Page 1

M

PAT400 Series

Portable Appliance Testers

User Manual

Page 2

2

Thank you for purchasing the Megger PAT400 portable appliance tester.

For your own safety and to get the maximum benefit from your instrument, please ensure that you read and

understand the safety warnings and instructions before attempting to use the instrument.

These instruments are designed and manufactured by:

Megger Instruments Ltd

Archcliffe Road

Dover Kent

CT17 9EN

England

Megger Instruments Limited reserves the right to change the specification of these instruments at any time without

prior notice.

Page 3

3

CONTENTS

X.1 Unpacking the carton..............................................................................................................................5

X.2 Safety Warnings ...................................................................................................................................... 5

X.3 Symbols used on the instrument...........................................................................................................6

1. Instrument Layout............................................................................................................................................ 8

1.1 Overview of the PAT400 ......................................................................................................................... 8

1.2 Instrument layout .................................................................................................................................... 9

1.3 Button functions.................................................................................................................................... 10

1.4 HOT KEY descriptions..........................................................................................................................10

1.5 Display information............................................................................................................................... 11

1.6 Screen navigation ................................................................................................................................. 11

1.7 Text fields (free form box) and Drop down boxes..............................................................................11

1.8 Battery and fuse location, fitting and replacement............................................................................ 12

2. Getting started ...............................................................................................................................................15

2.1 Switching ON the PAT400 .................................................................................................................... 15

2.2 HOME screen explained ....................................................................................................................... 17

2.3 Switching off the PAT400 ..................................................................................................................... 17

3. Testing with a PAT400................................................................................................................................... 18

3.1 Connecting an asset to the PAT400 .................................................................................................... 18

3.2 Testing an asset .................................................................................................................................... 19

3.3 Test progress ........................................................................................................................................ 24

3.4 Remote probe and clip.......................................................................................................................... 25

3.5 Short circuit assets...............................................................................................................................28

3.6 Aborting a test.......................................................................................................................................29

3.7 Completion of testing ........................................................................................................................... 29

3.8 Test fail screen ...................................................................................................................................... 29

3.9 Visual failure.......................................................................................................................................... 30

3.10 Repair code............................................................................................................................................ 31

3.11 Cable compensation ............................................................................................................................. 32

3.12 WARNINGS ............................................................................................................................................ 33

4. Using the memory.......................................................................................................................................... 35

4.1 Important overview ...............................................................................................................................35

4.2 Saving a test result ............................................................................................................................... 36

5. Adding assets to memory.............................................................................................................................38

5.1 Adding assets to memory before testing ...........................................................................................38

5.2 Copying the previously added asset................................................................................................... 39

6. Editing and deleting assets and results ...................................................................................................... 41

6.1 Editing asset data.................................................................................................................................. 41

6.2 Deleting assets......................................................................................................................................42

7. DATA – Test results and data transfer......................................................................................................... 43

7.1 Backup to USB memory stick .............................................................................................................. 43

7.2 Importing / restoring data from USB memory stick ........................................................................... 44

7.3 Export results to CSV ........................................................................................................................... 46

7.4 Accessing test results .......................................................................................................................... 47

8. Test groups ....................................................................................................................................................50

8.1 Creating a test group ............................................................................................................................ 50

8.2 Allocating test groups to Hotkeys....................................................................................................... 52

8.3 Editing a test group............................................................................................................................... 54

8.4 Deleting a test group.............................................................................................................................55

8.5 Repeated Tests...................................................................................................................................... 56

9. Quick test - QT ...............................................................................................................................................57

10. SETUP menu options ................................................................................................................................ 59

10.1 Clients ....................................................................................................................................................59

10.2 Locations ...............................................................................................................................................62

10.3 Company................................................................................................................................................ 65

10.4 Quick test configuration.......................................................................................................................65

10.5 Date / Time settings .............................................................................................................................. 66

10.6 Changing Language.............................................................................................................................. 67

10.7 Restoring default settings....................................................................................................................68

Page 4

4

10.8 ABOUT - PAT400 software version and Megger contact details ......................................................70

11. PAT400 enhancements: Firmware release V2.40 ................................................................................... 71

11.1 User names, account status and Login .............................................................................................. 71

11.2 Power Up and Log in/Log out options ................................................................................................ 72

11.3 Managing accounts............................................................................................................................... 74

11.4 Recovery Login ..................................................................................................................................... 83

12. Reverse L-N Polarity (not available on all instruments) ........................................................................ 85

12.1 To enable Reverse L-N Polarity testing: ............................................................................................. 85

13. Measure PE Option (not available on all instruments) .......................................................................... 88

14. PAT4 compatibility .................................................................................................................................... 90

15. Care and maintenance .............................................................................................................................. 92

16. Carry case .................................................................................................................................................. 93

Appendix A – Test types explained ...................................................................................................................... 94

A.1 Continuity & bond testing .................................................................................................................... 94

A.2 Insulation testing...................................................................................................................................95

A.3 Leakage testing..................................................................................................................................... 95

A.4 Load testing........................................................................................................................................... 96

A.5 RCD testing............................................................................................................................................ 96

A.6 Power lead/extension lead testing ......................................................................................................97

A.7 Flash testing (PAT450 only)................................................................................................................. 97

A.8 Parallel Earth Path WARNING:............................................................................................................. 97

A.9 PAT400 Factory Default Test Groups.................................................................................................. 99

Appendix C - Specification .................................................................................................................................. 105

Appendix D - Ordering information ....................................................................................................................107

Appendix E - Repair and Warranty .....................................................................................................................108

Page 5

5

===================================================================

X.1 Unpacking the carton

Unpack the carton contents carefully. There are important documents that you should read and keep for future

reference.

Please complete the pre-paid warranty card and return it to Megger Instruments Limited as soon as possible to

help us reduce any delays in supporting you should the need assistance.

UK carton contents

PAT410, PAT420 and PAT450

European carton contents

PAT410, PAT420 and PAT450

1

PAT400 series appliance tester

1

PAT400 series appliance tester

1

Carry case + carry handle and strap

1

Carry case + carry handle and strap

1

Quick-start guide

1

Quick-start guide

1

Black test lead set with probe and clip

1

Black test lead set with probe and clip

1

IEC type power cord 30cm (Extension

lead adaptor)

1

IEC type Power cord 30cm (Extension

lead adaptor)

1

PC power supply test adaptor

1

Warranty card

1

Warranty card

1

Owners CD manual

1

Owners CD manual

1

Flash test lead (PAT450 ONLY)

1

Flash test lead (PAT450 ONLY)

1

Screen protector

1

Screen protector

1

9 V PP3 rechargeable NiMH Battery

1

9 V PP3 rechargeable NiMH Battery

X.2 Safety Warnings

The following safety warnings and precautions must be read and understood before the instrument is

used. They must be observed during use.

! For safety, only connect the PAT to a supply that is properly earthed. If in doubt, the supply should be

checked by a qualified electrician.

! Do not use the instrument if there are any signs of damage.

! All test leads, probes and clips must be in good order, clean and with no broken or cracked insulation.

! Probes and clips should be held behind the finger guard.

! Test leads not used during a measurement should be disconnected from the appliance tester.

! For dual voltage testers, both sockets can be live simultaneously.

! Only connect one asset to the PAT during testing.

! Tests should be carried out in the order recommended below. An appliance that fails a test should be

repaired before further testing is carried out.

Recommended sequence:

1. Earth bond/ continuity of the protective earth conductor (Class I devices)

2. Insulation test (or earth leakage)

In addition further tests can be performed, but ONLY AFTER 1 & 2 above

3. Operation test

4. Leakage test

! Only perform an operational test after the earth bond and insulation tests have been completed, as this

test operates at mains voltage.

! During testing, ensure no hazard will exist as a result of normal running or under fault conditions.

! During testing the unit under test (asset) should not be touched, other than using the appropriate

accessories, as faulty appliances can present a shock hazard.

! Do not touch the exposed parts of test leads during tests as hazardous voltages may be present due to

Page 6

6

potentially faulty appliance.

! Do not touch the IEC extension lead socket pins especially during a test, as hazardous voltages may be

present due to a potentially faulty appliance

! Assets should not be routinely flash tested. Where flash testing is required, refer to further guidance on

Flash testing, section A7

! Replacement fuses must be of the correct rating and type. Refer to section 1.8

! The USB connection marked thus should only be used by approved service personnel; nothing should

be connected to the USB port during testing.

! Only use a NiMH rechargeable 8.4 V PP3 battery, do not use a non rechargeable type as this could

become dangerous if charged by the instrument.

! Serviceable fuses should only be replaced with those that are suitably rated

! In case of an emergency use an easily accessible power point

! Only use Megger approved accessories with this product

CAT II

Measurement category II: Equipment

connected between the electrical outlets and the user’s equipment.

CAT III

Measurement category III: Equipment connected between the distribution panel and the electrical outlets.

CAT IV

Measurement category IV: Equipment connected between the origin of the low-voltage mains supply and the

distribution panel.

X.3 Symbols used on the instrument

F

Caution: risk of electric shock

G

Caution: refer to accompanying notes.

c

Equipment complies with relevant EU Directives

Equipment complies with ‘C tick’ requirements

Fuse

This equipment should be recycled as electronic waste

HV test lead in unlocked position

HV test lead in locked position

Battery type fitted

Do NOT connect to mains supply

Page 7

7

Page 8

8

1. Instrument Layout

1.1 Overview of the PAT400

The PAT400 series of portable appliance testers are fully automated testers for the fast safety testing of

portable electrical equipment. The PAT400s will operate from 230 Vac or, for UK variants 230Vac and 110

Vac supplies.

All warnings must be read and understood before the tester is used.

All operators should also be competent in the safety testing of electrical equipment and meet all the local

legal requirements before testing.

9 V PP3 rechargeable NiMH Battery is supplied - not fitted. This should be installed prior to first use. See

section 1.8 for instructions.

Page 9

9

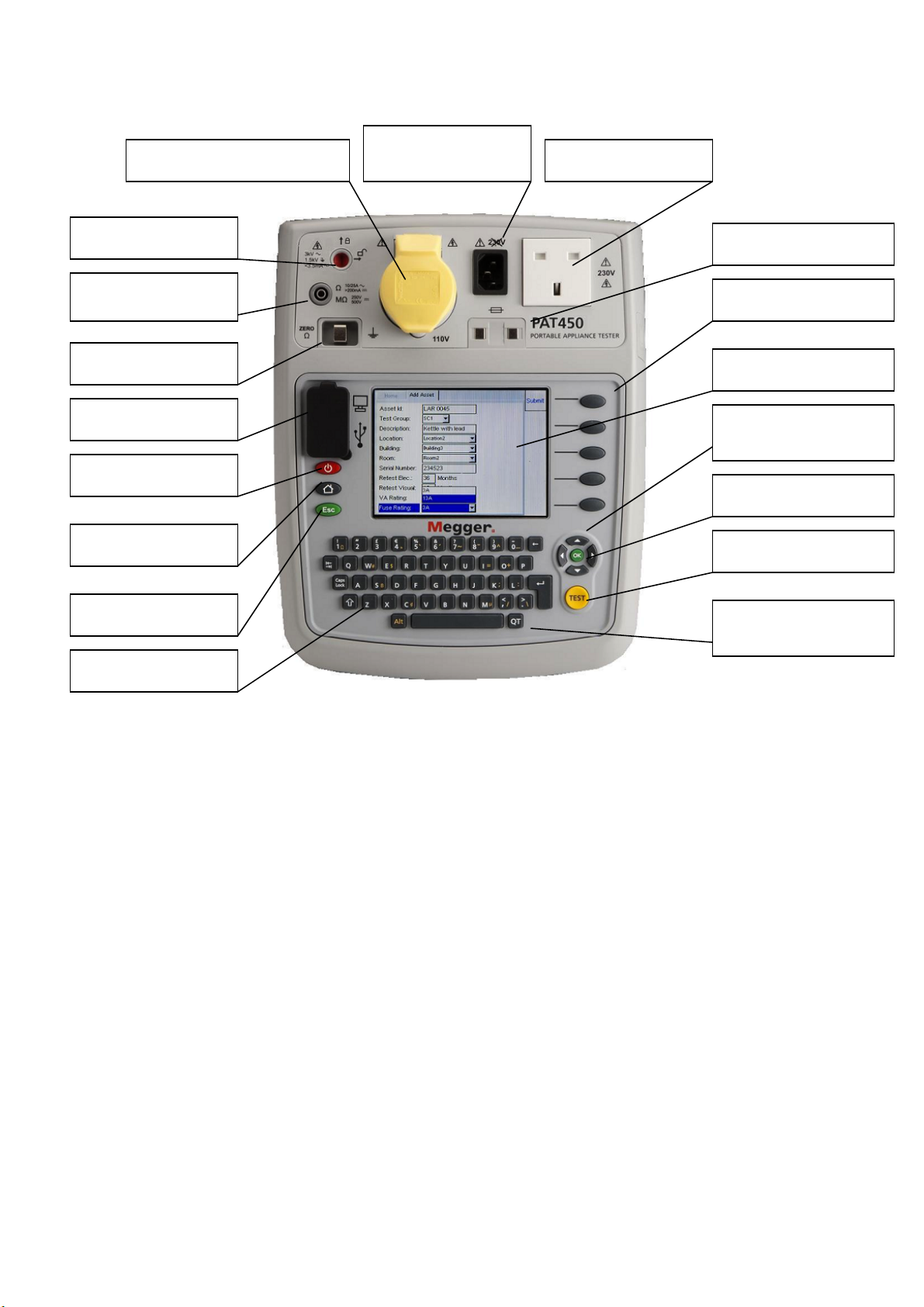

1.2 Instrument layout

Flash test socket

Bond/continuity

socket

Lead null post

USB interfaces

Power OFF

Home button

Escape button

Fuse checker

HOT KEYS

QVGA Colour display

Up/Down/Left/Right

navigation keys

OK button

TEST button

Quick test access

button

Qwerty keypad

110 V test socket (UK Only)

IEC/Extension lead

return test socket

Mains test socket

Page 10

10

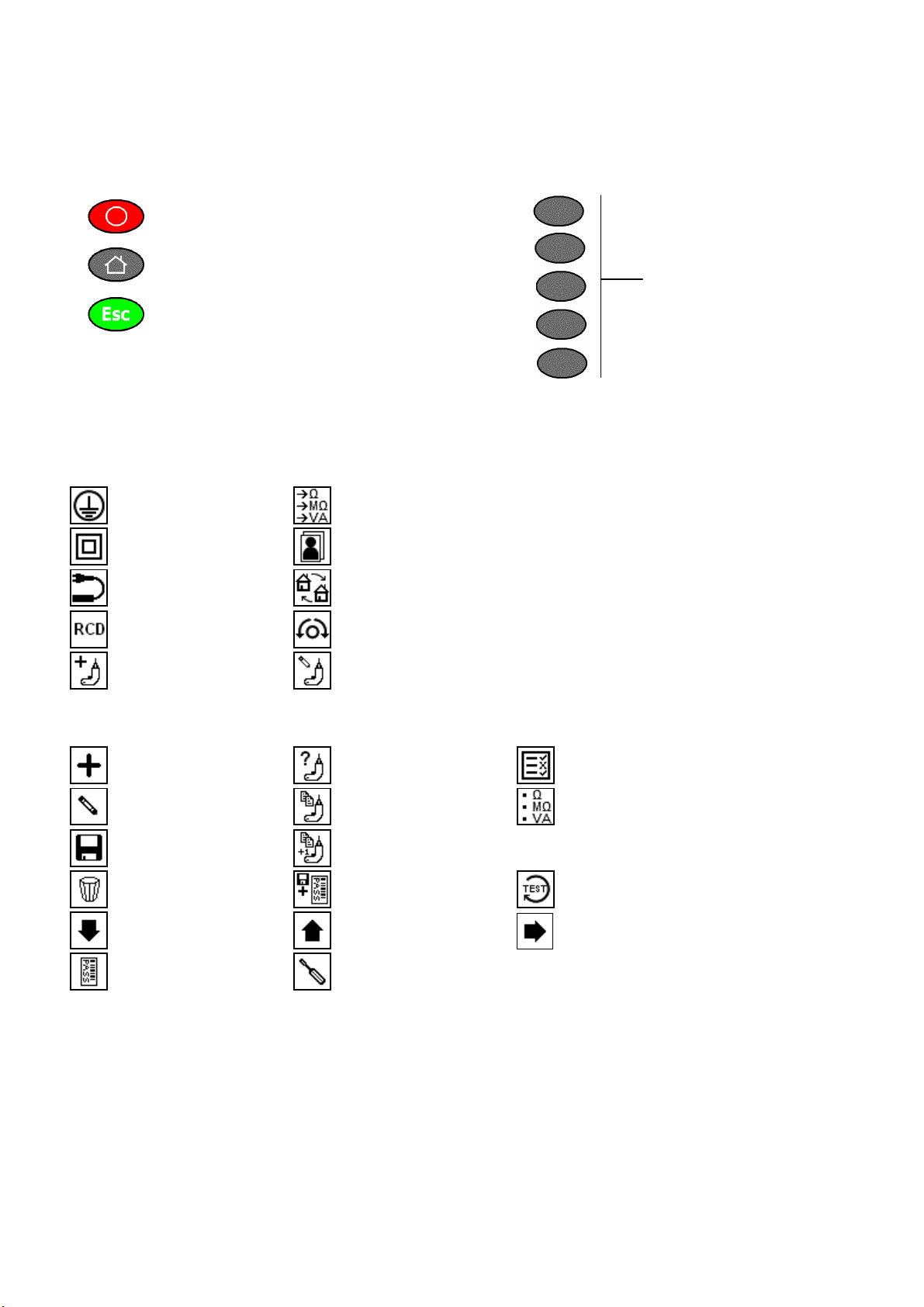

1.3 Button functions

Button functions

Power down – Prevents battery discharge

Returns to HOME screen

Escape – Exit screen without saving

1.4 HOT KEY descriptions

Home screen SETUP screen

Class 1 test groups Test group manager

Class II test groups Change client

Power/extension leads Change location

Portable RCDs Bond lead null

Add asset Edit asset

Other Hotkeys

Add Find asset View test result

Edit Copy last asset List test groups

Save Copy last asset (& increment asset ID)

Delete Save/print label Re-run test

Next page Previous page Login

Print barcode Repair code pop-up box activation

Hot keys.

Function depends on adjacent

display icon.

Used for fast selection of options

Page 11

11

1.5 Display information

NOTE: Users tab is only available on Firmware version V2.4 and above.

1.6 Screen navigation

Use the UP/DOWN and LEFT/RIGHT arrows to navigate around the menu and asset screens.

Use the OK button or CR (enter key) on the keyboard to select or confirm an action.

Use the HOME button to return to the main menu

Use the ESC button to exit or abort a function

1.7 Text fields (free form box) and Drop down boxes

When entering basic ASSET data, two types of text fields exist:

1) Free form boxes:

Main display area

Display and test

result information

Additional menu

options

Menu bar – Provides navigation path

and menu options. See NOTE below

Hot keys

Quick access to

frequently used test

groups, and other

options.

Page 12

12

Text can be entered from a keyboard or barcode scanner.

In some instances a “free form” box can become a “drop down” box, such as the asset ID field. In this case

it will appear with the drop down icon as below:

2) Drop down boxes:

Drop down boxes already contain a list of items. To access the list, navigate to the drop down box using

the UP/DOWN arrows then press the OK button.

1.8 Battery and fuse location, fitting and replacement

Battery type: 1 x 8.4V NiMH rechargeable (PP3, IEC6F22, NEDA 1604,6HR61)

Fuse type:

PAT400 EU, DE, AU, US 2 x 2A (F) HBC 50kA 600V (Part No. 90000-939)

PAT400 UK 1 x 250 Vac 100mA HBC 1.5KA (part No. 25413-295)

An 8.4V IEC6F22 NiMH rechargeable battery is fitted to all PAT400s. The battery is continuously charged

whilst the PAT400 is powered.

The battery provides a fast re-boot function when the PAT400 is unplugged, moved between locations and

Free form box.

Text or numbers can be

entered as required.

Drop down box.

Press OK to select from the available

list.

Alternatively, enter the first letter or

number of the contents you require,

and the search engine will jump to

that entry.

E.g. Enter “S” in the TEST GROUP

box and the cursor will jump to SC1.

If no contents start with that letter or

number, nothing will happen.

Page 13

13

re-started within 5 minutes.

The battery shall only be replaced by an equivalent rechargeable battery when the re-boot facility ceases

to work.

To replace the rechargeable battery:

1. Switch off the instrument.

2. Disconnect the instrument from any electrical circuits.

3. Remove the battery cover.

4. Remove the old battery and refit new battery following correct polarity (as marked on the battery

compartment)

5. Replace the battery cover.

Warning: Only use NiMH batteries! Do not attempt to recharge non-rechargeable (Primary)

cells in the PAT400. Doing so may result in instrument damage and may cause

personal injury.

Page 14

14

For Fuse replacement

Warning: Fuses are at mains potential. The electrical supply MUST be disconnected prior to

removing the fuse cover.

1. Switch off the instrument.

2. Disconnect the instrument from any electrical circuits.

3. Remove the fuse cover on the underside of the PAT tester.

4. Remove each fuse in turn and check for failure.

5. Replace as necessary.

6. If no fuses have failed, contact Megger Technical services group on 44 (0) 1304 502 102.

7. Replace fuse cover when complete.

Note: The symbol on the batteries is a reminder not to dispose of them with general

waste at the end of their life. Spent NiMH batteries are classified as Portable

Batteries and should be disposed of in the UK in accordance with Local Authority

requirements. For disposal of batteries in other parts of the EU contact your local

distributor.

Megger is registered in the UK as a supplier of batteries.

The Registration number is BPRN00142

Page 15

15

2. Getting started

2.1 Switching ON the PAT400

1) Connect the instrument to a suitable electrical supply, either 230 Vac (or 110 Vac for UK instruments).

For testing 230 V electrical equipment, connect the PAT tester to a 230 V electrical outlet.

For testing 110 V electrical equipment, connect the PAT tester to a 110 V electrical outlet, using the

optional 110 V to 230 V supply lead adaptor. Refer to section 3 for further details.

The appliance tester will automatically start when connected to the mains supply.

IMPORTANT: DO NOT connect any equipment to the PAT tester until it has been switched on and

passed its self test.

Connected equipment will create a relay error and necessitate restarting the PAT

tester. Power should be disconnected and reconnected.

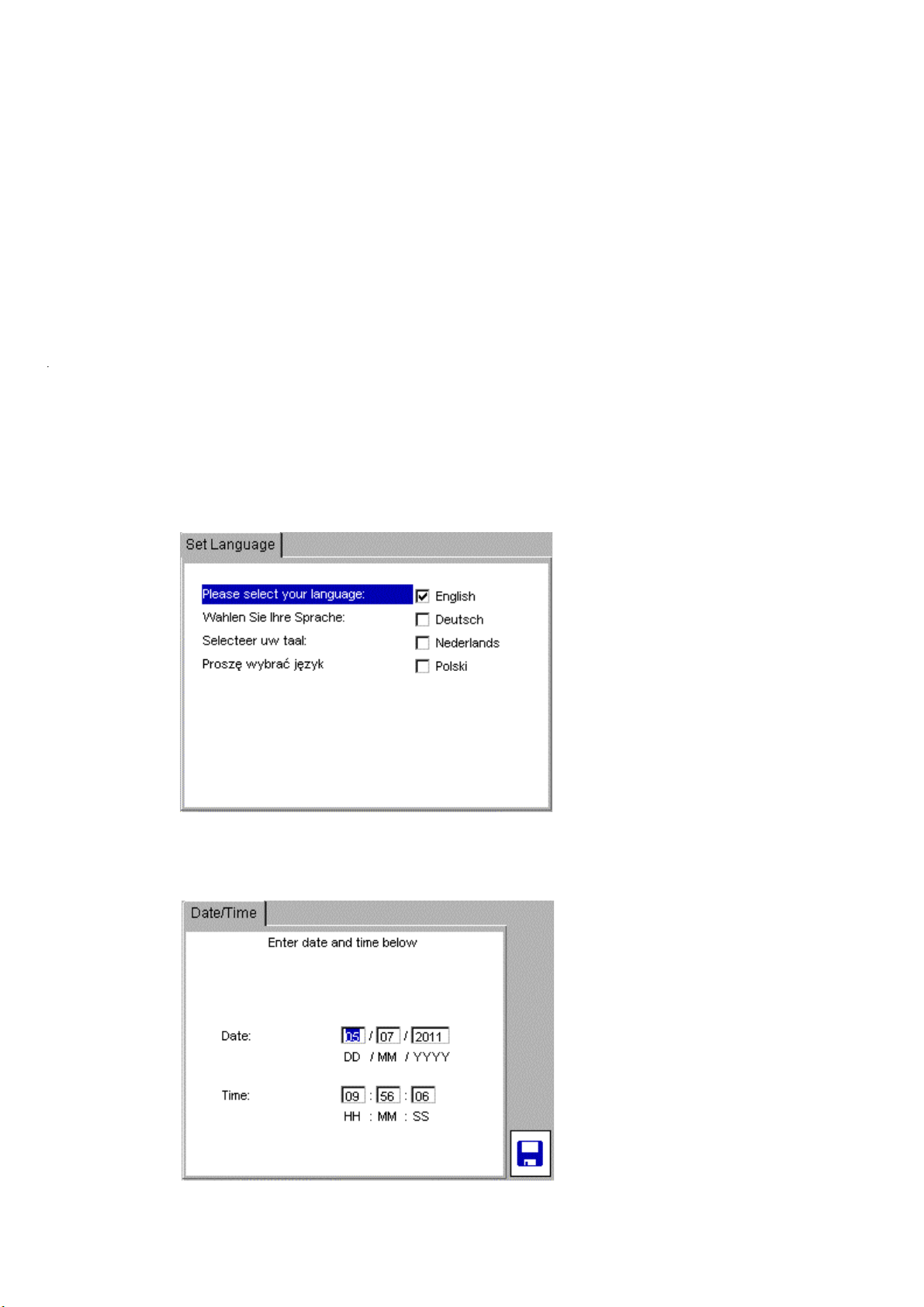

2.1.1 Start up- initialisation

The first time the PAT tester is started the instrument will ask for the operating language, time and

date to be set.

1) Use the UP/DOWN arrows to select the operating language from the options listed.

2) Press OK when complete

Page 16

16

3) Using the RIGHT/LEFT and OK keys to enter the date and time

Date format is DD / MM / YYYY

Time format is 24 Hr Hr / Min / Sec

4) Press the SAVE HOTKEY to accept changes.

Further changes can be made in the menu SETUP options section 10.5

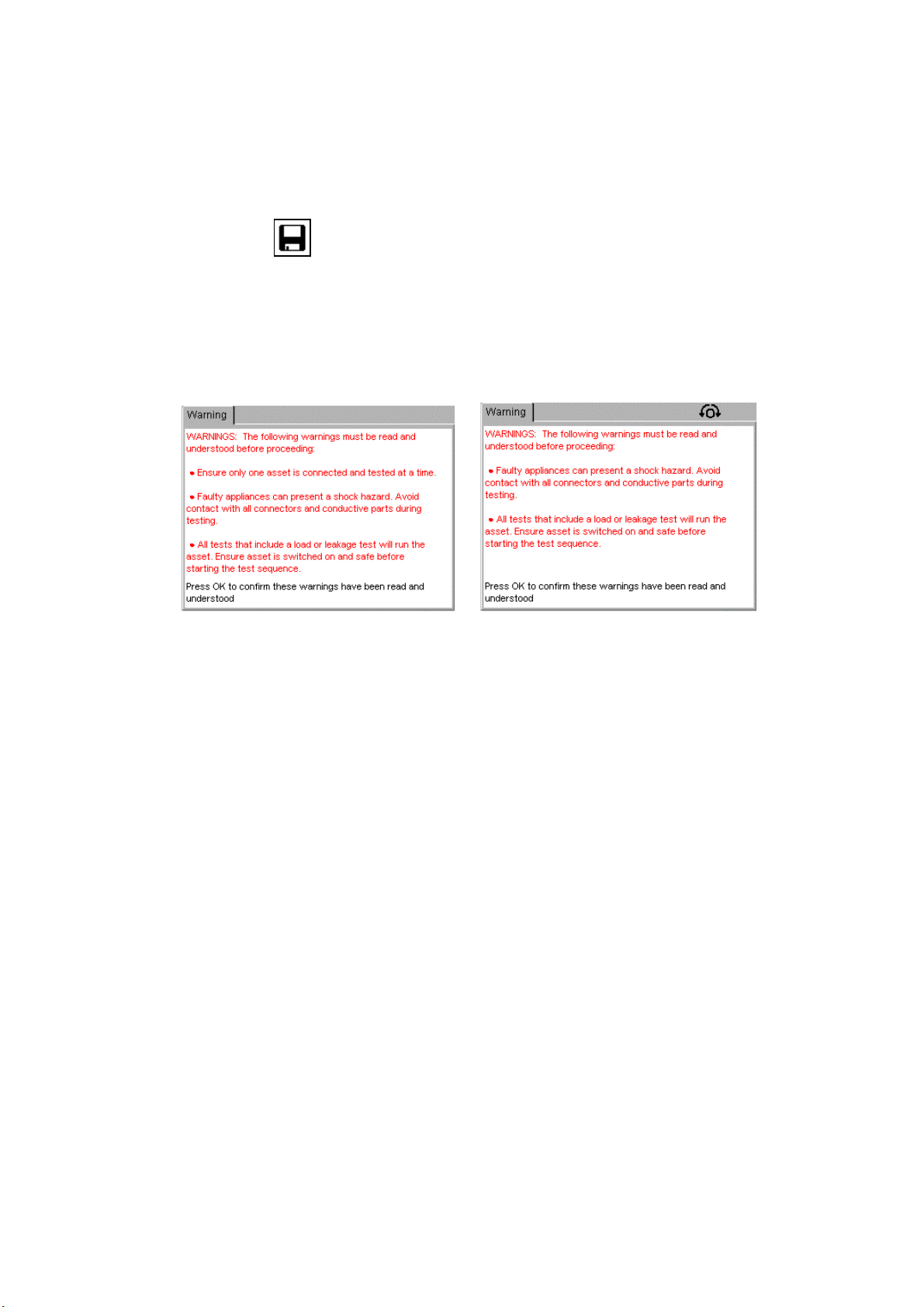

On completion of the initialisation the following warning screen is displayed when the PAT tester is

switched on.

UK configured PAT400 instruments Non- UK configured PAT400 instruments

NOTE: This screen is not displayed if the PAT tester is re-started within five minutes of

being un-plugged, or when the PAT tester restarts from the same screen as before.

5) Press OK to confirm you have read and understood these warnings. The instrument will display the

following HOME screen when all initial tests pass.

Page 17

17

2.2 HOME screen explained

The HOME screen is the start point of all testing.

2.3 Switching off the PAT400

2.3.1 Normal Power-Off

To switch off the tester, press the RED off button . The display will show the message

“It is now safe to remove power”

Now the mains plug can be removed from the supply.

Switching off using this button prevents the “FAST Re-start” battery from discharging unnecessarily.

2.3.2 FAST Re-start

If the tester is to be moved to a new location and testing continued, simply unplug the unit from the

mains supply and reconnect it in the new location. The appliance tester will enter a hibernation

mode during the move and restart instantly from the point power was disconnected, without any

delay.

Any test results are retained. On reconnection the previous test result can still be saved.

The rechargeable 8.4 V NIMH battery is used to maintain hibernation status whilst unplugged. This battery

is continuously charged whilst the appliance tester is connected to the mains supply.

Continuous use of the hibernation mode will discharge the battery. Should the move take longer than 5

minutes, the appliance tester will leave hibernation mode and complete a full power down.

Menu functions:

Home

Test launch screen

HOT KEY access

Instrument status

Setup

Client

Location

Company

Quick tests

Date/Time

Language

Default settings

About

DATA

Backup to USB

Restore from USB

Export to USB (CSV)

View results

Users

Login / Logout

Expert Options

Manage Users

Class I test groups

Class II test groups

Class IEC (Power) and

extension lead test groups

Plug-In RCD test groups

Add asset - fast access

Page 18

18

3. Testing with a PAT400

3.1 Connecting an asset to the PAT400

Assets are tested through the test connectors on the top of the instrument. An asset is simply plugged into

the appropriate socket.

A power cord (IEC lead), or an extension lead needs to be “wrapped back” to the small IEC socket on the

top of the instrument. This allows automatic testing of continuity and polarity without connecting the remote

probe.

Standard Class I and Class II assets will also use the additional remote probe for BOND, INSULATION or

LEAKAGE testing. The instruction to connect it is displayed on the screen at the appropriate time.

The following drawings show how the asset under test should be connected at the start of testing.

NOTE: The dotted line indicates where a 110 V asset would be connected (UK PAT testers only).

Other test leads may need to be connected during the test sequence. Follow onscreen instructions.

NEVER CONNECT MORE THAN ONE ASSET AT A TIME.

3.1.1 Connecting a Class I or Class II asset.

To connect standard Class I or Class II equipment to the

PAT400:

1) Plug the asset into the 230 V test socket on the PAT400.

To connect 110 V equipment to the PAT400:

1) Plug the asset into the 110 V test socket on the PAT400.

3.1.2 Connecting an IEC type power cord or 110 V (Power) lead

To connect a standard IEC type power cord (computer type

power lead) to the PAT400:

1) Connect the mains plug to the mains test socket on the

PAT400.

2) Connect the IEC plug to the IEC socket.

To connect a 110 V power lead, use the 110 V to IEC plug

adaptor (see optional accessories).

1) Connect the 110 V mains plug to the 110 V test socket

2) Connect the free end of the 110 V power lead to the 110V

adaptor plug.

3) Connect the 110 V adaptor IEC connector to the IEC socket

Page 19

19

on the PAT400.

3.1.3 Connecting an extension lead

To connect an extension lead to the PAT400:

1) Connect the mains plug to the mains test socket on the

PAT400

2) Using the extension lead adaptor, connect the furthest socket

on the extension lead to the IEC socket on the PAT400.

To connect a 110 V power lead, use the 110 V to IEC plug

adaptor (optional accessory).

1) Connect the 110 V mains plug to the 110 V test socket

2) Connect the free end of the 110 V power lead to the 110V

adaptor plug.

Connect the 110 V adaptor IEC connector to the IEC socket on

the PAT400.

3.1.4 Connecting a portable RCD

To connect a portable RCD to the PAT400:

1) Connect the RCD to the 230 V test socket on the

PAT400.

2) Using the IEC test lead adaptor, connect the IEC

plug of the adaptor lead into the IEC socket on the

PAT400.

3) Connect the MAINS plug of the IEC test lead

adaptor into the RCD.

3.2 Testing an asset

The PAT400’s are designed to automatically test electrical equipment, using TEST GROUPS.

A “TEST GROUP” is a specific group of tests suitable for the type of asset being tested.

The PAT tester is shipped with a pre-defined set of test groups. However others can be added as required,

up to a maximum of 100, see section 8.

Before a test will run, a TEST GROUP must be selected. There are three options to start the test

sequence:

• OPTION 1 Select a test group from the HOTKEY options

• OPTION 2 Press the TEST button – This takes you to the TEST ASSET screen.

• OPTION 3 Scan the asset ID with a bar-code scanner, then press TEST (asset details must

already be stored in the PAT400), otherwise PAT400 defaults to ADD ASSET

screen.

Page 20

20

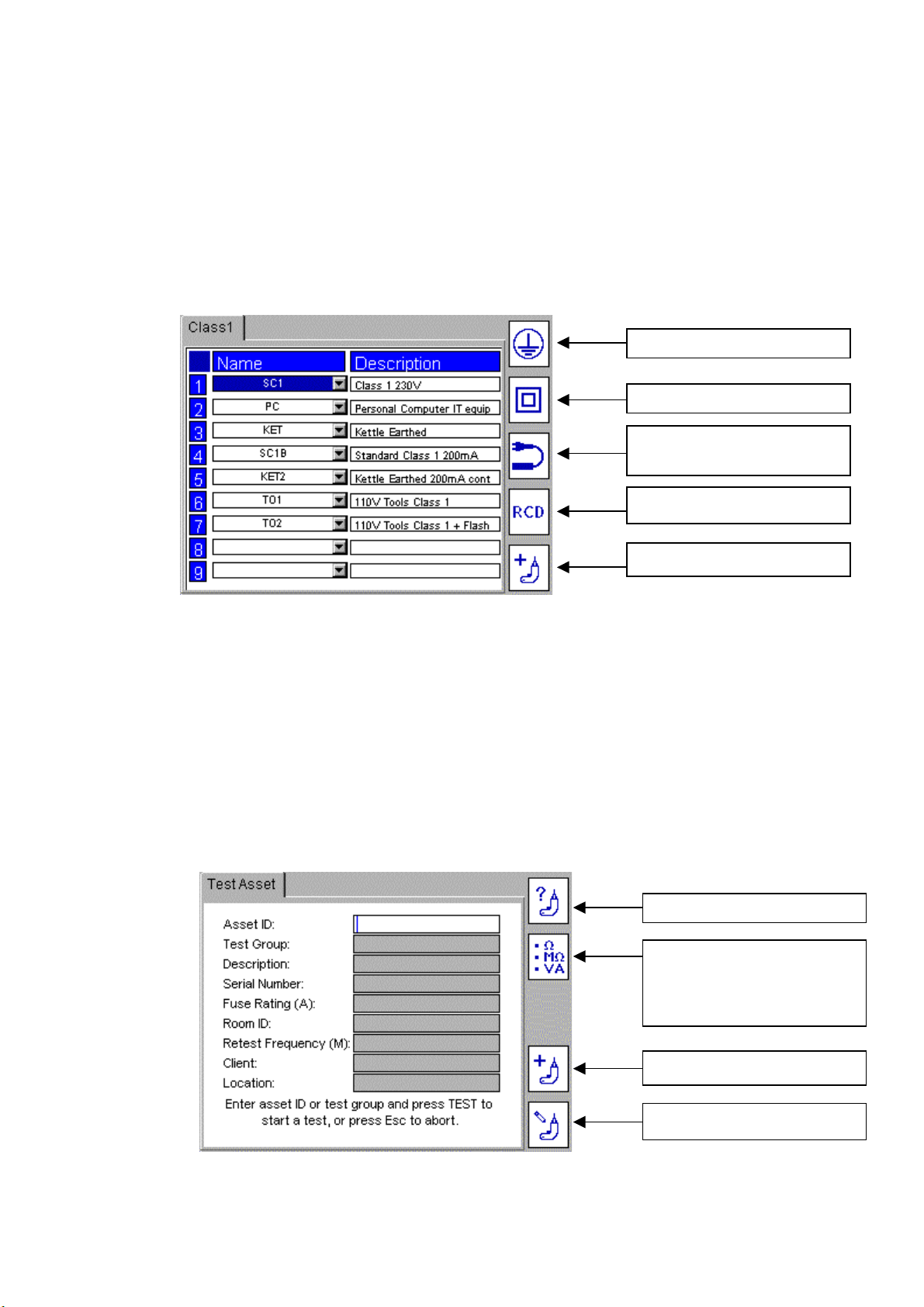

Option 1: Starting a TEST – USING HOT KEYS

.1 Select a Class I, Class II, IEC/extension lead or RCD test group by pressing one of the HOT KEY

options:

A list of TEST GROUPS are displayed that are relevant to that type of equipment

Example: Class I test groups

.2 Select one of the test groups by pressing the relevant number, then the TEST button.

or

Press the number twice to start the test sequence.

or

Scroll down to the required test group and press TEST.

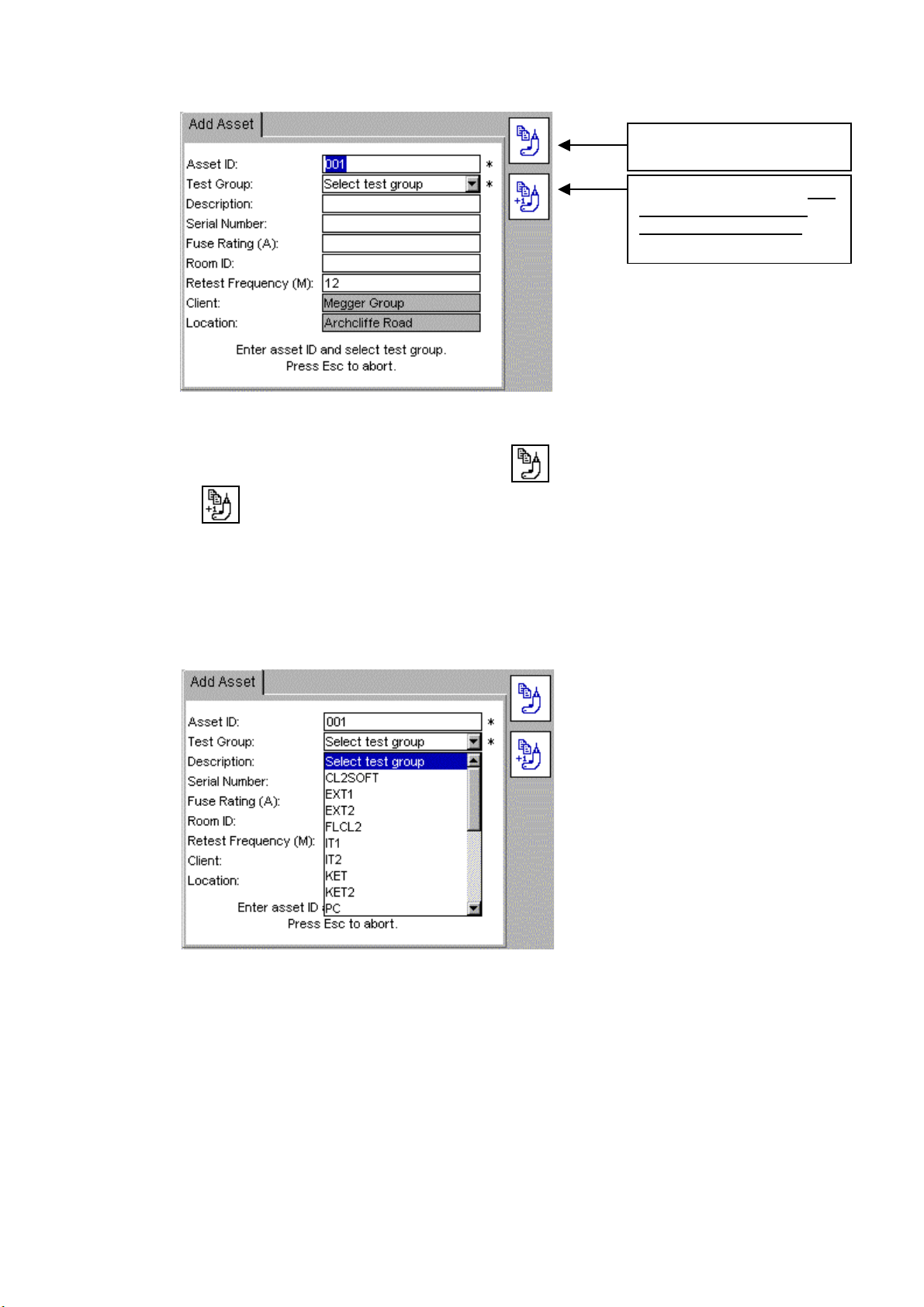

For more Information on test groups, adding, editing, configuration or deletion, go to section 8.

Option 2: Starting a TEST – PRESSING THE TEST BUTTON

.1 From the HOME screen, press the TEST button. The display will show the TEST ASSET page, as

below:

.2 Type in the “Asset ID” if available and press OK.

Class I test groups

Class II test groups

Class IEC (Power) and

extension lead test groups

Plug-In RCD test groups

Add Asset - fast access

Find asset

Search for TEST GROUPS

Press once for direct entry

Press twice for drop down

box.

Add ASSET

Edit ASSET

Page 21

21

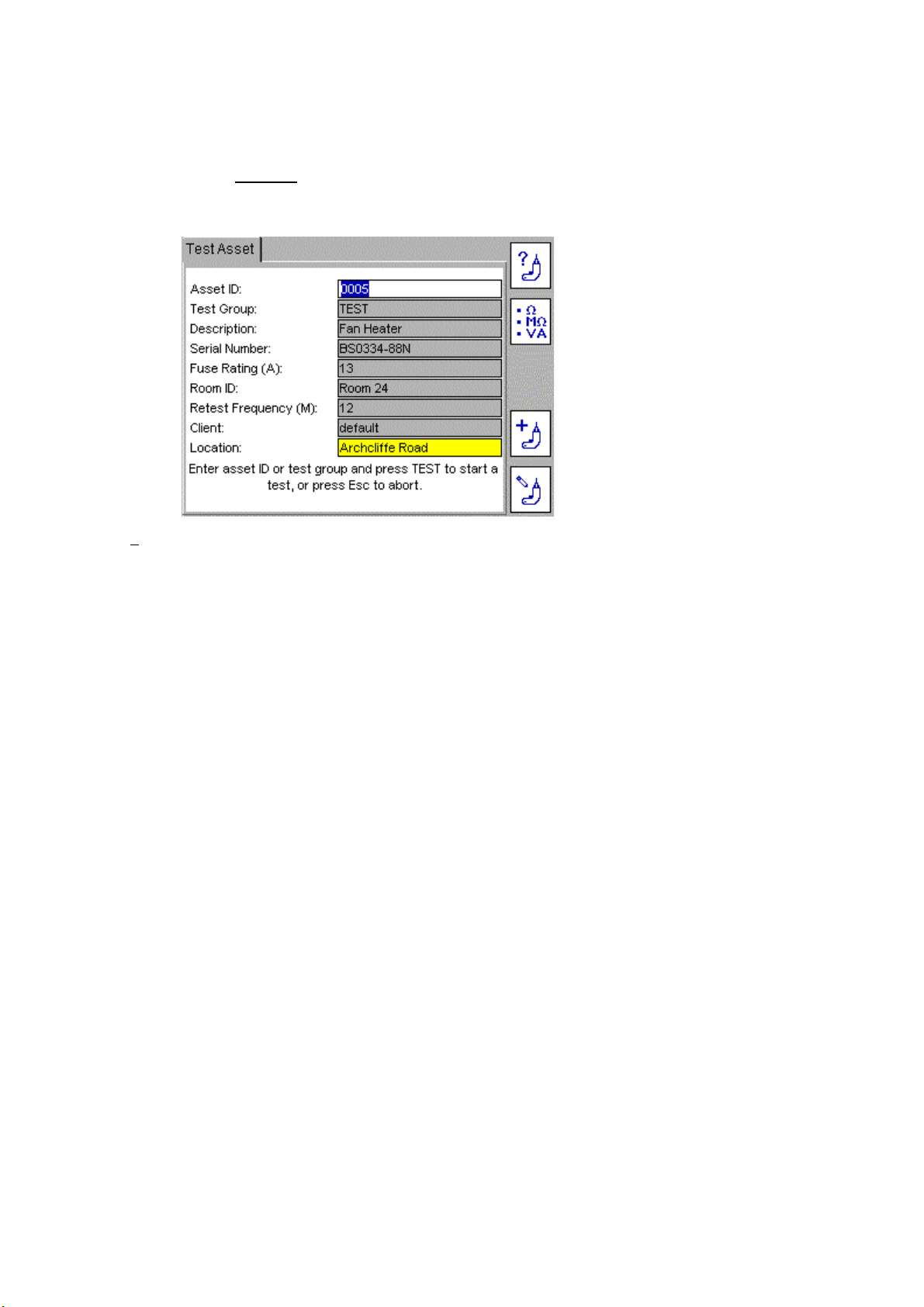

If the asset is already in the database the details of the asset will be displayed as below:

Press the TEST button and the test sequence will commence. Go to 3.3 TESTING PROGRESS.

Alternatively to search through the asset database, press the FIND ASSET Hotkey. A drop

down box of Asset IDs will appear.

If you know the Asset ID you wish to find, start typing in the Asset ID. The search engine will jump

to the Asset IDs that start with those characters.

To ADD an asset, simply press the ADD ASSET Hotkey.

.3 If the entered asset is not in the database, the following information box will appear:

Press OK to add a new asset.

A blank Add Asset screen will appear as below. This only contains the Asset ID entered in the

previous screen, plus current client and location.

If no client and location have been added, these will say “default”.

Page 22

22

* Indicates mandatory fields that are required to save the asset data.

Further information on the COPY LAST ASSET Hotkey and COPY & INCREMENT ASSET

ID Hotkeys can be found in section 5.

(A new asset ID can be added and saved at this stage, but it is recommended that this is added

after testing is completed).

.4 Press the DOWN arrow to access TEST GROUPS.

.5 Press OK to access the drop down list of test groups.

Use the UP/DOWN arrows to scroll through the list of test groups and then press OK

OR

Start typing the name of the test group. The cursor will jump to the relevant test groups with that

letter or number. Entering more than one letter will refine the search further. Then press OK.

Add any additional data in the available fields as required.

.6 Press TEST to commence testing.

.7 Go to section 3.3 Test Progress

Note: Only a TEST GROUP is required to start testing.

Copy last asset added

from list

Copy last asset added and

increments Asset ID to

next available number.

Page 23

23

On completion of a test, only Asset IDs and Test groups have to be added before

the test is completed. All other data is optional.

NOTE: If NO Asset ID is entered, press the Test Group Hotkey and type in the test

group.

Alternatively press the hotkey twice to select the test group drop down box.

Press OK to list all test group options, scroll down the list to select desired test

group and press OK to accept.

NOTE: Pressing the Right arrow key will “Page Down” the list.

FURTHER DETAILS ON ADDING ASSETS CAN BE FOUND IN SECTION 5.

Option 3: Starting a TEST – USING A BARCODE SCANNER

.1 From the home page, scan the Asset barcode with the optional barcode scanner.

If the ASSET ID does NOT exist in the PAT database, the PAT will jump to the ADD ASSET

screen and the ASSET ID will appear.

.2 If the asset information matches the asset to be tested the completed TEST ASSET screen will

appear as below:

Check the asset information matches the ASSET to be tested. If so, Press TEST and go to section

3.3 TEST PROGRESS.

If the asset information does not match the asset to be tested, check the CLIENT is correct.

The same ASSET ID can be used for different clients, but one client cannot have duplicate asset

IDs.

If the asset ID does not exist the screen will jump to Add Asset screen and automatically fill the

ASSET ID field with the scanned barcode data.

.3 Press the DOWN arrow to move to Test Groups.

The TEST GROUP is selected by pressing OK and selecting from a drop down list.

Typing the first letters or numbers of the test group will allow the search engine to jump to those

test groups without having to scroll down the list.

Find Asset

Search for TEST GROUPS

Press once for direct entry

Press twice for drop down

box.

Add ASSET

Edit ASSET

Page 24

24

Additional information can also be added, but this is not essential.

NOTE: When scanning an Asset ID that exists in the database under a location that is

different to that set in the PATs current status, a yellow warning indicator will show

on the Location field as below. Go to section 10 for additional information on Clients

and locations.

.4 Press the TEST button. Go to section 3.3 TESTING PROGRESS for further information on the

test sequence.

3.3 Test progress

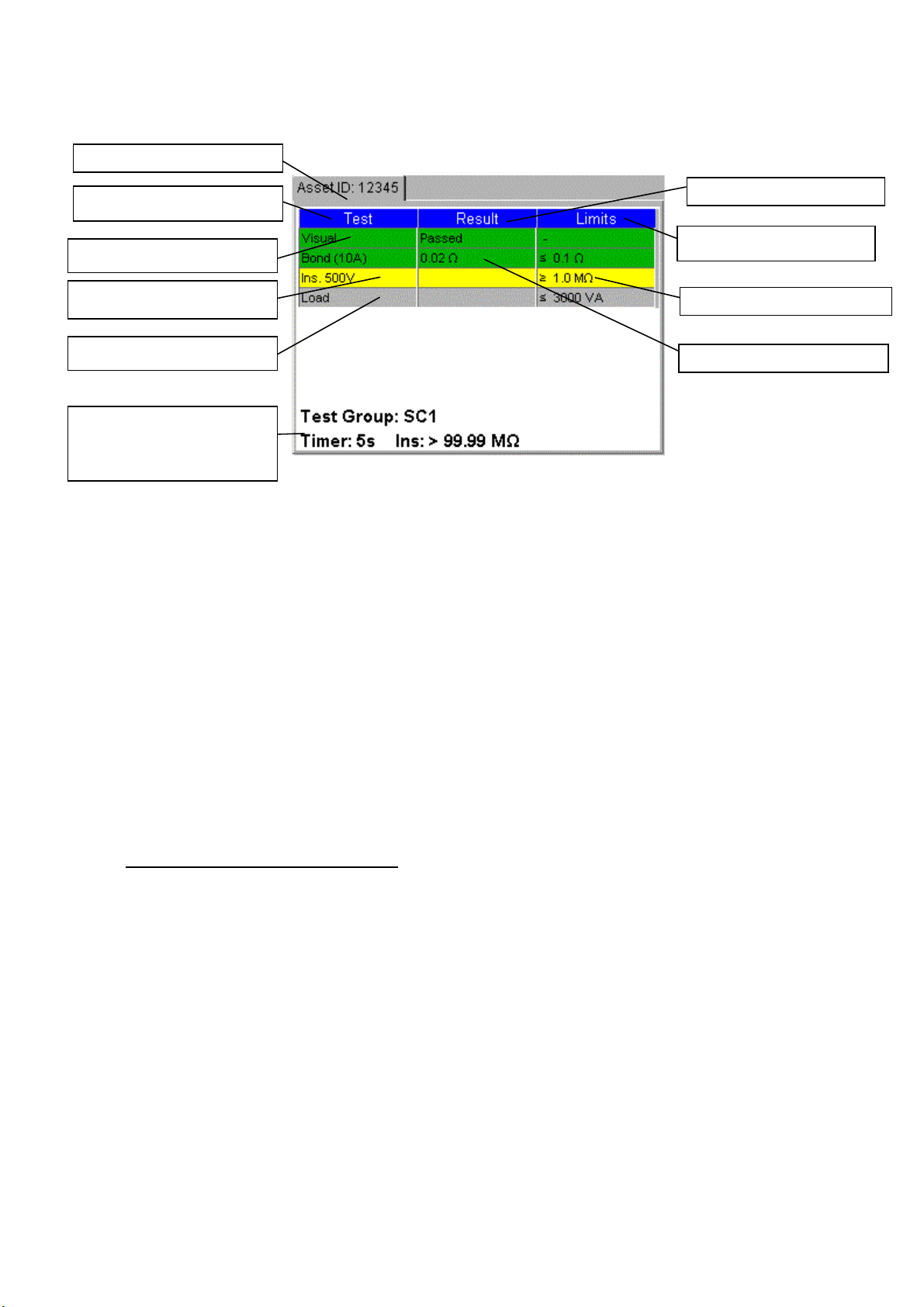

The PAT400 displays all tests to be performed within the selected test group.

Each test is run sequentially and the results displayed for each test before proceeding to the next test.

A “FAIL” on any test will prevent further testing for safety purposes.

Test screen example: Class I asset

Page 25

25

Interruption to automatic testing

Testing proceeds automatically unless an action is required from the operator.

Follow “on-screen” instructions as they appear.

3.4 Remote probe and clip

Some tests will require the use of the remote probe and clip. These are used where the asset under test

has no earth return (Class II assets). Test using the remote probe include:

Insulation testing on Class II equipment

Continuity/bond testing on Class I equipment

Touch leakage testing

Differential leakage test on Class II

Substitute leakage on Class II

The PAT400 will instruct the operator when the remote probe needs to be connected.

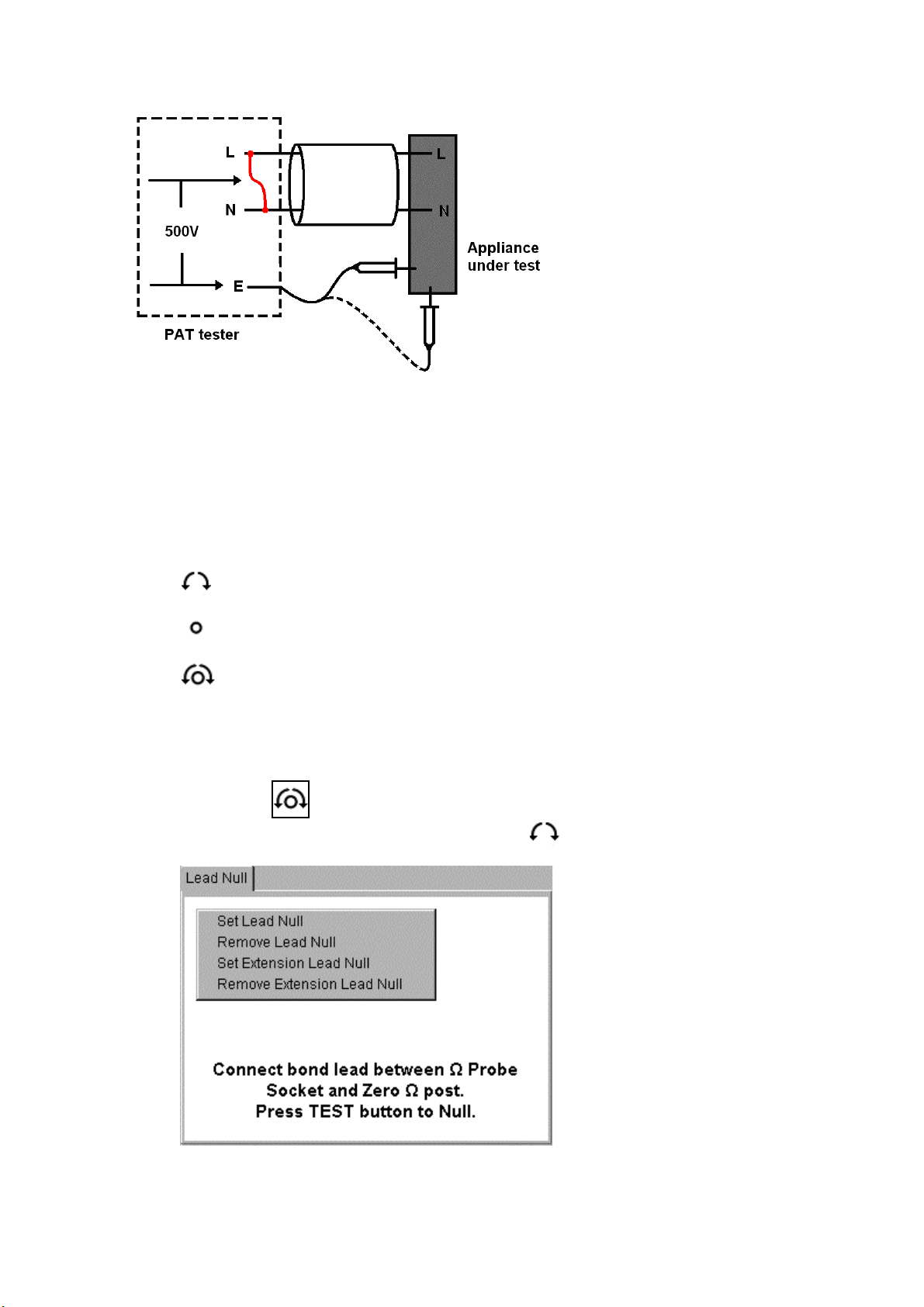

Example of remote probe application

Class II insulation test (Riso)

Live and neutral are shorted together automatically in the PAT (RED LINK) and a voltage (250 V or

500 V) is applied between the shorted L/N and the remote probe.

The probe is connected to any metallic locations on the “appliance under test” to ensure there is no

breakdown of the insulation.

Test results screen

Green – Test passed

Amber – Test in progress

Grey – Test pending

Current test values or

Instructions during the test

sequence

Test results column

Test limits column

Pass limit set for this test

Actual measurement result

List of tests in test group

Page 26

26

3.4.1 Test lead resistance null

The resistance of the Bond lead can be “nulled” to remove the lead resistance from the measured

resistance. This is important when testing very low resistances where the test limit is set to 0.1ohms.

Also, the resistance of an extension lead (IEC or Power cord) can be nulled, if the lead is longer than the

Red test lead supplied with the PAT.

Symbols used:

Test lead null is set

Extension lead adaptor null is set, see section 3.4.2

Both Test lead and extension lead adaptor null are set

To null the test lead resistance of a bond lead:

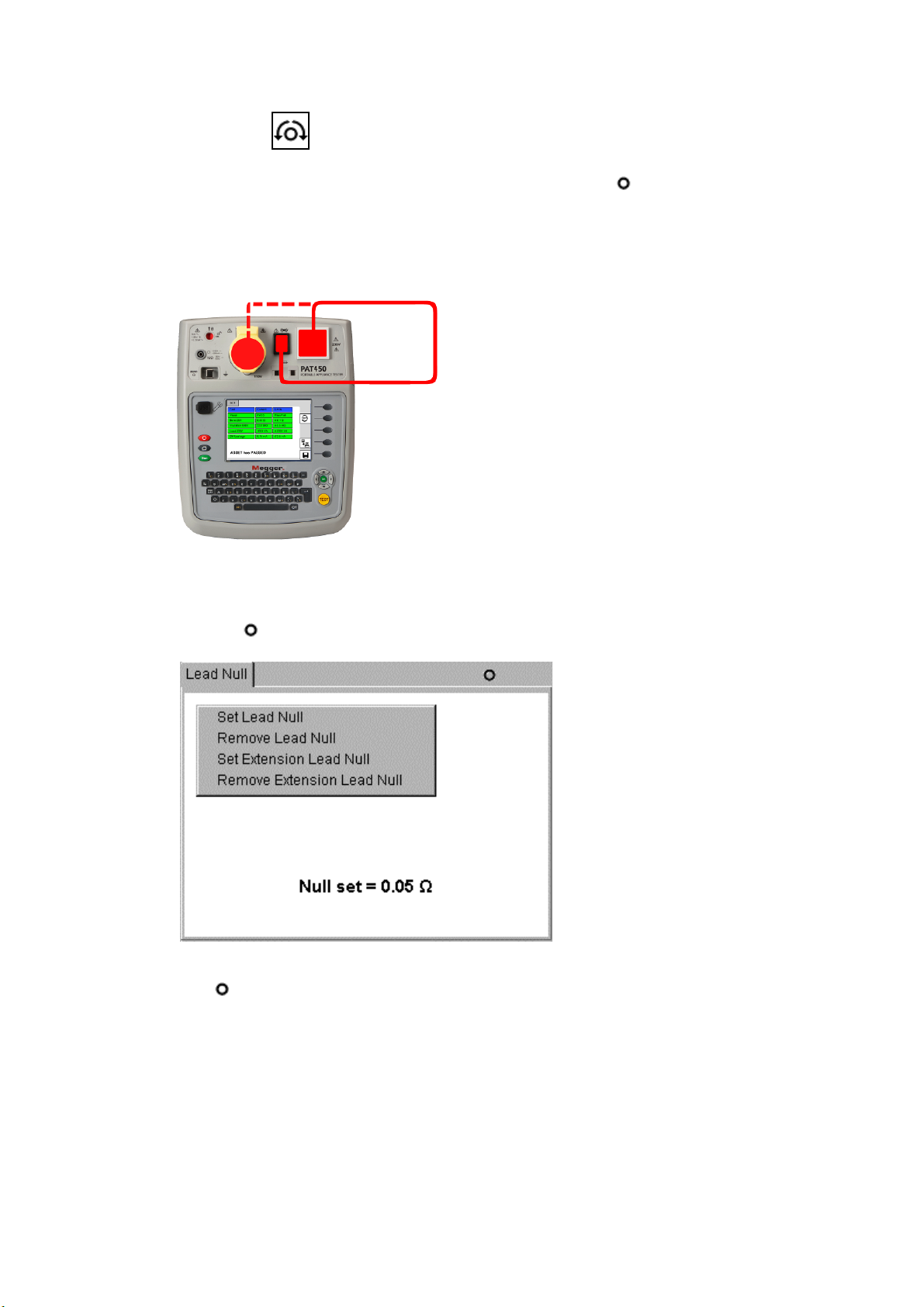

1) From the HOME screen, use the RIGHT arrow key to select the SETUP tab.

2) Press the NULL Hotkey. The Lead Null screen will appear as below:

(If a lead null value is already set the lead null symbol will be displayed)

3) Connect the Black bond lead between the Bond socket and the Zero post on the front panel as below:

The insulation test probe is

connected to all exposed metal

parts to ensure electrical

separation from earth.

Page 27

27

4) Press the TEST button. The PAT400 will display the value of the test lead as a Null SET value, and

display the symbol in the top of the screen as below:

The displayed inside means an extension lead null is also set.

5) To remove the Bond Lead Null select the “Remove Lead Null” and press the TEST or OK button. The

symbol will disappear.

3.4.2 Extension Lead Adaptor Resistance Null

Some tests require using an IEC lead or the short extension lead adaptor supplied with every PAT tester.

An example of this is testing a multiple sockets extension lead:

The resistance of the extension lead adaptor may be removed by performing an extension lead null.

1) From the HOME screen, use the RIGHT arrow key to select the SETUP tab.

Extension

lead adaptor

Page 28

28

2) Press the NULL Hotkey. The Lead Null screen will appear with the Set Lead Null option

highlighted:

(If an extension lead null value is already set the lead null symbol will be displayed)

3) Connect the extension lead adaptor between the Mains test socket and the IEC socket on the front

panel as below:

4) Scroll down to select “Set Extension Lead Null” on the menu

5) Press the TEST button. The PAT400 will display the value of the test lead as a Null SET value, and

display the symbol in the top of the screen as below:

To remove the extension lead null select the “Remove Extension Lead Null” and press the TEST or OK

button. The symbol will disappear.

3.5 Short circuit assets

Some assets may appear to the PAT400 to be short circuit. This can be caused by large inductive loads.

In such cases, the following warning message will be displayed:

Warning: Asset may be short circuit.

Press TEST to continue, ESC to abort

Page 29

29

Only if the operator is certain the equipment is not a short circuit, press TEST, otherwise press Esc to

abort the test

3.6 Aborting a test

All tests can be aborted at any time by pressing the TEST button or Esc (escape) button.

3.7 Completion of testing

On completion of testing all test fields should turn green as below. The test results are displayed in the

centre column with the pass limits for that test group on the right.

On completion of testing, the following options are available:

Re-test asset using current test group. Warning: test data will not be saved for the

previous test.

Repair codes – Allows repair details to be added to asset test results – See section 3.10

below.

Save the test results to memory and print a barcode label (a Megger USB barcode printer

must be connected prior to requesting this function).

Save test results to memory and return to the initial screen.

Go to Section 4 to learn about using the memory, or Section 4.2 Saving a test result to memory.

To return to the HOME screen without saving the results press HOME button

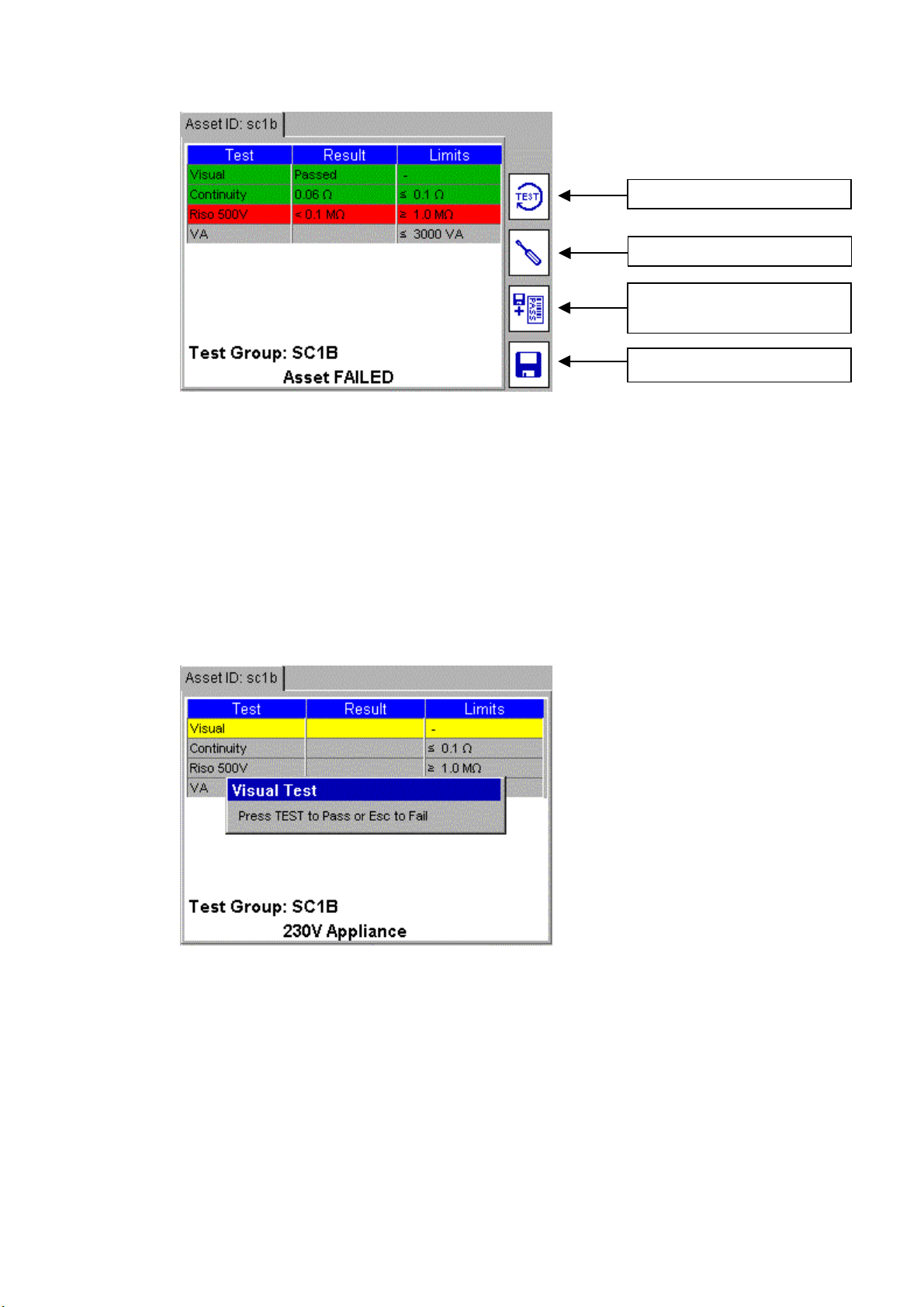

3.8 Test fail screen

Should an asset fail a test at any stage, the test sequence is stopped and the screen message ASSET

FAILED is displayed:

Repeat test sequence

Print bar code label & SAVE

results to memory

SAVE results to memory

Repair codes

Page 30

30

Example: Asset has failed the insulation test.

Pass limit set to 1.0 MΩ, Measurement recorded at < 0.1 MΩ.

The same options are available as an asset that has passed. See Section 3.7 for completion of testing.

3.9 Visual failure

If the current test group contains a visual test sequence then the visual test popup will appear. This allows

the user to log mechanical faults on the asset under test, such as a broken plug or damaged appliance

cord, the Esc key should be used to exit the test sequence during the Visual Inspection and initiate a

Visual Failure, as below:

1) During the Visual inspection option the “Visual Test” will be highlighted in yellow, as below:

2) Press the Esc key to initiate a Visual Failure. The display will show a Visual Test Failure screen as

below:

Repeat test sequence

Print bar code label & SAVE

results to memory

SAVE results to memory

Repair code

Page 31

31

3) Three types of information can be entered:

a) Notes - To describe the type of failure.

b) Check boxes - Quick entry for standard failure types.

c) Repair code - See Section 3.10 below

4) Press the TEST key to complete the test process. The display will now show the TEST FAILED

screen.

5) Press the SAVE Hotkey to save the results or the SAVE and PRINT Hotkey to save the results and

print a barcode label.

3.10 Repair code

A repair code can be entered at the completion of testing. To enter a repair code:

.1 Press the Hotkey and the following popup appears:

.2 Enter any notes as appropriate then press OK, followed by the DOWN arrow.

.3 Enter an appropriate repair code. Examples of the repair codes used in PowerSuite are given

below:

Page 32

32

On completion of the repair code screen press the TEST key to log the changes, then press the SAVE

or SAVE and PRINT Hotkeys to store the results.

3.11 Cable compensation

A power cord, appliance lead or extension lead will frequently exceed the nominal length and

consequently the resistance limit set in the standard test groups.

Rather than having many test groups with different lead lengths, the “Cable Resistance Calculator” screen

allows the limit of a Bond or Continuity test to be modified after the measurement. On a failed test,

entering the length of the lead and the conductor cross section, the pass limit is adjusted to the correct

resistance. The result is then passed or failed, as necessary.

To apply cable resistance calculation:

1) When a continuity or Bond test fails, the screen message alert will be displayed:

2) Press OK to access the Cable Resistance Calculator as below;

Page 33

33

OR

Press Esc to fail the Asset and save or abort the results,

OR

Press “R” to re-run the continuity test.

3) Enter the cable Length in metres and the conductor Cross-Section (mm2) OR a Resistance can be

entered if this is known.

4) Press TEST to complete the test. The PAT400 will now proceed to the next test if the resistance was

a PASS or to a fail screen if the resistance was still outside the modified limit.

See also Section A.6 for cable length limitations and RCD protection on long leads.

3.12 WARNINGS

3.12.1 Power-On tests

Running a leakage or load test will operate the asset under test. Some assets, such as vacuum cleaners,

disc cutters etc can draw high initial load currents (Inrush current). The PAT400 will under these

circumstances report the asset has a short circuit.

If this warning is displayed, it is recommended the following actions are taken:

1) Where possible check the asset does not have a short circuit (the fuse would normally be blown in

such circumstances, prior to it being replaced).

2) Proceed ONLY if you believe the asset is not a true short circuit, but has a high inrush current.

3.12.2 Reversed supply

UK instruments:

The PAT400 will detect a reversed polarity (Phase – Neutral) supply and abort the initialisation.

The display will show the warning:

ERROR 82: Mains polarity reversed

European instruments:

The instrument will pass initialisation and display the Home screen. The supply polarity will be

shown as “Reversed”.

3.12.3 Supply earth fault

Page 34

34

The PAT400 will test for a good supply earth during initialisation. A faulty or missing earth will return the

error:

Error 73 – Mains supply Earth Fault

3.12.4 Parallel earth paths

If the PAT400 detects more than one earth path, the warning:

Unable to verify earth connection,

Parallel paths may exist.

Refer to user guide.

The PAT400 has detected more than one earth path during the Earth continuity, Earth bond, Insulation or

Earth leakage tests. Refer to Appendix A.8 for further details.

3.12.5 Database full

Exceeding the storage capacity of the database will create the following warning:

Error - Database Full. Unable to save data!

Press OK to continue

The test result will NOT be saved.

To free up memory for further test results:

1. Backup the existing database to a USB storage device.

2. Delete records from the PAT400.

See Section 4 for further information on PAT400 memory.

Page 35

35

4. Using the memory

4.1 Important overview

All records are stored under a “client”. The PAT400 can store up to 100 (50 on firmware releases prior to

2.20) clients. Each client can have up to 2 000 (50 on firmware releases prior to 2.20) Locations.

There is a maximum of 25 000 total locations per database.

The client and locations are configured in SETUP, refer to Section 10.

The PAT400s are shipped with the client and first location set to “default”. All results will be stored

under this “default” client and location unless changed in SETUP.

These can be left as default, but it is recommended these are changed to the name of the client and

location of the test site. See Section 10.

Assets are stored with a minimum of an “Asset ID”, and a “Test Group”.

A client CANNOT have duplicate Asset IDs, even if they are in several locations. However the same

Asset ID can be used for different clients.

Test results are stored and referenced to an Asset ID. The internal memory will store up to 10 000 test

results.

Entering an asset ID that already exists in the current client will generate a “duplicate asset ID” warning.

Change the asset ID then press save.

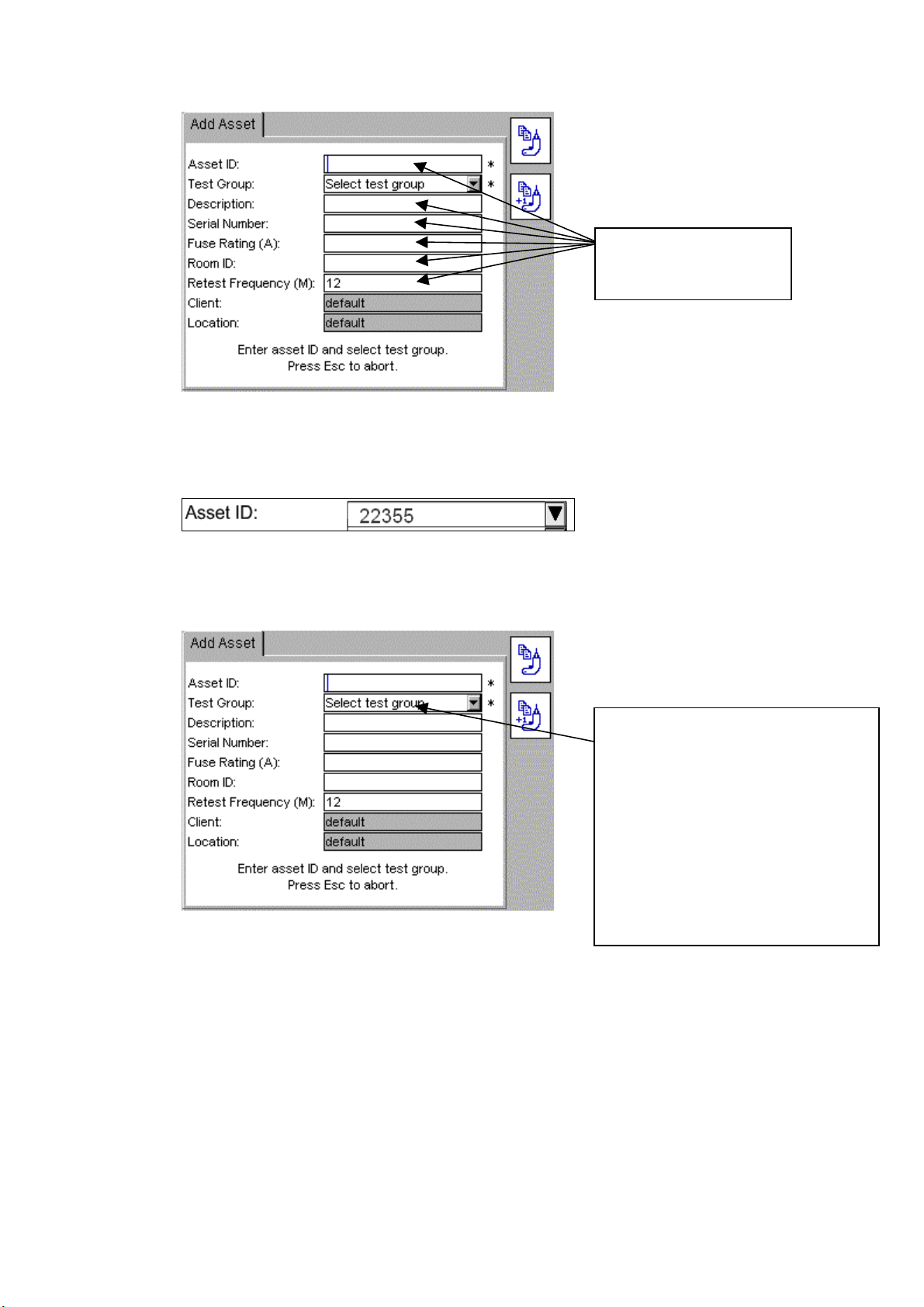

Assets can be saved to memory before or after testing. The add asset screen is shown below:

Default Add Asset screen Add Asset screen with asset data to be saved

COPY last ASSET

SAVE results to

memory

COPY last

ASSET and

Increment

Asset ID

Page 36

36

Definitions of fields

Field Limit Description

Asset ID:* 10 000 Unique number or combined letters and numbers. Enter by typing

from the keyboard or scanning a barcode.

Separate clients can use the same ID. But one Client cannot

have two identical Asset IDs.

Test Group:* 100 Drop down box of available test groups. Press OK to access list,

DOWN/UP arrow to select and OK to enter.

Description: --- General description of asset (Cooling fan, hand drill etc).

Serial Number: --- The manufacturer’s serial number.

Fuse Rating (A): --- Fuse fitted to the mains plug (or internal fuse if using continental

plugs).

Room ID: --- Location of asset to room level.

Retest Frequency (M): --- Repeat test frequency in months. The default is set to 12 months

Client: 1001 Customers name – This is created in SETUP.

Location: 2 0001 Site details. Each client can have multiple locations – This is

created in SETUP.

*Fields marked (*) are mandatory fields. Data cannot be saved unless these are completed.

1

Either DEFAULT or Client name and Location, required before data can be saved.

Note: Spaces can be saved as a Client or Location, but appear as blank fields when

reviewed in Asset data.

4.2 Saving a test result

On completion of a test sequence, the message “asset PASSED” and the SAVE key will appear.

1) Press the SAVE Hotkey or press the SAVE and PRINT (a barcode label) Hotkey to print a

barcode label and save.

Note: A Brother P-Touch 2430PC must be connected to print a barcode label.

Before connecting the printer to the PAT400, the MODE switch located on the rear of the printer MUST be

switched to the lower “E” position. If “EL” is selected, communication will not be established and the

PAT400 will report the error message: “PRINTER NOT CONNECTED”

2) If no Asset ID was entered before testing started, the asset screen will be displayed as below. The

test group will already be set, as this was selected when the test was run.

Page 37

37

3) Enter the Asset ID.

This can be via the keyboard or scanned in by barcode scanner.

If an Asset ID already exists in memory, a “duplicate Asset ID” warning will be displayed. In this case,

enter a different Asset ID number.

Examples of Asset ID formats: (Asset IDs are limited to 20 characters)

0001, 0002, 0179, 7082

MEGGER0001, MEGGER0002

AA0001,AA0002, BF0001, BF0002

4) Press OK

5) Press the DOWN arrow and complete the additional asset data as required.

Test Group, Client and Location cannot be changed in this screen.

6) When completed, Press the SAVE Hotkey. The asset will be added to the memory under the

current client and location.

To abort an “Add Asset” page, press Esc or HOME key. A warning will appear asking to confirm you wish

to exit without saving data.

To edit asset information go to section 6.

SAVE results to memory

Page 38

38

5. Adding assets to memory

Assets can be saved to memory after they are tested, as above, or before any testing starts.

Copying a previously added asset using the COPY ASSET Hotkey or COPY ASSET AND

INCREMENT ASSET ID Hotkey in Section 5.2.

Alternatively: Asset data can be loaded from PowerSuite via a USB stick, Section 7.2.

5.1 Adding assets to memory before testing

1) From the HOME screen, press the ADD ASSET Hotkey. The following empty asset screen will

appear:

2) Enter an ASSET ID, using the keyboard, or barcode scanner.

3) Select a TEST GROUP from the drop down list.

4) Completion of the remaining asset fields is optional.

5) Press the SAVE Hotkey. The asset data will be saved to memory. The screen should display

the SAVED message and return to the HOME screen.

COPY last ASSET

COPY last

ASSET and

Increment

Asset ID

SAVE results to

memory

Page 39

39

5.2 Copying the previously added asset

1) From the HOME screen, press the ADD ASSET Hotkey. The following empty asset screen will

appear:

2) To recall the last asset to the screen press the COPY ASSET Hotkey. This will recall the last

asset added to the database of the current Client. The Asset ID can then be edited as required.

3) Change the Asset ID. The SAVE Hotkey becomes available after the ASSET ID has been

changed.

OR

To recall the last asset to the screen and INCREASE the Asset ID by one, press the COPY ASSET

AND INCREMENT ASSET ID Hotkey.

Page 40

40

4) Change any other asset information as necessary.

5) Press the SAVE Hotkey to save the ASSET to memory.

Page 41

41

6. Editing and deleting assets and results

All asset data can be edited or deleted as required.

For deletion of Test Groups see section 8.

For deletion of Client and Locations see section 10.

6.1 Editing asset data

1) From the HOME screen, enter the SETUP menu option by pressing the RIGHT arrow key.

2) Press the EDIT ASSET Hotkey. The EDIT ASSET screen should be displayed.

Enter an Asset ID to be edited. Alternatively, to list the assets in the database, press the FIND ASSET

Hotkey. This will produce a drop down box,

Assets are sorted alphanumerically in ascending order.

Press the OK key and then the DOWN arrow to scroll through the list, or use the RIGHT arrow key to

page through the list.

OR

Type the desired Asset ID to jump to the matching item in the list. The search engine will find the

EDIT asset

FIND ASSET

DELETE asset

ADD asset

Page 42

42

closest match as you type.

Note: The first 2 000 Asset IDs are loaded into the drop down list. To access the next 2 000 assets,

press and hold the RIGHT ARROW to scroll down to the bottom of the first 2 000 assets. Select

‘Next…’ from the bottom of the list. The Asset ID list will now load the next 2 000 assets.

OR

Where available type ‘next…’ to jump to the end of the list or ‘previous…’ to jump to the start of the

list.

3) Edit the asset details as required and press the SAVE key to store changes.

NOTES: To move the location of an asset, simply change the location in the Location list.

It is not recommended to change the Client. Changing the Client will also change the appropriate

asset list. However on exiting this screen the Client will revert to the original Client prior to any

changes made here.

6.2 Deleting assets

1) From the HOME screen, use the RIGHT ARROW key to select the SETUP tab.

2) Press the EDIT ASSET Hotkey. The EDIT ASSET screen should be displayed

3) Scroll down the Asset ID field as in 6.1 above. When the required asset is displayed, press the

DELETE Hotkey.

4) A screen message to confirm the deletion is displayed.

5) Press OK to confirm or Esc to abort.

WARNING: The asset and its associated test records will be deleted. This deletion is not

reversible.

For Deletion of Clients and Locations see Section 10.

Page 43

43

7. DATA – Test results and data transfer

Data storage – backup and restore

The PAT400 can store up to 10 000 electrical assets with associated test records. Megger STRONGLY

RECOMMEND this data is backed up frequently.

MEGGER CANNOT ACCEPT RESPONSIBILITY OR ANY LOST DATA HOWEVER CAUSED.

The backup and recall operations are extremely fast. 10 000 records can be backed up to a USB stick in

<20 seconds. Smaller databases are significantly faster.

The file format for data backup is a db file. DO NOT ATTEMPT TO EDIT THIS FILE. Corruption of this file

shall prevent further transfer back to the PAT400 or to PowerSuite.

Export to CSV file

Test results can also be exported to a CSV (comma separated value) file. This can be viewed with

Microsoft Excel.

See Section 7.1, 7.2 or 7.3 for full details of Backup, Restore and Export options.

7.1 Backup to USB memory stick

1) Connect a USB stick to either of the type A USB sockets on the front of the PAT400.

‘Type A’ USB socket.

2) Use the RIGHT ARROW to select DATA in the main menu options.

3) Use the DOWN arrow to select “backup to USB” and press OK.

4) Enter the name of the file you wish to create. The file name can be up to eight characters, A to Z and

0 to 9. Do not use any other characters.

Page 44

44

5) Press OK to initiate backup. If the file name clears without backup starting, the file name contains

excluded characters. Only 0 to 9 and A to Z should be used.

6) On completion the display will show the message “Backup complete”. There are no limits to the

number of times you can backup a database. The stored file is a “.db” file. Do not attempt to edit this

file as this can corrupt the data and prevent further use of that file.

If the USB device is not recognised the following message will be displayed.

This error can be caused by a faulty USB stick. Replace the USB stick with another type and try again.

Note: A USB stick may take a few seconds to be recognised by the PAT400.

7.2 Importing / restoring data from USB memory stick

Importing data from PowerSuite to the PAT400 or restoring data from a saved file are the same. The file

must be in a .db format and located in the root directory of the memory stick. This would either have been

created by the PAT400 as a backup file or created from PowerSuite for import into the PAT400.

1) Connect a USB stick (containing the .db file) to either of the Type A USB sockets on the front of the

PAT400 ( Type A’ USB socket).

2) Select the “Restore From USB” option in the DATA menu, as below:

Page 45

45

WARNING: Importing or restoring a file will overwrite the existing assets, results, test groups,

clients and locations in the database.

3) Press OK to continue.

4) The PAT400 will search for any database files in the root directory. A drop down box appears.

Press the OK key and then the DOWN arrow to scroll through the list, or use the RIGHT arrow key to

page through the list.

OR

Type the desired file name to jump to the matching item in the list. The search engine will find the

closest match as you type.

5) Press OK to accept the file for import or restore. The PAT400 will display a message:

Page 46

46

6) Press OK to accept the file for import/restore.

7) The file will be imported. On completion a message will be displayed and the buzzer will sound.

DO NOT SWITCH OFF THE PAT400 DURING THE USB OPERATION!

WARNING: Importing or restoring a file will overwrite the existing assets, results, test groups,

clients and locations in the database.

Always ensure existing data has been backed up prior to importing new data.

Note: Databases restored from previous firmware versions will be automatically

upgraded. Once upgraded, the database will no longer be compatible with older

firmware versions. To maintain compatibility between multiple PAT400s upgrade all

PATs to the same firmware version.

Databases restored from different PAT models may have tests that are incompatible

with the model being imported into. For example a PAT450 can have Bond testing

setup, where PAT410 models do not have this test. In this case the test will be

skipped during testing.

7.3 Export results to CSV

Assets and test results can be exported to a CSV file format. This file can be opened with a CSV viewer.

To export data and test results to CSV:

1) Connect a USB stick to either of the type A USB sockets on the front of the PAT400.

Page 47

47

2) Select Export Results to USB and press OK. The following screen will appear.

3) Enter a name for the CSV file. Up to 8 characters can be used. Use letters and/or numbers. Press

OK when ready.

4) The CSV file will be saved to the USB memory stick. On completion the following message will be

displayed and the buzzer will sound.

Note: Exporting large amounts of data to CSV can take a significant time to complete. Once started a

CSV export cannot be aborted.

7.4 Accessing test results

Test results for each asset can be viewed through the View Results menu option of the DATA tab as

below.

Only test results belonging to the current Client and Location can be viewed.

7.4.1 To view a test result:

1) From the HOME screen, use the RIGHT ARROW key to select the DATA tab.

2) Use the DOWN arrow to select VIEW RESULTS and press OK

Page 48

48

The ‘View Test Results’ screen will be displayed as below:

3) Enter the Asset ID or press the FIND ASSET Hotkey. If there are a large number of Assets IDs,

this may take a few seconds.

4) When the desired Asset ID has been found, Press OK to accept. The VIEW TEST RESULTS

Hotkey will appear as below.

FIND asset

ADD asset

EDIT

VIEW TEST RESULTS

Page 49

49

5) Press the VIEW TEST RESULTS Hotkey. The Test Results screen will be displayed for that

asset as below.

6) To exit this screen press HOME or Esc.

Note: Barcodes can be printed by using the PRINT BARCODE Hotkey

7.4.2 Printing barcode labels

Duplicate barcode labels can be printed from the VIEW TEST RESULTS page. This allows replacement of

labels if they are damaged or multiple labels are required for an asset.

To print a barcode label:

1) Enter the Test Result screen as above.

2) Ensure the Brother 2430PC barcode label printer is switched on and connected to the USB port of the

PAT400.

3) Press the PRINT BARCODE Hotkey.

Page 50

50

8. Test groups

Overview of test groups

Test groups are used to simplify the testing of an asset. A test group is a collection of tests that when run,

perform all the tests allocated to that test group.

The PAT400’s are shipped with a range of test groups for the majority of electrical equipment that will

require testing, as detailed below.

Additional test groups can be added up to a limit of 100. Existing test groups can be edited or deleted as

required.

8.1 Creating a test group

1) From the HOME screen, use the RIGHT ARROW key to select the SETUP tab.

2) Press the TEST GROUP MANAGER Hotkey

3) Press the ADD Hotkey to add a new test group. The Add Test Group screen will appear.

TEST GROUP MANAGER

Add a TEST GROUP

Edit a TEST GROUP

Delete a TEST GROUP

Page 51

51

Note: If the number of test groups reaches 100, the ADD Hotkey will change to a Icon.

4) Complete the fields as required.

An example of a typical standard Class I test may look like:

Definitions to fields:

NAME1: Test group name - This can be up to 10 characters

- For compatibility with PAT4 see section 11

DESCRIPTION1: Text string - Keyboard or Barcode entry

SUPPLY: Asset operating voltage.

VISUAL: Check box

EARTH BOND Check box – configuration options available on second page

CONTINUITY Check box – configuration options available on second page

INSULATION Check box – configuration options available on second page

POLARITY Check box – configuration options available on second page

CLASS Drop down box. This is required so the instrument knows which test connectors

are to be used.

Next page

Page 52

52

Options - Class 1

- Class 2

- EXT

FLASH Check box – configuration options available on second page

LEAKAGE Check box – configuration options available on second page

LOAD Check box – configuration options available on second page

RCD Check box – configuration options available on second page

1

These fields require mandatory data. They cannot be left blank.

5) When complete, press the NEXT PAGE Hotkey. The test options for each of the selected tests

will appear as below:

6) Now the test limits, test times and repetition settings can de adjusted for each test if required. Use

the UP/DOWN arrow keys to navigate the screen. All options are drop down boxes. Press OK to

access each drop down list.

7) On completion press the SAVE Hotkey.

8) The test group can now be allocated to one of the test group HOT KEYS.

8.2 Allocating test groups to Hotkeys

Test groups can be allocated to one of four TEST GROUP Hotkeys on the HOME screen.

To allocate a test group:

1) Press one of the four TEST GROUP Hotkeys .

2) A list of test groups numbered 1 to 9 will appear. Blank fields indicate a number that has not yet been

allocated a test group.

Previous page

Save test group

Page 53

53

Using the DOWN ARROW, navigate to the desired row (1 – 9) as below:

Press OK to access the drop down list of available test groups.

3) Select the required TEST GROUP and press OK. The TEST GROUP will be allocated to the selected

field.

Class I

Class II

Power cord / Extension lead

RCD

Add Asset

Page 54

54

NOTE: The TEST GROUPS can be freely allocated to any of the nine fields and in any of the

four Hotkeys. If desired a CLASS I TEST GROUP can be allocated to the RCD Hotkey

for example.

8.3 Editing a test group

Each test group can be edited or deleted

NOTE: When restoring a database the test groups will also be overwritten. Always backup

your test records before restoring a database.

To edit a test group:

1) From the HOME screen use the RIGHT ARROW key to select the SETUP tab.

2) Press the TEST GROUP Hotkey.

3) Press the EDIT TEST GROUP Hotkey.

4) Press the OK button to access the drop down list.

Page 55

55

Select the test group to be edited and press OK to accept.

The test group settings can be adjusted and saved as per the test group ADD function above.

WARNING: Changing a Test Group will affect all assets that use that test group.

8.4 Deleting a test group

To delete a test group:

1) From the HOME screen use the RIGHT ARROW key to select the SETUP tab.

2) Press the TEST GROUP MANAGER Hotkey.

3) Press the DELETE Hotkey.

4) Press OK to activate the drop down list. Select the required test group then press OK.

5) Press the DELETE Hotkey.

6) The display will ask for confirmation that the test group is to be deleted.

7) Press OK to accept, Esc to exit.

Delete

Page 56

56

Note: A test group cannot be deleted whilst there are assets in the database that are using

that test group.

8.5 Repeated Tests

It is possible to create test groups with repeated Bond, Continuity, Insulation and Flash tests.

An example screen is shown below.

Repeated tests are setup by choosing an option in the Cycles column. Bond and Continuity test have the

ability to be repeated a set number of times (1 to 10) or repeated indefinably by choosing the ∞ symbol.

For example you may wish to test a multi way extension lead which has 4 sockets. In this case you would

set the Bond Cycles option to 4, this will automatically perform 4 Bond test and record the worst Bond

resistance.

An example screen is shown below:

If a Bond or Continuity test fails then the user is always allowed to repeat the test. If the test is repeated

then the failed results is disregarded. You may wish to repeat a test in this way if the test probe did not

make proper contact with the appliance.

Insulation and Flash test can also be repeated by selecting the ∞ symbol in the Cycles column. This

feature is convenient for testing appliances that have multiple exposed conductive areas.

Page 57

57

9. Quick test - QT

The Quick Test (QT) key provides instant access to continuity, bond, insulation, leakage, RCD, load

(Operational) and flash testing, without having to create a test group.

NOTE: Some tests shown below may not be available, depending on the instrument being

used.

Running a quick test

1) Press the QT key on the keyboard. The display will show a numerical list of options.

Example of QT screen options for a PAT450

2) Press the number key associated with the test you wish to run.

Example - Earth Leakage

Note: Where a test has several options, such as Earth Leakage, a sub menu of options will

appear.

3) Navigate through the sub-menu options if available.

4) Press OK or TEST key to start testing.

Page 58

58

5) Follow on-screen instruction as necessary.

On completion of the test the final measurement will be displayed.

Quick test times can be changed in SETUP. Refer to section 10.4

Page 59

59

10. SETUP menu options

The SETUP menu options allow changes to the instrument configuration that cannot be accessed by

Hotkeys.

10.1 Clients

The PAT400s are shipped with the CLIENT and LOCATION set to DEFAULT. This can be changed, or

additional Clients and locations can be added, edited or deleted.

The DEFAULT CLIENT and LOCATION can only be deleted after other additional CLIENTS AND

LOCATIONS are added.

10.1.1 Adding Clients

1) Select CLIENT from the SETUP menu and press OK.

2) The Client screen will be displayed with the ADD, EDIT and DELETE Client Hotkeys as below:

3) Select the ADD Hotkey to add a new Client to the database.

4) Complete the text fields with the necessary Client information.

Client Name is mandatory; once it has been saved the name can not be changed. Additional data is

optional.

Page 60

60

5) On completion, press the SAVE Hotkey.

6) The display automatically jumps to the ADD LOCATION screen.

7) Add the location details. Only Location name is mandatory.

8) On completion, press the SAVE Hotkey.

A new CLIENT and LOCATION has been added to the database.

The current CLIENT and LOCATION has been updated to the new CLIENT and LOCATION automatically.

10.1.2 Editing and Deleting Clients

This function should be used to change the details of a Client. If you wish to change to a different client, go

to Section 10.1.3 below.

Edit Client:

1) Select CLIENT from the SETUP menu and press OK. In the Client screen select the EDIT

Hotkey.

2) Select the desired Client then change the details as required.

3) After the details have been changed press the SAVE hotkey.

Delete Client:

WARNING: Deleting a Client will also delete all assets, locations and test results associated

with that Client

1) Select CLIENT from the SETUP menu and press OK. In the Client screen select the DELETE

hotkey.

2) Select the desired Client.

Page 61

61

3) Press the DELETE hotkey.

4) A popup message will ask you to confirm.

10.1.3 Changing Clients

To change between different Clients in the PAT400:

1) From the SETUP tab press the SELECT CLIENT Hotkey.

2) Press the OK key to open the drop down list. Select the desired Client and press OK.

3) Press the SAVE Hotkey to store the change.

4) The display will now change to the SELECT LOCATION screen.

Select the appropriate Location from the drop down list.

5) Press OK to accept the new location.

6) Press the SAVE Hotkey to store the change.

Page 62

62

10.2 Locations

Multiple locations can be added to one CLIENT, up to a maximum of 2 000*. To add a LOCATION, select

the LOCATION option from the SETUP menu. Follow the same process as adding Clients in Section 10.1.

* Firmware revisions earlier than 2.2 were limited to 50 locations per Client.

10.2.1 Adding Locations

1) Select LOCATION from the SETUP menu and press OK.

The Location screen will be displayed with the Add, Edit and Delete Location Hotkeys as below:

2) Select the ADD Hotkey to add a new Location to the current Client.

3) Complete the text fields with the necessary Location information. Only the Location name is

mandatory.

4) On completion, press the SAVE Hotkey.

10.2.2 Editing and Deleting Locations

Edit Location:

Page 63

63

1) Select LOCATION from the SETUP menu and press OK. In the Location screen select the EDIT

Hotkey.

2) Select the desired Location then press the NEXT PAGE Hotkey.

3) Change the Location details as required. It is not possible to change the associated Client.

4) After the details have been changed press the SAVE hotkey.

Delete Location:

Warning: Deleting a Location will also delete all assets and test results associated with that

Location

1) Select LOCATION from the SETUP menu and press OK. In the Location screen select the DELETE

hotkey.

Page 64

64

2) Select the desired Location then press the NEXT PAGE Hotkey.

3) Press the DELETE Hotkey.

4) A popup message will ask you to confirm.

10.2.3 Changing Locations

You may only change to a Location in the current client.

1) In the SETUP tab press the SELECT LOCATION Hotkey.

2) Select the desired Location and press OK.

Page 65

65

3) Press the SAVE Hotkey to store the changes.

10.3 Company

The Company page provides data entry for the testing company to add their company details to the

PAT400.

The “Label Text” is a field that is used to add text to printed labels. For example you may wish to add the

testers name to a label. This field appears at the top of the barcode label.

1) From the HOME screen, enter the SETUP menu option by pressing the RIGHT arrow key.

2) Select Company from the menu options and press OK.

3) Enter the Company details; all of these fields are optional.

4) Press the SAVE Hotkey to store the changes.

10.4 Quick test configuration

QUICK TESTS are available to aid in commissioning and repair of electrical equipment. The QUICK TEST

keys allow direct access to individual tests without the need to use test groups.

The test times of the QUICK TESTS can be adjusted independently of test groups.

Test times can be adjusted for the following tests:

Page 66

66

Insulation test

Bond test

Load (Operational) test

Leakage test

To adjust the QUICK TEST time settings:

1) Select QUICK TEST KEYS from the SETUP menu options.

2) Press OK to display the Quick Test Config screen.

3) Navigate to the desired field to adjust the test time.

4) Press ESC to save and exit.

10.5 Date / Time settings

To change the Time or Date settings: