Page 1

The Complete Guide

to Electrical Insulation

Testing

A STITCH IN TIME 1

WWW.MEGGER.COM

Page 2

“A Stitch In Time”

The Complete Guide to

Electrical Insulation Testing

Copyright 2006

A STITCH IN TIME 1

WWW.MEGGER.COM

Page 3

CONTENTS PAGE

WHAT IS “GOOD” INSULATION? ........................................................................ 3

WHAT MAKES INSULATION GO BAD? ................................................................ 4

HOW INSULATION RESISTANCE IS MEASURED .................................................. 5

HOW TO INTERPRET RESISTANCE READINGS .................................................... 6

FACTORS AFFECTING INSULATION RESISTANCE READINGS .............................. 8

TYPES OF INSULATION RESISTANCE TESTS .......................................................10

TEST VOLTAGE VS. EQUIPMENT RATING .......................................................... 16

AC TESTING VS. DC ............................................................................................ 17

USE OF DC DIELECTRIC TEST SET ...................................................................... 18

TESTS DURING DRYING OUT OF EQUIPMENT .................................................. 18

EFFECT OF TEMPERATURE ON INSULATION RESISTANCE................................ 21

EFFECTS OF HUMIDITY ...................................................................................... 23

PREPARATION OF APPARATUS TO TEST ........................................................... 24

SAFETY PRECAUTIONS ...................................................................................... 26

CONNECTIONS FOR TESTING INSULATION RESISTANCE OF

ELECTRICAL EQUIPMENT ..................................................................................27

ADDITIONAL NOTES ABOUT USING A MEGGER INSULATION TESTER ........... 33

INTERPRETATION-MINIMUM VALUES ..............................................................36

MINIMUM VALUES FOR INSULATION RESISTANCE .......................................... 38

TESTS USING MULTI-VOLTAGE MEGGER INSULATION TESTERS ......................42

STEP-VOLTAGE METHOD .................................................................................. 48

USE OF A GUARD TERMINAL ............................................................................ 50

BUSHINGS, POTHEADS AND INSULATORS ....................................................... 54

OUTDOOR OIL CIRCUIT BREAKERS ................................................................... 57

SETTING UP A MAINTENANCE PROGRAM ....................................................... 60

HOW OFTEN SHOULD YOU TEST? .................................................................... 60

MEGGER 5 AND 10 KV INSULATION TESTERS .................................................. 62

MEGGER 1 KV INSULATION TESTERS ................................................................64

2 A STITCH IN TIME

Page 4

WHAT IS “GOOD” INSULATION?

Every electric wire in your plant – whether it’s in a motor, generator, cable,

switch, transformer, etc. – is carefully covered with some form of electrical

insulation. The wire itself is usually copper or aluminum, which is known to

be a good conductor of the electric current that powers your equipment. The

insulation must be just the opposite from a conductor: it should resist current

and keep the current in its path along the conductor.

To understand insulation testing you really don’t need to go into the

mathematics of electricity, but one simple equation – Ohm’s law – can be very

helpful in appreciating many aspects. Even if you’ve been exposed to this law

before, it may be a good idea to review it in the light of insulation testing.

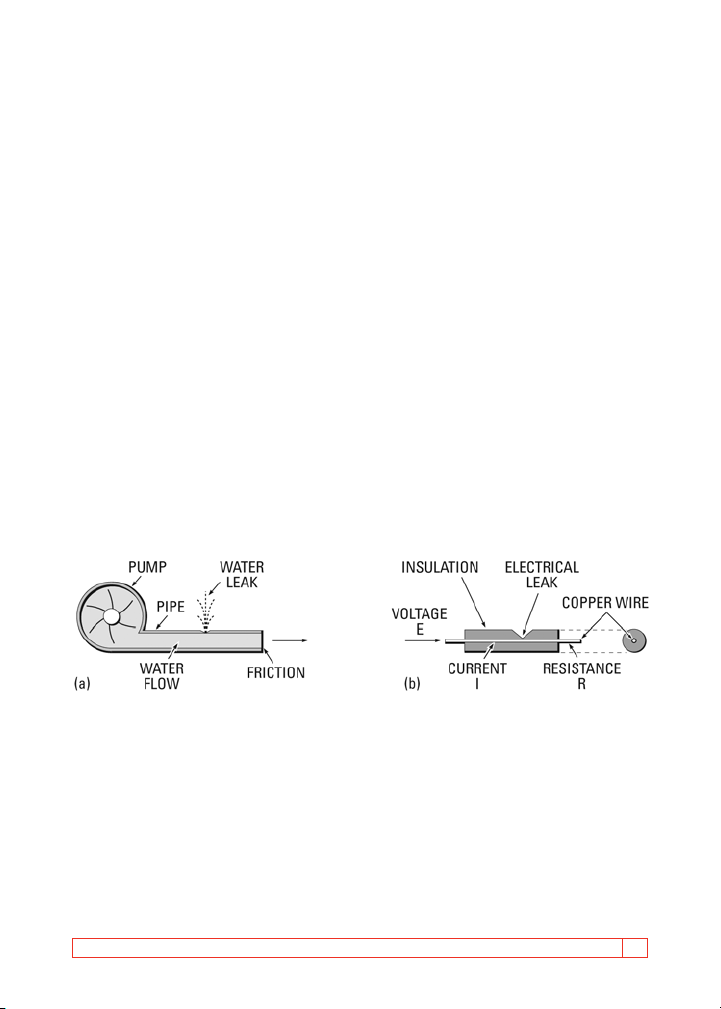

The purpose of insulation around a conductor is much like that of a pipe

carrying water, and Ohm’s law of electricity can be more easily understood by

a comparison with water flow. In Fig. 1 we show this comparison. Pressure on

water from a pump causes flow along the pipe (Fig. 1a). If the pipe were to

spring a leak, you’d waste water and lose some water pressure.

With electricity, voltage is like the pump pressure, causing electricity to flow

along the copper wire (Fig. 1b). As in a water pipe, there is some resistance

to flow, but it is much less along the wire than it is through the insulation.

Figure 1–Comparison of water flow (a) with electric current (b).

A STITCH IN TIME 3

Page 5

Common sense tells us that the more voltage we have, the more current

there’ll be. Also, the lower the resistance of the wire, the more current for

the same voltage.

Actually, this is Ohm’s law, which is expressed this way in equation form:

E = I x R

where, E = voltage in volts

I = current in amperes

R = resistance in ohms

Note, however, that no insulation is perfect (that is, has infinite resistance) so

some electricity does flow along the insulation or through it to ground. Such

a current may only be a millionth of an ampere (one microampere) but it is

the basis of insulation testing equipment. Note also that a higher voltage

tends to cause more current through the insulation. This small amount of

current would not, of course, harm good insulation but would be a problem

if the insulation has deteriorated.

Now, to sum up our answer to the question “what is ‘good’ insulation?”

We have seen that, essentially, “good” means a relatively high resistance

to current. Used to describe an insulation material, “good” would also

mean “the ability to keep a high resistance.” So, a suitable way of

measuring resistance can tell you how “good” the insulation is. Also, if you

take measurements at regular periods, you can check trends toward its

deterioration (more on this later).

WHAT MAKES INSULATION GO BAD?

When your plant electrical system and equipment are new, the electrical

insulation should be in top notch shape. Furthermore, manufacturers of wire,

cable, motors, and so on have continually improved their insulations for

services in industry. Nevertheless, even today, insulation is subject to many

effects which can cause it to fail – mechanical damage, vibration, excessive

heat or cold, dirt, oil, corrosive vapors, moisture from processes, or just the

humidity on a muggy day.

In various degrees, these enemies of insulation are at work as time goes

on – combined with the electrical stresses that exist. As pin holes or cracks

develop, moisture and foreign matter penetrate the surfaces of the

insulation, providing a low resistance path for leakage current.

4 A STITCH IN TIME

Page 6

Once started, the different enemies tend to aid each other, permitting

excessive current through the insulation.

Sometimes the drop in insulation resistance is sudden, as when equipment

is flooded. Usually, however, it drops gradually, giving plenty of warning,

if checked periodically. Such checks permit planned reconditioning before

service failure. If there are no checks, a motor with poor insulation, for

example, may not only be dangerous to touch when voltage is applied,

but also be subject to burn out. What was good insulation has become a

partial conductor.

HOW INSULATION RESISTANCE IS MEASURED

You have seen that good insulation has high resistance; poor insulation,

relatively low resistance. The actual resistance values can be higher or lower,

depending upon such factors as the temperature or moisture content of the

insulation (resistance decreases in temperature or moisture). With a little

record-keeping and common sense, however, you can get a good picture of

the insulation condition from values that are only relative.

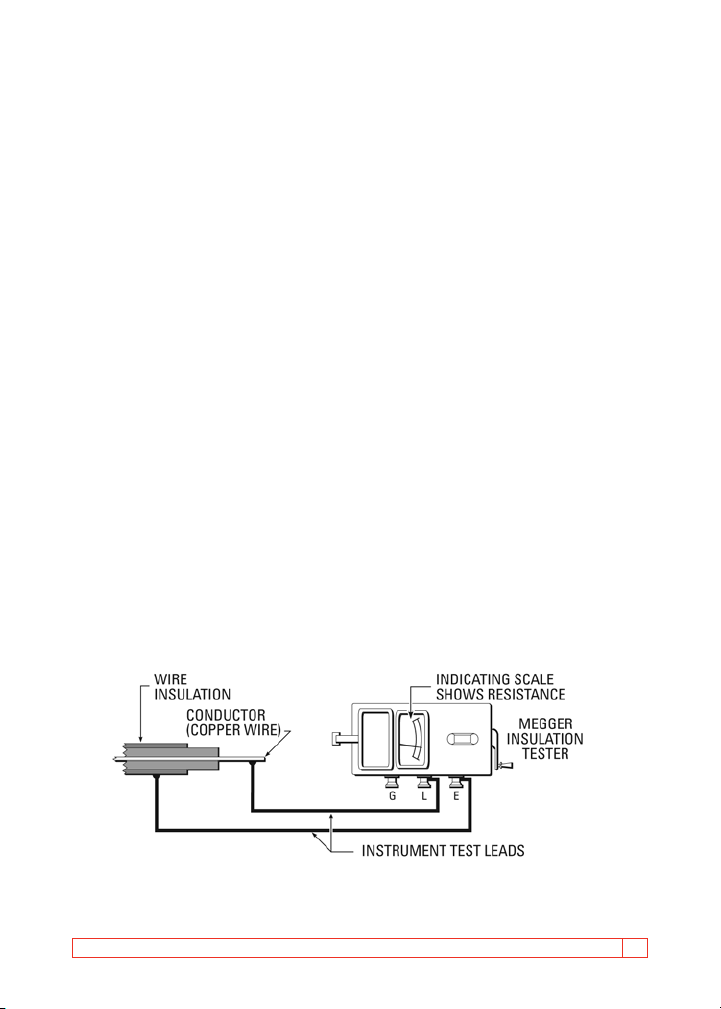

The Megger insulation tester is a small, portable instrument that gives you

a direct reading of insulation resistance in ohms or megohms. For good

insulation, the resistance usually reads in the megohm range.

The Megger insulation tester is essentially a high-range resistance meter

(ohmmeter) with a built-in direct-current generator. This meter is of special

construction with both current and voltage coils, enabling true ohms to be

read directly, independent of the actual voltage applied. This method is nondestructive; that is, it does not cause deterioration of the insulation.

Figure 2–Typical Megger test instrument hook-up to measure insulation resistance.

A STITCH IN TIME 5

Page 7

The generator can be hand-cranked or line-operated to develop a high

DC voltage which causes a small current through and over surfaces of the

insulation being tested (Fig. 2). This current (usually at an applied voltage

of 500 volts or more) is measured by the ohmmeter, which has an indicating

scale. Fig. 3 shows a typical scale, which reads increasing resistance values

from left up to infinity, or a resistance too high to be measured.

Figure 3–Typical scale on the Megger insulation tester.

HOW TO INTERPRET RESISTANCE READINGS

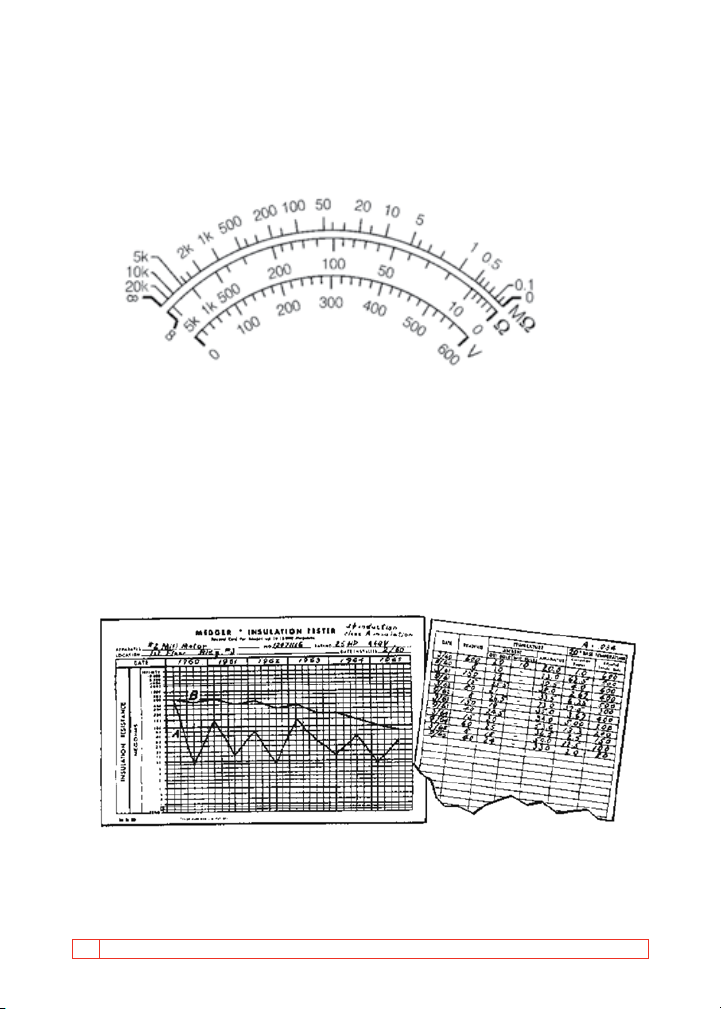

As previously mentioned, insulation resistance readings should be considered

relative. They can be quite different for one motor or machine tested three

days in a row, yet not mean bad insulation. What really matters is the trend

in readings over a time period, showing lessening resistance and warning

of coming problems. Periodic testing is, therefore, your best approach to

preventive maintenance of electrical equipment, using record cards as shown

in Fig. 4.

Figure 4–Typical record of insulation resistance of a mill motor. Curve A shows test values as

measured; Curve B shows same values corrected to 20°C (see page 22), giving a definite downward

trend toward an unsafe condition. Reverse side of card (at right) is used to record the test data.

6 A STITCH IN TIME

Page 8

Whether you test monthly, twice a year, or once a year depends upon the

type, location, and importance of the equipment. For example, a small

pump motor or a short control cable may be vital to a process in your plant.

Experience is the best teacher in setting up the scheduled periods for your

equipment.

You should make these periodic tests in the same way each time. That is,

with the same test connections and with the same test voltage applied for

the same length of time. Also you should make tests at about the same

temperature, or correct them to the same temperature. A record of the

relative humidity near the equipment at the time of the test is also helpful

in evaluating the reading and trend. Later sections cover temperature

correction and humidity effects.

In summary, here are some general observations about how you can interpret

periodic insulation resistance tests, and what you should do with the result:

Condition What To Do

(a) Fair to high values No cause for concern.

and well maintained.

(b) Fair to high values, Locate and remedy the cause and

but showing a check the downward trend.

constant tendency

towards lower values.

(c) Low but well maintained. Condition is probably all right, but

cause of low values should be

checked.

(d) So low as to be unsafe. Clean, dry out, or otherwise raise the

values before placing equipment in

service. (Test wet equipment while

drying out.)

(e) Fair or high values, Make tests at frequent intervals until

previously well the cause of low values is located

maintained but showing and remedied; or until the values

sudden lowering. have become steady at a lower

level but safe for operation; or until

values become so low that it is unsafe

to keep the equipment in operation.

A STITCH IN TIME 7

Page 9

FACTORS AFFECTING INSULATION RESISTANCE READINGS

Remember that the measured resistance (of the insulation) will be

determined by the voltage applied and the resultant current (R = E/I).

There are a number of things that affect current, including temperature

of the insulation and humidity, as mentioned in the previous section.

Right now, let’s just consider the nature of current through insulation

and the effect of how long voltage is applied.

Current through and along insulation is made up partly of a relatively

steady current in leakage paths over the insulation surface. Electricity

also flows through the volume of the insulation. Actually, as shown in

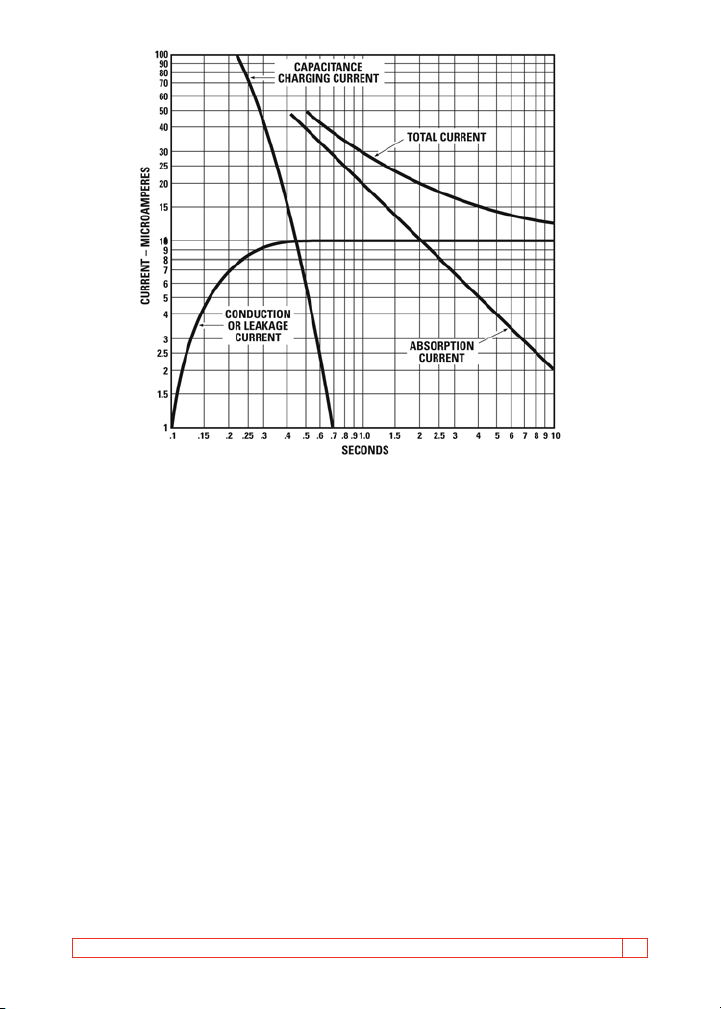

Fig. 5, our total current comprises three components:

1. Capacitance Charging Current

Current that starts out high and drops after the insulation has been

charged to full voltage (much like water flow in a garden hose when

you first turn on the spigot).

2. Absorption Current

Also an initially high current which then drops (for reasons discussed

under the section Time-Resistance Method).

3. Conduction or Leakage Current

A small essentially steady current both through and over the

insulation.

As shown in Fig. 5, the total current is the sum of the three components

and it is this current that can be measured directly by a microammeter,

or in terms of megohms at a particular voltage by means of a Megger

instrument (ohmmeter). Because the total current depends upon the

time that the voltage is applied, you can see now why Ohm’s Law R = E/I

only holds, theoretically, at an infinite time (that is, you’d have to wait

forever before taking a reading).

In practice, as you will see in the test methods described below, you

read a value that is the apparent resistance – a useful value to diagnose

troubles, which is what you want to do.

8 A STITCH IN TIME

Page 10

Figure 5–Curves showing components of current measured during DC testing of insulation.

Note also in Fig. 5 that the charging current disappears relatively rapidly

as the equipment under test becomes charged. Larger units with more

capacitance will take longer to be charged. This current also is the stored

energy initially discharged after your test, by short-circuiting and grounding

the insulation. ALWAYS TAKE THIS SAFETY MEASURE.

You can see further from Fig. 5 that the absorption current decreases at a

relatively slow rate, depending upon the exact nature of the insulation. This

stored energy, too, must be released at the end of a test, and requires a

longer time than the capacitance charging current – about four times as long

as the voltage was applied.

With good insulation, the conduction or leakage current should build up to a

steady value that is constant for the applied voltage, as shown in Fig. 5. Any

increase of leakage current with time is a warning of trouble, as discussed in

the tests described in the following section.

A STITCH IN TIME 9

Page 11

With a background now of how time affects the meaning of instrument

readings, let’s consider three common test methods: (1) short-time or spot

reading; (2) time-resistance; and (3) step or multi-voltage tests.

TYPES OF INSULATION RESISTANCE TESTS

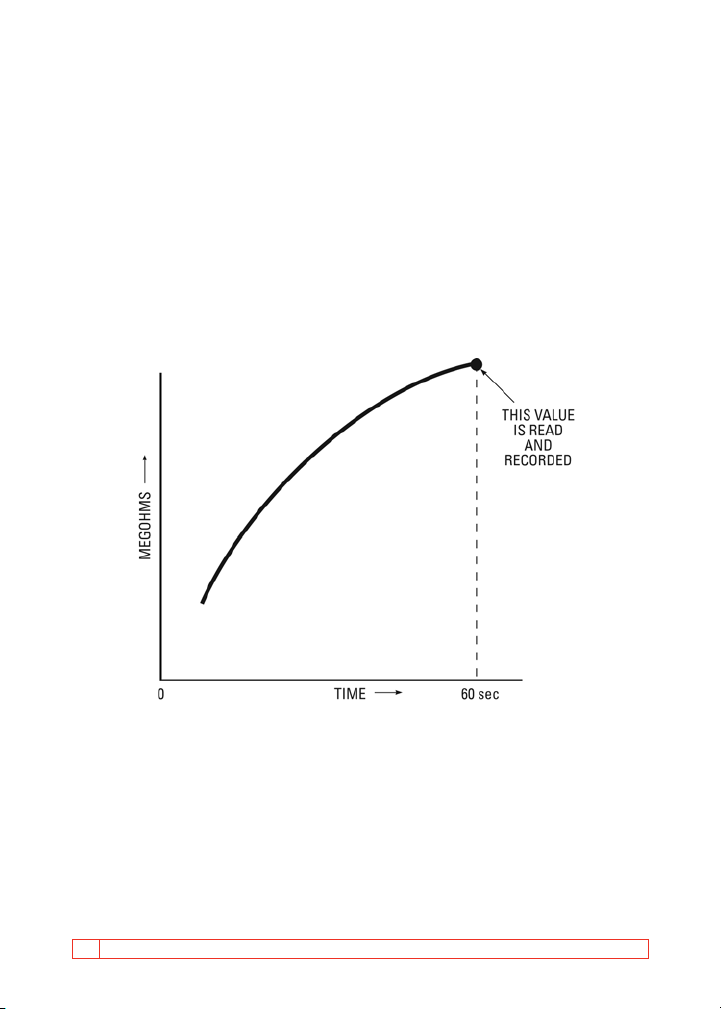

Short-Time or Spot-Reading Test

In this method, you simply connect the Megger instrument across the

insulation to be tested and operate it for a short, specific time period

(60 seconds is usually recommended). As shown schematically in Fig. 6,

you’ve simply picked a point on a curve of increasing resistance values;

quite often the value would be less for 30 seconds, more for 60 seconds.

Bear in mind also that temperature and humidity, as well as condition of

your insulation affect your reading.

Figure 6–Typical curve of insulation resistance (in megohms) with time for the “short time” or

“spot-reading” test method.

10 A STITCH IN TIME

Page 12

If the apparatus you are testing has very small capacitance, such as a

short run of house wiring, the spot reading test is all that is necessary.

However, most equipment is capacitive and so your very first spot reading

on equipment in your plant, with no prior tests, can be only a rough guide

as to how good or bad the insulation is. For many years, maintenance

professionals have used the one-megohm rule to establish the allowable

lower limit for insulation resistance. The rule may be stated:

Insulation resistance should be approximately one megohm for each 1,000

volts of operating voltage, with a minimum value of one megohm.

For example, a motor rated at 2,400 volts should have a minimum insulation

resistance of 2.4 megohms. In practice, megohm readings normally are

considerably above this minimum value in new equipment or when

insulation is in good condition.

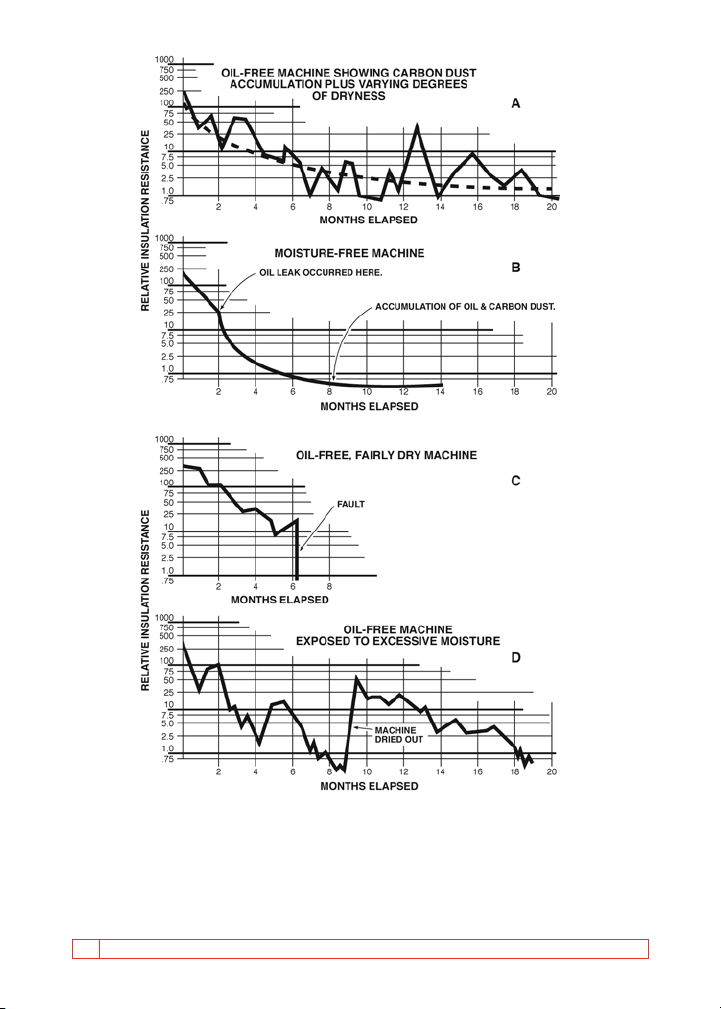

By taking readings periodically and recording them, you have a better basis

of judging the actual insulation condition. Any persistent downward trend

is usually fair warning of trouble ahead, even though the readings may be

higher than the suggested minimum safe values. Equally true, as long as

your periodic readings are consistent, they may be ok, even though lower

than the recommended minimum values. The curves of Fig. 7 show typical

behavior of insulation resistance under varying plant operating conditions.

The curves were plotted from spot readings taken with a Megger instrument

over a period of months.

A STITCH IN TIME 11

Page 13

Figure 7–Typical behavior of insulation resistance over a period of months under varying operating

conditions, (curves plotted from spot readings with a Megger instrument).

12 A STITCH IN TIME

Page 14

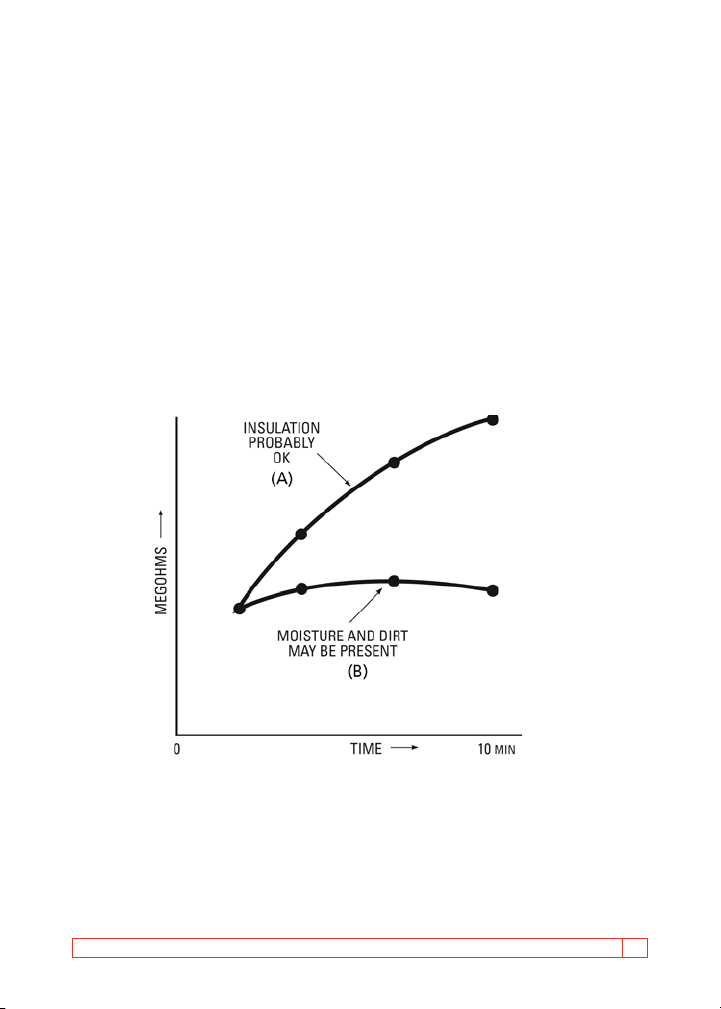

Time-Resistance Method

This method is fairly independent of temperature and often can give

you conclusive information without records of past tests. It is based on

the absorption effect of good insulation compared to that of moist or

contaminated insulation. You simply take successive readings at specific times

and note the differences in readings (see curves, Fig. 8). Tests by this method

are sometimes referred to as absorption tests.

Note that good insulation shows a continual increase in resistance (less

current – see curve A) over a period of time (in the order of 5 to 10 minutes).

This is caused by the absorption current we spoke of earlier; good insulation

shows this charge effect over a time period much longer than the time

required to charge the capacitance of the insulation.

If the insulation contains much moisture or contaminants, the absorption

effect is masked by a high leakage current which stays at a fairly constant

value, keeping the resistance reading low (remember: R = E/I).

Figure 8–Typical curves showing dielectric absorption effect in a “time-resistance” test, made on

capacitive equipment such as a large motor winding.

The time-resistance test is of value also because it is independent of

equipment size. The increase in resistance for clean and dry insulation occurs

in the same manner whether a motor is large or small. You can, therefore,

compare several motors and establish standards for new ones, regardless of

their horsepower ratings.

A STITCH IN TIME 13

Page 15

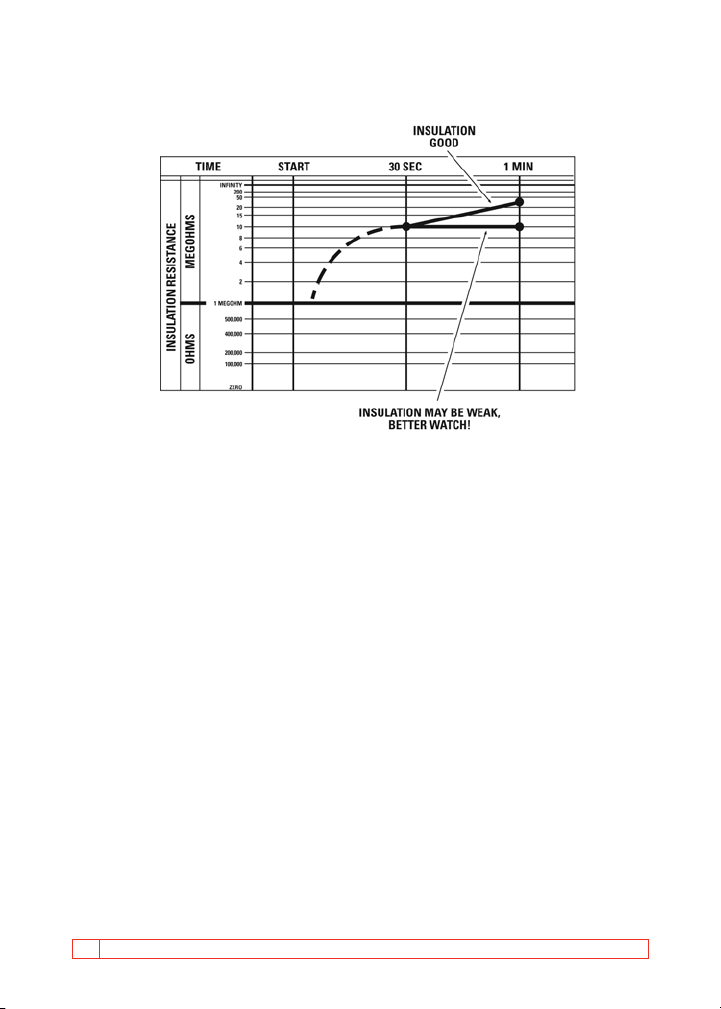

Fig. 9 shows how a 60-second test would appear for good and perhaps bad

insulation. When the insulation is in good shape, the 60-second reading is

higher than the 30-second reading.

Figure 9–Typical card plot of a time-resistance or double-reading test.

A further advantage of this double-reading test, as it is sometimes called,

is that it gives you a clearer picture, even when a spot reading says the

insulation looks fine.

For example, let’s say the spot reading on a synchronous motor was 10

megohms. Now, let’s assume that the double-reading check shows that the

insulation resistance holds steady at 10 megohms while you hold voltage up

to 60 seconds. This means there may be dirt or moisture in the windings that

bears watching. On the other hand, if the pointer shows a gradual increase

between the 30-second and the 60-second checks, then you’re reasonably

sure the windings are in good shape.

Time-resistance tests on large rotating electrical machinery – especially with

high operating voltage – require high insulation resistance ranges and a very

constant test voltage. A heavy-duty Megger test set, line-operated, serves

this need. Similarly, such an instrument is better adapted for large cables,

bushings, transformers and switchgear.

14 A STITCH IN TIME

Page 16

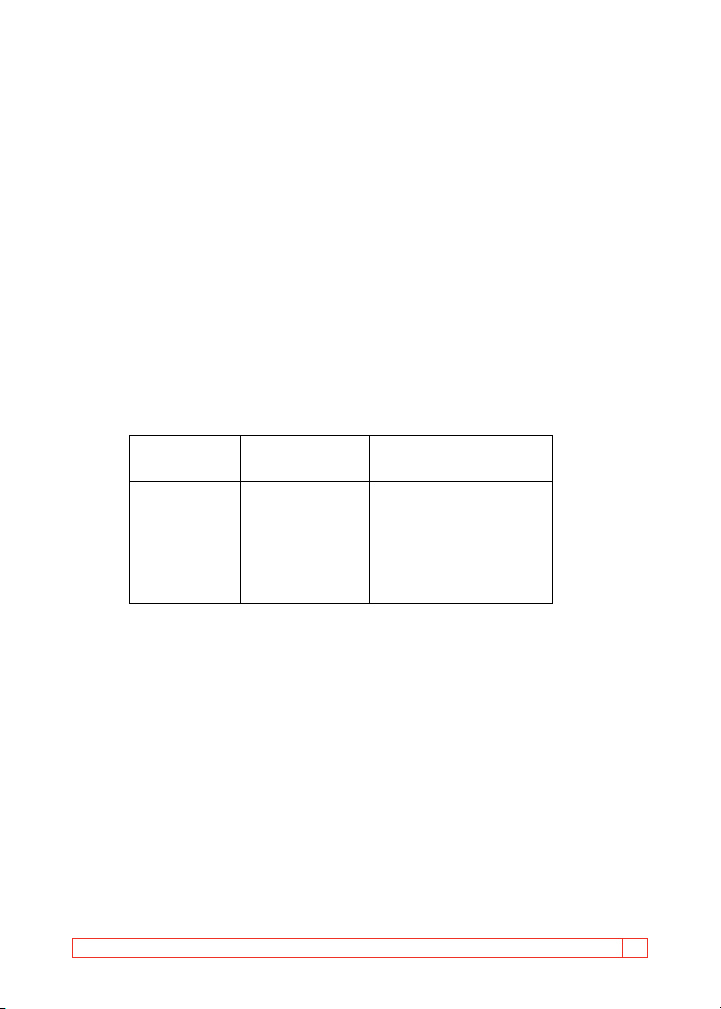

Dielectric Absorption Ratio

TABLE I — Condition of Insulation Indicated by

The ratio of two time-resistance readings (such as a 60-second reading

divided by a 30-second reading) is called a dielectric absorption ratio. It is

useful in recording information about insulation. If the ratio is a 10-minute

reading divided by a 1-minute reading, the value is called the polarization

index.

With hand-cranked Megger instruments, it’s a lot easier for you to run the

test for only 60 seconds, taking your first reading at 30 seconds. If you have a

line-operated Megger instrument, you’ll get best results by running the test

10 minutes, taking readings at 1- and at 10-minutes, to get the polarization

index. Table I gives values of the ratios and corresponding relative

conditions of the insulation that they indicate.

Dielectric Absorption Ratios*

INSULATION

CONDITION

Dangerous

A STITCH IN TIME 15

Questionable

Good

Excellent

*These values must be considered tentative and relative—

subject to experience with the time-resistance method

over a period of time.

**In some cases, with motors, values approximately 20%

higher than shown here indicate a dry brittle winding which

will fail under shock conditions or during starts. For preventive maintenance, the motor winding should be cleaned,

treated, and dried to restore winding flexibility.

***These results would be satisfactory for equipment with very

low capacitance such as short runs of house wiring.

60/30-SECOND

RATIO

—

1.0 to 1.25

1.4 to 1.6

Above 1.6**

10/1-MINUTE RATIO

(POLARIZATION INDEX)

Less than 1

1.0 to 2***

2 to 4

Above 4**

Page 17

TEST VOLTAGE VS. EQUIPMENT RATING

Commonly used DC test voltages for routine maintenance are as follows:

Equipment AC Rating DC Test Voltage

up to 100 volts 100 and 250 volts

440 to 550 volts 500 and 1,000 volts

2,400 volts 1,000 to 2,500 volts

or higher

4,160 volts and above 1,000 to 5,000 volts,

or higher

Test voltages used for proof testing of equipment are considerably higher

than those used for routine maintenance. Although there are no published

industry standards for DC maximum proof test voltages to be used with

rotating equipment, the schedule given below is customarily used. For

specific recommendations on your equipment, you should consult the

manufacturer of the equipment.

Proof Test Voltages for Rotating Equipment:

Factory AC Test = 2 x Nameplate Rating + 1000 volts

DC Proof Test on Installation = 0.8 x Factory AC Test x 1.6

DC Proof Test After Service = 0.6 x Factory AC Test x 1.6

Example:

Motor with 2,400 VAC nameplate rating–

Factory AC Test = 2(2,400) +1,000 = 5,800 VAC

Max. DC Test on Installation = 0.8(5,800)1.6 = 7,424 VDC

Max. DC Test After Service = 0.6(5,800)1.6 = 5,568 VDC

16 A STITCH IN TIME

Page 18

AC TESTING VS. DC

Up to now, we’ve talked about testing with DC voltage, but you will hear

of AC testing and need to know the difference. Remember that we spoke

of the kinds of current produced in insulation by DC? (The initial surge of

charging current, the drop with time to absorption current, and then, after

more time, the steady conduction current.) We saw that in insulation testing,

the conduction or leakage current is the one that gives us the information

we need.

In contrast, testing with AC gives a charging current that is extremely

large compared to the other kinds; leakage current is relatively minor. AC

frequently is used for high-potential testing; voltage is increased to some

specified point to see if the insulation can stand that particular voltage. It

is a GO/NO-GO type of test and can cause deterioration of the insulation, in

contrast to the DC test which is basically non-destructive.

If an AC test voltage has been used and you want to use DC tests as

an alternative, you will need to increase the maximum DC test voltage

somewhat to obtain equivalent results.

In some cases, AC testing may be more suitable for proof testing of

equipment (that is, seeing that the equipment meets prescribed standards).

You run the voltage up to the selected value and the equipment either

passes or doesn’t pass the test. With the DC test, you get a more qualitative

picture; you can meter the leakage current as you increase the voltage and

obtain specific values of insulation resistance.

As the size of your equipment increases, there are also marked economic

advantages in DC over AC testing. As the test voltage increases, both the

cost and weight of AC equipment go up much faster than with comparable

DC test equipment. This is because the AC test set must supply the charging

current which becomes and remains very high in the larger machines. As

explained previously, in DC testing, this current drops rapidly after the initial

charging period.

A STITCH IN TIME 17

Page 19

In summary, DC test sets are employed almost exclusively for high-voltage

maintenance and field testing for the following reasons:

1. Lower cost

2. Lighter weight

3. Smaller size

4. Non-destructive

5. Better information, both in quality and quantity

USE OF DC DIELECTRIC TEST SET

The Megger instrument, reading directly in ohms and megohms of

insulation resistance, is your best bet for routine in-plant maintenance.

However, some plants, particularly with higher voltage ratings in equipment,

use another Megger product – the dielectric test set. So, you should be

aware of this instrument and its use in insulation resistance measurements.

The dielectric test set can be used to determine insulation resistance by the

same test methods as outlined for the Megger instrument; that is, the shorttime, time-resistance and step-voltage tests. It is designed for other uses, too,

but for insulation testing it provides: (1) an adjustable output voltage and

(2) a monitoring of the resultant current in micro-amperes. The Megger DC

Dielectric Test Sets are available with voltage outputs ranging from 5 kV up

to 160 kV.

The curves of Fig. 5 are plotted as current versus time, as are curves for

insulation measurements on typical equipment given near the end of this

manual. Megger supplies graph paper which makes it easy to plot megohms

of insulation resistance from your voltage and current readings.

TESTS DURING DRYING OUT OF EQUIPMENT

Wet electrical equipment is a common hazard faced by all maintenance

engineers. If the equipment is wet from fresh water, you go right ahead

drying it out. However, if you’ve got salt water, you must first wash away the

salt with fresh water. Otherwise, you’ll leave very corrosive deposits of salt

on metal and insulating surfaces as well as in crevices of the insulation. With

moisture, such deposits form a very good conductor of electricity. Also, you

should remove oil or grease from the insulation, using a suitable solvent.

18 A STITCH IN TIME

Page 20

There are various ways to dry out electrical equipment, depending upon

its size and portability. You can use a blast of hot air, an oven, circulation

of current through conductors, or a combination of techniques. Local plant

conditions and facilities, together with information from the equipment

manufacturers, can serve as a guide to the best method for your particular

equipment.

In some cases, or with certain equipment, drying out may not be necessary.

You can check this by insulation resistance tests, if you have records of

previous tests on the apparatus. When drying out is required, such records

are also helpful to determine when the insulation is free of moisture.

NOTE: Wet equipment is susceptible to voltage breakdown. Therefore, you

should use a low-voltage Megger tester (100 or 250 VDC), at least

in the early stages of a drying-out run. If a low-voltage instrument

is not readily available, slow cranking of a 500-volt tester may be

substituted.

Many testers have an additional test range measuring in kilohms

(kW). This measurement is typically made at only a few volts, and

is the ideal initial measurement to be made on flooded equipment.

This range measures below the Megohm range, and can, therefore,

provide an actual measurement to use as a benchmark in monitoring

the drying process. If a kilohm measurement is obtained, insulation

has been thoroughly saturated, but may be reclaimable. Alternately

test and dry, watching the readings rise until they reach the Megohm

range, at which time higher voltage tests can be safely employed.

As an example of how important past readings are, let’s look at a 100-hp

motor that’s been flooded. After a clean-up, a spot reading with the Megger

tester shows 1.5 megohms. Offhand, you’d probably say this is ok. What’s

more, if past records showed the insulation resistance to run between 1 and

2 megohms, you’d be sure.

On the other hand, if past records showed the normal resistance values to

run 10 or 20 megohms, then you would know that water was still in the

motor windings.

A STITCH IN TIME 19

Page 21

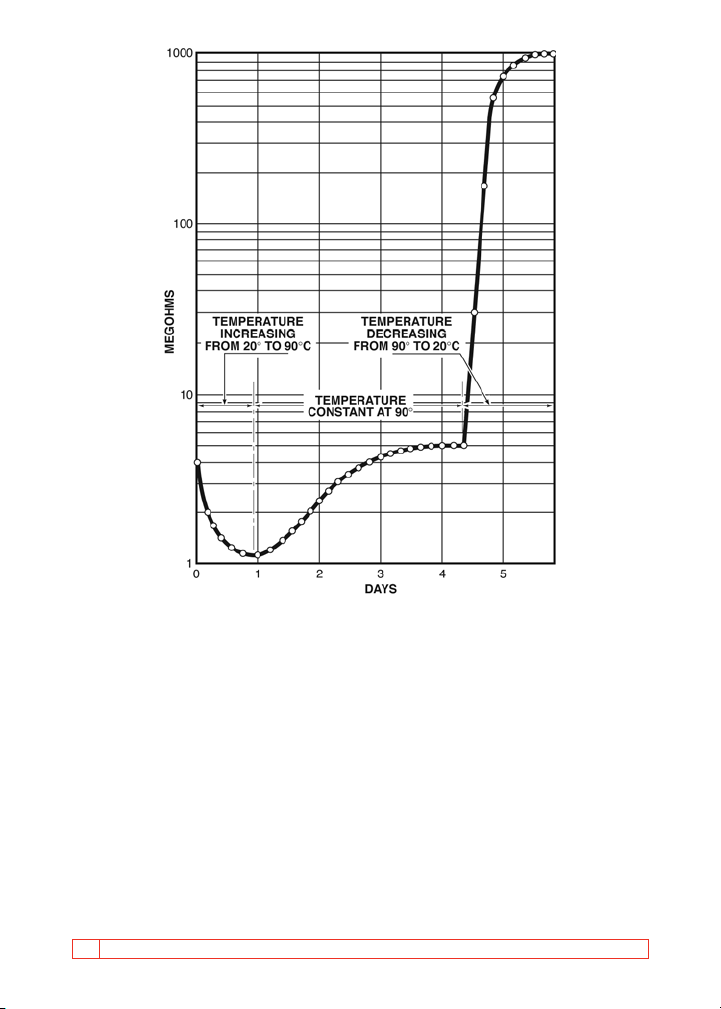

Figure 10-Typical drying curve where one-minute readings of insulation resistance are taken every

four hours.

The typical drying-out curve for a DC motor armature (Fig. 10) shows how

insulation resistance changes. During the first part of the run, the resistance

actually decreases because of the higher temperature. Then it rises at a

constant temperature as drying proceeds. Finally, it rises to a high value, as

room temperature (20°C) is reached.

Note that if you conduct insulation resistance tests during drying, and you

have readings of previous tests on the dry equipment, you’ll know when

you’ve reached the safe value for the unit. You may prefer to use a timeresistance test, taken periodically (say, once a shift), using the dielectric

absorption ratio or polarization index to follow dry-out progress (no need to

correct for temperature).

20 A STITCH IN TIME

Page 22

EFFECT OF TEMPERATURE ON INSULATION RESISTANCE

The resistance of insulating materials decreases markedly with an increase in

temperature. As we’ve seen, however, tests by the time-resistance and stepvoltage methods are relatively independent of temperature effects, giving

relative values.

If you want to make reliable comparisons between readings, you should

correct the readings to a base temperature, such as 20°C, or take all your

readings at approximately the same temperature (usually not difficult to do).

We will cover some general guides to temperature correction.

One thumb rule is:

For every 10°C increase in temperature,

halve the resistance;

or, for every 10°C decrease,

double the resistance.

For example, a two-megohm resistance at 20°C reduces to

at 40°C.

Each type of insulating material will have a different degree of resistance

change with temperature. Factors have been developed, however, to

simplify the correction of resistance values. Table II gives such factors for

rotating equipment, transformers and cable. You multiply the readings you

get by the factor corresponding to the temperature (which you need to

measure).

For example, assume you have a motor with Class A insulation and you get a

reading of 2.0 megohms at a temperature (in the windings) of 104°F (40°C).

From Table II you read across at 104°F to the next column (for Class A) and

obtain the factor 4.80. Your corrected value of resistance is then:

1

/2 megohm

2.0 megohms x 4.80 = 9.6 megohms

(reading (correction (corrected

at 104°F) factor for reading for

Class A 68°F or 20°C)

insulation

at 104°F)

A STITCH IN TIME 21

Page 23

Note that the resistance is almost five times greater at 68°F (20°C), as

compared to the reading taken at 104°F. The reference temperature for

cable is given as 60°F (15.6°C), but the important point is to be consistent

and correct to the same base.

TABLE II-Temperature Correction Factors*

ROTATING

TEMP. CABLES

EQUIP.

ϒC

ϒF

CLASS A

CLASS B

OIL-FILLED

TRANSFORMERS

CODE

NATURAL

CODE

GR-S

PERFORMANCE

NATURAL

HEAT RESIST.

NATURAL

HEAT RESIST. &

PERFORM. GR-S

OZONE RESIST.

NATURAL GR-S

VARNISHED

CAMBRIC

IMPREGNATED

PAPER

0

32

0.21

0.40

0.25

0.25

0.12

0.47

0.42

0.22

0.14

0.10

5

41

0.31

0.50

0.36

0.40

0.23

0.60

0.56

0.37

10

50

0.45

0.63

0.50

0.61

0.46

0.76

1.83

3.67

7.32

1.00

1.24

1.58

2.00

2.55

3.26

4.15

5.29

6.72

8.58

0.73

1.00

1.28

1.68

2.24

2.93

3.85

5.08

6.72

8.83

11.62

15.40

20.30

26.60

15.6

60

0.71

0.81

0.74

1.00

1.00

20

68

1.00

1.00

1.00

25

77

1.48

86

95

104

113

122

131

140

149

158

167

2.20

3.24

4.80

7.10

10.45

15.50

22.80

34.00

50.00

74.00

1.25

1.58

2.00

2.50

3.15

3.98

5.00

6.30

7.90

10.00

12.60

30

35

40

45

50

55

60

65

70

75

*Corrected to 20ϒ C for rotating equipment and transformers; 15.6ϒ C for cable.

1.40

1.98

2.80

3.95

5.60

7.85

11.20

15.85

22.40

31.75

44.70

1.47

2.27

3.52

5.45

8.45

13.10

20.00

14.60

29.20

54.00

116.00

0.58

1.00

1.53

2.48

4.03

6.53

10.70

17.10

27.85

45.00

73.00

118.00

193.00

313.00

0.26

0.49

1.00

1.75

3.29

6.20

11.65

25.00

41.40

78.00

0.20

0.43

1.00

1.94

4.08

8.62

18.20

38.50

81.00

170.00

345.00

775.00

0.28

0.43

0.64

1.00

1.43

2.17

3.20

4.77

7.15

10.70

16.00

24.00

36.00

22 A STITCH IN TIME

Page 24

Nomograph of temperature correction values for Megger readings

(corrected to 25°C). For rotating machinery with Class B insulation.

EFFECTS OF HUMIDITY

We have spoken at various points in this manual about the presence of

moisture in insulation and its very marked effect upon resistance values. You

might expect, therefore, that increasing humidity (moisture content) in the

surrounding (ambient) air could affect insulation resistance. And it can to

varying degrees.

If your equipment operates regularly above the dew-point temperature (the

temperature at which the moisture vapor in air condenses as a liquid), the

test reading normally will not be affected much by the humidity. Even if the

equipment to be tested is idle, the same is true – so long as its temperature is

kept above the dew point.

A STITCH IN TIME 23

Page 25

The aforementioned statement assumes that the insulation surfaces

are free of contaminants, such as certain lints and acids or salts,

which have the property of absorbing moisture (they’re called

“hygroscopic” or “deliquescent” materials by chemists). Their

presence could unpredictably affect your readings; they should be

removed before tests are made.

In electrical equipment we’re concerned primarily with the conditions on

the exposed surfaces where moisture condenses and affects the overall

resistance of the insulation. Studies show, however, that dew will form in the

cracks and crevices of insulation before it is visibly evident on the surface.

Dew-point measurements will give you a clue as to whether such invisible

conditions might exist, altering the test results.

As a part of your maintenance records, therefore, it’s a good idea to make

note at least of whether the surrounding air was dry or humid when the

test was made. Also, whether the temperature was above or below the

ambient. When you test vital equipment, record the ambient wet and dry

bulb temperatures, from which dew-point and percent relative or absolute

humidity can be obtained.

PREPARATION OF APPARATUS TO TEST

1. Take Out of Service

Shut down the apparatus. Open switches. De-energize. Disconnect from

other equipment and circuits, including neutral and protective (workmen’s

temporary) ground connections. See Safety Precautions, page 26.

2. Make Sure Just What is Included in the Test

Inspect the installation very carefully to determine just what equipment

is connected and will be included in the test, especially if it is difficult or

expensive to disconnect associated apparatus and circuits. Pay particular

attention to conductors that lead away from the installation. This is very

important, because the more equipment that is included in a test, the lower

the reading will be, and the true insulation resistance of the apparatus in

question may be masked by that of the associated equipment.

It is always possible, of course, that the insulation resistance of the complete

installation (without disconnecting everything) will be satisfactorily high,

especially for a spot check. Or, it may be higher than the range of the

24 A STITCH IN TIME

Page 26

Megger instrument in use, in which case nothing would be gained by

separating the components, because the insulation resistance of each part

would be still higher.

For an initial test, it may be necessary to separate the component parts, even

though labor and expense are involved, and test each one separately. Also

make a test of all the components connected together. With this information

on record, it may not be necessary to separate the components on future

tests unless unaccountably low readings are observed.

3. Discharge of Capacitance

It is very important that capacitance be discharged, both before and after

an insulation resistance test. It should be discharged for a period about four

times as long as test voltage was applied in a previous test.

Megger instruments are frequently equipped with discharge circuits for this

purpose. If a discharge function is not provided, a discharge stick should be

used. Leave high capacitive apparatus (i.e., capacitors, large windings, etc.)

short circuited until ready to re-energize.

4. Current Leakage at Switches

When apparatus is shut down for the insulation resistance test, make sure

that the readings are not affected by leakage over or through switches or

fuse blocks, etc. Such leakage may mask the true insulation resistance of the

apparatus under test. See Use of a Guard Terminal, page 50.

Or, what may be more serious, current from an energized line may leak into

the apparatus and cause inconsistent readings, particularly if the live line is

DC. However, such leakage usually can be detected by watching the pointer

of the Megger instrument at the moment the test leads are connected to

the apparatus and before the instrument is operated. Before making these

observations, be sure that all capacitance is discharged by short circuiting or

grounding the apparatus.

CAUTION: Never connect a Megger insulation tester to energized

lines or equipment. Never use the tester or any of its leads or

accessories for any purpose not described in this book.

A STITCH IN TIME 25

Page 27

SAFETY PRECAUTIONS

Observe all rules for safety when taking equipment out of service. Block out

disconnect switches. Test for foreign or induced voltages. Apply workmen’s

grounds.

Remember that when working around high voltage equipment there is

always a possibility of voltages being induced in apparatus under test

or lines to which it is connected, because of proximity to energized high

voltage equipment. Therefore, rather than removing a workmen’s ground in

order to make a test, it is more advisable to disconnect the apparatus, such

as a transformer or circuit breaker, from the exposed bus or line, leaving the

latter grounded. Use rubber gloves when connecting the test leads to the

apparatus and while operating the Megger instrument.

Apparatus Under Test Must Not Be Live!

See page 24 on Preparation of Apparatus for Test.

If neutral or other ground connections have to be disconnected, make sure

they are not carrying current at the time, and that when disconnected no

other equipment will lack necessary protection.

Pay particular attention to conductors that lead away from the circuit being

tested and make sure they have been properly disconnected from any source

of voltage.

Shock Hazard from Test Voltage

Observe the voltage rating of the Megger instrument and regard it with

appropriate caution. Large electrical equipment and cables usually have

sufficient capacitance to store up a dangerous amount of energy from the

test current. Make sure this capacitance is discharged after the test and

before handling the test leads. See also Discharge of Capacitance, page 25.

Explosion and Fire Hazard

So far as is known, there is no fire hazard in the normal use of a Megger

insulation tester. There is, however, a hazard when testing equipment

located in inflammable or explosive atmospheres.

26 A STITCH IN TIME

Page 28

Slight sparking may be encountered:

(1) When attaching the test leads to equipment in which the capacitance

has not been completely discharged

(2) During a test, arcing through or over faulty insulation

(3) Following a test when capacitance is discharged

CAUTION:

Do not use the instrument

in an explosive atmosphere.

Suggestions:

For (1) and (3): Arrange permanently installed grounding facilities and

test leads to a point where instrument connections can be made in a safe

atmosphere.

For (2): Use low-voltage testing instruments, or a series resistance.

For (3): Do not disconnect the test leads for at least 30 to 60 seconds

following a test, allowing time for capacitance discharge.

CONNECTIONS FOR TESTING INSULATION RESISTANCE

OF ELECTRICAL EQUIPMENT

The following diagrams show how to connect a Megger insulation tester to

various types of electrical equipment. The diagrams also show in principle

how equipment must be disconnected from other circuits before the

instrument is connected.

These illustrations are typical and will serve as guides for testing insulation

resistance of practically all types of apparatus and conductors.

Before proceeding with tests, read the article on Preparation of Apparatus

for Test, page 24.

REMEMBER! The Megger insulation resistance tester measures

whatever resistance is connected between its terminals. This may

include series or parallel leakage paths through insulation or over

its surface.

A STITCH IN TIME 27

Page 29

1. AC Motors & Starting Equipment

Figure 11

Connections for testing the insulation resistance of a motor, starting

equipment and connecting lines, in parallel. Note that the starter switch is

in the “on” position for the test. It is always preferable to disconnect the

component parts and test them separately in order to determine where

weaknesses exist.

2. DC Generators & Motors

Figure 12

With the brushes raised as indicated, the brush rigging and field coils can be

tested separately from the armature. Likewise the armature can be tested by

itself. With the brushes lowered, the test will be that of brush rigging, field

coils and armature combined.

28 A STITCH IN TIME

Page 30

3. Wiring Installation

Figure 13

Connections for testing to ground each circuit separately, working from the

distribution panel.

Figure 14

A STITCH IN TIME 29

Page 31

Connections at the main power board, from which point the entire

system can be tested to ground at one time, providing all switches in the

distribution panel are closed.

4. Appliances, Meters, Instruments & Miscellaneous Electrical Apparatus

Figure 15

Connections for testing an appliance. The test is made between the

conductor (the heating unit, motor, etc.) and exposed metal parts. The

apparatus must be disconnected from any source of power and placed on

some insulating material.

5. Control, Signaling & Communication Cables

Figure 16

Connections for testing insulation resistance of one wire in a multiconductor cable against all other wires and sheath connected together.

30 A STITCH IN TIME

Page 32

I6. Power Cables

Connections for testing the insulation resistance of a power cable. When

testing cable, it is usually best to disconnect at both ends in order to test

the cable by itself, and to avoid error due to leakage across or through

switchboards or panelboards. See also Use of Guard Terminal, page 50.

Figure 17

Figure 18

A STITCH IN TIME 31

Page 33

7. Power Transformers

Figure 19

Connections for testing insulation resistance of a transformer high voltage

winding and bushings, and the high tension disconnect switch, in parallel,

with reference to the low voltage winding and ground. Note that the low

voltage winding is grounded for this test.

8. AC Generators

Figure 20

With this connection, the insulation resistance will be that of the generator

stator winding and connecting cable combined. To test either the stator

winding or the cable itself, the cable must be disconnected at the machine.

32 A STITCH IN TIME

Page 34

ADDITIONAL NOTES ABOUT USING A MEGGER INSULATION TESTER

Testing Leads

Inferior or defective testing leads will cause erroneous and misleading results

of insulation resistance tests. Take care in this respect.

Uninsulated Leads

To avoid error due to the insulation of leads, place the Megger instrument

close to the ungrounded terminal or conductor of the apparatus under test

and connect a short piece of light bare wire directly from the Line terminal

of the instrument to the apparatus. If the Guard terminal is used, it may be

treated similarly. No. 18 or 20 gauge, solid wire will suffice. Support the lead

only by its connections to the instrument and the apparatus.

With this method of connecting from the Line terminal, the quality of the

insulation, if any, of the Earth or Ground lead becomes unimportant.

Insulated Leads

Where dependence is placed on the insulation of leads, they must be

durable and of the best quality insulating material. Oil resistant, synthetic,

rubber-insulated, single-conductor No. 14 stranded wire is recommended.

The outer jacket should be smooth, with no outer braid. Lugs should be

fitted for attaching to the instrument terminals, and stout spring clips are

recommended for connecting to the apparatus or circuit under test. Any

convenient length of lead may be used. Joints are to be avoided.

After connecting the leads to the instrument, and just before connecting

them to the apparatus, make sure there is no leak from lead to lead. Do this

by operating the instrument, which should read Infinity. Do not correct slight

lead leakage by attempting to reset the Infinity Adjuster on a high-range

instrument. Then touch the test ends of the leads together to make sure

they are not disconnected or broken.

Current testing with the high-range (50,000 megohms) Megger insulation

testers requires that the Line test lead be maintained at a high value so that

it will not enter into the measurement. The shielded test lead, with the shield

connected to Guard, prevents any leakages over its terminations or through

the lead insulating material, from being measured.

A STITCH IN TIME 33

Page 35

Instructions for Use

The untagged end of the shielded lead is to be connected to the Line and

Guard terminals of the Megger instrument – the end terminal to Line and

the side (shield) terminal to Guard. The clip on the Line lead is connected to

the apparatus under test in the regular way. The outboard Guard terminal

may be connected to that part of the apparatus under test which the user

wishes to guard. The conductor employed in making this connection must be

insulated for the voltage rating of the Megger instrument used.

Effect of Capacitance

Capacitance in apparatus under test must be charged up to the rated DC

voltage of the Megger insulation tester, and maintained for 30 to 60 seconds

before a final reading is taken. Make sure that capacitance is discharged,

by short circuiting and grounding the apparatus before connecting the test

leads. See Discharge of Capacitance, page 25.

NOTE: Capacitance causes the pointer to swing towards zero while the

instrument is being brought up to speed, and to swing off scale beyond

infinity when the generator is slowing down. This is simply the charge

flowing into and out of the capacitance and through the deflecting coil of

the ohmmeter.

Capacitance effects are most noticeable in large generators, in power and

communication cable more than a few hundred feet in length, and in

capacitors. In general, these effects are small with capacitance of less than

0.01 F. It becomes more noticeable as capacitance and/or the sensitivity

of the instrument increases. The heavy-duty series of Megger insulation

testers can be used on large capacitors with good results, particularly when

operated from the power line rather than the hand crank.

Operating Time

A very important consideration in making insulation resistance tests is the

time required for the reading of insulation resistance to reach a maximum.

The time required to charge the geometric capacitance is very short – usually

no more than a few seconds – and that which causes further delay in

reaching full charge is a dielectric absorption effect. It may be a matter of

minutes or even hours for this electrification time to be completed, and for

the pointer to reach an absolute maximum.

34 A STITCH IN TIME

Page 36

Short-Time Readings

For short-time readings of insulation resistance, operate the instrument for

a definite length of time, either 30 seconds or 1 minute, and read at the end

of that time. Continue cranking steadily at slip speed until the reading has

been taken. Make future tests with the same length of operating time.

Time-Resistance Method

When using a hand-cranked instrument, operate continuously for 1 minute.

Take a reading at the end of the first 30 seconds and another reading at the

end of the minute.

When using a motor-driven or rectifier-operated instrument, the time

intervals are usually 1 minute and 10 minutes from the time the testing

voltage is applied. Or, time-resistance curves may be taken over a period of

10 to 30 minutes or longer.

Voltage Scales

Some insulation testers may be supplied with a voltage scale to check for

the absence of voltage before insulation testing. As explained in the Safety

Precautions section, however, insulation testers should never be connected

to energized lines or equipment when operated in any of the Insulation Test

or Resistance Test modes.

A STITCH IN TIME 35

Page 37

INTERPRETATION-MINIMUM VALUES

Insulation resistance of electrical equipment is affected by many variables

such as the equipment design; the type of insulating material used, including

binders and impregnating compounds; the thickness of the insulation and

its area; cleanliness, moisture and temperature. For insulation resistance

readings to be a conclusive measure of the condition of the equipment

being tested, these variables must be taken into consideration.

After the equipment has been put into service, factors such as the design of

the equipment, the kind of insulating material used, and its thickness and

area cease to be variables, allowing minimum insulation resistance values

to be established within reasonable tolerances. The variables that must be

considered after the equipment had been put into service, and at the time

that the insulation resistance measurements are being made, are cleanliness,

moisture, temperature and mechanical damage (such as fractures).

Good Housekeeping

The most important requirements in the reliable operation of electrical

equipment are cleanliness, and the elimination of moisture penetration

into the insulation. This may be considered as good housekeeping, and

is essential in the maintenance of all types of electrical equipment. The

very fact that insulation resistance is affected by moisture and dirt, with

due allowances for temperature, makes the Megger insulation tester the

valuable tool that it is in electrical maintenance. It is at once a gauge of

cleanliness and good housekeeping as well as a detector of deterioration

and impending trouble.

What Readings to Expect – Periodic Tests

Several criteria for minimum values of insulation resistance have been

developed and are summarized here. They should serve as a guide for

equipment in service. However, periodic tests on equipment in service will

usually reveal readings considerably higher than the suggested minimum

safe values.

36 A STITCH IN TIME

Page 38

Therefore, it is strongly recommended that records of periodic tests be kept,

because persistent downward trends in insulation resistance usually give fair

warning of impending trouble, even though the actual values may be higher

than the suggested minimum safe values.

Conversely, allowances must be made for equipment in service showing

periodic test values lower than the suggested minimum safe values, so

long as the values remain stable or consistent. In such cases, after due

consideration has been given to temperature and humidity conditions at the

time of test, there may be no need for concern. This condition may be caused

by uniformly distributed leakages of a harmless nature, and may not be the

result of a dangerous localized weakness.

Here again, records of insulation resistance tests over a period of time reveal

changes which may justify investigation. The trend of the curve may be more

significant than the numerical values themselves.

The One-Megohm Rule

For many years one megohm has been widely used as a fair allowable lower

limit for insulation resistance of ordinary industrial electrical equipment

rated up to 1000 volts, and is still recommended for those who may not be

too familiar with insulation resistance testing practices, or who may not wish

to approach the problem from a more technical point of view.

For equipment rated above 1000 volts the one megohm rule is usually

stated as a minimum of one megohm per thousand volts. Although this

rule is somewhat arbitrary, and may be criticized as lacking an engineering

foundation, it has stood the test of a good many years of practical

experience. It gives some assurance that equipment is not too wet or dirty

and has saved many an unnecessary breakdown.

More recent studies of the problem, however, have resulted in formulas

for minimum values of insulation resistance that are based on the kind of

insulating material used and the electrical and physical dimensions of the

types of equipment under consideration.

A STITCH IN TIME 37

Page 39

MINIMUM VALUES FOR INSULATION RESISTANCE

Rotating Machinery

The IEEE guide, “Recommended Practices for Testing Insulation Resistance of

Rotating Machinery”, deals with the problem of making and interpreting

insulation resistance measurements for rotating machinery. It reviews the

factors which affect or change insulation resistance characteristics, outlines

and recommends uniform methods for making tests, and presents formulas

for the calculation of approximate minimum insulation resistance values for

various types of AC and DC rotating machinery. The guide states:

“The recommended minimum insulation resistance Rm for alternating-current

and direct-current machine armature windings and for field windings of

alternating-current and direct-current machines can be determined by:

R

= kV + 1

where:

= recommended minimum insulation resistance in megohms

R

m

at 40°C of the entire machine winding

kV = rated machine terminal to terminal potential, in kilovolts

In applications where the machine is vital, it has been considered good

practice to initiate reconditioning should the insulation resistance, having

been well above the minimum value given by Eq 2, drop appreciably to near

that level.”

It is recommended that those who operate and maintain rotating machinery

obtain copies of the IEEE publication, “Recommended Practices for Testing

Insulation Resistance of Rotating Machinery”, which can be obtained by

writing the IEEE at 345 East 47th St., New York, NY, 10017.

m

Bushings

In the case of outdoor oil circuit breaker bushings, experience has shown

that any bushing, with its assembled associated insulating members,

should, for reliable operation, have an insulation resistance value above

10,000 megohms at 20°C. This assumes that the oil within the tank is in

good condition, that the breaker is separated from its external connections

to other equipment, and that the porcelain weather shield is guarded.

This means that each component such as the stripped bushing itself,

cross-member, lift rod, lower arcing shield, etc., should have an insulation

resistance in excess of that value.

38 A STITCH IN TIME

Page 40

Any components which are superficially clean and dry and have values less

than 10,000 megohms are usually deteriorated internally, by the presence of

moisture or carbonized paths, to such an extent that they are not reliable

for good service unless reconditioned. This is particularly so when operating

under surge conditions such as during lightning disturbances. In the case of

the stripped bushing itself, the lower stem and upper weather shield must

be either perfectly clean or guarded before it is condemned as unreliable

because of an insulation resistance value less than 10,000 megohms.

What has been said for stripped oil circuit breaker bushings also applies

to bushings for other equipment, such as transformers. Since bushings

and other associated members have very high insulation resistance values

normally, a Megger insulation tester having a range of at least 10,000

megohms is necessary to test such equipment. Megger instruments having

ranges up to 50,000 megohms will permit observation of deteriorating

trends in bushings before they reach the questionable value of 10,000

megohms.

Cable and Conductors

Cable and conductor installations present a wide variation of conditions

from the point of view of the resistance of the insulation. These conditions

result from the many kinds of insulating materials used, the voltage

rating or insulation thickness, and the length of the circuit involved in the

measurement. Furthermore, such circuits usually extend over great distances,

and may be subjected to wide variations in temperature, which will have an

effect on the insulation resistance values obtained. The terminals of cables

and conductors will also have an effect on the test values unless they are

clean and dry, or guarded.

The Insulated Cable Engineers Association (ICEA) gives minimum values

of insulation resistance in its specifications for various types of cables and

conductors. These minimum values are for new, single-conductor wire and

cable after being subjected to an AC high voltage test and based on a DC

test potential of 500 volts applied for one minute at a temperature

of 60°F.

A STITCH IN TIME 39

Page 41

These standard minimum values (for single-conductor cable) are based on

the following formula:

R = K log

D/

10

d

where:

R = megohms per 1000 feet of cable

K = constant for insulating material

D = outside diameter of conductor insulation

d = diameter of conductor

Minimum Values of K at 60° F.

Insulation Type

Impregnated Paper ................................................................... 2,640

Varnished Cambric .................................................................... 2,460

Thermoplastic-Polyethylene ........................................ above 50,000

Composite Polyethylene ......................................................... 30,000

Thermoplastic-Polyvinyl:

Polyvinyl Chloride 60°C ........................................................ 500

Polyvinyl Chloride 75°C ..................................................... 2,000

Grade Natural Rubber Synthetic Rubber

Code ...............................................................................................950

Performance ....................................... 10,560 ............................2,000

Heat Resistant..................................... 10,560 ............................2,000

Ozone Resistant...................... 10,000 (Butyl) ............................2,000

Kerite ..........................................................................................4,000

See pages 44 and 45 for Tables of Log

D/

10

d

40 A STITCH IN TIME

Page 42

The insulation resistance of one conductor of a multiconductor cable to all

others and sheath is:

R = K log

D/

10

d

where:

D = diameter over insulation of equivalent single-conductor cable

= d + 2c + 2b

d = diameter of conductor (for sector cables d equals diameter

of round conductor of same cross-section)

c = thickness of conductor insulation

b = thickness of jacket insulation

(all dimensions must be expressed in same units)

Transformers

Acceptable insulation resistance values for dry and compound-filled

transformers should be comparable to those for Class A rotating machinery,

although no standard minimum values are available.

Oil-filled transformers or voltage regulators present a special problem in that

the condition of the oil has a marked influence on the insulation resistance

of the windings.

In the absence of more reliable data the following formula is suggested:

R = CE

√kVA

R = minimum 1-minute 500-volt DC insulation resistance in megohms

from winding to ground, with other winding or windings guarded,

or from winding to winding with core guarded

C = a constant for 20°C measurements

E = voltage rating of winding under test

kVA = rated capacity of winding under test

For tests of winding to ground with the other winding or windings

grounded, the values will be much less than that given by the formula.

R in this formula is based on dry, acid-free, sludge-free oil, and bushings

and terminal boards that are in good condition.

A STITCH IN TIME 41

Page 43

Values of C at 20°C

60-Hertz 25-Hertz

Tanked oil-filled type 1.5 1.0

Untanked oil-filled type 30.0 20.0

Dry or compound-filled type 30.0 20.0

This formula is intended for single-phase transformers. If the transformer

under test is of the three-phase type, and the three individual windings are

being tested as one, then:

E = voltage rating of one of the single-phase windings

(phase to phase for delta connected units and phase to

neutral for star connected units)

kVA = rated capacity of the completed three-phase winding under test

TESTS USING MULTI-VOLTAGE MEGGER INSULATION TESTERS

Maintenance practice trends indicate the value of testing insulation with

DC voltages at levels somewhat higher than the peak value of the rated AC

voltage of the equipment being tested. Such DC tests have in some cases

been shown to reveal non-destructively incipient weaknesses in insulation

which could not otherwise be found, except possibly by partial discharge

detection at non-destructive AC test voltage levels.

The technique involves the application of two or more DC voltages, and

critically observing any reduction of insulation resistance at the higher

voltage. Any marked or unusual reduction in insulation resistance for a

prescribed increase in applied voltage is an indication of incipient weakness.

It is important to mention that the merits of this technique arise from more

recent investigations which indicate that rather high DC voltage can be used

to detect weaknesses without damaging the insulation. The maximum value

of voltage which should be used will depend largely on the cleanliness and

dryness of the insulation to be tested.

In making tests on insulation at such DC voltages, the ohmmeter method

has at least two advantages. First, prescribed fixed voltages are switched

into use, and one instrument measurement made with the direct reading

ohmmeter. This is a simple and reproducible method compared to one in

which many choices of voltage are available. Another important advantage

42 A STITCH IN TIME

Page 44

of the ohmmeter can be explained by referring to Fig. 21. In this figure, the

change which may occur in leakage current after the absorption current has

disappeared is shown plotted in terms of insulation resistance against three

different voltages. Note that there is no change in resistance shown in the

figure between 500 and 1000 volts, indicating no change in the insulation

as a result of applying these two voltages. This is an assumption, but is a

condition which is not uncommon in practice. If the insulation continues to

be stable at 2500 volts, there will be no change in the insulation resistance

value obtained, which is shown by the dotted extension of the horizontal

line in the figure. When non-linear conditions appear at a higher voltage, the

voltage resistance curve reveals this very clearly by a lower resistance value,

indicated by the downward curve in the figure. The figure, therefore, reveals

the simplicity of determining the change in insulation stability by using three

fixed voltages which are easily reproducible when making three-voltage tests

on a routine basis.

Figure 21

We wish to emphasize that the curve in Fig. 21 indicates the resistance

change due to leakage current only, and not the absorption current which

may appear for a period of time with each change in voltage. It may be

necessary to wait an appreciable amount of time after each voltage change

for the absorption current to disappear before taking a reading.

A STITCH IN TIME 43

Page 45

129.

238.

847.

966.

055.

515.

084.

844.

614.

283.

453.

723.

103.

722.

612.

891.

381.

271.

761.

361.

551.

841.

672.

952.

052.

431.

3990.

521.

711.

801.

498.

608.

327.

546.

925.

594.

064.

924.

893.

563.

733.

113.

682.

668.

977.

896.

126.

605.

364.

044.

904.

973.

743.

023.

592.

172.

638.

157.

076.

495.

384.

054.

814.

883.

953.

823.

203.

872.

552.

408.

027.

146.

665.

354.

624.

593.

663.

833.

903.

482.

162.

SEHCNI–SSENKCIHTNOITALUSNI

077.

686.

906.

735.

134.

104.

173.

343.

613.

D

d

10

VALUES OF LOG

237.

156.

575.

505.

304.

373.

543.

813.

392.

196.

116.

835.

074.

373.

643.

813.

392.

962.

546.

865.

894.

234.

043.

413.

982.

562.

342.

495.

025.

354.

293.

503.

182.

752.

632.

512.

542.

422.

402.

735.

764.

404.

743.

762.

074.

504.

843.

692.

522.

740. 360. 870. 490. 901. 521. 141. 651. 271. 881. 302. 912. 432.

293.

433.

382.

932.

.loS

412101

.rtS

8

6

.M.Cro

.G.W.A

681.

602.

781.

171.

551.

54321

832.

242.

122

882.

462.

.

322.

402.

762.

442.

402.

581.

442.

322.

381.

661.

022.

102.

161.

641.

591.

771.

86

831.

521.

251.

1.

931.

621.

411.

201.

0/1

0/2

0/3

512.

402.

781.

371.

361.

751.

451.

641.

041.

262.

642.

922.

302.

391.

671.

361.

842.

232.

612.

332.

812.

302.

812.

402.

981.

202.

981.

571.

781.

371.

061.

861.

751.

541.

151.

041.

031.

231.

321.

311.

3690.

311.

401.

3290.

4580.

7870.

000,052

000,003

0/4

351.

091.

181.

561.

251.

341.

771.

861.

351.

141.

331.

461.

551.

141.

031.

221.

051.

241.

921.

911.

111.

631.

821.

611.

701.

001.

2590.

8880.

121.

411.

301.

5990.

1090.

3580.

9670.

601.

7980.

5480.

3670.

0070.

6860.

1370.

8860.

0260.

000,053

000,004

000,005

000,006

000,007

721.

841.

441.

731.

131.

911.

931.

531.

821.

221.

111.

921.

521.

021.

311.

301.

3490.

811.

511.

801.

401.

4990.

8490.

6580.

801.

501.

1790.

3490.

5980.

1580.

0770.

1680.

6380.

3970.

5570.

1860.

9470.

7270.

7860.

6560.

0950.

5660.

4460.

0850.

1550.

0050.

000,05

000,008

000,009

000,000,1

000,052,1

7

4390.

611.

011.

301.

5690.

4780.

011.

301.

4590.

8980.

2180.

201.

6490.

9980.

0380.

0570.

0780.

0180.

1670.

7860.

9870.

43

1960.

3260.

70.

8070.

8560.

9160.

8550.

5260.

1850.

6450.

2940.

1450.

2050.

2740.

5240.

6540.

3240.

7930.

7530.

000,005,1

000,057,1

000,000,2

000,005,2

Values continued on next page.

44 A STITCH IN TIME

Page 46

498.

067.

027.

876.

088.

647.

707.

666.

668.

437.

496.

356.

158.

027.

086.

046.

229.

638.

607.

766.

SEHCNI–SSENKCIHTNOITALUSNI

609.

D

d

10

VALUES OF LOG

988.

178.

358.

438.

418

397.

526.

256.

316.

128.

996.

736.

895.

408.

676.

226.

385.

787.

066.

606.

865.

077.

346.

985.

155.

157.

626.

275.

535.

137.

806.

455.

715.

217.

095.

525.

094.

754.

524.

204.

973.

953.

343.

713.

792.

182.

372.

762.

552.

046.

206.

165.

415.

084.

744.

514.

293.

963.

053.

433.

903.

826.

095.

945.

205.

964.

634.

504.

516.

875.

835.

306.

565.

525.

985.

355.

315.

675.

04

105.

5.

265.

625.

784.

745.

215.

474.

235.

794.

164.

615.

284.

544.

005.

664.

134.

384.

054.

514.

383.

194.

854.

524.

593.

373.

974.

644.

414.

483.

363.

664.

534.

304.

373.

253.

454.

224.

293.

263.

243.

144.

014.

083.

153.

133.

824.

793.

763.

933.

023.

414.

483.

553.

723.

903.

993.

073.

243.

513.

692.

583.

653.

923.

203.

482.

982.

063.

143.

623.

103.

182.

153.

233.

713.

292.

372.

143.

323.

803.

482.

562.

133.

313.

892.

572.

652.

123.

303.

982.

662.

842.

013.

392.

972.

752.

932.

003.

382.

962.

842.

032.

982.

272.

952.

832.

122.

872.

262.

942.

822.

212.

662.

052.

632.

812.

302.

542.

522.

012.

791.

781.

071.

372.

662.

062.

942.

932.

912.

402.

191.

181.

561.

662.

952.

252.

242.

232.

212.

791.

581.

671.

061.

852.

152.

542.

432.

522.

602.

091.

081.

071.

651.

991.

581.

471.

461.

052.

342.

732.

722.

812.

242.

632.

032.

912.

112.