Page 1

User’s Manual

MOM2

MOM2 Win

Micro-ohmmeter

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Art No. ZP-BD03E Doc. BD0333FE V06a 2016

Page 2

Page 3

MOM2

NOTICE OF COPYRIGHT & PROPRIETARY RIGHTS

© 2013-2016, Megger Sweden AB. All rights reserved.

The contents of this manual are the property of Megger Sweden AB. No part of this work may be reproduced or transmitted in any form or

by any means, except as permitted in written license agreement with Megger Sweden AB. Megger Sweden AB has made every reasonable

attempt to ensure the completeness and accuracy of this document. However, the information contained in this manual is subject to change

without notice, and does not represent a commitment on the part of Megger Sweden AB. Any attached hardware schematics and technical

descriptions, or software listings that disclose source code, are for informational purposes only. Reproduction in whole or in part to create

working hardware or software for other than Megger Sweden AB products is strictly prohibited, except as permitted by written license

agreement with Megger Sweden AB.

TRADEMARK NOTICES

Megger® and Programma® are trademarks registered in the U.S. and other countries. All other brand and product names mentioned in this

document are trademarks or registered trademarks of their respective companies.

Megger Sweden AB is certified according to ISO 9001 and 14001.

User’s Manual

MOM2 Win

Micro-ohmmeter

BD0333FE ZP-BD03E MOM2

3

Page 4

Contents

1 Safety

................................................................... 6

1.1 Safety instructions ............................................... 6

1.2 Symbols on the instrument ................................. 7

2 Introduction

................................................................... 8

2.1 Basic technical description ................................... 8

Kelvin test .......................................................... 8

2.2 DualGround – Both sides grounded .................... 9

3 MOM2 overview

................................................................. 10

3.1 The instrument ................................................. 10

3.2 Accessories ....................................................... 12

3.3 Optional accessories .......................................... 12

4 Functions and set up

................................................................. 14

4.1 General ............................................................. 14

Internal software version .................................. 14

4.2 Test positions .................................................... 14

4.3 Bluetooth –

SET / ............................................................ 15

4.4 Clock – CLK ...................................................... 16

SET / CLK .......................................................... 16

4.5 Minimum current – I min .................................. 17

SET / I min......................................................... 17

4.6 Data logger – LOG ............................................ 18

SET / LOG ......................................................... 18

4.7 Pass/Fail – P/F .................................................... 19

SET / P/F ............................................................ 19

4.8

PC communication – PC COM ...............................19

PC COM .......................................................... 19

4.9 Audio signals .................................................... 20

4.10 Battery power supply ...................................... 20

Charging ......................................................... 20

Replacing the batteries .................................... 20

Battery practice ................................................ 21

.................................. 15

5 Operating instructions

................................................................. 22

5.1 General instructions .......................................... 22

Important regarding all testing ......................... 22

Power supply ................................................ 22

LCD display ...................................................... 22

To choose measurement time ..........................22

To choose I > I min or I = I max ............................22

Working at low temperatures ..........................23

Kelvin Clamp/Probe practice ............................23

Save test results ............................................... 23

Hold present test result .................................... 23

Delete present test result .................................23

Recalling test results from the log ....................23

Delete results in the log ...................................23

Delete all results in the log ............................... 23

5.2 Measurement with max. charge, I=IMAX ......... 24

5.3 Measurement with minimum current guaran-

tee, I > Imin ...................................................... 25

5.4 Measurement using P/F – pass/fail ..................... 26

5.5 Measurement with user defined settings ........... 27

5.6 Measurement using the LOG function ............... 27

Running numbers mode .................................. 27

Circuit breaker testing mode ............................ 27

5.7 Measurement using P/F and Imin ..................... 29

5.8 Testing on circuit breakers having a current

transformer in the loop ..................................... 30

5.9 Trouble shooting ............................................... 30

Error messages ................................................30

6 Application examples

................................................................. 32

6.1 Safety ............................................................... 32

Important regarding all testing ......................... 32

6.2 Measurement using Kelvin probes ..................... 32

6.3 Test a CB using DualGround .............................. 33

6.4 Test a CB by injecting through the ground ca-

bles .................................................................. 33

Disconnection .................................................. 33

7 MOM2 Win

................................................................. 34

7.1 Introduction ...................................................... 34

7.2 MOM2 installation ............................................ 34

Preconditions ................................................... 34

Setup ............................................................... 34

Select language ............................................... 34

7.3 Start MOM2 Win .............................................. 35

Exit MOM2 Win ............................................... 35

7.4 Connecting to MOM2 ....................................... 35

Automatic connecting ..................................... 35

4 MOM2 ZP-BD03E BD0333FE

Page 5

Manual connecting .......................................... 35

7.5 Read the measurement log ............................... 37

Export data to file ............................................ 38

Delete all data on the instrument ..................... 38

7.6 User settings ..................................................... 39

Read existing settings ...................................... 39

Program "User" positions ................................ 39

7.7 Calibration ........................................................ 40

Required equipment ........................................40

Procedure ........................................................40

Voltmeter calibration .......................................40

Ammeter calibration ........................................ 40

Calibration report ............................................41

8 Specifications

................................................................. 42

Specifications MOM2 .............................................. 42

Index ....................................................... 44

BD0333FE ZP-BD03E MOM2

5

Page 6

1 SAFETY

1

Safety

1.1 Safety instructions

For your own safety and to get the maximum benefit

from your instrument, please ensure that you read

and understand the following safety instructions and

warnings before using the instrument.

Read and comply with the following

instructions.

Important

Warning

Connecting – before test

1.

Before measuring resistance in circuit breakers

or disconnecting switches (isolators), always

check to see that the object being tested is

closed and grounded at both sides.

2.

Always connect the protective ground on

MOM2 before making any other connections.

3.

Always connect the test cables to MOM2 before connecting them to the test object.

4.

Never connect MOM2 to live circuits.

During test

1.

The rising current waveforms produced by the

instrument may induce enough current into

the secondary of a current transformer (CT)

circuit to actuate a protective relay.

If there is a CT in the current circuit, the protective relay equipment that is connected to it

must be blocked to prevent actuation.

After completing the measurements, you can

follow the normal procedures that are used to

demagnetize current transformer cores after

DC has passed through their current transformer.

2.

Never open a circuit breaker while MOM2 is

connected to it.

3.

Connection points for current cables can become hot during current generation.

4.

High current on output terminals.

Always comply with local safety

regulations.

Disconnecting – after test

1.

First, disconnect all test cables from the test

object and then disconnect them from MOM2.

Last, disconnect the protective ground from

MOM2.

Important

1.

The instrument is intended for use in industrial

environment. It generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with these instructions

it may cause interference to other devices

in the vicinity. If this equipment does cause

interference with other devices, which can be

determined by turning the equipment off and

on, the user is encouraged to try to correct the

interference by one or more of the following

measures:

▪

Reorient or relocate the receiving device.

▪ Increase the separation between the equipments.

▪ Connect the equipment into an outlet on a circuit

different from that to which the other device(s) is

connected.

▪ Consult the manufacturer or field service

technician for help.

2.

Never leave the MOM2 unattended while it is

turned on.

3.

Do not use any accessories that are not intended for use together with the instrument.

4.

It is not possible to use the MOM2 for testing

during battery charging.

5.

Use a damp cloth for cleaning. Do not use

liquid cleaners or aerosol cleaners.

6.

Do not attempt to service the instrument yourself. If you attempt to service the instrument

yourself the warranty is no longer valid. Refer

all servicing to Megger authorized personnel.

7.

If you need to return the instrument, please

use either the original crate or one of equivalent strength.

6 MOM2 ZP-BD03E BD0333FE

Page 7

1.2 Symbols on the

instrument

Caution, refer to accompanying documents.

Protective conductor terminal.

WEEE, Waste Electrical and Electronic

Equipment. Please utilize your local WEEE collection facilities in the

disposal of this product and otherwise

observe all applicable requirements.

Equipment complies with current EU

directives.

1 SAFETY

BD0333FE ZP-BD03E MOM2

7

Page 8

2 INTRODUCTION

2

Introduction

The MOM2 is designed to measure the resistance of

circuit breaker contacts, bus-bar joints, contact elements in bus-bars and other high-current links.

When contact resistance rises because of oxidation,

loosened or improperly tightened threaded joints,

temperatures rise abnormally at the points of contact.

This abnormal heating reduces conductivity thereby

accelerating the rise in temperature — and this often

leads to serious trouble.

The MOM2 micro-ohmmeter can be used to detect

such problems early so that they can be remedied

long before trouble starts. Checking contact resistance

at regular intervals provides a clear indication of the

state of your system.

2.1 Basic technical description

The output current is delivered from a supercapacitor

which is charged from the built-in rechargeable batteries.

Kelvin test

The MOM2 uses Kelvin probes or clamps for the

measurement. A Kelvin test uses four wires and measures continuity resistances ensuring all contact and

lead resistances are compensated for, which allows a

much greater accuracy in measurements. Each Kelvin

probe assembly has two probe tips. When contacting

the test object it will be contacted with two plus two

probe tips. One pair is for the current generated. The

other pair will measure the very small voltage present.

Principle for the 4 wire Kelvin test.

8 MOM2 ZP-BD03E BD0333FE

Page 9

2.2 DualGround – Both

sides grounded

With MOM2 it is possible to make measurements

according to the DualGround™ method. The most important advantage is improved safety but the method

is also easier and saves time. The number of tasks is

reduced when the ground cable does not need to be

disconnected and reconnected. Permission related

work that may include paper work could many times

be avoided. However, the local safety regulations shall

always be followed.

Using the DualGround method might cause a small

measurement error cause by the current running

through the ground loop. The error value depends on

the relation between the two parallel circuits.

Example: If the test object is 50 µ and ground loop

is 10 m the error will be 0.5%

Two 10 m, 95 mm

of around 3.6 m. Transitional resistance in connections and clamps to be added.

2

grounding cables has a resistance

2 INTRODUCTION

With both sides grounded the induced current will not pass

through the test instrument.

BD0333FE ZP-BD03E MOM2

9

Page 10

3 MOM2 OVERVIEW

1

MOM2 overview

3

3.1 The instrument

3

5

2

4

6

7

Top view

9 10

12

8

13 14

11

Bottom view

10 MOM2 ZP-BD03E BD0333FE

Page 11

3 MOM2 OVERVIEW

1.

Current output terminal (-)

2.

Current output terminal (+)

3.

Protective conductor terminal

4.

Display

▪ The display offers a combination of analogue arc

and a dual digital readout:

▪ Analogue arc:

Shows the capacitor charge.

▪ Dual digital display:

Large main digital readout for good visibility of all

main measurement results

Second digital display for additional data.

5.

Keys

Keys for navigation and to make settings in the

display .

◀ ▶

▲ ▼

Left, right is used to navigate between

characters/digits.

Up, down is used to change each

character/digit.

OK Press and hold to enable edit of pa-

rameters select and confirm parameters. Press shortly to confirm.

Backlight

Automatic switch off after 20 s.

C Clear / Cancel

6.

TEST button

When the function selector is in any of the positions I > I min , I = I max or USER measurement is performed by pressing the button.

7.

Stand-by / Wake up

Press shortly to toggle

Clear log

(Press and hold for 5 s)

8.

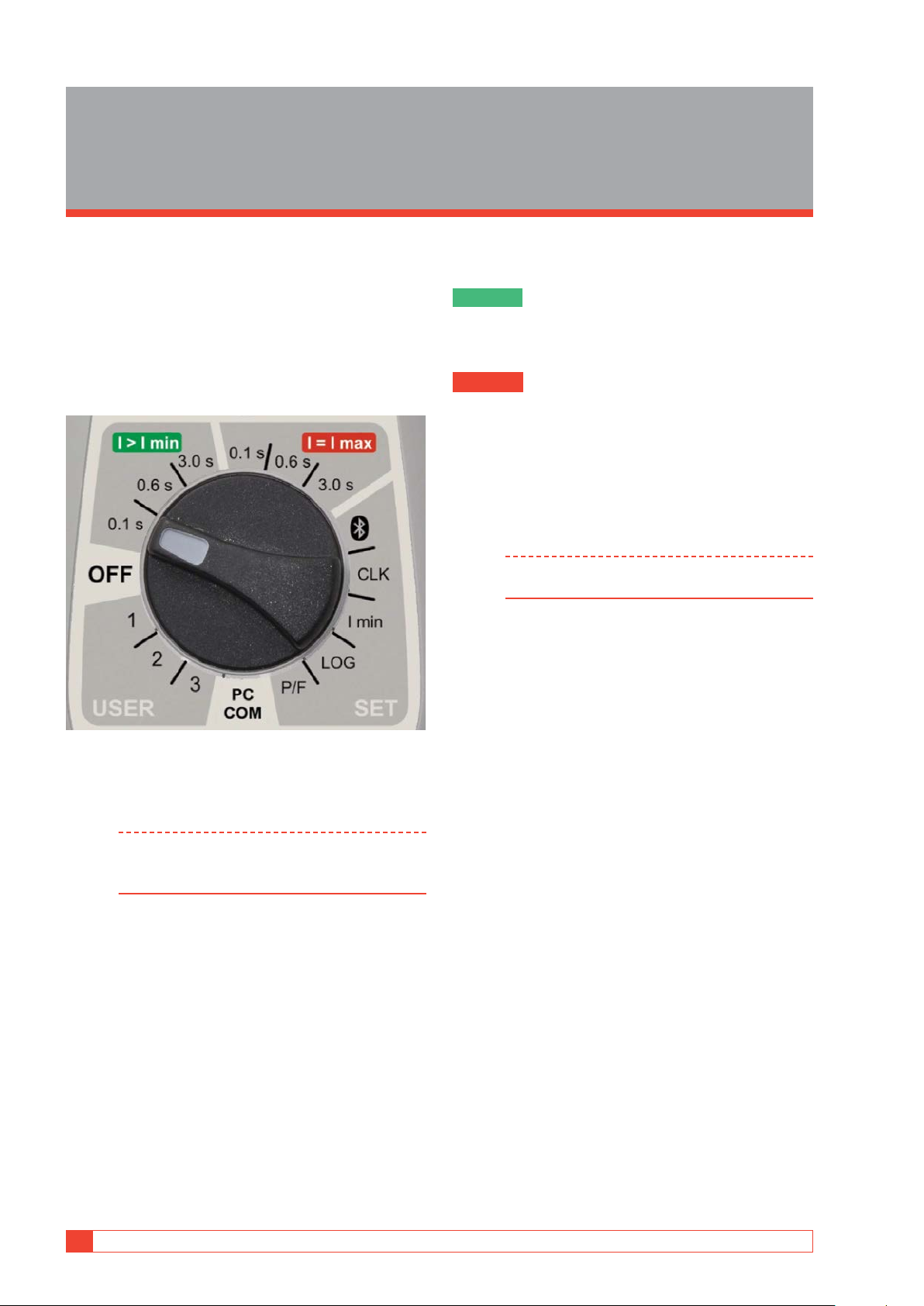

Function selector

OFF

0.1 s Test positions

I > I min

0.6 s

3 s

Measurement time with

minimum current guarantee

0.1 s Test positions

I = I max

0.6 s

3 s

Measurement time with

max. charge

Bluetooth “pair units”

CLK

▪ Set date and time

▪ Set volume for the internal

buzzer

SET

▪ Discharge the MOM2

internal capacitor

I min Minimum current guaran-

tee setting

LOG Data log settings

P/F Pass/Fail settings

PC COM

PC communication (dump

data to PC)

1 Test positions

USER

9.

Input for sensing voltage (-)

2

3

Stored settings (Set from

PC SW)

Connector for the negative test lead.

10.

Input for sensing voltage (+)

11.

Connector for trigger

12.

Battery lid

13.

Connector for the battery charger

14.

Battery charging indicator

BD0333FE ZP-BD03E MOM2

11

Page 12

3 MOM2 OVERVIEW

3.2 Accessories

▪ Test cables with Kelvin probes (one with trigger)

or

Test cables with Kelvin clamps

▪ Transport case

▪ Charger

▪ Rubber holster

▪ Carrying strap

▪ Belt clip

▪ MOM2 Win

3.3 Optional accessories

Test cables with Kelvin probes (current & sense)

2 x 1.3 (4 ft) m (one with trig button) GA-90000

Test cables with Kelvin clamps (current & sense)

1.3 m (4 ft) red, 3 m (10 ft) black

Current cable with Kelvin clamp

3 m (10 ft) black, 16 mm

Current cable with Kelvin clamp

1.3 m (4 ft) red, 16 mm

Current cable with Kelvin clamp

5 m (16 ft) black, 25 mm

Current cable with Kelvin clamp

10 m (33 ft) black, 16 mm

Cable kit 5 m (for use with the std. ground connectors)

Current cable 0.5 m (1.6 ft), Connection plate and

sense cables 5 m (16 ft), Ground cable

Cable kit 10 m

Current cable 0.5 m (1.6 ft), Connection plate and

sense cables 10 m (33 ft), Ground cable

Cable kit 15 m

Current cable 0.5 m (1.6 ft), Connection plate and

sense cables 15 m (49 ft), Ground cable

Bluetooth kit

Bluetooth headset and dongle for PC

Calibration kit

Soft carrying case

For MOM2, Charger and Cables

2

2

2

2

GA-90001

GA- 00372

GA-00373

GA -00374

GA-00376

GA-00380

GA-00382

GA-00384

XC-06000

BD-90002

GD- 00620

12 MOM2 ZP-BD03E BD0333FE

Page 13

4 FUNCTIONS AND SET UP

BD0333FE ZP-BD03E MOM2

13

Page 14

4 FUNCTIONS AND SET UP

4

Functions and set up

4.1 General

Internal software version

When turning the function selector from OFF to any

position the display will shortly show a number e.g.

008 and then during five seconds the internal software version e.g. "01C" (revision R01C).

4.2 Test positions

I > I min

Minimum current is set in position SET / I min.

Generation / measurement time: 0.1 s, 0.6 s or 3 s.

I = I max

The current is only limited by the total impedance of

the circuit.

Generation / measurement time: 0.1 s, 0.6 s or 3 s.

USER / 1, 2, 3

User defined settings as generation time, I min, pass/

fail and log.

Note The user defined settings can only be set via

MOM2 Win from a PC

OFF

The instrument should be in the OFF position when

not in use.

Note The MOM2 will go to stand by mode after

about 10 minutes of inactivity. To wake up,

press Stand-by / Wake up (CLR LOG) button.

14 MOM2 ZP-BD03E BD0333FE

Page 15

4.3 Bluetooth –

SET /

Display abbreviations

SEt Set

SPC Set-up PC

SHS Set-up headset

Prd Paired

E-d Enable / Disable (headset)

EnA Enabled (headset)

dIS Disabled (headset)

o Processing

ErA Erase all addresses

Enable / Disable Bluetooth

Use the ◀ ▶ keys to find "E-d".

1]

2] Press OK to toggle between "EnA" (Enabled

and "diS" (Disabled).

4 FUNCTIONS AND SET UP

Note Do not use the PC COM mode if there is a

requirement for non-electromagnetic interference in the environment.

The PC COM position is always enabled as it

overrides the disable setting.

Set up Bluetooth

Select SET / on the MOM2.

1]

2] Press ▶, "SPC" will be shown.

3] Press "OK. Display will show "o".

The MOM2 is now visible in the Bluetooth

network and ready to be paired.

4] On the PC, in the "Control Panel" select

"Bluetooth Devices".

6] Check the box and click "Next".

7] The PC should now find the MOM2.

5] Click "Add".

BD0333FE ZP-BD03E MOM2

15

Page 16

4 FUNCTIONS AND SET UP

8] Check and click Next.

9] Select the second option, see below, enter

"0000" and click Next.

4.4 Clock – CLK

SET / CLK

There are three functions in this position:

A] Set date and time.

B] Set volume for the internal buzzer.

C] Discharge the MOM2 internal capacitor, (used

for service only).

Display abbreviations

CLC Clock

UOL Volume

dIS Discharge (used for service only)

yy Year

non Month

dd Day

HH Hour

nIn Minute

10] Display shows "Prd" and set up is complete.

Note The procedure to pair and assign com port

varies depending on the equipment.

How to pair a headset

Select SET / on the MOM2.

1]

2] Use the ◀ ▶ keys to find out that Bluetooth

is enabled, "EnA".

3] Press right arrow key twice.

The display shows “SHS”

4] Set the headset in pair mode (See the instruc-

tions for the headset.)

5] Press the OK key on the MOM2.

6] When the display shows “Prd” the pairing is

ready.

Date and time

Select SET / CLC

1]

2] Press and hold OK key until digits start to

blink under the "yy" letters.

3] Set year using the ▲ ▼ keys.

4] Press OK key.

5] Press the ▶ key to go further and set month,

day, hour an minute in the same way as

above.

6] Press C key to return.

How to start the headset

See the instructions for the headset

1]

Select SET / CLC

1]

2] Press ▶ key, "UOL" is shown.

16 MOM2 ZP-BD03E BD0333FE

Volume for buzzer

Page 17

4 FUNCTIONS AND SET UP

3] Press and hold OK key until digit start to

blink.

4] Set level (1 to 5) using the ▲ ▼ keys.

5] Press OK key.

6] Press ▶ or ◀ to return.

4.5 Minimum current – I min

SET / I min

Display abbreviations

SEL Select

Set-up

Select SET / I min. Present setting is displayed.

1]

2] Press and hold OK key until digits start to

blink under the "SEL" letters.

3] Select value, 50 or 100, using the ▲ ▼ keys.

4] Press OK key to confirm.

To cancel press C key or turn the function

selector to another position.

Result after a measurement

If the chosen value is not reached during a measurement it will result in a notification on the display and

by an audio signal.

Picture shows an example after a measurement. The I min

limit "50 A" has not been achieved, indicated by the "<"

character to the left.

The current measured during the test is shown in the upper

row. The value shown toggles between the max and min

current during the test. In this case it is the minimum current showing "> 037 A".

BD0333FE ZP-BD03E MOM2

17

Page 18

4 FUNCTIONS AND SET UP

4.6 Data logger – LOG

The data memory can store totally 190 measurements

and this capacity is shared by the two log modes.

SET / LOG

Display abbreviations / description

SEL Select

oFF OFF

1A1 Label for Breaker, Phase, Interrupter

1234 Running numbers

LOG modes

OFF

Measurement is automatically stored, provided that

the memory is not full.

Set-up

Select SET / LOG. Present setting is displayed.

1]

2] Press and hold OK key until characters start

to blink under the "SEL" letters.

3] Use the ▲ ▼ keys to select mode.

4] Press OK key.

When the log is OFF only the latest value is stored and only

until the performance of a following measurement, which

overwrites the previous one.

Circuit breaker testing mode,1A1

This mode is primarily designed for measurement on circuit

breakers. The three characters (1A1) are supposed to indicate: Breaker, Phase, Interrupter.

Measurement is automatically stored, provided that

there are less than three measurements stored on the

selected object label. Each label can store three measurements. See also section 5.6 Measurement using

the log function.

Running numbers mode, 1234

The measurements are numbered in numerical order (1 to

1999)

18 MOM2 ZP-BD03E BD0333FE

Page 19

4 FUNCTIONS AND SET UP

4.7 Pass/Fail – P/F

In the P/F position you can enable and set the limit for

the Pass/Fail function. If the measured value exceeds

the set limit it will result in a notification on the display and by an audio signal

SET / P/F

Display abbreviations

SEL Select

oFF OFF

Set-up

Select SET / P/F. Present setting is displayed.

1]

2] Press and hold OK key until character, "<" or

"oFF" start to blink.

4.8

PC communication – PC

COM

The PC COM position is used for all operations performed from a PC using MOM2 Win. You can:

▪

Dump measurement data from the MOM2

▪ Delete all measurements in the data log

▪ Program "User" positions

▪ Set MOM2 clock

▪ Calibrate

PC COM

Display abbreviations

rEn Remote

Set-up

The following is needed:

▪

A PC with MOM2 Win installed

See chapter 8 MOM2 Win

3] Select "oFF" or a value using the ▲ ▼ keys.

4] Use the keys ▶ ◀ to select the digit to

change, it will blink.

5] Use the keys ▲ ▼ keys to set the desired

value.

6] Press OK key.

To cancel press C key or turn the function

selector to another position.

▪ A PC connected via Bluetooth

See section "Bluetooth set up"

Test Equipment Depot - 800.517.8431

99 Washington Street, Melrose, MA 02176

TestEquipmentDepot.com

BD0333FE ZP-BD03E MOM2

19

Page 20

4 FUNCTIONS AND SET UP

4.9 Audio signals

The MOM2 emits different sounds to give an audible

information / confirmation of an event / action. The

sound is emitted from a built-in buzzer and from the

Bluetooth headset (optional). The audio signals vary in

frequency, Low / High, and composition.

Audio signals Description

The MOM2 is charging the

◼ ◼ ◼ . . .

◼ ◼ ◼ ◼ . . .

◼◼

◼ ◼

capacitor and is not ready for

measurement.

Battery low

During capacitor charge

Measurement in progress

Pass signal

Measurement complete / Pass

Wake up

4.10 Battery power supply

Charging

Before using the MOM2 the batteries should be

charged. Use the supplied charger and connect it

to the socket at the bottom of the MOM2. Typical

recharge time for fully discharged batteries is 3 hours,

at 25°C (77°F).

Tip Place the MOM2 upside down to get bet-

ter the cooling of the batteries.

Important

MOM2 cannot be used for testing during

charging.

◼◼ ◼

◼

◼ ◼◼

◼ ◼

◼ ◼

Legend

◼

◼◼

◼

◼◼

. . .

Fail signal

Measurement complete / Fail

Label full

Stand-by

When pressing Test / Trigger

while lock symbol is shown

Delete confirmed

When press and hold the

Test / Trigger

Note: Only in LOG mode

Hold

When pressing Test / Trigger

Note: Only in LOG mode

Release

When pressing Test / Trigger

Note: Only in LOG mode

Short - High tone

Long - High tone

Short - Low tone

Long - Low tone

Continuous

LED

indicator

Green Fully charged

Yellow

Green

Red

Yellow

Green

Red

Green

Red Fault state. Wrong

None Battery fault /

Description Clarification /

Charging

Temperature limits

exceeded during

the charging.

Temperature limits

exceeded, too

high or too low,

before charging.

battery type,

faulty battery.

missing or other

fault

Remedy

Charging will restart

when temperature

has decreased.

Charging will start

when temperature is

within the limits.

Disconnect the

charger and check

the batteries.

Check batteries and

charger / cables

Replacing the batteries

1] Loosen the two screws that holds the battery

plate at the back of MOM2, see figure below.

20 MOM2 ZP-BD03E BD0333FE

Page 21

It is recommended to use the same type of batteries

(AA (HR6) 2700 mAh NiMH) as the original ones.

4 FUNCTIONS AND SET UP

Note

It is possible to use standard (non-rechargeable)

alkaline cells but then only for test using the 0.1 s

measurement position and I > I min.

Loosen the two screws that holds the battery lid at the back

of MOM2.

Important

Always replace all batteries at the same

time.

Do not mix old and new batteries.

Do not mix types or brands.

Battery practice

To extend the battery life cycle time it is a god practice

to recondition the batteries in a separate charger that

has recondition options like refresh / discharge. It is

a good idea to condition the batteries once in about

6 months or after around 12 regular charge cycles to

get the most out of them.

BD0333FE ZP-BD03E MOM2

21

Page 22

5 OPERATING INSTRUCTIONS

Operating instructions

5

5.1 General instructions

Important regarding all testing

Read and comply with the

safety instructions.

Important

Power supply

Prepare testing by charging the batteries se section

4.10 Battery power supply.

Note The MOM2 cannot be used for testing during

battery charging.

LCD display

The display can be backlighted by pressing the key .

It is switched off automatically after 20 seconds.

1 42 3

Always comply with local

safety regulations.

5 6 7

5.

Warning

See section 5.8 Troubleshooting

6.

Pass/Fail indicator

In this case the Pass/Fail is set to 100

7.

Padlock symbol

The lock symbol is shown when the capacitor

is charged prior to a test and when you lock a

test result.

1.

Analogue arc

Indicates level of the capacitor charge

2.

Measurement label

In this case the instrument is set in Running

numbers mode (SET / LOG)

3.

Measurement result

4.

Battery charge indicator

To choose measurement time

In an environment without electrical interference it is

wise to choose the shortest measurement time, which

means that you can get the largest number of measurements on a single battery charge.

Note The shortest measurement time (0.1 s) is not

suitable in environments with a frequency of

16 2 / 3 Hz.

Tip: Start making three tests with the

shortest measurement time to figure out

if the results vary. If they do not differ

significantly - use 0.1 s for the tests.

To choose I > I min or I = I max

If you want maximum current for the test, choose

I = I max. The capacitor will be charged to its maximum and requires much energy from the batteries.

If lower current is sufficient for the measurement,

it is advisable to use the I > I min position. In the

22 MOM2 ZP-BD03E BD0333FE

Page 23

5 OPERATING INSTRUCTIONS

SET / I min position you select the minimum current to

be 50 A or 100 A.

Min current guarantee

(I > I min)

Suitable for test objects ≤ 2 m Recommended for test objects

Capacitor only charged to

sufficient level to generate

selected minimum current for

set time

Saves instrument battery

Allows for shorter time between tests

Note If you get varying measurement results using

the I > I min position, change to I = I max.

Max current

(I = I max)

> 2 m

Capacitor is fully charged

Will push as much current as

possible through the test object

for set time. Current is determined as: I ≈ 2.5 V / [test object

R + 0.01 ] A

Requires longer capacitor

recharge times

Working at low temperatures

MOM2 can be operated down to -20°C provided that

the batteries keep a temperature over 0°C. When the

instrument is in use the batteries will generate heat

enough to keep themselves warm.

Kelvin Clamp/Probe practice

Important

To avoid adding unwanted transition

resistances to the measurement result the

Kelvin clamps or Kelvin probes shall be

connected directly to the test object and

not to e.g. a bolt head.

In some cases it might be advisable to use

separate sense cables, forming a conventional four point measurement, in order

to get a more accurate voltage sense.

symbol on the display and an audio signal.

2] To unlock, press shortly the trigger on the

Kelvin probe or the TEST button.

Delete present test result

1] Press and hold, about 1 s, the trigger on the

Kelvin probe or the TEST button just after a

measurement.

The latest test result is deleted from screen

and log. This is also confirmed by an audio

signal.

Note This is also possible to carry out when the

result is locked on display.

Recalling test results from the log

1] Saved results can be recalled by scrolling to

desired label using the ▲▼ keys.

Delete results in the log

1] Select label using the ▲▼ ◀ ▶ keys.

2] By pressing the C key the display will prompt

"CLR" in big characters.

3] Delete by pressing the OK key. Cancel can be

done by pressing the C key.

Note In Circuit breaker testing mode the measure-

ment results will be deleted one at a time.

Delete all results in the log

1] Press and hold, for 5 s, the red button below

the TEST button.

Note This will delete the log memory for both log

Save test results

A] When LOG is activated measurement results

are automatically saved in the memory.

modes, Circuit breaker testing and Running

numbers.

B] When the log is OFF only the latest value is

stored and only until the performance of a

following measurement, which overwrites

the previous one.

Hold present test result

When the LOG function is activated the measurement

result is shown on the display for about 3 seconds.

After that it is stored in the memory. If you want to

study the result longer you can lock the display view

by doing as follows.

1] Press shortly the trigger on the Kelvin probe

or the TEST button just after a measurement.

The latest test result is locked and shown on

the display. This is confirmed by a padlock

BD0333FE ZP-BD03E MOM2

23

Page 24

5 OPERATING INSTRUCTIONS

5.2 Measurement with

max. charge, I=IMAX

1] Read the section 5.1 General instructions.

2] If applicable, connect the ground cable (pro-

tective earth).

3] Make the desired settings in the SET options.

In this example LOG and P / F are disabled (set

to OFF).

4] Attach the test cables.

5] Turn the function selector to desired I = I max

position.

The instrument indicates that it is charging

the capacitor by a repeated sound and on

the display shows alternating "CAP" and

"CHG" and the lock symbol.

Over the resistance value "100 μΩ" toggles

the maximal and minimal current values during the test. "268 A" and "250 A"

Pictures shows the two display views..

Charging

6] The MOM2 is ready for a measurement when

the lock symbol disappears.

Ready for test

7] Press the TEST button on MOM2 or the pull

the trigger on the probe.

A continuous audio signal tells that the

measurement is in progress.

Two short signals tells that the measurement

is complete.

8] The result is shown on the display, see figures

below.

24 MOM2 ZP-BD03E BD0333FE

Page 25

5 OPERATING INSTRUCTIONS

5.3 Measurement

with minimum current

guarantee, I > Imin

1] Read the section 5.1 General instructions.

2] If applicable, connect the ground cable (pro-

tective earth).

3] Make the desired settings in the SET options.

Select I min to 50 or 100 A (in this example

set to 100 A).

In this example LOG and P / F are disabled (set

to OFF).

4] Attach the test cables.

5] Turn the function selector to desired I > I min

position.

The instrument indicates that it is charging

the capacitor by a repeated sound and on

the display shows alternating "CAP" and

"CHG" as well as the padlock symbol.

is complete.

A] If the current value is over the set min current

limit the result will be shown on the display

with big digits.

The small digits toggle between max and min

current value.

Charging

6] When the lock symbol disappears the MOM2

is ready for a measurement.

Pictures shows that the test current was below 219 A and

over 205 A.

B] If the current value is below the set min cur-

rent limit there is the fail signal and the <

character is displayed to the left of the set

min current value.

Picture shows that the test current was below 100 A.

Ready for test

7] Press the TEST button on MOM2 or Trigger

on the probe.

A continuous audio signal tells that the

measurement is in progress.

Two short signals tells that the measurement

BD0333FE ZP-BD03E MOM2

25

Page 26

5 OPERATING INSTRUCTIONS

5.4 Measurement using P/F – pass/fail

1] Make the desired settings in the SET options

Select P/F and enter desired limit value.

In this example LOG is set to OFF

2] Turn the function selector to one of the test

positions.

3] Press the TEST button on MOM2 or the pull

the trigger on the probe.

A continuous audio signal tells that the

measurement is in progress.

Another signal tells that the measurement is

complete, pass or fail.

A] If the resistance value is below the P/F limit.

The result will be shown on the display with

big digits.

The small digits toggle between the P/F limit

and the max, min current values.

Here P/F limit was set to 150 µΩ and the measured resistance value is 100 μΩ.

The small digits show the set P/F value (< 90 μΩ).

The character ">" to the left of the big digits indicates that

the P/F value was exceeded.

The minimum current was 80 A and the resistance value is

102 μΩ.

Max current during test was 219 A.

Min current during test was 205 A

B] If the resistance value is over the P/F limit

there is the fail signal and the > character is

displayed to the left of the set P/F value.

26 MOM2 ZP-BD03E BD0333FE

Page 27

5 OPERATING INSTRUCTIONS

5.5 Measurement with user

defined settings

There are three positions for storing user defined

settings. These can only be set via a PC with the

MOM2Win Software, see chapter MOM2 Win.

5.6 Measurement using the LOG function

See section 4.6 Data logger – LOG for how to set up.

Running numbers mode

The measurements are numbered in numerical order

1to1999

Measurement is automatically stored, provided that

the memory is not full (Running numbers =1999).

The display before first measurement.

The display after measurements

By using the ◀ ▶ and ▲ ▼ keys you can scroll between the saved test results.

Note You can only scroll through the measurements

in the selected LOG mode

Circuit breaker testing mode

Each label e.g. 1A1 in the memory for the circuit

breaker measurement can contain three measurements. These are indicated by commas, see picture

below.

The label is built of three elements

▪ Two-digit indication of circuit breaker (1 to 19)

A letter for phase (A,B,C)

▪

▪ Digit for interrupter (1 to 9)

142 3

5 6

BD0333FE ZP-BD03E MOM2

27

Page 28

5 OPERATING INSTRUCTIONS

1.

The first measurement on the present label

shown by a comma.

2.

The second measurement in the present

memory cell shown by a comma.

3.

The third measurement in the present memory

cell shown by a comma.

4.

Digit for the circuit breaker

5.

Letter for the phase

6.

Digit for the interrupter

The display before measurement

The display before first measurement, one comma:

The display shows "3" for the third measurement for the

specific label. The arrow sign to the left only represents the

omitted characters to the left of the digit "3".

To view all measurements stored on the

same label

1] Press the ▲ ▼ keys until an arrow sign is

shown to the left.

2] Scroll between measurements 1, 2 and 3 by

using the ◀ ▶ keys.

Example: Three measurements on one label

are shown as e.g. "1A1-1", "1A1-2", "1A1-3".

Note You can only scroll through the measurements

in the selected LOG mode

The display before second measurement, two commas:

The display before third measurement; three commas.

The display after measurements

When three measurements have been done and saved

to a label e.g. 1A1 the lock sign is shown.

Note To continue to measure you need to either

delete the latest measurement or scroll to a

blank label.

By using the ◀ ▶ and ▲ ▼ keys you can toggle between the saved test results

28 MOM2 ZP-BD03E BD0333FE

Page 29

5 OPERATING INSTRUCTIONS

5.7 Measurement using P/F

and Imin

In this example LOG is set to OFF.

1] Read the section 5.1 General instructions.

2] If applicable, connect the ground cable (pro-

tective earth).

3] Make the desired settings in the SET options.

Select P/F and enter desired limit value.

Select I min (50 or 100 A).

4] Attach the test cables.

5] Turn the function selector to desired I > I min

position.

The instrument indicates that it is charging

the capacitor by a repeated sound and on

the display shows alternating "CAP" and

"CHG" as well as the padlock symbol.

and the current value is over the set min

current limit the result will be shown on the

display with big digits e.g. as below.

The small digits toggle between max and min

current value and the P/F limit.

The minimum test current was 80 A and resistance is

102µ.

B] If the resistance value is over the P/F limit

there is the fail signal and the > character is

displayed to the left of the set P/F value.

Charging

6] When the lock symbol disappears the MOM2

is ready for a measurement.

Ready for test

7] Press the TEST button on MOM2 or pull the

trigger on the probe.

A continuous audio signal tells that the

measurement is in progress.

When the measurement is complete there

will be a pass or a fail signal.

The small digits show the set P/F value (< 90 μΩ).

The character ">" to the left of the big digits indicates that

the P/F value was exceeded.

C] If the current value is below the set min cur-

rent limit there is the fail signal and the <

character is displayed to the left of the set

min current value.

The maximum test current was 82 A and the test current

was below 100 A.

D] If both the P/F limit and the current limit are

contravened, the big digits will toggle between resistance value, < current limit and >

P/F limit.

A] If the resistance value is below the P/F limit

BD0333FE ZP-BD03E MOM2

29

Page 30

5 OPERATING INSTRUCTIONS

5.8 Testing on circuit breakers having a current transformer in the loop

If there is a current transformer (CT) in series with the

breaker contact to be tested then it is advisable to make

some basic checks.

Encapsulated or dead tank breakers are the most common

types which have a current transformer in the loop.

The technical reason is that the CT must be saturated before

it is possible to get a reliable result. To get a transformer

saturated it needs time and current or an open secondary

winding.

A CT included in the circuit may influence the DC resistance

reading. The CT need to be in saturation not to influence

the DC resistance measurement. The time required to drive

the CT in saturation depends on current level and secondary

side burden, the time is usually several seconds if secondary

side is shorted.

If possible make a visual check to be sure that there is no

current transformer in the loop. If this is not possible like in

encapsulated breakers then make the following check:

5.9 Trouble shooting

Problem Solution

Headset does

not work

Error messages

Message Cause Remedy

"OL" Bad connection

Warning sign

on display and

the battery

charge indicator blinks

Warning sign

on display

Check that it is paired to MOM2

Check on MOM2 that Bluetooth

is enabled

/ resistance out

of measurement

range

The batteries

cannot charge

the capacitor

A thermal

protection has

tripped.

Check cables and connections

Charge the batteries

Note: It might be possible

to proceed and make some

tests if it is realistic to select

a test position that requires

less power (shorter measuring time).

Turn off the MOM2 and let it

cool down.

1] Make two tests, one with 0.1 second and one

with 3 seconds setting. If the values are equal

then there is no current transformer in the

loop.

If you get different readings it might be a need for a

“workaround”.

1] If possible increase the current and / or test

time.

2] Increase the burden on the current trans-

former by opening the secondary winding

or connect a 5 to 10 ohm resistor across the

winding.

3] Repeat the measurement several times in

the same direction until a stable value is

achieved.

30 MOM2 ZP-BD03E BD0333FE

Page 31

6 APPLICATION EXAMPLES

BD0333FE ZP-BD03E MOM2

31

Page 32

6 APPLICATION EXAMPLES

6

Application examples

6.1 Safety

Important regarding all testing

Read and comply with the

safety instructions.

Important

Note If you are measuring resistance in a circuit

breaker or disconnecting switch (isolator),

make sure that it is closed and grounded at

both sides before testing.

Always comply with local

safety regulations.

6.2 Measurement using Kelvin probes

An example how to perform testing using the two

Kelvin probes. This example describes the performance if you only want to know if the test object pass

a preset value and you do not need to store the test

results.

1] Select LOG function "OFF", and set P/F value

(see section 4.6 and 4.7).

2] Attach the test cables with Kelvin probes (2 x

1.3 m) one with a trigger, to MOM2.

3] Turn the function selector to desired posi-

tion.

4] Hook the instrument to your belt or use the

strap.

5] Press and hold the two Kelvin probes to the

test object and pull the trigger.

If the value is outside the limits there is a

sound telling the result was fail.

The measurement value remains until another measurement is performed or until the

instrument is switched off.

Measurement on a test object

32 MOM2 ZP-BD03E BD0333FE

Page 33

6 APPLICATION EXAMPLES

6.3 Test a CB using

DualGround

You can perform testing with both sides grounded.

However the measurement accuracy will be somewhat lower with both sides grounded depending on

the ratio of the currents – circuit breaker / grounding

cables (see section 2.2). This example shows a test on

a HV CB using a man lift.

1] The circuit breaker shall be disconnected,

closed and grounded on both sides.

2] Attach the black (3 m) test cable with Kelvin

clamp and the Kelvin probe with trigger to

the instrument.

3] Hook the MOM2 to your belt or use the strap

to hang it around your neck.

4] Attach the black test cable with Kelvin clamp

to one side of the CB using the man lift.

5] Move yourself to the other side of the CB us-

ing the manlift.

6] Press and hold the Kelvin probe to the test

object and pull the trigger.

6.4 Test a CB by injecting through the ground cables

1] The circuit breaker (CB) shall be disconnect-

ed, closed and grounded on both sides.

2] Connect the MOM2 to ground.

3] Attach an extra ground cable (not included)

with at least 95mm2 cross section area to one

side of the CB.

4] Connect the 0.5 m current cable to the cur-

rent out minus terminal on the MOM2 and

attach the other end to ground close to

where the CB's grounding cable is attached.

(the opposite side of CB from where the extra ground cable is attached).

5] Mount the 0.1 m plate to the current out

plus terminal on the MOM2 and attach the

extra ground cable to the plate.

6] Connect the sensing cables (red and black) to

the CB.

7] Remove the original CB grounding cable on

the side where the extra grounding cable is

attached.

Measurement on CB with both sides grounded.

Note The test can also be done by using two Kelvin

clamps.

8] Press the TEST button.

Traditional measurement from ground. Injection is done

through existing grounding cable (earthing). Optional cable

kit is needed. Available kits have 5, 10 or 15 m cables.

Disconnection

1] Re-attach the original CB grounding on the

side where the extra grounding is attached.

2] Disconnect the sensing cables from the CB.

3] Disconnect the extra ground cable from the

0.1 m plate on plus terminal.

4] Disconnect the 0.5 m current cable from

ground.

5] Disconnect the ground cable from MOM2.

BD0333FE ZP-BD03E MOM2

33

Page 34

7 MOM2 WIN

7

MOM2 Win

7.1 Introduction

MOM2 Win is a Windows® program that communicates with the MOM2 micro-ohmmeter instrument.

It is used for:

▪

Reading measurement data from the instrument and save

it to file

▪ Configuring the instrument

▪ Calibrating the instrument

7.2 MOM2 installation

Preconditions

▪ Windows XP / 7

▪ .net Framework 4.0

If the PC has not the .net Framework 4.0 installed it

will automatically be installed provided that the PC is

connected to internet.

▪ USB Bluetooth dongle

The USB Bluetooth dongle must be installed, see the

installation instructions supplied with the dongle.

Setup

1] Insert the MOM2 Win CD into the CD-drive.

The installation will start automatically. If not

select and run the file "Setup.exe" to install

the program.

The program will be installed in the folder C:\Program

Files\Programma\Mom2 Win with program shortcuts on the desktop and in the Start->All programs>Programma folder.

Select language

1] Under "Settings" menu, select "Language".

All texts in all open windows will be updated

with the selected language.

Note If the translation is missing for some texts the

default language (English) will be used.

The language selection does not change the

time format or decimal separator which instead follows the Windows regional settings.

34 MOM2 ZP-BD03E BD0333FE

Page 35

7 MOM2 WIN

7.3 Start MOM2 Win

1] Click the MOM2 icon on the desktop or

run the file Mom2Win.exe

(Start->All programs->Programma)

The program will startup showing the start

page.

7.4 Connecting to MOM2

To establish the Bluetooth connection the MOM2

must be paired to the PC, see section 4.3.

Automatic connecting

1] Turn the function selector to the PC COM

position on the MOM2 instrument.

At program startup the SW will try to connect to

MOM2 using the same COM port that the last successful connection used. If there have been no previous MOM2 connections from this computer the SW

will scan all available COM ports. If there are several

paired MOM2 instruments nearby the SW will connect to the first one detected. The connection status is

shown on the start page, see Figure 8.3.1.

Manual connecting

1] Open the "Connection settings" window

from the "Settings" menu or double-click on

the connection status text field on the start

page.

The "Connection settings" window will then

pop up, see figure below

Figure 8.3.1 Start page

Exit MOM2 Win

1] Exit the program by selecting "Exit" from the

"File" menu or by clicking on the "X" button

in the upper right corner of the window.

The program will ask for a confirmation before it closes.

Figure 8.4.1 The Connection settings window, no connection established.

BD0333FE ZP-BD03E MOM2

35

Page 36

7 MOM2 WIN

2] Choose a COM port in the drop down list and

click the "Connect" button.

The program will try to connect to a MOM2

instrument over the specified COM port.

If it is unknown which COM port to use the program

can scan all available ports until it finds a MOM2

instrument.

3] Click the button “Scan for MOM2”.

The operation can be interrupted with the

“Cancel scan” button.

Figure 8.4.2 The Connection settings window, searching.

Figure 8.4.3 The Connection settings window, connection

established.

Refresh button

Provided that the MOM2 and the PC are connected

to each other the "MOM2 date and time" and the

"PC date and time" fields are updated every time you

open the "Connection settings" window or when you

click the "Refresh" button, see Figure 8.4.3

Synchronize clock PC -> MOM2

When you click the “Synchronize clock PC -> MOM2”

button the PC system time is written to the MOM2.

This is the easiest way to set the clock in MOM2, see

Figure 8.4.3

Test Equipment Depot - 800.517.8431

99 Washington Street, Melrose, MA 02176

TestEquipmentDepot.com

36 MOM2 ZP-BD03E BD0333FE

Page 37

7.5 Read the measurement log

1] Click the "Measurements" button on the

Start page or select "Measurements" from

the "Tools" menu.

7 MOM2 WIN

Figure 8.5.1 Data dumping dialog.

2] Click on the "Retrieve all data" button to

download all measurements stored in the

instrument.

A window will pop up showing the progress

of the download.

At any time the data dump can be stopped

by clicking the "Cancel" button. In that case

the data window will be closed.

Figure 8.5.2 Data dumping progress.

BD0333FE ZP-BD03E MOM2

37

Page 38

7 MOM2 WIN

Figure 8.5.3 Data dumping finished. The columns can be sorted by clicking the headers and arranged by click-hold and drag.

Export data to file

1] Click the "Save to file" button (this button is

not enabled if the list is empty).

A "Save as" window will be opened.

Delete all data on the instrument

1] In the "Measurements" window, click the

"Delete all data" button to erase all the

measurements in the instrument log.

2] Type a file name and click the "Save" button

to export the data to file.

A] The default file type is (*.csv) which will save

the data as an ASCII file with comma separated values, suited for import to e.g. Microsoft

Excel.

Note The value separator is dependent of the re-

gional setting in Windows, a semicolon when

comma is used for decimal separator and

comma otherwise.

The format of the exported data is not the same as

what is seen in the measurements table. There is no

mixing of values and units, the units are placed in the

column headers.

B] If file type (*.txt) is selected the data will be

saved with the values separated by tabs.

38 MOM2 ZP-BD03E BD0333FE

Page 39

7 MOM2 WIN

7.6 User settings

1] Click the Program "User" positions" button

on the start page or choose Program "User"

positions from the "Tools" menu .

Figure 8.5.4 Delete all measurements progress.

Figure 8.6.1 Program "User" positions

Read existing settings

1] Select "User" position No." (1 – 3).

2] Click the "Read from instrument" button to

see the current settings on the instrument.

All three user settings will be read, not only

the one selected in the combo box. The values for minimum current, pass/fail limit and

type of logging will be updated.

Program "User" positions

1] Make the desired settings and click the "Save

to instrument" button.

Note All three User positions will be updated on

the instrument, not just the currently selected

one.

BD0333FE ZP-BD03E MOM2

39

Page 40

7 MOM2 WIN

7.7 Calibration

Required equipment

▪ Stable DC voltage source

▪ Calibrated reference voltmeter

▪ Reference shunts 1 m and 10 m

Procedure

1] Click the "Calibration" button on the Start

page or select "Calibration" from the "Tools"

menu to switch to the calibration page.

The existing calibration factors will be read

from the instrument and the calibration page

will be disabled until it is finished.

6] Repeat from step 1 for the next two ranges.

Figure 8.7.2 Voltmeter calibration

Ammeter calibration

Note The voltmeter in the instrument must be

calibrated before it is possible to calibrate the

Ammeter.

The ammeter is calibrated in an indirectly manner by

measuring the resistance over two predefined shunts

and compare with the reference values. The resistance

is measured with a capacitor voltage suitable for the

voltage and current ranges.

Figure 8.7.1 Calibration page. Loading calibration factors

during startup.

Voltmeter calibration

The voltmeter should be tested in three ranges.

1] Connect the voltage source to the MOM2

sense input, correctly polarized

2] Adjust voltage so that it falls within ±10%

of the stated reference voltage, using the

calibrated voltmeter.

3] Type the value in the U reference column in

MOM2 Win

4] Click the "Measure" button next to the field.

The value measured by the MOM2 will then be

propagated to the "U measured" text field.

New calibration factors will automatically be

calculated.

1] Connect the current cables from the MOM2

to the reference shunt

2] Connect separate sense leads from the

MOM2 sense input to the sense outputs of

the reference shunt

3] Enter the value of the shunt in the "R refer-

ence" input field.

The "Measure" button will be enabled if the

resistance is within the limits.

4] Click the "Measure" button next to the field.

When the measurement is started a progress

window is shown, see fig. below. The two

uppermost fields show the measured capacitor voltage and the target voltage.

5] Click the "Verify" button.

The voltage measured with the new calibration

factor will be shown in the "U Verified" field. The

deviation (in percent) from the reference value

will be shown to the right.

40 MOM2 ZP-BD03E BD0333FE

Figure 8.7.3 Resistance measurement progress window

Page 41

5] The measurement goes on and when it is finished

the "R Measured" field is filled with the measured resistance value and a new calibration factor

for this measurement range is calculated, see fig.

below.

Figure 8.7.4 Ammeter calibration.

7 MOM2 WIN

6] Click the "Verify" button.

A measurement is started and the "Resistance measurement in progress" window will

be shown.

7] Repeat from step 1 for the next reference

shunt.

When the resistances over both the shunts

have been measured and the result is satisfactory you can save it to the MOM2.

8] Click the"Save to instrument" button.

9] If the result of the tests is not satisfying or

you want to start over, click the "Cancel"

button.

This will empty the calibration dialog and the

calibration factors are read from the instrument again.

Calibration report

1] Click the "Calibration Report" button to

show a preview of a calibration report.

It can be opened at any time during the

calibration. However, a complete report with

a calibration time can only be made when

the calibration is completed and saved to the

MOM2.

Figure 8.7.5 Calibration report.

2] The calibration report can be printed, either

by pressing ctrl-P or clicking on the "Print

report"button.

BD0333FE ZP-BD03E MOM2

41

Page 42

8 SPECIFICATIONS

8

Specifications

Specifications MOM2

Specifications are valid at fully charged batteries and an ambient temperature of +25°C, (77°F). Specifications are subject to

change without notice.

Environment

Application field For use in high-voltage substations

Temperature

Operation -20ºC to +50°C (-4°F to +122°F) *

Storage -40ºC to +70ºC (-40°F to +158°F)

Relative humidity %RH 5%-95%, non condensing

Pollution degree 2

Shock IEC 60068-2-27

Vibration I EC 60 068 -2-6

Transport ISTA 2A

Flammability class V0

*) Battery operation temperature 0ºC to +50° (32°F to

+122°F)

Battery charging temperature +10ºC to +40° (50°F to +104°F)

CE-marking

EMC 2004/108/EC

LVD 2006/95/EC

General

Battery power Five AA (HR6) 2700 mAh NiMH cells

Recharge time < 12 h

Typical recharge time at

25°C

Battery charger

Mains voltage 100 - 250 V AC, 50 / 60Hz

Power consumption 60 W

Protection Against wrong battery type, low/high

Real time clock battery life ≥10 ye ar s

Audible feedback Different buzzer sounds

User presets 3

Field calibration Yes

Encapsulation IP54

Dimensions (excl. binding

posts)

Weight 1.0 kg (2.2 lbs) instrument only

and industrial environments.

3 h

temperature.

217 H x 92 B x 72 D mm

8.5 H x 3.6 B x 2.8 D in.

5.0 kg (11 lbs) with accessories and

carrying case

Measurement section

Minimum current guarantee

Pass / Fail Settable from 1 µΩ to 1999 mΩ

Number of measurements

on fully charged batteries

Interference suppression Yes

Range 0 - 1000 mΩ

)

Range selection Auto

Resolution

0 – 999 µΩ 1 µΩ

1.0 – 9.99 mΩ 0.01 mΩ

10.0 – 99.9 mΩ 0.1 mΩ

100 – 1000 mΩ 1 mΩ

Inaccuracy

0 – 1999 µΩ ±1 % of reading ±1 digit

2 – 1000 mΩ ±2 % of reading ±1 digit

Selectable 50 A / 100 A

Valid at resistance ≤2mΩ

typ. 2200 at I min = 50 A and 0.1 s

typ. 800 at I min = 100 A and 0.1 s

Outputs + / –

Range > 100 A DC (R < 2 mΩ)

Output voltage (max) 2.5 V DC

Generation duration Selectable: 0.1 s, 0.6 s, 3 s

Recovery time at I min set to 100

A and load 100 μΩ

Generation time Max Typ

0.1 s 10 s 8 s

0.6 s 20 s 16 s

3 s 130 s 100 s

Inputs

SENSE + / –

Connector 4 mm banana jack

Voltage ±3 V DC

Trigger input Threshold 8 V DC

DC IN 12 – 24 V DC, 2 A max

Logger

Logger, Data Label. Timestamp, I max, I min, I Lim-

Labeling schemes Circuit breaker oriented or running

Capacity 190 measurements

it, Resistance, Meas.time, P/F limit

numbers

Wireless communication

Headset Bluetooth

PC communication Bluetooth

42 MOM2 ZP-BD03E BD0333FE

Page 43

BD0333FE ZP-BD03E MOM2

43

Page 44

INDEX

Index

A

K

Accessories ...................................................12

Application examples.....................................32

Audio signals .................................................20

B

Basic technical description ..............................8

Battery charging ............................................20

Battery charging indicator .............................. 11

Battery charging LED

indicator ......................................................20

Battery lid....................................................... 11

Battery power supply .....................................20

Bluetooth .......................................................15

Both sides grounded........................................9

C

Calibration .....................................................40

Clear log ........................................................ 11

CLK................................................................16

Clock..............................................................16

Connector for the battery charger.................. 11

Connectors for trigger .................................... 11

Current output terminal (-) ............................. 11

Current output terminal (+) ............................ 11

D

Delete all reults ..............................................23

Delete present test result...............................23

Delete results.................................................23

display ...........................................................22

Display ........................................................... 11

DualGround .....................................................9

F

Functions .......................................................14

Functions and set up .....................................14

Function selector ........................................... 11

H

Hold present test result..................................23

I

I min ...............................................................17

Input for sensing voltage (-) ........................... 11

Input for sensing voltage (+) .......................... 11

Kelvin Clamp/Probe practice .........................23

Kelvin test ........................................................8

Keys............................................................... 11

L

LCD display ...................................................22

LOG ...............................................................18

low temperatures ...........................................23

M

Measurement on using Kelvin probes ...........32

measurement time .........................................22

Measurement using P/F ................................26

Measurement using P/F and I min.................29

Measurement using the LOG function ...........27

Measurement with max. charge, I=I MAX .....24

Measurement with minimum current guarantee,

I>I MIN ........................................................25

Measurement with user dened settings .......27

MOM2 installation ..........................................34

MOM2 Win .....................................................34

O

OFF ...............................................................14

Operating instructions....................................22

Optional accessories .....................................12

overview ........................................................10

P

Pass/Fail ........................................................19

PC COM ........................................................19

PC communication ........................................19

P/F .................................................................19

Protective conductor terminal ........................ 11

R

Recalling test results .....................................23

Replacing batteries ........................................20

S

Safety ..............................................................6

Safety instructions ...........................................6

Save test results ............................................23

set up .............................................................14

Specications ................................................42

44 MOM2 ZP-BD03E BD0333FE

Page 45

Stand-by / Wake up .......................................11

T

Test a CB by injecting through the ground ca-

bles .............................................................33

Test a CB using DualGround .........................33

TEST button ..................................................11

Testing on circuit breakers having a current

transformer in the loop ................................30

Test positions .................................................14

T o choose I > I min or I = I max ........................22

To choose measurement time .......................22

Trouble shooting ............................................30

U

USER – 1/2/3 ..................................................14

W

Wake up ........................................................11

INDEX

BD0333FE ZP-BD03E MOM2

45

Page 46

INDEX

46 MOM2 ZP-BD03E BD0333FE

Page 47

Page 48

Your “One Stop” Source for all your electrical test equipment needs

Megger is a leading global manufacturer and supplier

of test and measurement instruments used within the

electric power, building wiring and telecommunication

industries.

With research, engineering and manufacturing facilities

in the USA, UK, Germany and Sweden, combined with

sales and technical support in most countries, Megger

is uniquely placed to meet the needs of its customers

worldwide.

Megger is certified according to ISO 9001 and 14001.

Megger is a registered trademark.

▪ Battery Test Equipment

▪ Cable Fault Locating Equipment

▪ Circuit Breaker Test Equipment

▪ Data Communications Test Equipment

▪ Fiber Optic Test Equipment

▪ Ground Resistance Test Equipment

▪ Insulation Power Factor (C&DF) Test Equipment

▪ Insulation Resistance Test Equipment

▪ Line Testing Equipment

▪ Low Resistance Ohmmeters

▪ Motor & Phase Rotation Test Equipment

▪ Multimeters

▪ Oil Test Equipment

▪ Portable Appliance & Tool Testers

▪ Power Quality Instruments

▪ Recloser Test Equipment

▪ Relay Test Equipment

▪ T1 Network Test Equipment

▪ Tachometers & Speed Measuring Instruments

▪ TDR Test Equipment

▪ Transformer Test Equipment

▪ Transmission Impairment Test Equipment

▪ Watthour Meter Test Equipment

▪ STATES® Terminal Blocks & Test Switches

▪ Professional Hands-On Technical and

Safety Training Programs

Test Equipment Depot - 800.517.8431

99 Washington Street, Melrose, MA 02176

TestEquipmentDepot.com

Subject to change without notice. Printed matter No. ZP-BD03E Doc. BD0333FE V06a 2016

Loading...

Loading...