Page 1

M

MFT1500/2, MFT1552 and MFT1553 Series

Multifunction Tester

USER MANUAL

Page 2

GSAFETY WARNINGS

■ Safety Warnings and Precautions must be read and understood before the instrument is used. They must be observed during use.

■ The circuit under test must be switched off, de-energised and isolated before test connections are made when carrying out insulation and continuity

tests.

■ Continuity of protective conductors and earthed equipotential bonding of new or modified installations must be verified before carrying out an earth

fault loop impedance test, or RCD test.

■ Circuit connections and exposed metalwork of an installation or equipment under test must not be touched.

■ The live circuit warning and Automatic discharge are additional safety features and should not be regarded as a substitute for normal safe working

practices.

■ Do not change the rotary switch positions while a test is in progress.

■ The LCD ‘neon’ voltage indicators cannot reveal a Neutral - Earth reversal. They cannot be relied upon to identify circuit correctness and are for

guidance only.

■ After insulation tests, capacitive circuits must be allowed to discharge before disconnecting test leads.

■ The instrument should not be used if any part of it is damaged.

■ Test leads, probes and crocodile clips must be in good order, clean and with no broken or cracked insulation.

■ Ensure that hands remain behind guards of probes/clips when testing.

■ UK Safety Authorities recommend the use of fused test leads when measuring voltage on high energy systems.

■ Replacement fuses must be of the correct type and rating.

Failure to fit the correctly rated fuse will result in damage to the instrument in the event of an overload.

■ The battery cover must be in place whilst conducting tests.

NOTE

THE INSTRUMENT MUST ONLY BE USED BY SUITABLY TRAINED AND COMPETENT PERSONS.

Users of this equipment and/or their employers are reminded that Health and Safety Legislation requires them to carry out valid risk assessments of all

electrical work so as to identify potential sources of electrical danger and risk of electrical injury such as inadvertent short circuits. Where the assessments

show that the risk is significant then the use of fused test leads constructed in accordance with the HSE guidance note GS38 'Electrical Test Equipment for

use by Electricians' should be used.

2

Page 3

CONTENTS

Safety Warnings 2

Description 4

Overview of MFT1500 Series 4

Instrument layout 4

Display 4

Control panel 4

Front switch panel 4

Connection panel 4

Test leads 4

Battery /fuse warning, fitting and replacement 5

Setup 5

Operation 6

General operation 6

Live circuit warning 6

Test button lock 6

Backlight (MFT1502/1552 and 1553 only) 6

Auto shut-off 6

Polarity indication 6

Illuminated switched probe 6

Operation 6

Voltage measurement (V) 7

Continuity 7

Continuity measurement 7

Lead null 8

Continuity buzzer 8

Buzzer threshold 8

Insulation 8

Insulation resistance 8

Insulation voltage ranges 8

Test lock 9

Loop impedance 9

NO TRIP (15 mA) loop test 10

High Current loop test 10

P-N and P-P loop test 11

PFC 12

Residual current device (RCD testing) 14

1/2I, I, 5I, 0 & 180° 14

RCD auto test sequence (MFT1552 only) 15

Ramp testing 15

DC Sensitive RCDs 16

Bluetooth downloading (MFT1553 only) 17

Technical specification 21

Accessories 24

Repair and warranty 25

Appendix - Additional Bluetooth information

(Attaching a Dongle) 26

Symbols used on the instrument are:

F Caution: risk of electric shock

G Caution: refer to accompanying notes

t Equipment protected throughout by Double

Insulation (Class II)

c Equipment complies with current EU directives.

>500V

G

Max 300 V

CAT III

Maximum nominal system voltage of 500 V

Maximum 300 V a.c. CAT III to Earth

g

3

Page 4

DESCRIPTION

Thank you for purchasing the MFT1500 Multifunction Tester. The

MFT1500 series of tester is compact and designed to perform all of the

functions required by the electrical contractor to fully test domestic,

commercial and industrial wiring. Specially designed to comply with UK,

European and other International wiring regulations and standards, the

MFT may be used on all single and three phase systems with rated voltages

up to 300 Volts a.c. rms to earth/ground.

All test leads supplied with the MFT form part of the measuring circuit of

the instrument and must not be modified or changed in any way, or be

used with any other electrical instrument or appliance.

A plug severed from the power cord

MUST be destroyed, as a plug

with bare conductors is hazardous in a live socket outlet.

OVERVIEW OF MFT SERIES

BLUE (RCD)

ORANGE (BUZZER THRESHOLD)

BLACK (BACKLIGHT)

(1502/1552/1553 ONLY)

YELLOW (TEST BUTTON)

RED (TEST LOCK)

(BLUETOOTH)

Connection

indicators

Ohms

Null

Warning

Continuity and

insulation

connections

Switched probe

Test selection

Display

Contact Noise warning

Battery cover (side panel)

RCD range

selection

Fuse warning

Battery status

Temperature

warning

LOOP & RCD

connections

Mains plug test

lead

4

Page 5

REPLACING FUSES AND BATTERIES

Battery and Fuse fitting/Replacement

Battery type: 8 x 1.5 V alkaline LR6 (AA). Rechargeable batteries must not

be used.

Fuse type: 500 mA (F) HBC 10 kA 500 V

Low battery warning symbol

Fuse blown symbol

Battery charge indication

The battery charge level is automatically indicated when the MFT is turned

on.

To replace batteries

Switch off the instrument and disconnect (the instrument) from any

electrical circuits.

Remove the battery cover.

Slide out the battery clip and remove the dead cells.

Refit new batteries following correct polarity as marked on the battery

holder.

Replace the battery holder and cover.

Note:- Incorrect battery cell polarity can cause electrolyte leakage,

resulting in damage to the instrument.

To replace the fuse

Should the main fuse fail, the symbol fwill be displayed.

Disconnect the instrument from any circuits.

Remove the battery cover as above.

The blown fuse should be replaced with a 500 mA (F) HBC 10 kA 500 V

fuse (Megger part no.25950-039)

f

b

Replace the battery cover.

Setup

RCD Touch voltage selection (to select either 25 V or 50 V)

1. With the instrument turned OFF, hold down the YELLOW test button

and turn the left hand rotary switch to any ON position.

2. Keep the button held down until the instrument displays the ‘SET’

warning.

3. Now release the TEST button.

4. Press the TEST button again to view the current setting for the touch

voltage.

The display shows the touch voltage limit, either ‘25 V’ or ‘50 V’.

Note: The MFT can also display the measured Touch Voltage on a bargraph display.

If the touch voltage display is active, a bar-graph display will also

appear.

5. Press the ORANGE (buzzer) button to change the touch voltage limit

setting.

6. Press the BLUE (RCD) button to turn the bar-graph display ON or

OFF.

7. Press the TEST button to exit from the set-up menu.

5

Page 6

OPERATION

GENERAL OPERATION

Note: These functions are generally applied and not limited to an

individual test function.

Live circuit warning - Test inhibit

Testing is automatically inhibited if:

During insulation testing - an external voltage >55 V is

present on the terminals

During continuity testing - a voltage >10 V is present on the

terminals

During RCD or No-Trip loop testing - a voltage >270 V is

present

During Loop testing - a voltage >480 V is present

Test button lock

To lock the test button hold down the RED L test lock button whilst

holding down the YELLOW TEST button.

Intelligent backlight (MFT1502/1552/1553 only)

Both the display and range knobs have a backlight. To activate, press the

BLACK Jbutton.

To disable the Intelligent backlight function, press the BLACK

and the RED Llock button together.

Repeat to enable the intelligent backlight.

Instrument auto shut-off

Automatically activated after 5 minutes of instrument inactivity.

To restore operation press the RED lock button or switch the instrument

off and on.

J

button

Polarity indication

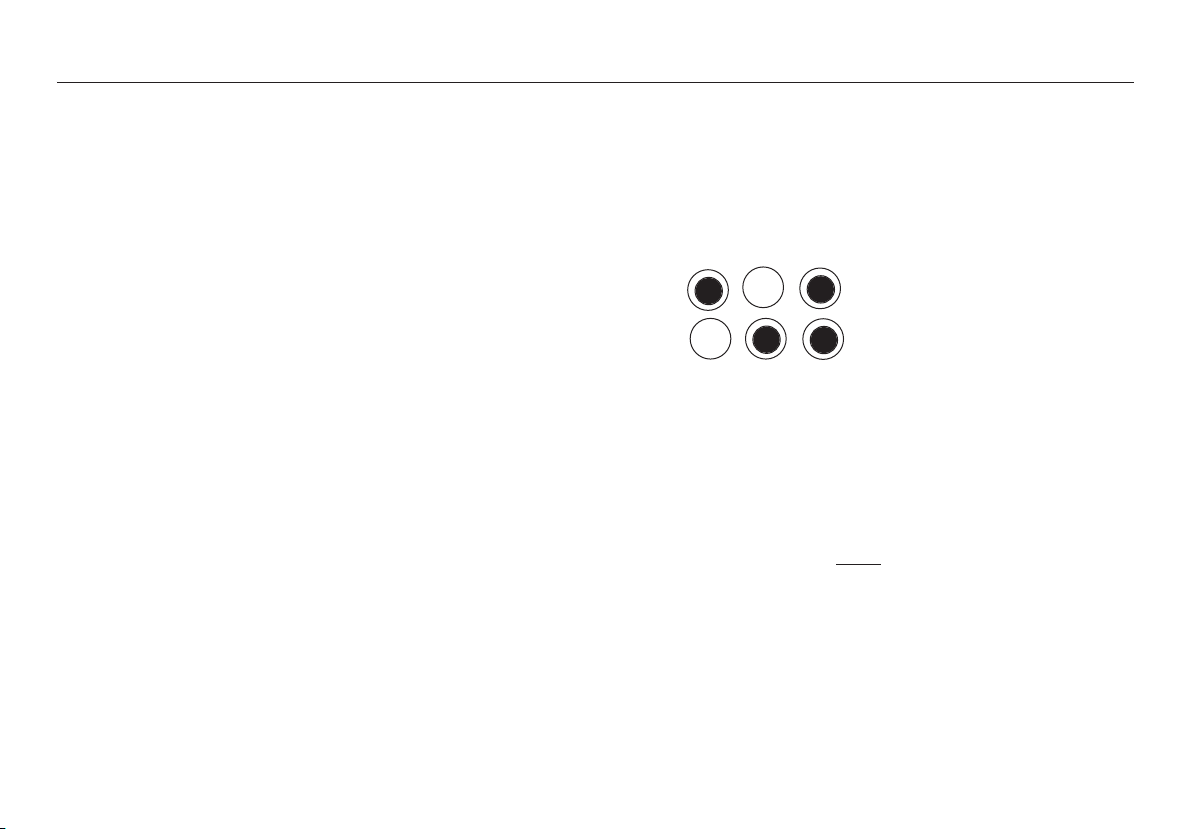

If connected to a single-phase power supply by a plug or by the 3-wire lead

set, three LCD ‘neons‘ marked L-PE, N-PE and L-N respectively will indicate

supply polarity.

If a voltage is detected between their respective two wires, the ‘neon’(s)

will activate.

L-PE N-PE L-N

Correct supply indication

Live –neutral swapped

Any other combinations should be investigated further. However the LCD

'NEONS' cannot be relied upon to identify circuit correctness and are for

guidance only.

Note:- The presence of a voltage between phase and earth does not prove

earth continuity, as the earth could have a high resistance and a voltage

would still be measured. To test earth continuity refer to the sections on

loop resistance or RCD testing.

Warning: The LCD 'Neons' are invalid when using the two wire lead-set

and should be ignored.

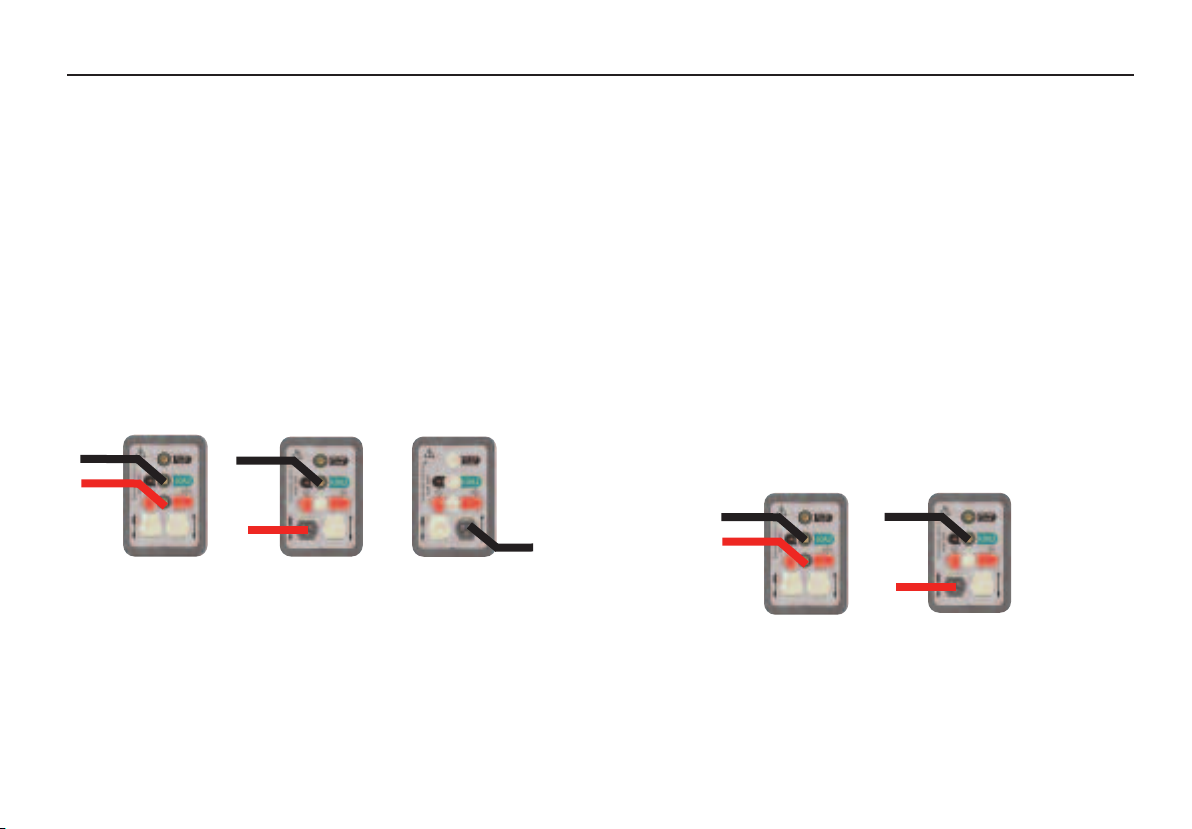

ILLUMINATED SWITCHED PROBE SPL1000 (MFT1502/1552/1553 ONLY)

The Illuminated switched probe accessory replaces the RED 4 mm test

lead. It can be used anywhere that the 4 mm lead set is specified in this

user guide, and it will also add extra resistance to a loop test measurement.

Operation (SPL1000)

The YELLOW button duplicates the function of the TEST key on the

instrument, allowing quick and easy testing.

6

Page 7

The BLACK switch operates a white LED, which illuminates the probe tip

for use when testing under low light levels.

There is also a visual indication via a red/green LED to notify the user of

the display status, the meanings are as follows:

Green : A valid result is present on the display or the

continuity buzzer is buzzing.

Red: A warning is being shown on the display, testing

will be inhibited.

VOLTAGE MEASUREMENT [V]

TEST LEAD CONNECTION

OPTION 1

2 wire lead

set

BLACK

RED

BLACK

PROBE

OPTION 2

Switched

probe

OPTION 3

Mains plug

test lead L-E

PLUG

OR Using the mains plug lead set (OPTION3)

Voltage between the L and E pins is displayed

Note:- When connected to the circuit under test the instrument will

automatically display AC or DC voltage measurement up to 500 V.

Warning: The voltage measurement range should not be used for

verifying power has been removed (isolated) from a circuit for testing of

documentation, a test lamp should be used.

This function will continue to work if the fuse is blown.

CONTINUITY

Z

Warning: Prior to any continuity testing, ensure the circuits under test are

isolated and not live

TEST LEAD CONNECTION

OPTION 1

2 wire lead

set

BLACK

RED

OPTION 2

Switched

probe

BLACK

Set the Rotary range knob to the [V] range

(The position of the right hand ‘mA’ rotary range knob does not matter)

Two wire lead set or Switched Probe connection

Using the 2-wire lead set OPTION 1 or OPTION 2

1. Connect the test leads as shown.

2. DC Voltage (V) or AC Voltage (V~) is automatically displayed.

PROBE

Set the left hand rotary range knob to the range required.

(The position of the right hand rotary range knob does not matter).

Continuity measurement can be made using one of the 2 options shown

above.

A continuity measurement is made automatically when the test leads

7

Page 8

are connected to the circuit under test. The contact symbol on the

display closes when a resistance of approximately 200 kΩ or less is

detected.

Lead null (up to 9.99 Ω)

Short test probes or clips together and press the YELLOW TEST button on

the instrument (or on the switched probe if fitted). The

displayed to indicate lead null is active.

This null value is stored until the YELLOW TEST button is pressed

again.

To cancel the LEAD NULL, press the YELLOW TEST button.

Continuity Buzzer

Test leads OPTIONS 1 or 2 above

The MFT buzzer will sound continuously if the resistance between the

leads is less than a set limit (Default value 2 Ω).

If being used with the illuminated switched probe (OPTION 2) continuity

is also indicated by a GREEN LED on the probe.

To turn off the buzzer press the TEST button whilst in BUZZER mode. The

display will indicate ON or OFF status.

Buzzer threshold

The resistance at which the buzzer stops sounding can be changed to

meet individual test requirements. Press the ORANGE Zbutton to select

the resistance limit.

Selectable limits of 2 Ω, 5 Ω, 10 Ω, 20 Ω, 50 Ω and 100 Ω.

This setting is stored even when the instrument is switched off.

Z

z

will be

Notes:Method of measurement

The 2-wire lead set must be used for this measurement. The instrument

produces a d.c. voltage of nominally 4,5 V with a current limit of at least

200 mA when measuring 2 Ω.

Possible sources of error

Measurement results can be affected by the following:

■ The impedance of operating circuits connected in parallel.

■ Impedance such as inductors that vary during the measurement.

■ A poor connection to the circuit under test, which can give readings as

much as 100 mΩ (0,10 Ω) high. The best way to avoid this error is to

use sharp prods and press these firmly into the conductors being

measured.

INSULATION RESISTANCE [MΩ] [250 V] [500 V] [1000 V]

Warning: Prior to any insulation testing, ensure the circuits under test are

isolated and not live.

TEST LEAD CONNECTION

OPTION 1

2 wire lead

set

BLACK

RED

OPTION 2

Switched

probe

BLACK

PROBE

8

Page 9

Set the left hand rotary range knob to the required INSULATION Range.

250 V Insulation measurement to 99.9 MΩ

500 V Insulation measurement to 299 MΩ

1000 V Insulation measurement to 499 MΩ

(The position of the right hand rotary range knob does not matter.)

To initiate insulation testing press and hold the YELLOW TEST button on

the instrument or the switched probe if connected.

Release the test button after the displayed reading has settled.

TEST LOCK

To lock down the test button press the YELLOW TEST button followed by

the RED LOCK L button.

A warning triangle

Press the YELLOW TEST button to stop the test.

Note:- A 1000 V warning is displayed whenever the 1000 V range is selected

and the test button pressed

Warning: The test voltage will be permanently present on the test probes

or crocodile clips when in the locked modes.

Notes:- Auto discharge - Auto discharge facility automatically and safely

discharges connected circuit after test via 250 kΩ resistor.

Live circuit warning - operates when connected to Live circuits > 25 V.

Test Inhibited - an audible alarm operates at >55 V. The instrument

will not perform a test until the voltage source has been removed.

G will appear in the display while the test lock is active.

Method of measurement

A current limited (2 mA) d.c source is used, and the resistance is calculated

from measurements of the voltage and current.

The voltage is only present when the test button is pressed or the test lock

is active. A measurement of the terminal voltage is made before the test and

if this exceeds 55 V the test is disabled. The reading is stable with a circuit

capacitance up to 5 µF.

LOOP IMPEDANCE [LOOP] TESTING

Loop impedance measurement can be made via installation sockets using

the plug terminated test lead at any other convenient point on the

installation, using a two/three wire lead set.

The MFT will measure the loop resistance from the supply end of the

standard test leads, allowing for their resistance.

NON TRIPPING LOOP TESTS [NO TRIP]

Set the LEFT rotary range knob to the required LOOP range as

described below:

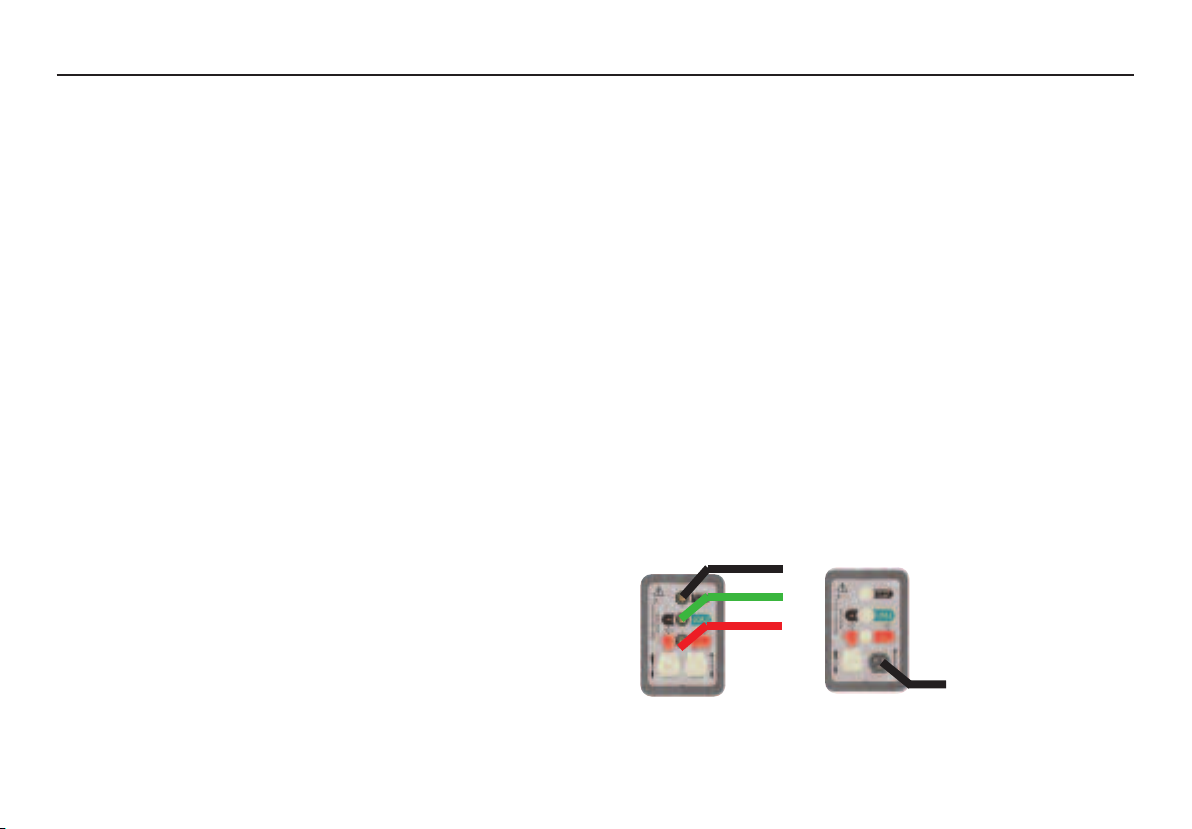

OPTION 1

3 wire

measurement

BLACK

GREEN

RED

(The position of the right hand rotary range knob does not matter.)

OPTION 2

Mains plug

test lead

PLUG

9

Page 10

[NO TRIP] LOOP-TESTING - SINGLE PHASE TESTING ONLY

The NO TRIP loop test is a high resolution low current earth loop resistance

measurement (Loop L-PE 0.01 Ω) range which does not trip RCDs with a

rated current 30 mA or higher.

[NO TRIP] PHASE TO EARTH LOOP IMPEDANCE MEASUREMENT

(AT A POWER SOCKET)

Test Lead set: OPTION 2

1. Select

NO TRIP Loop test range.

2. Insert the plug into an installation socket.

3. Supply voltage and polarity are displayed.

4. The test will ‘beep’ and automatically start when voltage is

detected.

5. Measured loop value is displayed

If desired the test can be repeated by pressing the YELLOW TEST button.

[NO TRIP] EARTH LOOP IMPEDANCE MEASUREMENT (NOT AT A

POWER SOCKET)

Test Lead set: OPTION 1

1. Firmly connect the GREEN lead to EARTH, the BLACK lead to

NEUTRAL and the RED lead to PHASE.

2. Perform the loop test, as above for power socket.

If desired the test can be repeated by pressing the YELLOW TEST

button.

PFC MEASUREMENT [NO TRIP PFC]

Use Test Lead set OPTION 1 or OPTION 2

1. Select NO TRIP PFC test range.

2. Connect the leads as shown.

3. Supply voltage and polarity are displayed.

4. The test will ‘beep’ and automatically start when sufficient

voltage is detected.

5. The measured PFC result is displayed.

HIGH CURRENT LOOP-TESTING [HI]

Single Phase and Phase to Phase loop testing on circuits that are NOT

protected by RCD

OPTION 1

2 wire lead

set

GREEN

RED

OPTION 2

Mains plug

test lead

PLUG

Set the instrument to the [HI] Loop test range

High current Phase to Earth loop impedance measurement (at a

power socket):

Test Lead set: OPTION 2

1. Insert the plug into an installation socket.

2. Supply voltage and polarity are displayed.

3. The test will ‘beep’ and automatically start when voltage is

detected.

10

Page 11

4. Measured loop value is displayed.

If desired the test can be repeated by pressing the YELLOW

TEST button.

High current Phase-Earth loop impedance (not at a power

socket):

Test Lead set: OPTION 1

1. Connect the GREEN lead to EARTH and the RED lead to PHASE

2. Supply voltage is displayed.

Warning: The LCD 'Neons' are invalid when using the two wire lead-set

and should be ignored.

3. The test will automatically start when voltage is detected.

4. Measured loop value is displayed.

If desired the test can be repeated by pressing the YELLOW

TEST button.

BONDED METALWORK TESTING

Test Lead set: OPTION 1

1. Connect the GREEN lead to the bonded metalwork.

2. Connect the RED lead to PHASE.

3. Supply voltage is displayed.

Warning: The LCD 'Neons' are invalid

and should be ignored.

4. The test will automatically start when voltage is detected.

5. Measured loop value is displayed.

when using the two wire lead-set

If desired the test can be repeated by pressing the YELLOW

TEST button.

PHASE-NEUTRAL OR PHASE-PHASE LOOP IMPEDANCE

Test Lead set: OPTION 1

1. Connect the GREEN lead to NEUTRAL and the RED lead to

PHASE (or the 2nd PHASE for Phase to Phase loop

measurement).

2. The supply voltage is displayed.

Warning: The LCD 'Neons' are invalid when using the two wire lead-set

and should be ignored.

3. The test will automatically start when voltage is detected.

4. Measured loop resistance is displayed.

If desired the test can be repeated by pressing the YELLOW

TEST button.

11

Page 12

PROSPECTIVE FAULT CURRENT [PFC HI]

OPTION 1

2 wire measurement

GREEN

RED

OPTION 2

Mains plug

test lead

PLUG

Set the instrument to the [PFC Hi] range

Hi current PFC is a 25 A two wire test.

PHASE TO EARTH PFC

Test Lead set: OPTION 1,2

1. For Single phase measurement connect the test leads as

shown above.

For Phase to Phase measurement connect the GREEN lead

to the 2nd Phase.

2. Supply voltage and polarity are displayed.

3. The test will ‘beep’ and automatically start when voltage is

detected.

4. Measured PFC value is displayed.

If desired the test can be repeated by pressing the YELLOW

TEST button.

PHASE TO NEUTRAL PFC

As for the 25 A Phase to Earth PFC test but with the following test lead

connections:

1. Connect the GREEN lead to the NEUTRAL and the RED lead to

PHASE.

2. The test will ‘beep’ and automatically start when voltage is

detected.

3. Measured PFC value is displayed.

Notes:The PSCC of a circuit is the largest Prospective Fault Current (PFC). In a

single phase system, this would be the larger of the earth loop PFC and

the neutral loop PFC. In a multi-phase system phase-phase loops also need

to be considered and these can be measured using the Loop 25 A switch

position.

The PFC is calculated by using the sum:-

Nominal supply voltage

PFC =

Loop resistance

The supply voltage used in the calculation depends on the measured

voltage. The instrument uses the following voltage values:-

Actual measured voltage Nominal voltage

> 45 V and < 80 V 55 V

>80 V and <150 V 110 V

>150 V and <300 V 230 V

>300 V 400 V

12

Page 13

PFC measurement accuracy

An accurate PFC measurement requires an accurate measurement of the

loop resistance. The difference of a few digits in the loop resistance

measured will have a large effect on the PFC displayed.

Noise Indication

The symbol is displayed when excessive noise caused by other

equipment exists on the circuit under test. This noise can effect the

accuracy of the loop measurement. The operator is advised to repeat the

measurement or, if the noise symbol continually appears, investigate the

cause.

Method of measurement

The phase-earth, phase-neutral or phase-phase loop resistance can be

measured. The instrument takes a current from the supply and measures

the difference between the unloaded and loaded supply voltages. From this

difference it is possible to calculate the loop resistance. The test duration

will depend on the loop resistance value and the presence of noise on the

supply.

The NO TRIP loop test range performs a test with a current of up to 25 A

flowing Line to Neutral to measure the resistance of the source and line

wires, followed by a current of 15 mA flowing Line to Earth to measure the

resistance of the earth wire .

Possible sources of error

The reading depends on a measurement of the supply voltage and

therefore noise or transients caused by other equipment during the test

could cause an error in the reading. One way to check for these is to do

two tests and look for any difference in value. The instrument will detect

some sources of noise and warn the user, where other instruments may

give an incorrect reading. Any leakage current as a consequence of other

appliances connected to the supply under test may affect the reading. If the

Phase-Earth loop is being measured, this leakage may be due to filter

capacitors, etc.

Test results may be adversely affected by supply voltage fluctuations or

electrical ‘noise’ during a measurement. It is recommended that tests are

repeated and the results verified, if measurement results are considered

abnormal.

Errors can be reduced by:-

■ The two-wire lead set with prods and make a firm connection

to clean conductors.

■ Several tests and take the average value.

■ Ensure that potential sources of noise in the installation are isolated

(switched off), eg: automatically switched loads or motor controllers

■ Ensuring that the instrument is calibrated.

Thermal Protection

To protect the MFT from overheating during Loop testing, thermal

protection is fitted. If the message ‘HOT’ appears in the display when loop

testing, the instrument must be allowed to cool down before further

attempts are made at loop testing.

13

Page 14

RESIDUAL CURRENT DEVICE [RCD] TESTING

OPTION 1

2 wire lead

set

GREEN

RED

OPTION 2

Switched

probe

OPTION 3

Mains plug

test lead

GREEN

PROBE

The MFT can perform the following RCD tests:

1/2I Non-tripping test at half the rated RCD trip current for 2

seconds, during which the RCD should not trip.

I Tripping test at the rated RCD trip current. The trip time will

be displayed.

5I Tripping test at 5 x the rated RCD trip current. The trip time

will be displayed in milliseconds.

DC 1/2I, I and 5I tests can be performed as DC tests.

0 or 180°

Some RCDs are sensitive to the polarity of the supply, i.e

whether the test current is applied with the instantaneous

voltage rising or falling. Trip tests should therefore be

performed with both polarities 0° and 180° and the

maximum time recorded.

Ramp Test

Used to check the trip current of an RCD.

PLUG

Note: The Breaker symbol indicates whether the test

function selected is a NON-TRIPPING or TRIPPING test:

CLOSED = NON-TRIPPING test

OPEN = TRIPPING test

1/2 I RCD Testing

Set the LEFT [RCD] rotary range knob to the [ 1/2I ] RCD test range.

Set the RIGHT [mA] rotary range knob to current rating of the RCD under

test.

Test lead set: OPTION 1, 2 or 3

1. Ensure the right hand Rotary knob is set to the correct range

for the RCD under test.

2. Press the YELLOW TEST button.

3. After 2 seconds the message >1999 ms is displayed.

4. If enabled, the touch voltage is displayed on the bar-graph

display.

If the RCD trips unexpectedly the message ‘trP’ will be

displayed.

1 x I RCD Testing

Set the LEFT [RCD] rotary range knob to the [ I ] RCD test range.

1. Press the YELLOW TEST button.

2. The RCD trip time is displayed.

3. If enabled, the touch voltage is displayed on the bar-graph

display.

14

Page 15

4. If the RCD fails to trip, >400 ms is displayed (indicating a

failed test).

5 x I RCD Testing

Set the LEFT [RCD] rotary range knob to the [ 5I ] test range.

1. Press the YELLOW TEST button.

2. The trip time will be displayed.

3. If enabled, the touch voltage will be displayed on the bargraph display.

4. If the RCD fails to trip, >40 ms is displayed (indicating a failed

test).

Note:- The instrument can only test up to 1 A a.c. or 300 mA d.c. Any tests

that exceed these limits are disabled.

0 or 180° testing

0° or 180° is selected by pressing the BLUE button on the side of the MFT

on either the I or 5I RCD test.

The

I, and 5I RCD tests should be performed at 0° and 180° and the

greater trip time recorded.

AUTO RCD TEST SEQUENCE (MFT1552 AND MFT1553 ONLY)

The AUTO test function will run the 1/2I, I, and 5I plus 0º and 180º tests

automatically, and store the test results, while the operator stands by the

RCD to reset it when it trips.

To start the RCD AUTO-test:

1. Connect the RED test lead to the “Live” terminal of the RCD and

GREEN and BLACK test leads to the earth conductor.

Alternatively connect the mains plug test lead to a supply outlet.

2. Select the AUTO RCD TEST function on the main range knob,

and the appropriate RCD current rating on the small range

knob.

3. Press the TEST button to start the test. The display will show

‘t1’ to ‘t5’ to indicate the current test.

t1 =

1/2I, t2 = I at 0º, t3 = I at 180º, t4 = 5I at 0º and t5

= 5I at 180º

4. Reset the RCD each time it trips.

5. On completion of testing the results can be recalled by

repeatedly pressing the lock button. To indicate each test result,

segments of the bar graph are displayed as below:

NO BARS =

ONE BAR =

FIVE BARS =

Example shows a 13.9 ms trip time at

RAMP TEST

The RCD trip current is measured by applying a test current of half the

rated trip current and increasing this every 200 ms. When the RCD trips,

the current flowing is recorded and displayed in mA.

To determine the trip current of an RCD.

1. Select the appropriate RCD rated current on the right hand

rotary switch.

2. Select the RAMP test on the left hand range knob.

1/2 I test

I test

5I test

5I on 180º.

15

Page 16

3. Press the YELLOW TEST button

4. The trip current is displayed.

5. If the RCD fails to trip, ">***mA" will be displayed, where

*** indicates the last test current applied.

DC SENSITIVE RCD TESTING

D.C. sensitive RCDs are tested with a pulsed waveform. The RMS current is

√2 x the rated operating current of the RCD. As with the normal RCDs,

these should be tested with 0° and 180° polarity.

1. Select the appropriate RCD rated current on the right hand

rotary switch.

2. Select the [

1/2I, I, or 5I] test on the left hand range knob

3. Use the BLUE button to cycle through the test options,

selecting DC and the required polarity.

4. Press the YELLOW TEST button

5. The trip time will be displayed in ms.

6. If enabled, the touch voltage will be displayed on the bargraph display.

7. If the RCD fails to trip, ">400 ms" will be displayed.

TIME DELAYED (SELECTIVE) RCDS

The selective RCD testing is enabled by a long press on the blue degree

button. As selective RCD test mode is enabled the MFT will emit a long

beep and the display will show the exclamation mark (!) symbol. Once the

selective RCD mode is chosen, testing of the RCDs can be performed in

the same way as normal RCDs (see above for Residual Current Device

(RCD) Testing, ). To disable selective RCD mode press the degree button

for two seconds.

Method of measurement

The two wire lead or plug should be used for this measurement. A

constant current source is connected across the supply and the time taken

for the supply to trip is measured by the instrument in ms.

Possible sources of error

Measurement results can be affected by the following:

■ Significant operating errors can occur if loads, particularly rotating

machinery and capacitive loads are left connected during tests.

■ A poor connection to the circuit under test.

Thermal Protection T

The RCD circuit has thermal protection fitted to prevent overheating in

the event of multiple ramp tests being performed. The T symbol or the

message "Hot" will be displayed. Allow the instrument time to cool down

before continuing.

16

Page 17

BLUETOOTH DOWNLOADING

Bluetooth Pairing (PC or Laptop)

1. Set the MFT Range knob to the Bluetooth SET UP position.

2. Press the Bluetooth (Lock) button on the MFT, the MFT will show

‘- - -‘ if no pairing exists or the last three digits of a paired identity if

already paired.

If these three digits are the last three digits of your Bluetooth identity

code (e.g. 963) then you are already paired with it. If you don’t

recognise them or are unsure then continue with the pairing process.

3. Push the Bluetooth (Lock) button again to start the pairing process, the

MFT will display ‘<> - - - -‘

4. Activate the “Add Bluetooth Devices” tool on your PC or mobile device

to search for Bluetooth devices.

5. Your PC or mobile device will prompt for an “access key”. When this

happens enter 1234.

6. The MFT will display the last three digits of your Bluetooth identity

code when a successful pairing has been achieved (e.g. <>963).

Bluetooth Pairing (Windows CE)

1. Set the MFT Range knob to the Bluetooth SET UP position.

2. Press the Bluetooth (Lock) button on the MFT, the MFT will show

‘- - -‘ if no pairing exists or the last three digits of a paired identity if

already paired. If these three digits are the last three digits of your

Bluetooth identity code (e.g. 963) then you are already paired with it. If

you don’t recognise them or are unsure then continue with the pairing

process.

3. (i) Turn on your PDA and select ‘Start’ then ‘Settings’.

(ii) Select the ‘Connections’ Tab.

(iii) Select the ‘Bluetooth’ symbol and select ‘Turn on’.

(iv) Select ‘Use Bluetooth Manager’ option.

(v) Select ‘Menu’ and ‘Paired Devices’

(vi) If there are no paired MFTs shown then select ‘Add’.

Note: If there is a MFT symbol present check that it has the serial

number displayed as your MFT. If this isn’t the case then delete the MFT

from the PDA and continue with the pairing procedure.

(vii) Select the Magnifying Glass symbol to start the pairing process.

4. Push the Bluetooth (Lock) button again to start the pairing process, the

MFT will display ‘<> - - - -‘

5. Once paired double click the MFT symbol on the PDA and enter the

access key code 1234.

6. The MFT will display the last three digits of your Bluetooth identity

code when a successful pairing has been achieved (e.g. <>963).

Bluetooth Pairing (Windows Mobile 5 Smartphone)

1. Set the MFT Range knob to the Bluetooth SET UP position.

2. Press the Bluetooth (Lock) button on the MFT, the MFT will show

‘- - -‘ if no pairing exists or the last three digits of a paired identity if

already paired. If these three digits are the last three digits of your

Bluetooth identity code (e.g. 963) then you are already paired with it.

If you don’t recognise them or are unsure then continue with the

pairing process.

17

Page 18

3. (i) Turn on your mobile and press the left hand button to select

‘Start’ menu.

(ii) Select the ‘Connections’ symbol.

(iii) Select the ‘Bluetooth’ symbol.

(iv) Press the right hand Menu button.

(v) Select the Devices symbol.

(vi) Select the ‘Menu’ symbol and the select the ‘New’ symbol.

(vii) If there are no paired MFTs shown then select ‘Add’.

Note: If there is a MFT symbol present check that it has the serial

number displayed as your MFT. If this isn’t the case then delete the MFT

from the PDA and continue with the pairing procedure.

4. Push the Bluetooth (Lock) button again to start the pairing process,

the MFT will display ‘<> - - - -‘

5. On the Windows Mobile 5 once paired select the MFT symbol on the

mobile and enter the access key code 1234.

6. The MFT will display the last three digits of your Bluetooth identity

code when a successful pairing has been achieved (e.g. <>963).

7. On the Windows Mobile 5 press the left hand menu button four times

to select the following in sequence; ‘Next’, ‘OK’, ‘Next’ and ‘Done’.

8. Continue to press the left hand button until you return to the

Windows Desktop display.

18

Bluetooth Pairing (Palm v5)

1. Set the MFT Range knob to the Bluetooth SET UP position.

2. Press the Bluetooth (Lock) button on the MFT, the MFT will show

‘- - -‘ if no pairing exists or the last three digits of a paired identity if

already paired.

If these three digits are the last three digits of your Bluetooth identity

code (e.g. 963) then you are already paired with it. If you don’t

recognise them or are unsure then continue with the pairing process.

3. (i) Select ‘Bluetooth’ from the main Palm desktop and make sue

that it is turned on..

(ii) Select the ‘Setup Devices’ symbol.

(iii) Select the ‘Trusted Devices’ symbol.

(iv) Select the ‘Add Devices’ symbol.

Note: If there is a MFT symbol present check that it has the serial

number displayed as your MFT. If this isn’t the case then delete the MFT

from the Palm and continue with the pairing procedure.

4. Push the Bluetooth (Lock) button again to start the pairing process, the

MFT will display ‘<> - - - -‘

5. On the Palm device once paired select the MFT symbol on the display

and select ‘OK’.

6. Enter the access and select key code ‘1234’ and select the top left hand

menu button ‘OK’.

7. The MFT will display the last three digits of your Bluetooth identity

code when a successful pairing has been achieved (e.g. <>963).

8. On the Palm device select the ‘Done’ twice to get back to the Bluetooth

Page 19

screen.

9. Select the ‘Home’ button to return to the main Palm desktop.

Bluetooth Pairing (Symbian S60 Version 3)

1. Set the MFT Range knob to the Bluetooth SET UP position.

2. Press the Bluetooth (Lock) button on the MFT, the MFT will

show ‘- - -‘ if no pairing exists or the last three digits of a paired

identity if already paired.

If these three digits are the last three digits of your Bluetooth identity

code (e.g. 963) then you are already paired with it. If you don’t recognise

them or are unsure then continue with the pairing process.

3. (i) Select ‘Bluetooth’ from the main Symbian desktop and make sue

that it is turned on..

(ii) Select the right hand Tab to show paired devices..

(iii) Select the top left hand menu button then the ‘New Paired

devices’ symbol.

Note: If there is a MFT symbol present check that it has the serial

number displayed as your MFT. If this isn’t the case then delete the MFT

from the Symbian and continue with the pairing procedure.

4. Push the Bluetooth (Lock) button again to start the pairing process, the

MFT will display ‘<> - - - -‘

5. Once paired select the MFT symbol on the display and select ‘OK’.

6. Enter the access and select key code ‘1234’ and select ‘OK’.

7. The MFT will display the last three digits of your Bluetooth identity code

when a successful pairing has been achieved (e.g. <>963).

8. On the Symbian device select the top left hand menu button’Yes’ to

authorise the Symbian device to make the connection automatically.

9. Select ‘Exit’ to return to the main Symbian desktop.

Downloading Test Results

Table of Symbols

Symbol Definition

L - E Live to Earth Test

L – n Live to Neutral Test

n – E Neutral to Earth Test

L - L Live to Live Test

r1 Circuit Protective Conductor

r2 R1 + R2

r12 Live

rr1 Ring Circuit Phase-Phase

rr2 Ring Circuit CPC-CPC

rrn Ring Circuit Neutral-Neutral

19

Page 20

TESTING WITH A PAIRED MFT1553

Insulation Testing

1. Perform a Insulation test described previously

2. Press the Bluetooth (Lock) button once to display the various options; LE, L-n, n-E and L-L.

3. Press the Bluetooth (Lock) button repeatedly to scroll through these

options until the one you need is reached.

4. Press and hold the Bluetooth (Lock) button again to send the test result

to your PC or mobile device. The MFT test result will flash whilst the

result is transmitted.

5. The test results will now appear in the correct box in the certificate open

on your PC or mobile device.

Continuity Testing

1. Perform a Continuity test described previously

2. Press the Bluetooth (Lock) button once to display the various options;

r2, r12, r1, rr1 and rr2.

3. Press the Bluetooth (Lock) button repeatedly to scroll through these

options until the one you need is reached.

4. Press the Bluetooth (Lock) button again to send the test result to your

PC or mobile device. The MFT test result will flash whilst the result is

transmitted.

5. The test results will now appear in the correct box in the certificate open

on your PC or mobile device.

Loop Testing

1. Perform a Loop test described previously

2. Press the Bluetooth (Lock) button once to display the various options; Ln, L-E and L-L.

3. Press the Bluetooth (Lock) button repeatedly to scroll through these

options until the one you need is reached.

4. Press the Bluetooth (Lock) button again to send the test result to your

PC or mobile device. The MFT test result will flash whilst the result is

transmitted.

5. The test results will now appear in the correct box in the certificate open

on your PC or mobile device.

RCD Testing

1. Perform a RCD test described previously

2. Press and hold the Bluetooth (Lock) button again to send the test result

to your PC or mobile device. The MFT test result will flash whilst the

result is transmitted.

3. The test results will now appear in the correct box in the certificate open

on your PC or mobile device.

4. Each of the RCD tests (1/2I, I @ 0° & 180° and 5 x I @ 0° & 180°) will

automatically be sent to the correct box when the Bluetooth (Lock)

button is pushed and held.

5. For Auto RCD tests all results are automatically transmitted to the correct

boxes on the certificate (the appropriate value must be selected on the

PC or mobile device for each box when prompted) when the Bluetooth

(Lock) button is pushed and held on the MFT.

To force a test result into a specific certificate box double click the box

within the certificate and then push and hold the Bluetooth (Lock) button.

20

Page 21

TECHNICAL SPECIFICATIONS

Electrical specification

Voltage range

The voltage will enable the user to ascertain if a system is live prior to

testing.

Accuracy ±2% ±2 digits

Voltage a.c. - 000 V - 500 V 50/60Hz

Voltage d.c. - 000 V - 500 V (Indication of polarity above 10 V)

Insulation ranges (to EN 61557-2)

Accuracy ±2% ±2 digits up to 99 MΩ

Short circuit current <2 mA

1 mA at min. pass value of insulation specified in BS7671, HD384 and

IEC364

250 V 0.01 - 99.9 MΩ

500 V 0.01 - 299 MΩ

1000 V 0.01 - 499 MΩ

250 V, 500 V and 1 kV into 1 mA load

Output voltage +20% - 0% at rated load or less.

Auto discharge facility safely discharges connected circuit after test.

Live circuit warning/inhibit when connected to live circuits (Threshold

55 V)

EN 61557 Operating Range 0.10 MΩ to 99.9 MΩ

Loop ranges (to EN 61557-3)

Line/Earth (Single phase)

Supply

25 A 0.01 Ω - 9.99 Ω (±5% ±0.03 Ω)

EN 61557 Operating Range 0.25 Ω to 3.00 kΩ

Line/Line(Three phase)

Supply

25 A 0.01 Ω -19.99 Ω (±5% ±0.03 Ω) (at 230 V)

EN 61557 Operating Range 0.25 Ω to 19.99 Ω

Low current Loop (No Trip)

Supply

15mA 0.01 Ω - 2.00 kΩ (±5% ±0.03 Ω ± Noise Margin) (at 230 V)

EN 61557 Operating Range 0.5 Ω

55 V - 270 V 45Hz to 65Hz

10.0 Ω - 89.9 Ω (±5% ±0.5Ω)

90 Ω - 899 Ω (±5% ±5Ω)

900 Ω - 3.00 kΩ (±5% ±20Ω)

55 V - 480 V 45Hz to 65Hz

55 V - 270 V 45Hz to 65Hz

to 2.00 kΩ

21

Page 22

Prospective Short-circuit Current (PSC)

Prospective Short circuit current = Nominal Voltage / Loop Resistance

Accuracy is therefore derived from the loop test.

1 A - 199 A 1 A resolution

0.02 kA - 1.99 kA 10 A resolution

2.0 kA - 19.9 kA 100 A resolution

Continuity (to EN 61557-4)

Ohms

EN 61557 Operating Range 0.10 Ω to 99.9 kΩ

Buzzer Operates continuously at less than selected limit .

Open circuit voltage 4 - 5 V d.c.

Test current >200 mA at 2 Ω

Test Lead resistance zeroing Up to 9.99 Ω (zero uses test button)

RCD ranges (to EN-61557-6)

Supply

Ranges 1000 mA, 500 mA, 300 mA, 100 mA, 30 mA, 10 mA

1/2I 1/2 times the selected current

I One times selected current.

5I Five times I current.

22

0.01 Ω - 99.9 Ω (±2% ±2 digits)

100 Ω - 99.9 kΩ (±5% ±2 digits)

Selectable limits of 2 Ω, 5 Ω, 10 Ω, 20 Ω, 50 Ω, 100 Ω

100 V - 270 V 45Hz to 65Hz

I trip A ramp test that displays actual trip current .

DC sensitive A DC test current at I current.

Current accuracy 1/2I -8% to -2%

I +2% to +8%

5I +2% to +8%

Intrinsic Accuracy of ramp test current ±3%

Trip time

accuracy ±1% ±1 ms

Touch (Fault) Voltage

Displayed range

Remote Probe MFT1502 only (Optional on MFT1501)

Torch feature

Safety CLASS 1 LED to IEC 60825:2001

Interchangeable tips

Lengths 30 mm GS38

Battery 9 V PP3

0 V - 100 V

Error +5% to +15%

±0.5V

5 mm White LED

1500 mcd

112 mm GS38

Page 23

Red/Green LED

RED

indicates that the instrument is displaying a warning (eg volts

on an insulation range)

GREEN indicates that the display on the instrument is valid or that

the Continuity Buzzer on the instrument is sounding.

Power Supply

Instrument 8 x 1.5 V Alkaline cells type LR6 (AA cells)

Note: Rechargeable batteries must not be used

Illuminated switched Probe 1 x 9 V Alkaline cell type PP3 (6LR61)

Fuses

Instrument:- Replaceable 500 mA (F) HBC 10 kA 500 V

Non-replaceable 7 A (SIBA 70-065-63) x 2

Non-replaceable 1 A

Probe:- Non-replaceable 7 A (SIBA 70-065-63)

Safety

Double insulated to IEC1010-1:2001, Installation Category III, 300 V phase to

earth, 500 V phase to phase.

In addition Probe designed to meet IEC 1010-031:2002, Double insulated to

Installation Category III, 300 V phase to earth, 500V phase to phase.

EMC

In accordance with IEC61326 including amendment No. 1

Environmental

Operating range -5 to +40ºC

Operating Humidity 90% RH at 40ºC max

Storage temperature -25 to 65ºC

Maximum altitude 2000 m

Dust and water protection: Instrument IP54, Probe no rating.

IEC61557

Complies with the following parts of 61557, Electrical safety in low voltage

systems up to 1000 V a.c. and 1500 V d.c.- Equipment for

testing, measuring or monitoring of protective measures:-

Part 1 - General requirements

Part 2 - Insulation resistance

Part 3 - Loop resistance

Part 4 - Continuity

Part 5 - Earth test

Part 6 - Residual current devices (RCD)

Part 10 - Combined measuring equipment

23

Page 24

ACCESSORIES

Product Order Code

Multifunction tester standard MFT1501

Multifunction tester with illuminated

switched probe MFT1502

Multifunction tester with automatic RCD testing MFT1552

Multifunction tester with

Bluetooth®Downloading MFT1553

PowerSuite On-site software 6111-777

Accessories included with MFT1501

Quick start guide

3 wire test lead

Crocodile clips (red, black and green)

Probes (red, black)

Mains plug (BS1363) test lead

CD (including full user guide)

Additional accessories with MFT1502/MFT1552/MFT1553

As MFT1501 plus:

Illuminated switched probe

Instrument/document carry case

Optional accessories Order code

Replacement 3 wire test lead set 6220-796

Fused prod and clip set 6180-405

Standard switched probe 6220-836

Illuminated switched probe 6311-089

Test lead with Schuko plug 6231-593

Test lead with UK mains plug 6231-601

Test lead with USA mains plug 6220-643

Earth bond test lead set 6231-586

Instrument/Document carry case 6420-143

Replacement Probe Tip Set (for SPL1000) 6121-562

MFT1501/2E / MFT1502/2E

As MFT1501/MFT1502 but supplied with a Schuko mains lead plug

(6231-593) instead of a BS plug.

The Bluetooth word mark and logo are owned by Bluetooth SIG. Inc. and

any use of such marks by Megger is under licence.

24

Page 25

REPAIR AND WARRANTY

The instrument contains static sensitive devices, and care must be taken in

handling the printed circuit board. If an instrument’s protection has been

impaired it should not be used, but sent for repair by suitably trained and

qualified personnel.

The protection is likely to be impaired if for example; it shows visible

damage; fails to perform the intended measurements; has been subjected to

prolonged storage under unfavourable conditions, or has been subjected to

severe transport stresses.

NEW INSTRUMENTS ARE WARRANTED FOR 3 YEARS FROM THE

DATE OF PURCHASE BY THE USER.

NOTE: Any unauthorized prior repair or adjustment will automatically

invalidate the Warranty.

CALIBRATION, REPAIR AND SPARE PARTS

For service requirements for Megger Instruments contact:

Megger Limited or Megger

Archcliffe Road Valley Forge Corporate Centre

Dover 2621 Van Buren Avenue

Kent CT17 9EN Norristown PA 19403

England. U.S.A.

Tel: +44 (0) 1304 502 243 Tel: +1 610 676 8579

Fax: +44 (0) 1304 207 342 Fax: +1 610 676 8625

Megger operate fully traceable calibration and repair facilities, ensuring your

instrument continues to provide the high standard of performance and

workmanship you expect. These facilities are complemented by a worldwide

network of approved repair and calibration companies to offer excellent inservice care for your Megger products.

Returning your product to Megger - UK and USA service

centres

1. When an instrument requires recalibration, or in the event of a repair

being necessary, a Returns Authorisation (RA) number must first be

obtained from one of the addresses shown. You will be asked to

provide the following information to enable the Service Department to

prepare in advance for receipt of your instrument, and to provide the

best possible service to you.

■ Model, e.g. MFT1501

■ Serial number, (e.g. 61110357050305/1234)

■ Reason for return, (e.g. calibration required, or repair)

■ Details of the fault (if the instrument is to be repaired)

2. Make a note of the RA number. A returns label can be emailed or faxed

to you if you wish.

3. Pack the instrument carefully with plenty of padding, but no pressure on

window or glass.

4. Ensure the returns label is attached, or that the RA number is clearly

marked on the outside of the package and on any correspondence,

before sending the instrument, carriage paid, to Megger.

5. You make track the progress of your return on line by accessing the

Service/Support facilities at www.megger.com

Approved Service Centres

A list of Approved Service Centres may be obtained from the UK address

shown. If outside UK/USA please consult your distributor for the most

convenient Service Organisation.

25

Page 26

ADDITIONAL BLUETOOTH INFORMATION (ATTACHING A DONGLE)

Megger MFT1553 Bluetooth Procedure

This guide provides detailed methods of attaching a Bluetooth Dongle to a

laptop or PC.

1. Initial Installation and setup

Installation of “Bluetooth Dongle”

Unless previously installed or built in you must first install a third party

“Bluetooth Dongle” on your computer. There are three common “Bluetooth

Stacks” employed by third party dongles. This will not normally be stated on

the dongle packaging but each will install slightly differently. A brief

summary of the common types will follow but follow any instructions

supplied with the product.

Some machines have Bluetooth communications built in but not enabled by

default. The IBM T43 laptop series are such an example where you need to

hold down the “Fn” key and press the “F5” key to enable “Bluetooth”

operation.

It is vital that you reboot you computer after the installation is complete and

before running “Megger Download Manager” for the first time.

2. Typical install process for A Widcomm Driver (Belkin in this

case)

The install process starts when the vendor CD is placed in the drive.

This message may appear

…..Click OK.

Plug the Dongle in when requested.

…..Click OK.

Click “Finish”

The “Bluetooth Drivers are only partially setup at this stage. To finish the

setup “Right Click” on the “Bluetooth” icon in the system tray.

26

Click Next,

The Following box will appear.

Page 27

Click Next.

Click Next.

Confirm ticks are shown in the boxes shown……Click Next.

This will be confirmed with a message balloon as shown.

MUST Click Skip at this Stage

You

Click Finish and you must reboot the computer.

3. Typical install process for A Bluesoleil Driver.

The install process starts when the vendor CD is placed in the drive.

27

Page 28

Click OK.

Click Next.

Click “I Accept…” and Next.

Accept the default settings and Next.

To start Install, Click on Install.

Click on Finish.

Accept the default settings and Next.

28

Page 29

4. Typical install process for Microsoft Drivers.

Click on “Open

Bluetooth

Settings”.

Click “Add”

Click on “Com

Ports” Tab

Plug “Bluetooth” Dongle into computer.

you must reboot the computer.

Plug the Dongle in when requested.

Switch Security level from Medium by removing the “Tick”. This driver

exhibits unusual behaviour when set to “Medium” but “High” or “Low” work

correctly.

Auto detect and install will now start.

Right Click on “Bluetooth” icon

in the system tray.

29

Page 30

Incoming should be selected by default.

Click on “Turn

Discovery On”

Click on

“Options” tab.

If not click on radio button. Click OK.

Click Finish and you must reboot the computer.

30

Page 31

31

Page 32

M

Megger Limited

Archcliffe Road, Dover

Kent CT17 9EN England

T +44 (0)1 304 502101

F +44 (0)1 304 207342

E uksales@megger.com

Megger products are distributed in 146 countries worldwide.

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification or design without prior notice.

Megger is a registered trademark

Part No. 6172-914 V08 Printed in England 0307

www.megger.com

Megger

4271 Bronze Way, Dallas,

Texas 75237-1019 USA

T +1 800 723 2861 (USA ONLY)

T +1 214 333 3201

F +1 214 331 7399

E ussales@megger.com

Megger

Z.A. Du Buisson de la Couldre

23 rue Eugène Henaff

78190 TRAPPES France

T +33 (0)1 30.16.08.90

F +33 (0)1 34.61.23.77

E infos@megger.com

Megger Pty Limited

Unit 26 9 Hudson Avenue

Castle Hill

Sydney NSW 2125 Australia

T +61 (0)2 9659 2005

F +61 (0)2 9659 2201

E ausales@megger.com

Megger Limited

110 Milner Avenue Unit 1

Scarborough Ontario M1S 3R2

Canada

T +1 416 298 9688 (Canada only)

T +1 416 298 6770

F +1 416 298 0848

E casales@megger.com

Loading...

Loading...