Page 1

Earth/Ground Resistance & Soil Resistivity Testers

DET4 Series

4-Terminal Earth/Ground Resistance

and Soil Resistivity Testers

n

2, 3 and 4 point testing

n

Stakeless (clamp-on) testing capability

n

ART (Attached Rod Technique) capability

n

Multiple, user selectable test frequencies

n

Resistance measurement range to

200,000 Ω

n

IP54 rated

n

Warning indicators prevent test failure

n

Simple one button operation

n

Included leads, stakes, calibration

certificate and rugged carry case

DET4 Series

DESCRIPTION

Megger’s popular 4-terminal ground testing instrument

family includes four basic models with different kit variants

for each that include select accessories for greater testing

flexibility. The four basic units are:

Model Description

DET4TD2 Dry-cell battery powered basic 4-terminal

tester

DET4TR2 Rechargeable battery powered basic

4-terminal tester

DET4TC2 Dry-cell battery powered 4-terminal tester

with selectable test frequencies, greater

measurement sensitivity and attached rod

technique and stakeless measurement

capability

DET4TCR2 Rechargeable battery powered 4-terminal

tester with selectable test frequencies,

greater measurement sensitivity and

attached rod technique and stakeless

measurement capability

The top-end models (DET4TC2 and DET4TCR2) include

a current measuring function for ART (Attached Rod

Technique) testing capabilities. With this added function,

on-site grounds can be tested separately without having to

remove the utility connection (as explained further in this

document). They also provide stakeless testing capability.

This method allows the operator to use the instrument

like a clamp-on ground tester in applications where that

method is viable, while also being able to operate as a fall

of potential tester if required.

The basic kit includes the test leads, stakes, batteries and

calibration certificate, delivered in a tough polypropylene

carry case – everything you need to start testing in one

package.

All models are rated to IP54, making them truly outdoor

instruments. They are designed to meet stringent safety

standards and are rated CAT IV 100 V. The ground testers

have been designed to be easy to use – a large selector

switch makes selection of 2, 3 or 4 pole tests easy with

gloved hands – and the design makes the fitting of shorting

links to perform 2-pole tests a thing of the past. A large,

clear, easy to read LCD and thumb sized test button

also make the instruments particularly well suited to the

outdoor conditions of ground testing. In addition to this

ease of use feature, the instruments automatically check

the connection and conditions of the P spike, C spike,

and also the level of ground noise, indicating the status

on the display. They also include a voltmeter to enable

measurement of ground voltage.

The DET4TD2 and DET4TR2 can measure resistance from

0.01 ohms to 20 kΩ, while the DET4TC2 and DET4TCR2

can measure resistance from 0.01 ohms to 200 kΩ, a key

capability for soil resistivity testing. Also, to allow accurate

testing in noisy environments, the instruments are capable

of rejecting noise up to 40 V peak to peak.

The DET4TD2 and DET4TC2 are powered by eight AA

batteries which are widely available and also give excellent

testing time – the status of these batteries is given by a bar

graph on the LCD display, allowing the operator to decide

when to change the batteries before they expire. The

DET4TR2 and DET4TCR2 are powered from rechargeable

Page 2

DET4 Series

Earth/Ground Resistance & Soil Resistivity Testers

AA cells. The battery charger is built in and the instrument

is supplied with an AC/DC adapter. For all instruments, the

battery status is displayed using a bar-graph.

The DET4TC2 and DET4TCR2 include additional

capabilities. By using the optional ICLAMP the user can

augment the traditional fall-of-potential measurement

method with ART (Attached Rod Technique), which allows

electrode testing without disconnection and also leakage

current measurements down to 0.5 mA. A second optional

clamp, the VCLAMP, enables true stakeless (clamp-on)

measurements to be made in situations where driving

stakes is not practical.

The DET4TC2 and DET4TCR2 also feature a backlit

display, which extends the operational environment of

the instrument to cable cellars and other dark locations.

Finally, all units have selectable 25 V or 50 V output for

compliance with IEC 61557-5. The 25 V output is required

for testing in agricultural environments.

The maintenance of an adequate low resistance ground

connection is essential to both the protection and

performance of any electrical system. Ground testing

should be performed both upon installation, to meet

design specification, and periodically thereafter in order

to maintain service. All Megger models can also perform

bonding tests (using an ac signal), to determine that

adequate connection has been made from equipment to

the grounding system, and can perform soil resistivity

tests. This additional function can be used in prospecting,

locating, and designing new grounding electrodes and

systems. Furthermore, the addition of built-in current

clamp capability enables fall of potential testing of attached

grounds (ART) without lifting the utility connection and

the addition of voltage clamp technology enables stakeless

testing from the same instrument.

Grounding electrodes from simple to complex systems can

be tested, including:

n

Primary and secondary electrical grounding systems

n

Utility pole grounds

n

Lightning protection systems

n

Residential grounds

n

Machinery safety grounds

n

Computer and communication system grounds

n

EMI/RFI system grounds

n

Antenna and pedestal grounds

n

CATV system grounds

Model DET4TCR2 shown performing the stakeless ground testing method

using only clamps.

APPLICATIONS

Proper grounding provides many varied benefits to both

people and facilities. It lessens the chance of injury due

to faulty installation, reduces the likelihood of damage

from lightning strikes and induced voltages, improves

the performance of computer, communication and other

sensitive equipment and protects against static electricity

from friction. Over time, ground systems can degrade or

become ineffective. Corrosion and weather influences

exert mechanical strain on ground rods and cause metallic

corrosion. Catastrophic events like lightning strikes or large

fault currents can cause instant degradation. In addition,

soil resistivity can change over time due to environmental

conditions and facility expansion can create different

ground system needs.

The risks from ground system deterioration include

potentially deadly electrical shock situations, plant-wide

equipment damage, disruption in the performance of

sensitive equipment and heat build-up on a single piece of

electrical equipment.

FEATURES AND BENEFITS

n

Stakeless testing capability, which allows the operator

to use the instrument like a clamp-on tester in applications where the method is viable

n

Attached Rod Technique capability, which allows fall

of potential testing without the need to disconnect the

ground rod

n

Multiple, user selectable test frequencies allows the

operator to find the most effective frequency for making

the measurement

n

200,000 Ω measurement range provides the ability to

measure the resistivity of any type of soil

n

User selectable test voltage ensures that the units can be

used in agricultural environments

n

Microprocessor control for improved error detection

n

Clear, unambiguous warnings and error indications en-

sure the reliability of the reading and reduce test time

n

Rugged, weatherproof case to IP54 makes the units truly

outdoor instruments

n

Backlit LCD allows for testing in dark environments

n

Noise rejection to 40 V pk to pk allows accurate testing

in noisy environments

n

Testing kits and certificates supplied — everything

needed to start testing immediately

n

Accuracy of 2% of reading enhances reliability of mea-

surements

n

Voltmeter function included allows you to measure the

ground voltage and enhances operator safety

n

CAT IV 100V provides increased operator safety

Page 3

DET4 Series

Earth/Ground Resistance & Soil Resistivity Testers

SPECIFICATIONS

Resistance range: 0.01 to 200 kΩ autoranging

(0.01 to 20kΩ for models DET4TD2 and DET4TR2)

Resistance accuracy:

2P measurements 2% ±3 digits

3P measurements 2% ±3 digits

4P measurements 2% ±3 digits

ART measurements 5% ±3 digits

Stakeless measurements 7% ±3 digits

Maximum probe resistance:

DET4TD2 and DET4TR2

Rp limit: 100kΩ (50V output voltage)

Rc limit: 100kΩ (50V output voltage)

Limits reduced to 50kΩ for 25V output voltage

Limits reduced to 5kΩ for 0.01 Ω resolution

DET4TC2 and DET4TCR2

Rp limit: 200kΩ (50V output voltage)

Rc limit: 200kΩ (50V output voltage)

Limits reduced to 100kΩ for 25V output voltage

Limits reduced to 5kΩ for 0.01 Ω resolution

Earth voltage range: 0 – 100 V

Earth voltage accuracy: 2% ±2 V

2-wire test: Yes, all models

3-wire test: Yes, all models

4-wire test: Yes, all models

ART (Attached Rod Technique): DET4TC2, DET4TCR2

Stakeless test: DET4TC2 and DET4TCR2

Ground current range (with current measuring clamp):

0.5 mA to 19.9 A

Ground current accuracy: 5% ±3 digits

Display:

DET4TD2 and DET4TR2: 3-1/2 digit high contrast LCD

DET4TC2 and DET4TCR2: 3-1/2 digit high contrast LCD, backlit

Test frequency: 94, 105, 111 and 128 Hz

(128 Hz for DET4TD2 and DET4TR2)

Test voltage: 25 V or 50 V, user selectable (factory setting 50 V)

Test current: 450 micro-amps at 25 V or 50 V (selectable),

4.5 mA at 25 V

Noise rejection: 40V pk to pk

Noise check: Automatic

C spike check: Automatic

P spike check: Automatic

Battery type: 8 1.5 V AA cells (8 1.5 V AA NiMH rechargeable

cells – DET4TR2 and DET4TCR2)

Battery life: 3 hours, 700 consecutive tests

Safety: EN61010-1 CAT IV 100 V

Terminals: 4 mm plug type (test leads)

Ingress protection: IP54

EMC: Meets the requirements of EN61326-1:1998 for use in heavy

industrial areas, including amendment 1

Dimensions: 8 x 5.7 x 3.2 in. (203 x 148 x 78 mm)

Weight: 2.2 lb (1 kg)

Operating temperature range: 5º to +131º F (-15º to +55º C)

Storage temperature range: -40º to +158º F (-40º to +70º C)

Humidity: 95% RH non-condensing at 104º F (40º C)

Standards Compliance

Complies with the requirements of KEMA K85B.

Complies with the following parts of EN61557, “Electrical safety

in low voltage distribution systems up to 1000 V a.c. and 1500 V

d.c. - Equipment for testing, measuring or monitoring of protective

measures”.

Part 1 - General requirements

Part 5 - Resistance to earth

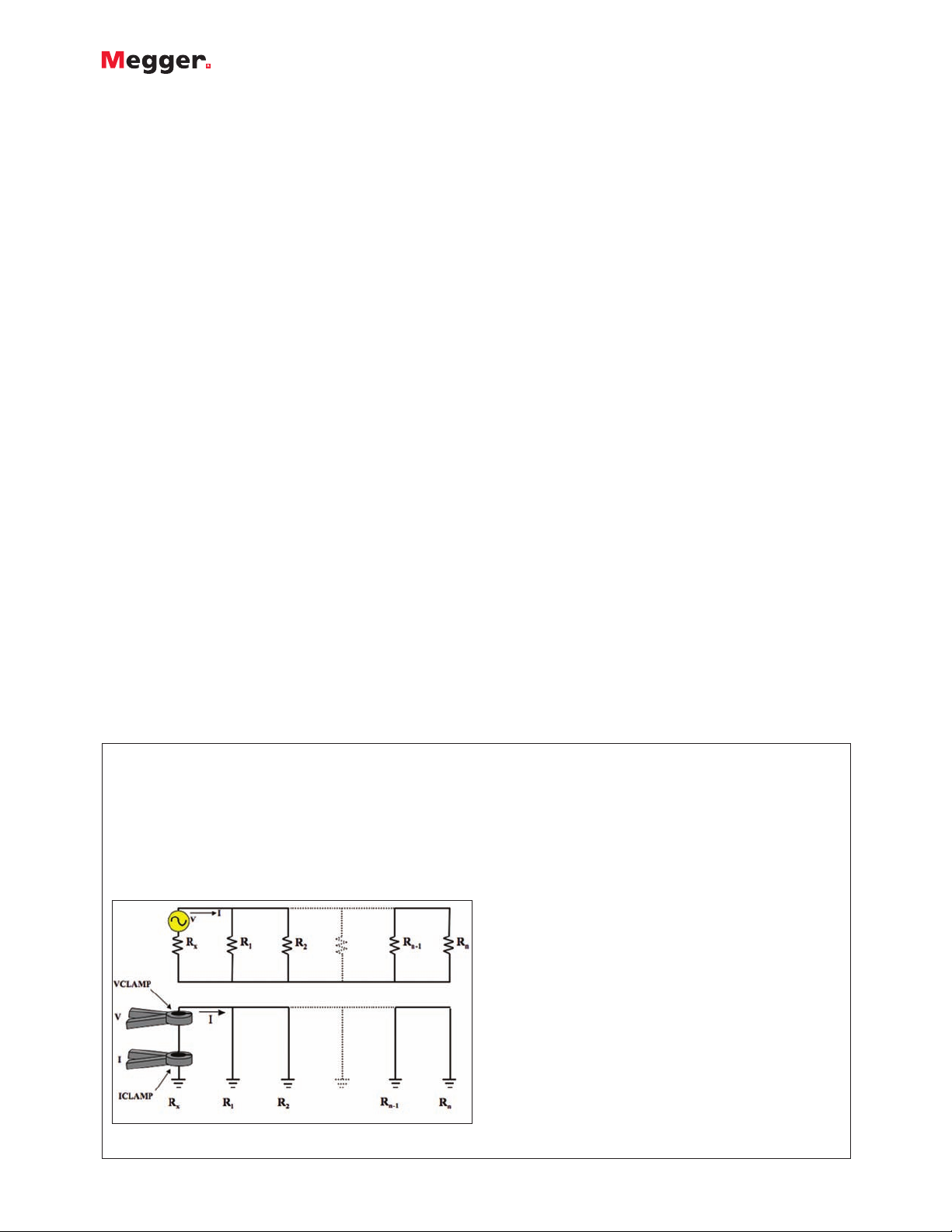

STAKELESS (CLAMP-ON) TESTING

The DET4TC2 and DET4TCR2 include stakeless, or

clamp-on testing capability. In effect, these models can

be operated in the same way as a clamp-on ground

tester, eliminating the need to disconnect the ground

under test and drive test probes in certain ground system

testing applications. This method is also useful when

there is insufficient space to perform a classic fall-ofpotential measurement. In addition the units can be used

to measure ground leakage or phase current.

The user simply clamps the optional ICLAMP (current

clamp) and VCLAMP (voltage clamp) around the ground

under test in the manner prescribed in the operator’s

manual and takes the reading. A defined test voltage is

injected into the system using the VCLAMP, inducing a

current, I, to flow and be measured by the ICLAMP. The

instrument then calculates the approximate resistance of

the ground under test.

The stakeless method is subject to the same limitations

faced by the traditional clamp-on ground tester. It is

effective only in situations with multiple grounds in

parallel and cannot be proofed like a fall-of-potential

test. In situations where the stakeless method reading is

questionable, a full fall-of-potential test is recommended.

The advantage of the DET4TC2 and DET4TCR2 is that the

units include both test methods in a single instrument,

making them the most versatile units available.

Page 4

DET4 Series

Earth/Ground Resistance & Soil Resistivity Testers

ART (ATTACHED ROD TECHNIQUE)

TESTING CAPABILITY

The DET4TC2 and DET4TCR2 include the additional

testing capability that we have termed ART, for

Attached

Rod Technique. A nagging problem with traditional

ground testing has been the requirement to “lift” (i.e.,

disconnect) the utility connection. Once the grounding

conductor (the main conductor that connects the facility

to the ground rod or grid) has been attached to the

grounding electrode, the utility ground becomes a parallel

resistance. The utility neutral is typically bonded to the

ground bus at the service entrance and this connection,

during a ground test, causes test current to flow back

through the utility ground as well as through the test

electrode. Test current divides according to Law of Parallel

Resistance, but the tester makes its measurement based on

total current flow. The reading is the combined parallel

resistance of the on-site ground and the utility protection.

This is a valid measurement, but not of the test electrode

exclusively.

This poses a considerable problem in many common

testing situations. If a commissioning test were required to

determine if design specifications had been met for a new

facility, such a reading would be insufficient. Lightning

protection requiring a short, straight path into the earth,

could also not be properly validated. But lifting the utility

connection poses several problems, not the least of which

is the breaking of what is often a welded bond, in addition

to the temporary loss of protection.

Clamp-on ground testers, which measure ground

resistance by clamping around the rod and inducing a

test current onto it, are only a limited solution. They can

accurately measure resistance of a single rod in a parallel

system by inducing the test current onto the clamped

rod and utilizing all the parallel grounds as the return.

Collectively, these returns, typically the multiple grounds

of the utility, contribute little to the loop measurement.

This is essentially the reverse of the operation of a

traditional tester, which uses the current probe as

the return while current “goes to ground” through all

parallels collectively. This technique solves the problem

of separately measuring an attached rod, but leaves the

problem that it cannot be proven.

A clamp-on measurement has to be accepted on faith

and its reliability is based squarely on the knowledge

and experience of the operator, leaving a large margin

for “human error.” In complex, multiply connected grids

and other grounding schemes, return paths may exist

that are entirely metallic, not including earth at all. The

clamp-on test current will circulate through such paths

and give a reading, essentially a continuity reading of the

grid structure having nothing to do with soil resistance.

Such readings will be low, and appear to the uninformed

as acceptable grounds. The responsibility for making

these determinations falls squarely on the operator.

But even when properly addressed, there is no way of

demonstrating the competence of the readings to a third

party, such as a client. They must simply be accepted.

The ART testing capability combines the advantages of

both of these technologies to produce a method that

can reliably measure an attached ground, and prove

it! A built-in clamp input, used in conjunction with the

optional ICLAMP accessory, connected below the point of

separation of the parallel test currents, measures only the

current flowing through the test ground, not that going

back through the utility. This current value is then used by

the microprocessor to calculate ground resistance, strictly

in accordance with

Fall of Potential or its derivative

procedures, supported by IEEE Standard 81 for proper

ground testing, and subject to the appropriate proofs.

The

ART method employs leads and probes just as does

any traditional tester. Ground resistance can be profiled

and graphed by moving the potential probe against the

position of the current probe, and a Fall of Potential graph,

Slope Method mathematical proof, or any of the other

proven methods utilized to demonstrate the accuracy of

the test. The only thing different from the operation of a

familiar, traditional ground tester is that the clamp permits

separation of the test currents in an attached or otherwise

parallel-grounded system. This technique enables local

grounds to be tested without lifting the utility connection,

yet with the ease, reliability and confidence of a separate

commissioning test.

Current measuring clamp (inset)

for ART testing capability

Page 5

DET4 Series

Earth/Ground Resistance & Soil Resistivity Testers

Model No. DET4TD2 DET4TR2 DET4TC2 DET4TCR2

SELECTION GUIDE

Cat. No. 1000-347 1000-324 1000-345 1000-346

2-Pole Measurement n n n n

3-Pole Measurement n n n n

4-Pole Measurement n n n n

Soil Resistivity n n n n

Tests ART (Attached Rod n n

Technique) Capability

Stakeless (Clamp-on) n n

Measurement Capability

Resistance Range 0.01 to 20,000 Ω 0.01 to 200,000 Ω

Ground Voltage Range 0 to 100 V

Ground Current Range 0.5 mA to 19.9 A

(with ICLAMP) Capability

Output Selectable Voltage (25/50 V) n n n n

Test Frequency 128 Hz 94, 105, 111, 128 Hz

Power Supply Alkaline Batteries n n

Rechargeable Batteries n n

Noise Rejection 40 V Peak-to-Peak n n n n

Safety Rating CAT IV 100 V n n n n

Ingress Protection Rated to IP54 n n n n

Hard Carry Case n n n n

Included Accessories Test Leads (49 ft, 33 ft, n n n n

33 ft, 10 ft) and Spikes

Certificate of Calibration n n n n

Warranty 3 Year n n n n

CONFIGURATION OPTIONS

Power

Included Accessories Supply

Model No. Cat. No.

Hard carry case

4 Right-angle

terminal adapters

Leads (49 ft, 33 ft,

External ac/dc

Adapter

Field Calibrator

ICLAMP and

33 ft, 10 ft) and Spikes

VCLAMP

Earth/ground kit,

C/N 6320-245

Rechargeable

Alkaline batteries

DET4TC2+Clamps 1000-365 n n n n n n

DET4TC2+Kit 1000-404 n n n n n n n

DET4TCR2+Clamps 1000-366 n n n n n n n

DET4TCR2+Kit 1000-405 n n n n n n n n

*The Professional Ground Testing Kit (C/N 6320-245) includes two 164 ft (50 m) leads and two 98 ft

(30 m) leads on retractable reels, four auger-style ground spikes, a tape measure and a separate hard

carry case.

NOTE: Using the ICLAMP allows the operator to make ART measurements. Using the ICLAMP and

VCLAMP allows the operator to make stakeless (clamp-on) measurements.

batteries

Page 6

DET4TC2 OPERATION

LCD Display

25V / 50V output

voltage select

button

DET4 Series

Earth/Ground Resistance & Soil Resistivity Testers

Test lead connections

(at rear)

Resistance

measurement

settings

Test button

DET4TC2 DISPLAY EXAMPLE

Output

voltage

indicator

Frequency

select button

Ruptured

fuse

indicator

Warning - refer

to user manual

Backlight

control button

Battery charge

indicator

Selector switch

Voltage and current

measurement settings

Measuring

range

Over/under

range indicator

Potential probe resistance

indicator (OK or high)

Current probe resistance

(OK or high)

Ground noise voltage

indicator (OK or high)

Page 7

DET4 Series

Earth/Ground Resistance & Soil Resistivity Testers

OPTIONAL ACCESSORY KITS

Professional Kit

Cat. No. 6320-245

Red and black cable reels,

164 ft (50 m); yellow and

green cable reels, 98 ft

(30 m); earth electrode

leads, 13 ft (4 m) green;

4 mm shrouded plug and

large croc clip; 4 auger-style

spikes; molded polyethylene

carrying case; fiberglass

measuring tape, 164 ft (50 m)

Each instrument comes complete with three sets of leads, two test

spikes, instruction manual CD, and a rugged carrying case, (current

measuring clamp, shown, is an optional accessory for performing the

ART testing capability using the DET4TC2 and DET4TCR2 only.)

Terminal Adapters are used to

allow the DET4 Series units’

terminals to accept alternative

cable connections.

Soil Resistivity Kit

Cat. No. 250586

Set of four test leads, 50

ft. (15 m); two pair of 20

in. (51 cm) ground rods;

padded case to hold

instrument, leads and

rods

Deluxe Kit,

Cat. No. 250581

Set of three color-coded

test leads, 25, 50, 100 ft.

(8, 15, 30 m); two 20-in.

(51 cm) ground rods;

padded case to hold

instrument, leads and rods

Standard Kit,

Cat. No. 250579

Three color-coded test

leads, 25, 50, 100 ft.

(8, 15, 30 m); two 20-in.

(51 cm) ground rods;

canvas accessory case for

leads and rods only

Standard Kit

Cat. No. 6310-755

Hammer, 2.5 lb (1.13

kg); four galvanized steel

spikes, 0.5 in. (12 mm);

two spike extractors; four

leads in carrying case

Page 8

DET4 Series

Earth/Ground Resistance & Soil Resistivity Testers

ORDERING INFORMATION

Item (Qty) Cat. No.

DET4TD2 1000-347

DET4TR2 1000-324

DET4TC2 1000-345

DET4TC2+Clamps 1000-365

DET4TC2+Kit 1000-404

DET4TCR2 1000-346

DET4TCR2+Clamps 1000-366

DET4TCR2+Kit 1000-405

See Configuration Options chart for detailed information

Optional Accessories

Current measuring clamp and connecting

lead for ART testing method ICLAMP

Voltage inducing clamp, calibration check PCB

(two-clamp measurements) and connecting lead VCLAMP

Calibration check box 6220-824

Right angled terminal adaptor set 6220-803

Auxiliary 12V socket charger

(DET4TR2 and DET4TCR2 only) 6280-375

Standard accessory kit (leads, rods, canvas

accessory case for leads & rods) 250579

Deluxe accessory kit (leads, rods, padded case) 250581

Item (Qty) Cat. No.

Standard accessory kit (hammer, spikes, leads) 6310-755

Professional ground testing kit

(2 x 50m, 2 x 30m, 4 auger stakes, carry case) 6320-245

Soil resistivity kit (leads, rods, padded case) 250586

“Getting Down to Earth”

a Megger guide to earth testing AVTM25-TA

Replacement hard carry case 5410-429

Replacement calibration check PCB

(two-clamp measurements) 6220-831

Replacement ground test stakes (x2)

for included kit (200mm, 8mm dia) 6220-804

Replacement ground test leads (x4)

for included kit (15m, 10m, 10m, 3m) 6220-806

Replacement auger stakes (x2)

for professional kit 6220-839

Replacement cable reel (50m, red cable)

for professional kit 6220-840

Replacement cable reel (50m, black cable)

for professional kit 6220-841

Replacement cable reel (30m, green cable)

for professional kit 6220-843

Replacement cable reel (30m, yellow cable)

for professional kit 6220-842

UK

Archcliffe Road, Dover

CT17 9EN England

T +44 (0) 1 304 502101

F +44 (0) 1 304 207342

UKsales@megger.com

UNITED STATES

4271 Bronze Way

Dallas, TX 75237-1019 USA

T 1 800 723 2861 (USA only)

T +1 214 333 3201

F +1 214 331 7399

USsales@megger.com

OTHER TECHNICAL SALES OFFICES

Valley Forge USA, College Station

USA, Sydney AUSTRALIA, Täby

SWEDEN, Ontario CANADA, Trappes

FRANCE, Oberursel GERMANY, Aargau

SWITZERLAND, Kingdom of BAHRAIN,

Mumbai INDIA, Johannesburg SOUTH

AFRICA, and Chonburi THAILAND

ISO STATEMENT

Registered to ISO 9001:2000 Reg no. Q 09250

Registered to ISO 14001 Reg no. EMS 61597

DET4T2SERIES_DS_US_V04

www.megger.com

Megger is a registered trademark

Loading...

Loading...