Page 1

DLRO100E, 100EB, 100X, 100XB,

100H & 100HB

Digital Low Resistance Ohmmeter

User guide

100A High Performance

Page 2

Contents

Safety warnings 3

Safety and hazard symbols used on the instrument 4

General description 5

Instrument controls and indicators 6

Preparations for use 7

Operating instructions 8

Lead connections 9

1 - Testing modes 10

2 - Instrument set-up 12

2 - DLRO100A Resetting Battery Charge 16

3 - Saving a test record 17

4 - Delete results 18

5 - Download a test record 19

6 - Remote operation 20

7 - Asset tagging 21

8 - Screen symbol reference 22

Battery indicator 23

Error Indicator 24

Preventive maintenance 25

Technical specification 26

Accessories 27

Acknowledgements 27

Repair and warranty 28

Calibration, service and spare parts 28

Approved service centres 28

www.megger.comDLRO100E, 100X & 100H – 100A

2

Page 3

G Safety warnings

These must be read and understood before use. Retain these safety warnings for future reference.

■ CAUTION: THE INSTRUMENT MUST BE OPERATED ONLY BY SUITABLY TRAINED AND COMPETENT PERSONS

■ Users of this equipment and their employers are required by National Health and Safety Legislation to carry out valid

risk assessments of all electrical work so as to identify potential sources of electrical danger and risk of electrical injury.

■ The instrument must NOT be used if any part of it is damaged.

■ Damaged test leads must NOT be used. Test leads, connectors and mechanical guards must be in good order, clean and

with no broken or cracked insulation.

■ Fan filters and covers giving access to internal conductive parts must be correctly fitted before use.

■ Testing inductive circuits can be hazardous: The DLRO100 is a high power instrument, designed for testing resistive

loads. It must NOT be used to test inductive loads.

■ DANGER! The instrument is not fully protected when switched off.

• Switch the instrument ON before connecting to the test subject.

• The test subject must be switched off, de-energised and checked before test connections are made. Ensure that the

test subject cannot be re-energised whilst the instrument is connected.

• Do not leave the equipment unattended when connected to the test subject.

• Do not leave the equipment connected to the test subject after the test is completed.

■ The user must exercise caution when connecting to and disconnecting from the test subject.

• Always connect test leads to the instrument before attaching to test subject.

• Keep hands behind tactile barriers on probe clips and clamps when making or breaking connections.

• High current connections between the instrument and test subject must be secured against accidental detachment

and must not be disengaged whilst test current is flowing.

• High current test leads must be a minimum of 3 milliohm resistance.

• Circuit terminals must not be touched during test.

• Do not disconnect the instrument from the test subject until the test current has stopped and the TEST warning

indicator is extinguished.

• Test leads and connections may become hot during use. Exercise caution when handling.

• Disconnect from the test subject before switching the instrument OFF.

■ DANGER! Some models can be operated by remote control. A test can be started at any time by remote control. These

additional precautions must be taken for instruments with a remote control function.

• Measurement connections must be handled only when precautions have been taken to prevent a remote control

test start.

• If the remote control link should fail, the test must be stopped manually by pressing the TEST button.

■ If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

■ Fan filters are user-serviceable. Disconnect all measurement leads and switch the instrument OFF before servicing the

fan filters.

■ There are no user-serviceable parts inside the instrument; all servicing, including fuse replacement, must be referred to

Megger approved service centres.

■ Use only Megger approved battery pack, and follow the instructions provided with the battery

■ Warning! This instrument contains a Lithium Ion High Energy Battery Pack and a lithium coin cell.

• Do not pierce, damage, disassemble or modify the battery. The battery contains safety and protection devices

which, if tampered with may cause the battery to generate heat, rupture or ignite.

• Never heat (or dispose of) the battery in a fire.

• Do not subject the battery to strong impact, mechanical shock or excessive heat.

• Do not expose the battery to water, salt water or other liquids, or allow the battery to get wet.

• Never short-circuit or reverse the polarity of the battery pack.

• In the event of a battery cell leaking, do not allow the released fluid to come into contact with the skin or eyes. If

contact has been made, wash the affected area with plenty of water and seek medical advice immediately.

www.megger.comDLRO100E, 100X & 100H – 100A

3

Page 4

Safety and hazard symbols used on the instrument

G Caution: refer to user instructions

F Caution: risk of electric shock

IP54 Enclosure is dust proof and protected against

water splashes

Equipment protected throughout by

t

Double Insulation.

Line Power / mains

600V ac rms maximum between terminals,

and between terminals and earth

Measurement Connection

■ Only Megger supplied test leads designed for this instrument provide the full safety rating.

Equipment complies with current EU directives.

N13117 Equipment complies with current

“C tick” requirements.

Do not dispose of in the normal

waste stream.

g Connect to earth for Voltage

measurement reference

Universal Serial Bus (USB)

Bluetooth

®

Voltage

The rated measurement connection voltage is the maximum line to earth voltage at which it is safe to connect.

CAT IV

Measurement category IV: Equipment connected between the origin of the low-voltage mains supply and the distribution panel.

CAT III

Measurement category III: Equipment connected between the distribution panel and the electrical outlets.

CAT II

Measurement category II: Equipment connected between the electrical outlets and the user’s equipment.

■ Measurement equipment may be safely connected to circuits at the marked rating or lower. The connection rating is

that of the lowest rated component in the measurement circuit.

WEEE Directive

The crossed out wheeled bin symbol placed on Megger products is a reminder not to dispose of the product at the end of its life with

general waste.

Megger is registered in the UK as a Producer of Electrical and Electronic Equipment. The Registration No is WEE/HE0146QT.

For further information about disposal of the product consult your local Megger company or distributor or visit your local Megger

website.

www.megger.comDLRO100E, 100X & 100H – 100A

4

Page 5

General description

The new Megger DLRO100 range of Low Resistance Ohmmeters provide high accuracy with noise immunity, are robust yet light and

portable.

The range consists of three models:

■ DLRO100E/EB has advanced features of configurable tests, manual, auto and continuous tests,

■ DLRO100X/XB in addition has internal memory storage for test records and USB connectivity,

®

■ DLRO100H/HB in addition to the above has Bluetooth

Key features

■ CAT IV 600 VAC / 500 VDC up to 2000 m on all test terminals for safe operation

■ CAT IV 300 V up to 4000 m

■ Lightweight 100 A battery powered unit for portability – 7.9 Kg (17 lbs)

■ Li-ion battery for high power and fast charge - works from an AC supply if the battery is fully discharged

■ High noise immunity for stable readings

■ Smooth DC Output for circuit breaker testing

■ IP54 (lid open) for protection against ingress during operation (IP65 lid closed)

■ Adjustable 10 - 100 A output, 4 terminal measurement for flexibility

■ Adjustable current ramp rates and test duration for flexibility

■ Battery capacity - 200 single tests or up to 2x 10 minutes continuous 100 A output for extended use

■ Mains only units for manufacturing and production applications where AC is always available

■ Ultra tough outer case construction designed for use in demanding environments with a flame retardant UL94 V0 inner

case for safety

■ DualGround™ - Using the optional DC clamp enables circuit breaker testing with ground protection in place (100X &

100H variants) for safety

■ Large, clear LCD for all light conditions

■ Time and Date stamped memory for recording of results (220 readings)

■ Range and test mode rotary switches for simplicity of operation

■ Memory Storage and USB download capability (100X & 100H variants) for effective results management

■ Remote Operation - Control the instrument remotely via a PC or laptop (100H variants) for added safety

■ Smart device support - Running a Power DB app on Windows 8 tablet or smart phone to populate unique asset ID’s

(100H variants) for efficient asset management

■ Two year warranty - second year conditional on free product registration

, remote operation and smart device capability.

This product and its accessories are covered by EU design registrations 002349134-0001 and 002349134-0002.

This product and its accessories are the subject of patents pending.

www.megger.comDLRO100E, 100X & 100H – 100A

5

Page 6

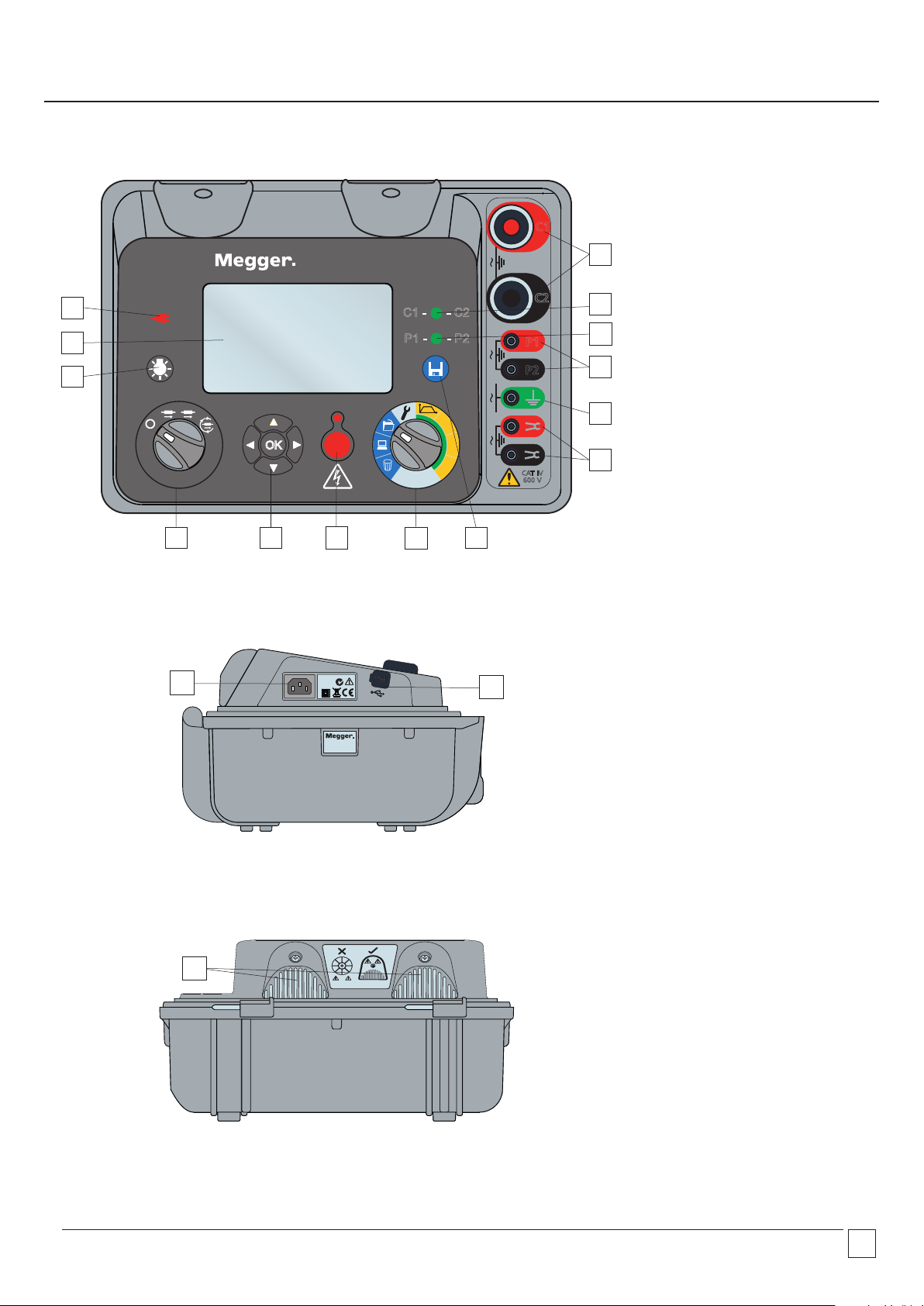

Instrument controls and indicators

1. Current terminals

– C1 - C2

14

13

12

C1

DLRO100

MAX

600 V

C2

C1 - - C2

P1 - - P2

AUTO

MAN

OK

TEST

10A

Ω

50A

100A

MAX

600 V

MAX

600 V

MAX

600 V

P1

P2

CAT IV

600 V

1

2

3

4

5

6

2. C1 - C2 LED

indicates continuity

on the C terminals

3. P1 - P2 LED

indicates continuity

on the P terminals

4. Potential terminal

- P1 - P2

5. Measurement earth

terminal

6. DualGround™ terminal

100X and 100H only

7. Save button

100X and 100H only

11

910

8

7

8. Range rotary switch

9. TEST button with

associated warning lamp

10. Navigation / OK buttons

11. Test mode rotary switch

15

17

90-264 V

47-63 Hz

500 VA

DLRO100EB

Made in UK by Megger

N13117

16

12. Backlight button

13. Display

14. LED indicating line

power / mains

15. Power socket

16. USB Device port

100X and 100H only

17. Cooling fans with

IP54 cover

www.megger.comDLRO100E, 100X & 100H – 100A

6

Page 7

Preparations for Use

C1

C1 - - C2

P1 - - P2

10A

Ω

100A

MAX

600 V

C2

P1

MAX

600 V

P2

MAX

600 V

MAX

50A

600 V

CAT IV

600 V

DLRO100

AUTO

MAN

TEST

OK

Initial instructions

■ Remove instrument, power lead and pouch from the packing box.

■ Open the lid noting position of the IEC 60320 power inlet and USB device port on the left panel.

Test terminals are located to the right of the front panel.

■ Read the safety warnings.

■ A quick reference is provided in the instrument lid.

■ Keep the original packaging for re-use.

Power lead and battery charging

■ If the power lead supplied is not suitable for your AC connection, do not use an adaptor. Always use a Megger

approved power lead

■ Use the supplied AC lead ONLY

■ Supply voltage: 90 to 265 V rms ac at 50 / 60 Hz.

■ A red LED illuminates when line power/mains is present.

■ The battery will charge when an AC source is connected, except when a test is in progress.

■ For optimum battery life, charge the battery after each use. Full charge duration is 2.5 hours.

■ The battery must be charged between 0 °C and 40 °C ambient temperature. If the battery detects a

temperature outside this range the battery symbol will flash and charging will be prevented.

DLRO100EB

CAT IV 600 V

IP 54

www.megger.com

DLRO100EB

Made in UK by Megger

N13117

90-264 V

47-63 Hz

500 VA

DLRO100EB

Made in UK by Megger

Functional verification

Simply turning on the instrument at the test mode switch will initiate a start-up process and the display will respond. The initialisation

screen (right) shows the firmware version.

Calibration

The DLRO100 is supplied with a calibration certificate.

An ISO17025 (UKAS) Calibration Certificate is available if ordered with the instrument.

Storage

Instruments should be stored within its temperature and humidity specifications.

Intermittent operation limits

The DLRO100 is a high-power instrument and, as such, can generate significant heat. To prevent damage, the instrument contains

internal thermal protection which can disable the test current if excessive temperature rise is detected. In this event, the thermometer

symbol will be displayed on the screen. If this should occur, switch the instrument off and allow it to cool before repeating the test. If

possible, do not position the instrument in direct sunlight.

www.megger.comDLRO100E, 100X & 100H – 100A

7

Page 8

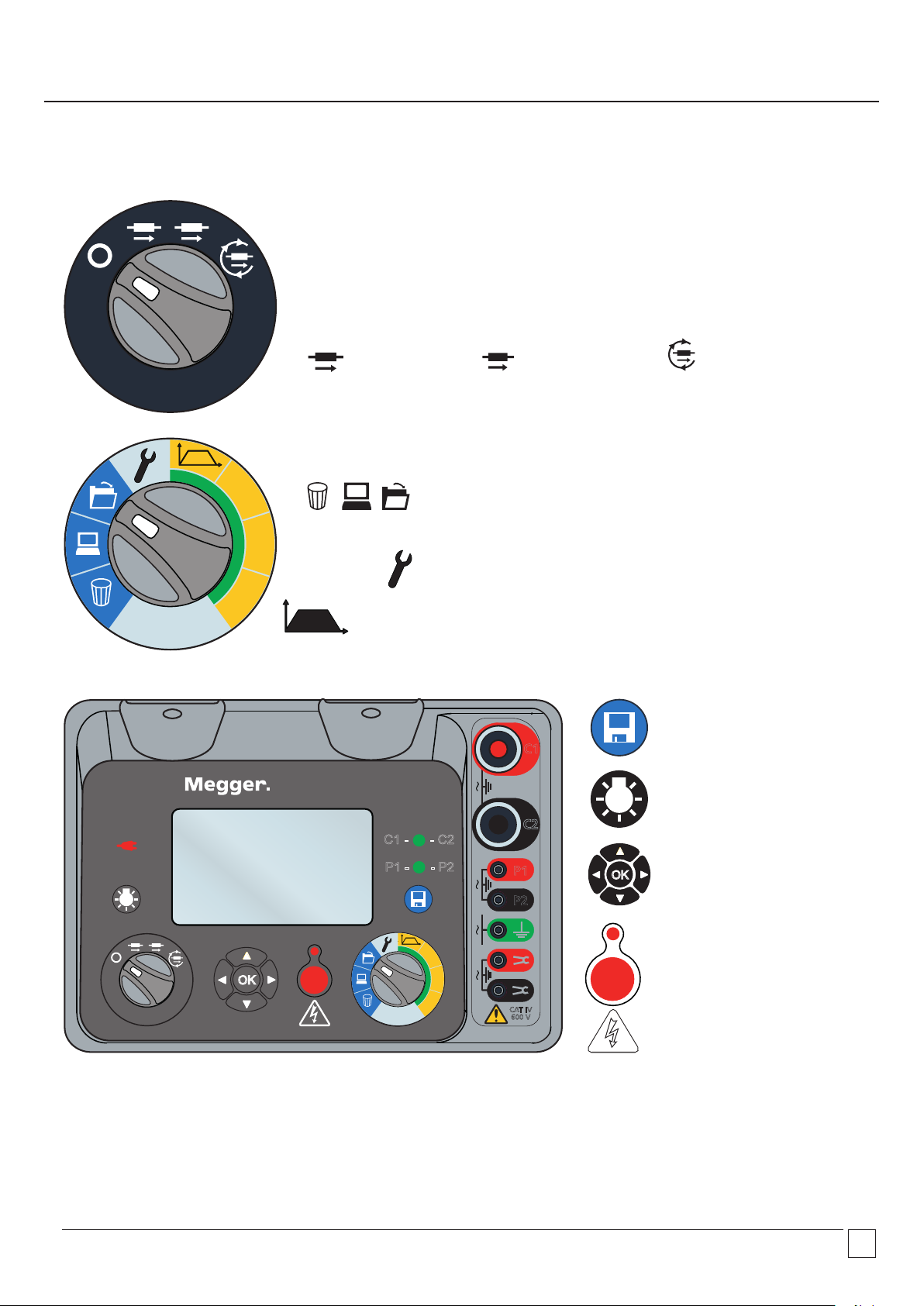

Operating instructions

100A

50A

10A

Ω

100A

50A

10A

General operation

The DLRO100E, 100X and 100H are primarily controlled by two rotary switches and a TEST button used to start and stop a test (see

section entitled, “Instrument control and indicators”).

AUTO

MAN

Test Mode rotary switch

The Test Mode rotary switch includes an ‘OFF’ position; the instrument switches on by

rotating the switch clockwise from this position. Test modes provided are:

MAN

Manual Auto Continuous

AUTO

Range rotary switch

A light blue coloured section which denotes memory functions; delete

10A

Ω

50A

100A

DLRO100

AUTO

MAN

OK

TEST

records; download records via USB or Bluetooth® and retrieve records.

(100X and 100H Only)

A spanner enabling instrument and test settings.

A custom test selection, 10 A, 50 A and 100 A pre-set test currents.

Save button

(100X and 100H only)

C1

MAX

600 V

Backlight button

C2

C1 - - C2

P1 - - P2

10A

10A

Ω

Ω

50A

50A

100A

100A

MAX

600 V

MAX

600 V

MAX

600 V

P1

P2

CAT IV

600 V

OK

TEST

Navigate via Directional and

an OK buttons

TEST button to start and stop

a test.

www.megger.comDLRO100E, 100X & 100H – 100A

8

Page 9

Lead connections

Test Leads

DLRO100

C1 - - C2

P1 - - P2

AUTO

MAN

TEST

OK

10A

Ω

50A

100A

P1

P2

Section of test piece under test.

C1

C2

P1

P2

Leads connected to the instrument with the Kelvin arrangement

below showing correct positioning of Current (C1,C2) and

Potential probes (P1,P2).

The earth terminal

g is used to detect floating voltage on the

test subject relative to the DLRO 0 V. High floating voltage on

the test subject could present a hazard to the user and the DLRO.

If the test subject is ±200 mV from the DLRO 0 V, test will be

inhibited.

The current terminals (C1 and C2) must be connected outside of

the potential terminals (P1 and P2), to ensure accurate readings.

P1 P2

C1

DualGround™ and DC Clamp connection

C2

As an additional safety precaution, perform the test with both

ends of the test object grounded.

Connect the DC clamp to one of the ground connections. The

DC clamp measures current flowing through the ground loop

and the DLRO100 compensates for this current loss automatically

resulting in a more reliable reading.

Refer to the MCPD100L manual for how to use the DC current

clamp.

Connect the earth connector to a suitable earth.

www.megger.comDLRO100E, 100X & 100H – 100A

9

Page 10

50A

1. Testing modes

50A

50A

Manual and auto test

1.1 Preset test

100/50/10A - Initial

AUTO

MAN

10A

Ω

100A

Select current on rotary switch.

Press test button to start the test.

To configure date and time for saved results - refer to Instrument

set-up section 2.6

MAN

TEST

AUTO

1.3 User configured Manual and Auto test - Initial

AUTO

MAN

AUTO

MAN

1.2 Preset test

100/50/10A - Progress

Active test screen.

AUTO

MAN

10A

Ω

100A

AUTO

MAN

1.4 User configured Manual and Auto test - Progress

AUTO

MAN

AUTO

MAN

10A

Ω

TEST

50A

100A

Press test button to start a custom test.

Active custom test screen.

To configure test setting for user configured test, date and time

for saved results - refer to Instrument set-up section 2.6

Continuous test

1.5 Preset test 100/50/10A - Initial 1.6 Preset test 100/50/10A - Progress

AUTO

MAN

10A

Ω

100A

Press test button to start a continuous test.

Active continuous test screen.

10A

Ω

50A

100A

AUTO

MAN

10A

Ω

50A

100A

To configure date and time for saved results - refer to Instrument

set-up section 2.6

www.megger.comDLRO100E, 100X & 100H – 100A

10

Page 11

50A

1.7 User configured continuous test - Initial

50A

AUTO

MAN

1.8 User configured continuous test - Progress

AUTO

MAN

10A

Ω

100A

Press test button to start a custom continuous test.

To configure test setting for user configured test, date and time

for saved results - refer to Instrument set-up section 2.6

End of Test

1.9 End of test screen

Display shows the current through the test piece, measured

voltage and calculated resistance. If the required current is not

achieved the current value will flash.

Active continuous test screen.

10A

Ω

100A

Test aborted

1.10 Test aborted by instrument

Aborted test - A number of conditions can cause an abort. This

example shows a bad connection.

1.11 Test stopped by user

User stopped test by pressing the test button.

www.megger.comDLRO100E, 100X & 100H – 100A

11

Page 12

2. Instrument set-up

Charging and turning the instrument on

2.1 Charging screen – Instrument 0ff

AUTO

MAN

Instrument switched off, mains connected and battery charging.

Fans will be running.

User settings

2.3 Set max current

10A

Ω

50A

100A

2.2 Screen

Successful initialisation.

2.4 Set test duration

AUTO

MAN

10A

Ω

50A

100A

OK

Maximum current adjusted between 10 A and 100 A with UP

and DOWN arrows. Select OK to accept and progress to set test

duration.

For test durations of greater than 10 minutes the current setting

is limited to a maximum of 59A

2.5 Set Ramp Up/Down

10A

Ω

50A

100A

OK

Ramp Up/Down duration adjusted with UP and DOWN arrows.

Seconds and half seconds selected with LEFT and RIGHT arrows.

Select OK to accept.

OK

Test duration is adjusted with UP and DOWN arrows. Minutes and

seconds are selected with LEFT and RIGHT arrows. Select OK to

accept.

For currents of above 59A the test duration is limited to a .

maximum of 10 minutes.

www.megger.comDLRO100E, 100X & 100H – 100A

12

Page 13

Time and date (X and H models only)

2.6 Set date format

10A

Ω

50A

100A

Change format with LEFT and RIGHT arrows. Adjust date by

selecting DOWN arrow or select OK to accept.

2.8 Set month

10A

Ω

50A

100A

2.7 Set date

10A

Ω

50A

100A

OK

OK

Adjust day with UP and DOWN arrows. Navigate using LEFT and

RIGHT arrows or select OK to accept.

2.9 Set year

10A

Ω

50A

100A

OK

Adjust month with UP and DOWN arrows. Navigate using LEFT

and RIGHT arrows or select OK to accept.

2.10 Set Time

10A

Ω

50A

100A

OK

Adjust time by selecting DOWN arrow or select OK to accept.

OK

Adjust year with UP and DOWN arrows. Navigate using LEFT and

RIGHT arrows or select OK to accept.

2.11 Set Hours

10A

Ω

50A

100A

OK

Adjust hours with UP and DOWN arrows. Navigate using LEFT

and RIGHT arrows or select OK to accept.

www.megger.comDLRO100E, 100X & 100H – 100A

13

Page 14

2.12 Set minutes

10A

Ω

50A

100A

OK

Adjust minutes with UP and DOWN arrows. Navigate using LEFT

and RIGHT arrows or select OK to accept.

Bluetooth

®

(H models only)

2.13 Bluetooth®—Begin pair

10A

Ω

50A

100A

OK

Press and hold OK for 3 seconds to begin pairing, or press OK to

skip.

2.15 Bluetooth®—Paired

2.14 Bluetooth®—Pairing

10A

Ω

50A

100A

Pair instrument from PC/Smart Device. Enter PIN 1234 on PC.

10A

Ω

50A

100A

OK

Pairing complete for bt1. Scroll using UP and DOWN arrows to

access other Bluetooth® pairs. Select current pair with LEFT or

RIGHT arrows.

www.megger.comDLRO100E, 100X & 100H – 100A

14

Page 15

2.16 Bluetooth®—overwriting

Select existing pair.

Press OK for 3 seconds to begin pairing process.

Clamp gain (X and H models only)

2.17 Set clamp gain

10A

Ω

50A

100A

OK

10A

Ω

50A

100A

OK

Adjust Gain with UP and DOWN arrows between 0.1 mV/A and 20.00 mV/A.

Navigate using LEFT and RIGHT arrows or select OK to accept.

NOTE: The clamp must be zeroed before measurements start for accurate readings. The clamp current measurement is not displayed

on the instrument.

Buzzer settings

2.18 Buzzer settings - ON 2.19 Buzzer settings - OFF

10A

Ω

50A

100A

10A

Ω

50A

100A

OK

Press Up and Down arrows to adjust setting ON to OFF.

Select OK to set and proceed.

Press Up and Down arrows to adjust setting OFF to ON.

Select OK to set and proceed.

NOTE: When in settings, user can exit by moving the Range rotary switch away from the setting position (Spanner icon)

www.megger.comDLRO100E, 100X & 100H – 100A

OK

15

Page 16

DLRO100A Resetting Battery Charge

Battery reset enable

2.20 Setup

Progress to Battery Reset screen.

‘AC’ is shown if charger lead plugged in.

Remove lead to proceed.

2.22 Setup proceed

2.21 Lead removed:

10A

Ω

50A

100A

OK

Press ’Up’ key to proceed.

10A

Ω

50A

100A

2.23 Battery reset complete

10A

Ω

50A

100A

Press ‘Ok’ to proceed.

OK

Reapply the AC. Menu automatically proceeds to the next item with

battery symbol animated showing charge cycle.

www.megger.comDLRO100E, 100X & 100H – 100A

16

Page 17

3 Saving a test record (X and H models only)

50A

Manual save

3.1 End of test

AUTO

MAN

3.2 Completion of save

10A

Ω

100A

Press the SAVE button to save results. Save completed.

Showing date, time and slot number for 2 seconds, then reverts

to the End of Test screen.

3.3 Results memory full

10A

Ω

50A

100A

Internal memory is full.

Delete some results to create space.

www.megger.comDLRO100E, 100X & 100H – 100A

17

Page 18

Auto save and logging results

3.4 Auto Save — Auto and continuous

AUTO

MAN

10A

Ω

100A

Press save before running

i) Auto test - save all auto test results.

ii) Continuous test - log results every 5 seconds.

iii) If internal memory is full, delete some records to create space

- refer to Saving a test record section 3.3

AUTO

MAN

50A

3.6 Continuous test progress screen - Logging results

AUTO

MAN

3.5 Auto test progress screen with auto save

AUTO

MAN

10A

Ω

50A

100A

10A

Ω

50A

100A

www.megger.comDLRO100E, 100X & 100H – 100A

18

Page 19

50A

50A

4 Delete results

Delete single results

4.1 Delete results — Single 4.2 Delete results — Progress screen

Delete last saved slot. Press OK to accept.

Delete all results

4.3 Results screen—Delete ALL

10A

Ω

100A

OK

10A

Ω

100A

OK

Press OK to accept.

10A

Ω

50A

100A

OK

Select LEFT or RIGHT arrows to toggle dEL and dEL ALL.

Press OK to accept.

Press OK to delete all results.

www.megger.comDLRO100E, 100X & 100H – 100A

19

Page 20

5 Download a test record

50A

Download single result

5.1 Download results — All 5.2 Download results — Progress screen

10A

Ω

50A

100A

OK

Select LEFT or RIGHT arrows to toggle dnL and dnL ALL.

Press OK to download all results.

Recall a test record

5.4 Listing slot numbers

10A

Ω

100A

The countdown counter will show number of records being

downloaded.

5.5 Test record

OK OK

Scroll up and down through results with Slot Number. Press OK

to display results.

Press OK to drill into result. Press OK to go back to previous

screen showing Slot Numbers.

Flash between Date & Time, Voltage & Current

NOTE: Display DMY/MDY

www.megger.comDLRO100E, 100X & 100H – 100A

20

Page 21

6 Remote operation

Remote operation (DLRO100H models only)

6.1 PC position

10A

Ω

100A

50A

10A

Ω

50A

100A

Moving the rotary switch to the PC position will show

the download screen. Test switch can be MAN, AUTO or

CONTINUOUS.

6.2 Remote control mode

10A

Ω

50A

100A

Instrument under PC control showing PC then Ctrl

Remote control of DLRO100 is possible on 100H models only and

is over USB but not with a Tablet or Smart phone. (PC/Laptop

only.)

Remote control mode is activated with the Range switch.

6.3 Test under remote control

10A

Ω

50A

100A

NOTE: Results cannot be remotely saved on the instrument. The

user can save results into a Power DB form on the PC. Remote

control can be terminated from the PC or by moving either rotary

switch. If a test is in progress the test can be terminated from the

PC or again on the instrument by moving either rotary switch or

pressing the test button.

www.megger.comDLRO100E, 100X & 100H – 100A

21

Page 22

7 Asset tagging

Asset tagging (DLRO100H models only)

7.1 PC position

AUTO

MAN

Moving the rotary switch to the PC position will show

the download screen. Test switch can be MAN, AUTO or

CONTINUOUS. For Bluetooth® pair as defined before here.

7.3 End download

AUTO

MAN

7.2 Asset tag

10A

Ω

50A

100A

Instrument ready to receive tag data

10A

Ω

50A

100A

AUTO

MAN

10A

Ω

50A

100A

Tagged data received successfully

www.megger.comDLRO100E, 100X & 100H – 100A

22

Page 23

8 Screen symbol reference

1 2 3 4 5 6 7 8 9 10 11 12

1. Delete

2. Download / Remote operation

3. Retrieve results

4. Settings

5. Save

6. DualGround™ Clamp

7. USB

8. Bluetooth

9. Noise

10. Temperature

11. Mains

12. Battery

®

1 2 3 4 5 6 7 8

1

4

9

1. Exception

2. Tick

3. Cross

4. C – current

10

5. D:M:Y:M:D:H:M:S – Date and Time

6. A – Amps

7. P – Potential – voltage measurement

8. mV – milliVolts

9. µV – microVolts

10. Hazard warning

1 2 3 4

2

3

1. Greater than

2. Minus/dash

3. Less than

5

4. mW MilliOhms

5. µW MicroOhms

1. Im – maximum

current

2. Ramp Up duration

3. Constant current

duration

4. Ramp Down

duration

www.megger.comDLRO100E, 100X & 100H – 100A

23

Page 24

Battery indicator

The battery symbol on the LCD display contains 8 segments. The battery is monitored continuously when the instrument is turned on.

The charge remaining in the battery is indicated by segments as follows:

Fully charged battery

50% charged battery

When mains power is present the indicator shows the battery is being

charged by animating the segments of the bar graph.

A flashing battery icon, showing the current charge level, indicates that the battery is prevented from charging due to the temperature

being out of the allowable charge temperature range, 0 ºC to 40 ºC, or that the battery has failed.

Tests cannot be started,

insufficient charge

Symbol flashes when there

is not enough charge for a test

and the instrument will turn

itself off.

Error indicators

A lit red LED above the test button, when the instrument is not conducting a test, indicates a fault. Do NOT use the instrument if this

happens. Do not attempt to repair the instrument. See Repair and Warranty section for details.

If the internal temperature of the instrument exceeds a safe level, the test will be aborted and indicated on the screen. The

temperature must drop before testing can be continued.

www.megger.comDLRO100E, 100X & 100H – 100A

24

Page 25

Preventive maintenance

Routine inspection

Look for any cracks or other damage to the enclosure; missing ports, etc.

Cleaning

Disconnect the instrument and wipe it with a clean cloth slightly damped with water or Isopropyl alcohol (IPA). Care should be taken

near the terminals, IEC power and USB sockets.

Care of the instrument

The instrument should always be handled with care and not dropped. Always ensure that the instrument is secured when being

transported to prevent mechanical shock.

Fan cover replacement

The cover is a single piece and can be removed by unscrewing and cleaned with clean cloth. Do not use the instrument without the

fan covers in place. Do not allow the fan covers to become blocked.

Leads

Leads are silicone insulated and perform well in all weather conditions. Always keep the leads in a suitable lead bag during storage

and transportation.

Regular inspection of leads is recommended to ensure they are not damaged in any way. Damaged leads could affect resistance

readings and are a safety hazard.

Battery care

The battery should be charged at a minimum of 3 month intervals. This is to prevent deep discharge.

Never attempt to charge the battery below 0 °C or above +40 °C ambient. The battery is charged by connecting line power at the

instrument IEC power socket.

Store the instrument in a cool, dry location to improve battery life. Storage temperatures below freezing should be avoided.

They can be safely removed by an Authorised Service Centre. Do not attempt to remove the batteries from this unit.

Battery disposal

The crossed out wheeled bin symbol placed on the batteries is a reminder not to dispose of them with general waste at the end of

their life.

This product contains lithium ion batteries and a coin cell.

They are located inside the instrument.

The Lithium ion coin cell can be safely removed by an Authorised Service Centre. Do not attempt to remove the coin cell from this

unit.

Spent Lithium ion and a coin cell batteries are classified as Industrial Batteries. For disposal in the UK contact Megger Instruments Ltd

For disposal of batteries in other parts of the EU contact your local Megger company or distributor.

Megger is registered in the UK as a producer of batteries.

The Registration number is BPRN00142

For further information see www.megger.com

www.megger.comDLRO100E, 100X & 100H – 100A

25

Page 26

Technical Specification

Measurement range 0.1 μΩ - 1.999 Ω

Resolution 0.1 μΩ

Noise rejection Differential 100 mV @ 50-60 Hz on Test Leads

DC output Smooth DC

IP rating IP54 Lid open / IP65 Lid closed

Operating temperature range -20°C up to 50°C

Storage temperature range -30°C up to 70°C

Humidity <85% R.H. non-condensing

Battery life 200 single 100 A tests or up to 2x 10 minutes continuous 100 A output

Battery type User replaceable Li-ion battery pack

Battery charge time Full charge in 2.5 Hrs from flat

Maximum output voltage 2 V (battery), 3 V (AC)

EMC IEC61326-1

Safety IEC61010

CAT IV 600 VAC / 500 VDC up to 2000 m

CAT IV 300 V up to 4000 m

Dimensions 400 x 300 x 200 mm

Weight 7.0 kg (AC Only)

7.9 kg (with Battery)

Accuracy

Current setting

50 - 110 A 0 - 100.00 mΩ Typical ± (0.2% + 0.2 μΩ)

Max. ± (0.2% + 0.8 μΩ)*

11 - 49 A 10 μΩ - 100.00 mΩ Typical ± (0.2% + 0.5 μΩ)

Max. ± (0.2% + 2.0 μΩ)*

10 A 10 μΩ - 1000.0 mΩ Typical ± (0.2% + 1.0 μΩ)

Max. ± (0.2% + 2.5 μΩ)*

#

Resistance range Accuracy

#

Actual test current may be limited by maximum output voltage

k = ±4σ

*

Operational uncertanity, 85% RH, -20°C to +50°C

Current setting

#

Resistance range +

50 - 110 A 0 - 100.00 mΩ ± (0.0% + 0.0 μΩ)

11 - 49 A 10 μΩ - 100.00 mΩ ± (0.0% + 1.0 μΩ)

10 A 10 μΩ - 1000.0 mΩ ± (0.1% + 2.0 μΩ)

www.megger.comDLRO100E, 100X & 100H – 100A

26

Page 27

Product

Feature DLRO100E DLRO100EB DLRO100X DLRO100XB DLRO100H DLRO100HB

100A Manual,

Auto & Continuous Test.

■ ■ ■ ■ ■ ■

Custom test

CAT IV 600 VAC / 500 VDC

and IP54

Battery

Internal memory

USB data download

DualGround™

Smart device

Bluetooth

®

Remote control

■ ■ ■ ■ ■ ■

■ ■ ■

■ ■ ■ ■

■ ■ ■ ■

■

*

■

*

■

*

■ ■

■ ■

■ ■

■

*

* with optional DC Clamp

Accessories

Description Order Code

Optional Accessories

DLRO100 CAT IV 600V Lead Set (5m) 1004-448

DLRO100 CAT IV 600V Lead Set (10m) 1004-449

DLRO100 CAT IV 600V Lead Set (15m) 1004-450

DLRO100 Terminal adaptors (x2) 1005-555

DLRO100 CAT IV 600 V Kelvin Lead Set (5m) 1005-634

DLRO100 CAT IV 600 V Kelvin Lead Set (10m) 1005-635

DLRO100 CAT IV 600 V Kelvin Lead Set (15m) 1005-636

DLRO100 DC Clamp (MCPD 100L) 1005-622

DLRO100 UKAS Calibration Certificate 1005-888

DLRO100 Lithium Ion Battery Pack 1005-973

Acknowledgments

The DLRO100:

(i) uses the FreeRTOS operating system from http://www.freertos.org.

(ii) contains RADSOK® technology from Amphenol RADSOK is a registered trademark of Amphenol-Tuchel Electronics.

(iii) uses the HCC-Embedded FLASH file system as provided by HCC Embedded

(iv) uses the SCPI Parser library of commands from http://jaybee.cz/software/

www.megger.comDLRO100E, 100X & 100H – 100A

27

Page 28

Repair and warranty

If the protection of an instrument has been impaired it should not be used, but sent for repair by suitably trained and qualified

personnel. The protection is likely to be impaired if, for example, the instrument shows visible damage, fails to perform the intended

measurements, has been subjected to prolonged storage under unfavourable conditions, or has been exposed to severe transport

stresses.

New instruments are covered by a two year warranty from the date of purchase by the user, the second year being conditional on

the free registration of the product on www.megger.com. You will need to log in, or first register and then login to register your

product. The second year warranty covers faults, but not recalibration of the instrument which is only warranted for one year. Any

unauthorised prior repair or adjustment will automatically invalidate the warranty.

These products contain no user repairable parts and if defective should be returned to your supplier in original packaging or packed

so that it is protected from damage during transit. Damage in transit is not covered by this warranty and replacement/repair is

chargeable.

Megger warrants this instrument to be free from defects in materials and workmanship, where the equipment is used for its proper

purpose. The warranty is limited to making good this instrument (which shall be returned intact, carriage paid, and on examination

shall disclose to their satisfaction to have been defective as claimed). Any unauthorised prior repair or adjustment will invalidate the

warranty. Misuse of the instrument, from connection to excessive voltages, fitting incorrect fuses, or by other misuse is excluded from

the warranty. The instrument calibration is warranted for one year.

This Warranty does not affect your statutory rights under any applicable law in force, or your contractual rights arising from a sale and

purchase contract for the product. You may assert your rights at your sole discretion

Calibration, Service and Spare Parts

For service requirements for Megger Instruments contact Megger or your local distributor or authorised repair centre.

Megger operates fully traceable calibration and repair facilities, ensuring your instrument continues to provide the high standard

of performance and workmanship you expect. These facilities are complemented by a worldwide network of approved repair and

calibration companies to offer excellent in-service care for your Megger products.

See the back of this user guide for Megger contact details.

Details of your Authorised Service Centre is available by contacting ukrepairs@megger.com and giving details of your location.

www.megger.comDLRO100E, 100X & 100H – 100A

28

Page 29

M

MEGGER LIMITED

ARCHCLIFFE ROAD

DOVER

KENT

CT17 9EN

ENGLAND

T +44 (0)1 304 502101

F +44 (0)1 304 207342

MEGGER CANADA

UNIT 106-550

ALDEN ROAD

MARKHAM

ON L3R 6A8

CANADA

T. 416-298-6770

MEGGER MIDDLE EAST

PO BOX 500503 @DIC13

OFFICE 209 BLDG 14,

DUBAI INTERNET CITY,

UNITED ARAB EMIRATES

T. +971 4 443 5489

MEGGER USA - VALLEY FORGE

VALLEY FORGE CORPORATE CENTER

2621 VAN BUREN AVENUE

NORRISTOWN

PENNSYLVANIA,

19403 USA

T. 1-610 676 8500

F. 1-610-676-8610

MEGGER (INDIA) PVT LIMITED

211 CRYSTAL PARADISE MALL

OFF VEERA DESAI ROAD ANDHERI (W)

MUMBAI

400 053

INDIA

T. +91 22 2674 0468

F. +91 22 2674 0465

MEGGER GMBH

OBERE ZEIL 2 61440

OBERURSEL,

GERMANY

T. 06171-92987-0

F. 06171-92987-19

OTHER TECHNICAL SALES OFFICES

Toronto CANADA, Sydney AUSTRALIA, Madrid SPAIN, Mumbai INDIA, and the Kingdom of BAHRAIN.

Megger products are distributed in 146 countries worldwide.

This instrument is manufactured in the United Kingdom.

The company reserves the right to change the specification or design without prior notice.

Megger is a registered trademark

DLRO100_UG_en_V01

www.megger.com

Loading...

Loading...