Page 1

PAT300 Series

Portable Appliance Testers

User Manual

Page 2

2

Thank you for purchasing the Megger portable appliance tester.

For your own safety and to get the maximum benefit from your instrument, please ensure that you read and

understand the safety warnings and instructions before attempting to use the instrument.

These instruments are designed and manufactured by:

Megger Limited

Archcliffe Road

Dover Kent

CT17 9EN

England

Megger Limited reserves the right to change the specification of these instruments at any time without prior

notice.

Page 3

3

1. Contents

1.1 Unpacking the carton ....................................................................................................................4

1.2 Safety Warnings.............................................................................................................................5

1.3 Symbols used on the instrument .................................................................................................6

2. Getting started ........................................................................................................................................7

2.1 Carry case....................................................................................................................................... 7

2.2 Instrument layout ........................................................................................................................... 8

2.3 Controls layout............................................................................................................................... 8

2.4 Instrument start-up ........................................................................................................................9

2.5 Switching off the appliance tester................................................................................................ 9

2.6 Testing an asset...........................................................................................................................10

2.7 Remote test probe and clip.........................................................................................................12

3. Test options ..........................................................................................................................................13

3.1 110 V or 230 V selection:.............................................................................................................13

3.2 Class I - Assets with an earth return conductor ............................................................. 14

3.3 Class II – Assets with no earth conductor ......................................................................... 15

3.4 IEC - Power leads fitted with 10 A IEC connector............................................................16

3.5 Extension leads - Single and multi-way extension leads .............................................17

3.6 RCD ....................................................................................................................................18

3.7 Test failure....................................................................................................................................19

3.8 Changing PASS limits .................................................................................................................19

4. Individual tests – Quick tests: ............................................................................................................. 20

4.1 Bond (Rpe) ...........................................................................................................................20

4.2 Insulation (also referred to as Riso) .................................................................................21

4.3 Leakage (Ipe) ....................................................................................................................22

4.4 VA ........................................................................................................................................26

4.5 1.5 kV/ 3 kV (not available on PAT310 or 320) ..................................................................27

5. SETUP....................................................................................................................................................29

5.1 Test Group key configuration.....................................................................................................29

5.2 Quick test key setup .................................................................................................................... 30

5.4 Lead Null ....................................................................................................................................... 31

6. Battery and fuses..................................................................................................................................32

6.1 Battery function............................................................................................................................32

6.2 Battery replacement.....................................................................................................................32

6.3 Fuse replacement.........................................................................................................................32

7. Care and maintenance .........................................................................................................................32

8. Specification .........................................................................................................................................33

9. Repair and Warranty.............................................................................................................................36

Page 4

4

1.1 Unpacking the carton

Unpack the carton contents carefully. There are important documents that you should read and keep for

future reference.

Please complete the pre-paid warranty card and return it to Megger Limited as soon as possible to help us

reduce any delays in supporting you should the need arise.

PAT310 & 320 carton contents

PAT350 Carton contents

1

PAT300 series appliance tester

1

PAT300 series appliance tester

1

Carry case

1

Carry case

1

Quick-start guide

1

Quick-start guide

1

Black test lead set with probe and clip

1

Black test lead set with probe and clip

1

IEC lead 0.5 m (Extension lead adaptor)

1

IEC lead 0.5 m (Extension lead adaptor)

1

Warranty card

1

Warranty card

1

Owners CD manual

1

Owners CD manual

1

PP3 9 V NiMH rechargeable battery

1

Flash test lead

Page 5

5

1.2 Safety Warnings

The following Safety Warnings and Precautions must be read and understood before the instrument

is used. They must be observed during use.

! For safety, only connect the PAT to a supply that is properly earthed. If in doubt, the supply should

be checked by a qualified electrician.

! Do not use the instrument if there are any signs of damage.

! All test leads, probes and clips must be in good order, clean and with no broken or cracked

insulation.

! Probes and clips should be held behind the finger guard.

! Test leads not used during a measurement should be disconnected from the Appliance tester.

! For dual voltage testers, both sockets can be live simultaneously.

! Only connect one asset to the PAT during testing.

! Tests should be carried out in the order recommended below. An appliance that fails a test should

be repaired before further testing is carried out.

Recommended Sequence:

1. Earth Bond/ Continuity of the protective earth conductor (Class I devices)

2. Insulation test (or earth leakage)

In addition further tests can be performed

3. Operation test

4. Leakage test

! Only perform an operational test after the Earth bond and insulation tests have been completed, as

this test operate at mains voltage.

! During testing, ensure no hazard will exist as a result of normal running or under fault conditions.

! During testing the unit under test (asset) should not be touched, other than using the appropriate

accessories, as faulty appliances can present a shock hazard.

! Do not touch the exposed parts of test leads during tests as hazardous voltages may be present due

to potentially faulty appliance.

! Do not touch the IEC extension lead socket pins especially during a test, as hazardous voltages may

be present due to a potentially faulty appliance

! Assets should not be routinely flash tested. Where flash testing is required, refer to further guidance

on Flash testing, section 4.5.

! Replacement fuses must be of the correct rating and type. Refer to section 6.3

! The USB connection should only be used by approved service personnel; nothing should be

connected to the USB port during testing.

! Only use NiMH rechargeable 9 V PP3 battery, do not use a non rechargeable type as this could

become dangerous if charged by the instrument.

! Serviceable fuses should only be replaced with those that are suitably rated

! In case of an emergency use an easily accessible power point

CAT II

Measurement category II: Equipment

connected between the electrical outlets and the user’s equipment.

CAT III

Measurement category III: Equipment connected between the distribution panel and the electrical outlets.

CAT IV

Measurement category IV: Equipment connected between the origin of the low-voltage mains supply and the

distribution panel.

Page 6

6

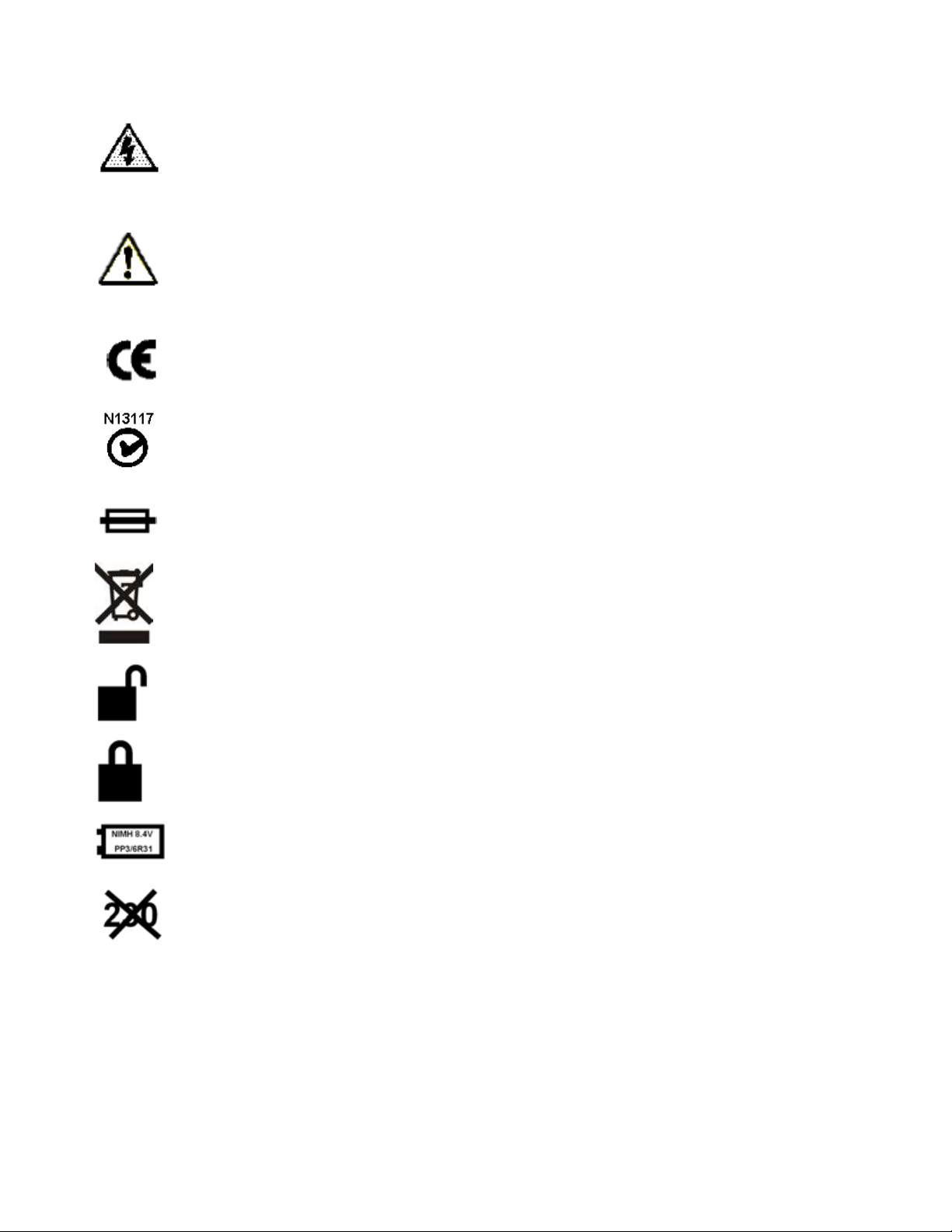

1.3 Symbols used on the instrument

Caution: risk of electric shock

Caution: refer to accompanying notes. When displayed at the start of an insulation test,

warns that a hazardous voltage may exist at the test lead probes

Equipment complies with relevant EU Directives

Equipment complies with ‘C tick’ requirements

FUSED

THIS EQUIPMENT SHOULD BE RECYCLED AS ELECTRONIC WASTE

HV TEST LEAD IN UNLOCKED POSITION

HV TEST LEAD IN LOCKED POSITION

BATTERY TYPE FITTED

DO NOT CONNECT TO 230 V SUPPLY

Page 7

7

2. Getting started

2.1 Carry case

The carry case for the appliance tester has a lead storage pouch in the lid of the case when opened.

This is designed for basic lead and document storage.

Further items can be stored in the pouch. If it becomes difficult to close the case, the storage pouch

can be removed from inside the case and attached to the front using the straps on the reverse of the

pouch.

These are passed through the D-loops on the outside of the case and secured to the underside of

the pouch using the Velcro fixings.

An additional storage pouch is available from Megger Ltd for extended storage, such that there is a

pouch on both the inside and outside of the carry case.

9 V PP3 rechargeable NiMH Battery is supplied- not fitted. This should be installed prior to first use.

See section 6 for instructions.

Page 8

8

2.2 Instrument layout

2.3 Controls layout

The following tests are available on the PAT350.

Note: The PAT310 & 320 does not include the Flash test option (j).

Test groups (a) to (d) – See section 3 for details

Test group

Description

(a)

Class I test

For testing assets with an earth return conductor

(b)

Class II test

For testing assets without an earth return conductor

(c)

IEC lead and

Extension lead test

For testing extension leads and IEC type power leads (found on computers,

kettles etc)

(d)

RCD tests

For testing Plug-in RCDs and extension leads fitted

with RCDs.

(e)

Information

Provides technical support contact information

Individual tests (f) to (j)

(f)

Bond test (Rpe)

Performs an earth bond/continuity test at 200 mA,10 A or 25 A

(g)

INS test (Riso)

Performs an Insulation test at either 250 V or 500 V

(h)

Leakage test (Ipe)

Performs a RUN test and measures the power drawn

(i)

Load test (VA)

Performs an earth leakage test, either:

Differential earth leakage

Touch leakage

Substitute leakage

(j)

Flash1.5 kV/3 kV

Performs a flash test at the required voltage

1

Appliance test socket 110 V

2

Flash test socket (PAT 350 only)

3

Earth bond and Insulation test probe socket

4

Lead null post

5

Firmware upgrade port

6

Power off (Red), Home (Grey) and Escape

(Green) keys

7

Test keypad

8

Mains lead entry

9

Extension lead / IEC lead test return socket

10

Appliance test socket (230 V)

11

Fuse checker

12

Display

13

Display navigation

UP / DPWN / LEFT / RIGHT

OK

14

TEST button

(a)

(h)

(i)

(j)

(g)

(b)

(f)

(e)

(d)

(c)

1

2 3 4

13

14

12

11

10 6 8 9 7

5

Page 9

9

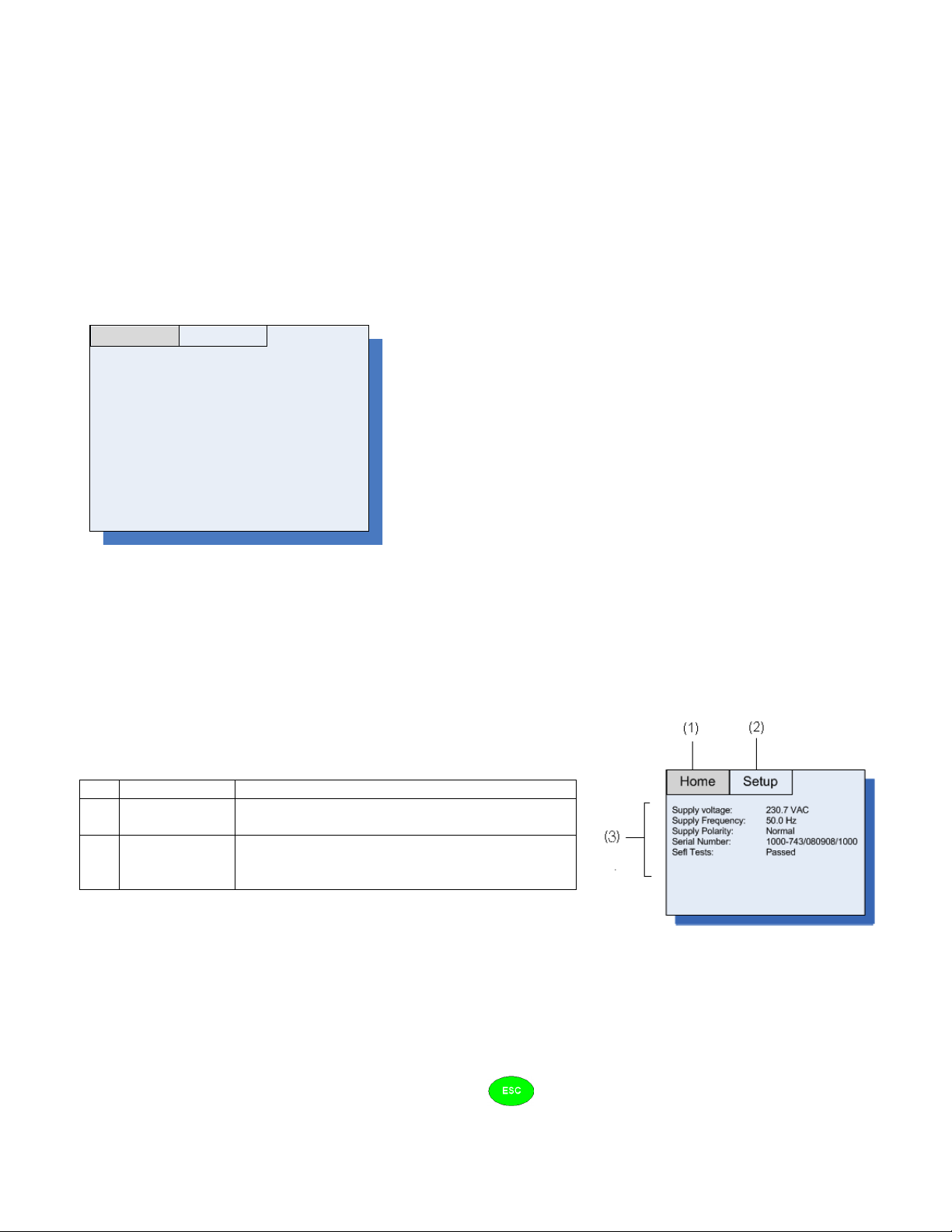

2.4 Instrument start-up

Connect the instrument to a suitable electrical supply:

The appliance tester will automatically start when connected to the mains supply.

NOTE:

DO NOT connect any equipment to the PAT tester until it has been switched on and passed self test.

Connected equipment will create a relay error and necessitate restarting the appliance tester by

pressing the OFF button. Once switched off the power should be disconnected and reconnected.

The following warning screen is displayed when the PAT tester is switched on. This screen is not displayed if

the PAT tester is re-started within five minutes of switching off, when the PAT tester restarts from the same

screen as before.

Home Setup

WARNINGS: The following warnings must be read and

understood before proceedingt :

_ Power is applied to both sockets during testing . Ensure only

one asset is connected and tested at a time .

_ Faulty appliances can present a shock hazard . Avoid contact

with al conductors and conductive parts during testing .

_ All tests that include a load or Leakage test will run the asset .

Ensure asset is switched on and safe before starting the test

sequence .

Press OK to confirm these warnings have been read and

understood

Press OK to confirm you have read and understood these warnings.

Important:

For testing 230 V electrical equipment, connect the PAT tester to a 230 V electrical outlet.

For testing 110 V electrical equipment, connect the PAT tester to a 110 V electrical outlet, using the

optional 110 V to 230 V supply lead adaptor (not applicable to PAT310).

The instrument will display the following when all initial tests pass.

1

Home screen

All testing can be run from this screen

2

Setup options

Test limits, test duration, Language, Auto or

Manual test modes etc can be changed here.

3

Power-up

status and

test results

Displays supply status and Self test results

2.5 Switching off the appliance tester

To switch off the tester, press the RED off button. The display will show the message

“It is now safe to remove power”. Now the mains plug can be removed from the supply.

Failure to press the RED off button will discharge the FAST START battery un-necessarily as per section

2.5.1.

If the RED off button is pressed accidentally, pressing the

button will return the PAT to normal testing

mode.

Page 10

10

2.5.1 FAST Restart

If the tester is to be moved to a new location and testing continued, simply unplug the unit from the mains

supply and reconnect it in the new location. The appliance tester will enter a hibernation mode during the

move and restart instantly from the point power was disconnected, without any delay.

The rechargeable 9 V NIMH battery is used to maintain hibernation status whilst unplugged. This cell is

continuously charged whilst the appliance tester is connected to the mains supply.

Continuous use of the hibernation mode will discharge the battery. Only use the hibernation mode when a

fast restart is required.

Should the move take longer than 5 minutes, the appliance tester will leave hibernation mode and complete

a full power down.

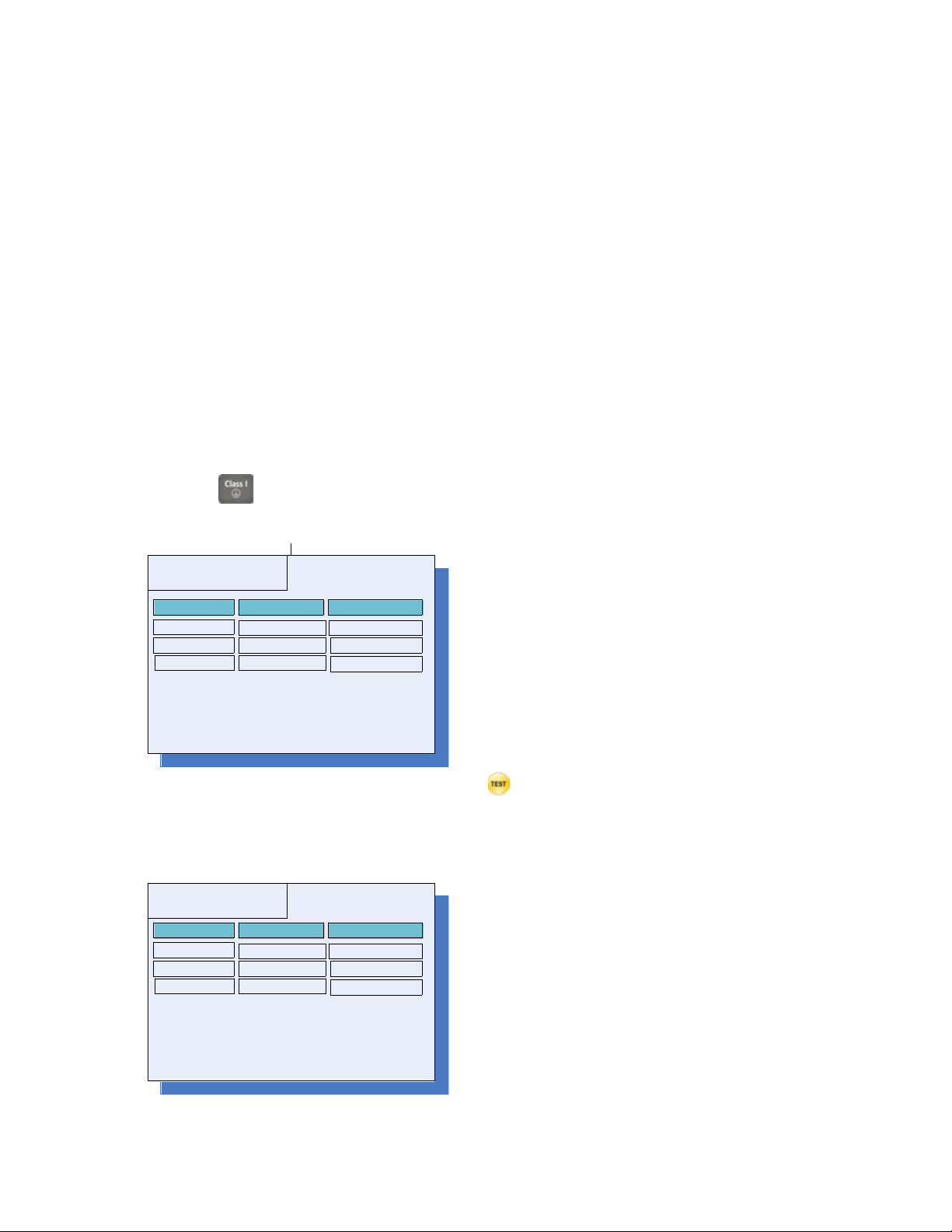

2.6 Testing an asset

2.6.1 To run a test - (Example shows a Class I test in AUTOMATIC test mode)

(a) Connect the asset to be tested to the portable appliance tester.

(b) Press the

button for a CLASS I test for assets with a protective earth conductor.

The display will show the initial test information:

Class I results

Ins

Bond

≥ 0.5 M_

≤ 0.1 _

Test Result Limits

Load

≤ 3000 VA

Test Result Limits

Attach probe and press TEST to start

(c) Connect the bond lead to the asset and press the

button to start the test.

(d) The Appliance tester will display any operational warnings as well as the measured values during the

test and the remaining test time.

Class I results

Ins

Bond

≥ 0.5 M_

≤ 0.1 _

Test Result Limits

Load

≤ 3000 VA

Test Result Limits

Timer: 5s

Bond: 0.08

_

The first test will be an Rpe (Earth continuity / bond) test.

The resistance during the test is displayed.

Page 11

11

The Timer shows the number of seconds remaining of the test.

After each test the worst case measurement will be displayed and tagged with a GREEN marker for a PASS,

or a RED marker for a FAIL.

Note – ABORTING A TEST:

A test can be aborted at any time by pressing the

button.

Each test will run automatically unless there is a manual operation required.

Example:

Earth bond test passed

Example:

Isolation (Insulation) test failed

To return to the HOME screen or run a different type of test, press the

button

At the completion of a successful set of tests the display will show all results marked GREEN and the “Asset

PASSED” message displayed:

Example:

OPTIONS:

(1) To return to the HOME screen press the

button.

Page 12

12

(2) To repeat the same test (or test another CLASS I asset) press the test button. The

appliance tester will return to the first test screen and wait for the TEST

button to be pressed to

commence testing.

(3) To change the test type, press the appropriate function button.

Should a test fail it will be marked with a RED tag, testing will stop and the display will show “Asset Failed”.

Any fault should be made good before testing is re-started.

2.7 Remote test probe and clip

Some tests will require the use of the remote probe and clip. These are used where the asset under test has

no earth return (Class II assets). The probe is used for both insulation and bond testing, under the control of

the instrument.

Example:

Class I Insulation test (Riso)

Live and neutral are shorted together automatically in the PAT tester and a voltage (250 V or 500 V) is

applied between the shorted L/N and the earth conductor as below.

Class II Insulation test (Riso)

Live and neutral are shorted together automatically in the PAT and a voltage (250 V or 500 V) is applied

between the shorted L/N and the remote probe.

The probe is connected to any metallic locations on the “Appliance Under Test” to ensure there is no

breakdown of the insulation.

Remote probe not required

Remote probe required

Page 13

13

3. Test options

Each test option (button) consists of a group of tests required for that class of test. The instrument will

display the tests to be completed and the status of each test as they are completed, against the set Pass

limit for that test. TO change PASS limits, refer to section 5 – Setup.

The following sections show the difference between automatic and manual operation, what is displayed

during each test and which connections are required during the test sequence.

All tests commence from the HOME screen as below:

Home Setup

Supply voltage: 230.7 VAC

Supply Frequency: 50.0 Hz

Supply Polarity: Normal

Serial Number: 1000-743/080908/1000

Sefl Tests: Passed

Any test can be selected or changed until the OK or TEST buttons are pressed.

On completion of the test the PAT can be returned to the home screen by pressing the

button.

Alternatively the test can be repeated by pressing the test

button twice. In this case the PAT will return

to the first test screen of the previous test selected.

3.1 110 V or 230 V selection:

Testing 110 V ac or 230 V ac equipment is dependent on the supply voltage. Connecting the appliance

tester to a 110 V ac supply automatically switches the appliance tester to the yellow 110 V test socket.

Connecting the appliance tester to a 230 V ac supply switches the tester to the 230 V test socket.

Testing examples in this document use the 230 V test socket and assume the appliance tester is connected

to a 230 V ac supply.

Page 14

14

3.2 Class I - Assets with an earth return conductor

Class I equipment depends on having an earth within the equipment and an earth return in the supply cable

to provide protection should a part of the equipment become live under fault conditions.

3.2.1 Class I – automatic testing mode

AUTOMATIC

Manual action required

(1)

Bond (Rpe)

Connect remote probe to asset and press OK to continue

(2)

Insulation (Riso)

Disconnect bond probe from asset

(3)

Load (VA)

Press TEST button

Connections:

Test sequence:

(1)

Connect remote probe to metal

parts of asset

Class I results

Ins

Bond

≥ 0.5 M_

≤ 0.1 _

Test R esult Limi ts

Load

≤ 3000 VA

Test R esult Limi ts

Attach probe and press TEST t o start

Class I results

Ins

Bond

≥ 0.5 M_

≤ 0.1 _

Test Result Limits

Load

≤ 3000 VA

Test Result Limits

Timer: 5s

Bond: 0.07

_

Testing sequence continued…

(2)

Class I results

Ins.

Bond 0 .07_

≥ 0.5 M_

≤ 0.1 _

Test R esult Limits

Load

≤ 3000 VA

Timer: 5s

Ins: >99.9M

_

Note: Disconnect remote probe.

(3)

Class I results

Ins.

Bond 0.07_

>199M_ ≥ 0.5 M_

≤ 0.1 _

Test Re sult Limits

Load

≤ 3000 VA

Asset will operate. Ensure asset is safe.

Press OK to continue

Timer: 5s

Class I results

Ins.

Bond 0.07_

>199M_ ≥ 0.5 M_

≤ 0.1 _

Test Re sult Limits

Load

≤ 3000 VA

Timer: 5s

Load: >195 VA

Class I results

Ins.

Bond

0.07_

>199M_ ≥ 0.5 M_

≤ 0.1 _

Test R esult Limits

Load

135VA ≤ 3000 VA

Asset PASSED

Page 15

15

3.3 Class II – Assets with no earth conductor

3.3.1 Class II - automatic test mode

AUTOMATIC mode

Operator action required

(1)

Insulation (Riso)

Connect remote probe to asset and press OK to continue.

(2)

Load (VA)

Disconnect remote probe

Press TEST button

Connection required:

Test sequence:

(1)

Connect remote probe

to metal parts of asset

Class II results

Ins. ≥ 0.5 M_

Test Result Limits

Load

≤ 3000 VA

Attach probe and press TEST t o start

Class II results

Ins. ≥ 0.5 M_

Test Result Limits

Load

≤ 3000 VA

Timer: 5s

Ins: >99.9M

_

Testing sequence continued…

(2)

Class II results

Ins. >199M_ ≥ 0.5 M_

Test Re sult Limits

Load

≤ 3000 VA

Asset will operate. Ensure asset is safe.

Press OK to continue

Timer: 5s

Note: Disconnect remote probe

Class II results

Ins. >199M_ ≥ 0.5 M_

Test Re sult Limits

Load

≤ 3000 VA

Timer: 5s

Load: 135VA

Class II results

Ins. >19 9M_ ≥ 0.5 M_

Test Re sult Li mits

Load

135VA ≤ 3000 VA

Asset PASSED

Page 16

16

3.4 IEC - Power leads fitted with 10 A IEC connector

3.4.1 IEC lead - automatic test mode

AUTOMATIC

Operator action required

(1)

Bond (Rpe)

None

(2)

Insulation (Riso)

None

(3)

Polarity

None

Connection required:

Test sequence:

(1)

Extension (IEC) lead

Ins

Bond

≥ 0.5 M_

≤ 0.1 _

Test Result Limits

Load

≤ 3000 VA

Test Result Limits

Timer : 5s

Bond : 0.07

_

(2)

Extension (IEC) lead

Ins.

Bond 0.07_

≥ 0.5 M_

≤ 0.1 _

Test Result Limits

Polarity

Pass/Fail

Timer: 5s

Ins: >99.9M

_

Testing sequence continued…

(3)

Extension (IEC) Lead

Ins.

Bond

0.07_

>99.99M_ ≥ 0.5 M_

≤ 0.1 _

Test R esult Limits

Polarity test:

Reverse polarity not permitted

Polarity Pass/Fail

Extension (IEC) Lead

Riso

Rpe 0.07_

>199M_

≥ 0.5 M_

≤ 0.1 _

Test Result Limits

Polarity

Normal Normal/Rev

Asset PASSED

Page 17

17

3.5 Extension leads - Single and multi-way extension leads

3.5.1 Extension leads – automatic mode

AUTOMATIC

Manual

action

required

(1)

Bond (Rpe)

None

(2)

Insulation (Riso)

None

(3)

Polarity

None

Connection required:

Test sequence:

(1)

Extension (IEC) lead

Ins

Bond

≥ 0.5 M_

≤ 0.1 _

Test Result Limits

Load

≤ 3000 VA

Test Result Limits

Timer : 5s

Bond : 0.07

_

(2)

Extension (IEC) Lead

Ins.

Bond 0.07_

≥ 0.5 M_

≤ 0.1 _

Test Result Limits

Polarity

Pass/Fail

Timer: 5s

Ins: >99.9M

_

Testing sequence continued…

(3)

Extension (IEC) Lead

Ins.

Bond

0.07_

>99.99M_ ≥ 0.5 M_

≤ 0.1 _

Test R esult Limits

Polarity test:

Reverse polarity not permitted

Polarity Pass/Fail

Extension (IEC) Lead

Riso

Rpe 0.07_

>199M_

≥ 0.5 M_

≤ 0.1 _

Test Result Limits

Polarity

Normal Normal/Rev

Asset PASSED

Note: Test sequence can be repeated on the remaining

sockets to ensure all outlets are compliant.

Page 18

18

3.6 RCD

3.6.1 Testing portable residual current devices (RCDs) – Manual only

As there is a need to reset the RCD during the test sequence there is no fully automated test sequence, no

AUTO mode exists. All testing is completed in manual mode.

AUTOMATIC

Manual action required

(1)

Test button function

Set RCD on

(2) Press test button on RCD

(3)

½ x 30 mA

Reset RCD

1 x 30 mA (0°)

None

(4)

1 x 30 mA (180°)

Reset RCD after trip

(5)

5 x 30 mA (0°)

Reset RCD after trip

(6)

5 x 30 mA (180°)

None

Connection required:

Test sequence:

Plug in the RCD to the

230 V appliance test socket

Connect the RCD to the IEC

socket using the red 0.5 m IEC test lead.

(1)

(2)

RCD test

Test Result Limits

1 x I

0.5 x I >20 00ms

21.3ms <3 00ms

>2000ms

5 x I

7.6ms

<40ms

Test button

Pass Pass/Fail

Press the M ANUAL TES T BUTTON

on the RCD. Does RCD trip?

Testing sequence continued…

(3)

RCD Test

1 X I

0.5 x I

<300ms

>2000ms

Test Result Limits

5 x I

<40ms

Timer : 1

Test button

Pass/Fail

Reset t he RCD and Press OK.

RCD Test

1 x I

0.5 x I >2000ms

<300ms

>2000ms

Test Resul t Limits

5 x I

<40ms

1 x I at 0º trip test : 22ms

Please reset the RCD and press OK

Test button

Pass

Pass/Fail

(4)

RCD Test

Test Resul t Limits

1 x I at 180 º trip test: 20ms

Please reset the RCD and press OK

1 x I

0.5 x I >2000ms

<300ms

>2000ms

5 x I

<40ms

Test button

Pass

Pass/Fail

(5)

RCD Test

Test Resul t Limits

5 x I at 0 º trip test: 7ms

Please reset the RCD and press OK

1 x I

0.5 x I >2000ms

22ms <3 00ms

>2000ms

5 x I

<40ms

Test button

Pass Pass/Fail

(6)

RCD Test

Test Resul t Limits

1 x I

0.5 x I >20 00ms

21.3ms <300ms

>2000ms

5 x I

9ms <40ms

Test button

Pass

Pass/Fail

Asset PASSED

Page 19

19

3.7 Test failure

3.7.1 Test failure - automatic test mode

Should any test fail during the test sequence, the PAT will abort further testing and display a test failure

screen as below:

Visual

Ins.

Bond

PASS

0.35_

Pass/Fail

≥ 0.5 M_

≤ 0.1 _

Test Result Limits

Load

≤ 3000 VA

Class I results

Asset FAILED

The failed test will be tagged with a RED marker and the failed result will be recorded in the appropriate

column.

No further testing should be attempted until the fault is rectified. However individual tests can be run for

diagnostic purposes. However some tests may be hazardous depending on the failure mode of the asset

and should only be undertaken after a risk assessment of the failed asset.

3.8 Changing PASS limits

See section 5 - SETUP

3.9 Changing test duration

See section 5 - SETUP

Page 20

20

4. Individual tests – Quick tests:

These tests are individual tests and perform a single type of test. Where several options exist under the one

function (such as Bond with 25 A, 10 A or 200 mA) then those options will be available for selection.

Notes:

There is no automatic mode for these tests.

Pass fail limits are not enabled. Actual measurement values are displayed during and at the

completion of testing.

4.1 Bond (Rpe)

MANUAL ONLY

Manual action required

Bond (Rpe)

Select the Bond test current

Press OK to accept

Test sequence: Connection required:

Bond Menu

Select test current and Press OK or TEST

Note: Use remote prob e

Test duration: 5s

25 Amp Earth Bond

10 Amp test Earth Bond

200 mA test Continuity

25 Amp Earth Bond

Select the test current using the up/down arrows

Note:For PAT310, only 200 mA test is available.

When ready press:

or to continue

Bond Results

Bond

Test Re sult

Timer: 3

Bond: 0.07_

Continued…

Bond Results

Test Resu lt

Bond 0.07Ω

Timer: 0 s

Bond: 0.07Ω

Press to navigate back to HOME screen or

Press to return to the INS selection screen

or

Press to retest

NOTE:

To abort a test, press the button.

Page 21

21

4.2 Insulation (also referred to as Riso)

4.2.1 Running an Insulation (Isolation) test

This test will apply a 250 V or 500 V (default) test voltage between the live/neutral pair and earth conductor.

During this test the live and neutral are shorted together by the PAT tester for the duration of the test.

MANUAL ONLY

Manual action required

Insulation (Riso)

Select insulation test voltage

Select class of test

Press OK to accept

Connection required:

Class I equipment Class II equipment

Test sequence:

Insulation Menu

Select voltage and Press OK or TEST

Note: For Class II use the remote probe.

Test Duration: 4 seconds

230V Appliance

110V Appliance

Class I 500V >

Class II 500V >

Class I 250V >

Class II 250V >

Select the “Class type” and “Test voltage”

Note: 110 V Appliance options are not available on the

PAT310

Select the “Voltage rating”

When ready, press:

or

Continued…

Insulation results (230V test socket)

Ins 500V

Result

Please ensure appliance is switched on .

Press OK to continue, TEST to abort

Class I T est

to continue or to abort

Ins 500V

Result

Timer: 3

Riso: >199M_

Class I test

Insulation results ( 230V test socket)

Test

Result

Ins 500V >99.99M_

Insulation results (230V test socket)

Timer: 0s

Ins: >99.99M_

Press to navigate back to HOME screen or

Press to return to the Insulation selection

screen or

Press to retest

NOTE: To abort a test, press the button.

Page 22

22

4.3 Leakage (Ipe)

The Leakage test provides three different methods for measuring leakage current of equipment:

Differential leakage test: (section 4.3.1)

This measures the difference in current between the live and neutral conductors. The difference is

displayed as the leakage current. The test socket will be automatically chosen depending on the

supply voltage. The measured value is adjusted to reflect the worst leakage current at the upper

operating voltage limit.

Touch leakage: (section 4.3.2)

Where no earth return path exists, (Class II) one has to be provided to simulate the equipment being

held in the hand. The test socket will be automatically chosen depending on the supply voltage. The

measured value is adjusted to reflect the worst leakage current at the upper operating voltage limit.

Substitute leakage: (section 4.3.3)

This measures the leakage current in the earth conductor using a low AC voltage (typically 40 Vac).

This reduces the risk of electric shock and prevents the equipment from running during the test,

where this would otherwise be considered dangerous. The test socket is optional since this test is

independent of the supply voltage. The measured value is adjusted to reflect the worst leakage

current at the upper operating voltage limit.

IMPORTANT: The equipment must be running in its normal operating mode for the test, i.e. a hair dryer

must be set to its hottest setting and have its trigger depressed.

4.3.1 Ipe Differential

MANUAL ONLY

Manual action required

Leakage - Differential

Select the differential test voltage

Select classification of test type

Press OK to accept

Connection required:

Test sequence:

(1)

Leakage Menu

Select voltage and Press OK or TEST

Differential leakage >

Touch current (230v)

Substitute leakage >

Class I 230V

Class II 230V

Asset will operate.

Ensure asset is switched on and safe.

Note: For Class II appliances, use the remote

probe

Test duration: 5 seconds

Select the test type using the up/down arrows

Continued…

Select the class of test using right arrow then up/down

arrows

When ready press:

or

(2)

Leakage results (230V test socket)

Leakage (Diff)

Class I test Result

Please ensure appliance is switched on .

Press OK to continue, TEST to abort.

(This is displayed if the PAT does not detect an asset

connected to the test socket or the asset is open

circuit)

Page 23

23

Continued…

to continue or to abort

(3)

Leakage results (230V test socket)

Timer: 3s

Ipe: 0.15mA

Leakage (Diff)

Class I test Result

Leakage results (230V test sock et)

Timer: 0s

Ipe: 0.15mA

Leakage (Diff)

0.15mA

Class I test Result

Press to navigate back to HOME screen or

Press to return to the Leakage Menu selection

screen or

Press to retest

NOTE:

To abort DURING a test, press the button.

Page 24

24

4.3.2 Touch Leakage – Itouch

Test sequence is the same as Ipe – differential, except the earth leakage connection must be made

using the remote probe to simulate contact by the operator.

MANUAL ONLY

Manual action required

Touch leakage (Itouch)

Press OK to accept

Connect remote test probe

Connection required:

Test sequence:

Select the test type using the UP/Down arrows

(1)

Leakage Menu

Select voltage and Press OK or TEST

Touch current (230V)

Differential leakage >

Substitute leakage >

Note: For Class II appliances, use the remote

probe

Test duration: 5 seconds

Asset will operate.

Ensure asset is switched on and .safe

When ready press:

or

(2)

Leakage results (230V test socket)

Leakage (Touch)

Class II test Result

Please ensure appliance is switched on .

Press OK to continue , TEST to abort.

Continued…

This is displayed if the PAT does not detect an Asset

connected to the test socket or the asset is open

circuit.

When ready press:

to continue or to abort

(3)

Leakage results (230V test socket)

Timer: 3s

Ipe: 0.15mA

Leakage (Touch)

Class II test

Result

Leakage results (230V test sock et)

Timer: 0s

Ipe: 0.15mA

Leakage (Touch)

0.15mA

Class II test Result

Press to navigate back to HOME screen or

Press to return to the Leakage Menu selection

screen or

Press to retest

NOTE:

To abort DURING a test press the button.

Page 25

25

4.3.3 Ipe – Substitute leakage

MANUAL ONLY

Manual action required

Ipe - Substitute

Select the test socket

Select classification of test type

Press OK to accept

Connection required:

Class I assets Class II assets

Test sequence:

Select the test type using the up/down arrows

(1)

Leakage Menu

Select voltage and Press OK or TEST

Substitute leakage >

Differential leakage >

Touch current (230v)

Note: For Class II appliances, use the remote

probe

Test duration: 5 seconds

Class I 230V

Class I 110V

Class II 230V

Class II 110V

Asset will operate.

Ensure asset is switched on and .safe

Select the class of test using right arrow then

up/down arrows

NOTE: 110 V not available on PAT310

When ready press:

or

Continued…

(2)

Leakage results (230V test socket)

Leakage (Sub)

Class I test Result

Please ensure appliance is switched on .

Press OK to continue, TEST to abort.

This is displayed if the PAT does not detect an asset

connected to the test socket, or the asset is open

circuit.

to continue or to abort

(3)

Leakage results (230V test socket)

Timer: 3s

Ipe: 0 .15mA

Leakage (Sub)

Class I test Result

Leakage results (230V test socket)

Timer: 0s

Ipe: 0 .15mA

Leakage (Sub)

0.15mA

Class I test Result

Press to navigate back to HOME screen or

Press to return to the Riso selection screen or

Press to retest

NOTE: To abort DURING a test press the button.

Page 26

26

4.4 VA

This test measures the power consumption of the equipment when running. The results are displayed in VA.

IMPORTANT: The equipment must be running in its normal operating mode for the test, i.e. a hair dryer

must be set to its hottest setting and have its trigger depressed.

MANUAL ONLY

Manual action required

Load (VA)

Press OK to accept

Connection required:

Test sequence:

(1)

Load test

Asset will operate.

Ensure asset is switched on and safe.

Press OK or TEST to continue.

Test Duration: 5s

When ready press:

or

(2)

Load test

Load

Class II test Result

Please ensure appliance is switched on .

Press OK to continue, TEST to abort.

Continued…

When ready press:

to continue or to abort

(3)

Load test

Timer: 3s

Load: 356VA

Load

Test

Result

Load test

Timer: 3s

Load: 356VA

Load 356VA

Test

Result

Press to navigate back to HOME screen or

Press to return to the VA initial screen

Press to retest appliance

NOTE:

To abort a test press the button.

Page 27

27

4.5 1.5 kV/ 3kV (not available on PAT310 or 320)

Warning: The flash test should not be used for general “In-service” testing. It should only be used when

instruments have been repaired.

The flash test provides a high AC test voltage (1500 V or 3000 V) and measures the leakage current. This

can be a destructive test and is usually only used on equipment that has been repaired. It is not generally

used for “IN-service testing” of electrical equipment.

MANUAL ONLY

Manual action required

Flash

Select Flash test voltage

Press OK to accept

Hold down TEST key to apply Flash test voltage

Connection required:

Test sequence:

Flash lead connection:

The flash test lead should be inserted fully

and turned so the arrows align with the

lock symbol before testing.

(1)

Flash Menu

Select test voltage and Press OK or TEST:

Note: For Class II use the remote FLASH

TEST probe

Test Duration: NA

Flash 3000Vac >

Flash 1500Vac >

230V appliances

110V appliances

Select the test voltage using the up/down arrows

Continued…

Select the class of test using right arrow

then up/down arrows

Press to select

(2)

Flash menu

To commence testing, press and

HOLD DOWN the TEST button

When ready press and HOLD DOWN the TEST button

The test will only run while the button is

depressed.

Page 28

28

Class II test Result

Flash 3000Vac 0.85uA

Flash result (230V test socket)

Test Aborted

(3)

Release the

button to abort the test.

(4)

Press

Press

Press

to navigate back to HOME screen or

to return to the Riso selection screen or

to retest

Disconnecting the flash probe lead

To release the flash test probe, turn the arrow on the probe connector to the unlock symbol before

attempting to extract the connector.

Note:

The flash test is only available on the PAT350. The following message is displayed on the PAT310 or

320 if the flash test function is selected:

“This function is not available on this model” www.megger.com

Page 29

29

5. SETUP

5.1 Test Group key configuration

Allows changes the test parameters of the individual test groups Class I, Class II, IEC and RCD

tests.

(1)

Home Setup

Supply voltage: 230.7 VAC

Supply Frequency: 50.0 Hz

Supply Polarity : Normal

Serial Number: 1000-743/080908/1000

Sefl Tests : Passed

Press

O

K

to select setup

Press

O

K

to select “Test Group”

(2)

Home Setup

Test group keys >

Quick test keys

Lead null

Test group keys

Class I

Class II

Ext Lead

RCD

Press

O

K

to select Test Group

Press to accept selection.

(3)

Class I Setup

Ins Pass limit:

Ins Test type:

Bond Test time:

Bond Pass limit:

Bond Test type:

Load Test time:

Load rating:

Ins. Test time

5s

20M_

5s

0.1_

25A Earth bond

10s

3000VA

Class I 500V

Press followed by

O

K

to change test limits

Continued…

(4)

Ins Pass limit:

Ins Test type:

Bond Test time:

Bond Pass limit:

Bond Test type:

Load Test time:

Load rating:

1s

2s

3s

4s

5s

10s

20s

5s

5s

Ins. Test time

Class I Setup

Press to accept.

To return to Main test screen press

Alternatively press

O

K

first to select a different test

then and

O

K

to change the test limits, test

time or test type,

for example selecting RCD:

(5)

RCD Test type:

30mA Test

Full sequence

Full sequenceRCD Test type

RCD Setup

Press to accept.

To repeat process for Test times, pass limits etc

To return to Setup menu press

O

K

To return to Main test screen press

Page 30

30

5.2 Quick test key setup

Changes the test parameters of the individual test groups Riso, Rpe Ipe and Flash test.

Note: The Flash test function is only available on the PAT350 models.

(1)

Home

AUTO

Setup

Supply voltage: 230 Vac

Supply frequency: 50Hz

Polarity: Passed

Self Test: Passed

Battery: OK

Select a test...

Press

O

K

to select “Setup”

(2)

Home Setup

Test group keys >

Quick test keys

Lead null

Test group keys

Class I

Class II

Ext Lead

RCD

Press

O

K

to select “Quick test keys”

(3)

Home Setup

Test group keys >

Quick test keys

Lead null

Quick test keys

Press to select Quick Test

(4)

Quick test config

Bond test time:

Load test time:

Leakage test time:

Ins. test time: 5s

5s

5s

5s

Continued…

Press followed by

O

K

to change test times

(5)

Quick test config

Bond test time:

Load test time:

Leakage test time:

Ins. test time: 5 s

1s

2s

3s

4s

5s

10s

20

Infinite

5s

Press to accept

To return to Main test screen press

Alternatively press

O

K

first to select a different test

then to change the test time or test limits.

Press to accept

To return to Main test screen press

Page 31

31

5.4 Lead Null

Allows the compensation for additional lead resistance when performing Bond and continuity

measurements.

Lead null will remove test lead resistance up to 9.99 Ω. Setting a null value greater than 9.99 Ω will

generate the warning message:

“Lead NULL > 9.99 Ω Null not set”

(1)

Home

AUTO

Setup

Supply voltage: 230.7 VAC

Supply Frequency: 50.0 Hz

Supply Polarity : Normal

Serial Number: 1000-743/080908/1000

Sefl Tests: Passed

Press

O

K

to select setup

Press

O

K

to select “Lead Null”

(2)

Press to enter “Lead Null”

(3)

Lead null

Connect bond lead between Ω probe

socket and ZERO Ω post

Press TEST button to NULL

Set Lead null

Remove Lead null >

Connect Bond lead as instructed and press to

set Null

Continued…

(4)

Null s et = 0.08

Set Lead null

Remove Lead null >

Lead null

Press to return to initial screen

To remove Lead Null select “Remove Lead Null”.

Open circuit the Bond test lead and press

(5)

Lead null OFF

Set Lead null

Remove Lead null

Lead null

Page 32

32

6. Battery and fuses

6.1 Battery function

The PAT300 series are mains powered instruments. However a 9 V PP3 rechargeable NiMH battery is fitted

to allow fast restart should the PAT be unplugged and reconnected to an electrical supply in less than 5

minutes.

The PAT tester will operate with a discharged battery or no battery fitted, but will perform a full power-up

sequence when re-connected to a supply.

The battery is continually charged whilst the Appliance tester is operating. Only fit NiMH rechargeable

batteries.

Low battery is indicated by the battery warning in the main screen.

Warning: Do not switch on the instrument or connect test leads with the battery cover removed.

Only use NiMH rechargeable battery, other types may cause battery explosion.

6.2 Battery replacement

Warning: Do not switch the instrument on with the battery cover removed or test leads connected.

1. Disconnect any test leads from the instrument.

2. Switch off the instrument and disconnect (the instrument) from any electrical circuits.

3. Remove the battery cover with a small crosshead screwdriver.

4. Remove the old battery and refit a new one, observing the terminal polarity.

5. Replace the cover and retaining screw.

Note: Battery cells should not be left in an instrument which may remain unused for an extended period.

Warning: Only use NiMH rechargeable cells. It is dangerous to fit alkaline cells which could explode or catch

fire.

6.3 Fuse replacement

Warning: Do not switch the instrument on with the fuse cover removed or test leads connected.

1. Disconnect any test leads from the instrument.

2. Switch off the instrument and disconnect (the instrument) from any electrical circuits.

3. Remove the fuse cover with a small crosshead screwdriver.

4. Replace the blown fuse with the correct type and rating, e.g. 5 x 20 mm 250 V, 100 mA, 1.5 kA high

breaking capacity (HBC) type.

5. Replace the fuse cover

7. Care and maintenance

The PAT300 series instruments require very little maintenance. Instrument and test leads should be checked

before use to ensure there is no damage.

When necessary, the instrument can be cleaned with a damp cloth or Isopropyl alcohol.

Page 33

33

8. Specification

All quoted accuracies are stated at +20 °C.

Power Supply: 110 V ±10% ±1 V 50 Hz ±1% ±0.1 Hz 60 Hz

230 V ±10% ±1 V 50 Hz ±1% ±0.1 Hz

Internal battery: 1 x 9V type NiMH rechargeable cell (PP3, MN1604, 6F22, 6LR61, U9LV-J).

Battery types need to be checked e.g. PP3 type is an old zinc carbon not

NiMH

DO NOT USE NON-RECHARGEABLE (Alkaline) CELLS - Risk of

explosion.

Accuracy (at 20 °C)

Supply

Voltage measurement: ± 2% ± 1 V

Frequency measurement: ± 1% ± 0.1Hz

Bond test

Open circuit test voltage: 9 V ac ± 10% ± 0.1 V (supply :230 V 50Hz)

10 A Bond test current: 10 A rms ±20% ± 0.5 A into 0.1 Ω

26 A Bond test current: 26 A rms ± 5% ± 0.5 A into 0.1 Ω

Earth Bond resistance accuracy: ±5% ± 3 digits (0 to 0.5 Ω)

±5% ± 5 digits (0.5 to 1.99 Ω)

Earth bond resistance resolution: 10 mΩ (0 to 1.99 Ω)

Display range: 0 to 1.99 Ω

Bond test nulling: Up to 9.99 Ω

Adjustable test duration: User selectable from 1 sec to 60 sec + ∞

Continuity test

Continuity test compliance voltage: > +4 V dc –0%/+10% open circuit

Continuity test current: ±210 mA ± 10%

≥ 200 mA when measuring load 0.2 Ω to 2 Ω

Continuity resistance accuracy: ±5% ± 3 digits (0 to 0.99 Ω)

±5% ± 5 digits (1 to 19.99 Ω)

Continuity resistance resolution: 10 mΩ (0 to 19.99 Ω)

Display range: 0 to 19.99 Ω

Continuity test nulling: up to 9.99 Ω

Test duration: User selectable from 1 sec to 60 sec + ∞

Insulation test

Insulation test voltage: 250 V dc –0%/+25% open circuit

500 V dc –0%/+25% open circuit

≥ 500 V –10% dc across 0.5 MΩ load

Short circuit current: < 2 mA dc

Insulation resistance accuracy: ±2% ±3 digits < 20 MΩ

±5% ±10digits > 20 MΩ

Insulation resistance resolution: 0.01 MΩ (0.10 to 99.99 MΩ)

Display Range: 0.01 MΩ to 99.99 MΩ

Test duration: User selectable from 1 sec to 20 sec + ∞

Page 34

34

Substitute leakage test

Test voltage: 40 V ac ±5%

Test frequency: Nominal mains 50/60 Hz

Leakage current accuracy: ±5% ± 5 digits

Leakage current resolution: 0.01 mA

Display range: 0 to 19.99 mA

Test duration: User selectable from 1 sec to 10 sec + ∞

Reading corrected to 230 V + 10% or 110 V + 10% ac.

Differential leakage current

Test voltage: Nominal mains 110/230 V ac

Test frequency: Nominal mains 50/60 Hz

Differential leakage current accuracy: ±5% ± 0.05mA (1.0mA to 19.99mA)

±5% ± 0.1mA (0.1mA to 0.99mA)

Resolution: 0.01 mA

Display range: 0.00mA to 19.99mA

Test duration: User selectable from 1 sec 10 sec + ∞

Reading corrected to 230 V + 10% or 110 V + 10% ac.

Touch current test

Test voltage: Nominal mains 110/230 V ac

Test frequency: Nominal mains 50/60 Hz

Touch current accuracy: ±5% ± 5 digits

Touch current resolution: 0.01 mA

Display range: 0 to 10 mA

Test duration: User selectable from 1 sec to 10 sec + ∞

Reading corrected to 230 V + 10% or 115 V + 10% ac.

Operational test

Test voltage: Nominal mains 110/230 V ac

Accuracy: ±5% ± 5 digits (0 VA to 99 VA)

±5% ± 50 digits (100 VA to 999 VA)

±5% ± 100 digits (1000 VA to 3700 VA)

Resolution: 1 VA (0 to 3700 VA)

Display range: 0 to 3990 VA

Reading corrected to 230 V or 110 V ac. Results show load VA,

Test duration: User selectable from 1 sec to 60 sec + ∞

Extension lead test

Test includes insulation and bond tests.

Polarity test voltage: 12 V

Polarity: Lead OK

Live Neutral shorted

Live Neutral Reversed

Live/Neutral Open Circuit

Flash test

Flash test voltage: 1500 V ac nominal for Class 1

3000 V ac nominal for Class 2

Flash test current: < 3.5 mA short circuit @ 253 V primary supply voltage

Flash test breakdown current accuracy: ±5% ± 5 digits

Flash test breakdown current resolution: 0.01 mA

Display range: 0 to 3 mA

Test duration: For as long as the TEST button is pressed

Page 35

35

Portable RCD test

RCD test voltage: Nominal mains 110 V/230 V

RCD test frequency: 50 Hz

Test current accuracy: -8% to –2% (½ x I)

+2% to +8% (1 x I, 5 x I)

Trip time accuracy: ±1% ± 5 digits

Trip time resolution: 0.1 ms

Display range: 0 to 1999 ms (

½ x I)

0 to 300 ms (1 x I)

0 to 40 ms (5 x I)

Fuse test

Fuse test voltage: 3.3 V

Indication: Audible buzzer for OK

Circuit test (Carried out automatically, not available to user)

Circuit test voltage: 12 V

Circuit test frequency: Nominal Mains 50/60 Hz

Circuit test current: < 100 mA short circuit

Dimensions:

Instrument 250 mm x 320 mm x 175 mm

Instrument + case 290 mm x 400 mm x 190 mm

Auxiliary pouch: 60 mm x 300 mm x 200 mm

Weight:

PAT310

Instrument only: 2.5 kg

Instrument plus case: 3.0 kg

PAT320

Instrument only: 3 kg

Instrument plus case: 3.5 kg

PAT350

Instrument only: 4 kg

Instrument plus case: 4.5 kg

Fuses: Mains plug fuse uses BS1363 13 A fuse type: 5 x 20 mm 250 V, 100 mA,

1.5 kA High Breaking Capacity (HBC) type.

Safety protection The instruments meet EN 61010-1 (2001) to 300 V phase to earth,

Category II. Also refer to safety warnings supplied.

E.M.C. In accordance with IEC 61326:2006 including amendment No.1.

Operating temperature: -10 °C to +50 °C

Storage temperature: -20 °C to +60 °C

Humidity: 90% RH @ -10 °C +30 °C

75% RH @ +30 °C to +50 °C

Supply Voltage: 99 V to 253 V @ 50 Hz

Free fall: 0.25 m

Bump test: 6 x 1000 bumps at 40 g

Push button switch life: >50,000 operations

Maximum altitude: 2,000 m to full safety spec.

Dust and water: IP40

Page 36

36

9. Repair and Warranty

The instrument contains static sensitive devices, and care must be taken in handling the printed circuit

board. If an instrument’s protection has been impaired it should not be used, but sent for repair by suitably

trained and qualified personnel. The protection is likely to be impaired if for example, it shows visible

damage, fails to perform the intended measurements, has been subjected to prolonged storage under

unfavourable conditions, or has been subjected to severe transport stresses.

NEW INSTRUMENTS ARE GUARANTEED FOR 1 YEAR FROM THE DATE OF PURCHASE BY THE

USER.

Note: Any unauthorized prior repair or adjustment will automatically invalidate the Warranty.

CALIBRATION, REPAIR AND SPARE PARTS

For service requirements for Megger Instruments contact:

Megger Limited or Megger

Archcliffe Road Valley Forge Corporate Centre

Dover 2621 Van Buren Avenue

Kent CT17 9EN Norristown PA 19403

England. U.S.A.

Tel: +44 (0) 1304 502 243 Tel: +1 610 676 8579

Fax: +44 (0) 1304 207 342 Fax: +1 610 676 8625

Megger operate fully traceable calibration and repair facilities, ensuring your instrument continues to provide

the high standard of performance and workmanship you expect. These facilities are complemented by a

worldwide network of approved repair and calibration companies to offer excellent in-service care for your

Megger products.

Returning your product to Megger - UK and USA service centres

1. When an instrument requires recalibration, or in the event of a repair being necessary, a Returns

Authorisation (RA) number must first be obtained from one of the addresses shown above. You will

be asked to provide the following information to enable the Service Department to prepare in

advance for receipt of your instrument, and to provide the best possible service to you.

• Model, e.g. PAT300.

• Serial number, to be found on the underside of the case or on the calibration certificate.

• Reason for return, e.g. calibration required, or repair.

• Details of the fault if the instrument is to be repaired.

2. Make a note of the RA number. A returns label can be emailed or faxed to you if you wish.

3. Pack the instrument carefully to prevent damage in transit.

4. Ensure the returns label is attached, or that the RA number is clearly marked on the outside of the

package and on any correspondence, before sending the instrument, freight paid, to Megger. Copies

of the original purchase invoice and packing note should be sent simultaneously by airmail to

expedite clearance through customs. In the case of instruments requiring repair outside the warranty

period, an immediate quotation can be provided when obtaining the RA number.

5. You may track the progress of your return on line at www.megger.com

Approved Service Centres

A list of Approved Service Centres may be obtained from the UK address above, or from Megger’s website

at www.megger.com

Page 37

37

Megger Limited

Archcliffe Road

Dover Kent, CT17 9EN

England

Tel: +44 (0) 1304 502100

Fax: +44 (0) 1304 207342

Megger

4271 Bronze Way

Dallas

TX 75237-1017 U.S.A.

Tel: +1 (800) 723-2861 (U.S.A. only)

Tel: +1 (214) 330-3203 (International)

Fax: +1 (214) 337-3038

Megger

Valley Forge Corporate Centre

2621 Van Buren Avenue

Norristown, PA 19403, USA

Tel: +1 (610) 676-8500

Fax: +1 (610) 676-8610

Megger SARL

Z.A. Du Buisson de la Couldre

23 rue Eugène Henaff

78190 TRAPPES

France

Tel : +33 (1) 30.16.08.90

Fax : +33 (1) 34.61.23.77

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification or design without prior notice.

Megger is a registered trademark.

PAT300-UG_en_V07

www.megger.com

Loading...

Loading...