Page 1

10 A Digital Low Resistance Ohmmeter

DLRO10HDX

10 Amp Digital Low Resistance

■ NEW Onboard memory storage for test

results up to 200 records (HDX only)

■ Download to PowerDB

■ NEW interchangeable test lead terminations

■ High or low output power selection for

condition diagnosis

■ Operates from battery or AC mains supply

■ Protected to 600 V without blowing a fuse,

test lead live voltage warning light

■ Heavy duty case: IP 65 lid closed,

IP54 operational

DLRO10HDX

DESCRIPTION

Augmenting Megger’s DLRO10 and 10X range the

DLRO10HDX combines ultimate simplicity of operation with

a rugged IP65 case designed for stable ground and bench

operation and provides memory storage.

These units are powered from either rechargeable battery

or AC power making it suitable for continuous testing in

production line/repetitive use environments.

Rotary switch controls are simple and easy to operate in all

weather conditions and with gloved hands. A large, clear,

backlit LCD display is easy to read from a distance. The

DLRO10HDX provides significantly enhanced compliance

and is capable of delivering 10 A into measurements up

to 250 mΩ and 1 A into measurements up to 2.5 Ω. The

duration of each test may be up to 60 seconds.

The DLRO10HDX is rated CAT III 300 V provided the

optional terminal cover is fitted to the instrument. Details can

be found in the ordering information panel of this data sheet.

The DLRO10HDX provides five test modes each of which is

selected through a simple rotary control on the Mode selection

rotary switch. All memory functions, delete, download to

PowerDB and recalling test results are also accessible via the

Range Selection rotary switch.

A simple control panel enables easy navigation for

configuration settings.

■ Simple rotary switch selection of five test

modes, including auto start on connection

History of ‘DUCTER’ Testing

For over 100 years the ‘Ducter’ test has been used to describe

a simple test for measuring ver low contact resistances and

‘Ducter’, which is still used as a trademark, was the name

origianally given to the low resistance ohmmeter manufactured

by Megger. The name ‘Ducter’ was registered by Megger in

June 1908 and ‘Ducter’ has since become the inudstry standard.

FEATURES AND BENEFITS

n Rugged case well suited to transportation with shoulder

strap and lead set pouch

n Removable lid facilitates easy test lead connection

n Operational ingress protection is IP 54 (battery power only)

ensuring protection from the elements

n 7Ah lead acid battery provides extended operation and can

be charged whilst operating from line power

n Rotary mode switch with bidirectional (current reversal with

averaging cancels thermal EMFs), unidirectional, automatic,

continuous and inductive modes

n Large, clear LCD display with backlight and contrast

adjustment

n Auto power off function conserves battery

Page 2

DLRO10HDX

10 A Digital Low Resistance Ohmmeter

APPLICATIONS

The DLRO10HDX measures low resistance values in applications

ranging from railways and aircraft to resistance of components

in industry.

Any metallic joint can be measured but users must be aware

of measurement limitations depending on application. For

example, if a cable manufacturer plans to make resistive

measurements on a thin wire, a low test current should be

selected to prevent heating the wire thereby changing its

resistance.

Measurements on electric motors and generators will

be inductive and require the user to understand the

inductive mode and charging process before a correct result

is achieved.

The DLRO10HDX is well suited to measuring thick conductors,

bonds and quality of welding because of its 10 A range for

resistance values up to 250 mΩ.

Electromagnetic noise induced into the leads can interfere

with a reading. A noise symbol alerts the user and prevents

a measurement when the instrument detects noise above its

threshold.

When dissimilar metals are joined a thermocouple effect is

created. Users should select a bidirectional mode to ensure

cancellation of this effect. The instrument measures with

current flowing in both directions and averages the result.

Normal mode is initiated by pressing the ‘Test’ button after

connecting the test leads to the unit under test. Continuity

of all four connections is checked. Current is applied in both

forward and reverse direction following which measurement

is displayed.

Automatic mode is started as soon as the probes make

contact. Forward and reverse current measurements are made

and the average value is displayed. This mode is ideal when

working with handspikes. Each time the probes are removed

and reconnected to the load a new test will be performed

without the need to press the test button.

TEST modes

Automatic unidirectional mode applies current in one

direction only to speed up the measurement process.

However thermal EMF resulting from dissimilar metal bonds

can cause lower accuracy. Test starts automatically when

probes are connected.

Continuous mode allows repeated measurements to be made

on the same sample. Simply connect the test leads and press

the test button. The measurement is updated every three

seconds until the circuit is broken.

Inductive mode is selected when measuring resistance on, for

example, motors and generators. When measuring inductive

loads it is necessary to wait for the voltage to stabilize as the

inductive element is charged. Test leads are firmly connected

to the device under test and the ‘Test’ button pressed. The

instrument will pass the selected current through the sample

continuously in one direction only and take repetitive readings

that will gradually decrease to the true value as the voltage

stabilizes. The operator decides when the result is stable and

presses the ‘Test’ button to terminate the test.

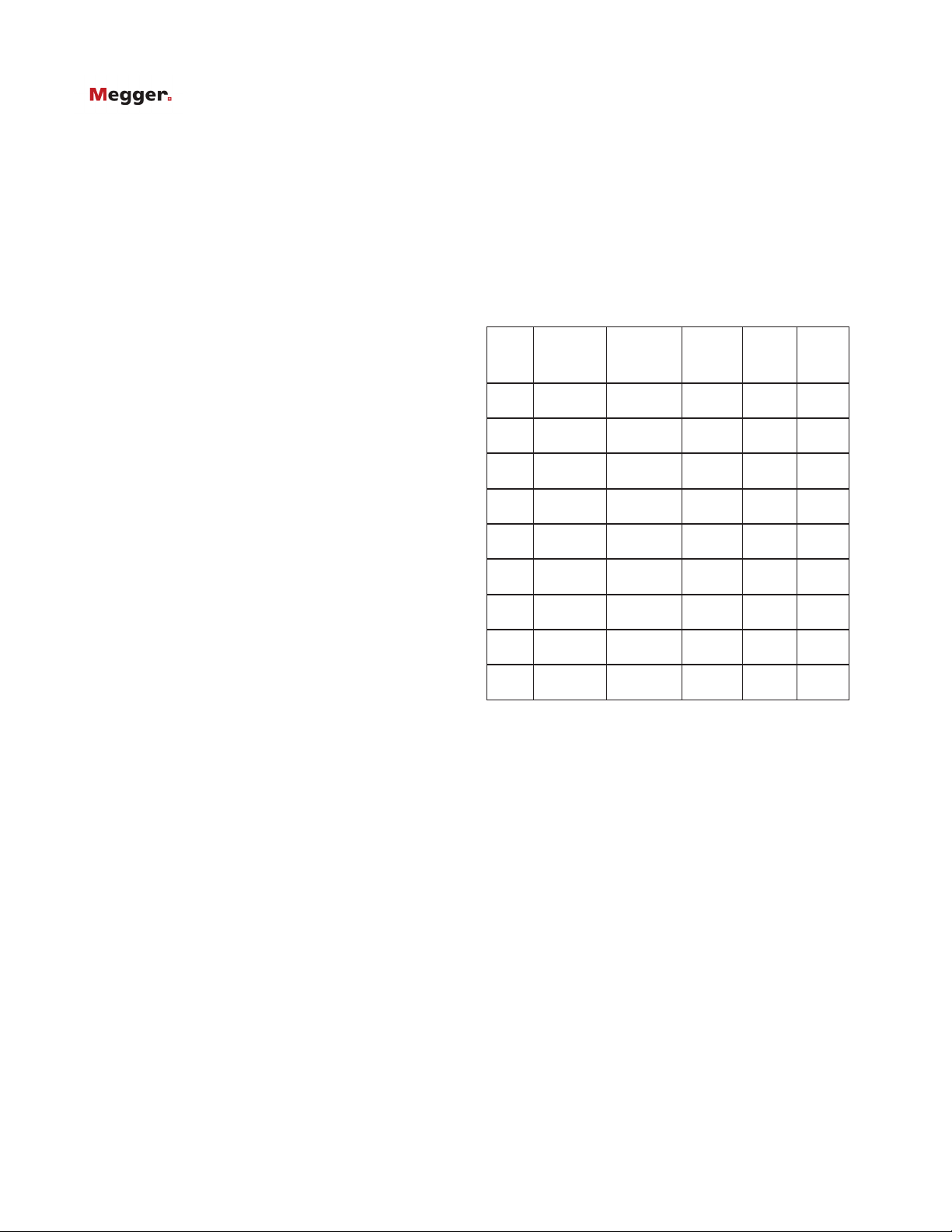

ELECTRICAL SPECIFICATIONS

Resistance/Current Ranges

The green resistance ranges on the keypad indicate low

output power (<0.25 W) outputs. Red ranges indicate higher

2.5 W (1 A) and 25 W (10 A) power outputs.

Resolution and Accuracy

Test current accuracy ±10%

Voltmeter input impedance >200 kΩ

Test

current

Resistance

range

0.1 mA0 to

2500.0 Ω

0.1 mA0 to

250.00 Ω

0 to

1 mA

25.000 Ω

0 to

10 mA

2500.0 mΩ

100 mA0 to

250.00 mΩ

0 to

1 A

25.000 mΩ

0 to

10 A

2500.0 µΩ

0 to

1 A

2500.0 mΩ

0 to

10 A

250.00 mΩ

Resolution

(as

displayed)

0.1 Ω ±0.2% 25 mV

0.01 Ω ±0.2% 25 mV

1 mΩ ±0.2% 25 mV 25 μW

0.1 mΩ ±0.2% 25mV 250 μW

0.01 mΩ ±0.2% 25 mV 2.5 mW

1 μΩ ±0.2% 25 mV 25 mW

0.1 μΩ ±0.2% 25 mV 0.25 W

0.1 mΩ ±0.2% 2.5 V 2.5 W

0.01 mΩ ±0.2% 2.5 V 25 W

Basic

accuracy*

Full

scale

voltage

Max.

power

output

25 μ

W

W

2.5 μ

* The accuracy stated assumes forward and reverse

measurements.

Inductive mode or undirectional mode will introduce an

undefined error if an external EMF is present.

Basic accuracy at reference conditions.

GENERAL SPECIFICATIONS

Temperature coefficient < 0.01% per ºC, from 5 ºC to

40 ºC

Maximum altitude 2000 m (6562 ft) to full safety

specifications

Display size/type Main 5 digit + 2 x 5 digit

secondary displays

Battery type 6 V, 7Ah sealed lead acid

Voltage input range 100 - 240 V 50 / 60 Hz 90 VA

Charge time 8 hours

Backlight LED backlight

Battery life >1000 Auto (3 sec) tests

Page 3

DLRO10HDX

10 A Digital Low Resistance Ohmmeter

Auto power down 300s

Mode selection Rotary switch

Range selection Rotary switch

Memory features selection Rotary switch

Weight 6.7 kg (14.8 lb)

Case dimensions L 315 x W 285 x H 181 mm

(L 12 x W 11 x H 7 in.)

Pouch for test leads Yes (lid mounted)

Test leads included depending on

chosen option:

DH4C lead set

KC1 Kelvin Clip lead set

IP rating IP65 case closed, IP54 battery

operation

Record storage 200 test records

Safety rating

In accordance with IEC61010-1, CATIII 300V when used

with optional terminal cover (details in ordering information)

Operating temperature and humidity

-10 °C to +50 °C

(14 °F to 122 °F) <90% RH

Reference conditions 20 °C ±3 °C (68 °F ±37 °F)

Storage temperature and humidity

-25 °C to +60 °C (-13 °F to +60 °F), <90% RH

EMC

In accordance with IEC61326-1 (Heavy industrial)

Noise rejection

Less than 1% ±20 digits additional error with 100 mV peak

50/60 Hz. on the potential leads. Warning will show if hum

or noise exceeds this level.

Maximum lead resistance

100 mΩ total for 10 A operation irrespective of battery

condition.

OPTIONAL TERMINAL COVER

The CAT III 300 V rating on the

DLRO10HDX is only valid when

the instrument is fitted with

the optional terminal cover to

provide the required creepage

and clearances at the instrument

terminals. Although the terminal

cover may be used with any test

leads, only the Megger DH4,

DH5 and DP1-C duplex handspikes, and KC2-C insulated

kelvin clips have suitable probe insulation to comply with the

requirements of IEC61010-1 and the CATIII 300 V rating.

SUPPLIED LEADSET OPTIONS

DLRO10HDX

+ DH4-C probe 1.5 m leads

+ KC1 Kelvin clip 3 m leads

+ No test leads supplied

Page 4

ORDERING INFORMATION

Item (Qty) Order No.

DLRO10HDX, no leads supplied 1008-052

DLRO10HDX, suplied with hand spikes 1008-075

DLRO10HDX, supplied with Kelvin clips 1008-095

Standard included accessories

Test lead pouch (lid mounted) 1000-036

DLRO10HDX user guide CD

Optional Accessories at extra cost

Calibration Shunt,10 Ω, current rating 1 mA 249000

Calibration Shunt, 1 Ω, current rating 10 mA 249001

Calibration Shunt, 100 mΩ current rating 1A 249002

Calibration Shunt, 10 mΩ current rating 10 A 249003

Certificate of Calibration for Shunts, NIST CERT-NIST

Optional Test Leads at extra cost

Normal test leads not fitted with in-line connector:

Duplex Leads

DH5 straight duplex handspikes (2)

One has indicator lights. 2.5m/8ft 6111-517

Terminal cover (use in conjunction with DH4 test leads

supplied as standard, or optional DH5 test leads for

CATIII 300 V compliance 1002-390

Duplex Handspikes (2) with spring loaded helical contacts

2m/7ft 242011-7

DH1 2.5m/8ft 1006-442

DH1 5.5m/18ft 242011-18

DH2 6m/20ft (only 1 lead supplied) 1006-443

DH2 9m/30ft (only 1 lead supplied) 242011-30

DLRO10HDX

10 A Digital Low Resistance Ohmmeter

Item (Qty) Order No.

Duplex Heavy Duty 5cm (2”) C-Clamps. (2)

2m/7ft 242004-7

Duplex Heavy Duty 5cm (2”) C-Clamps. (2)

5.5m/18ft 242004-18

Duplex Heavy Duty 5cm (2”) C-Clamps. (2)

9m/30ft 242004-30

Duplex handspikes with replaceable

Needle Points 2m/7ft 242003-7

Duplex 1.27 cm (1/2“) Kelvin Clips (2)

gold plated 2m/7ft 241005-7

Duplex 1.27 cm (1/2“) Kelvin Clips (2)

silver plated 2m/7ft 242005-7

Duplex 3.8 cm (11/2”) Kelvin Clips (2)

2m/7ft 242006-7

Duplex 3.8 cm (11/2”) Kelvin Clips (2)

5.5m/18ft 242006-18

Duplex 3.8 cm (11/2”) Kelvin Clips (2)

9m/30ft 242006-30

Single handspike (1) for potential measurement

2m/7ft 242021-7

Single handspike (1) for potential measurement

5.5m/18ft 242021-18

Single handspike (1) for potential measurement

9m/30ft 242021-30

Current clip (1) for current connections

2m/7ft 242041-7

Current clip (1) for current connections

5.5m/18ft 242041-18

Current clip (1) for current connections

9m/30ft 242041-30

6m/20 ft ext 1006-460

Straight Duplex Handspikes (2) Heavy Duty

with fixed contacts. 2m/7ft 242002-7

Straight Duplex Handspikes (2) Heavy Duty

with fixed contacts 5.5m/18ft 242002-18

Straight Duplex Handspikes (2) Heavy Duty

with fixed contacts 9m/30ft 242002-30

SALES OFFICE

Megger USA Valley Forge Corporate Center

2621 Van Buren Avenue, Norristown,

Pennsylvania, 19403, USA

T. 1-610 676 8500

F. 1-610-676-8610

DLRO10HDX_DS_US_V04

www.megger.com

ISO 9001

The word ‘Megger’ is a registered trademark

Loading...

Loading...