Page 1

M

PAT32 Series

P o rtable Appliance Testers

USER GUIDE

GUIDE DE L’UTILISATEUR

GEBRAUCHSANLEITUNG

Page 2

SAFETY WARNINGS

✱ PAT 32 must be properly earthed. A supply socket that has a protective earth contact must be used.

✱ Test leads, probes and crocodile clips must be in good order, clean and with no broken or cracked insulation.

✱ Circuit connections and exposed metalwork of an appliance under test must not be touched.

✱ Tests must be performed in the specified sequence. If an appliance fails a test, the fault causing the failure must be

rectified before testing. Re-testing must commence from the start of the sequence.

✱ Replacement fuses must be of the correct size, type and rating. See 'Specification' section.

✱ The instrument must not be used in damp conditions or if any part of it is damaged.

✱ Safety Warnings and Precautions must be read and understood before the instrument is used. They must be observed

during use.

NOTE

THE INSTRUMENT MUST ONLY BE USED BY SUITABLY TRAINED AND COMPETENT PERSONS

.

Symbols used on the instrument

Evaluate display reading against appliance details and refer to this User Guide

Caution: Refer to accompanying notes.

Equipment complies with relevant EU Directives

Page 3

User Guide

Safety Warnings 2

General Description 4

Features and Controls 6

Test Mode Summary 7

Performing tests – General 9

Appliance Testing 10

Extension lead testing (UK) 14

Specifications 15

Accessories 18

Repair and Warranty 19

Guide de l’utilisateur

Avertissments de Securité 22

Description génerale 23

Dispositifs et Commandes 25

Sommaire de Mode d’essai 23

Exécution des essais – Géneralitiés 26

Mise à l’essai de l’appareil 29

Mise à l’essai de la Rallonge 33

Spécification 34

Accessoires 37

Réparation et Garantie 38

Gebrauchsanleitung

Sicherheitswarnung 42

Allgemeine Beschreibung 43

Funktionen und Steuerelemente 45

Zusammenfassung des Testmodus 46

Durchführung von Tests 48

Testen von Geräte 49

Verlängerrungskabeltest 53

Spezifikation 54

Zubehör 57

Reparaturen und Garantie 58

Contents

3

Page 4

Introduction

Megger PAT 32 series are designed to check the

electrical safety of any product fitted with an appropriate

mains plug, including information technology (IT)

equipment, domestic appliances, industrial appliances

and power tools.

The following tests are available:

• Circuit check

• Fuse check

• Earth Continuity test

• 10 Amp Earth Bond test

• 25 Amp Earth Bond test

• Insulation test

• Extension lead tests (ELT1 or ELT2

required)

- Polarity (UK only)

- Earth Bond

- Insulation

Tests are effected by plugging the portable appliance or

extension lead into the relevant socket and pressing the

relevant Test switch. The readings from each test are

shown on the unique analogue / digital liquid crystal

display.The measurement scale for Earth Bond is

marked with pass bands. This provides a rapid indication

of a test Pass or Failure and allows proper test results to

be kept.

Applications

Appliances and electrical equipment with Safety Class I,

Class II and Safety Class III insulation may be tested.

These classes of safety are defined in various IEC and

BS safety specifications, and in general are:-

Class I Appliances which have functional

insulation throughout and an

earth connected body i.e. an ‘Earthed‘

appliance.

Class II Appliances which have both functional

and additional insulation, and where

any metal parts cannot become ‘Live’

under fault conditions. This is ‘Double

Insulation’ indicated by .

Class I / II Appliances having part of the

enclosure which meets Class I

requirements and part which meets

Class II.

Class III Appliance where protection against

electric shock is provided by an SELV

supply. Class III construction is

indicated by the mark.

General Description

4

III

Page 5

Typical uses for Megger PAT 32 are:

• Periodic tests of equipment used in

Factories, Offices, Local Education

Authorities, Hospitals etc.

• Routine tests before and after hiring

electrical equipment.

• Basic tests following equipment repair.

• Tests by manufacturers and distributors.

Specifications

The Megger PAT 32 may be used to test equipment

originally manufactured to a range of specifications such

as:

• IEC 335 -1 / BS3456

• BS 2769

• BS 4533

• BS415

• BS 7002

Power cord

The colour code of the cord is:

Phase Brown

Protective Earth Yellow / Green

Neutral Blue

If using a fused plug, a 3 Amp fuse to BS 1362 should be

fitted.

Note: A plug severed from the power cord should be

destroyed, as a plug with bare conductors is hazardous

in a live socket outlet.

5

Page 6

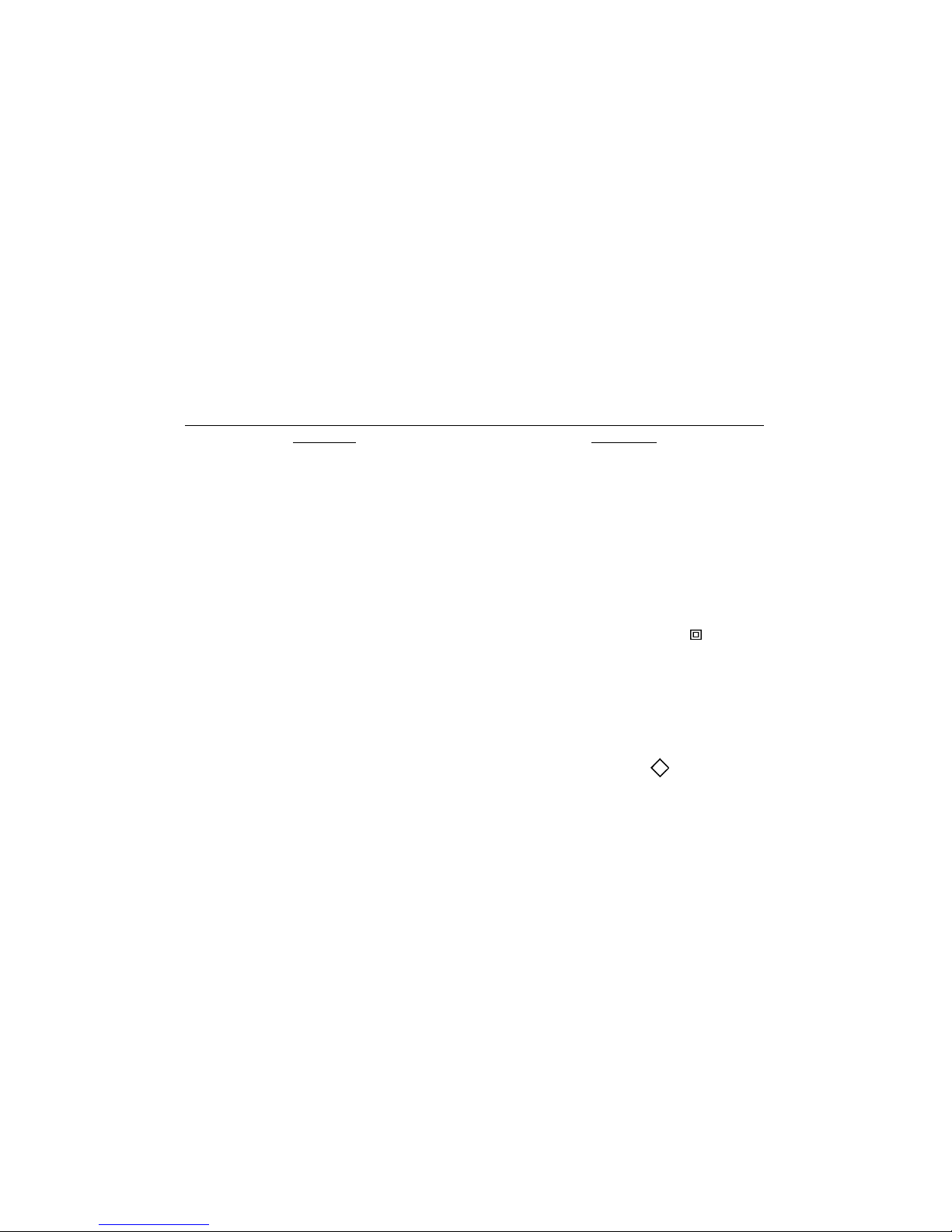

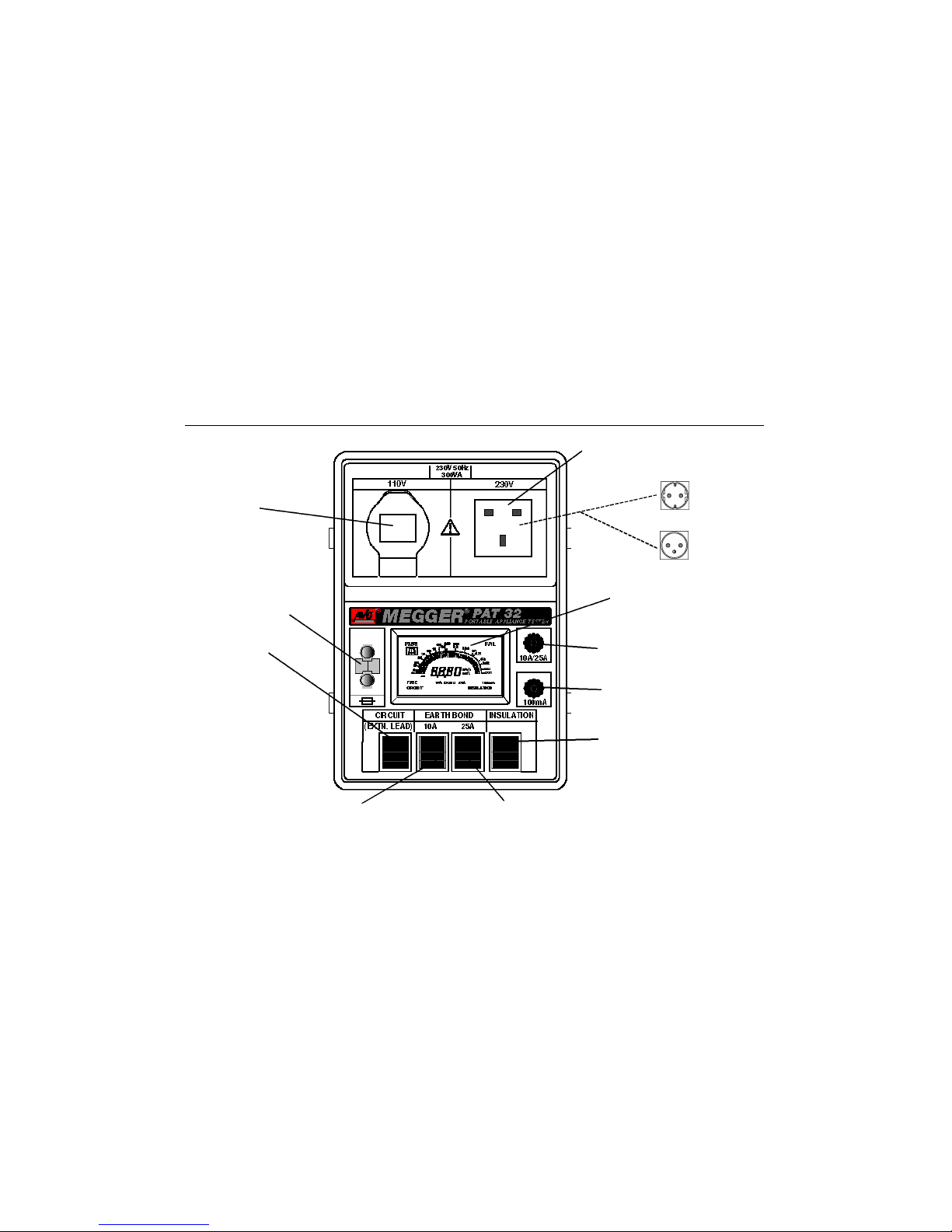

Features and Controls

6

Fuse test terminals

110 Volt Socket

to BS4343 /IEC309

230 V Socket

to BS1362

230 V Belgian / French socket

230 V

Circuit Test switch

10 A Earth Bond Test switch

25 A Earth Bond Test switch

Insulation Test switch

Earth Bond Test

Earth Continuity Test terminal

Analogue / Digital LCD

Page 7

Test Sequence

For safety reasons, it is important that appliance tests

are carried out in the correct sequence:-

• Circuit Test

• Fuse Test (if necessary)

• Earth Continuity Test

and / or

• Earth Bond Test

• Insulation Test

If a fault on an appliance is detected, testing must be

stopped and the fault rectified. Testing must then recommence from the beginning of the test sequence.

Circuit Test

A low voltage d.c. Resistance test of the Phase to

Neutral circuit.

FuseTest (if supply or appliance fuse is suspect)

Checks the continuity of most types of fuses when

removed from the appliance.

Earth Continuity Test

The earth continuity test may only be performed on

Class I (Earthed) appliances.The test checks protective

conductor continuity and the earth connection to the

metal parts of the appliance at a current of 100 mA.

This test is used where a higher current Earth Bond test

may cause damage to the appliance. Avery low voltage

(100 mV) is established between the main supply plug

earth pin and the metal parts of the appliance. The low

voltage of this test is designed to reveal bad connections

by not breaking down any oxide films.

Earth Bond Test

The Earth Bond test may only be carried out on Class I

(earthed) appliances.

The test checks protective conductor continuity and the

earth connection (or Bonding) to the metal parts of the

appliance. Avery low voltage is established between the

main supply plug earth pin and the metal parts of the

appliance.

A choice of two Earth Bond tests is available:i) Passing a current of 10 Amp. Used for

appliances and equipment fused at 5 Amp or

less.

ii) Passing a current of 25 Amp. Used for

equipment fused at greater than 5 Amp.

Test Mode Summary

7

Page 8

Insulation Test

Checks the integrity of the insulation. For class I

appliances, the test voltage is applied to the main supply

plug between Phase and Neutral (shorted together) and

the Earth pin, which is held at earth potential.

For Class II appliances, the Earth Bond lead is used to

make the return connection from the appliance to the

instrument earth bond terminal.

The PAT 32 develops 500 V d.c. into 0.5 MΩ and

complies with the 1mA load current requirement.

Caution:- If an Insulation test fails, there will be a

leakage path to earth somewhere on the appliance.

Any metal parts of the appliance could become ‘Live’

and give the user an electric shock. Do not touch

the appliance when applying the test.

Extension Lead Test

Using the Megger ELT1 or ELT2 optional accessory,

the PAT 32 checks Continuity, Earth Bond and Insulation

of both 230 V and 110 V extension leads. (110 V adaptor

required). ELT1 (UK version) also checks the Polarity of

the extension lead connections.

Error displays

Internal faults within the instrument are indicated by error

messages consisting of the letter ‘ ‘ followed by a 2 digit

number. Continuous testing on the Earth bond ranges

may cause the display of , and the analogue pointer

to move off the left hand end of the scale. Cease testing

and allow the instrument to cool for about 15 minutes.

If any error message displays, and the instrument will not

re-set itself, return the instrument for service. See Repair

and Warranty.

Test Mode Summary

8

Page 9

Appliance Visual Checks

Before carrying out PAT32 electrical tests, the appliance

and its accessories must be given a visual inspection to

identify any physical faults that may not be revealed by

electrical testing.

Visually examine and check the condition of the:-

• Supply plug

• Plug fuse type and rating (if applicable)

• Mains cord

• Cord connection grommet (if applicable)

• Mains On /Off switch

• Auxiliary switches

• Conducting / Insulated parts of the outer case

• Removable covers which must be in place.

Any significant faults or defects must be rectified before

proceeding with the PAT 32 electrical tests.

Auto Nulling and Self check

When not being operated, PAT 32 will periodically carry

out measurement nulling. The word is displayed.

Press any Test switch to override this function.

A self check function is also continuously performed on

the selected test range.

If testing is interrupted, for instance due to the appliance

not being switched On, or the mains fuse being ruptured,

testing must be repeated from the start of the test

sequence in the corrected condition. i.e. with a sound

fuse and with the appliance switched On.

Performing Tests – General

9

Tests must be performed with the appliance

switched On and with good fuse(s) fitted.

Page 10

Preliminary Testing Procedure

1. Plug the PAT32 into the 230 V mains

power supply, and switch the supply on. Full

screen details are displayed, and a self check is

carried out. On completion, the ‘Home’ screen is

displayed.

2. Determine the Class / type of the appliance to

be tested.

Class I – Earthed appliance

Class II – Double insulated appliance

Class III - S.E.L.V appliance

3. Plug the appliance into the appropriate socket

on the instrument front panel and switch the

appliance On.

Appliance Testing Procedure

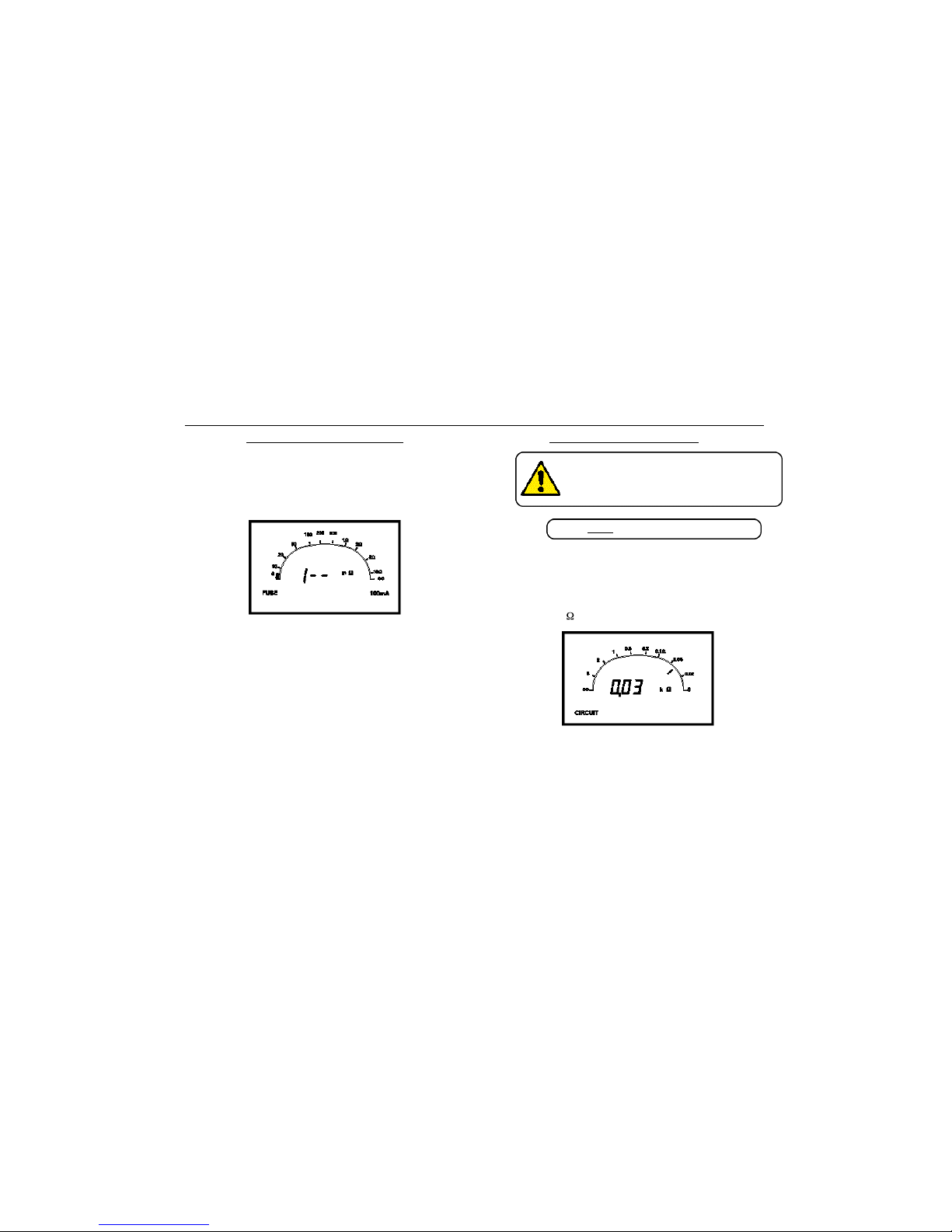

Circuit Test

1. Press and hold the Circuit Test switch. The

Circuit screen is displayed.

2. Phase to Neutral resistance is displayed

directly in k .

Note:- Readings of approximately 0,01 kΩ can be

expected from appliances incorporating large wound

components such as large transformers and motors.

Heating appliances may give readings of approximately

0,02 kΩ.

3. Release the Test switch.

Appliance Testing

10

Tests must follow the given sequence

If fault(s) are indicated, cease testing and

rectify. Re-commence testing from the

start of the test sequence.

Page 11

Note:- During the test, a display of indicates Open

circuit. Check that the appliance is switched On, that any

fuses fitted are good, the continuity of the power cord is

good and that the appliance itself is not open circuit.

Appliances with a switch mode power supply may indicate

Open circuit. In this case, omit the Circuit test.

Note:- If the appliance circuit appears to be Open circuit,

fuses (if applicable) may be checked as follows:

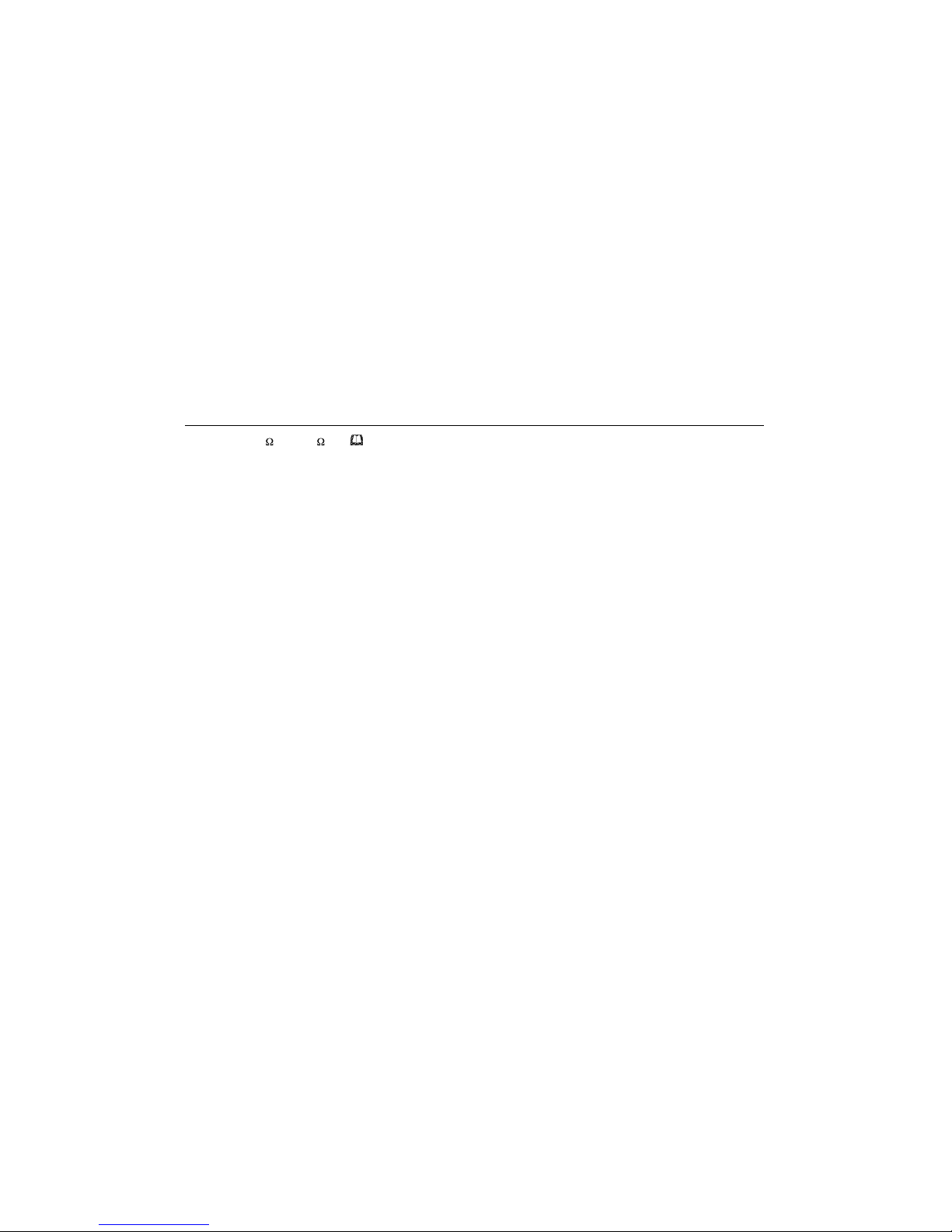

Fuse Check

1. Remove the suspect fuse from the appliance.

With the ‘Home‘ screen displayed (no switches

pressed) press the suspect fuse across the

contacts.

A good fuse is indicated by the display of

accompanied by a continuous beep note.

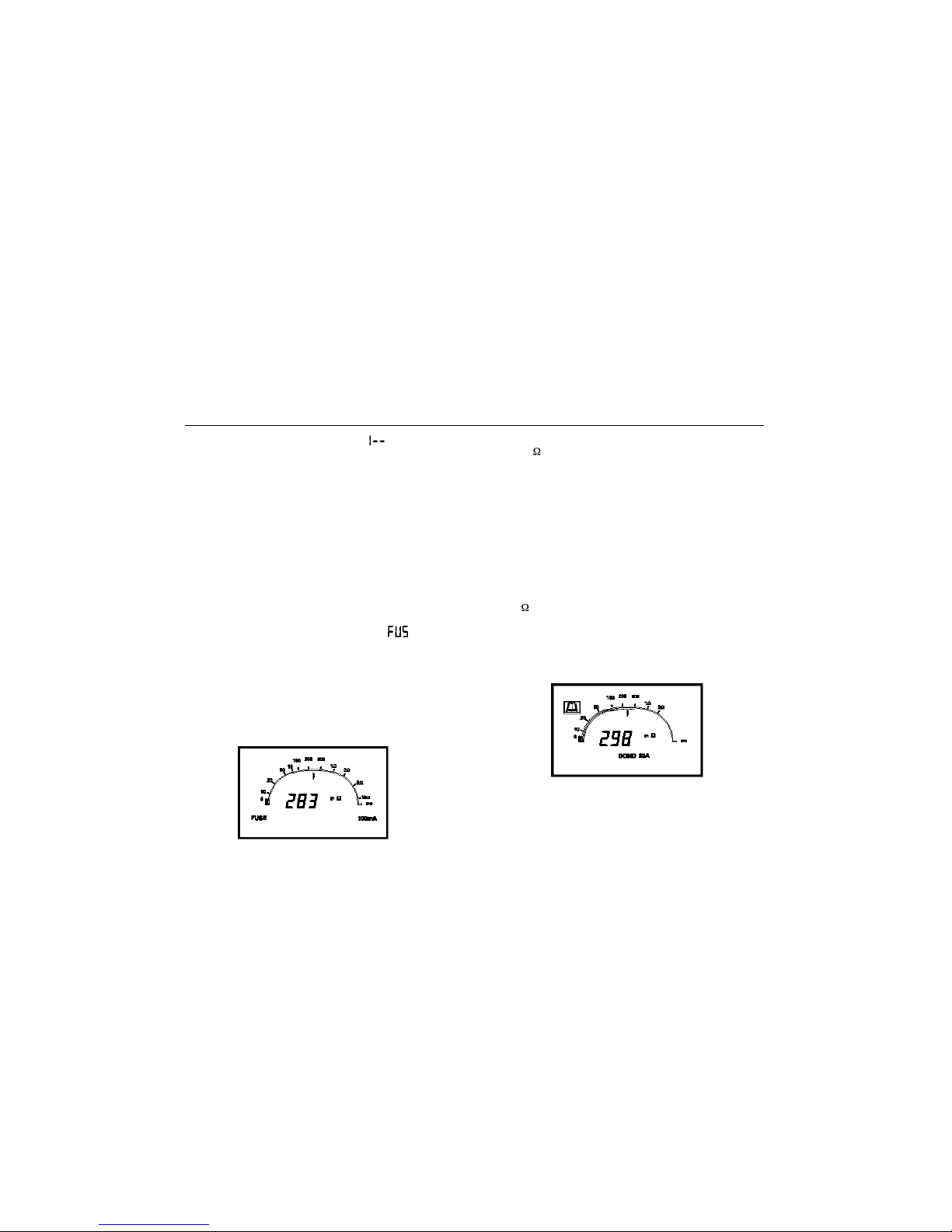

Earth Continuity Test (Class I appliances only)

1. With the ‘Home‘ screen displayed (no switches

pressed) connect the Earth Bond test lead to

the 100mA terminal.

2. Firmly connect the crocodile clip to the metalwork of

the appliance.

3. Earth continuity resistance is displayed directly

in m .

4. Disconnect the Earth Bond test lead.

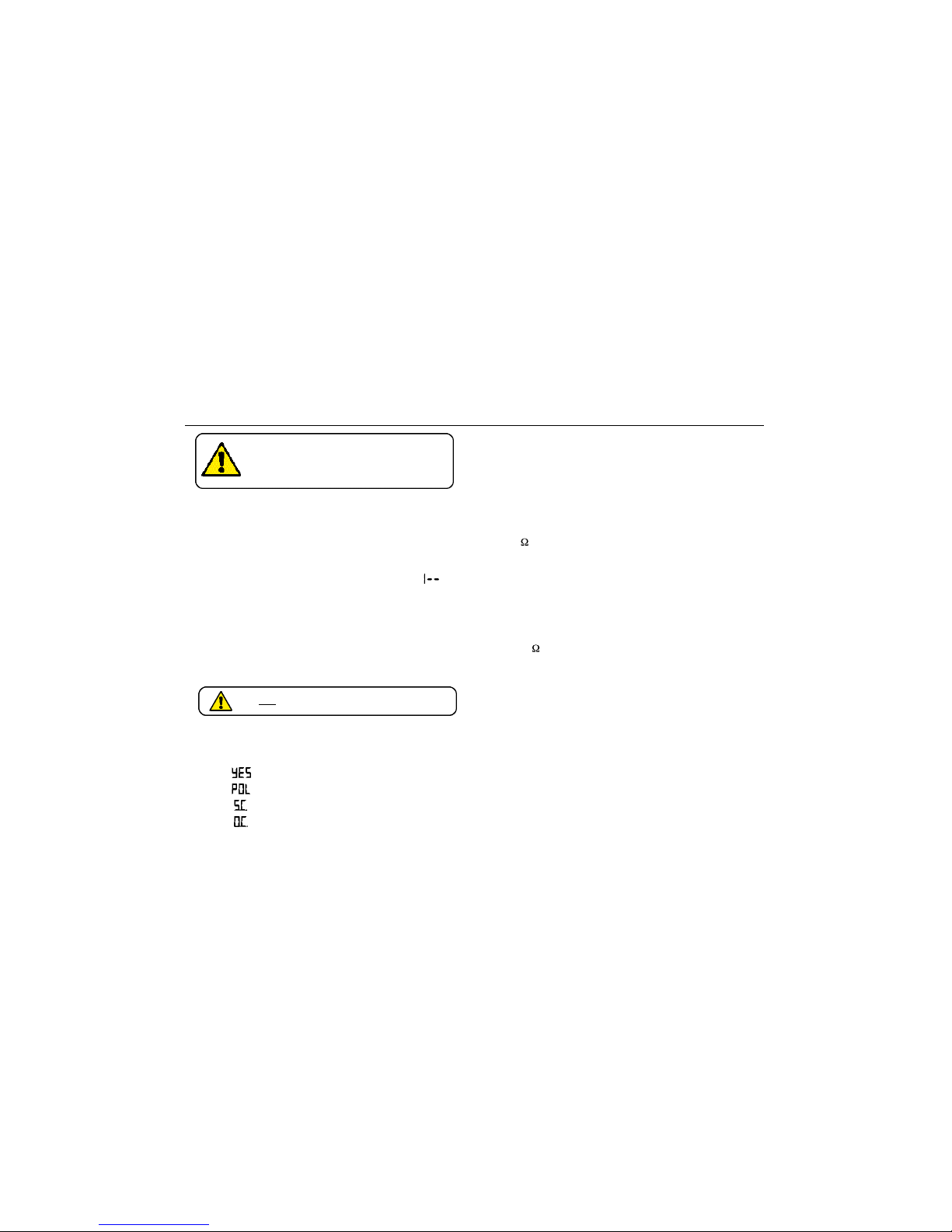

Earth Bond Test (Class I appliances only)

1. With the ‘Home‘ screen displayed (no switches

pressed) connect the Earth Bond test lead to

the 10A/25A terminal.

2. Firmly connect the crocodile clip to the

metalwork of the appliance.

3. Press and hold either the 10A or the 25A test

switch. The Earth Bond screen is displayed.

4. Earth Bond resistance is displayed directly in

m .

5. Release the Test switch.

6. Disconnect the Earth Bond test lead.

A successful test is indicated on the solid scale line and

the word PASS is displayed.

As a general rule, an appliances should have an Earth

Bond resistance of less than 100 mΩ. Appliances with

long supply leads will give higher readings due to

conductor resistance. Corrections may be applied if lead

11

Page 12

resistance figures are available and lead length is

measured.

A reading of between 100 mΩ and 500 mΩ will be

indicated on the broken scale line together with the display

of . Refer to the appliance manufacturer.

Readings greater than 500 mΩ are indicated by t h e

flashing display of the word FAIL.

On the 10 Amp range, the flashing display of w i l l

appear for resistance greater than 600 mΩ, indicating that

the test current is below a satisfactory test level. It is

suggested that the 25 A m p range should then be used.

Insulation Te s t

Class I Appliance

1. Press and hold the Insulation Test switch. The

Insulation screen is displayed.

2. Insulation resistance value is displayed directly

in M .

3. Release the Test switch.

As a general rule, Class I appliances should have an

insulation resistance value greater than 1 M .

A reading of less than 0.25 M is indicated with the word

FAIL.

Class II Appliance

1. Connect the Earth Bond test lead (or probe if

available) to the 10A/25A terminal.

2. Press and hold the Insulation Test switch. The

Insulation screen is displayed.

3. Using the crocodile clip, probe areas of likely

leakage around the insulation areas. i.e. joins /

apertures / metal parts.

4. Release the Test switch.

5. Disconnect the Earth Bond test lead.

As a general rule, Class II appliances should have an

insulation resistance value greater than 2 M .

A reading of greater than 2 M is indicated on the solid

scale line together with the word PASS.

A reading of less than 0.25 M is indicated with the word

FAIL.

Appliance Testing

12

Page 13

Between 0.25 M and 2 M , the is displayed. In this

instance, the user must judge whether to PA S S or FA I L

the test, depending upon the insulation class of the

a p p l i a n c e .

Appliance Testing

13

Page 14

Plug the extension lead into the appropriate socket on the

instrument front panel.

Circuit Test

1. Press and hold the Circuit Test switch. The

Circuit screen is displayed.

For an unterminated extension lead a reading of

should be displayed. Any other reading indicates a faulty

lead and must be investigated.

2. Release the Test switch.

Polarity Test

Plug Extension Lead Tester ELT1 into the socket end of

the Extension lead (use the adaptor for 110 V leads).

1. Press the Circuit Test switch twice.

2. Check the polarity of the extension lead against

the following display options:

- Polarity Correct

- Connections reversed

- Short Circuit

- Open Circuit

Earth Bond Test

1. Connect the Earth Bond test lead to the 2 5 A

terminal.

2. Firmly connect the crocodile clip to the E LT1

metal stud.

3. Press and hold the 25A Test switch. The Earth

Bond screen is displayed.

4. Earth Bond resistance is displayed directly in

m .

5. Release the Test switch.

6. Disconnect the Earth Bond test lead.

Insulation Test (Class I leads only)

1. Press and hold the Insulation Test switch. The

Insulation screen is displayed.

2. Insulation resistance value is displayed directly

in M .

3. Release the Test switch.

Extension Lead Testing (UK)

– ELT1 Required

14

Do not plug the ELT1 into a live circuit

If fault(s) are indicated, cease testing

and rectify. Re-commence testing from

the start of the test sequence.

Page 15

Circuit Test

Meter reading range: 0 to 9,9 kΩ

Range Resolution Accuracy

0 to 1 kΩ 0,01 kΩ 2,5% of reading ± 0,02 kΩ

1 kΩ to 2 kΩ 0,02 kΩ 2,5% of reading ± 0,02 kΩ

2 kΩ to 5 kΩ 0,05 kΩ 2,5% of reading ± 0,05 kΩ

5 kΩ to 9,9 kΩ 0,1 kΩ 2,5% of reading ± 0,1 kΩ

Open Circuit Voltage: 4,5 V d.c.

Short Circuit Current: 1 mA d.c.

Fuse Check

5 V. d.c. 0,5 mA Typical

Earth Continuity Test

Range Resolution Accuracy

0 to 999 mΩ 1 mΩ 2,5% of reading ±5 mΩ

900 mΩ to1990 mΩ 10 mΩ 2,5% of reading ±10 mΩ

Open Circuit Voltage: Typically 100 mV d.c.

Constant Current: Typically 100 mA into <1Ω

10A Earth Bond Test

Meter reading range: 0 to 1990 mΩ

Range Resolution Accuracy

0 to 600 mΩ 1 mΩ 2,5% of reading ±5 mΩ

600 to 999 mΩ 1 mΩ Current below level for

900-1990 mΩ 10 mΩ satisfactory Bond test.

Transfer to 25A test

Pass Band Limits: 100 and 500 mΩ

Open Circuit Voltage: Typically 3 V rms a.c. 50 Hz

Specification

15

Page 16

Specification

Spec Point Current 10A into 100 mΩ at 240 V. 8,7 A into 100 mΩ at 230 V.

Short Circuit Current Typically 12 A

25A Earth Bond Test

Meter reading range: 0 to 1990 mΩ

Range Resolution Accuracy

0 to 999 mΩ 1 mΩ 2,5% of reading ±5 mΩ

900-1990 mΩ 10 mΩ 2,5% of reading ±10 mΩ

Pass Band Limits: 100 and 500 mΩ

Open Circuit Voltage: Typically 6 V rms a.c. 50 Hz

Spec Point Current: Typically 25A into 100 mΩ (10A into 500 mΩ)

Short Circuit Current Typically 36.5 A

Insulation Test

Meter reading range: 0-99 MΩ

Range Resolution Accuracy

0 to 10 MΩ 0,1 MΩ 2,5% of reading ± 0,1 MΩ

10MΩ to 20 MΩ 0,2 MΩ 5% of reading ± 0,2 MΩ

20MΩ to 50 MΩ 0,5 MΩ 5% of reading ± 0,5 MΩ

50MΩ to 99 MΩ 1 MΩ Indication only

Pass Band limit: 2 MΩ (Class I) – 7 MΩ (Class II)

Open Circuit Voltage: ≤ 600 V d.c.

Spec Point Voltage ≥ 500 V d.c. into 0.5 MΩ

Short Circuit Current: < 2 mA

General

Temperature Range

Operating: 5 ˚C to +40˚ C

Storage: -25˚C to +65˚ C

16

Page 17

Humidity Range

Operating: ≤ 90% RH at 25˚C

Supply 230 V(+10% -6%) 50 Hz 300 VA

Safety Meets the requirements for double insulation to IEC 1010 (1995) EN

61010 (1995)

Fuses 2 x 2 A (F) 20 mm x 5 mm HBC, IEC 127/1

2 x 250 mA (F) mm x 5 mm HBC, IEC 127/1

Mains power cord fused plug (as applicable) – 3 Afuse to BS1362

EMC In accordance with IEC61326 including amendment No.1

Dimensions 314 mm x 152 mm x 206 mm (12,5” x 6” x 8”)

Weight 3,75 kg (8,25 lb approx.)

Cleaning: Wipe the disconnected instrument with a clean cloth dampened with

soapy water or Isopropyl Alcohol (IPA).

Specification

17

Page 18

Supplied Part Number

User Guide 6172-265

Accessory Pouch 6420-108

Earth Bond test lead with crocodile clip 6280-043

Optional Extras

Extension lead tester ELT1 (UK) 6111-130

Extension lead tester ELT2 (France & Germany) 6111-320

Earth Bond lead and Probe EP1 6320-225

Bare wire adaptor lead with 3 pin plug to BS1363/A 6111-230

Appliance safety log book (complete) 6131-813

Log book test sheets (pack of 30 sheets) 6171-417

Log book test stickers (Pack of 3 sheets [72 stickers]) 6171-418

Training Media

VHS Video: ‘Portable Appliance Testing‘ 6131-999

Accessories

18

Page 19

The instrument circuit contains static sensitive devices,

and care must be taken in handling the printed circuit

board. If the protection of an instrument has been

impaired it should not be used, and be sent for repair by

suitably trained and qualified personnel. The protection is

likely to be impaired if, for example, the instrument

shows visible damage, fails to perform the intended

measurements, has been subjected to prolonged

storage under unfavourable conditions, or has been

exposed to severe transport stresses.

New Instruments are Guaranteed for 1 Year from the

Date of Purchase by the User.

Note: Any unauthorized repair or adjustment will

automatically invalidate the Warranty.

Instrument Repair and Spare Parts

For service requirements for Megger Instruments contact:

Megger Limited or Megger

Archcliffe Road ValleyForge Corporate Center

Dover 2621 Van Buren Avenue

Kent, CT17 9EN. Norristown, PA19403

England. U.S.A.

Tel: +44 (0) 1304 502100 Tel: +1 (610) 676-8579

Fax: +44 (0) 1304 207342 Fax: +1 (610) 676-8625

or an approved repair company.

Approved Repair Companies

A number of independent instrument repair companies

have been approved for repair work on most Megger

instruments, using genuine Megger spare parts. Consult

the Appointed Distributor / Agent regarding spare parts,

repair facilities and advice on the best course of action to

take.

Returning an Instrument for Repair

If returning an instrument to the manufacturer for repair, it

should be sent freight pre -paid to the appropriate

address. A copy of the Invoice and of the packing note

should be sent simultaneously by airmail to expedite

clearance through Customs. A repair estimate showing

freight return and other charges will be submitted to the

sender, if required, before work on the instrument

commences.

Repair and Warranty

19

Page 20

Notes

20

Page 21

M

PAT32 Series

P o rtable Appliance Testers

GUIDE DE L’UTILISATEUR

Page 22

AVERTISSEMENTS DE SECURITE

• L'unité PAT32 doit être mise à la terre correctement. Une prise d'alimentation électrique qui a un contact

de protection de mise à la terre doit être utilisée.

• Les câbles d'essai, les détecteurs et les pinces-crocodile doivent être en bon état, propres et sans

isolation rompue ou fissurée.

• Les connexions de circuit et les parties métalliques exposées d'un appareil à l'essai ne doivent pas être

touchées.

• Les essais doivent être effectués dans la séquence spécifiée. Si un appareil ne passe pas avec succès un

essai donné, la faute causant la panne doit être rectifiée avant une nouvelle mise à l'essai. La nouvelle

mise à l'essai doit commencer à partir du début de la séquence.

• Les fusibles de remplacement doivent être de la taille, du type et de la qualité corrects. Voir la section

'Spécification'.

• L'instrument ne doit pas être utilisé dans des conditions humides ou en cas de dégâts à une partie

quelconque de celui-ci.

• Les avertissements et les précautions de sécurité doivent être lus et compris avant utilisation de

l'instrument. Ils doivent être observés pendant l'utilisation de celui-ci.

REMARQUE

CONFIEZ L

’UTILISATION DE CET INSTRUMENT A UN PERSONNEL QUALIFIE ET COMPETENT.

Symboles utilisés sur cet instrument

Evaluer la lecture provenant de l'affichage par comparaison aux détails relatifs à l'appareil et se

rapporter à ce Guide de l'Utilisateur.

Attention: Consultez les notes jointes.

Cet équipement respecte les directives en viguer de l’UE.

22

Page 23

Introduction

La série Megger PAT 32 a été conçue pour contrôler la

sécurité électrique de tout produit équipé d’une fiche

secteur approriée, y compris les appareils ménagers, les

matériels industriels et les outils électroportatifs.

Les essais suivants sont disponibles :

• Contrôle des circuits

• Contrôle des fusibles

• Essai de continuité à la terre

• Essai de liaison à la terre 1 A

• Essai de liaison à la terre 25 A

• Essai d’isolement

• Essai des cordons prolongateurs

(ELT1 ou ELT2 requis)

• Polarité (Royaume-Uni seulement)

• Liaison à la terre

• Isolement

Les essais s’effectuent en branchant l’appareil portatif ou

le cordon prolongateur dans la prise puis en appuyant

sur le commutateur d’Essai correspondant. Les lectures

de chaque essai sont présentées sur l’afficheur

analogique/numérique unique à cristaux liquides.

L’échelle des mesures de Liaison à la Terre est marquée

par des bandes passantes. Ceci fournit une indication

rapide de la Réussite ou de l’Echec du test et permet de

conserver les résultats de mesure appropriés.

Les appareils et matériels électriques d’application avec

un isolement de Sécurité Classe I, Class II et Sécurité

Classe III peuvent être testés. Ces classes de sécurité

sont définies dans diverses prescriptions de sécurité IEC

et BS et sont en général :

Classe I Appareils qui disposent d’un isolement

fonctionnel sur tout le circuit et d’une

carrosserie reliée à la terre, c’est à dire

un appareil "à la terre".

Classe II Appareils qui disposent d’un isolement

fonctionnel et d’un isolement

supplémentaire, et dans lesquels

aucune pièce métallique ne peut

passer "sous tension" en cas de

défaut. Il s’agit du "double Isolement"

indiqué par .

Classe I /II Appareils dont une partie de

l’enveloppe répond aux exigences de

la Classe I et l’autre répond à la

Classe II.

Classe III Appareils où la protection contre

l’électrocution est assurée par une

alimentation SELV (circuit à tension de

sécurité extra-basse). La construction

de Classe III est indiquée par la

marque .

Description générale

23

III

Page 24

Les emplois typiques du Megger PAT 32 sont :

• Les essais périodiques des matériels

utilisés dans les usines, les groupes

scolaires, les hôpitaux, etc.

• Les essais de routine avant et après

location d’un matériel électrique

• Les essais de base à la suite de la

réparation d’un matériel.

• Les essais réalisés par les fabricants et

distributeurs.

Spécifications

Le Megger PAT 32 peut être utilisé pour tester les

matériels fabriqués d’origine suivant un éventail de

prescriptions telles que :

• IEC 335 – 1 / BS3456

• BS 2769

• BS 4533

• BS 415

• BS 7002

Cordon d’alimentation

Le code couleur du cordon est :

Phase Marron

Terre de protection Jaune / Vert

Neutre Bleu

EN cas d’utilisation d’une fiche à fusible, un fusible 13 A

à la norme BS 1362 devra être utilisé

Note : Une fiche désolidarisée du cordon d’alimentation

devra être détruite, car avec des conducteurs dénudés,

une telle fiche peut s’avérer dangereuse dans une prise

sous tension.

24

Description générale

Page 25

25

Dispositifs et commandes

Bornes d'essai

de fusibles

Prise 110V

IEC309/BS 4343

Prise 230 V

Commutateurs

d'essai de circuit

Commutateur d'essai de

liaison à la terre 10 A

Commutateur d'essai de

liaison à la terre 25 A

Commutateur

d'essai d'isolation

Borne d'essai de

liaison à la terre

Borne d'essai de

continuité de mise

à la terre

Affichage

analogue/numérique

Page 26

26

Sommaire de mode d'essai

Séquence d'essai

Pour des raisons de sécurité, il est important d'effectuer

les essais de l'appareil dans la séquence correcte:

• Essai de circuit

• Essai de fusible (si besoin est)

• Essai de continuité de mise à la

terre

et/ou

• Essai de liaison à la terre

• Essai d'isolation

S'il y a détection d'une faute dans l'appareil, la mise à

l'essai doit être interrompue et la faute doit être rectifiée.

La mise à l'essai doit alors être reprise à partir du

commencement de la séquence d'essai.

Essai de circuit

Un essai de résistance basse tension à courant continu

du circuit phase au circuit neutre.

Essai de fusible (s'il y des doutes quant à l'alimentation

électrique ou au fusible de l'appareil) Vérifie la continuité

de la plupart des types de fusibles quand ils sont retirés

de l'appareil.

Essai de continuité de mise à la terre

L'essai de continuité de mise à la terre ne peut être

effectué que sur des appareils de la classe I. L'essai

vérifie la continuité du conducteur de protection et la

connexion de mise à la terre des parties métallique d'un

appareil à un courant de 100 mA. Cet essai est utilisé là

où un essai de liaison à la terre à courant plus élevé

pourrait causer des dégâts à l'appareil. Une tension très

basse (100 mV) est établie entre la broche de mise à la

terre de la prise principale d'alimentation électrique et les

parties métalliques de l'appareil. La basse tension de cet

essai est conçue pour mettre en évidence des

mauvaises connexions sans détruire des films d'oxyde

quelconques.

Essai de liaison à la terre

L'essai de liaison à la terre peut seulement être effectué

sur des appareils (mis à la terre) de la classe I.

L'essai vérifie la continuité du conducteur de protection

et la connexion (ou liaison) à la terre aux parties

métalliques de l'appareil. Une tension très basse est

établie entre la broche de mise à la terre de la prise

principale d'alimentation électrique et les parties

métalliques de l'appareil.

Un choix de deux essais de liaison à la terre est

disponible:

i) Passage d'un courant de 10 Ampères. Utilisé

pour des appareils et des équipements à fusible

ou à puissance nominale de 5 Ampères ou

moins.

ii) Passage d'un courant de 25 Ampères. Utilisé

pour des appareils et des équipements à fusible

ou à puissance nominale de 5 Ampères ou plus.

Avertissement: S'il existe une faute de liaison à la

terre et une faute d'isolation, une partie métallique

quelconque de l'appareil pourrait passer à l'état

"sous tension" et infliger à l'utilisateur un choc

électrique. Ne pas toucher l'appareil pendant la mise

en oeuvre de l'essai.

Page 27

27

Essai d'isolation

Vérifie l'intégrité de l'isolation. Pour les appareils de la

classe I, la tension d'essai est appliquée à la prise

d'alimentation électrique principale entre le fil phase et le

fil neutre (mis en court-circuit l'un par rapport à l'autre) et

la borne de terre, qui est maintenue au potentiel de terre.

Pour des appareils à isolation double, le câble de liaison

à la terre est utilisé pour réaliser la connexion de retour

de l'appareil à la borne de liaison à la terre de

l'instrument.

Le Megger PAT32 développe 500 V c.c. en 0,5 MΩ et

est conforme avec l’impératif d’intensité de charge de 1

mA.

Avertissement: Si un essai d'isolation échoue, il y

aura un trajet de fuite vers la terre quelque part dans

l'appareil. Toute pièce métallique de l'appareil

pourrait passer à l'état "sous tension" et infliger à

l'utilisateur un choc électrique. Ne pas toucher

l'appareil pendant la mise en oeuvre de l'essai.

Essai de rallonge

En utilisant l'accessoire facultatif Megger ELT2, l'unité

PAT32 vérifie la continuité, la liaison à la terre et

l'isolation à la fois des rallonges 230V et 110V. L'unité

ELT1 (version Royaume Uni) vérifie également la

polarité des connexions de rallonge.

Affichages d'erreurs

Des fautes internes au sein de l'instrument sont

indiquées par des messages d'erreur se composant de

la lettre ‘ ‘ suivie d'un nombre à 2 chiffres. Une mise à

l'essai en continu des domaines de liaison à la terre

peuvent provoquer l'affichage de la mention [Chaud]

et le passage de l'indicateur analogue à l'extrémité

gauche de l'échelle. Interrompre la mise à l'essai et

laisser refroidir l'instrument pendant environ 15 minutes.

S'il y a affichage d'un message d'erreur quelconque, et si

l'instrument ne se corrige pas de lui-même, retourner

l'instrument pour remise en état. Consulter la section

Réparation et Garantie.

Sommaire de mode d'essai

Page 28

28

Exécution des essais – Généralités

Vérifications visuelles de l'appareil

Avant d'effectuer les essais électriques de l'unité PAT32,

l'appareil et ses accessoires doivent subir une inspection

visuelle pour identifier toute faute physique qui pourrait

ne pas être détectée par la mise à l'essai électrique.

Examiner visuellement et vérifier l'état:

• de la prise d'alimentation électrique

• du type et de la spécification du fusible de la

prise (s'il y a lieu)

• du cordon d'alimentation électrique

• de l'oeillet de connexion du cordon (s'il y a lieu)

• du commutateur Marche/Arrêt d'alimentation

électrique

• des commutateurs auxiliaires

• des parties conductrices/isolées du boîtier

externe

• la mise en place de tout couvercle.

Il faut rectifier tout défaut ou toute défectuosité

d'importance avant de procéder aux essais électriques

de l'unité PAT32.

Mise à zéro automatique et auto-contrôle

En période de non utilisation, l'unité PAT32 exécutera

périodiquement une mise à zéro de mesure. Le mot ‘

‘ est affiché. Appuyer sur un commutateur Essai

quelconque pour obtenir la priorité vis-à-vis de cette

fonction.

Une fonction d'auto-contrôle est également exécutée en

continu sur le domaine d'essai choisi. Si la mise à l'essai

est interrompue, par exemple du fait que l'appareil n'est

pas en position de marche, ou si le fusible d'alimentation

électrique a claqué, la mise à l'essai doit être répétée du

début de la séquence d'essai dans la condition corrigée,

c'est-à-dire avec un fusible en bon état et avec l'appareil

en position de marche.

Les essais doivent être exécutés avec l'appareil

enclenché et après mise en place d'un ou de

fusible(s) en bon état.

Page 29

29

Procédure de mise à l'essai préliminaire

1. Brancher l'unité PAT32 dans le secteur

d'alimentation électrique 230V et mettre en

marche l'alimentation électrique. Il y affichage

des détails sur la totalité de l'écran, et un auto-

contrôle est effectué. Une fois celui-ci achevé, il

y affichage de l'écran ‘Home‘.

2. Déterminer le type de l'appareil à mettre à

l'essai.

Classe I– Appareil mis à la terre

Classe II – Appareil à isolation double

Appareils de Classe III SELV (circuit à

tension de sécurité extra-basse)

3. Brancher l'appareil dans la prise correspondante

sur le panneau avant de l'instrument et mettre

l'appareil en marche.

Procédures de mise à l'essai d'appareils

Essai de circuit

1. Appuyer sur et maintenir appuyé le

commutateur d'essai de circuit. L'écran Circuit

est affiché.

2. La résistance Phase à Neutre est affichée

directement en kΩ.

Note: On peut s'attendre à des valeurs de lecture

d'approximativement 0,01 kΩ en provenance d'appareils

incorporant des composants à enroulements importants

tels que des transformateurs et des moteurs de grande

taille. Les appareils de chauffage peuvent donner des

valeurs de lecture d'approximativement 0,02 kΩ.

3. Relâcher le commutateur d'essai.

Mise à l'essai de l'appareil

Les essais doivent suivre la séquence donnée

S'il y a indication d'une ou de faute(s),

interrompre la mise à l'essai et rectifier.

Recommencer la mise à l'essai depuis le

début de la procédure.

Page 30

Mise à l'essai de l'appareil

30

Note: Pendant l'essai, un affichage de indique un

circuit ouvert. Vérifier que l'appareil est enclenché, que

tous les fusibles sont en bon état, que la continuité du

cordon d'alimentation est bonne et que l'appareil luimême n'est pas en circuit ouvert.

Des appareils avec une alimentation électrique à

découpage peuvent indiquer un circuit ouvert. Dans ce

cas, omettre l'essai de circuit.

Note:- Si le circuit de l'appareil semble être un circuit

ouvert, on peut vérifier les fusibles (s'il y a lieu) comme

suit:

Vérification des fusibles

1. Retirer le fusible suspect de l'appareil. Avec

l'écran 'Home' affiché (sans pression sur un

commutateur quelconque), appuyer le fusible

sur les contacts.

Un fusible en bon état est indiqué par l'affichage de ,

accompagné d'une tonalité bîp continue.

Essai de continuité de mise à la terre (appareils de la

classe I seulement).

1. Avec l'écran 'Home' affiché (sans pression sur

un commutateur quelconque), relier le câble

d'essai de liaison à la terre à la borne 100 mA.

2. Relier fermement la pince-crocodile au boîtier

métallique de l'appareil.

3. La résistance de continuité de mise à la terre

est affichée directement en m .

4. Débrancher le câble d'essai de liaison à la terre.

Essai de liaison à la terre (appareils de la classe I

seulement)

1. Avec l'écran 'Home' affiché (sans pression sur

un commutateur quelconque), relier le câble

d'essai de liaison à la terre à la borne 10A/25A.

2. Relier fermement la pince-crocodile au boîtier

métallique de l'appareil.

3. Appuyer et maintenir appuyé soit le

commutateur d'essai 10A, soit le commutateur

d'essai 25A. L'écran Liaison à la terre est

affiché.

4. La résistance de liaison à la terre est affichée

directement en m .

5. Relâcher le commutateur d'essai.

6. Débrancher le câble d'essai de liaison à la terre.

En règle générale, un appareil devrait avoir une

résistance de liaison à la terre de moins de 100 mΩ.

Page 31

31

Des appareils ayant des cordons d'alimentation longs

donneront des valeurs de lecture plus élevées du fait de

la résistance des conducteurs. Des corrections peuvent

être appliquées si l'on dispose de chiffres de résistance

de cordon et si l'on mesure la longueur du cordon.

Une valeur de lecture comprise entre 100 mΩ et 500 mΩ

sera indiquée sur la ligne d'échelle à traits interrompus,

conjointement à l'affichage clignotant de . Consulter

le fabricant de l'appareil.

Des valeurs de lecture supérieures à 500 mΩ sont

indiquées par un affichage de , mot FAIL [Echec].

Dans le domaine 10 Ampères, l'affichage clignotant de

apparaîtra pour une résistance supérieure à 600 mΩ,

indiquant que le courant d'essai est inférieur à un niveau

d'essai satisfaisant. Il est fortement suggéré alors

d'utiliser le domaine de 25 Ampères.

Essai d'isolation

Appareil de la classe I

1. Appuyer sur et maintenir appuyé le

commutateur d'essai d'isolation. L'écran

Isolation est affiché.

2. La valeur de résistance d'isolation est affichée

directement en M .

3. Relâcher le commutateur d'essai.

En règle générale, les appareils de la classe I devraient

avoir une valeur de résistance d'isolation supérieure à

1 M . Une lecture de moins de 0.25 M est indiquée par

le au mot FAIL [Echec].

Appareil de la classe II

1. Relier le câble d'essai de liaison à la terre (ou le

détecteur s'il y a lieu) à la borne 10A/25A.

2. Appuyer sur et maintenir appuyé le

commutateur d'essai d'isolation. L'écran

Isolation est affiché.

3. En utilisant la pince-crocodile, mettre à l'essai

les zones de fuite probables au voisinage des

zones d'isolation, les blindages / les ouvertures /

les parties métalliques.

4. Relâcher le commutateur d'essai.

5. Débrancher le câble d'essai de liaison à la terre.

Page 32

32

En règle générale, les appareils à isolation double

devraient avoir une valeur de résistance d'isolation

supérieure à 2 M

Une valeur de lecture supérieure à 2 M est indiquée

par le mot PASS [Succès].

Une valeur de lecture inférieure à 0.25 M est indiquée

par le mot FAIL [Echec].

Entre 0.25 M et 2 M , un est affiché. Dans ce cas,

l'utilisateur doit décider du verdict PASS [Succès] ou

FAIL [Echec], en fonction de la classe d'isolation de

l'appareil.

Page 33

33

Brancher la rallonge dans la prise appropriée sur le

panneau avant de l'instrument.

Essai de circuit

1. Appuyer sur et maintenir appuyé le

commutateur d'essai de circuit. L'écran Circuit

est affiché. Pour une rallonge sans terminaison,

il devrait y avoir affichage de :--. Toute autre

valeur de lecture indique une rallonge

défectueuse et requiert une inspection.

2. Relâcher le commutateur d'essai.

3. Mettre le dispositif d'essai de rallonge ELT2

dans l'extrémité de prise de la rallonge (utiliser

l'adaptateur pour une rallonge 110V).

Ne pas brancher le dispositif ELT2 dans un circuit sous

tension.

4. Appuyer sur le commutateur de circuit à deux

reprises.

5. Vérifier la rallonge par rapport aux options

d'affichage suivantes:

- Continuité correcte

- Résistance haut

- Court-circuit

- Circuit ouvert

Essai de liaison à la terre

1. Relier le câble d'essai de liaison à la terre à la

borne 25A.

2. Relier fermement la pince-crocodile à la broche

métallique du dispositif ELT2.

3. Appuyer sur et maintenir appuyé le

commutateur d'essai 25A. L'écran Liaison à la

terre est affiché.

4. La résistance de liaison à la terre est affichée

directement en m .

5. Relâcher le commutateur d'essai.

6. Débrancher le câble d'essai de liaison à la terre,

Essai d'isolation (appareils de la classe I seulement).

1. Appuyer sur et maintenir appuyé le

commutateur d'essai d'isolation. L'écran

d'isolation est affiché.

2. La valeur de résistance d'isolation est affichée

directement en M .

3. Relâcher le commutateur d'essai.

Mise à l'essai de la rallonge le dispositif – ELT2 étant requis

S'il y a indication d'une ou de faute(s),

interrompre la mise à l'essai et rectifier.

Recommencer la mise à l'essai à partir

du début de la séquence.

Ne pas brancher le dispositif ELT2

dans un circuit sous tension.

Page 34

34

Spécification

Essai de circuit

Domaine de lecture de l'indicateur: 0 à 9,9 kΩ

Domaine Résolution Précision

0 à 1 kΩ 0,01 kΩ 2,5% de la valeur de lecture ± 0,02 kΩ

1 kΩ à 2 kΩ 0,02 kΩ 2,5% de la valeur de lecture ± 0,02 kΩ

2 kΩ à 5 kΩ 0,05 kΩ 2,5% de la valeur de lecture ± 0,05 kΩ

5 kΩ à 9,9 kΩ 0,1 kΩ 2,5% de la valeur de lecture ± 0,1 kΩ

Tension de circuit ouvert: 4,5 V d.c.

Courant de court-circuit: 1 mA d.c.

Vérification des fusibles

Typiquement 5V, sous courant continu de 0,5 mA

Essai de continuité de mise à la terre

Domaine Résolution Précision

0 à 999 mΩ 1 mΩ 2,5% de la valeur de lecture ±5 mΩ

900 mΩ à1990 mΩ 10 mΩ 2,5% de la valeur de lecture ±10 mΩ

Tension de circuit ouvert: Typiquement de 100 mV courant continu.

Courant constant: Typiquement de 100 mA dans <1Ω

Essai de liaison à la terre 10A

Domaine de lecture de l'indicateur: 0 à 1990 mΩ

Range Resolution Accuracy

0 à 600 mΩ 1 mΩ 2,5% de la valeur de lecture ±5 mΩ

600 à 999 mΩ 1 mΩ Courant inférieur au niveau pour

900 à 1990 mΩ 10 mΩ un essai de liaison satisfaisant.

Transfert à l'essai de 25A.

Limites passe-bande: 100 and 500 mΩ

Tension de circuit ouvert: Typiquement de 3 V rms a.c. 50 Hz

Courant de point spécifique – 10A dans 100 mΩ (240 V). 8,7 Adans 100 mΩ (230 V).

Courant de court-circuit: Typiquement 12 A

Page 35

35

Essai de liaison à la terre 25A

Domaine de lecture de l'indicateur: 0 à 1990 mΩ

Domaine Résolution Précision

0 à 999 mΩ 1 mΩ 2,5% de la valeur de lecture ±5 mΩ

900 à 1990 mΩ 10 mΩ 2,5% de la valeur ±10 mΩ

Limites passe-bande: 100 et 500 mΩ

Tension de circuit ouvert: Typiquement de 6 V rms a.c. 50 Hz

Courant de point spécifique: Typiquement 25Adans 100 mΩ (10A dans 500Ω)

Courant de court-circuit: Typiquement 36,5 A

Essai d'isolation

Domaine de lecture de l'indicateur: 0-99 MΩ

Domaine Résolution Précision

0 à 10 MΩ 0,1 MΩ 2,5% de la valeur de lecture ± 0,1 MΩ

10MΩ à 20 MΩ 0,2 MΩ 5% de la valeur de lecture ± 0,2 MΩ

20MΩ à 50 MΩ 0,5 MΩ 5% de la valeur de lecture ± 0,5 MΩ

50MΩ à 99 MΩ 1 MΩ Indication seulement

Limites passe-bande: 2 MΩ (Class I) – 7 MΩ (Class II)

Tension de circuit ouvert: ≤ 750 V d.c.

Tension de point spécifique: 560 V d.c. dans 2 MΩ nominale

Courant de court-circuit: Typiquement 2 mA

Généralités

Domaine de Température:

En fonctionnement: 5 ˚C à +40˚ C

Stockage: -25˚C à +65˚ C

Domaine d'humidité

En fonctionnement: ≤ 90 % d'humidité relative à 25˚C

Page 36

36

Spécification

Alimentation 230 V (+10% -6%) 50 Hz 300 VA

Sécurité Satisfait aux exigences relatives à l'isolation double conformément aux normes IEC 1010 (1995)

EN61010 (1995)

Fusibles 2 x 2 A (F) 20 mm x 5 mm HBC, IEC 127/1

2 x 100 mA (F) mm x 5 mm HBC, IEC 127/1

Prise à fusibles de cordon d'alimentation électrique principale (s'il y a lieu)

- fusible 3 A conformément à la norme BS1362

CEM Conformité avec la CEI61326 l’amendement No.1

Dimensions 314 mm x 152 mm x 206 mm

Poids 3,75 kg

Nettoyage: Essuyer l'instrument débranché à l'aide d'un chiffon propre humecté à l'aide d'eau savonneuse ou

d'alcool isopropylique (AIP)

Page 37

37

Fournis Numéro de Réference

Guide de l'utilisateur 6172-265

Poche à accessoires 6420-108

Câble d'essai de liaison à la terre avec pince-crocodile 6231-043

Eléments auxiliaires en option

Dispositif d'essai de rallonge ELT2 (France et Allemagne) 6111-320

Dispositif d'essai de rallonge ELT1 (Royaume Uni) 6111-130

Câble de liaison de rallonge et détecteur EP1 6320-225

Câble d'adaptateur 'Safebloc' à fil nu avec prise à 3 broches 6111-230

conformément à la norme BS1363/A

Journal de suivi de sécurité d'appareil (complet) 6131-813

Feuilles d'essai du journal de suivi (paquet de 30 feuilles) 6171-417

Etiquettes autocollantes d'essai du journal de suivi 6171-418

(paquets de 3 feuilles [72 étiquettes autocollantes])

Matériaux de formation

Bandes vidéo VHS: ‘Portable Appliance Testing‘ 6131-999

Accessoires

Page 38

38

Les circuits de l’instrument contiennent des éléments

sensibles à l’electricite statique et il y a lieu de prendre

des précautions en manipulant la carte de circuits

imprimes. Si la protection d’un instrument s’est trouvee

affectée de quelque maniére il ne doit pas être utilisé et

doit être expeedié pour réparation par du personnel

convenablement formé et qualifié. La protection de

l’appareil peut s’être trouvée endommagée si par

exemple l’instrument apparaît visiblement abîmee, ne

donne pas les performances attendues, s’est trouvé

entreposé de façon prolongée dans des conditions

défavorables ou a été exposé a des contraintes

extrêmes durant son transport.

Les nouveaux instruments sont garantis pendant

une période d’un an à partir de la date de leur achat

par l’utilisateur.

Note: Toute réparation ou tout réglage préalable non

autorisé invalidera automatiquement la garantie.

Societés d’entretien agréées

Un certain nombre de sociétés indépendantes de

reparation d’instruments ont êté agréées pour faire des

opérations de réparation sur la plupart des instruments

Megger utilisant des pièces d’origine Megger Consultez

le distributeur désigné / agent officiel concernant la

fourniture de pièces de rechange, les installations de

réparation et pour être conseillé concernant les

meilleures mesures à prendre.

Réparation d’instruments et pièces de rechange

Pour le service des instruments Megger prendre contact

soit:

avec ou

Megger Limited Megger

Archcliffe Road Z.A. Du Buisson de la Couldre

Dover 23 rue Eugène Henaff

Kent CT17 9EN 78190 TRAPPES

Angleterre France

Tél: 44+ (0) 1304 502234 Tél: +33 (0)1 30.16.08.90

Télécopie: 44+ (0) 1304 207342 Télécopie: +33 (0)1 34.61.23.77

ou avec une societe d’entretien agréée.

Renvoi D’un Instrument Pour le faire Réparer

Si un instrument est réexpédiê au fabricant pour être

reparé il doit être envoyé port payé a l’adresse

appropriée. Un exemplaire de la facture et la note

d’envoi doivent être envoyé par avion au même moment

afin de hâter les formalités de douane. Un devis estimé

des réparations indiquant les frais de réexpedition et

autres frais sera si nécessaire adressé a l’expéditeur

avant que les opérations de réparation ne soient

enterprises.

Réparation et Garantie

Page 39

Notes

39

Page 40

Notes

40

Page 41

M

PAT32 Series

P o rtable Appliance Testers

GEBRAUCHSANLEITUNG

Page 42

SICHERHEITSWARNUNG

• PAT32 muß korrekt geerdet werden. Anschluß nur an Netzsteckdose mit Erdungsschutzkontakt.

• Testkabel, Prüfspitzen und Klemmen müssen einwandfrei in Ordnung und sauber sein und dürfen keine

Verletzungen an der Isolierung aufweisen.

• Stromanschlüsse und ungeschützte Metallteile von zu testenden Geräten dürfen nicht berührt werden.

• Die Tests sind in der angegebenen Reihenfolge durchzuführen. Wird bei einem Test ein Defekt an dem

Gerät erkannt, muß der zugrundeliegende Fehler vor Wiederholung des Tests behoben werden. Bei der

Testwiederholung ist die Testreihenfolge von Anfang an durchzuführen.

• Ersatzsicherungen müssen in Größe, Typ und Nennwert den Anforderungen entsprechen. Siehe Abschnitt

"Spezifikation".

• Das Instrument darf in feuchten Umgebungen, oder wenn es irgendwelche Schäden aufweist, nicht

verwendet werden.

• Die Sicherheitswarnungen und Vorsichtsmaßnahmen sind vor Einsatz des Instruments zu lesen und

HINWIES

DAS INSTRUMENT DARF NUR VON ENTSPRECHEND AUSGEBILDETEN UND KOMPETEN PERSONEN VERVENDET WERDEN.

Auf Diesem Gérat verwendete Symbole

Bei der Testauswertung die angezeigten Werte mit den Gerätedetails vergleichen und die Gebrauchsanleitung

zur Referenz verwenden.

Die Anlage ist rundum durch doppelte oder verstärkte Isolierung (Klasse I I) geschutzt.

Die Anlage entspricht den gegenwärtig gültigen EU-Direktiven.

42

Page 43

43

Allgemeine Beschreibung

Einleitung

Die Geräte der Megger Serie PAT32 wurden für das

Überprüfen der elektrischen Sicherheit von Produkten

entworfen, die mit einem geeigneten Netzstecker

ausgestattet sind, einschliesslich Haushaltsgeräte,

industrielle Geräte, und Handwerkzeuge.

Die folgenden Tests sind erhältlich:

• Schaltkreisprüfung

• Sicherungsprüfung

• Erdungskontinuitätstest

• 1Amp Erdungsverbundtest

• 25Amp Erdungsverbundtest

• Isolationstest

• Verlängerungskabeltest (ELT1 oder

ELT2 erforderlich)

• Polarität (nur für Großbritannien)

• Erdungsverbund

• Isolierung

Diese Tests werden durch das Einstecken des tragbaren

Gerätes oder des Verlängerungskabels in die jeweilige

Steckdose und das Drücken des jeweiligen Testschalters

aktiviert. Die Resultate eines jeden Tests werden auf der

einzigartigen Analog- / Digital-Flüssigkristallanzeige

aufgeführt. Der Meßbereich für den Erdungsverbund ist

mit Bandmarkierungen ausgezeichnet. Diese

ermöglichen die rapide Anzeige der Tatsache, dass ein

Test entweder bestanden oder nicht bestanden wurde,

und ermöglichen weiterhin das Aufzeichnen von

korrekten Testresultaten.

Anwendungsgeräte und elektrische Geräte mit einer

Isolierung der Sicherheitsklasse I, Klasse II und

Sicherheitsklasse III können auch getested werden.

Diese Sicherheitsklassen werden in verschiedenen IECund BS-Sicherheitsspezifikationen definiert, und

bestehen im allgemeinen aus:-

Klasse I Geräte mit totaler funktioneller

Isolierung und einem geerdeten

Gehäuse, d.h. ein "geerdetes" Gerät.

Klasse II Geräte mit sowohl funktioneller wie

auch zusätzlicher Isolierung, deren

Metallkomponente ausserdem bei einer

Störung nicht "stromführend" sind. Dies

ist eine durch das Zeichen

angezeigte "Doppelisolierung"..

Klasse I/II Geräte, deren Gehäuse zum Teil den

Anforderungen von Klasse I, und zum

Teil denen der Klasse II entsprechen.

Klasse III Geräte, die durch eine SELV-Zufuhr

gegen elektrischen Schlag geschützt

sind. Die Konstruktion der Klasse III

wird durch das Zeichen bestätigt.

III

Page 44

44

Allgemeine Beschreibung

Typische Anwendungen für Megger PAT 32 sind:

• Periodisches Testen von Geräten in

Fabriken, Schulgebäuden,

Krankenhäusern, usw.

• Routinetests vor und nach dem

Vermieten von elektrischen Geräten

• Einfache Tests nach einer

Gerätereparatur

• Tests, die von Herstellern und

Vertretungen durchgeführt werden

Spezifikationen

Die Geräte Megger PAT32 können für das Testen von

Geräten angewendet werden, die ursprünglich nach den

folgenden Spezifikationen hergestellt wurden:

• IEC 335 – 1 / BS3456

• BS 2769

• BS 4533

• BS 415

• BS 7002

Stromkabel

Der Farb-Code des Kabels ist:

Phase Braun

Geschützte Erde Gelb / Grün

Neutral Blau

Wenn Sie einen Stecker mit Sicherung verwenden, sollte

eine 13 Amp Sicherung nach BS 1362 montiert sein.

Hinweis: Ein vom Stromkabel abgeschnittener Stecker

sollte stets vernichtet werden, da ein Stecker mit

freiliegenden Leitdrähten eine gefährliche, stromführende

Quelle darstellt.

Page 45

Funktionen und Steuerelemente

45

Pole für Sicherungstest

110-V-Steckdose

(IEC309/BS4343)

230-V-Schuko-Steckdose

Stromkreis-Testschalter

10-A-Erdungskontakt-Testschalter

25-A-Erdungskontakt-Testschalter

Isolierungs-Testschalter

Pol Erdungskontakttest

Pol Erdungsdurchgangstest

Analog-/Digital-LCD

Page 46

46

Testreihenfolge

Aus Sicherheitsgründen müssen die Tests in der

angegebenen Reihenfolge durchgeführt werden:

• Stromkreistest

• Sicherungstest (falls erforderlich)

• Erdungsdurchgangstest

und/oder

• Erdungskontakttest

• Isolierungstest

Wird bei einem Test ein Defekt am Gerät erkannt, muß

das Testverfahren gestoppt und der Defekt behoben

werden. Anschließend ist das Testverfahren vom Anfang

der Testreihenfolge an zu wiederholen.

Stromkreistest

Ein Widerstandstest mit niedriger Gleichstrom-Spannung

im Kreislauf von Phase zu Neutralleiter.

Sicherungstest (bei Verdacht auf Defekt an

Versorgungs- oder Gerätesicherung)

Prüft Sicherungen der meisten Typen in ausgebautem

Zustand auf Durchgang

Erdungsdurchgangstest

Der Erdungsdurchgangstest darf nur an Geräten der

Klasse I durchgeführt werden. Der Test prüft den

Schutzleiter auf Durchgang und die Erdungsverbindung

mit Metallteilen des Gerätes mit einem Strom von

100 mA. Dieser Test kommt zum Einsatz, wenn ein

Erdungskontakttest, der mit stärkerem Strom

durchgeführt wird, zur Beschädigung des Gerätes führen

kann. Eine sehr niedrige Spannung (100-mV) wird

zwischen dem Erdungspol des Netzversorgungssteckers

und den Metallteilen des Gerätes angelegt. Die niedrige

Spannung dieses Tests ist dafür ausgelegt, schlechte

Verbindungen dadurch kenntlich zu machen, daß die

Oxidschicht nicht verletzt wird.

Erdungskontakttest

Der Erdungskontakttest darf nur an Geräten der Klasse I

(geerdet) durchgeführt werden.

Der Test prüft den Schutzleiter auf Durchgang und den

Erdungskontakt mit Metallteilen des Gerätes. Eine sehr

niedrige Spannung wird zwischen dem Erdungspol des

Netzversorgungssteckers und den Metallteilen des

Gerätes angelegt.

Zwei Erdungskontakttests stehen zur Auswahl:

1) 10-A-Test, geeignet für Geräte und Anlagen, die

mit Sicherungen versehen oder für einen

Nennstrom von 5 A oder weniger zugelassen

sind.

2) 25-A-Test, geeignet für Geräte und Anlagen, die

mit Sicherungen versehen oder für einen

Nennstrom von über 5 Azugelassen sind.

Zusammenfassung des Testmodus

Page 47

47

Vorsicht: Liegt ein Erdungskontakt- oder

Isolierungsdefekt vor, können alle Metallteile unter

Strom stehen und Elektroschocks verursachen. Beim

Durchführen des Tests das Gerät nicht berühren.

Isolierungstest

Prüft die Unversehrtheit der Isolierung. Bei Geräten der

Klasse I wird eine Prüfspannung am

Netzversorgungsstecker zwischen spannungsführendem

und neutralem Leiterpol (kurzgeschlossen) und

Erdungspol, der auf Erdungspotential gehalten wird,

angelegt. Bei doppelt isolierten Geräten wird das

Erdungskontaktkabel für den Rückanschluß vom Gerät

zum Erdungskontaktpol des Instruments verwendet.

Der Megger PAT32 entwickelt 500 V DC bei 0.5 MΩ

und erfüllt die Anforderungen einer 1mAStromlast.

Vorsicht: Wird bei der Durchführung eines

Isolierungstests ein Defekt erkannt, fließt irgendwo

am Gerät ein Kriechstrom zur Erde. Metallteile des

Gerätes können unter Strom stehen und

Elektroschocks verursachen. Beim Durchführen

dieses Tests das Gerät nicht berühren.

Verlängerungskabeltest

Mit dem Megger ELT2 Zubehör testet PAT32

Durchgang, Erdungskontakt und Isolierung von 230-Vund 110-V-Verlängerungskabeln. ELT1 (GB-Version)

prüft zudem die Polarität der

Verlängerungskabelverbindung.

Fehleranzeigen

Interne Fehler im Instrument werden durch

Fehlermeldungen angezeigt, die aus dem Buchstaben‘ ‘

gefolgt von einer zweistelligen Zahl bestehen. Bei

fortwährendem Testen in Erdungskontaktbereichen kann

die Anzeige ' ‘ (Heiß) erscheinen, wobei sich der

analoge Zeiger auf der linken Seite über den

Skalenbereich hinausbewegt. In diesem Fall

Testverfahren einstellen und Gerät ca. 15 Minuten lang

abkühlen lassen.

Werden Fehlermeldungen angezeigt, und das Instrument

stellt sich nicht zurück, ist das Instrument zur Wartung

einzuschicken. Siehe Reparatur und Garantie.

Zusammenfassung des Testmodus

Page 48

48

Geräte-Sichtprüfung

Vor der Durchführung elektrischer Tests mit PAT32 ist

das Gerät samt Zubehör einer Sichtprüfung zu

unterziehen, um Materialdefekte zu orten, die durch

elektrische Tests nicht erkannt werden.

Folgende Komponenten sind auf ihren Zustand zu

sichtprüfen:

• Netzstecker

• Steckersicherung und Nennwert (falls

zutreffend)

• Netzversorgungskabel

• Kabelanschluß-Isolierscheibe (falls

zutreffend)

• Betriebsschalter

• Zusätzliche Schalter

• Leitende/isolierte Teile des Gehäuses

• Alle Abdeckungen korrekt angebracht

Ernste Fehler oder Defekte sind vor Fortfahren mit den

PAT32-Elektrotests zu beseitigen.

Auto-Rückstellung und Selbsttest

Wenn PAT32 nicht in Betrieb ist, stellt das Instrument in

regelmäßigen Abständen Meßanzeige auf Null. In der

Anzeige erscheint der Begriff ' '. Um diese Funktion

zu übergehen, einen beliebigen Testschalter drücken.

Für den ausgewählten Testbereich wird zudem

kontinuierlich ein Selbsttest durchgeführt. Kommt es zu

einer Testunterbrechung, z.-B. weil das Gerät nicht

eingeschaltet oder die Sicherung der Netzversorgung

unterbrochen ist, muß der Test vom Anfang der

Testreihenfolge an und in korrektem Zustand, d.-h.

intakte Sicherung und Gerät eingeschaltet, wiederholt

werden.

Kommt es zu einer Testunterbrechung, z.-B. weil das

Gerät nicht eingeschaltet oder die Sicherung der

Netzversorgung unterbrochen ist, muß der Test vom

Anfang der Testreihenfolge an und in korrektem Zustand,

d.-h. intakte Sicherung und Gerät eingeschaltet,

wiederholt werden.

Durchführung von Tests – Allgemein

Tests müssen bei eingeschaltetem Gerät und

mit intakten Sicherungen durchgeführt werden.

Page 49

49

Testverfahren-Vorbereitung

1. PAT32 in 230-V-Netzversorgung einstecken

und Stromversorgung ggf. anschalten.

Vollständige Bildschirmdetails werden angezeigt,

und ein Selbsttest wird durchgeführt. Im

Anschluß daran wird der Start-Bildschirm

angezeigt.

2. Feststellen, welcher Klasse das zu testende

Gerät angehört:

Klasse I – geerdetes Gerät

Klasse II – doppelt isoliertes Gerät

Geräte der Klasse III SELV

3. Gerät in zutreffende Steckdose am Steuerpult

des Instruments einstecken und einschalten.

Gerätetestverfahren

Stromkreistest

1. Stromkreis-Testschalter drücken und festhalten.

Der Stromkreis-Bildschirm wird angezeigt.

2. Widerstand von Phase gegen Neutral wird direkt

in kΩ angezeigt.

Hinweis: Von Geräten, die große Wicklungsteile, z.-B.

große Transformatoren und Motoren enthalten, sind

Meßwerte von ca. 0,01k zu erwarten. Heizgeräte

können Meßwerte von ca. 0,02k erzeugen.

3. Testschalter loslassen.

Testen von Geräte

Die Testverfahren müssen in der angegebenen

Reihenfolge durchgeführt werden.

Werden Fehler erkannt, Testverfahren

einstellen und Fehler beheben.

Anschließend Testreihenfolge von Anfang

an wiederholen.

Page 50

50

Hinweis: Die Anzeige während des Tests verweist

auf einen offenen Stromkreis. Prüfen, ob das Gerät

eingeschaltet ist, eventuell vorhandene Sicherungen

intakt sind, das Stromkabel Durchgang aufweist oder das

Gerät selbst die offene Stelle im Stromkreis darstellt.

Geräte mit einer Stromversorgung mit Schaltmodus

können offenen Stromkreis anzeigen. In diesem Fall den

Stromkreistest auslassen.

Hinweise: Wenn der Gerätestromkreis offen erscheint,

können Sicherungen (falls zutreffend) wie folgt getestet

werden:

Sicherungstest

1. Verdächtige Sicherung aus dem Gerät

entfernen. Sicherstellen, daß der Start-

Bildschirm angezeigt wird (kein Schalter

gedrückt), und Sicherung an die Kontakte

drücken.

Ist die Sicherung intakt, erscheint die Anzeige und

ein Dauerton wird ausgegeben.

Erdungsdurchgangstest (Nur Geräte der Klasse I)

1. Sicherstellen, daß der Start-Bildschirm

angezeigt wird (kein Schalter gedrückt), und das

Erdungskontakt-Testkabel an den 100-mA-Pol

anschließen.

2. Krokodilklemme fest an Metallteilen des Geräts

befestigen.

3. Erdungsdurchgangswiderstand wird direkt in mΩ

angezeigt.

4. Erdungskontakt-Testkabel entfernen.

Erdungskontakttest (Nur Geräte der Klasse I)

1. Sicherstellen, daß der Start-Bildschirm

angezeigt wird (kein Schalter gedrückt), und das

Erdungskontaktkabel an den 10-A-/25-A-Pol

anschließen.

2. Krokodilklemme fest an Metallteilen des Geräts

befestigen.

3. 10-A-Testschalter oder 25-A-Testschalter

drücken und festhalten. Der ErdungskontaktBildschirm wird angezeigt.

4. Erdungskontaktwiderstand wird direkt in mΩ

angezeigt.

5. Testschalter loslassen.

6. Erdungskontakt-Testkabel entfernen.

Im allgemeinen sollte ein Gerät einen

Erdungskontaktwiderstand von unter 100 mΩ aufweisen.

Testen von Geräte

Page 51

51

Geräte mit langen Versorgungsleitungen liefern aufgrund

des Leiterwiderstandes höhere Meßwerte. Sofern

Angaben zum Leiterwiderstand vorhanden sind, kann die

Länge der Leitung gemessen werden, um Korrekturwerte

zu ermitteln.

Ein Meßwert zwischen 100 mΩ und 500 mΩ wird auf der

unterbrochenen Skalenlinie zusammen mit der Anzeige

angezeigt. Hersteller des Gerätes kontaktieren.

Meßwerte über 500 mΩ werden durch. Die Angabe FAIL

(Fehler) angezeigt.

Im 10-A-Bereich erscheint die Anzeige für

Widerstände über 600 mΩ, was darauf hinweist, daß der

Strom eine befriedigende Teststärke unterschreitet. Es

empfiehlt sich, in diesem Fall den 25-A-Testbereich zu

verwenden.

Isolierungstest

Geräte der Klasse I

1. Isolierungs-Testschalter drücken und

festhalten. Der Isolierungs-Bildschirm wird

angezeigt.

2. Der Isolierungswiderstand wird direkt in M

angezeigt.

3. Testschalter loslassen.

Im allgemeinen sollten Geräte der Klasse I einen

Isolierungswiderstand von über 1 M aufweisen.

Meßwerte unter 0.25 M werden mit der Angabe FAIL

(Fehler) angezeigt.

Page 52

52

Geräte der Klasse II

1. Erdungskontakt-Testkabel (oder Prüfspitze, falls

verfügbar) an den 10-A-/25-A-Pol anschließen

2. Isolierungs-Testschalter drücken und

festhalten. Der Isolierungs-Bildschirm wird

angezeigt.

3. Bereiche, an denen möglicherweise

Kriechströme auftreten können, z.-B. an

Verbindungsstellen, Öffnungen, Metallteilen, mit

der Krokodilklemme prüfen.

4. Testschalter loslassen.

5. Erdungskontakt-Testkabel entfernen.

Im allgemeinen sollten doppelt isolierte Geräte einen

Isolierungswiderstand von über 2 M aufweisen.

Ein Meßwert über 2 M wird auf der durchgezogenen

Skalenlinie zusammen mit der Angabe PASS (in

Ordnung) angezeigt.

Ein Meßwert unter 0.25 M wird auf der unterbrochenen

Skalenlinie zusammen mit der Angabe FAIL (Fehler)

angezeigt.

Zwischen 0.25 M und 2 M erscheint die blinkende

Anzeige . In diesem Fall muß der Benutzer je nach

Isolierungsklasse des Gerätes beurteilen, ob der Test als

PASS (in Ordnung) oder FAIL (fehlerhaft) zu bewerten

ist.

Testen von Geräte

Page 53

53

Stecker des Verlängerungskabels in die zutreff e n d e

Steckdose an der Steuertafel des Instruments einstecken.

Stromkreistest

1. Stromkreis-Testschalter drücken und festhalten.

Der Stromkreis-Bildschirm wird angezeigt.

Für ein nicht angeschlossenes

Verlängerungskabel muß der Wert angezeigt

werden. Andere Anzeigenwerte deuten auf einen Defekt

im Kabel hin und müssen genauer untersucht werden.

2. Testschalter loslassen.

3. Verlängerungskabeltester ELT2 am

Steckdosenende des Verlängerungskabels

anschließen (für 110-V-Kabel Adapter

verwenden).

4. Stromkreis-Testschalter zweimal drücken.

5. Verlängerungskabel im Hinblick auf die

folgenden Anzeigeoptionen prüfen:

- Korrekter Durchgang

- Hoher Wiederstand

- Kurzschluß

- Offener Stromkreis

Erdungskontakttest

1. Erdungskontakt-Testkabel an 25-A-Pol

anschließen.

2. Krokodilklemme fest an ELT2-Metallstift

anschließen.

3. 25-A-Testschalter drücken und festhalten. Der

Erdungskontakt-Bildschirm wird angezeigt.

4. Der Erdungskontaktwiderstand wird direkt in mΩ

angezeigt.

5. Testschalter loslassen.

6. Erdungskontakt-Testkabel entfernen.

Isolierungstest (Nur Ve r l ä n g e r u n g s k a b e l s der Klasse I)

1. Isolierungs-Testschalter drücken und festhalten.

Der Isolierungs-Bildschirm wird angezeigt.

2. Der Isolierungswiderstand wird direkt in MΩ

angezeigt.

3. Testschalter loslassen.

Verlängerungskabeltest – ELT2 erforderlich

Falls Fehler angezeigt werden,

Testverfahren einstellen und Fehler

beheben. Testreihenfolge anschließend

von Anfang an wiederholen.

ELT2 nicht an spannungsführenden

Stromkreis anschließen.

Page 54

54

Stromkreistest

Meßwertbereich: 0 bis 9,9 kΩ

Gültigkeitsbereich Auflösung Genauigkeit

0 bis 1 kΩ 0,01 kΩ 2,5% der Meßwerte ± 0,02 kΩ

1 kΩ bis 2 kΩ 0,02 kΩ 2,5% der Meßwerte ± 0,02 kΩ

2 kΩ bis 5 kΩ 0,05 kΩ 2,5% der Meßwerte ± 0,05 kΩ

5 kΩ bis 9,9 kΩ 0,1 kΩ 2,5% der Meßwerte ± 0,1 kΩ

Offener-Kreis-Spannung: 4,5 V d.c.

Kurzschluß-Strom: 1 mA d.c.

Sicherungstest Typischerweise 5 V Gleichstrom 0,5 mA

Erdungsdurchgangstest Gültigkeitsbereich Auflösung Genauigkeit

0 bis 999 mΩ 1 mΩ 2,5% der Meßwerte ±5 mΩ

900 mΩ bis1990 mΩ 10 mΩ 2,5% der Meßwerte ±10 mΩ

Offener-Kreis-Spannung:: Typischerweise 100 mV d.c.

Konstanter Strom: Typischerweise 100 mA zu <1Ω

10-A-Erdungskontakttest

Meßwertbereich: 0 bis 1990 mΩ

Gültigkeitsbereich Auflösung Genauigkeit

0 bis 600 mΩ 1 mΩ 2,5% der Meßwerte ±5 mΩ

600 bis 999 mΩ 1 mΩ Strom unter befriedigender

900 bis1990 mΩ 10 mΩ Stärke für Kontakttest.

Zu 25-A-Test übergehen.

Grenzwerte für Test-Pass 100 und 500 mΩ

Offener-Kreis-Spannung: Typischerweise 3 V rms a.c. 50 Hz

Spezifischer Spitzenstrom 10 A zu 100 mΩ (240 V). 8,7 Azu 100 mΩ (230 V).

Kurzschluß-Strom Typischerweise 12 A

Spezifikation

Page 55

55

25-A-Erdungskontakttest

Meßwertbereich: 0 bis 1990 mΩ

Gültigkeitsbereich Auflösung Genauigkeit

0 bis 999 mΩ 1 mΩ 2,5% der Meßwerte ±5 mΩ

900 bis1990 mΩ 10 mΩ 2,5% der Meßwerte ±10 mΩ

Grenzwerte für Test-Pass 100 und 500 mΩ

Offener-Kreis-Spannung: Typischerweise 6 V rms a.c. 50 Hz

Spezifischer Spitzenstrom Typischerweise 25Ainto 100 mΩ (10A into 500 mΩ)

Kurzschluß-Strom Typischerweise 36.5 A

Isolierungstest

Meßwertbereich: 0 bis 99 MΩ

Gültigkeitsbereich Auflösung Genauigkeit

0 bis 10 MΩ 0,1 MΩ 2,5% der Meßwerte ± 0,1 MΩ

10MΩ bis 20 MΩ 0,2 MΩ 5% der Meßwerte ± 0,2 MΩ

20MΩ bis 50 MΩ 0,5 MΩ 5% der Meßwerte ± 0,5 MΩ

50MΩ bis 99 MΩ 1 MΩ Nur Anzeige

Grenzwerte für Test-Pass 2 MΩ (Class I) – 7 MΩ (Class II)

Offener-Kreis-Spannung: ≤ 750 V d.c.

Spezifischer Spitzen-Spannung 560 V d.c. zu 2 MΩ nennwert

Kurzschluß-Strom Typischerweise 2 mA

Allgemein

Temperaturbereich

Betrieb: 5 ˚C to +40˚ C

Speicherung: -25˚C to +65˚ C

Luftfeuchtigkeit

Betrieb: ≤ 90 % relative Luftfeuchtigkeit bei 25 ˚C

Page 56

56

Versorgung 230 V(+10% -6%) 50 Hz 300 VA

Sicherheit Entspricht den Anforderungen für doppelte Isolierung nach IEC 1010 (1995) EN 61010 (1995)

Sicherungen 2 x 2 A(F) 20 mm x 5 mm HBC, IEC 127/1

2 x 100 mA (F) mm x 5 mm HBC, IEC 127/1

Netzstecker mit Sicherung (falls zutreffend) – 3-A-Sicherung gemäß BS1362

EMV Gamäss IEC61326 inkl. änderung Nr.1

Maße 314 mm x 152 mm x 206 mm

Gewicht 3,75 kg

Reinigung: Instrument in nicht angeschlossenem Zustand mit einem sauberen Tuch, das mit Seifenwasser oder

Reinigungsalkohol (Isopropyl) befeuchtet wurde, abwischen.

Spezifikation

Page 57

57

Mitgeliefert Bestellnummer

Gebrauchsanleitung 6172-265

Zubehörtasche 6420-108

Erdungskontakt-Testkabel mit Krokodilklemme 6231-043

Sonderzubehör

Verlängerungskabeltester ELT1 (GB) 6111-130

Verlängerungskabeltester ELT2 (Frankreich und Deutschland) 6111-320

Erdungskontaktkabel und Prüfspitze EP1 6320-225

Blankdraht-Adapterkabel mit 3-poligem Stecker gemäß BS1363/A 6111-230

Gerätesicherheits-Protokollbuch (vollständig) 6131-813

Protokollbuch-Testblätter (30-Stck.-Packung) 6171-417

Protokollbuch-Testaufkleber (3 Blatt, 72 Aufkleber) 6171-418

Schulungsmaterial

VHS Video: ‘Portable Appliance Testing‘ 6131-999

Zubehör

Page 58

Reparaturen und Garantie

Das Instrument enthält statisch empfindliche Bauteile,

weshalb die gedruckte Schaltung sorgfältig behandelt

werden muß. Falls die Schutzvorrichtungen eines

Instruments beschädigt worden sind, sollte es nicht

verwendet, sondern an eine geeignete

Reparaturwerkstatt geschickt werden. Die

Schutzvorrichtungen sind wahrscheinlich beschädigt,

wenn folgende Bedingungen vorliegen: sichtbare

Beschädigung, fehlende Anzeige der erwarteten

Meßergebnisse; längere Lagerung unter widrigen

Bedingungen oder starke Transportbelastung.

NEUE INSTRUMENTE UNTERLIEGEN EINER

GARANTIE VON 1 JAHR AB DEM DATUM DES

KAUFS DURCH DEN BENUTZER.

Hinweis: Das Gehäuse darf nur von entsprechend

autorisierten Reparaturfirmen geöffnet werden, da sonst

die Garantie für dieses Instrument automatisch erlischt.

Reparaturarbeiten und Ersatzteile

Wenden Sie sich zwecks Wartungsarbeiten an Megger-

lnstrumenten entweder an:

Megger Limited oder an Megger

Archcliffe Road Valley Forge Corporate Center

Dover 2624 Van Buren Avenue

Kent CT17 9EN Norristown, PA19403

England U.S.A.

Tel: +44(0)1304 502100 Tel: +1 (610) 676-8579

Fax: +44(0)1304 207342 Fax: +1 (610) 676-8625

oder an eine autorisierte Reparaturfirma.

Autorisierte Reparaturfirmen

Eine Reihe von Firmen sind für die Reparatur der

meisten Megger-lnstrumente unter Verwendung von

Original Megger-Ersatzteilen autorisiert. Wenden Sie

sich wegen Ersatzteilen, Reparaturwerkstatten und

Beratung über die jeweils bestgeeigneten Maßnahmen

an eine autorisierte Auslieferung bzw. Vertretung.

Einsenden Eines Instruments Zur Reparatur

Wenn ein Instrument zwecks Reparatur zurück

geschickt werden muß, sollte es mit vorbezahiter

Fracht an die angebrachte Anschrift gesandt werden.

Gleichzeitig sollte zur Erledigung der britischen

Zollformalitäten per Luftpost eine Kopie der Rechnung

zusammen mit dem Packzettel eingesandt werden. Auf

Wunsch wird dem Absender vor Ausführung

irgendwelcher Arbeiten am Instrument ein

Kostenvoranschlag unter Berücksichtigung der

Frachtkosten und anderer Gebühren zugesandt.

58

Page 59

M

Megger Limited

Archcliffe Road Dover

Kent CT17 9EN ENGLAND

T +44 (0)1 304 502101

F +44 (0)1 304 207342

Megger

4271 Bronze Way, Dallas,

TX 75237-1019 USA

T +1 800 723 2861

T +1 214 333 3201

F +1 214 331 7399

Megger

Z.A. Du Buisson de la Couldre

23 rue Eugène Henaff

78190 TRAPPES France

T +33 (0)1 30.16.08.90

F +33 (0)1 34.61.23.77

OTHER TECHNICAL SALES OFFICES

Toronto CANADA, Sydney AUSTRALIA, Madrid SPAIN, Mumbai INDIA and the Kingdom of BAHRAIN.

Megger products are distributed in 146 countries worldwide.

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification or design without prior notice.

Megger is a re g i s t e red trademark

Part No. 6172-265 V11 Printed in England 0808

www.megger.com

Loading...

Loading...