Page 1

OTS60SX

Semi Automatic Oil Test Set

User Guide

Guide de l’utilisateur

M

Gebrauchsanleitung

Guía del usuario

Page 2

Contents Guide de l’utilisateur - p14 Gebrauchsanleitung - s24 Guía del usuario - p34

Safety Warnings 3

General Description 4

Preparing the Oil Test Set 5

Operation 5

Oil Sampling 5

Preparing the Oil Test Vessel 5

Control Panel 6

Breakdown Testing 6

Withstand Testing 6

Warning messages 7

Testing to National Standards 7

Sampling and Testing Oil for Dielectric strength 8

Oil Testing Specifications 10

Test Set Specification 10

Accessories 12

Repair and Warranty 13

2.

Page 3

SAFETY WARNINGS

• Safety warnings and precautions must be read and understood before the instrument is used.

must be observed during use.

They

• The oil test set must be properly earthed.

• The test chamber must be kept scrupulously clean.

• If the test chamber cover is cracked or damaged in any way the test set must not be used, but sent

for repair to an authorised agent.

• The chamber door hinges are fitted with earth contact springs. These must not be damaged or

corroded.

• The correct type of oil test vessel must be used, and correctly positioned on the support horns

before carrying out any testing.

• Replacement fuses must be of the correct type and rating.

THE TEST SET MUST ONLY BE USED BY SUITABLY TRAINED AND COMPETENT PERSONS.

NOTE

Symbols used on the Test Set

Caution: Refer to accompanying notes.

Risk of electric shock.

Equipment complies with relevant EU Directives

3.

Page 4

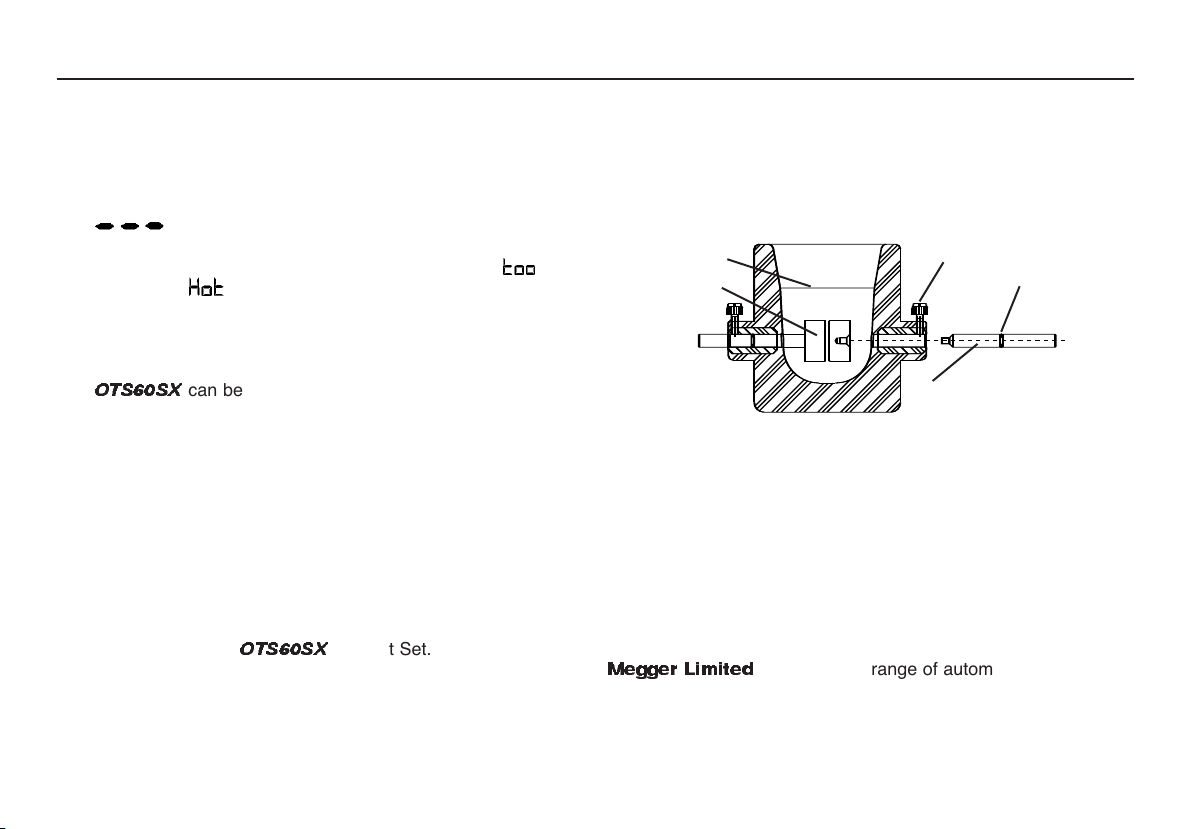

General Description

The OTS60SX is a lightweight, semi-automatic, oil dielectric

strength test set. The instrument is suitable for protected field

use and can be powered from a range of mains supplies. The

maximum 60 kV output allows tests to be performed on oil from

a wide variety of electrical installations including transformers,

circuit breakers and other equipment. The operation of the test

set is extremely simple and the results are displayed on a bright

LED display. A selection of vessels enables the instrument to be

configured for a variety of tests.

The semi automatic operation allows all types of testing to be

performed. An automatic one minute timer operates when the

high voltage is paused for Withstand (proof) testing. Oil samples

can also be tested according to breakdown specification by using

a suitable sequence of tests.

The instrument is constructed in a strong, sheet steel case.

Handles are provided for ease of transportation. A pouch is

located on the side of the instrument to contain accessories such

as the power cord, additional electrodes and the spacing gauge.

An optional carrying case incorporates a shoulder strap.

A number of vessels are available suitable for testing to a wide

range of national specifications. Three types of electrode are

available; spherical (IEC type), mushroom (VDE/ASTM D1816)

and cylindrical (ASTM D877). The oil sample can be stirred by a

motor driven impeller available in selected vessels. The vessel is

located in the top of the instrument and covered by a transparent

polycarbonate door with a mesh screen so that the oil breakdown

can be viewed. A safety interlock ensures that the high voltage is

disconnected when the chamber door is opened.

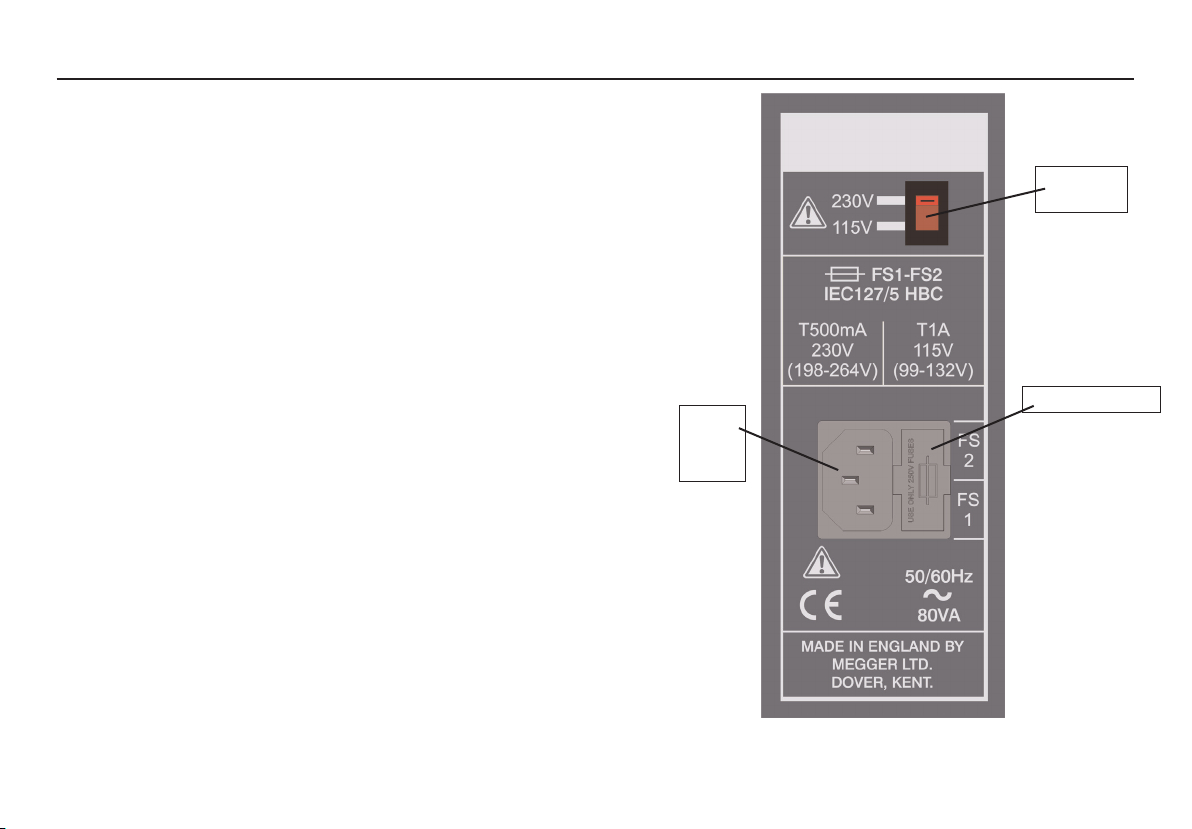

Voltage

Selector

Fuseholders

Mains

power

input

Mains Input Panel

4.

Page 5

Preparing the Oil Test Set

Operation

Ensure that the instrument is properly earthed. The test set must

be connected to a socket (receptacle) with a protective earth

(ground) conductor.

Before connecting the instrument to the mains power supply,

ensure the voltage selector located on the mains input panel is

set to the required voltage. The correct fuse value should be

fitted for the supply voltage (See

holders are located next to the supply inlet.

Power cord

If the power cord plug is not suitable for your type of socket

outlets, do not use an adaptor. You should use a suitable

alternative power cord, or if necessary change the plug by cutting

the cord and fitting a suitable plug.

The colour code of the cord is:

Earth (Ground) Yellow / Green

Neutral Blue

Phase (Line) Brown

If using a fused plug, a 3 Amp fuse to BS 1362 should be fitted.

Note: A plug severed from the power cord should be destroyed,

as a plug with bare conductors is hazardous in a live socket

outlet.

Specification). The fuse

Oil Sampling

The relevant test specification will give advice on the best

methods to use when sampling oil. Contamination of the oil may

lead to misleading results. Always run off a small amount of oil

before sampling and ensure that the flow of oil is steady.

Preparing the Oil Test Vessel

Optional vessels are available for testing to national

specifications (See table and Accessories). Some

specifications require stirring of the oil sample as well as different

test electrode shapes. Once the correct vessel has been chosen

for the required test the electrode gap should be set. This is

achieved by adjusting the threaded nut on the side of the vessel.

Small adjustment of the gap can be made by hand tightening the

nuts and rotating the spindle. A slot is provided on the end of the

spindle for this purpose.

A set of individual 0,5mm feeler gauges is provided for accurate

measurement of the gap. Gauges can be combined to measure

from 1mm to 4mm. (see page 12)

Clean the vessel in accordance with the instructions given in the

relevant test specification. Allowing space for the lid to be fitted,

fill the vessel with the oil sample. The amount of oil required will

depend upon the type of lid used. Load the vessel in the test

chamber, connecting the motor power cable, if fitted, and

carefully shut the door so that the safety interlock switch

operates.

5

Page 6

Main

controls

HV on

indicator

Control Panel

LED

Display

Ramp rate

selection

Mains

on/off

switch

Control Panel

The control panel contains the supply on/off switch, the high

voltage display, voltage ramp rate selection and the three control

keys. The operation of the instrument is very simple. When the

instrument is turned on, the on/off switch is illuminated, and the

software edition code will be flashed up on the display.

Breakdown Testing

The suitable ramp rate for the test to be performed should be

selected using the ‘s' key. The START key ‘ ‘ will then turn on

the high voltage. The red H.V. indicator will light to show the

output voltage is on. The voltage will then increase at the

selected ramp rate and the corresponding value will be shown on

the display. If oil breakdown occurs the instrument will detect this

and immediately shut off the high voltage. The breakdown

voltage value will be left on the display until the next test is

started. If no breakdown occurs, the high voltage will rise to

60 kV. At this point the test voltage is cut off and this maximum

value left on the display.

A test can be stopped at any time by pressing the

button. This will remove the high voltage from the oil sample and

leave the display at

Withstand Testing

A Withstand (proof) test can be carried out by pressing the

PAUSE ‘ ‘ key. This will maintain the high voltage at the current

value for one minute. After this time the high voltage will continue

to rise until one of the following:-

1) Oil breakdown occurs

2) The STOP ‘

0,0 kV.

key is pressed

n'

s

STOP ‘

n’

6.

Page 7

3) The output voltage reaches the maximum value of the test set.

During withstand testing the ramp rate can be changed while the

pause is in progress. This can allow the withstand test value to be

accurately set by adjusting the ramp rate to the lowest value.

Warning Messages

Door Open

If the instrument overheats, the words ‘ ‘ and

‘ ‘ will be alternately displayed and the

operation disabled. This will reset automatically,

when cooled, after a few minutes.

Dismantling the vessel

1. Loosen both white locking screws.

2. Hold each electrode in turn, and unscrew, and remove the

sliding arm from each electrode.

3. Remove both electrodes from the vessel.

4. Wash hands, and clean and dry the vessel as specified in

ASTM D.877.

Fill level

Electrode

Locking

screw

Viton

(Oil resistant)

‘O’ Ring

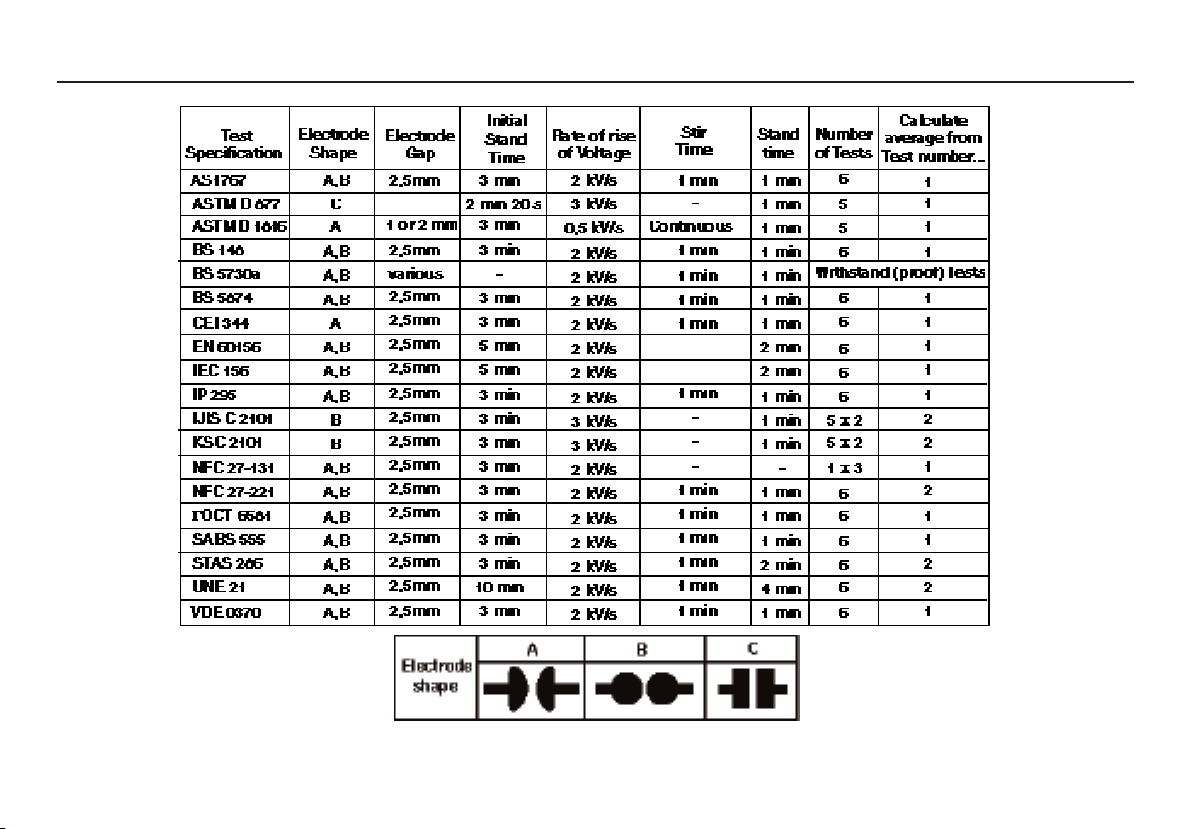

Testing to National Standards

The

OTS60SX

can be used to test to any international standard.

A table of the standards is given on page 10. To perform these

tests it is necessary to select the correct vessel so that the

specified electrodes and suitable stirring are used. Most standards

require repetitive breakdown tests to be carried out and the

average taken. Note that sometimes the first breakdown result is

omitted from the average calculation. If continuous stirring is not

required the stirrer motor supply can be disconnected when

appropriate by opening the chamber door.

100 ml Oil Test Vessel

The D877 Low Volume Test Vessel is an optional accessory for

use with the Megger®

OTS60SX

Oil Test Set.

The test vessel must be kept scrupulously clean. Before each

use, dismantle the test vessel, clean and dry, re-assemble, and

set the electrode gap to 2,54 mm (0.100 inch).

Sliding arm

Re-assembling the vessel

1. With clean, uncontaminated hands, place the cleaned

electrodes in the vessel.

2. Position each electrode in turn with the fingers, and screw

in a sliding arm through the vessel into the each electrode

in turn.

3. Centre the electrodes, and set the gap, using the

appropriate gauge.

4. Ensuring that the Viton ‘O’ rings are not fouled, hand tighten

both locking screws.

Megger Limited

also supply a range of automatic oil test sets.

These have the parameters of a wide range of specifications

programmed into the instrument for unattended operation.

7

Page 8

Sampling and Testing Oil for Dielectric Strength

The following notes should be read in conjunction with the relevant

oil testing specifications.

Causes of Bad Oil

Transformers and switchgear oil may be rendered unsuitable for

further use due to four main reasons:-

1. Low dielectric strength.

2. High acidity.

3. High sludge content.

4. Excessive free water content.

Low dielectric strength may result from many causes, the most

common of which is foreign particles or fibres and water in

combination. Individually their effect may be relatively small, but

together a contamination of only a few parts in a million can cause

considerable lowering of the breakdown voltage of the oil. High

acidity, sludge and free water should not be tolerated, but will not

necessarily reduce the dielectric strength below acceptable or

specified levels.

Appearance of the Sample

Only an experienced person can judge the condition of an

insulating oil from its appearance, but a general guide may be

obtained from the following observations:-

1. A cloudy appearance may indicate that sludge has

been formed.

2. A dark yellow colour could be a sign of overheating.

3. A blackish colour often results from an arc having taken

place with either carbonisation of the oil or of the

insulation within the equipment.

4. A green colour may be due to copper salts dissolving

in the oil.

Cleanliness of the Apparatus

The necessity for scrupulous cleanliness in the apparatus and

during the process of sampling, cannot be over emphasised. The

measurement of the dielectric strength of the sample is as

dependent on the cleanliness of the test cell and the sampling

apparatus as the condition of the oil itself.

After cleaning the apparatus, it should under no circumstances be

wiped, dried or even handled with a dusty or fibrous cloth as loose

dust or fibres are liable to cause contamination.

Precautions Necessary During Sampling

Since the oil taken from a drain cock will inevitably contain an

excess of settled out solid impurities, and will not necessarily be

representative of the bulk of the oil, it should be run to waste until

clear.

Always run off a quantity of oil into a glass bottle or a test tube for

an initial check on the appearance of the oil. Attention to this point

may prevent contamination of a clean test vessel.

If necessary, thoroughly clean and dry the sample point using a

suitable solvent. Any cloth used should be lint free. Open the

sample cock and drain to waste enough oil to ensure that the

sample cock is fully flushed and the sample is representative of

the bulk of oil to be tested. This quantity will depend upon the size

of the transformer or main container. About 2 litres is usually

suitable.

When sampling from a drum or supply container, the oil should

flow at a steady rate into the test vessel and after being swilled

around the sides it should be discarded. Without altering the rate

of flow of the oil the quantity required for the test should then be

8

Page 9

run off while taking extreme care to prevent the ingress of

atmospheric dust, cloth fibres or moisture.

Do not use a syphon. In the absence of a useable sample point,

use a ‘thief’.

Shield the sample from direct light until ready to be tested.

Turbulence and air bubbles should be avoided when pouring the

oil. Relevant national specifications should be observed.

Particular care to prevent contamination is necessary when a

test is to be made on a bulk delivery tanker, and on all occasions

when a high value of dielectric strength is anticipated. The

procedure suggested above should be rigorously applied.

9

Page 10

Oil Testing Specifications

2.54mm

Continuous/None

Continuous/None

10

Page 11

Specification

Output voltage 0 - 60 kV rms

Test Frequency 61,8 Hz

Transformer rating 500 VA

Output disconnection Within 1 ms of detection of breakdown

Power supply 115 V (99 - 132 V), 230 V (198 - 264 V) (switch selectable) 50/60 Hz, 80 VA

Fuses 500 mA (T) HBC to IEC127/5 for 220/240 V supply

1 A (T) HRC to IEC127/5 for 110/120 V supply

Mains power cord fused plug (when applicable): 3 Amp to BS1362

Operation Semi automatic with 0,5, 2 or 3 kV/s selectable rate of voltage rise

Pause function with automatic 1 minute timer for Withstand testing

Display 0,0 - 60,0 kV LED digital display

HV on LED

Ramp rate LED

Measurement Accuracy 2% ± 3 digits

Controls Start, Pause, Stop, Ramp Rate select and Power On/Off switch

Safety The instrument meets the requirements of IEC 61010-1

EMC In accordance with IEC 61326-1

Operational uncertainties Refer to www.megger.com

Temperature Range Operating: 0 to 40 ºC

Humidity Range Operating: 80% RH at 40 ºC

Dimensions 336 mm (13,2 in) (H) x 400 mm (5,7 in) (L) x 235 mm (9,3 in) (D)

Weight 17,5 kg (38,5 lb)

Cleaning Wipe disconnected test set with a clean cloth dampened with soapy water or Isopropyl Alcohol (IPA)

Storage: -40 to +70 ºC

Storage: 93% RH at 40 ºC, 95% RH at 25 ºC

11

Page 12

Accessories

Supplied with Instrument Part Number

User Guide 6172-120

Spacing Gauge (0,5, 1,0, 1,5, 2,0, 2,5, 2,54 & 4mm) 6132-009

Accessory Pouch 6320-232

Fuses:

2 x 500 mA (T) for 230 V supply

(fitted to the instrument) 25950-014

2 x 1 A (T) for 115 V supply 25950-004

Mains lead (fit your own plug) 25424-860

Mains lead with US plug 25970-002

Optional Accessories

Carrying Case 6420-106

Test Vessels

0,5 l for IEC156 (spherical electrodes) 6320-233

0,5 l for IEC156 with stirrer (spherical electrodes) 6320-236

0,5 l for VDE0370 (mushroom electrodes) 6320-234

0,5 l for ASTM D1816 with stirrer

(mushroom electrodes) 6320-237

0.15 litre vessel with cylindrical electrodes

for ASTMD 877 6111-356

Spare electrodes for 0.5 L vessels Part Number

Spherical (12,7 mm, 0,5 in. dia.) 6220-484

Mushroom (36 mm dia.) 6220-580

Cylindrical (25,4 mm, 1 in. dia.) 6220-483

Cylindrical with 0,5 mm edge radius 6220-538

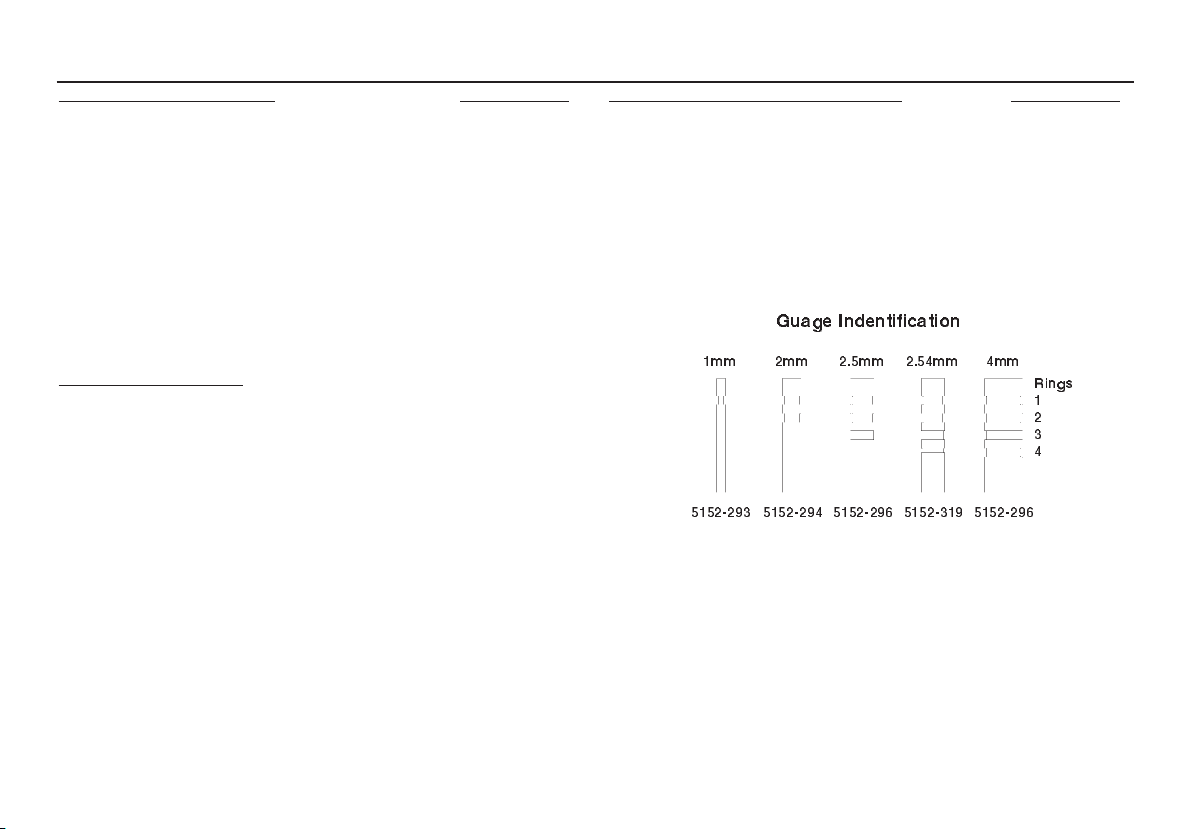

Guage Indentification

1mm 2mm 2.5mm 2.54mm 4mm

Rings

1

2

3

4

5152-293 5152-294 5152-296 5152-319 5152-296

12

Page 13

Repair and Warranty

The instrument circuit contains static sensitive devices, and care

must be taken in handling the printed circuit board. If the

protection of an instrument has been impaired it should not be

used, and be sent for repair by suitably trained and qualified

personnel. The protection is likely to be impaired if, for example,

the instrument shows visible damage, fails to perform the

intended measurements, has been subjected to prolonged

storage under unfavourable conditions, or has been exposed to

severe transport stresses.

New Instruments are Guaranteed for 1 Year from the Date of

Purchase by the User.

Any unauthorized prior repair or adjustment will

Note:

automatically invalidate the Warranty.

Instrument Repair and Spare Parts

For service requirements for Megger Instruments contact:

Megger LImited or Megger

Archcliffe Road Valley Forge Corporate Center

Dover 2621 Van Buren Avenue

Kent, CT17 9EN. Norristown, PA 19403

England. U.S.A.

Tel: +44 (0) 1304 502243 Tel: +1 (610) 676-8579

Fax: +44 (0) 1304 207342 Fax: +1 (610) 676-8625

Approved Repair Companies

A number of independent instrument repair companies have been

approved for repair work on most Megger

instruments, using genuine Megger spare parts. Consult the

Appointed Distributor / Agent regarding spare parts, repair

facilities and advice on the best course of action to take.

Returning an Instrument for Repair

If returning an instrument to the manufacturer for repair, it should

be sent freight pre -paid to the appropriate address. Acopy of the

Invoice and of the packing note should be sent

simultaneously by airmail to expedite clearance through

Customs. A repair estimate showing freight return and other

charges will be submitted to the sender, if required, before work

on the instrument commences.

or an approved repair company.

13

Page 14

Contenu User Guide - p2 Gebrauchsanleitung - s24 Guía del usuario - p34

Avertissments relatifs a la securité 15

Description générale

Préparation du boîtier d'essai d'huile 17

Fonctionnement 17

Echantillonnage d'huile 17

Préparation du récipient d'huile 17

Panneau de commande 18

Essai de claquage 18

Essai de résistance (Epreuve) 18

Témoins d’affichage 19

Essais selon les normes nationales 19

Echantillonnage et essai de résistance

diélectrique des huiles 20

Spécifications essai des huiles 22

Réparation et Garantie 23

16

14

Page 15

GAVERTISSEMENTS RELATIFS A LA SECURITE

• Les avertissements et précautions concernant la sécurité doivent être lus et compris avant de commencer

à utiliser l'instrument. Ils doivent être observés pendant l'emploi.

• Le boîtier d'essai d'huile doit être correctement mis à la masse.

• La chambre d'essai doit être conservée scrupuleusement propre.

• Le boîtier d'essai ne doit pas être utilisé si le couvercle de la chambre d'essai est fissuré ou endommagé

d'une manière quelconque, auquel cas il doit être renvoyé à un agent autorisé pour réparation.

• Les charnières de la porte de la chambre sont équipées de ressorts de mise à la masse. Ces ressorts ne

doivent pas être endommagés ou rouillés.

• Le type correct de récipient d'essai d'huile doit être utilisé, et positionné correctement sur les guignols de

support

• Les fusibles de remplacement doivent être du type et de la puissance corrects.

avant d'effectuer un essai quelconque.

REMARQUE

CONFIEZ L’UTILISATION DE CET INSTRUMENT A UN PERSONNEL QUALIFIE ET COMPETENT.

Symboles utilisés sur cet instrument:

G Attention: Consultez les notes jointes.

F Risque de choc électrique

c Cet équipement respecte les directives en viguer de l’UE

15

Page 16

Description générale

Le modèle OTS60SX est un boîtier d'essai de résistance

diélectrique des huiles, léger et semi-automatique. L'instrument

convient à un usage en service protégé et peut être alimenté à partir

de toute une gamme de tensions secteur. La puissance de sortie

maximale de 60 kV permet d'effectuer des mesures sur des huiles de

diverses installations électriques, y compris les transformateurs, les

disjoncteurs et autres équipements. L'exploitation du boîtier d'essai

est extrêmement simple, et les résultats sont affichés sur un

affichage clair à LED. Une sélection de récipients permet de

configurer l'instrument pour une variété d'essais.

Le fonctionnement semi-automatique permet la réalisation de tous

les types d'essais. Une minuterie automatique d'une minute se

déclenche lorsque la haute tension est mise en pause pour les essais

d'épreuve (résistance). Des échantillons d'huile peuvent aussi être

testés selon des spécifications de claquage en employant une

séquence appropriée d'essais.

L'instrument est monté dans un boîtier robuste en tôle d'acier, muni

de poignées pour faciliter le transport. Une pochette est prévue sur le

côté de l'instrument pour le rangement des accessoires tels que le

cordon d'alimentation, des électrodes supplémentaires et la jauge

d'espacement. Une valise de transport avec bandoulière est

disponible en option.

Des récipients convenant aux essais d'une gamme étendue de

spécifications nationales sont disponibles. Trois types d'électrodes

sont disponibles: sphérique (type IEC), à champignon (VDE/ASTM

D1816) et cylindrique (ASTM D877). Dans certains récipients,

l'échantillon d'huile peut être agité par une turbine motorisée. Le

récipient est situé en haut de l'instrument et est couvert par une porte

en polycarbonate transparent munie d'un grillage de manière à ce

que le claquage de l'huile puisse être constaté. Une sécurité assure

la coupure de la haute tension lorsque la porte de la chambre est

ouverte.

16

Selecteur

de tension

Fusibles

Connecteur

de ligne

CEI

Panneau de alimentation secteur

Page 17

Préparation du boîtier d'essai d'huile

Vérifier que l'instrument est correctement mis à la masse. Le

boîtier d'essai doit être branché dans une prise femelle ayant un

conducteur de mise à la masse (terre).

Avant de brancher l'instrument sur le secteur, vérifier que le

sélecteur de tension, situé sur le panneau d'entrée

d'alimentation, est bien réglé à la tension requise. En outre, un

fusible de valeur adaptée à la tension d'alimentation (voir

spécifications) doit être installé. Les porte-fusibles sont situés à

côté de l'entrée de l'alimentation.

Cordon électrique de recharge de batterie

Si la prise de ce cordon ne peut pas s'enficher dans l'une de

vos prises murales, vous ne devez pas utiliser d'adaptateur.

Vous devez employer un cordon électrique de type approprié

ou, le cas échéant, retirer la prise du cordon en tranchant ce

dernier avant d'y fixer une prise de type approprié.

Ce cordon respecte le code de couleurs suivant:

Terre (masse) jaune/vert

Neutre bleu

Sous tension marron

Si vous utilisez une prise protégée par un fusible, vérifiez qu'il

s'agit d'un fusible de 3 A conforme à la norme BS 1362.

Remarque: après avoir retiré du cordon la prise électrique en

la tranchant, mettez cette dernière au rebut car une prise

comportant des conducteurs dénudés présente un danger en

cas de branchement sur une prise murale sous tension.

Fonctionnement

Echantillonnage d'huile

La spécification d'essai appropriée fournira des conseils quant

aux meilleures méthodes à employer pour le prélèvement d'un

échantillon d'huile. La contamination de l'huile peut conduire à

des résultats erronés. Laisser toujours couler une petite quantité

d'huile avant de prélever l'échantillon et veiller à ce que

l'écoulement d'huile soit constant.

Préparation du récipient d'huile

Divers récipients optionnels sont disponibles pour les essais

selon les spécifications nationales (voir tableau et ‘Accessoires‘).

Certaines spécifications exigent l'agitation de l'huile ainsi que

différentes formes d'électrodes. Lorsque le récipient correct est

choisi pour l'essai requis, l'écartement des électrodes doit être

ajusté. Ce réglage est effectué à l'aide de l'écrou fileté sur le côté

du récipient. Un jeu de jauges d’espacement, de 0,5 mm

chacune, est fourni pour la verification de l’ecartement des

electrodes. Les jauges permettent de mesurer un ecartement

entre 1 mm et 4mm.

Nettoyer le récipient conformément aux instructions fournies

dans les spécifications d'essai concernées. Tout en prévoyant un

espace pour l'installation du couvercle, verser l'échantillon

d'huile dans le récipient. La quantité d'huile requise sera fonction

du type de couvercle utilisé. Placer le récipient dans la chambre

d'essai, en branchant, le cas échéant, le câble du moteur, et

fermer soigneusement la porte de manière à actionner

l'interrupteur de sécurité.

17

Page 18

Fonctionnement (suite)

Commandes

principales

Voyant HT

en service

Panneau de commande

Affichage

LED

Sélection

de taux

d’augmentation

de tension

Interrupteur

Sous/Hors

tension

Panneau de commande

Le panneau de commande comporte l'interrupteur de mise

sous/hors tension, l'affichage haute tension, un sélecteur de taux

d'augmentation de tension et trois touches de commande.

L'exploitation de l'instrument est extrêmement simple. Lorsque

l'instrument est sous tension, l'interrupteur marche/arrêt s'allume

et le code de version du logiciel clignote sur l'affichage.

Essai de claquage

Le taux d'augmentation de tension approprié à l'essai à exécuter

doit être sélectionné en utilisant la touche 's'. La touche marche

s

' ' appliquera la haute tension. Le voyant rouge HT s'allumera

pour indiquer que la haute tension est appliquée. La tension

augmentera alors au taux sélectionné, et la valeur

correspondante sera affichée. L'instrument détecte le claquage

de l'huile et coupe immédiatement la haute tension. La valeur de

la tension de claquage reste affichée sur l'instrument jusqu'au

début de l'essai suivant. Si le claquage ne se produit pas, la

haute tension monte jusqu'à

est coupée et cette valeur maximum reste affichée.

Un essai peut être interrompu à tout moment en appuyant sur la

touche STOP ‘

tension à l'échantillon d'huile, et l'affichage revient à 0,0 kV.

Essai de résistance (Epreuve)

Un essai de résistance (Epreuve) peut être effectué en appuyant

sur la touche de

tension à la valeur courante pendant une minute, après quoi la

haute tension continuera à augmenter jusqu'à ce que :

1) l'huile claque

. Cette touche coupe l'application de la haute

n'

PAUSE ‘ ‘. Cette action maintient la haute

60 kV. En ce point, la haute tension

18

Page 19

2) le bouton STOP ‘n‘ (Arrêt) est pressé

3) la tension de sortie atteint la valeur maximum du boîtier

d'essai.

Pendant l'essai de résistance, le taux d'augmentation peut être

modifié pendant la pause. Ceci permet de régler avec précision

la valeur d'essai de résistance en ajustant le taux

d'augmentation à sa valeur la plus basse.

Témoins d’affichage

Porte ouverte

Essais selon les normes nationales

L'appareil

selon n'importe quelle norme internationale. Les normes sont

indiquées au tableau de la page 22. L'exécution de ces essais

exige la sélection du récipient correct de manière à ce que les

électrodes spécifiées et l'agitation appropriée puissent être

utilisées. La majorité des normes spécifient des essais de

claquage répétitifs, puis le calcul de la moyenne. Il convient de

noter que parfois le premier résultat de claquage est omis du

calcul. Si une agitation continue est requise, l'alimentation du

moteur de l'agitateur peut être déconnectée en ouvrant la porte

de la chambre.

OTS60SX

peut être utilisé pour effectuer des essais

En cas de surchauffe de l'instrument, les mots

' ' (trop) et ' ' (chaud) sont affichés alter-

nativement et l'opération est abandonnée.

L'instrument se remet à zéro automatiquement

une fois qu'il s'est refroidi après quelques minutes.

Megger Limited

boîtiers d'essai automatiques. Les paramètres d'une gamme

étendue de spécifications sont programmés dans l'appareil pour

assurer le fonctionnement automatique.

fournit également toute une gamme de

19

Page 20

Echantillonnage et essai de résistance diélectrique des huiles

Ces notes doivent être lues conjointement aux spécifications

d’essai d’huile appropriées.

Causes des mauvaises huiles

L’huile de transformateur et d’appareillage de commutation peut

être devenir inutilisable à cause de quatre raisons :

1. Faible résistance diélectrique

2. Forte acidité

3. Haute teneur en boues

4. Teneur excessive en eau libre

La faible résistance diélectrique a de nombreuses causes, la plus

courante étant la présence de particules étrangères ou d’une

combinaison de fibres et d’eau. Individuellement, leurs effets

peuvent être relativement faibles, mais ensemble une

contamination de quelques parties par million peut causer une

réduction considérable de la tension de claquage de l’huile. Une

forte acidité, les boues et l’eau libre ne doivent pas être tolérées,

mais ne réduiront pas la résistance diélectrique en dessous des

niveaux acceptables ou spécifiés.

Aspect de l’échantillon

Seule une personne compétente peut juger l’état d’une huile

d’isolement à partir de son aspect, mais une indication générale

peut être déduite des observations suivantes :

1. Un aspect nuageux peut indiquer la formation de boues.

2. Une couleur jaune sombre peut indiquer un échauffement

excessif.

3. Une couleur noirâtre est souvent le résultat d’un arc avec soit

carbonisation de l’huile ou de l’isolement à l’intérieur du

matériel.

4. Une teinte verdâtre peut être causée par la dissolution

desels de cuivre dans l’huile.

Propreté des appareils

La nécessité d’une propreté scrupuleuse des appareils et pendant

l’échantillonnage ne peut pas être suffisamment soulignée. La

mesure de la résistance diélectrique de l’échantillon dépend tout

aussi bien de la propreté de la cellule d’essai que de l’état même

de l’huile.

Une fois nettoyé, l’appareil ne doit jamais être essuyé, séché ou

même manipulé avec un chiffon poussiéreux ou fibreux étant

donné que les poussières ou les fibres libres peuvent causer une

contamination.

Précautions à prendre pendant l’échantillonnage

Etant donné que l’huile prélevée à partir d’un robinet de

prélèvement contiendra inévitablement une forte teneur

d’impuretés solides décantées, et ne sera pas nécessairement

représentative de la masse de l’huile, il convient de laisser couler

l’huile dans un bac de déchet jusqu’à ce qu’elle soit claire.

Laisser toujours couler une certaine quantité d’huile dans une

bouteille en verre ou dans une éprouvette pour effectuer une

inspection initiale de l’aspect de l’huile. Cette observation peut

éviter la contamination d’un récipient d’essai propre.

Si nécessaire, nettoyer et sécher le point d’échantillonnage en

utilisant un solvant approprié. Tout chiffon utilisé doit être du type

non pelucheux. Ouvrir le robinet de prélèvement et laisser couler

l’huile pour s’assurer que le robinet est totalement rincé et que

l’échantillon est représentatif de la masse d’huile à tester. Cette

quantité est fonction de la taille du transformateur ou du récipient

principal. En règle générale, 2 litres suffisent.

20

Page 21

Pour le prélèvement dans un fût ou dans un réservoir

d’alimentation, l’huile doit couler à un débit uniforme dans le

récipient d’essai, puis répandue sur les parois du récipient et jetée.

Sans modifier le débit, prélever ensuite la quantité d’huile requise

pour l’essai tout en prenant soin de pas laisser entrer de poussière

atmosphérique, de fibres de chiffon ou d’humidité. Ne pas utiliser

de siphon. En l’absence d’un point de prélèvement adéquat,

utiliser une louche.

Protéger l’échantillon de la lumière directe jusqu’à ce qu’il soit

testé.

Eviter toute turbulence ou bulles d’air lors du versement de l’huile.

Observer les spécifications nationales appropriées.

21

Page 22

Spécifications essai des huiles

2.54mm

continue/aucun

continue/aucun

22

Page 23

Réparation et Garantie

Les circuits de boîtier d'essai contiennent des éléments sensibles

à l’electricite statique et il y a lieu de prendre des précautions en

manipulant la carte de circuits imprimes. Si la protection d’un

instrument s’est trouvee affectée de quelque maniére il ne doit

pas être utilisé et doit être expeedié pour réparation par du

personnel convenablement formé et qualifié. La protection de

l’appareil peut s’être trouvée endommagée si par exemple

l’instrument apparaît visiblement abîmee, ne donne pas les

performances attendues, s’est trouvé entreposé de façon

prolongée dans des conditions défavorables ou a été exposé a

des contraintes extrêmes durant son transport.

Les nouveaux instruments sont garantis pendant une

période d’un an à partir de la date de leur achat par

l’utilisateur.

Note:

Toute réparation ou tout réglage préalable non autorisé

invalidera automatiquement la garantie.

Réparation d’instruments et pièces de rechange

Pour le service des instruments Megger®prendre contact soit:

avec ou

Megger Limited Megger

Archcliffe Road Z.A. Du Buisson de la Couldre

Dover 23 rue Eugène Henaff

Kent CT17 9EN 78190 TRAPPES

Angleterre France

Tél: +44 (0) 1304 502234 Tél: +33 (1) 30.16.08.90

Télécopie: +44 (0) 1304 207342 Télécopie: +33 (1) 34.61.23.77

ou avec une societe d’entretien agréée.

Societés d’entretien agréées

Un certain nombre de sociétés indépendantes de reparation

d’instruments ont êté agréées pour faire des opérations de

réparation sur la plupart des produits Megger utilisant des pièces

d’origine Megger

.

Consultez le distributeur désigné / agent officiel

concernant la fourniture de pièces de rechange, les installations

de réparation et pour être conseillé concernant les meilleures

mesures à prendre.

Renvoi D’un Instrument Pour le faire Réparer

Si un boîtier d'essai est réexpédiê au fabricant pour être reparé il

doit être envoyé port payé a l’adresse appropriée. Un exemplaire

de la facture et la note d’envoi doivent être envoyé par avion au

même moment afin de hâter les formalités de douane. Un devis

estimé des réparations indiquant les frais de réexpedition et

autres frais sera si nécessaire adressé a l’expéditeur avant que

les opérations de réparation ne soient enterprises.

23

Page 24

Inhalt User Guide - p2 Guide de l’utilisateur - 14 Guía del usuario - p34

Sicherheitshinweise 25

Allgemeine Beschreibung 26

Ölprüfgerät vorbereiten 27

Betrieb 27

Entnahme von Ölproben 27

Vorbereitung des Ölprüfbehälters 27

Steuertafel 28

Prüfung der Durchschlagsspannung 28

Überlastprüfung 28

Meldungen auf der Anzeige 29

Prüfungen nach nationalen Standards 29

Entnahme von Ölproben und Prüfung der

Durchschlagsfestigkeit des Öls 30

Öltest-Normen 32

Reparaturen und Garantie 33

Auf dem Gerät verwendete Symbole

In Bedienungsanleitung nachsehen

Elektroschockgefahr

Gerät entspricht den gegenwärtigen

Richtlinien der EU

24

Page 25

SICHERHEITSHINWEISE

• Die Sicherheitshinweise und Warnungen müssen vor Gebrauch des Instruments gelesen und

verstanden und beim Gebrauch beachtet werden.

• Das Ölprüfgerät muß ordnungsgemäß geerdet werden.

• Die Prüfkammer muß absolut sauber gehalten werden.

• Wenn die Abdeckung der Prüfkammer in irgendeiner Weise gerissen oder beschädigt ist, darf das

Prüfgerät nicht verwendet, sondern

muß zur Reparatur an eine autorisierte Vertretung gesendet

werden.

• Die Angeln der Kammertür sind mit Erdkontaktfedern ausgestattet, die nicht beschädigt oder

korrodiert sein dürfen.

• Es muß die richtige Art von Prüfbehälter verwendet und richtig auf den Trägerhörnern aufgestellt

werden, bevor eine Prüfung durchgeführt wird.

• Beim Austausch von Sicherungen muß die richtige Klasse und Sorte verwendet werden.

DAS INSTRUMENT DARF NUR VON ENTSPRECHEND AUSGEBILDETEN UND KOMPETETEN PERSONEN VERVENDET WERDEN.

HINWEIS

25

Page 26

Allgemeine Beschreibung

Das OTS60SX ist ein leichtes halbautomatisches Gerät zum

Prüfen der Durchschlagfestigkeit von Öl. Das Instrument ist für

geschützte praxisnahe Versuche geeignet und läßt sich an

verschiedene Stromquellen anschließen. Der Ausgang von

maximal 60 kV ermöglicht Ölprüfungen für eine große Anzahl

elektrischer Anlagen wie Transformatoren, Schutzschalter und

anderer Ausrüstung. Das Prüfgerät ist extrem einfach zu

bedienen. Die Prüfergebnisse werden auf einer hellen LEDAnzeige dargestellt. Mit Hilfe verschiedener Behälter läßt sich

das Gerät für eine Vielzahl von Prüfungen konfigurieren.

Durch den halbautomatischen Betrieb können alle Arten von

Tests durchgeführt werden. Wenn die Hochspannung für eine

Stehstoß- oder Überlastprüfung unterbrochen wird, aktiviert sich

nach einer Minute ein automatischer Zeitschalter. Durch eine

geeignete Prüfsequenz lassen sich Ölproben außerdem auf die

jeweils vorgegebene Durchschlagspannung prüfen.

Das Instrument ist in einem Gehäuse aus solidem Stahlblech

untergebracht. Zum leichteren Transport sind Griffe angebracht.

Zubehör wie das Netzkabel, zusätzliche Elektroden und der

Abstandsmesser können in einem Beutel an der Seite des

Gerätes verstaut werden. Auf Wunsch ist außerdem ein

Tragekoffer mit Schulterriemen erhältlich.

Um eine große Zahl verschiedener Prüfungen nach den

jeweiligen Vorgaben eines Landes zu ermöglichen, ist eine

Vielzahl geeigneter Behälter erhältlich. Es können drei Arten von

Elektroden geliefert werden: kugelförmig (nach IEC), halbrund

(VDE/ASTM D1816) und zylinderförmig (ASTM D877). Die

Ölprobe kann von einem motorgetriebenen Propeller umgerührt

werden, der für bestimmte Behälter erhältlich ist. Das Gefäß

selber befindet sich in der Oberseite des Instruments und wird

von einer durchsichtigen Tür aus Polycarbonat mit Drahtschirm

abgedeckt, durch die der Durchschlag beobachtet werden kann.

Beim Öffnen der Tür wird die Hochspannung durch einen

Sicherheitsschalter unterbrochen.

Netzspannungs-

eingang

Spannungs-

regler

Sicherungshalter

Haupteingangstafel

26

Page 27

Ölprüfgerät vorbereiten

Betrieb

Auf ordnungsgemäße Erdung des Gerätes achten. Das

Prüfgerät muß an eine Steckdose (Buchse) mit Schutzerdung

(Masse) angeschlossen werden.

Vor dem Anschluß des Instruments an den Netzstrom

Spannungsregler der Haupteingangstafel auf die gewünschte

Stromspannung stellen. Sicherstellen, daß die richtige Sicherung

für die jeweilige Netzspannung verwendet wird (siehe

Technische Daten). Die Sicherungshalterungen befinden sich

neben dem Netzeingang.

Netzanschlußkabel für Batterieladung

Bitte benutzen Sie keinen Adapter, wenn der Stecker des

Netzanschlußkabels nicht für ihre Steckdose geeignet ist.

Der Farbcode des Kabels ist:

Erde (Masse) Gelb/Grün

Nulleiter Blau

Außenleiter Braun

Bitte verwenden Sie eine 3-Ampere-Sicherung für Stecker mit

Sicherung.

Bitte beachten Sie: Ein Stecker sollte zerstört werden, wenn

er vom Stromkabel abgetrennt ist, da ein Stecker mit blanken

Leitern in einer stromführenden Steckdose gefährlich ist.

Entnahme von Ölproben

In den Spezifikationen zu den jeweiligen Prüfungen sind

Hinweise über die besten Methoden zur Ölprobenentnahme

enthalten. Durch verunreinigtes Öl können die Ergebnisse

verfälscht werden. Vor der Probenentnahme muß das Öl daher

stets einen Moment lang laufen gelassen werden. Außerdem ist

auf einen gleichmäßigen Ölfluß zu achten.

Vorbereitung des Ölprüfbehälters

Für Prüfungen nach den jeweiligen nationalen Vorgaben sind als

Zubehör geeignete Behälter erhältlich (siehe Tabelle und

Zubehör). Bei einigen Vorgaben ist ein Umrühren des Öls oder

ein Einsatz von Prüfelektroden in verschiedenen Formen

erforderlich. Nach der Auswahl des richtigen Behälters für die

Prüfung muß der Elektrodenabstand eingestellt werden, indem

die Gewindemutter an der Seite des Behälters gedreht wird.

Zur genauen Messung des Abstands wird ein Satz

verschiedener Fühllehren von 0,5 mm mitgeliefert, die zur

Messung von Abständen zwischen 1 und 2,5 mm miteinander

kombiniert werden können.

Der Behälter muß unter Beachtung der Anleitung zur jeweiligen

Prüfung gereinigt werden. Öl in Behälter einfüllen und darauf

achten, daß genug Platz für den Deckel verbleibt. Wieviel Öl

benötigt wird, hängt von der Art des verwendeten Deckels ab.

Behälter in Prüfkammer setzen, Stromkabel des Motors (wenn

vorhanden) anschließen und Tür vorsichtig schließen, bis sich

der Sicherheitsschalter einschaltet.

27

Page 28

Hauptregler

Hochspannungs-

anzeige

LED Anzeige

Wähler der linearen

Spannungssteilheit

Netzschalter

Steuertafel

Auf der Steuertafel befinden sich der Netzschalter, die

Hochspannungsanzeige, der Wähler der linearen

Spannungssteilheit und die drei Kontrolltasten. Das Instrument

ist äußerst einfach zu bedienen. Bei eingeschaltetem Gerät ist

der Netzschalter erleuchtet. Beim Einschalten des

OTS60SX

blinkt auf der Anzeige die Nummer der Softwareversion.

Prüfung der Durchschlagsspannung

Die für den Test geeignete lineare Spannungssteilheit wird über

die Taste ‘▲‘ gewählt. Über die Starttaste ‘ ‘ wird die

▲

Hochspannung anschließend eingeschaltet. Durch die

aufleuchtende rote Hochspannungsanzeige wird signalisiert,

daß die Ausgangsspannung eingeschaltet ist. Die Spannung

steigt dann mit der gewählten Steilheit, während der jeweilige

Wert auf der Anzeige dargestellt wird. Wenn der Durchschlag

des Öls auftritt, wird er vom Instrument registriert, das daraufhin

die Hochspannung sofort abschaltet. Die ermittelte

Durchschlagspannung wird auf dem Bildschirm angezeigt, bis

mit dem nächsten Test begonnen wird. Wenn kein Durchschlag

auftritt, steigt die Hochspannung bis auf

60 kV, woraufhin die

Prüfspannung abgeschaltet und dieser Maximalwert auf der

Anzeige dargestellt wird.

Durch Drücken der Taste ’

’ kannn die Überprüfung jederzeit

■

abgebrochen werden. In einem solchen Fall wird die

Hochspannung aus der Ölprobe entfernt, und die Anzeige zeigt

0,0 kV.

28

Steuertafel

Überlastprüfung

Eine Stehstoß- oder Überlastprüfung wird durch Drücken der

Page 29

Pausetaste ‘ ‘in Gang gesetzt. Die zu diesem Zeitpunkt

erreichte Spannung bleibt eine Minute lang bestehen.

Anschließend steigt die Hochspannung an, bis einer der

folgenden Fälle eintritt:-

1) Durchschlagspannung des Öls wird erreicht

2) Stoptaste wird gedrückt

3) Die Ausgangsspannung erreicht den Maximalwert des

Gerätes.

Bei der Überlastprüfung läßt sich die lineare Spannungssteilheit

verändern, solange die Pause andauert. Auf diese Weise läßt

sich der Wert der Überlastprüfung durch Wählen der niedrigsten

linearen Spannungssteilheit genau ermitteln.

Meldungen auf der Anzeige

Tür offen

Bei überhitztem Instrument erscheinen auf der

Anzeige abwechselnd die Wörter ‘ ‘ und ‘ ‘

und der Betrieb wird unterbrochen. Wenn das

Gerät nach einigen Minuten abgekühlt ist, endet

dieser Zustand automatisch.

Prüfungen nach nationalen Standards

Mit dem OTS60SX kann nach allen internationalen Standards

geprüft werden. Eine Tabelle der Standards befindet sich auf

Seite 32. Für diese Prüfungen müssen die richtigen Behälter

ausgewählt werden, um einen Einsatz der passenden

Elektroden und Rührvorrichtungen zu ermöglichen. Bei den

meisten Standards werden wiederholte Durchschlagsprüfungen

verlangt, aus denen anschließend der Mittelwert errechnet wird.

Der erste ermittelte Durchschlagswert wird allerdings zuweilen

nicht zur Berechnung herangezogen. Wenn kein kontinuierliches Rühren erforderlich ist, läßt sich die Stromversorgung

des Rührmotors auf Wunsch durch Öffnen der Kammertür

unterbrechen.

Megger Limited bietet außerdem eine Auswahl automatischer

Ölprüfsätze an, die mit den Parametern zahlreicher

Spezifikationen programmiert sind und einen unbeaufsichtigten

Betrieb erlauben.

29

Page 30

EEnnttnnaahhmmee vvoonn ÖÖllpprroobbeenn uunndd PPrrüüffuunngg ddeerr DDuurrcchhsscchhllaaggssffeessttiiggkkeeiitt ddeess ÖÖlls

s

Die folgenden Hinweise richten sich in erster Linie an Bediener,

die mit der Materie noch nicht vollkommen vertraut sind, und

sollten zusammen mit den entsprechenden technischen Daten

zur Ölprüfung gelesen werden.

Unbrauchbares Öl und seine Ursachen

Es gibt vier hauptsächliche Ursachen, aus denen das Öl von

Transformatoren und Schaltvorrichtungen unbrauchbar werden

kann

1. Geringe Durchschlagsfestigkeit

2. Hoher Säuregehalt

3. Hoher Schlammgehalt

4. Zuviel nichtgebundenes Wasser

Eine geringe Durchschlagsfestigkeit kann auf verschiedene

Ursachen zurückzuführen sein, von denen Fremdkörper oder

Fasern in Verbindung mit Wasser am häufigsten auftreten. Für

sich alleine genommen wirken sie sich nur geringfügig aus;

zusammengenommen jedoch können sie bereits bei einer

Verunreinigung von wenigen Teilchen pro Millionen zu einer

beachtlichen Verringerung der Durchschlagsspannung des Öls

führen. Ein hoher Säure- oder Schlammgehalt des Öls sollte

ebensowenig toleriert werden wie nichtgebundenes Wasser;

diese Merkmale verringern jedoch die Durchschlagsfestigkeit

nicht zwangsläufig unter einen akzeptablen oder

vorgeschriebenen Stand.

Aussehen der Probe

Nur erfahrene Bediener können vom Aussehen eines Isolieröls

auf dessen Zustand schließen. Als generelle Anhaltspunkte

können jedoch die folgenden Richtlinien dienen:

1. Ein trübes Aussehen läßt auf Schlammbildung schließen.

2. Eine dunkelgelbe Färbung kann auf Überhitzungzurückzuführen sein.

3. Eine schwärzliche Färbung wird oft dadurch verursacht,

daß sich ein Lichtbogen gebildet hat und entweder das Öl

oder die Isolierung des Gerätes karbonisiert ist.

4. Eine grüne Färbung weist auf im Öl gelöste Kupfersalze

hin.

Sauberkeit des Instruments

Es kann nicht genug betont werden, wie wichtig es ist, beim

Betrieb des Geräts und während der Probenentnahme auf

peinlichste Sauberkeit zu achten. Welche Durchschlagsfestigkeit

bei der Probe gemessen wird, hängt genauso von der Sauberkeit

der Prüfzelle und des Probengeräts wie vom Zustand des Öls

selber ab.

Das Gerät darf nach der Reinigung auf keinen Fall mit einem

staubigen oder fusseligen Tuch abgewischt, getrocknet oder

auch nur angefaßt werden, da loser Staub oder Fusseln leicht zu

Verunreinigungen führen.

Vorsichtsmaßnahmen bei der Probenentnahme

Wenn das Öl über einen Ablaßhahn gewonnen wird, enthält es

30

Page 31

unweigerlich zu viele abgelagerte Verunreinigungen und ist u. U.

für das übrige Öl nicht repräsentativ. Das Öl sollte daher so

lange abfließen, bis es klar wird.

Beim Ausgießen des Öls sind Erschütterungen oder Luftblasen

zu vermeiden und die jeweiligen nationalen Bestimmungen

einzuhalten.

Für eine erste Überprüfung des Aussehens sollte ein Teil des Öls

stets in einer Glasflasche oder einem Reagenzglas aufgefangen

werden. Auf diese Weise wird eine unnötige Verunreinigung

sauberer Prüfgefäße vermieden.

Wenn nötig, muß die Prüfspitze mit einem geeigneten

Bei einer Probenentnahme aus Lieferungen von Tankfahrzeugen

und bei allen anderen Gelegenheiten, bei denen eine hohe

Durchschlagsfestigkeit zu erwarten ist, muß mit besonderer

Sorgfalt vorgegangen und das oben beschriebene Verfahren

genau eingehalten werden.

Lösungsmittel gereinigt und anschließend mit einem fusselfreien

Tuch getrocknet werden. Ablaßhahn öffnen und soviel Öl

ablaufen lassen, daß der Hahn vollständig gespült wird und die

Probe für das übrige Öl repräsentativ ist. Wieviel Öl abgelassen

werden muß, hängt von der Größe des Transformators oder

Hauptbehälters ab. In der Regel sind etwa 2 Liter ausreichend.

Bei der Entnahme von Proben von einem Faß oder

Versorgungsbehälter sollte das Öl mit gleichmäßiger

Geschwindigkeit in das Prüfgefäß fließen. Anschließend wird das

Öl um die Seiten des Gefäßes geschwenkt und fortgeschüttet.

Ohne Veränderung der Fließgeschwindgkeit wird dann die für die

Prüfung erforderliche Menge entnommen, wobei das Eindringen

von Staub, Tuchfasern oder Feuchtigkeit unbedingt zu vermeiden

sind. Siebe dürfen nicht verwendet werden. Wenn kein

geeignetes Probenstück vorhanden ist, kann ein Pegelstab

benutzt werden.

Die Probe muß bis zur Prüfung lichtgeschützt aufbewahrt

werden.

31

Page 32

Öltest-Normen

Test

Spezifikation

AS1767 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

ASTM D877 C 2,54 mm 2 min 20 s 3 kV/s - 1 min 5 1

ASTM D 1816 A 1 or 2 mm 3 min 0,5 kV/s Kontinuität 1 min 5 1

BS 148 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

BS 5730a A,B Verschiedene - 2 kV/s 1 min 1 min

BS 5874 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

CEI 344 A 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

EN 60156 A,B 2,5 mm 3 min 2 kV/s

IEC 156 A,B 2,5 mm 3 min 2 kV/s

IP 295 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

IJIS C 2101 B 2,5 mm 3 min 3 kV/s - 1 min 5 x 2 2

KSC 2101 B 2,5 mm 3 min 3 kV/s - - 5 x 2 2

NFC 27-131 A,B 2,5 mm 3 min 2 kV/s - - 1 x 3 1

NFC 27-221 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 2

„OCT

SABS 555 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

STAS 286 A,B 2,5 mm 3 min 2 kV/s 1 min 2 min 6 2

UNE 21 A,B 2,5 mm 10 min 2 kV/s 1 min 4 min 6 2

VDE 0370 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

Elektroden

form

A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

Elektroden-

abstand

Anfangsstandzeit

Ansteigsrate

der

Prüfspannung

Rührzeit Standzeit

Kontinuität/Keine

Kontinuität/Keine

Anzahl

der Tests

2 min 6 1

2 min 6 1

Errechne Mittelwert

aus Test Nummer.....

Durchschlagsprüfung

32

Page 33

Reparaturen und Garantie

Das Instrument enthält statisch empfindliche Bauteile, weshalb

die gedruckte Schaltung sorgfältig behandelt werden muß. Falls

die Schutzvorrichtungen eines Instruments beschädigt worden

sind, sollte es nicht verwendet, sondern an eine geeignete

Reparaturwerkstatt geschickt werden. Die Schutzvorrichtungen

sind wahrscheinlich beschädigt, wenn folgende Bedingungen

vorliegen: sichtbare Beschädigung, fehlende Anzeige der

erwarteten Meßergebnisse; längere Lagerung unter widrigen

Bedingungen oder starke Transportbelastung.

NEUE INSTRUMENTE UNTERLIEGEN EINER

GARANTIE VON 1 JAHR AB DEM DATUM DES

KAUFS DURCH DEN BENUTZER.

Hinweis:

Einstellung führt automatisch zum Erlöschen der Garantie.

Reparaturarbeiten und Ersatzteile

Wenden Sie sich zwecks Wartungsarbeiten an Megger®-

lnstrumenten entweder an:

Megger Limited oder an Megger

Archcliffe Road Valley Forge Corporate Center

Dover 2621 Van Buren Avenue

Kent CT17 9EN Norristown, PA 19403

England USA

Tel: +44(0)1304 502100 Tel: +1 (610) 676-8579

Fax: +44(0)1304 207342 Fax: +1 (610) 676-8625

Jede nicht zuvor genehmigte Reparatur oder

Autorisierte Reparaturfirmen

Eine Reihe von Firmen sind für die Reparatur der meisten

Megger

Ersatzteilen autorisiert. Wenden Sie sich wegen Ersatzteilen,

Reparaturwerkstatten und Beratung über die jeweils

bestgeeigneten Maßnahmen an eine autorisierte Auslieferung

bzw. Vertretung.

Einsenden Eines Instruments Zur Reparatur

Wenn ein Instrument zwecks Reparatur zurück geschickt

werden muß, sollte es mit vorbezahiter Fracht an die

angebrachte Anschrift gesandt werden. Gleichzeitig sollte zur

Erledigung der britischen Zollformalitäten per Luftpost eine

Kopie der Rechnung zusammen mit dem Packzettel eingesandt

werden. Auf Wunsch wird dem Absender vor Ausführung

irgendwelcher Arbeiten am Instrument ein Kostenvoranschlag

unter Berücksichtigung der Frachtkosten und anderer

Gebühren zugesandt.

- lnstrumente unter Verwendung von Original Megger-

oder an eine autorisierte Reparaturfirma.

33

Page 34

Contenido User Guide - p2 Guide de l’utilisateur - p14 Gebrauchsanleitung - s24

Advertencias de Seguridad 35

Descripción general 36

Preparación del aparato de pruebade Aceite 37

Operación 37

Muestreo de aceite 37

Preparación del recipiente de prueba de aceite 37

Panel de control 38

Prueba de descomposición 38

Mensajes visualizados 39

Especificaciones por la Prueba de Aceites 42

Prueba de conformidad con las normas nacionales 39

Reparacione y Garantia 43

34

Page 35

GADVERTENCIAS DE SEGURIDAD

• Las precauciones y advertencias de seguridad deben leerse y comprenderse antes de utilizar el instrumento.

• El aparato de prueba debe estar conectado a tierra correctamente.

• La cámara de prueba debe mantenerse escrupulosamente limpia.

• Si la tapa de la cámara está agrietada o dañada de cualquier manera no debe usarse el aparato de prueba sino

que deben enviarse para su reparación a un agente autorizado.

• Las bisagras de la puerta de la cámara incorporan muelles de contacto a tierra. Estos muelles no deben dañarse

ni oxidarse.

• Debe usarse el tipo correcto de recipiente de prueba de aceite, el cual debe colocarse en los salientes de soporte

antes de llevar a cabo cualquier prueba.

• Los fusibles de repuesto deben ser del tipo y régimen correctos.

NOTA

EL INSTRUMENTO SOLO SERA UTILIZADO POR PERSONAS CAPACITADAS Y COMPETENTES.

Símbolos usados en el instrumento

G Referirse a la Guía del usuario

F Riesgo de sacudida eléctrica

c El equipo está conforme con las directrices actuales de la UE

35

Page 36

Descripción general

El OTS60SX es un instrumento para la prueba de resistencia

dieléctrica, semiautomático y de peso liviano. El instrumento es

apropiado para uso en campo protegido y puede ser impulsado a

través de una gama de suministros de la red. La salida máxima de

60 kV permite realizar pruebas en aceite procedente de una

amplia variedad de instalaciones eléctricas, incluidos transformadores, disyuntores y equipos parecidos. El funcionamiento del

aparato es sumamente sencillo y los resultados son presentados

en un brillante display por LED. Una selección de recipientes

permite configurar el instrumento para una variedad de pruebas.

El funcionamiento semiautomático del instrumento permite

realizar todos los tipos de pruebas. Un temporizador de un minuto

automático funciona cuando se interrumpe el voltaje alto para la

prueba de resistencia. Las muestras de aceite también pueden

probarse de acuerdo con la especificación de descomposición

utilizando una secuencia de pruebas adecuada. El instrumento

está construido dentro de una recia caja de chapa de acero. El

aparato incorpora asas para facilitar su transporte. Se incluye una

bolsa en el lateral del instrumento para alojar accesorios tales

como el cable eléctrico, electrodos adicionales y el calibre

espaciador. Una caja de transporte opcional incluye un tirante

para colgar sobre el hombro. Hay disponible cierto de recipientes

para realizar pruebas de acuerdo con una amplia variedad de

especificaciones nacionales. Se incluyen tres tipos de electrodos:

esférico (tipo IEC), en forma de seta (VDE/ASTM D1816) y

cilíndrico (ASTM D877). La muestra de aceite puede agitarse con

una hélice impulsada por motor disponible en recipientes

seleccionados. El recipiente se coloca en la parte superior del

instrumento y se cubre mediante una puerta de policarbonato

transparente con pantalla de malla, de modo que puede

observarse la descomposición del aceite. Un dispositivo de

enclavamiento asegura que el alto voltaje sea desconectado

cuando se abre la puerta de la cámara.

Conector de

Alimentation

Selector

de

Voltage

Porto

fusibles

Panel de entrada de la red

36

Page 37

Preparación del aparato de pruebade Aceite

Asegure que el instrumento esté correctamente conectado a

tierra. El aparato de prueba debe conectarse a una toma

(receptáculo) con un conductor de protección a tierra (masa).

Antes de conectar el instrumento al suministro de la red, asegure

que el selector de voltaje situado en el panel de entrada de la red

esté situado en el voltaje requerido. También deberá instalarse

el fusible del régimen correcto para el voltaje de suministro (vea

especificaciones). Los portafusibles están situados

las

adyacentes a la entrada del suministro.

Cable de alimentación

Si el cable de alimentación no es compatible con la toma

eléctrica, no use ningún adaptador. Emplee un cable de

alimentación adecuado, o si es necesario, cambie el enchufe

cortando el cable e instalando uno idóneo.

El código de los colores del cable es el siguiente:

Tierra Amarillo/Verde

Neutro Azul

Fase Marrón

Si el enchufe tiene un fusible integrado, utilice uno que sea de 3

Amp y que cumpla con la norma BS 1362.

Nota: deseche el enchufe cortado del cable ya que su uso puede

ser peligroso.

Operación

Muestreo de aceite

Las especificaciones de prueba pertinentes aportarán consejos

sobre los mejores métodos que deben utilizarse para el

muestreo de aceite. La contaminación del aceite puede conducir

a resultados engañosos. Deje escapar siempre una pequeña

cantidad de aceite antes de muestrear y asegure que el aceite

fluye de manera uniforme.

Preparación del recipiente de prueba de aceite

Hay recipientes opcionales para probar de acuerdo con las

especificaciones nacionales (vea la tabla y accesorios). Ciertas

especificaciones requieren el agitado de la muestra de aceite así

como diferentes formas de electrodos de prueba. Una ves

seleccionado el recipiente correcto para la prueba requerida

deberá establecerse el entrehierro del electrodo, lo cual se logra

ajustando la tuerca roscada situada en el costado del recipiente.

Se incluye un juego de galgas palpadoras individuales de 0,5mm

para la medición precisa del entrehierro. Las galgas pueden

combinarse para medir de 1 a 2,5mm.

Limpie el recipiente de acuerdo con las instrucciones incluidas

en las especificaciones pertinentes. Dejando espacio para

colocar la tapa, llene el recipiente con la muestra de aceite. La

cantidad de aceite requerida dependerá del tipo de tapa

utilizada. Ponga el recipiente en la cámara de prueba,

conectando el cable eléctrico del motor, si se incluye, y cierre

con cuidado la puerta, de modo que funcione el interruptor de

enclavamiento de seguridad.

37

Page 38

Controles

principales

Indicador

de alto

voltaje

Panel de control

Display

LED

Selector de

promedio de

rampa

Interruptor de

conexión/

desconexión de la

red

Panel de control

El panel de control contiene el interruptor de conexión /

desconexión de suministro, display de alto voltaje, selector de

promedio de rampa de voltaje y las tres teclas de control. El

funcionamiento del instrumento es muy sencillo. Cuando se

conmuta el instrumento el código de la edición del software

parpadeará en el display et se enciende el interruptor de

conexión/desconexión.

Prueba de descomposición

El promedio de rampa apropiado para la prueba a realizar

deberá seleccionarse usando la tecla ‘

▲

inicio ` ' conmutará entonces el alto voltaje. El indicador de alto

▲' START. La tecla de

voltaje rojo se encenderá para indicar que está conmutado el

voltaje de salida. El voltaje incrementará entonces al promedio

de rampa seleccionado y el valor correspondiente será

mostrado en el display. Si se produce descomposición del

aceite el instrumento detectará esto e inmediatamente cortará

el alto voltaje. El valor del voltaje de descomposición

permanecerá en el display hasta que se pone en marcha la

prueba siguiente. Si no se produce descomposición alguna, el

alto voltaje ascenderá a

60 kV. En este momento se corta el

voltaje de prueba y su valor máximo permanece en el display.

La prueba se podrá detener en cualquier momento pulsando el

botón

STOP ‘

■

. Con esto se retirará el alto voltaje de la

’

muestra de aceite y el display mostrará 0,0 kV.

Prueba de resistencia

Podrá efectuarse una prueba de resistencia pulsando la tecla

de pausa ` '. Con esto se mantendrá el valor corriente durante

un minuto. Después de transcurrir este tiempo, el alto voltaje

continuará ascendiendo hasta que ocurre uno de los eventos

siguientes:

38

Page 39

1) Se descompone el aceite.

2) Se pulsa el botón de parada.

3) El voltaje de salida alcanza el máximo valor del aparato

de pruebas.

Durante la prueba de resistencia el promedio de rampa puede

cambiarse mientras está en curso la pausa. Esto puede permitir

establecer precisamente el valor de prueba de resistencia

ajustando el promedio de rampa al valor más bajo.

Mensajes visualizados

Puerta abierta

Si el instrumento se calienta excesivamente,

las palabras ‘ ‘(demasiado) y ` '

(caliente) serán visualizadas de manera alterna

alternativamente y la operación será desactivada.

Una vez frío, el instrumento se reposicionará

automáticamente, después de unos minutos.

Prueba de conformidad con las normas nacionales

El OTS60SX puede utilizarse para hacer pruebas de

conformidad con cualquier norma nacional. En la página 42 se

incluye una tabla de las normas. Para realizar estas pruebas es

necesario seleccionar el recipiente correcto de modo que

puedan usarse los electrodos especificados y un agitado

adecuado. La mayoría de las normas requieren que sean

llevadas a cabo pruebas de descomposición repetidas y que

sean tomados los promedios. Nótese que algunas veces el

primer resultado de descomposición es omitido del cálculo

medio. Si no se requiere agitado continuo, el suministro al motor

agitador podrá desconectarse cuando sea apropiado abriendo la

puerta de la cámara.

Recipiente de prueba de aceite Megger D877 de 100 ml

El recipiente de prueba de bajo volumen D877 es un accesorio

opcional para ser usado con el conjunto de prueba de aceite

®

semiautomático Megger

OTS60SX. El recipiente de prueba

debe ser limpiado concienzudamente. Antes de cada uso,

desmonte, limpie, seque y rearme el recipiente, ajustando la

separación del electrodo a 2,5 mm (0.100 pulgada).

Desarmado del recipiente

1. Afloje ambos tornillos de bloqueo blancos.

2. Sujete cada electrodo por turno, y desenrosque y retire el

brazo deslizante de cada electrodo.

3. Retire ambos electrodos del recipiente.

4. Lave las manos y luego limpie y seque el recipiente como

se especifica en ASTM D.877.

Rearmado del recipiente

1. Con las manos limpias y desprovistas de contaminación,

coloque los electrodos limpios en el recipiente.

2. Coloque cada electrodo por turno con los dedos, y rosque

un brazo deslizante a través del recipiente en cada

electrodo por turno.

3. Centre los electrodos y ajuste la separación, usando una

galga apropiada.

4. Asegurando que los aros tóricos de vitón no estén sucios,

apriete ambos tornillos de bloqueo.

Megger Limited ambién suministra una gama de aparatos de

prueba de aceite automáticos. Estos instrumentos tienen

programados los parámetros de una amplia gama de especificaciones para funcionamiento sin personal.

39

Page 40

Muestreo del aceite y prueba de su resistencia dieléctrica

Las notas deberán leerse en conjunción con las especificaciones de prueba de aceite pertinentes.

Causas de aceite defectuoso

El aceite usado en transformadores y equipos de

conmutación pueden acabar siendo inservibles a causa de

cuatro motivos principales:

1. Baja resistencia dieléctrica

2. Alto contenido de acidez

3. Alto contenido de fangos

4. Contenido excesivo de agua libre

La baja resistencia dieléctrica puede producirse por muchas

causas, siendo la más común partículas extrañas o fibras y agua

combinadas. Individualmente su efecto puede ser relativamente

pequeño, pero juntos una contaminación de solamente unas

pocas partes por millón puede causar una reducción considerable

del voltaje de ruptura del aceite. Alta acidez, fangos y agua libre

no deben ser tolerados, pero no reducirán necesariamente la

resistencia dieléctrica por debajo de unos niveles aceptables o

especificados.

Aspecto de la muestra

Solamente una persona con experiencia podrá juzgar por su

aspecto la condición de un aceite aislante, pero una guía general

podrá obtenerse a través de las siguientes observaciones:

1. Un aspecto nebuloso puede indicar que se ha formado

fango.

2. Un color amarillo apagado oscuro podría ser una señal de

calentamiento excesivo.

3. Un color negruzco con frecuencia es consecuencia de

haberse formado el arco concarbonización ya sea del

aceite o bien del aislamiento dentro del equipo.

4. Un color verde puede ser debido a la presencia de sales de

cobre disueltas en el aceite.

Limpieza del aparato

La necesidad de una limpieza escrupulosa del aparato y durante

el proceso de muestreo nunca podrá subrayarse demasiado. La

medición de la resistencia dieléctrica de la muestra depende de la

limpieza de la célula de prueba y del aparato de muestreo así

como de la condición del aceite propiamente dicho.

Después de limpiar el aparato, de ninguna manera deberá ser

frotado, secado ni incluso manejado con un trapofibroso o

polvoriento, ya que el polvo y las fibras sueltas pueden causar

contaminación.

Precauciones necesarias durante el muestreo

Como el aceite tomado de un grifo de vaciado inevitablemente

contiene un exceso de impurezas sólidas depositadas, y no será

representativo de la totalidad del aceite, éste deberá dejarse fluir

al desagüe hasta que sale transparente. Vaciar siempre cierta

cantidad de aceite en una probeta o botella de vidrio para verificar

inicialmente el aspecto del aceite. Si se observa este punto se

podrá prevenir la contaminación de un recipiente de prueba

limpio. Si es necesario, limpie y seque a fondo el punto de

muestra usando un disolvente adecuado. Todos los trapos

utilizados deberán estar carentes de hilazas. Abra el grifo de

muestreo y vacíe al desagüe suficiente aceite para asegurar que

40

Page 41

el grifo de muestreo quede completamente lavado y que la

muestra sea representativa de la totalidad del aceite que se desea

probar. Esta cantidad depende del tamaño del transformador o

recipiente principal. Normalmente se vacían unos 2 litros. Cuando

se muestrea el aceite contenido en un bidón o recipiente de

suministro, el aceite deberá fluir a un promedio uniforme dentro

del recipiente de prueba y una vez circulado alrededor de los

lados deberá ser desechado. Sin alterar el promedio de flujo del

aceite, la cantidad requerida para la prueba deberá recogerse

ahora teniendo cuidado extremado de prevenir el ingreso de polvo

atmosférico, fibras de trapo o humedad. No use un sifón. Si no hay

un punto de prueba utilizable, use un `ladrón'.

Proteja la muestra contra la luz directa hasta que vaya a probarse.

Cuando se vierte el aceite deberá impedirse la formación de

burbujas de aire y turbulencia. Deberán observarse las especificaciones nacionales pertinentes al caso.Es preciso tener cuidado

especial para evitar contaminación si la prueba ha de hacerse en

un camión cisterna de suministro a granel y en todos los casos

donde se espera alto nivel de resistencia dieléctrica. El

procedimiento sugerido arriba deberá ser observado

estrictamente.

41

Page 42

Especificaciones por la Prueba de Aceites

Prueba

Especificado

AS1767 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

ASTM D877 C 2,54 mm 2 min 20 s 3 kV/s - 1 min 5 1

ASTM D 1816 A 1 or 2 mm 3 min 0,5 kV/s Continuo 1 min 5 1

BS 148 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

BS 5730a A,B varie - 2 kV/s 1 min

BS 5874 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

CEI 344 A 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

EN 60156 A,B 2,5 mm 3 min 2 kV/s

IEC 156 A,B 2,5 mm 3 min 2 kV/s

IP 295 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

IJIS C 2101 B 2,5 mm 3 min 3 kV/s - 1 min 5 x 2 2

KSC 2101 B 2,5 mm 3 min 3 kV/s - - 5 x 2 2

NFC 27-131 A,B 2,5 mm 3 min 2 kV/s - - 1 x 3 1

NFC 27-221 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 2

„OCT

SABS 555 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

STAS 286 A,B 2,5 mm 3 min 2 kV/s 1 min 2 min 6 2

UNE 21 A,B 2,5 mm 10 min 2 kV/s 1 min 4 min 6 2

VDE 0370 A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

Forma de

Electrodo

Electro Interralo

A,B 2,5 mm 3 min 2 kV/s 1 min 1 min 6 1

Tiempo da la

Posicion Inicial

Velocidad de

subida del

voltaje

Tiempo de

movimiento

Continuo/no continco

Continuo/no continco

Teimpo de

parada

2 min 6 1

2 min 6 1

Numero

pruebas

Pruebas de resistancia

Calcuda la media de la

de

prueba numero....

42

Page 43

Reparacione y Garantia

El circuito del instrumento contiene dispositivos sensibles a la

electricidad estática y deberá tenerse cuidado cuando se maneje

el panel de circuito impreso. No deberá utilizarse ninguna

protección de un instrumento que haya sido dañada y deberá

enviarse para ser reparada por personal debidamente preparado

y capacitado. Se dañará la protección si, por ejemplo, el

instrumento muestra desperfectos visibles, no realiza las

mediciones esperadas, se ha visto sujeto a un almacenamiento

prolongado bajo condiciones desfavorables o ha estado

expuesto a presiones rigurosas de transporte.

Los instrumentos nuevos tienen una garantia de 1 año a

partir de la fecha de adquisicion del usuario.

Nota:

Cualquier ajuste o reparación no autorizada previamente

anulará automáticamente la garantía.

Reparación de Instrumentos y Piezas de Repuesto

Para un servicio de los instrumentos Megger®contacte por favor

con:

Megger Limited o Megger

Archcliffe Road, Valley Forge Corporate Center

Dover 2621 Van Buren Avenue

Kent CT17 9EN, Norristown, PA 19403

Inglaterra USA

o una compañia de reparaciones aprobada.

Companias de reparaciones aprobadas

Varias compañias independientes han sido aprobadas para

realizar trabajos de reparación de la mayoría de los instrumentos

Megger

Consulte con su Agente/Distribuidor con referencia a las pi ezas

de repuesto, facilidad es de reparación y asesoramiento sobre la

mejor línea de conducta a seguir.

Devolviendo un Instrumento Para Su Reparación

Si se devuelve un instrumento al fabricante para su reparación,

deberá enviarse a porte pagado a la dirección adecuada. Al

mismo tiempo, deberá adjuntarse una copia de la factura y de la

nota de envío, por correo aéreo, a fin de acelerar los trámites de

aduanas. Se enviará un presupuesto de reparación en el que

aparecerá la tarifa de flete de retorno y otros gastos, si procede,

antes de empezar el trabajo en el instrumento.

, utilizando auténticas piezas de repuesto Megger.

Tel.: +44 (0) 1304 502243 Tel.: +1 (610) 676-879

Fax: +44 (0) 1304 207342 Fax: +1 (610) 676-8625

43

Page 44

M

Megger Limited

Archcliffe Road Dover

Kent CT17 9EN ENGLAND

T +44 (0)1 304 502101

F +44 (0)1 304 207342

OTHER TECHNICAL SALES OFFICES

Toronto CANADA, Sydney AUSTRALIA, Madrid SPAIN, Mumbai INDIA, and the Kingdom of BAHRAIN.

Megger products are distributed in 146 countries worldwide.

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification or design without prior notice.

Megger is a registered trademark

Part No. 6172-120 V15 Printed in England 1108

www.megger.com

Megger

4271 Bronze Way, Dallas,

TX 75237-1019 USA

T +1 800 723 2861

T +1 214 333 3201

F +1 214 331 7399

Megger

Z.A. Du Buisson de la Couldre

23 rue Eugène Henaff

78190 TRAPPES France

T +33 (1) 30.16.08.90

F +33 (1) 34.61.23.77

Loading...

Loading...