Page 1

RCD & LOOP TESTERS

MEGGER LCB2000/2500

User Guide

MEGGER

®

Page 2

Dear Customer,

Thank you for purchasing one of the new premium range

of Combinations products from AVO International. The

Combinations concept was created after listening to the

views of many users, and combine quality and versatile

features with the reliability and dependability you expect

from MEGGER products. Every instrument is designed

and manufactured to exacting standards and as such is

guaranteed for a full three years.

The MEGGER LCB2000 and LCB2500 are part of an

advanced range of combined loop and circuit breaker

testers designed to fully test RCDs and measure loop

impedance and prospective short circuit current, (PSCC),

on single and three phase systems rated up to 300V ac

r.m.s. to earth. Designed to comply with all relevant wiring

regulations, the units feature both standard and low

current loop test ranges guaranteed not to trip RCDs

rated at 30mA and above. Acomprehensive range of

RCD test facilities is provided to cater for the most

demanding situations whilst ingenius facilities such as

ramp and auto-sequence tests provide diagnostics for

troubleshooting nuisance tripping and reduce the time

taken for a series of tests considerably.

2

Results are clearly indicated on a large backlit liquid

crystal display. The LCB2500 also allows results to be

stored against specific circuit and distribution board

references. This instrument is directly compatible with

®

PowerSuite™for Windows™and NICEone

AVO

software and stored data may be quickly downloaded for

™

creation of professional installation test certificates.

Alternatively direct connection to a serial printer is

possible.

Page 3

Contents

Safety Warning 4

Function Keys and Warning Symbols 5

Initial Setup 6

General Description 7

Wiring Diagram 9

Operation 10

Specifications 29

Accessories 33

Publications 34

Loop Resistance Tables 35

Repair and Warranty 36

Symbols used on the instrument are:

Caution: Refer to

accompanying notes

Maximum nominal system

voltage of 440V

Maximum 300V a.c.

CATIII to Earth

3

Page 4

SAFETY WARNINGS

★ Safety Warnings and Precautions must be read and understood before the instru-

ment is used. They must be observed during use.

★ Continuity of protective conductors and earthed equipotential bonding of new or

modified installations must be verified before carrying out an earth fault loop

impedance test, or RCD test.

★ Circuit connections and exposed metalwork of an installation or equipment under

test must not be touched.

★ Do not move the rotary selector switch position while a test is in progress.

★ The LCD ‘neon’ voltage indicators cannot reveal a Neutral-Earth reversal.

★ The instrument should not be used if any part of it is damaged.

★ Test leads, probes and crocodile clips must be in good order, clean and with no

broken or cracked insulation.

NOTE

THE INSTRUMENTS MUST ONLY BE USED BY SUITABLY TRAINED AND COMPETENT PER-

4

Page 5

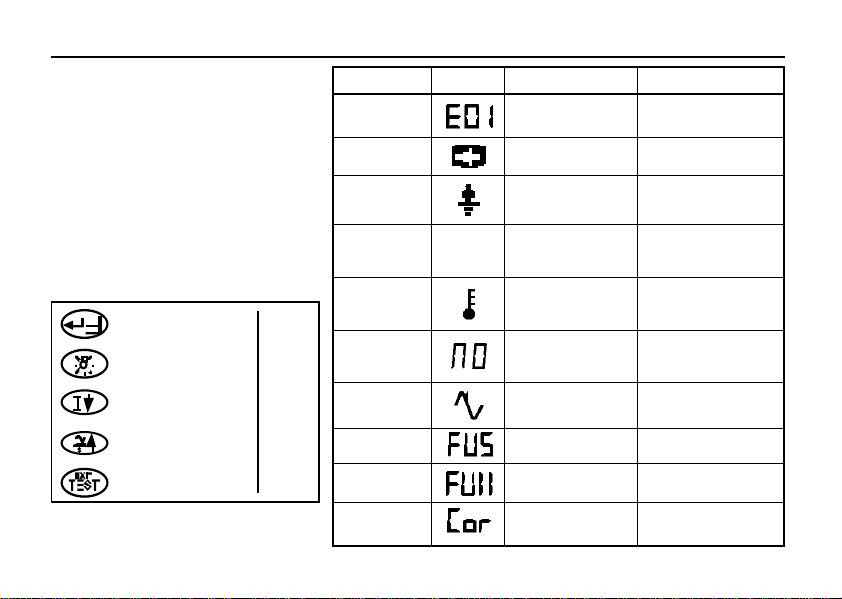

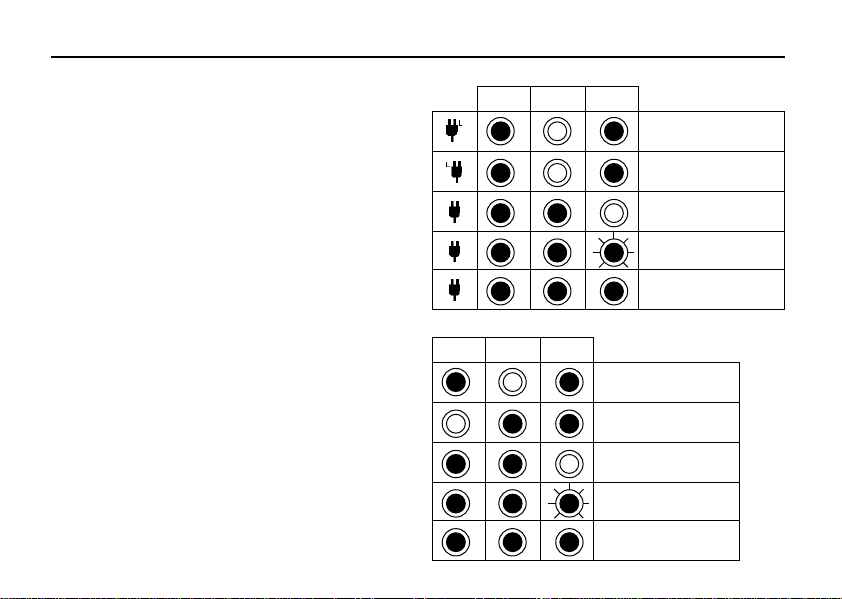

Function Keys and Warning Symbols

KEYS:

ENTER SAVE

BACKLIGHT

RCD TEST TYPE DOWN

RCD TYPE UP

TEST EXIT

Note: On LCB2000 storage and download

functions are not available and are

not marked on the keys

Condition

System error

Low battery

Touch pad

>100V

Supply voltage

and frequency

out of range

Thermal trip

operated

Supply

interrupted

during test

Noise

Fuse ruptured

Memory full

Memory

corrupted

> or <

and limit

value

CauseDisplay Action

Hardware or

software fault.

Battery voltage

too low.

Earth voltage

too high.

Supply voltage or

frequency too high or

low for test.

Too rapid testing with no

pauses for heat

dissipation.

RCD tripped or

supply failure.

Excessive external

supply noise during

earth loop or RCD test.

Blown fuse.

Results memory full.

Results memory

unintelligible.

Switch ‘Off’, then ‘On’

and attempt re-test.

Replace battery.

Check installation or

wiring to the instrument.

—

Pause between tests

to allow cooling.

Confirm RCD rating and

check for excess earth

leakage current.

Identify and rectify, or

wait and re-test.

Return instrument

for repair.

Download results

and clear memory.

Press TEST to

attempt recovery.

5

Page 6

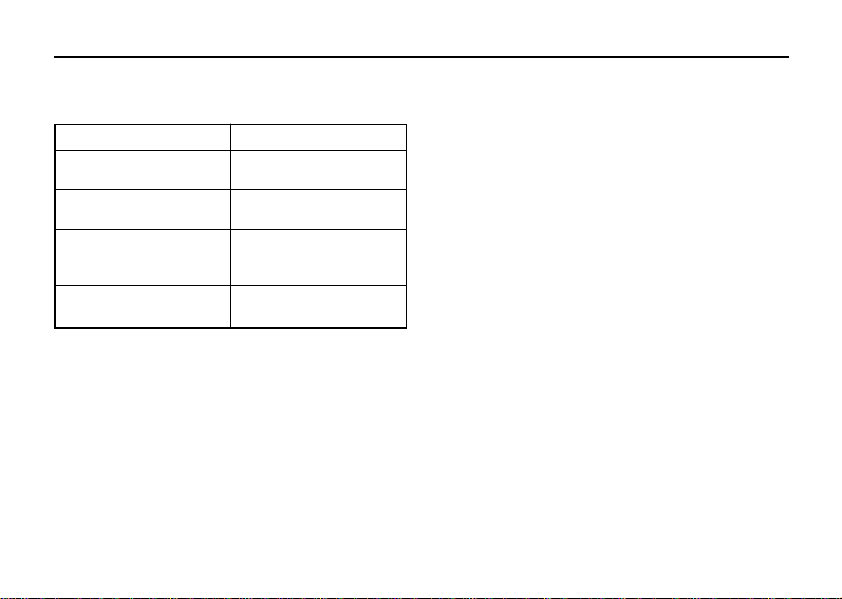

Initial Setup

Instrument Setting

The instrument setting modifies the way the instrument

behaves, shown in the following table.

Setting A (Europe)

Line and Neutral Swap

allowed.

Auto Sequence RCD

does 5I test.

After RCD trip test,

contact voltage

displayed first.

1

⁄2I no trip RCD test not

2s

performed.

To change the setting:

1. Press and hold the Backlight key, then turn the

rotary selector switch from the OFF position to the

RCD 150mA 40ms position. The current setting will

be displayed.

2. To change the setting, toggle the I key until the

required setting is displayed.

3. To save the new setting, press the SAVE key. The

bleeper sounds and SET is displayed. To leave the

setting as it was, press the EXIT key.

6

Setting b (UK)

Line and neutral swap

not allowed.

Auto Sequence RCD

does 150mA test.

After RCD trip test,

trip time or current

displayed first.

1

⁄2I no trip RCD test

2s

performed.

Reset Factory Default Settings

The instrument will remember certain values such as

the VAR range RCD test current, even if the instrument

is switched off and the battery removed.

These can be reset to factory default settings as follows:

1. Press and hold the BACKLIGHT key, then turn the

rotary selector switch from the OFF position to the

RCD 150mA 40ms position. The current setting will

be displayed. Release the BACKLIGHT key.

2. Press the up and down keys together. The code clr

is displayed.

3. Confirm the operation by pressing the SAVE key, or

abort by pressing any other key. The current setting

will be displayed.

Page 7

General Description

This instrument has been designed to fully test RCDs

and measure loop impedance and PSCC on single and

three phase systems with a rated voltage up to

300V a.c. r.m.s. to earth. It has been designed to

comply with U.K., European and other international

wiring regulations and standards.

Measured values are displayed on a large backlit digital

LCD. With the LCB2500 these values may also be stored

in internal memory for later recall to display, direct printing

to a standard serial printer, or downloaded to a PC for

storage, analysis and report generation.

Key Features

Storage of test results in memory (LCB2500 only)

Selectable backlight

Large clear liquid crystal display

Operates regardless of mains polarity

Automatic test start on voltage detection

Loop Tests

Direct indication of short circuit current

Phase-phase (up to 480V), phase-neutral and

phase-earth tests

No trip loop impedance tests with a resolution

down to 0.01Ω

No neutral needed for line to earth testing

(except for No Trip Loop L-PE 0.01Ω)

RCD tests

Tests selective (delayed), general and d.c. sensitive

RCDs

Contact voltage and loop resistance displayed

Selectable test current for programmable devices

Auto sequence test

Ramp test

General

Supply voltage and frequency measurement

Three Phase sequence indication

Mains outlet polarity indication

Application

The instrument may be be connected live to earth or

between live conductors of systems that have a rated

voltage of 300V a.c. rms to earth and an Installation

(Overvoltage) Category III or lower. This means that the

instrument may be connected to any fixed wiring of a

building installation, but not to primary supply circuits

such as overhead cables. To maintain user safety and

ensure accurate measurements, only use the test leads

supplied or recommended for use with this instrument.

The instrument is fuse protected to 440V 10kA. The

maximum current which could flow through this fuse in

the case of a fault is limited to 10 kA by the impedance

of the test leads.

When the low battery symbol appears, the cells are

nearly exhausted and should be replaced as soon as

possible. When the battery is exhausted, the instrument

will not perform tests and the cells must be replaced.

Use alkaline cells IEC LR6 (AA) or 1,5V nickel cadmium

7

Page 8

cells only.

To install or replace the cells, disconnect the test leads,

switch the instrument off and loosen the captive screws

holding the battery compartment cover in place.

Remove the cover, lift out and disconnect the battery

holder to access the cells. Replace the cells, ensuring

that correct polarity is observed (shown on battery

Incorrect battery cell polarity

can cause electrolyte leakage resulting in

damage to the instrument

holder moulding).

Carefully re-connect the battery holder to the connector,

replace the battery holder in the compartment, and resecure the cover. Remove the cells if the instrument is

not going to be used for any extended period of time.

Stored results are retained when the battery is

disconnected.

8

Test Leads

All test leads form part of the measuring circuit of the

instrument and must not be modified or changed in any

way, or be used with any other electrical instrument or

appliance. The power cord supplied with the Installation

Testers is a test lead that forms part of the measuring

circuit of the instrument. The overall length of this lead

must not be altered. If the power cord plug is not

suitable for your type of socket outlets, do not use an

adaptor. You may change the plug once only by cutting

the cord as close to the plug as possible and fitting a

suitable plug.

The colour code of the cord is:

Earth (Ground) Yellow/Green

Neutral Blue

Phase (Line) Brown

Note: A plug severed from the power cord must be

destroyed, as a plug with bare conductors is

hazardous in a live socket outlet.

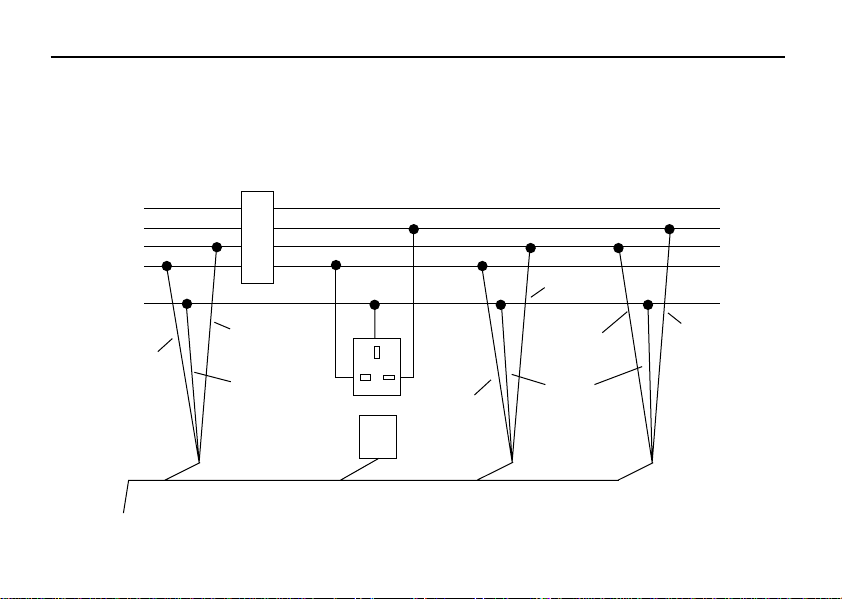

Page 9

Wiring Diagram

LOOP L-PE

LOOP L-N

Supply

Black

RCD

Red

Green

RCD

LOOP L-PE 0.1Ω (no trip)

LOOP L-PE 0.01Ω (no trip)

LOOP L-N

Black

Red

Black

Green

LOOP L-L

L1

L2

L3

N

P-E

Red

9

Page 10

Operation

Backlight

The display backlight gives a clear display of

measurements in poor lighting conditions. The backlight

will briefly operate when the instrument is switched on.

To switch the backlight on, press the backlight key (see

key on page 4). Press the key again to switch the

backlight off.

To conserve battery power, the backlight will

automatically switch off after about 15 seconds (if the

battery voltage is low, this period is automatically

reduced).

Auto Shut-off

To extend battery life after a period of instrument

inactivity the instrument will switch itself off, preceded by

a series of bleeps. To switch the instrument back on,

press any key other than the TEST key.

Switched Probe SP2

This accessory can be used anywhere that the 2-wire

lead set is specified in this User Guide. The press switch

on the probe duplicates the function of the TEST key on

the instrument, allowing quick and easy testing.

Checking Earth Potential

To quickly distinguish live and earth, this feature provides

display indication if a voltage greater than 100V exists

between the earth connection and your finger.

1. In any switch position except OFF and RCL

10

(LCB2500 only), connect the earth connection (black

for the 2-wire lead set, green for the 3-wire lead set)

to earth.

2. Touch a finger to the metal pad on the top. This is

safe and will not endanger you.

3. If a voltage greater than 100V exists between the

finger (normally at earth potential) and the earth

wire, the warning symbol is displayed.

Voltage and Frequency Measurement

This instrument will display the supply voltage and

frequency in all switch positions except RCL and OFF.

The ENTER key will alternate between voltage and

frequency.

Power plug connection

1. Insert the power cord plug into an installation socket.

2. Supply voltage and polarity are displayed.

3. Press ENTER to alternate between supply voltage

and frequency.

3-Wire Lead Set Connection

If an installation socket is not available and it is

necessary to connect to all three conductors, use the 3wire lead set.

1. On a single phase system connect the red lead to

phase, the black to neutral and the green to earth.

2. Supply voltage and polarity are displayed.

3. Press ENTER to alternate between supply voltage

and frequency.

Page 11

Note: For connection to a three phase system, see

‘Determining Phase Sequence’.

When connected the instrument will display the Line to

Earth voltage except on the loop L-N switch position

when the line to neutral voltage is displayed or shown.

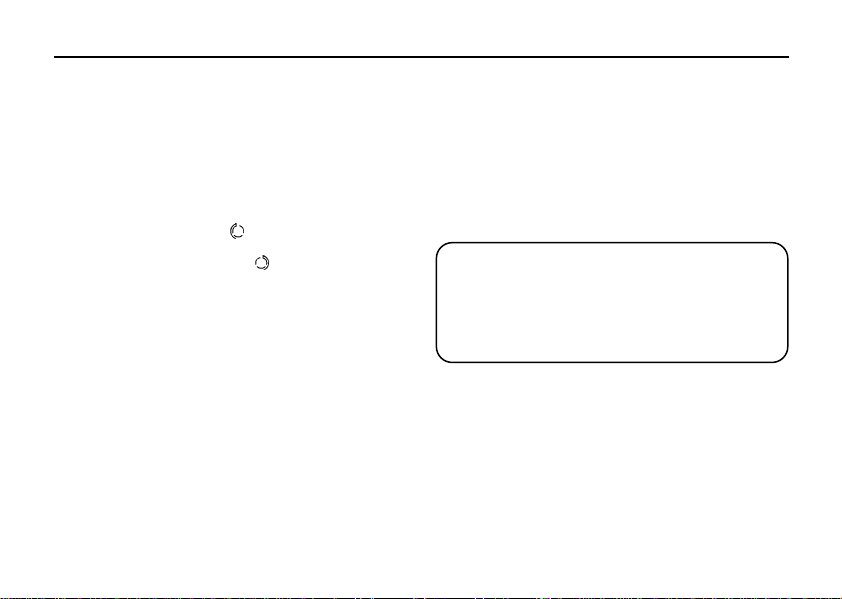

Polarity Indication

If connected to a single phase power supply by a plug

or by the 3-wire lead set, three LCD ‘neons’ marked LPE, N-PE and L-N respectively will indicate supply

polarity. If a voltage is detected between their respective

two wires, the ‘neon(s)’ will activate. A ‘neon’ will usually

flash if one connection is open circuit.

Note: The presence of a voltage between phase and

earth does not prove earth continuity, as the earth

could have a high resistance and a voltage would

still be measured. To test earth continuity refer to

the sections on loop resistance or RCD testing.

If Setting A(see page 4) is set, the instrument will

automatically switch Line and Neutral as appropriate.

This enables a test to be performed without inverting the

plug connections. The live terminal of the wall socket is

identified by the addition of a separate symbol adjacent

to the ‘neons’.

Setting A (Europe)

L-PE N-PE L-N

Normal Supply (1)

Normal Supply (2)

Neutral Live

Neutral Open Circuit

Earth Open Circuit

Setting b (U.K.)

L-PE N-PE L-N

Normal Supply

L-N Reversed

Neutral Live

Neutral Open Circuit

Earth Open Circuit

11

Page 12

Operation

Determining Phase Sequence

When connected to all conductors of a three phase

system, the instrument automatically displays the

sequence of phase rotation.

Connect the the Installation Testers as follows:Line 1 Red phase Red lead

Line 2 Yellow phase Green lead

Line 3 Blue phase Black lead

If connected as above, the symbol is displayed

when the sequence is

1:2:3, or Red-Yellow-Blue. The symbol is displayed

when the sequence is 1:3:2,

or Red-Blue-Yellow. If one of the lines is faulty, neither

of the symbols is displayed and the normal ‘neon’

polarity indication is shown.

In the Loop L-N switch position the voltage between the

red and black leads is displayed. In other switch

positions the voltage between the red and green leads

is measured and displayed.

12

Loop Impedance measurement

Loop impedance measurement of 0,01Ω up to 3,00kΩ

can be made via installation sockets using the plug

terminated test lead, or at any other convenient point on

the installation using the two wire lead set. If Setting A

(see page 4) is selected when using the plug terminated

lead set, the polarity of the mains socket is immaterial.

Line and Neutral will be swapped if necessary, and an

indication given on the display. Setting b requires Line

and Neutral to be fixed.

Test results may be adversely affected by

supply voltage fluctuations or electrical noise

during measurement. It is recommended that

tests are repeated and the results verified, if

measurment results are considered abnormal.

The Installation Testers will measure the loop resistance

from the supply end of the standard test leads, allowing

for their resistance.

Page 13

Automatic Testing

To aid rapid testing, the instruments can be set to

start a test automatically when connected to the

supply. This may be of use for example, when using

a clip and a probe. Select the range required and

press the test key without the supply present. The

instrument will display <100V for approximately

30 seconds. Apply the supply voltage within this time

and the instrument will pause before performing one

test automatically.

Phase to Neutral or Earth loop impedance measurement

(at a power socket):

1. Select Loop L-PE or L-N as required.

2. Insert the plug into an installation socket.

3. Supply voltage and polarity are displayed.

4. Press the TEST key.

5. Measured loop value is displayed.

On completion of this test, prospective fault current can

be displayed by pressing the ENTER key.

If desired the test can be repeated by pressing TEST

again.

Phase-Earth loop impedance measurement (not at a

power socket):

If an installation socket is not available, use the 3-wire

lead set.

1. Select Loop L-PE.

2. Connect the red lead to phase and the green lead to

earth. No connection to neutral is required.

3. Supply voltage is displayed.

Note: If the black lead is not connected to neutral,

although displayed the polarity indications are invalid.

4. Press the TEST key.

5. Measured loop value is displayed.

On completion of this test, the prospective fault current

can be displayed by pressing the ENTER key.

If desired the test can be repeated by pressing TEST

again.

Bonded Metalwork Testing (1)

This test is performed using the three wire lead set.

1. Connect the green lead to the bonded metalwork.

2. Connect the red lead to phase.

3. Select Loop L-PE.

4. Supply voltage is displayed.

5. Press the TEST key.

6. Measured resistance value is displayed.

13

Page 14

Operation

Bonded Metalwork Testing (2)

This test can also be performed using the optional earth

bond test lead, allowing connection to an installation

socket.

1. Connect the black flying test lead to the bonded

metalwork.

2. Insert the power plug test lead into a socket

(receptacle).

3. Select Loop L-PE.

4. Supply voltage is displayed.

5. Press the TEST key.

6. Measured resistance value is displayed.

Phase-Neutral or Phase-Phase loop resistance

measurement

To measure the loop resistance of a circuit

Phase-Neutral, or between two phases of a multi-phase

system, connect using the 3-wire lead set.

1. Connect the red lead to phase and the black lead to

neutral or the other phase. There is no need to

connect the green lead.

2. Select Loop L-N/L-L.

3. The supply voltage is displayed. The polarity

indications are invalid and should be ignored.

4. Press the TEST button.

5. Measured loop resistance is displayed.

The prospective fault current may be displayed by

pressing the ENTER key.

14

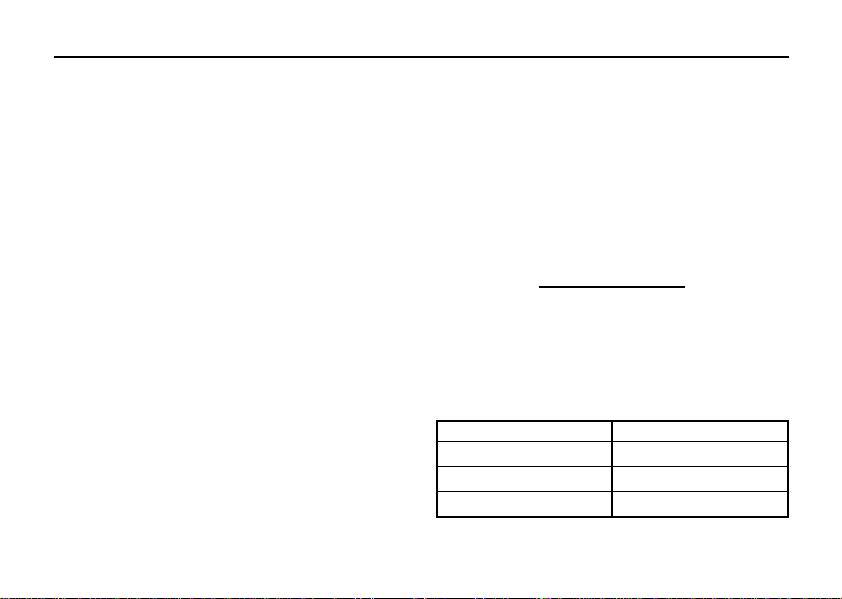

Prospective Short Circuit Current measurement (PSCC)

The PSCC of a circuit is the largest Prospective Fault

Current (PFC). In a single phase system, this would be

the larger of the earth loop PFC and the neutral loop

PFC. In a multi-phase system phase-phase loops also

need to be considered and these can be measured

using the Loop L-L switch position.

When the instrument measures the loop resistance, it

also calculates the PFC. After any loop test, this may be

displayed by pressing the ENTER key.

The PFC is calculated by using the sum:-

The supply voltage used in the calculation depends on

the measured voltage and the configuration of the

instrument. As supplied, the instruments are configured

as follows:-

Actual Measured Voltage

>150V and <300V

Nominal supply voltage

Loop resistance

150V

>300V

Assumed Nominal Voltage

110V

230V

400V

Page 15

PFC measurement accuracy

An accurate PFC measurement requires an accurate

measurement of the loop resistance. The difference of a

few digits in the loop resistance measured will have a

large effect on the PFC displayed.

Errors can be reduced by:-

• Using the 3 wire lead set with prods and making a

firm connection to clean conductors.

• Making several tests and taking the average.

• Ensuring that potential sources of noise in the

installation are isolated (switched off), eg:

automatically switched loads or motor controllers

• Ensuring that the instrument is calibrated.

No trip loop-testing

The Loop L-PE 0.1Ω range is a low test current earth

loop resistance measurement range. The 15mA current

enables the earth loop resistance to be measured

without tripping all types of RCDs with a rated current of

30mA or higher. Tests may be made via installation

sockets with the plug terminated test lead, or at any

other point using the 2-wire lead set. Connections are

required to Line and Earth only.

The Loop L-PE 0.01Ω range is a high resolution low test

current earth loop resistance measurement range. It

requires a connection to neutral, but allows quick and

accurate measurement of the earth loop resistance without

tripping all RCDs with a rated current 30mA or higher.

If a neutral connection is not possible, then the Loop

L–PE 0.1Ω must be used. Connecting the black lead to

earth and performing the Loop L-PE 0.01Ω will cause an

RCD to trip.

15mA-Phase to Earth loop impedance measurement (at

a power socket)

1. Select Loop L-PE 0.1Ω or 0.01Ω as appropriate.

2. Insert the plug into an installation socket.

3. Supply voltage and polarity are displayed.

4. Press the TEST key. Test progress is displayed.

5. Measured loop value is displayed

If desired the test can be repeated by pressing TEST

again.

15mA-Earth loop impedance measurement (not at a

power socket)

1. Select Loop L-PE 0.1Ω or 0.01Ω as appropriate.

2. Firmly connect the red lead to phase and the green

lead to earth. Connection to neutral with the black

lead is only required for the Loop L-PE 0.01Ω range.

3. Supply voltage is displayed.

4. Press the TEST key. Test progress is displayed.

5. Measured loop value is displayed.

If desired the test can be repeated by pressing TEST

again.

After a Loop L-PE 0.01Ω test, the component

resistances of the circuit under test may be stepped

through by pressing the ENTER key.

15

Page 16

Operation

They will be shown in the following order:

Loop L-PE

PFC L-PE

Loop L-N

PFC L-N

R1

R2

Rn

R1

Rn

R2

All results may be stored under a single circuit

reference. See ‘Test Result Storage’.

16

Method of measurement

The phase-earth, phase-neutral or phase-phase loop

resistance can be measured. The instrument takes a

current from the supply and measures the difference

between the unloaded and loaded supply voltages.

From this difference it is possible to calculate the loop

resistance. The test current will vary from 15mA to 40A,

depending on supply voltage and the loop resistance

value. The test duration will depend on the loop

resistance value.

The Loop L-PE 0.01Ω range performs a test with a current

up to 25A flowing Line to Neutral and the resistance of the

source and line wires are measured. This is followed by a

current of 15mA flowing Line to Earth and the resistance

of the earth wires are measured.

Possible sources of error

The reading depends on a measurement of the supply

voltage and therefore noise or transients caused by other

equipment during the test could cause an error in the

reading. One way to check for these is to do two tests

and look for any difference in value. The instrument will

detect some sources of noise and warn the user, where

other instruments may give an incorrect reading. Any

leakage current as a consequence of other appliances

connected to the supply under test may affect the

reading. If the Phase-Earth loop is being measured, this

leakage may be due to filter capacitors, etc.

Page 17

RCD Testing

The instrument can test the operation of a variety of

types of Residual Current Devices (RCD), measure the

phase to earth loop resistance, and the contact voltage

of the installation. If Setting A(see page 4) is selected

when using the plug terminated lead set, the polarity of

the mains socket is immaterial. Line and Neutral will be

swapped if necessary, and an indication given on the

display. Setting b requires Line and Neutral to be fixed.

Pre-Test Configuration

Before performing an RCD test it is necessary to ensure

that the instrument is correctly configured for the rated

current and the specific type of RCD to be tested, and

for the type of test to be performed.

RCD Current Rating

From information given on the RCD to be tested, select

the RCD current rating on the rotary switch.

RCD VAR switch position

This position enables any RCD with a non standard

rated current between 10 mA and 1000 mA to be tested.

The test is performed at the selected current, taking the

5I multiplier into consideration

1. Select (RCD) VAR.

2. Toggle the ENTER key to display the test current.

3. Press the up and down keys until the required test

current is displayed. (LCB2000: These are marked

RCD Test Type and RCD Type). Hold a key down to

auto-repeat.

4. Press the ENTER key. The Supply Voltage, Test

Type and RCD Type are shown. These may be set

up as given in the following sections.

Ramp and Auto Sequence tests are only available

on the RCD VAR if the test current is set to 10mA.

The maximum possible test current (including 5I

multiplier) is 1000mA (300mA for d.c. sensitive

RCDs). These limits are halved if the supply voltage

is less than 200V.

Setting precision:

10-50mA 1mA steps

50-500mA 5mA steps

500mA-1000mA 10mA steps

17

Page 18

Operation

RCD Type

Pressing the TYPE key displays the RCD type symbols.

From information given on the RCD to be tested, select

and set the type of RCD.

Symbol Test

General

Selective (delayed)

D.C. sensitive

D.C. Sensitive RCDs

Some RCDs are electromechanical devices which can

be saturated by the presence of d.c. Therefore if a d.c.

fault occurs, or an a.c. fault occurs in the presence of

quite a small direct current, the RCD may not trip. In this

way the RCD is disabled and this becomes a potential

hazard. Because of this, ‘d.c. sensitive’ RCDs are

available.

18

Selective or Time delayed RCDs

In some cases it may be necessary to have an RCD

protecting an individual circuit or group of circuits. If a

fault occurs, the RCD nearest to the fault should trip to

clear it, maintaining supplies to the other circuits.

Selective RCDs (normal symbol) are used to

discriminate faults occurring on circuits, and these have

a minimum as well as a maximum trip time.

Page 19

Type of Test

Display Type of Test

1

⁄2I

0°

180°

No Trip

Trip Test

Trip Test

Ramp Test

5I

Trip Test

Pressing the I key displays the Type of Test symbols individually

in sequence. Select the type of the test to be perofrmed.

Description

Performs a no-trip test at half the

rated current of the selected

RCD.

The test measures the earth loop

resistance and contact voltage.

Trip test at the rated current of

the selected RCD. A

carried out before this, and the

resistance and voltage are

available after the test. The test is

always started on a zero crossing

when the instantaneous voltage

is on the rise.

As above, but the test is always

started on a zero crossing when

the voltage is on the fall.

Test current increases from half

the rated current of the RCD. The

result is the current at which the

trip opens.

Trip test at 5 x the rated current

of the selected RCD. The choice

of 0° or 180° gives greater

accuracy of measurement. A

test is carried out before this, and

the resistance and voltage are

available after the test.

1

⁄2I test is

1

⁄2I

No Trip Tests

When an 1⁄2I (or No Trip) test is performed, the loop or

earth resistance is measured, and in Setting b, a two

second No Trip test follows.

Loop resistance measurement

The loop resistance is measured at half the rated RCD

current selected. Contact voltage is displayed which is

the loop resistance multiplied by the rated RCD current.

A high loop resistance will cause the instrument to

display >90V, and safely abort the test.

2 second No Trip test (Setting B only)

This tests that the RCD does not trip when half the rated

operating current of the RCD is drawn for 2 seconds.

Tripping of the RCD will indicate that it is over sensitive, or

that excessive earth leakage current is being drawn in the

system. The load put onto the circuit is resistive and

therefore the test current is sinusoidal if the supply is

sinusoidal.

No Trip testing

The test is the same for all RCD types. Select the Rated

Current, the RCD Type and

installation and press the TEST key. If the settings are

1

⁄2I. Connect to the

correct, and the RCD is in order, the RCD trip should not

operate and the contact voltage will be displayed. If the

RCD trip does operate during the test, the message is

displayed. This could be due to incorrect current rating

selection, excessive leakage current in the circuit, or a

19

Page 20

Operation

faulty RCD. If the problem is excessive leakage current,

the source of the problem must be located and rectified

before a trip test is performed, otherwise the result of the

trip test will be invalid. Loop resistance can be shown by

pressing the ENTER key.

Trip Tests

The instrument will measure the trip time or trip current of

common, selective (time delayed) and d.c. sensitive RCDs.

The trip time is measured by timing the period from the

application of a resistive load to when the supply fails.

Some RCDs are sensitive to the polarity of the supply,

i.e. whether the test current is applied with the

instantaneous rising or falling. Tests should therefore be

performed with the polarity 0° and 180° and the

maximum time taken.

D.C. sensitive RCDs are tested with a pulsed waveform.

The rms current is √2 x the rated operating current of

the RCD. As with the normal RCDs, these should be

tested with 0° and 180° polarity.

As the No Trip test can affect the trip time of some

selective RCDs, there is a 30 second delay before

activation of the trip test. It is possible to override this

delay by pressing the TEST button when the instrument

is counting (1...2...3...).

Note: Significant operating errors can occur if loads,

particularly rotating machinery and capacitive

loads are left connected during tests.

20

RCD Rating D.C. sensitive RMS currents

10mA 14,1mA

30mA 42,4mA

100mA 141mA

300mA 424mA

500mA Not available

1000mA Not available

†

For supply voltages above 200V only.

Trip Testing (measuring the trip time)

1. Select the RCD rated current on the rotary switch.

2. Connect to the supply as detailed below.

3. Select the required test using the TEST TYPE key –

0° or 180° for the normal trip tests, or 5I together

with 0° or 180° for a 5I test.

4. Select the RCD type using the TYPE key.

5. Press the TEST button.

If the RCD trips, the first display depends upon the

Setting selected.

Setting A: The contact or fault voltage is displayed with

the Loop or earth resistance and trip time available by

pressing the ENTER key.

Setting b: The trip time is displayed with the contact/fault

voltage and Loop/earth resistance available by pressing

the ENTER key.

†

Page 21

150mA 40ms test

When an RCD is fitted for personal protection, a test

current of 150mA must cause the RCD to trip in less

than 40ms.

1. Select 150mA 40ms on the rotary switch.

2. Connect to the supply as detailed below.

3. Select and set the Trip Test to 0° or 180° using the

TEST TYPE key.

4. Press the TEST key.

If the RCD trips within 40ms, the trip time is displayed.

Ramp Test (measuring the trip current)

The trip current is measured by applying a test current

of half the rated trip current and increasing this every

200 ms. When the supply is cut, the current flowing is

recorded and displayed.

A low trip current could be due to an overly sensitive

RCD, or to leakage currents in the supply.

To determine the trip current of an RCD.

1. Select an appropriate RCD rated current on the

rotary switch.

2. Connect to the supply as detailed on the next page.

3. Select the Ramp test using the TEST TYPE key.

4. Select the RCD type using the TYPE key.

5. Press and hold the TEST button.

If the RCD trips, the first displayed result depends upon

the Setting selected.

RCD Rating Current Range Step Value

10mA 5..15mA 1mA

30mA 15..50mA 1mA

100mA 50..150mA 2mA

300mA 150..300mA 6mA

500mA 250..500mA 10mA

1000mA 500..1040mA 52mA

Setting A(Europe): The contact or fault voltage is

displayed with the Loop resistance, trip current and trip

resistance available by pressing the ENTER key.

Setting b (UK): The trip time is displayed with the trip

resistance, contact voltage and loop resistance available

by pressing the ENTER key.

The trip current and the trip resistance values are

displayed with the TEST TYPE symbol. The Trip

resistance is the fault required to trip the RCD.

Auto Sequence RCD Test

If the RCD is not located near a convenient installation

socket, it could mean walking back and forward

between the RCD and the instrument to reset the RCD

each time it trips out. To simplify and speed up

sequence testing, the instrument can be set to

automatically perform each subsequent test in the

21

Page 22

Operation

sequence each time that the power is restored. This test

depends upon whether Setting Aor Setting b is

selected. The Overcurrent or Fast Trip is 150mAif

Setting b is selected, and 5 x I if Setting A is selected.

The display shows 150mA or 5I symbols as

appropriate.The test procedure is as follows:-

1. Connect to the supply as detailed on the next

page.

2. Select the RCD rated current on the rotary switch.

3. Select Auto RCD test sequence by pressing the

TEST TYPE key until the

symbols are displayed in sequence. Auto test is only

applicable to a.c. sensitive non delayed RCDs,

therefore TYPE segments are not displayed.

4. Press and release the TEST button.

5. Reset the RCD within 30 seconds after each trip

test.

6. Tests will be carried out in the sequence

180°, Fast Trip 0° and 180°. After each trip test, the

instrument will wait for up to 30 seconds for the

supply to be switched back on before continuing with

the next test. The test sequence will abort if any of

the tests fail, or if the RCD is not reset within the

time limit.

22

1

⁄2I; 0°; 180° and Fast trip

1

⁄2I, 0°,

On completion, the result of the last Fast trip test is

displayed. Press the ENTER key to sequentially

display:-

Supply voltage

Supply Frequency

Contact voltage

Earth Loop Resistance

0° trip test time

180° trip test time

0° Fast trip test time

180° Fast trip test time

All results can be stored under a single circuit reference.

See ‘Test Result Storage, Deletion and Retrieval’.

Page 23

Connecting to the Supply

Automatic Testing

To aid rapid testing, the instruments can be set to

start a test automatically when connected to the

supply. This may be of use for example, when using

a clip and a probe. Select the range required and

press the test key without the supply present. The

instrument will display <100V for approximately

30 seconds. Apply the supply voltage within this time

and the instrument will pause before performing one

test automatically.

At a power socket

The simplest way of connecting to the installation is by

inserting the power plug into a convenient installation

socket. If Setting Ais selected when using the plug

terminated lead set, the polarity of the mains socket is

immaterial. Line and Neutral will be swapped if

necessary, and an indication given on the display.

Setting b requires Line and Neutral to be fixed.

1. Insert the power plug into an installation socket.

2. Select and set the rated current, RCD type and the

test type.

3. Supply voltage, configuration symbols and polarity

are displayed.

4. Press the TEST key.

5. See previous notes for type of test.

If desired the test can be repeated by pressing TEST

again.

Not at a power socket

If an installation socket is not available use the 3-wire

lead set

1. Connect the red lead to phase and the green lead to

earth. No connection to neutral is needed.

2. Select and set the rated current, RCD type and the

test type.

3. Supply voltage and polarity are displayed prior to the

test.

4. Press the TEST key.

5. See previous notes for type of test.

If desired the test can be repeated by pressing TEST

key again.

23

Page 24

Operation

Error Numbers

In the unlikely event of a hardware or software fault or

error the display willshow an error number in the form

of a digital ‘E’ together with an identifying 2-digit

number.

If such an error number is displayed, switch the

instrument off and back on again. Then repeat the test

that was originally being carried out, or as given in the

following table.

If the error number is again displayed, switch the

instrument to off, and return the instrument to the

manufacturer for service, together with a description of

the events leading to the message display. See

‘Returning an Instrument for Repair’.

24

Error Number Appropriate Action

EEPROM failure.

Stored data is lost.

Attempt to delete the stored test

results and then store another

result. If error number persists,

return the instrument for service.

(Loop LE, LN or LL)

Secondary internal thermal cutout is open circuit.

Return the instrument for service.

Possibly due to excessive ‘noise’

on the supply, or the RCD

unexpectedly trips together with

an internal fault. If error number

persists, return the instrument for

service.

Page 25

Operation (LCB2500 only)

Saving Results (LCB2500 only)

After a test, the result is displayed on the screen and

this may be saved with additional information. Acircuit

number (1-99) may be assigned, and when moving site

or building, circuits may be grouped using the

distribution board feature. In this way, when

downloading to PC software such as AVO

or NICEone™, the results can be easily split into different

test schedules. When the results are displayed or

printed, a change in the distribution board is indicated.

Changing Distribution Boards (DB)

Before a test the distribution board number may be

changed as follows:

1. Move the rotary selector switch to the RCL position.

The code is displayed.

currently selected DB code is displayed, e.g. d01.

3. This number may be changed using the up and

down keys to display the required number.

4. The number can be accepted by pressing the SAVE

key, or the procedure aborted by pressing the EXITkey.

5. When the number is saved the code Std is displayed

(accompanied by a long bleep) to confirm that the

data has been saved.

Testing may now continue with all subsequent results

being stored associated with the new distribution board

number.

2. Press the SAVE key. The

®

PowerSuite

Saving a result

On completion and display of the measurement:

1. Press and hold the SAVE key. After about 1 second,

a bleep will be heard. For a (Loop) L-N test, a code,

as given in the following table is displayed. Acode is

™

used to describe the circuit tested and can

accordingly be modified by the user. For all other

tests, a circuit number code is displayed, and you

should proceed directly to step 4.

2. The code may be changed by pressing the up and

down keys

3. The code may be accepted by pressing the SAVE

key, or aborted by pressing the EXIT key.

4. The circuit number is displayed as 2 digits, e.g. c01.

Note: Many different tests may be saved under the

same circuit number.

5. The circuit number may be changed by pressing the

up and down keys to display an appropriate number.

Hold the key down to step through the circuit

numbers.

6. The number can be accepted and the results saved

by pressing the SAVE key, or the procedure aborted

by pressing the EXIT key.

7. When the result is saved, the code Std is displayed

(accompanied by a long bleep) to confirm that the

data has been saved. The display of FULL indicates

that there is no more test storage.

25

Page 26

Operation (LCB2500 only)

Delete all data

1. Move the rotary selector switch to the RCL position.

The code is displayed.

2. Press the up and down keys

together. The code dELis displayed.

3. Confirm that the data is no longer required by

pressing the SAVE key or abort by pressing any

other key. The code is displayed.

Print Results

1. Connect printer and the instrument with a serial

printer lead.

2. Move the rotary selector switch to the RCL position.

The code is displayed.

3. Commence the printout by

pressing the TEST key. Abort at any time by

pressing and holding the ENTER key. The code

is displayed.

Printer Setup Mode

The instrument cannot respond to a busy signal given

by a printer, and therefore waits at the end of each line.

This wait time and the printer report language can be

changed.

1. Press and hold the BACKLIGHT key then turn the

rotary selector switch from the OFF position to the

RCL position. The code is displayed.

2. Release the

BACKLIGHT key.

To change the Printer wait time

26

1. Toggle the TEST TYPE key to scroll through and

display the code .

2. Press the ENTER

key. The current setting is displayed.

3. Toggle the up and down keys until the required

setting is displayed.

4. To save the new setting, press the SAVE key. The

bleeper sounds and STD is displayed. To abort the

new setting, press the EXIT key.

To select the printer language

1. Toggle the TEST TYPE key to scroll though and

display the code .

2. Press the SAVE key.

The current printer report language is displayed as 1

(English) or 2 (as given on the type label on the

User Guide cover). AVO Download Manager

supplied with your instrument enables the second

printer language to be changed. Refer to the

instructions supplied with the disk.

3. Toggle the TEST TYPE key until the required

language setting is displayed.

4. To save the new setting, press the SAVE key. The

bleeper sounds and STD is displayed. To abort the

new setting, press the EXIT key.

Retrieve Stored Results

It is possible to view previously stored test results as

follows:

1. Move the rotary selector switch to the RCL position.

Page 27

The code is displayed.

2. Select the required distribution

board by pressing the up and down keys. The

distribution board numbers are shown in order that

the the results were stored. Hold a key down to

auto-repeat. Along bleep is sounded when the end

of the list is reached.

3. Press the ENTER key to list the circuit numbers

used in the currently displayed distribution board or

press the EXIT key to return to the RCL display

4. Select the required circuit number by pressing the

up and down keys. The circuit numbers are shown in

numerical order. Hold a key down to auto-repeat. A

long bleep is sounded when the end of the list is

reached.

Loop Test

RCD Test

5. Press the ENTER key to show the stored test codes

or press the EXIT key to return to the distribution

board selection screen.The following codes are used

to identify test results:-

6. Select the required test by pressing the up and

down keys. The tests are shown in the above order.

Hold a key down to auto-repeat. Along bleep is

sounded when the end of the list is reached.

7. Press the ENTER key to scroll through the stored

test results, together with any additional connection

information or press the EXIT key to return to the

circuit number selection screen.

Signal Installation PC

Tester 9-way ‘D’ 25-way ‘D’

Rx 2 3 2

Tx 3 2 3

DTR* 4 6

DSR 6 4 20

GND 5 5 7

Downloading to a PC

Normally, a double-ended 9-way ‘D’female socket lead

suitable for connecting PC to PC is required. This lead

should not exceed 3m in length. Alead is available as

an accessory, or one can be made up as follows:-

The CD-ROM supplied with the instrument includes AVO

Download Manager which will allow you to retrieve and

edit saved results, and export into other Microsoft

™

Windows

the disk for further information.

packages. Follow instructions supplied with

27

Page 28

Operation (LCB2500 only)

To a serial printer for printing reports

Normally, a 9-way ‘D’female socket to a 25-way ‘D’

female socket lead suitable for connecting PC to printer

is required. This lead should not exceed 3m in length. A

lead is available as an optional accessory, or one can

be made up as follows:-

Signal LCB2500 Printer

25-way ‘D’

Tx 2 2

DSR 6 20

GND 5 7

28

To a serial printer for printing reports

The printer should be set to 9600 baud, 8 bits data, no

parity and 1 stop bit. This instrument uses a special

isolated serial interface which is powered from the PC or

printer. In the unlikely event that your PC or printer is

not able to power the interface, it will be necessary to

provide an additional supply. Contact AVO Product

Support for details.

Page 29

Specifications

Supply Voltage Measurement

25-500V Intrinsic accuracy ±2% ±2 digits

Supply Frequency Measurement

d.c., 16-460Hz Intrinsic accuracy ±0,1% ±1 digit

Loop Resistance Measurement (to EN 61557-3)

Line/Earth Loop

Displayed Range: 0,01Ω to 3,00kΩ

Nominal Supply: 230V, 50Hz

EN61557

Operating Range: 0,25Ω to 3,00kΩ

Intrinsic accuracy:

0,01Ω-9,99Ω ±4% ±0,03Ω

10,0Ω-89,9Ω ±5% ±0,5Ω

90Ω-899Ω ±5% ±5Ω

900Ω-3,00Ω ±5% ±20Ω

Line-Line (Phase/Phase) Loop Resistance

measurement (to EN 61557-3)

Displayed Range: 0,01Ω to 19,99Ω

Intrinsic accuracy: ±5% ±0,03Ω

Nominal Supply: 230V, 50Hz

EN61557

Operating Range: 0,25Ω to 19,99Ω

Prospective Fault Current

Prospective fault current =

Measured Voltage Nominal Voltage

>150V 110V

150V-300V 230V

>300V 400V

Prospective Fault Current is calculated from the

respective loop resistance. Ranges and accuracies are

therefore derived from the previous section.

Nominal voltage

Loop resistance

Line Earth Loop Resistance Measurement at

15mA (to EN 61557-2)

Loop L-PE 0.1Ω

Displayed Range: 0,1Ω to 2,00kΩ

Intrinsic accuracy: up to 200Ω ±3% ±0,3Ω

Noise Immunity: 1σ of reading within 0,3Ω on a

Nominal Supply: 230V 50Hz

EN61557

Operating Range: 5,0Ω to 2,00kΩ

Loop L-PE 0.01Ω

Displayed Range: 0,01Ω to 10,00Ω

Intrinsic accuracy: ±5% ±0,05Ω

over 200Ω ±5% ±5Ω

normal domestic supply

29

Page 30

Specifications

Noise Immunity: 1σ of reading within 0,05Ω on a

Nominal Supply: 230V 50Hz

EN61557

Operating Range: 0,5Ω to 10,00Ω

RCD Testing

Selectable Ranges: 30mA, 100mA, 300mA,

Test Facilities: Contact voltage tests at

RCD Types: General purpose, delayed

Nominal Supply: 230V, 50Hz

Supply Range: 100-280V, 45-65Hz

Note: The maximum possible test current (including the

5I multiplier) is 1000mA/300mA for d.c. sensitive

RCDs. These limits are halved if the supply

voltage is less than 200V.

1

⁄2I∆n Test

Contact Voltage

Displayed range: 0V to 90V

Measurement range: 5V to 90V

Intrinsic error: +5%/+15%±0.5V

30

normal domestic supply

(to EN61557-6 up to 500mA)

500mA, 1000mA

Variable 10mAto 1000mA

Loop resistance tests at

No Trip tests at

1

⁄2I∆n

Trip tests at I∆n, 5I∆n

Fast Trip test at 150mA

Ramp tests

(Selective) and d.c. Sensitive

1

⁄2I∆n

1

⁄2I∆n

Loop resistance (measured at

1

⁄2I∆n)

I∆n Resolution

10 0,5Ω to 9kΩ

30 170Ω to 3kΩ

100 50Ω to 900Ω

300 17Ω to 300Ω

500 10Ω to 180Ω

1000 5Ω to 90Ω

2 second No Trip test at

1

⁄2I∆n (optional)

The test current flows for 2 seconds. Atripped RCD will

result in a display of <1999ms

Intrinsic Test Current accuracy: -8% to -2%

Trip Tests

I∆n Trip Test

This test will perform a short automatic

followed by a 30 second delay (Selective type only) then

execute a Trip test.

General purpose Test I∆n test for up to 300ms

Selective Test I∆n test for up to 2000ms

Timed Trip Tests

Trip time displayed Range

Intrinsic Trip time accuracy ±1% ±1ms

1

⁄2I∆n test,

0,1ms to test time limit

Page 31

Intrinsic Test Current accuracy +2% to +8%

Ramp Test (Trip current measurement)

1

This test will perform an automatic

a 30 second delay (Selective type RCD only) and then

execute an incremental ramp test.

Intrinsic Ramp Test Current accuracy ±3%

I∆n Ramp Range Increment

10 5-15mA 1mA

30 15-50mA 1mA

100 50-150mA 2mA

300 150-300mA 6mA

500 250-500mA 10mA

1000 500-1020mA 52mA

⁄2I∆n test followed by

150mA 40ms Trip Test

This is a stand alone test at 150mA for 40ms

Displayed Range 0,1ms to 40ms

There is no associated

1

⁄2I∆n test or Delay.

Power Supply

6 x 1,5V Alkaline cells type LR6 or 1,5V nickel cadmium

rechargeable cells.

Fuses

Non replaceable 2 x 7A(SIBA 70-065-63)

The 7A fuses protect the instrument and are not

replaceable by the user.

Safety

Meets the requirements for double insulation to

IEC61010-1 (1995), EN61010-1 (1995) Installation

Category III***, up to 230V to earth and 400V phase to

phase, without the need for separately fused test leads.

If required, fused test leads are available as an optional

accessory.

Complies with the relevant parts of EN 61557:1997-02

as detailed below.

*** Relates to the transient overvoltages likely to be met

in fixed wiring installations.

E.M.C. Meets EN61326-1 (1997)

Environmental Protection

IP54 The instrument is designed for

indoor and outdoor use.

Temperature Range

Operating -5°C to +40°C up to 90% RH

Storage -25°C to +65°C up to 90% RH

31

Page 32

Specifications

General

Dimensions 230mm x 114mm x 62mm

Weight 920g with battery but without

Cleaning Wipe the disconnected

IEC 61557/EN 61557

Complies with the following parts of EN 61557,

Electrical safety in low voltage systems up to 1000V a.c.

and 1500 V d.c. – Equipment for testing, measuring or

monitoring of protective measures:-

Part 1 - General requirements

Part 3 - Loop resistance

Part 6 - Residual current devices (RCDs)

32

leads and test & carry case

instrument with a clean cloth

dampened with soapy water or

Isopropyl Alcohol (IPA).

Page 33

Accessories

Part Number

Test and carry case Holds, and supports the instrument to allow ‘hands free’

Pouch Holds and protects the instrument when not in use. 6420-121

Carrying strap Attaches to case or instrument. 6220-611

2-wire Test lead set With prods and clips. 6231-631

3-wire test lead For three phase sequence testing, including 2 prods and 3 clips. 6231-632

U.K. Mains plug test lead Fitted with BS1363 fused plug. 6231-633

Euro Mains plug test lead Fitted with CEE7/7 plug. 6231-635

U.K. Earth bond test lead Fitted with BS1363 fused plug. 6231-634

Switch Probe SP2 2-wire lead set with a ‘Test’ key in the black probe. 6231-636

2-wire test lead set (5m) 2 wire lead set with 5m long leads. 6231-637

Fused probe and clip set Replace normal probes and clips supplied with 2- and 3-wire test

Computer Serial lead To connect the instrument to PC with 9-way ‘D’ connector, 1,8m long. 25955-025

Printer serial lead To connect the instrument to serial printer, with 25-way ‘D’ socket 25955-026

Download Manager Installation Tester Setup and simple download software 6111-442

AVO

AVO

®

PowerSuite

®

NICEone

™

™

operation in use, and protection when not in use. 6420-114

(2 probes and 3 clips) test lead kits. 600V max. 10A fuse. 6180-405

Windows™program for Installation Testing

Certificate generation etc. Contact Distributor

Windows™program for Installation Testing certificate generation etc. 6111-403

33

Page 34

Publications

User Guide

‘Testing Electrical Installations’ Adetailed account of how to carry out practical testing to

‘A Stitch in Time’ The complete guide to electrical installation testing. AVTM21-P8B

‘Getting Down to Earth’ A practical manual on earth resistance testing. AVTB25-TA

†

Available in several languages. Please contact your local distributor for availability.

†

BS 7671 (16th Edition IEEE Wiring Regulations). 6172-129

34

Part Number

6172-428

Page 35

Loop Resistance Tables

Limit

Min.

Limit

Min.

Limit

Min.

indicated

reading

17,0

21,5

26,0

30,5

35,0

44,0

53,0

62,0

71,0

80,0

89,0

125

170

215

Limit

300

350

400

450

500

600

700

800

900

1,00

1,50

2,00

2,50

3,00

0,10

0,15

0,20

0,25

0,30

0,35

0,40

0,45

0,50

0,60

0,70

0,80

0,90

1,00

indicated

reading

0,03

0,08

0,12

0,17

0,21

0,26

0,30

0,35

0,39

0,48

0,57

0,66

0,75

0,84

1,50

2,00

2,50

3,00

3,50

4,00

4,50

5,00

6,00

7,00

8,00

9,00

10.0

15,0

indicated

reading

1,29

1,74

2,19

2,64

3,09

3,54

3,99

4,44

5,34

6,24

7,14

8,04

8,94

12,5

20,0

25,0

30,0

35,0

40,0

50,0

60,0

70,0

80,0

60,0

100

150

200

250

Loop Resistance L-N/L-PE/L-L

Use these tables to determine the lowest allowed

reading for a limit, taking into account the maximum

service error of the instrument.

Min.

indicated

reading

260

305

350

395

440

530

620

710

800

0,86

1,31

1,76

2,21

2,66

Limit

Min.

Limit

3,0

3,5

4,0

4,5

5,0

6,0

7,0

8,0

9,0

10,0

15,0

20,0

25,0

30,0

35,0

40,0

45,0

50,0

60,0

indicated

reading

1,2

1,7

2,2

2,6

3,1

4,0

5,0

5,9

6,9

7,8

12,5

17,2

21,9

26,6

31,3

36,0

40,7

45,4

54,8

70,0

80,0

90,0

100

150

200

250

300

350

400

450

500

600

700

800

900

1,00k

1,50k

2,00k

Min.

indicated

reading

64,2

73,6

83,0

92,4

139

183

230

277

324

371

418

465

559

653

747

841

935

1,41k

2,00k

Loop Resistance L-PE 0.1Ω

35

Page 36

Repair and Warranty

The instrument circuit contains static sensitive devices,

and care must be taken in handling the printed circuit

board. If the protection of an instrument has been

impaired it should not be used, and be sent for repair by

suitably trained and qualified personnel. The protection

is likely to be impaired if, for example, the instrument

shows visible damage, fails to perform the intended

measurements, has been subjected to prolonged

storage under unfavourable conditions, or has been

exposed to severe transport stresses.

New instruments are guaranteed for 3 year period from

the date of purchase by the user.

Note: Any unauthorised prior repair or adjustment will

automatically invalidate the Warranty.

Instrument Repair and Spare Parts

For service requirements for MEGGER®Instruments

contact:-

AVO INTERNATIONAL or AVO INTERNATIONAL

Archcliffe Road Valley Forge Corporate Center

Dover 2621 Van Buren Avenue

Kent, CT17 9EN. Norristown, PA 19403

England. U.S.A.

Tel: +44 (0) 1304 502243 Tel: (610) 676-8579

Fax: +44 (0) 1304 207342 Fax:(610) 676-8625

or an approved repair company.

36

Approved Repair Companies

A number of independent instrument repair companies

have been approved for repair work on most MEGGER

instruments, using genuine MEGGER®spare parts.

Consult the Appointed Distributor/Agent regarding spare

parts, repair facilities and advice on the best course of

action to take.

Returning an Instrument for Repair

If returning an instrument to the manufacturer for repair,

it should be sent freight pre-paid to the appropriate

address. Acopy of the Invoice and of the packing note

should be sent simultaneously by airmail to expedite

clearance through Customs. Arepair estimate showing

freight return and other charges will be submitted to the

sender, if required, before work on the instrument

commences.

®

Page 37

37383940414243

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

AVO INTERNATIONAL

Archcliffe Road PO Box 4651 S. Westmoreland Road MEGGER SA,

Dover Valley Forge Dallas 29 Allée de Villemomble

Kent, CT17 9EN. PA 19484-9007 TX 75237-1017 93340 Le Raincy

England. U.S.A. U.S.A. Paris, France

Tel: +44 (0) 1304 502100 Tel: +1 (610) 676-8500 Tel: +1 (800) 723-2861 (U.S.A. only) Tel: +33 (1) 43.02.37.54

Fax: +44 (0) 1304 207342 Fax: +1 (610) 676-8610 Tel: +1 (214) 330-3203 (International) Fax: +33 (1) 43.02.16.24

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification or design without prior notice.

MEGGER is the registered Trade Mark of AVOINTERNATIONAL LIMITED. Copyright © AVO INTERNATIONALLIMITED

Part No 6172-428 – Edition 1 – Printed in England – 12EE

Fax: +1 (214) 337-3533 Fax: +1 (214) 337-3038

Loading...

Loading...