Megger PFL40A Instruction Manual

AVTMPFL40A-EN

Rev. C

June 2008

Instruction Manual

Portable Fault Locator

PFL40A

HIGH-VOLTAGE EQUIPMENT

Read this entire manual before operating equipment

M

Valley Forge Corporate Center

2621 Van Buren Avenue

Norristown, PA 19403-2329

U.S.A.

610-676-8500

www.megger.com

Instruction Manual

Portable Fault Locator

PFL40A

Copyright © 2007 Megger. All rights reserved.

The information presented in this manual is believed to be adequate for the intended use of the product.

The products described herein should not be used for purposes other than as specified herein.

Specifications are subject to change without notice.

WARRANTY

Products supplied by Megger are warranted against defects in material and workmanship for a period of

one year following shipment. Our liability is specifically limited to replacing or repairing, at our option,

defective equipment. Equipment returned to the factory for repair must be shipped prepaid and insured.

This warranty does not include batteries, lamps, or other expendable items, where the original

manufacturer's warranty shall apply. We make no other warranty. The warranty is void in the event of

abuse (failure to follow recommended operating procedures) or failure by the customer to perform

specific routine maintenance as indicated in this manual.

M

Valley Forge Corporate Center

2621 Van Buren Ave

Norristown, PA 19403-2329

610-676-8500 (Telephone)

610-676-8610 (Fax)

www.megger.com

Table of Contents

Upon Receipt of Product.........................................................................................................................................1

1 GETTING TO KNOW THE PFL..................................................................................................................3

1.1 Top Panel Controls ................................................................................................................................3

1.2 Rear Panel Connections.........................................................................................................................4

2 SAFETY ................................................................................................................................................................5

2.1 Safety is the responsibility of the user .................................................................................................5

2.2 General Safety Precautions....................................................................................................................5

2.3 Safety in Using the PFL.........................................................................................................................6

3 PREPARING FOR TEST .................................................................................................................................7

3.1 Site Preparation.......................................................................................................................................7

3.2 Making Circuit Connections .................................................................................................................7

4 CABLE TESTING ............................................................................................................................................ 11

4.1 Main Menu Operation ........................................................................................................................ 11

4.2 Typical Fault Location Strategy ......................................................................................................... 12

4.3 ARC Reflection Method..................................................................................................................... 13

4.4 Impulse Current (Surge) ..................................................................................................................... 14

4.5 Pulse Echo (Time Domain Reflectometry, TDR) .......................................................................... 17

4.6 Cable Burn Down (Fault Conditioning)........................................................................................... 18

4.7 Dielectric Test (Proof) ........................................................................................................................ 19

4.8 Decay Test (Optional Accessory)...................................................................................................... 20

5 SYSTEM WARNINGS.................................................................................................................................... 23

Warning Messages:............................................................................................................................................ 23

6 DE-ENERGIZE AND SYSTEM SHUTDOWN...................................................................................... 25

7 MAINTENANCE ............................................................................................................................................ 27

7.1 Pre-Maintenance Precautions ............................................................................................................ 27

7.2 Inspection and Maintenance .............................................................................................................. 27

7.3 Repairs................................................................................................................................................... 28

8 SPECIFICATIONS.......................................................................................................................................... 29

Available Modes ................................................................................................................................................ 29

Voltage Output.................................................................................................................................................. 29

Current Output.................................................................................................................................................. 29

Energy................................................................................................................................................................. 30

Coupling.............................................................................................................................................................. 30

Metering.............................................................................................................................................................. 30

Environmental ................................................................................................................................................... 30

Physical ............................................................................................................................................................... 31

Input Voltage Source (User specified) ........................................................................................................... 31

Standard Accessories ........................................................................................................................................ 31

Optional Modules/Accessories....................................................................................................................... 32

AVTMPFL40A-EN Rev C June 2008

i

Addendum A MTDR Analyzer........................................................................................................................33

Specifications ......................................................................................................................................................33

Top Panel Controls............................................................................................................................................35

Communications ports......................................................................................................................................35

Home Screen.......................................................................................................................................................36

Home Screen - Mode Options.........................................................................................................................36

Utilities.................................................................................................................................................................37

Test Parameters – Display Header ..................................................................................................................38

Trace Viewer Control ........................................................................................................................................39

TDR - Multiple Trace Capture.........................................................................................................................40

Arc Reflection – Test Contro...........................................................................................................................41

Impulse Current (Surge)....................................................................................................................................42

Decay Method ....................................................................................................................................................42

MTDR Lead length Calibration - Left Cursor Offset ..................................................................................43

Troubleshooting .................................................................................................................................................44

Addendum B CBL100HV Cable Reels...........................................................................................................45

Connections ........................................................................................................................................................45

Specifications ......................................................................................................................................................46

Connecting the Cable Reels..............................................................................................................................46

Addendum C COMLink (Version 1.08).........................................................................................................49

Introduction........................................................................................................................................................49

Software Installation ..........................................................................................................................................50

Connecting the PC to the MTDR ...................................................................................................................50

COMLink Home Screen...................................................................................................................................51

Transferring Wave Forms from the MTDR ..................................................................................................53

Multiple Waveform viewing .............................................................................................................................55

Print Waveform..................................................................................................................................................55

Communications functions...............................................................................................................................55

Setup Serial Port.................................................................................................................................................56

COM32................................................................................................................................................................56

AVTMPFL40A-EN Rev C June 2008

ii

List of Figures

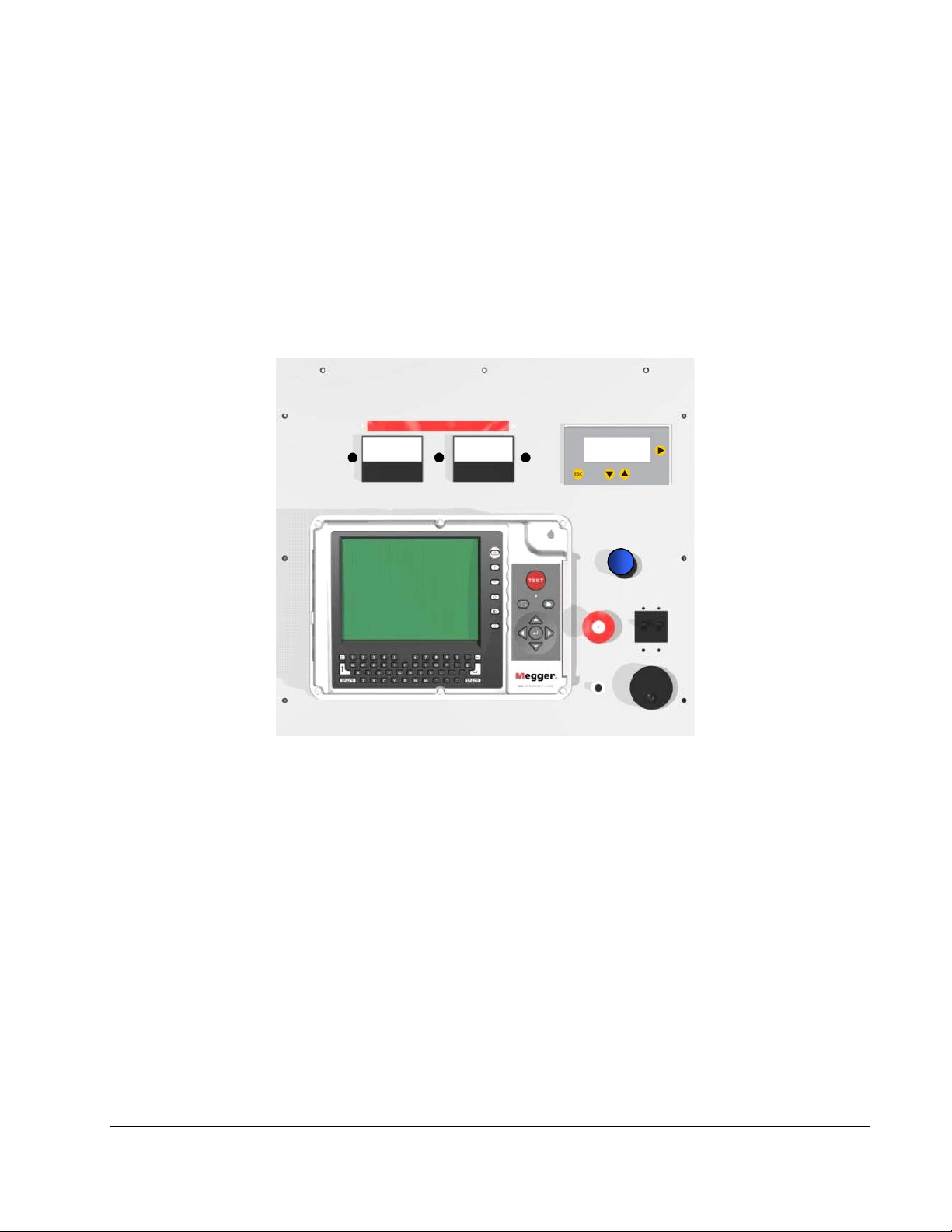

PFL40A Cable Fault Location System...................................................................................................................1

Figure 1-1. Top Panel Controls ..............................................................................................................................3

Figure 1-2. Rear Panel Connections.......................................................................................................................4

Figure 3-1 PFL40A Connection Diagram.......................................................................................................... 10

Figure 4 1: Main Control Menu........................................................................................................................... 11

Figure 4-2. Decay Coupler Connections ............................................................................................................ 22

Figure B-1. High-Voltage and Ground Cable Reel connections. ................................................................... 45

Figure C-1. COMLink Installation screen.......................................................................................................... 50

Figure C-2. COMLink Home Screen.................................................................................................................. 51

Figure C-3. Successful Connection Confirmation Screen ............................................................................... 51

Figure C-4. Select Operating Mode Screen........................................................................................................ 52

Figure C-5. MTDR Waveform Viewer............................................................................................................... 52

Figure C-6. File Transfer Menu ........................................................................................................................... 53

Figure C-7. MTDR Waveform Viewer............................................................................................................... 54

Figure C-8. MTDR Waveform Viewer – Control Box .................................................................................... 55

Figure C-9. Serial Port Set Screen........................................................................................................................ 56

M

iv

AVTMPFL40A-EN Rev C June 2008

Upon Receipt of Product

Prior to operation, check for loosened hardware or damage incurred during

transit. If these conditions are found, a safety hazard is likely, DO NOT attempt

to operate equipment. Please contact Megger as soon as possible.

AVTMPFL40A-EN Rev C June 2008

PFL40A Portable Cable Fault Location System

1

M

M

2

AVTMPFL40A-EN Rev C June 2008

1

GETTING TO KNOW THE PFL

1.1 Top Panel Controls

7

7

89

10

10

89

12

11

11

MTDR

MTDR

12

3

3

4

4

2

2

1

1

1. Power ON/OFF and Circuit Breaker

2. Emergency OFF (available with key option)

3. Main Menu Controller (See Section 4.1)

4. Dielectric Test Current Limit Control (See Proof Section 4.7)

5. Voltage Rate knob (controls the rate at which Voltage Control operates)

6. Voltage Control

7. High Voltage Power Supply ON Indicator

8. Voltage Meter (4/40kV dual range)

AVTMPFL40A-EN Rev C June 2008

5

5

Figure 1-1. Top Panel Controls

3

6

6

M

1.2 Rear Panel Connections

9. Current Meter (30/300 mA dual range)

10. 4kV (Optional module) Range Indicator

11. +24V Indicator (illuminates when Circuit Breaker is ON)

12. 30 mA Range indicator (active during Proof mode only)

1

1

3

3

2

2

89

89

7

7

5

5

4

4

6

6

Figure 1-2. Rear Panel Connections

1. External Warning Beacon circuit

2. Safety Interlock circuit

3. Input Power Connector

4. High-Voltage Output Receptacle

5. Ground Chassis Lug

6. Air Intake Fan (DO NOT BLOCK WHILE UNIT IS OPERATING)

7. Air Exhaust Fan (DO NOT BLOCK WHILE UNIT IS OPERATING)

8. Decay Coupler Input (optional)

9. External Ground Monitor Probe Input (optional)

4

AVTMPFL40A-EN Rev C June 2008

2

SAFETY

2.1 Safety is the responsibility of the user

Only qualified and trained operators should operate the PFL40A system.

Operator must read and understand this entire Instruction Manual prior to

operating the equipment. Operator must follow the instructions of this

Instruction Manual and attend the equipment while the equipment is in use. In

the event of equipment malfunction, the unit should immediately be deenergized and returned to Megger for repair.

2.2 General Safety Precautions

The PFL40A and the Cable Specimen (containing the fault) are both sources of

instantaneously lethal levels of electrical energy. Observe the following safety

precautions:

Observe all safety warnings on the equipment. They identify areas of

immediate hazard that could result in injury or death.

Use this equipment only for the purposes described in this manual. Observe

strictly the Warning and Caution information provided in this manual

Treat all terminals of high-voltage power equipment as potential electric

shock hazards. Use all practical safety precautions to prevent contact with

energized parts of the equipment and related circuits.

Use suitable barriers, barricades, or warnings to keep persons not directly

involved with the work away from test activities.

Never connect the test equipment to energized cables.

Do not connect to energized equipment or use in an explosive atmosphere.

Use the grounding and connection procedures recommended in this manual.

Personnel using heart pacemakers should obtain expert advice on the

possible risks before operating this equipment or being close to the

equipment during operation.

AVTMPFL40A-EN Rev C June 2008

5

M

2.3 Safety in Using the PFL

Never assume that either the PFL40A High-Voltage Output Cable or the

Cable Specimen is de-energized. Always treat exposed conductors and

connections as potential electric shock hazards

Do not use this equipment to locate faults on direct-buried unshielded or

secondary cable. Otherwise, dangerously high differences in potential may be

developed in the Surge Return path.

Do not use this equipment to locate faults on any cable that may be close

enough to an energized cable to allow a burn-through of the insulation of the

energized cable.

Do not operate the equipment without all metal panels securely fastened.

Do not operate the PFL if it has not first been stabilized in an upright

position.

Remain at least 3 ft (1 m) away from all parts of the High-Voltage circuit,

including all connections, unless the equipment is de-energized and all parts

of the test circuit are grounded. Be aware that any voltage applied to the

Cable Specimen will be present at the remote end(s) and at any other

exposed part of the cable, usually out of sight of the operator.

Use the grounding and connection procedures provided in this Instruction

Manual. If other manufacturers' equipment is used with the PFL, the user is

responsible for verifying that the grounding and interconnections between

the systems comply with each Manufacturer's Instructions.

Use Industry Accepted practices for making reliable, low-impedance

connections, capable of carrying large surge currents.

Maintain adequate air clearances between the exposed High-Voltage

conductor and any adjacent grounds to prevent spark-over. An uncontrolled

spark-over can create a safety hazard. Also, ensure the air intake fan filter

media (See Figure 1-2, No. 6) is clean and dry before each use.

Megger recommends the use of appropriately rated rubber gloves when

connecting and disconnecting to the High-Voltage terminals.

An Interlock circuit is provided (and its use is highly recommended) to

enable the operator to safely control access to the complete high-voltage

circuit.

An external beacon circuit is provided to enable the operator to install an

auxiliary warning beacon which will illuminate whenever the high voltage

power supply is energized.

AVTMPFL40A-EN Rev C June 2008

6

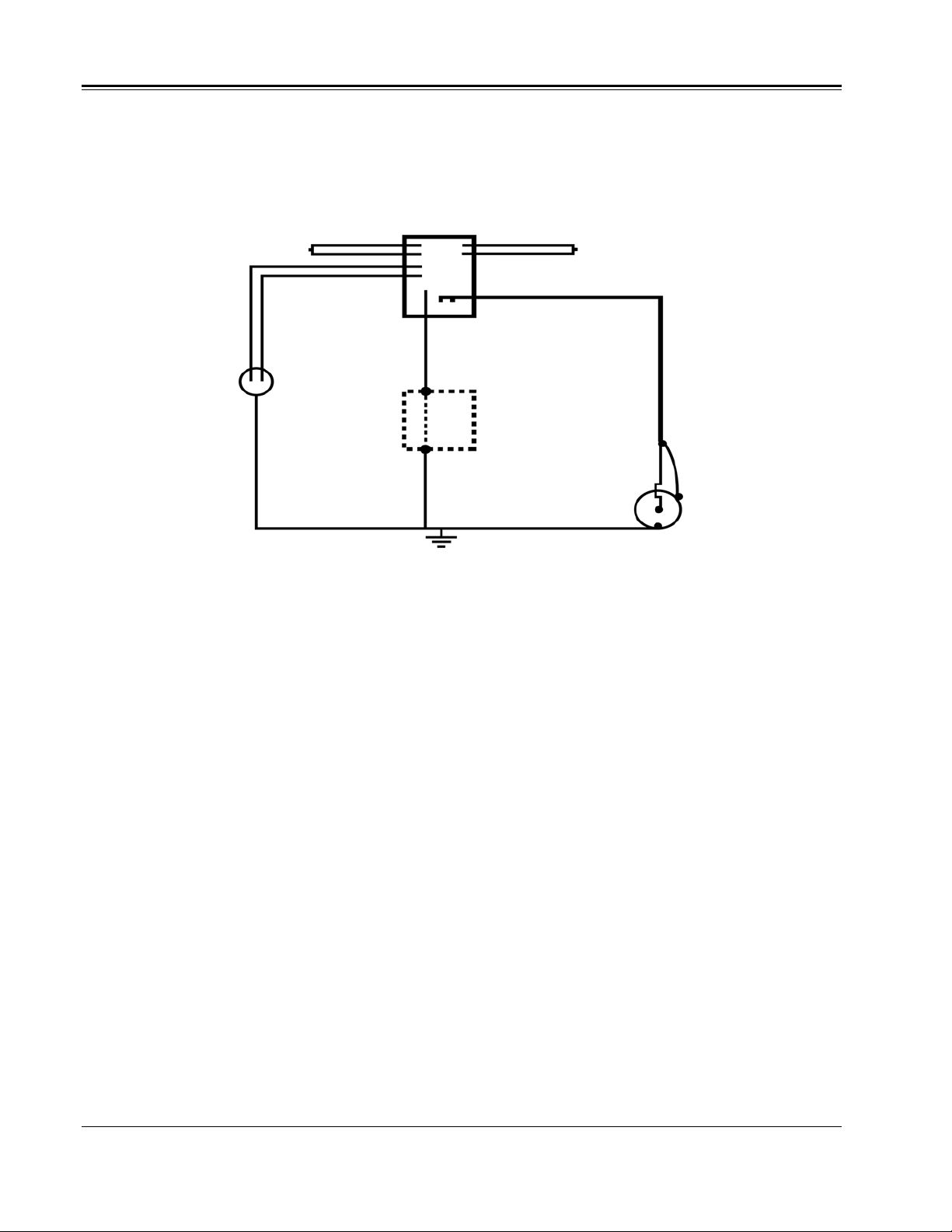

3

PREPARING FOR TEST

3.1 Site Preparation

Choose a location that meets the following conditions:

The vehicle (if used) can be safely parked. Set the brakes or block the wheels.

The location is as dry as possible.

There is no flammable material stored in the vicinity.

The test area is adequately ventilated.

Both the High-Voltage conductor and the Shield of the Cable Specimen are

accessible. Be sure all equipment is de-energized. Identify the faulted cables,

obtain access to both ends, and erect suitable safety barriers to protect the

operator from traffic hazards and to prevent intrusion by unauthorized

personnel. Beacon Warning lights are recommended.

Verify that the station ground is intact and presents an impedance of LESS

3.2 Making Circuit Connections

Connections should be made in the order as listed below and as shown in

Figure 3-1.

3.2.1 Vehicle Ground. If using a vehicle mounted PFL40A, ensure the

3.2.2 PFL Chassis Ground. If using a vehicle mounted PFL40A, use the

AVTMPFL40A-EN Rev C June 2008

than 100 milliohms to earth.

Vehicle Ground Terminal has less than 100 milliohm impedance to the

local station earth ground.

Megger supplied Safety Ground Cable to connect the PFL40A Chassis

Ground Terminal directly to the Vehicle Ground Terminal. If using a

portable PFL40A, use the Megger supplied Safety Ground Cable to

connect the PFL40A Chassis Ground Terminal directly to local station

earth ground. In all cases, take great care to ensure that the ground cable

connection is as short as possible. If your system is equipped with the

optional Safety Ground Monitor circuit, then at this time, connect the

7

M

External Ground Monitor probe between the PFL and an alternate local

station earth ground (outside the vehicle, if used).

3.2.3 Input Power Source Ground. If using a Vehicle Mounted PFL, ensure

the Input Power Source Ground Terminal is less than 100 milliohms

impedance to the Vehicle Ground Terminal. If using a portable PFL,

ensure the Input Power Source Ground Terminal is less than 100

milliohms of impedance to Local Station Earth Ground.

3.2.4 Cable Specimen Concentric Neutral. Ensure the Cable Specimen

concentric neutral has less than 100 milliohm impedance to Local Station

Earth Ground.

3.2.5 De-energize the PFL HV Cable and Cable Specimen, prior to

testing (Temporary connection). NEVER assume that either the PFL

High-Voltage Output cable or the Cable Specimen is completely

discharged. After ensuring an adequate Ground system (as above) and

before making any connections, the PFL40A High-Voltage output cable

and Cable specimen’s High Voltage conductor should be de-energized by

temporarily grounding each (to Local Station Earth Ground) with a

Safety Ground Stick (not supplied). Be sure that any stored energy is

completely discharged before continuing. Once de-energized, and while

wearing rated rubber gloves, connect a temporary Safety Ground Jumper

cable between the cable specimen’s high voltage conductor and its

concentric neutral.

3.2.6 Interlock circuit. User must provide a closed electrical circuit path

across pins B/E of the interlock jack before the PFL40A will function

properly. The connection should be made with the mating plug

(supplied) using a two-wire twisted pair, 18 gauge or larger, 300 V

insulated cable. Megger recommends the User remove the shorting wire

from the plug and run the circuit through a suitable test area interlock

system. In the event the interlock loop is opened, the test is automatically

terminated. When the optional external Decay Module is used, plug the

interlock into the Decay Module interlock cable jack and then connect

the Decay Module interlock plug into the normal PFL40A interlock

connector.

3.2.7 External Warning Beacon. The User is provided access to an electrical

circuit path, which closes only when the High Voltage Output is

energized. To utilize this path, using a two-wire twisted pair, 18 gauge or

larger and 600 V insulated cable, connect an external high voltage

warning beacon circuit across the provided pins A and B on the External

Beacon plug. The circuit can handle 3 A, 250 VAC, 60 W, 125 VA.

3.2.8 Surge Return. Only after the PFL40A has been properly grounded,

connect the high voltage output cable to the PFL40A. Then connect the

Surge Return Terminal (thin, black lead terminated with a Vise Grip™

style clamp) to the cable specimen concentric neutral.

AVTMPFL40A-EN Rev C June 2008

8

PREPARING FOR TEST

Do not allow any other conductors (if bundled) to “float” during test.

Connect all such conductors, if any, to the cable neutral, making firm,

short connections.

The Surge Return is the path that is designed to safely return the Surge

Current directly back to the Surge Capacitor through the coaxial shield of

the PFL high voltage output cable.

WARNING

THE SURGE RETURN IS ISOLATED FROM CHASSIS GROUND BY A 2000

OHM RESISTOR. THIS LIMITS CURRENT IN THE CASE OF A FAILED

CONCENTRIC NEUTRAL. THE SURGE RETURN CANNOT BE USED AS A

SUBSTITUTE SYSTEM GROUND.

SAFETY GROUND MUST BE CONNECTED TO THE LOCAL STATION EARTH

GROUND. THE IMPEDANCE OF THE LOCAL STATION EARTH GROUND

MUST BE VERIFIED AS HAVING AN IMPEDANCE OF LESS THAN 100

MILLIOHM TO GROUND. THE CONNECTION FROM THE STATION GROUND

TO THE SPECIMEN CONCENTRIC NEUTRAL MUST BE VERIFIED AS HAVING

LESS THAN 100 MILLIOHM OF IMPEDANCE.

FAILURE TO FOLLOW THIS PROCEDURE CAN RESULT IN THE DEATH OF

THE OPERATOR AND/OR THE DESTRUCTION OF THE EQUIPMENT.

The operator is isolated from transient voltages along the surge return by the

insulation system in the PFL and by the insulated jacket of the high voltage

output cable. Tears or breaks in the insulating jacket of the High-Voltage output

cable expose the Surge Return to the operator and poses a safety hazard and the

cable should be replaced.

DO NOT EXTEND the Surge Return lead of the HV Output Cable must not

be extended because this introduces excessive impedance in the Surge Return

and could result in exposed hazardous voltages.

3.2.9 High-Voltage Output Cable – Core Conductor. Once the Surge

Return connection is made as per section 3.2.8, then connect the HighVoltage Output Terminal (white lead with a red band terminated with a

Vise Grip™ style clamp) to the high voltage conductor of the cable

specimen. Be sure that the exposed conductor and clamp are sufficiently

insulated to withstand the test voltage.

3.2.10 Connect the Input Power Cord. Before making this connection,

Ensure the Input Power Source meets the requirements as listed in

Section 3.2.2 and Specifications Section 8. Also make sure that the

ON/OFF switch (Figure 1-1, No. 1) is in the OFF position. Connect the

input power cable to the PFL40A first, then to the power source.

3.2.11 Remove the Safety Ground Jumper cable. Once all of the above

connections are made, and while wearing rated rubber gloves, remove the

AVTMPFL40A-EN Rev C June 2008

9

M

temporary safety ground jumper cable (applied in Section 3.2.5.) between

the cable specimen’s high voltage conductor and its concentric neutral.

The system is now ready to begin testing.

PFL40A

Beacon Circuit

Input Power

110-130VAC /

220-265VAC

50/60 Hz

100 milliohms max

Figure 3-1 PFL40A Connection Diagram

Interlock Circuit

High-Voltage Output Cable

Safety Ground Cable (supplied)

100 milliohms max

Van (if used) Surge Return

100 milliohms max

100 milliohms max

Local Station

Earth Ground

Cable

Specimen

10

AVTMPFL40A-EN Rev C June 2008

4

p

3

2

CABLE TESTING

4.1 Main Menu Operation

The PFL system provides the User with up to six separate test or specimen

conditioning modes:

Arc Reflection

Impulse Current (surge, IC)

Pulse Echo (Time Domain Reflectometer, TDR)

Cable Burn Down

Dielectric Withstand (Proof)

Decay

To select any of the options listed, press the Up/Down arrows until

the Selection Arrow (corresponding to the desired Option) begins to flash.

Then press the Right Arrow button to activate the desired option.

PLEASE SELECT A MODE

ARC REFLECTION

SURGE (IC)

PULSE ECHO (TDR)

CABLE BURN DOWN

PROOF (0-40KV)

DECAY

LANGUAGE

ESC

Figure 4 1: Main Control Menu

Press to Activate the

Selected Option

Flashing arrow

indicates Selected

O

tion

Press to Select

1

Option

AVTMPFL40A-EN Rev C June 2008

11

M

4.2 Typical Fault Location Strategy

4.2.1 The most important aspect of locating a cable fault is the development of

a strategy that will allow the fault location to be safely and positively

identified. The following steps illustrate a typical approach to finding a

fault.

1. Deploy equipment, making sure that all company and equipment

manufacturers’ safety guidelines are followed.

2. Positively identify the faulted cable. If this has not been

accomplished by network diagnostics, isolate all of the suspect circuit

elements and use the TDR to determine if all of the elements appear

to have the same electrical length and the same features (splices,

transformers, etc., etc.) at approximately the same distance. (Please

see the MTDR operating instructions in Addendum A).

3. If all circuit elements appear to be equal, determine if the electrical

length of the circuit elements is in agreement with the known

physical length of the circuit. If it does not agree, adjust the TDR

propagation velocity accordingly. (Please see the MTDR operating

instructions in Addendum A for the propagation velocity adjustment

procedure).

4. If the MTDR data is inconclusive, use either the Dielectric Test or

Cable Burn Down function to positively identify the faulted phase.

Bring each phase up to test voltage individually. Note the breakdown

voltage when the faulted phase is found.

5. After the faulted phase has been identified, begin pre-location by

engaging the Arc Reflection Test (Please see section 4.3) mode and

configuring the MTDR for Arc Reflection Testing. Start testing at the

breakdown voltage noted during the previous step. Increase the test

voltage slowly. Note that the longer the cable is, the greater the cable

capacitance. The Arc Reflection breakdown voltage will be

significantly higher than the breakdown voltage observed during step

4 when dealing with very long cables due to capacitive voltage

division. If the fault signature seems to be unstable, increase the

discharge voltage slightly.

6. If the fault does not consistently breakdown at the maximum

allowable voltage, select the Cable Burn Down function. Raise the

voltage to either the maximum allowable voltage or until the fault

breaks down in a relatively consistent manner as indicated by

relatively stable current and voltage. Let the Cable Burn Down

function operate until the discharge current is stable. After a few

minutes of stable discharge, return to Arc Reflection.

7. Once the fault location has been pre-located by using the Arc

Reflection test, the fault can be pinpointed either by acoustic or

electroacoustic methods. Set the PFL to Impulse Current and set the

discharge voltage to the final voltage noted in step 5. Set the

AVTMPFL40A-EN Rev C June 2008

12

Loading...

Loading...