Page 1

The Megger guide to

insulating oil dielectric

breakdown testing

The word ‘Megger’ is a registered trademark

WWW.MEGGER.COM

Page 2

Contents

1. Introduction ......................................................................................................................... 3

2. What are the methods for testing oil? .................................................................................. 3

3. What is oil dielectric breakdown voltage testing? ................................................................. 4

4. Who needs to perform dielectric breakdown voltage tests? .................................................. 4

5. Which types of insulating oil can be tested? ......................................................................... 4

6. Why, when and how often is oil testing performed? ............................................................ 6

7. What are the test standards and their differences? ...............................................................6

7.1 ASTM standards (USA) ............................................................................................... 8

7.2 IEC standards (international) ...................................................................................... 9

8. How should an oil sample be taken? .................................................................................. 10

9. Preparing the test vessel ..................................................................................................... 12

10. Why measure oil sample temperature? ...............................................................................13

11. How do I know whether my test results are valid? ..............................................................14

12. How do I know if my fluid has passed the test? ..................................................................14

12.1 USA – ASTM and IEEE standards .............................................................................. 15

12.2 International IEC standards ...................................................................................... 15

13. Can new oil fail a dielectric breakdown test? ......................................................................16

14. Can I verify my test instrument performance? ....................................................................17

15. How do oil test sets detect dielectric breakdown? ..............................................................17

15.1 Testing silicone oil .................................................................................................... 18

16. Choosing an oil dielectric breakdown voltage test set .........................................................18

16.1 On-site versus laboratory testing .............................................................................. 18

16.2 General instrument selection considerations ............................................................18

16.3 Selection considerations specific to laboratory instruments .......................................24

16.4 Selection considerations specific to portable instruments .........................................25

17. Megger OTS range summary .............................................................................................. 27

Acknowledgments

Megger gratefully acknowledges the support of John Noakhes of TJ/H2b Analytical Services for his help in compiling this publication.

2 www.megger.com The Megger guide to insulating oil dielectric breakdown testing

Page 3

1. Introduction

Oils that combine a high flashpoint with high dielectric strength have long been used as an insulating medium in

transformers, switchgear and other electrical apparatus. To ensure that the dielectric strength of the oil does not

deteriorate however, proper maintenance is essential, and the basis of proper maintenance is testing.

For over 100 years, Megger has been a world leader in the development and manufacture of test equipment for

electrical power applications. The famous Megger trademark was first registered in 1903, and jealously guarded

by the company. Megger’s experience in the design and production of oil test sets also reaches back to the early

20th century, when pioneering equipment was produced by Foster Transformers, a company that became part of

Megger Group in 1968.

Today, all of Megger’s oil test set design, development and manufacture is carried out at the company’s

manufacturing facility in Dover, England.

2. What are the methods for testing oil?

For in-service equipment in particular, there are many test techniques for evaluating the condition of the insulating

oil. If the technique of dissolved gas analysis is excluded, oil tests can be divided into two basic groups.

The first group includes tests that are concerned with the immediate condition and acceptability of the insulation

in an item of electrical equipment. This group includes dielectric breakdown voltage testing as well as moisture

measurement by the Karl Fischer (KF) method, and determination of insulation condition by measuring the dielectric

dissipation factor.

The Megger OTS range of dielectric breakdown voltage test sets

The Megger KF range of moisture content test sets

The Megger guide to insulating oil dielectric breakdown testing

www.megger.com

3

Page 4

The second group includes tests that look at the degree of degradation and aging of the equipment’s insulation

system. These tests include interfacial tension, acidity (neutralisation value), resistivity and visual determination of

colour and appearance of the insulating oil.

Typical oil colour specimens

The darker the colour the more contaminants present

Good Fair Bad

While all of these tests are useful in particular circumstances, the most convenient and most universally applicable is

dielectric breakdown voltage testing, which is why it has been selected as the subject of this technical guide.

3. What is oil dielectric breakdown voltage testing?

Put simply, a dielectric breakdown voltage test is a measure of the electrical stress that an insulating oil can

The exact method of performing the test is determined by the standard that is being used, as will be explained later.

The standard typically defines parameters such as the size and shape of the electrodes, the gap between them, the

rate at which the test voltage is increased, how many times the test is repeated and whether or not the oil is stirred

during the test.

withstand without breakdown. The test is performed

using a test vessel that has two electrodes mounted in it, with a gap between

them. A sample of the oil to be tested is put into the vessel and an ac voltage is

applied to the electrodes. This voltage is increased until the oil breaks down –

that is, until a spark passes between the electrodes. The test voltage is then

immediately turned off. The voltage at which breakdown occurred is the test

result, and is typically evaluated by comparing it with guidelines set out in various

standards, or in the oil manufacturer’s specifications.

4. Who needs to perform dielectric breakdown voltage tests?

There are many types of organisation that benefit from carrying out tests on transformer oil. These include:

Utility contractors (principally in substations)

Utility companies (principally in power stations)

Rail companies (locomotive HV step-down transformers and switchgear)

Oil test laboratories (providing testing services)

Transformer and switchgear manufacturers (quality control of oil)

Oil companies (testing new oil during manufacture)

5. Which types of insulating oil can be tested?

While the generic term ‘oil’ is almost universally used to describe insulating fluids, there are currently five different

types of insulating fluid in common use. These are:

Mineral oil

High molecular weight hydrocarbon (HMWH) fluids

Silicone fluids

Synthetic ester fluids

Natural ester (vegetable oil) fluids

4 www.megger.com The Megger guide to insulating oil dielectric breakdown testing

Page 5

All of these oil types can be tested for dielectric breakdown voltage and tested with Megger OTS range test sets.

Mineral oil is the most common insulating fluid and has been in use since the late 19th century. There are many

mineral oil filled transformers that have been in continuous use for more than 50 years. Mineral oils are refined from

either naphthenic crude or more recently, from paraffinic crude.

HWMH, silicon, synthetic ester and natural ester fluids are more recent developments and are often preferred

because they are much less flammable than mineral oil. ASTM D5222 specifies that for insulating fluids to qualify

as ‘less flammable’ they must have a fire point of at least 300 ºC.

The five fluids differ significantly in the way they behave in the presence of moisture. Mineral oil is the least

satisfactory, and even small amounts of water significantly reduce its breakdown voltage. Silicone fluid is also quickly

affected by small amounts of moisture, whereas ester fluids behave very well in the presence of moisture and can

typically maintain a breakdown voltage of greater than 30 kV with more than 400 ppm water content. This is one of

the reasons that esters last much longer in service.

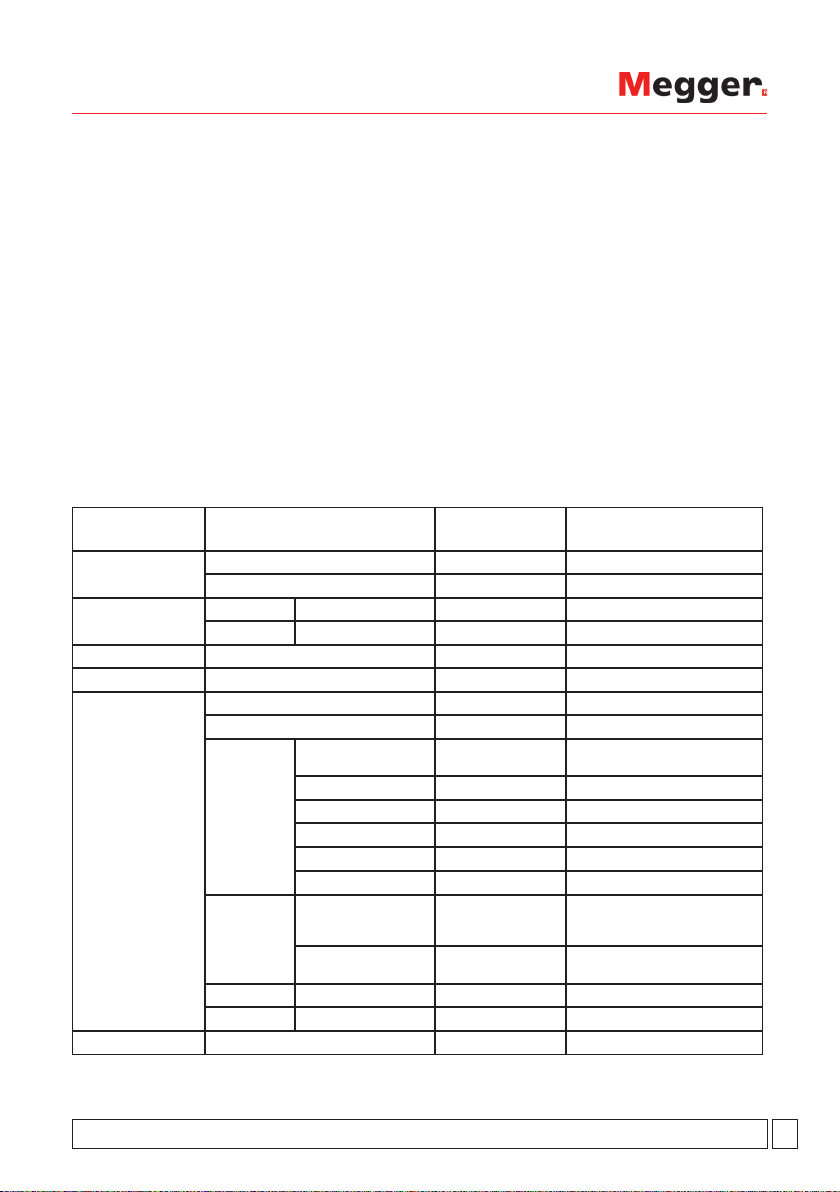

This table is not exhaustive, but does give a good indication of the types of insulating fluid that are used in various

applications. It also shows which types of fluid can be tested with the Megger OTS range of dielectric breakdown

voltage test sets.

Equipment Fluid Type Example/Sub-type

Capacitors

Medium and high voltage

cables

Bushings Mineral oil Various types Yes

Oil filled circuit breakers Mineral oil Various types Yes

Transformers

LTC (Load Tap Changers) Mineral oil Various types Yes

Synthetic aromatic hydrocarbons PXE Yes

Aromatic esters Various types Yes

New Synthetic hydrocarbons Polybutenes Yes

Old Mineral oil Various types Yes

Mineral oil Shell Diala AX Yes

Perflurocarbon (PFC) 3M PF-5060 Ye s

High molecular weight

(HMW) oil

Silicone Dow Corning 561 Yes

Low flammability

fluids

Old fluids

Gases Sulphur Hexafluoride SF6 No

Old gases Freon R-113 Vapotrans No

Synthetic hydrocarbons Polyalohaolefins (PAOs) Yes

Synthetic polyol esters Envirotemp® 200 Yes

Vegetable oils - natural ester Envirotemp® FR3 Ye s

Hydroflurocarbon Vertrel

PCBs - Polychlorinated

biphenyls

Tetrachloroethylene/

perchloroethylene (PCE)

Various types Yes

®

VX Yes

®

Askarel

®

Pyranol

Phenochlor

Askarel® (contained 50%)

Wecosol

Can be tested with Megger OTS

®

®

No - Harzardous - requires special

No - Harzardous - requires special

range?

handling

handling

The Megger guide to insulating oil dielectric breakdown testing

www.megger.com

5

Page 6

6. Why, when and how often is oil testing performed?

BDV (kV)

Period between tests (e.g. years)

6.1 Why and when?

The dielectric breakdown voltage test is a relatively quick and easy way of determining the amount of contamination

in insulating oil. Usually the contaminant is water, but it can also be conductive particles, dirt, debris, insulating

particles and the by-products of oxidation and aging of the oil.

For in-service equipment, the dielectric breakdown voltage test offers a useful and convenient way to detect

moisture and other contamination in the oil before it leads to a catastrophic failure. The information gained from

the test can also be used as an aid to:

Predicting the remaining life of a transformer

Enhancing operational safety

Preventing equipment fires

Maintaining reliability

Dielectric breakdown voltage testing is also carried out on new oil before it is used to fill equipment, and as part of

the acceptance testing for deliveries of new and reprocessed oil.

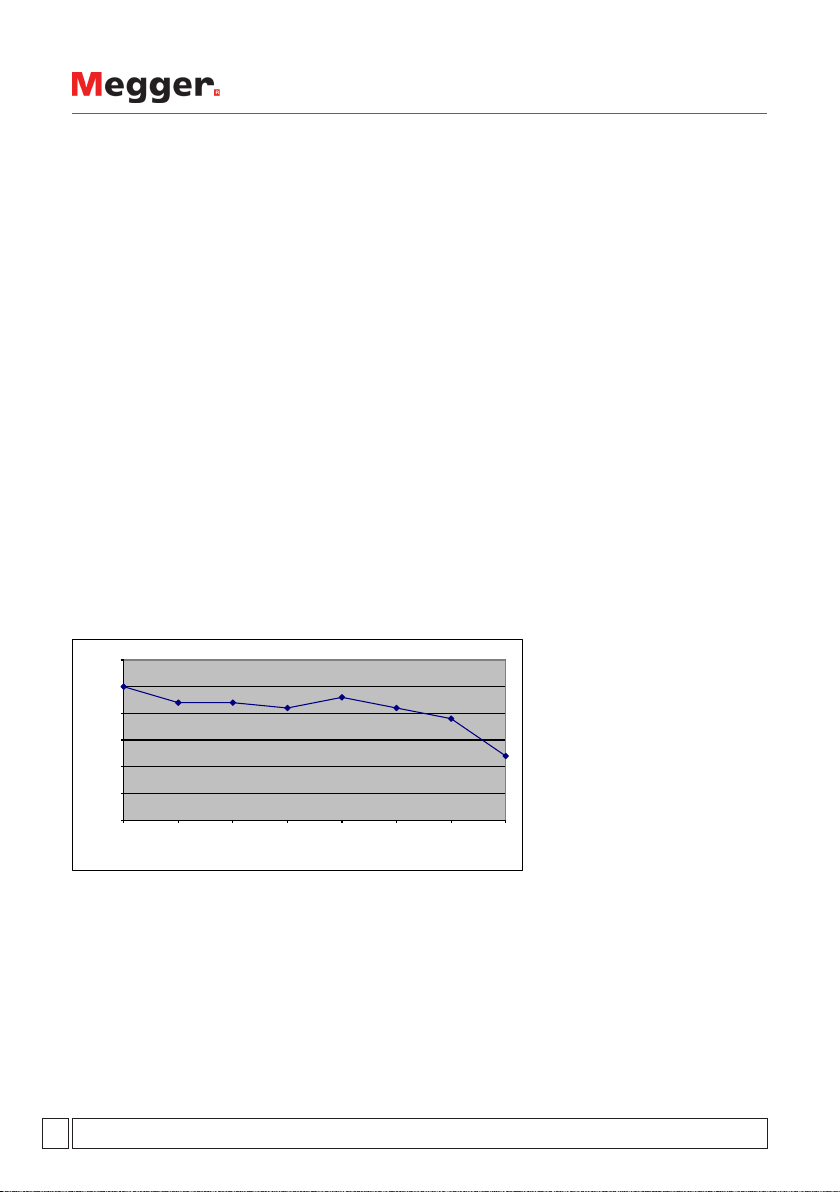

6.2 How often?

Dielectric breakdown voltage testing is an important element in the maintenance programme of any item of oilinsulated electrical equipment. However, to get the maximum benefit from this type of testing, Megger strongly

recommends that the oil is tested at least once a year and preferably twice a year. The results should be recorded,

as trending the data will make it easier to identify sudden or unexpected changes. If a sudden change in the results

is found, the transformer can be inspected for leaks, the oil level can be checked and the water content of the oil

evaluated. If contamination is confirmed, it will often be possible to dry and filter the oil, thereby reconditioning it

rather than having to replace it with expensive new oil.

50

45

40

35

30

25

20

1 2 3 4 5 6 7 8

7. What are the test standards and their differences?

There are many test standards for insulating liquids, but they are derivatives of three main standards. Two of these

are from ASTM International (USA) and the other is from the IEC (Europe). These main standards are:

ASTM D877 – Standard Test Method for Dielectric Breakdown Voltage of Insulating

Liquids Using Disk Electrodes.

ASTM D1816 – Standard Test Method for Dielectric Breakdown Voltage of Insulating

Oils of Petroleum Origin Using VDE Electrodes.

IEC 60156 Insulating Liquids – Determination of the breakdown voltage at power

frequencies – Test method.

There is also a Japanese standard not based on these ASTM or IEC standards.

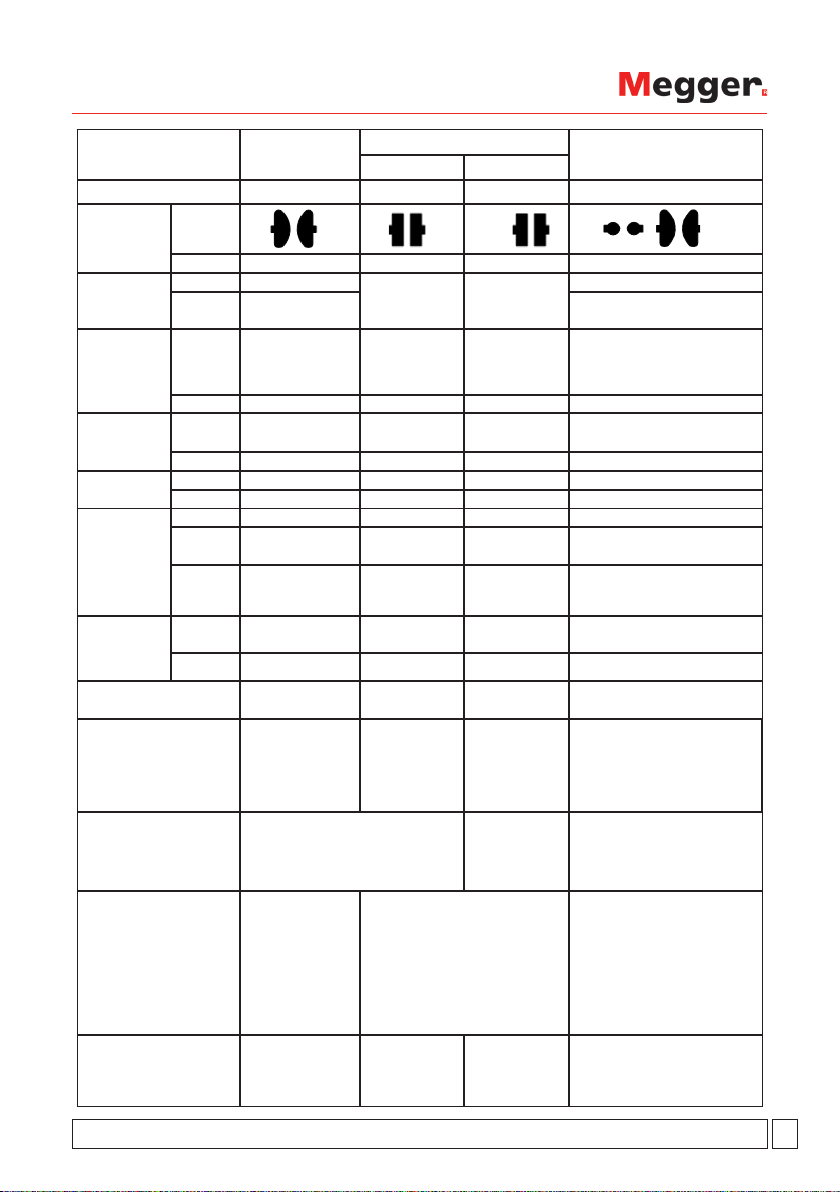

The following table is not exhaustive, but it shows the main differences between the ASTM and IEC standards.

6 www.megger.com The Megger guide to insulating oil dielectric breakdown testing

Page 7

Standards ASTM D1816

ASTM D 877

Procedure A Procedure B

Origin USA USA USA Europe

IEC 60156

Electrodes

Oil sample stirring

Laboratory test

temperature

Outside test

temperature

Test voltage

Breakdowns

Test voltage

switch off

time following

breakdown

Time between filling and start

of test

Equivalent standards (adopted

into)

Notes on testing silicon oil

Special conditions

Comments

Shape

Gap size 2 mm or 1 mm* 2.54 mm 2.54 mm 2.5 mm

Impeller yes

Magnetic

bead

Liquid

Ambient 20 - 30 ºC Must record Must record Within 5 ºC of oil sample

Liquid

Ambient Referee tests 20 - 30 ºC Must record Must record Within 5 ºC of oil sample

Rise rate 0.5 kV/s 3 kV/s 3 kV/s 2 kV/s

Frequency 45 - 65 45 - 65 45 - 65 45 - 62

Definition <100 V <100 V <100 V 4 mA for 5 ms

Number in

sequence

Time

between

breakdown

Normal (e.g.

mineral oil)

Silicon oil Not specified Not specified Not specified <1 ms

no option optional

At ambient - must

record

At ambient - must

record

5** 5*

1 to 1.5 min 1 min n/a 2 min

Not specified Not specified Not specified <10 ms

3 - 5 min 2 - 3 min 2 - 3 min

None None None

Can be used provided discharge energy in

sample <20 mj

* If breakdown does

not occur at 2 mm,

reduce gap to 1 mm

** Tests must be

repeated if range of

BD voltages recorded

are more than 120%

of mean with 1 mm

electrode gap and 92%

of mean with 2 mm

electrode gap

Test vessel requires

cover or baffle to

prevent air from

contacting circulating oil

not stirred not stirred

20 - 30 ºC must

record temperature

as collected and

when tested

Must record Must record 15 - 25 ºC

*Tests must be repeated if range of BD

voltages recorded are more than 92% of

mean. If range of 10 BD voltages is more

than 151% investigate why

Used if any insoluble

breakdown products

in oil completely

settle between

breakdown tests

20 - 30 ºC must

record temperature

as collected and

when tested

1 - 5 different

samples

Can be used if

modified in accordance

with D2225 if

procedure A cannot

be used

Used if any insoluble

breakdown products

do not settle

between breakdown

tests

BS EN 60156

CEI EN 60156

IRAM 2341

UNE EN 60156

FN EN 6056

OK if test instrument can comply with

voltage switch off time requirements

Expected range of standard deviation/

mean ratio as a function of the mean

provided as a chart

*With some stand/stir timing differences.

Test cell/vessel must be transparent.

Reconditioned/reclaimed oil to BS148

is tested to IEC60156 following update

in 2009.

optional

15 - 25 ºC

for referee tests

6

2 min

SABE EN 60156

VDE0370 part 5

PA SEV EN 60156

AS1767.2.1

NRS 079-1*

IS6729*

The Megger guide to insulating oil dielectric breakdown testing

www.megger.com

7

Page 8

There are many standards based on IEC 60156 and in addition Japanese standard JIS C2101 also includes

requirements for dielectric breakdown voltage testing. JIS C2101 calls for spherical electrodes similar to those

specified by IEC 60156, but requires a different sequence of five breakdowns. JIS C2101-99 (M) for mineral oils calls

for two oil samples to be tested each with a sequence of five breakdown tests. JIS C2101-99 (S) for silicon oils calls

for a sequence five tests but each test is performed on a different sample of oil.

7.1 ASTM standards (USA)

There are two standard test methods from ASTM International. The first is ASTM D877-02 (latest edition 2002) –

Standard Test Method for Dielectric Breakdown Voltage of Insulating Liquids Using Disk Electrodes. The second is

ASTM D1816-04 (latest edition 2004) – Standard Test Method for Dielectric Breakdown Voltage of Insulating Oils of

Petroleum Origin Using VDE Electrodes. Although this is essentially an American standard, it borrows from VDE, a

German standards organisation.

ASTM D877

ASTM D877 is an older standard, and is generally not very sensitive to the presence of moisture. For that reason

it is not widely used for in-service applications. In 2002 the IEEE revised C51.106, Guide for the Acceptance and

Maintenance of Insulating Oil in Equipment the values from D877 were removed from their criteria for evaluating

in-service oil in transformers. Generally ASTM 877 is recommended only for acceptance testing of new oil received

from a supplier, either in bulk loads or containers, to ensure the oil was correctly stored and transported. Typically a

minimum breakdown value of 30 kV is specified.

The ASTM D877 standard specifies the use of disc shaped electrodes that are 25.4 mm (1 inch) in diameter and

at least 3.18 mm (0.125 inch) thick. These electrodes are made of polished brass and are mounted to have their

faces parallel and horizontally in line in the test vessel. The edges are specified to be sharp with no more than a

0.254 mm (0.010 inch) radius. The sharp edges should be regularly inspected to ensure that they have not become

too rounded. Excessively rounded edges will have the effect of falsely raising the breakdown voltage, possibly

passing oil that should have failed the test. It is also important that the electrodes are kept very clean, with no

pitting or signs of corrosion, otherwise breakdown values can be falsely low. Instrument users should regularly

inspect electrodes, cleaning and polishing as required.

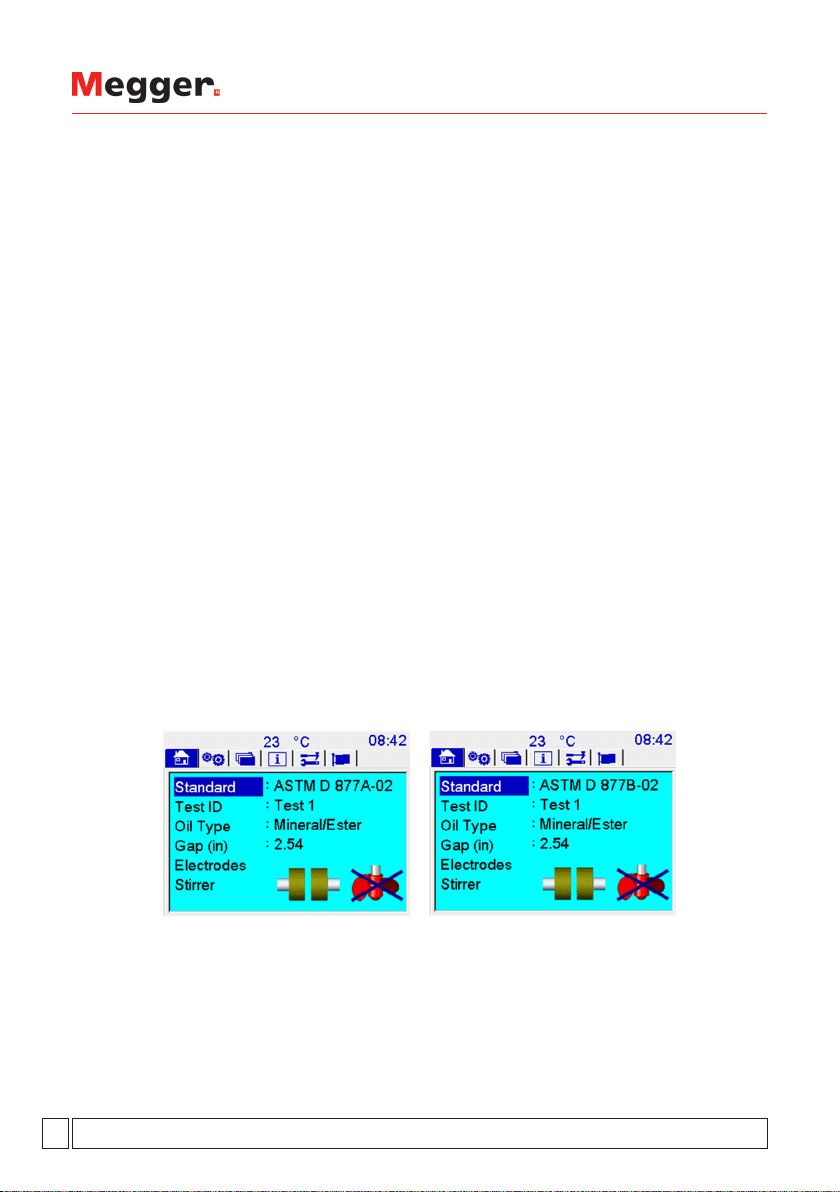

The Megger OTS instrument test set up screens for D877:

ASTM D1816

ASTM D1816 has become widely used over the years, even being used outside the standard’s stated application of

petroleum origin insulating oils and viscosity limits. D1816 is more sensitive than D877 to moisture, oil aging and

oxidisation, and is more affected by the presence of particles in the oil. When the IEEE revised C51.106 in 2002,

breakdown voltage limits for new and in-service oil using D1816 were added.

ASTM D1816 specifies the use of mushroom-shaped electrodes 36 mm in diameter. As with D877, the electrodes

are made of brass must be polished to be free of any etching, scratching, pitting, or carbon accumulation. The oil is

stirred throughout the test sequence, and a two-bladed motor-driven impellor is specified. The standard prescribes

the impellor dimensions and pitch as well as the operating speed, which must be between 200 rpm and 300 rpm.

To prevent air coming into contact with the circulating oil, the test vessel must have a cover or baffle.

8 www.megger.com The Megger guide to insulating oil dielectric breakdown testing

Page 9

The D1816 standard, although generally accepted as more useful than D877, has got one significant limitation:

when testing in-service oil this test method is very sensitive to dissolved gases. Excessive amounts of gas in the oil

can lower the test results to the point that a perfectly good sample of oil, with low moisture and particle content,

will fail the test. It is important to bear this in mind when testing oil from small gas blanketed transformers and

even, in some cases, from free-breathing transformers.

The Megger OTS instrument test set up screen for D1816:

The insulating fluid manufacturer will usually quote typical breakdown values for both new and in-service fluid in

the insulating fluid data sheet. In addition the test standards will refer to another oil condition standard that will

provide guidance as to what is acceptable. Test houses will also provide guidance as to what is acceptable.

7.2 IEC standards (International)

The International Electrotechnical Commission (IEC) defines only one method for oil breakdown dielectric

voltage testing. This is IEC 60156 Insulating Liquids – Determination of the Breakdown Voltage at Power

Frequencies – Test Method.

IEC 60156

IEC 60156 is an international standard that appears in many forms as IEC member national committees from various

countries have adopted it. Examples are British Standard BS EN 60156 and German VDE 0370 part 5. IEC 60156

specifies the use of (either spherical, or) mushroom (shaped) electrodes the same those used in the ASTM D1816

standard. The IEC standard differs in a number of ways from D1816, but the main difference is the IEC standard

allows the optional use of a stirring impeller, the use of a magnetic bead stirrer or even no stirring at all. The standard

states that differences between tests with or without stirring have not been found to be statistically significant. The

use of a magnetic stirrer is only permitted when there is no risk of removing magnetic particles from the oil sample

under test. When oil is used as a coolant and therefore circulating it would be stirred during testing. For example oil

from a transformer normally circulates if it is used as coolant, so an oil sample taken here would normally be stirred

to ensure the best chance of detecting particle contamination. Oil from a circuit breaker is normally static in use so

particles would naturally fall to the bottom where they are unlikely to cause a problem. So in static use applications,

an oil sample would usually not be stirred.

The dielectric breakdown values from the IEC 60156 method are usually higher than those from the ASTM methods.

Possibly this is in part because of the differences in voltage ramp up speed and electrode gap compared with

D1816, and electrode shape compared with D877. (The IEC electrode shape provides a more uniform electric field).

The result is that for well-maintained transformers the breakdown voltages may be higher than a 60 kV test

instrument can reach.

This may not be a problem when evaluating new oil from a supplier or even for in-service oil, but often an actual

breakdown voltage value is required. When testing to IEC 60156, therefore, the use of an instrument capable of

applying a higher voltage is advisable. As with D1816, dissolved gas in the oil sample may reduce breakdown values

but the effect is much less pronounced than with the IEC 60156 standard.

The Megger guide to insulating oil dielectric breakdown testing

www.megger.com

9

Page 10

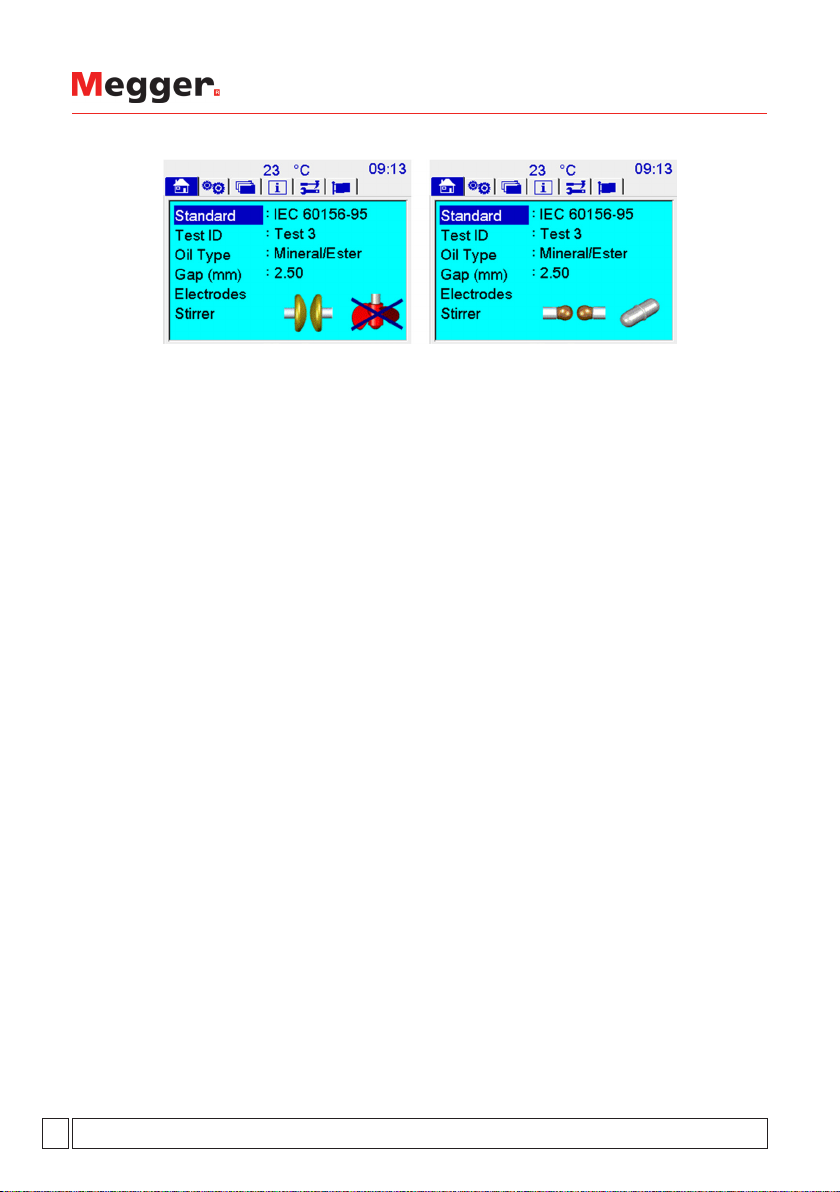

Some Megger OTS instrument test set up screen examples for IEC60156:

8. How should an oil sample be taken?

Two things are particularly important when taking oil samples. The first is to ensure that the proper sampling

procedure is followed, and the second is to ensure that all of the essential information is properly recorded.

If the sample is to be sent to a test house for testing, the test house should be able to advise on the information

needed, but it’s important to bear in mind that the condition diagnosis will only be as good as the information

supplied. The test house should also advise on the volume of the sample, and the type of container to use.

For oil samples from transformers, this information that oil test laboratories generally require is:

Description of the sample

List of tests to be performed

Transformer name plate information

Type of transformer

Type of insulating fluid

Any leaks noted

Insulating fluid service history (has it been dried, etc)

Transformer service history (has it been rewound, etc)

Type of breather

Type of insulation, including temperature rise rating

Details of cooling equipment (fans, radiators, etc)

Temperature of top of fluid, read from gauge

Actual fluid temperature measured

Fluid level

Vacuum and pressure gauge readings

For load tap changers, it is also advisable to record the counter reading, the selector range and the sweep range.

Sampling should be performed in accordance with the appropriate standard, and is not, therefore, discussed in

detail in this technical guide.

In the USA, there are two standards for sampling:

D923 – Standard Practices for Sampling Electrical Insulating Liquids

D3613 – Standard Practice for Sampling Electrical Insulating Oils for Gas Analysis and Determination

of Water Content

Internationally, there are two further sampling standards:

10 www.megger.com The Megger guide to insulating oil dielectric breakdown testing

Page 11

IEC 60475 Ed. 2.0 – Method of Sampling Insulating Liquids

IEC 60567 Ed. 3.0 – Oil-filled electrical equipment – Sampling of gases and of oil for analysis of free and

dissolved gases – Guidance

The IEC standards should be consulted together, especially as part of IEC 60567 has been transferred to IEC 60475.

8.1 Hints and tips for taking oil samples

For a sample to be truly useful, it must be representative of the oil in the equipment. This means that cleanliness is

extremely important.

Samples are normally drawn from a drain valve or sampling cock. This must be cleaned both inside

and out before the sample is taken to ensure that dirt does not fall into the sampling container.

The drain valve is at the bottom of the equipment, where all of the sludge, water and contaminant

particles collect. It is important therefore, to flush the system thoroughly to ensure that the sample is

drawn from the main bulk of the oil. This may involve removing two litres of oil, and even more if the

equipment has been out of service for some time.

Do not be tempted to use old engine oil bottles, even for a few p.p.m. of engine oil will cause the

sample to fail a breakdown test.

Do let the oil flow down the side of the sample bottle, or use a clean tube run to the bottom of the

bottle; it will prevent air being mixed with the oil.

Do store the oil samples in glass or clear plastic bottles in the dark, mineral oil will deteriorate if

exposed to UV light.

Safety

Before taking samples, ensure that you have all of the required permissions and permits

Have everything you need to lock out/tag out to hand

Make sure that the PCB (polychlorinated biphenyl) content of the oil, if any, is known and that the

equipment is labelled. PCB is very hazardous and requires special handling

Use all of the correct personal protective equipment (PPE) and correctly rated tools

Check the area for electrical and tripping hazards

Check for wildlife – snakes, bees, etc like transformers!

Check that the transformer is under positive pressure – are the pressure gauges reliable? Could they

be blocked or broken? NEVER try to take a sample from a transformer under negative pressure. Air

could be drawn into the transformer and cause it to fail.

Sampling equipment

Take extra sample bottles and syringes – they’re often needed

Ensure that the sample bottle seals are airtight

Use only ground glass syringes

If rubber hose is used, discard after each sample is taken

A sampling syringe

The Megger guide to insulating oil dielectric breakdown testing

www.megger.com

11

Page 12

Flushing the system

When flushing the system, a spare sample bottle is usually repeatedly filled and emptied into the waste.

It is good practice to measure the oil temperature using the last bottle that will be discarded, as this

avoids having to put the thermometer into the actual sample.

Taking the sample

Wherever possible, try to take samples during times of relatively steady loads and temperature – in other

words, when the equipment is at equilibrium. (This is particularly important with transformers, as if the

sample happens to be taken after the transformer has cooled following a long period of running at full

load, the breakdown voltage of the oil will be much lower than normal. This is because moisture in the

paper insulation will have migrated to the oil during the period of full load, and will not yet have had

time to migrate back. This is usually considered to be a normal phenomenon, but it is possible that it

may also be a factor in so-called ‘suddendeath’ transformer incidents where, for no apparent reason, a

seemingly healthy transformer suddenly fails. This is another good reason for recording as much infor

mation about the transformer as possible and for trending results to look for unexplained changes).

Do not take samples when it is raining or snowing, or when the relative humidity is above 50%, as

there is a high probability that samples taken in these conditions will be contaminated.

Do not take samples when it is windy, as dust blown by the wind may contaminate the sample.

Try not to take samples when the ambient temperature is high, as perspiration is a common source of

contamination problems.

9. Preparing the test vessel

Successful dielectric breakdown voltage testing depends not only on obtaining a good sample, as discussed in the

previous section, but also on ensuring that the test vessel is properly prepared. The preparation of the test vessel can be

divided into two key elements – the first is storing, cleaning and filling, and the second is setting the electrode gap.

9.1 Storing and cleaning test vessels

IEC 60156 recommends that a separate test vessel assembly is used for each type of insulating fluid that it is

required to test. This standard requires that the test vessels are filled with dry insulating fluid of the type that they

will be used to test, then covered and stored in a dry place. ASTM offers an alternative option of storing the vessels

empty in dust-free cabinet.

Immediately prior to testing, vessels stored full must be drained and then all internal surfaces, including the electrodes,

rinsed with fluid taken from the sample to be tested. The vessel should then be drained again, and carefully filled

with the test sample, taking particular care to avoid the formation of bubbles.

If the vessel was stored empty, or if it is to be used for a different type of fluid from that with which it was filled

during storage, it should be cleaned with an appropriate solvent before the rinsing and filling procedures described

above are followed. ASTM D1816 specifies the use of a dry hydrocarbon solvent such as kerosene, which meets

the requirements of D235. Solvents with a low boiling point should not be used as these evaporate rapidly, cooling

the vessel and giving rise to the risk of condensation. Solvents commonly used include acetone and, in the USA,

toluene. Toluene is banned in Europe.

Use lint-free clean-room wipes to clean the vessel. Do not use paper towels as they may introduce particles that hold

moisture, causing breakdown values to be dramatically reduced. Touching the electrodes or the inside of the vessel

should be avoided and during cleaning, the electrodes should be checked for pitting or scratches that may cause

breakdown voltage values to be decreased.

9.2 Setting the electrode gap

Setting the electrode gap accurately is very important, as the results obtained are only valid if the gap is correct. A

big problem is movement of the electrodes after the gap has been set and for this reason, many users of oil test

sets check the electrode gap frequently – sometimes before every test. A better solution is to use test sets where the

electrodes can be locked in position, such as the instruments in Megger’s latest OTS range.

Megger recommends the use of flat, smooth gap gauges. The latest Megger gauges have a black anodized coating,

which not only provides a smooth surface but also shows when the gauge is worn, as the shiny aluminium starts to

show through the coating.

12 www.megger.com The Megger guide to insulating oil dielectric breakdown testing

Page 13

9.3 Hints and tips for vessel preparation

If rinsing the test vessel with the sample oil before testing, it is most important to immediately fill the

test vessel with the oil sample to be tested. Any significant delay will result in the oil film on the vessel’s

walls absorbing water from the air, and since the walls have a large surface area, this will contaminate

the oil sample and reduce the breakdown voltage once it has been mixed with the sample.

Pour the oil into the vessel swiftly with minimum turbulence so as not to entrap air.

Allow the sample to stand for a few minutes before the testing to allow air bubbles to clear.

Do not leave the sample in the vessel to stand for too long before testing as it will absorb water from

the air in the headspace above it. This will reduce the breakdown voltage.

If you are using an impeller stirrer that utilises a baffle plate to exclude air from the oil sample ensure that:

Oil does not pass over the upper surface of the baffle plate

Oil is in full contact with the underside of the baffle plate

The use of a magnetic bead for IEC60156 will circulate oil in the lower portion of the test vessel,

whereas the impeller will circulate all of the oil in the test vessel. The magnetic bead therefore has the

advantage that moisture absorbed by oil in contact with air is not stirred into the sample, avoiding

unwanted contamination.

Remember that the rules of cleaning and preparing the vessel also apply to the magnetic bead, impeller,

baffle plate and electrodes, not just the vessel walls.

When performing continuous testing of many oil samples, such as in laboratory environments it is

important to clean or rinse the test vessel between every sample tested.

Always refer to the appropriate test standard to ensure the preparation is performed as specified.

10. Why measure oil sample temperature?

The breakdown voltage of an oil sample increases significantly with temperature. For example, a natural ester sample

with a breakdown voltage of around 35 kV at 30 ºC could easily have a breakdown voltage of nearly 60 kV at

70 ºC. For this reason, all oil test standards specify that the temperature of the sample must be recorded in the test

report. Here, from the chart included earlier in this technical guide, is the section that refers to temperature.

ASTM D 877

20-30 ºC must record temp as

collected and when tested

IEC 60156

15 - 20 ºC for referee tests

Laboratory

test

temperature

Outside test

temperature

Standards

Liquid

ambient 20 - 30 ºC Must record Must record Within 5 ºC of oil sample

Liquid

ambient

ASTM D

1816

At ambient must record

At ambient must record

Referee tests

20 - 30 ºC

Procedure A Procedure B

20-30 ºC must record temp as

collected and when tested

Must record Must record 15 - 25 ºC

Must record Must record Within 5 ºC of oil sample

Note The trending of test results to identify changes in breakdown voltage is only valid if the sample and ambient

temperatures for all results have been taken into account. Some breakdown testers measure oil temperature

automatically. This helps to ensure that the sample temperature has been measured and avoids the possibility of

introducing contamination by placing a thermometer into the oil sample.

The Megger guide to insulating oil dielectric breakdown testing

www.megger.com

13

Page 14

11. How do I know whether my test results are valid?

This extract from the chart comparing standards, which was included in full earlier in this application note, shows that

each standard specifies different conditions that must be met if the results of a test are to be accepted as valid.

Standards ASTM D 1816

Valid test conditions

Mean is the average of the breakdown values recorded in the test sequence. For example, if the

If breakdown does not

occur at 2 mm, reduce gap

to 1 mm.

Tests must be repeated if

range of BD voltages recorded

are more than 120% of mean

with 1 mm electrode gap and

92% of mean with 2 mm

electrode gap.

Procedure A Procedure B

Tests must be repeated if range of BD voltages recorded are more

than 92% of mean. If range of 10 BD voltages is more than 151%

investigate why.

ASTM D 877

IEC 60156

Expected range of standard

deviation/mean ratio as

a function of the mean

provided as a chart.

breakdown values are 33 kV, 37 kV, 32 kV, 35 kV, 38 kV and 34 kV, the mean value would be the total

of these results – 209 – divided by the number of results – 6 – which gives a mean value of 209/6 =

34.83 kV. (Note that in this example there are six results as required by the IEC standard. The ASTM

standards require either five or ten results.)

Range of breakdown voltage is referred to in the ASTM standards. For example, D877 specifies that the

test sequence must be repeated if the range of breakdown voltages recorded is more than 92% of their

mean value. Two examples will make this easier to understand.

In the first example, the breakdown voltages recorded are 43, 45, 52, 40 and 38 kV. The lowest value is

40 kV and the highest is 52 kV, so the range is 12 kV. The mean of the recorded values is 43.6 kV, so the

range is only 12/43.6 x 100% = 27.5% of the mean value. These test results are, therefore, valid.

In the second example, the breakdown voltages recorded are 33, 45, 52, 18 and 20 kV. The lowest

value is 18 kV and the highest is 52 kV, so the range is 34 kV. The mean of the recorded values is 33.6

kV, so the range is 34/33.6 x 100% = 101%. This is above the 92% limit, which means that the

test must be repeated.

Standard deviation - In IEC 60156, there is a graphical representation of standard deviation – otherwise

known as the coefficient of variation – versus the mean breakdown voltage. Calculation of the mean

has already been covered, but what about the standard deviation? IEC 60156 does not explain how to

calculate this. The procedure however, is to calculate the difference between each of the six test results

and the mean value of those test results. Square each of the differences and add them together. Divide

the figure obtained by 2, and then take the square root. The final answer is the standard deviation for

the set of test results.

IEC 60156 states that, for the test results to be considered valid, the following procedure must be followed:

Perform six tests

Calculate the mean of the results

Calculate the standard deviation (see above)

Divide the standard deviation by the average value, noting that scatter is expected and acceptable.

(See the chart at the end of IEC 60156)

If the value is acceptable, conclude testing

If not, perform six more tests

Repeat the calculations using all 12 results

12. How do I know if my fluid has passed the test?

The manufacturer of the insulating fluid normally quotes typical breakdown values for both new and in-service fluid

in its data sheets. In addition, the test standards refer to oil condition standards that provide guidance about the

acceptability of results.

14 www.megger.com The Megger guide to insulating oil dielectric breakdown testing

Page 15

12.1 USA – ASTM and IEEE standards

D877 as already mentioned, is usually only recommended for the acceptance of new oil from a supplier.

However, some oil testing laboratories still recommend its use for specific in-service applications. In these cases,

a breakdown voltage of 30 kV or more is usually considered to be acceptable, with values below 25 kV

unacceptable. Values between 25 and 30 kV are considered questionable. For new oil, a minimum value of 30 kV

is normally specified.

Typical breakdown values

using D877 test methods

Oil type New oil

Mineral oil 45 kV

Silicone oil 40 kV

HMWM 52 kV

Sythetic ester 43 kV

Natural ester 56 kV

D1816 is more widely used and is accepted by the IEEE as the test method to be used for dielectric breakdown

testing for the acceptance and maintenance of insulating oil. The IEEE C57.106 standard incorporates the D1816

limits – which are shown below – for new and in-service oil. Note that the values provided in this table are for

mineral oil.

IEEE C57.106-2006

IEEE Guide for acceptance and maintenance of insulating oil in equipment

Applications Voltages

class/group

New mineral insulating oil as received from supplier Not specified >20 kV >35 kV

New mineral insulating oil received in new equipment,

prior to energisation

New mineral insulating oil processed from equipment, prior to energisation

Service aged insulating oil - for continued use

(Group 1)

Shipments if new mineral insulating oils OCB (Oil

Circuit Breaker)

New OCB insulating oil - after processing, prior to

energisation

Service aged OCB insulating oil - for continued use OCB >20 kV >27 kV

New mineral oil for LTC (Load Tap Changer), prior to

energisation

Service aged LTC insulating oil - for continued use

≤69 kV >25 kV >45 kV

69 to 230 kV >30 kV >52 kV

230 to 345 kV >32 kV >55 kV

≥345 kV >35 kV >60 kV

≥69 kV >23 kV >40 kV

69 to 230 kV >28 kV >47 kV

≥230 kV >30 kV >50 kV

OCB >20 kV >30 kV

OCB >30 kV >60 kV

LTC >35 kV >55 kV

LTC - Netural >20 kV >27 kV

LTC - ≤69 kV >25 kV >35 kV

LTC - >69 kV >28 kV >45 kV

D1816

(1 mm gap)

D1816

(2 mm gap)

The Megger guide to insulating oil dielectric breakdown testing

www.megger.com

15

Page 16

12.2 International IEC standards

IEC 60156 uses acceptance values that are contained in two further standards, IEC 60296 and IEC 60422.

IEC 60296 – Fluids for electrotechnical applications – Unused mineral insulating oils for transformers and switchgear.

As its title indicates, this standard applies only to new, unused oil as received from the manufacturer, which must

have a dielectric breakdown voltage of 30 kV or more, determined using the IEC 60156 test method. Oil that has

been vacuum filtered in a laboratory must have a minimum dielectric breakdown voltage of 70 kV.

IEC 60422 – Mineral insulating oils in electrical equipment – Supervision and maintenance guide. This standard

prescribes acceptable dielectric breakdown values for new oil (after filling but before energising) and for in-service

oil. The values are:

New oil

Equipment voltage Dielectric BD voltage

≥72.5 kV >55 kV

>72.5 kV

≤170 kV

>270 kV >60 kV

>60 kV

In-service

oil

Equipment

voltage

≥72.5 kV >40 kV 30 - 40 kV >30 kV

>72.5 kV

≤170 kV

>270 kV >60 kV 50 - 60 kV >50 kV

Dielectric

BD voltage

Good Fair Poor

>50 kV 40 - 50 kV >30 kV

The IEC recommends that if values are in the ‘fair’ range, testing should be performed more frequently, and that the

test results should be crosschecked with other testing methods. If the test results are in the ‘poor’ range, the oil must

be brought back into a good state by reconditioning. This might, for example, involve filtering and drying the oil.

13. Can new oil fail a dielectric breakdown test?

The simple answer is yes, new oil can fail a breakdown test. Sometimes users suspect that their test set is faulty

because it is failing new oil. When the test set is checked however, almost invariably no fault is found. The true

situation is that the oil being tested really does have a low breakdown value, so the test results are actually correct,

even if they are hard to accept.

The problem usually relates to the way the oil has been stored. Often oil is delivered in drums that are stacked on

site in readiness for filling a transformer or other equipment. In hot climates, pressure rises in the drums when they

are exposed to the heat of the sun, but falls at night when the ambient temperature drops. Sometimes this pressure

cycling damages the seals on the drums, and they start to allow the penetration of moisture. It only takes a very

small amount of moisture to degrade the properties of the oil to the extent that it fails the test.

16 www.megger.com The Megger guide to insulating oil dielectric breakdown testing

Page 17

To give an idea how quickly oil can deteriorate, after a drum of new oil is opened it is often less than three weeks

before it fails a breakdown test.

In circumstances where such problems may occur, it is useful to verify the performance of the oil test set, so that the

real situation can be quickly determined. One approach is to use a voltage check meter to ensure that the test set

is supplying the correct voltage. An alternative method is to perform a breakdown test in air with the instrument

electrode gap set as wide as possible. If the value obtained when the instrument is new or when it has recently been

calibrated is recorded, this can be used as a reference value to confirm that it is still working correctly at a later date.

Note that some variation in the air breakdown test results are to be expected, due to changes in atmospheric

pressure and humidity, but this is a good ‘quick check’ that has the advantage of requiring no additional equipment.

As a guide, Megger’s older OTS AF2 instruments typically give a breakdown voltage of around 37 kV in air, while

instruments in the newer OTS AF series typically give a result of approximately 19 kV.

14. Can I verify my test instrument performance by comparing the

results from two instruments on the same sample of oil?

Yes, but you must consider these potential issues:-

Even if you can transfer the oil sample from one instrument to another in the same test vessel you may

not get exactly the same test results. This is because by-products produced by the breakdown arcs from

the first set of tests are now somewhere in the oil sample and likely to effect any subsequent tests.

Changes in oil sample temperature will produce changes in test results.

Pouring oil from one vessel to another vessel is likely to produce bubbles that will introduce additional

air and moisture to the sample resulting in lower test results than the previous testing

If the time between comparative tests on the same oil sample is excessive it will absorb moisture from

the air, even if a test vessel has a lid as it is not sealed in the same manner as an oil sample bottle.

Two oil samples taken from the same drum are in effect two different samples of oil. They can, if

particle contamination is present, exhibit different levels of breakdown voltage.

Oil with unknown contamination can cause large changes in test results, particles or moisture can

circulate in the oil between the electrodes, causing variation in test results. This can easily lead to an

incorrect conclusion with regard to the performance of the test instruments being compared. That is

why five or six breakdown tests are performed during each test sequence to take into account this variation

Cleanliness is extremely important to ensure reliable test results that can be reliably compared.

15. How do oil test sets detect dielectric breakdown?

Efficient breakdown detection is very important as it determines the ability of the instrument to correctly register

the breakdown voltage of the oil, and also to limit the amount of energy dissipated in the arc in the oil. For these

reasons, the oil testing standards specify the precise conditions that must be met to trigger the instrument’s

breakdown detection system. There are, however, differences between the standards, as shown in the table below:

Standards ASTM D 1816

When output

Breakdown Definition

Test voltage

switch off

time following

breakdown

Normal (e.g.

mineral oil)

Silicon oil Not specified Not specified Not specified <1 ms

voltage had

dropped to

below 100 V

Not specified Not specified Not specified <10 ms

The Megger guide to insulating oil dielectric breakdown testing

ATSTM D 877

procedure A procedure B

When output

voltage had

dropped to

below 100 V

When output

voltage had

dropped to

below 100 V

IEC 60156

When output current has

been 4 mA or more for at

least 5 ms

www.megger.com

17

Page 18

Modern test instruments detect breakdowns directly on the instrument output, which improves detection accuracy.

Very few instruments are capable of breakdown detection that meets both IEC and ASTM requirements. Instruments

in the new Megger OTS range are an exception as they can detect breakdown in terms of current increase or in

terms of voltage drop.

It is worth noting that some older instruments do not include automatic breakdown detection. IEC 60156 states

that the circuit applying the test voltage may be opened manually if a transient spark (audible or visible) occurs

between the electrodes. This statement is included specifically to cover the use of these older instruments where, if

a spark is heard or seen between the electrodes, a breakdown has occurred and the test is complete.

15.1 Testing silicone oil

Silicon oil has much higher viscosity than mineral oil, and is more susceptible to the breakdown arc producing

carbon track solids. For these reasons, the standards specify special conditions when testing silicone oils:

IEC 60156 reduces the test voltage switch-off time after breakdown detection from the standard 10 ms to 1 ms for

silicone oils.

ASTM D877 and D1816 both specify that, for silicone oils, the energy discharged into the breakdown arc must not

exceed 20 mJ.

16. Choosing an oil dielectric breakdown voltage test set

It would be easy to assume that because all dielectric breakdown voltage test sets have to work to the same strict

test standards, there is little to choose between them. This is far from true and a little effort put into selecting the

best instrument will be amply repaid by time and cost savings over the life of the instrument.

The first decision to make is whether the tests will be performed in a laboratory or on-site, as there are differences

between laboratory and portable instruments.

16.1 On-site versus laboratory testing

The relative merits of on-site and laboratory testing have long been debated by engineers and the debate is still

going on. The underlying issue is that test results are greatly influenced by contamination. There are those who

argue that this means it is better to test on-site because, if a sample has to be bottled and the bottle sent to a

laboratory, there will always be doubt about whether the bottle was cleaned adequately before use and whether it

was sealed sufficiently well to guard against contamination in transit.

Others will point out that testing on site provides no guarantees against contamination, as the most likely time for

a sample to be contaminated is while it is being collected. They may also argue that, if a sample is sent to a laboratory,

it will be tested by a skilled technician who will follow all of the procedures needed to ensure accurate results.

Conversely, tests carried out on site are performed under less-than-ideal conditions and often under significant time

pressure, which may lead to errors.

On-site testing undeniably has the benefit of immediacy. If a suspicious result is obtained, it is usually possible to

repeat the test without delay and, if the problem is confirmed, the affected transformer can, at least in principle, be

taken out of service immediately.

There is no clear answer to the question of whether on-site or laboratory testing is best. It is really a matter for

individual users to decide which approach best suits their particular circumstances. Megger is always happy to

provide advice in making this decision and, as a company that manufactures both on-site and laboratory test sets,

the impartiality of that advice is guaranteed.

16.2 General instrument selection considerations

An instrument is a long-term investment, so it’s important to choose one that’s built to last and that is as future

proof as possible. This section looks at additional considerations that apply to all oil test sets, while sections 15.3

and 15.4 deal with considerations relating specifically to laboratory instruments and portable instruments respectively.

Instruments in Megger’s new OTS range have been designed to address all of the issues identified in these sections.

18 www.megger.com The Megger guide to insulating oil dielectric breakdown testing

Page 19

16.2.1 Cleanliness

n Insulating fluids are hazardous. Skin contact with

these fluids should be avoided. Instrument should

be designed to minimise the risk of spilage, and to

make spillage as easy as possible to deal with if it

should occur.

n Test vessel ease of cleaning. The vessel should be

designed so that it has no corners, as these trap dirt

and are difficult to clean.

n Chemical resistance. The test vessel should be made of a material that is highly resistant

to chemical attack. Glass is not the best choice because of its fragility. A correctly specified

moulded material will not affect test results – note that even glass vessels have moulded

bushes to support the electrodes, and these bushes are in contact with the test sample.

The test vessels on the new Megger OTS range instruments are manufactured from a

material which is virtually shatterproof and which is widely used in the chemical industry

because of its excellent resistance to chemical attack. The vessels have been extensively

tested to confirm that they are unaffected by any of the chemicals likely to be encountered

in oil testing applications.

n Ease of pouring. Always look for a test vessel that has a spout to aid pouring.

n Testing to ASTM D1816. Remember that this standard requires the oil sample to be stirred

with an impeller, and also specifies that the test vessel must have a cover of be fitted with a

baffle to prevent air from coming into contact with the sample. In many instruments, oil is

displaced by the lid, resulting in messy spills. Look for a test set that does not have this problem.

The stirrer lid for the new Megger test vessel has a unique baffle plate design. When the

test vessel is filled with oil to the fill line and the stirrer lid fitted, the baffle plate touches the

oil without displacing it. No oil is spilled, so no clean up is necessary.

The Megger guide to insulating oil dielectric breakdown testing

www.megger.com

19

Page 20

n Test chamber ease of cleaning. Like the test vessel itself, the test chamber should be

designed so that it has no corners to trap dirt and contaminants.

n Dealing with spillage. Inevitably, oil is sometimes spilled into the instrument’s test

chamber. With many instruments, the only way of removing this spilt oil is by using cloth or

tissues to mop it up, a task that is both time consuming and inconvenient. Make life easier

by specifying an instrument that has a test chamber with a means of quickly and easily

draining spilled oil.

16.2.2 Ease of use

n An instrument that is difficult to use is not just an irritation, it also wastes time and reduces

productivity. Look for an instrument that has a clear and straightforward user interface.

Operation of the instrument should be intuitive and it should not be necessary to repeatedly

refer to the user guide. This is particularly important for instruments that are made available

for hire, and in cases where they will be used by engineers and technicians who do not

perform oil tests regularly. Here are some specific points to consider.

n User interface. The user should be able to easily identify and access the main functions of

the instrument, such as test method selection, test sequence set up, stored data functions

and user settings including, for example, the operating language.

The user interface in the new Megger OTS AF instruments has a clear and easy to under

stand menu system, with simple navigation keys. The interface presents the user with a

set of six tabbed top-level windows, as shown below. The left and right arrow keys on the

keypad navigate between the tabs.

20 www.megger.com The Megger guide to insulating oil dielectric breakdown testing

Page 21

Home – Test set up Set up – Instrument settings File – data functions

Information – help Tools – additional functions Language - selection

n Display. The display should be clear and bright, and preferably in colour. The display

is a window into the functioning of the instrument – the bigger and clearer this

window is, the better.

n Test chamber access. Good test chamber access will aid instrument operation and cleaning.

Deep and dark chambers are bad, not least because they make it difficult to see if the

chamber is dirty. Most users prefer top access instruments.

n Automatic testing. Most modern instruments

support automatic testing, and will follow the

test sequence specified in the chosen test standard

with little or no operator intervention. Low-cost

manual instruments are still available, but think

carefully about day-to-day operation is needed

before purchasing one of these. They may be

appropriate for some users, but a high degree of

skill is needed to use them successfully.

16.2.3 Ownership costs

n Additional and replacement test vessels. As mentioned earlier, IEC 60156 recommends

that a separate test vessel is used for each type of fluid to be tested. Many laboratories

adhere to this advice and as a result, have six or more test vessels. It is important, therefore,

to check the price of spare vessels before purchasing an instrument. Some are very

expensive and purchasing several vessels can

greatly increase overall costs.

n Broken test vessels. The previous comments

about the price of test vessels are also relevant

to broken test vessels, but note that moulded

test vessels are much less fragile and far less

likely to break than glass vessels. When

correctly specified a moulded vessel will provide

all the advantages of a glass vessel and more, at

a lower price.

The Megger guide to insulating oil dielectric breakdown testing

www.megger.com

21

Page 22

16.2.4 Sample temperature measurement

An instrument that features built-in automatic oil-sample temperature measurement offers

important benefits. With these instruments, the temperature sensor is in contact with a thin

section of the test cell; unlike a conventional thermometer, the sensor does not come into

direct contact with the sample, and the risk of contamination is eliminated. Also the user is

less likely to be tempted to save time by not waiting for the sample to cool before testing.

Finally, there is no fragile thermometer to break.

Chamber mounted temperature sensor on the new Megger OTS range

16.2.5 Test voltage verification

n Checking between calibration dates. Test results are only as accurate as the instrument’s

ability to measure and control its output voltage, so it is good practice to verify the operation

of the instrument between calibrations. This is not because instruments are likely to lose

accuracy, but because if something occurs that affects calibration and it isn’t noticed, it

could mean that a lot of inconvenient and potentially expensive retesting is needed.

n Voltage check meters. Many manufacturers offer a voltage check meter that can be fitted

to the instrument in place of the measuring vessel. This allows the user to compare the

voltage shown on the check meter with that shown on the instrument display. Check

meters are not sufficiently accurate to use as a calibration standard, but they provide

a very good way of detecting changes in instrument calibration. Users should record the

check meter readings each time a voltage check is carried out, so that changes can be easily

identified. If any significant change is detected, the instrument should not be used until it

has been returned to the manufacturer for servicing and recalibration.

The Megger VCM100D check meter can be used with any of the portable or

laboratory test sets in the new OTS range. Since the meter is not oil filled, there

is no risk of leakage. It also features a bright, easy-to-read LED digital display.

16.2.6 Changes to test standards

n When choosing a test instrument, it is essential to be sure that it

can handle future changes to test standards and the introduction

of new test standards. It should be possible to eaily load new test

sequences into the instrument to reflect these changes. It is

worth checking that the instrument supports custom test

sequences that can be programmed by the user.

Testers in the Megger OTS range allow existing pre-loaded

standards to be updated and new standards to be added via

a standard USB flash drive. New and amended standards

are made available for download from the Megger website.

22 www.megger.com The Megger guide to insulating oil dielectric breakdown testing

Page 23

16.2.7 Reliability of test results

Note There are five key areas that directly affect an instrument’s ability to produce accurate test results.

These are cleanliness, the method of breakdown detection, the speed at which the instrument switches

off the test voltage after a breakdown, the accuracy of the voltage measurement and the accuracy of

the electrode gap setting mechanism. The issues of cleanliness and output voltage verification have

already been discussed; the remaining issues are dealt with here.

n Breakdown detection. Ensure that the instrument complies with the requirements of the

test standard(s) that will be used. Megger OTS AF test sets offer both voltage- and current based breakdown detection, to provide compliance with ASTM and IEC requirements.

n Voltage switch-off time. The faster the voltage is switched off after breakdown, the better.

This is because arcing continues in the oil until the voltage is switched off, and arcing

results in decomposition of the oil to produce by-products that can affect subsequent test

results. For this reason, the IEC 60156 standard requires that the test voltage is switched

off in less than 10 ms for mineral oil and in less than 1 ms for silicone oil. The ASTM standards

require that no more than 20 mJ of energy is discharged into silicone oil, and a fast switch off time is needed to achieve this.

The switch-off time for instruments in the new Megger OTS range is typically 10 µs - 100

times faster than required to minimise decomposition of silicone oil.

n Electrode gap setting. An accurate electrode gap is extremely important for obtaining

accurate test results. If the gap is too large, the test result will be too high and conversely if

it is too small, the test result will be too low. The easier it is for users to adjust the gap, the

more likely it is that it will be accurately set.

n Ease of gap adjustment. The most popular method for adjusting the electrode gap is with

a thumbwheel. With this method, no tools are needed and it is easy to adjust the gap.

n Unwanted movement of electrodes. A common problem is that the electrodes move

while the vessel is being handled or cleaned, resulting in an inaccurate gap setting. This is

particularly true of instruments that have thumbwheel electrode gap adjustment as thumb wheels are easy to move accidentally. In addition, backlash in the adjustment mechanism

can make movement of the electrodes inconsistent, which means that they are difficult to

adjust accurately, and marked graduations are rendered inaccurate. Because of this, many

test set users resort to checking the electrode gap every day or even before every test.

Some older instruments provide screw clamp locking that is effective in preventing electrode

movement, but it is hard to see and use.

Megger’s new OTS instruments have convenient thumbwheel adjustment for setting the electrode gap, but have the

unique benefits of pre-tensioned electrodes and an easy-to-use locking mechanism that ensures the electrodes can

be adjusted accurately and never move accidentally once set.

Precision thumbwheel gap adjustment Gap is then locked with unique mechanism

The Megger guide to insulating oil dielectric breakdown testing

www.megger.com

23

Page 24

16.3 Selection considerations specific to laboratory instruments

Users of oil test sets who work in the laboratory have priorities that are different from those of users who work in

the field. For example, in a laboratory environment, the weight of the instrument is usually not a concern, but the

ability to carry out large numbers of tests rapidly in succession most certainly is. For this reason, Megger produces

separate ranges of dielectric breakdown test sets for laboratory and field applications. This section deals specifically

with laboratory instruments.

Test chamber access

When large numbers of tests are being performed, easy access to the test chamber is essential. For this reason,

instruments in the new Megger OTS AF range have large test chambers that are fast to clean and convenient to use.

OTS PB chamber OTS AF chamber

Test result recording

Recording test results and producing reports are among the most time-consuming tasks in a laboratory. Speed and

ease of data entry are therefore, key considerations when choosing a test instrument. It is a matter of personal

preference whether the user favours entering data into a PC or directly into the instrument, but in either case the

task should fast and straightforward. If a laboratory instrument management system (LIMS) is in use, it is important

to check that the test set can output data in a compatible format.

Megger OTS AF laboratory instruments have a keypad that is specifically designed to speed up data entry, and all

current OTS instruments allow data to be transferred to a PC using a standard USB flash drive. In addition, OTS

instruments are supplied with a free copy of Megger’s PowerDB Lite software, which allows professional test reports

to be generated quickly and easily, and can export test data in Excel and CSV formats. The instruments are compatible

with the full version of PowerDB.

OTS AF keypad

24 www.megger.com The Megger guide to insulating oil dielectric breakdown testing

Page 25

Barcode scanning

A timesaving feature that is often worth considering is barcode scanning, as it provides a fast and error-free way of

entering sample identification numbers.

OTS AF instruments can scan barcode labels using the optional barcode scanner

16.4 Selection considerations specific to portable instruments

The priorities of those who use portable instruments are different in several key areas from those of laboratory

instrument users. Among the main points to consider for portable instruments are:

16.4.1 Weight

Portable instruments routinely have to be carried from a van to a transformer. Weight is of

particular interest, especially when the instrument has to be carried by just one person. The

government or the organisation you work for may have rules on the maximum weight that

you should carry; often it is specified at 25 kg. From the user’s point of view however, the

lighter the instrument the better.

Megger has made great efforts to minimise the weight of its latest OTS instruments and, starting at just 15.4 kg,

the OTS60PB oil dielectric breakdown test set is well within most health and safety guidelines on weight.

16.4.2 Ease of carrying

How easy the instrument is to carry is an important consideration.

Handles on the sides of the instrument are generally easiest to

use, as they provide a more natural lifting position than a single

handle on the top of the instrument.

16.4.3 Toughness

When an instrument is damaged, testing must stop until it can be repaired. Portable

instruments are particularly likely to take a few knocks during transportation and use, and

they must be able to withstand this treatment. Items might fall on the instrument when it is

in the back of a van, and it is desirable to choose an instrument that has been

designed with this type of incident in mind.

Instruments in the new Megger OTS range have

curved tops that deflect falling objects. In addition,

the chamber cover and display protection window

are both manufactured from strong impact-resistant

transparent polycarbonate material. Not only is the

chamber cover very strong, it also allows the

discharge to be seen clearly.

The Megger guide to insulating oil dielectric breakdown testing

www.megger.com

25

Page 26

Occasionally instruments also get dropped. The most frequent types of damage suffered by oil test sets dropped from a

modest height are crumpled corners and/or twisting of the instrument frame. Dielectric breakdown test sets

include a heavy transformer that must be properly supported, and a quick look at the underside of the instrument

will often give a good idea of whether it has sufficient structural strength. In particular, the corners should be

checked to see whether they are likely to be able to withstand impacts. It is also worth bearing in mind that lighter

instruments are less likely to suffer damage.

Megger OTS rubber feet / corner protection

16.4.4 Transferring stored data

When the time comes to transfer stored test data from the instrument to a PC, consider the

inconvenience of having to carry the instrument into an office so that it can be connected to

the PC. A better solution is to choose an instrument that can store test results on a standard

USB flash drive, as then it is only necessary to carry the USB flash drive into the office.

All of the new Megger OTS instruments transfer data via a USB flash drive. This method is

simple, convenient and secure.

16.4.5 Power sources

Many portable instruments can operate only from their internal battery. Bearing in mind

that the typical time needed to fully recharge the battery is around four hours, this can be

inconvenient if the instrument is needed urgently and is found to have a discharged battery,

or if a large number of tests have to be carried out during a fixed shutdown period. It is

better to choose an instrument that can operate either from its internal battery or direct

from the mains.

Instruments in the new Megger portable range can operate from either a mains supply or

from their internal batteries. The batteries can be charged from the mains or from a 12 V dc

vehicle socket, using the 12 V charger lead supplied as standard.

26 www.megger.com The Megger guide to insulating oil dielectric breakdown testing

Page 27

Megger NEW range Megger

Laboratory optimised instruments Portable optimised instruments

Feature Sub-feature OTS60AF OTS80AF OTS100AF OTS60PB OTS80PB OTS60SX

Max. output voltage 60 kV 80 kV 100 kV 60 kV 80 kV 60 kV

Direct output voltage

measurement

Voltage slow rate (kV/s) 0.1 to 5 kV/s 0.1 to 5 kV/s 0.1 to 5 kV/s 0.1 to 5 kV/s 0.1 to 5 kV/s 0.5, 2 and 3 kV

Switch off time on flashover < 10 µs <10 µs <10 µs <10 µs <10 µs not specified

Direct output breakdown

Test voltage etc

Oil temperature

measurement

Test vessel

Test chamber Spilt oil drain

Electrode gap

adjustment

Power supply

User interface

Auto test sequences

Types of oil tested Includes silicone

Other data Date and time on unit

Printer

* CTB = configure to build

detection

Voltage (ASTM) and current

(IEC) triggered breakdown

detection

Measurement accuracy

±1 kV or better

Measurement accuracy

±0.1 kV or better

Built in to instrument

Moulded - impact resistant

Magnetic stirring

Propeller stirring

Auto power connection

for above

Spout for pouring

Micrometer style adjustment

Lockable as above

Mains operation

NiMH battery

NiMH battery life 10 hours 10 hours

Lead acid

Vehicle 12 V socket

operation

Multi language

Memo entry

Multikey keypad

Display backlight

Colour TFT display

ASTM

IEC - and related

Custom programable

Recording results int

Recording results USB

flash drive

PowerDB Lite supplied

Built in

External Option Option Option Option Option

n n n n n

n n n n n

n n n n n

n n n n n n

n n n n n n

n n n n n

n n n n n n

n n n n n

Option

(CTB) *

n n n n n

n n n n n n

n n n n n

n n n n n

n n n n n

n n n n n n

n n n n n

n n n n n

n n n

n n n n n

n n n n n

n n n n n

n n n n n

n n n n n

n n n n n

n n n n n

n n n n n

n n n

n n n n n

Option

(CTB)*

Option

(CTB)*

Option

(CTB)*

Option

(CTB)*

Option

(CTB)*

Option

(CTB)*

Option

(CTB)*

n n

TBA TBA

Option

(CTB)*

Option

(CTB)*

Option

(CTB)*

Option

(CTB)*

Option

(CTB)*

Option

Manual

LED

Manual

Manual

Manual

The Megger guide to insulating oil dielectric breakdown testing

www.megger.com

27

Page 28

Megger NEW range Megger

Laboratory optimised instruments Portable optimised instruments

Feature Sub-feature OTS60AF OTS80AF OTS100AF OTS60PB OTS80PB OTS60SX

Environmental

Physical

Accessories

supplied

Voltage check

meter available

* CTB = configure to build

Operating temperatures 0 to +50 ºC 0 to +50 ºC 0 to +50 ºC 0 to +50 ºC 0 to +50 ºC 0 to +40 ºC

Storage temperatures -30 to +65 ºC -30 to +65 ºC -30 to +65 ºC -30 to +65 ºC -30 to +65 ºC -40 to +70 ºC

Dimensions (W x H x D) m