Page 1

Baker Instruments

MTR105

Rotating Machine Tester

User Guide

Page 2

This document is copyright of:

Megger Limited, Archcliffe Road, Dover, Kent CT17 9EN. ENGLAND

T +44 (0)1304 502101 F +44 (0)1304 207342 www.megger.com

Megger Ltd reserves the right to alter the specification of its products from time to time without

notice. Although every effort is made to ensure the accuracy of the information contained within

this document it is not warranted or represented by Megger Ltd. to be a complete and up - to - date

description.

For Patent information about this instrument refer to the following web site:

http://uk.megger.com/patents

ii www.megger.com

Page 3

This manual supersedes all previous issues of this manual. Please ensure that you are using the most recent issue of this

document. Destroy any copies that are of an older issue.

Declaration of Conformity

Hereby, Megger Instruments Limited declares that radio equipment manufactured by Megger Instruments Limited

described in this user guide is in compliance with Directive 2014/53/EU. Other equipment manufactured by Megger

Instruments Limited described in this user guide is in compliance with Directives 2014/30/EU and 2014/35/EU where they

apply.

The full text of Megger Instruments EU declarations of conformity are available at the following internet address:

uk.megger.com/company/about-us/eu-dofc

www.megger.com iii

Page 4

Contents

1. Safety Warnings ........................................................................................................2

1.1 Warnings, Cautions and Notes ........................................................................................ 2

1.1.1 Warnings ........................................................................................................................ 2

1.1.2 Cautions ......................................................................................................................... 2

1.1.3 Notes .............................................................................................................................. 2

1.2 Safety warnings ................................................................................................................ 2

1.2.1 Test lead safety warnings ................................................................................................. 3

1.3 Product Safety Category - Measurement Connection .................................................... 3

1.3.1 Voltage ........................................................................................................................... 3

1.3.2 CAT IV ............................................................................................................................ 3

1.3.3 CAT III ............................................................................................................................. 3

1.3.4 CAT II .............................................................................................................................. 3

1.4 Safety, Hazard and Warning Symbols on the Instrument .............................................. 4

1.4.1 Warning Icons ................................................................................................................. 4

2. Introduction ...............................................................................................................5

2.1 Product Description .......................................................................................................... 5

2.2 Applications ...................................................................................................................... 6

2.3 Features ............................................................................................................................. 6

2.4 Company web site. ........................................................................................................... 6

2.5 Instrument Controls ......................................................................................................... 7

2.6 Instrument Display ........................................................................................................... 8

2.7 Instrument Controls.......................................................................................................... 9

2.8 Instrument Connections and Leads ................................................................................. 10

2.8.1 View on top of MTR105 .................................................................................................. 10

3. Instrument Set up ......................................................................................................11

3.1 Warnings and exception conditions ................................................................................ 11

3.2 Power ................................................................................................................................ 11

3.2.1 First use ......................................................................................................................... 11

3.2.2 Turn the instrument on and off ....................................................................................... 11

3.2.3 Power options ................................................................................................................. 12

3.3 Lockout Voltage ............................................................................................................... 12

4. Insulation Resistance Tests .......................................................................................13

4.1 Insulation test options...................................................................................................... 13

4.2 Two Terminal and Guard .................................................................................................. 13

4.3 Automatic discharge ........................................................................................................ 14

4.4 Insulation Resistance (IR) Test .......................................................................................... 14

4.4.1 Buzzer settings ................................................................................................................ 16

4.4.2 Temperature compensation ............................................................................................. 17

4.5 3 Phase (3P) ....................................................................................................................... 18

4.6 Polarization Index (PI) ...................................................................................................... 20

iv www.megger.com

Page 5

4.7 Timed (T(s))Test ................................................................................................................. 22

4.8 Dielectric Absorption Ratio (DAR) .................................................................................. 24

4.9 Variable voltage .............................................................................................................. 26

5. Voltmeter ...................................................................................................................28

5.1 TRMS (True RMS) .............................................................................................................. 28

5.2 AC or DC ........................................................................................................................... 29

5.3 Supply Phase Rotation...................................................................................................... 30

6. Continuity ..................................................................................................................32

6.1 Uni-direction ..................................................................................................................... 32

6.2 Bi-direction ....................................................................................................................... 34

6.3 Diode test .......................................................................................................................... 36

7. DLRO Digital Low Resistance Ohmmeter ................................................................38

7.1 Manual single direction test ............................................................................................ 38

7.2 Auto Single direction test ................................................................................................ 40

7.3 Manual bi-direction test................................................................................................... 41

7.4 Auto Bi direction test ....................................................................................................... 44

7.5 Test failure ...................................................................................................................... 46

7.5.1 Lost connection ............................................................................................................... 46

8. Direction of Motor Rotation .....................................................................................47

9. Inductance (L); Capacitance (C); Resistance (R) (LCR) ..............................................48

9.1 Auto .................................................................................................................................. 48

9.2 Capacitance or inductance ............................................................................................... 49

9.3 LCR Calibration ................................................................................................................. 51

10. Temperature measurement ....................................................................................54

10.1 Thermocouple temperature measurement................................................................... 54

10.2 Manual Temperature measurement .............................................................................. 56

11. Data management ...................................................................................................58

11.1 Creating a new asset ID ................................................................................................. 58

11.2 Using an existing asset ID............................................................................................... 59

11.3 Deleting an asset ............................................................................................................ 60

11.4 Deleting items from within an asset ............................................................................. 61

11.5 Deleting a single test ..................................................................................................... 63

11.6 Exporting entries to USB ................................................................................................ 65

12. Firmware update .....................................................................................................68

13. Error and Warning Conditions................................................................................70

13.1 Failed export ................................................................................................................... 70

13.2 Fuse Failure ..................................................................................................................... 70

13.3 Battery Low ..................................................................................................................... 70

14. Settings ....................................................................................................................71

14.1 IR Test Settings ................................................................................................................ 71

www.megger.com v

Page 6

14.1.1 DAR Settings ................................................................................................................. 71

14.1.2 Insulation threshold ....................................................................................................... 72

14.1.3 Lock .............................................................................................................................. 72

14.1.4 Temperature compensation ........................................................................................... 72

14.1.5 Terminal lock out ........................................................................................................... 72

14.1.6 Timed Insulation ............................................................................................................ 73

14.1.7 Variable Voltage ............................................................................................................ 73

14.2 General Settings ............................................................................................................. 73

14.2.1 Back-light timer ............................................................................................................. 73

14.2.2 Battery Technology ........................................................................................................ 73

14.2.3 Date .............................................................................................................................. 74

14.2.4 Instrument information ................................................................................................. 74

14.2.5 Key Press Notification ................................................................................................... 74

14.2.6 Sleep timer .................................................................................................................... 74

14.2.7 Time ............................................................................................................................. 75

14.2.8 Restore factory settings ................................................................................................. 75

14.3 Language settings .......................................................................................................... 75

15. Maintenance ............................................................................................................76

15.1 General Maintenance ..................................................................................................... 76

15.2 Cleaning .......................................................................................................................... 76

15.3 Battery ............................................................................................................................. 76

15.3.1 Battery status ................................................................................................................ 76

15.3.2 12 V supply ................................................................................................................... 77

15.3.3 Battery Charging ........................................................................................................... 77

15.3.4 Battery error screens .................................................................................................. 77

15.4 Battery and Fuse Replacement ...................................................................................... 78

15.4.1 Replace battery cells and remove isolation tab ............................................................... 79

15.4.2 To replace the fuses ....................................................................................................... 79

16. Specifications ...........................................................................................................80

17. Accessories and Equipment ....................................................................................83

17.1 Included Accessories ....................................................................................................... 83

17.2 Optional Accessories....................................................................................................... 83

18. Calibration, Repair and Warranty ..........................................................................84

18.1 Return procedure ........................................................................................................... 84

19. Decommissioning ....................................................................................................85

19.1 WEEE Directive ............................................................................................................... 85

19.2 Battery disposal .............................................................................................................. 85

vi www.megger.com

Page 7

www.megger.com vii

Page 8

Safety Warnings

1. Safety Warnings

The safety instructions given in this document are indicative of safe practice and are not be considered exhaustive.

Additionally, they are not intended to replace local safety procedures in the region where the instrument is used. If

the equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

1.1 Warnings, Cautions and Notes

This user guide follows the internationally recognized definition of warnings, cautions and notes. These instructions

must be adhered to at all times.

1.1.1 Warnings

Warnings alert the reader to hazardous situations where injury to personnel can occur. They are set in red type

to make them stand out. They are placed before the item to which they relate and repeated at each applicable

occasion.

1.1.2 Cautions

Cautions alert the reader to situations where equipment damage may result if a process is not followed properly.

They are set in bold type. They are placed before the item to which they relate and repeated at each applicable

occasion.

1.1.3 Notes

Notes give additional important information that will help the reader. They are not used when a Warning or Caution

is applicable. They are not safety related and may be placed either before or after the associated text as required.

1.2 Safety warnings

These safety warnings must be read and understood before the instrument is used. Retain for future reference.

Warning: This instrument must be operated only by suitably trained and competent people.

Protection provided by the instrument may be impaired if it is not used in a manner specified by the

manufacturer.

Local Health and Safety Legislation requires users of this equipment and their employers to carry out valid risk

assessments of all electrical work to identify potential sources of electrical danger and risk of electrical injury such

as inadvertent short circuits. Where the assessments show that the risk is significant then the use of fused test

leads may be appropriate.

The voltage indicator and automatic discharge features must be regarded as additional safety features and not a

substitute for normal safe working practice which MUST be followed.

The circuit under test must be switched off, de-energized, securely isolated and proved dead before test

connections are made unless measuring voltage or phase rotation.

Circuit connections, exposed conductive parts and other metalwork of an installation or equipment under test

must not be touched during testing.

When inductive loads are measured it is essential that the current carrying leads are securely clamped to the item

being tested and that they are not removed before any stored charge has been discharged at the end of the test.

Failure to comply with these instructions might result in an arc being produced, which might be dangerous for

the instrument and the operator.

The Voltmeter function will operate only if the instrument is switched on and working correctly.

After an insulation test, the instrument must be left connected until the circuit has been discharged to a safe

voltage.

The instrument must not be used if any part of it is damaged or if the terminal shutter is missing.

2 www.megger.com

Page 9

Safety Warnings

All test leads, probes and crocodile clips must be in good order, clean and with no broken or cracked insulation.

Verify the integrity of the test leads before use. Only “Megger” approved test leads must be used with this

product.

The safe maximum limit of a measurement connection is that of the lowest rated component in the

measurement circuit formed by the instrument, test leads and any accessories.

Ensure that hands remain behind finger guards of probes/clips.

Replacement fuses must be of the correct type and rating. Failure to fit the correctly rated fuse will result in fire

and burns hazards and cause damage to the instrument in the event of an overload.

All covers must be in place whilst conducting tests.

This product is not intrinsically safe. Do not use in an explosive atmosphere.

Ensure every cell in the battery compartment is of identical type. Never mix rechargeable and non-chargeable

cells.

1.2.1 Test lead safety warnings

The circuit under test must be switched off, de-energized, isolated and checked to be safe before insulation test

connections are made. Make sure the circuit is not re-energized while the instrument is connected.

Test leads, including crocodile clips, must be in good condition, clean, dry and free of broken or cracked

insulation. The lead set or its components must not be used if any part of it is damaged.

The safe maximum limit of a measurement connection is that of the lowest rated component in the

measurement circuit formed by the instrument, test leads and any accessories.

The CAT III 600 V rated thermocouple probe tip and protective ring are conductive. Care must be taken when

using the probe on live systems not to short-circuit to adjacent conductors.

1.3 Product Safety Category - Measurement Connection

Only Megger supplied test leads designed for this instrument provide the full safety rating.

1.3.1 Voltage

The rated measurement connection voltage is the maximum line to earth voltage at which it is safe to connect.

1.3.2 CAT IV

Measurement category IV: Equipment connected between the origin of the low-voltage Mains Power supply and the

distribution panel.

1.3.3 CAT III

Measurement category III: Equipment connected between the distribution panel and the electrical outlets.

1.3.4 CAT II

Measurement category II: Equipment connected between the electrical outlets and the User’s equipment.

Measurement equipment may be safely connected to circuits at the marked rating or lower. The connection rating is

that of the lowest rated component in the measurement circuit.

www.megger.com 3

Page 10

i

Safety Warnings

1.4 Safety, Hazard and Warning Symbols on the Instrument

This section details the various safety and hazard icons on the instruments outer case.

Icon Description

Warning: High Voltage, risk of electric shock

F

Caution: Refer to User Guide.

G

Equipment complies with current EU directives.

c

Equipment complies with current ‘C tick’ requirements.

Do not dispose of in the normal waste stream.

Equipment protected throughout by double insulation.

t

Fuse

f

CAT III

600 V

CAT rating

600 V ac RMS maximum between terminals and between terminal and earth

g

dc

d

G >1100 V

IP54 IP rating

1.4.1 Warning Icons

This section details the warning icons that can show on the display.

Icon Warning Description

F

G

Do not use in distribution systems with voltages higher than 1100 V

External Voltage Warning If an external voltage is applied between the terminals and the

instrument is set to On, the High Voltage warning will flash

on the display. This is a warning that the item under test is

live and might be dangerous and testing is disabled. The High

Voltage warning message will flash if more than 50 V potential

difference is applied between the Voltage terminals and the

Current terminals. This warning will not show if all terminals are

at the same high voltage.

NOTE: The warning will not operate if the instrument is set to

Off.

Internal Error Warning Internal Error Warning switch off and back on. Contact Megger

if not cleared.

Read the User Guide Refer to the user guide if this message shows.

4 www.megger.com

Page 11

Introduction

2. Introduction

2.1 Product Description

This user guide details the operational and functional details of the Megger MTR105 Rotating Machine Tester. Please

read this user guide fully before attempting to use the MTR105. The MTR105 instrument is designed to perform a

number tests that are typical for rotating machines.

These tests include

Insulation resistance,

Voltage measurement,

Continuity,

DLRO, digital low resistance ohmmeter - 4 wire kelvin mΩ,

Motor direction of rotation test,

Capacitance,

Inductance

Temperature.

The MTR105 is powered by six AA alkaline primary cells. As an optional accessory, rechargeable NiMH AA cells can

be used with an external power supply and adaptor to charge the batteries whilst in the instrument. Lithium primary

(not Lithium Ion) cells can also be used.

For personal safety and to get the maximum benefit from this instrument, make sure that the safety warnings and

instructions are read and understood before the instrument is used, see Refer to 1. Safety Warnings on page 2.

This user guide must be thoroughly read before attempting to operate the MTR105.

NOTE: This manual includes instructions for all MTR105 variants. Some facilities may not be available on your model

of this equipment.

The MTR105 takes the test abilities of Megger’s proven MIT400 test instruments adding; DLRO four wire tests,

inductance and capacitance to provide a versatile motor tester, all packaged in a robust hand held instrument, which

up to now has simply not been available.

In addition the MTR105 also incorporates temperature measurement and compensation (for IR tests), direction of

rotation plus supply phase rotation tests.

All these new test abilities go together to make the MTR105 a real world, versatile, hand held test instrument for

rotating machinery.

The MTR105 also comes in an over-moulded case, providing increased protection, robustness and achieving an IP54

rating against moisture and dust ingress.

Refer to the image at Refer to 2.5 Instrument Controls on page 7 for detail of the MTR105 layout.

For the safety of all personnel and to get the maximum benefit from this instrument, ensure the safety instructions of

Refer to 1. Safety Warnings on page 2 are read and thoroughly understood before the MTR105 is used.

Tests and connections detailed in this user guide are not exhaustive. Refer to the booklet Guide to Motor Testing

(published by Megger) for further information about motor testing.

www.megger.com 5

Page 12

Introduction

2.2 Applications

The MTR105 is an OFF LINE motor tester that can be used on small to medium sized rotating machines, typically up

to 500 hp.

Typical applications include but are not limited to:

New manufactured motor – test in production process.

Refurbished/Repaired motor – test in repair workshop.

Monitoring and maintenance of in service motors (off line) – workshop or in the field.

Where there is doubt about a particular application, refer to the booklet Guide to Motor Testing.

2.3 Features

Guard Terminal - to eliminate any surface leakage current.

Detachable insulation resistance test leads with interchangeable clips and probes for different applications.

Stores test results for up to 256 motors, which can be downloaded to a USB drive.

Rotary dial control and full graphic display - simple and easy to use.

Sealed to IP54, providing protection against moisture and dust ingress, including the battery and fuse

compartments.

Tough housing: A ‘rubber over moulding’ combines a tough shock absorbing outer protection with excellent

grip, on a strong modified ABS housing, providing an almost indestructible case.

Rechargeable batteries with mains charger kit option.

2.4 Company web site.

Occasionally an information bulletin may be issued via the Megger web site. This may be new accessories, new usage

instructions or a software update. Please occasionally check on the Megger web site for anything applicable to your

Megger instruments.

www.megger.com

6 www.megger.com

Page 13

2.5 Instrument Controls

2

Introduction

1

3

6

4

5

7

8

9

Item Description Item Description

1 External electrical connections 6 Save

2 Display 7 Test

3 Soft keys (multifunction) 8 Information / Lock / OK

4 Buzzer control 9 Rotary selection switch

5 Back-light control

www.megger.com 7

Page 14

Introduction

2.6 Instrument Display

7

1 2

3

4

6

5

Item Description Item Description

1 Status / Mode 5 Soft key functions

2 Battery indicator 6 Secondary field

3 Primary field 7 Time

4 Status symbols

8 www.megger.com

Page 15

2.7 Instrument Controls

Introduction

10

11

13 1412

9

8

17

6

5

4

3

2

Item Description Item Description

Rotary switch positions

1 Settings (Grey) 8 Off (Grey)

2 Data management (Blue) 9 Voltmeter, 3 phase supply, direction of

rotation and frequency (Black)

3 Temperature (White) 10 Insulation Resistance Test, 50 V (Red)

4 Inductance capacitance and resistance

11 Insulation Resistance Test, 250 V (Red)

(Green)

5 Motor direction of rotation (Light grey) 12 Insulation Resistance Test, 500 V (Red)

6 Digital Low Resistance Ohmmeter (Yellow) 13 Insulation Resistance Test, 1 kV (Red)

7 Continuity and diode test (Orange) 14 Insulation Resistance Test, user

selectable voltage (Red)

www.megger.com 9

Page 16

Introduction

2.8 Instrument Connections and Leads

2.8.1 View on top of MTR105

Slider to front Slider to back

1

2

4

1

3

6

6

Item Description Item Description

1 Rear attachment point for strap 4 Slider in rear position

2 Battery charger connection / switch probe 5 USB port

3 Slider in front position 6 Front

The external connections are all situated on top of the MTR105. A sliding cover is installed to prevent any other

connection being made at the same time as the USB port. Connection to the USB port can only be made when the

sliding cover is pushed completely to the back of the instrument.

5

For charging or connection to any test leads the sliding cover must be in the forward position.

The charger connection is designed so that no other lead can be connected while the battery is being charged in the

instrument.

10 www.megger.com

Page 17

Instrument Set up

3. Instrument Set up

Before each use of the instrument, visually inspect the instrument case, test leads and connectors to confirm their

condition is good, with no damaged or broken insulation

3.1 Warnings and exception conditions

There are two types of alerts that interrupt the standard process, they are the warnings for an external condition alert

and the exception condition for an internal fault alert. The alert message is overlaid on the display screen with the

fault message. The images below are examples illustrating the two types of alerts:

Alert for dangerous external fault. Alert for internal fault.

c

3.2 Power

3.2.1 First use

NOTE: Before the MTR105 can be turned on the battery isolation tab must be removed.

1. Remove the battery cover.

2. Pull the battery isolation tab clear of the battery cells.

3. Replace cover.

For further details on accessing the battery panel, Refer to 15.4 Battery and Fuse Replacement on page 78.

For initial date and time set up, Refer to 14.2.3 Date on page 74 and Refer to 14.2.7 Time on page 75.

NOTE: If the MTR should lose the date and time setting, (for example if the batteries have been replaced and the

instrument has been without them for more than 3 minutes) the instrument will display a prompt screen when

turned on to enter the date and time details - this can appear anytime after first set up.

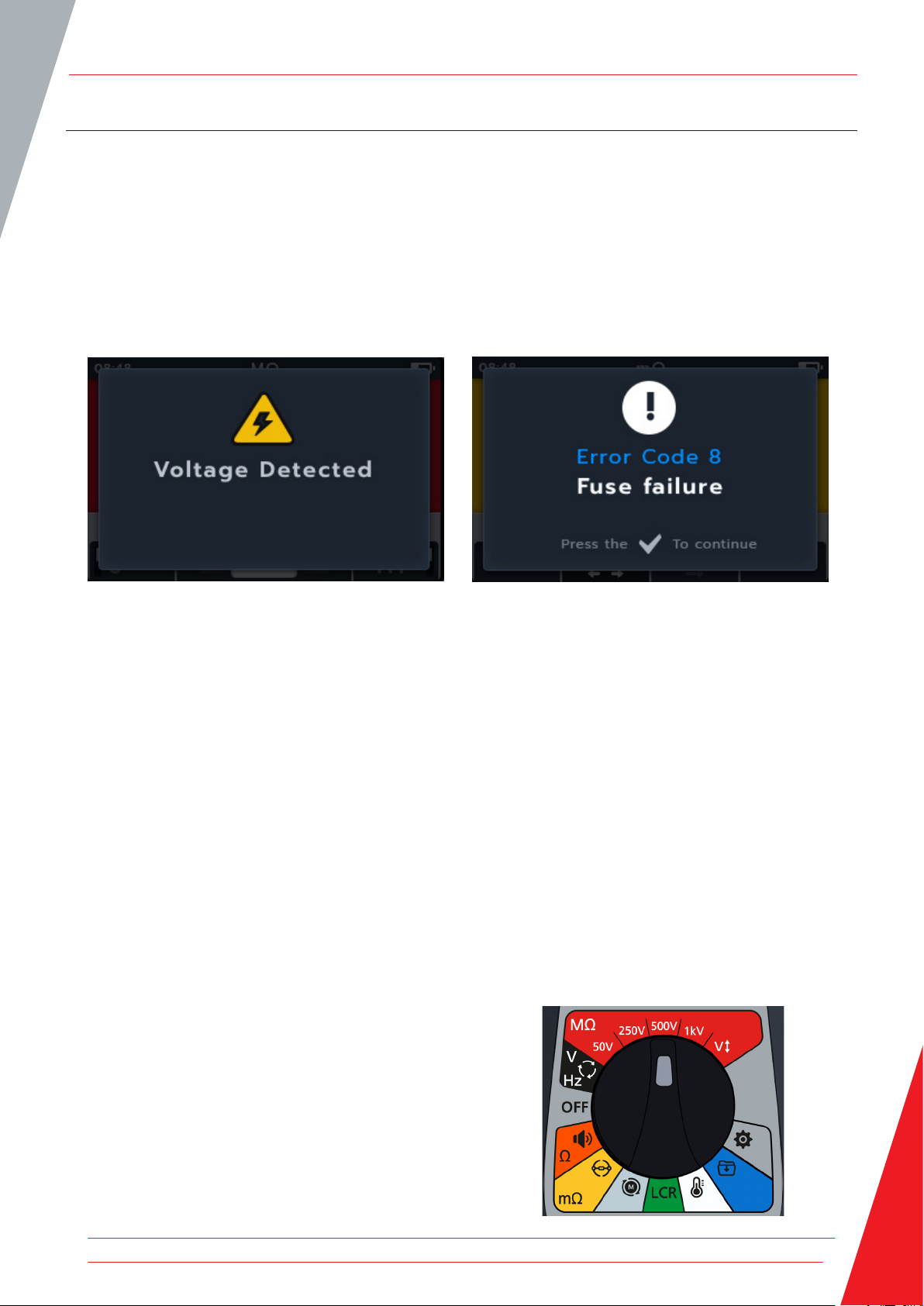

3.2.2 Turn the instrument on and off

1. Turn the instrument ON by turning the rotary switch away

from the OFF position to activate the instrument.

www.megger.com 11

Page 18

Instrument Set up

2. Turn the instrument OFF by turning the rotary switch to the

OFF position to deactivate the instrument.

NOTE: The MTR105 switches off after a period of inactivity,

which is user adjustable, Refer to 14. Settings on page 71.

To start the instrument again rotate the mode switch to Off

and then select a mode or press the TEST button to wake the

instrument up.

3.2.3 Power options

Caution: Do not attempt to recharge alkaline or Lithium cells, this action is a high potential fire hazard.

The MTR105 is powered by Internal batteries,

These cells may be used:

6 x LR6 1.5 V Alkaline (AA)

6 x IEC HR6 1.2V NiMH

6 x IEC FR6 1.5 V Lithium (LiFeS2).

The instrument charges using the dc adapter (NiMH cells only), which will work at voltages between 100 and 240 V

ac. Charging will only occur if the battery type is set to NiMh.

Warning: Charge NiMH cells only between 0 ºC and +40 ºC ambient.

The battery cell type is selected from the settings menu, Refer to 14. Settings on page 71. It will not charge

Alkaline or LiFeS2 cells.

To charge the cells in the instrument, it has to have the mains charger kit plugged into the terminal connections.

Testing or access the USB is not possible while the instrument is being charged.

See also Refer to 16. Specifications on page 80

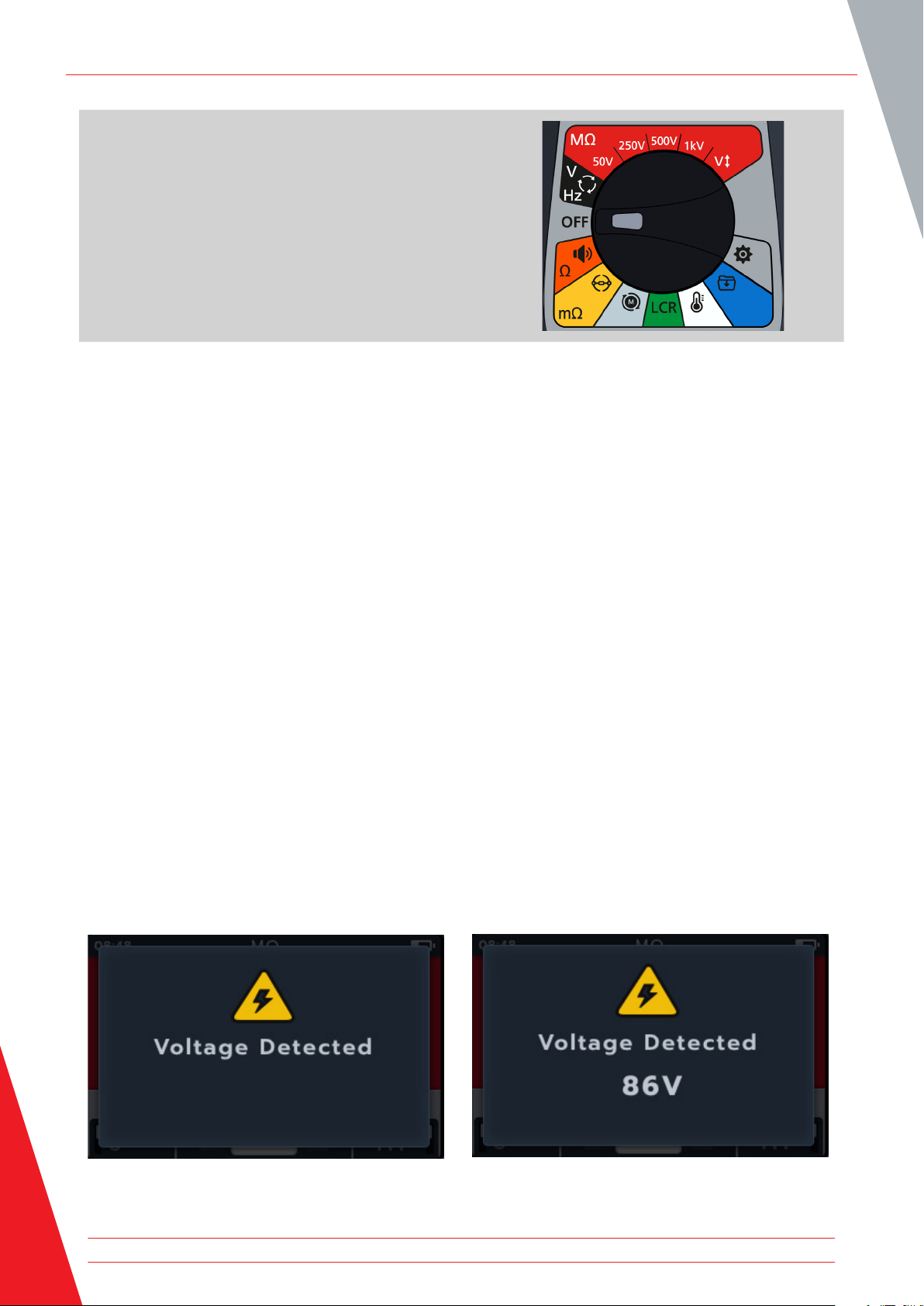

3.3 Lockout Voltage

Before testing, the measurement board will carry out a short a pre-test voltage check. If the lockout voltage is

exceeded, the user will see an overlay menu showing the current voltage measured. The overlay will disappear if the

voltage is lowered below the lockout voltage threshold.

The lockout voltage is active on all test modes. It is hard-coded to activate at 20 V. The only exception is the

insulation resistance tests, where the lockout voltage can be set in the settings (as 20 V, 30 V, 50 V or 75 V).

12 www.megger.com

Page 19

Insulation Resistance Tests

4. Insulation Resistance Tests

Warning: Hazardous voltages are emitted throughout the insulation resistance tests. Do not touch the

test leads while testing is in progress (after test button has been pressed). The warning triangle will flash

on the display during these tests.

Insulation resistance tests can be carried out at the following settings 50 V, 250 V, 500 V, 1 kV and variable voltage

(variable symbol). These are all coloured red and are positioned across the top of the rotary switch.

The test method for each voltage setting is identical.

Variable voltage is user selectable, Refer to 14. Settings on page 71. The variable voltage setting is configurable

between 10 V to 999 V.

4.1 Insulation test options

Icon Description

IR: Insulation resistance.

PI: Polarization Index is the ratio between insulation resistance values recorded at 1 minute

(assigned t1) and 10 minutes (assigned t2).

DAR: Dielectric Absorption Ratio, it is the ratio between the insulation resistance values at 15 or

30 seconds (assigned t1) and at 60 second interval (assigned t2). i.e. after 30 seconds and 60

seconds. DAR = 15 or 30 (default) second value / 60 second value

T(s): Time IR = Selectable from 1 minute to 10 minutes, in 1 minute increments.

3P 3 Phase. To test insulation resistance phase to phase.

F This warning triangle flashes when any voltage is being output in the insulation resistance test

process.

4.2 Two Terminal and Guard

The MTR105 is fitted with a guard terminal. The guard terminal is used to conduct leakage currents away from the

measured circuit to reduce errors.

The guard terminal is only used for insulation testing and as and additional connection in 3-phase testing. The lead is

coloured blue.

The guard lead (G) is optional. When used, it should be connected to the guard conductor, screen, steel wire

armoured conductor, or “user added” conductive wire or wrapper, such as foil.

For further information refer to Guide to Motor Testing published by Megger.

www.megger.com 13

Page 20

Insulation Resistance Tests

4.3 Automatic discharge

Following any insulation test, when the TEST button is released, the discharge loop begins to discharge the test piece.

The automatic discharge loop will discharge the unit under test, removing any hazardous voltage introduced by the

insulation test.

During the automatic discharge loop, the lightening symbol will flash and the falling voltage displayed on the left of

the secondary field.

After the automatic discharge loop has finished, the secondary result is displayed in the secondary field again and the

buzzer sounds for a second.

4.4 Insulation Resistance (IR) Test

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: when the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen

This test can also be performed with just the red and the black

lead.

2. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only

When performing phase to phase measurements, the star or

delta configuration has to be disconnected.

3. Select the required insulation test voltage.

4. The display will show the selected voltage, in this case 500 V.

14 www.megger.com

Page 21

5. Press soft keys 2 and 3 to move the carousel left or right

through sub-modes. IR is default, scroll through to 3P, PI,

T(s) DAR.

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

6. If required, press soft key 1 to toggle between temperature

compensation on and off.

NOTE: this is only available in IR test mode.

To adjust the temperature compensation, Refer to 4.4.2

Temperature compensation on page 17

Insulation Resistance Tests

7. If required, Turn the buzzer on, off or visual as required by

pressing buzzer button. Refer to 4.4.1 Buzzer settings on

page 16

NOTE: This is only available in IR test mode.

To adjust the insulation threshold, Refer to 14. Settings on page

71

8. Start the test by pressing and holding down the TEST button.

The buzzer will sound on test initiation.

8.1. To hold the test voltage, press the LOCK button while

the TEST button is held. Once the lock symbol is

displayed and the buzzer has sounded, the TEST button

can be released. This test will continue until the TEST

button or the LOCK button is pressed to stop the test.

To enable this Refer to 14.1.3 Lock on page 72

NOTE: As the test starts the Soft Key Function field disappears,

secondary and function fields drop to the bottom of the screen.

Sub-mode initials separate the secondary fields.

www.megger.com 15

Page 22

Insulation Resistance Tests

9. During the tests,

Test results in the primary field show the IR value.

Status symbols will appear in the bottom right-hand

corner of the primary field.

The secondary field shows the actual voltage and current.

10. The test may be stopped at any time by pressing or releasing

the TEST button again

11. When the test has completed

The primary field displays the test results.

The secondary field displays actual voltage output and the

current measured.

12. To save the test result press the SAVE button. A message

will inform you the data was saved and which asset ID it was

saved to.

13. To restart the test press the TEST button again.

NOTE: To set up an asset ID Refer to 14. Settings on page 71

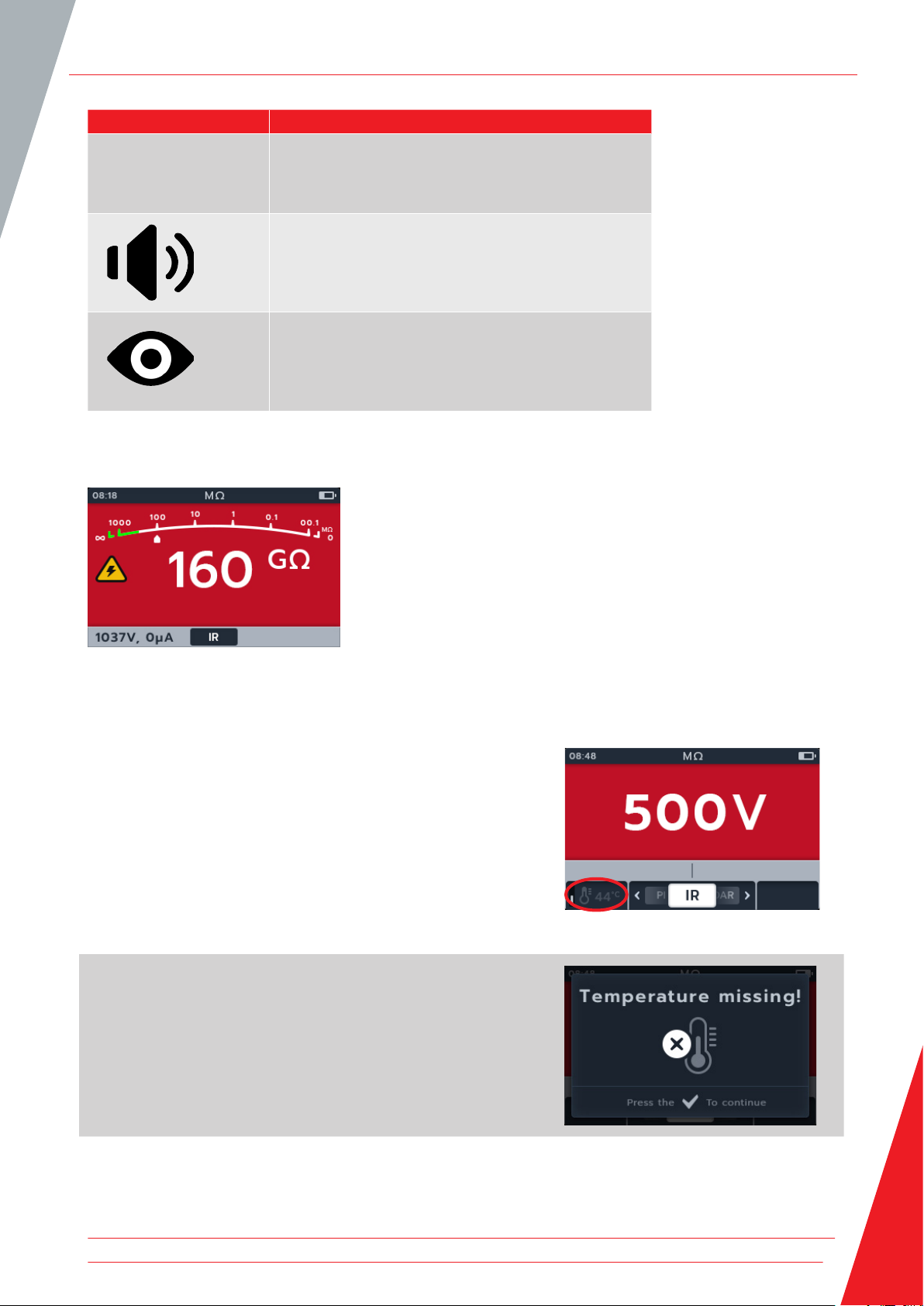

4.4.1 Buzzer settings

Set the buzzer to the preferred option before starting a test.

Buzzer status is indicated at the bottom right hand corner of

the primary field. The buzzer threshold is shown just above the

status indicator.

The buzzer has 3 options and is set by pressing the fixed key.

The options are off (default), on and optical. Press and release the buzzer key until the desired function is reached.

16 www.megger.com

Page 23

Insulation Resistance Tests

Visual indicator Description

Buzzer off.

No indication given.

Buzzer on

Buzzer will give both audio and visual on screen

indication.

Buzzer optical

Buzzer will only give a visual, on screen indication.

When running an IR test, if the threshold is exceeded the buzzer will activate and the background will flash. A pass

band is shown in the analogue scale and is highlighted in green.

4.4.2 Temperature compensation

NOTE: Temperature compensation is only available in IR sub-mode. Temperature compensation is off by default.

Before an insulation resistance test can be carried out with

temperature compensation enabled, the temperature of the unit

under test must be established.

For this procedure Refer to 14.1.4 Temperature compensation on

page 72

If a temperature measurement hasn’t been made, the left of the

secondary field will show -- °C.

If a test is attempted the unit will display Temperature missing.

www.megger.com 17

Page 24

Insulation Resistance Tests

If the temperature reading is more than 30 minutes old, a red

time stamp will be displayed in the secondary field above the

temperature reading.

4.5 3 Phase (3P)

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: when the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

2. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only

When performing phase to phase measurements, the star or

delta configuration has to be disconnected.

3. Select the required insulation test voltage.

4. The display will show the selected voltage, in this case 500 V.

18 www.megger.com

Page 25

5. Press soft keys 2 and 3 to move the carousel left or right

through sub-modes to 3P (3 phase).

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

6. To start the test press the TEST button.

A warning triangle will flash on screen.

NOTE: The test can be stopped at any time by pressing the TEST

button.

Insulation Resistance Tests

7. During the tests:

The primary field displays the test results and the active

and completed phase to phase tests in the three phase

sequence.

The secondary field displays actual voltage output and the

current measured.

8. When the test has completed:

The primary field displays the test results and also the

actual voltage output and the current measured.

www.megger.com 19

Page 26

Insulation Resistance Tests

9. The result can be saved by pressing the SAVE button. A

message will inform you the data was saved and which asset

ID it was saved to.

NOTE If the test was stopped before completion, it cannot be

saved.

10. To restart the test press the TEST button again.

4.6 Polarization Index (PI)

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: when the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

This test can also be performed with just the red and the black

lead.

2. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only.

When performing phase to phase measurements, the star or

delta configuration has to be disconnected.

3. Select the required insulation test voltage.

20 www.megger.com

Page 27

4. The display will show the selected voltage, in this case 500 V.

5. Press soft keys 2 and 3 to move the carousel left or right

through sub-modes to PI (Polarization Index).

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

Insulation Resistance Tests

6. To start the test press the TEST button.

The test will start and the clock will appear in the bottom left of

the primary screen. The test will continue for 10 minutes. The

clock will countdown the test. An interval result will appear after

1 minute.

A warning triangle will flash on screen.

NOTE: The test can be stopped at any time by pressing the TEST

button.

7. During the tests,

The primary field displays the test results.

The secondary field displays actual voltage output and the

current measured.

8. When the test has completed,

The primary field displays the test results.

www.megger.com 21

Page 28

Insulation Resistance Tests

9. The result can be saved by pressing the SAVE button. A

message will inform you the data was saved and which asset

ID it was saved to.

NOTE If the test was stopped before completion, it cannot be

saved.

10. To restart the test pressing the TEST button again.

4.7 Timed (T(s)) Test

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: When the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

This test can also be performed with just the red and the black

lead.

2. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only

When performing phase to phase measurements, the star or

delta configuration has to be disconnected.

3. Select the required insulation test voltage.

22 www.megger.com

Page 29

4. The display will show the selected voltage, in this case 500 V.

5. Press soft keys 2 and 3 to move the carousel left or right

through sub-modes to T(s) (Timed Test).

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

Insulation Resistance Tests

6. To start the test press the TEST button.

The clock will appear in the bottom left corner of the primary

field. The Timed test is user configurable and can run for

1,2,3,4,5,6,7,8,9, or 10 minutes Refer to 14.1.6 Timed Insulation

on page 73

A warning triangle will flash on screen.

NOTE: The test can be stopped at any time by pressing the TEST

button.

7. During the tests,

The primary field displays the test results.

The secondary field displays actual voltage output and the

current measured.

8. When the test has completed,

The primary field displays the test results.

The secondary field displays actual voltage output and the

current measured.

www.megger.com 23

Page 30

Insulation Resistance Tests

9. The result can be saved by pressing the SAVE button.

A message will inform you the data was saved and which

asset ID it was saved to.

10. To restart the test pressing the TEST button again.

4.8 Dielectric Absorption Ratio (DAR)

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: when the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

This test can also be performed with just the red and the black

lead.

2. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only.

When performing phase to phase measurements, the star or

delta configuration has to be disconnected.

3. Select the required insulation test voltage.

24 www.megger.com

Page 31

4. The display will show the selected voltage, in this case 500 V.

5. Press soft keys 2 and 3 to move the carousel left or right

through sub-modes to DAR (Dielectric Absorption Ratio).

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

Insulation Resistance Tests

6. To start the test press the TEST button.

The clock will appear in the bottom left corner of the primary

field as the DAR test runs for one minute.

A warning triangle will flash on screen.

NOTE: The test can be stopped at any time by pressing the TEST

button.

7. During the tests,

The primary field displays the test results.

The secondary field displays actual voltage output and the

current measured.

8. When the test has completed,

The primary field displays the test results.

The secondary field displays actual voltage output and the

current measured.

www.megger.com 25

Page 32

Insulation Resistance Tests

9. The result can be saved by pressing the SAVE button. A

message will inform you the data was saved and which asset

ID it was saved to.

NOTE If the test was stopped before completion, it cannot be

saved.

10. To restart the test pressing the TEST button again.

4.9 Variable voltage

1. Set the voltage required under the variable voltage test

setting. Refer to 14.1.7 Variable Voltage on page 73

2. Connect the test leads to the MTR105.

2.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: when the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

This test can also be performed with just the red and the black

lead.

3. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only

When performing phase to phase measurements, the star or

delta configuration has to be disconnected.

4. Turn rotary switch to select variable voltage position.

26 www.megger.com

Page 33

5. The display will show the selected voltage, in this case 10 V.

6. Press soft keys 2 and 3 to move the carousel left or right

through sub-modes. IR is default, scroll through to 3P, PI,

T(s) DAR.

Insulation Resistance Tests

7. Run the chosen test as described in the previous sections.

www.megger.com 27

Page 34

Voltmeter

5. Voltmeter

5.1 TRMS (True RMS)

Default is TRMS mode shows true RMS voltage. In TRMS mode the MTR105 will measure both ac and dc components

of the supply voltage (ac+dc).

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: When the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

2. Turn rotary switch to select Voltmeter (V) position.

3. The TRMS test starts automatically.

4. During the tests,

The primary field displays the measured voltage.

The secondary field displays frequency.

5. The result can be saved by pressing the SAVE button. A

message will inform you the data was saved and which asset

ID it was saved to.

28 www.megger.com

Page 35

5.2 AC or DC

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: When the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

2. Turn rotary switch to select Voltmeter (V) position.

Voltmeter

3. Press soft keys 2 and 3 to move the carousel left or right

through sub-modes to ac or dc as required.

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

4. The ac and dc tests start automatically.

5. During the ac tests,

The primary field displays the measured voltage.

The secondary field displays frequency.

6. During the dc tests,

The primary field displays the measured voltage.

www.megger.com 29

Page 36

Voltmeter

7. The result can be saved by pressing the SAVE button. A

message will inform you the data was saved and which asset

ID it was saved to.

5.3 Supply Phase Rotation

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: when the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen

2. Turn rotary switch to select Voltmeter (V) position.

3. Press soft keys 2 and 3 to move the carousel left or right

through sub-modes to Supply Phase Rotation.

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

30 www.megger.com

Page 37

4. This test starts automatically.

NOTE: Phase rotation result requires all phases connected

before a result can be given.

5. During the tests,

The primary field displays the phase rotation sequence of

the supply and constantly updating results for each phase

sequence of the supply.

The secondary field displays frequency.

6. The result can be saved by pressing the SAVE button. A

message will inform you the data was saved and which asset

ID it was saved to.

Voltmeter

www.megger.com 31

Page 38

Continuity

6. Continuity

NOTE: Results of measurements can be adversely affected by impedances of additional operating circuits connected

in parallel or by transient current.

6.1 Uni-direction

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: When the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

2. Turn rotary switch to select Continuity position.

3. If required, Turn the buzzer on, off or visual as required by

pressing buzzer button.

NOTE: This is only available in uni-direction mode.

4. To adjust the threshold press soft key 4.

NOTE: The buzzer mode bypasses the continuity detection and

voltage pretesting.

32 www.megger.com

Page 39

5. A new screen will open where the threshold can be adjusted

pressing soft keys 2 and 3.

6. Press soft key 4 to save and return to the original screen.

OR

Press soft key 1 to cancel and return to the original screen.

7. Press soft keys 2 and 3 to move the carousel left or right

through sub-modes to uni-direction

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

Continuity

8. The test current can be toggled between 200 mA and

20 mA pressing soft key 1.

9. NULL the test leads by touching the two test probe ends.

Press the TEST button until the NULL (symbol) appears on the

screen. The ohmic value on the primary screen will read 0 Ω.

10. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only showing

winding resistance across phase 1.

www.megger.com 33

Page 40

Continuity

11. This test starts automatically when the test leads are

connected to the unit under test.

12. During the tests,

The primary field displays the result of the true resistance

of the unit under test.

The secondary field displays test current and the previous

resistance value in Uni direction.

6.2 Bi-direction

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: When the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

2. Turn rotary switch to select Continuity position.

3. Press soft keys 2 and 3 to move the carousel left or right

through sub-modes to bi-direction

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

34 www.megger.com

Page 41

4. The test current can be toggled between 200 mA and

20 mA pressing soft key 1.

5. NULL the test leads by touching the two test probe ends.

Press the TEST button until the NULL (symbol) appears on the

screen. The ohmic value on the primary screen will read 0 Ω.

Continuity

6. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only showing

winding resistance across phase 1.

7. This test starts automatically.

8. During the tests,

The primary field displays the result of the true resistance

of the unit under test

The secondary field displays the test current and the

resistance values in both directions - highest value shown

in Primary.

The test in bi-direction mode runs continually

www.megger.com 35

Page 42

Continuity

6.3 Diode test

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: When the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

2. Turn rotary switch to select Continuity position.

3. Press soft keys 2 and 3 to move the carousel left or right

through sub-modes to Diode test.

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

4. This test starts automatically.

5. During the tests, the primary field displays the voltage drop

as it is measured.

A good forward-biased diode displays a voltage drop ranging from 0.5 to 0.8 V for the most commonly used

silicon diodes. Some germanium diodes have a voltage drop ranging from 0.2 to 0.3 V. The voltage drop is also

dependent on the test current.

The meter displays O/C when a good diode is reverse-biased. The O/C reading indicates the diode is functioning

as an open switch.

A bad (open circuit) diode does not allow current to flow in either direction. The meter will display O/C in both

directions when the diode is opened.

A short circuited diode has zero voltage drop reading in both directions.

36 www.megger.com

Page 43

Continuity

If a voltage between 0 V and 3 V is detected, the buzzer will sound and background flash /or background flash

depending on what buzzer mode is activated.

If a voltage above 3 V is detected, the buzzer will NOT sound and the background will not flash, the display will

show “OL”.

NOTE: The user is responsible for connecting test probes across the diode under test. There is no information

displayed in the secondary field at this point. The only information to display is the diode drop voltage if the

instrument senses a voltage across the device. If no current flows the main display will show “O/C”.

www.megger.com 37

Page 44

DLRO Digital Low Resistance Ohmmeter

7. DLRO Digital Low Resistance Ohmmeter

7.1 Manual single direction test

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: When the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

2. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only showing

winding resistance across phase 1.

3. Turn rotary switch to select the DLRO (mΩ) position.

4. Press soft keys 3 to choose the sub-mode uni-directional.

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

38 www.megger.com

Page 45

5. If there is a continuity reading detected for C and P

connections the secondary fields will display with a tick and

background will be green.

6. To start the test press the TEST button.

7. The test runs for a few seconds, then automatically stops.

DLRO Digital Low Resistance Ohmmeter

8. During the tests,

The primary field displays the result with the actual

current being delivered. As the resistance gets higher the

current will get lower.

The secondary field displays the continuity on the Current

(C1-C2) and potential (P1-P2) circuits.

9. The result can be saved by pressing the SAVE button. A

message will inform you the data was saved and which asset

ID it was saved to.

10. To restart the test, press the TEST button again.

www.megger.com 39

Page 46

DLRO Digital Low Resistance Ohmmeter

7.2 Auto Single direction test

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: When the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

2. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only showing

winding resistance across phase 1.

3. Turn rotary switch to select the DLRO (mΩ) position.

4. Press soft keys 3 to choose the sub-mode uni-directional

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

40 www.megger.com

Page 47

5. Press soft key 1 to enable auto mode.

6. If there is a continuity reading detected for C and P

connections the secondary fields will display with a tick and

background will be green.

If all the leads are connected correctly, test will start immediately.

7. The test runs for a few seconds then automatically stop

8. During the tests,

The primary field displays the result with the actual

current being delivered. As the resistance gets higher the

current will get lower.

The secondary field displays the continuity on the Current

(C1-C2) and potential (P1-P2) circuits.

DLRO Digital Low Resistance Ohmmeter

9. The result can be saved by pressing the SAVE button. A

message will inform you the data was saved and which asset

ID it was saved to.

10. To restart the test, re-connect to a new test piece and the

test will start automatically.

7.3 Manual bi-direction test

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: When the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

www.megger.com 41

Page 48

DLRO Digital Low Resistance Ohmmeter

2. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only showing

winding resistance across phase 1.

3. Turn rotary switch to select the DLRO (mΩ) position.

4. Press soft keys 2 to choose the sub-mode bi-directional.

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

5. If there is a continuity reading detected for C and P

connections the secondary fields will display with a tick and

background will be green.

42 www.megger.com

Page 49

6. To start the test press the TEST button.

7. The test runs for a few seconds, then automatically stop.

8. During the tests,

The primary field displays a rotating circle to show a test

is underway.

The secondary field displays the continuity on the Current

(C1-C2) and potential (P1-P2) circuits.

DLRO Digital Low Resistance Ohmmeter

9. When the test has completed,

The primary field displays the result for current and

resistance in each direction and an average of the two.

The secondary field displays the continuity on the Current

(C1-C2) and potential (P1-P2) circuits.

10. The result can be saved by pressing the SAVE button. A

message will inform you the data was saved and which asset

ID it was saved to.

11. To restart the test, press the TEST button again.

www.megger.com 43

Page 50

DLRO Digital Low Resistance Ohmmeter

7.4 Auto Bi direction test

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: When the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

2. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only showing

winding resistance across phase 1.

3. Turn rotary switch to select the DLRO ( mΩ ) position.

4. Press soft keys 2 to choose the sub-mode bi-directional.

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

44 www.megger.com

Page 51

5. Press soft key 1 to enable auto mode.

6. If there is a continuity reading detected for C and P

connections the secondary fields will display with a tick and

background will be green.

7. If all the leads are connected correctly, test will start

immediately, runs for a few seconds and then automatically

stop.

8. During the tests,

The primary field displays a rotating circle to show a test

is underway

The secondary field displays the continuity on the Current

(C1-C2) and potential (P1-P2) circuits

DLRO Digital Low Resistance Ohmmeter

9. When the test has completed,

The primary field displays the result for current and

resistance in each direction and an average of the two.

The secondary field displays the continuity on the Current

(C1-C2) and potential (P1-P2) circuits.

10. The result can be saved by pressing the SAVE button. A

message will inform you the data was saved and which asset

ID it was saved to.

11. To restart the test, re-connect to a new test piece and the

test will start automatically.

www.megger.com 45

Page 52

DLRO Digital Low Resistance Ohmmeter

7.5 Test failure

7.5.1 Lost connection

Should the connection be lost during the test the MTR105 will

notify the user. The user can re-make the connection then

restart the test after a few seconds by pressing the test button or

by reconnecting to a test piece.

46 www.megger.com

Page 53

8. Direction of Motor Rotation

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

Connect L1 to phase 1

Connect L2 to phase 2

Connect L3 to phase 3

Please ensure the motor is configured for star (Y) or delta

configuration before performing the test.

NOTE: when the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

2. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only.

Direction of Motor Rotation

3. Turn rotary switch to select direction of motor rotation

position.

4. Rotate the motor in one direction. Check if display matches

L1 L2 L3 correct phases of rotation.

5. Rotate the motor in opposite direction. Check if display

matches L3 L2 L1 correct phases of rotation

www.megger.com 47

Page 54

Inductance (L); Capacitance (C); Resistance (R) (LCR)

9. Inductance (L); Capacitance (C); Resistance (R) (LCR)

NOTE: Results of measurements can be adversely affected by impedances of additional operating circuits connected

in parallel or by transient current.

9.1 Auto

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: When the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

2. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only showing

connection across phase 1.

3. Turn rotary switch to select the LCR position.

4. Press soft keys 2 and 3 to move the carousel left or right

through sub-modes to auto capacitance / inductance test.

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

48 www.megger.com

Page 55

Inductance (L); Capacitance (C); Resistance (R) (LCR)

5. Press soft keys 1 to toggle between 120 Hz and 1000 Hz.

6. To start the test press the TEST button.

The MTR105 determines if the load is inductive, capacitive or

resistive automatically.

7. During the tests,

The primary field displays the result for the reactive

component. (This could be capacitance, inductance or

resistance).

The secondary field displays the frequency.

9.2 Capacitance or inductance

1. Connect the test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: When the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

www.megger.com 49

Page 56

Inductance (L); Capacitance (C); Resistance (R) (LCR)

2. Connect the test leads to the unit under test.

NOTE: The connection is for illustrative purposes only showing

connections across phase 1.

3. Turn rotary switch to select the LCR position.

4. Press soft keys 2 and 3 to move the carousel left or right

through sub-modes to capacitance or inductance test.

NOTE: The full title text of the sub-mode will appear in the

secondary field for a few seconds.

( ) capacitance

( ) inductance

5. Press soft keys 1 to toggle between 120 Hz and 1000 Hz.

50 www.megger.com

Page 57

Inductance (L); Capacitance (C); Resistance (R) (LCR)

6. To start the test press the TEST button.

The MTR105 determines if the load is inductive, capacitive or

resistive automatically.

7. During the tests,

The primary field displays a rotating circle to show a test

is underway.

The secondary field displays the frequency.

8. During the tests,

The primary field displays the result for the reactive

component. (This could be capacitance, inductance or

resistance).

The secondary field displays the frequency.

9.3 LCR Calibration

NOTE For full MTR105 re-calibration procedure refer to Refer to 18. Calibration, Repair and Warranty on page 84.

1. Inductance calibration can be accessed from any sub-mode

within the LCR family by pressing soft key 4.

www.megger.com 51

Page 58

Inductance (L); Capacitance (C); Resistance (R) (LCR)

2. The open circuit calibration screen appears.

3. With the leads connected to the instrument but the circuit

kept open (separated).

4. Press soft key 4 to begin calibration.

5. Calibration will run for about 14 seconds (progress animation

will show).

6. After calibration the confirmation screen will appear.

7. Continue by pressing the tick button ( ) or Soft key 4.

8. The closed circuit calibration screen appears.

9. With the leads connected to the instrument, close the circuit

(short circuit)

10. Press soft key 4 to begin calibration.

11. Calibration will run for about 14 seconds (progress animation

will show).

12. After calibration the confirmation screen will appear.

13. Press the tick button ( ) or soft key 4 to return to the last

LCR test mode.

The MTR105 has been successfully recalibrated and is ready for

use. The new calibration will be stored.

52 www.megger.com

Page 59

14. If calibration fails, 2 options appear:

Press soft key 1 to go back

or

Press the tick button ( ) or soft key 4 to try again

Inductance (L); Capacitance (C); Resistance (R) (LCR)

www.megger.com 53

Page 60

Temperature measurement

10. Temperature measurement

Thermocouple connected, type “T” is set as default, the MTR105 can also be configured for “J” and “K” type

thermocouples.

Before an insulation resistance test can be carried out with temperature compensation enabled a temperature

measurement must be carried out to establish the temperature of the unit under test.

1. Temperature measurement screen will display O/C when the

thermocouple is not detected and there is not a previous

temperature measurement reordered.

2. Two options are displayed:

2.1. Connect the thermocouple for an accurate temperature

measurement.

2.2. Press soft key 4 for a manual temperature

measurement.

10.1 Thermocouple temperature measurement

1. Connect the thermocouple test leads to the MTR105.

1.1. Press the Information ( ) button to view the lead set

up diagram.

NOTE: When the diagram is displayed a test cannot be

performed. Press Information ( ) button to return to the test

screen.

NOTE: The thermocouples are sensitive to polarity.

2. Turn rotary switch to select the Thermometer position.

54 www.megger.com

Page 61

3. Press soft keys 2 and 3 to move the carousel left or right to

choose thermocouple type T, K or J.

A thermocouple symbol appears in the bottom left of the

primary screen, alongside the type of thermocouple selected.

4. Press soft key 1 to toggle between ºC (Centigrade) or ºF

(Fahrenheit).

Temperature measurement

5. Place the thermocouple against the test piece and allow the

thermocouple to rise to a stable temperature.

6. The unit starts measuring the temperature as soon as it

detects the probe is connected.

7. During the test the primary field displays the measured

temperature.

NOTE : If the thermocouple is not connected or is damaged the

primary field will display “O/C”

www.megger.com 55

Page 62

Temperature measurement

8. The result can be saved by pressing the SAVE button. A

message will inform you the data was saved and which asset

ID it was saved to.

10.2 Manual Temperature measurement

1. Turn rotary switch to select the Thermometer position.

2. Press soft key 4.

56 www.megger.com

Page 63

3. Press soft keys 2 and 3 to select a positive or negative

temperature.

4. Press soft key 4 to confirm.

or

Soft key 1 to cancel.

5. Press soft key 2 and 3 to scroll through the digits.

6. Press soft key 4 to accept the first digit and move to the

next.

7. Press soft key 2 and 3 to scroll through the digits.

8. Press soft key 4 to accept the second digit and move to the

next.

Temperature measurement

9. Press soft key 2 and 3 to scroll through the digits.

10. Press soft key 4 to accept the third digit and move to the

next.

11. Press soft key 2 and 3 to scroll through the digits.

12. Press soft key 4 to accept the temperature value.

13. Press soft key 1 to cancel and return to the previous menu at

any point.

14. The new temperature will be displayed.

The result can be saved by pressing the SAVE button. A

message will inform you the data was saved and which asset