunction of normal

operation

Page 9

Technical description

9

2 Technical description

2.1 Abbreviations

The following abbreviations are used in this manual:

APN Access Point Name

CSV Comma-separated values

DHCP Dynamic Host Configuration Protocol

(network communication protocol)

GPS Global Positioning System

GSM Global System for Mobile Communications

LAN Local Area Network

M2M Machine-to-Machine

LH Niederspannungs-Hochleistungs-Sicherung (low-voltage high-power fuse)

SIM Subscriber Identity Module

SMS Short Message Service

SSID Service Set Identifier

(ID / name of a wireless network)

UMTS Universal Mobile Telecommunications System

URL Uniform Resource Locator

VPN Virtual Private Network

WLAN Wireless Local Area Network

WPA Wi-Fi Protected Access

(encryption method for a wireless network)

Page 10

Technical description

10

2.2 System description

The use of the SmartFuse 250 allows the low-voltage power supply to be safely

disconnected and automatically restored in the event of faults and overload. The

possibility to configure how often and how fast the power network is reconnected and to

be informed about any events increases the reliability and stability of the power supply

for consumers and minimises downtime.

To this end, the SFC250 is inserted into the fuse holder (sizes NH 2 and NH 3; fuse

value ≤250 A) in place of the normal NH fuse link. After successful installation and

configuration the SFC250 behaves similar to a normal fuse element. Unlike a normal

fuse, after being tripped, the SFC250 can switch the fused circuit back on if desired

(after a short wait).

The consumer does not, as is the case for classic fault location using high voltage, have

to be completely disconnected from the power supply network. This is often not even

possible, for example because the residents are not accessible, leading to a risk of

property damage to the household appliances and building wiring. Instead, the prelocation of detected faults can be carried out under voltage either directly with the

internal location algorithm (optional) or with a reflectometer connected in parallel.

For pinpointing the fault position (with the help of a surge wave receiver or the Fault

Sniffer), the SmartFuse 250 can be switched to pulse mode, in which flash-overs are

continuously provoked at the fault location. Pulse mode can be started and stopped

from remote during pinpointing of the fault using a mobile device (GSM connection) or

the SFC250-RC remote control.

Alternative corrective actions, which require the use of a test van, can be scheduled with

some lead time, because in most cases the SFC250 can maintain the supply of the

fused network section for a certain period.

The SmartFuse 250 combines the following features in one device:

• Intelligent monitoring of the low-voltage network

• Minimised downtimes

• Cable fault location with households connected

• Safe installation in the distribution box

• Intuitive user interface

• Variable control via Touchscreen, Smartphone, Tablet, PC or remote control

• Monitoring of up to three phases with one supply module

Intended use

Features

Page 11

Technical description

11

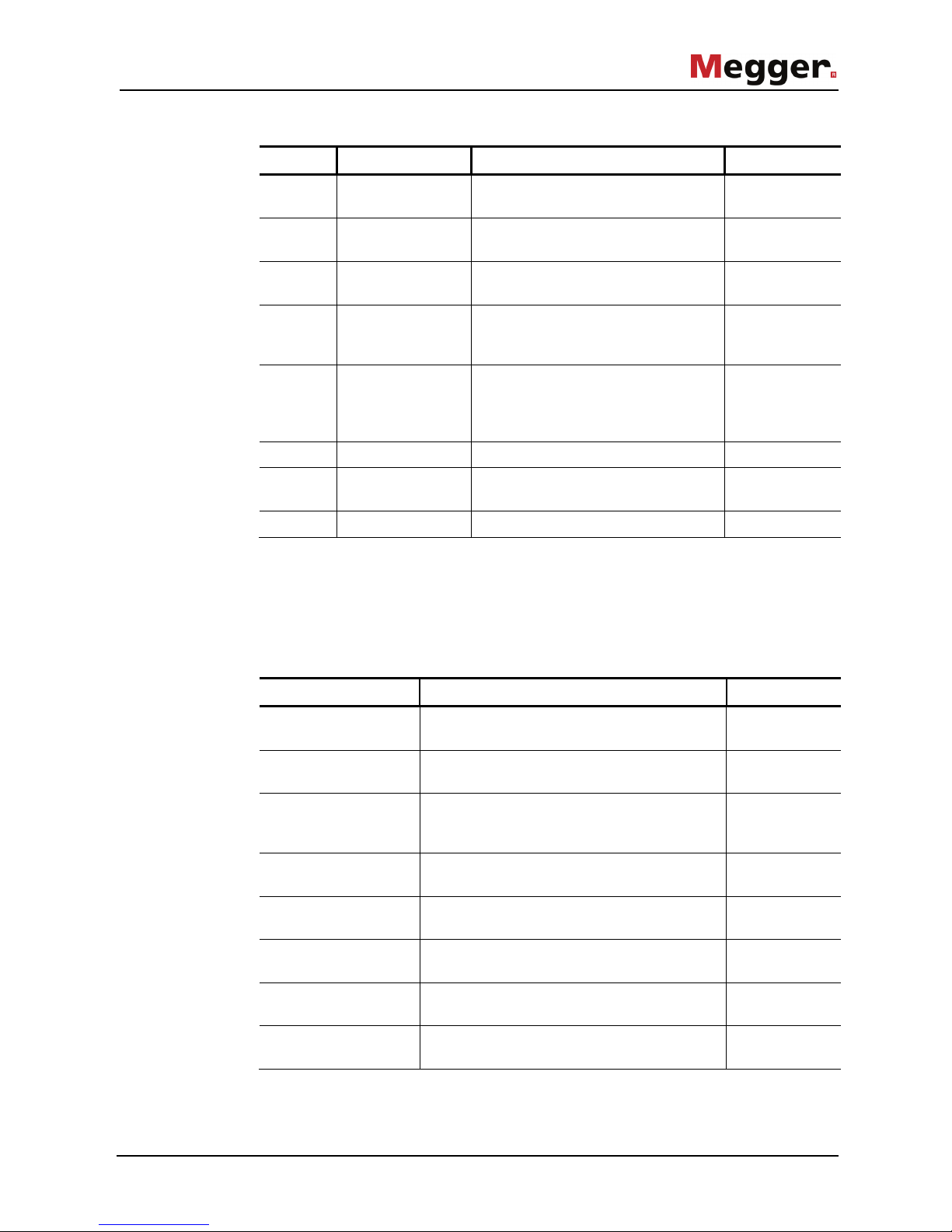

The delivery scope includes at least the following components:

Quantity Component Description Item number

1 … 3 Power module

SFC250-PM

Fuse unit incl. Thyristor switch and

measuring technology

1005787

1 Supply module

SFC250-SM

Control and processing unit incl.

communication interfaces

1005924

1 Remote control

SFC250-RC

Incl. antenna and batteries 1006110

1 Connection cable,

black/blue

1.5 m long line with Kelvin terminal

for connecting to the neutral

conductor

90015363

1 Plug-in power

adapter

Universal power supply

(90 … 264 VAC; 12 VDC / 2.08 A) for

configuration of the device in the

office

90025083

1 Transport case 90014263

10 Fuse F1.25 A / 500 V, 6.3x32 mm,

breaking capacity: 50 kA

90013082

1 Manual 85431

Check the contents of the package for completeness and visible damage right after

receipt. In the case of visible damage, the device must under no circumstances be taken

into operation. If something is missing or damaged, please contact your local sales

representative.

The following optional accessories can also be ordered from the sales department if

required:

Accessory Description Item number

Upgrade kit

SFC 250-1-2-VS

To upgrade a single-phase set to a two-

phase

set

1010753

Upgrade kit

SFC 250-1-3-VS

To upgrade a single-phase set to a threephase set

1010754

"Fault location" option

SFC 250-FL

Automatic fault location with display of the

determined distance and fault pinpointing in

pulse mode

90015840

SFC 250-CA Adapter for connecting up to three power

modules to a supply module

1009649

Additional emergency

backup

Size: SQB1 (with flush end connections);

rated breaking capacity: 200 kA (AC 700 V)

90007524

External GPS receiver

SFC 250-GPS

Incl. cable (approx. 3 m) 2007960

SFC 250-HC Robust and waterproof 7“ tablet for remote

control of the SmartFuse 250

1008357

Fork adapter

SFC 250-GA

Adapter for narrow fuse bases 2009960

Scope of delivery

Check contents

Optional accessories

Page 12

Technical description

12

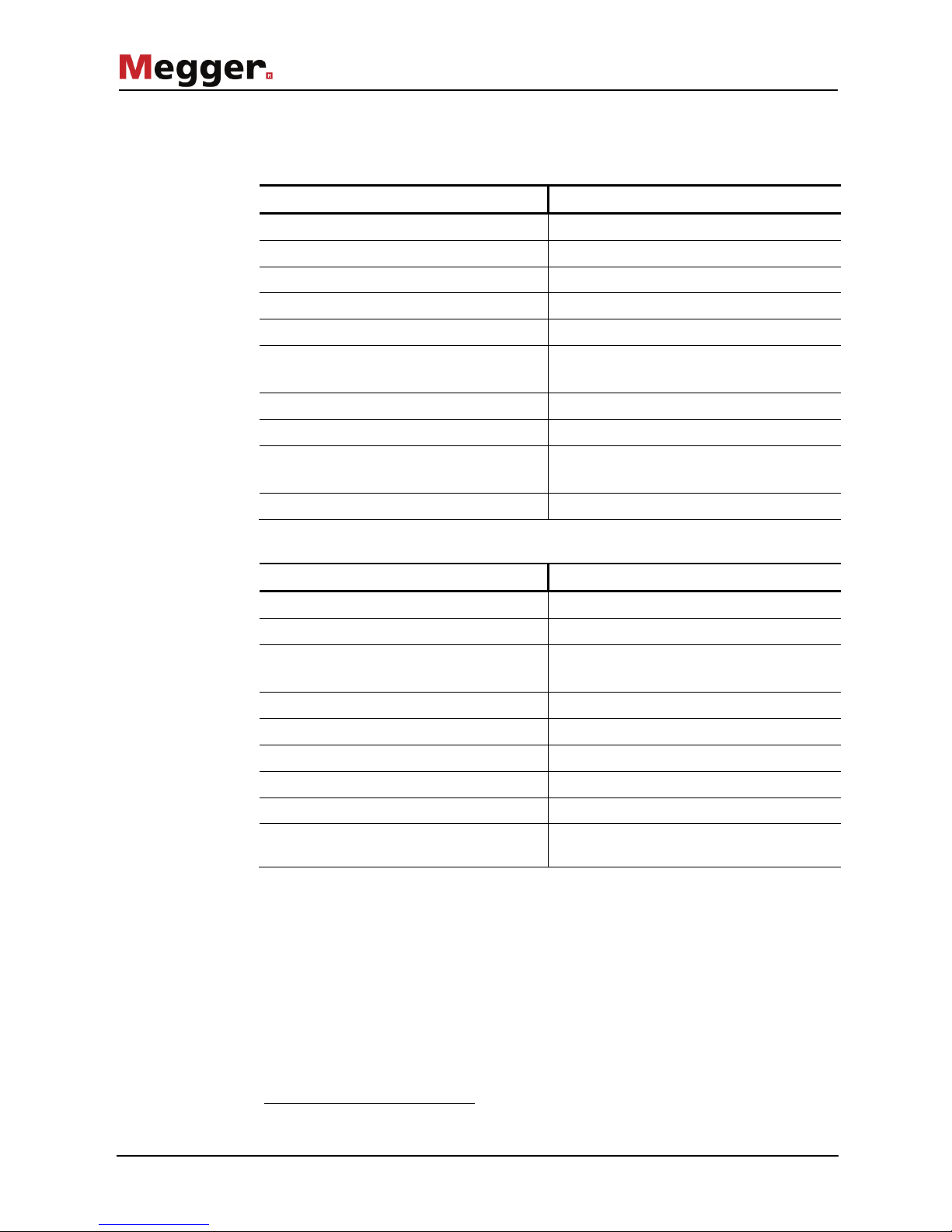

2.3 Technical data

The SmartFuse 250 is defined by the following parameters:

Parameter Value

Triggering threshold

10 A … 250 A (adjustable)

Reclose attempts

0 – unlimited

Waiting time until reclose

1 – 120 seconds

Surge energy control1

1 – 50 half-waves

Operating temperature

-20°C to 50°C

Operating humidity

50% at 40 °C

90% at 30°C

Storage temperature

-25°C to 70°C

Memory for mains failure

Non-volatile event memory

Power supply

Power and supply module

100 … 240 V, 50 Hz / 60 Hz (direct tap at

low-voltage distributor)

Power consumption

20 VA + 1 W/A load current

The power module is defined by the following parameters:

Parameter Value

Load current

max. 250 A continuous current

Short-circuit/surge current

max. 9000 A

Internal fuses

F1: 1 x 800 A and

F2: 1 x 1.25 A

Cut-out capacity

200 kA

Compatibility

Fuse holders NH 2 or NH 3

Display elements

LED for indicating the switching status

Weight

3 kg

Dimensions (W x D x H)

130 x 155 x 82 mm

Ingress protection rating (in accordance

with IEC 60529 (DIN VDE 0470-1))

IP 20

1

with "fault location" option

Page 13

Technical description

13

The supply module is defined by the following parameters:

Parameter Value

Display

Illuminated 3.5-inch colour touch screen

(resistive)

Indicator elements

LED for indicating the switching state (when

the cover is closed)

Memory

microSD card, 16 GB

Interfaces and connections

• GSM / UMTS (SIM card required)

• WLAN (IEEE 802.11x) with WPA2

safety standard

• Ethernet

• Radio interface (868 MHZ)

(communication with remote control)

• USB 2.0

• GPS receiver (integrated)

• Connection for external GPS receiver

(optional)

• Neutral conductor connection

• Trigger output (15 ... 20 V voltage pulse

with fuse tripping)

• Connection coupling for direct

connection of a power module or for

connection of the three-phase adapter

Weight

900 g

Dimensions (W x D x H)

160 x 103 x 97 mm

Ingress protection rating (in accordance

with IEC 60529 (DIN VDE 0470-1))

IP 42

Protection class (in accordance with

IEC 61140 (DIN VDE 0140-1))

II

The remote control is defined by the following parameters:

Parameter Value

Batteries

2 x Mignon (AA)-Batterie Alkali-Mangan

Operating time

>10 hours with fresh batteries

Radio interface

868 MHZ

(communication with remote control)

Weight (incl. batteries and antenna)

200 g

Dimensions (W x D x H)

62 x 31 x 150 mm

Ingress protection rating (in accordance

with IEC 60529 (DIN VDE 0470-1))

IP 40

Page 14

Technical description

14

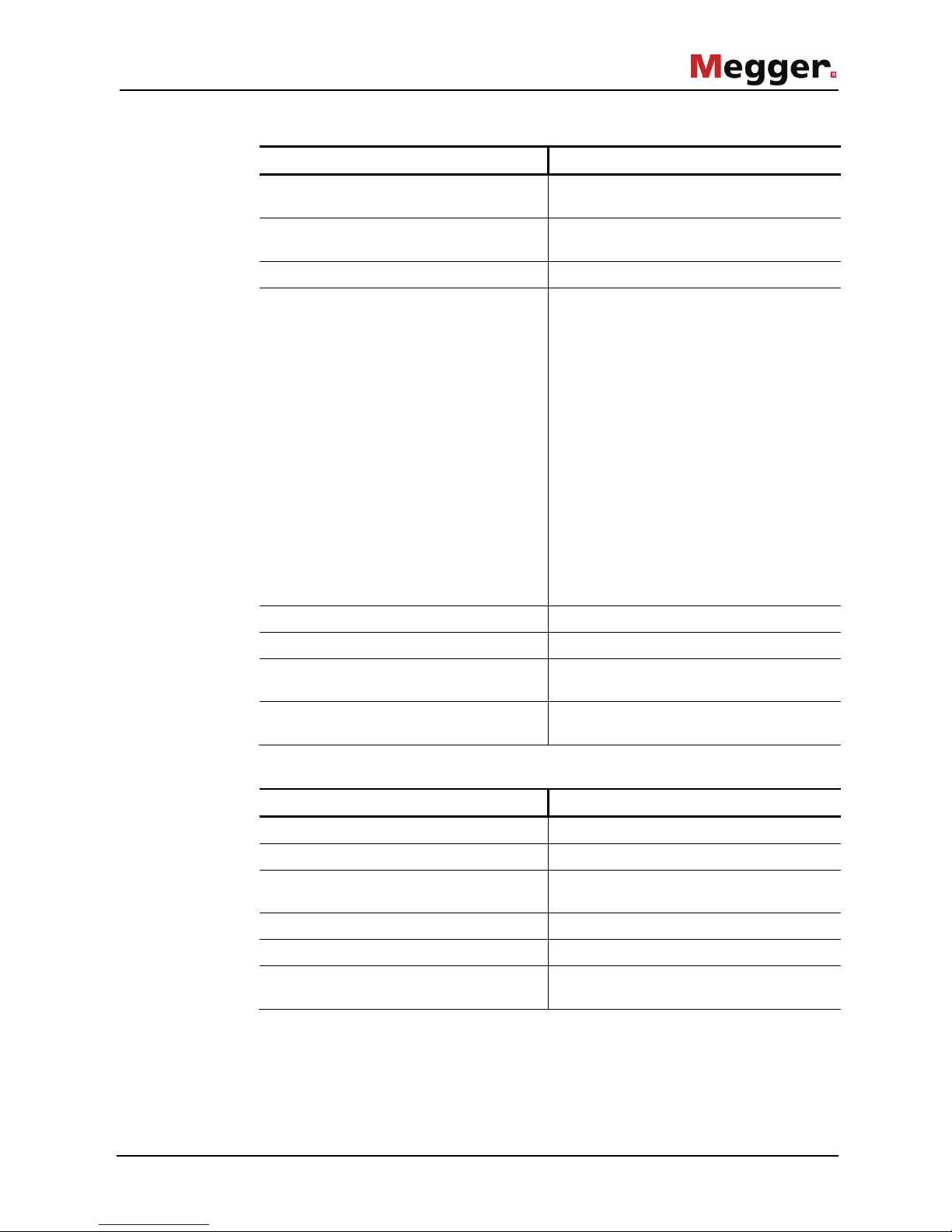

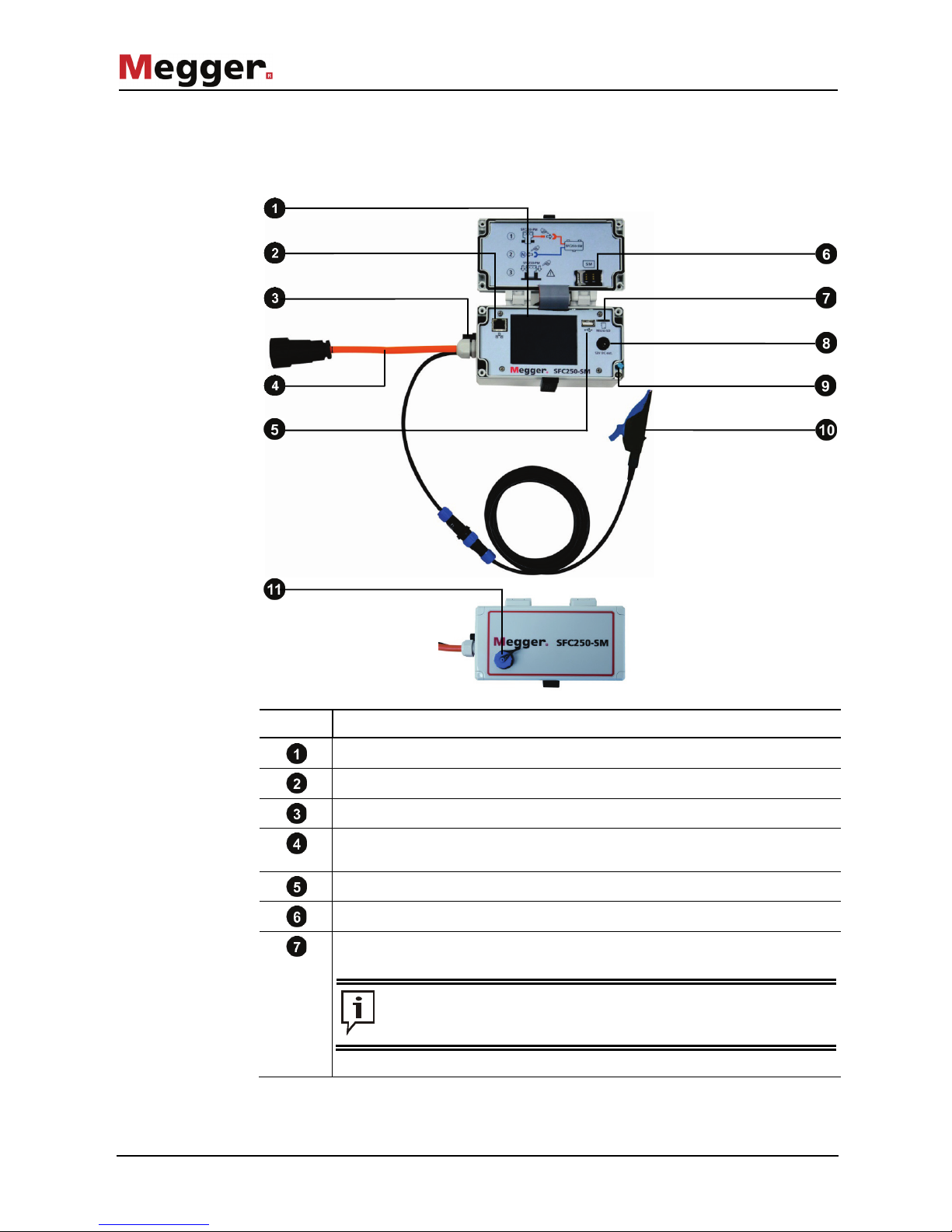

2.4 Connections, controls and display

The supply module has the following connection, display and control elements:

Element Description

Touchscreen

Ethernet port

Trigger output (see page 32)

Connection cable for direct connection to a power module or for connection

to the three-phase adapter SFC 250-CA

USB port

SIM card slot

microSD card slot

The microSD card contains the software needed for operation and

may only be removed from the device and the content changed upon

express instruction of an authorised service technician.

Supply module

Inside of cover

Outside of cover

Page 15

Technical description

15

Element Description

12 V DC input for connecting the supplied power supply

Stylus for operating the touch screen

Connection cable for connecting to the neutral conductor

Socket for connecting the external GPS module (see page 32)

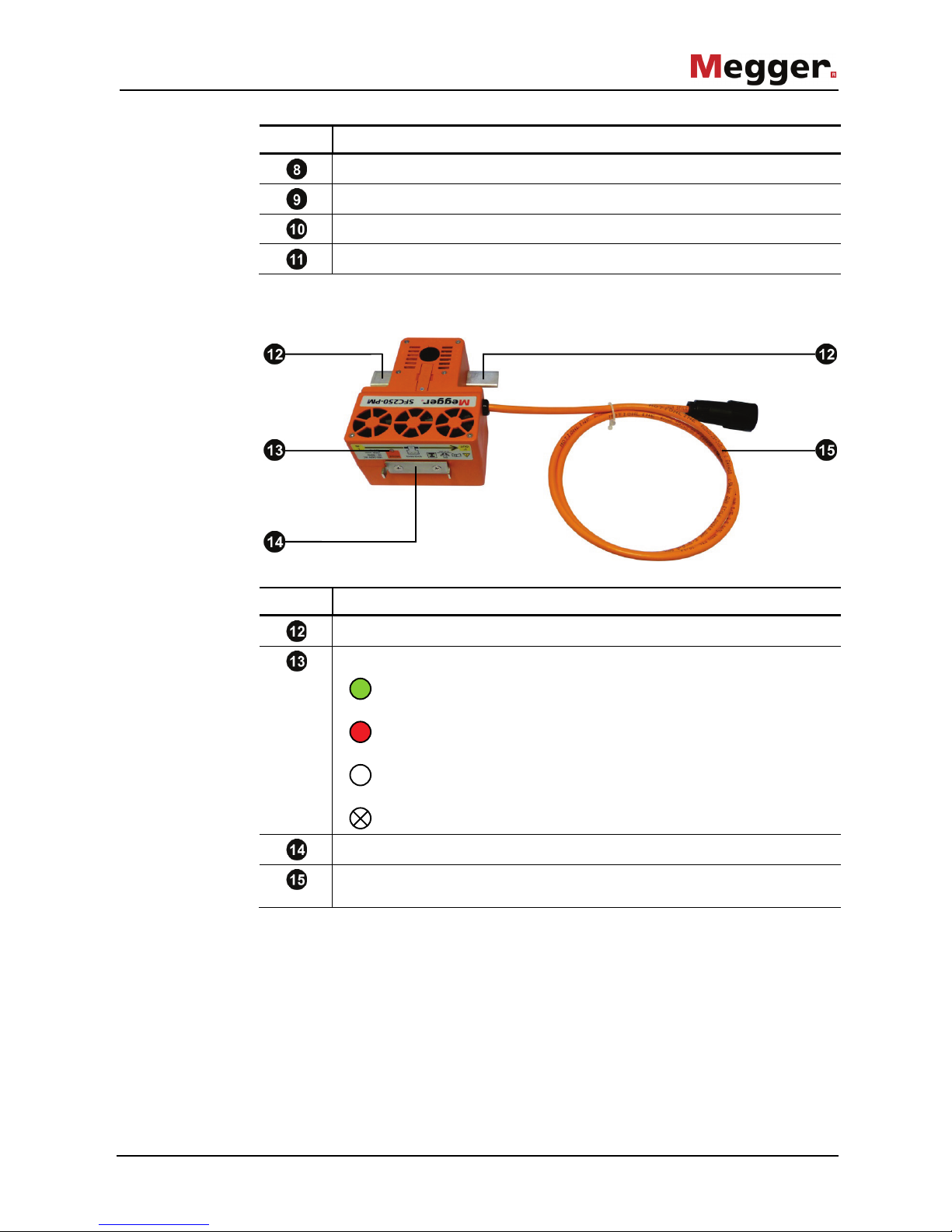

The power module has the following connection and display elements:

Element Description

Blade contacts

Status indicator

The power switch is switched off and there is no mains voltage in

the fuse-protected phase output.

The power switch is on and the protected circuit connected to the

power network.

Ongoing start or update procedure. If the LED is white over a longer

period, this may indicate firmware incompatibility (see page 63).

The supply module does not supply power (see page 63).

Grip lugs for attaching a fuse plug-in grip

Connection cable for direct connection to the supply module or to the threephase adapter SFC 250-CA

Power module

Page 16

Technical description

16

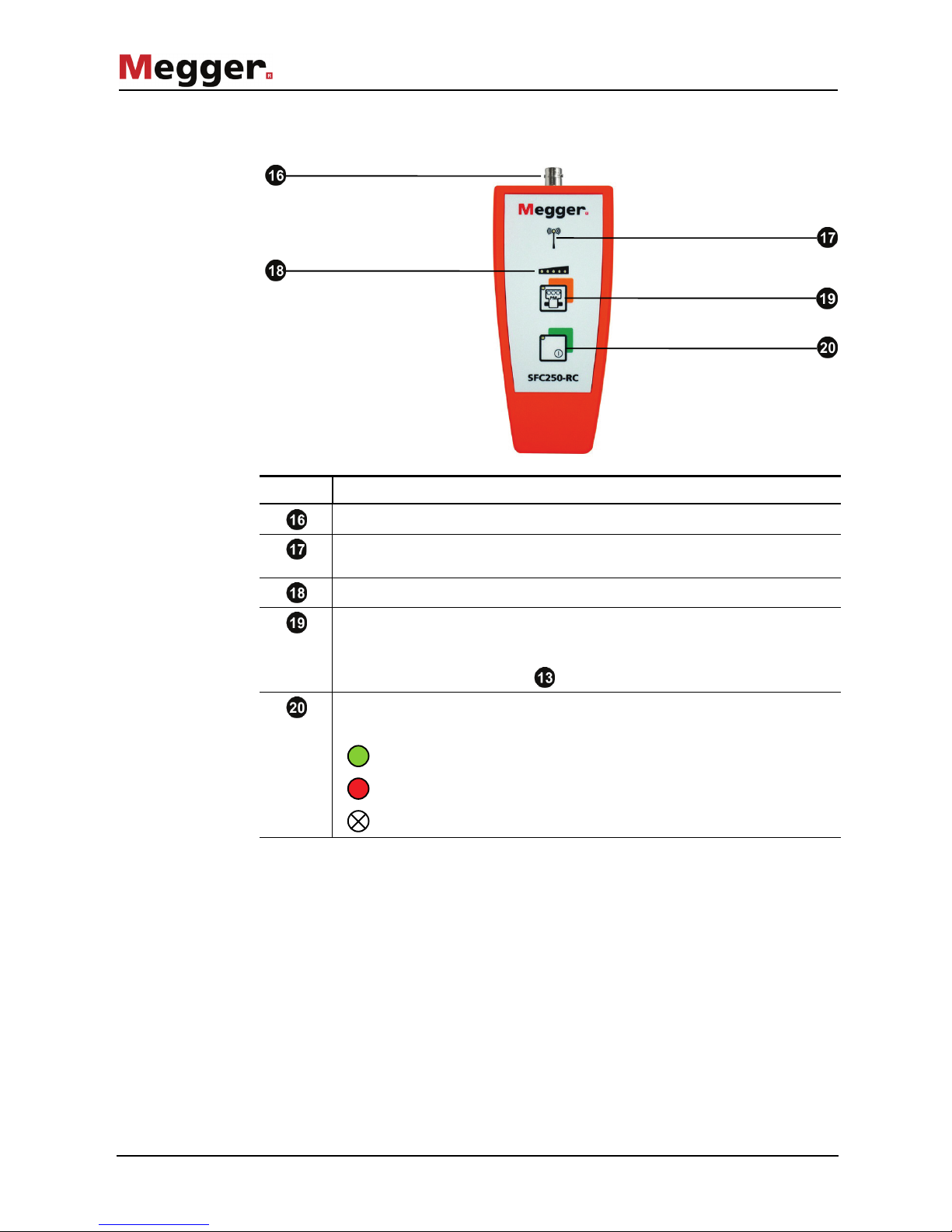

The remote control features the following connection, display and control elements:

Element Description

BNC coupling for connecting the antenna

LED for display of the wireless connection (is lit when wireless connection is

established)

LEDs for display of the amount of current

Buttons for switching the power switch on and off, or for triggering a pulse in

pulse mode.

The integrated LED signals the status of the power switch the same way as

the LED on the power module (see previous page).

Buttons for switching the remote control on and off.

The integrated status LED can assume the following states:

Remote control switched on

Low battery power

Remote control switched off

Remote control

Page 17

Technical description

17

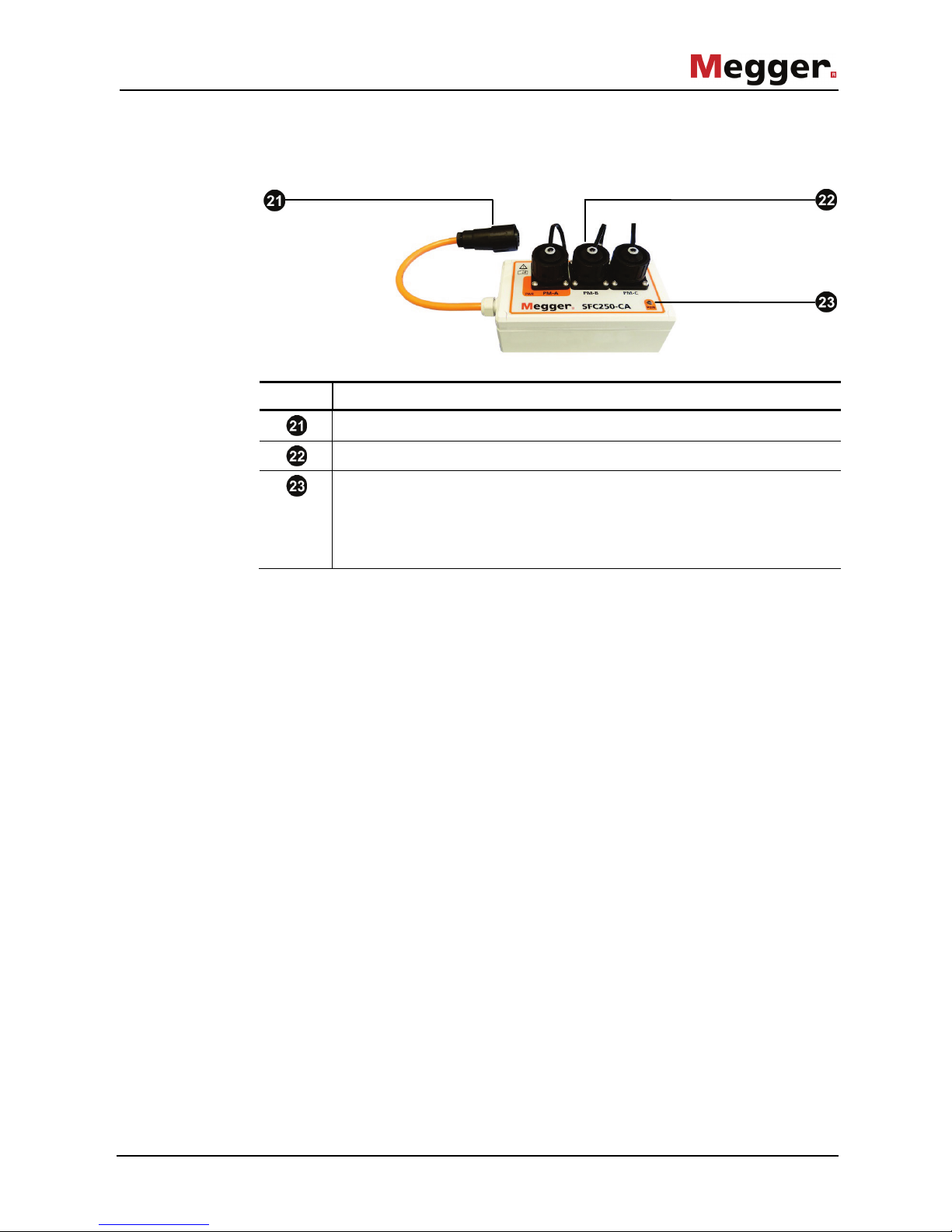

The connection adapter is used to connect up to three power modules to a supply

module and has the following connection and display elements:

Element Description

Connection cable to the supply module

Sockets for connecting up to three power modules

Power LED

The LED lights up as soon as the power module connected to the PM-A

socket has been installed in the control cabinet and provides mains voltage.

From this moment on, the connected supply module is also supplied with

voltage and automatically switched on.

Connection adapter

SFC 250-CA

Page 18

Technical description

18

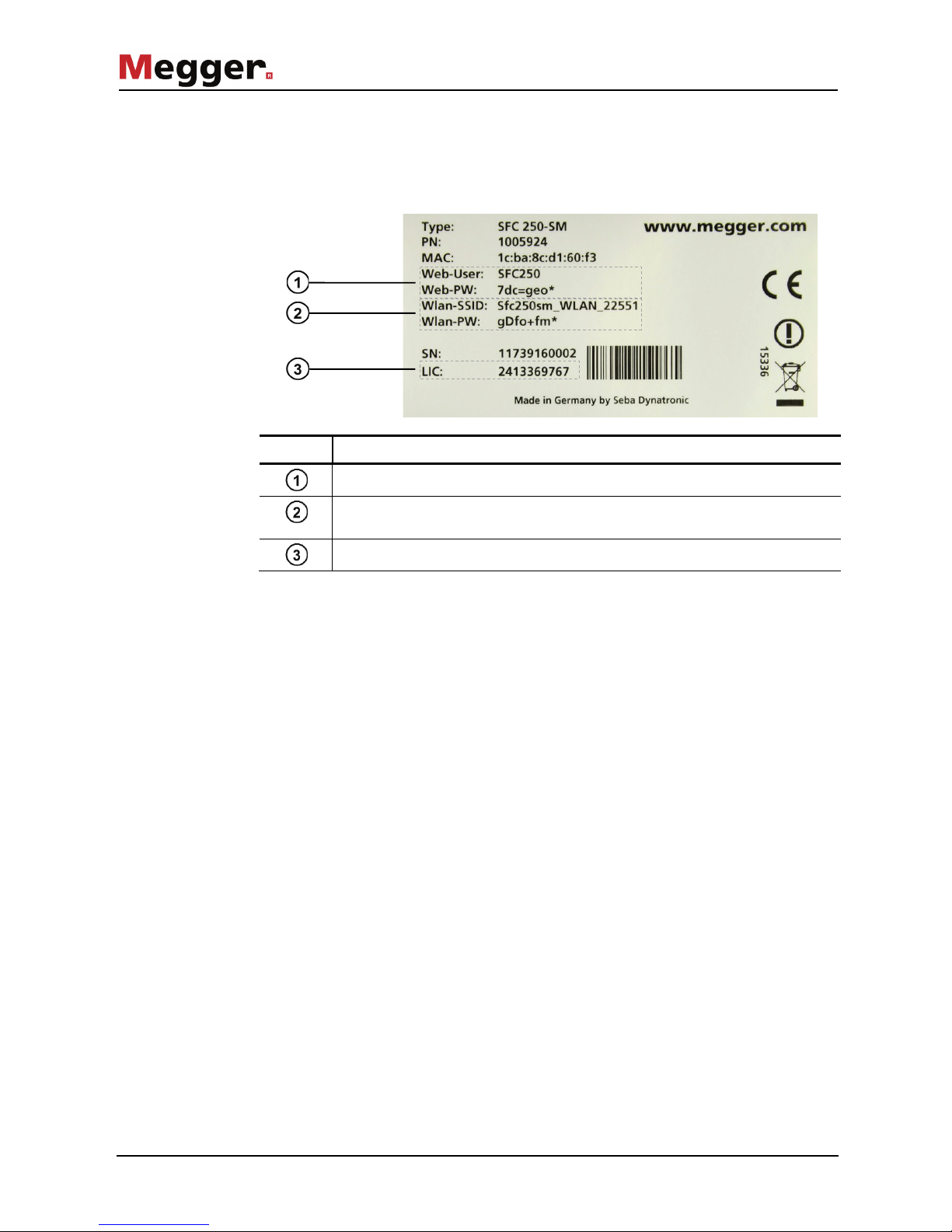

2.4.1 Information plate

The information plate is attached to the backside of the supply module and provides the

following information necessary for the operation of SmartFuse 250:

Element Description

The factory preset login information for access via web browser

The factory preset name of the wireless network (WLAN SSID) and the

password for authentication (WLAN PW)

[optional] License key for activation of the "fault location" option

Page 19

User interface

19

3 User interface

3.1 Access to the user interface

The user interface can be accessed both locally on the supply module and remotely

(using a web browser). The latter requires a data connection between the SFC250 and

the device (PC, smartphone or tablet).

In general, the software can be operated remotely just like as it is operated on the

device itself. However, when the symbol indicates in the status bar (see page 23)

that the cover of the supply module is open, it is not possible to make changes to the

settings.

3.1.1 Local operation

Local operation is performed using the stylus on the touch screen of the supply

module and is in principle always possible as long as the supply module is supplied with

voltage from the power module or the power supply unit.

Page 20

User interface

20

3.1.2 Access through a web browser

The supply module provides various network interfaces, through which users can

connect to the device and access the user interface.

In general, the user interface can be accessed from any internet-connected device (PC,

smartphone or tablet) that has a JavaScript-capable web browser.

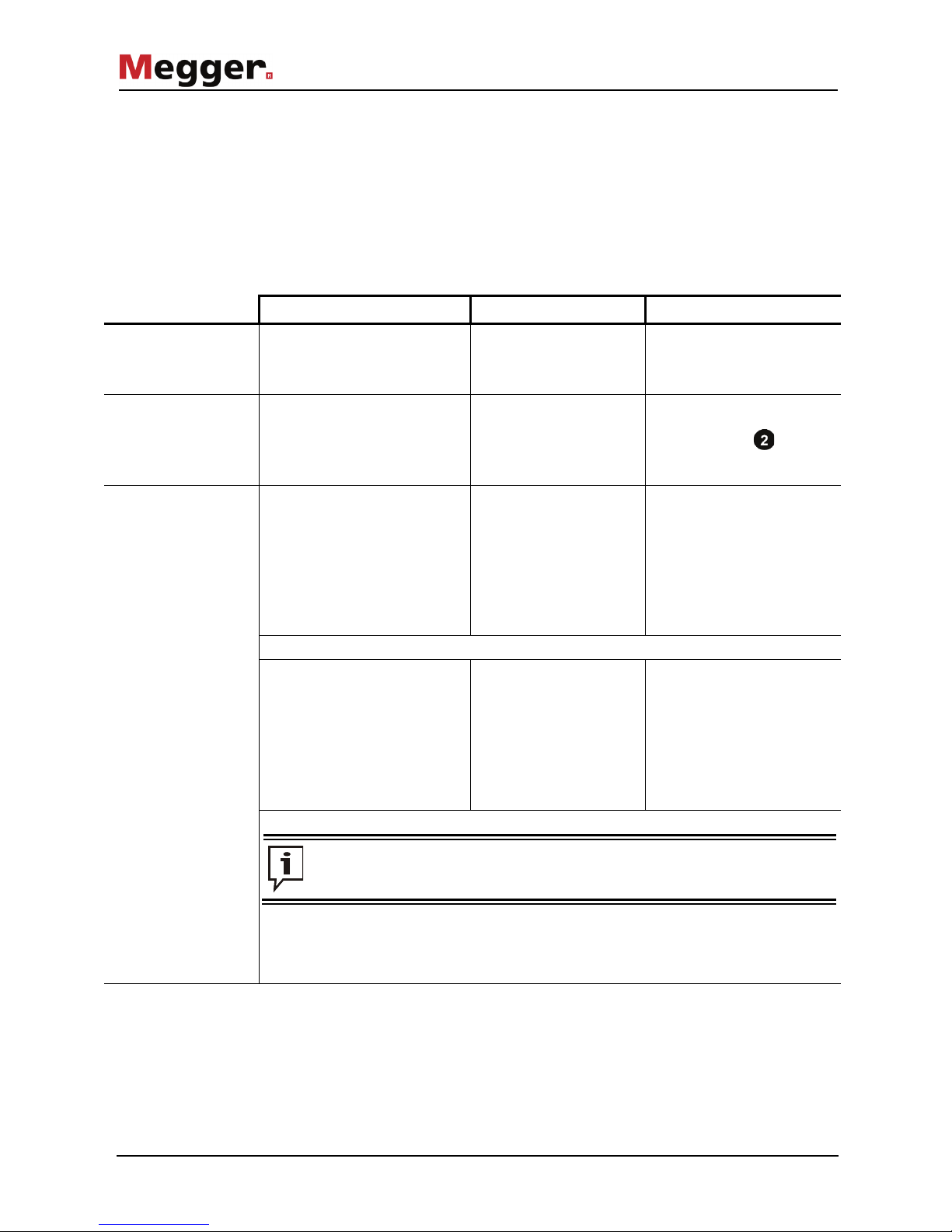

The following table provides an overview of the advantages/limitations of each network

interface and the requirements and steps needed to obtain access:

GSM connection WLAN connection LAN connection

When is the use of this

network interface

recommended?

Complete remote control over the

internet, including notifications

(see page 49)

Wireless access in the

vicinity (for example, for

configuration after

installation)

Preliminary configuration in the

office

Which requirements

need to be fulfilled?

The activated supply module must

be equipped with a suitable SIM

card and accessible via the

internet (see page 51)

The smartphone / tablet

may be up to 15 m from the

activated supply module

The activated supply module

must be connected via the

Ethernet port with a

network socket of the local

network

What steps are

necessary?

Connect to the wireless

network of the supply

module and enter the

password.

The factory preset network

name and password can be

found on the nameplate

(see page 18

) on the bottom

of the supply module.

Locally on the supply module,

ensure that the stored network

settings (see page 50) can be

used to log on in the local

network.

On the terminal device you are using, open a JavaScript-capable web browser.

Enter the IP address / URL of the

supply module in the address line

of the browser or call up the direct

link in the portal of the

commissioned service provider

(see page 53).

Enter the IP address stored

in the WLAN settings as

URL in the address bar of

the browser.

If the browser attempts to

connect to this IP over the

Internet, you must disable

the mobile data connection

of your device

Enter the IP address of the

supply module into the address

bar of the browser.

The IP address used by the

network can be read locally on

the supply module if necessary

(see page 50).

Depending on the connection type and quality, it may take up to two minutes before the

login screen appears.

Log in with the corresponding login information.

The factory preset login information can be found on the information plate (see page 18) on the

backside of the supply module.

3.2 Elements of the main screen

Main screen

Page 21

User interface

21

After logging in, the main screen will appear, containing the following buttons and

information:

If only one power module is connected directly to the supply module without using the

adapter, it will always be displayed in the left-hand column and the two remaining

columns will be used to display the event log.

Fuse

Reclose

Pulse mode

Fuse

Reclose

Pulse mode

Fuse

Reclose

Pulse mode

Header with information on switching status, load

flow direction of the individual connected power

modules (see below)

Current protection settings

(tap to open the respective

menu):

- Shutdown limit

- Reclose operations (see

next page)

- Currently active pulse mode

Current readings:

U/I: RMS values averaged

over the last 10 periods

Imax: Maximum current

measured during operation

(RMS)

Ipeak: Peak value of the

current in the event of a fault

Notifications about

thresholds being exceeded,

shutdowns and other

problems

Access to the main menu

(settings, system information,

U/I curves, event log)

Status icons (see

next page)

Page 22

User interface

22

The designation in the header (PM-A, PM-B and PM-C) is used to identify the power

modules and corresponds to the designation on the sockets of the three-phase adapter.

After clicking/tapping on the designation, the status LED of the respective power module

flashes for about 5 seconds, which enables a reliable visual identification of the power

modules installed in the control cabinet (for example, in the case of tangled connecting

cables).

In normal operation, the button signals the current status of the power switch and

makes direct switching possible:

Symbol Meaning

The power switch is switched off and there is no mains voltage in the fuseprotected phase output.

The power switch can be activated by pressing the button.

The power switch is on and the protected circuit connected to the power

network.

The power switch can be deactivated by pressing the button.

With the pulse mode enabled (man. or auto. is displayed in the Pulse mode row), the

button is used instead for switching automated pulse mode on and off or for initiating a

single pulse in manual pulse mode (see page 24).

The display in the Reclose line depends directly on the configuration (see page 24) of

the individual power modules and can take on the following states:

Display Meaning

---

Automatic re-activation has been deactivated for this power module.

XX/YY This power module is allowed to automatically reclose up to YY times and has

already done so XX times.

∞

This power module can automatically switch back on an unlimited number of

times.

Information and

functions in the header

Automatic reclose

status

Page 23

User interface

23

The status bar contains the following information about the status of the device:

Symbol Meaning

Cover of the supply module is closed.

The device can be monitored and configured remotely using a web browser.

The cover of the supply module is open.

The device is probably being operated locally right now. Remote access to the

user interface for a status query is possible. However, changing the settings

can only be performed locally on the device. With the cover open, switching

operations with the remote control also cannot be performed.

The remote control is coupled with the supply module and activated.

Switching operations and changes to the settings can only be made using the

remote control or directly on the supply module (but not via remote

accessing).

If this icon is not visible, the remote control must first be paired and activated

(see page 47) to be used.

The supply module is not registered in the GSM network. This indicates that

either the GSM signal strength is too weak or no SIM card is inserted and

configured (see page 51).

There is a GSM connection and therefore notifications can be sent via SMS.

However, no mobile data connection could be established (necessary for email delivery and remote access), indicating a very weak GSM signal strength

or an access point (see page 51) that is not configured or configured

incorrectly. The current GSM signal strength is indicated by the white dots (4

points = very good signal strength).

The supply module is registered in the GSM network and there is a mobile

data connection. The basic requirements for sending notifications (via SMS

and e-mail) and remote access via the Internet (if configured accordingly) are

present.

Status bar symbols

Page 24

Start-up

24

4 Start-up

4.1 Preliminary configuration in the office

It is recommended to prepare the SFC250 for the upcoming usage in advance in the

office so that this does not have to be done in bad weather or under time constraints

directly on site.

To this end, the supplied power cable must be used to create a connection between an

outlet and the 12 V DC input of the supply module.

Then, locally or using a web browser, the interface can be accessed (see page 19) and

the software preliminary configured for the intended application.

If the device has been configured before and if these settings have been saved to

preferences, it does not need to be reconfigured from scratch. Normally, only the

fuse settings and the cable data need to be checked and adapted while the

internet settings and the coupled remote control remain the same.

In order to be able to later monitor and configure a currently used SFC250 from the

office or the control centre, various conditions must be met (see page 51):

• A suitable SIM card must be inserted in the SIM card slot of the supply

module.

• The access point (APN) data through which the supply module is to register

itself in the cellular network must be stored in the system settings.

• The user interface can be called up through a fixed IP/URL or a VPN

connection.

Once the Internet connection has been set up, it should be checked whether the

transmission of messages and the remote access to the user interface are functioning

trouble-free.

In order to be able to perform switching operations on the power modules using the

remote control, it must be ensured that the remote control is paired with the supply

module and activated (see page 47).

Making preparations

Fulfilling the

requirements for

remote access via the

internet

Establishing the

conditions for use of

the remote control

Page 25

Start-up

25

The relevant individual parameters for disconnecting and reclosing the power modules

can be defined in the menu Settings Fuse (they can also be accessed by

clicking on the fuse value in the main screen).

The operating parameters can also be adapted during operation at any time,

either directly on the supply module or remotely.

A change to the parameters does not influence the switching state of the power

switch.

The following parameters are configurable:

Parameter Description

Fuse thresholds

Fuse rating

Here the rated current is to be set according to the replaced

fuse.

When the current set here is exceeded for a certain amount

of time, the power switch automatically turns off and

disconnects the protected LV distribution line from the

supply network.

Warning threshold

Current value above which a warning is displayed in the

main menu and, depending on the notification settings (see

page 49), when desired a notification is sent. The warning

threshold monitoring can be activated/deactivated via the

switch.

Reclose

PM-A | PM -B | PM-C

Activate/deactivate automatic reclosing for the connected

power modules individually

Count (x)

Number of automatic reclosing operations until final

shutdown.

If the slide is pushed to all the way to the right, the number

of automatic reclosures is unlimited.

If this setting is changed during operation, the counter for

the previously performed reclosing operations is reset.

Pause (sec.)

Wait time in seconds after which the power switch turns

back on independently.

The settings must then be saved using the button.

Configuring the

shutdown and reclose

behaviour

Page 26

Start-up

26

If you use the optional fault location function, it is recommended that you enter the data

for the protected cable stretch directly after installation under Settings Fault

location. The fault location algorithm needs this data to calculate the distance to the

fault location when a circuit breaker is tripped.

If the license key required to activate the “fault location” option has not yet been entered,

access to the menu is blocked and instead the following screen appears:

The license key to be entered can be found on the nameplate (see page 18) on the back

of the supply module. If the license was purchased directly with the device, it can be

ordered at any time (see page 10).

After entering the license key, it must be saved using the button. The basic settings

should then also be overwritten (see page 45) to save the license key permanently.

When the Settings Fault location is opened the next time, the Cable type

screen should now be available.

Proceed as follows to enter the cable data:

Step Action

1

Look for the correct cable type and tap a conductor to activate it. In doing this, it

is not the designation of the conductor but its position relative to the neutral

conductor (adjacent or opposite-lying) that is of key importance for locating

cable faults.

2

Enter the conductor cross-section, the cable length and, if necessary, the

neutral conductor cross-section.

3

Save the settings using the button.

Entering cable data

License key:

Page 27

Start-up

27

4.2 Installation on site

The SmartFuse 250 must be connected in the following sequence:

WARNING

Danger to life due to arcing

• Insertion into the fuse holder may only be performed by qualified

electricians.

• During insertion, the prescribed personal protective equipment (PPE)

must be used for this type of work.

Connection sequence

Connect power modules to the

supply module

Connect supply module to

neutral conductor

Insert power module into fuse

holder

Page 28

Start-up

28

If the power module cannot fit into the fuse base due to design issues, the optionally

available fork adapter (see page 10) can help under certain circumstances. The

installation is carried out with the help of a Torx and a slotted screwdriver according to

the following figure.

After inserting a power module with a fork adapter, check for a firm hold of the blade

contacts by pulling lightly.

Installation of the fork

adapter (optional)

Page 29

Start-up

29

Proceed as follows to install the SmartFuse 250 on site:

Step Action

1

Clean the interior of the distribution cabinet to remove dirt that could otherwise

accumulate in the vents of the power module during operation.

When necessary, also clean the vents themselves again before insertion (see

page 58).

2

If you only want to install one power module in the distribution cabinet, you can

connect it directly to the supply module using the RS-485 connection cable .

If you want to install 2 or 3 power modules, you will need to connect the

optionally available three-phase adapter (see page 10) to the supply module

and then connect the individual power modules to the adapter.

It is important to connect a power module to the socket PM-A, as the supply

module receives its supply voltage via this connection.

3

Connect the supply module using the black/blue connection cable with the

neutral conductor of the low voltage distribution.

4

Inform yourself about the flow of direction of the load in the low-voltage

distribution and the necessary orientation for inserting the power module into the

fuse holder. A corresponding warning sign can be found on the back of the

power module.

Procedure

Outgoing LV distribution line

Feed bus bar

Page 30

Start-up

30

Step Action

5 Insert the power module connected directly to the supply module or the PM-A

socket of the adapter into the fuse base with the aid of a slip-on handle with cuff.

Result: The power module now draws its supply voltage from the bus bar and

also passes it on to the supply module, whose software starts directly

afterwards.

CAUTION

Even when switched off, the power switch (thyristor switch) does

not represent a galvanic isolation. For this reason, it must always

be assumed that the outgoing cable is energised!

With a voltage tester (for example, Duspol), the mains voltage can

be measured on the cable at any time. Only under load (for

example due to the load resistance integrated in the voltage

tester), does the voltage drop to a much lower value.

Page 31

Start-up

31

Step Action

6

If applicable, also insert the second and third power modules.

Result: The green glowing status indicators signal on the power modules

that the circuit breaker is not yet switched on and the feeding bus bar is still

disconnected from the outgoing cable strands.

Single-phase installation Three-phase installation

Page 32

Start-up

32

On the top of the cover of the supply module there is

a socket , to which an optionally available GPS

received (see page 10) can be connected.

In this way, it can be ensured that the supply

module is able to determine time and position data

and to display it on the software interface, even if

the internal GPS module fails to receive GPS signal

(the value shown under Info

Communication GPS

Signal is 0).

The GPS module has an M8 thread on its

underside, making it possible to fasten it securely to

the distribution cabinet.

If the conditions in the distribution cabinet do not

allow for fixed installation, the GPS module can be

secured on the ceiling of the cabinet using the

supplied Velcro/adhesive tape. To ensure good

adhesion, the surfaces to be used with the adhesive

tape on the GPS and module and on the cabinet

should be cleaned with a suitable cleaner and

degreased.

In order to be able to locate, for example, a sporadic error a measuring device (such as

a reflectometer) can be connected to the trigger output of the supply module with a

suitable trigger input, which in the moment of triggering (short voltage pulse between 15

and 20 V) measures into the safe low-voltage circuit.

Depending on which phases the meter is connected to and at which time it is to be

triggered, the trigger events must be configured (see page 54) in the settings of the

supply module.

The connected measurement device is to be configured according to its

operating instructions so that when triggering occurs, the desired

measurement procedure (for example, an arc reflection measurement) can be

performed.

Installing the GPS

receiver (optional)

Connecting a meter to

the trigger output

(optional)

Page 33

Start-up

33

4.3 Completing configuration, power up and commissioning

After the installation, proceed as follows to configure and switch on the SFC250:

Step Action

1

Access the user interface locally on the supply module or via the web browser

(see page 19).

2

Perform all required software settings (see page 24), if you have not done so

already in the office.

In the settings, ensure that pulse mode is deactivated (see page 42) for each

connected power module. Otherwise, the power module would work in pulse

mode when switched back on.

3

Activate the remote control in the software (see page 48) in order to be able to

use it later to switch on the power modules.

4

Close the distribution cabinet.

If, due to its design, the distribution cabinet cannot be closed with the power

modules installed, suitable protective measures must be taken to ensure safe

operation despite this situation!

5

Turn on the remote control, wait for the blue LED to light up permanently, and

then press the button to close the switches of the installed power modules.

Alternatively, the switching operation can also be performed using the

button on the main page of the user interface.

Result: After a few moments, the status LEDs on the installed power

modules and on the remote control should light up red. The circuit

breaker is now switched on and the phase outlets protected by power modules

are connected to the supply network.

After installation was successfully completed and the power switches have been turned

on, the following must be ensured before leaving the premises:

• If the SFC250 is to be monitored and configured via the internet, there needs to

be an existing connection to the cellular network (see page 23) and the housing

cover must be closed.

• The components and the connection cables of the SFC250 must be placed

appropriately and stumbling hazards eliminated.

• The distribution cabinet must be closed and secured against unauthorised

access according to the operational stipulations.

Configuration and

switching on

Completing

commissioning

Page 34

Controlling and monitoring in running operation

34

5 Controlling and monitoring in running operation

The user interface of the SFC250 can at any time during running operation be called up

(see page 19) directly on the supply module or from a remote device in order to…

• investigate problems (see page 37) that were signalled,

• change operating parameters (see page 24) or

• adapt the device configuration (see page 45).

A change in the operational or configuration parameters in the normal case has no

influence on the switching state of the circuit breaker, unless a reduction in the fuse

value directly triggers a tripping.

5.1 Performing switching operations with the remote control

With the aid of the remote control, the following switching operations can be performed

in close range (150 m with unobstructed view) at the press of a button, without having to

open the distribution cabinet or log on via remote accessing:

• Open / close the power switch in the power module

• Start / stop the automatic pulse mode

• Trigger a single current pulse in manual pulse mode

Once you switch on the remote control and are within wireless range, you are also

continuously informed of the switched state of the power switches through the status

LED .

To be able to perform switching operations with the remote control, the following

conditions must be met:

• The remote control has been paired with the supply module (see page 47)

• The remote control has been activated in the software (see page 48)

The software-based activation/deactivation of a paired remote control serves to ensure

operator safety and has the following effects on the availability of the individual

operating methods:

Switching

operations

using the

remote control

Operation and

configuration

locally on the

supply module

Operation and

configuration

through remote

accessing

Remote

control active

Remote

control inactive

If the remote control in the software is disabled by default to enable

operation/configuration via remote access, it must always be activated (see page 48) via

the user interface before use.

Purpose

Requirements

Page 35

Controlling and monitoring in running operation

35

The remote control can be switched on with a brief press of the button . If, after

switching on, the LED integrated in this button lights up red, this indicates that the

residual capacity of the batteries is low.

Directly after switching on, the remote control attempts to establish the wireless

connection to the coupled supply module. This is signalled by the flashing blue wireless

status LED .

As soon as the connection has been established, the LED lights up permanently blue.

The remote control will attempt to connect to the supply module for about 1 minute

before turning off automatically. If no radio connection can be established within this

time, this may indicate that the distance to the supply module is too great or one of the

conditions described on the previous page has not been met. In order to be able to rule

out the first cause safely, you should work with the antenna plugged in (without antenna

the range is only 20 m max.) and the distance to the supply module should be reduced.

As soon as a radio connection has been established, the current switching state of the

power switches is signaled by the button . It can take the following states:

Color Meaning

Green

The power switches in all connected power modules are switched off.

Red

The power switch of at least one connected power module is on.

By pressing the button , depending on the configuration and the current status of the

power switches, the following switching operations can now be carried out:

Status Pressing the key causes the

following switching action

LED

The power switches in all

connected power modules are off

All power switches are switched on.

The power switches in at least

one but not all connected power

modules are on

All open power switches are now

switched on as well.

The power switches in all

connected power modules are on

All power switches are switched off.

If the button is pressed for at least 3 seconds, a kind of emergency shutdown

is performed and all power switches are switched off, independent of the current

status.

Switching on and

establishing the

wireless connection

Performing switching

operations

Page 36

Controlling and monitoring in running operation

36

The situation is different if, for at least one power module, the pulse mode for fault

location (see page 42) has been activated. In this case, depending on the setting, either

individual pulses can be triggered with the button or the automatic pulse mode can be

started/stopped. However, no switching operations are performed on the power modules

that are not in pulsed mode.

The height of the respective surge current is signalled by the LED bar . Here, the

following scaling applies:

1 LED >= 5 A

2 LEDs >= 150 A

3 LEDs >= 500 A

4 LEDs >= 1000 A

5 LEDs >= 3000 A

After the desired switching operations have been carried out and the remote control is

no longer required, it should be switched off with the button for a few seconds.

Page 37

Controlling and monitoring in running operation

37

5.2 Monitoring, analysis and fault location

When the necessary conditions for sending notifications have been created, depending

on the notification settings (see page 49), the configured recipients will be informed

immediately and reliably about problems that occur.

Furthermore, it is recommended to regularly log on to every SmartFuse 250 in operation

in order to check the switch status and the recorded events / measurements.

5.2.1 Event and measurement data evaluation

When the "fault location" option on the supply module is enabled (see page 26), critical

events, such as a threshold overshoot, are signaled directly on the main screen.

In addition to the peak value of the maximum measured fault current, an error message

is also displayed which, depending on the type of fault and the cable data entered,

provides the following information:

Based on the measured current and voltage values, an

impedance calculation could be performed and, in correlation to

the entered cable data, the probable fault distance could be

determined.

In addition to the fault distance, the conductors affected by the

fault are also displayed (first example: L-L fault; second example

L-N fault).

Although the algorithm was able to perform a calculation, the

resulting fault distance exceeds the entered cable length by far.

In this case, the indicated fault distance is preceded by a “>”.

Event display on the

main screen

Page 38

Controlling and monitoring in running operation

38

Based on the measured values, no impedance/distance

calculation could be made.

This especially occurs in the case of a multi-pole fault between

more than two conductors (e.g. between two phases and the

neutral conductor or between all three phases).

The cable data necessary for calculating the fault distance has

not yet been saved (see page 26).

Page 39

Controlling and monitoring in running operation

39

If multiple shutdowns and automatic reclose operations have already taken place in the

past, the displayed current and distance values always refer to the last shutdown. The

values of the earlier shutdowns can be found in the event log (see below).

For systems without the "fault location" option, these images are not displayed. The

color of the power symbol and the number of performed reclose operations indicate,

however, whether automatic shutdown/reclosing operations have taken place.

Since the main screen always only provides information on the last events that have

occurred and some events (for example, warning threshold overruns) are displayed only

briefly, all events that have occurred since the installation can be found in the event

protocol ( Event protocol).

The entries in this log are arranged chronologically and provide all relevant information

about the time, phase, type and parameters of the event. The fault location results are

only displayed in the log if the "fault location" option on the supply module is enabled

(see page 26).

Event Log

Fuse

Reclose

Pulse mode

Performed reclose operations /

Maximum number of reclose operations

Event protocol

11:45:33 | PM A: Off, auto., Ipeak = 10 A

07:12:06 | PM B: Fault location, 109 m, Ipeak = 281 A

07:12:06 | PM B: Off, auto., Ipeak = 283 A

07:12:05 | PM B: Warning threshold reached, I >= 255 A

Page 40

Controlling and monitoring in running operation

40

The U/I loggers menu item can be used to view the recorded current and voltage

waveforms and check for abnormalities.

The current and voltage values are stored in 1-second intervals and held for 30 days

before they are deleted from the internal memory.

The buttons on the bottom of the diagram can be used to toggle between the previous

days. The button serves to jump back to the current day. In addition to the date, the

displayed time range (Range) and the gap between the individual measuring points

(Resolution) can also be adjusted via the drop-down menu.

The buttons on the upper right edge of the display can be used to show or hide the

curves of individual the power modules.

In order to display a specific voltage or current value, just click/tap on that point on the

curve.

If required, the measured values can also be exported as CSV files and thus

conveniently analyzed on a workstation PC in a suitable application (for example,

Microsoft Excel). Follow these steps to export the files:

Step Action

1

Insert the USB stick into the USB port of the supply module.

2 Open the menu Settings Fault location.

3 Call up the menu item Data export.

4

Export the desired data:

U/I measured data

CSV files with timeline of the following current and

voltage values (in separate columns):

• Average of the last 5 periods

• Average of the last 150 periods

• Average of the last 10 minutes

• Average of the last 2 hours

A separate file is created for each day since

commissioning.

Fault location data

Log files in XML format which are primarily used by the

technical support of Megger for purposes of analysis.

Analysis of current and

voltage measurements

Page 41

Controlling and monitoring in running operation

41

Step Action

5 If preferred, call up menu item Delete data? to delete the downloaded files from

the internal memory once download is successfully completed (so that they do

not need to be downloaded again the next time).

6 Call up the menu item Remove USB Stick and then pull out the USB flash

drive.

Page 42

Controlling and monitoring in running operation

42

5.2.2 Fault location in pulse mode (optional „fault location“

function required)

If repeated failures/shutdowns indicate a cable fault, the SFC250 provides a number of

options for localizing the fault without having to disconnect the consumer from the grid.

In some cases, the fault distance determined by the location algorithm (see page 37)

may already provide sufficiently accurate conclusions about the fault location. A

measuring device that is connected in parallel to the line and triggered by the supply

module can also be used for exact fault location. Assuming that the fault reliably ignites

shortly after switching on the fuse, the position can be tracked down to the meter with

the aid of a suitable ground microphone (for example, digiPHONE+) or the fault sniffer

system. For this purpose, the SFC250 has a pulse mode, in which the power switch is

switched on repeatedly for a defined number of half-cycles, and in each case an ignition

of the fault is forced.

Pulse mode must be enabled before the start of pinpointing using the Settings

Fault location Pulse mode menu (also accessible by clicking Pulse mode in the

main screen) and configured as desired.

Parameter Description

PM-A | PM-B | PM-C

Activate/deactivate pulse mode for the connected power modules

individually.

Pulse mode can only be enabled, if the power switch is off.

auto. / man.

Selection between automatic and manual pulse mode.

In the setting man., when the button is pressed in the main

menu or with the button on the remote control, exactly one

pulse is triggered.

In the setting auto., after pressing the button in the main

menu or with the button on the remote control, periodic

pulses are automatically generated. The interval of the pulse

sequence can be set under Pause (sec.).

Pause (sec.)

Interval of automatic pulse sequence in pulse mode.

Half-waves

After each reclosure, the power switch will remain on for the

number of halfwaves defined here, unless a short circuit or fault

current causes a shutdown beforehand.

If changes have been made, they must be saved via the button.

If pulse mode has been activated for at least one of the connected power

modules, the button in the software and the button on the remote control

are only used to control the pulse operation (see next page). Power modules that

are not in pulse mode are switched on with the first actuation (if the switch was

not already been closed), but thereafter no longer respond to further actuations of

the button/key. This behavior only changes again once pulse mode has been

deactivated for all power modules.

Activating/deactivating

and configuring pulse

mode

Page 43

Controlling and monitoring in running operation

43

After activating pulse mode for the phase affected by the fault, the fault can be located

as follows:

Step Action

1

With the surge wave receiver, go to the area in which you suspect the cable

fault is located.

2

Log on with a mobile device on the corresponding SFC250.

If not data connection can be created with the device, the pulse mode can also

be started by a second person in the vicinity of the device (via local

operation,SFC250-RC or WLAN connection).

Press the button in the main menu or the button on the remote control

to start pulse mode (automatic mode) or trigger a single pulse (manual

mode).

Result: In automatic mode, a fault ignition is provoked continuously at the set

interval.

In manual mode the button must be pressed again for each additional pulse.

On the LED bar of the remote control, you can see whether current is

flowing and the fault ignites (see page 35).

3

Locate the exact position of the fault using one of the following methods:

The acoustic and electromagnetic

waves that propagate with each flashover can be located using a surge

wave receiver (for example,

digiPHONE

+

).

Repeated closing of the breaker

causes burn-up of the insulation at the

fault location. The resulting gases can

be located with the Fault Sniffer

system.

For information on operation of the surge wave receiver or the Fault

Sniffer system, refer to the associated operating manual.

Fault location in pulse

mode

Page 44

Controlling and monitoring in running operation

44

Step Action

4

Exit pulse mode after successful fault location by pressing the button in the

main menu or the button on the remote control (only necessary in

automatic mode).

5 Disable the pulse mode in the device settings as well ( Settings Fault

location

Pulse mode).

Page 45

Configuration

45

6 Configuration

6.1 Defining basic settings

Using the Settings Basic settings menu item, the following basic settings and

adjustments can be defined:

Parameter Description

Status

Device name

Device name, which can also be modified when necessary

Serial number

Serial number of the device, which should also be provided

when contacting customer service

License key

The license key entered for activation of the "Fault location"

option.

Tools

Reboot SFC250-SM

Forces a restart of the supply module

Load factory

settings

Resets all settings back to the original factory settings

Calibrate touch

screen

Starts the procedure for touch-screen calibration (see

page 61)

Firmware update

SFC250-PM

Starts a manual software update of the connected power

module. Such an update may also help when the status

indicator on the power module does not go on after

starting.

Causes for these kinds of problems could be a failed software

update of the power module or mixing of modules with

different software versions.

The files needed for the update are loaded from the internal

memory of the supply module and do not need to be provided

by a USB flash drive. After pressing the button, the update

starts immediately and is indicated using the following symbol

in the main screen:

The installation may take several minutes. Do not

disconnect the supply module from the supply voltage

or the power module during installation!

Import / Export VPN

configuration

Import / Export of a VPN configuration (see page 51)

Page 46

Configuration

46

Parameter Description

Date/Time/Language

Date, time and menu language of the supply module.

With GPS reception (see page 32), the time and date are

determined automatically and cannot be entered manually.

Service

This password-protected area is only accessible to authorized

service staff and only locally on the supply module.

When changes have been made to the basic settings, they must be saved using the

button.

Page 47

Configuration

47

6.2 Pairing and enabling the remote control

In order to use the remote control for switching operations (power switch on/off, pulse

mode on/off), it must be coupled with the supply module. For reasons of safety, the

coupling can only be performed directly on the supply module. Proceed as follows:

Schritt Aktion

1

If not already installed, insert two mignon-type batteries (AA) in the remote

control. However, do not switch the remote control on yet!

2

Open the user interface locally on the supply module and open the page

SFC250-RC.

Result: The dialogue for managing the remote control opens.

3 Call up the menu item Couple a SFC250-RC.

Result: The message Perform RC pairing appears in the Status line.

4

Take the remote control and move about 2 meters away from the supply

module.

5

Press and hold the button on the remote control. Now press the button

briefly and let it go again directly. Then release the button as well.

Coupling the remote

control

Page 48

Configuration

48

Schritt Aktion

Result: The beginning of the pairing process is acknowledged at the supply

module with a signal tone. All three LEDs should light up on the remote control.

After the pairing has been successfully completed, the line Status displays the

message SFC250-RC active and the serial number of the paired remote

control. The remote control can now be used (see page 34).

The pairing also remains active after a change of location of the supply module

and is only canceled when another remote control is connected to the supply

module.

6

Turn on the remote control by briefly pressing the button, if you do not want

to use it directly after pairing.

One and the same remote control can in principle be paired with several supply

modules. However, it is imperative to ensure that the distance of the supply

modules from each other is large enough (> 500 m), so as not to accidentally

cause switching operations on the wrong power module!

Immediately after pairing, the remote control is activated on the software side and

remains so until it is manually deactivated in the software. A permanently activated

remote control has the advantage that it can be switched on and used directly if

required. However, in order to avoid parallel and conflicting operator actions, operation

and configuration via remote access is deactivated when the remote control is activated.

If you do not want to give up the option of remote configuration, you can also disable the

remote control by default. When needed, however, you will need to reactivate it before

using it.

To enable/disable the remote control, proceed as follows:

Step Action

1 Call up the page SFC250-RC locally on the device or via remote

accessing (only possible if remote control is deactivated).

Result: The dialogue for managing the remote control opens.

The Status line shows whether the remote control is active or inactive.

2 Call up the menu item SFC250-RC ON/OFF.

Result: The coupled remote control is either activated or deactivated,

depending on its current status.

Activating/deactivating

the remote control

Page 49

Configuration

49

6.3 Modifying the notification and network settings

6.3.1 Modifying the notification settings

SMS or E-mail notifications can only be sent when the supply module has been

configured for mobile data communication (see page 51) and is connected with a

cellular network or cellular data network (see page 23).

Using the menu Settings Communications GSM Notifications, the

following notification settings can be defined (also accessible by clicking on the

communications symbol in the main screen):

Parameter Description

Notification in

case of warning

threshold

crossing?

Using this drop-down menu, you can define how often a notification

should be sent when a warning threshold is violated.

Send notification

for the following

events:

Using these checkboxes, you can specify the events for which a

notification should be sent.

SMS recipient

number 1 / 2

Mobile phone numbers to which notifications will be sent by SMS.

The country code does not need to be used as long as the number

to be notified is in the same country. In this case, the numbers must

be entered with a leading 0 (for example, 0172 *******).

If the number is entered with country code, a + must be used as a

prefix (for example, +49172 *******).

There must be no spaces or special characters between the

individual digits.

Send test SMS

Using this button, a test message (SMS and/or E-mail) can be sent

to the specified phone numbers / E-mail addresses as a way to

check for correct entry of the numbers and to also test the GMS

connection.

E-Mail 1 / 2

E-mail addresses to which notifications will be sent.

In order to be able to send notifications to the specified email

addresses, the data of an SMTP outgoing mail server must be

specified (see page 54).

The settings must then be saved using the button.

Page 50

Configuration

50

6.3.2 Modifying LAN and WLAN settings

Using the Settings Communication WLAN menu, the following settings of

the wireless access point can be modified:

Parameter Description

Network

ID

Network name (or SSID) that is displayed when the device searches for

wireless networks.

Password

Password that authorises the connection to the wireless network.

IP

address

IP address that opens the user interface in the browser with an active

WLAN connection (see page 20).

Subnet

mask

Subnet mask of the wireless network. It is recommended to keep the

default: 255.255.255.0.

The settings must then be saved using the button.

A restart is necessary for the changes to the WLAN settings to take effect!

When changes are made to the name and/or password of the WLAN network,

the data on the information plate (see page 18) on the backside of the supply

module are no longer applicable. It may therefore be necessary to inform other

colleagues about the change.

Using the Settings Communication LAN menu, the network adapter

settings can be modified:

Parameter Description

Static /

DHCP

Because most local networks automatically distribute the network settings

to the clients, it is recommend that you select the setting DHCP. After a

successful registration in the network, the provided settings (including the

IP address at which the device is accessible) are displayed in the fields

below.

If the network to which the supply module is connected does not support

DHCP, the switch must be set to Static and the network settings must be

adapted to the configuration of the network.

IP address

IP address at which the device is available within the network.

When a fixed IP address is entered manually, it must be ensured that this

address is not already assigned to another computer.

Subnet

mask

Subnet mask of the local network.

Broadcast

Broadcast address of the local network.

Gateway

Address of the standard gateway computer (router) of the local network.

The settings must then be saved using the button.

Modifying WLAN

settings

Modifying LAN settings

Page 51

Configuration

51

6.3.3 Ensuring Internet accessibility

Due to the diverse solution approaches and network types, within the scope of

this section actions can only be described in detail which are to be undertaken on

the SFC250 itself.

When adaptations to the network configuration are necessary and when selecting

a suitable service provider, you should seek the assistance of your

IT administrator.

To connect the supply module with the cellular network and to make accessing from the

Internet possible, the following options are available:

Complete solutions from a single supplier

Various service providers, such as the German company mdex AG, have specialised in

making industrially used systems and devices accessible via the Internet. These service

providers offer all necessary services – from compatible SIM cards, in-house access

points and IP services to the required data security – in a one-stop solution.

VPN connection over an OpenVPN server

In the event that in-house SIM cards are available or if the previously described solution

is not appropriate for other reasons, the connection to the supply module can also be

established through a secure VPN tunnel. The OpenVPN server required for this must

either be rented from a VPN service provider or made available through an in-house IT

department.

In the SIM card slot of the supply module, only data-compatible and M2M

communication suitable SIM cards in the Mini-SIM size should be inserted.

The monthly data volume used by status queries and sending notifications

depends greatly on the device settings and the user behaviour and can rise to a

few gigabytes. Data that exceeds the volume included in the package may be

charged at an expensive rate by the mobile operator. For this reason, it is

recommended that you select a data plan with a high included volume (for

example, 5 GB) and modify this selection later based on the actual consumption,

if necessary.

Proceed as follows to prepare the supply module for data communication via the cellular

network:

Step Action

1

Insert a suitable SIM card into the SIM card slot of the switched-off supply

module.

2

Use the supplied power cable to create a connection between an outlet and

the 12 V DC input of the supply module.

3 Open the menu Settings SIM card PIN code.

4 Enter the card PIN in the field PIN and confirm the input with OK.

Often, the PIN code query is deactivated for the specially designed SIM cards

for M2M usage. For reasons of security however, we recommend activating

the PIN query using the switch Switch SIM Card PIN code on/off.

5 Open the menu Settings Communication GMS Access point.

Available technical

solutions

Inserting the SIM card

and defining the

access point

Page 52

Configuration

52

Step Action

6 Activate Mobile data.

7 Under Login, Password and APN, enter the access point data into the mobile

data network.

If you have selected the SIM card of an All-In-One service provider with inhouse access points (see above), you must enter the data made available by

this provider here.

Otherwise, you need only enter the access point of your network provider (e.g.

Web.vodafone.de) and you can dispense with the entering of Login and

Password.

8

Save the settings using the button and then also as basic settings (see

page 45).

9