Page 1

M

LCR131

Dual display meter

User Manual

Page 2

LCR131

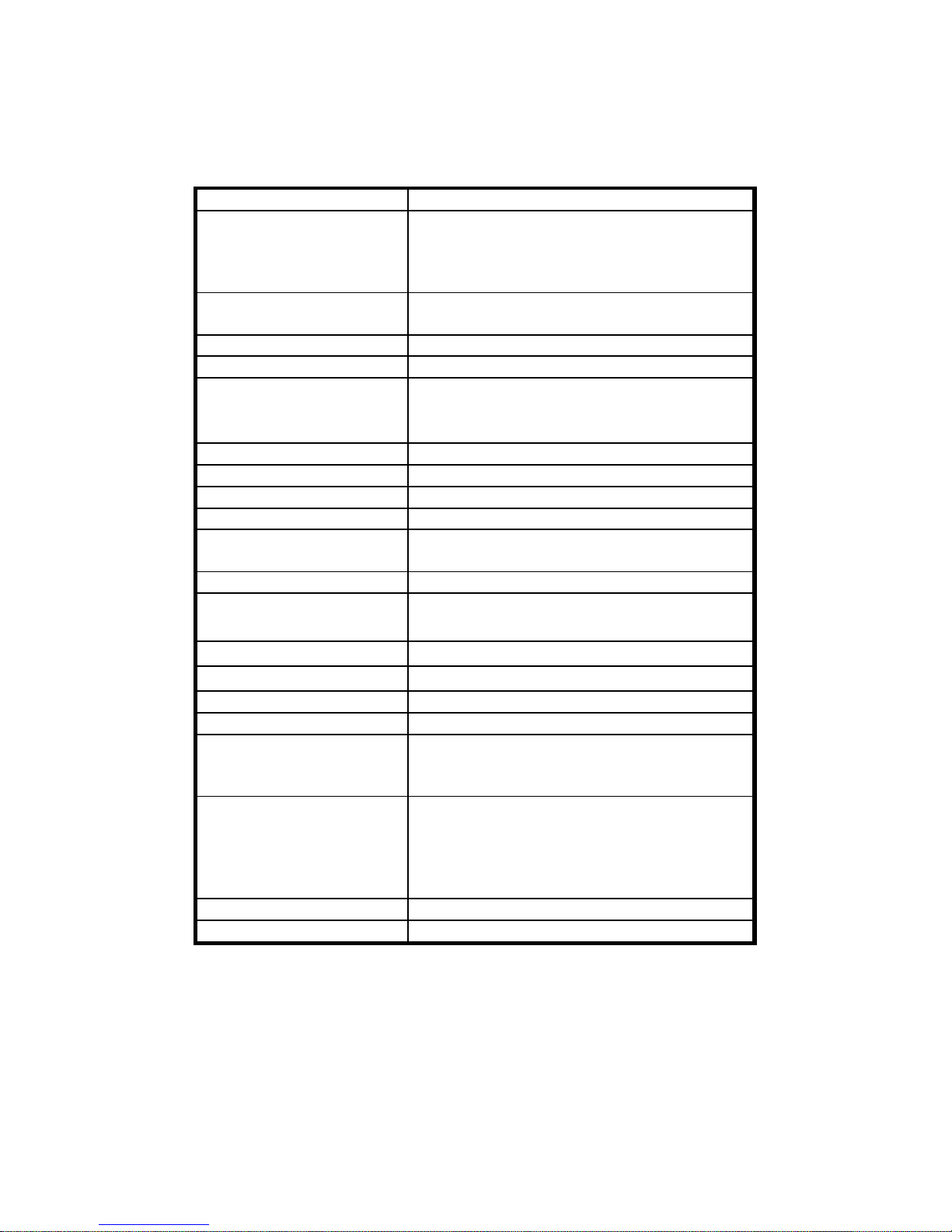

Parameters Measured L/C/R/D/Q

Measuring Circuit Mode

Inductance (L)

–Defaults to series mode

Capacitance/ Resistance (C/R)

-Defaults to parallel mode

Displays L/C/R: Maximum display 19999

D/Q: Maximum display 999 (Auto Range).

Ranging Mode Auto & Manual

Measuring Terminals 3 terminals with sockets

Test Frequency

Accuracy:

±0.1 %

120Hz= 120 Hz

1KHz =1010 Hz

Backlit display Excluded

Tolerance mode 1%, 5%, 10%

Test Signal Level 0.6Vrms approx.

Measuring Rate 1 time/second, nominal

Response time

Approx. 1 second/ DUT (device under

test)(@ manual range)

Auto Power-Off 5 minutes approx. without operation

Temperature Coefficient

0.15 x (Specified Accuracy) / (0-18 or

28-40 )

Operation Temperature

0 to 40 ; 0-70% R.H.

Storage Temperature

-20 to +50 ; 0-80% R.H.

Low Battery Indication

Approx. 6.8V

Protective Fuse 0.1A/250V Fuse (input protective)

Standard Accessories Test alliga t or clips (pair)

DC 9V Battery.

User manual

Optional Accessories Carrying case

RS232 package

SMD Tweezers

DC Adaptor (EA112: AC120V) / (EA55:

AC220V).

Dimensions (L/W/H) 184/ 87/ 41 mm

Weight 330 grams

Page 3

i

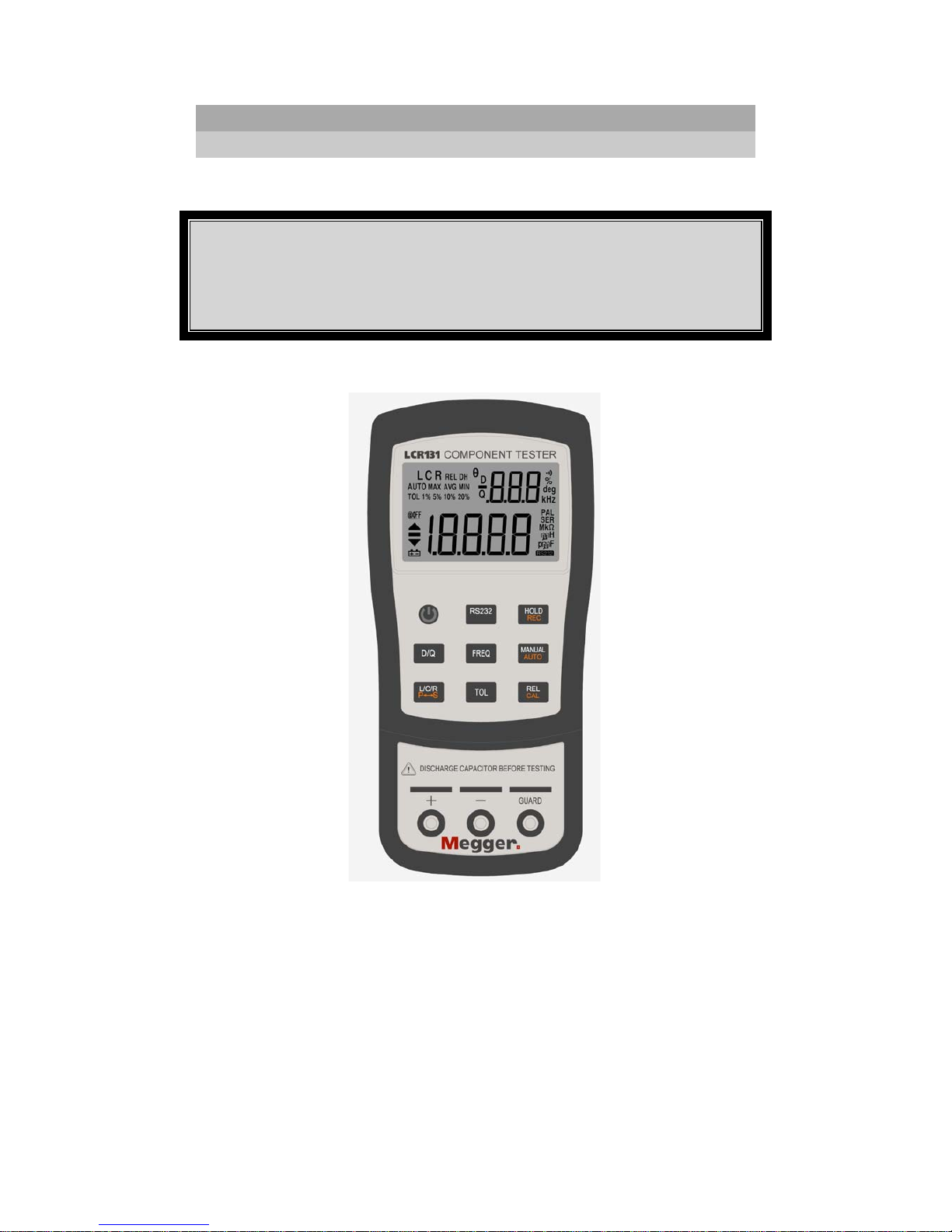

LCR131 COMPONENT TE STER

USER MANUAL

Page 4

ii

T able of Contents

PAGE

Safety

1

Introduction

3

Front Panel Illustration

4

LCD Display Illustration

5

How to Operate

7

Operating Instructions

11

Data Hold

11

Static Recording

11

Dissipation Factor / Quality Factor

11

Test Frequency

12

L/C/R function selector

12

Relative

12

Tolerance

12

Auto/manual ranging

13

Automatic Fuse Detection

13

Parallel / Series Mode

13

Calibration

14

Auto Power Off/ Disable Auto Power Off

15

Low Battery Indication

15

Communication

15

General Specification

17

Electrical Specification

18

Maintenance

21

Page 5

1

Safety

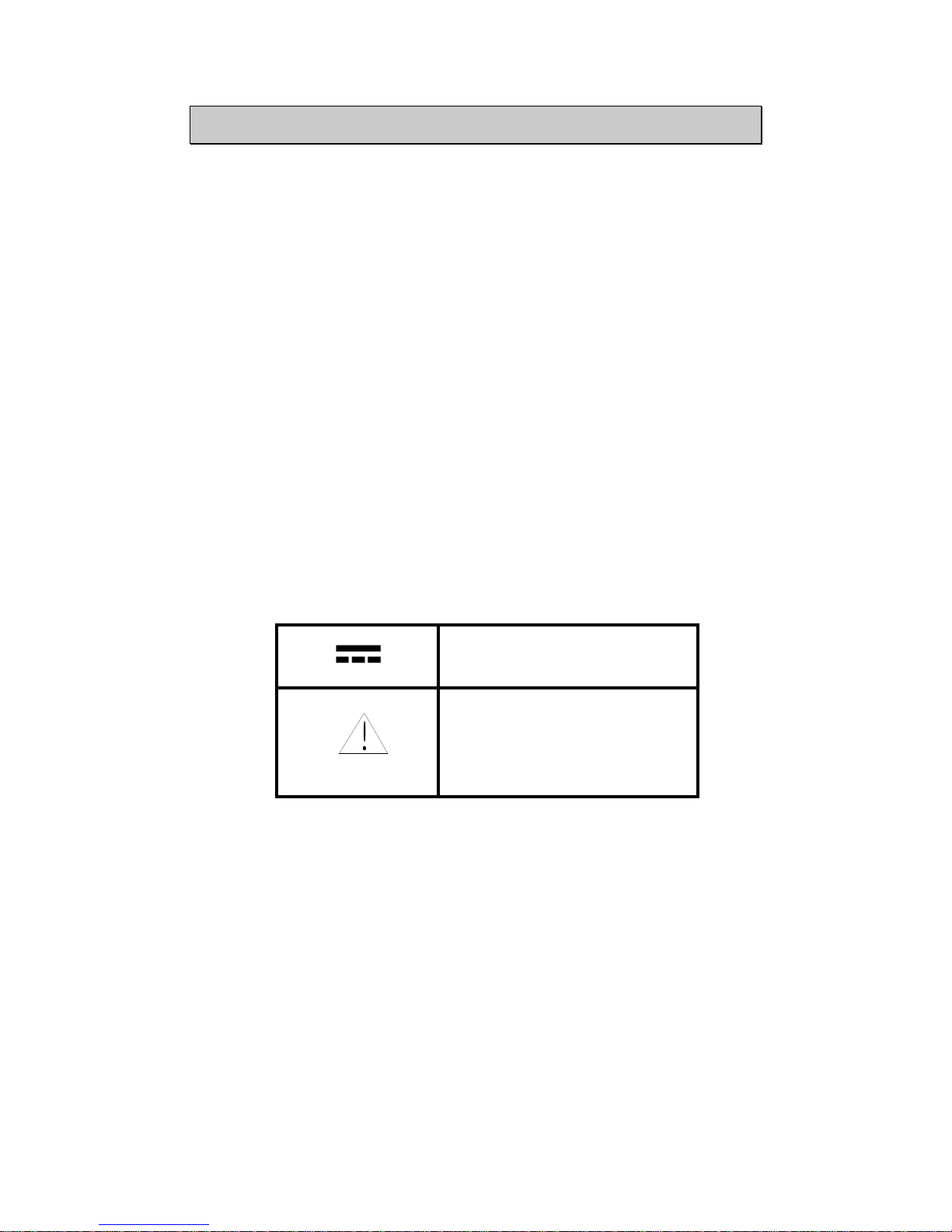

Read "SAFETY INFORMATION" before using this meter.

NOTE

This meter is a hand-held, battery-operated instrument for

testing inductance, capacitance and resistance. If this device

is damaged or has any parts mi ssin g, c ontact the retailer

immediately.

This manual contains information and warnings which must

be followed to ensure safe operation as well as to ensure the

meter remains in a safe condition. Some common

international electrical symbols used in this manual are

shown in the table below:

DC - Direct Current

See Explanation In The

Manual

Table 1-1. International Electrical Symbols

Before usin g the m eter, re ad the f ollowing s afety i nformatio n

carefully. In this manual, "WARNING", is reserved for

conditions and actions that pose hazard(s) to the user;

"CAUTION", is reserved for con ditions and actio ns that may

damage your meter.

Page 6

2

SAFETY INFORMATION

To ensure that you use this device safely, follow the

safety guide lin es lis te d bel ow :

This meter is for indoor use, altitude up to 2,000 m.

The warnings and precautions should be read and well

understood before the instrument is used.

Use this device only as specified in this manual; otherwise,

the protection provided by the meter may be impaired.

When measuring in-circuit components, first de-energize

the circuits before connecting to the test leads.

Discharge capacitors before testing.

The power for the meter is supplied with a single standard

9V batter y. It is also possibl e t o use exter nal pow er usi n g

a 12V DC adaptor conforming to IEC 60950.

Page 7

3

Introduction

This 19,999-count L/C/R hand-held meter is a special

microprocessor-controlled meter for measuring functions of

inductance, capacitance and resistance. Extremely simple

to operate, the instrument not only takes absolute parallel

mode measurements, but is also capable of series mode

measurement. The meter provides direct and accurate

measurements of inductors, capacitors and resistors with

different testi ng frequencies. It is possible to select betw een

auto and manual ranging.

Front panel pushbuttons maximize the convenience of

function and feature selection such a s data hold; maxim um,

minimum a nd average rec ord m od e; r el ati ve mo de; tolerance

sorting mode; frequency and L/C/R selection.

The test data can be transferred to PC through an optional full

isolated optical RS232C interface and CP-09 software.

A tilt stand provides position flexibility for viewing and

operating the meter. The rubber over-molded case both

protects t he mete r in hars h envi ronments, and i mproves grip

in the han d. Whil e single 9V b attery opera tion is stand ard f or

the meter, a standard DC 12V power adaptor can also be

used as an optional power input.

Page 8

4

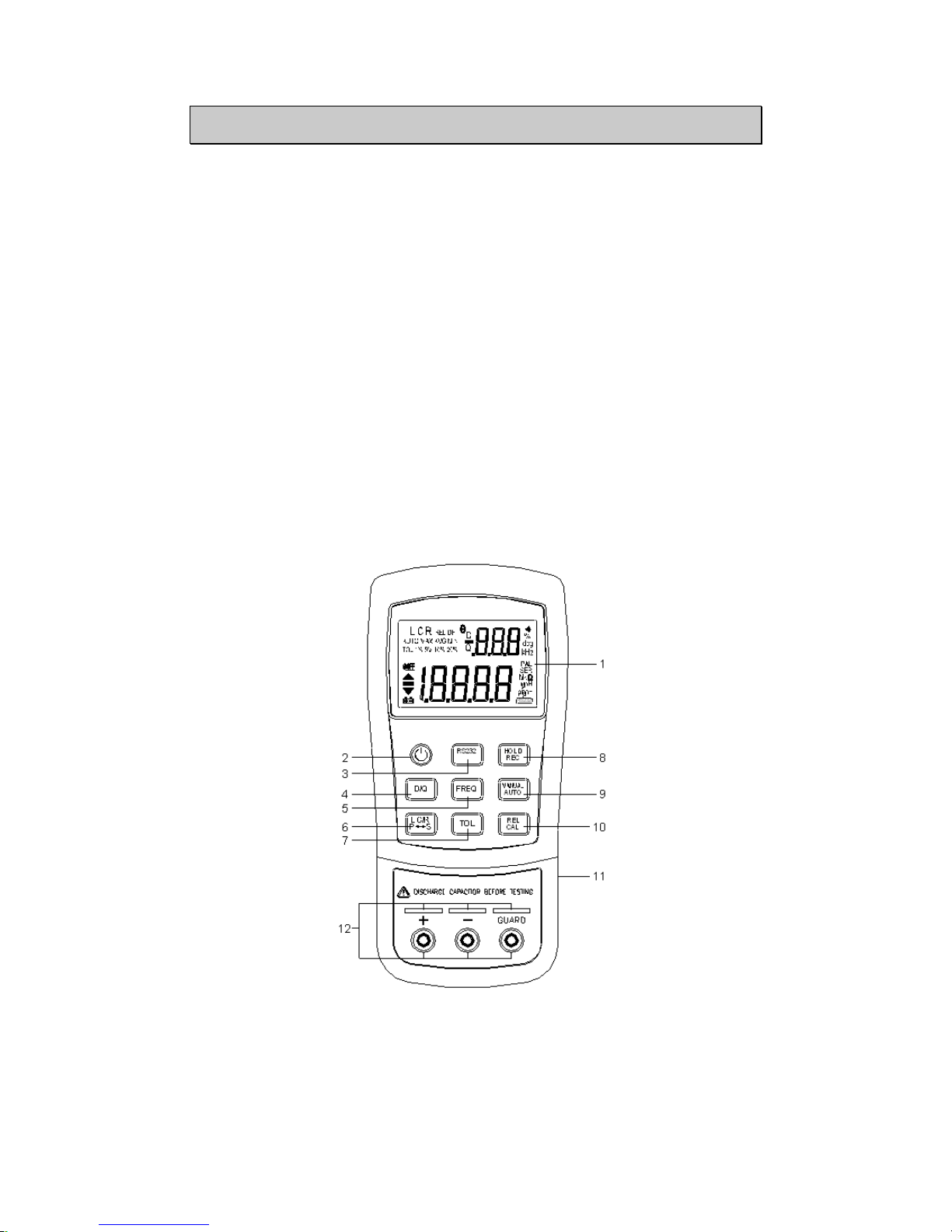

Front Panel Illustration

1. LCD display

2. Power ON/OFF button

3. RS232 selector

4. Dissipation factor and Quality factor selection button

5. Test frequency selection button

6. Inductance, Capacitance and Resistance function

selection button. Parallel and series mode selection

button

7. Tolerance mode selection button

8. Data hold, Maximum, Minimum and Average reading

selection butto n

9. Range selection button

10. Relative mode and Calibration selection button

11. DC 12V adaptor input

12. Input sockets and Terminals

Figure -1. Fr o nt pan el for LC R131.

Page 9

5

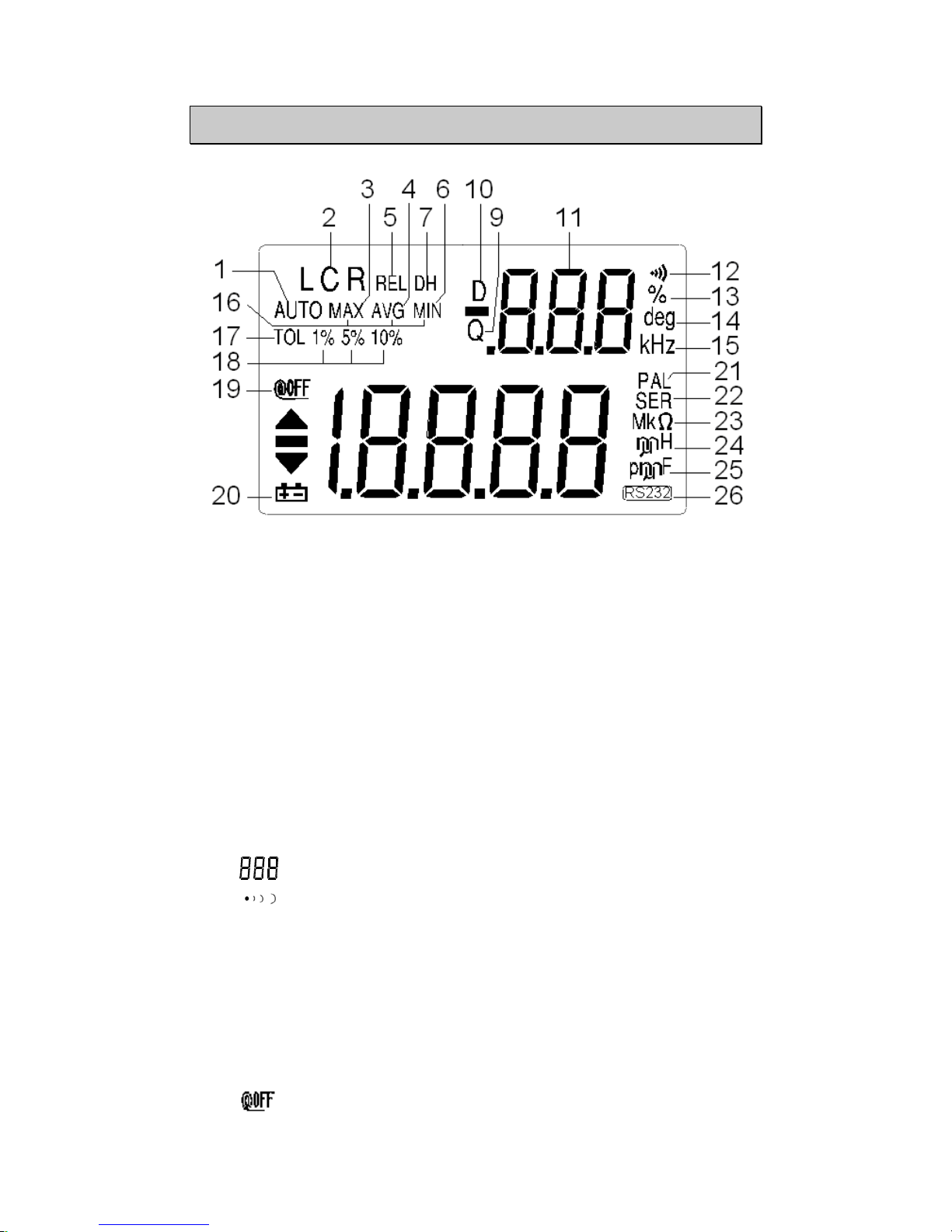

LCD Display Illustration

Figure 2. LCD Di s play.

1. AUTO: Auto-ranging indicator

2. LCR: L, C or R function indicator

3. MAX: Maxim um re adi n g indi ca to r

4. AVG: Average reading indicator

5. REL: Relative mode indicator

6. MIN: Minimum reading indicator

7. DH: Data hold indicator

9. Q: Quality factor indicator

10. D: Dissipation factor indicator

11.

: Secondary display

12.

: Beeper tone indicator for tolerance mode

13. %: Tolerance (percentage) indicator

14. deg: Phase Angle degree indicator (Model-A only )

15. kHz: Frequen cy indica tor

16. MAX AVG MIN: Recording mode indicators

17. TOL: Tolerance mode indicator

18. 1%5%10%: Tolerance sorting (percent) indicator

19.

: Auto power- off indicator

Page 10

6

20. : Low battery indicator

21. PAL: Parallel mode indicator

22. SER: Series mode indicator

23. Mk: Resistance (Ohm) indicator

24.

: Inductance (Henry) indicator

25.

: Capacitance (Farad) indicator

26.

: RS232 indicator

Special Indication Characters

: Indicates short connectors

: Indicates open con nec tor s

: Indicates calibration mo de

: Indicates damaged or open fuse

Page 11

7

How To Operate

Caution

When measuring within a circuit, the circuit must be

de-energized before connecting the test leads.

Instruments used in dusty or dirty environment should be

wiped and cleaned regularly.

Do not expose instrument to direct sunlight or other heat

sources for long peri ods .

E nsure the inst rument is di sconne cted fro m any circuit a nd

powered "OFF" before removing battery cover.

Note:

For achieving optimum precision for all L, C and R

measurements throughout all ranges, the instrument

should be internally calibrated before each use.

Page 12

8

Inductance Measureme nt

1. Press the "POWER" button to turn on the meter.

2. Press “L/C/R” button to select inductance measurement.

3. Insert an inductor into component receptacle socket or

connect the test clip to the component leads as required.

4. Press “FREQ” button to select testing frequency.

5. Press “D/Q” button to select Q factor for secondary

display.

6. Read the display readings for inductance value and quality

factor.

Figure-3. In d uctan ce Measuremen t.

Page 13

9

Capacitance Measureme nt

1. Press "POWER" button to turn on the met er.

2. Press “L/C/R” button to select capacitance measurement.

3. Insert a capacitor i nt o t he co mp on ent r ecep tacl e s ock et or

connect the test clip to the component leads as required.

4. Press “FREQ” button to select testing frequency.

5. Press “D/Q” button to select D factor for secondary

display.

6. Read the display readings for capacitance value and

dissipation factor.

Warning

To avoid electrical hazards, discharge all capacitors before

measuring.

Figure-4. Capacitance Measureme nt .

Page 14

10

Resistance Measurement

1. Press "POWER" button to turn on the met er.

2. Press “L/C/R” button to select Resistance measurement.

3. Insert a resistor into the component receptacle socket or

connect the test clip to the component leads as required.

4. Press “FREQ” button to select testing frequency.

5. Read the display readings for resistance value.

Figure-5. Resistance Measurement.

Page 15

11

Operating Instructions

Data Hold

This data hold function allows the operator to freeze the

displa y. To ente r this m ode, pr ess the " HOLD" pushb utton;

press again to release.

Sta tic Recording

Press the "REC" pushbutton for more than one second to

enter the static reco rdi n g mo de. The maximum and

minimum readings are then stored in memory, while a

beeping tone is produced when a new tested value has been

rec orde d. Push th e same but ton to cycle th roug h the curr ent

maximum, minimum and aver age readi ngs.

The MAX, MIN or AVG indicators on LCD will turn on to

indicate which value is shown.

To ex it this mo de, press an d hold the pushb utt on for mor e

than one second.

Notes:

1. Static recordi ng captur es only st able val ues and upd ates

the memory; it will not record any "OL" (overl oa d) val ue fo r

any of the L/C/R f unctions. In additi on, the meter will not

record values below 50 counts in Capacitance

measurement.

2. Static recording is only available in manual ranging;

however, activati on while in auto-r anging will automaticall y

set meter to ma nual r angi ng a nd caus e cali brati on p rompt s

to be displayed in the relevant ranges.

Dissipation Factor / Quality Factor

The "D/Q" value can b e displ aye d al t er nat ely by pressing the

"D/Q" button when the meter is set to Inductance or

Capacitance mode. It does not apply to resistance

measurement.

Page 16

12

Test Frequency

Default testing frequency is 1KHz. Push "FREQ" key to select

the desired test frequency.

L/C/R Function Selector

Press "L/C/R" pushbutton to select the desired L, C or R

function.

Relative

Press the "RE L" key t o e nter the r elativ e mode and st ore th e

display reading as a reference value. It will then dis play all

subsequent readings relative to the reference value. Press

"REL" button again to exit the relative mode.

Notes:

1. The relative mo de ca n not be activate d if the di s play value

is either "OL" or "0000".

2. Relative mode is only available in manual ranging;

however, activation while in auto-ranging will automatically

set the meter to manual ranging and cause calibration

prompts to be displayed in the relevant ranges.

3. The relative mode cannot be activated if the meter is set at

auto-ranging with data hold activated.

To leran ce

There are 1%, 5% and 10% tolerance range. To enter this

tolerance mode, insert the appropriate component as a

standard v alue into the socket or co nnect the component to

the test prob es, then press th e "TOL" pushbutto n to set this

value, as the standard reference tolerance. Similarly, any

value which appears on the LCD display, such as DH or

MAX/MIN/AVG, can be used as a standard value to sort

components. Press this button again to cycl e through 1%,

5% and 10% tolerance as required.

This functi on is designed for convenient c omponent sortin g.

An audible tone of “Be-Be-Be” will sound whenever the

component under test exceeds the setting tolerance.

Conversel y, a singl e ton e of “Be” indic ates the c ompone nt is

within the setting tolerance.

Page 17

13

Notes:

1. The t olerance mode can not be activated if the display is

either "OL" or "0000"; nor can it be activated where

capacitance value is below 10 counts.

2. Tolerance mode is only available in manual ranging;

however, activation while in auto-ranging will automatically

set the meter to manual ranging and cause calibration

prompts to be displayed in the relevant ranges.

3. The tolerance mode can’t be activated if the meter is set at

auto-ranging with data hold mode activated.

Auto / Manual Range

The auto-ranging mode is default status when the meter is

powered on. For specific measurement applications, press

"AUTO" button to set manual ranging. To return to the

auto-ranging mode, press and hold the "AUTO" button for

more than one second.

Automatic Fuse Detection

When the meter detects that the protective fuse has ruptured,

the "FUSE" character will appear and an internal beep will

sound continuously. In this situation, none of the function

keys can be operated and all other meter functions will be

inhibited. Fuse replacement is required.

Figure-6. F us e Dete ction

Parallel / Series Mode

The met er is cap able o f displa ying Pa rallel and Se ries mod e

data for all ranges. The parallel mode is default for

Capacitance and Resistance measurements, and the series

mode is default for Inductance measurement. Press "L/C/R"

button for more than 1 second to toggle "SER" and "PAL "

mode.

Page 18

14

Calibration

Calibration is avail able to all rang es. Si mply press and hol d

"CAL" button for more than one second to enter the

calibration mode and calibration prompts will be displayed.

Follow the prompts for open connector (

) or short

connector (

) connection and press the "CAL" button.

After calibration is completed, the meter will be restored to

normal display and ready for normal usage.

Figure-7. Ope n/ Short Cali br a tion

The function calibrates the meter’s internal parameters as

well as external connector influences for greater accuracy.

It is highly recommended to calibrate extremely high or low

ranges for L, C and R before making precision measurements.

Calibration prompts will be displayed automatically every time

those rang es are selec te d manu ally or by functi on (e. g. REL,

TOL, REC etc.), and calibration is recommended. Simply

follow the o pen connector (

) or short c onnector ( )

instruction an d then press the "CA L" b utton. You may skip

the calibration by pressing the "D/Q" button.

Notes:

1. Changing measurement frequencies is handled in the

same way as selecting a di ffer ent hardw are r an ge, a nd s o

automatic calibration prompts will be displayed in the

recommended ranges.

2. Be sure to use the same testing position after short

calibration.

Page 19

15

Auto Power Off/ Disable Auto Power Off

When the met er has not b een used f or five mi nutes after t he

last operation, a long "beep" tone will sound. The meter will

then automatically e nter a "slee p" mode and th ere will be n o

display on the LCD. T o reactivate the meter, simply press any

pushbutton.

When the meter is to be used for long period, the auto

power-off can be disabled by pressing and holding "L/C/R"

button while turning meter ON. Release the button, then

press any button. The

symbol will disappear to confirm

that the auto power off has been disabled.

When us in g a 12 V DC al ter n at e po w er sou rc e , au t o po wer off

is disabled automatically.

Note: It is recommended that the meter shou ld always be

switched off when not in use.

Low Battery Indication

When the "

" symbol flashes on the display, the battery

voltage is below normal working voltage and is weakening.

Replace battery with a new one to maintain accuracy of the meter.

Communication

The meter is provided with communication capability by using

the option al CP-09 RS232 package, with full optical isolat ed

cable and software.

Refer to the following procedures to set up communication

between your meter and personal computer.

1. Fix one side of cable to the meter, with the text-side facing

up. Connect the 9-pin terminal of cable to RS232

communicati on port 1 or 2 of person al comput er. See the

Figure-8.

2. Press "RS232" button to enable interface.

Symbol “

” is enabled on the display.

3. Operate the software to record data for your application.

4. Ensure the side-catches on the cable connector are

disengaged prior to removing the cable.

Page 20

16

Figure -8. Cable Connec tion Of Comm uni cation

Tex t side

facing up.

Page 21

17

General Specification

LCR131

Parameters Measured L/C/R/D/Q

Measuring Circuit Mode

Inductance (L)

–Defaults to series mode

Capacitance/ Resistance (C/R)

-Defaults to parallel mode

Displays L/C/R: Maximum display 19999

D/Q: Maximum display 999 (Auto Range).

Ranging Mode Auto & Manual

Measuring Terminals 3 terminals with sockets

Test Frequency

Accuracy:

±0.1 %

120Hz= 120 Hz

1KHz =1010 Hz

Tolerance mode 1%, 5%, 10%

Test Signal Level 0.6Vrms approx.

Measuring Rate 1 time/second, nominal

Response time

Approx. 1 second/ DUT (device under

test)(@ manual range)

Auto Power-Off 5 minutes approx. without operation

Temperature Coefficient

0.15 x (Specified Accuracy) / (0-18 or

28-40 )

Operation Temperature

0 to 40 ; 0-70% R.H.

Storage Temperature

-20 to +50 ; 0-80% R.H.

Low Battery Indication

Approx. 6.8V

Power Consumption

Approx. 40mA for operation/ 0.08mA after

Auto Power-off.

Power Requirements

1) DC 9V Battery

2) Ext. DC Adaptor: DC 12Vmin –15Vmax.

(Load 50mA Min.)

Protective Fuse 0.1A/250V Fuse (input protective)

Standard Accessories Test alligator clips (pair)

DC 9V Battery.

User manual

Optional Accessories Carrying case

RS232 package

SMD Tweezers

DC Adaptor (EA112: AC120V) / (EA55:

AC220V).

Dimensions (L/W/H) 184/ 87/ 41 mm

Weight 330 grams

Page 22

18

Electrical Specification

Accuracy is expressed as: ± (% of reading + no. of least significant

digits) at 23 ±5 and <75% R.H.

Resistance (parallel mode)

Test Frequency: 120Hz / 1KHz

Accuracy

Range

Maximum

Display

@120 Hz @1KHz

Specified Note

10M 9.999M

2.0%+8 *3 2.0%+8

*3

After open cal.

2000K

1999.9K

0.5%+5 0.5%+5 After open cal.

200K 199.99K

0.5%+3 0.5%+3 -

20K 19.999K

0.5%+3 0.5%+3 -

2000 1999.9

0.5%+3 0.5%+3 -

200 199.99

0.8%+5 0.8%+5 After short cal.

20 19.999

1.2%+40 1.2%+40 After short cal.

Notes:

1. This specification is based on measurements performed at the test

socket.

2. DUT (Device Under Test) & Test leads should be properly shielded

to GUARD if necessary.

3. This specification is based on battery operation.

Capacitance (parallel mode)

Test F requency: 120 Hz

Accuracy Range Maximum

Display

Capacitance

DF

Spec. Note

10mF 19.99mF

*5

3.0%+5

(DF<0.1)

10%+100/Cx+5

(DF<0.1)

After short

cal.

1000μF 1999.9μF

*6

1.0%+5

(DF<0.1)

2%+100/Cx+5

(DF<0.1)

After short

cal.

200μF 199.99μF

0.7%+3

DF<0.5

0.7%+100/Cx+5

(DF<0.5)

-

20μF 19.999μF

0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

2000nF 1999.9nF 0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

200nF 199.99nF 0.7%+5

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

After open

cal.

20nF 19.999nF 1.0%+5

(DF<0.1)

2%+100/Cx+5

(DF<0.1)

After open

cal.

Page 23

19

Test Frequency: 1 KHz

Accuracy

Range

Maximum

Display

Capacitance

DF

Spec. Note

1mF 1.999mF

*5

3.0%+5

(DF<0.1)

10%+100/Cx+5

(DF<0.1)

After short

cal.

200μF 199.99μF

1.0%+5

(DF<0.1)

2.0%+100/Cx+5

(DF<0.1)

After short

cal.

20μF 19.999μF

0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

2000nF 1999.9nF 0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

200nF 199.99nF 0.7%+3

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

-

20nF 19.999nF 0.7%+5

(DF<0.5)

0.7%+100/Cx+5

(DF<0.5)

After open

cal.

2000pF 1999.9pF 1.0%+5

(DF<0.1)

2.0%+100/Cx+5

(DF<0.1)

After open

cal.

Notes:

1. Q Value is the reciprocal of DF.

2. This specification is based on measurements performed at

the test socket.

3. DUT & Test leads s hould b e properl y shield ed to GUAR D

if necessary.

4. Cx=Counts of di splayed C value, e. g. if C=88.88μF, then

Cx=8888.

5. This reading can be extended to 1999 MAX display with

accuracy not specified.

6. This reading can be extended t o 19999 MAX display wit h

accuracy not specified.

Page 24

20

Inductance (Series mode)

Test Frequency: 120Hz

Accuracy (DF<0.5)

Range

Maximum

Display

Inductance DF

Spec. Note

1000H 999.9H 1.0%+(Lx

/10000) %+5

2%+100/Lx+5 After open

cal.

200H 199.99H 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5

-

20H 19.999H 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5

-

2000m 1999.9mH 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5

-

200mH 199.99mH 1.0%+(Lx

/10000)%+5

3%+100/Lx+5 After short

cal.

20mH 19.999mH 2.0%+(Lx

/10000)%+5

10%+100/Lx+5 After short

cal.

Test Frequency: 1 KHz

Accuracy (DF<0.5)

Range

Maximum

Display

Inductance DF

Spec. Note

100H 99.99H 1.0%+(Lx

/10000) %+5

2.0%+100/Lx+5 After open

cal.

20H 19.999H 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5

-

2000mH 1999.9mH 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5

-

200mH 199.99mH 0.7%+(Lx

/10000)%+5

1.2%+100/Lx+5

-

20mH 19.999mH 1.0%+(Lx

/10000)%+5

3.0%+100/Lx+5 After short

cal.

2000μH 1999.9μH

2.0%+

(Lx/10000)%+5

10%+100/Lx+5 After short

cal.

Notes:

1. Q Value is the reciprocal of DF.

2. This specification is based on measurements performed at

the test socket.

3. DUT & Test leads shall be properly shi elded to GUARD if

necessary.

4. Lx=counts of displayed L value, e.g. if L=88.88H, then

Lx=8888.

Page 25

21

MAINTENANCE

WARNING

To avoid ele ctr ic al sh oc k, do not perform any ser vici n g

unless you are qualified to do so.

SERVICE

If the instrument fails to operate, check battery and test leads,

and replac e as n ec essa ry. If the instrumen t still d oes n’t wo rk ,

confirm operating procedure as described in this User Manual.

Use specified replacement parts only. The meter must be

completely turned off while replacing either fuse or battery.

Battery Replacement

The meter is powered using a single 9V battery, NEDA1604,

JIS006P, IEC6F22 carbon-zinc or alkaline battery. Replace

battery if the low battery sign (

) is displayed and flashing.

Use the following procedure to replace the battery:

1. Loosen screws wit h suitable screwdriver and remove

battery cover as Figure-9.

2. Replace the used battery with a new battery of the

correct type.

Figure-9. Bat ter y Replacement.

Page 26

22

Fuse Replacement

The met er can self- detect if its input pr otective fus e is eithe r

ruptured or damaged. In this case , the LCD will display th e

symbol "FUS E" a nd an a udible beep wi l l sou nd co nti n uo usly,

warning the user to replace the damaged fuse. While

replacing the fuse, the power must be completely shut off.

1. Loosen screws with suitable screwdriver and remove

battery cover as Figure-9.

2. Loosen screws with suitable screwdriver and remove

bottom cover as Figure-10.

3. Replace the damaged fuse with an equivalent of the

correct specification.

Figure-1 0. Fu se R ep la cem e nt

Page 27

23

Cleaning the Meter

WARNING

To avoid ele ctr ic al sh oc k or dam ag e to th e me ter, never

allow water to access the inside of the case.

Before cleaning this meter, make sure the power is

switched to OFF, and remove external DC adaptor. To

clean the meter, wipe the dirt away with gauze or soft

cloth soaked with diluted neutral detergent. Do not

saturate, and prevent detergent from penetrating inside

case so causing damage. After cleaning, make sure the

instrument is dried completely before use.

Specified Accessories

Description

User Manual

5x20mm 0.1A/250VAC slow blow fuse

CP-09 PC Download Software

Page 28

M

Megger Limited

Archcliffe Road

Dover

Kent CT17 9EN T: +44 (0) 1304 502100

England F: +44 (0) 1304 207342

Megger

4271 Bronze Way

Dallas T: +1 (800) 723-2861 (U.S.A. only)

TX 75237-1017 T: +1 (214) 330-3203

(International) F: +1 (214) 337-3038

U.S.A.

Megger

PO Box 9007

Valley Forge

PA 19484-9007 T: +1 (610) 676-8500

U.S.A. F: +1 (610) 676-8610

Megger SARL

Z.A. Du Buisson de la Couldre

23 rue Eugène Henaff

78190 TRAPPES France T +33 (1) 30.16.08.90

F +33 (1) 34.61.23.77

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification

or design without prior notice.

Megger is a registered trademark

Part No LCR131_UG_V02 0205

www.megger.com

Loading...

Loading...