Page 1

BM15/MJ15

Insulation Testers

USER GUIDE

GUIDE DE L’UTILISATEUR

GEBRAUCHSANLEITUNG

M

GUÍA DEL USUARIO

Page 2

CONTENTS GUIDE DE L’UTILISATEUR - P.14 GEBRAUCHSANLEITUNG - S.26 GUÍA DEL USUARIO - P.38

Safety Warnings 3

General Description 4

Features and Controls 5

Working with Capacitive Loads 6

Operation

Preliminary Checks 7

Battery Replacement 7

Voltage Measurement 8

Insulation Testing 8

Choice of Test Leads 8

Using the Guard terminal 9

Specification 10

Accessories 12

Repair and Warranty 13

Before using the instrument, follow the separate instructions provided to fit

either the locking or non-locking test button.

If the locking button is fitted, extra care must be taken. See page 6.

Symbols used on the instruments

F Risk of electric shock.

G Caution, refer to accompanying documents

t Equipment protected throughout by Double Insulation

(Class II)

c Equipment complies with current EU Directives

2

Page 3

GSAFETY WARNINGS

■ ‘Safety Warnings‘ and ‘Working with Capacitive Loads‘ must be read and understood before the instrument is used. Safety

precautions must be observed during use.

■ The circuit under test must be switched off, de-energised and isolated before any test connections are made.

■ Circuit connections must not be touched during a test.

■ On completion of a test, decaying voltage across the terminals is indicated on the display. Capacitive load circuits must be discharged

to below 60 V before disconnecting the test leads.

■ Capacitive load circuits should be shorted with a shorting link after discharge.

■ Remove the test leads from the instrument before opening the battery compartment.

■ Test leads and crocodile clips must be in good order, clean and with no broken or cracked insulation.

■ The instrument should not be used if any part of it is damaged.

■ U.K. Safety Authorities recommend the use of fused test leads when measuring voltage on high energy systems. See ‘Choice of Test

Leads‘.

NOTE

The instruments must only be used by suitably trained and competent persons.

NOTE

Users of this equipment and or their employers are reminded that Health and Safety Legislation requires them to carry out valid risk assessments of

all electrical work so as to identify potential sources of electrical danger and risk of electrical injury such as from inadvertent short circuits. Where the

assessments show that the risk is significant then the use of fused test leads constructed in accordance with the HSE guidance note GS38 ‘Electrical

Test Equipment for use by Electricians’ should be used. See ‘Choice of Test Leads’.

3

Page 4

GENERAL DESCRIPTION

BM15, and MJ15 testers are completely self contained instruments designed

for high voltage insulation resistance testing in the maintenance and servicing

of rotating plant machinery, transformers, switchgear and industrial

installations.

Tests can be performed at 500 V, 1000V, 2500 V or 5000 V. Insulation measuring

range is 100 kΩ to 20 GΩ and Infinity. Automatic discharge for capacitive

circuits under test is provided and decaying voltage displayed.

A guard terminal can be used to minimise the effects of surface leakage when

carrying out insulation resistance tests.

Tests are initiated by pressing the BM15 ‘Test’ button (or by turning the MJ15

generator handle). Releasing the ‘Test’ button (or ceasing handle rotation)

causes the instrument to default to ac/dc voltmeter mode, with a discharge

resistor internally connected across the terminals. This feature will give

decaying voltage indication following the testing of equipment possessing

capacitance.

The moving coil meter operates a black pointer to display the readings on a

single logarithmic black scale on a white scale-plate for clarity of reading. The

movement is resiliently mounted for field use.

A slide - in ‘Pass Band‘ overlay can be inserted over the display. Appropriate

Pass/Fail bands can be marked on these windows with a permanent marker for

‘Go / No Go’ testing.

BM15 is powered by eight 1,5 V (IEC LR6) cells.

Normal power for the MJ15 is by low voltage, hand cranked, brushless a.c

generator. Fitting the battery container supplied, with eight 1,5 V IEC LR6 cells

gives the instrument a dual (independent) supply capability. Both instruments

are fitted with a battery check range, operated by pressing the ‘Test‘ push

button. Cranking the handle too slowly (<180 RPM) results in an unstable

pointer reading. Excess handle speed cannot harm the instrument as the

output voltage is electronically regulated.

The case is robust, yet light-weight, made from a flame retardant ABS, with a

polycarbonate display window. Mounted on top of the case is a 6 position,

rotary, range selection switch and a ‘Test‘ push button.

Three recessed sockets are provided, and marked ‘+’, ‘-’ and ‘G’. These have

safety covers which open when the plugs are inserted. When inserted into the

sockets, the shrouded test lead plugs lock into position. They are released by

twisting the plug a quarter turn and pulling out.

For this reason, only the test leads supplied or suitable Megger replacement

ones should be used.

Design safety features include:

■ External voltage, a.c. or d.c., displayed.

■ Load automatically discharged at the end of a test, and decaying

voltage displayed.

■ Test leads can lock into the case to prevent accidental disconnection.

4

Page 5

FEATURES AND CONTROLS

Rotary Selector

Switch

Non Locking Button

(recommended

option)

Generator Handle (MJ15)

Locking Button

(Extra care must

be taken if this

option is chosen.

See page 6)

- Terminal

Guard Terminal

+ Terminal

TO INSERT TERMINAL PLUGS, PUSH IN - TO RELEASE, TWIST A QUARTER TURN AND PULL OUT

5

Page 6

WORKING SAFELY WITH CAPACITIVE LOADS

G

Circuit connections and the instrument terminals may become

hazardous when connected to Capacitive loads.

1. These instruments are designed to safely charge and discharge

capacitive loads up to 5 µF. To safeguard against malfunction however,

you are advised to take your own precautions when working with

capacitive loads. Remember that when charged, even low value

capacitors can be fatal on contact .

2. Extra care must be taken if the locking Test button is selected.

3. Circuit connections must not be touched when testing.

Do not forget to release a locked Test button and discharge

any capacitance before touching the item under test or

disconnecting the test leads.

4. Care must be taken to prevent capacitive circuits becoming

disconnected during a test, leaving the circuit in a charged state.

5. On completion of a test, the instrument indicates circuit decaying

voltage. Do not disconnect test leads until the load capacitance has

discharged to below 60 V.

6. The voltmeter and automatic discharge feature of the instruments

should be regarded as additional safety features and not a substitute

for normal safe working practice.

7. If any part of the instrument is damaged, it should not be used, but

returned to the manufacturer or an approved service organization for

repair.

6

Page 7

PRELIMINARY CHECKS

Preliminary Performance Checks

The instrument will operate in any position, but best results are achieved

when the instrument is face up, on a firm level surface. This is particularly true

for hand cranked units to obtain a crank speed of >180 rev/min.

1) If battery cells are fitted, switch to Battery Check range and press the

‘Test‘ push button. Confirm that the pointer settles within the battery

symbol portion of the scale.

2) With the test leads disconnected, set the rotary selector switch to the

appropriate insulation range, press and hold down the ‘Test‘ button,

(or turn the generator handle). The meter pointer should move up the

scale briefly and then return to the ‘∞ ‘ (infinity) position on the scale.

This establishes that there is no leakage through the instrument itself.

3) Check that the test leads and crocodile clips are in good order, clean

and with no broken or cracked insulation. Connect two of the test

leads to the ‘+’ and ‘-’ terminals and ensure that their clips are not

touching anything.

4) Press the ‘Test‘ button again (or turn the generator handle) and

observe the meter pointer. The pointer should rest over the ‘∞‘

position on the scale. If it does not, the test leads may be faulty and

should be inspected more closely for damage. Replace them if

necessary.

5) Connect the test lead clips together, press the ‘Test‘ button (or turn the

generator handle) and observe the meter pointer. The meter should

read ‘0Ω‘. If it indicates infinity or a high resistance value the leads

may be open circuit and should be inspected further. Replace them if

necessary. (Shorting the leads together and obtaining a ‘0 Ω‘ reading

also indicates that the instrument is working).

Battery Replacement

GWARNING

The battery contacts are not isolated from the test leads. Remove the test

leads from the instrument before opening the battery compartment.

The cells are housed in a battery compartment in the base of the instrument.

To change the cells, use a screwdriver to remove the battery cover securing

screws and lift off the battery compartment cover. Observing the correct

polarity as marked on the battery housing, install 8 replacement IEC LR6 (AA)

cells. Replace and secure the battery compartment cover on completion.

7

Page 8

OPERATION

Voltage measurement

When switched to the ‘V’ position, the instrument measures up to 600 V a.c.

to the specified accuracy of the instrument. DC voltage is also indicated on the

display, but not to the specified accuracy. When not testing (i.e. in standby

mode) and connected to a live circuit, the instruments default to voltmeter (0

to 600 Volts a.c. or d.c.) irrespective of the rotary switch position. Any voltage

present will immediately be shown. Thus indication is given that the item has

not been completely de-energized. The instrument also monitors circuit

discharge when the ‘Test‘ button is released following an insulation test on a

capacitive item, e.g. a long cable.

Insulation Testing

After connecting the test leads to the instrument and carrying out the

Preliminary Performance Checks:

1) Set the selector switch to the required test voltage. Connect the test

leads to the isolated circuit to be tested, as follows:-

(a) For insulation tests to earth (ground):- Connect either test

lead to earth (ground) or the frame of the equipment,and

the other lead to that part of the circuit to be tested.

b) For insulation tests between wires:- Connect a lead to the

core of each of the wires.

2) Press the ‘Test‘ button (or turn the generator handle).

3) The meter pointer will indicate the value of insulation resistance on

the Ω scale.

If a capacitive circuit is tested, the pointer will initially deflect towards 0 Ω and

then gradually rise to its final steady value as the capacitance is charged up to

the output voltage of the tester.

If several successive readings of ∞ (infinity) are obtained, connect the two

farthest ends of the test leads together and carry out a check on the leads. A

0Ω reading should result which double checks that the leads are not

disconnected or broken and therefore, the insulation resistance readings are

correct.

Capacitive circuits automatically discharge through the tester when the ‘Test‘

button is released. Decaying discharge voltage will be indicated on the voltage

scale. Wait a few moments for the voltage to decay to below 60 V before

disconnecting the test leads.

Do not forget to release a locked Test button, and discharge

any capacitance before touching the item under test, or

disconnecting the test leads.

Choice of Test Leads

BM15/MJ15 are supplied with three unfused leads terminated in crocodile

clips. These are the best leads to use for insulation tests on non-live circuits.

The crocodile clips ensure that any capacitive load remains connected until it

is automatically discharged at the end of a test.

GS 38 (UK Safety Authority Guidance Note) advises the use of fused test prods

if the instrument is to be used for making voltage measurements on live, high

energy circuits. These leads are available as an optional extra. See

‘Accessories’.

Fused prods must not be used for insulation testing. If the fuse should

rupture, or the prods lose contact during a test, the system under test would

remain charged without any apparent evidence of danger!

8

Page 9

Using the Guard terminal (G)

For basic insulation tests and where there is little possibility of surface leakage

affecting the measurement, it is unnecessary to use the guard terminal (if the

insulator is clean and there are unlikely to be any adverse current paths).

However in cable testing, there may be surface leakage paths across the

insulation between the bare cable and the external sheathing due to the

presence of moisture or dirt. Where it is required to remove the effect of this

leakage, particularly at high testing voltages, a bare wire may be bound tightly

around the insulation and connected via the third test lead to the guard

terminal ‘G’.

The guard terminal is at the same potential as the negative terminal. Since the

leakage resistance is effectively in parallel with the resistance to be measured,

the use of the guard causes the current flowing through surface leakage to be

diverted from the measuring circuit. The instrument therefore reads the

leakage of the insulator, ignoring leakage across its surface.

Leakage Path

to ‘+’ve

terminal

to ‘G’

terminal

Tightly bound bare wire

to ‘-’ve

terminal

OPERATION BLOCK DIAGRAM

9

Page 10

SPECIFICATION

Insulation

Range: 100 kΩ to 20 GΩ (also 0 Ω and ∞ )

Test Voltages (d.c.): 500 V, 1000 V, 2500 V & 5000 V

Test Voltage Accuracy: ±5% of nominal test voltages on 20 MΩ load

Test Voltage Stability: <±1% (180 r.p.m. to 240 r.p.m. MJ15)

Insulation Accuracy see page 11

Short Circuit Current: 1,5 mA ± 0,5 mA

Maximum capacitance of load: 5 µF

Interference Rejection: 1 mA rms at 50 to 60 Hz

Discharge Resistor: <500 kΩ

Voltage

Range: 0 to 600 V a.c. indication of d.c.

Accuracy: see page 11

General

Overload rating: 720 V a.c. or d.c.

Scale Length: 72 mm (96˚)

Power Supply: BM15 8 x LR6 (AA alkaline or rechargeable) cells

MJ15 Low voltage brushless Generator or 8 x LR6 (AA alkaline) cell battery

Battery life: Typically 2000 five second tests at 5 kV on 100 MΩ load

Battery Indicator: Loaded battery test

10

Page 11

Safety: IEC 61010-1

Non replaceable Fuse: 1 Amp, 250 V, HBC type (F) (20 mm x 5 mm) to IEC 127/1

This fuse protects the instrument against any faults occurring when using rechargable batteries.

E.M.C: IEC 61326-1

Operational uncertainties: Refer to www.megger.com

Temperature Range:

Operating: 0˚C to 30˚C (32˚F to 86˚F) at full specification

Operating: -20˚C† to 50˚C (-4˚F to 122˚F) to temperature coefficient ±0,1% / ˚C

Storage: -25˚C to 65˚C (-13˚F to 149˚F)

Humidity: 90% RH maximum at 40˚C (104˚F)

Dimensions: 220 mm x 160 mm x 115 mm (8,9 in x 6,3 in x 4,5 in)

Weight: BM15 Approx 1.2 kg

MJ15 Approx 1,6 kg, or 1,8 kg with battery holder and cells.

Cleaning: Wipe the disconnected instrument with a clean cloth dampened with soapy water or Isopropyl Alcohol (IPA)

***Relates to transient overvoltage likely to be found in fixed installation wiring.

*Relates to transient overvoltage likely to be found in special equipment or parts of equipment, telecommunication, electronic etc.

† Note: MJ15 will operate as normal by generator at full temperature range

BM15 will require new healthy battery cells to operate as normal at -20˚C

11

Page 12

ACCESSORIES

SUPPLIED WITH THE INSTRUMENT PART NUMBER

User Guide 6172-209

Battery of 8 x 1,5 V LR6 (AA Alkaline) cells

3 x 3 m HV leads 8101-181

Test Record Card (5 supplied) 6172-111

(U.S. 210949)

Carrying case with lead storage 6420-117

Slide in Pass Band overlay (5 supplied) 6121-401

AVAILABLE AS AN OPTIONAL EXTRA

5 kV Fused Prod Set 6320-240

5 kV Calibration Box - CB101 6311-077

Test Record Card (Pack of 20) 6111-216

PUBLICATIONS

‘A Stitch In Time’ AVTM21-P8B

’Lowdown on HV d.c. Testing’ AVTM22P-1

12

Page 13

REPAIR AND WARRANTY

The instrument circuit contains static sensitive devices, and care must be taken

in handling the printed circuit board. If the protection of an instrument has

been impaired it should not be used, and be sent for repair by suitably trained

and qualified personnel. The protection is likely to be impaired if, for example,

the instrument shows visible damage, fails to perform the intended

measurements, has been subjected to prolonged storage under unfavourable

conditions, or has been exposed to severe transport stresses.

New Instruments are Guaranteed for 1 Year from the

Date of Purchase by the User.

Note: Any unauthorized prior repair or adjustment will automatically

invalidate the Warranty.

Instrument Repair and Spare Parts

For service requirements for Megger Instruments contact:

Megger Limited or Megger

Archcliffe Road Valley Forge Corporate Center

Dover 2621 Van Buren Avenue

Kent, CT17 9EN. Norristown, PA 19403

England. U.S.A.

Tel: +44 (0) 1304 502243 Tel: +1 (610) 676-8579

Fax: +44 (0) 1304 207342 Fax: +1 (610) 676-8625

ukenquires@megger.com usenquires@megger.com

or an approved repair company.

Approved Repair Companies

A number of independent instrument repair companies have been approved

for repair work on most Megger instruments, using genuine Megger spare

parts. Consult the Appointed Distributor / Agent regarding spare parts, repair

facilities and advice on the best course of action to take.

Returning an Instrument for Repair

If returning an instrument to the manufacturer for repair, it should be sent

freight pre -paid to the appropriate address. A copy of the Invoice and of the

packing note should be sent simultaneously by airmail to expedite clearance

through Customs. A repair estimate showing freight return and other charges

will be submitted to the sender, if required, before work on the instrument

commences.

13

Page 14

GUIDE DE L’UTILISATEUR - TABLE DES MATIÈRES GEBRAUCHSANLEITUNG - S.26 GUÍA DEL USUARIO - P.38

Avertissements relatifs à la sécurité 15

Description Générale 16

Caractéristiques et Commandes 17

Opérations sur des charges capacitive 18

Exploitation

Vérifications Préliminaires 19

Remplacement des piles 19

Mesure des tensions 20

Essai d’isolement 20

Choix des câbles d’essai 20

Utilisation de la borne de protection 21

Spécifications 22

Accessoires 24

Réparation et Garantie 25

Avant d’utiliser l’instrument, suivre les instructions séparées pour monter soit

le bouton d’essai verrouillable soit le bouton d’essai non verrouillable. Le

bouton d’essai verrouillable exige des soins supplémentaires.

Symboles utilisés sur l'instrument

F Risque de choc électrique

G Consulter le Guide de l'utilisateur

t Équipement entièrement protégé par un isolement

double (Classe II).

c Équipement conforme aux Directives en vigueur de

l'UE.

14

Page 15

GAVERTISSEMENTS RELATIFS À LA SÉCURITÉ

■ Les Avertissements relatifs à la sécurité et les instructions Opérations sur des charges capacitives doivent être lus et compris

avant d’utiliser l’instrument. Les précautions de sécurité doivent être observées pendant l’usage.

■ Le circuit à tester doit être coupé, désexcité et isolé avant d’effectuer des connexions d’essai quelconques.

■ Les connexions du circuit ne doivent pas être touchées pendant l’essai

■ A la fin de l’essai, la tension de déclin aux bornes est indiquée sur l’affichage. Les circuits à charge capacitive doivent être déchargés

en dessous de 60 V avant de déconnecter les câbles d’essai.

■ Les circuits à charge capacitive doit être court-circuités avec un cavalier de court-circuit après la décharge.

■ Enlever les câbles d’essai de l’instrument avant d’ouvrir le compartiment des piles.

■ Les câbles d’essai et les pinces crocodiles doivent être en bon état, propres et avec un isolement sans cassures ni fissures.

■ L’instrument ne doit pas être utilisé si l’un de ses constituants est endommagé.

■ Les Services de sécurité Britanniques recommandent l’utilisation de câbles d’essai équipés de fusibles pour lade la mesure de la

tension des systèmes à haute énergie. Voir “Choix des câbles d’essai”.

REMARQUE

Seule une personne düment formée et compétente doit se servir de cet instrument.

NOTE

ll est rappelé aux utilisateurs de cet instrument et/ou à leurs employeurs qu’ils doivent évaluer les risques de tous les travaux électriques de manière à

identifier les sources possibles de danger électrique et les risques de blessure tels que ceux des courts-circuits involontaires. Lorsque ces évaluations

indiquent des risques importants, des câbles d’essai équipés de fusibles tels que recommandés par les Services de sécurité Britanniques doivent être

employés. Des sondes équipées de fusibles ne doivent pas être utilisées pour les essais d’isolement. En cas de rupture du fusible ou si les sondes

perdent contact pendant l’essai, le circuit testé peut rester chargé sans aucun signe évident du danger !

15

Page 16

DESCRIPTION GÉNÉRALE

Les testeurs BM15 et MJ15 sont des instruments autonomes conçus pour la

mesure des résistances d’isolement sous haute tension pour l’entretien et le

dépannage des machines rotatives, des transformateurs, des appareillages de

commutation et des installations industrielles.

Les tensions d’essai peuvent être sélectionnées à 500 V, 1000 V, 2500 V ou 5000

V. La plage des mesures d’isolement est de 100 kΩ à 20 GΩ et l’infini. La

décharge automatique des circuits capacitifs est prévue, et la tension de déclin

est affichée. La borne de protection peut être utilisée pour minimiser les effets

de fuites de surface lors des essais de résistance d’isolement.

Les essais sont initiés en appuyant sur le bouton “Test” du BM15 (ou en

tournant la manivelle du générateur du MJ15). Le relâchement du bouton

“Test” (ou l’arrêt de la rotation de la manivelle) remet l’instrument dans le

mode voltmètre ca/cc par défaut, avec une résistance de décharge connectée

intérieurement aux bornes. Cette fonction donnera une indication de la

tension de déclin à la suite d’essai d’équipements ayant une capacité.

L’appareil de mesure à bobine mobile actionne une aiguille noire pour afficher

clairement les résultats sur une échelle logarithmique noire simple sur fond

blanc. Le mouvement est monté de façon élastique pour utilisation sur le

terrain.

Un gabarit transparent de bande passante peut être glissé sur l’affichage. Des

repères Bon/Mauvais appropriés peuvent être marqués sur ces fenêtres avec

un marqueur permanent.

L’instrument BM15 est alimenté par huit piles de 1,5V (IEC LR6).

L’alimentation normale du MJ15 est assurée par une génératrice c.a. basse

tension, sans balais, tournée à la main. L’installation du boîtier de piles et de

huit piles de 1,5 V (IEC LR6) donne à l’instrument une alimentation double

(indépendante). Une rotation trop lente de la manivelle (< 180-t/mn) produit

des lectures instables. Une rotation excessive ne peut pas endommager

l’instrument car la tension de sortie est régulée électroniquement.

Le boîtier robuste, mais léger, est réalisé en ABS ignifuge, avec une fenêtre

d’affichage en polycarbonate. Le dessus du boîtier comporte un commutateur

rotatif de sélection de gamme à six positions, et un bouton poussoir “Test”.

Trois douilles encastrées sont prévues, marquées “+”, “-” et “G”. Elles sont

dotées de couvercles de sécurité qui s’ouvrent lorsque les prises sont insérées.

Les prises gainées des câbles d’essai se verrouillent dans les douilles. Elles sont

libérées en tournant la prise d’un quart de tour et en la tirant.

Pour cette raison, seuls les câbles d’essai fournis, ou les remplacements

Megger convenables, doivent être utilisés.

Les caractéristiques intégrales de sécurité comprennent:

■ Affichage de tension extérieure c.a. ou c.c.

■ Décharge automatique de la charge en fin d’essai, avec affichage de la

tension de déclin.

■ Les douilles d’essai verrouillent les câbles d’essai dans le boîtier et

empêchent toute déconnexion accidentelle.

16

Page 17

CARACTÉRISTIQUES ET COMMANDES

Commutateur de

sélection rotatif

Bouton non

verrouillable (option

recommandée)

Borne -

Borne de protection

Manivelle de génératrice (MJ15)

Bouton verrouillable

(prendre des soins

particuliers lorsque

cette option est

choisie)

Borne +

POUR INSÉRER LA PRISE, POUSSER - POUR LA LIBÉRER, TOURNER D’UN QUART DE TOUR ET TIRER.

17

Page 18

OPÉRATIONS SUR DES CHARGES CAPACITIVE

G

Les connexions du circuit et les bornes del’instruments

peuvent devenir dangereuses lorsque connectées à des

charges capacitives.

1. Ces instruments sont conçus pour charger et décharger en toute

sécurité des charges capacitives allant jusqu’à 5 µF. Cependant, pour

vous protéger contre tout mauvais fonctionnement, nous vous

conseillons de prendre vos propres précautions lorsque vous travaillez

sur des circuits capacitifs. N’oubliez jamais qu’une fois chargés, mêmes

les condensateurs de faible valeur peuvent être mortels au contact.

2. Prendre des soins particuliers lorsque le bouton “Test” verrouillable

est choisi.

3. Les connexions du circuit ne doivent pas être touchées pendant les

essais.

Ne pas oublier de libérer le bouton “Test” verrouillé,et de

décharger toute capacitance avant de toucher au composant

testé, ou de débrancher les câbles d’essai.

4. Veiller à ce que les circuits capacitifs ne se déconnectent pas en cours

d’essai, laissant le circuit dans un état chargé.

5. A la fin de l’essai, l’instrument indique la tension de déclin. Ne jamais

déconnecter les câbles d’essai tant que la capacitance de charge n’est

pas déchargée en dessous de 60 V.

6. Le voltmètre et la fonction de décharge automatique de l’instrument

doivent être considérés comme des fonctions de sécurité

supplémentaires et non pas comme remplaçant les pratiques normales

de travail sûr.

7. L’instrument ne doit pas être utilisé si l’un de ses constituants est

endommagé. Il doit être renvoyé au fabricant ou à un organisme

d’entretien approuvé pour réparation.

18

Page 19

EXPLOITATION

Vérifications préliminaires de performance

L’instrument fonctionne dans n’importe quelle position, mais les meilleurs

résultats sont obtenus lorsque l’instrument est face vers le haut, sur une

surface horizontale ferme. Ceci est plus particulièrement vrai pour les

instruments à manivelle qui nécessitent une vitesse de rotation constante et

supérieure à 180 t/mn.

1. Lorsque des piles sont montées, sélectionner la gamme Contrôle Pile et

appuyer sur le bouton “Test”. Vérifier que l’aiguille se stabilise dans la

partie de l’échelle portant le symbole des piles.

2. Les câbles d’essai étant déconnectés, placer le commutateur rotatif sur

la gamme d’isolement requise, appuyer sur le bouton “Test” et le

maintenir appuyé, (ou tourner la manivelle de la génératrice). L’aiguille

de l’instrument devrait monter brièvement sur l’échelle puis revenir à

la position ∞ de l’échelle. Ceci vérifie qu’il n’y a pas de fuite dans

l’instrument lui-même.

3. Vérifier que les câbles d’essai et les pinces crocodiles sont en bon état,

propres et avec un isolement sans cassures ni fissures. Connecter deux

des câbles d’essai aux bornes “-” et “+”, et vérifier que leurs pinces ne

touchent rien.

4. Appuyer de nouveau sur le bouton “Test” (ou tourner la manivelle de

la génératrice) et observer l’aiguille. Elle doit reposer sur le symbole ∞

de l’échelle. Sinon, les câbles d’essai peuvent être défectueux et

devront être soigneusement inspectés pour tout signe

d’endommagement. Les remplacer si nécessaire.

5. Connecter les pinces des câbles d’essai ensemble et appuyer sur le

bouton “Test” (ou tourner la manivelle de la génératrice) et observer

l’aiguille. L’instrument doit indiquer “0Ω“. S’il indique l’infini ou une

résistance élevée, les câbles peuvent être en circuit ouvert et devront

être inspectés. Les remplacer si nécessaire. (Le court-circuitage des

câbles et l’obtention d’une lecture de “0Ω“ indiquent aussi que

l’instrument fonctionne correctement).

Remplacement des piles

GATTENTION

Les contacts des piles ne sont pas isolés des câbles d’essai. Retirer les câbles

d’essai de l’instrument avant d’ouvrir le compartiment des piles. Les piles

sont logées dans un compartiment dans la base de l’instrument.

Pour changer les piles, utiliser un tournevis pour déposer les vis de fixation du

couvercle et déposer le couvercle du compartiment des piles.

En observant la polarité correcte marquée dans le logement des piles, installer

huit piles de rechange IEC LR6 (AA). Remonter et fixer le couvercle du

compartiment des piles.

19

Page 20

EXPLOITATION

Mesure des tensions

Lorsqu’il est à la position “V”, l’instrument peut mesurer des tensions allant

jusqu’à 600 V c.a.avec la précision spécifiée pour l’instrument. Les tensions c.c.

sont également indiquées sur l’affichage, mais pas avec la précision spécifiée.

Lorsqu’il n’effectue pas d’essai (c’est-à-dire en mode d’attente) et s’il est

connecté à un circuit sous tension, l’instrument passe automatiquement au

mode de voltmètre (0 à 600 V c.a. ou c.c.) quelle que soit la position du

commutateur rotatif. Toute tension présente sera immédiatement affichée.

Ceci indique donc que le circuit testé n’est pas complètement désexcité.

L’instrument contrôle également la décharge du circuit lorsque le bouton

“Test” est relâché à la fin d’un essai d’isolement sur un article capacitif, par

exemple un câble long.

Essai d’isolement

Une fois que les câbles d’essai sont connectés à l’instrument et que les

vérifications préliminaires sont terminées:

1) Placer le commutateur de sélection sur la tension requise. Connecter

les câbles d’essai au circuit isolé à tester, comme suit-:

(a) Pour les essais d’isolement à la terre (masse) :- Connecter

un des câbles d’essai à la terre (masse) ou au châssis de

l’équipement, et l’autre câble à la partie du circuit à tester.

(b) Pour les essais d’isolement entre conducteurs : -

Connecter un câble au fil de chaque conducteur.

2) Appuyer sur le bouton “Test” (ou tourner la manivelle de la

génératrice).

3) L’aiguille de l’instrument indiquera la valeur de la résistance

d’isolement sur l’échelle Ω.

Dans le cas d’essai d’un circuit capacitif, l’aiguille déviera initialement vers 0Ω

puis augmentera progressivement vers sa valeur stable finale au fur et à

mesure de la charge de la capacitance jusqu’à la tension de sortie du testeur.

Si plusieurs lectures successives de ∞ (infini) sont obtenues, connecter les

deux extrémités les plus éloignées des câbles d’essai et effectuer un contrôle

des câbles. Une lecture de 0Ω doit être obtenue, ce qui confirme que les

câbles ne sont pas déconnectés ou cassés, et que par conséquent les lectures

d’isolement sont correctes.

Les circuits capacitifs se déchargent automatiquement par l’intermédiaire du

testeur lorsque le bouton “Test” est relâché. La tension de déclin de la

décharge est affichée sur l’échelle de tension. Attendre quelques instants pour

que la tension tombe en dessous de 60 volts avant de déconnecter les câbles

d’essai.

Ne pas oublier de libérer un bouton “Test” verrouillé, et de

décharger la capacitance avant de toucher au circuit testé, ou

de déconnecter les câbles d’essai.

Choix des câbles d’essai

Les instruments BM15 et MJ15 sont fournis avec trois câbles d’essai sans

fusible, équipés de pinces crocodile. Ce sont les meilleurs câbles d’essai à

utiliser pour les essais d’isolement sur circuits hors tension. La pince crocodile

garantit que toute charge capacitive reste connectée jusqu’à ce qu’elle soit

automatiquement déchargée à la fin de l’essai.

Les Services de sécurité britanniques recommandent l’utilisation de câbles

d’essai équipés de fusibles pour la mesure de la tension des systèmes sous

tension à haute énergie. Ces câbles sont disponibles en option contre

supplément. Voir “Accessoires”.

Les sondes équipées de fusible ne doivent pas être utilisées pour les essais

d’isolement. En cas de rupture du fusible ou si les sondes perdent contact

pendant l’essai, le circuit testé peut rester chargé sans aucun signe évident

du danger!

20

Page 21

Utilisation de la borne de protection

Pour les essais d’isolement ordinaires ou dans le cas où les fuites de surface

n’affecteront pas les mesures, il n’est pas nécessaire d’utiliser la borne de

protection (si l’isolant est propre et si aucunes trajectoires de courant adverses

existent). Cependant, lors des essais de câbles, des trajectoires de fuites de

surface peuvent exister entre le câble nu et la gaine extérieure en cas

d’humidité ou de saletés. Lorsque les effets de ces fuites doivent être éliminés,

en particulier dans le cas de hautes tensions d’essai, un fil nu peut être

enroulé de façon serrée autour de l’isolement et connecté par le troisième

câble d’essai à la borne de protection “G”.

La borne de protection est au même potentiel que la borne négative. Etant

donné que la résistance de fuite est en fait en parallèle avec la résistance à

mesurer, l’utilisation de la borne de protection détourne le courant de fuites

de surface du circuit de mesure. L’instrument lit donc le courant de fuite de

l’isolement, et ne tient pas compte des fuites sur sa surface.

Trajectoire de fuite

vers borne

‘+’ve

vers

borne

‘G’

Fil nu enroulé serré

vers borne ‘-’ve

ORGANIGRAMME DE FONCTIONNEMENT

21

Page 22

SPÉCIFICATIONS

Isolement

Gamme: 100 kΩ à 20 GΩ (aussi 0 Ω and ∞ )

Tensions d’essai (c.c.): 500 V, 1000 V, 2500 V et 5000 V

Précision de tension d’essai: ± 5% des tensions nominales sur une charge de 20 MΩ

Stabilité de tension d’essai: <± 1% (180 à 240 t/mn - MJ15)

Précision d’isolement (à 0 - 30˚C): ± 2,5% de l'echelle

Courant de court-circuit: 1,5 mA ± 0,5 mA

Capacitance maximale de charge: 5 µF

Rejet d’interférence: 1 mA efficace à 50 - 60 Hz

Résistance de décharge: < 500 kΩ

Tension

Gamme: 0 à 600 V c.a. - Indication c.c

Précision: ± 2,5% de la déviation maximale (avec commutateur à la position ‘V’) ± c.c. non spécifiée

Généralités

Surcharge nominale: 720 V c.a. ou c.c.

Longueur de l’échelle: 72 mm (96˚)

Alimentation électrique:

BM15 8 piles LR6 (AA alcalines ou pile rechargeable)

MJ15 Génératrice basse tension sans balais ou 8 piles LR6 (AA alcalines)

Durée des piles: 2000 essais typiques de cinq secondes à 5 kV sur une charge de 100 MΩ.

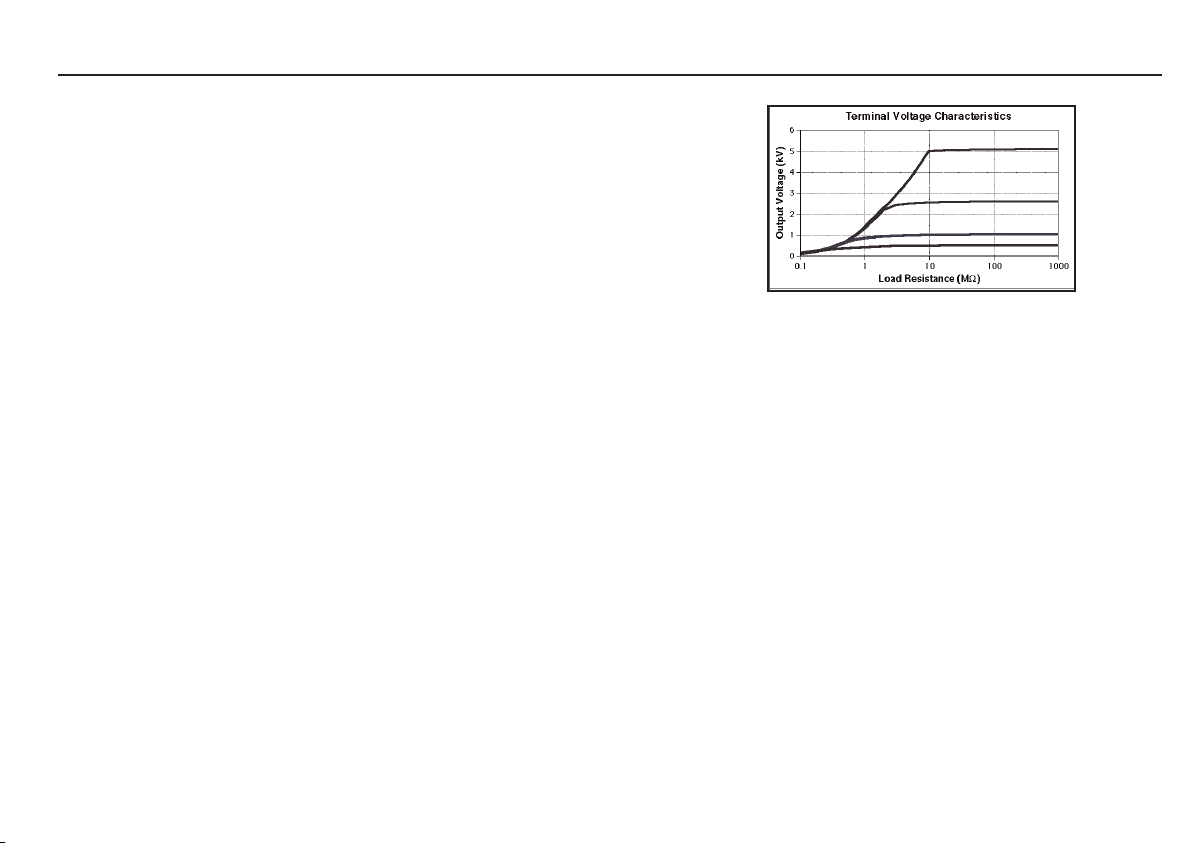

Caracteristiques de la Tension aux Bornes

Tension de Sortie (kV)

Résistance de Charge (MΩ)

22

Page 23

Indicateur des piles: Test de batterie chargée.

Sécurité: Conforme aux exigences de sécurité de double isolement de l’IEC 61010-1 pour une installation de Catégorie III***,

300 volts entre phase et terre (masse) ou 600 volts Catégorie I*.

Fusible non remplaçable: 1 A, 250 V, Type HBC (F) (20 mm x 5 mm) selon IEC 127/1.

Ce fusible protège l’instrument contre toute défaillance lors de l’emploi de piles rechargeables.

Compatibilité électromagnétique: En conformité avec la CEI 61326-1

Incertitudes opérationnelles: visite www.megger.com

Plage de températures: Exploitation : 0˚C à 30˚C à pleine spécification

Exploitation: -20˚C † à 50˚C avec un coefficient de température de ± 0,1%/˚C

Stockage: -25˚C à 65˚C

Humidité: 90% d’humidité relative maximal à 40˚C Dimensions :

Dimensions: 220 mm x 160 mm x 115 mm

Poids: BM15: 1,2 kg environ

MJ15: 1,6 kg ou 1,8 kg avec boîtier de piles et piles

Nettoyage: Essuyer l’instrument déconnecté avec un chiffon propre imbibé d’eau savonneuse ou d’alcool isopropylique (IPA).

***Concerne une surtension transitoire pouvant être rencontrée dans les câblages d’installations fixes.

*Concerne une surtension transitoire pouvant être rencontrée dans les équipements ou parties d’équipements spéciaux, en télécommunications, électronique,

etc.

† Note:

MJ15 fonctionnera normalement avec sa génératrice sur toute la plage de température

BM15 nécessitera de nouvelles piles saines pour fonctionner normalement à -20˚C.

23

Page 24

ACCESSORIES

FOURNI AVEC L’INSTRUMENT NUMERO DE REFERENCE

Guide Utilisateur 6172-209

8 piles de 1,5 V LR6 (AA Alcalines)

Jeu de câbles d’essai, longueur 3 m, (3 câbles sont fournis) 8101-181

Fiches d’enregistrement d’essai (Paquet de 5) 6172-111 (U.S. 210949)

Coffret de transport avec rangement des câbles 6420-117

Transparents de bande passante (5 fournis) 6121-401

DISPONIBLE EN OPTION AVEC SUPPLEMENT

Jeu de sondes 5 kV à fusibles 6320-240

Boîte d’étalonnage 5 kV - CB101 6311-077

Fiches d’enregistrement d’essai (Paquet de 20) 6111-216

PUBLICATIONS

‘A Stitch In Time’ AVTM21-P8B

’Lowdown on HV d.c. Testing’ AVTM22P-1

24

Page 25

RÉPARATION ET GARANTIE

Les circuits de l’instrument contiennent des éléments sensibles à

l’electricite statique et il y a lieu de prendre des précautions en manipulant la

carte de circuits imprimes. Si la protection d’un instrument s’est trouvee

affectée de quelque maniére il ne doit pas être utilisé et doit être expeedié

pour réparation par du personnel convenablement formé et qualifié. La

protection de l’appareil peut s’être trouvée endommagée si par exemple

l’instrument apparaît visiblement abîmee, ne donne pas les performances

attendues, s’est trouvé entreposé de façon prolongée dans des conditions

défavorables ou a été exposé a des contraintes extrêmes durant son transport.

Les nouveaux instruments sont garantis pendant une période

d’un an à partir de la date de leur achat par l’utilisateur.

Note: Le fait d’ouvrir le boîtier annule automatiquement la garantie couvrant

l’instrument à moins que l’opération ne soit faite par un organisme de

réparation agréé

Réparation d’instruments et pièces de rechange

Pour le service des instruments Megger prendre contact soit:

avec ou

Megger Limited Megger

Archcliffe Road Valley Forge Corporate Center

Dover 2621 Van Buren Avenue

Kent CT17 9EN Norristown, PA 19403

Angleterre USA

Tél: + 44 (0) 1304 502243 Tél: +1 (610) 676-8579

Fax: + 44 (0) 1304 207342 Fax: +1 (610) 676-8625

ou avec une societe d’entretien agréée.

Societés d’entretien agréées

Un certain nombre de sociétés indépendantes de reparation d’instruments ont

êté agréées pour faire des opérations de réparation sur la plupart des

instruments Megger utilisant des pièces d’origine Megger. Consultez le

distributeur désigné/agent officiel concernant la fourniture de pièces de

rechange, les installations de réparation et pour être conseillé concernant les

meilleures mesures à prendre.

Renvoi d’un instrument pour le faire réparer

Si un instrument est réexpédiê au fabricant pour être reparé il doit être

envoyé port payé a l’adresse appropriée. Un exemplaire de la facture et la

note d’envoi doivent être envoyé par avion au même moment afin de hâter les

formalités de douane. Un devis estimé des réparations indiquant les frais de

réexpedition et autres frais sera si nécessaire adressé a l’expéditeur avant que

les opérations de réparation ne soient enterprises.

ou

Megger

Z.A. Du Buisson de la Couldre

23 rue Eugène Henaff

78190 TRAPPES

France

Tél: + 33 (1) 43.02.37.54

Fax: + 33 (1) 43.02.16.24

25

Page 26

GEBRAUCHSANLEITUNG - INHALT GUÍA DEL USUARIO - P.38

Sicherheitshinweise 27

Allgemeine Beschreibung 28

Funktionen und Regler 29

Arbeiten mit kapazitiven Belastungen 30

Betrieb

Eingangsprüfungen 31

Wechseln der Batterien 31

Spannungsmessung 32

Isolierprüfung 32

Auswahl der Prüfkabel 32

Verwendung des Schutzanschlusses 33

Technische Daten 34

Zubehör 36

Reparaturen und Garantie 37

Vor Gebrauch des Geräts separate Bedienungsanleitung zum Einbau der

feststellbaren oder nicht feststellbaren Prüftaste beachten. Wenn die

feststellbare Taste eingebaut wird, muß mit besonderer Vorsicht vorgegangen

werden.

Auf Diesem Gérat verwendete Symbole

F Vorsicht Elektroschockgefahr.

G Vorsicht: Bitte beiliegende Anmerkungen beachten.

t Die Anlage ist rundum durch doppelte oder verstärkte

Isolierung (Klasse II) geschutzt.

c Die Anlage entspricht den gegenwärtig gültigen EU-

Direktiven.

26

Page 27

GSICHERHEITSHINWEISE

■ Vor Gebrauch des Geräts müssen die "Sicherheitshinweise" und der Abschnitt "Arbeiten mit kapazitiven Ladungen" gelesen und

verstanden werden. Die Sicherheitshinweise sind beim Bedienen zu beachten.

■ Der geprüfte Stromkreis muß ausgeschaltet, entladen und isoliert werden, bevor die Prüfanschlüsse vorgenommen werden.

■ Die Anschlüsse des Stromkreises dürfen während der Prüfung nicht berührt werden.

■ Nach Abschluß einer Prüfung wird der Spannungsabfall an den Anschlüssen auf der Anzeige dargestellt. Kapazitiv belastete Stromkreise

müssen vor dem Abnehmen der Prüfkabel auf unter 60 V entladen werden.

■ Nach der Entladung müssen die die kapazitiv belasteten Stromkreise mit einer Kurzschlußverbindung kurzgeschlossen werden.

■ Vo r dem Öffnen des Batteriefachs Prüfkabel vom Instrument entfernen.

■ Die Prüfkabel und Krokodilklemmen müssen sich in einem guten Zustand befinden und sauber sein. Die Isolierung darf keine

Bruchstellen oder Risse aufweisen.

■ Gerät nicht verwenden, wenn irgendein Teil von ihm beschädigt ist.

■ Die britischen Sicherheitsbehörden empfehlen den Einsatz von Prüfkabeln mit Sicherungen zur Spannungsmessung bei

Starkstromanlagen. Siehe "Auswahl der Prüfkabel".

ANMERKUNG

dieses instrument dürfen nur von ausreichend geschulten und kompetenten personen bedient werden.

HINWEIS

Die Benutzer dieses Geräts bzw. ihre Arbeitgeber werden daran erinnert, daß bei allen elektrischen Arbeiten eine Gefahrenprüfung stattfinden muß,

um potentielle Gefahren und ein Verletzungsrisiko durch Strom (z. B. bei unbeabsichtigten Kurzschlüssen) zu vermeiden. Wenn sich bei der Prüfung

herausstellt, daß eine bedeutende Gefahr vorliegt, müssen die von den Britischen Sicherheitsbehörden empfohlenen Prüfkabel mit Sicherungen

verwendet werden. Prüfspitzen mit Sicherungen dürfen nicht zur Isolierprüfung eingesetzt werden. Wenn eine Sicherung durchbrennt oder der

Kontakt mit den Prüfspitzen während der Prüfung abreißt, bleibt die geprüfte Anlage geladen, ohne daß die Gefahr bemerkbar wird!

27

Page 28

ALLGEMEINE BESCHREIBUNG

Die Prüfer BM15 und MJ15 sind vollkommen selbständig funktionierende

Geräte zur Überprüfung des Widerstands der Isolierung von

Hochspannungsanlagen, z. B. bei der Wartung und Reparatur von rotierenden

Kraftwerksmaschinen, Transformatoren, Schaltvorrichtungen und

Industrieanlagen.

Die Prüfungen können in einem Bereich von 500 V, 1000 V, 2500 V oder 5000 V

durchgeführt werden. Der Isoliermeßbereich beträgt zwischen 100 kΩ und 20

GΩ oder unendlich. Die geprüften kapazitiven Stromkreise werden

automatisch entladen, der Spannungsabfall angezeigt.

Zur weitgehenden Ausschließung der Auswirkungen von

Oberflächenableitungen kann bei Isolierwiderstandprüfungen ein

Schutzanschluß verwendet werden.

Die Prüfungen werden beim BM15 durch Drücken des Prüftaste (mit der

Beschriftung "Test") und beim MJ15 durch Drehen des Generatorschalters

begonnen. Wenn die Prüftaste losgelassen (bzw. der Drehschalter nicht weiter

gedreht) wird, schaltet das Gerät automatisch in den Modus zur AC/DCSpannungsmessung um, wobei die Anschlüsse intern über einen

Entladewiderstand verbunden sind. Durch diese Funktion läßt sich nach einer

Prüfung von Geräten mit Kapazitanz der Spannungsabfall messen.

Die Messungen werden auf dem Spulenmeßgerät über einen schwarzen Zeiger

auf einer einzelnen logarithmischen schwarzen Skala angezeigt, die auf einem

weißen Hintergrund leicht ablesbar ist. Die Anzeige ist für Außeneinsätze

robust konstruiert.

Über dem Display kann eine Durchgangsschablone eingeschoben werden. Auf

diesen Fenstern lassen sich mit einer permanenten Markierung die jeweiligen

Grenzwertbereiche für eine "Gut / Schlecht"-Prüfung festlegen.

Der BM15wird über acht 1,5 V-Batterien (IEC LR6) versorgt.

Die normale Stromversorgung für den MJ15 erfolgt über einen bürstenlosen

Niederspannungsgenerator mit Handkurbel. Wenn das mitgelieferte

Batteriefach mit acht 1,5 V-Batterien (IEC LR6) gefüllt wird, kann das Gerät auf

zwei Weisen (unabhängig) versorgt werden. Beide Geräte sind mit einer

Batterieprüffunktion ausgestattet, die über die Prüftaste aktiviert wird. Wenn

die Kurbel zu langsam gedreht wird (< 180 U/min), bleibt der Zeiger auf der

Anzeige nicht stabil. Eine zu schnelle Kurbeldrehung wirkt sich auf das Gerät

nicht schädlich aus, da die Ausgangsspannung elektronisch reguliert wird.

Das robuste und zugleich leichte Gehäuse ist aus flammenhemmenden ABS

hergestellt und besitzt ein Anzeigefenster aus Polycarbonat. Auf der Oberseite

des Gehäuses befinden sich ein Drehschalter zur Bereichsauswahl mit 6

Stellungen und die Prüftaste.

Die drei vertieften Buchsen sind mit "+", "-" und "G" gekennzeichnet. Die

Buchsen sind mit Sicherheitsabdeckungen versehen, welche sich beim

Einschieben der Stecker öffnen. Wenn die abgeschirmten Stecker der

Prüfkabel in die Buchsen eingesteckt werden, rasten sie in der richtigen

Position ein. Die Stecker werden gelöst, indem sie eine Viertelumdrehung

gedreht und herausgezogen werden.

Wegen dieser Eigenschaften sollten nur die mitgelieferten Prüfkabel oder

geeignete Ersatzkabel von MEGGER® verwendet werden.

Zu den Sicherheitsvorkehrungen gehören die folgenden

Eigenschaften:

■ Angezeige der externen AC- oder DC-Spannung.

■ Automatische Entladung nach der Prüfung, Spannungsabfall wird

angezeigt.

■ Die Prüfkabel rasten im Prüfanschluß des Gehäuses ein, so daß eine

unbeabsichtigte Trennung verhindert wird.

28

Page 29

FUNKTIONEN UND REGLER

Drehwählschalter

Nicht feststellbare

Prüftaste

(empfohlene Option)

Generatorschalter (MJ15)

Feststellbare

Prüftaste (bei

Verwendung dieser

Option muß mit

besonderer Vorsicht

vorgegangen

werden)

- Anschluß

Schutzpol

+ Anschluß

ANSCHLUßSTECKER ZUM EINFÜHREN HINEINSCHIEBEN UND ZUM LÖSEN EINE

VIERTELUMDREHUNG DREHEN UND HERAUSZIEHEN.

29

Page 30

ARBEITEN MIT KAPAZITIVEN BELASTUNGEN

G

Die Anschlüsse von Stromkreis und Gerät können bei

Verbindung mit kapazitiven Belastungen gefährlich werden.

1. Mit diesem Gerät können Belastungen von bis zu 5 µF gefahrlos

geladen und entladen werden. Zum Schutz vor Defekten empfiehlt es

sich jedoch, beim Arbeiten mit kapazitiven Belastungen besondere

Vorsichtsmaßnahmen vorzunehmen. Selbst Kondensatoren mit

geringen Werten können bei Berührung tödlich sein.

2. Wenn die feststellbare Prüftaste verwendet wird, muß besonders

vorsichtig vorgegangen werden.

3. Die Anschlüsse des Stromkreises dürfen bei der Prüfung nicht berührt

werden.

Eine festgestellte Prüftaste muß unbedingt wieder gelöst und

die gesamte Kapazitanz entladen werden, bevor der geprüfte

Gegenstand berührt oder die Prüfkabel getrennt werden.

4. Kapazitive Stromkreise dürfen bei der Prüfung nicht unterbrochen

werden, da sie sonst geladen bleiben.

5. Nach Abschluß einer Prüfung wird der Spannungsabfall des

Stromkreises auf der Anzeige dargestellt. Prüfkabel erst abnehmen,

wenn die Belastungskapazitanz auf unter 60 V gesunken ist.

6. Die Spannungmesser- und automatische Entladefunktion des Geräts

dienen zur zusätzlichen Sicherheit und ersetzen keinesfalls die

üblichen Vorsichtsmaßnahmen bei der Arbeit.

7. Wenn ein Teil des Prüfgeräts beschädigt ist, darf das Gerät nicht

verwendet werden, sondern ist zur Reparatur an eine autorisierte

Wartungsniederlassung zu senden.

30

Page 31

BETRIEB

Eingangsprüfungen

Das Gerät funktioniert zwar in jeder Stellung, liefert jedoch die besten

Ergebnisse, wenn die Vorderseite nach oben zeigt und das Gerät auf einer

festen und ebenen Unterlage steht. Dies gilt insbesondere für Geräte mit

Handkurbel, weil auf diese Weise leichter die benötigte konstante

Kurbeldrehzahl von > 180 U/min erreicht wird.

1. Wenn Batterien eingesetzt sind, auf Batterieprüfung stellen und die

‘Test‘ (Prüftaste) drücken. Prüfen, ob der Zeiger auf das

Batteriesymbol der Skala zeigt.

2. Bei getrennten Prüfkabeln Drehschalter auf den passenden

Isolierbereich stellen und ‘Test‘ (Prüftaste) drücken und festhalten

(bzw. Generatorschalter drehen). Der Meßzeiger sollte sich auf der

Skala kurz nach oben bewegen und anschließend auf die Position "∞"

(unendlich) der Skala zeigen. Durch diese Prüfung wird sichergestellt,

daß keine Oberflächenableitung über das Gerät stattfindet.

3. Sicherstellen, daß die Prüfkabel und Krokodilklemmen sauber und

intakt sind und die Isolierung keine Risse oder Schäden aufweist. Zwei

Prüfkabel an den "+"- und "-" -Polen anschließen und darauf achten,

daß die Klemmen nichts anderes berühren.

4. Prüftaste erneut drücken (bzw. Generatorschalter drehen) und

Meßzeiger beobachten. Der Zeiger sollte auf die Position "∞“

(unendlich) der Skala zeigen. Ist dies nicht der Fall, so sind evtl. die

Prüfkabel defekt. Kabel genau untersuchen und ggf. erneuern.

5. Klemmen der Prüfkabel miteinander verbinden, ‘Test‘ (Prüftaste)

drücken (bzw. Generatorschalter drehen) und Meßzeiger beobachten.

Der Zeiger sollte auf "0Ω" stehen. Wenn ein unendlicher oder sehr

hoher Widerstandswert dargestellt wird, ist evtl. der Stromkreis der

Prüfkabel unterbrochen. Kabel genau untersuchen und ggf. erneuern.

(Das Gerät kann auch überprüft werden, indem die Kabel

kurzgeschlossen werden; wenn "0Ω" angezeigt werden, ist die

Funktion in Ordnung.)

Wechseln der Batterien

GWARNING

Die Batteriekontakte sind nicht von den Prüfkabeln isoliert. Vo r dem

Öffnen des Batteriefachs müssen die Prüfkabel daher vom Instrument

getrennt werden. Die Batterien befinden sich im Batteriefach an der

Unterseite des Geräts.

Zum Wechseln der Batterien Befestigungsschrauben des Batteriefachs mit

Schraubenzieher entfernen und Abdeckung des Batteriefachs abheben.

8 neue IEC LR6 Batterien (Mignonzellen) unter Beachtung der Polarität

einsetzen. Anschließend Abdeckung des Batteriefachs wieder einsetzen und

befestigen.

31

Page 32

BETRIEB

Spannungsmessung

Wenn das Gerät auf "V" geschaltet wird, mißt es Spannungen bis zu 600 V AC

mit der angegebenen Genauigkeit. Auch Gleichstrom kann auf der Anzeige

dargestellt werden, allerdings nicht mit der angegebenen Genauigkeit. Wenn

das Gerät an einen spannungsführenden Stromkreis angeschlossen ist und

momentan nicht zur Prüfung verwendet wird (Standby-Betrieb), funktioniert

es unabhängig von der Stellung des Drehschalters automatisch als Voltmeter

(0 bis 600 V AC oder DC). Jede vorhandene Spannung wird sofort dargestellt,

so daß sofort bemerkbar wird, wenn ein Gegenstand noch nicht vollständig

entladen wurde. Bei der Isolierprüfung eines kapazitiven Gegenstands, z. B.

eines langen Kabels, überwacht das Gerät auch die Entladung des

Stromkreises nach Loslassen der Test (Prüftaste).

Isolierprüfung

Wenn die Prüfkabel am Instrument angeschlossen und die Eingangsprüfungen

beendet sind:

1) Wählschalter auf die gewünschte Prüfspannung stellen. Prüfkabel wie

folgt an den zu prüfenden Stromkreis anschließen:

a) Zur Isolierprüfung an Erde (Masse): Ein Prüfkabel an

Masse oder das Gerätgehäuse und das andere Kabel an

den zu prüfenden Stromkreis anschließen.

b) Zur Isolierprüfung zwischen Kabeln: Jeweils ein Kabel an

den Draht jedes Kabels anschließen.

2) Prüftaste drücken (bzw. Generatorschalter drehen).

3) Der Meßzeiger zeigt den Wert des Isolierwiderstands auf der Ω Skala

an.

Wenn ein kapazitiver Stromkreis getestet wird, sinkt der Zeiger zunächst gegen

0 Ω. Während des Aufladens der Kapazitanz bis auf den Wert der

Ausgangsspannung des Prüfers steigt der Zeiger dann allmählich an und bleibt

schließlich auf einem konstanten Wert stehen.

Wenn mehrmals hintereinander ein Wert von ∞ (unendlich) angezeigt wird,

müssen die beiden äußeren Enden der Prüfkabel miteinander verbunden und

die Kabel überprüft werden. Wenn ein Wert von 0Ω angezeigt wird, kann mit

Sicherheit davon ausgegangen werden, daß die Kabel nicht getrennt oder

beschädigt sind und der angezeigte Wert des Isolierwiderstands stimmt.

Nach Loslassen der Prüftaste werden kapazitive Stromkreise vom Prüfgerät

automatisch entladen. Der Spannungsabfall wird auf der Spannungsskala

angezeigt. Vor dem Trennen der Prüfkabel muß die Spannung auf unter 60 V

gesunken sein.

Auswahl der Prüfkabel

Eine festgestellte Prüftaste muß unbedingt wieder gelöst und

die gesamte Kapazitanz entladen werden, bevor der geprüfte

Gegenstand berührt oder die Prüfkabel getrennt werden.

Der BM15 und der MJ15 werden mit drei Kabeln ohne Sicherung geliefert, die

mit Krokodilklemmen versehen sind. Diese Kabel sind optimal für

Isolierprüfungen bei nicht spannungsführenden Stromkreisen. Durch die

Krokodilklemmen wird sichergestellt, daß die kapazitive Belastung so lange

angeschlossen bleibt, bis sie nach der Prüfung automatisch entladen wird.

Die britischen Sicherheitsbehörden empfehlen zur Spannungsmessung bei

Starkstromanlagen den Einsatz von Prüfkabeln mit Sicherungen. Diese Kabel

sind als Sonderzubehör erhältlich. Siehe "Zubehör".

Prüfspitzen mit Sicherungen dürfen nicht zur Isolierprüfung eingesetzt

werden. Wenn die Sicherung durchbrennt oder der Kontakt mit den

Prüfspitzen während der Prüfung abreißt, bleibt die geprüfte Anlage geladen,

ohne daß die Gefahr bemerkbar wird!

32

Page 33

Verwendung des Schutzanschlusses (G)

Für einfache Isolierprüfungen und für Prüfungen, bei denen nicht zu erwarten

steht, daß die Messung durch Oberflächenableitung beeinflußt wird, braucht

der Schutzanschluß nicht verwendet zu werden (sofern die Isolierung sauber

ist und störende Strömungspfade unwahrscheinlich sind). Bei der Prüfung von

Kabeln kann jedoch aufgrund von Feuchtigkeit oder Schmutz durch die

Isolierung hindurch eine Oberflächenableitung zwischen dem blanken Kabel

und der äußeren Hülle auftreten. Um den Effekt dieser Ableitung

auszuschalten, sollte insbesondere bei hohen Prüfspannungen die Isolierung

fest mit einem blanken Draht umwickelt und über das dritte Prüfkabel mit

dem Schutzanschluß "G" verbunden werden.

Der Schutzanschluß besitzt dasselbe Potential wie der Minuspol. Da der

Widerstand des Kriechstroms zu dem gemessenen Widerstand effektiv parallel

verläuft, wird durch den Schutzanschluß der von der Oberflächenableitung

verursachte Kriechstrom vom gemessenen Stromkreis weggeleitet. Da Gerät

zeigt daher nur den Kriechverlust des Isolators an und ignoriert den durch

Oberflächenableitung verursachten Kriechverlust.

Pfad des

Kriechstroms

zum

Anschluß

"+" ve

zum

Anschluß

"G"

Fest umwickelter

blanker Draht

zum

Anschluß

"-" ve

BETRIEBS-BLOCKSCHALTBILD

33

Page 34

TECHNISCHE DATEN

Isolierung

Bereich: 100 kΩ bis 20 GΩ (auch 0Ω und ∞ )

Prüfspannung (DC): 500 V, 1000 V, 2500 V oder 5000 V

Genauigkeit der Prüfspannung: ± 5% der nominalen Prüfspannung bei einer Belastung von 20 MΩ

Stabilität der Prüfspannung: < ± 1% (180 U/min bis 240 U/min - MJ15)

Isoliergenauigkeit (bei 0 - 30˚C): ±2,5 % des Zeigerausschlags

Kurzschlußstrom: 1,5 mA ± 0,5 mA

Maximale Kapazitanz der Ladung: 5 µF

Störschutz: effektiver Mittelwert: 1 mA bei 50 - 60 Hz

Entladewiderstand: < 500 kΩ

Spannung

Bereich: 0 - 600 V AC, DC wird angezeigt

Genauigkeit: ± 2,5 % bei vollem Zeigerausschlag (Drehschalter in Stellung V) ± DC ohne Angaben

Allgemein

Größte Nutzlast: 720 V AC oder DC

Skalenlänge: 72 mm (96˚)

Stromversorgung: BM15: 8 x LR6 Alkali-Mignonbatterien oder Akkubatterie

MJ15: Bürstenloser Niederspannungsgenerator oder 8 x LR6 Alkali-Mignonbatterien

Haltbarkeit der Batterien: In der Regel 2000 Prüfungen von je 5 Sekunden Dauer bei einer Belastung von 100 MΩ

Batterieanzeige: Überprüfung der Batterieladung

Eigenschaften der Anschlußspannung

Ausgangsspannung (kV)

Lastwiderstand (MΩ)

34

Page 35

Sicherheit: IEC 61010-1

Nicht erneuerbare Sicherungen: 1 A, 250 V, HBC-Art (F) (20 mm x 5 mm) nach IEC 127/1

AllgemeinElektromagnetische Störfreiheit: IEC 61326-1

Betriebliche Unklarheiten: Besuch www.megger.com

Temperaturbereich: Betrieb: 0˚C bis 30˚C bei voller Einhaltung der Spezifikationen

Betrieb: -20˚C † bis 50˚C bei einem Temperaturkoeffizienten von ± 0,1 % / ±C

Lagerung: -25˚C bis 65˚C

Feuchtigkeit: 90 % relative Luftfeuchitgkeit bei 40˚C

Maße: 220 mm x 160 mm x 115 mm

Gewicht: BM15: ca 1,2 kg

MJ15: ca 1,6 kg oder 1,8 kg mit Batteriehalter und Batterien

Reinigung: Anschlüsse des Geräts trennen und Gerät mit sauberem Tuch und Seifenwasser oder

Isopropylalkohol (IPA) abwischen.

*** bezieht sich auf eine Stoßspannung, die bei der Verkabelung von fest installierten Geräten auftreten kann

* bezieht sich auf eine Stoßspannung, die bei Spezialgeräten, Geräteteilen, Fernmelde- oder elektronischen

Anlagen usw. auftreten kann

† Hinweis: Der MJ15 arbeitet im gesamten Temperaturbereich bei Generatorbetrieb normal Der BM15 benötigt für einen

Normalbetrieb bei -20˚C frische Batterien.

35

Page 36

ZUBEHÖR

MIT DEM GERÄT GELIEFERT TEILENUMMER

Gebrauchsanleitung 6172-209

2 x 1,5 V LR6 Alkali-Mignonbatterien

Prüfkabelsatz aus 3 Kabeln, Länge 3 m 8101-181

Karten (5 Stück) zum Notieren der Prüfdaten 6172-111 (U.S. 210949)

Tragekoffer mit Stauraum für Kabel 6420-117

Einschiebbare Durchgangsschablonen (5 Stück) 6121-401

SONDERZUBEHÖR

5 kV Prüfspitzensatz mit Sicherung 6320-240

5 kV Kalibrierbox - CB101 6311-077

Karten zum Notieren der Prüfdaten (20 Stück) 6111-216

Publikationen

‘A Stitch In Time’ AVTM21-P8B

’Lowdown on HV d.c. Testing’ AVTM22P-1

36

Page 37

REPARATUREN UND GARANTIE

Das Instrument enthält statisch empfindliche Bauteile, weshalb die gedruckte

Schaltung sorgfältig behandelt werden muß. Falls die Schutzvorrichtungen

eines Instruments beschädigt worden sind, sollte es nicht verwendet, sondern

an eine geeignete Reparaturwerkstatt geschickt werden. Die

Schutzvorrichtungen sind wahrscheinlich beschädigt, wenn folgende

Bedingungen vorliegen: sichtbare Beschädigung, fehlende Anzeige der

erwarteten Meßergebnisse; längere Lagerung unter widrigen Bedingungen

oder starke Transportbelastung.

NEUE INSTRUMENTE UNTERLIEGEN EINER GARANTIE VON 1 JAHR

AB DEM DATUM DES KAUFS DURCH DEN BENUTZER.

Hinweis: Das Gehäuse darf nur von entsprechend autorisierten

Reparaturfirmen geöffnet werden, da sonst die Garantie für dieses Instrument

automatisch erlischt.

Reparaturarbeiten und Ersatzteile

Wenden Sie sich zwecks Wartungsarbeiten an Megger-lnstrumenten entweder

an:

Megger Limited oder Megger

Archcliffe Road Valley Forge Corporate Center

Dover 2621 Van Buren Avenue

Kent CT17 9EN Norristown, PA 19403

England USA

Tél: + 44 (0) 1304 502243 Tél: +1 (610) 676-8579

Fax: + 44 (0) 1304 207342 Fax: +1 (610) 676-8625

Autorisierte Reparaturfirmen

Eine Reihe von Firmen sind für die Reparatur der meisten Meggerlnstrumente unter Verwendung von Original Megger-Ersatzteilen autorisiert.

Wenden Sie sich wegen Ersatzteilen, Reparaturwerkstatten und Beratung über

die jeweils bestgeeigneten Maßnahmen an eine autorisierte Auslieferung bzw.

Vertretung.

Einsenden Eines Instruments Zur Reparatur

Wenn ein Instrument zwecks Reparatur zurück geschickt werden muß, sollte

es mit vorbezahiter Fracht an die angebrachte Anschrift gesandt werden.

Gleichzeitig sollte zur Erledigung der britischen Zollformalitäten per Luftpost

eine Kopie der Rechnung zusammen mit dem Packzettel eingesandt werden.

Auf Wunsch wird dem Absender vor Ausführung irgendwelcher Arbeiten am

Instrument ein Kostenvoranschlag unter Berücksichtigung der Frachtkosten

und anderer Gebühren zugesandt.

oder an eine autorisierte Reparaturfirma.

37

Page 38

GUÍA DEL USUARIO - CONTENIDO

Avisos de Seguridad 39

Descripción General 40

Características y Controles 41

Trabajo con cargas capacitivas 42

Funcionamiento

Comprobaciones preliminares 43

Recambio de las pilas 43

Medición de voltaje 44

Prueba de aislamiento 44

Elección de conductores de prueba 44

Uso del borne de protección 45

Especificaciones 46

Accesorios 48

Reparación y Garantía 49

Antes de usar el instrumento, observe las instrucciones separadas incluidas

para instalar el botón de prueba ya sea bloqueable o bien no bloqueable. Si se

instala el botón bloqueable, Deben adoptarse precauciones adicionales.

Símbolos usados en el instrumento

F Riesgo de sacudida eléctrica.

G Referirse a la Guía del Usuario.

t Equipo totalmente protegido por aislamiento

doble (Clase II).

c El equipo está conforme con las directrices

actuales de la UE.

38

Page 39

GAVISOS DE SEGURIDAD

■ Las secciones 'Avisos de seguridad' y 'Trabajando con cargas capacitivas' deben ser leídas y comprendidas antes de

usar el instrumento. Las precauciones de seguridad deben ser observadas durante el uso.

■ El circuito en prueba debe ser desconectado, desenergizado y aislado antes de efectuar conexiones de prueba.

■ Las conexiones del circuito no deben tocarse durante la prueba.

■ Al finalizar la prueba se indica en la pantalla el voltaje decreciente que fluye a través de los bornes. Los circuitos de

carga capacitiva deben ser descargados a menos de 60V antes de desconectar los conductores de prueba.

■ Los circuitos de carga capacitiva deben ser conectados a tierra con una conexión de cortocircuitar después de la descarga.

■ Retire los conductores de prueba del instrumento antes de abrir el compartimiento de las pilas.

■ Los conductores de prueba y los clips de mandíbulas deben estar en buen estado de servicio, limpios y con el

aislamiento intacto.

■ El instrumento no debe ser usado si cualquier parte está dañada.

■ Las autoridades de seguridad del Reino Unido recomiendan usar conductores de prueba provistos de fusibles cuando se

mide el voltaje en sistemas de alta energía. Vea 'Elección de conductores de prueba'.

NOTA

EL INSTRUMENTIO SOLO SERA UTILIZADO POR PERSONAS CAPACITADAS Y COMPETENTES.

NOTA

Se recuerda a los usuarios de este equipo, o sus empleados, que deben llevar a cabo evaluaciones válidas de riesgo en todo el trabajo

eléctrico a fin de identificar los posibles puntos de peligro eléctrico que pueden resultar en lesiones para el personal a causa de

cortocircuitos, por ejemplo. Si las evaluaciones muestran que el riesgo es significativo, deberán usarse conductores de prueba provistos

de fusibles como recomiendan las autoridades de seguridad del Reino Unido. No se deben usar sondas provistas de fusibles para la prueba

de aislamiento. Si se funde el fusible, o si las sondas pierden su contacto durante una prueba, el sistema en prueba debería permanecer

cargado ¡sin ninguna señal de peligro aparente!

39

Page 40

DESCRIPCIÓN GENERAL

Los probadores BM15 y MJ15 son instrumentos completamente autónomos

diseñados para efectuar pruebas de resistencia de aislamiento de alto voltaje

en el mantenimiento y servicio de maquinaria giratoria, transformadores,

mecanismos de conmutación e instalaciones industriales.

Las pruebas pueden ser realizadas a 500, 1000, 2500 ó 5000 voltios de manera

seleccionable. La gama de mediciones de aislamiento es de 100 kΩ a 20 GΩ e

infinidad. Se incluye descarga automática para circuitos capacitivos y se

visualiza el voltaje decreciente.

Puede usarse un borne de protección para reducir al mínimo los efectos de la

fuga superficial cuando se realizan pruebas de resistencia del aislamiento.

Las pruebas se inician pulsando el botón de prueba ('Test') BM15 (o girando la

manivela del generador MJ15). Al soltar el botón 'Test' (o dejar de girar la

manivela), el instrumento pasará por defecto al modo de voltímetro ca/cc, con

un resistor de descarga conectado internamente entre los bornes. Esta

característica aportará una indicación de voltaje decreciente seguido de la

prueba del equipo que posee la capacitancia.

El medidor de cuadro móvil acciona una aguja indicadora negra que visualiza

las lecturas en una escala negra logarítmica sencilla situada sobre una placa

con escala blanca para ofrecer mayor claridad de la lectura. El conjunto móvil

está montado sobre una base resistente para uso en pie de obra.

Puede insertarse sobre la visualización una diapositiva superpuesta sobre la

banda de pasa. Pueden trazarse en estas ventanas bandas de pasa/falla con un

marcador indeleble para la pruebas de tolerancia máxima y mínima. El BM15

funciona con ocho pilas de 1,5 V (IEC RL6).

La potencia normal requerida por el MJ15 la desarrolla un generador de c.a.

sin escobillas, de giro manual y bajo voltaje. Colocando en el recipiente de la

batería suministrado ocho pilas de 1,5 V IEC RL6, se aporta al instrumento una

capacidad de suministro doble (independiente). Ambos instrumentos

incorporan una gama de comprobación de batería, la cual funciona al pulsar el

botón 'Test'. Si se gira la manivela con demasiada lentitud (<180 rpm), la

lectura de la aguja indicadora será inestable. Una velocidad excesiva de la

manivela no podrá dañar el instrumento porque el voltaje de salida está

regulado de modo electrónico.

La caja es robusta, pero liviana, fabricada con un ABS pirorretardante, e

incorpora una ventana de visualización de policarbonato. Montado en la parte

superior de la caja hay un interruptor selector de gama giratorio de 6

posiciones, así como un botón pulsador de prueba ('Test').

Se incluyen tres tomas en rebaje marcadas '+', '-' y 'G'. Estos interruptores

tienen cubiertas de seguridad que se abren cuando se insertan los enchufes.

Una vez insertados en sus tomas, los enchufes de los conductores de prueba

cubiertos quedan bloqueados en su posición. Se sueltan girando el conductor

un cuarto de vuelta y tirando del mismo para desenchufarlo.

Por este motivo solamente deberán usarse los conductores de prueba

suministrados o repuestos Megger adecuados.

Las características de seguridad incluidas son:

■ Visualización externa de voltaje c.a. o c.c.

■ La carga se descarga automáticamente al final de la prueba, y se

visualiza el voltaje decreciente visualizado.

■ Los conductores de prueba se bloquean en sus tomas en la caja para

prevenir una desconexión accidental.

40

Page 41

CARACTERÍSTICAS Y CONTROLES

Interruptor selector

giratorio

Botón

no bloqueable

(opción

recomendada)

Manivela de generador (MJ15)

Botón bloqueable

(debe adoptarse

precaución

adicional si se

selecciona esta

opción)

Borne -

Borne de protección

Borne +

PARA INSERTAR LOS ENCHUFES DE LOS BORNES, EMPÚJENSE ESTOS; PARA SOLTARLOS GÍRENSE UN

CUARTO DE VUELTA Y TÍRENSE DE ELLOS PARA SACARLOS.

41

Page 42

TRABAJO CON CARGAS CAPACITIVAS

G

Las conexiones del circuito y los bornes del instrumento

pueden resultar peligrosos si se conectan a cargas capacitivas.

1. Estos instrumentos están diseñados para cargar y descargar con

seguridad cargas capacitivas de hasta 5 µF. No obstante, para

asegurarse contra un mal funcionamiento, se aconseja adoptar

precauciones propias cuando se trabaja con cargas capacitivas.

Recuérdese que cuando están cargados, incluso los capacitores de bajo

valor pueden resultar fatales a su contacto.

2. Debe adoptarse precaución adicional si se selecciona el botón de

prueba ('Test') bloqueable.

3. Las conexiones del circuito no deben tocarse durante la prueba.

No se olvide de soltar el botón de prueba bloqueado, y de

descargar cualquier capacitancia antes de tocar el aparato en

prueba, o de desconectar los conductores de prueba.

4. Debe tenerse cuidado de impedir que sean desconectados los circuitos

capacitivos durante la prueba, dejando el circuito cargado.

5. Al finalizar la prueba, el instrumento indica un voltaje decreciente. No

desconecte los conductores de prueba hasta que la capacitancia de

carga se haya descargado a menos de 60 V.

6. El voltímetro y la descarga automática del instrumento deberán

considerarse como características de seguridad adicionales, no como

sustitutos para la práctica normal de trabajo seguro.

7. Si cualquier parte del instrumento está dañada, éste no deberá ser

usado sino que deberá ser devuelto al fabricante o a una empresa de

servicio aprobada para su reparación.

42

Page 43

FUNCIONAMIENTO

Comprobaciones de ejecución preliminares

El instrumento funcionará en cualquier posición, pero los mejores resultados

se obtienen cuando el instrumento está boca arriba, situado sobre una

superficie firme nivelada. Esto es especialmente aplicable en aparatos

accionados por manivela para obtener una velocidad de giro de manivela

constante y uniforme de >180 rpm.

1. Si se incorporan pilas de batería, conmute a gama de comprobaciones

de batería y pulse el botón de prueba ('Test'). Asegure que la aguja

indicadora asienta dentro de la parte de la escala donde aparece el

símbolo de la batería.

2. Con los conductores de prueba desconectados, fije el interruptor

selector giratorio en la gama de aislamiento apropiada, pulse y retenga

el botón de prueba (o gire la manivela del generador). La aguja

indicadora deberá moverse un poco hacia arriba de la escala y luego

retornar a la posición '∞ ' (infinidad) de la escala. Con esto se establece

que no hay fugas por el propio instrumento.

3. Asegure que los conductores de prueba y los clips de mandíbula están

en buen estado de servicio, limpios y con su aislamiento intacto.

Conecte dos de los conductores de prueba en los bornes '+' y '-' y

asegure que sus clips no estén en contacto con nada.

4. Pulse otra vez el botón de prueba (o gire la manivela del generador) y

observe la aguja indicadora del medidor. La aguja deberá descansar

sobre la posición '∞ ' de la escala. En caso contrario, los conductores

de prueba pueden estar defectuosos y deberán ser inspeccionados con

más detenimiento por si tienen daños. Recambie los conductores si es

necesario.

5. Conecte los clips del conductor de prueba, pulse el botón de prueba (o

gire la manivela del generador) y observe la aguja indicadora del

medidor. El medidor debe mostrar '0 Ω'. Si indica infinidad o un alto

valor de resistencia, los conductores pueden estar en circuito abierto y

deberán inspeccionarse con mayor detenimiento. Recambie los

conductores si es necesario. (Si se cortocircuitan los conductores y se

obtiene una lectura '0 Ω', esto también indicará que el instrumento está

funcionando.

Recambio de la batería

GAVISO

Los contactos de la batería no están aislados de los conductores de

prueba. Retire los conductores de prueba del instrumento antes de abrir

el compartimiento de las pilas. Las pilas están alojadas en su compartimiento

en la base del instrumento.

Para cambiar las pilas, quite con un destornillador los tornillos de sujeción de

la tapa de la batería y saque la tapa del compartimiento de la batería.

Observando la correcta polaridad marcada en el alojamiento de la batería,

instale las 8 pilas IEC RL6 (AA) de repuesto. Al finalizar esta operación,

reinstale y sujete la tapa del compartimiento de la batería.

43

Page 44

FUNCIONAMIENTO

Medición del voltaje

Cuando se conmuta a la posición 'V', el instrumento mide hasta 600 V c.a. de

acuerdo con la precisión especificada del instrumento. El voltaje c.c. también

es visualizado, pero no de acuerdo con la precisión especificada. Cuando no

se hacen pruebas con el instrumento (i.e. está en la función de espera) y está

conectado a un circuito nergizado, pasará por defecto a la función de

voltímetro (de 0 a 600 voltios c.a. o c.c.) sin tener en cuenta la posición del

interruptor giratorio. Cualquier voltaje presente será visualizado

inmediatamente. Así pues, el instrumento indica que el elemento no ha sido

totalmente desenergizado. El instrumento también supervisa la descarga del

circuito cuando se suelta el botón de prueba después de una prueba de

aislamiento en un elemento capacitivo, e.g. un cable largo.

Pruebas de aislamiento

Después de conectar los conductores de prueba al instrumento, y de realizar

las comprobaciones de ejecución preliminares:

1. Sitúe el interruptor selector en el voltaje de prueba requerido.

Conecte los conductores de prueba al circuito aislado que se desea

probar, como sigue:

a) Para pruebas de aislamiento a tierra (masa): Conecte uno de los

conductores de prueba a tierra (masa) o a la estructura del

equipo, y el otro conductor a la parte del circuito que se desea

probar.

b) Para pruebas de aislamiento entre hilos: Conecte el conductor al

núcleo de cada uno de los hilos.

2. Pulse el botón de prueba (o gire la manivela del generador).

3. La aguja indicará el valor de la resistencia del aislamiento en la escala

de Ω. Si se prueba un circuito capacitivo, la aguja se desviará

inicialmente hacia 0 Ω y luego ascenderá gradualmente hasta su valor