Page 1

MTO106

Transformer ohmmeter

User’s Manual

Art No. ZP-BN01E Doc. BN034794AE V01a 2018

WWW.MEGGER.COM

Page 2

Page 3

MTO106

Transformer ohmmeter

User’s Manual

NOTICE OF COPYRIGHT & PROPRIETARY RIGHTS

© 2018, Megger Sweden AB. All rights reserved.

The contents of this manual are the property of Megger Sweden AB. No part of this work may be reproduced or transmitted in any form or

by any means, except as permitted in written license agreement with Megger Sweden AB. Megger Sweden AB has made every reasonable

attempt to ensure the completeness and accuracy of this document. However, the information contained in this manual is subject to change

without notice, and does not represent a commitment on the part of Megger Sweden AB. Any attached hardware schematics and technical

descriptions, or software listings that disclose source code, are for informational purposes only. Reproduction in whole or in part to create

working hardware or software for other than Megger Sweden AB products is strictly prohibited, except as permitted by written license

agreement with Megger Sweden AB.

TRADEMARK NOTICES

Megger® and Programma® are trademarks registered in the U.S. and other countries. All other brand and product names mentioned in this

document are trademarks or registered trademarks of their respective companies.

Megger Sweden AB is certified according to ISO 9001 and 14001.

Postal address:

Megger Sweden AB

Box 724

SE-182 17 DANDERYD

SWEDEN

T +46 8 510 195 00

F +46 8 510 195 95

BN034794AE ZP-BN01E MTO106

Visiting address:

Megger Sweden AB

Rinkebyvägen 19

SE-182 36 DANDERYD

SWEDEN

seinfo@megger.com

www.megger.com

3

Page 4

Contents

1 Introduction

............................................................. 6

1.1 Product description ......................................6

Features and benefits .................................................. 6

Applications ................................................................ 6

1.2 Winding resistance testing ..........................6

1.3 Receiving instructions ...................................7

1.4 Warranty .....................................................7

Warranty repair ........................................................... 7

2 Safety

............................................................. 8

2.1 General ........................................................8

Symbols on the instrument .......................................... 8

2.2 Safety instructions ........................................8

Maintenance ............................................................... 9

3 Instrument description and

Accessories ....................................... 10

3.1 Panel .........................................................10

3.2 The display .................................................11

3.3 Accessories ................................................11

Included .................................................................... 11

Optional .................................................................... 11

4 Setup and operation

........................................................... 12

4.1 Preparations ...............................................12

4.2 Testing Single and Dual windings ...............12

4.3 Testing Delta winding resistance .................13

5 Application examples

........................................................... 14

5.1 Testing transformers with tap changers ......14

5.2 Temperature correction ..............................14

5.3 Manual demagnetization of a transformer .15

6 Troubleshooting and Calibration ....... 16

6.1 Troubleshooting .........................................16

7 Specifications

........................................................... 18

Specifications ...................................................18

4 MTO106 ZP-BN01E BN034794AE

Page 5

BN034794AE ZP-BN01E MTO106

5

Page 6

1 INTRODUCTION

1

Introduction

1.1 Product description

The MTO106 transformer ohmmeter is an easy-to-use,

line-operated instrument specifically designed for safe

and accurate field measurement of winding resistance

in smaller transmission and distribution transformers.

It has dual channels with a wide measurement range

and can accurately provide information about the

vast majority of power transformers, reactors and

instrument transformers. The test current can be

manually set in five different ranges to fit transformers

of various sizes.

The unit has built-in safety protection for testing

transformers and other components with high

inductance. To ensure operator safety, MTO 106

automatically discharges the stored energy in the

transformer at the end of each test. If a current lead

is disconnected while current is flowing through

the transformer, the current will flow through the

alternate path of the potential lead without damage

to the instrument or risk to the operator

Features and benefits

▪ Test current up to 6 A and stable current generation

▪ Up to 48 V output voltage for fast charging of

transformer windings

▪ Light weight and portable

▪ Very short start-up time

▪ Ease of use

▪ Resistance range, 10 µOhm to 30 kOhm, for testing a

wide variety of transformers.

1.2 Winding resistance

testing

Transformer winding resistances are measured in

the field in order to check for abnormalities due to

loose connections, broken strands, and high-contact

resistance in tap changers. Interpretation of results is

usually based on a comparison of measurements

made separately on each phase in the case of a

wye-connected winding or between pairs of terminals

on a delta-connected winding. Comparison may also

be made with original data measured in the factory.

Winding resistance measurements in transformers

are of fundamental importance for the following

purposes:

▪

Calculations of the I2R component of conductor losses.

▪ Calculation of winding temperature at the end of a

temperature test cycle.

▪ As a diagnostic tool for assessing possible damage in the

field.

Problems or faults occur due to poor design, assembly,

handing, poor environments, overloading or poor

maintenance. Measuring the resistance of the

windings assures that the connections are correct and

the resistance measurements indicate that there are

no severe mismatches or opens. Many transformers

have taps built into them. These taps allow ratio to be

increased or decreased by. Any of the ratio changes

involve a mechanical movement of a contact from one

position to another. To tetect contact wear, winding

resistance measurements are usually performed at

each tap in a load tap changer.

Applications

The MTO106 is mainly intended for field

measurements of smaller transmission and distribution

transformers:

▪

To verify factory test readings

▪ As part of a regular maintenance program.

▪ To help locate the presence of defects in transformers

such as increased contact resistance in terminal

connections and tap changers.

The instrument can also be used for general resistance

measurements of for instance control wiring, voltage

regulators, motors, generators and all types of

connections.

6 MTO106 ZP-BN01E BN034794AE

Page 7

1 INTRODUCTION

1.3 Receiving instructions

▪ Check the equipment received against the packing list to

ensure that all materials are present. Notify Megger of any

shortage.

▪ Examine the instrument for damage received in transit. If

damage is discovered, file a claim with the carrier at once

and notify Megger, giving a detailed description of the

damage.

▪ This instrument has been thoroughly tested and inspected

to meet rigid specifications before being shipped. It

is ready for use when set up as indicated in this user

manual.

1.4 Warranty

Products supplied by Megger are warranted against

defects in material and workmanship for a period of

one year following shipment.

Our liability is specifically limited to replacing or

repairing, at our option, defective equipment.

This warranty does not include batteries, lamps

or other expendable items, where the original

manufacturer’s warranty shall apply.

We make no other warranty. The warranty is void

in the event of negligence abuse (failure to follow

recommended operating procedures) or failure by

the customer to perform specific maintenance as

indicated in this manual.

Warranty repair

▪ Equipment returned to the factory for repair must be

shipped prepaid and insured.

▪ Contact your Megger representative for instructions and a

return authorization (RA) number.

▪ Indicate all pertinent information, including problem

symptoms.

▪ Specify the serial number and the catalog number of the

unit.

▪ If you need to return the instrument, please use either the

original crate or one of equivalent strength.

BN034794AE ZP-BN01E MTO106

7

Page 8

2 SAFETY

Safety

2

2.1 General

For your own safety and to get the maximum benefit

from your instrument, please ensure that you read

and understand the following safety instructions and

warnings before using the instruments.

Read and comply with the following instructions.

Always comply with local safety regulations.

Symbols on the instrument

Caution, refer to accompanying

documents.

Protective conductor terminal.

WEEE, Waste Electrical and Electronic

Equipment. Please utilize your

local WEEE collection facilities in

the disposition of this product and

otherwise observe all applicable

requirements.

The unit can also be returned to

Megger at any time at no charge for

the disposal.

2.2 Safety instructions

1.

Single ground system - This equipment can

be used only in electrical systems with single

ground. Before connecting this unit to power

you must verify that High Voltage Ground

and Low Voltage Protective Ground create a

single protective ground with no measurable

voltage potential existing between these ground

systems. If a voltage potential is found between

the ground systems please consult local safety

regulations.

2.

Mains cord protective conductor - The

instrument is equipped with a power cord with

integral safety ground pin. Do not defeat the

safety ground in any manner. The equipment

must be connected to a grounded mains outlet.

3.

Ground lead - The first connection made, and

last removed is the connection of instrument

Protective conductor terminal to station ground

using the separate ground lead.

Make sure ground lead is checked for continuity

and securely fastened.

4.

Use an easily accessible power outlet - This

will ensure that you can disconnect the power

quickly in case of a problem. The instrument

should be operated only from the type of power

source indicated on its nameplate.

5.

Connecting - It is very important not to

connect any leads on top of or too close to

one another. Take the necessary precautions

to as-sure one lead falling off will not take a

second lead with it. Never connect the test

equipment to energized equipment. Never make

any connection or disconnections while the test

equipment is generating or discharging.

6.

Testing - When applying current to a

transformer with very high inductance,

additional care should be taken not to remove

current leads while current is still flowing.

Removal of terminals while current flowing

may generate an arc that may result in lethal

injury: electrical, thermal or by fall. Ensure that

the transformer to be tested is completely deenergized. Check every winding. Ensure that all

terminals of the transformer are disconnected

from line or load at the transformer.

Connections to ground may be left in place.

8 MTO106 ZP-BN01E BN034794AE

Page 9

7.

Water and moisture - Do not use the

instrument near water. To prevent fire or shock

hazard, do not expose the instrument to rain or

moisture. Do not touch the plug with wet hands

8.

Ventilation - Slots and openings in the

instrument are provided for ventilation. They

ensure reliable operations of the instrument,

keeping it from overheating. These openings

must not be blocked nor covered during

operation.

9.

Accessories - Do not use any accessories that

are not intended for use together with the

instrument.

Maintenance

1.

DISCONNECT the MAINS plug before any

cleaning or maintenance.

2.

Refer all servicing to Megger authorized

personnel.

Do not attempt to service the instrument

yourself. If you attempt to service the instrument

the warranty is no longer valid.

3.

Read and understand Safety in the User

Manual before performing any service.

4.

Routine maintenance is all that is required

for these test sets. The cables and connector

panel should be inspected frequently to be

sure all connections are tight and all ground

connections intact.

5.

Cleaning - Use a damp cloth for cleaning. Do

not use liquid cleaners or aerosol cleaners.

2 SAFETY

BN034794AE ZP-BN01E MTO106

9

Page 10

3 INSTRUMENT DESCRIPTION AND ACCESSORIES

Instrument description and

3

3.1 Panel

Accessories

2 3 41

65

7

1. R1 SENSE

R2 SENSE

Voltage input

2. CURRENT OUTPUT

1 mA - 6 A , 48 VD C

Current output

3. R2 SENSE

Switch for selection of single/dual channel measurement. Dual channel measurement is active

when the switch is in the “ON”position.

4. Touchscreen

4 inch, backlit, monochrome display

5. DISCHARGE

Built-in discharge circuit safely discharges the test

object when test is completed. LED and audio signal indicate the charging status.

6. 100 -240 V ~ 5 A

50 / 60 Hz

Mains input and fuse box: Always use the power

cord supplied with the unit. The unit is powered

when the switch for power input is in the “on”

position.

8

7. RANGE

8. ON/OFF

9.

9

Selector for test currents.

Toggle switch ON / OFF for generation of test currents. Red Indicator lamp lit during generation.

Protective conductor terminal: To be connected to

station earth (ground) using separate ground lead,

see "2.2 Safety instructions" on page 8.

10 MTO106 ZP-BN01E BN034794AE

Page 11

3 INSTRUMENT DESCRIPTION AND ACCESSORIES

3.2 The display

1 2

43

1. Injected current. The current value displayed may

differ slightly from the selected current.

2. Measured resistance value. The value is typically

displayed with four significant digits. If fewer digits are displayed, it is recommended to lower the

test current.

3. Voltage measured over the “R1 SENSE” connectors.

This voltage is divided by the injected current to

calculate the resistance reading.

4. Stability reading. Reaches 100% when the measurement is stable.

Note: In large transformers the MTO106 may be

unable to fully saturate the core and the reading

may approach 100% only very slowly.

Note If dual channel measurement is selected, the

above values are duplicated.

3.3 Accessories

Included

Test lead black with banana connector and Kelvin

clamp, 10 m (33 ft)

Test lead red with banana connector and Kelvin

clamp, 10 m (33 ft)

Ground lead, 5 m (16 ft) 2.5 mm² 1 GA-00200

Mains cable 1 AA-00010

User’s manual 1 ZP-BN 01E

MTO106 Report pad 1 XP -BN 01E

MTO106 Reporting template file 1 SB- 0022E

Carry bag 1 2000-091

GC- 3 2 3 1 0

GA-00200

Optional

Transport case for instrument and leads 1009-74 4

MTO106 dual channel measurement lead set

Parts included in the MTO106 dual channel measurement lead set (GA-19000).

Sensing lead, black, 10 m (33 ft) 1 KG - 0 0530

Sensing lead, red, 10 m (33 ft) 1 KG - 0 0532

Timing clamp 2 KD-03040

Test cable, black, 2 m (6.5 ft) 1 0 4-35030

1 G C- 3 2 3 1 0

1 G C- 3 2 3 1 2

GC- 3 2 3 1 2

2000-091

GA-19000

1009-74 4

KG- 0 0530

BN034794AE ZP-BN01E MTO106

KG- 0 0532

KD- 03040

11

Page 12

4 SETUP AND OPERATION

4

Setup and operation

4.1 Preparations

Important

Always follow the safety instructions in

Chapter 2 of this manual. Always comply

with local safety regulations.

Use the Megger supplied safety ground lead to connect

▪

the MTO106 protective conductor terminal directly to

local station earth (Ground).

Note If using separate voltage and current leads

instead of the standard Kelvin-type leads,

do not clip potential leads on to the current

leads, since this will add contact resistance

to the measurement. Potential leads should

always be placed inside (between) current

leads

4.2 Testing Single and Dual

windings

1] Make sure that the test current switch is set

to “OFF”.

2] Connect the Kelvin-type test leads to the

MTO106, see figures below.

The leads marked "Generator" to the "CURRENT OUTPUT" terminals of corresponding

colour and the leads marked "P/Meas" to

"R1 SENSE" terminals of corresponding colour.

If using separate voltage (sense) and current

leads, connect them to the corresponding

"CURRENT OUTPUT" and "R1 SENSE" terminals.

For Dual windings:

Connect the second channel sense leads to

the terminals "R2 SENSE" of corresponding

colour.

Use a jumper cable to connect two phases

(according to table 1 on next page) for simultaneous winding measurement.

3] Connect the test lead Kelvin clamp to the

test object (e.g. transformer) according to

the required configuration.

4] Once all the precautions and steps of sections

"2 Safety" on page 8 and "4.1 Prepara-

Connection diagram for single winding test. Connection diagram for dual winding test.

12 MTO106 ZP-BN01E BN034794AE

Page 13

4 SETUP AND OPERATION

tions" on page 12 are complete, the mains

power cord is connected to the power outlet.

5] Set the "RANGE"selector to the required

test current, as high as possible but not more

than 10% of rated current (power transformers, reactors, rotating machines). For a CT,

preferably use 1 A.

6] For Single winding

Set switch "R2 SENSE" to "OFF" position.

For Dual windings:

Set switch "R2 SENSE" to "ON" position.

7] Set switch "TEST CURRENT" to "ON", to initi-

ate current.

8] The current and resistance values must be

observed on the display. Wait for the stability reading to reach 100% and then note the

displayed resistance value in the supplied

reporting sheet or other location.

9] When the measurement is finished set the

"TEST CURRENT" switch to "OFF".

The "DISCHARGE" lamp and sound will indicate that the discharging is in progress.

10] Discharge is complete when both discharge

indicator and "TEST CURRENT" lamp are off.

Warning

Do not disconnect any test leads until

the "DISCHARGE" light goes out and the

sound stops.

Note The discharge of a transformer after testing is

critical to prevent excessive voltage build-up

across the transformer bushings upon removal

the test leads. The MTO106 discharge circuitry

is built-in and will automatically initiate when

the current source is disconnected from the

transformer. It will also provide visual and

audible indication of discharging.

4.3 Testing Delta winding

resistance

Testing Delta winding resistance may be a very time

consuming procedure, in particular LV winding

deltas. The correct balance time can take up to 30-60

minutes for a large transformer, which far exceeds the

time restriction of many tests.

The method for quickly testing delta configurations

requires that both the high side and low side be

connected in series with the Transformer Ohmmeter’s

current source (see connection table 1). By using

both HV and LV windings to magnetize the core, the

effective test current increases with the turn ratio.

Table 1. Transformer connection schemes for

injecting test current and measuring two

windings

Measurement setup

Vector

Group

Dd0

Dyn7

Dy n1

YNyn0

Ynd1

Dy1

YNd7

Dyn5

Dy11

Dy n11

Current Connections

+ Current Jumper - Current + - + -

H1 H3-X1 X3 H1 H3 X1 X3

H2 H1-X2 X1 H2 H1 X2 X1

H3 H2-X3 X2 H3 H2 X3 X2

H1 H3-X0 X1 H1 H3 X0 X1

H2 H1-X0 X2 H2 H1 X0 X2

H3 H2-X0 X3 H3 H2 X0 X3

H1 H3-X1 X0 H1 H3 X1 X0

H2 H1-X2 X0 H2 H1 X2 X0

H3 H2-X3 X0 H3 H2 X3 X0

H1 H0-X1 X0 H1 H0 X1 X0

H2 H0-X2 X0 H2 H0 X2 X0

H3 H0-X3 X0 H3 H0 X3 X0

H1 H0-X1 X2 H1 H0 X1 X2

H2 H0-X2 X3 H2 H0 X2 X3

H3 H0-X3 X1 H3 H0 X3 X1

H1 H3-X1 X2 H1 H3 X3 X2

H2 H1-X2 X3 H2 H1 X1 X3

H3 H2-X3 X1 H3 H2 X2 X1

H1 H0-X2 X1 H1 H0 X2 X1

H2 H0-X3 X2 H2 H0 X3 X2

H3 H0 -X1 X3 H3 H0 X1 X3

H1 H2-X0 X1 H1 H2 X0 X1

H2 H3-X0 X2 H2 H3 X0 X2

H3 H1-X0 X3 H3 H1 X0 X3

H1 H3-X1 X3 H1 H3 X1 X3

H2 H1-X2 X1 H2 H1 X2 X1

H3 H2-X3 X2 H3 H2 X3 X2

H1 H2-X1 X0 H1 H2 X1 X0

H2 H3-X2 X0 H2 H3 X2 X0

H3 H1-X3 X0 H3 H1 X3 X0

Meas

ch 1

Meas

ch 2

BN034794AE ZP-BN01E MTO106

13

Page 14

5 APPLICATION EXAMPLES

5

Application examples

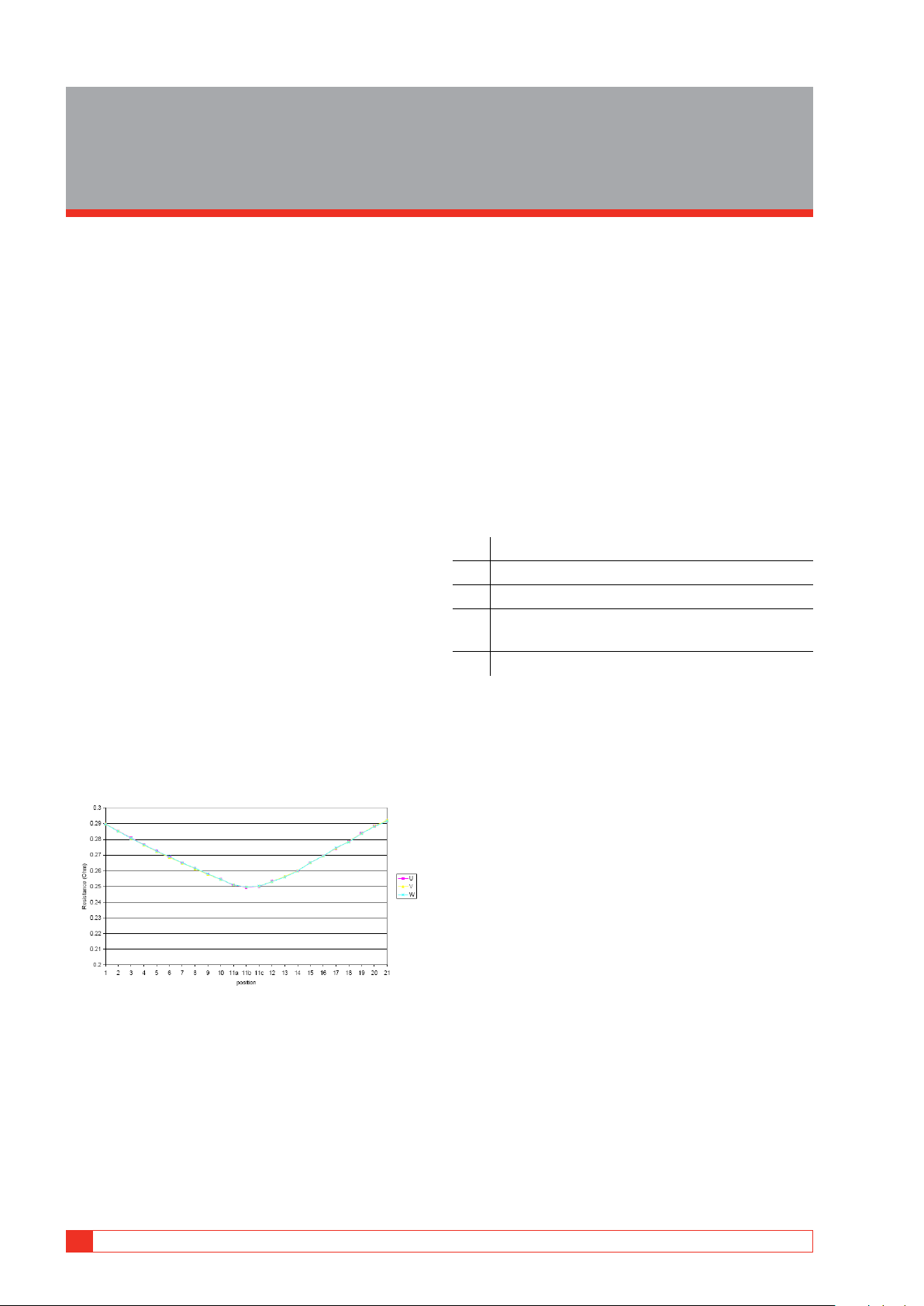

5.1 Testing transformers

with tap changers

The tap changer allow ratio to be increased or

decreased. Any of the ratio changes involve a

mechanical movement of a contact from one position

to another. It is this contact that needs to be checked

by way of its resistance. The contact may go bad for a

number of reasons.

▪

Misaligned when manufactured causing insufficient

surface contact. Full load current overheats contact

surface causing it to burn.

▪ Current passing through contact exceeds full load rating.

▪ Load tap changing operation not "Make before break"

creating internal arcing of contact surface.

Winding resistance measurements (WRM) are

normally performed for every tap the same way as

WRM for individual windings. The test instrument is

continuously injecting test current and the resistances

for each tap are measured sequentially as the tap

changer is stepped through its positions. Results are

typically presented as a graph or table with resistance

values for each tap. Resistance changes between

taps should be consistent with only small deviations

between different tap position changes. Fig 1 shows

a typical behavior for a transformer/tap-changer in

as-new condition.

5.2 Temperature correction

Cold winding resistance measurements are normally

converted to a standard reference temperature equal

to the rated average winding temperature rise plus

20ºC. In addition, it may be necessary to convert

the resistance measurements to the temperature

at which the impedance loss measurements were

made. If winding resistances are to be compared to

factory values, resistance measurements will have

to be converted to the reference temperature used

at the factory (usually 75°C). The conversions are

accomplished by the following formula:

Rs = Rm ( Ts + Tk ) / ( Tm + Tk )

where:

Rs resistance at desired temperature Ts

Rm measured resistance

Ts desired reference temperature, in °C.

Tm temperature at which resistance was

measured, in °C.

Tk 235 (copper) 225 (aluminum)

Fig 5.1. Winding resistance vs tap position for a new transformer

Measuring the winding resistance for each individual

tap is quite straightforward. The most common

issue is probably that the tester has not waited for a

sufficient time for taking measurements after a tap

change. Monitor the resistance value closely before

storing the value to make sure the resistance value has

stabilized!

14 MTO106 ZP-BN01E BN034794AE

Page 15

5.3 Manual

demagnetization of a

transformer

The MTO106 does not include and automated

demagnetization feature and demagnetization, if

deemed necessary, must be performed manually

according to the method below.

1] Run a normal winding resistance test accord-

ing to the instructions in section "4.2 Testing

Single and Dual windings" on page 12.

2] Swap the terminals, preferably by swapping

the Kelvin clamps, select the next lower test

current and inject current until the current

reading has reached at least 50% of the set

value.

3] Repeat step 2 for each test current range

down to the lowest selectable test current

value.

5 APPLICATION EXAMPLES

BN034794AE ZP-BN01E MTO106

15

Page 16

6 TROUBLESHOOTING AND CALIBRATION

Troubleshooting and

6

Calibration

6.1 Troubleshooting

Resistance

value

“----“ is

displayed

“< 0.010 mΩ”

is displayed

“< 0.10 mΩ”

“< 1.0 mΩ”

“< 0.010 Ω”

or

“< 0.10 Ω”

Voltage

value

U < 0.06

mV

U < 0.06

mV

U > 20 V

Current value Probable cause Action

Close to set value

0.0 A

Typical less than 50%

of set current value

1. Increase test

1. Too low test current

2. Sense leads switched

3. Sense leads not connected

4. Current leads shorted

No current loop, current leads

not properly connected

Too high test current Lower test current

Resistance below measurement

range

Too low test current Increase test current

current

2. Check sense leads

3. Check sense leads

4. Check current

leads

Check current leads

16 MTO106 ZP-BN01E BN034794AE

Page 17

7 SPECIFICATIONS

BN034794AE ZP-BN01E MTO106

17

Page 18

7 SPECIFICATIONS

Specifications

7

Specifications

Specifications are valid at nominal input voltage. Specifications are

subject to change without notice.

Environment

Application field The instrument is intended for use in

Temperature

Operating -20°C to +50°C (-4°F to +122°F)

Storage & transport -50°C to +70°C (-58°F to +158°F)

Humidity (operating) 0% – 90% RH, non-condensing

CE-marking

LVD 2014/35/EU

EMC 2014/30/EU

RoHS 2011/ 6 5 / E U

General

Mains voltage 100 - 240 V AC, 50 / 60 Hz

Input power 400 VA (max)

Case Ruggedized plastic case with removable lid

Dimensions (W x D x H) 360 x 304 x 194 mm (14.2 x12 x 7.6”)

Weight 7.3 kg (16 lbs) excl. cables

Display 4-inch, backlit, monochrome

Test l eads 2 x 10 m (33 ft), with banana connectors

Ground lead 1 x 5 m (16 ft), 2.5 mm²

Measurement section

Measurment range 10 µOhm to 30 kOhm

Resolution Up to 4 digits

Open circuit test voltage up to 48 V DC

Measurement voltage up to 20 V DC

Current

range

6 A 10.00 mΩ to 5.00 0 Ω ±(0.25%rdg + 1 digit) 4 digits

1 A 100.0 mΩ to 30.00 Ω ±(0.25%rdg + 1 digit) 4 digits

100 mA 1.000 Ω to 300.0 Ω ±(0.25%rdg + 1 digit) 4 digits

10 m A 10.00 Ω to 3000 Ω ±(0. 25%rdg + 1 digit) 4 digits

1 mA 100.0 Ω to 30.0 0 kΩ ±(0.25%rdg + 1 digit) 4 digits

Resistance range Inaccuracy Resolution

0.010 mΩ to 9.999 mΩ

0.10 mΩ to 99.99 mΩ ±(0.25%rdg + 2 digits) 0.01 m Ω

1.0 mΩ to 999.9 mΩ ±(0. 25%rdg + 2 digit s) 0 .1 m Ω

0.010 Ω to 9.999 Ω ±(0.25%rdg + 2 digits) 0.0 01 Ω

0.10 Ω to 99.99 Ω ±(0.25%rdg + 2 digits) 0.01 Ω

high-voltage substations and industrial

environments.

and carrying handle, IP 67 when closed

alphanumerical display

and Kelvin clamps

±(0.25%rdg + 2 digits) 0.001 mΩ

18 MTO106 ZP-BN01E BN034794AE

Page 19

Page 20

Your “One Stop” Source for all your electrical test equipment needs

▪ Battery Test Equipment

▪ Cable Fault Locating Equipment

▪ Circuit Breaker Test Equipment

▪ Data Communications Test Equipment

▪ Fiber Optic Test Equipment

▪ Ground Resistance Test Equipment

▪ Insulation Power Factor (C&DF) Test Equipment

▪ Insulation Resistance Test Equipment

▪ Line Testing Equipment

▪ Low Resistance Ohmmeters

▪ Motor & Phase Rotation Test Equipment

▪ Multimeters

▪ Oil Test Equipment

▪ Portable Appliance & Tool Testers

▪ Power Quality Instruments

▪ Recloser Test Equipment

▪ Relay Test Equipment

▪ T1 Network Test Equipment

▪ Tachometers & Speed Measuring Instruments

▪ TDR Test Equipment

▪ Transformer Test Equipment

▪ Transmission Impairment Test Equipment

▪ Watthour Meter Test Equipment

▪ STATES® Terminal Blocks & Test Switches

▪ Professional Hands-On Technical and

Safety Training Programs

Megger is a leading global manufacturer and supplier

of test and measurement instruments used within the

electric power, building wiring and telecommunication

industries.

With research, engineering and manufacturing facilities

in the USA, UK, Germany and Sweden, combined with

sales and technical support in most countries, Megger

is uniquely placed to meet the needs of its customers

worldwide.

Megger is certified according to ISO 9001 and 14001.

Megger is a registered trademark.

Megger Group Limited

UNITED KINGDOM

Dover, Kent CT17 9EN

ENGLAND

▪ AUSTRALIA

▪ BULGARIA

▪ CANADA

▪ CZECH REPUBLIC

▪ CHINA

▪ FRANCE

▪ GERMANY

▪ HUNGARY

▪ INDIA

▪ INDONESIA

▪ KINGDOM OF BAHRAIN

▪ KOREA

▪ MALAYSIA

▪ PAKISTAN

▪ POLAND

▪ ROMANIA

▪ RUSSIA

▪ SINGAPORE

▪ SLOVAK REPUBLIC

▪ SOUTH AFRICA

▪ SPAIN

▪ SWEDEN

▪ SWITZERLAND

▪ TAIWAN

▪ THAILAND

▪ UNITED ARAB EMIRATES

▪ USA

▪ VIETNAM

▪ PHILIPPINES

WWW.MEGGER.COM

Postal address:

Megger Sweden AB

Box 724

SE-182 17 DANDERYD

SWEDEN

T +46 8 510 195 00

F +46 8 510 195 95

Subject to change without notice. Printed matter No. ZP-BN01E Doc. BN034794AE V01a 2018

Visiting address:

Megger Sweden AB

Rinkebyvägen 19

SE-182 36 DANDERYD

SWEDEN

seinfo@megger.com

www.megger.com

Loading...

Loading...