Page 1

www . ElectricalPartManuals . com

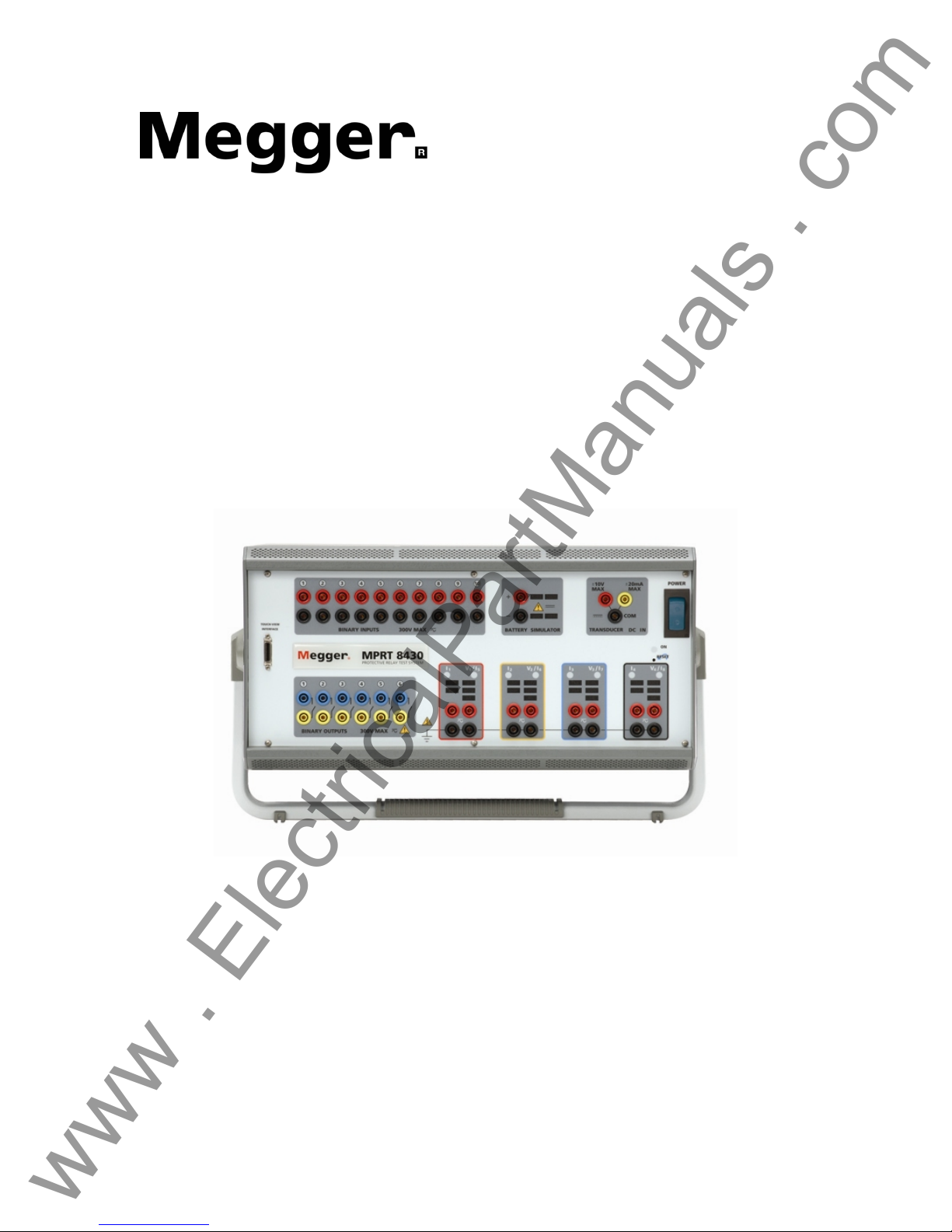

User

Manual

Model MPRT

Megger Protective Relay Tester

Part 710000

Rev 3 Date 11/15/2005

* MPRT shown with optional large carry handle

Page 2

Revision History

www . ElectricalPartManuals . com

Revision

1 Initial Release 12/17/2003

2 30043 3/07/2005

3 30207 11/16/2005

This manual, as well as the hardware and software described in it, is furnished under license and

may be used or copied only in accordance with the terms of such license. The content of this

manual is furnished for informational use only, is subject to change without notice. Megger

assumes no responsibility or liability for any errors or inaccuracies that may appear in this

manual.

The information and data in this User Manual are proprietary. The equipment described herein

may be protected by U.S. patents. Megger specifically reserves all rights to such proprietary

information as well as rights under any patent, none of which is waived by the submission of this

user manual.

ECN # Date

IMPORTANT

2

Page 3

www . ElectricalPartManuals . com

Except as permitted by such license, no part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form or by any means, electronic, mechanical, recording,

or otherwise, without the prior written permission of Megger.

Megger, the Megger logo are trademarks of Megger. VXWorks, Zinc, and Tornado are either

registered trademarks or trademarks of the WindRiver Corporation in the US and other countries.

Adobe, the Adobe logo, and Adobe Reader are trademarks of Adobe Systems Incorporated. All

other trademarks are the property of their respective owners.

Notice to U.S. government end users. The hardware, software and documentation are

“commercial items”, as that term is defined at 48 C.F.R. §2.101, consisting of “commercial

computer software” and “commercial computer software documentation,” as such terms a re u sed

in 48 C.F.R. §12.212 or 48 C.F.R. §227.7202, as applicable. Consistent with 48 C.F.R. §12.212

or 48 C.F.R. §§227.7202-1 through 227.7202-4, as applicable, the commercial computer software

and commercial computer software documentation are being licensed to U.S. government end

users (1) only as commercial items and (2) with only those rights as are granted to all other end

users pursuant to the terms and conditions set forth in the Megger standard commercial

agreement for this software and hardware. Unpublished rights reserved under the copyright laws

of the United States. The recipient, if a Government agency, acknowledges that this manual and

the equipment described were procured with "Limited Rights" to technical data as described in

ASPR 9-203 (b).

The MPRT test set includes an RTOS-resident computer program. This program belongs to

Megger and contains trade secret ideas and information of Megger.

Written and designed at Megger, 4271 Bronze Way, Dallas, Texas 75237.

__________________________

Printed in the USA.

© 2003, 2005 Megger. All rights reserved.

3

Page 4

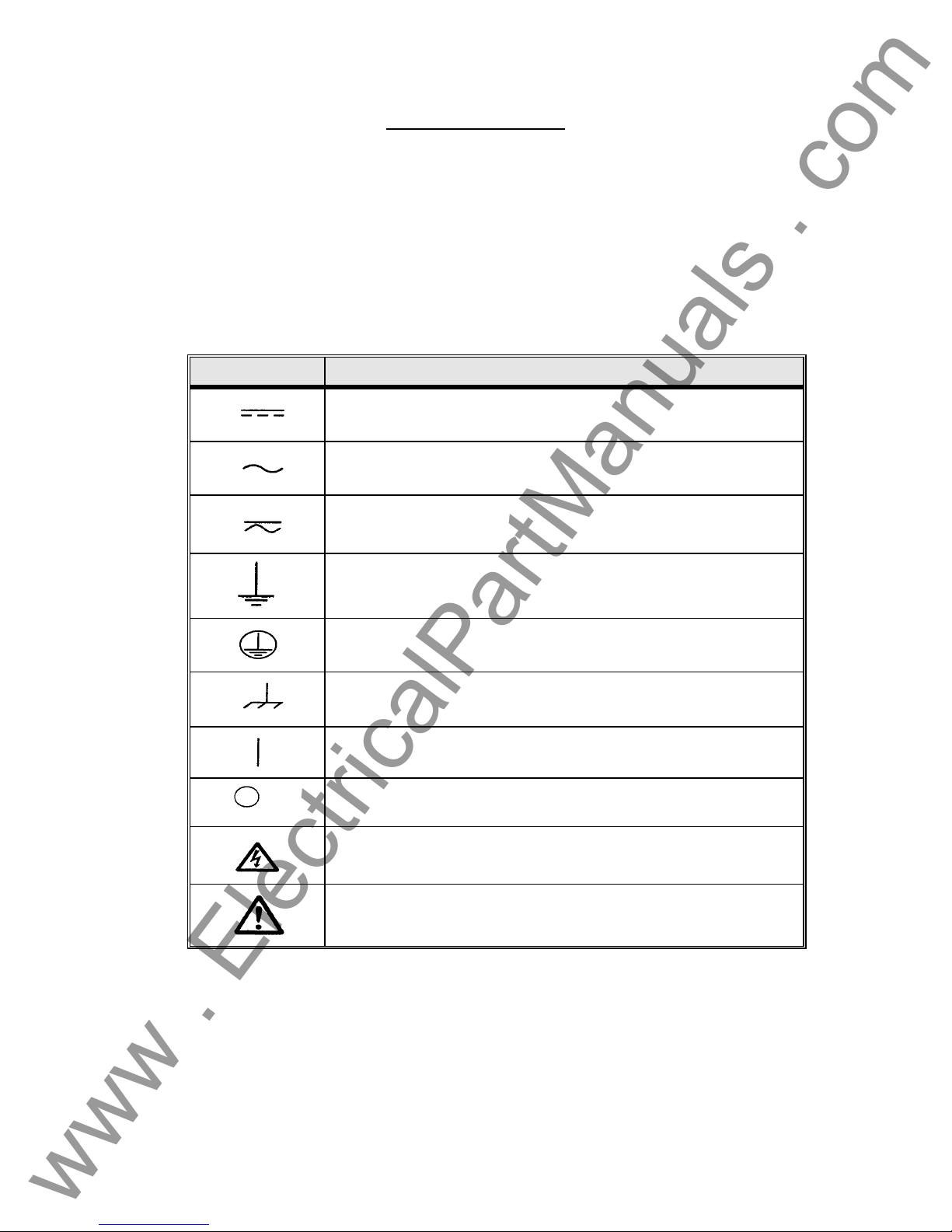

SAFETY PRECAUTIONS

www . ElectricalPartManuals . com

WARNING:

VOLTAGES GENERATED BY THIS INSTRUMENT CAN BE HAZARDOUS

This instrument has been designed for operator safety; however, no design can

completely protect against incorrect use. Electrical circuits are dangerous and can be

lethal when lack of caution and poor safety practices are used. There are several

standard safety precautions that should be taken by the operator. Where applicable, IEC

safety markings have been placed on the instrument to notify the operator to refer to the

user manual for instructions on correct use or safety related topics. Refer to the following

table of symbols and definitions.

Symbol Description

Direct Current

Alternating Current

Both direct and alternating current

Earth (ground) Terminal. There is a common chassis ground

terminal located on the back panel (see Back Panel under

Description of Controls.

Protective Conductor Terminal

Frame or Chassis Terminal

On (Supply)

Off (Supply)

Caution, risk of electric shock

Caution (refer to accompanying documents)

WARNING: Under no circumstances should the operator or technician attempt to open or

service this instrument while connected to a power source. Lethal voltages are present

and may cause serious injury or death!

4

Page 5

SAFETY PRECAUTIONS (Continued)

www . ElectricalPartManuals . com

The following are some specific safety related items associated with the

MPRT test system.

Always start with the power OFF, before connecting the power cord.

Make sure outputs are off before attempting to make test

connections.

Always use properly insulated test leads. The test leads supplied

with the unit are rated for the continuous output ratings of the test

system, and should be properly used and cared for. DO NOT use

cracked or broken test leads.

Always turn the test system off before disconnecting the power cord

or removing / inserting output modules. Turn the power off when

removing or inserting the Voltage / Current module(s).

DO NOT power up without the modules secured in their respective

slot.

DO NOT attempt to use the unit without a safety ground connected.

DO NOT attempt to use the unit if the power cord ground prong is

broken or missing.

Under no circumstances should the operator put their hand or

tools inside the test system chassis area with the test system

connected to a power source. Lethal voltages are present and

may cause serious injury or death!

5

Page 6

Table of Contents

www . ElectricalPartManuals . com

Section Page

Revision History ............................................................................................................................ 2

Safety Precautions........................................................................................................................ 4

1.0 Operation........................................................................................................................... 11

1.1 Control Description.......................................................................................................... 11

1.1.1 Front Panel...................................................................................................................... 11

1.1.2 Rear Panel...................................................................................................................... 12

1.1.3 Touch View Interface ...................................................................................................... 14

1.2 Terminology ...................................................................................................................... 15

1.2.1 Acronyms ........................................................................................................................ 15

1.2.2 Glossary of Terms........................................................................................................... 15

1.2.2.1 Tap............................................................................................................................... 15

1.2.2.2 Time Dial ..................................................................................................................... 16

1.2.2.3 Instantaneous (Inst.) Tap............................................................................................. 16

1.2.2.4 Reset Time.................................................................................................................. 16

1.2.2.5 Target Tap...................................................................................................................16

1.2.2.6 Test Multiple................................................................................................................ 16

1.2.2.7 Reach.......................................................................................................................... 16

1.2.2.8 Torque......................................................................................................................... 16

1.2.2.9 Operation (Op) Time.................................................................................................... 16

1.2.2.10 Winding Number............................................................................................................. 17

1.2.2.11 Percent (%) Slope .......................................................................................................... 17

1.2.2.12 Percent (%) Harmonic....................................................................................................17

1.3 Touch View Interface (TVI)............................................................................................... 17

1.4 Input Power and Control..................................................................................................... 17

1.4.1 Input Power.....................................................................................................................17

1.4.2 Control Section................................................................................................................ 17

1.4.2.1 V/I Generator Module.................................................................................................. 17

1.4.2.1.1 Voltage and Current Ranges................................................................................... 18

1.4.2.1.1.1 Model 8415 (each output module)........................................................................... 18

1.4.2.1.1.2 Model 8430 (each output module)........................................................................... 18

1.4.2.1.2 Frequency Ranges................................................................................................... 18

1.4.2.1.3 Phase Angle............................................................................................................. 18

1.5 Timer Control .................................................................................................................... 18

1.5.1 Binary Inputs – Timer...................................................................................................... 19

1.5.1.1 Start, Stop, and Monitor Gates.................................................................................... 19

1.5.1.1.1 Dry Contacts Open.................................................................................................. 19

1.5.1.1.2 Dry Contacts Close.................................................................................................. 19

1.5.1.1.3 Application or Removal of AC or DC voltage........................................................... 19

1.5.2 Binary Outputs – Timer.................................................................................................... 20

1.6 Battery Simulator.............................................................................................................. 20

1.7 Transducer DC IN Measuring Circuit.............................................................................. 20

1.8 Operation of Optional High Current Interface................................................................ 20

2.0 SETUP................................................................................................................................20

2.1 System...............................................................................................................................20

2.2 Touch View Interface Operation...................................................................................... 21

2.2.1 Touch Panel Display....................................................................................................... 22

2.2.1.1 Keypad Entry...............................................................................................................22

2.2.1.2 Alphanumeric Keypad ................................................................................................. 22

2.2.2 Control Knob................................................................................................................... 22

2.2.3 Factory Defaults..............................................................................................................23

2.2.3.1 Language..................................................................................................................... 23

6

Page 7

2.2.3.2 Color Palette................................................................................................................ 23

www . ElectricalPartManuals . com

2.2.3.3 Brightness.................................................................................................................... 23

2.2.3.4 About - Information Screen ......................................................................................... 24

2.2.3.5 Date and Time............................................................................................................. 24

2.2.3.6 Battery Simulator Setting............................................................................................. 24

2.2.3.7 IP Address...................................................................................................................24

2.2.3.8 Serial Port.................................................................................................................... 24

2.2.3.9 GPIB Address.............................................................................................................. 25

2.2.3.10 Convertible V/I Control ................................................................................................ 25

2.2.3.11 Phase Angle Setting.................................................................................................... 25

2.2.3.12 System Frequency....................................................................................................... 26

2.2.3.13 Default Current Output ................................................................................................ 26

2.2.3.14 Default Voltage Output................................................................................................26

2.2.4 File Management ............................................................................................................ 27

2.2.4.1 Test Files.....................................................................................................................27

2.2.4.2 Test Results................................................................................................................. 27

2.3 Communication Ports ...................................................................................................... 27

2.3.1 RS-232C Serial Port........................................................................................................ 28

2.3.2 IEEE-488 GPIB............................................................................................................... 28

2.3.3 Ethernet 10 BaseT.......................................................................................................... 28

2.3.4 USB Port ......................................................................................................................... 28

2.3.5 Printer Port......................................................................................................................28

2.4 Error Reporting.................................................................................................................28

2.5 Advanced Visual Test Software (AVTS)......................................................................... 28

3.0 OPERATING PROCEDURES............................................................................................ 28

3.1 Touch View Interface........................................................................................................ 28

3.2 Setting Phase Angle Relationships................................................................................ 29

3.3 Current Sources................................................................................................................ 31

3.3.1 Parallel Operation ........................................................................................................... 31

3.3.2 Currents in Series Operation .......................................................................................... 32

3.3.3 Harmonic Restraint Test................................................................................................. 33

3.3.3.1 Basic Harmonic Restraint Test Proced ure..................................................................34

3.4 Voltage Sources................................................................................................................ 35

3.4.1 Outputs Summed Together............................................................................................. 35

3.4.2 Dynamic Voltage Relay Test........................................................................................... 35

3.4.3 3Ø, 3-Wire, Open-Delta and T-Connection..................................................................... 35

3.4.3.1 Open Delta .................................................................................................................. 35

3.4.3.1.1 Voltage Output Connections.................................................................................... 36

3.4.3.2 T-Connection............................................................................................................... 37

3.4.4 3Ø, 4-Wire, Y-Connection............................................................................................... 39

3.5 Internal Software Test Profiles........................................................................................ 40

3.5.1 Pulse Ramping................................................................................................................ 40

3.5.2 Ramping.......................................................................................................................... 40

3.5.3 Angle of Torque............................................................................................................... 41

3.5.4 Step................................................................................................................................. 41

3.5.5 Dynamic Frequency Hz/S ............................................................................................... 42

3.5.6 Auto Synchronizing......................................................................................................... 43

3.5.7 Pickup.............................................................................................................................. 43

3.5.8 Seal-In (Target)............................................................................................................... 44

3.5.9 Timing.............................................................................................................................. 44

3.5.10 Harmonic Restraint......................................................................................................... 44

3.5.11 Slope............................................................................................................................... 44

3.5.12 Through Fault.................................................................................................................. 44

3.5.13 Polarizing........................................................................................................................ 44

3.6 Timer..................................................................................................................................45

Basic Timer Setup Menu............................................................................................................ 45

7

Page 8

Description............................................................................................................................... ..45

www . ElectricalPartManuals . com

Controls...................................................................................................................................... 45

Complex Timer Setup Menu...................................................................................................... 47

Description............................................................................................................................... ..47

3.7 Battery Simulator.............................................................................................................. 47

3.8 Relay Testing .................................................................................................................... 47

3.8.1 Touch View Interface Graphical User Interface..............................................................48

3.8.1.1 Main Menu Screen ...................................................................................................... 48

3.8.1.2 Pre-set Test Menu....................................................................................................... 49

3.8.2 Impedance Relay Testing Menu .................................................................................. 50

3.8.2.1 Impedance Relay Setting Screen................................................................................ 51

3.8.2.2 The Reach Test Setting Screen.................................................................................. 52

3.8.2.3 Impedance Relay Pre-fault Setting Screen.................................................................53

3.8.2.4 Impedance Relay Reach Test Result Screen............................................................. 54

3.8.2.5 Impedance Relay Test Timing Settings....................................................................... 55

3.8.2.6 Impedance Relay Timing Test Result Screen............................................................. 56

3.8.2.7 Impedance Relay Angle of Torque Test Settings Screen...........................................58

3.8.2.8 Impedance Relay Angle of Torque Test Results Screen............................................59

3.8.2.9 Impedance Relay Target & Seal-In Test and Results................................................. 61

3.8.3 Overcurrent Relay Test Menu...................................................................................... 62

3.8.3.1 Over-Current Relay Setting Screen............................................................................. 63

3.8.3.2 Overcurrent Relay Test Configuration Screen............................................................ 64

3.8.3.3 Overcurrent Relay Pickup Test Results ...................................................................... 66

3.8.3.4 Overcurrent Relay Target & Seal-In Test Results....................................................... 67

3.8.3.5 Overcurrent Relay Instantaneous Test Results .......................................................... 68

3.8.3.6 Overcurrent Relay Timing Test Results ...................................................................... 69

3.8.4 Differential Relay Test Menu........................................................................................ 70

3.8.4.1 Differential Relay Setting Screen ................................................................................ 71

3.8.4.2 Differential Relay Test Configuration Screen..............................................................73

3.8.4.2 Differential Relay Winding 1, 2 or 3 Pick-Up Test Results.......................................... 75

3.8.4.3 Differential Relay Harmonic Restraint Test Results.................................................... 76

3.8.4.4 Differential Relay Slope Test Results.......................................................................... 77

3.8.4.5 Differential Relay Seal-In Test Results........................................................................ 78

3.8.4.6 Differential Relay Instantaneous Test Results............................................................ 79

3.8.4.7 Differential Relay Through Fault Test Results............................................................. 80

3.8.4.8 Differential Relay Polarizing Test Results................................................................... 81

3.8.5 Voltage Relay Test Menu.............................................................................................. 82

3.8.5.1 Voltage Relay Setting Screen ..................................................................................... 83

3.8.5.2 Voltage Relay Pickup Test Results............................................................................. 84

3.8.5.3 Voltage Relay Target & Seal-In Test Results.............................................................. 86

3.8.5.3 Voltage Relay Timing Test Results............................................................................. 87

3.8.6 Synchronous Relay Test Menu.................................................................................... 89

3.8.6.1 Synchronous Relay Setting Screen............................................................................. 90

3.8.6.2 Synchronous Relay Pickup Test Results .................................................................... 91

3.8.6.2.1 Testing Sync-Check, Synchronizing and Auto-Synchronizing Relays.................... 92

3.8.6.3 Synchronous Relay Timing.......................................................................................... 93

3.8.7 Power Relay Test Menu................................................................................................ 94

3.8.7.1 Power Relay Setting Screen ....................................................................................... 95

3.8.7.1.1 Test Configuration Screen.......................................................................................98

3.8.7.2 Power Relay Pickup Test Results............................................................................. 100

3.8.7.3 Power Relay Target & Seal-In Test and Results....................................................... 101

3.8.7.4 Power Relay Timing Test Results.............................................................................102

3.8.8 Reclose Relay Test Menu........................................................................................... 103

3.8.8.1 Reclose Relay Setting Screen................................................................................... 104

3.8.8.2 Reclose Relay Pickup Test Setting Screen............................................................... 105

3.8.8.3 Reclose Relay Timing Test Results .......................................................................... 106

8

Page 9

3.8.8.3.1 Testing Reclosing Relays - Theory of Operation................................................... 107

www . ElectricalPartManuals . com

3.8.8.3.2 Testing Reclosing Relays (Reclose Only), Timing and Sequence to Lockout ...... 110

3.8.8.3.3 Testing Distribution Relays with Trip, Reclosing and Sequence to Lockout......... 114

3.8.9 Frequency Relay Test Menu ...................................................................................... 118

3.8.9.1 Frequency Relay Setting Screen............................................................................... 119

3.8.9.2 Frequency Relay Pickup Test Results ...................................................................... 120

3.8.9.3 Frequency Relay Target & Seal-In Test Screen ....................................................... 120

3.8.9.4 Frequency Relay Timing Test Screen....................................................................... 122

3.8.9.4.1 Dynamic Frequency Timing Test........................................................................... 122

3.8.10 Manual Test Menu Screen.......................................................................................... 124

3.8.10.1 Manual Voltage/Current Test Screen..................................................................... 125

Description...............................................................................................................................125

Operation ................................................................................................................................. 125

Controls.................................................................................................................................... 125

3.8.10.2 Manual Frequency Test Settings Screen..............................................................128

Description...............................................................................................................................128

Operation ................................................................................................................................. 128

Controls.................................................................................................................................... 128

Dynamic Frequency Operation................................................................................................131

3.8.10.3 Manual Auto Synchronizing Test Screen..............................................................132

Description...............................................................................................................................132

Operation ................................................................................................................................. 132

Controls.................................................................................................................................... 132

Testing Synchronizing and Auto-Synchronizing Relays.......................................................... 133

3.8.10.4 Manual Transducer Test Settings Screen............................................................. 135

3.8.10.4.1 Select Transducer Type..................................................................................... 135

3.8.10.4.2 Transducer Description......................................................................................135

3.8.10.4.3 System Default Settings..................................................................................... 136

3.8.10.4.4 Transducer Output............................................................................................. 137

3.8.10.5 Manual Transducer Test Screen............................................................................ 139

3.8.10.5.1 MPRT Output Section........................................................................................139

3.8.10.5.2 Transducer Output Section................................................................................ 140

3.8.10.6 Testing Transducers...............................................................................................140

3.8.10.6.1 Saving Results.................................................................................................. 141

3.8.10.7 Watt / Var / Va / Power Factor Applications.......................................................... 141

3.8.10.7.1 Watt/VAR 1 Element..........................................................................................141

3.8.10.7.2 Power Factor 1 Element..................................................................................... 142

3.8.10.7.3 Watt/VAR1 1/2 Element.....................................................................................144

3.8.10.7.4 Watt/VAR 2 Element..........................................................................................145

3.8.10.7.5 Watt/VAR 2 1/2 Element....................................................................................147

3.8.10.7.6 Watt/VAR 3 Element..........................................................................................149

3.8.10.7.7 Power Factor 3 Element..................................................................................... 151

3.8.10.8 Single Phase Applications ..................................................................................... 152

3.8.10.8.1 AC and DC V oltage Transducers....................................................................... 152

3.8.10.8.2 AC and DC Current Transd ucers....................................................................... 153

3.8.10.8.3 Frequency Transducers..................................................................................... 154

4.0 External High Current Amplifier.................................................................................... 156

5.0 Warranty Statement........................................................................................................ 156

6.0 Service Data.................................................................................................................... 157

6.1 Preventive Maintenance................................................................................................. 157

6.1.1 Examine the Unit........................................................................................................... 157

6.2 MPRT Ethernet Port and IP Networks........................................................................... 157

6.2.1 Setting MPRT IP Address Dialog Box........................................................................... 158

6.2.2 Updating MPRT Software / Firmware........................................................................... 158

6.3 Service and Repair Instructions.................................................................................... 159

6.3.1 Basic Troubleshooting................................................................................................... 159

9

Page 10

6.3.1.2 Power Input............................................................................................................ 160

www . ElectricalPartManuals . com

6.3.1.3 Input Power and Control........................................................................................160

6.3.1.4 Binary Inputs and Battery Simulator...................................................................... 161

6.3.1.5 Voltage/Current Amplifier Module.......................................................................... 162

6.2.1.3 Input Power and Control........................................................................................162

6.4 Calibration Check........................................................................................................... 163

6.4.1 Checking Transducer DC IN.........................................................................................164

6.4.2 Checking Battery Simulator........................................................................................... 164

6.4.3 Checking AC Volts / DC Volts....................................................................................... 164

6.4.4 Checking AC Amperes / DC Amperes.......................................................................... 165

6.4.5 Checking AC Current – Convertible Channel............................................................... 166

6.4.6 Checking Phase Angle.................................................................................................. 167

6.4.7 Checking Frequency.....................................................................................................168

6.5 Preparation for Reshipment .......................................................................................... 168

10

Page 11

1.0 Operation

www . ElectricalPartManuals . com

The unit’s design is a "modular" concept. All controls and outputs are clearly marked and

logically grouped so continual reference to the instruction manual should not be necessary once

the test operator is acquainted with the operation of the test system. The unit’s rear panel will

appear different among units since each unit may have up to four V/I Generator Modules and

may have an optional EPOCH II / EPOCH 20 interface, or other type. However, there must be at

least one V/I Generator Module installed for this unit to operate properly.

1.1 Control Description

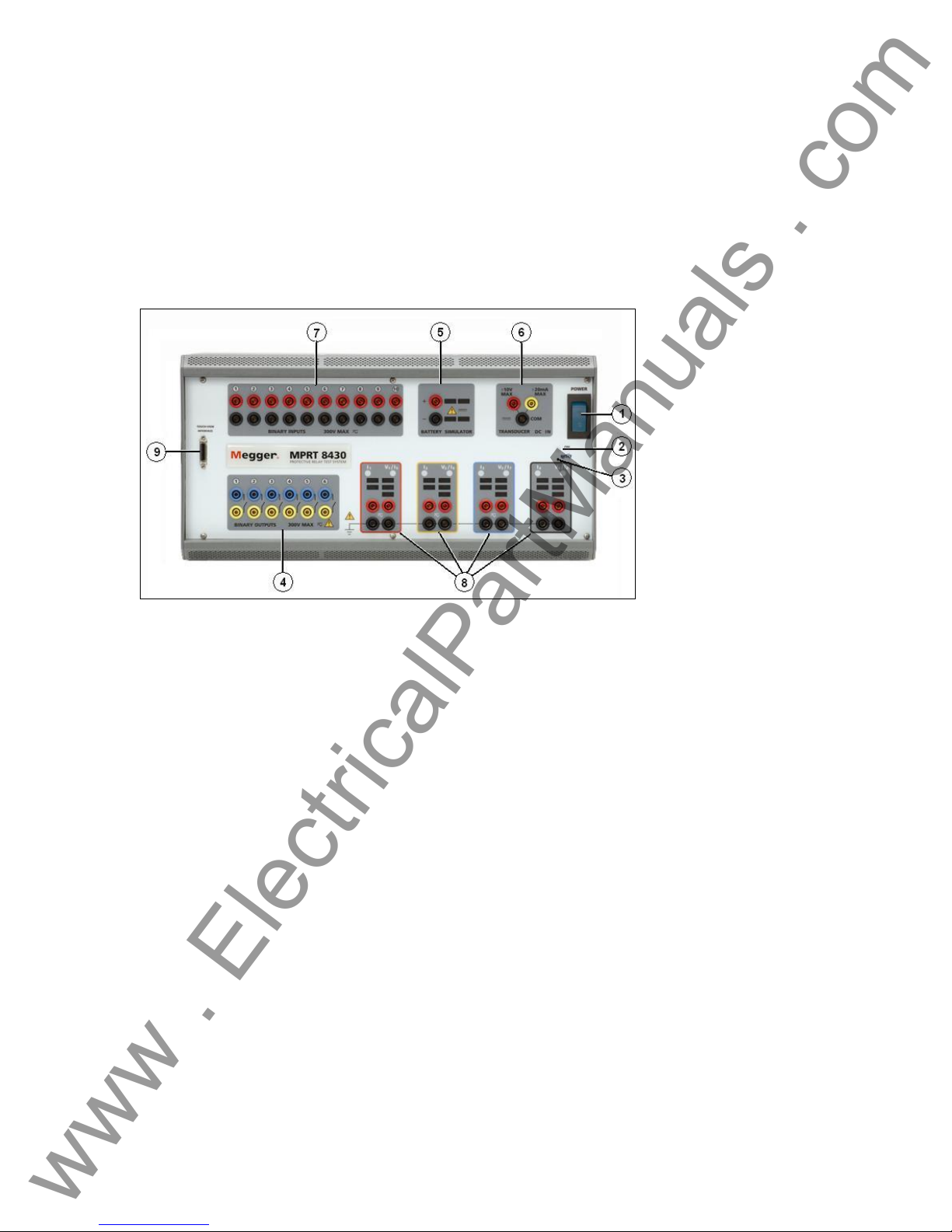

Figure 1 MPRT Front Panel

1.1.1 Front Panel

1. POWER ON/OFF Switch – used to switch unit on and off.

2. ON Light – indicates power is on when illuminated.

3. Reset Button – the reset button provides a soft reboot for the unit and restores the unit

to its normal Power-On state. The reset will clear all values entered into various screens.

The data should be saved before performing a reset, if possible.

4. Binary Outputs – there are 6 internal to the MPRT Unit. Each output can be configured

as Normally Open or Normally Closed contacts providing logic to the device under test.

The output can switch up to 300 VAC or 250 VDC with 1 Amp continuous. The

programmable wait duration is from 1 millisecond to 10,000 milliseconds.

5. Battery Simulator – the output voltages are 24, 48, 125 and 250 Volts DC with current

limiting output power protection. If a voltage is powered ON, that respective voltage will

have a lighted value.

6. Measurement (DC IN) – the DC IN will allow measurements up to ± 10 Volts DC or ± 20

milliamps of current.

7. Binary Inputs – there are 10 internal to the MPRT unit. The input will accept a voltage

range of 5 to 300 VAC or 5 to 250 VDC or dry Normally Open / Normally Closed contacts.

8. Three Phase Power Indication – the three phases are noted by the red, yellow, and

blue color boxes surrounding each output. Phase A (V1 & I1) is denoted by the red color;

11

Page 12

Phase B (V2 & I2) is denoted by the yellow color; and Phase C (V3 & I3) is denoted by

www . ElectricalPartManuals . com

the blue color. An optional fourth output module is denoted by the black color box. With a

fourth output module installed, there may be up to four phases of voltage and current, or

two three phase open delta voltages, with four currents, or up to eight phases of current.

The first four phases are indicated by V1/I1, V2/I2, V3/I3 and V4/I4. Once the voltage

generators are converted to current generators, they will change as indicated below:

V1 ⇒ I5

V2 ⇒ I6

V3 ⇒ I7

V4 ⇒ I8

9. TVI Connector – connects the Touch View Interface to the unit. Used for manual

operation, and display outputs when under computer control.

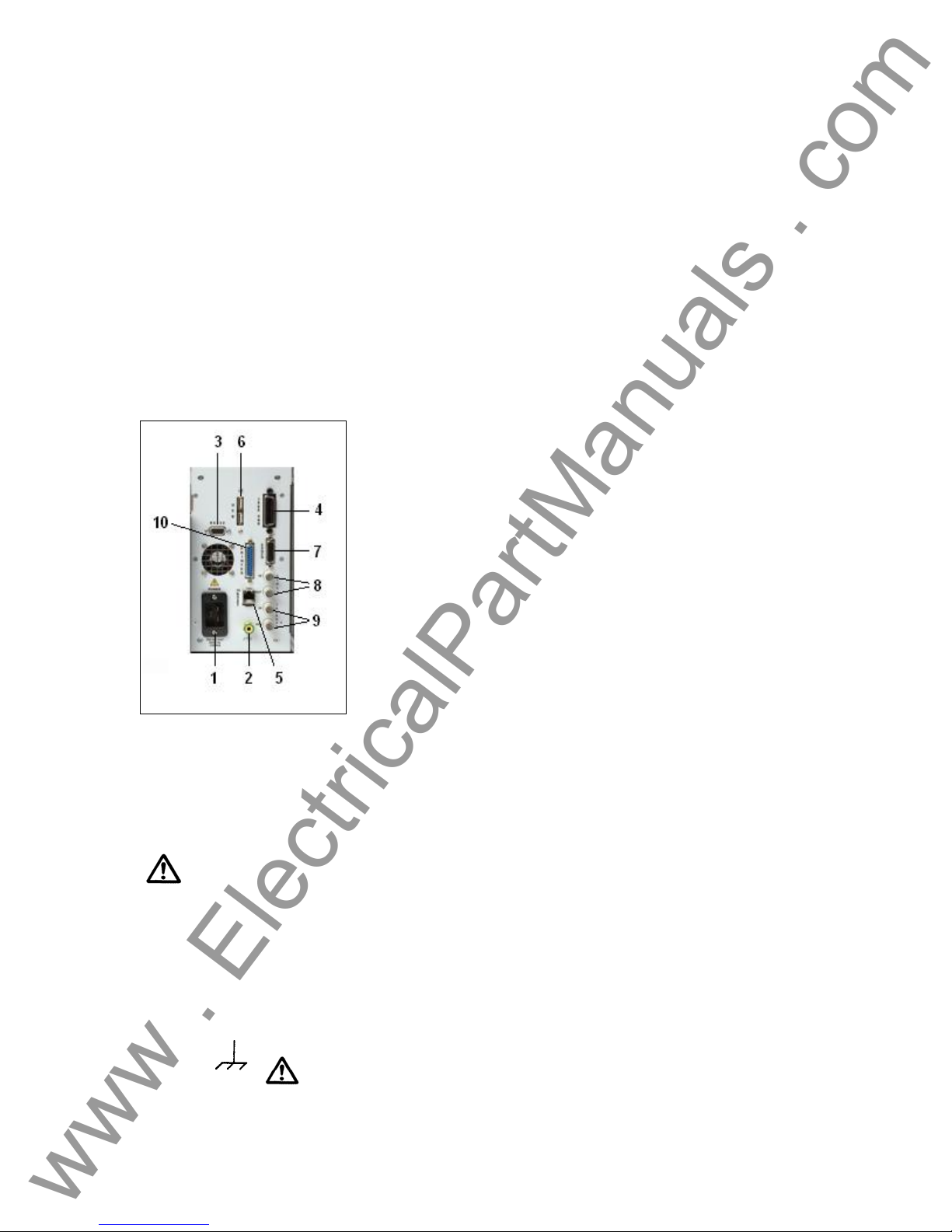

1.1.2 Rear Panel:

Figure 2 MPRT Rear Panel

1. Incoming Power / Line Cord – the input line cord, ground terminal, are mounted on the

back panel of the test set.

Input Line Cord

The test set is equipped with a line cord; see the accessory kit, which

connects to the male plug on the back panel. Verify the input voltage

before connecting the line cord to the power source.

NOTE: The unit can be powered from an input source with a rating of

100 VAC to 240 VAC. The unit automatically adjusts to the available

power if it is within the specified range.

2. Earth Ground Jack – use this terminal to connect chassis ground to earth ground.

A chassis ground (earth) point on the back panel is provided as an

additional safety ground.

12

Page 13

www . ElectricalPartManuals . com

3. RS-232C Serial Port - The serial port can operate at a maximum baud rate of 115,200

and will send / receive data in a serial fashion. See section 2.2.3.8 for more description.

4. IEEE-488 GPIB –The IEEE-488 GPIB port enables the unit to function as a talker-listener

as well as operate at speeds much faster than the serial bus, which will send / receive

data in a parallel fashion. This will allow DFR and EMTP files to be downloaded at a

faster rate. See section 2.2.3.9 for more description.

5. Ethernet 10BaseT – The Ethernet 10BaseT port will typically operate very efficiently and

effectively in real time. This port is the fastest communication method within this unit.

The setup will be similar to Microsoft

addition, this port provides the optimal method for downloading EMTP files, DFR

streaming, and updating the unit’s firmware as required. See sections 2.2.3.7 and 6.2 for

more descriptions.

6. USB Interface – Provides a communication port for connecting external devices, such as

the optional external binary input/output box to the unit (when more than 10 binary inputs

and/or more than 6 binary outputs are required).

7. EPOCH High Current Interface Port –The High Current Interface port is provided on the

rear panel of the unit. It is designed to interface with the Multi-Amp Models EPOCH-II or

EPOCH-20 High-Current Output Units (reference the EPOCH-20 or EPOCH-II Bulletins

for output specifications). This port interfaces with the optional interface module box to

provide control of up to three EPOCH-20 or EPOCH-II current amplitude, phase angle

and frequency outputs. Status of the EPOCH-20/II output can be seen on the TVI display.

8. External Clock –The external clock has separate input and output connections. The

Clock In is used in conjunction with a Clock Out from another unit or other clock source

for multiple unit operations or other special test applications. The Clock Out provides a

24 KHz clock signal to another unit that phase locks these units together.

9. External Trigger –The External Trigger has separate input and output connections. They

enable the unit to sync with another unit, or TTL (+ 5Vdc) signal source such as a GPS

satellite receiver. The Trigger In is used in conjunction with another unit to establish a

trigger for a special operation or programmed event. Typically the Trigger In

synchronizes to the Trigger Out unit and acts as a slave to it. The Trigger Out provides a

TTL digital signal to another unit in order to synchronize a multiple unit operation when it

needs to establish a trigger for a special operation or programmed event. The TTL signal

and pulse width for the GPS receiver is:

Voltage Input Signal: 3V peak minimum Pulse Width: 50µS nominal

10. PRINTER Interface Port– For future use (not used at this time).

®

Windows where one may set the protocol. In

Voltage/Current Modules (or V/I Gen). –There are four available slots for the Voltage/Current

Amplifier Modules. The slots are numbered from right to left with the back of the unit facing you.

Looking at the back of the unit, the rightmost slot equates to Phase A; the second slot from the

right equates to Phase B; the third slot from the right equates to Phase C; and left most slot may

be used to provide a fourth phase, polarizing voltage and/or current, residual voltage and/or

current, or other required sources.

13

Page 14

Amplifier EXT Inputs – There can be up to four sets of BNC connectors labeled V1/I5, I1; V2/I6,

www . ElectricalPartManuals . com

I2; V3/I7, I3 and V4/I8, I4 on the back panel depending on the number of amplifier modules

installed. These connectors are used to amplify an external analog signal using the MPRT

amplifiers. Application of ± 10 Volts Peak will provide Full Scale output from the selected output.

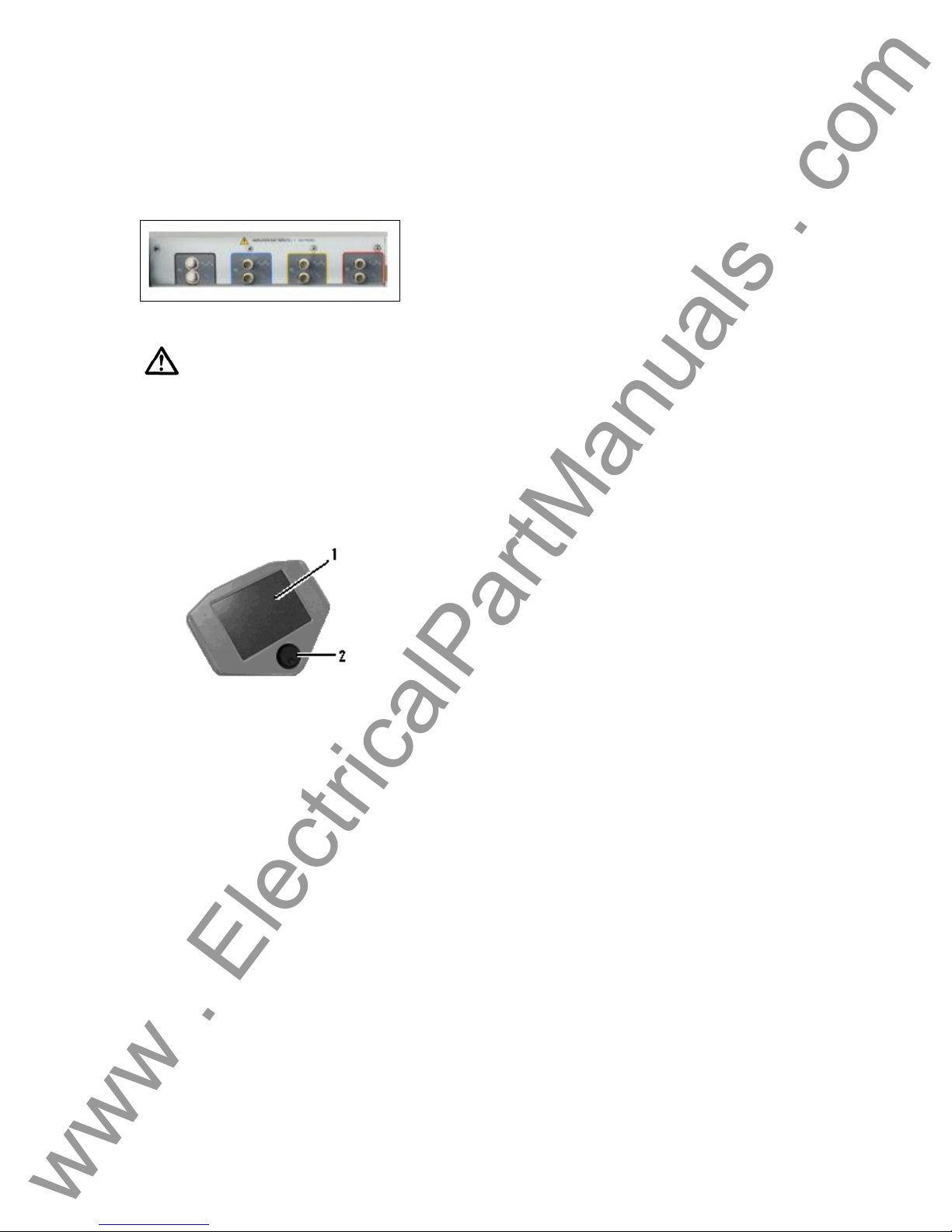

Figure 3 MPRT Rear Panel, Analog Input Terminals

CAUTION: DO NOT APPLY MORE THAN ± 10 VOLTS PEAK TO THE EXT INPUT

TERMINALS. APPLICATIION OF MORE THAN 10 VOLTS PEAK MAY DAMAGE THE

AMPLIFIER.

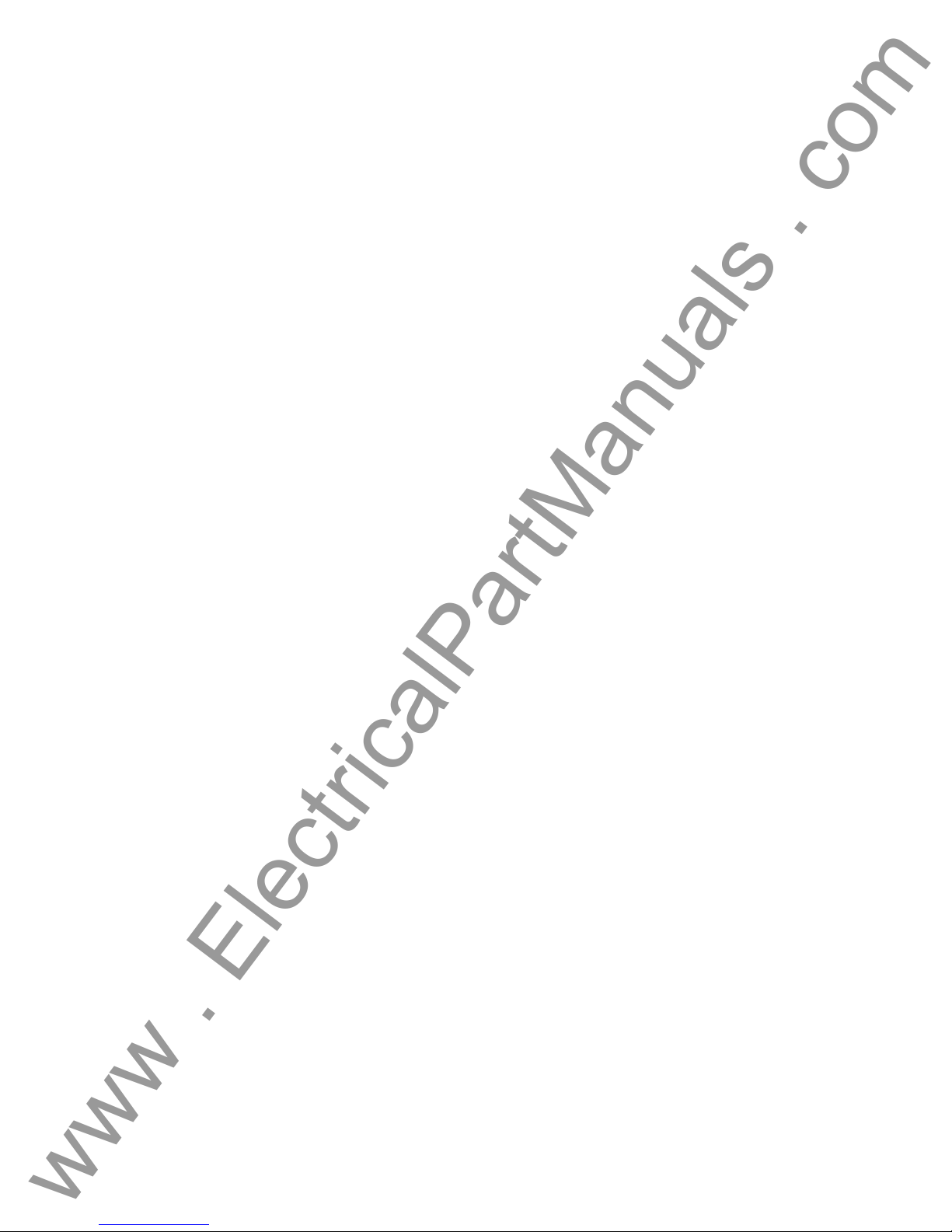

1.1.3 Touch View Interface

The Touch View Interface is used in manual operation of the unit. The color LCD touch-panel

display and control knob are the operator interface for the unit.

Figure 4 Touch-View Interface

1. LCD Color Display – this is an 8.5 inch touch panel display.

2. Control Knob – this knob will adjust values once the cursor is in the box location of the

value to be changed.

14

Page 15

www . ElectricalPartManuals . com

1.2 Terminology

The acronyms, terms, and definitions used throughout this manual are described below:

1.2.1 Acronyms

AC Alternating Current

AVTS Advanced Visual Test Software

CW Clockwise (rotation)

CCW Counter Clockwise (rotation)

DC Direct Current

GPIB General Purpose Interface Bus (IEEE-488)

GPS Global Position System

GUI Graphical User Interface

Hz Hertz

ID Identification

I/O Input/Output

kHz Kilo Hertz

LCD Liquid Crystal Display

LED Light Emitting Diode

MAG Magnitude

MHz Megahertz

MTA Maximum Torque Angle

NVRAM Non-volatile Random Access Memory

PC Personal Computer

ROM Read-Only Memory

RS-232 Serial Communication Interface

RTS Relay Test System

SRAM Static Random Access Memory

SSD Solid State Disk

TCM Timer Control Module

TVI Touch View Interface

USB Universal Serial Bus

VAC Volts Alternating Current

VDC Volts Direct Current

V/I Gen Voltage / Current Generator Module

VRMS Volts Root Mean Square

UUT Unit Under Test

1.2.2 Glossary of Terms

The MPRT TVI display screens prompt the user to select, or set, various values. The values vary

depending on the relay under test, and the relay setting screen. Many of the terms used are

similar in nature and mean virtually the same thing regardless of the type of relay. For example,

the term Time Dial is the used to define the time dial setting on the relay under test. The Time

Dial could be on an overcurrent relay, or just as easily be on a under voltage relay.

Unfortunately, some of the terms described here may apply to different types of relays in different

ways, and thus may not cover every possible relay made. However, it is hoped that this glossary

will help the user to understand every setting value on every relay setting screen.

1.2.2.1 Tap

A numerical value associated with a tap setting on the relay. Tap is normally associated with a

value of current, voltage, frequency or watts. Tap is used to define a setting value, pick up value,

or minimum operating point, of the relay under test.

15

Page 16

www . ElectricalPartManuals . com

1.2.2.2 Time Dial

A numerical value normally associated with a TIME CURVE, or defines the use of a specific time

curve from a family of curves. Used when conducting a timing test. The TIME DIAL number also

may be used in a Time-Curve algorithm in calculating the theoretical operating time of the relay

under test.

1.2.2.3 Instantaneous (Inst.) Tap

A numerical value associated with a tap setting on the instantaneous element of the relay.

Normally associated with a value of current or voltage. Used to define a pick up value, or

minimum operating point, of the instantaneous element of the relay under test.

1.2.2.4 Reset Time

Is a numerical value of time in seconds. Normally associated with electromechanical relays, this

is the amount of time required for the operating disk to reset. If multiple timing tests are

conducted on a relay, the test system will wait the Reset Time value prior to applying the next

timing test.

Note, if the Reset Time is too short, and the disk does not completely reset, then timing error

will be introduced to the test. Note that numerical relays also can have reset times to coordinate

with electromechanical relays.

1.2.2.5 Target Tap

Is a numerical value of dc current. This value is used when conducting the Target and Seal-in

tests on electromechanical relays.

1.2.2.6 Test Multiple

A numerical value normally associated with conducting timing tests. Multiples are normally

expressed in terms of 2, 3, 4, etc., times the Relay Tap, or Pickup, value of the relay under test.

If only one Test Multiple is entered, then only one timing test point will be conducted. If two or

three multiples are entered, then the test system will wait the Reset Time before applying the next

Test Multiple.

1.2.2.7 Reach

A numerical value expressed in Ohms. This value is used to determine the “distance”, in Ohms,

that the relay under test “sees” either into the transmission line or a generator.

1.2.2.8 Torque

A numerical value expressed in degrees. A value used in impedance relays to define the

“maximum torque angle” or “line angle” setting of the relay under test.

1.2.2.9 Operate, (Op) or Trip Time

A numerical value which expresses the operating time of the relay under test. Normally used to

specify a definite operating time for a given fault value.

16

Page 17

1.2.2.10 Winding (1,2,3,4) Tap

www . ElectricalPartManuals . com

A numerical value associated with the Winding Number i.e. 1, 2, 3, 4, etc., of a transformer

differential relay. Used to define the tap setting value and test for each winding.

1.2.2.11 % Slope

A numerical value which establishes the operating characteristic of a differential relay. The

operating characteristic of the differential relay is a line, with a slope defined by the ratio of the

operating and restraint values.

1.2.2.12 % Harmonic

A numerical value which establishes the percent of harmonic restraint for a harmonic restrained

transformer differential relay. This value will be used to determine Pass/Fail during the Harmonic

Restraint test.

1.3 Touch View Interface (TVI)

The Touch View Interface is the operator’s interface for the manual operation of this unit.

Variable or value changes are performed by the touch panel keypad or by rotating the control

knob after touching the display with your finger where the change is required. See section 2.2 for

operational details.

1.4 Input Power and Control

1.4.1 Input Power

The input voltage may be from 100 to 240 VAC, 50/60 hertz. Input current required varies with

the number of output modules in use and load. The maximum input power is 2100VA. The input

is protected by an ON/OFF switch / circuit breaker.

American power cord (part number 801046).

Model 84XX-XXXXEX comes with a Continental Europe power cord (part number 15021).

The 84XX-XXXXIX comes with a standard International Color code power co rd as shown below.

The cord, part number 14525, is ready for wiring to the appropriate plug (depending on country).

The following colors apply, Brown = Line, Blue = Neutral and Green/Yellow = Ground.

Model 84XX-XXXXAX comes with a North

Figure 5 International Color Coded Power Cord

1.4.2 Control Section

1.4.2.1 V/I Generator Module

The voltage and current ranges may be set to zero for automatic range adjustments or manually

set to the number desired in volts or amps as indicated below. The unit will choose the lowest

range which contains the desired value.

17

Page 18

www . ElectricalPartManuals . com

1.4.2.1.1 Voltage and Current Ranges

1.4.2.1.1.1 Model 8415 (each output module)

Voltage Range Power / Current (Max)

30.00V 150VA @ 5A

150.00V 150VA @ 1A

Current Range (RMS) Power / Voltage (Max)

4.0A 200VA @ 50.0 V

7.5A 200VA @ 26.7 V

15.0A 200VA @ 13.4 V

1.4.2.1.1.2 Model 8430 (each output module)

Voltage Range Power / Current (Max)

30.00V 150VA @ 5.0A

150.00V 150VA @ 1.0A

300.0V 150VA @ 0.5A

Current Range (RMS) Power / Voltage (Max)

4.0A 200VA@ 50.0 V

7.5A 200VA @ 26.6 V

15.0A 200VA @ 13.4 V

30.0A 200VA @ 6.67 V

1.4.2.1.2 Frequency Ranges

The output module is able to provide a variable frequency output with the following ranges:

DC

00.001 to 99.999

100.01 to 999.99

1.4.2.1.3 Phase Angle

The phase angle may be set from 0° to 359.9° in either lead or lag configuration, clockwise or

counterclockwise rotation. In addition, the user may select the angle display configuration of

±180°. See section 2.2.3.11, Phase Angle Setting, for information regarding Factory Default

settings.

1.5 Timer Control

The Timer can indicate the elapsed time either in seconds or in cycles. The Timer is prearranged

in the setup screens of the respective relay types that are to be evaluated. There are factory

default settings for the timer inputs.

RMS

RMS

RMS

RMS

RMS

RMS

RMS

18

Page 19

1.5.1 Binary Inputs – Timer

www . ElectricalPartManuals . com

The Timer is specifically designed to measure high speed operation of electro-mechanical, solidstate and microprocessor-based protection relays. In addition, it will perform timing tests on EHV

to low voltage breakers, trip circuits, and contactors. The factory default settings are:

Input 1: Timer start, normally open position, and latched ON

Input 2: Timer stop, normally open position, and latched ON

Input 3: Dry Contact monitor, normally open position, and latched OFF

And Inputs 4 through 16 as dry contact monitor, normally open position, and

latched OFF.

It incorporates the banana plug receptacles that may be programmed to be: Start Gates, Stop

Gates, and Monitor Gates, all Stop Gates, all Contact Continuity Monitors, or all Voltage

Applied/Removed Monitors.

1.5.1.1 Start, Stop, and Monitor Gates

In the TVI there are up to sixteen identical, independent, programmable gate circuits (Start, Stop,

and Monitor) that permit simple selection of the desired mode for timing or contact monitoring

operation. There are 10 internal inputs and 6 optional external inputs for the unit.

To monitor operation of the contacts or trip SCR in the device under test, an "ACTIVE" light is

provided for each gate. The gate circuit is isolated for voltage-sensing and can monitor solidstate logic signals. Each “Active” light will illuminate once contacts close or voltage is applied to

the gate. If desired, a tone generator (horn) may provide an audible indication when the contacts

close or voltage is applied.

1.5.1.1.1 Dry Contacts Open

Timer starts, stops or a continuity indicator goes out at the opening of normally closed contacts,

or when conduction through a semiconductor device, such as a triac or a transistor, is interrupted.

1.5.1.1.2 Dry Contacts Close

Timer starts, stops or a continuity indicator glows at the closing of the normally open contacts, or

upon conduction through a semiconductor device such as a triac or a transistor.

1.5.1.1.3 Application or Removal of AC or DC voltage

This will either start the Timer or stop the Timer. The continuity indicator will glow (application) or

darkens (removal) upon the application or removal of either an AC or DC voltage. A higher

threshold voltage helps to eliminate false triggers due to a noisy source. Lower thresholds allow

starting and stopping of timer from TTL voltage signals. The allowable voltage applied is 5 to 300

Volts AC or 5 to 300 Volts DC, current limiting resistors provide protection.

1.5.1.1.4 The Timer can be started when turning on any selected generator s.

1.5.1.1.5 The Timer can be started simultaneously with a change in Frequency, Phase

Angle, or Amplitude. Also, it can be started simultaneously with a Voltage or Current waveform

step.

1.5.1.1.6 The Timer can be stopped upon Phase Synchronization between two voltage

channels (normally used to time auto synchronizing relays).

19

Page 20

www . ElectricalPartManuals . com

1.5.2 Binary Outputs – Timer

There are 6 internal outputs and 10 optional external outputs for the unit. The contacts can

switch up to 300 VAC, 1 Amp or 250 VDC, 1 Amp continuous. The contacts may be to open or

closed, thus simulating circuit breaker operation. The programmable wait duration is from 1

millisecond to 10,000 milliseconds.

1.6 Battery Simulator

The receptacles provide 24, 48, 125, or 250 VDC with current limiting protection. The primary

application is to provide DC logic voltage to solid-state and microprocessor relays.

CAUTION:

NOTE: DC voltage is ON and available when the output is turned on using

the LCD touch panel or via software command. Do not plug or insert any

test lead into the BATTERY SIMULATOR binding posts without first

connecting the test leads to the load!

1.7 Transducer DC IN Measuring Circuit

The DC measuring circuit’s voltage is from 0 ±10VDC and current from either 0±1mADC or 1 to

±20mADC. This circuit is used for testing transducers. See Section 3.8.10.4 for more description.

1.8 Operation of Optional High Current Interface

The High Current Interface may be initiated in the Main Menu Screen. The High Current Interface

button is located at the bottom of the TVI. When initiated, the “High I” will change to “Unit I”.

When a relay test is completed and the HIGH CURRENT INTERFACE is no longer required, turn

OFF the EPOCH-20/II test unit.

2.0 SETUP

2.1 System

Unpack the unit and check for evidence of any shipping damage. If there is any visual damage,

notify the freight carrier to make a damage claim and notify Megger of the damage.

Potentially lethal voltages may be present on the output terminals. It is

highly recommended the operator read the user manual thoroughly and have an

understanding of the test set operation prior to turning power on.

1. Plug the Touch View Interface into the front of the unit. The TVI will be active once the

CAUTION

power is turned ON. A personal computer (PC) will take control of the unit if it is

connected. The unit power must be OFF before the PC is connected to the unit.

20

Page 21

2. Before connecting power to the unit, make sure the POWER ON/OFF Switch is in the

www . ElectricalPartManuals . com

OFF position (0). Plug the unit line cord into a power source and turn the POWER

ON/OFF Switch to ON (I).

2.2 Touch View Interface Operation

The TVI is the manual control and user interface for the unit. All manual entries will be made

through the TVI unless the unit is connected to a personal computer. During the power up

sequence the test system automatically does self-test to insure everything is operating properly.

Once the system has completed its self checks the Introduction screen will appear.

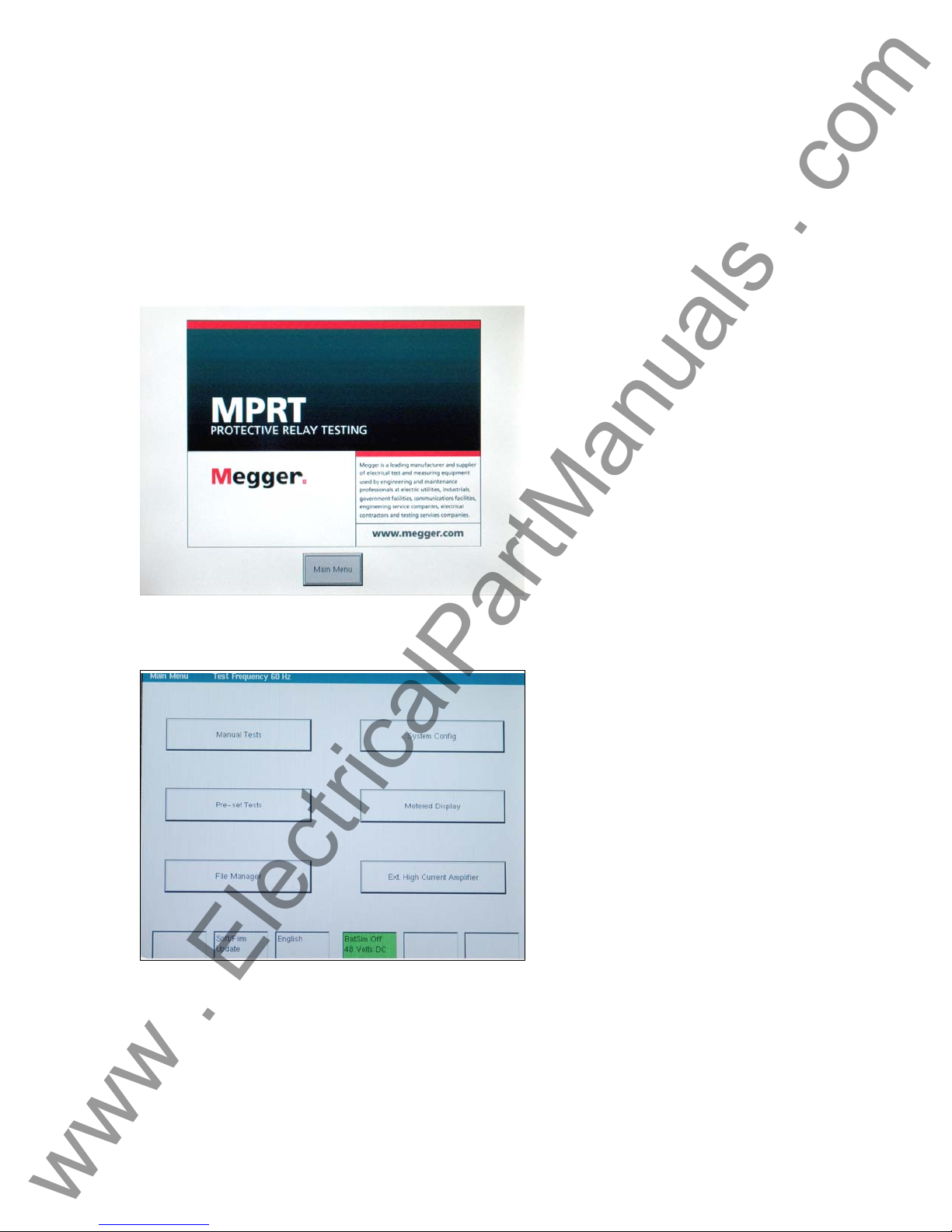

Figure 6 Introduction Screen

Pressing the Main Menu button will produce the following screen.

Figure 7 Main Menu Screen

If a PC is connected, the TVI will display the monitored outputs when the PC is in control of the

unit. The Timer button will be available to select time ONLY. In addition, the vector graph will be

displayed on the TVI.

21

Page 22

2.2.1 Touch Panel Display

www . ElectricalPartManuals . com

The TVI Touch Panel Display is the means by which data is entered into the unit, while the unit is

in manual control. The TVI will display all active (ON) generators in red and all selected, but

inactive (OFF), generators in green. If a generator is not selected it will be grey. If an entered

value is out-of-range, an error screen will appear to notify the setting is out-of-range.

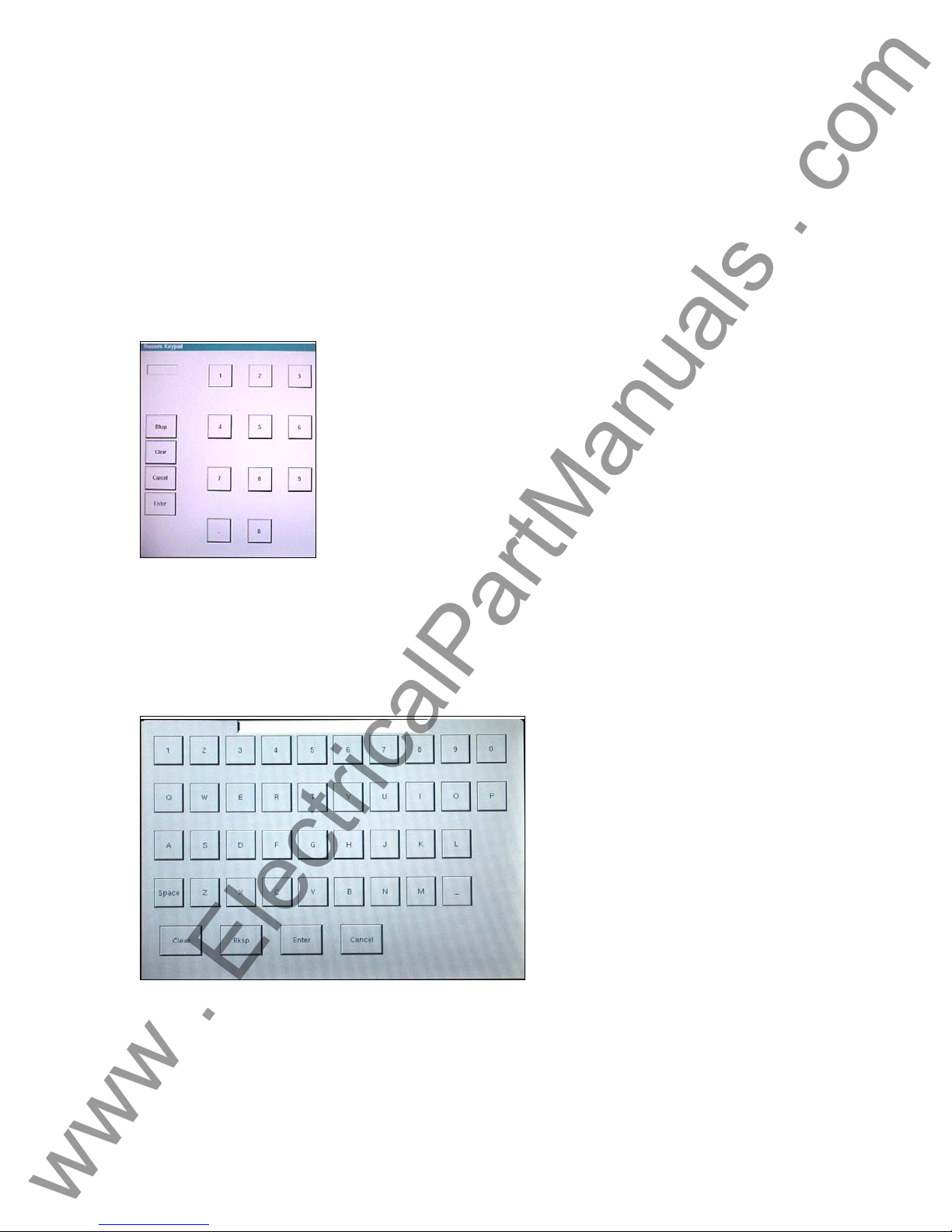

2.2.1.1 Keypad Entry

The keypad entry provides an interface to the user when entering a value in the various screens.

Touching a data entry window on the TVI will activate the Numeric Keypad. Pressing Enter or

Cancel will return the user to the previous screen that is in use. Pressing Ramp will select that

value to ramp when using the control knob. Pressing Clear will clear the value you just entered.

Figure 8 TVI Numeric Keypad

2.2.1.2 Alphanumeric Keypad

The alphanumeric keypad allows the entry of ASCII text into the TVI. This keypad is used to enter

file names in length for the primary name, and a 3 character extension in the file management

screen. This screen is also used when using the Transducer Test Setting Screen.

Figure 9 TVI Alphanumeric Keyboard

2.2.2 Control Knob

The control knob will change the values after touching the display to highlight the value that

requires ramping. Clockwise rotation increases and counterclockwise decreases. The control

22

Page 23

knob uses a speed control algorithm to provide fine adjustment, with a slow rotation, and a larger

www . ElectricalPartManuals . com

step adjustment with a faster rotation.

2.2.3 Factory Defaults

There are several factory default settings including language, system frequency, phase angle

rotation, battery simulator, GPIB address, IP address, brightness and contrast, unit and V/I Gen

serial numbers, and the color palette. Pressing the System Config. button on the Main Menu will

result in the following,

Figure 10 Default System Configuration Screen

2.2.3.1 Language

The factory default is English, but may be changed to French, Spanish, German, Italian, or

Portuguese. Other languages will be added to the list at a later date. To change language, press

the language select button on the Main Menu Screen, see Figure 7.

2.2.3.2 Color Palette

The background and color scheme is adjustable. Press the button to select from a variety of other

color schemes.

Figure 11 Color Palette Selection Screen

2.2.3.3 Brightness

The brightness is adjustable. The display will always be visible since hardware limits the

brightness from becoming too bright or too dark to be seen. Press the brightness + or - buttons to

make adjustments.

23

Page 24

2.2.3.4 About - Information Screen

www . ElectricalPartManuals . com

The V/I Generators, Timer and Unit Serial Numbers, software/firmware versions and unit

configuration will be displayed once the About button is pressed. This information is useful when

calling Dallas for service or technical support related issues.

2.2.3.5 Date and Time

Press this button to reset the Date and Time. This information is critical for saving tests and test

results in the unit internal file manager.

2.2.3.6 Battery Simulator Setting

The Battery Simulator output voltage can be set to 24, 48, 125, or 250 Volts DC. The Volts DC

selection only establishes the voltage values, but does not turn power ON for the Battery

Simulator. The various test setup screens will allow the Battery Simulator to be powered ON/OFF

as applicable. Pressing the DC Battery Simulator setting button the following selection screen will

appear.

Figure 12 Battery Simulator Voltage Selection Screen

2.2.3.7 IP Address

The IP address allows the unit to be connected and controlled on a local area network. Pressing

the IP Address button will produce the IP Address Dialog box. See Section 6.2 MPRT Ethernet

Port and IP Networks for details associated with use of the Ethernet port and IP address settings.

Figure 13 Ethernet IP Address Dialog Box

2.2.3.8 Serial Port

The Serial port will operate at various baud rates. Pressing the Baud Rate button will provide a

list of baud rates to choose from. Popular rates are 9600, 19200, 38400, 57600 and 115200. The

higher bauds rates provide faster downloads and response to commands.

24

Page 25

www . ElectricalPartManuals . com

2.2.3.9 GPIB Address

The GPIB address is selectable from 01 to 15. The factory default is 01. This will permit

communication between a personal computer and the unit once the IEEE-488 GPIB driver is set

to communicate with the respective address.

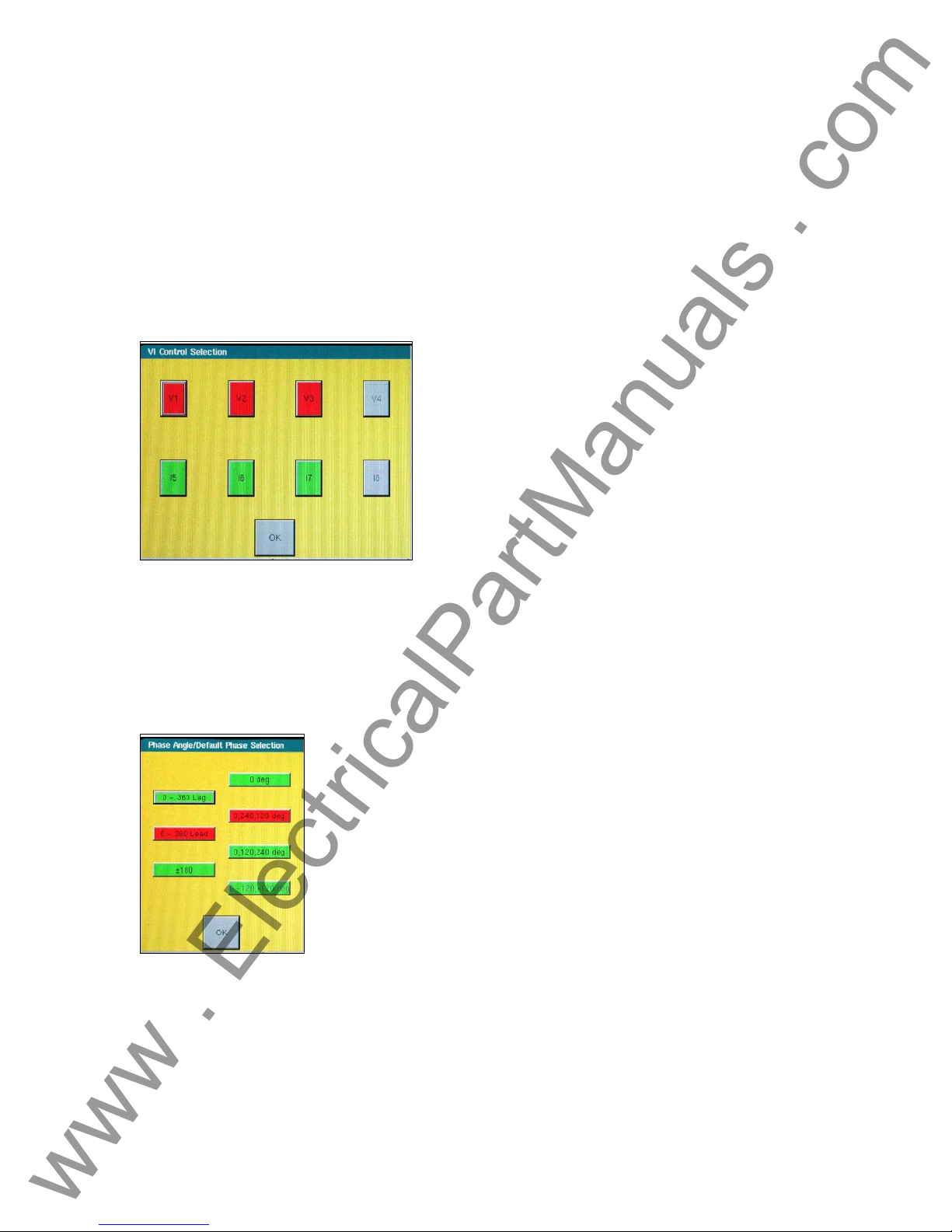

2.2.3.10 Convertible V/I Control

Used to change voltage channel to a current channel. Current configuration will be highlighted in

red, while the unselected channels will be in green. If the channel is not present, it will be in grey

and not available for selection.

Figure 14 Convertible V/I Selection Screen

Note: If channel is not installed, the channels will be grey (see Figure 15 above).

2.2.3.11 Phase Angle Setting

The Phase Angle Setting has three selections: 0-360° Lead, Lag or ±180°. In addition, the user

can set the display for clockwise and counterclockwise rotations. The factory default is 0-360°

lagging. Press the Phase Angle select button, and the following screen will appear.

Figure 15 Phase Angle Display Selection Screen

Select either Leading or Lagging and the phase indicators 0 deg., or 0, 240, 120 deg. or 0, 120,

240 deg. or 0, - 120, +120 deg. Selecting 0 -360 Lead and 0, 240, 120 deg. will result with V1

referenced at 0˚, V2 at 240˚ Leading V1 and V3 at 120˚ Leading V1, Counterclockwise rotation.

Currents when entered will Lead their respective voltages by the angle entered. Selecting 0 – 360

Lag, and 0, 120, 240 will result with the voltage V2 and V3 lagging V1 by 120 and 240 degrees

respectively. Any current values entered will lag their respective voltages by the angle indicated.

See section 3.2 for more details on setting phase angle relationships.

25

Page 26

www . ElectricalPartManuals . com

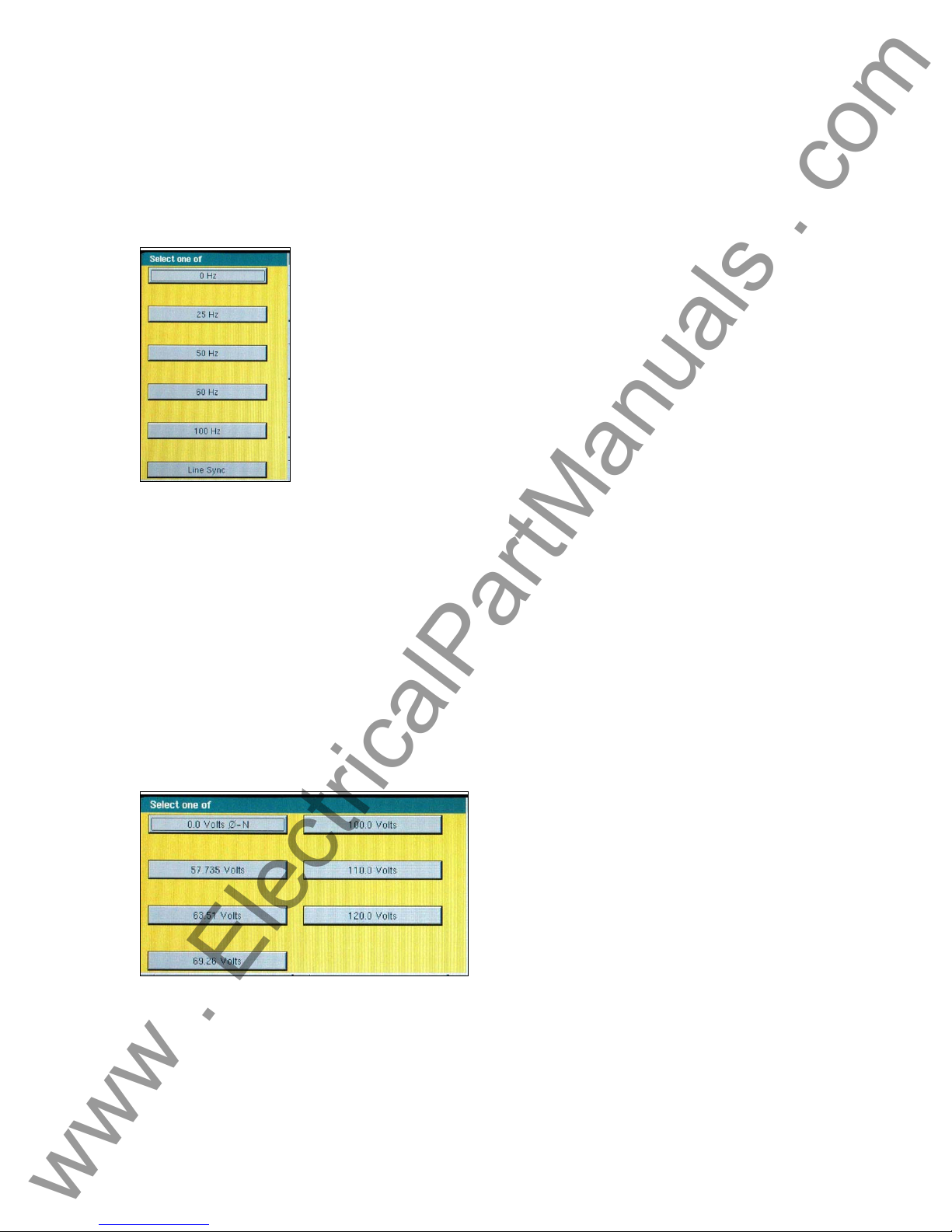

2.2.3.12 System Frequency

The system frequency will be set to the typical value of the country, either 50 or 60 hertz. Other

fixed frequencies are available. The unit can provide a fixed output frequency of 0 (DC), 25, 50,

60, 100 hertz, or Line Sync 50/60 Hz. To change the default frequency press the System

Frequency button and the following selection screen will appear.

Figure 16 System Default Frequency Select

2.2.3.13 Default Current Output

The Default Current provides a default value (set for 0 Amps) and provides the selectable setup

values for the current. The selectable currents are 0, 1, and 5 amps phase-to-neutral. This will

also be the value used in the prefault settings screen as well some other preset test screens.

These settings will change once the values are changed by the user in the relay settings screen.

2.2.3.14 Default Voltage Output

The Default Voltage output provides a default value (set for 0 volts) and provides the selectable

setup values for the voltage. These settings can be changed by the user in the relay settings

screen. Press the Default Voltage button and a list of popular phase-to-neutral values will be

provided to choose from. This is a big time saver when testing three-phase relays, the user does

not have to enter each individual voltage value, they will already be preset ready to use.

Figure 17 Default Voltage Setting Screen

26

Page 27

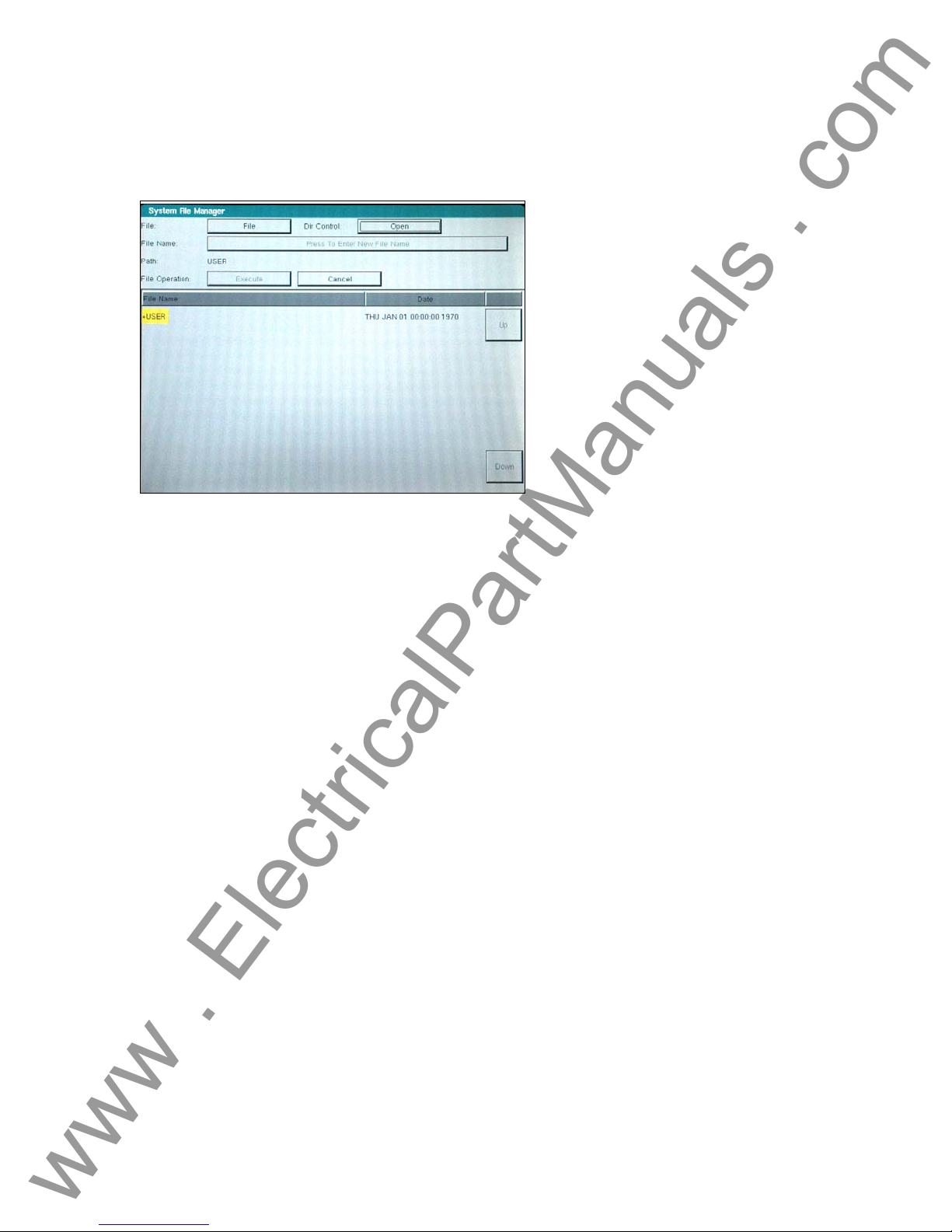

2.2.4 File Management

www . ElectricalPartManuals . com

The file management display is used by the TVI to access files stored on the unit’s internal

memory. This display will allow test files to be loaded, make or change directories, rename files

and directories, delete files and directories that were created by the customer.

Figure 18 File Manager Screen

The display is divided into two parts: the upper half is used to define the user action; and the

lower half displays the files and directories. File names are limited to 99 capital letter characters.

The alphanumeric keypad is used to enter file or directory names. In addition, the name of a file

or directory will appear in the name area as the cursor moves (using Up and Down buttons)

through the list of files or directories.

The following list of actions may be used in this display through pull down menus: Save Data,

Read Data, Make Directory, Rename, Delete, Save User Sys Defaults, Read User Sys Defaults,

Read Factory Defaults and Delete Factory Defaults. If files are to be deleted or written over, a

warning message will alert the operator this action is about to take place. This allows the

operator to cancel the action.

2.2.4.1 Test Files

The test files are used to verify the functionality of specific relays. These files typically verify the

functionality of the entire relay to ensure the operational readiness of this unit under test (UUT).

The test files may be provided by Megger or generated by the customer. Default files may be

added to or removed from the database. These files will reside in a specific directory in the

MPRT internal memory.

2.2.4.2 Test Results

The test results may be stored in the MPRT internal memory as a soft copy or downloaded into a

PC for soft and/or hard copy. The test results file must be saved using the file management

display. This is performed using a file naming convention that uniquely identifies the test results.

2.3 Communication Ports

There are several different communication ports. These ports are: Serial, USB, GPIB, Parallel,

and Ethernet. The function of these ports are similar, but are differentiated by their respective

speed at performing a set of operations.

27

Page 28

2.3.1 RS-232C Serial Port

www . ElectricalPartManuals . com

The Serial port will operate at various baud rates. The connection to it is limited by this speed.

Check baud rate using the System Configuration screen.

2.3.2 IEEE-488 GPIB

The IEEE-488 GPIB port will allow a faster baud rate and connectivity to the Unit. This port is

recommended for connection to the unit except when DFR streaming or EMTP files need to be

controlled in real-time.

2.3.3 Ethernet 10 BaseT

The Ethernet port will allow the fastest method for DFR playback streaming in real-time.

Firmware updates use this port for downloading purposes, since it is the most effective and

efficient communication. Simply connect the port to the networked PC and download accordingly.

2.3.4 USB Port

The USB ports are used for communication to external devices, such as an optional I/O interface

box.

2.3.5 Printer Port

The Printer port is for future use and is not available at this time.

2.4 Error Reporting

There are over 300 possible error messages that the operator may witness. Some have to do

with manual operation, some have to do with automated operation, and some have to do with unit

errors or overload situations. For example, errors will be reported when out-of-range values are

entered. The error screen will display the range for that value to ensure a value is entered that

resides within the tolerance of the range.

2.5 Advanced Visual Test Software (AVTS)

AVTS is external software specifically constructed to work with Megger relay test equipment

(MPRT and Pulsar). The software contains the necessary steps to perform specific relay tests. It

is designed to perform manual or automated relay testing for distance (impedance), over-current,

differential, frequency, voltage, synchronous, power and reclose relays. Also, AVTS is

specifically designed to perform DFR testing and playback including GPS synchronized end-toend tests. The MPRT comes with a Basic version of AVTS, while the Advanced and Professional

versions are optional.

3.0 OPERATING PROCEDURES

This section describes basic operating procedures for using the multiple output modules of the

unit for such applications as paralleling current outputs, conducting harmonic restraint tests,

series of potential sources to provide higher than rated potential, testing over/under voltage relays

and forming three phase voltage outputs.

3.1 Touch View Interface

The Touch View Interface (TVI) is used to operate the MPRT manually. It is controlled via a

touch screen and a control knob. The touch screen allows the operator to change a parameter by

simply touching the location for the value. Then, a keypad can be used to change the value or

the operator may use the knob to modify the value.

28

Page 29

3.2 Setting Phase Angle Relationships

www . ElectricalPartManuals . com

Think of each V/I Generator module as a vector generator. Each module has an internal zero

reference to which it references its phase angle settings as displayed on the TVI. This applies to

phase angle settings between the voltage and current outputs. When setting a phase angl e

between two outputs, it is recommended that one output be set at 0° and the other output be

referenced to the 0° . This is for operator convenience only. When setting an angle, the operator

has a multiple of choices, depending on the Default Phase Angle setting in the Default Setting

Screen, see 2.2.3.9. In the engineering world and in the following figures, the lagging diagram

displays negative rotation and will create negative sequence components, while the Lead and +/180 diagrams display positive rotation which is normal system activity.

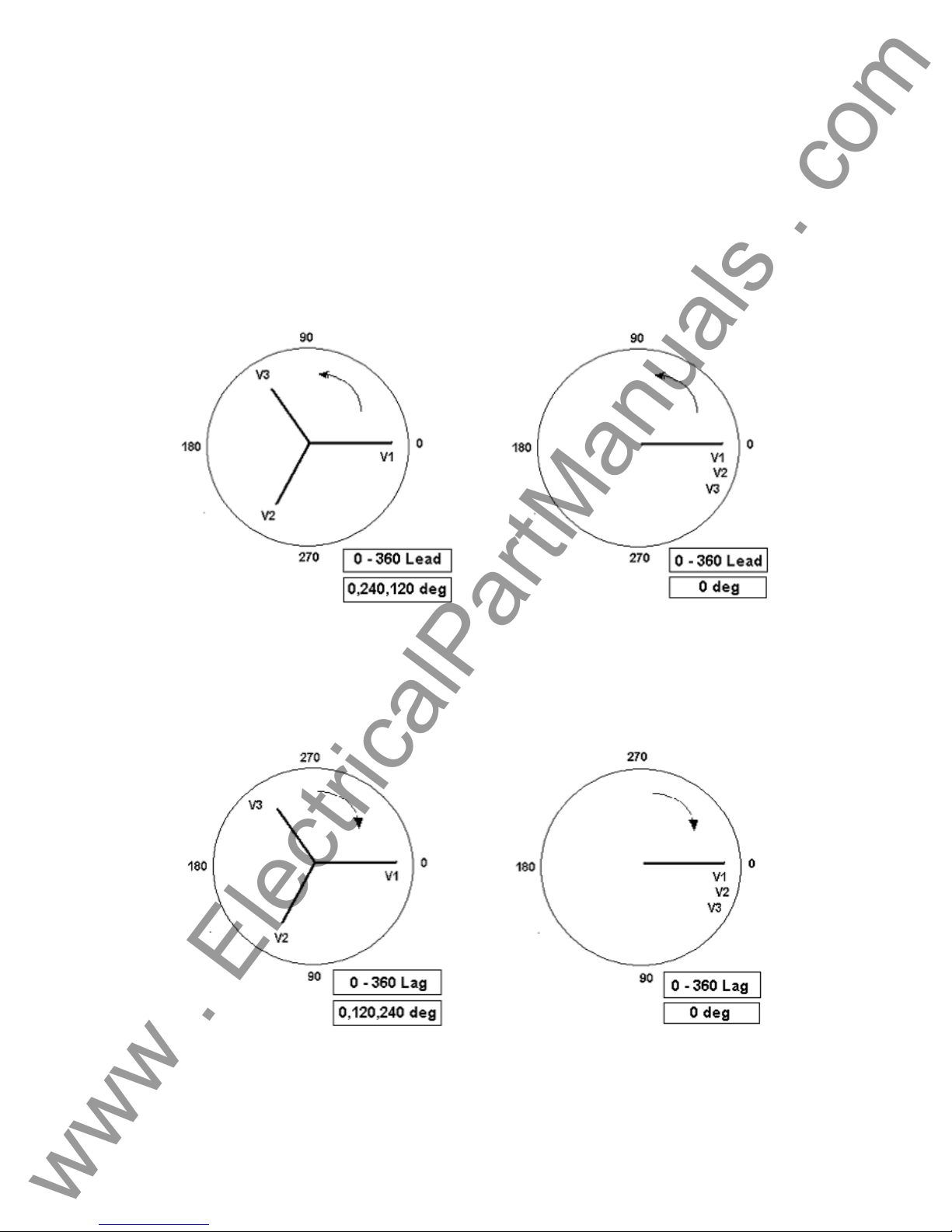

Figure 19 Positive Phase Rotation Diagrams

Figure 20 Negative Sequence Phase Rotation Diagrams

29

Page 30

www . ElectricalPartManuals . com

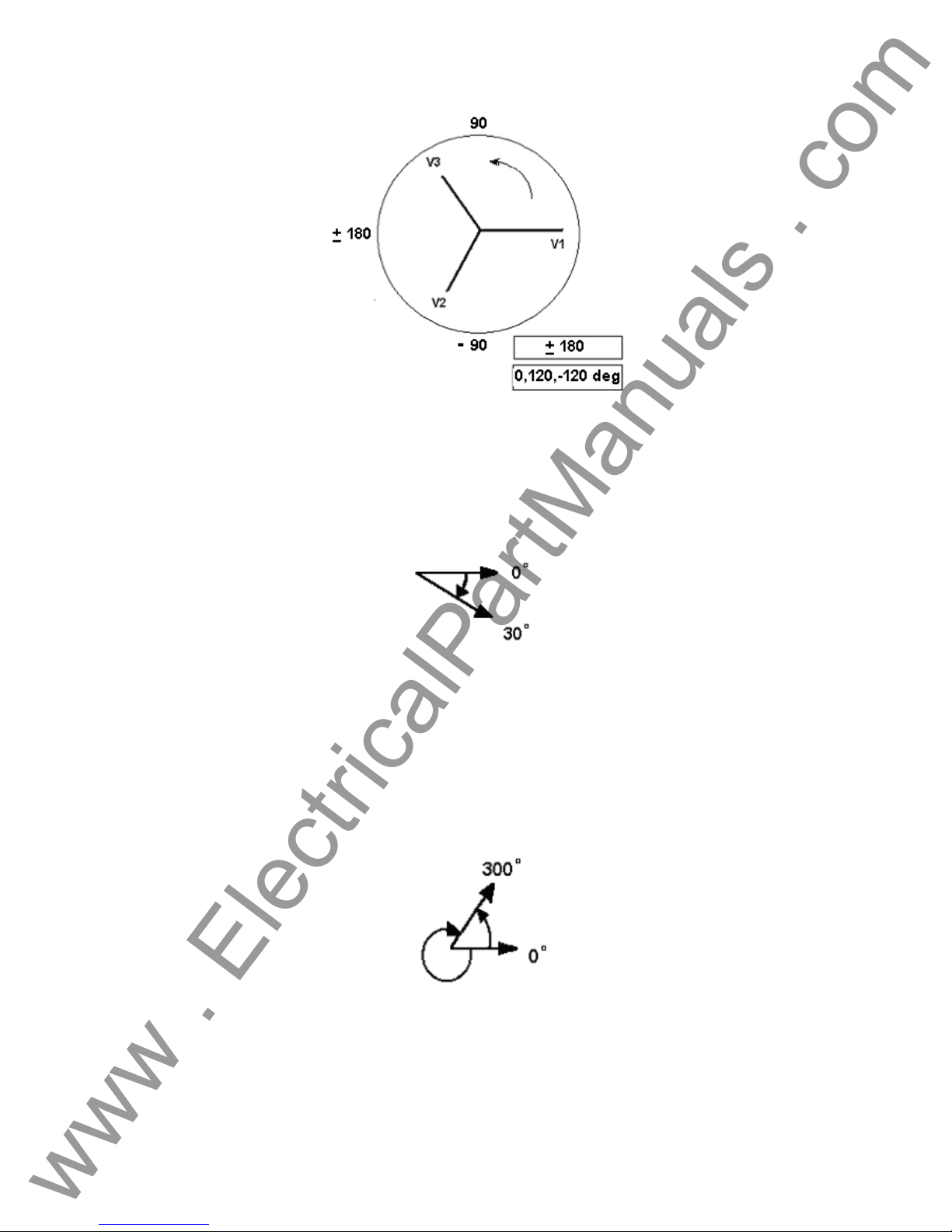

Figure 21 Positive Phase Sequence Rotation Using ± 180˚

For example, using 0-360 Lag (0, 120, 240) setting an angle of 30° between the two outputs

would look like:

The reference output is 0° and the second output is rotated 30° clockwise. In other words, the

angle is lagging the referenced source by 30°.

Conversely, if the angle decreases in the counterclockwise direction from 359.9° toward 0.0°, for

a setting angle of 300.0°, the second output would look like:

The reference output is 0° and the second output is rotated to 60° in the counterclockwise

direction. In other words, the second output lags the reference output by 300° or leads it by 60°.

The user may default to phase angles to ±180° with the

- (negative) angles lagging and the +

30

Page 31

(positive) angles leading. Therefore, to set an angle of

www . ElectricalPartManuals . com

would be:

+ 10° leading, the vector relationship

3.3 Current Sources

3.3.1 Parallel Operation

Two, three or four current channels may be connected in parallel to provide additional current

capacity. This is necessary when higher test currents are needed for testing instantaneous trip

elements.

To parallel the current channels of the unit, perform the following:

1. Note that all units with a style number T in the 7

commons are grounded. Those units with a style number F the current commons are

floating. Using the current channel test leads, connect each

under test (both red and black terminals to the load). Obviously, for the floating common

units you have to connect the black common return to the relay or there would not be any

current flow from that channel. By connecting the commons together, all of the current

channels would then have a common reference point. For the grounded commo n return

units, there is an internal common ground between the current channels. By not

connecting a return lead to all of the current channels in use, part or all of the return

current will be forced through the internal ground. That means with a 4 channel unit up to

120 Amperes could be forced through the internal common ground. Because of size and

weight restrictions, the unit is protected internally against too high of a current through the

common ground using surface mounted fuse type elements. Blowing a ground fuse

element will require the unit be returned to the factory for repair! Therefore, it is important

that the parallel connections must be made at the relay, not at the source through the

common ground return. See the following figure.

th

digit (i.e. 8430L3T6A1) the current

current channel to the relay

Figure 22 Parallel of All Four Current Outputs

NOTE: All current channels should be set to the same phase angle.

31

Page 32

2. If two current channels that are to be used in parallel, set each to one-half of the output

www . ElectricalPartManuals . com

requirement. The settings between three current channels will be one-third the output

requirement, and four channels would be one-fourth. Initiate all current channels

simultaneously by pressing the Start button. All parallel current outputs must be ON to

prevent internal shunting of current. Note: If only two currents are to be used, only

connect two currents in parallel, etc. for three or four channels. In other words do not

parallel a current channel if you do not intend to use it.

3. All current channels have amplitude control now operates simultaneously to provide the

desired test current. Selecting Ramp of the current Magnitudes will allow the user to ramp