Page 1

Guide to

low voltage

motor testing

99 Washington Street

Melrose, MA 02176

Phone 781-665-1

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

400

Page 2

Contents

Contents

Introduction 5

Motor types 6

DC Motor 6

DC Motor Types – Series; Shunt; Compound; Permanent Magnet 6

DC Motor Types - Series 7

DC Motor Types - Shunt 8

DC Motor Types - Compound 8

DC Motor Types - Permanent Magnet 9

Advantages of a DC motor 10

AC Motor 10

AC Motors Types 10

Star Configuration 11

Delta configuration 12

Star vs Delta configuration 12

Why perform Motor Tests? 13

What problems create the need for a test? 13

Testing and Diagnostics 14

Trending of test data 17

Megger Baker MTR105 – The Tests 18

Insulation resistance 19

Spot or Timed insulation resistance test 20

Polarisation Index (PI) 21

Dielectric Absorption Ratio (DAR) 22

Temperature correction 24

Guard Terminal 25

Three phase test 28

Voltmeter 28

Phase rotation 28

Continuity 28

Diode test 29

2 Guide to Motor testing

Page 3

Contents

Digital Low Resistance Ohmmeter (DLRO) 29

Motor Direction of Rotation test 30

Inductance 32

Capacitance 32

Temperature measurement 32

Megger Baker MTR105 Overview 33

Description 33

Features 33

Applications 34

Safety 34

Insulation resistance tests 34

Voltmeter 35

Continuity (Resistance) tests 35

DLRO Four wire Kelvin low resistance 35

Motor Direction of Rotation test 35

Inductance, Capacitance and Resistance meter (LCR) 36

Temperature 36

Display 36

Guard Terminal 36

Storage and download of results 36

Instrument software updates 36

Specifications 37

Guide to Motor testing 3

Page 4

Contents

This is the first in a series of information booklets that will support electrical testing in the

benchmarking, maintenance and repair of rotating machines. This guide uses the specific tests

of the Megger Baker MTR105 to demonstrate the importance and application of these tests for

low voltage machines rated up to 2300 volts, as described in IEEE Standards which are listed at

the end of this document.

4 Guide to Motor testing

Page 5

Introduction

Introduction

Electric motors are made up of a multitude of components that when combined and assembled

into a motor have to endure extreme electrical and mechanical operating stress as well as

varying environmental conditions during their service life. To prevent premature failure, regular

testing is necessary to ensure reliable operation and, importantly, to extend the motor’s service

life. Electrical testing usually consists of Insulation Resistance (Meg Ohm MΩ) tests and a Low

Resistance tests (Milli-Ohm mΩ). These tests are essential in determining the health of a motor,

however, not all faults or early detection of potential faults can be detected with these tests.

Performing a suite of different test types where each test provides a ‘piece of the puzzle’ helps

to build up to a clearer picture which is essential in determining the of the health of the electric

motor.

Guide to Motor testing 5

Page 6

Motor types

Motor types

There are two main types of motors “ac” and “dc”. A Direct Current (dc) motor has direct

current connected to the windings and rotor (armature) to produce rotation. An Alternating

Current (ac) motor has alternating current connected to the stator (stationary windings). In

both types this produces rotation on the rotor (armature) through a magnetic field.

DC Motor

DC Motor Types – Series; Shunt; Compound; Permanent Magnet

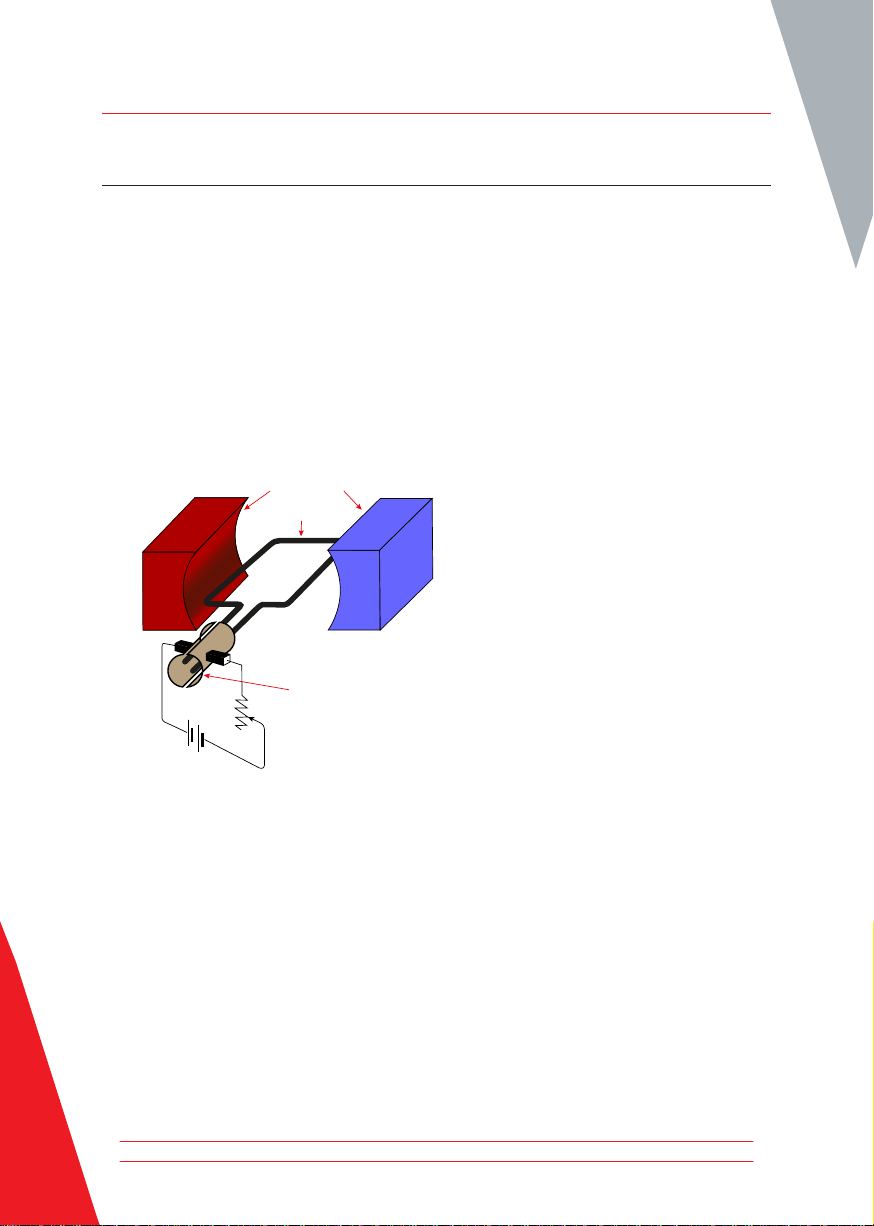

A simplified representation of a DC motor showing a single loop of the armature

Magnetic poles

Coil

N

Commutator

Fig 1: Simplified DC motor

6 Guide to Motor testing

S

Page 7

Motor types

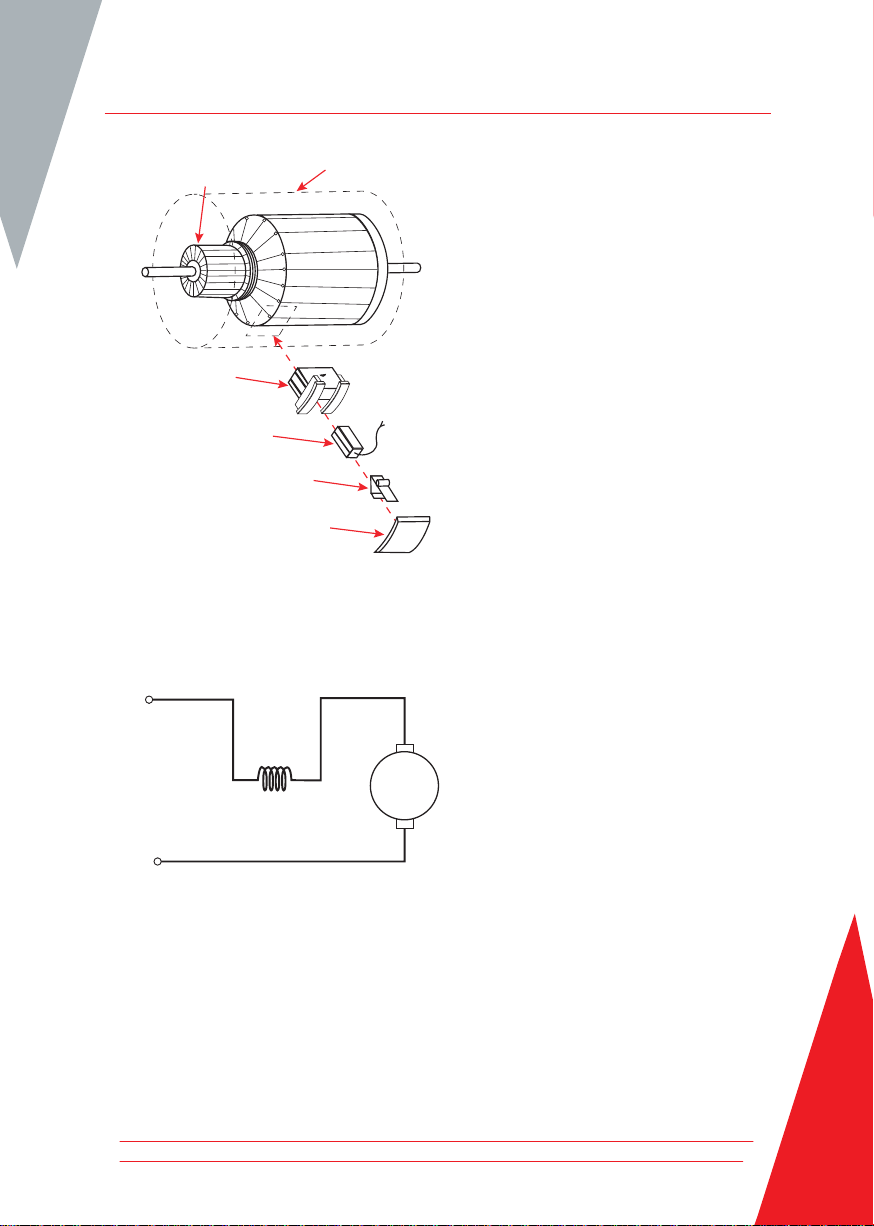

Commutator

Brush holder

Brush

Brush holder spring

Motor enclosure

Cover

Fig 2: A typical representation of a DC motor showing an exploded view of the

brush components and with multiple loops making up the armature.

DC Motor Types - Series

DC Supply

Field

Armature

Fig 3: Series excited DC motor

An electric motor powered by direct current where the field windings are connected in series

to the armature windings.

Guide to Motor testing 7

Page 8

Motor types

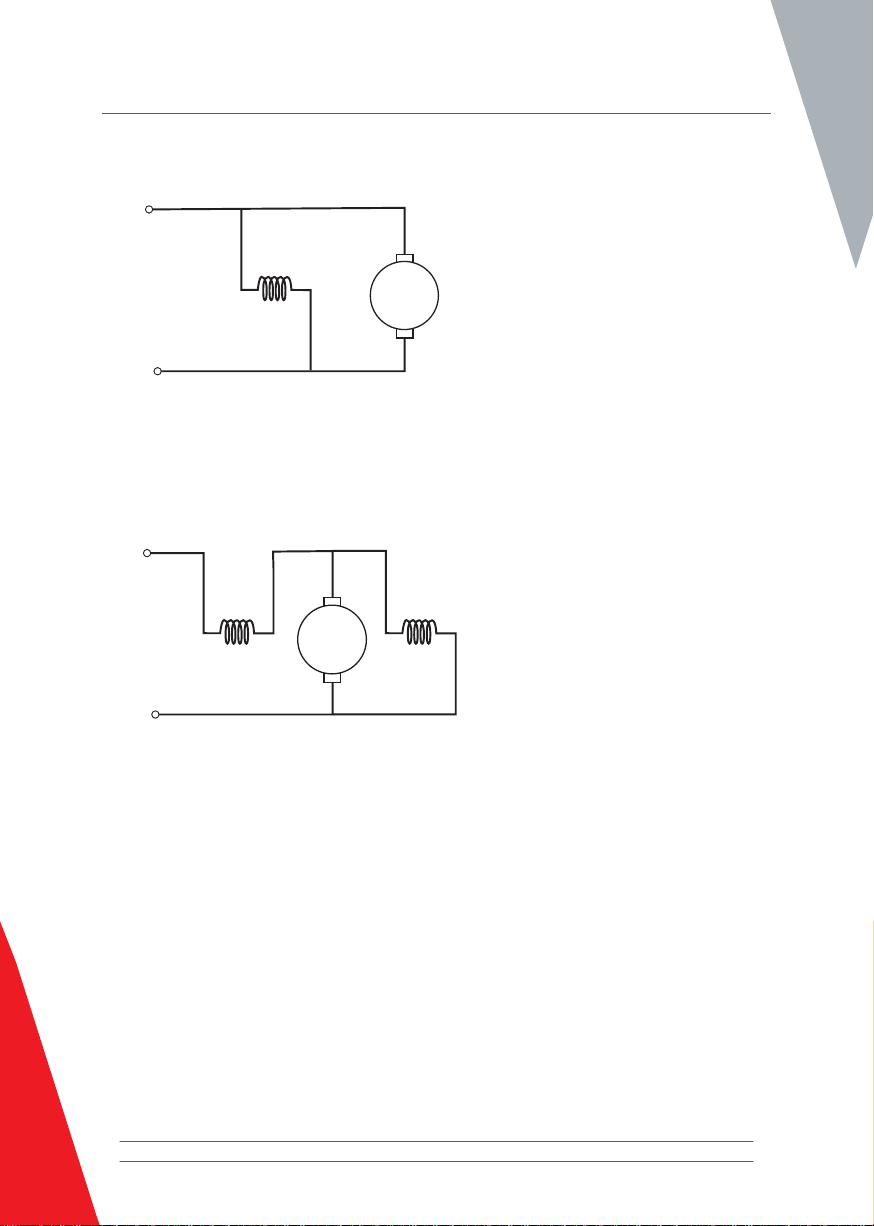

DC Motor Types - Shunt

DC Supply

Field

Armature

Fig 4: Shunt excited DC motor

An electric motor powered by direct current where the field windings are connected in parallel

to the armature windings. This allows both coils to be powered by the same source.

DC Motor Types - Compound

DC Supply

Field Field

Armature

Fig 5: Cumulatively compound excited DC motor

The dc compound motor is a combination of the series motor and the shunt motor. It has a

series field winding that is connected in series with the armature and a shunt field that is in

parallel with the armature

8 Guide to Motor testing

Page 9

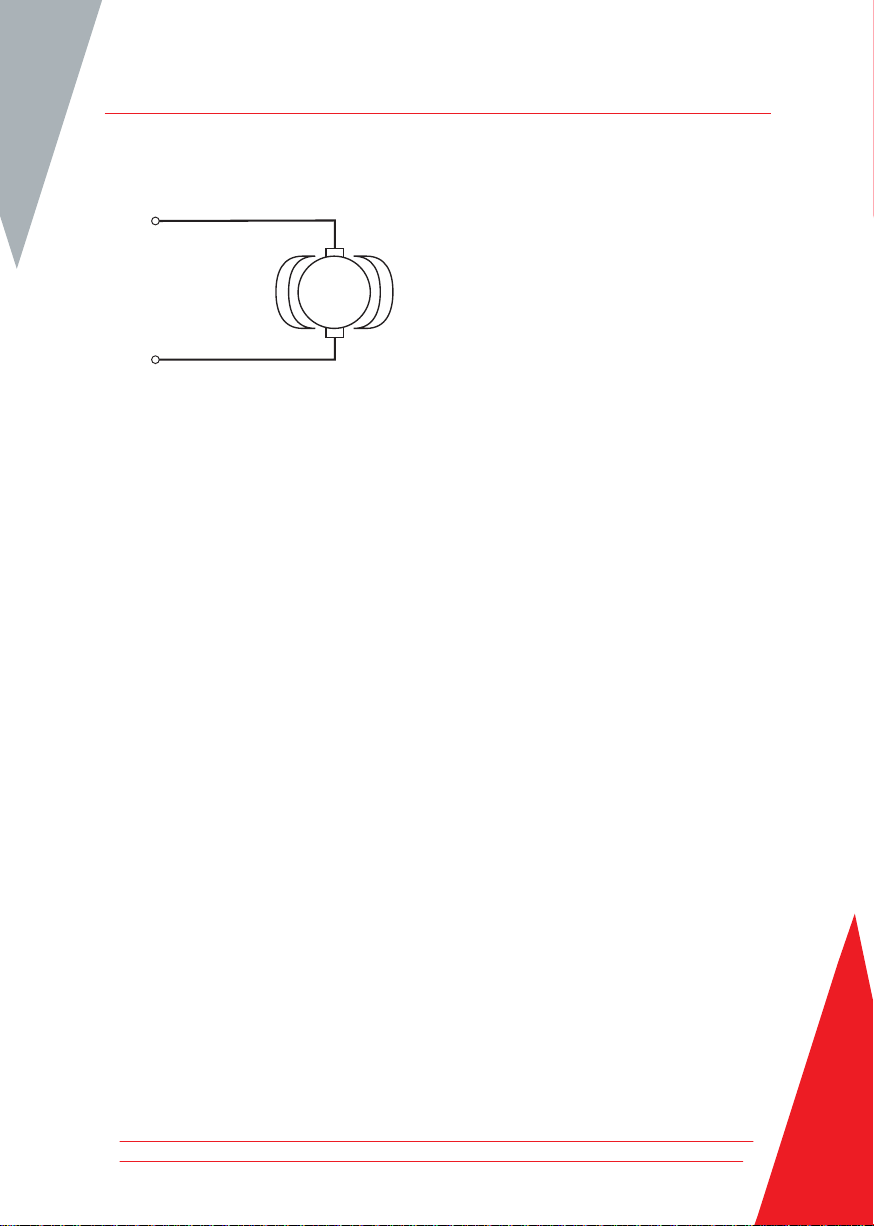

DC Motor Types - Permanent Magnet

Motor types

DC

Armature

Supply

Field

magnet

Armature

Field

magnet

Fig 6: Permanent magnet DC motor

A DC Motor whose poles are made of permanent magnets is known as a Permanent Magnet

DC (PMDC) Motor. The magnets are radially magnetized and are mounted on the inner

periphery of the cylindrical steel stator. The stator of the motor serves as a return path for the

magnetic flux.

Guide to Motor testing 9

Page 10

Motor types

Advantages of a DC motor

Used in applications where only a dc voltage source is available. The motor speed is easily

controlled by change to the applied voltage. They are mainly used where high torque is

required at low speed and constant high torque is needed at variable speed ranges.

AC Motor

AC Motors Types

Single phase (shaded pole; split-phase; capacitor start; capacitor-run; capacitor-start and

run).

Three phase

Advantages over dc – used in all other applications and due to the brush-less design less

maintenance is required.

Advantages of three phase over single phase motors – more energy efficient and have no

capacitors or centrifugal switches to drive or maintain

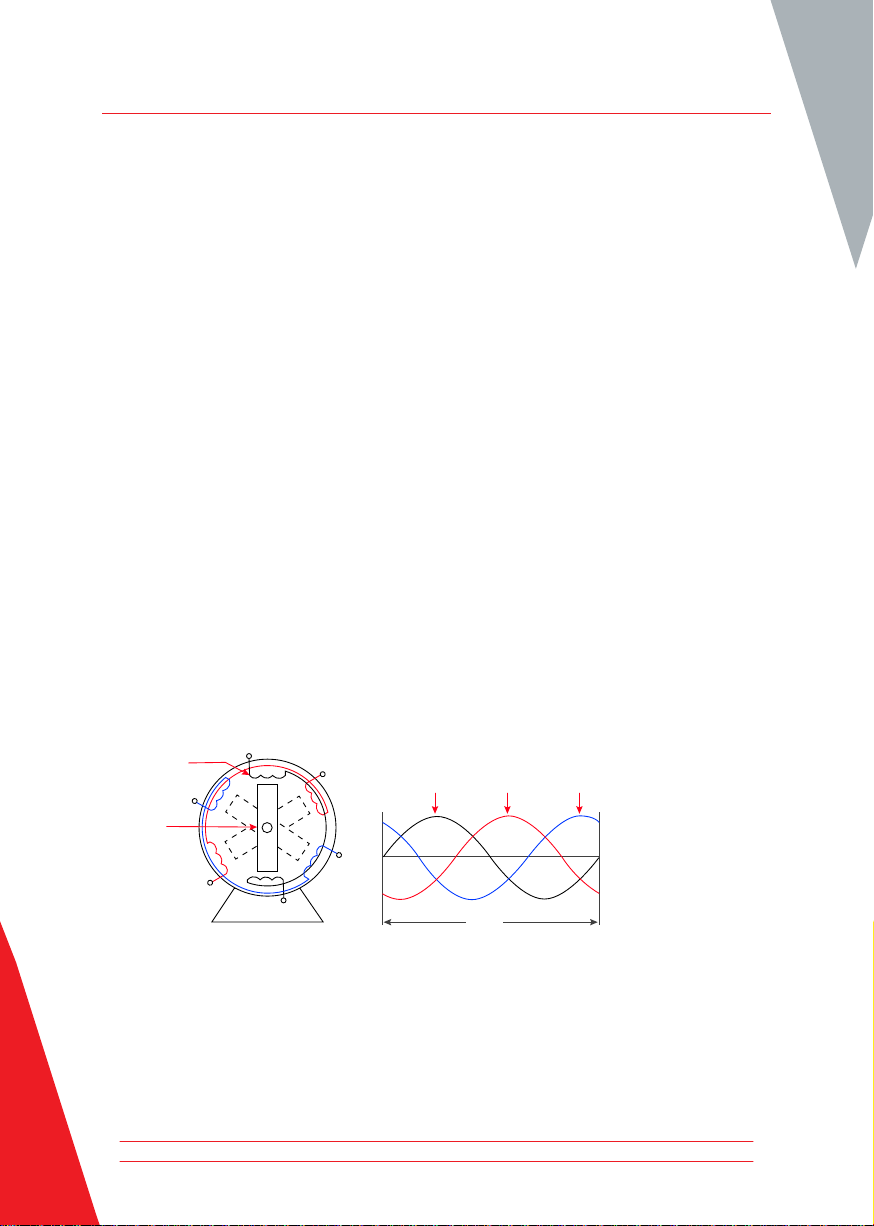

This guide will focus on three phase AC motors as they represent the majority of motors in

use today. The diagram shows a typical construction of a three phase motor with an open

configuration i.e. the motor is not configured for Star or Delta configuration and all three

phases are isolated. See ‘Star configuration’ and ‘Delta configuration’ for additional details.

Stator Coil

Rotor

Phase B

Phase A

Phase C

Phase A

Motor

Fig 7: 3 phase motor

10 Guide to Motor testing

Phase B

Phase C

Phase A

+ V

0

60 120 180 240 300

-V

Phase B Phase C

360

1 Cycle

Page 11

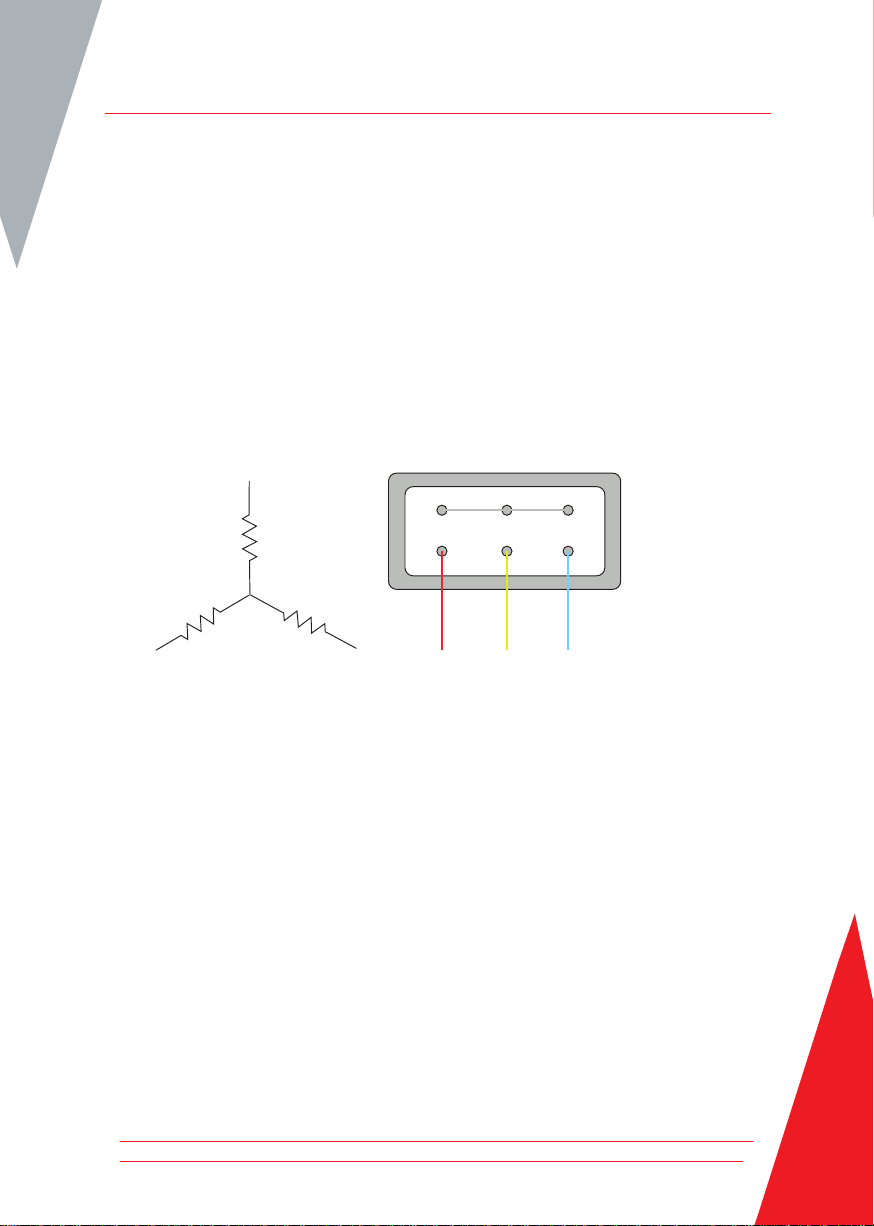

Star Configuration

In a STAR configuration the three phases are connected together to form a neutral point.

Line current is equal to the Phase current

Allowed supply voltage is higher (than Delta)

The phase voltage is 1/√3 of the line voltage

Voltage per phase is lower (than Delta)

Lower inrush current

Less power

U1

W2

U2

V2

Motor types

U2

W2

V2

V1

W1

Fig 8: Star connection of motor winding

U1

W1

V1

Guide to Motor testing 11

Page 12

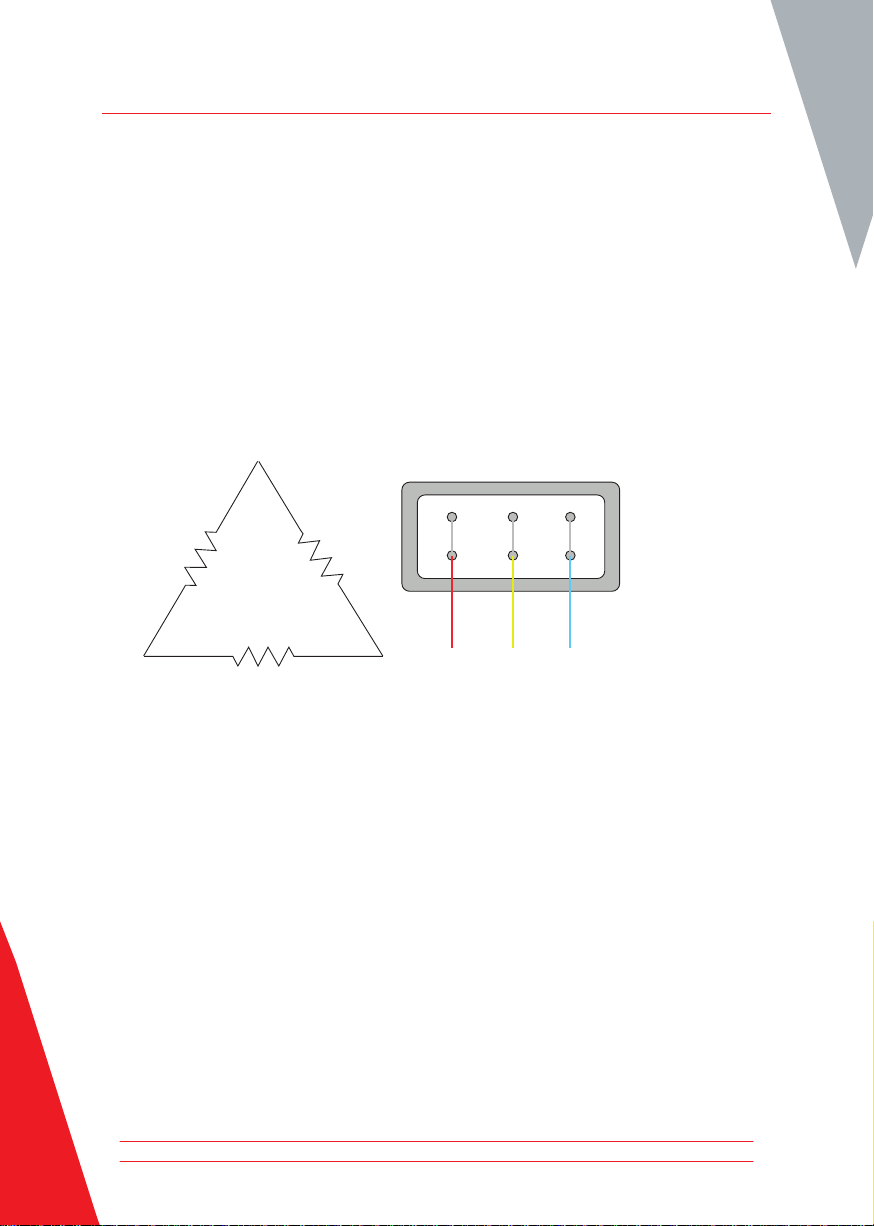

Motor types

Delta configuration

In a DELTA configuration the opposite ends of the three phases are connected together where

the end of a phase is connected to the start of another phase.

The line voltage is equal to the phase voltage

Allowed supply voltage is lower (than Star)

The line voltage is equal to the phase voltage

Voltage per phase is higher (than Star)

Higher inrush current

More power

U1

W2

W2

V1

U2

V2

W1

U2

V2

U1

W1

V1

Fig 9: Delta connection of motor winding

Star vs Delta configuration

Delta is typically used where a high starting torque is required. Star is used where a low starting

current is required.

12 Guide to Motor testing

Page 13

Why perform Motor Tests?

Why perform Motor Tests?

Early detection of faults during manufacture of new motors is vital. This is important at both

component and assembly levels. Detection of faults, for in service motors, as soon as they

begin to develop results in a reduction of ‘downtime’ and reduced repair costs.

Early detection and correct diagnosis of developing faults will help determine the condition

of in-service equipment. We can then predict when maintenance should be performed or

arrange routine maintenance, i.e. a time-based preventive maintenance schedule, to provide

sufficient time for the planned controlled shut down of the affected process. Both predictive

and preventative maintenance can reduce financial losses, maintain production levels and avoid

catastrophic consequences.

What problems create the need for a test?

When motors and generators are new, the electrical system should be in a very good condition.

Additionally rotating machine manufacturers have continually improved the quality of their

products. Nevertheless, even today, motors and generators are subject to many changes to

conditions which can cause these products to fail, i.e. mechanical damage, vibration, excessive

heat or cold, dirt, oil, corrosive vapours, moisture from processes, or just the humidity of the air.

In varying degrees these factors are at work and as time goes on, combined with the electrical

stresses that exist, create a harsh environment for daily operation. As pin holes or cracks

develop, moisture and foreign matter penetrate the surfaces of insulation, providing a low

resistance path for leakage current.

Once started, the different enemies tend to aid each other, permitting excessive current

through the insulation. Sometimes the drop in insulation resistance is sudden, as when

equipment is flooded. Usually, however, it drops gradually, giving plenty of warning, if tested

periodically. Such tests permit planned reconditioning before service failure. If not tested

periodically, a motor with poor insulation, for example, may not only be dangerous to touch

when voltage is applied, but also be subject to burn out. What was good insulation has

become a partial conductor.

Guide to Motor testing 13

Page 14

Testing and Diagnostics

Testing and Diagnostics

Electrical testing and diagnostics can be segmented to two main categories:

Static (De-Energised) Electrical Testing –

When the supply to the machine is isolated, electrical tests are carried out to find

faults or to provide data which can be used as a benchmark or trended over time.

Dynamic (Energised) Electrical Testing –

This will include live testing, analytics and compliment static testing

Although static tests are discussed, there are three important dynamic tests which have been

included, these are supply voltage, frequency and phase rotation.

The industrial and utility market is driven by the simple need to keep production moving

without interruption. There are many other reasons to test rotating machines, these include:

Safety - people and property

Compliance with standards and regulations

Reduce downtime

Save money / time – plan downtime to repair or replace

Save energy

Maintain service to the end user

Maintain critical services

Maintain performance / productivity

Trend data to predict failure

Lifetime (or end of life) planning

Research, development, design, prototyping

During and after manufacture

On receipt

Prior to installation

Commissioning

Maintenance

After servicing

Fault finding in situ

Fault finding on the bench

During the repair process

14 Guide to Motor testing

Page 15

Testing and Diagnostics

After the repair

Recommissioning

Again maintenance

Reactive

This is the “run it till it breaks” maintenance mode.

No actions or efforts are taken to maintain the equipment as the designer

originally intended to ensure design life is reached.

Corrective

‘Repair of equipment/machinery in order to bring it back to original operating

condition’.

Preventative

‘Schedule of planned maintenance actions aimed at the prevention of breakdowns

and failures’.

Primary goal - Preserve and enhance equipment reliability.

Predictive

‘Techniques that help determine the condition of in-service equipment in order

to predict when maintenance should be performed’. Primary goal – minimize

disruption of normal system operations, while allowing for budgeted, scheduled

repairs.

The examination of trended data is a crucial aspect of PdM.

At each point in the lifespan of a motor there are opportunities to test, retest, trend, predict,

observe and diagnose normal or unusual behaviour which can extend its duty cycle. Although

most engineering maintenance systems and procedures have strict regimes a vast amount of

data is often missed.

Guide to Motor testing 15

Page 16

Testing and Diagnostics

All the maintenance methods fit into the product lifecycle which can be seen as the

‘bathtub curve’. The Observed Failure Rate is made up of the 3 failure curves

Decreasing

Failure Rate

Failure Rate

Constant

Failure Rate

Increasing

Failure Rate

Time

Fig 10: Motor failure rate

Constant random

failures

Early “Infant

Mortallity Failure”

Wear out failures

Observered failure

rate

16 Guide to Motor testing

Page 17

Trending of test data

Trending of test data

The collection of data is extensively used across many disciplines and has immense value

when analysed over time to predict trends. When used for rotating machines this analysis of

electrical testing data can be used to reveal downward trends towards the imminent failure

of the machine. Systematic trending of test data is a key element of a high quality electrical

maintenance program and recognising a degrading trend strongly indicates impending trouble,

especially if the trend is accelerating.

These tests include insulation resistance, leakage current, capacitance and inductance. To

provide meaningful information the trending program must be structured to consider the

effects of external factors which affect the measured results but which are irrelevant to the

actual condition of machines health and reliability.

For example insulation resistance readings which are taken at varying temperatures must be

corrected to a base temperature before comparison with one another.

1 TΩ

100 GΩ

10 GΩ

1 GΩ

100 MΩ

10 MΩ

sulation Resistance

n

I

1 MΩ

0

Year 1 Year 2 Year 3 Year 4 Year 5 Year 6 Year 7

Apparatus A

Apparatus B

Fig 11: Insulation resistance rate graph

Taking insulation resistance as an example, Apparatus ‘A’ in year 5 has an insulation resistance

of about 20 GΩ which normally would be accepted as an excellent result. But following the

downward trend which started at year 1 with an insulation resistance of about 1 TΩ it can be

seen that the insulation is on an accelerating path towards failure.

However Apparatus ‘B’ in year 7 has a much lower insulation resistance by comparison at

50 MΩ and the trend from year 1 which initially had a reading of 90 MΩ reveals a much more

gradual trend indicating that this machine is in much better condition than Apparatus ‘A’.

Guide to Motor testing 17

Page 18

Megger Baker MTR105 – The Tests

Megger Baker MTR105 – The Tests

Insulation resistance up to 1000 volts

Spot

Timed

Polarisation Index

Dielectric Absorption Ratio

Temperature correction

Guard Terminal

Three Phase test - Fully automated

phase to phase Insulation Resistance

measurement of all three phases

Voltmeter

Voltage – ac; dc; TRMS;

Frequency

Phase Rotation

Continuity

Diode test

Low resistance

DLRO – Digital Low Resistance Ohmmeter

Motor Direction of Rotation

LCR meter

Inductance

Capacitance

Resistance

Temperature measurement

18 Guide to Motor testing

Page 19

Megger Baker MTR105 – The Tests

Insulation resistance

See Megger’s guide to insulation resistance testing ‘A Stitch in Time’

Before going into the different tests it is time to mention the different types of test current used

for insulation resistance testing. When the button is pressed to start a test, the high voltage is

produced and a current is generated. This current is made up from 3 elements.

100

80

60

res

40

pe

30

20

oam

10

r

c

8

Mi

6

-

5

t

4

3

2

Curren

1

0

0.1 .15 .2 .25 .3 .4 .5 .6 .7 .8 .9 1.0 1.5 2 3 4 5 6 7 8 10

Time - Minutes

Fig 12: Current elements under test

Although these currents are generally considered together as the total test current, they behave

differently.

Total current

Capacitive charging

current

Absorption or

Polarisation current

Conduction or leakage

current

The capacitive charging current starts quite high but drops quickly as the device under test

charges in much the same way as a capacitor.

The absorption or polarisation current also starts high but decays over a longer period of

time as the molecules of the insulation of the device under test line up to oppose the flow of

current, this polarisation may take some time to occur.

Conduction or leakage current normally begins at a low level, settling to a constant value it is

the current that travels through the insulation and flows along the surface.

We see this as one current that can be measured with an ammeter but using Ohms Law we

can represent this as a resistance.

Guide to Motor testing 19

Page 20

Megger Baker MTR105 – The Tests

The IEEE offers the following guidance for insulation resistance test voltages with respect to the

rated line-to-line voltage for three-phase ac machines, line-to-ground voltage for single-phase

machines and rated direct voltage for dc machines or field windings.

Winding rated Voltage Test Voltage (DC)

<1000 500

1000 – 2500 500 - 1000

2501 – 5000 1000 - 2500

5001 – 12000 2500 - 5000

>12000 5000 - 10000

Table 1: Rated voltage and corresponding test voltage

Spot or Timed insulation resistance test

The Spot test still remains the basic insulation resistance test that most engineers will use to

test equipment although it has evolved over time.

How long does the test last? That is up to the user, but the Spot test usually runs for about 60

seconds. The value of a quick test can’t be under stated but, as we will see, this test combined

with the other types of insulation resistance test provides a more reliable indication of the state

of the motor.

Insulation resistance should be approximately 1 MΩ for each 1,000 volts of operating

voltage, with a minimum value of 1 MΩ. For example, a motor rated at 2,400 volts should

have a minimum insulation resistance of 2.4 MΩ. In practice, the readings are normally are

considerably above this minimum value in new equipment or when insulation is in good

condition.

20 Guide to Motor testing

Page 21

Megger Baker MTR105 – The Tests

Polarisation Index (PI)

This test is similar to the DAR test, but the times at which the readings are taken are much

longer. This allows the device under test to be fully charged and the insulation to be polarised

A

A

B

Insulation

resistance

B

1 Minute 10 Minute

Fig 13: Ratio of time resistance readings over 10 minutes

Usually carried out over 10 minutes the PI is calculated in a similar way to DAR.

In this test, the voltage is applied and IR measurements are taken after 1 minute and 10

minutes.

The Polarisation Index or PI is calculated as PI = R10 ÷ R1

Table 2 shows the condition of the insulation.

Polarisation Index Insulation Condition

<1 Dangerous

1.0 – 2.0 *** Questionable

2.0 – 4.0 Good

>4 ** Excellent

Table 2: Condition of Insulation Indicated by Polarisation Index

*These values must be considered tentative and relative - subject to experience with the timeresistance method over a period of time.

**In some cases, with motors, values approximately 20% higher than shown here indicate

a dry brittle winding which will fail under shock conditions or during starts. For preventive

maintenance, the motor winding should be cleaned,treated and dried to restore winding

flexibility.

***These results would be satisfactory for equipment with very low capacitance such as short

runs of house wiring.

Guide to Motor testing 21

Page 22

Megger Baker MTR105 – The Tests

Why do we need to use this test?

The PI test provides a relative and not absolute measurement. It is a self-contained evaluation

of the condition of the insulation and can be used independently or with historical PI

measurements for trending. It indicates insulation quality in 10 minutes, which is an advantage

when working on large pieces of equipment which can take an hour to charge for an insulation

measurement reading. The PI reading shows up moisture ingress, contamination and insulation

degradation in a specific time-resistance test.

IEEE 43-2000 states “If the R1 value (at 40 °C) is greater than 5000 MΩ, the P.I. may be

ambiguous and can be disregarded”.

Dielectric Absorption Ratio (DAR)

The ratio of two time-resistance readings is called a dielectric absorption ratio. It is useful in

recording information about insulation.

A

B

A

B

Insulation

resistance

30 Seconds 60 seconds

Fig 14: Ratio of time resistance readings over 60 seconds

22 Guide to Motor testing

Page 23

Megger Baker MTR105 – The Tests

The dielectric absorption ratio (DAR) is calculated as: DAR = R60 ÷ R30. The ratio is indicative

of the condition of the insulation using Table 3.

DAR Insulation Condition

<1 Dangerous

1.0 – 1.4 Questionable

1.4 – 1.6 ** Good

>1.6 Excellent

Table 3: Condition of Insulation Indicated by Dielectric Absorption Ratios

*These values must be considered tentative and relative - subject to experience with the timeresistance method over a period of time.

**In some cases, with motors, values approximately 20% higher than shown here indicate

a dry brittle winding which will fail under shock conditions or during starts. For preventive

maintenance, the motor winding should be cleaned,treated and dried to restore winding

flexibility.

Why do we need to use this test?

It is a quick test to determine the health of the insulation and a DAR of 1.4 or greater, in pre-

1970 insulation systems, is considered acceptable. Otherwise, trending is required. Reference

IEEE Std 43-2000.

Used for equipment with “thin” insulation

Used on materials with a low absorption current – e.g. Polyethylene

Guide to Motor testing 23

Page 24

Megger Baker MTR105 – The Tests

Temperature correction

Insulation resistance values differ considerably at various temperatures, so in order to trend

IR values over a long period it is important to correct the IR measurement to a common

temperature for IEEE this is 40C.

Temp Rotating

CABLES

Equip

ϒC

ϒF

Class A

Class B

OIl-filled

transformers

Code Natural

0

5

10

15.6

20

25

30

35

40

45

50

55

60

65

70

75

32

41

50

60

68

77

86

95

104

113

122

131

140

149

158

167

0.21

0.31

0.45

0.71

1.00

1.48

2.20

3.24

4.80

7.10

10.45

15.50

22.80

34.00

50.00

74.00

0.40

0.31

0.45

0.71

1.00

1.25

1.58

2.00

2.50

3.15

3.98

5.00

6.30

7.90

10.00

12.60

0.25

0.36

0.50

0.74

1.00

1.40

1.98

2.80

3.95

5.60

7.85

11.20

15.85

22.40

31.75

44.70

0.25

0.40

0.61

1.00

1.47

2.27

3.52

5.45

8.45

13.10

20.00

Code GR-S

0.12

0.23

0.46

1.00

1.83

3.67

7.32

14.60

29.20

54.00

116.00

Performance

0.47

0.60

0.76

1.00

1.24

1.58

2.00

2.55

3.26

4.15

5.29

6.72

8.58 11.62

Table 4: Temperature correction factors For Rotating Machines

Class A and Class B. Corrected to 20 ϒC for rotating equipment

and transformers; 15.6 ϒC for cable.

Heat Resist. and

Perfrom. GR-S

Ozone resist

0.42

0.14

0.56

0.26

0.73

0.49

1.00

1.00

1.28

1.75

1.68

3.29

2.24

6.20

2.93

11.65

3.85

25.00

5.08

41.40

6.72

78.00

8.83

15.40

20.30

26.60

natural GR-S

Varnished

cambric

0.10

0.20

0.43

1.00

1.94

4.08

8.62

18.20

38.50

81.00

170.00

345.00

755.00 36.00

Impregnated

paper

0.28

0.43

0.64

1.00

1.43

2.17

3.20

4.77

7.15

10.70

16.00

24.00

24 Guide to Motor testing

Page 25

Megger Baker MTR105 – The Tests

Guard Terminal

During insulation testing, the resistance path on the outer surface of the insulation material is

often not considered. However, this resistance path is an important part of the measurement

and can dramatically affect the results. For example, if dirt, contamination or moisture is

present on the outer surface of a motor, the surface leakage current can be up to ten times of

that flowing through the actual insulation.

When conducting an insulation resistance test, we may note a low test result. Before

condemning the item there is one factor that is often not considered, that is surface leakage

due to contamination. This may be dust, dirt, oil, grease, metal filings, food products,

moisture, rust, even some types of paint and ‘protective’ coverings may cause problems

The surface leakage needs to be eliminated from the reading and that is where the Guard

terminal comes into play.

Note: If there is a high or compliant reading there is no need to use the Guard terminal.

The connection below shows an IR test between L1 and L2.

Fig 15: IR test between L1 and L2

If a low phase to phase reading is obtained there is possibly contamination. This is shown here

as a low resistance path between U and V phase to ground, where U is equivalent to L1 and V

is equivalent to L2.

Guide to Motor testing 25

Page 26

Megger Baker MTR105 – The Tests

Fig 16: Low resistance path between U and V to ground

To guard out this low resistance path connect the GUARD (Blue) test lead to ground

Fig 17: Guard connected to ground

If contamination is present the IR reading will increase to the expected level when the GUARD

is connected. If no change is noted with the GUARD connected then the insulation has

degraded.

Unresolved the contamination can lead to insulation failure and flashover

26 Guide to Motor testing

Page 27

Terminal

Megger Baker MTR105 – The Tests

Instrument circuit

simplified

Current meter - Only

measures current

through insulation

HV DC current

source

Instrumental

Terminal

Instrumental

Motor equivalent

circuit

–

Instrumental

Terminal

G

+

0.25 M ohm

100 M ohm

0.25 M ohm

MAX ERROR 2%

Leakage current

through motor

measured

Surface leakage

current ignored

Fig 18: Guard Diagram

The surface leakage is essentially a resistance in parallel with the true insulation resistance of

the material under test. By using the guard terminal to perform a ‘three-terminal test’, the

surface leakage current can be ignored. This may be important when high values of resistance

are expected, such as motors and supply cables. These tend to have large surface areas that

are exposed to contamination, resulting in high surface leakage currents across them.

In addition to the big improvements in the reliability of insulation condition diagnosis and

predictive maintenance discussed, the guard terminal is an important diagnostic tool. To carry

out this test the windings of the motor must be separated and not left connected in a star or

delta configuration.

The amount of current that is surface leakage can be quickly identified simply by performing

two tests; one using the guard terminal and one without, then calculating the difference

between measurements. With the guard terminal connected, if the insulation resistance is

high showing a good level of insulation but considerably lower when the guard terminal is

disconnected, the indication is of a parallel path conducting surface leakage across the outer

facings of the component between the two terminals.

Why we perform this test?

There have been many instances of poor insulation resistance measurements leading to motors

being replaced needlessly, some at huge cost, only to find later, that by employing the guard

terminal, they simply needed a good clean!

Guide to Motor testing 27

Page 28

Megger Baker MTR105 – The Tests

Three phase test

Similar in operation and performance to the spot test the phase to phase test is a standard

test performed on a three phase ac motor to determine the integrity of the insulation of each

phase. This test can only be performed when the motor is NOT configured as Star (Y) or Delta.

All phases must be isolated.

Voltmeter

Voltage and frequency measurements can be made to ensure that the supply is within that

indicated on the nameplate.

Why we perform this test?

Voltage measurements are used to ensure that the supply voltage remains within +/- 10% of

the nameplate voltage.

Phase rotation

Phase rotation can be determined to ensure that the supply is compatible with the motor prior

to connection and energising.

See Motor direction of rotation.

Why do we need to use this test?

The direction of rotation of the three phase supply voltage is determined to ensure that it

matches the direction of rotation of the motor. If the supply direction of rotation does not

match the motor direction of rotation, apparatus under the control of the motor will not

operate as intended e.g. fans won’t blow and pumps won’t pump correctly with the required

operation.

Continuity

The Continuity test is a 2 wire measurement that involves the output current and the voltage

drop measurement combined within the 2 test leads. So the entire resistance of the closed

loop (test leads + test piece) is combined in the resistance measurement. NULLing the test

leads does not eliminate variation in contact resistance, i.e. NULLing the leads across two

points of the test object, then proceeding to test continuity across several other different

test points introduces a variance in the contact resistance for all subsequent test points. The

contact resistance will almost certainly be different for each test point. The measuring circuit

28 Guide to Motor testing

Page 29

Megger Baker MTR105 – The Tests

for a continuity test is low impedance and any variation in the contact resistance will affect the

measurement.

The continuity test can quickly identify an unexpectedly high resistance in a conductor which

may be due to a break in the conductor or a open connection in a supply cable or faulty control

gear.

This is typically performed for each phase i.e. A-a; B-b; C-c;.

Continuity tests are also used as a comparative test to determine phase imbalance by

comparing the results of all three phases. In a star configured motor each phase is measured

i.e. A-Star point; B-Star point; C-Star point. Any significant difference in the resistance

measurement will indicate a phase imbalance.

Why we perform this test?

When do we need to measure low resistance?

Go/No Go

Ensure resistance is correct after motor repairs and before installation

Condition Monitoring

Identify unacceptable increase in resistance

Like Testing

Ensure ‘like’ elements of a system are of similar resistance

Diode test

This test has been included to show the integrity of diodes. It measures the forward and

reverse voltage drop over the device. Diode testing - diodes are not usually found on motors

but are on alternators and help with polarity control of the excitation circuit.

Digital Low Resistance Ohmmeter (DLRO)

When accurate very low resistance readings are required to be taken, the 4 wire ‘kelvin’ test

configuration is recommended.

Simply stated this test applies a current via 2 of the test leads while measuring the voltage with

the other 2 test leads, the result is displayed as a resistance. This test is unaffected by lead

or contact resistance and is particularly useful for measuring low winding resistances and the

contact resistance of control gear or overloads.

The test can be unidirectional or bidirectional. When testing connection built with dissimilar

materials it is recommended to use the bidirectional test.

Guide to Motor testing 29

Page 30

Megger Baker MTR105 – The Tests

Why we perform this test?

The DLRO test is performed where an accurate low resistance measurement is required in the

mΩ range.

Motor Direction of Rotation test

Determining the direction of rotation of a motor in relation to the phase rotation of the

supply is important, if not crucial for some applications where damage to pumps, compressors

or gearboxes can occur. The ‘bump’ test is often used prior to installation. The motor

is momentarily energised and the direction of rotation is noted with regard to the phase

connections.

Sometimes there is confusion as to how clockwise and anticlockwise rotation is perceived.

The answer lies with DIN EN 60034-8 where the direction of rotation of a motor is defined as

follows:

1. The direction of rotation is the direction viewed from the drive end.

2. The drive end is the side with the shaft extension.

3. For machines with two shaft extensions, the drive end is:

3.1. the end with the bigger shaft diameter

3.2. the end on the opposite side to the fan, (if both shaft extensions have the same

diameter).

So motors with clockwise rotation turn the shaft clockwise when viewed from the drive end

(viewing direction from drive end to non-drive end).

Fig 19: Clock wise motor

30 Guide to Motor testing

Page 31

Megger Baker MTR105 – The Tests

Motors with counter-clockwise rotation turn the shaft in a counter-clockwise direction when

viewed from the drive end (viewing direction from drive end to non-drive end).

Fig 20: Counter clock wise motor

As the direction of rotation for the motor and driven machine is defined with reference to the

respective shaft extension, the motor requires the opposite direction of rotation to that of the

driven machine.

That is to say, a counter-clockwise driven machine requires a clockwise-rotating motor and a

clockwise driven machine requires a counter-clockwise-rotating motor.

Why we perform this test?

The direction of rotation of the motor is determined to ensure that it matches the direction

of rotation of three phase supply voltage. If the motor direction of rotation does not match

the supply direction of rotation, apparatus under the control of the motor will not operate as

intended e.g. fans won’t blow and pumps won’t pump correctly.

This test may eliminate the need to perform a ‘bump’ test. Typically this test is performed on

a motor by pressing the start button ON and OFF quickly to determine the motor direction of

rotation. The bump test can cause problems when the motor is coupled to apparatus, which

is being driven by the motor and is not designed to run backwards. Here severe damage can

result to equipment such as screw compressors and some pumps.

Guide to Motor testing 31

Page 32

Megger Baker MTR105 – The Tests

Inductance

Phase-to-phase inductance measurements can be used to identify several conditions:

Poor or incorrect re-work e.g. reversed coil winding leads.

Power cable faults or power circuit main contacts.

Air gap eccentricity problems.

Shorted turns e.g. stator phase-to-phase and coil to coil.

Rotor porosity and lamination damage.

Cracked rotor bars or end rings.

Why we perform this test?

Inductance measurements can be useful in determining stator problems, even in cases where

the resistance measurements do not show a problem. The winding resistance of each phase

can be very low meaning that the amount of resistance per turn may seem negligible. With

such a negligible value it would be easy to see how losing a few turns may not be seen by

simply measuring resistance. Inductance, however, is exponentially affected by turn changes

within windings and therefore provides a more sensitive method to detect changes in stator

windings.

Capacitance

Measurement is trended and values to ground increasing over time indicate surface

contamination, high humidity, high temperature or insulation breakdown.

Temperature measurement

The temperature of the unit under test is measured in order to perform temperature correction.

Before an insulation resistance test can be carried out with temperature compensation enabled,

a temperature measurement must first be taken to establish the temperature of the unit under

test.

32 Guide to Motor testing

Page 33

Megger Baker MTR105 Overview

Megger Baker MTR105 Overview

Description

The MTR105 is a dedicated Static Motor

Tester with Megger’s tried and trusted suite

of insulation resistance tests (IR), plus all the

great traditional features and reliability of

Megger’s testers.

The MTR105 takes the test abilities of Megger’s proven IR test instruments adding DLRO four

wire Kelvin low resistance test, inductance and capacitance tests to provide a versatile motor

tester, all packaged in a robust hand held instrument, which up to now has simply not been

available.

Additionally the MTR105 incorporates temperature measurement and compensation (for IR

tests), motor direction of rotation plus supply phase rotation tests.

These new test abilities make the MTR105 a real world, versatile, hand held motor test

instrument.

The MTR105 comes in an over-moulded case, providing increased protection and robustness,

achieving an IP54 weatherproof rating.

Features

Guard terminal, to eliminate any surface leakage current.

Detachable test leads with interchangeable clips and probes for different applications.

Stores test results for up to 256 motors, which can be downloaded to a USB mass

storage device.

Rotary dial control, full graphic display, simple and easy to use.

Environmental protection to IP54, providing protection against moisture and dust ingress,

including the battery and fuse compartment.

Tough housing: A ‘rubber over moulding’ combines a tough shock absorbing outer

protection with excellent grip, on a strong modified ABS housing, providing a robust

case.

Rechargeable batteries with mains charger kit option.

Guide to Motor testing 33

Page 34

Megger Baker MTR105 Overview

Applications

Production tests for new manufactured motors and generators.

Test repaired and refurbished motors and generators.

Monitoring and maintenance of in service motors (off line) in the field.

Safety

The MTR105 is designed to be exceptionally safe to use. The fast detecting circuitry reduces

the likelihood of damage to the instrument if accidentally connected to live circuits or across

phases.

Meets the international requirements of IEC61010 and IEC61557.

Live circuit detection and test inhibit on all measurements with user notification (except

for direction of rotation measurements).

User selectable insulation test terminal lockout voltage 25 V, 30 V, 50 V, 75 V (default is

50 V).

Detection and inhibit functions when the protection fuse has failed.

Suitable for use on CAT III applications and supply voltages to 600 V.

Insulation resistance tests

Resistance range 100 Ω up to 200 GΩ.

Supports PI, DAR, Timed, Three Phase and Temperature Compensation.

Stabilised insulation test voltage accurate to -0% +2% ±2 V, which provides a more

accurate test voltage without the risk of over-voltage damage to circuits or components.

The output voltage is maintained between 0 and 2% throughout the test range.

Where a non-standard test voltage is required, a variable range allows the exact test

voltage to be selected from 10 V up to 999 V and is subject to the same stabilised output

control.

Dedicated buzzer button either ON, VISUAL or OFF.

Adjustable buzzer for minimum resistance limit (0.5 MΩ up to 1000 MΩ).

Buzzer sounds on test pass.

34 Guide to Motor testing

Page 35

Megger Baker MTR105 Overview

Voltmeter

Measures ac 10 mV up to 1000 V; dc 0 to 1000 V; TRMS (15 Hz up to 400 Hz).

Three phase supply and direction of rotation.

Continuity (Resistance) tests

Single automatic resistance range from 0.01 Ω to 1.0 MΩ.

Automatic test current selection uses the preferred test current for the load resistance

under test (200 mA up to 4 Ω).

Bi-directional tests option automatically reverses the current without reconnecting leads.

Lead resistance compensation (NULL) operates up to 10 Ω of resistance.

Dedicated buzzer switch either ON, VISUAL or OFF.

Adjustable buzzer for maximum resistance limit (1 Ω to 200 Ω in 12 steps).

Buzzer sounds on test pass.

DLRO Four wire Kelvin low resistance

Automatic resistance range from 1 mΩ up to 10 Ω.

Selectable auto or manual test.

Bi-direction or single direction.

Bi-directional tests option automatically reverses the current without reconnecting leads.

200 mA test current.

Motor Direction of Rotation test

Tests the direction of rotation of the motor under test and displays the phase sequence on

screen.

The connected motor is rotated in one direction and the display shows sequence of the phases

of rotation. The motor is next rotated in the opposite direction, the phases are checked again

and shown on the display.

Guide to Motor testing 35

Page 36

Megger Baker MTR105 Overview

Inductance, Capacitance and Resistance meter (LCR)

Auto inductive, capacitive and resistive test. Frequency selectable to 120 Hz or 1000 Hz.

In AUTO mode, the MTR105 automatically determines if the main element of the load is

inductive, capacitive or resistive and displays the result on screen.

Selectable inductance and capacitance test.

Temperature

Temperature measurement of unit under test, via the supplied thermocouple, allows

temperature compensation to be applied in insulation resistance tests.

Temperature measurement of the unit under test, is carried out via a thermocouple,

allowing temperature compensation to be applied to insulation resistance tests. A type “T”

thermocouple is supplied with the MTR but “J” and “K” type thermocouples can also be used.

Display

Full colour graphic display makes the MTR105 simple to understand and easy to use.

Guard Terminal

The Guard Terminal (G) is a third terminal on the connection panel.

Connection of the guard terminal, on certain applications, provides a return path for parallel

leakage currents, which could otherwise create significant errors in the insulation measurement.

This is especially so for surface contamination of equipment or cables.

Storage and download of results

Test results can be downloaded to a USB mass storage device , which can be accessed by

connecting to a PC or a Laptop running PowerDB.

Instrument software updates

Occasional information bulletins and software updates may be issued on the Megger web site.

36 Guide to Motor testing

Page 37

Specifications

Specifications

All quoted accuracies are at 20 °C (68 °F).

Insulation resistance

Volts Accuracy

50 V 10 GΩ ±2% ±2 digits ±4.0% per GΩ

100 V 20 GΩ ±2% ±2 digits ±2.0% per GΩ

250 V 50 GΩ ±2% ±2 digits ±0.8% per GΩ

500 V 100 GΩ ±2% ±2 digits ±0.4% per GΩ

1000 V 200 GΩ ±2% ±2 digits ±0.2% per GΩ

Polarisation index (PI): 10 min / 1 minute ratio

Dielectric absorption

ratio (DAR):

Guard terminal

performance

Resolution 0.1 kΩ

Short circuit/charge

current

Terminal voltage

accuracy

Test current 1 mA at min. pass value of insulation to a max. of 2 mA

Operation range 0.10 MΩ to 1.0 GΩ (IEC61557-2)

Leakage current

display

Voltage display ±3% ±2 digits ±0.5% of rated voltage

Note: Above specifications only apply when high quality silicone leads are being used

- as supplied with the instrument.

User configurable 15 s or 30 s t1 start time with t2 fixed at 60 s

<5% error at 500 kΩ parallel circuit resistance with 100 MΩ load

2 mA +0% -50% (IEC61557-2)

-0% +2% ±2 V

0.1 uA resolution 10% (±3 digits)

Continuity

Measurement 0.01 Ω to 1 MΩ

0 to 1000 kΩ analogue scale)

Accuracy ±3% ±2 digits (0 to 99.9 Ω )

±5% ±2 digits (100 Ω - 500 kΩ)

Test current 200 mA (–0 mA +20 mA)

(0.01 Ω - 4 Ω)

Polarity Single or Dual (factory default) polarity

Lead resistance Null up to 10 Ω

Selectable current limit 20 mA and 200 mA

Guide to Motor testing 37

Page 38

Specifications

Capacitance

Range 0.1 nF - 1 mF

Accuracy ±5.0% ±2 digits (1 nF - 10 μF)

Voltmeter

Range dc: 0 - 1000 V

ac: 10 mV - 1000 V

TRMS sinusoidal (15 Hz - 400 Hz)

Accuracy dc: ± 2% ±2 digits (0 - 1000 V)

ac: ± 2% ±2 digits

(10 mV - 1000 V TRMS)

Frequency range 15 - 400 Hz (50 mV - 1000 V)

Frequency resolution 0.1 Hz

Frequency accuracy ±0.5% ±1 digit

Diode Test Diode test accuracy: ±2% ±2 digits

0.01 V to 3.00 V

Display range: 0.00 V to 3.00 V

Temperature measurement and compensation

Thermocouple Type T (Type K and Type J)

Thermocouple range -20 °C to 200 °C (4 °F - 392 °F)

Instrument range -20 °C to 1000 °C (4 °F - 1832 °F)

Instrument resolution 0.1 °C (0.18 °F)

Instrument accuracy ±1.0 °C ±20 digits (1.8 °F). (Basic accuracy stated assumes

forward and reverse measurements.)

DLRO four wire Kelvin low resistance

Test current 200 mA dc

Range 1 mΩ to 10 Ω

Resolution 0.01 mΩ

Accuracy ± 0.25% rdg. ± 10 digits, accuracy stated includes forward and

reverse measurements.

38 Guide to Motor testing

Page 39

Specifications

Inductance

Instrument accuracy

Range Accuracy Test Frequency

1 H ±(0.7 % +(Lx/10000) % +5 digits) 1 kHz

200 mH ±(1.0 % +(Lx/10000) % +5 digits) 120 Hz

±(0.7 % +(Lx/10000) % +5 digits) 1 kHz

20 mH ±(2.0 % +(Lx/10000) % +5 digits) 120 Hz

±(1.2 % +(Lx/10000) % +5 digits) 1 kHz

2 mH ±(2.0 % +(Lx/10000) % +5 digits) 1 kHz only

Results storage

Storage capacity 256 motor results

(date / time stamped)

Data download USB Type A (USB Mass Storage Device)

Power

Battery 6 x IEC LR6 1.5 V Alkaline (AA), IEC FR6 1.5 V Lithium (LiFeS2), IEC

HR6 1.2 V NiMH (rechargeable option).

Battery life 10 motors per (complete suite of tests at 100 V into 100 MΩ)

IEC61557-2 - test cycle, 1200 insulation tests with duty cycle of 5

s testing on 25 sec standby @ 500 V into 0.5 MΩ.

IEC61557-4 test cycle, 1200 continuity tests with duty cycle of 5

sec testing on 25 sec standby on 1 Ω resistance.

Battery charging Mains battery charger kit.

Safety protection IEC61010-1 CAT III 600 V

EMC Industrial IEC61326

Temperature

<0.1% per °C up to 1 GΩ

coefficient

Guide to Motor testing 39

Page 40

Specifications

Environment

Operating temperature

range

-10 °C to 50 °C (14 °F to 122 °F)

Storage temperature

-25 °C to 65 °C (-13 °F to 149 °F)

range

Humidity 90% RH at 40 °C (104 °F) max.

Calibration

20 °C (68 °F)

temperature

Maximum altitude 3000 m (9843 ft.)

IP rating IP54

Physical

Display Full LCD colour screen with user configurable backlight

Languages English, French, German and Spanish.

Dimensions 228 x 105 x 75 mm

(8.98 x 4.1 x 2.95 in)

Weight 1.00 kg (2.2 lbs)

Fuse x2 500 mA (FF) 1000 V 32 x 6 mm ceramic fuse, high break

capacity HBC, 30 kA minimum. Glass fuses must not be

installed.

IEE Standards

IEEE Std 43-2013 IEEE Recommended Practice for Testing Insulation Resistance of Electric

Machinery

IEEE 1415-2006 IEEE Guide for Induction Machinery Maintenance Testing and Failure Analysis

IEEE 112-2017 IEE Standard Test Procedure for Polyphase Induction Motors and Generators

NEMA MG-1

40 Guide to Motor testing

Page 41

Specifications

Guide to Motor testing 41

Page 42

42 Guide to Motor testing

Page 43

Guide to Motor testing 43

Page 44

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification or design without prior notice.

Megger is a registered trademark

The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG,

Inc and is used under licence.

Guide to low voltage Motor Testing--2012-431_en_V01 06 2019

Part No: 2012-431

© Megger Limited 2019

Loading...

Loading...