Megger PAT300, PAT350, PAT320 Quick Start Manual

Getting started

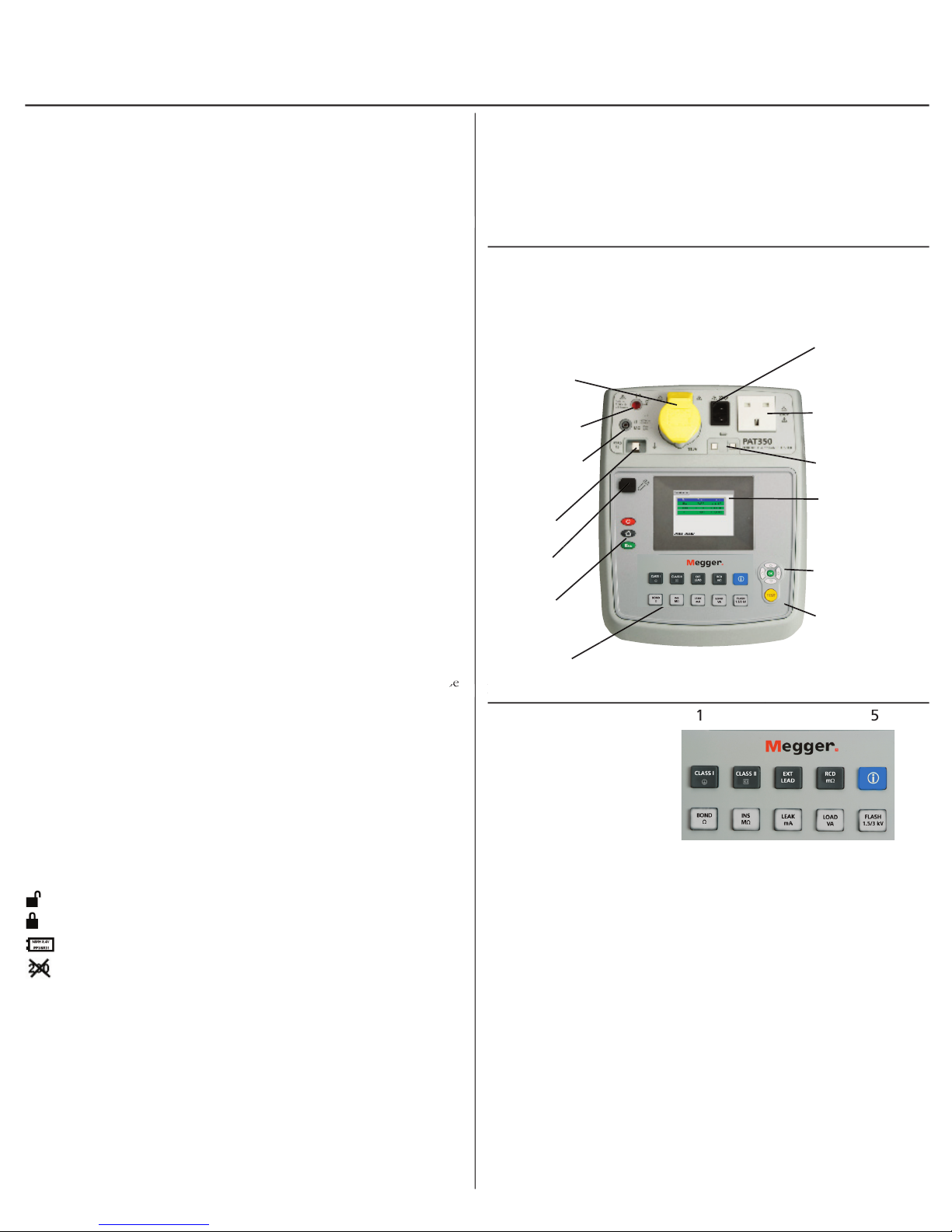

Appliance test

socket 110 V

Flash test socket

(PAT 350 only

)

Firmware

upgrade port

Power off /

Escape and

Home keys

Test keypad –

See Test key layout

Extension lead

/ IEC lead test

socket

Appliance test

socket (230 V)

Fuse checker

Display

Display

navigation

UP/DOWN/

LEFT/RIGHT

and OK

TEST button

Earth bond and

insulation

test probe socket

NOTE: Do not connect any equipment until the PAT tester

has been switched on and passed a self test.

post

Note: The PAT320 does not include the Flash test option.

The following safety warnings and precautions

must

be read and understood before

the supply should be checked by a qualifi ed electrician.

the instrument if there are any signs of damage.

All test leads, probes and clips must be in good order, clean and with no broken or

cracked insulation.

Probes and clips should be held behind the fi nger guard.

Test leads not used during a measurement should be disconnected from the

appliance tester.

For dual voltage testers, both sockets can be live simultaneously.

Only connect one asset to the PAT during testing.

Tests should be carried out in the order recommended below. An appliance that

fails a test should be repaired before further testing is carried out.

Only perform an operational test after the earth bond and insulation tests

have been completed, as this test operate at mains voltage.

During testing, ensure no hazard will exist as a result of normal running or

under fault conditions.

During testing the unit under test (asset) should not be touched, other than

using the appropriate accessories, as faulty appliances can present a shock

hazard.

Do not touch the exposed parts of test leads during tests as hazardous

voltages may be present due to potentially faulty appliance.

Do not touch the IEC extension lead socket pins especially during a test, as

hazardous voltages may be present due to a potentially faulty appliance

Assets should not be routinely Flash tested. Where fl ash testing is required,

refer to further guidance on Flash testing, section 4.5.

Replacement fuses must be of the correct rating and type. Refer to section 6.3

The USB connection should only be used by approved service personnel,

nothing should be connected to the USB port during testing.

Only use NiMH rechargeable 9V PP3 battery, do not use a non rechargeable type

as this could become dangerous if charged by the instrument.

Serviceable fuses should only be replaced with those that are suitably rated

In case of an emergency use an easily accessible power point

insulation test, warns that a hazardous voltage may exist at the test lead

probes

A 9 V PP3 rechargeable NiMH battery is fi tted to allow fast

Warning:

1. Switch off the instrument and disconnect the instrument from any electrical

circuits.

2. Remove the battery cover.

3. Remove the old battery and refi t a new one, observing the terminal polarity.

4. Replace the cover and retaining screw.

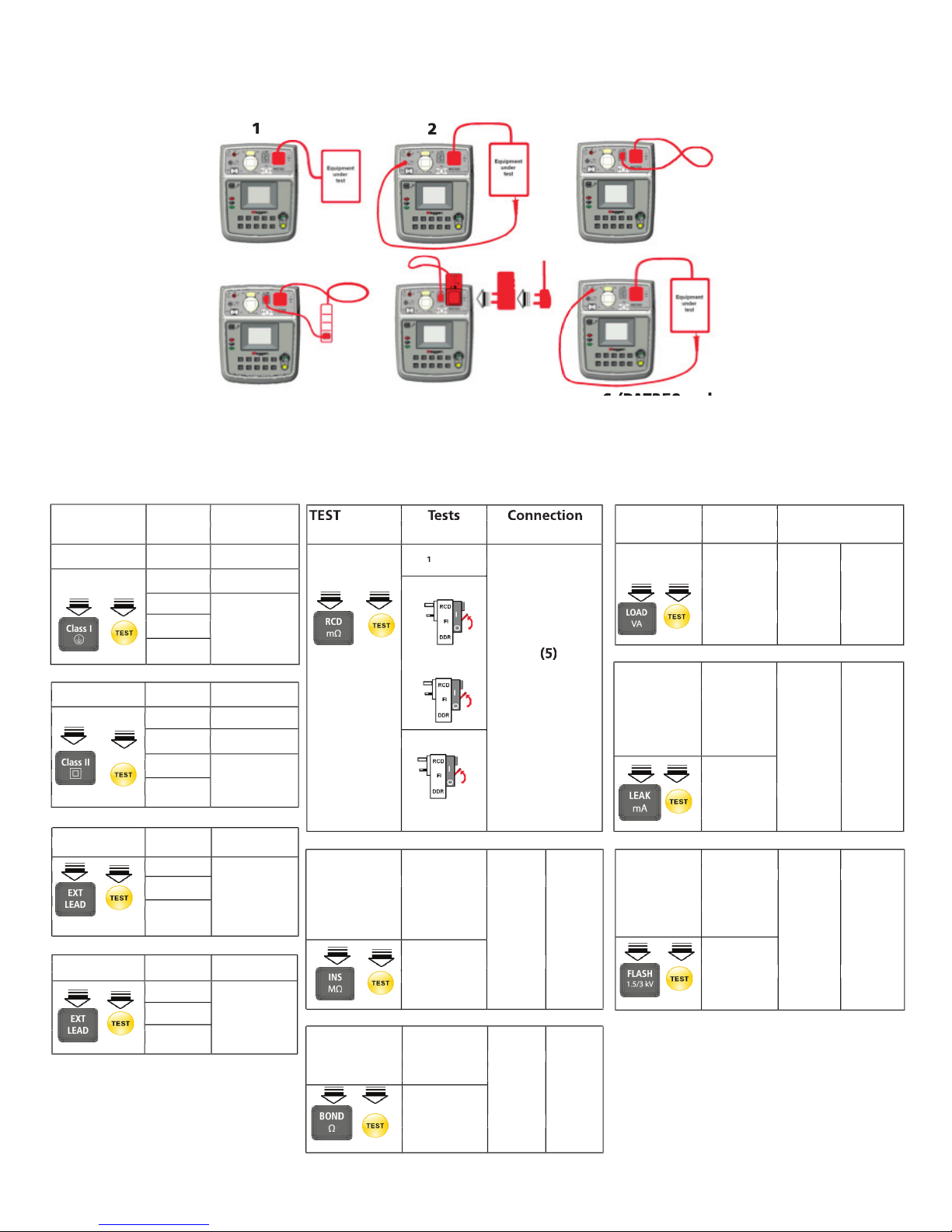

Test group 1 to 5 Description

Extension (found on computers, kettles etc)

lead test

with RCDs

10 A or 25 A

Test groups summary

Warning: Do not switch the instrument on with the fuse cover

removed or test leads connected.

1. Switch off the instrument and disconnect (the instrument) from any

electrical circuits.

2. Remove the fuse cover.

3. Replace the blown fuse with the correct type and rating.

4. Replace the fuse cover.

TEST Tests Connection

options run: required:

CLASS I

INS

LOAD (1)

BOND

INS (4)

Polarity

Warning:

TEST Tests Connection

x I

1 xI 0º

1 xI 180º

5 xI 0º

250 V (1) (2)

500 V

25 A

10 A (1) (2)

200 mA

TEST Tests Connection

test

(1) (2)

I-diff

I-touch (1) (2)

I-sub

Flash

test (6) (6)

IEC LEAD

BOND

INS (3)

Polarity

CLASS II

INS (2)

LOAD (1)

(Touch)

Loading...

Loading...