Page 1

M

S1-1054/2

10kV Digital Insulation Tester

USER MANUAL

Page 2

GSAFETY WARNINGS

Safety Warning must be observed during use.

n

The circuit under test must be switched off, de-energised, isolated and checked to be safe before insulation test connections are made. Make sure

the circuit is not re-energised whilst the instrument is connected.

n

Circuit connections must not be touched during an insulation test.

n

After completing a test, capacitive circuits must be completely discharged before disconnecting the test leads. Capacitive charges can be lethal.

n

Tested items should be firmly shorted out with a shorting link, after discharge, until required for use. This is to guard against any stored dielectric

absorption charge subsequently being released thereby raising the voltage to potentially dangerous levels.

n

The voltage indicator and automatic discharge features should be regarded as additional safety features and not a substitute for normal safe working

practice.

n

It is rare, but in certain circumstances, breakdown of the circuit under test may cause the instrument to terminate the test in an uncontrolled manner,

possibly causing a loss of display while the circuit remains energised. In this event, the unit must be turned off and the circuit discharged manually.

n

Test leads, including crocodile clips, must be in good order, clean and with no broken or cracked insulation.

n

The instrument should not be used if any part of it is damaged.

n

Insulation testing in wet weather conditions might be hazardous. It is recommeded that this instrument is not used in these circumstances. If this

unavoidable, the user must take all necessary precautions.

n

This instrument is not intrinsically safe and must not be used in hazardous atmospheres.

2

NOTE

THE INSTRUMENT MUST ONLY BE USED BY SUITABLY TRAINED AND COMPETENT PERSONS.

Users of this equipment and/or their employers are reminded that National Health and Safety Legislation requires them to carry out valid risk

assessments of all electrical work so as to identify potential sources of electrical danger and risk of electrical injury such as inadvertent short circuits.

Where the assessments show that the risk is significant then the use of fused test leads may be appropriate.

CAT II

Measurement category II: Equipment

connected between the electrical outlets and

the user’s equipment.

CAT III

Measurement category III: Equipment

connected between the distribution panel and

the electrical outlets.

CAT IV

Measurement category IV: Equipment connected

between the origin of the low-voltage mains

supply and the distribution panel.

Page 3

Test mode summary 16

Insulation resistance ‘IR’ test 16

Breakdown mode / burn mode 16

Alarm limit mode 16

Step voltage ‘SV’ test 17

Polarisation index ‘PI’ test, and dielectric absorption

ratio ‘DAR’ test 17

Dielectric discharge ‘DD’ test 17

Measurements above 100 GΩ 18

Circuit block diagram 19

Specifications 21

Accessories 22

Repair and warranty 23

Battery replacement 23

Symbols used on the instrument are:

F Caution: risk of electric shock

G Caution: refer to accompanying notes

t Equipment protected throughout by Double

Insulation (Class II)

c Equipment complies with current EU directives.

This equipment should be recyled as electronic

waste.

Terms used in this manual

The word must is used to indicate that the instructions following should

be followed under all circumstances. Failure to follow these instructions

could result in damage to the instrument and / or a hazard to the

operator. The word should is used to indicate that the instructions

indicate best practice.

CONTENTS

3

Safety warnings 2

Introduction 4

General description 4

Features 4

Cleaning 5

Power lead and battery charging 5

Instrument controls and indicators 6

Power On/Off button 7

Test voltage s and t buttons 7

Test start / stop button 7

Ω/I button 7

B button 10

Fn button 10

Mode button 10

Timer s and t buttons 11

Record button 11

Recording to on-board memory 11

Downloading results 11

Deleting results 11

Recording to a PC 12

High voltage warning LED 12

Line input present LED 12

Test terminals 12

Guard terminal 12

RS232 / USB connections 13

Battery bar graph 13

Voltage at terminals 13

Timer indicator 13

Digital display 13

Analogue display 14

Secondary display 14

Pre-Test / during test key action table 14

Breakdown detection 15

Noise detection 15

Page 4

A comprehensive LCD display shows resistance, current, filter setting,

capacitance, time constant, voltage, timer measurements, and figure of

merit measurements such as polarisation index.

Features

n Continuous resistance or current measurement on main display.

n Optional resistance, current, or figure of merit measurements on

secondary display.

n Standard test voltages – 250 V, 500 V, 1 kV, 2.5 kV, 5 kV, 10 kV

n Non-standard test voltages – selectable between 50 V and 1 kV in 10

V steps, and selectable between 1 kV and 10 kV in

25 V steps.

n Test modes include insulation resistance, polarisation index, step

voltage and dielectric discharge.

n 4 mA rms hardware noise current filter (selectable)

n Firmware filter 10, 30, and 100 seconds (optional)

n The dielectric absorption ratio is automatically calculated if the

corresponding timers are set.

n Either burn or breakdown selectable in insulation resistance mode.

n Insulation ‘Alarm Limit’ available in insulation resistance mode.

n Programmable timers include a main test duration timer, plus T1 and

T2 timers for time resistance method type tests.

n Load capacitance and time constant measurements – displayed at end

of test.

n LCD backlight.

n Data storage, data retrieval and real time data output.

n USB or RS232 communications.

n Battery level / charge level indicator.

INTRODUCTION

4

General Description

The S1-1054/2 is a microprocessor controlled 10 kV insulation tester

offering measurement capability of up to 35 TΩ. The instrument

performs automatic tests and has data storage and data retrieval facilities.

Polarization index and dielectric discharge tests are performed

automatically, and test duration and voltages can be adjusted according

to user preference for these tests. A step voltage test can be performed

automatically, with a default voltage of 1 kV, and test duration of 5

minutes. It is possible for the user to set different voltages and test

durations for the step voltage test.

The S1-1054/2 incorporates a hardware filter designed to tolerate at

least 4 mA rms of noise current at 50Hz and above. This filter is enabled

by default, but may be switched off in order to speed up the settling

time when there is little noise current. The Insulation Resistance mode

offers additional firmware filtering to average out slow variations during

testing.

The S1-1054/2 can be powered from the mains supply or by its own

internal rechargeable battery, which provides for at least 4 hours of

continuous testing with a 100 MΩ load. A battery level indicator on

the LCD display indicates battery capacity. Connecting power to the

mains supply connector will automatically charge the battery whether

the instrument is switched ‘on’ or ‘off’, except during testing. A high

level of internal isolation allows the instrument to be used while the

unit is supplied from the mains. An internal battery management system

switches the instrument off after ten minutes of inactivity. If the battery

approaches a very low state of charge the instrument turns itself off, and

mains power must be applied before the instrument can be used again.

Recorded test results and settings will not be lost when the instrument is

switched off.

Page 5

If the power lead supplied is not suitable for your mains connection,

do not use an adaptor. Always use a power lead fitted with the correct

plug.

The instrument is fitted with a two-pin IEC60320 power inlet. Most

power leads are made with three-core cable, so the ground connection

will not be used.

Power lead connection table

Connection UK/International USA

Earth/Ground Yellow/Green Green

Neutral Blue White

Live (Line) Brown Black

If using a fused plug, ensure that it is fitted with a 3 Amp fuse.

The instrument can be powered from 85 - 265 Vrms a.c. at 50/60 Hz.

The battery will charge as long as the mains supply is connected, except

when a test is in progress. The power On/Off button has a green LED,

which illuminates when mains power is present. For optimum battery

life, charge the battery after each use. A completely exhausted battery

will take 14 hours to recharge.

POWER LEAD AND BATTERY CHARGING

5

Cleaning

Disconnect the instrument and wipe it with a clean cloth slightly

damped with soapy water or Isopropyl alcohol (IPA).

Page 6

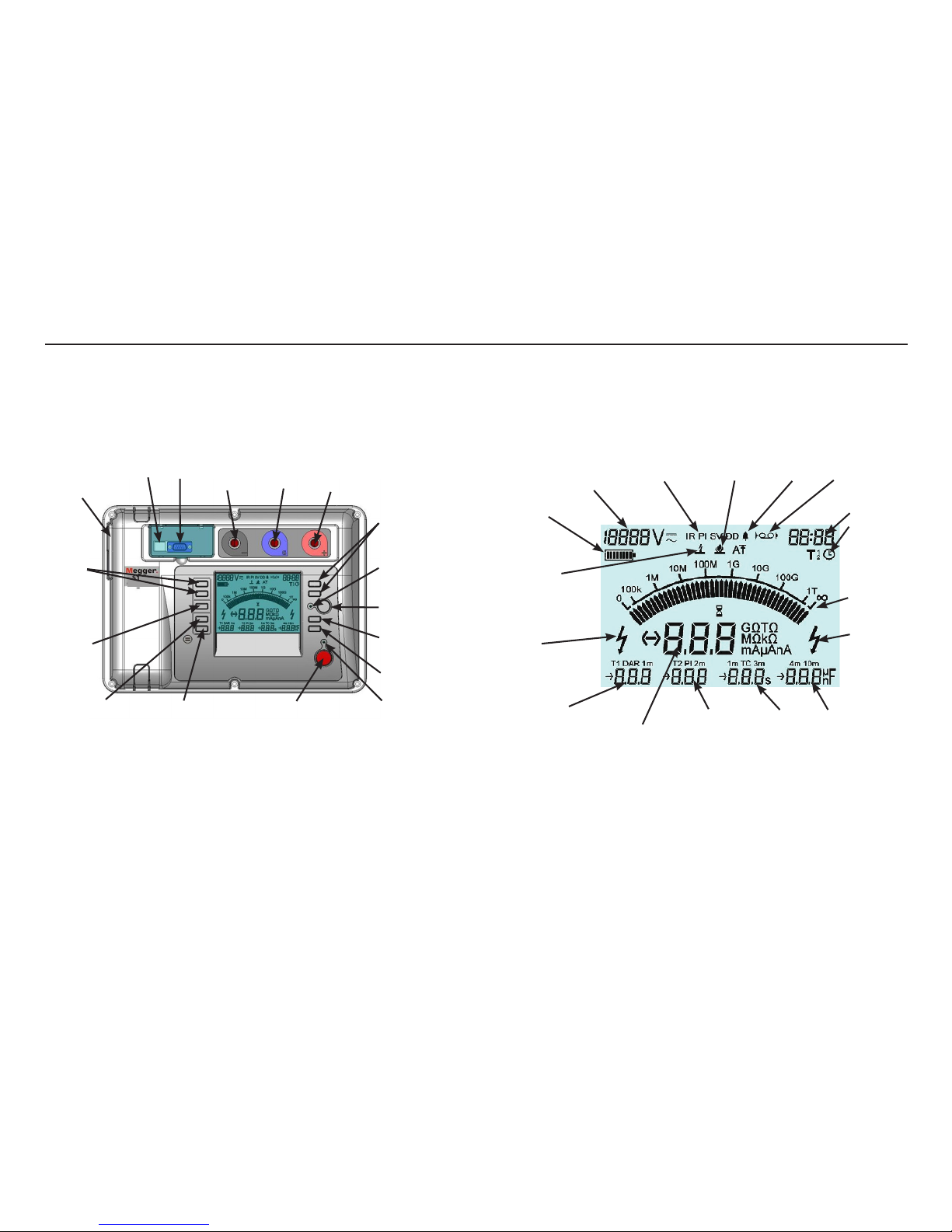

INSTRUMENT CONTROLS AND INDICATORS

6

Measurement terminals

-ve guard +ve

RS232

USB

Line

input

Time s and

t selectors

Voltage s

t selectors

Line input

Present

indicator

Power on/off

Ω/I selector

Burn indicator

Alarm

Data recording

Test modes

Voltage at

terminals

Battery level

Breakdown

indicator

High voltage

warning

indicator

High

voltage

warning

indicator

Analogue

display

Timers

Main, T1,

T2

Dielectric

absorption

ratio/T1 timer

Digital

display

Polarisation

index/timer

T2

Time

constant

Capacitance

display

Data record

High voltage

warning indicator

Test start/stop

ModeFunction

Backlight

on/off

S1-554

Page 7

7

During a test the display shows the actual voltage on the test leads. If

the test voltage is changed during a test, the new test voltage will be

displayed briefly.

When the test has stopped, the display continues to show the voltage

present on the test leads. Pressing either test voltage s or t button will

then display the test voltage immediately before the end of the test.

Test start / stop button

A test will only start if this button is pressed, held and then released as

soon as the red high voltage warning indicator LED lights. The LCD and

red LED high voltage warning indicators flash when the test starts.

A test will not start if the button is released before the red LED shows,

or pressed continuously for longer than 5 seconds. This is a safety

feature to prevent a test being started inadvertently.

The presence of a voltage greater than 50 V on the test leads is indicated

with flashing high voltage warning indicators. Testing is disabled if the

external voltage exceeds 160 V.

Testing will stop if the test start / stop button is pressed again, the

preset test time is reached, or, if the unit is not in burn mode, insulation

breakdown is detected.

When a test has finished, the instrument will discharge the load, which

may take some time. The operator must always check the load has been

discharged before touching the test leads.

Ω/I button

Pressing this button toggles the digital and secondary displays. The

Power On/Off button

The instrument will only turn on if this button is pressed, held and then

released when the display responds. The instrument will not turn on if

the button is released before the display responds, or if the button is

held down for too long. This is a safety feature to prevent the instrument

being inadvertently turned on.

The instrument is turned off either by pressing the button again, or if the

instrument is running on the battery, by timing out after 10 minutes of

inactivity.

Upon switching the instrument on the display will first show ‘Ini’ while it

undergoes a self-checking routine. When Ini disappears, the instrument is

ready for use.

Test voltage s and t buttons

Using these buttons one of six test voltages can be selected: 250 V, 500

V,

1 kV, 2.5 kV, 5 kV, and 10 kV. The selected voltage is shown on the

display.

A non standard voltage between 50 V and 10 kV can be selected by

holding down the ‘Fn’ function button whilst operating the buttons. The

selectable voltage is adjustable in 10 V steps between 50 V and 1 kV, and

adjustable in 25 V steps between 1 kV and 10 kV. An auto repeat facility

is enabled when the button is held down, allowing faster travel through

the range.

If there is an external voltage greater than 50 V on the test leads, the

high voltage warning indicators are flashed, and the display shows this

voltage instead. The instrument will not perform a test if this voltage is

greater than 160 V.

Page 8

8

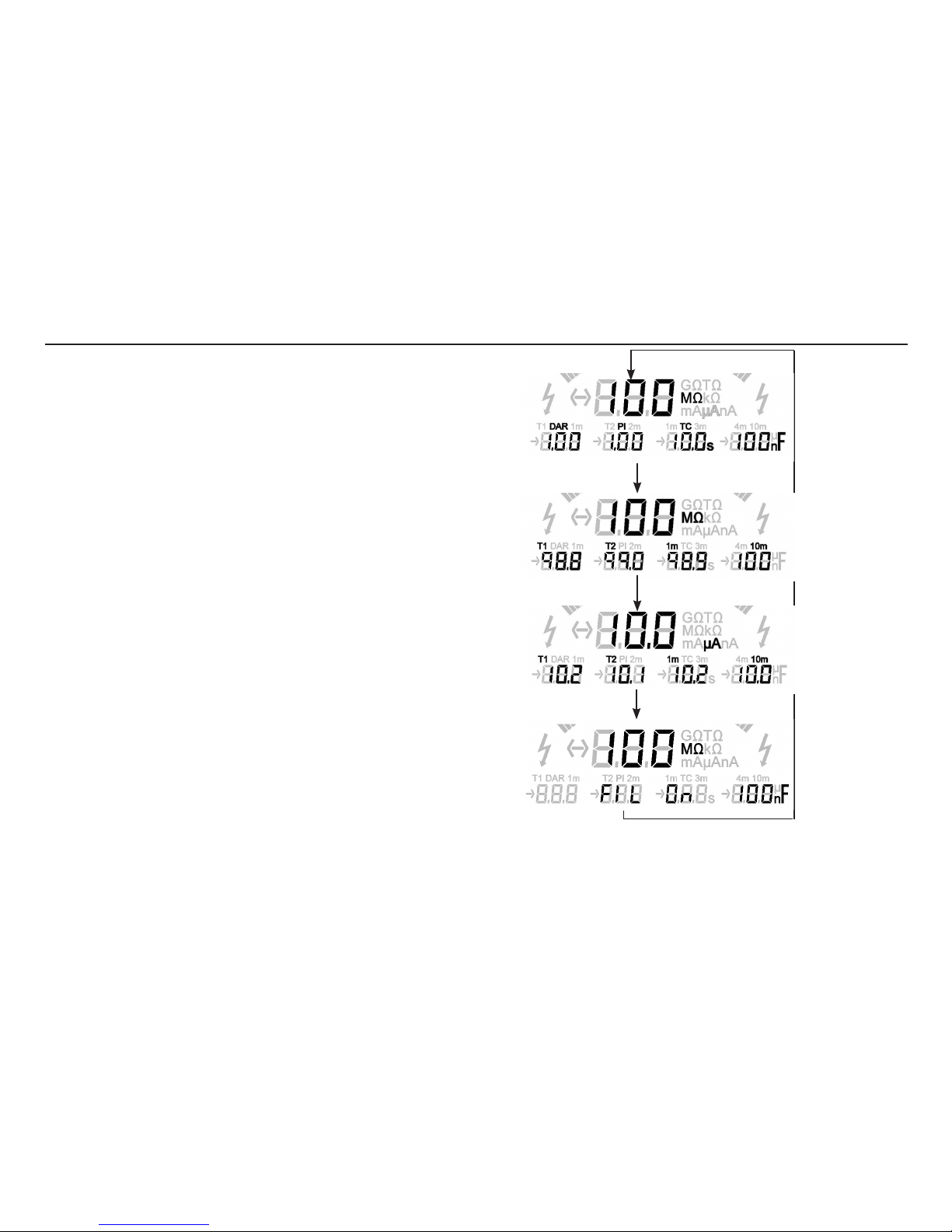

Figure 1 - The result of an insulation resistance test (IR)

Test settings: T1 and T2 times set in order to measure the DAR

Test conditions: test runs for longer than 10 minutes as this is required

for a PI reading.

details available when scrolling the secondary display will depend upon

the test mode selected, whether timers T1 and T2 have been set, and

the duration of the test. The digital display toggles between insulation

resistance and current.

In the ‘IR’, ‘PI’, and ‘DD’ modes the secondary display initially shows the

PI (polarity index), DAR (dielectric absorption ratio), and, on completion

of the test, the TC (time constant) and capacitance measurements.

Further presses of the Ω/I button cycles the display through insulation

resistances, currents, and the filter setting.

In the ‘SV’ (step voltage) mode, the secondary display cycles through

insulation resistances, currents, and the filter setting.

Figures 1 to 4 illustrate the display status for sequential ‘Ω/I’ key presses

in the different modes.

Press Ω/I

Press Ω/I

Press Ω/I

Press Ω/I

Page 9

Figure 2 - The result of a polarity index test (PI)

T

est settings: T1 and T2 times set in order to measure the DAR

Test conditions: timer defaults to 10 minutes, as this is required for a PI

reading

Figure 3 - The result of a dielectric discharge test (DD)

Test settings: T1 and T2 times set in order to measure the DAR

Test condition: test runs for longer than 10 minutes as this is required

for a PI reading.

9

Press Ω/I

Press Ω/I

Press Ω/I

Press Ω/I

Press Ω/I

Press Ω/I

Press Ω/I

Press Ω/I

Page 10

Figure 4 - The result of a step voltage (SV) test

Test condition: timer defaults to 5 minutes and test voltage defaults to

1000 V.

B button

Pressing this button toggles the display backlight on and off.

Fn button

The function button when pressed allows other keys to perform another

10

function. This is summarized in the table below. ‘Vs and ‘Vt represent

the

test voltage buttons. ‘Ts and ‘Tt represent the timer buttons.

Button Press Function Comment

Fn + Vs Increment in 10 V steps Voltage range between

50 and 1000 V

Fn + Vt Decrement in 10 V steps Voltage range between

50 and 1000 V

Fn + Vs Increment in 25 V steps Voltage range between

1000 and 10000 V

Fn + Vt Decrement in 25 V steps Voltage range between

1000 and 10000 V

Fn + Ts or Tt Cycle through timers Select main timer, T1 or

T2

Fn + Mode Cycle through IR modes Select breakdown, burn

or alarm limit for IR test

Fn + Ω/I Cycle through filter options Additional filtering

options are available in

IR mode

Fn +

Download mode See ‘Downloading

results’

Fn + Clear stored data The ‘record’ button is

pressed twice

Mode button

Press down on the ‘MODE’ button to cycle through and select the test

mode. Modes of test to be chosen from include an insulation resistance

‘IR’ test, a polarization index ‘PI’ test, a step voltage ‘SV’ test, and a

dielectric discharge ‘DD’ test.

Press Ω/I

Press Ω/I

Press Ω/I

Page 11

11

Manager will substantially reduce any such risk.

Recording to on-board memory

Press the record button to start and stop recording. When data recording

is enabled the record symbol will flash on and off repeatedly. Recording

can only be activated before testing commences. Results are stored at

15, 30, 45 and 60 seconds. After 60 seconds, at minute intervals up to

10 minutes. After 10 minutes, results are recorded at 5 minute intervals

until the test terminates. At each interval the recorded data will contain

selected voltage, test time elapsed, voltage applied, leakage current, and

insulation resistance.

Downloading results

Connect the instrument to the RS232 / USB port of a PC running

Download Manager. Refer to section ‘RS232 / USB connection’ for set up

details. Start Download Manager on your PC, select the S1-1054 driver

and right click the icon. Select ‘Download’.

Switch the instrument on and wait until initialisation is complete. Press

the function key along with the record key. The instrument now displays

‘dld’ to indicate download mode. Press and hold down test button until

download begins, shown by analogue display lighting clockwise.

Results will not be erased during this operation and so may be

downloaded repeatedly.

Deleting test results

Switch the instrument on and wait until initialisation is complete. Hold

down the function key and press the record key twice. The instrument

now displays ‘clr’ to indicate clear mode. Press and hold down test

button until clear process begins, shown by analogue display lighting anti

clockwise. Press the MODE button to exit without deleting the results.

The insulation resistance ‘IR’ test operates in either ‘burn’ or ‘breakdown’

mode, with an option of setting a resistance threshold ‘alarm limit’.

These modes can be cycled through and selected by holding down the

Fn button and pressing the Mode button.

Timer s and t buttons

The main timer can be set up to 99mins 59secs. The Ts button

increments the time, and the Tt button decrements the time in ten

seconds steps. An auto repeat facility allows the time to be set more

quickly. Setting a time of 00:00 disables the timer. With the timer

disabled a test has to be manually stopped.

To select timer Tmain, T1 or T2 hold down the Fn button whilst

repeatedly pressing the Ts or Tt buttons. To set the selected timer,

release the Fn button, and use the Ts or Tt buttons.

The minimum timer setting is 15 seconds for test voltages of 1000 V or

more, and 30 seconds below this.

Note: T2 cannot exceed the time on main timer unless it is disabled

(00:00). T1 cannot exceed the time on T2.

Record button

This button is used to start and stop recording. Recording can only be

activated before testing. When data recording is enabled the ‘record’

symbol flashes.

Data is stored in solid-state memory and under normal circumstances

will maintain its integrity for in excess of ten years, but may rarely be

corrupted or lost by external influences such as transients and static

discharge. Megger Limited cannot accept responsibility for any losses of

data. Regular downloading to a PC using software such as Download

Page 12

12

Recording to a PC

While carrying out a test, the instrument will output the test voltage,

test current and resistance every second. Refer to section ‘RS232 / USB

connection’ for setup details. Connect the instrument to the RS232 / USB

port of the PC. The data may be captured with Microsoft® HyperTerminal

or another suitable programme.

High voltage warning LED

This is a red LED next to the TEST button on the front panel. The LED

flashes when the voltage on the test inputs exceeds 50 V.

Line input present LED

This is a green LED next to the power On/Off button on the front panel.

It is illuminated whenever the mains power is connected.

Test terminals

There are three test terminals marked +, - and G. These terminals are

designed to accept only the test leads supplied. Shutters across the

terminals prevent accidental ingress of dirt and other objects. Test lead

plugs interlock with the shutters and are released by rotating the test lead

plug a quarter turn.

The Guard terminal is explained below and is only used in cases where

surface leakage currents need to be eliminated. Most measurements use

just the + and – terminals. The instrument’s internal voltage generator

drives the + terminal with respect to the – terminal, current being

measured in the – terminal.

Guard terminal

For basic insulation tests and where there is little possibility of surface

leakage affecting the measurement, it is unnecessary to use the guard

terminal i.e. if the insulator is clean and there are unlikely to be any

adverse current paths. However in cable testing for example, there may

be surface leakage paths across the insulation between the bare cable and

the external sheathing due to the presence of moisture or dirt. Where it is

required to remove the effect of this leakage, particularly at high testing

voltages, a bare wire may be bound tightly around the insulation and

connected via the third test lead to the guard terminal ‘G’.

The guard terminal is at the same potential as the negative terminal.

Since the leakage resistance is effectively in parallel with the resistance

to be measured, the use of the guard causes the current flowing through

surface leakage to be diverted from the measuring circuit. The instrument

therefore reads the leakage of the insulator, ignoring leakage across its

surface.

The display will show ‘FUS’ if the internal guard terminal fuse is found to

have blown. The instrument must be switched off to clear the message

before further testing is permitted. The fuse should be replaced by an

authorised repairer. The instrument may be used in the mean time if the

guard terminal not used. Refer to notes regarding measurements above

100 GΩ on page 17.

Page 13

13

RS232 / USB connection

Data can be transferred to a PC via an RS232 or USB port. If using the

RS232 port, use the null modem cable supplied. The RS232 settings

are 38400 Baud, 8 data bits, 0 parity, 1 stop bit, no flow control

(handshake).

If using the USB port, ensure that the USB driver supplied on the

accompanying product CD has been installed BEFORE connecting the

instrument. Installation instructions are also to be found on the CD.

Programmes such as Megger Download Manager may be used to

download the results stored in memory. Programmes such as Microsoft

®

HyperTerminal may be used to record real time data.

Battery bar graph

This is a battery symbol on the LCD display comprising 4 pairs of

segments. The battery is monitored continuously when the instrument

is turned on. The charge remaining in the battery is shown in the table

below.

Fully charged battery

50% charged battery

Tests cannot be started, and the battery

may fail at any time

Symbol flashes when there is not

enough charge for a test. The

instrument then turns itself off

When mains power is present the indicator shows the battery is being

charged by animating the segments of the bar graph.

Voltage at terminals

The test voltage will default to that selected in the previous test. If the

instrument has been switched off since the previous test, the test voltage

defaults to 250 V.

If there is an external voltage greater than 160 V present, this will be

displayed regardless of changes made to the test voltage. In this case the

instrument will not perform a test. The high voltage warning indicators

flash, and the beeper sounds, to warn of the hazard until the external

voltage becomes less than 50 V.

When testing, the voltage displayed is the voltage present at the test

terminals of the instrument. If the test voltage is changed, by pressing

either of the test voltage s and t buttons during a test, the new test

voltage is displayed momentarily.

After testing, the voltage displayed is the voltage present on the

terminals. To see what the voltage was immediately prior to the end on

the test, press either test voltage s or t buttons.

Timer indicator

The timer shows minutes and seconds. At the start of a test the timer

will start from zero and at the end of a test it will stop. The duration of

the last test remains on the display until another test is started.

Digital display

The digital display shows the resistance or current being measured

during a test. The Ω/I button toggles between the two. After a test the

Page 14

14

display shows the last measurement made until the timer or voltage test

settings are changed, or the test start/stop button is pressed.

Analogue display

This simulates an analogue meter movement to give the user a better

“feel” for how a measurement is progressing. The analogue display

shows resistance only.

The display is also used to indicate how ‘result download’ and ‘deletion

of results’ is progressing.

Secondary display

This part of the display shows the results of ‘time resistance’ method

tests.

‘Pre-Test / During test’ Key action table.

Button press Key action Fn + Key action

Pre-test During test Pre-test During test

Vs/Vt Increase / Increase / Increase / Increase /

decrease the decrease the decrease the decrease the

test voltage in test voltage in test voltage in test voltage in

major steps major steps minor steps minor steps

(IR only) (IR only)

Vs AND Vt Sets voltage Show set

to 500V voltage

Ts/ Tt Increase / Display set time Select main Display time

decrease the on main timer timer T1 or T2 set for main

time of the briefly timer, T1 or

selected timer T2 briefly

Ts AND Tt Reset timer to Display set Reset selected Display set

zero time on main timer to zero time on main

timer briefly timer briefly

Mode Select Test Cycle through

Mode IR modes

Ω/I Cycle through Cycle through Select filter Select firmware

results display results display option filtering level

of last test of current (IR only,

completed active test hardware filter

ON)

Record Turn recording Select

On/Off download or

clear stored

data

Vs and Vt represent the test voltage buttons. Ts and Tt represent the

timer buttons.

Page 15

15

On screen warning codes

Breakdown detection

If insulation breakdown is detected, the unit aborts the test and flashes

“brd” and the final test result alternately in the main digital display. This

display is disabled when in burn mode as the unit will continue the test

without aborting. The instrument detects breakdown in terms of a rapid

drop in test voltage commensurate with that caused by an arc across or

though the insulation under test.

Noise detection

Excessive noise during test

In environments such as HV switch yards or substations electrical noise

levels can be high enough to effect insulation test measurements. This

noise takes the form of induced currents in the measurement circuit.

The noise current is either picked up by test leads or induced directly in

the item under test. The MIT510/2, MIT520/2, MIT1020/2, S1-552/2 and

S1-1052/2 are all capable of accurate measurements with up to 2mA of

induced noise current. The S1-554/2 and S1-1054/4 are design for very

high noise environments and can provide accurate measurements with

up to 4mA of noise current present.

A level of noise exceeding the instruments specified capability will be

indicated by an alternating sine wave on the display. The test continues

while displaying the noise. If the noise drops back down the normal

display is resumed.

The effects of noise can be reduces significantly with the use of high

quality Megger screened test leads.

The picture displayed on the right shows the expected screen result of

an IR test on with a 5000V test voltage after 2 minutes 9 seconds. The

black and grey waveforms are displayed alternately while the noise is

present. When the noise is removed the wave form is replaced by the

correct reading.

Test aborted due to extremely high noise

Should an extremely high level of noise be present, particularly at the

start of a test, the instrument will indicate nSE (Noise). The instrument

will require switching off and on again to reset.

In certain rare circumstances breakdown of the circuit under test may

interfere with the sensitive current measuring circuit. In this event the

unit stops and also displays nSE. The instrument will again require

switching off and on again to reset.

Page 16

Press the ‘MODE’ button to cycle through and select the test mode.

Modes of test to be chosen from include an insulation resistance

‘IR’ test, a polarization index ‘PI’ test, a step voltage ‘SV’ test, and a

dielectric discharge ‘DD’ test. If timers T1 and T2 are set, the instrument

will automatically calculate the dielectric absorption ratio ‘DAR’ of

the insulation. PI, DAR, and IR values are automatically stored and

displayed if the data is available, irrespective of the selected test mode.

At the end of a test the instrument can be made to display either the

insulation resistances, insulation currents, the filter setting, or ratios plus

capacitance measurements by using the ‘Ω/I’ toggle button. See section

‘Ω/I button’ for cycling through results and toggling units.

Hardware filter

The hardware noise current filter may be switched on or off before, but

not during, testing. Turning the hardware filter off may be beneficial for

short test durations and higher load capacitances providing there is little

noise current.

This feature may be set in any mode, i.e. IR, PI, SV, or DD. Press and

hold the Fn button while repeatedly pressing the Ω/I button to scroll

through the filter options. Select FIL OFF for the fastest settling time, or

FIL ON for the default 4mA noise filter. Note that if FIL OFF is selected,

the firmware filtering option (refer to section “Insulation Resistance “IR”

test”) will be disabled. This setting may not be adjusted during a test.

Insulation Resistance ‘IR’ test

This is the default mode in which the instrument powers up. This

test mode measures insulation resistance continuously at the selected

voltage. The test voltage may be varied during an ‘IR’ test by pressing

the test voltage s or t buttons. The test duration can be set using the

‘main timer’. The test will finish automatically after this time has elapsed.

16

TEST MODE SUMMARY

On test completion, insulation capacitance and the time constant

associated with it is calculated and displayed.

Time Constant (TC) = R

ins

x C

ins

If timers T1 and T2 are set, the instrument will calculate and display

the DAR value under the segment ‘DAR’. On completion of the test,

the instrument will display the insulation resistances, measured at these

times under the segment symbols ‘T1’ and ‘T2’. If the test runs for longer

than 10 minutes, the instrument will calculate the ‘polarisation index’.

This value will be displayed under the display segment symbol ‘PI’.

On completion of the test, the instrument will display the insulation

resistance recorded at 1 minute and 10 minutes under the segment

symbols ‘1m’ and ‘10m’.

Pressing the ‘Ω/I’ button toggles the display to show the insulation

resistances, insulation currents, the filter setting, DAR and PI ratios, and

capacitance. The resistances and currents will be displayed under the

‘T1’, ‘T2’, ‘1m’ and ‘10m’ segment headings, the ratios under the ‘DAR’

and ‘PI’ segment headings. The capacitance reading is indicated by its

units of either ‘nF’ or ‘µF’. Refer to section ‘Ω/I button’.

Firmware filtering

There is an option (in Insulation Resistance mode only) to switch in

firmware filtering to average out slow variations. The firmware filter time

constants are 10, 30, and 100 seconds. The additional firmware filter

setting may be adjusted before or during a test, unless the filter was set

to FIL OFF before the test started, in which case the additional firmware

filtering option will be unavailable during testing. If the additional

firmware filter is switched in during a test, then any subsequent PI, DAR,

or TC calculated results are regarded as invalid, and are consequently

not displayed. The resistances and currents at these times are still

Page 17

17

indicated in the secondary displays should they be needed.

Press and hold the Fn button while repeatedly pressing the Ω/I button

to scroll through the filter options.

Breakdown mode / burn mode

The insulation resistance ‘IR’ test operates in either the ‘Burn’ or

‘Breakdown’ mode of operation. The default mode is breakdown. To

change mode press and hold the function button, then press and release

the mode button repeatedly until the desired mode is indicated by the

flashing symbol on the display. Release the function button to select it.

In the breakdown mode the ‘Breakdown Indicator’ will be illuminated –

refer to page 6. In this mode the test will automatically terminate should

the insulation break down to prevent damage to the insulation under

test.

In the burn mode the ‘Burn Indicator’ is illuminated – refer page 6.

The burn mode disables the normal breakdown detection and enables

the insulation test voltage to continue even after breakdown of the

insulation. This will enable the location of the failure to be seen and

heard. Due to the potential damage that could occur, the unit produces

two long beeps when starting a test with burn mode activated.

Alarm limit mode

The insulation resistance ‘IR’ test has an option of setting an alarm limit.

If this mode is selected, the instrument will beep should the resistance

reading exceed a user selectable threshold. To set the limit, hold down

the function button, then press and release the mode button repeatedly

until

the ‘A ’ symbol is flashing on the display. Use the timer s and t

buttons to set the resistance threshold between the limits of 10 kΩ and

35 TΩ. Release the function button to save the current limit. Adjusting

the alarm threshold level automatically activates the alarm limit mode.

This is indicated by the ‘A ’ symbol turning solidly on.

To toggle the alarm limit mode on/off, hold down the function button,

then press and release the mode button repeatedly until the ‘A ’ symbol

is flashing on the display. Release the function key to toggle.

Step voltage ‘SV’ test

This is a test based on the principle that an ideal insulator will produce

identical readings at all voltages, while an insulator which is being

over stressed, will show lower insulation values at higher voltages. The

main timer and test voltage settings can be adjusted if desired from

their default values of 5 minutes and 1 kV respectively. During the

test the applied test voltage incrementally steps by one fifth of the test

voltage setting final value every minute, for 5 minutes, taking successive

measurements until the final voltage is reached. Readings for the first 4

recorded values are displayed under the consecutive segment headings

‘1m’ to ‘4m’. The 5 minute reading is displayed by the main display.

If the range of measured insulation between readings is too wide for the

instrument to display, then those readings too small compared to the

final reading will be represented by ‘---’.

Polarisation index ‘PI’ test, and dielectric absorption ratio

‘DAR’ test

The ‘PI’ test is a particular example of a time/resistance method, which

takes the ratio of the insulation measured at 1 minute and at 10 minutes.

Good insulation generally shows an increase in resistance over a 10

minute period. Readings for contaminated insulation are fairly constant

because any absorption effects are masked by high leakage currents.

On completion of the test the polarisation index is displayed under the

segment heading ‘PI’.

Page 18

Polarisation Index (PI) = R

10 min

R

1 min

The ‘Dielectric Absorption Ratio’ is the term applied to the polarisation

index using other time intervals set by T1 and T2.

If timers T1 and T2 are both set, then the insulation resistance measured

at these times is also recorded. These are displayed together with

the calculated dielectric absorption ratio under the T1, T2, and DAR

segments respectively.

The instrument can be made to display either the insulation resistances,

insulation currents or ratios plus capacitance measurements by using the

Ω/I toggle button. See section ‘Ω/I button’ for cycling through results

and toggling units.

Dielectric Absorption Ratio (DAR) = R

T2 min

R

T1 min

Dielectric discharge ‘DD’ test

The ‘DD’ test is a diagnostic insulation test that allows ageing,

deterioration, and voids in the insulation to be assessed. The result is

dependent on the discharge characteristic, so the internal condition

of the insulation is tested, largely independent of any surface

contamination. On discharge the capacitive component of the discharge

current decays from a high value with a relatively short time constant of

a few seconds. The other current component, comprising the released

absorption current, decays from a lower value with a relatively long time

constant of up to several minutes. If this component of the discharge

current is large (>7 @ 500 V test voltage) then the insulation condition is

poor.

18

The main timer will default to 30 minutes, which is normally sufficient

time for full absorption to take place in an insulation material. The

default test voltage is set to 500 V. The ‘DD’ test requires the instrument

to measure the discharge current 1 minute after the removal of the

test voltage. At this time the capacitive current should be insignificant

compared with the released absorption current. On completion of the

test, the instrument uses this measurement along with the test voltage

and calculated capacitance to produce a figure of merit indicating the

quality of the insulation.

Dielectric Discharge (DD) = I

1 min

V x C

where I is the measured current expressed in milliamps (mA), V is the

test voltage in Volts (V), and C is the measured capacitance in Farads (F)

Measurements above 100 GΩ

Measurements up to 100 GΩ can be made without any special

precautions, assuming that the test leads are reasonably clean and dry.

The guard lead can be used to remove the effects of surface leakage

if necessary. When measuring resistances above 100 GΩ, the test leads

should not be allowed to touch each other, or any other object since this

will introduce leakage paths. Sharp points at the test lead connections

should also be avoided since this will encourage corona discharge.

The output is isolated, and so will float relative to ground such that

the positive terminal is at plus half of the test voltage, and the negative

terminal is at minus half of the test voltage with respect to ground.

Leakages therefore occur between the positive terminal and ground,

between the negative terminal and ground, and directly between the

positive and negative terminals. These leakages have a significant effect

and can occur through the air itself.

Page 19

19

If the guard lead is connected to ground, then since the negative

terminal is at the same voltage as the guard terminal, the leakage into

the negative terminal will be considerably reduced. This will improve

accuracy because the current flowing into the negative terminal is

measured by the instrument and used to calculate resistance. This

technique is only permissible if the item under test is isolated from

ground. “Isolated” in this context means insulated by a resistance of at

least 5 MΩ for the positive terminal, or at least 10 kΩ for the negative

terminal.

Conversely, if the positive terminal is grounded, then the negative

terminal will be at a voltage equal to the test voltage relative to ground,

which will result in an increase in leakage current, and worsening of

measurement accuracy.

When making measurements above 100 GΩ therefore, the user should

ground the Guard Lead where possible, otherwise parallel leakage paths

may occur.

+ Test V

2

- Test V

2

Ground

+

-

+ Test V

0V

Ground

Guard

+

-

Alternatively, screened leads are available as an optional accessory from

Megger. The lead to the negative terminal is fully screened. The screen

is plugged into the Guard terminal, diverting any stray leakage currents.

This considerably improves measurements made with a floating output,

where the leads might touch each other or anything other than the test

piece.

Circuit block diagram

For 5 kV instruments C1 = 47 nF, R1 = 50 kΩ, R2 = 40 kΩ

For 10 kV instruments C1 = 15 nF, R1 = 156 kΩ, R2 = 110 kΩ

+

-

100 MΩ

R1

R2

C1

Volts

Fuse

Cable

under

test

+

-

G

Discharge

resistance

Current

Ref

Voltage

control

Current

Limit

High

voltage

source

Page 20

Voltage input range

85-265 V rms, 50/60 Hz, 60 VA

Battery life

Typical capacity is 4 hours continuous testing at 10 kV with a 100 MΩ

load

Test voltages

250 V, 500 V, 1 kV, 2.5 kV, 5 kV, 10 kV ranges, adjustable in 10 V steps

from 50 V to 1 kV, and 25 V steps from 1 kV to 10 kV

Accuracy (23 °C, 10 kV)

10 kV 5000 V 2500 V 1000 V 500 V 250 V

±5% bis 2 TΩ 1 TΩ 500 GΩ 200 GΩ 100 GΩ 50 GΩ

±20% bis 20 TΩ 10 TΩ 5 TΩ 2 TΩ 1 TΩ 500 GΩ

Guard

2% error guarding 500 kΩ leakage with 100 MΩ load

Display range

Digital display 10 kΩ to 35 TΩ (3 digits)

Analogue display 100 kΩ to 1 TΩ

Short circuit/charge current

5 mA @ 10 kV

Capacitor charge time

<3 seconds per µF at 5mA to 10 kV

Capacitor discharge time

<250 ms per µF to discharge from 10 kV to 50 V

Capacitance measurement (500 V minimum test voltage)

10 nF to 50 µF (dependent on test voltage)

20

Capacitance measurement accuracy (23 °C)

±5% ±5 nF

Voltage output accuracy (0 °C to 30 °C)

+4%, -0% ±10 V of nominal test voltage at 1 GΩ load

Current measurement range

0.01 nA to 5 mA

Current measurement accuracy (23 °C)

±5% ±0.2 nA at all voltages

Interference rejection

1 mA per 600 V up to a maximum of 4 mA (selectable)

Filter

10, 30 and 100 second time constants (selectable)

Timer range

Counts up to 99 minutes and 59 seconds from start of test

15 second minimum setting for test voltage ≥1000 V

30 second minimum setting for test voltage <1000 V

Test regimes

Auto IR, PI, SV, DD

DAR is calculated automatically if timers T1 and T2 are set

Interface

RS232: 38400 Baud, 8 data bits, 0 parity, 1 stop bit, no flow control.

USB

Data storage

Data stored: selected voltage, test time elapsed, voltage applied, leakage

current, and insulation resistance. The PI, DAR, capacitance, time

constant and DD values are also stored if available at the end of the test.

Megger Download Manager may be used to transfer this data to a PC.

SPECIFICATIONS

Page 21

21

ACCESSORIES

Data output

Real time serial data output once per second of the test voltage, test

current, and resistance

Lead set

Three flexible silicon insulated leads with compact clamp

Safety

Meets the requirements of IEC61010-1 CATIV 600 V

EMC

Meets the requirements of EN61326-1

Operating uncertainties

Refer to www.megger.com

Operating temperature

-20 °C to 50 °C

Storage temperature

-25 °C to 65 °C

Ingress protection (lid closed)

IP65

Humidity

90% RH non-condensing at 40 °C

Dimensions

305 x 194 x 360 (mm) (12 x 7.6 x 14.2 inches)

Weight

7.1 kg (16lb) approx.

Order code

Included Accessories

3 m lead set, medium size insulated clips 6220-820

User guide on CD-ROM 2000-213

RS232 cable 25955-025

USB cable 25970-041

3 x 3 m lead set with large insulated clips 6220-811

Optional Accessories

HV test lead sets

3 x 3 m with un-insulated small clips 8101-181

3 x 8 m with un-insulated small clips 8101-182

3 x 15 m with un-insulated small clips 8101-183

3 x 10 m with medium insulated clips 1000-441

3 x 15 m with medium insulated clips 1000-442

3 x 3 m with large insulated clips 6220-811

3 x 10 m with large insulated clips 1000-443

3 x 15 m with large insulated clips 1000-432

Control circuit test lead set

2 x 3 m with small insulated clips 6220-822

Screened HV test leads

1 x 3 m, with 10 kV screened un-insulated small clips 6220-834

1 x 10 m, with 10 kV screened un-insulataed small clips 6220-861

1 x 15 m, with 10 kV screened un-insulated small clips 6220-833

Page 22

REPAIR AND WARRANTY

The instrument contains static sensitive devices, and care must be taken in handling the printed circuit board. If an instrument’s protection has been

impaired it should not be used, but sent for repair by suitably trained and qualified personnel. The protection is likely to be impaired if for example, it

shows visible damage, fails to perform the intended measurements, has been subjected to prolonged storage under unfavourable conditions, or has been

subjected to severe transport stresses.

NEW INSTRUMENTS ARE GUARANTEED FOR 1 YEAR FROM THE DATE OF PURCHASE BY THE USER.

Note: Any unauthorized prior repair or adjustment will automatically invalidate the Warranty.

CALIBRATION, REPAIR AND SPARE PARTS

For service requirements for Megger Instruments contact:

Megger Limited or Megger

Archcliffe Road Valley Forge Corporate Centre

Dover 2621 Van Buren Avenue

Kent CT17 9EN Norristown PA 19403

England. U.S.A.

Tel: +44 (0) 1304 502 243 Tel: +1 610 676 8579

Fax: +44 (0) 1304 207 342 Fax: +1 610 676 8625

Megger operate fully traceable calibration and repair facilities, ensuring your instrument continues to provide the high standard of performance and

workmanship you expect. These facilities are complemented by a worldwide network of approved repair and calibration companies to offer excellent

in-service care for your Megger products.

Returning your product to Megger - UK and USA service centres

1. When an instrument requires recalibration, or in the event of a repair being necessary, a Returns Authorisation (RA) number must first be obtained

from one of the addresses shown above. You will be asked to provide the following information to enable the Service Department to prepare in

advance for receipt of your instrument, and to provide the best possible service to you.

n Model, e.g. S1-1054/2.

n Serial number, to be found on the underside of the case or on the calibration certificate.

n Reason for return, e.g. calibration required, or repair.

n Details of the fault if the instrument is to be repaired.

2. Make a note of the RA number. A returns label can be emailed or faxed to you if you wish.

22

Page 23

3. Pack the instrument carefully to prevent damage in transit.

4. Ensure the returns label is attached, or that the RA number is clearly marked on the outside of the package and on any correspondence, before

sending the instrument, freight paid, to Megger. Copies of the original purchase invoice and packing note should be sent simultaneously by airmail to

expedite clearance through customs. In the case of instruments requiring repair outside the warranty period, an immediate quotation can be provided

when obtaining the RA number.

5. You may track the progress of your return on line at www.megger.com

Approved Service Centres

A list of Approved Service Centres may be obtained from the UK address above, or from Megger’s website at www.megger.com

Service note

Battery replacement

Should the internal lead acid battery require replacement the unit must be sent to a Megger authorised service agent. A replacement battery connection

wiring loom must be fitted to ensure future connection integrity. In addition the on screen battery charge level indicator will need to calibrated to the

new battery’s characteristics.

End of life disposal

WEEE

The crossed out wheeled bin placed on the Megger products is a reminder not to dispose of the product at the end of it’s product life with general

waste.

Megger is registered in the UK as a Producer of Electrical and Electronic Equipment.

The Registration No is WEE/HE0146QT

Batteries

The crossed out wheeled bin placed on the batteries is a reminder not to dispose of them with general waste at the end of their life.

This product contains a sealed lead acid battery 12V, 4Ah (NP4-12 type)

Battery replacement should only be performed by a Megger authorised repair agent, who will correctly dispose of the spent battery.

For the purpose of end of life disposal only, the battery can be accessed by removing the four recessed screws on rear of instrument and lifting inner

instrument out of outer case. Remove screws and remove the inner front cover to access battery.

The battery fitted in this instrument is classified as a Portable Battery and should be disposed of in the UK in accordance with Local Authority

requirements.For disposal of batteries in other parts of the EU contact your local distributor. Megger is registered in the UK as a producer of batteries.

The registration number is BPRN00142

23

Page 24

M

Megger Limited

Archcliffe Road, Dover

Kent CT17 9EN England

T +44 (0)1 304 502101

F +44 (0)1 304 207342

E uksales@megger.com

Megger

4271 Bronze Way, Dallas,

Texas 75237-1019 USA

T +1 800 723 2861 (USA ONLY)

T +1 214 333 3201

F +1 214 331 7399

E ussales@megger.com

Megger

Z.A. Du Buisson de la Couldre

23 rue Eugène Henaff

78190 TRAPPES France

T +33 (0)1 30.16.08.90

F +33 (0)1 34.61.23.77

E infos@megger.com

Megger Pty Limited

Unit 1, 11-21 Underwood Road

Homebush

NSW 2140 Australia

T +61 (0)2 9397 5900

F +61 (0)2 9397 5911

E ausales@megger.com

Megger Limited

Unit 106-550 Alden Road

Markham ON L3R 6A8 Canada

T +1 416 298 9688 (Canada only)

T +1 416 298 6770

F +1 416 298 0848

E casales@megger.com

Megger products are distributed in 146 countries worldwide.

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification or design without prior notice.

Megger is a registered trademark

Part No. S1-1054_2_UG_en_V08 0913

www.megger.com

Megger

501 Crystal Paradise Mall

Off Veera Desai Road

Andheri(w), Mumbai - 400053

Maharashtra

India

T +91 22 26740468

F +91 22 26740465

Megger GmbH

Obere Zeil 2

61440 Oberursel

Germany

T 06171-92987-0

F 06171-92987-19

Megger AB

Eldarvägen 4

Box 2970

SE-187 29 TÄBY

Sweden

T +46 8 510 195 00

F +46 8 510 195 95

Megger AG

Ob. Haselweg 630

5727 Oberkulm

Aargau

Switzerland

T +41 62 768 20 30

F +41 62 768 20 33

Loading...

Loading...