Page 1

Megger

User Manual

MPQSIM

Power Quality Simulator

AVTMMPQSIM

Rev 1

May 2017

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Page 2

Page 3

MPQSIM

User Manual

Page 4

Copyright© 2017 by Megger. All rights reserved.

The information presented in this manual is believed to be adequate for the intended use of the product.

f the product or its individual instruments are used for purposes other than those specified herein,

I

confirmation of their validity and suitability must be obtained from Megger. Refer to the warranty

information below. Specifications are subject to change without notice.

WARRANTY

Products supplied by Megger are warranted against defects in material and workmanship for a period of

one year following shipment. Our liability is specifically limited to replacing or repairing, at our option,

defective equipment. Equipment returned to the factory for repair must be shipped prepaid and insured.

Contact your MEGGER representative for instructions and a return authorization (RA) number. Please

indicate all pertinent information, including problem symptoms. Also specify the serial number and the

catalog number of the unit. This warranty does not include batteries, lamps or other expendable items,

where the original manufacturer’s warranty shall apply. We make no other warranty. The warranty is

void in the event of abuse (failure to follow recommended operating procedures) or failure by the

customer to perform specific maintenance as indicated in this manual.

M

Page 5

Table of Contents

1 INTRODUCTION ............................................................................................................................................. 1

2 RECEIVING INFORMATION ...................................................................................................................... 3

MPQ-SIM-01 ........................................................................................................................................................ 3

Contents Received: ............................................................................................................................................... 3

3 OVERVIEW ......................................................................................................................................................... 5

Intended Use ......................................................................................................................................................... 5

Applications .......................................................................................................................................................... 5

Definitions ............................................................................................................................................................. 6

4 SPECIFICATIONS ............................................................................................................................................. 7

5 SAFETY ................................................................................................................................................................ 9

Warnings and Safety Precautions ....................................................................................................................... 9

Safety and Warning Symbols ........................................................................................................................... 10

6 PRODUCT INSTALLATION ...................................................................................................................... 11

Connector Layout / Interconnect .................................................................................................................. 11

7 PRODUCT OPERATION ............................................................................................................................. 15

Operation Controls and Modes ...................................................................................................................... 15

Initial Settings ..................................................................................................................................................... 16

Simulations ......................................................................................................................................................... 17

Power Reversal .................................................................................................................................................. 17

Method # 1 Real Time Demand DVM Screen ................................................................................... 17

Method # 2 Real Time Demand Scope Screen ................................................................................... 18

Method # 3 Recording Data .................................................................................................................. 18

Active Power vs. Reactive Power.................................................................................................................... 19

Method # 1 Real Time Demand DVM Screen ................................................................................... 19

Method # 2 Recording Data .................................................................................................................. 19

Displacement Power Factor (Leading and Lagging Current) ..................................................................... 20

Method # 1 Real Time Demand DVM Screen ................................................................................... 20

Method # 2 Real Time Demand Scope Screen ................................................................................... 20

Method # 3 Recording Data .................................................................................................................. 21

Harmonic Effect on Power ............................................................................................................................. 22

Method # 1 Real Time Demand DVM Screen ................................................................................... 22

Method # 2 Recording Data .................................................................................................................. 22

Voltage Dips / Sags .......................................................................................................................................... 23

Voltage Swells .................................................................................................................................................... 24

Voltage Transients ............................................................................................................................................. 24

Phase Angle Event ............................................................................................................................................ 25

Voltage and Current Harmonics ..................................................................................................................... 26

Method # 1 Real Time Harmonics DMM Screen .............................................................................. 26

Method # 2 Real Time Harmonics Scope Screen ............................................................................... 26

Method # 3 Recording Data .................................................................................................................. 27

Flicker .................................................................................................................................................................. 28

AVTMMPQSIM Rev 1 May 2017

i

Page 6

Method # 1 Real Time Flicker DVM Screen ....................................................................................... 28

Method # 2 Recording Data ................................................................................................................... 28

8 UNIT MAINTENANCE ................................................................................................................................. 29

Instructions for Cleaning and Decontamination ........................................................................................... 29

9 SPARE PARTS .................................................................................................................................................. 31

ADDENDUM A SAMPLE QUICK TRAINING ......................................................................................... 33

ADDENDUM B SAMPLE DEMAND TRAINING.................................................................................... 37

ADDENDUM C SAMPLE POWER QUALITY TRAINING ................................................................... 43

ADDENDUM D COMPLETE 115V MPQ SETUP FILE .......................................................................... 63

ADDENDUM E COMPLETE 230V MPQ SETUP FILE .......................................................................... 65

AVTMMPQSIM Rev 1 May 2017

ii

Page 7

1

INTRODUCTION

Thank you for purchasing the MPQSIM Power Quality Simulator, from Megger.

If you find any discrepancies in the product or its accessories or have any comments,

please send them to Megger via fax, e-mail or phone.

AVTMMPQSIM Rev 1 May 2017

1

Page 8

M

M

2

AVTMMPQSIM Rev 1 May 2017

Page 9

2

RECEIVING INFORMATION

MPQ-SIM-01

Contents Received:

QTY. PART NO. DESCRIPTION

1 1007-055 Power Quality Simulator

1 90017-548 AC Adapter

3 2008-124 Current Cables

When your Megger product arrives, check the equipment received against the

packaging list to ensure that all materials are present. Notify Megger of any shortages.

Examine the contents for damage received during transit. If any damage is

discovered, file a claim with the carrier at once and notify Megger or it’s nearest

authorized sales representative, giving a detailed description of the damage.

AVTMMPQSIM Rev 1 May 2017

3

Page 10

M

M

4

AVTMMPQSIM Rev 1 May 2017

Page 11

3

OVERVIEW

Intended Use

Applications

The MPQSIM is a power quality event simulator. This simulator is intended for use with

the Megger MPQ line of power quality analyzers. The MPQSIM power quality simulator

box is a training tool that simulates various power quality phenomenons. The MPQSIM is

not intended to be used for instrument calibration or troubleshooting.

Applications include:

Demonstrating Power Quality Phenomenon

Power Quality Phenomenon Locating and Identification Training.

NOTE: If this product is to be used in an industrial location with high ambient

EMI levels, some degradation of performance may occur. If this

degradation is objectionable, the unit should be moved to a more benign

location.

AVTMMPQSIM Rev 1 May 2017

5

Page 12

M

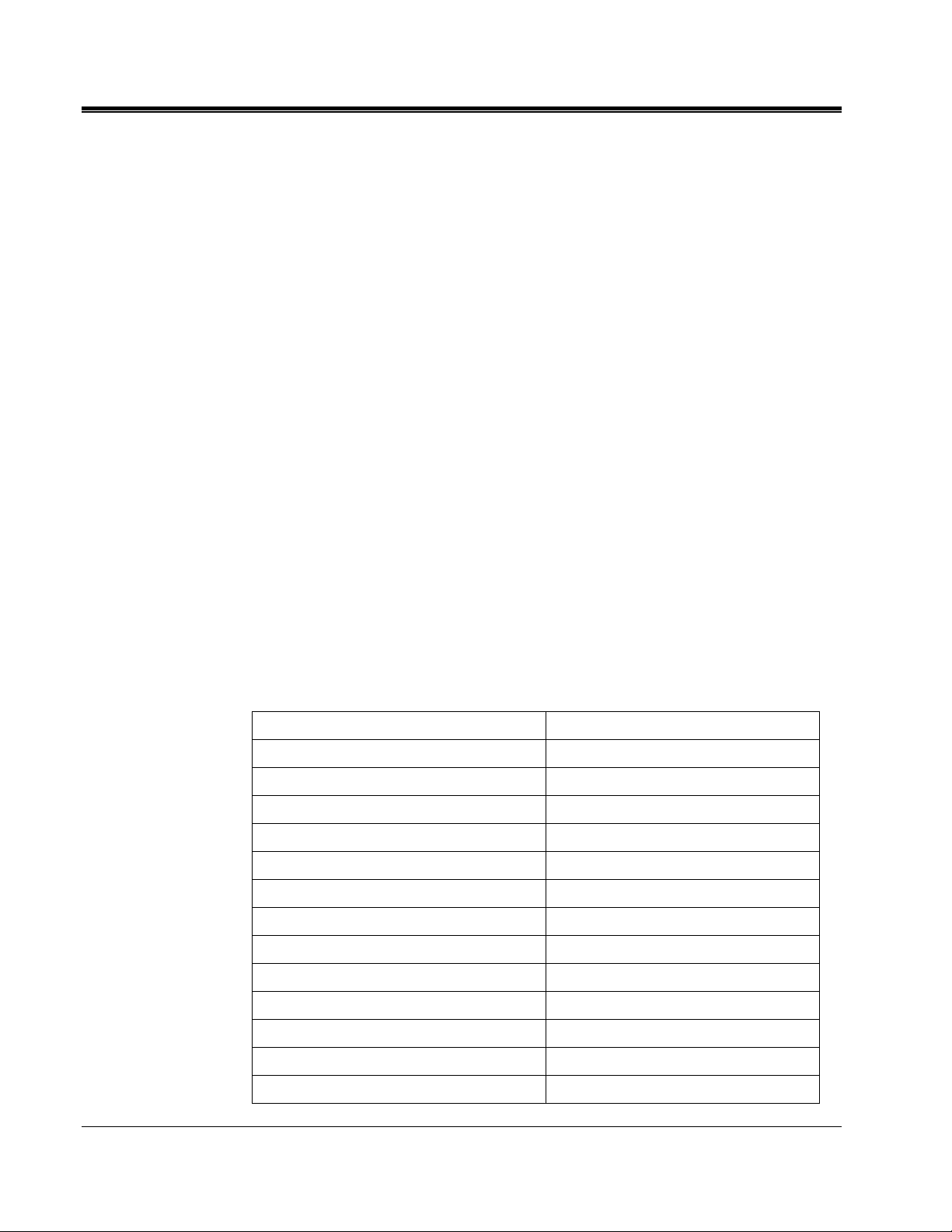

Definitions

Term Definition

Power Quality

Transient

Amplitude

Phase Angle

Harmonics

Flicker

Source

Load

Line Frequency

The concept of powering and grounding sensitive equipment

in a manner that is suitable to the operation of that equipment.

A sudden, non-power frequency change in the steady-state

condition of voltage, current, or both.

In this document amplitude will refer to the percentage of

change from 100% of the RMS voltage and or current value.

In this document phase angle will refer to the number of

degrees between the phase voltages as well as the number of

degrees between the phase voltage and phase current.

Sinusoidal components of periodic waves that have

frequencies that are multiples of the fundamental frequency.

The MPQSIM product creates 3

Flicker is a very specific problem related to human perception

and incandescent light bulbs. It is not a general term for

voltage variations. The MPQSIM product produces voltage

variations over time that will create Flicker phenomenon in

incandescent lighting.

The source of electrical generation or supply.

The load of an electrical generator or supply.

The fundamental AC frequency of the power network.

rd

and 5th order harmonics.

6

AVTMMPQSIM Rev 1 May 2017

Page 13

4

SPECIFICATIONS

DC Input Voltage:

AC Adapter:

Nominal Output Voltage:

Voltage Selections Accuracy:

(% of nominal)

nt Ranges:

Curre

Current Accuracy:

Nominal Pha

Phase Angle Selection

(from nominal)

Phase Accuracy:

Voltage Transient Amplitude:

Voltage Transient Rise Time:

Voltage Transient Duration:

Harmonic Orders:

se Angles:

12VDC +/-0.5VDC

100-240VAC 50/60

115VAC +/- 1.2VAC

230VAC +/- 2.4VAC

85.0 %+/- 0.5%

102.0% +/- .2%

115.0% +/- 0.5%

10A, 100A, 1000A & 6000

+/-2% Full Scale

0°, 120°, 240°

-30°, -11°, 0°, +11°

+/-1.5°

1075 +/-50Vpk

18 +/-5μsec

35+/-10μsec

rd

3

and 5th

Hz

A

Harmonic Amplitudes

Frequency Output:

Frequency Accuracy:

Flicker:

(Square wave modulation)

Physical size

Weight:

Operating Temperature:

Storage Temperature:

Humidity:

AVTMMPQSIM Rev 1 May 2017

7

10.0 +/-3.% of fundamental

50Hz / 60Hz

+/-0.05Hz

2% ∆U @ 0.2

2% ∆U @ 1.0Hz

2% ∆U @ 5.0Hz

14.2” x 12.0” x 7.6”

(36cm x 30.5cm x 19.3cm)

11.5lbs (5.2kg)

0C to +40C

-20C to +

0 to 95% non-condensing

50C

z

H

Page 14

M

Altitude:

EMF

Safety

IP Rating

CAT Rating

2000 meters

IEC 61326:2012 Class A, Basic Immunity

IEC61010-1

40

CAT II @ 300V

8

AVTMMPQSIM Rev 1 May 2017

Page 15

5

SAFETY

Warnings and Safety Precautions

WARNING!

Death, serious injury, or fire hazard could result from improper

use/installation of this instrument. Read and understand this

manual before installing this instrument.

Installation of this instrument MUST be performed in compliance with the

National Electric Code and any additional safety requirements applicable to

your installation.

Installation, operation and maintenance of this instrument MUST be

performed by qualified personnel only. The National Electrical Code defines

a qualified person as one familiar with the construction and operation of the

equipment and the hazards involved.

Do not leave the instrument connected to the system under test when not in

use.

Do not touch circuit connections or any metal that is exposed due to

damaged insulation.

Do not use the instrument or connect it to any external system if it shows

any visible signs of damage, malfunction or if it has been stored in

unfavorable conditions.

Always inspect the instrument prior to use.

Replace any defective parts or return the instrument to an authorized center

for repair.

Do not use the instrument or connect it to any external system if the

enclosure is open or any parts of the enclosure are missing.

Only use specified batteries as described by this document, if applicable.

The instrument shall not be used if any parts are damaged.

This instrument is not intrinsically safe and must not be used in hazardous

The following safety precautions MUST be taken whenever this product is installed.

AVTMMPQSIM Rev 1 May 2017

atmospheres.

9

Page 16

M

These warnings and safety precautions are to be used where appropriate when

following instructions in this manual.

Wear safety glasses and insulated gloves when making connections to

power circuits

Hands, shoes, floor/ground must be dry when making any connection to

a power line

CAUTION!

If this equipment is used in the manner not specified by

the manufacturer, the protection provided by the

equipment may be impaired.

PROTECTIVE TERMINAL

The Phase C RTN banana jack must be connected to

Earth Ground prior to the connection of any of the other

voltage output banana jacks.

Safety and Warning Symbols

SYMBOL REFERENCE DESCRIPTION

IEC 60417-5031 (2002-10) Direct current

d

IEC 60417-5019 (2006-08) Protective conductor terminal

g

Warning, possibility of electric shock

F

ISO 7000-0434B (2004-01) Caution

G

The crossed out wheeled bin placed on

Megger products is a reminder not to

dispose of the product at the end of its life

WEEE

with general waste. Megger is registered

in the UK as a Producer of Electrical and

Electronic Equipment. The Registration

No is WEE/DJ2235XR.

10

AVTMMPQSIM Rev 1 May 2017

Page 17

6

PRODUCT INSTALLATION

Connector Layout / Interconnect

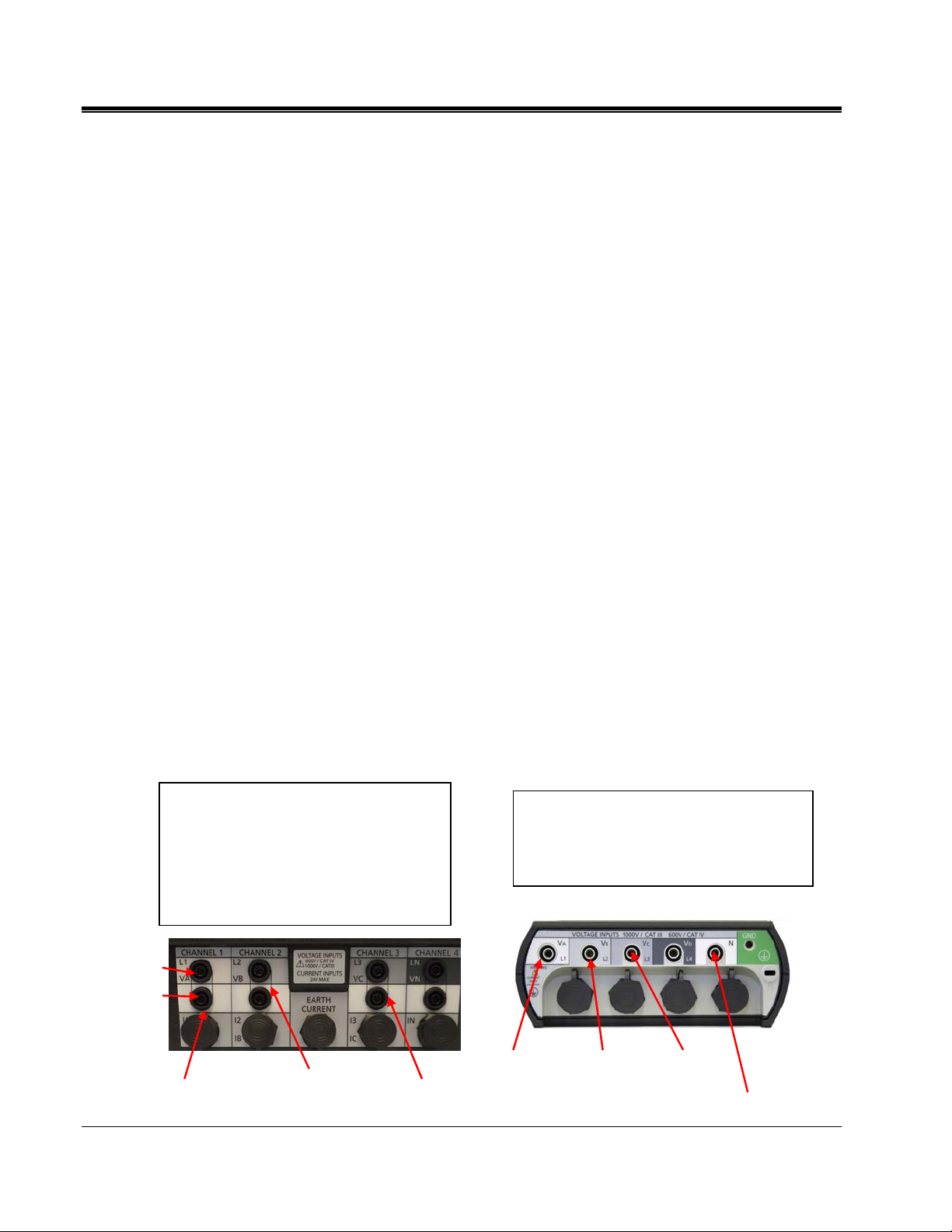

White Jacks - Return

Current Channel

Connectors

Plug the AC Adapter into the AC Adapter jack of the MPQSIM product.

Yellow Jacks – 115VAC

Red Jacks – 230VAC

AC Adapter

Jack

When used with an MPQ1000:

1. Connect the Phase C RTN jack on the MPQSIM to Earth Ground.

2. Connect the GND input on the MPQ1000 to Earth Ground.

3. Plug the Phase A voltage lead (supplied with the Megger PQ Product) between

the Phase A 115V or 230V banana jack on the MPQ-SIM and the Phase A

voltage input of the MPQ1000.

4. Plug the Phase B voltage lead (supplied with the Megger PQ Product) between

the Phase B 115V or 230V banana jack on the MPQ-SIM and the Phase B voltage

input of the MPQ1000.

AVTMMPQSIM Rev 1 May 2017

11

Page 18

M

5. Plug the Phase C voltage lead (supplied with the Megger PQ Product) between

6. Plug the Neutral lead (supplied with the Megger PQ Product) between the Phase

When used with the MPQ2000:

1. Connect the Phase C RTN jack on the MPQSIM to Earth Ground.

2. Connect the GND input on the MPQ2000 to Earth Ground.

3. Using two of the white Jumper Leads (supplied with the Megger PQ Product),

4. Using the voltage leads supplied with the Megger PQ Product connect the Phase

the Phase C 115V or 230V banana jack on the MPQ-SIM and the Phase C voltage

input of the MPQ1000.

A RTN banana jack on the MPQ-SIM and the Neutral lead of the MPQ1000.

connect the VA-Low, VB-Low and VC-Low banana jack inputs on the MPQ2000

together in daisy-chain fashion.

A high input on the MPQ2000 analyzer to either the Phase A 115V or 230V

banana jack on the MPQ-SIM.

5. Using the voltage leads supplied with the Megger PQ Product connect the Phase

A low input to the Phase A RTN jack on the MPQ-SIM.

6. Using the voltage leads supplied with the Megger PQ Product connect the Phase

B high input on the MPQ2000 analyzer to either the Phase B 115V or 230V

banana jack on the MPQ-SIM.

7. Using the voltage leads supplied with the Megger PQ Product connect the Phase

C high input on the MPQ2000 analyzer to either the Phase C 115V or 230V

banana jack on the MPQ-SIM.

The MPQ2000 has differential voltage

inputs. Using the jumpers supplied with

MPQ2000 jump the voltage neutrals (lows)

together. Then connect the jumped

neutrals to the Phase A neutral jack on the

PQ Simulator. Then plug each channel to

the corresponding voltage channel on the

PQ simulator.

High

Low

The MPQ1000 has a common neutral so no

jumpers are required. Plug each channel to

the corresponding voltage channel on the

PQ simulator. Plug the neutral lead into the

Phase A neutral jack of the simulator.

Phase A

Voltage

Phase B

Voltage

Phase C

Voltage

12

Phase A

Voltage

Phase B

Voltage

Phase C

Voltage

Neutral / Return

AVTMMPQSIM Rev 1 May 2017

Page 19

PRODUCT INSTALLATION

8. Plug the Phase A current lead into the MPQSIM Phase A current connector.

9. Plug the other side of the Phase A current lead into the Phase A current

connector of the Megger PQ Product.

10. Plug the Phase B current lead into the MPQSIM Phase B current connector.

11. Plug the other side of the Phase B current lead into the Phase B current

connector of the Megger PQ Product.

12. Plug the Phase C current lead into the MPQSIM Phase C current connector.

13. Plug the other side of the Phase A current lead into the Phase A current

connector of the Megger PQ Product.

Both the MPQ1000 and MPQ2000 use the same type self-identifying current clamps. No actual

current clamps are required to use the PQ Simulator with an MPQ Analyzer. Connect the MPQ

Analyzer CT connector directly to the PQ Simulator using the provided current cable.

Phase A

Current

Phase B

Current

Phase C

Current

Phase A

Current

Phase B

Current

Phase C

Current

AVTMMPQSIM Rev 1 May 2017

13

Page 20

M

M

14

AVTMMPQSIM Rev 1 May 2017

Page 21

7

PRODUCT OPERATION

Operation Controls and Modes

The following section describes the operation of the MPQSIM Power Quality

Simulator. This section will describe in a step by step manner how to operate the unit.

Definitions of switch and control functions.

Current Selector

Transient Button

Amplitude

Selector Voltage

Amplitude

Selector Current

Phase Angle

Selector

Flicker

Source / Load

Selection

CONTROL FUNCTION

Phase A Section

Phase B Section

Phase C Section

Current and Voltage

Harmonic Switches

Power On / Off

Frequency

Selection

Current Selector

Transient Button

Amplitude Selector

(Voltage)

AVTMMPQSIM Rev 1 May 2017

Sets the full scale range of the simulated current probe.

Applies a momentary transient pulse on the voltage

signal.

Sets the voltage amplitude. This value is set as a

percentage of the voltage output. If the voltage output

being used is 230VAC then 100% = 230VAC and 80% =

184V.

15

Page 22

M

CONTROL FUNCTION

Amplitude Selector

(Current)

Phase Angle Selector

(Voltage)

Phase Angle Selector

(Current)

Harmonics Switch

Flicker Selector

Power Direction Switch

Line Frequency Switch

Power Switch

Initial Settings

Sets the current amplitude. This value is set as a

percentage of the full scale current range. If the current

selector is set to 6000A output then 100% = 6000AAC

and 80% = 4800AAC.

Sets the voltage phase angles. Phase A is used as the

reference.

Sets the current phase angles. The Phase A Voltage is

used as the reference.

Turns ON and OFF the voltage and / or current

harmonics.

Sets the level and rate of voltage variation which causes

flicker in incandescent lighting.

Sets the power flow. The power flow can either be from

the source or the load.

Sets the fundamental line frequency. The line frequency

can be at either 50Hz or 60Hz.

Turns the MPQSIM ON and OFF.

Connect the Power Quality Simulator to the Megger MPQ Analyzer as described in

Section 6.

Set the controls to the following initial settings.

CONTROL SETTING

PHASE A

Phase A Current Range

Phase A Voltage Amplitude

Phase A Current Amplitude

Phase A Current Angle

Phase A Voltage Harmonics

Phase A Current Harmonics

PHASE B

Phase B Current Range

Phase B Voltage Amplitude

Phase B Current Amplitude

Phase B Voltage Angle

Desired Current Range

100%

100%

0°

OFF

OFF

Desired Current Range

100%

100%

120°

Phase B Current Angle

120°

AVTMMPQSIM Rev 1 May 2017

16

Page 23

PRODUCT OPERATION

CONTROL SETTING

PHASE C

GENERAL

Flicker

Power Direction

Line Frequency

Power

Simulations

Phase B Voltage Harmonics

Phase B Current Harmonics

Phase C Current Range

Phase C Voltage Amplitude

Phase C Current Amplitude

Phase C Voltage Angle

Phase C Current Angle

Phase C Voltage Harmonics

Phase C Current Harmonics

OFF

OFF

Desired Current Range

100%

100%

240°

240°

OFF

OFF

OFF

SOURCE

Desired Frequency

ON

Power Reversal

Verify the Power Quality instrument connected to the simulator is programmed to

record power in a 4-wire wye 3-wattmeter configuration.

Method # 1 Real Time Demand DVM Screen

1. Verify the controls are set to their initial settings.

2. View the real time demand (DVM screen) and note the KW is positive.

3. Set the Power Direction switch on the PQ Simulator to Sink.

4. The KW now reads negative. This indicates a reversal of power.

NOTE: The current vectors are now 180° out of phase with the voltage. Current

vectors should never exceed 90° of the voltage. If the current does exceed

90° of the voltage angle then this indicates a reverse power flow.

AVTMMPQSIM Rev 1 May 2017

17

Page 24

M

Method # 2 Real Time Demand Scope Screen

1. Verify the controls are set to their initial settings.

2. View the Phase A voltage and current on the scope screen.

3. Note the current is in Phase with the Voltage.

4. Set the Power Direction switch on the PQ Simulator to Sink.

Method # 3 Recording Data

1. Verify the Power Quality instrument connected to the simulator has a

NOTE: The current is now 180° out of phase with the voltage. This indicates a

reversal of power.

programmed demand interval of no more than 1 minute. This simulation will

require that at least 6 demand intervals are captured. The longer the demand

interval the longer this test will take.

2. Verify the controls are set to their initial settings.

3. Start the unit recording.

4. Allow the unit to record for at least 2 demand intervals.

5. Set the Power Direction switch on the PQ Simulator to Sink.

6. Allow the unit to record for at least 2 demand intervals.

7. Set the Power Direction Switch back to Source.

8. Allow the unit to record for at least 2 demand intervals.

9. Stop the recording.

10. View the Active Power (KW).

11. Note that during the phase reversal the KW value went negative.

18

AVTMMPQSIM Rev 1 May 2017

Page 25

Active Power vs. Reactive Power

Verify the Power Quality instrument connected to the simulator is programmed to

record power in a 4-wire wye 3-wattmeter configuration.

Method # 1 Real Time Demand DVM Screen

1. Verify the controls are set to their initial settings.

2. View the real time demand (DVM screen) and note the KW displays a value and

the KVAR is near 0.

3. Set any of the Current Phase Angle selectors to 30° from its nominal angle.

(-30° for Phase A, 90° for Phase B or 210° for Phase C)

NOTE: The KW value for the selected channel goes down while the KVAR

value goes up. As inductive load is added the phase angle increases which

reduces the active power and increases the reactive power.

Method # 2 Recording Data

PRODUCT OPERATION

1. Verify the Power Quality instrument connected to the simulator has a

programmed demand interval of no more than 1 minute. This simulation will

require that at least 6 demand intervals are captured. The longer the demand

interval the longer this test will take.

2. Verify the controls are set to their initial settings.

3. Start the unit recording.

4. Allow the unit to record for at least 2 demand intervals.

5. Set any of the Current Phase Angle selectors to 30° from its nominal angle.

(-30° for Phase A, 90° for Phase B or 210° for Phase C)

6. Allow the unit to record for at least 2 demand intervals.

7. Set the Current Phase Angle Selectors back to their nominal angles

(0°, 120° and 240°).

8. Allow the unit to record for at least 2 demand intervals.

9. Stop the recording.

10. View the Active Power (KW) and Reactive Power (KVAR).

NOTE: As the phase angle increases the reactive power increases and the active

power decreases.

AVTMMPQSIM Rev 1 May 2017

19

Page 26

M

Displacement Power Factor (Leading and Lagging Current)

Verify the Power Quality instrument connected to the simulator is programmed to

record power in a 4-wire wye 3-wattmeter configuration.

Method # 1 Real Time Demand DVM Screen

1. Verify the controls are set to their initial settings.

2. Set the Phase A, B and C Current Phase Angle selector switches to -11°.

3. View the real time demand (DVM screen) and note the DPF for each channel is

4. Set the Phase A, B and C Current Phase Angle selector switches to 11°.

5. View the real time demand (DVM screen) and note the DPF for each channel is

positive.

negative.

NOTE: When the load is inductive (as in a motor) the current lags the voltage.

This will be seen as a positive displacement power factor (DPF). When

the load is capacitive (as in a cap bank) the current leads the voltage.

This will be seen as a negative displacement power factor (DPF).

The sign of the DPF will always equal the sign of the KVAR.

Method # 2 Real Time Demand Scope Screen

1. Verify the controls are set to their initial settings.

2. Set the Phase A Phase Angle selector switch to -30°.

3. View the Phase A voltage and current on the scope screen.

4. Note the current lags the voltage.

5. Set the Phase A Phase Angle selector switch to 11°.

6. View the Phase A voltage and current on the scope screen.

NOTE: The current now leads the voltage.

NOTE: When the load is inductive (as in a motor) the current lags the voltage.

This will be seen as a positive displacement power factor (DPF). When

the load is capacitive (as in a cap bank) the current leads the voltage.

This will be seen as a negative displacement power factor (DPF).

The sign of the DPF will always equal the sign of the KVAR.

20

AVTMMPQSIM Rev 1 May 2017

Page 27

Method # 3 Recording Data

1. Verify the Power Quality instrument connected to the simulator has a

programmed demand interval of no more than 1 minute. This simulation will

require that at least 8 demand intervals are captured. The longer the demand

interval the longer this test will take.

2. Verify the controls are set to their initial settings.

3. Set the Voltage Phase A, B and C Phase Angle selector switches to 11°.

4. Start the unit recording.

5. Allow the unit to record for at least 3 demand intervals.

6. Set the Voltage Phase A, B and C Phase Angle selector switches to -30°.

7. Allow the unit to record for at least 3 demand intervals.

PRODUCT OPERATION

8. Set the Voltage Phase A, B and C Phase Angle selector switches to 11°.

9. Allow the unit to record for at least 2 demand intervals.

10. Stop the recording.

11. View the Displacement Power Factor (DPF).

NOTE: When the phase angle was 30° the DPF was positive. When the phase

angle was -30° the DPF was negative.

NOTE: When the load is inductive (as in a motor) the current lags the voltage.

This will be seen as a positive displacement power factor (DPF). When

the load is capacitive (as in a cap bank) the current leads the voltage.

This will be seen as a negative displacement power factor (DPF).

The sign of the DPF will always equal the sign of the KVAR.

AVTMMPQSIM Rev 1 May 2017

21

Page 28

M

Harmonic Effect on Power

Verify the Power Quality instrument connected to the simulator is programmed to

record power in a 4-wire wye 3-wattmeter configuration.

Method # 1 Real Time Demand DVM Screen

1. Verify the controls are set to their initial settings.

2. Set the Phase A, B and C Current Phase Angle selector switches to 30°.

3. View the real time demand (DVM screen) and note the Apparent Power (KVA),

the Active Power (KW) and the Reactive Power (KVAR).

NOTE: The Power Triangle holds true

S = Apparent Power

P = Active Power

Q = Reactive Power

4. Set the voltage and current harmonic switches to ON.

5. View the real time demand (DVM screen) and note the Apparent Power (KVA),

the Active Power (KW) and the Reactive Power (KVAR).

NOTE: The power triangle now has increased errors. This shows that power

triangle does not hold true for non-sinusoidal waveforms.

Method # 2 Recording Data

1. Verify the Power Quality instrument connected to the simulator has a

programmed demand interval of no more than 1 minute. This simulation will

require that at least 6 demand intervals are captured. The longer the demand

interval the longer this test will take.

2. Verify the controls are set to their initial settings.

3. Set the Phase A, B and C Phase Angle selector switches to 30°.

4. Start the unit recording.

5. Allow the unit to record for at least 3 demand intervals.

6. Set the voltage and current harmonic switches to ON.

Test Equipment Depot - 800.517.8431

99 Washington Street, Melrose, MA 02176

TestEquipmentDepot.com

Page 29

PRODUCT OPERATION

7. Allow the unit to record for at least 3 demand intervals.

8. Stop the recording.

9. View the Apparent Power (KVA), the Active Power (KW) and the Reactive

Power (KVAR).

NOTE: The Power Triangle holds true when the harmonics are off.

S = Apparent Power

P = Active Power

Q = Reactive Power

The power triangle now has increased errors when the harmonics are on. This shows

that power triangle does not hold true for non-sinusoidal waveforms.

Voltage Dips / Sags

1. Verify the Power Quality instrument connected to the simulator has a

programmed sag / dip limit of no more that 10% of the MPQSIM voltage output

that it is connected.

NOTE: If you wish to record RMS values as well it may be best to set the RMS

2. Verify the controls are set to their initial settings.

3. Start the unit recording.

storage interval to 3 seconds, so you do not need to wait a long period to

acquire saved RMS intervals.

4. Allow the unit to record for several seconds.

5. Note there are no recorded Sags / Dip events.

6. Set one of the voltage phase Amplitude selector switches to 85%.

7. Allow the unit to record for several seconds.

8. Set the voltage phase Amplitude selector switch back to 100%.

9. Allow the unit to record for several seconds.

10. Note the unit now displays a Sag / Dip event.

11. Stop the recording.

12. The Sag event can now be viewed on the unit.

AVTMMPQSIM Rev 1 May 2017

23

Page 30

M

Voltage Swells

Verify the Power Quality instrument connected to the simulator has a programmed

swell limit of no more that 10% of the MPQSIM voltage output that it is connected.

1. Verify the controls are set to their initial settings.

2. Start the unit recording.

3. Allow the unit to record for several seconds.

4. Note there are no recorded Swell events.

5. Set one of the voltage phase Amplitude selector switches to 115%.

NOTE: If you wish to record RMS values as well it may be best to set the RMS

storage interval to 3 seconds, so you do not need to wait a long period to

acquire saved RMS intervals.

6. Allow the unit to record for several seconds.

7. Set the voltage phase Amplitude selector switch back to 100%.

8. Allow the unit to record for several seconds.

9. Note the unit now displays a Swell event.

10. Stop the recording.

11. The Swell event can now be viewed on the unit.

Voltage Transients

1. Verify the Power Quality instrument connected to the simulator has a

programmed with sag and swell limit of no more that 10% of the MPQSIM

voltage output that it is connected.

2. Verify the Power Quality instrument connected to the simulator has a

programmed with transient limit of 140.00 for a 115VAC voltage connection or a

transient limit of 280.00 for a 230VAC voltage connection.

NOTE: If you wish to record RMS values as well it may be best to set the RMS

storage interval to 3 seconds, so you do not need to wait a long period to

acquire saved RMS intervals.

3. Verify the controls are set to their initial settings.

AVTMMPQSIM Rev 1 May 2017

24

Page 31

4. Start the unit recording.

5. Allow the unit to record for several seconds.

6. Note there are no recorded Transient events.

7. Depress and release one of the transient buttons.

8. Allow the unit to record for several seconds.

9. Note the unit now displays a Transient event.

10. Stop the recording.

11. The Transient event can now be viewed on the unit.

Phase Angle Event

1. Verify the Power Quality instrument connected to the simulator has the following

settings programmed.

PRODUCT OPERATION

a. Phase Ange Events – Enabled

b. Rotation – ABC

c. Phase A Nominal Angle = 0

d. Phase B Nominal Angle = 120

e. Phase C Nominal Angle = 240

f. Phase B Angle Deviation = 2.00

g. Phase C Angle Deviation = 2.00

NOTE: If you wish to record RMS values as well it may be best to set the RMS

storage interval to 3 seconds, so you do not need to wait a long period to

acquire saved RMS intervals.

2. Verify the controls are set to their initial settings.

3. Start the unit recording.

4. Allow the unit to record for several seconds.

5. Note there are no phase angle events.

6. Set Phase B Voltage Angle to 131°

7. Allow the unit to record for several seconds.

AVTMMPQSIM Rev 1 May 2017

25

Page 32

M

8. Set Phase B Voltage Angle to 120°

9. Allow the unit to record for several seconds.

10. Note the unit now displays a Phase Angle Event.

11. Set Phase C Voltage Angle to 251°

12. Allow the unit to record for several seconds.

13. Set Phase C Voltage Angle to 240°

14. Allow the unit to record for several seconds.

15. Note the unit now displays another Phase Angle Event.

16. Stop the recording.

17. The Phase Angle events can now be viewed on the unit

Voltage and Current Harmonics

Verify the Power Quality instrument connected to the simulator is programmed to

record power in a 4-wire wye 3-wattmeter configuration.

Method # 1 Real Time Harmonics DMM Screen

1. Verify the controls are set to their initial settings.

2. Verify the Voltage and Current Harmonic switches are set to OFF.

3. View the real time harmonics in the units real time DMM screen and note the

harmonic content is near 0.

4. Set the Phase A, B and C Voltage Harmonics to ON.

5. View the real time harmonics in the units real time DMM screen and note the 3rd

order and 5th order voltage harmonics now display

Method # 2 Real Time Harmonics Scope Screen

1. Verify the controls are set to their initial settings.

2. Verify the Voltage and Current Harmonic switches are set to OFF.

3. View the real time harmonics in the units real time Scope screen and note the

harmonic content is near 0.

4. Set the Phase A, B and C Current Harmonics to ON.

AVTMMPQSIM Rev 1 May 2017

26

Page 33

5. View the real time harmonics in the unit’s real time Scope screen and note the 3rd

order and 5th order current harmonics now display.

6. Set the Phase A, B and C Voltage Harmonics to ON.

7. View the real time harmonics in the units real time Scope screen and note the 3rd

order and 5th order voltage harmonics now display.

Method # 3 Recording Data

1. Verify the Power Quality instrument connected to the simulator is programmed

to record power in a 4-wire wye 3-wattmeter configuration and has the following

settings programmed.

a. RMS Storage Interval – 3 Seconds

b. Timed Waveform Capture – Enabled

c. Timed Capture Rate = 1 Minute

d. Timed Capture Duration in Cycles = 6

PRODUCT OPERATION

e. Enable THD Recording = Enabled

f. Enable IEC Harmonics Recording = Enabled

g. THD / Harmonic Storage Interval = 3 Seconds

2. Verify the controls are set to their initial settings.

3. Verify the Voltage and Current Harmonic switches are set to OFF.

4. Start the unit recording.

5. Allow the unit to record for at least 30 seconds to 1 minute.

6. Set the Phase A, B and C Current Harmonics to ON.

7. Allow the unit to record for at least 30 seconds to 1 minute.

8. Set the Phase A, B and C Voltage Harmonics to ON.

9. Allow the unit to record for at least 30 seconds to 1 minute.

10. Set the Phase A, B and C Voltage and Current Harmonics to OFF.

11. Allow the unit to record for at least 30 seconds to 1 minute.

12. Stop the recording.

13. You can now view the recorded harmonic on the unit.

NOTE: You can transfer the data to the PC for a more advanced analysis.

AVTMMPQSIM Rev 1 May 2017

27

Page 34

M

Flicker

Method # 1 Real Time Flicker DVM Screen

1. Verify the controls are set to their initial settings.

2. Load a setup file into the MPQ Analyzer that has flicker recording enabled. (Pst

3. Verify the flicker knob on the unit Power Quality Simulator is set to OFF.

4. View the real time flicker on the flicker portion of the DVM screen and note the

5. Set the flicker knob on the Power Quality Simulator to one of the flicker settings.

6. Note the instantaneous flicker value on the MPQ DVM screen is now showing a

and Plt)

flicker content is near 0.

value.

7. Wait one minute for the Pst 1 Minute value to display.

Method # 2 Recording Data

1. Verify the Power Quality instrument connected to the simulator is programmed

to record power in a 4 wire wye 3 wattmeter configuration and has the flicker

capture enabled. (Pst and Plt)

2. Verify the controls are set to their initial settings.

3. Set the flicker knob on the Power Quality Simulator to one of the flicker settings.

4. Start the MPQ Analyzer recording.

5. Let the unit record for 30 minutes, in order to record several flicker intervals.

6. Stop the recording and view the flicker data on the unit or download the data to

the Megger PQ PC software.

28

AVTMMPQSIM Rev 1 May 2017

Page 35

8

UNIT MAINTENANCE

Instructions for Cleaning and Decontamination

This unit has no field serviceable parts within it.

The unit should not be cleaned with anything more than a clean dry cloth.

AVTMMPQSIM Rev 1 May 2017

29

Page 36

M

M

30

AVTMMPQSIM Rev 1 May 2017

Page 37

9

SPARE PARTS

PART NO. DESCRIPTION

2008-124 Current Cable

90017-548 AC Adapter

\

AVTMMPQSIM Rev 1 May 2017

31

Page 38

M

M

32

AVTMMPQSIM Rev 1 May 2017

Page 39

ADDENDUM A

SAMPLE QUICK TRAINING

This Addendum is meant to offer a possible sample training routine for the MPQ line

of power quality analyzers.

1. Initial PQ Simulator Configuration

Configure the PQ Simulator as shown in Section 7 Initial Settings of this manual

2. Program the MPQ Analyzer

Programming the MPQ Analyzer for 115V input from simulator.

Voltage sag / dip limit

Voltage swell limit

Fast transient limit

THD limit

RMS storage interval

See Addendum D - Complete 115V MPQ Setup File for full setup file.

108.00

132.00

400.00

5.0

3 Seconds

Programming the MPQ Analyzer for 230V input from simulator.

Voltage sag / dip limit

Voltage swell limit

Fast transient limit

THD limit

RMS storage interval

See Addendum E - Complete 230V MPQ Setup File for full setup file.

207.00

262.00

600.00

5.0

3 Seconds

Connect the unit to the simulator as shown in Section 6 Product Installation of this

manual.

3. Operation of Scope Mode and DVM Mode

a. View the voltages and demand values on the DVM screen of the MPQ Analyzer.

b. View the waveforms on the Scope screen of the MPQ Analyzer. Scroll through

the phases.

AVTMMPQSIM Rev 1 May 2017

33

Page 40

M

4. Harmonic Bar Chart

a. View the waveforms on the Scope screen of the MPQ Analyzer. Scroll through the

b. Turn ON the Voltage Harmonics switch on the PQ Simulator. The harmonics are

c. Turn OFF the Voltage Harmonics switch ON the PQ Simulator.

5. Phase Angles

a. View the Vectors on the Unbalance screen of the MPQ Analyzer.

b. Change the Current phase angles on the PQ Simulator. View the changes on the

c. Set the Current phase angles on the PQ Simulator back to nominal.

6. Source Reversal

a. View the demand values on the DVM screen of the MPQ Analyzer.

phases.

displayed.

vector diagram.

b. Set the Power Direction Switch on the PQ Simulator to SINK. The KW values are

now negative, indicating reversed power flow.

NOTE: This can also be viewed in the scope mode and in the unbalance vectors

as currents being 180° out of phase.

c. Set the Power Direction Switch on the PQ Simulator to SOURCE.

7. Leading/Lagging Current

a. View the Waveforms on the Scope screen of the MPQ Analyzer.

b. Change the Current phase angle on the PQ Simulator to -30°. The current now lags

the voltage. This is indicative of an inductive load, such as a motor.

c. View the Vectors on the Unbalance screen of the MPQ Analyzer.

d. View the phase rotation caused by a lagging current.

e. Change the Current phase angle on the PQ Simulator to +11°.

f. View the Waveforms on the Scope screen of the MPQ Analyzer.

The current now leads the voltage. This is indicative of a capacitive load, such as a cap bank.

g. View the Vectors on the Unbalance screen of the MPQ Analyzer.

NOTE: The phase rotation caused by a leading current.

h. Set the Current phase angles on the PQ Simulator back to nominal.

AVTMMPQSIM Rev 1 May 2017

34

Page 41

ADDENDUM A- SAMPLE QUICK TRAINING

8. Start a Recording

Start the MPQ Recording.

9. Create a SAG / DIP

a. Allow the unit to record for approximately 15 seconds (minimum).

b. Start a SAG / DIP on one of the voltage phases by setting the voltage selector to

85%.

c. Wait about 1 second.

d. Stop the SAG / DIP by setting the voltage selector back to 100%. The record screen

now will register a sag.

10. Create a Swell

a. Allow the unit to record for approximately 15 seconds (minimum).

b. Start a SWELL on one of the voltage phases by setting the voltage selector to

115%.

c. Wait about 1 second.

d. Stop the SWELL by setting the voltage selector back to 100%. The record screen

now will register a swell.

11. Create a Transient

a. Allow the unit to record for approximately 15 seconds (minimum).

b. Create a transient by depressing and releasing one of the transient switched on

the PQ Simulator. The record screen now will register a transient.

12. Create THD Event

a. Allow the unit to record for approximately 15 seconds (minimum).

b. Start a THD Event by turning ON one of the voltage harmonic switches.

c. Wait about 2 second.

d. Stop the THD Event by turning OFF one of the voltage harmonic switches.

The record screen now will register a THD Event.

13. Create a Phase Event

a. Allow the unit to record for approximately 15 seconds (minimum).

b. Start a Phase Event by setting one of the Voltage Phase switches to +11°.

c. Wait about 1 second.

d. Stop the Phase Event by setting the voltage phase switch selector back to

nominal. The record screen now will register a Phase Event.

AVTMMPQSIM Rev 1 May 2017

35

Page 42

M

14. Turn on Harmonics

a. Allow the unit to record for approximately 15 seconds (minimum).

b. Turn ON one of the voltage and current harmonic switches.

c. Let the unit record for about 1 minute.

d. Turn OFF the voltage and current harmonic switches.

e. Let the unit record for about another 15 seconds then stop the recording.

15. View the data on the MPQ Analyzer

a. View the RMS Charts.

b. View the Power Charts.

c. View the Harmonic Charts.

d. View the Event Data Charts.

NOTE: This data can also be transferred and viewed in the Megger PQ software.

36

AVTMMPQSIM Rev 1 May 2017

Page 43

ADDENDUM B

SAMPLE DEMAND TRAINING

This Addendum is meant to offer a possible sample training to illustrate power and

energy parameters.

1. Initial PQ Simulator Configuration

Configure the PQ Simulator as shown in Section 7: Initial Settings of this manual.

2. Program the MPQ Analyzer

Programming the MPQ Analyzer for 115V input from simulator.

Voltage sag / dip limit

Voltage swell limit

Fast transient limit

THD limit

RMS storage interval

Demand Configuration

Demand Storage Interval

See Addendum 4 - Complete 115V MPQ Setup File for full setup file.

Programming the MPQ Analyzer for 230V input from simulator.

Voltage sag / dip limit

Voltage swell limit

Fast transient limit

THD limit

RMS storage interval

Demand Configuration

Demand Storage Interval

108.00

132.00

400.00

5.0

3 Seconds

4-Wire Wye 3-Wattmeter

5 Minutes

207.00

262.00

600.00

5.0

3 Seconds

4-Wire Wye 3-Wattmeter

5 Minutes

See Addendum 5 - Complete 230V MPQ Setup File for full setup file.

Connect the unit to the simulator as shown in Section 6 Product Installation of this

manual.

Test Equipment Depot - 800.517.8431

99 Washington Street, Melrose, MA 02176

TestEquipmentDepot.com

Page 44

M

3. RMS and Demand Values

a. View the voltages and demand values on the DVM screen of the MPQ Analyzer.

Confirm the following:

The Displacement Power Factor (DPF) is the power factor of the fundamental value.

(COS of the phase angle between the voltage and current)

b. View the waveforms on the Scope screen of the MPQ Analyzer. Scroll through

NOTE: The phase angles of the voltage and current. Voltages and current are at

0, 120 and 240. This is true under purely resistive loads only.

The KW is positive. This indicates the power is flowing from the source to

the load.

The KVAR is near zero. This indicates there is minimal phase shifting due to

reactive loads.

The DPF is 1.0 and is positive. This is a sign of a resistive load.

the phases. The currents are in phase with the voltages.

4. Phase Rotation

a. View the Vectors and Power Factor on the DVM Power screen of the MPQ

Analyzer.

The phase rotation is as follows:

Phase A Voltage = 0°

Phase B Voltage = 120°

Phase C Voltage = 240°

This is an ABC Phase rotation.

b. Swap Phase B and C voltage inputs.

The phase rotation is as follows:

Phase A Voltage = 0°

Phase B Voltage = 240°

Phase C Voltage = 120°

This is an ACB phase rotation

Notice the currents are still in an ABC Phase rotation. The Phase B and C current

phase angles now have a phase angle difference of greater than 90° from their

voltages.

AVTMMPQSIM Rev 1 May 2017

38

Page 45

ADDENDUM B - SAMPLE DEMAND TRAINING

Different phase rotations can be used however the current phase angle can never be

more than 90° away from the phase voltage. This is a sign that something is not

connected properly.

c. Swap Phase B and C voltage inputs back to normal.

5. Phase Angles and Power Factor

a. View the Phase A Voltage and Current Waveforms on the Scope screen of the

MPQ Analyzer.

b. Change the Phase A Current phase angle on the PQ Simulator to -30°.

This simulates an inductive load, such as a motor.

The current now lags the voltage. This is because the coil is resistant to the change in ac current, per

Lenz law.

Lenz's law states that when an electromagnetic field (EMF) is generated by a change in

magnetic flux. The polarity of the induced EMF is such, that it produces a current

that's magnetic field opposes the change which produces it.

c. View the Vectors and Power Factor on the DVM Power screen of the MPQ

Analyzer. The phase rotation due to the lagging current moves the current vector

clockwise.

NOTE: The DPF is now less than 1.0 and is positive. A positive DPF is a

sign of a lagging current (Inductive load).

d. Change the Phase A Current phase angle on the PQ Simulator to +11°. This

simulates a capacitive load such as a cap bank.

e. View the Waveforms on the Scope screen of the MPQ Analyzer. The current

now leads the voltage. This is because the capacitors will charge and discharge as

the voltage changes. This creates a phase shift.

f. View the Vectors and Power Factor on the DVM Power screen of the MPQ

Analyzer. The phase rotation due to the leading current moves the current vector

counter-clockwise.

NOTE: The DPF is now less than 1.0 and is negative. A negative DPF is a

sign of a leading current (Capacitive load).

g. Set the Current phase angles on the PQ Simulator back to nominal.

AVTMMPQSIM Rev 1 May 2017

39

Page 46

M

6. Source Reversal

a. View the demand values on the DVM screen of the MPQ Analyzer.

b. Set the Power Direction Switch on the PQ Simulator to SINK. The KW values are

If the KW is negative when the power quality device is connected this can be an

indication that the current probes are backwards. Verify the arrows on the current

probes point toward the load.

c. Set the Power Direction Switch on the PQ Simulator to SOURCE.

7. Power Triangle

now negative, indicating reversed power flow. The power is now flowing from the load to the

source. This can be due to local sources such as solar power locations, distributed generation

devices.

NOTE: This can also be viewed in the scope mode and in the unbalance vectors

as currents being 180° out of phase.

a. View the demand values on the DVM screen of the MPQ Analyzer.

NOTE:

Active Power (P): measured in W / (KW): Performs real work

Reactive Power (Q): measured in VAR / (KVAR): Out of phase power,

does not perform real work.

Apparent Power (S): measured in VA / (KVA)

POWER TRIANGLE

b. Change the Phase A Current phase angle on the PQ Simulator to -30°. The

KVAR on Phase A increased due to the increase in reactive current caused by the added

inductive load.

AVTMMPQSIM Rev 1 May 2017

40

Page 47

ADDENDUM B - SAMPLE DEMAND TRAINING

However the power triangle still holds true. √

The more reactive power in a system the greater the amount of apparent power

(KVA) is required. As inductive loads are added to a network they increase the lag in

the current. This increases the amount of reactive power in that network. The energy

provider needs to create larger amounts of apparent power to carry that burden. By

switching in a capacitive load such as a capacitor bank, this compensates for the

lagging current and therefore reduces the reactive power in the network. This means

the energy provider can produce less apparent power to run the network. This makes

the energy provider more efficient.

c. Set the Current phase angles on the PQ Simulator back to nominal.

8. Harmonic Effects on the Power Triangle

a. View the demand values on the DVM screen of the MPQ Analyzer.

NOTE: the √

b. Change the Phase A Current phase angle on the PQ Simulator to -30°. The

KVAR on Phase A increased due to the increase in reactive current caused by

the added inductive load.

c. Turn ON the Phase A Voltage and Current Harmonics on the PQ Simulator. The

power triangle does NOT hold true √

.

The power triangle only holds true for sinusoidal waveforms. Once harmonics are

introduced the waveform is no longer sinusoidal, therefore the power triangle will

have errors. In the real world virtually all power will have some amount of harmonics.

This means that calculating a single power parameter based on the other two will

always have some error. In a PQ Instrument these values need to be measured values

not calculated values.

There is now a difference between the DPF and the TPF.

This is because the Displacement Power Factor (DPF) is the power factor of the

fundamental value only (COS of the phase angle between the voltage and current).

The True Power Factor (TPF) is the power factor of the fundamental plus the

harmonics (TPF = KW/KVA).

The greater the difference between the TPF and DPF, the greater the harmonic

content.

d. Set the Current phase angles on the PQ Simulator back to nominal.

AVTMMPQSIM Rev 1 May 2017

41

Page 48

M

9. Start a recording

a. Change the Phase A Current phase angle on the PQ Simulator to -30°.

b. Change the Phase B Current phase angle on the PQ Simulator to -30°.

c. Change the Phase C Current phase angle on the PQ Simulator to -30°.

d. Start the MPQ Recording.

Allow the unit to record for 20 minutes.

10. Energy

a. Stop the recording.

b. View the recorded energy graph on the unit.

Confirm the following:

NOTE: The KW, KVA and KVA values on the DVM Demand screen.

Each KWH 5 minute interval = KW/12

Each KVAR 5 minute interval = KVAR/12

Each KVA 5 minute interval = KVA/12

This is because the demand interval was set to 5 minutes. There are 12 (5 minute)

intervals in an hour. So the power is aggregated over a 5 minute interval to calculate

energy. If the demand interval was set to 15 minutes then the energy would be

aggregated 4 times every hour. So if the active power draw was constant the over the

15 minute demand interval then the KWH = KW/4.

When verifying revenue meters the demand aggregation should be set to the same

value as the revenue meter.

NOTE: This data can also be transferred and viewed in the Megger PQ software.

42

AVTMMPQSIM Rev 1 May 2017

Page 49

ADDENDUM C

SAMPLE POWER QUALITY TRAINING

This Addendum is meant to offer a possible sample training to illustrate power quality

phenomenon.

1. Initial PQ Simulator configuration

Configure the PQ Simulator as shown in Section 7 Initial Settings of this manual.

2. Program the MPQ Analyzer

Programming the MPQ Analyzer for 115V input from simulator.

Voltage sag / dip limit

Voltage swell limit

Fast transient limit

THD limit

RMS storage interval

See Addendum 4 Complete 115V MPQ Setup File for full setup file.

Programming the MPQ Analyzer for 230V input from simulator.

Voltage sag / dip limit

Voltage swell limit

Fast transient limit

THD limit

RMS storage interval

See Addendum 5 Complete 230V MPQ Setup File for full setup file.

Connect the unit to the simulator as shown in Section 6 Product Installation of this

manual.

108.00

132.00

400.00

5.0

3 Seconds

207.00

262.00

600.00

5.0

3 Seconds

AVTMMPQSIM Rev 1 May 2017

43

Page 50

M

3. RMS, Phases and THD

a. View the voltages and current values on the DVM screen of the MPQ Analyzer.

b. View the phase angles of the voltage and current on the DVM screen of the

c. View the scope screen of the MPQ Analyzer.

Verify RMS voltages and currents are correct. This should always be done prior

to performing a power quality investigation.

MPQ Analyzer.

NOTE: Always verify the voltage phase angles are correct per the power

configuration.

Always verify the current angles are less than 90° from their respective

voltage angles.

Current phase angle can never be more than 90° away from the phase

voltage. This is a sign that something is not connected properly.

Examinations of voltage waveforms can indicate power quality problem. These can

include harmonic distortion, notching and noise.

d. View the scope harmonics screen of the MPQ Analyzer.

Examinations of the harmonics can indicate power quality problems without the need

of doing a recording.

NOTE: Harmonics can cause various problems, including heating of

transformers, and motors, reduced efficiency in motors, neutral line

overheating, capacitor bank failures, as well as equipment failure.

Even harmonics (2, 4, 6…etc) are indications of a faulty rectifier.

Negative sequence harmonics (5, 11, 17…etc) have magnetic fields that

rotate opposite the fundamental. This creates inefficiencies in motors.

Odd Zero Sequence harmonics also known as triplens (3, 9, 15…etc)

do not cancel out. They add together. This can create high neutral

currents.

44

AVTMMPQSIM Rev 1 May 2017

Page 51

ADDENDUM C - SAMPLE POWER QUALITY TRAINING

4. Unbalance

a. View the Vectors and Unbalance on the SCOPE/UNBALANCE screen of the

MPQ analyzer.

b. Change the Phase A Current phase angle on the PQ Simulator to -30°.

c. Change the Phase A Voltage to 85% on the PQ Simulator. Note the change in the

unbalance.

NOTE: Voltage unbalance causes heating in neutral lines, motors, unbalanced

currents and uncharacteristic harmonics for electronic equipment such as

adjustable speed drives.

|

High-efficiency motors can be more susceptible to negative sequence

unbalance.

Negative sequence harmonics have a magnetic field that rotate opposite of

the fundamental.

This can lead to loss of efficiency as it resists the rotation of the motor.

The negative sequence factor [(negative sequence / positive sequence) *

100] is most the key unbalance value to reference when working with

motor loads.

Negative sequence unbalance is the basis of most international standards

for unbalance.

It is recommended that the voltage unbalance be within 2% for 95% of

the time measured over a period of a week at 10 minute intervals. For

systems with large single-phase loads, the unbalance can be as high as

3%.

d. Use the UP/DOWN button on the MPQ analyzer to change from an IEC

Unbalance measurement to an ANSI unbalance measurement.

The ANSI method of measuring unbalance compares the individual line-to-line voltage to the average

of the sum of all the line to line voltages. This value can be influenced by the zero sequence voltage as

well as by the negative sequence voltage.

ANSI C84.1-2006 recommends that voltage unbalance be limited to 3%.

e. Change the Phase A Current phase angle on the PQ Simulator to 0°.

f. Change the Phase A Voltage to 100% on the PQ Simulator.

AVTMMPQSIM Rev 1 May 2017

45

Page 52

M

5. Harmonics

a. View the Harmonics Bar Chart on the SCOPE / HARMONICS screen of the

b. Turn on the voltage and current harmonics on the PQ simulator. Note the

c. View the waveform on the SCOPE screen of the MPQ analyzer. Note the

Immediate effects of harmonics can include the misoperation of electronic controls

or uninterruptible power supplies. Over time harmonic distortion can results in

increased heating in transformers, motors, capacitors and conductors. In addition

voltage distortion can excite resonances overloading customer power factor

correction equipment.

AC current flowing though coils create eddie currents. These eddie current create

magnetic fields in opposition of the flow of current. This causes the current to be

pushed out to the edge of the wire. This is known as "skin effect". As the skin effect

increases the usable cross sectional area of the wire decreases. This increases the

impedance of the wire which in turn increases the heat. The higher the harmonic

order the greater this effect. Eddie current losses increase with approximately the

square of the frequency.

MPQ analyzer.

change in the harmonic bar chart as the harmonics are applied.

distortion.

IEC 61000-2-2 specifies harmonic distortion compatibility levels dependent on the

harmonic order. The compatibility level for the voltage THD is 8% for 95% of the

time measured over a period of a week at 10 minute intervals.

IEEE 519 recommends voltage distortion limits of 8% for the total harmonic

distortion (THD) IEEE 519 recommends individual harmonic components limits be

at 5%. The compatibility level is for 95% of the time measured over a period of a

week at 10 minute intervals.

d. Turn off the voltage and current harmonics on the PQ simulator.

6. Start a Recording

Before starting a recording it is always recommended to verify several parameters.

a. Go to the DVM screen of the MPQ Analyzer. Verify the voltages and currents

look correct.

b. Go to the DVM / POWER screen of the MPQ Analyzer

Verify the KW is positive. If it is not then the power flow is reversed. This

can be demonstrated by placing the SOURCE / LOAD switch on the PQ

Simulator in the SOURCE position.

Verify the voltage phases angles are correct per the programmed power

configuration. This can be demonstrated by reversing the cable connection

of one of the voltage lead cables.

AVTMMPQSIM Rev 1 May 2017

46

Page 53

ADDENDUM C - SAMPLE POWER QUALITY TRAINING

Verify the current phases angles are correct. Each phase current should be

within 90° of its phase voltage. If it is not within 90° then the current clamp

may be backwards.

Once these parameters are verified, start the recording by pressing the record button

on the MPQ Analyzer.

7. Create a Sag/Dip

a. Allow the unit to record for approximately 15 seconds (minimum).

b. Start a SAG / DIP on one of the voltage phases by setting the voltage selector to

85%.

c. Wait about 1 second.

d. Stop the SAG / DIP by setting the voltage selector back to 100%. Note the record

screen now will register a sag.

Facility operations can be affected by both long and short duration dips (sags).

Momentary voltage dips (sags) lasting less than 100 ms are often sufficient to cause

disruptions to equipment and operations. Momentary or short duration dips (sags)

can occur more frequently. Dips (sags) can be generated from either the load side of

the source side. Large loads turning on this can create high inrush currents that

create momentary dips (sags) on the voltage. Dips (sags) can also result from faults on

distribution circuits and transmission circuits.

Short duration dips (sags) are defined as a decrease in rms voltage between 0.1 pu and

0.9 pu for durations from 0.5 cycles to 1 min. Under-voltages with durations

exceeding 1 minute are considered to be long term duration events.

A dip (sag) event can either be a single phase event or a poly-phase phase event.

A dip (sag) is initiated when the ½ cycle RMS voltage of a single phase falls below the

dip (sag) threshold. The event ends when all phases are within above the dip (sag)

threshold plus any hysteresis programmed by the user.

The recommended thresholds for dip (sag) detection is 0.9pu the RMS value

aggregated every 1/2 cycle.

For example:

A 230V system the dip (sag) limit would be 228V.

A 120V system the dip (sag) limit would be 108V.

AVTMMPQSIM Rev 1 May 2017

47

Page 54

M

8. Create a Swell

a. Allow the unit to record for approximately 15 seconds (minimum).

b. Start a SWELL on one of the voltage phases by setting the voltage selector to

c. Wait about 1 second.

d. Stop the SWELL by setting the voltage selector back to 100%. Note the record

Facility operation scan be affected by swells. Swells can cause systems and operations

to trip off line. Swells can be caused by switching off a large load, load shedding, or

switching on a large capacitor bank. Swells can also be caused by system fault

conditions.

For example: a single line to ground (SLG) fault can cause a temporary voltage rise

(swell) on the un-faulted phases.

A swell is defined as an increase in rms voltage above 1.1 pu for durations from 0.5

cycle to 1 min.

115%.

screen now will register a swell.

A swell is initiated when the 1/2 cycle RMS voltage of a single phase rises above the

swell threshold. The event ends when all phases are below the swell threshold minus

any hysteresis programmed by the user.

The recommended thresholds for swell detection is 1.1pu the the RMS value

aggregated every 1/2 cycle.

For example:

A 230V system the dip (sag) limit would be 253V.

A 120V system the dip (sag) limit would be 132V.

9. Create a Transient (Low Frequency / High Frequency / EFT)

a. Allow the unit to record for approximately 15 seconds (minimum)

b. Create a transient by depressing and releasing one of the transient switched on

the PQ Simulator. Note the record screen now will register a transient.

Transient over-voltages can result in degradation or immediate dielectric failure in all

classes of equipment. Repetitive lower magnitude application of transients decreases

equipment mean time between failures. High magnitude and fast rise time of transient

over-voltages contribute to insulation breakdown in electrical equipment. This

equipment can include rotating machinery, transformers, capacitors, cables, current

and potential transformers (CTs and PTs), as wells as switchgear. In electronic

equipment, power supply component failures can result from transients. Transients

can also cause tripping of Adjustable Speed Drives due to the dc link overvoltage

protection circuitry.

48

AVTMMPQSIM Rev 1 May 2017

Page 55

ADDENDUM C - SAMPLE POWER QUALITY TRAINING

Transients are caused by lightning or almost any switching event on the power

system.

Transients can be categorized into several categories.

Oscillatory transients: These are typically low frequency transients in the few

hundred Hz range. They are caused by capacitor bank

switching.

Impulse transients: These are typically high frequency transients in the few hundred

KHz range. They are caused by lightning or equipment

switching operations. They can be either uni-directional or bidirectional.

Impulsive transients can pass through transformers and appear on the low side of the

transformer. They are not reduced by the turns ratio. This can cause damage on

equipment connected to the low side of the transformer.

Extremely Fast Transients (EFT): These typically have rise times in the nano-

seconds. The EFT has limited energy and is

typically dampened out by just a few meters of

wire.

These only become an issue in locations with short cable runs, such as off shore

platforms or mines.

AVTMMPQSIM Rev 1 May 2017

49

Page 56

M

10. Create a THD Event

a. Allow the unit to record for approximately 15 seconds (minimum).

b. Turn ON one of the voltage and current harmonic switches.

c. Let the unit record for about 1 minutes.

d. Turn OFF the voltage and current harmonic switches.

e. Let the unit record for about another 15 seconds then stop the recording.

The MPQ PQ Analyzer will record harmonics as a trended value. It will also record

Total Harmonic Distortion (THD) as a PQ event.

A THD event is initiated when the THD value (aggregated over a 200msec period) of

a single channel rises above the THD threshold. The event ends when the THD

value (aggregated over a 200msec period) of a single channel drops below the THD

threshold.

Note THD value for current channels can be misleading. THD is represented as a

percentage of the fundamental value. The voltage fundamental value is a constant

value. The current fundamental value can fluctuate based on the changing load

impedance. This make THD evaluation on current channel difficult. IEEE 519

recommends using Total Demand Distortion (TDD) to analyze current distortion.

TDD references the harmonic content of the current channels to the maximum

average current drawn within the test interval. This can be analyzed in the PC

software provided the unit is programmed to capture periodic waveforms.

11. Create a Phase Event (Loss of phase)

a. Allow the unit to record for approximately 15 seconds (minimum).

b. Start a Phase Event by setting one of the Voltage Phase switches to +11°.

c. Wait about 1 second.

d. Stop the Phase Event by setting the voltage phase switch selector back to

nominal. Note the record screen now will register a Phase Event.

The phase angle shift (jump) manifests itself as a shift in zero crossing of the

instantaneous voltage. Change in the phase angle of the voltage can affect powerelectronics converter and relays that use phase angle information for their firing

instant. The inconsistent nature of renewable energy such as wind and solar can lead

to inverters turning on and off leading to phase shift phenomenon. These can also be

caused by system faults.

The phase angle is referenced from Phase A voltage. The phase angle of the Phase B

Voltage and Phase C voltage are measured relative to Phase A voltage. If the Phase B

or C voltage deviated by more than the programmed amount from nominal then a

phase shift event occurs.

AVTMMPQSIM Rev 1 May 2017

50

Page 57

ADDENDUM C - SAMPLE POWER QUALITY TRAINING

12. View the Data on the Unit

a. Allow the unit to record for at least 10 minutes to obtain enough data for

adequate charts.

b. Stop the unit recording.

c. Press the HOME button.

d. Select VIEW DATA.

View the RMS Charts: Scroll through the phase and note the RMS variation

throughout the test period. The RMS variation should

not exceed 10% of nominal for 95% of the test interval.

It is recommended that this value is measured in 10

minute intervals over a period of 1 week.

View the Unbalance Charts: View the Unbalance data and note the unbalance

deviation throughout the test period. It is recommended

that the voltage unbalance does not exceed 2% of

nominal for 95% of the test interval. It is recommended

that this value is measured in 10 minute intervals over a

period of 1 week.

View the THD Chart: View the THD data for the various channels and note

the deviation throughout the test period. It is

recommended that the voltage THD does not exceed

8% of nominal for 95% of the test interval. It is

recommended that this value is measured in 10 minute

intervals over a period of 1 week.

View the Harmonic Charts: View the Zero Sequence harmonics and Negative

Sequence Harmonics. The PQ simulator will generate

3rd and 5th order harmonic. The third harmonic is a

zero sequence harmonic. The 5th harmonic is a negative

sequence harmonic. Per EN50160 standards 3rd

harmonic should not exceed 5% of the declared value.

The 5th harmonic should not exceed 6% of the declared

value.

IEEE519 recommends that the individual harmonics do not exceed 5% of the

fundamental value.

13. View the Event Data Charts

View the Dip/Sag events: Note the start and stop times as well as the duration and